technical and operational documentation

Doc. version: 3.0.100

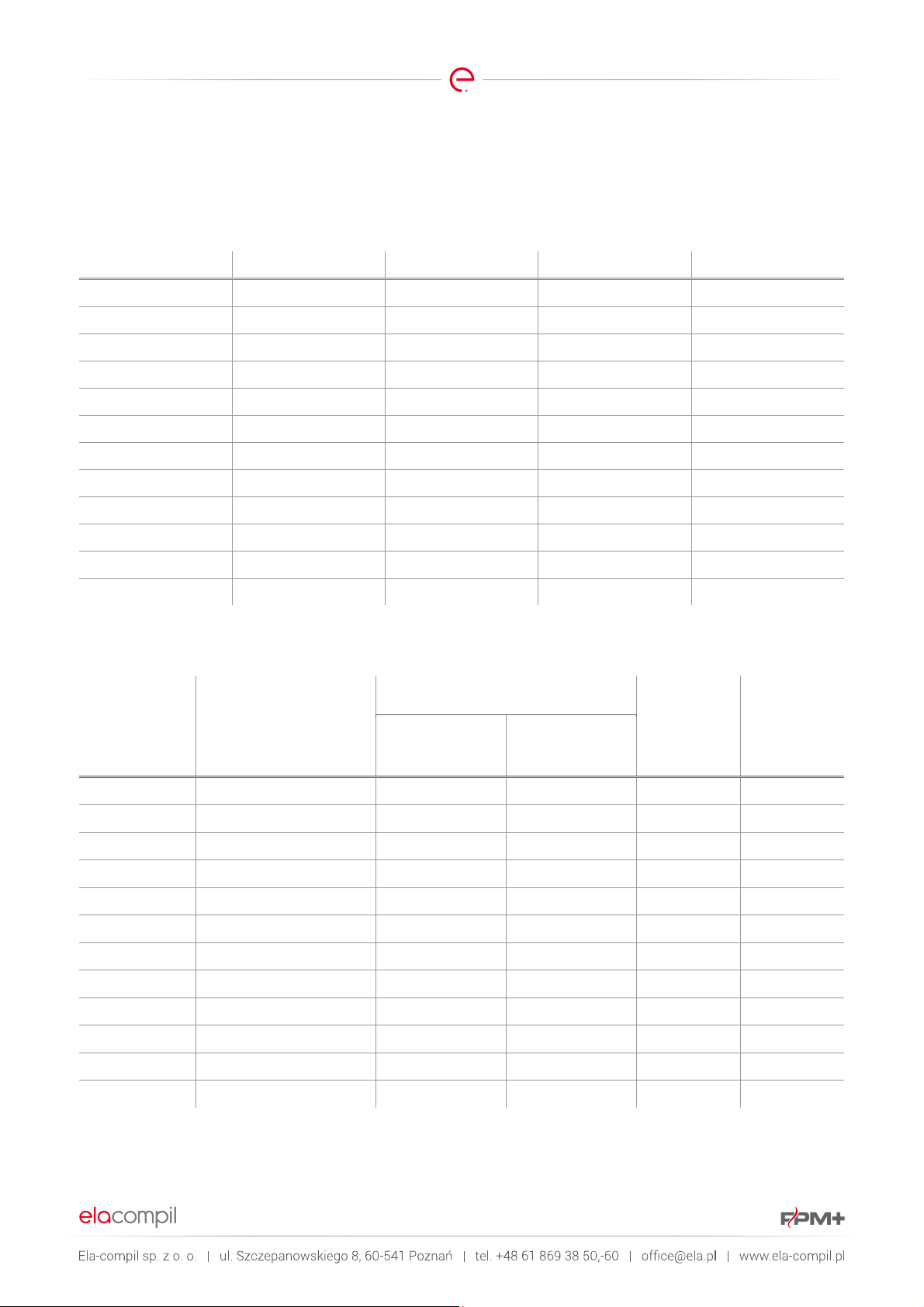

Contents

1.

2.

3.

3.1.

3.2.

4.

4.1.

4.2.

4.3.

4.4.

5.

6.

6.1.

6.2.

6.3.

6.4.

6.5.

6.6.

6.7.

6.8.

APPLICATION OF THE FPM+ UNIT ..................................................................................................... 4

FPM+ ARCHITECTURE AND TOPOLOGY ............................................................................................. 5

REQUIREMENTS FOR EXTERNAL COMPONENTS .............................................................................. 7

FPM+ power supply .......................................................................................................................................................................... 7

Electrical installation ......................................................................................................................................................................... 7

FPM+ LIMITATIONS ........................................................................................................................... 8

No. of items per bus .......................................................................................................................................................................... 8

Length of bus between modules .................................................................................................................................................... 8

Length of MP-Bus .............................................................................................................................................................................. 8

Number of zones ............................................................................................................................................................................... 8

FPM+ UNIT AND MODULE SPECIFICATIONS ..................................................................................... 9

FPM+ MODULES .............................................................................................................................. 15

FPM+ control unit - central (MASTER) module ......................................................................................................................... 15

LSK ..................................................................................................................................................................................................... 17

e.LSK .................................................................................................................................................................................................. 18

EPSCUS ............................................................................................................................................................................................. 19

e.USP..................................................................................................................................................................................................20

SKC .....................................................................................................................................................................................................20

SKC-A ................................................................................................................................................................................................. 21

FPM+ bus repeater module ........................................................................................................................................................... 22

7.

7.1.

7.2.

7.3.

7.4.

7.5.

7.6.

7.7.

8.

8.1.

8.2.

8.3.

8.4.

8.5.

8.6.

8.7.

8.8.

9.

9.1.

9.2.

9.3.

10.

10.1.

10.2.

10.3.

10.4.

10.5.

10.6.

10.7.

10.8.

10.9.

CONNECTING MODULES .................................................................................................................. 24

FPM-X-YY-ZZ housings .................................................................................................................................................................. 24

EPSCUS ............................................................................................................................................................................................. 25

e.UPS.................................................................................................................................................................................................. 25

LSK ..................................................................................................................................................................................................... 26

e.LSK .................................................................................................................................................................................................. 29

SKC-A ................................................................................................................................................................................................. 29

FPM+ bus repeater .......................................................................................................................................................................... 32

MAIN HOUSINGS FOR CONTROL UNIT MODULES ........................................................................... 33

EPSCUS ............................................................................................................................................................................................. 33

LSK ..................................................................................................................................................................................................... 33

SKC ..................................................................................................................................................................................................... 33

SKC-A ................................................................................................................................................................................................. 34

Main housing of the control unit, type FPM-M-YY-ZZ .............................................................................................................. 34

FPM-X-YY-ZZ .................................................................................................................................................................................... 35

FPM-U-x-x-x-x-x and FPM-L-x-x-x-x-x ........................................................................................................................................... 36

Plastic multiple-module housings ................................................................................................................................................ 36

ASSEMBLY INSTRUCTIONS ............................................................................................................. 40

Bus......................................................................................................................................................................................................40

Shielding ............................................................................................................................................................................................40

External power supplies .................................................................................................................................................................40

TYPES OF INPUTS IN THE UNIT ....................................................................................................... 40

Input type: unused ........................................................................................................................................................................... 41

Input type: digital NO ...................................................................................................................................................................... 41

Input type: digital NC....................................................................................................................................................................... 41

Input type: digital three-state ........................................................................................................................................................ 42

Input type: analog resistive ........................................................................................................................................................... 42

Input type: digital supervised NO ................................................................................................................................................. 42

Input type: digital supervised NC .................................................................................................................................................. 42

Input type: analog 0-5V .................................................................................................................................................................. 43

Input type: analog 4-20mA ............................................................................................................................................................ 43

11.

TYPES OF OUTPUTS IN THE UNIT ................................................................................................... 44

11.1.

Output type: relay ............................................................................................................................................................................ 44

11.2.

Output type: Open Collector .......................................................................................................................................................... 44

11.3.

Output type: actuators and appliances compatible with MP-Bus standard ........................................................................ 44

12.

INPUT FUNCTIONS .......................................................................................................................... 45

12.1.

Input function: disabled .................................................................................................................................................................. 45

12.2.

Input function: fire alarm ................................................................................................................................................................ 45

12.3.

Input function: smoke alarm in a duct ........................................................................................................................................ 45

12.4.

Input function: smoke alarm in air intake ................................................................................................................................... 45

12.5.

Input function: smoke warning in air intake ............................................................................................................................... 45

12.6.

Input function: smoke warning in a duct .................................................................................................................................... 45

12.7.

Input function: fire reset ................................................................................................................................................................. 45

12.8.

Input function: firefighting action ................................................................................................................................................. 45

12.9.

Input function: technical alarm ..................................................................................................................................................... 45

12.10. Input function: ventilation .............................................................................................................................................................. 45

12.11. Input function: forced air supply from downstairs ................................................................................................................... 45

12.12. Input function: forced air supply from upstairs ......................................................................................................................... 45

12.13. Input function: indicator light test ................................................................................................................................................ 45

12.14. Input function: measurement ....................................................................................................................................................... 45

12.15. Input function: venting open ......................................................................................................................................................... 45

12.16. Input function: venting close ......................................................................................................................................................... 46

12.17. Input function: drive start test....................................................................................................................................................... 46

12.18. Input function: power failure ......................................................................................................................................................... 46

12.19. Input function: limit switch ............................................................................................................................................................ 46

12.20. Input function: limit switch group ................................................................................................................................................ 46

12.21. Input function: manual control ..................................................................................................................................................... 46

12.22. Input function: manual fire alarm ................................................................................................................................................. 46

12.23. Input function: smoke detector alarm ......................................................................................................................................... 46

12.24. Input function: smoke detector warning ..................................................................................................................................... 46

12.25. Input function: evacuation with firefighting action ................................................................................................................... 46

12.26. Input function: general alarm ........................................................................................................................................................ 46

12.27. Input function: pressure control ................................................................................................................................................... 46

12.28. Input function: external temperature sensor ............................................................................................................................. 46

12.29. Input function: internal temperature sensor .............................................................................................................................. 47

12.30. Input function: upper pressure sensor ........................................................................................................................................ 47

12.31. Input function: bottom temperature sensor............................................................................................................................... 47

13.

OUTPUT FUNCTIONS ....................................................................................................................... 48

13.1.

Output function: normal fan switch on ....................................................................................................................................... 48

13.2.

Output function: reverse fan switch on ....................................................................................................................................... 48

13.3.

Output function: upper fan rotation direction ............................................................................................................................ 48

13.4.

Output function: lower fan rotation direction ............................................................................................................................. 48

13.5.

Output function: fan switch on with firefighting action ........................................................................................................... 48

13.6.

Output function: evacuation with firefighting action ................................................................................................................ 48

13.7.

Output function: sensor power supply reset .............................................................................................................................. 48

13.8.

Output function: indicator lights ................................................................................................................................................... 48

13.9.

Output function: fire alarm............................................................................................................................................................. 48

13.10. Output function: technical alarm .................................................................................................................................................. 48

13.11. Output function: line actuator plus .............................................................................................................................................. 48

13.12. Output function: line actuator minus ........................................................................................................................................... 48

13.13. Output function: failure ................................................................................................................................................................... 48

13.14. Output function: actuator .............................................................................................................................................................. 48

13.15. Output function: actuator disabled .............................................................................................................................................. 48

13.16. Output function: cut-off gate ......................................................................................................................................................... 49

13.17. Input function: pressure regulator ............................................................................................................................................... 49

13.18. Output function: exhaust bottom ................................................................................................................................................. 49

13.19. Output function: exhaust top ........................................................................................................................................................ 49

13.20. Output function: supply bottom ................................................................................................................................................... 49

13.21. Output function: supply top ........................................................................................................................................................... 49

14.

COMMISSIONING INSTRUCTIONS ................................................................................................... 50

15.

15.1.

15.2.

15.3.

16.

16.1.

16.2.

16.3.

17.

PRODUCT SAFETY PRECAUTIONS .................................................................................................. 51

Proper usage regulations ............................................................................................................................................................... 51

Periodical inspection and maintenance regulations ................................................................................................................ 51

Safety precautions .......................................................................................................................................................................... 51

PACKAGING, TRANSPORT AND STORAGE ....................................................................................... 53

Packaging ......................................................................................................................................................................................... 53

Transport regulations ..................................................................................................................................................................... 53

Storage regulations ......................................................................................................................................................................... 53

ENVIRONMENT IMPACT .................................................................................................................. 54

LIST OF DRAWINGS ....................................................................................................................................... 55

18.

APPENDIX A: FPM-X-YY-ZZ HOUSING SPECIFICATIONS ................................................................. 56

19.

APPENDIX B : - DRAWINGS OF FPM-X-YY-ZZ HOUSINGS ............................................................... 57

19.1.

FPM-2-YY-ZZ .................................................................................................................................................................................... 57

19.2.

FPM—4-YY-ZZ .................................................................................................................................................................................. 59

19.3.

FPM-6-YY-ZZ .................................................................................................................................................................................... 61

19.4.

FPM-8-YY-ZZ .................................................................................................................................................................................... 63

19.5.

FPM-10-YY-ZZ .................................................................................................................................................................................. 65

20.

APPENDIX C : FPM-U-X-X-X-X-X AND FPM-L-X-X-X-X HOUSING SPECIFICATIONS ......................... 67

21.

APPENDIX D : FPM-U-X-X-X-X-X AND FPM-L-X-X-X-X HOUSINGS - DRAWINGS .............................. 68

21.1.

FPM-U-4-6-0-A-D .............................................................................................................................................................................. 68

21.2.

FPM-U-4-6-18-A-G ........................................................................................................................................................................... 69

21.3.

FPM-U-4-6-0-B-D .............................................................................................................................................................................. 69

21.4.

FPM-U-4-6-18-B-G ...........................................................................................................................................................................70

21.5.

FPM-U-6-6-0-A-D ..............................................................................................................................................................................70

21.6.

FPM-U-6-6-26-A-G ........................................................................................................................................................................... 71

21.7.

FPM-U-6-6-0-B-D .............................................................................................................................................................................. 71

21.8.

FPM-U-6-6-26-B-G ........................................................................................................................................................................... 72

21.9.

FPM-L-8-6-0-A-D .............................................................................................................................................................................. 72

21.10. FPM-L-8-6-18-A-G ............................................................................................................................................................................ 73

21.11. FPM-L-8-6-0-B-D .............................................................................................................................................................................. 73

21.12. FPM-L-8-6-18-B-G ............................................................................................................................................................................ 74

22.

APPENDIX E: CUSTOM HOUSINGS .................................................................................................. 75

1. APPLICATION OF THE FPM+ UNIT

The FPM Plus fire alarm control panel is a modular device

for monitoring the operating status and control of all the

pieces of equipment triggered as a result or during a fire.

These can be dedicated firefighting systems, such as:

Fire emergency ventilation system,

Fire shutdown systems,

Evacuation support system,

Other building systems triggered to do any action as a result

of fire.

Other systems include:

Access control system,

Burglary and robbery alarm system,

Escalator,

Lifts,

Utilities control (shut-off) systems,

Heat pumps and HVAC systems.

The unit features integration of various types of systems

(with different functions) and building a single control

algorithm (control matrix).

9) (…) equipment (fixed or semi-fixed, actuated manually or

automatically) having the function of prevention, detection

and putting out or containment of fires, particularly fixed or

semi-fixed fire extinguishing and fire protection systems,

Page 4 of 78

inerting systems, voice alarm system and fire alarm system

equipment, including alerting/alarm devices, fire alarm

receiving equipment, damage alert receiving system,

evacuation lighting systems, internal standpipes and

standpipe valves, external standpipes, pumps in fire water

pumping stations, fire dampers, smoke extraction

equipment, explosion prevention and containment

equipment, smoke curtains and doors, fire doors and other

fire rated closures if fitted with control systems, fire

emergency power shutdown devices, and hoists for rescue

teams;

The control unit is responsible for technical handling of fire

controls in the building. In response to an alarm from the Fire

Alarm System, the unit will control all the firefighting

equipment according to the assumed fire scenario.

As a minimum, the link between the Fire Alarm System and

the Control Unit can consist of:

Zone alarms (‘Fire in a zone’) - number of signals equals the

number of zones - signal from FAS to the FPM+control unit,

Feedback alarms - these should be matched to the needs of

the building. Feedback alarms may include notifications of

the control unit operation in fire mode (trigger confirmation),

notifications of damage to the FAS, indications of alarms and

hazards discovered by the control unit (if needed)

Fig. 1 Location of the control unit within the overall fire safety system in the building

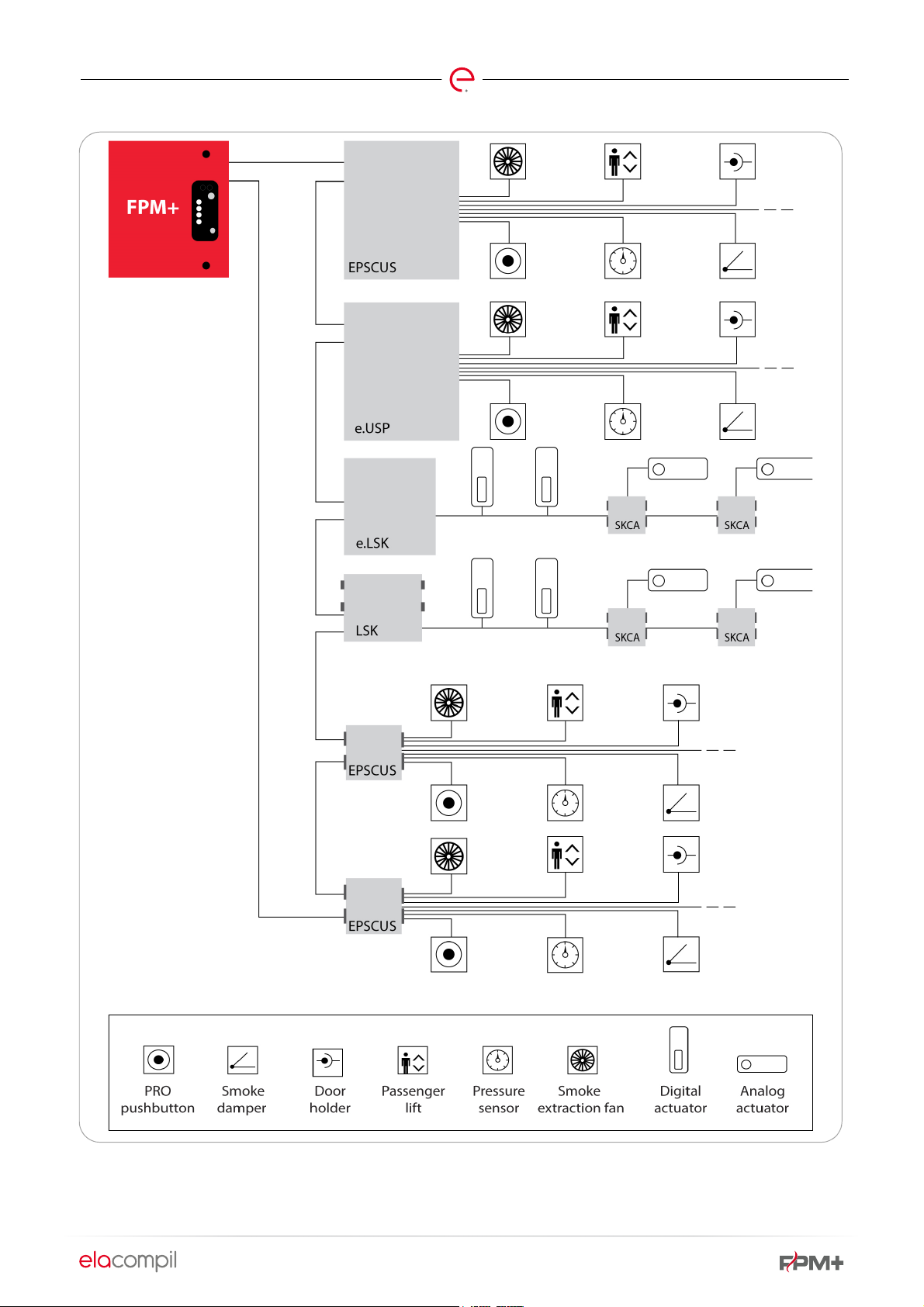

2. FPM+ ARCHITECTURE AND TOPOLOGY

Page 5 of 78

The FPM+ unit has a modular design and is composed of

modules of various types with various functions. Specific

modules may be enclosed in separate single-module

housings or in group housings where more than one module

can be placed in each.

All the modules are connected with a bus loop. Every module

on the bus is addressable. Information is exchanged digitally

between the modules.

The MASTER module is unique among all the unit modules.

This is the main module of the unit, with the function of

overseeing the exchange of information between the other

modules and the exchange of information between the

control unit and the higher level system (BMS, firefighting

equipment integration system). The MASTER module with

additional control unit handling items (buttons and indicator

lights) is always housed in a separate housing (main

housing of the control unit). Together with the MASTER, this

housing can accommodate the power supply and a

maximum of two EPSCUS controllers.

Other modules can be housed in ABS housings or steel

housings.

Page 6 of 78

Fig. 2 Control unit topology diagram

3. REQUIREMENTS FOR EXTERNAL COMPONENTS

3.1. FPM+ POWER SUPPLY

Page 7 of 78

The FPM+ modules, according to type, can be powered from:

The control unit internal power supply,

External power supply,

Mains power ~230V.

Mains power can only be used when the unit performs

control and monitoring functions over systems which are

not required to work during a fire. An example system of this

type can be a fire damper control system. In this case, mains

3.2. ELECTRICAL INSTALLATION

Electrical installation should be built with flame retardant or

non-flammable cables. The choice of cable depends on the

use of the FPM+ unit in the building. If the FPM+ controls

any equipment or systems which are required to operate

during a fire, a non-flammable cable must be used. If the

FPM+ controls any equipment or systems which are not

required to operate during a fire, a flame retardant cable can

be used.

The general rule is that if at least one system or one

appliance connected to the FPM+ must be operating during

a fire, FPM+ action at the time of fire must be assured.

Therefore, the bus and controller power supply installations

must be wired in non-flammable cables. Connections to

appliances and systems should be wired with a cable

adequate for the requirements prevailing in the building.

For fire safety applications, Certificates of Approval should

be issued for the cables by CNBOP-PIB Scientific and

Research Center for Fire Protection National Research

Institute.

voltage or secure voltage from external power supply units

can be used.

If the FPM+ is expected to monitor and control equipment

and systems which are required to operate during a fire, all

the FPM+ modules should be powered with a buffered

power supply, certified for conformity with EN-PN 54-4 or

EN-PN12101-10, with the supply voltage and output current

appropriate for the specific application.

Cable ways for fire safety applications should be produced

to appropriate rating, i.e. E30/E60/E90, etc. For a specific

application. Conformity with the classification requirements

should be verified by an appropriate certificate.

Example cables:

YnTKSYekw 1x2x0.8 – fire retardant cable for wiring

installations not required to operate during a fire. Can be

used for example to wire a bus linking the modules, or to wire

an MP-Bus.

HTKSHekw PH90 1x2x1 – fire resistant cable for wiring

installations required to operate during a fire. Can be used for

example to connect bus lines.

HDGs 2x1 – fire resistant cable for power supply and control

of systems which need to be powered with electricity during

a fire.

The designer should always make sure that the cable they

intend to use has the requisite approvals and certificates

required by law.

4. FPM+ LIMITATIONS

Page 8 of 78

4.1. NO. OF ITEMS PER BUS

In terms of technical feasibility, a maximum of 254

controllers can be covered within a single bus. These

modules are divided into two groups:

126 x LSK / e.LSK controllers

126 x EPSCUS/e.USP controllers

LSK/e.LSK modules have an address pool attributed on

bus 1..126, while the pool attributed to EPSCUS/e.UPS

modules is 129…254.

LSK controllers can be addressed on the basis of settings

of controls on the front panel of the respective module, or

on the basis of controller serial numbers.

EPSCUS, e.USP and e.LSK controllers are addressed on the

basis of controller serial numbers.

4.2. LENGTH OF BUS BETWEEN

MODULES

The bus is divided into sections. Each module on the bus

is the end and the start of the respective sections to which

it is connected. The length of sections between specific

modules should not exceed 1200 meters.

4.3. LENGTH OF MP-BUS

The overall length of a single MP-Bus (connecting 8

actuators with a single LSK module) should not exceed

600 meters.

4.4. NUMBER OF ZONES

Notwithstanding the number of all zones (fire, control,

smoke extraction zones) that can be covered by the FPM+

unit, there is a limitation of the number of zones to which

a specific output can be assigned. This number is limited

to 70 in the software. Should outputs (EPSCUS and e.USP

relay outputs and LSK and e.LSK actuators) need to be

assigned to a higher number of zones, contact the FPM+

unit manufacturer.

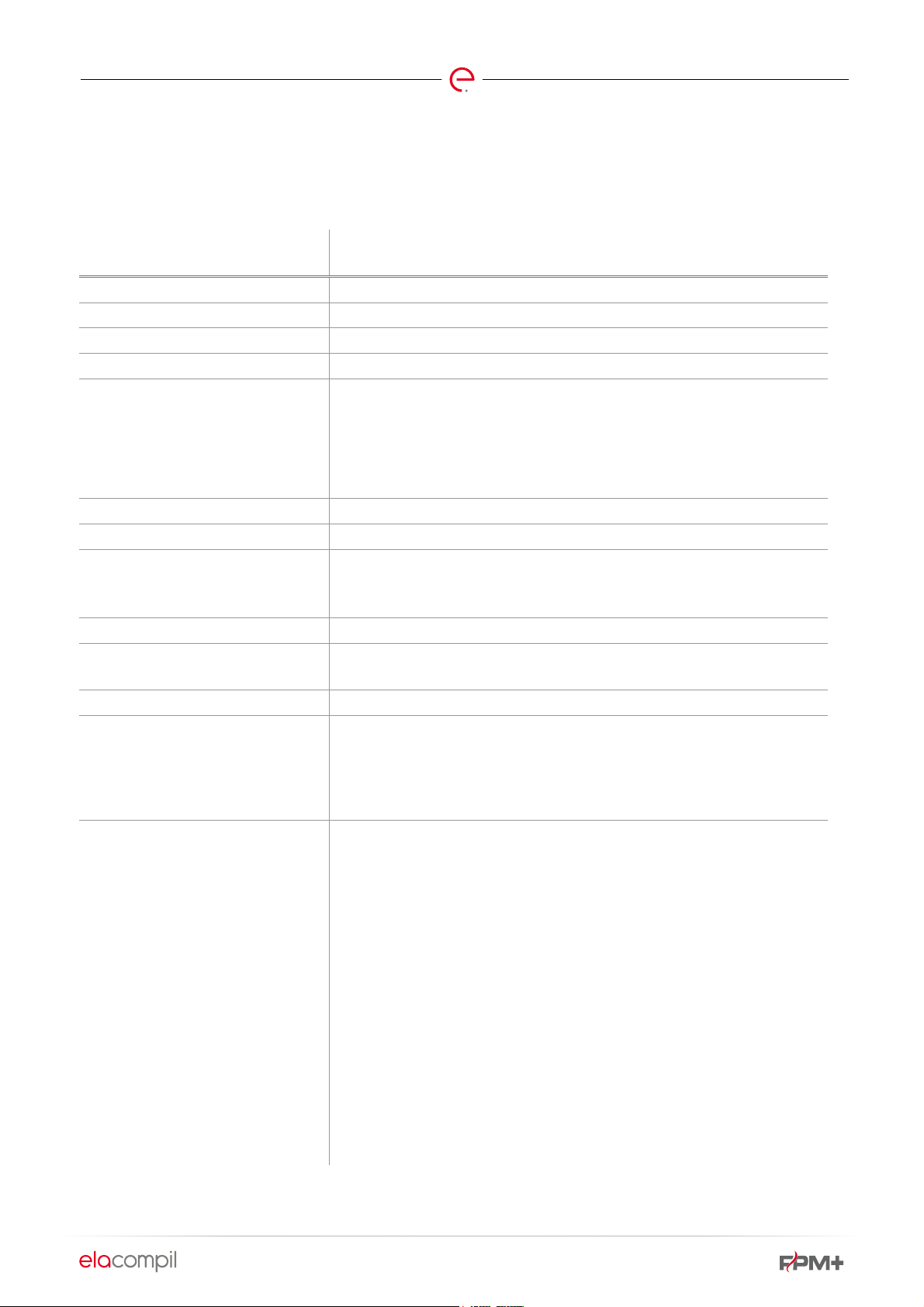

5. FPM+ UNIT AND MODULE SPECIFICATIONS

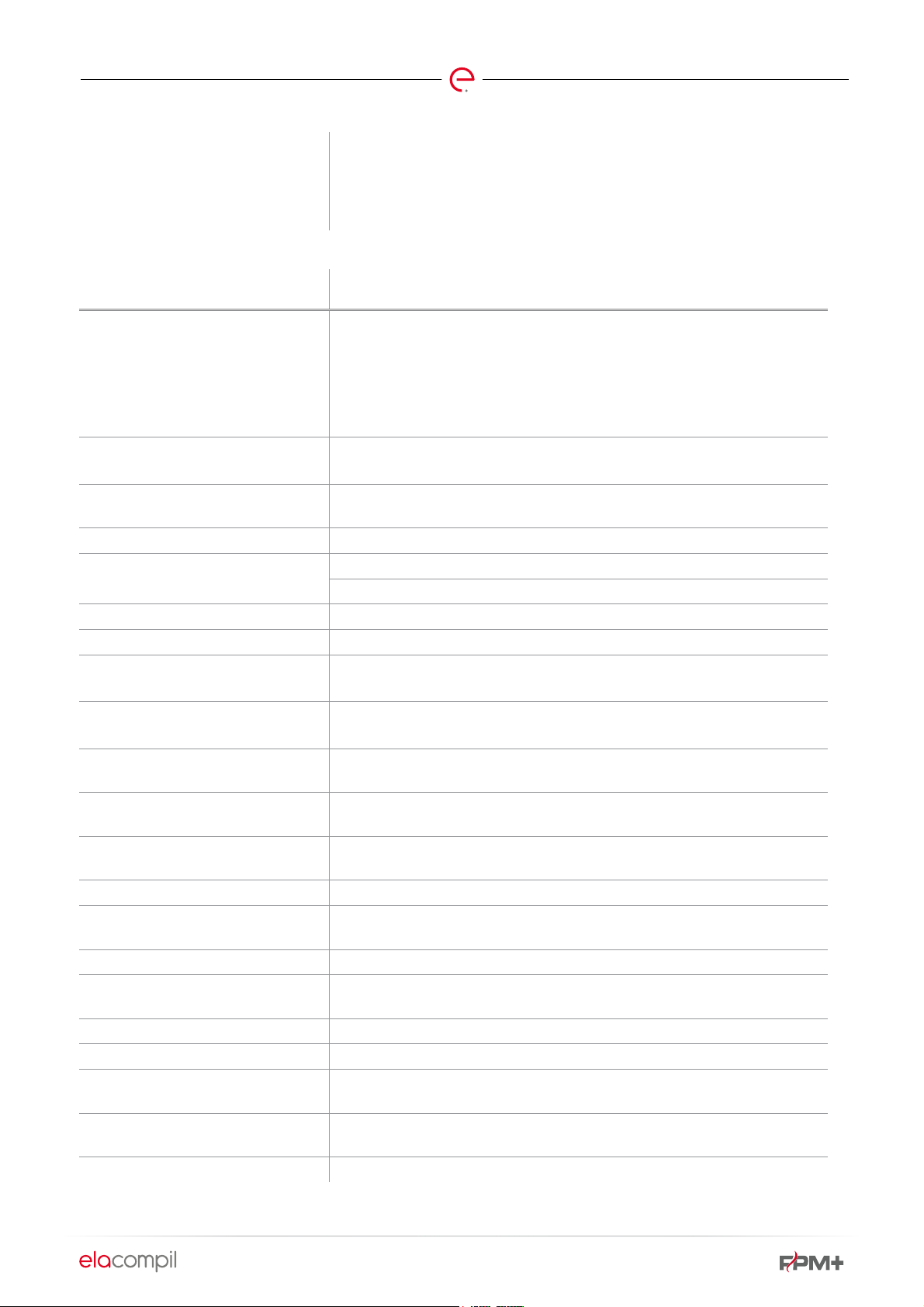

Table 1 FPM+ unit and module specifications

GENERAL DESCRIPTION

Page 9 of 78

FPM+ architecture

Climate class

Loops

Minimum no. of modules

Maximum no. of modules

Max. bus voltage

Max. bus current

IP

Operating temperature range

Dimensions (L x W x H)

Firmware version

Manual/auto options

Systems and appliances integrated

with the control unit

Modular, loop, addressable unit

2

1x

1x, as per 3.1.1 of this approval

1 MASTER

126 EPSCUS/e.USP

126 LSK or LSK/24 or e.LSK

2016 SKC, SKC-A (using 126 e.LSK), or 1008 SKC, SKC-A (using 126 LSK)

A MASTER module is required for more than 1 module

5VDC

Short-circuit current 50mA (limited with a polyfuse)

IP42 for external housing of the control unit and individual housings

IP55 for SKC modules

IP65 for LSK and LSK/24 modules

-50C to +550C (relative humidity 80% at 550C)

Min. 500x600x250

Other dimensions as per the control unit documentation

FPMplus

Automatic, through a signal from the fire alarm system control panel, smoke

extraction system control panel, or automatic smoke detectors of the fire

alarm system.

Manual trigger with the smoke extraction button

Manual control from the integrating system

Fire alarm control panels

Smoke and heat propagation control system components (shut-off dampers,

smoke vents, fire vents, smoke curtains, etc.)

Conventional fire detectors (readings on parametric lines)

Smoke extraction buttons and manual call points

Pressure sensors

Temperature sensors

Wind direction and wind force detectors

Voltage presence detectors

Fire dampers

Electromagnetic holders (releases)

Voice alarm systems

Fixed fire extinguishing equipment

Emergency exit controls

Other building control systems

Intermediary devices, such as: contacts, inverters, switches

Other external appliances and systems that may or must be controlled during

a fire, where the design and operating mode makes them integrable with the

control unit

Other systems and appliances without firefighting functions where the

design and operating mode makes them integrable with the control unit

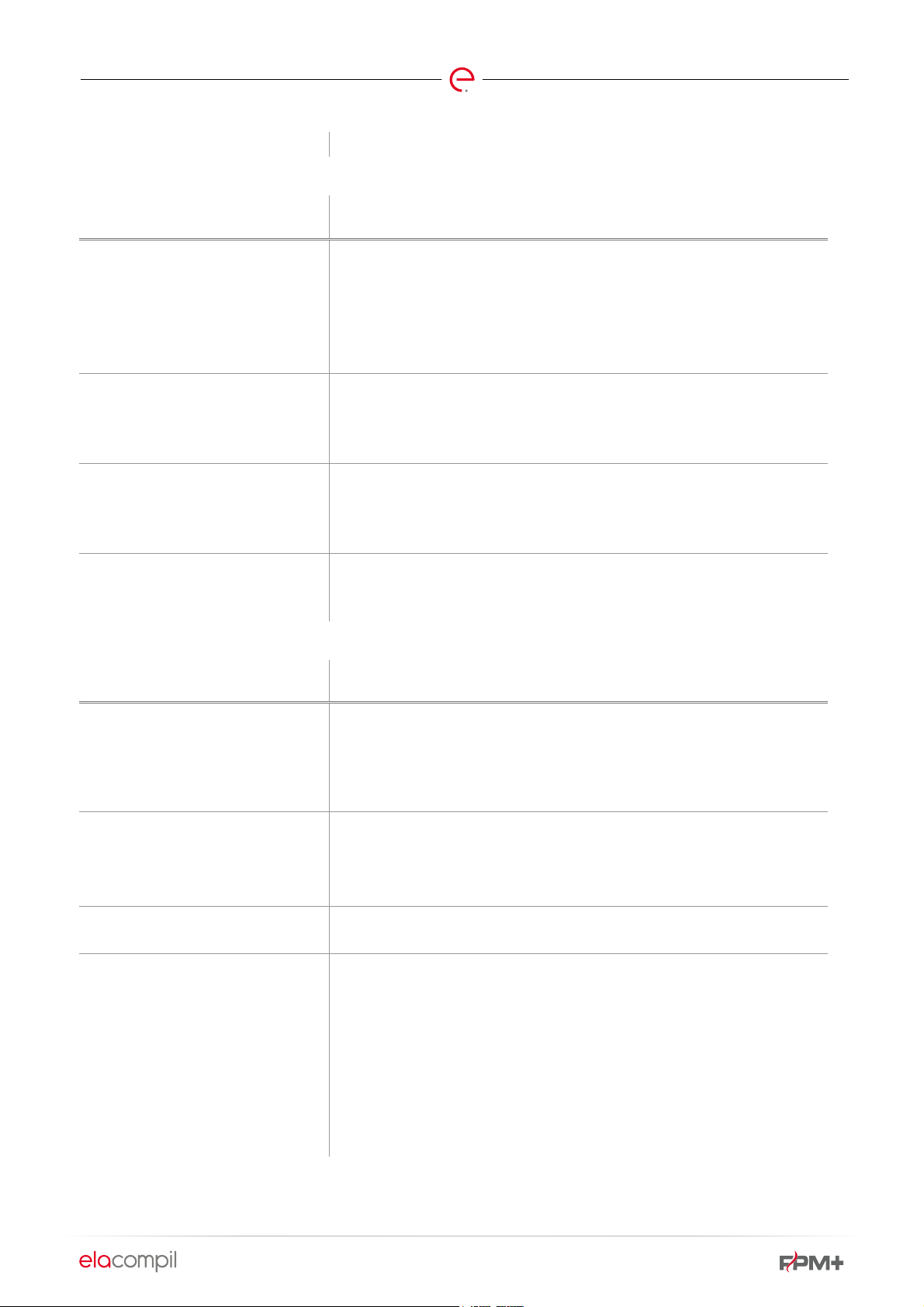

POWER SUPPLY DESCRIPTION

Page 10 of 78

Power supply

Supply voltage

Max. power consumption

Internal operating voltage

Power supply type or other

identification

Operating temperature range

Housing protection grade

Dimensions (L x W x H)

Main power supply: supply voltage

Max. power consumption from

mains

Max. continuous load on power

supply

Max. short-term load on power

supply

Ripples

Uninterrupted power supply: battery

type

Max. battery capacity

Battery charging voltage in buffer

mode

Max. battery charging current

Battery cut-off voltage

Max. resistance of battery bank

circuit

Output circuits: power supply output

voltage range

Functional class

External power supply conforming to PN-EN12101-10 and PN-EN 54-4

Dedicated control unit power supply, type CAMELEON, series ZM24VxxA-

yyyPZ(C), specifically

ZM24V6A-151PZ(C), ZM24V8A-200PZ(C) ZM24V12A-300PZ(C), ZM24V16A-

400PZ(C) and ZM24V24A-600PZ(C)

~230V mains for LSK module

24-48VDC from external power supply

For LSK module powered from ~230VAC mains

2A @ 24VDC (excluding power supply to appliances, such as actuator,

holders, etc.)

24-48VDC

CAMELEON

ZM24V24A-600PZ(C)

-25..70°C

n.a. (installed in multiple-module IP42 housing)

262x111x66mm

With connections 279x111x66mm

184..230..253VAC

230 V AC (-20% / +10%)

2.1A

I

=18A

maxA

I

=24A

maxB

150mV

AGM type (VRLA) lead acid batteries

120Ah

26.4…..28.8V

6A

<21.0V

100mΩ

21.0…28.8V

A

Page 11 of 78

Environmental class

2 (when installed in the control unit in IP42 housing)

OUTPUTS DESCRIPTION

Potential-free relay outputs

Potential-free relay contacts

Contact type: changeover

Current capacity: 2A for 30VDC

Resistance of contacts: < 50mΩ

For loads with higher current or voltage, use additional high current relays

Number of zones assignable to a single output: 70

OC outputs

OC type outputs

Max. external voltage 48VDC

Current capacity: 100mA per output at 25°C

Induction load operation only with idling diode!

MP-Bus outputs

MP-Bus output

No. of items on bus: 8

Operating voltage >20VDC

Maximum current >10mA

Maximum outputs

MP-Bus: 126*8 = 1008 x MP-Bus devices for LSK, 2016 for e.LSK

Relay outputs: 1008

O/C: 756

INPUTS DESCRIPTION

Digital inputs

Digital inputs, supervised, with the option of switching off supervision (NO,

NC mode)

Typical line resistance values

Supervision state 1kΩ

Alarm state 3,3kΩ

Analog inputs

Analog inputs for signal acquisition:

4..20mA (with external resistor)

0..5V direct

0..10V with external resistor

Max. inputs

Digital, monitored: 504

Digital/analog (configurable): 1008 for EPSCUS, 2016 for e.LSK

Recommended cable types

For control unit bus: non-flammable cables (for fire ventilation systems and

smoke extraction systems) or flame retardant cables (for fire damper

control), single pair, shielded. Min. core section 0.5mm

Sample cables:

Flame retardant YnTKSYekw 1x2x0.8

Fire resistant HTKSHekw 1x2x1.0 PH90

If the control unit covers at least one appliance requiring uninterrupted power

supply during a fire alarm, fire resistant cables should be used to produce the

bus, in accordance with the applicable legal requirements, including § 187 of

Regulation of the Minister of Infrastructure of 12 April 2002 concerning

Supply voltage

IP

No. of inputs

No. of outputs

FPM+ bus

Configuration/visualization bus

Page 12 of 78

technical requirements applicable to buildings and their locations (Journal of

Laws No. 75, item 690, as amended).

For powering actuators - cables should be selected in accordance with the

legal requirements, including § 187 of Regulation of the Minister of

Infrastructure of 12 April 2002 concerning technical requirements applicable

to buildings and their locations (Journal of Laws No. 75, item 690, as

amended).

E.g. fire resistant cable HDGs 2x1

Use of a flame retardant cable, e.g. YnTKSYekw 3x2x0.8, is permitted for

powering and controlling appliances for which uninterrupted power supply is

not required during a fire (e.g. fire cut-off dampers with springreturn

actuator).

If the appliances connected to the control unit require the use of cabling with

varying flammability classifications, use highest rated cables out of the

applicable requirements to build the bus.

Cables must be provided with relevant approval documents for use in fire

protection installations (Certificate of conformity, Certificate of Approval by

CNBOP-PIB Scientific and Research Center for Fire Protection National

Research Institute).

24-48VDC

n.a. (installed in multiple-module IP42 housing)

Digital/analog inputs: 8

Relay outputs: 8

2xRS485

Ethernet

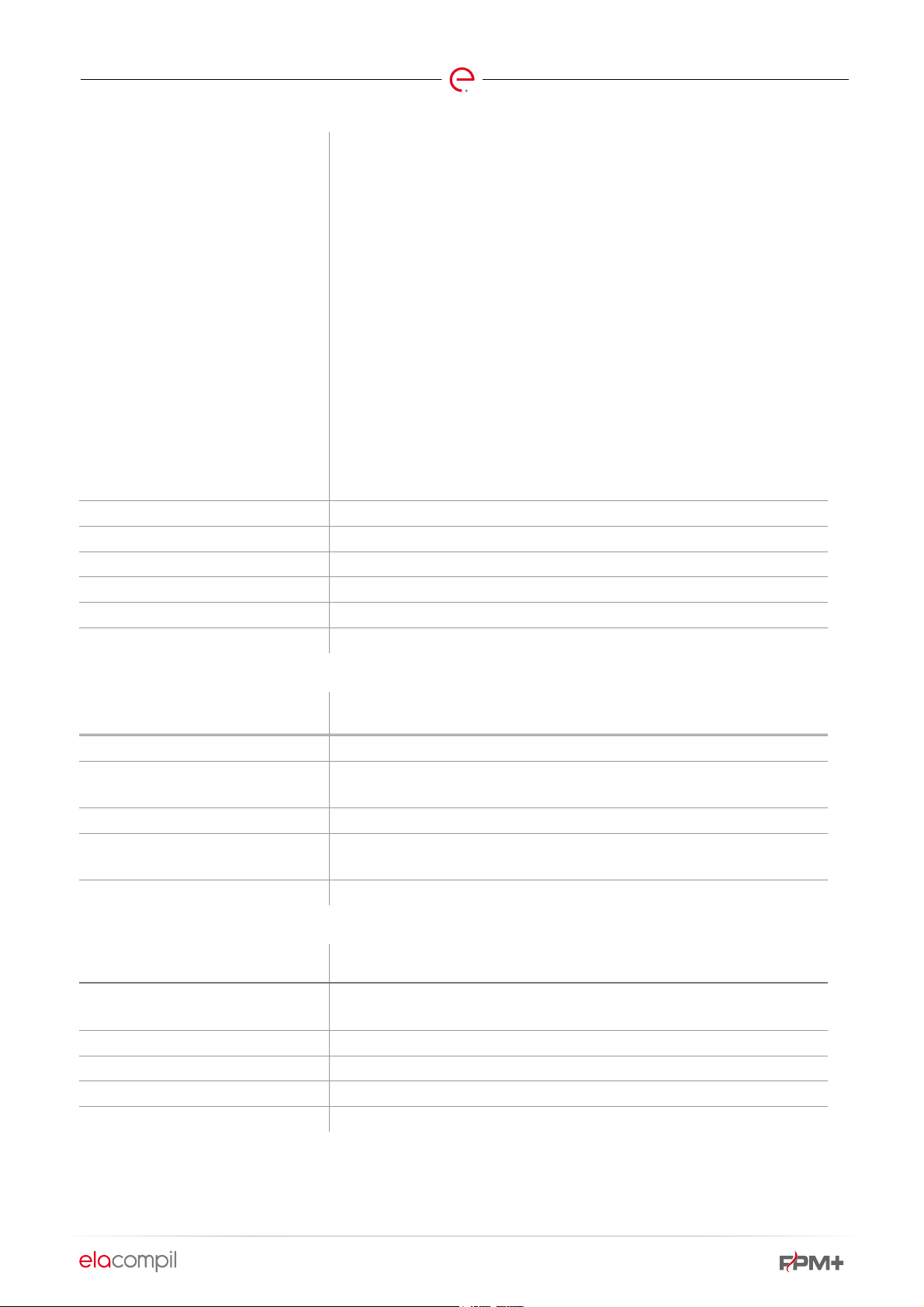

EPSCUS module DESCRIPTION

Supply voltage

IP

24-48VDC

n.a. (installed in multiple-module IP42 housing)

IP42 – for individual housing with ABS

No. of inputs

No. of outputs

Digital/analog inputs: 8

Relay outputs: 8

O/C outputs: 6

FPM+ bus

2xRS485

LSK and LSK/ MODULE DESCRIPTION

Supply voltage

24 - 48VDC for LSK/24

230VAC for LSK

IP

No. of inputs

No. of outputs

FPM+ bus

IP65

Digital inputs: 4

MP-Bus: 1

2xRS485

FPM+ BUS REPEATER MODULE DESCRIPTION

Page 13 of 78

Supply voltage

IP

No. of inputs

24VDC

n.a. (installed in multiple-module IP42 housing)

2x RS485

SKC module DESCRIPTION

Supply voltage

IP

No. of inputs

No. of outputs

230VAC

IP55

n/a (power supply module)

24VAC power supply output

SKC-A MODULE

Supply voltage

IP

No. of inputs

230VAC or 24VAC or 24VDC

IP42

MP-Bus: 1

Analog actuator limit switches: 1

No. of outputs

230VAC or 24VDC control output

MP-Bus: 1

e.LSK MODULE DESCRIPTION

Supply voltage

IP

24-48VDC/VAC

IP 20 for the module itself

IP 42 for steel housings (module installed in FPM+ multiple-module housing)

IP 42 for ABS housings (module installed in same housing as SKC-A)

Maximum power consumption

In/out lines

2.4W @ 24VDC

System bus – 2x – EIA-485 (RS-485) standard, galvanically isolated

MP-BUS – 2 x – MP-BUS standard

System bus voltage

Max. bus current in supervised state

Dimensions

+/-5VDC

50mA (typical 0.05mA)

88 x 108 x 62 mm

In ABS housing: 172 x 132 x 78 mm

Weight

ca. 180 g

In ABS housing: 450 g

e.USP MODULE DESCRIPTION

Supply voltage

24-48VDC/VAC

Page 14 of 78

IP

Maximum power consumption

In/out lines

System bus voltage

Max. bus current in supervised state

Dimensions

Weight

IP 20 for the module itself

IP 42 for steel housings (module installed in FPM+ multiple-module housing)

IP 42 for ABS housings (module installed in same housing as EPSCUS)

2.4W @ 24VDC

System bus – 2x – EIA-485 (RS-485) standard, galvanically isolated

Inputs – 16 x

Outputs – 8 x - relays

+/-5VDC

50mA (typical 0.05mA)

214 x 108 x 62 mm

In ABS housing: 252 x 202 x 90 mm

ca. 400 g

In ABS housing: 1100 g

6. FPM+ MODULES

Page 15 of 78

The FPM Plus system is composed of multiple units (the

central module and local modules) with different functions.

The central module monitors the service of local controllers

Modules are set up in FPM+ Configurator.

and facilitates communication between them.

6.1. FPM+ CONTROL UNIT - CENTRAL (MASTER) MODULE

The master module of FPM+ control unit has the following

functions:

exchange of information between other modules

monitoring loop continuity

connection of FPM+ unit with a visualization system (BMS,

SMS).

Fitted with Ethernet port, two RS485 ports, an RS232 port,

eight relay outputs, and eight inputs.

The communication ports as well as two 5A@VDC relays are

installed on the main board of the module, while the inputs

and the six additional 1A@30VDC outputs are located on the

extension board.

Module inputs are used to monitor and control the unit

(managing lights, buttons, access key).

The main unit housing consists of: the housing itself, a

control & alert panel, a power supply with batteries (the

power supply and batteries can be waived upon request and

the unit can be powered from an external certified power

supply), installation pieces (cable grommets, DIN bus bars,

cable trays).

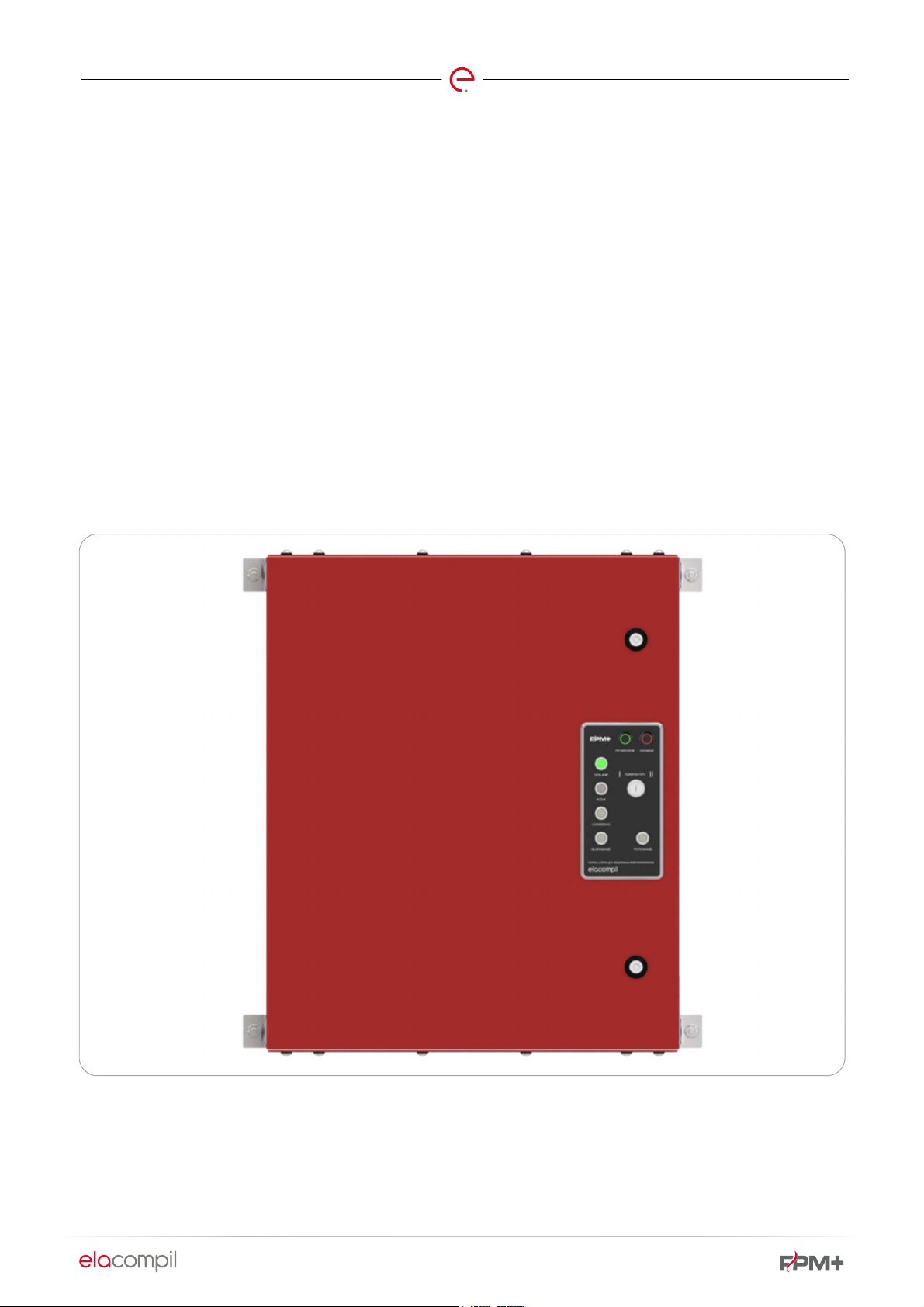

Fig. 3 FPM+ unit housing (MASTER housing)

A control & alert panel is located on the main housing of the FPM+ unit, fitted with the following controls:

Page 16 of 78

Fig. 4 Control panel

Confirm

for shutting down voice alarms

Reset

button

button

for a fire reset triggered from access level 2

light

Power

indicates that the unit is powered and working

Malfunction light

indicates that the unit has discovered a malfunction

light

Fire

indicates that the unit is in the fire state

light

Locked

indicates that the unit has certain components in locked state

6.2. LSK

Page 17 of 78

The LSK module is designed for controlling and monitoring

actuators and other devices fitted with MP-Bus interface.

Such actuators may include:

fire shut-off damper actuators (e.g. BF24-TL-T-ST),

line actuators of air dampers in HVAC systems, and slide

valves (e.g. LH24A-MP, NM24A-MP, SM24A-MP, GM24A-MP)

SA actuators for dampers and louvres (e.g. LU24A-MP)

actuator valves for water installations (e.g. LV24A-MP-TPC,

NVC24A-MP-TPC)

actuators for water installation valves (e.g. LR24A-MP)

VAV regulators (e.g. LMV-D3-MP)

air pressure regulators (e.g. VRP-M)

Apart from devices supporting the MP-BUS standard, the LSK

module can also control and monitor analog equipment

items, e.g. fire damper actuators. In order to support such

devices, the LSK must be connected to SKC-A module.

The LSK module is also fitted with four potential-free signal

inputs. These inputs can operate in supervised, NO or NC

modes. For the purpose of receiving alarm signals from the

FAS, an input should be configured in line supervision mode.

The primary method of installation of an LSK module is to

place it in a separate housing in the building, near the

equipment it supervises.

Two versions of LSK modules are available: fitted for 230VAC

or 24VAC/VDC power supply. The difference between these

modules is the non-existence of a transformer in the power

system. Besides, the modules are identical and have the

same properties.

Fig. 5 LSK module

6.3. E.LSK

Page 18 of 78

The e.LSK is a more recent version of LSK, a module

designed for controlling and monitoring actuators and other

devices fitted with MP-Bus interface.

Fig. 6 e.LSK module

Below are the primary differences between e.LSK and LSK:

e.LSK is fitted with two MP-Bus items (1 bus in LSK), capable

of accommodating up to 16 actuators (8 actuators can be

connected to an LSK module);

no trip inputs in e.LSK (there are 4 trip inputs in an LSK

module);

different installation method: by default, e.LSK should be

installed in a multiple-module housing of the FPM+ unit on a

DIN bus bar, while LSK is installed in a separate housing.

The primary method of installation of an LSK module is to

place it in a multiple-module housing of the FPM+ unit, while

an e.LSK can be installed in a separate housing in the

building, near the equipment it supervises. Such additional

housing for e.LSK is the same as that for SKC-A.

e.LSK modules are powered with 24- 40VDC/VAC voltage.

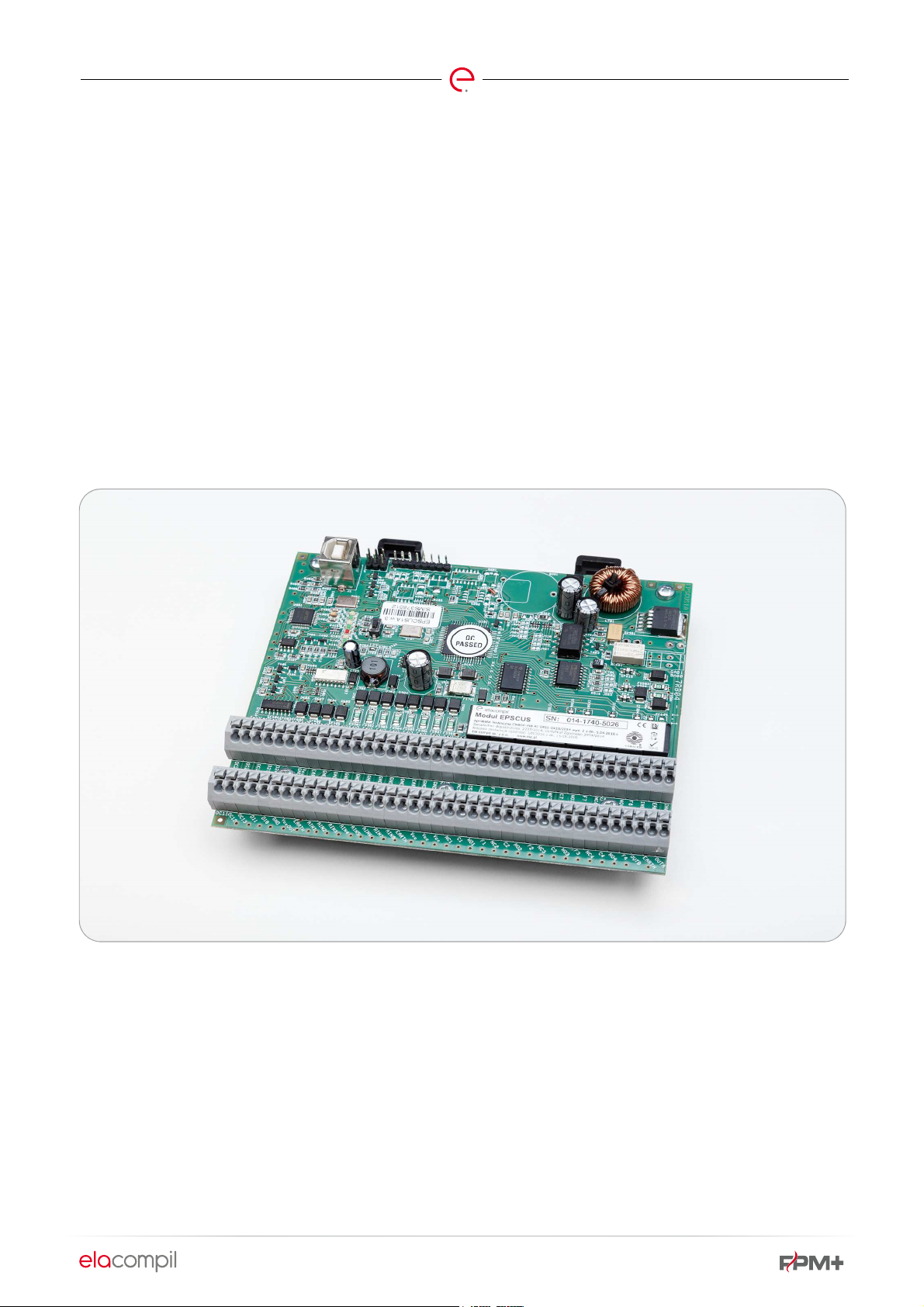

6.4. EPSCUS

Page 19 of 78

EPSCUS is the primary control and monitoring module of an

FPM+ unit. It can receive potential-free signals from external

equipment and systems, and is fitted with 8 relay outputs for

controlling external hardware.

In addition, an EPSCUS module has 6 OC outputs which can

be used for connecting indicator elements, such as lights.

A module adapted to measurement of analog values from

different types of detectors is referenced as EPSCUS(A).

An EPSCUS module can be placed:

in the main housing, together with the MASTER module max. 2 items;

in one of the steel housing versions (OZ-FPMPLUS-xx or

OBZ-FPMPLUS-xx);

in an ABS housing for a single module.

EPSCUS modules are installed in multiple-module housings

on a DIN bus bar.

The choice of the specific housing and number of modules

in a housing depends on the building design and the need to

build a control system for fire safety equipment.

The EPSCUS model is designed for 12-48VDC.

Fig. 7 EPSCUS module

6.5. E.USP

Page 20 of 78

e.USP is the more recent version of the EPSCUS module. It

can receive potential-free signals from external equipment

and systems, analog signals (0 30V or 0-24mA, shared

Fig. 8 e.USP module

ground wire) and is fitted with 8 relay (toggle) outputs

designed for external device control.

Differences between USP and EPSCUS modules:

no OC outputs in e.USP (there are 6 OC outputs in an

EPSCUS module);

e.USP has 16 inputs (EPSCUS - 8 inputs);

higher current capacity of e.USP outputs (up to 5A);

additional indicator items (LEDs) for easier startup and

servicing;

terminals supporting cables with core diameters up

to 2.5mm2 (28-12AWG);

closed DIN bus bar enclosure.

6.6. SKC

SKC modules are designed for powering and monitoring the

service of type BF24TL-T-ST actuators. These actuators are

used to energize fire shut-off dampers.

EPSCUS modules are installed in FPM+ unit housings on a

DIN bus bar. Installation in an additional ABS housing is also

possible, such as the housing for EPSCUS module. The

choice of the specific housing and number of modules in a

housing depends on the building design and the need to

build a control system for fire safety equipment.

The EPSCUS model is designed for 12-48VDC.

A single module supports the connection of a single damper

with a single actuator. It converts ~230V mains voltage to

the supply voltage for ~24V actuator.

Page 21 of 78

Fig. 9 SKC module

6.7. SKC-A

The function of SKC-A modules is to supervise the service of

analog equipment controlled by 24VDC or 230VAC voltage

input. Such equipment can include fire damper actuators.

The modules are adapted for integration with LSK modules.

The modules are available in 2 versions, depending on

equipment operating voltage:

230V version - for equipment powered from ~230VAC mains

24V version - for equipment powered with 24VDC

The module can be configured for transmission at 230VAC,

24VDC voltage relay output, or as a potential-free output

only.

The module is configured in terms of output signal (230VAC

voltage, 24VDC voltage, potential-free signal) by the

manufacturer. Such setup can also be done by a trained

service operative. In such case, the manufacturer is not

responsible for service personnel errors.

Identification of SKC-A module. According to module

configuration, additional power supply and output data is

provided in the identification.

Identification of

SKC-A-XXX-YYY.

Where:

SKC-A – module type

-XXX – supply voltage

-

-

– 230VAC power supply

-230

– 24VDC power supply

-24

- output type

YYY

-

-

-

– 230VAC output

-230

– 24VDC output

-24

– relay output

-R

Example:

Example:

Page 22 of 78

Example:

SKC-A-230-230

– SKC-A module

configured for 230VAC voltage supply

and generating 230VAC voltage signal

at output

SKC-A-230-24

configured for 230VAC voltage supply

and generating 24VDC voltage signal

at output

– SKC-A module

SKC-A-230-R

– SKC-A module

configured for 230VAC voltage supply

and generating potential-free signal at

output

NOTE: For technical reasons, the module cannot be configured according to the pattern SKC- A- 24- 230

Fig. 10 SKC-A module

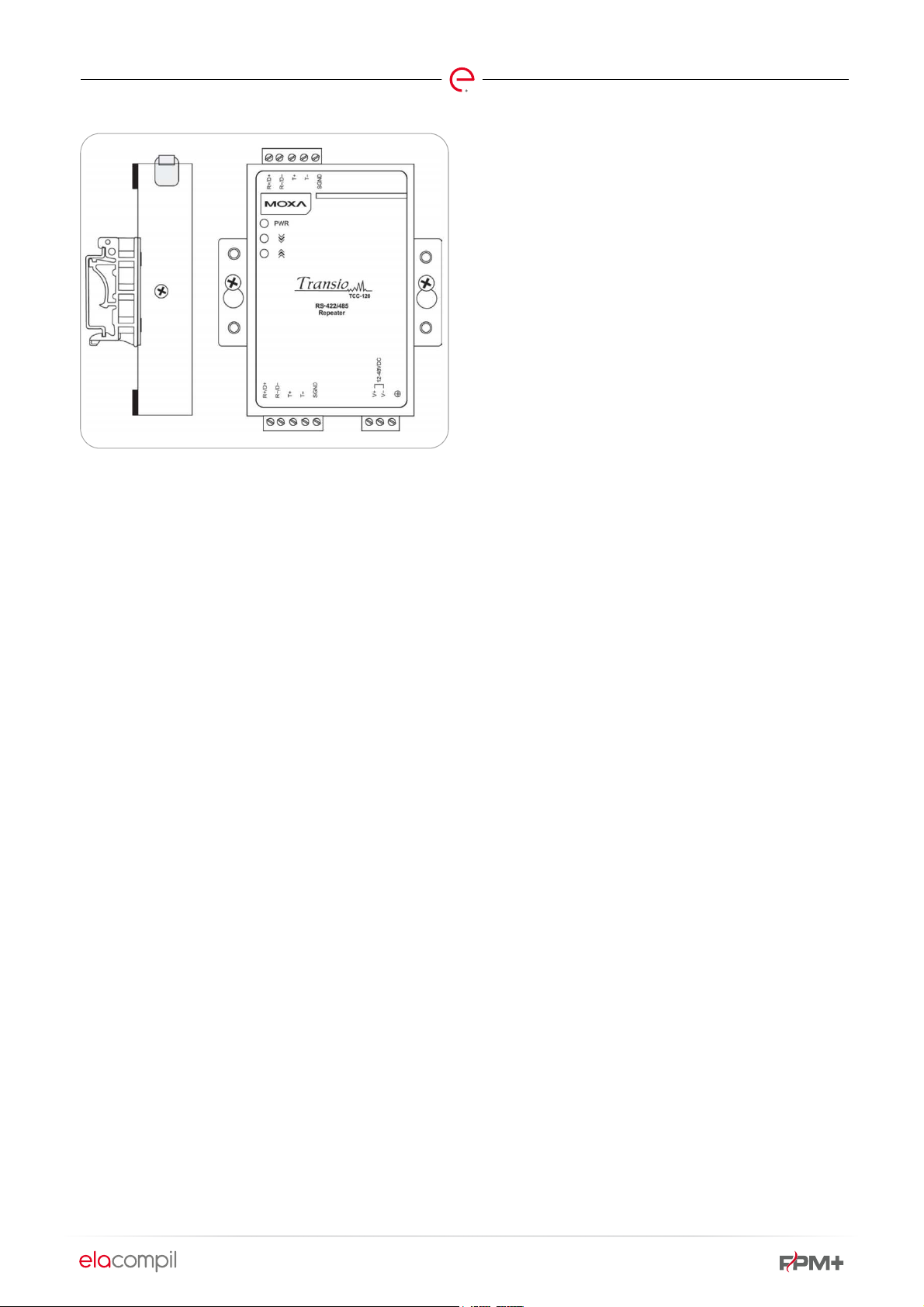

6.8. FPM+ BUS REPEATER MODULE

The function of FPM+ bus repeater module is to provide bus

signal gain. It is used in layouts with very large distances

between modules, and in high-interference environments

(primarily at industrial sites).

The FPM+ bus repeater module is manufactured by MOXA

as TCC-120I module, but will be tuned by the control unit

manufacturer to the operating parameters of the FPM+

control unit bus. The control unit manufacturer cannot

warrant proper operation of the bus if a TCC-120I module is

used without appropriate tuning.

The FPM+ bus repeater module is installed inside the

housing of an FPM+ unit module and powered with the

supply voltage dedicated to that module. The FPM+ bus

repeater module will always be installed so that one of the

FPM+ bus repeater module buses extends outside the

housing in which the module is installed and the other bus

connects to an EPSCUS or MASTER module installed locally.

Fig. 11 FPM+ bus repeater module

The FPM+ bus repeater module is not addressable and

invisible for the FPM+ control unit. Any damage to that

module can be diagnosed on the basis of broken bus

continuity. If the control unit generates an alert of loss of bus

continuity:

Check the power supply to FPM+ bus repeater module(s);

Check the connection between the FPM+ bus repeater

module and other FPM+ unit modules;

Check the connections between other FPM+ unit modules.

Damage to the bus is indicated by a joint damage alert

(DAMAGE indicator light on the unit’s control panel), in the

visualization system and in FPM Configurator.

Page 23 of 78

Page 24 of 78

7. CONNECTING MODULES

The modules must be connected with the use of appropriate precautions, in accordance with the applicable guidelines. Failure

to comply with the applicable requirements can have an adverse effect on the functioning of the control unit and result in a

security impairment.

7.1. FPM-X-YY-ZZ HOUSINGS

Below is a presentation of power

supply connector and bus layout for

an FPM+ unit.

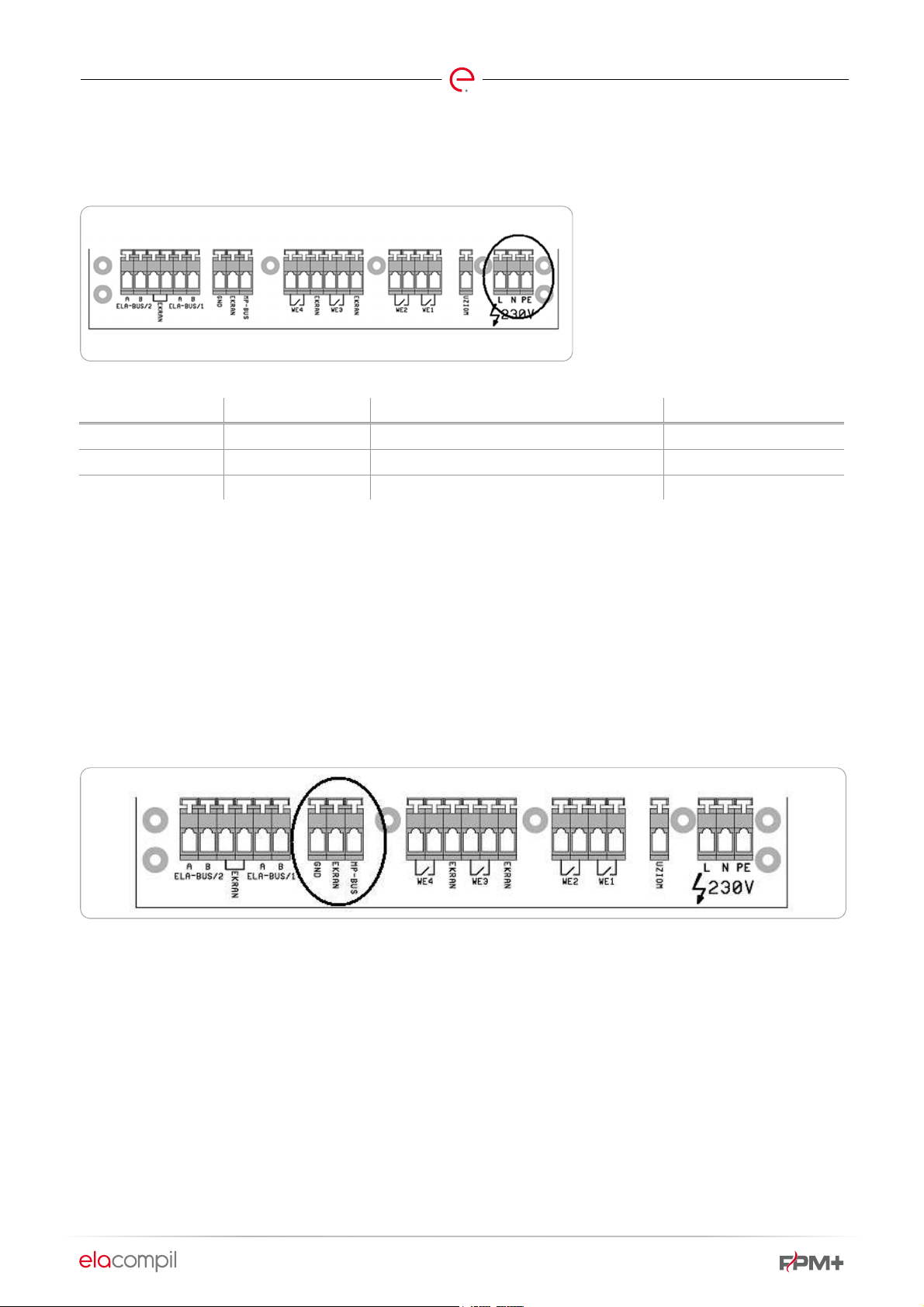

Fig. 12 FPM+ unit power supply connector and bus layout

Table 2 Identification and functions of FPM-X-YY-ZZ housing

ITEM IDENTIFICATION FUNCTION

1 230VAC L Power supply ~230V – L wire

2 230VAC N Power supply ~230V – N wire

3 PE Power supply ~230V – protective wire

4 +24 VDC Internal FPM+ power supply +24 VDC

5 0 VDC Internal FPM+ power supply 0 VDC

6 ELA-BUS1 A ELA-BUS1 A

7 ELA-BUS1 B ELA-BUS1 B

8 SCREEN ELA-BUS1 and ELA-BUS2 screens

9 ELA-BUS2 A ELA-BUS2 A

10 ELA-BUS2 B ELA-BUS2 B

11 USZK. ZAS. + Power supply failure signal input

12 USZK. ZAS. - Power supply failure signal input

Page 25 of 78

7.2. EPSCUS

The diagram below shows the layout of EPSCUS module interfaces. Input and output connections are identified, which we will

be using while connecting the EPSCUS module supplied in an ABS housing. When the EPSCUS module is ordered together with

other modules in a steel housing, the interfaces are already connected.

Fig. 13 EPSCUS module connectors

Bus interfaces,

i.e. unit bus input and unit bus output, are identified

as INA, INB for inputs and OUTA, OUTB for outputs.

Relay output interfaces

are identified as Cx, NOx, NCx. These

outputs are designed to control external equipment.

Auxiliary terminal

is identified as Fx and can be used for example

to connect an external resistor.

Power supply connectors: Vcc

– 24VDC power supply, polarity +;

GND – power supply 24VDC polarity

is the identification of an input interface no. x and GND is the

AINx

input neutral (shared with power)

OC type inputs

are identified as follows: OC11, OC12, OC13, OC21,

OC22, OC23.

EARTH terminals are used for connecting cable shields

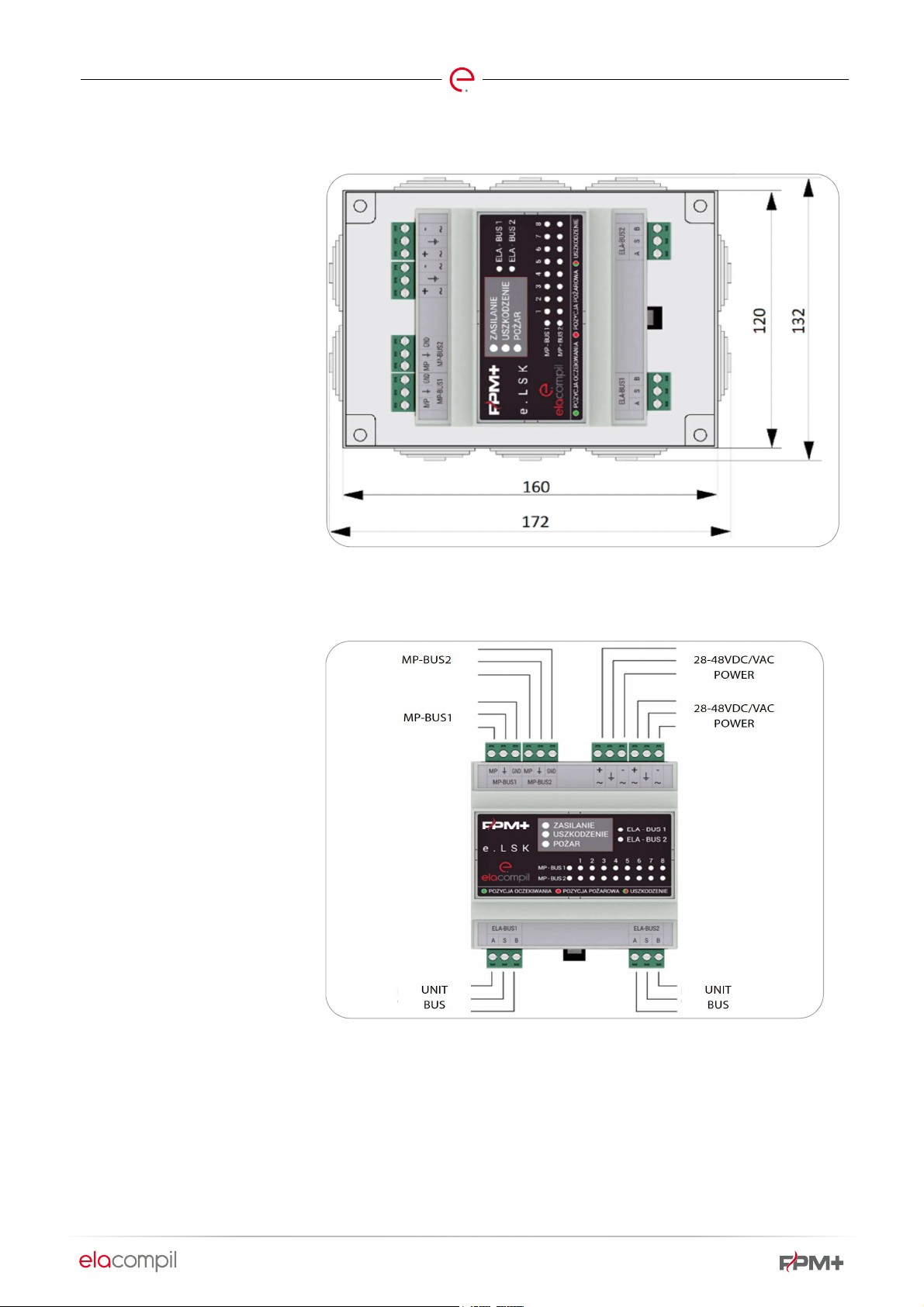

7.3. E.UPS

e.USP modules are installed in

multiple-module housings (FPM-XYY-ZZ) on a DIN bus bar, or in a

plastic housing and on a DIN bus

bar as well.

An e.UPS module has 16

analog/digital inputs. Neutral wiring

is shared for all the inputs. In

addition, the module has 8 potentialfree (relay) outputs.

Module power supply is connected

to the two terminals in the left upper

section of the housing. The unit bus

is connected in the left bottoms

section of the housing. The bus

should be set up with shielded cable

- terminal S is used to connect the

bus line shielding.

Page 26 of 78

Fig. 14 e.USP module in a plastic housing

Fig. 15 Connection of e.USP module

7.4. LSK

The gland chokes identified on the drawing as 1, 2, 3, and 6

should be removed from every LSK controller. If the design

sets out fire zone triggering via FACP unit modules and if

signals for trigger inputs should be connected to a specific

module, the following gland chokes should be removed:

For gland identified as 4 on the drawing - when WE3 and/or

WE4 input is used;

For gland identified as 5 on the drawing - when WE2 and/or

WE1 input is used.

Glands should be tightened with significant force so that

they have no slack in the housing; however, the installer

should be careful not to damage the glands.

Gland 1 is manufactured to size PG9, the remaining glands

are sized PG11.

Fig. 16 Gland chokes

7.4.1. CONNECTING TO POWER SUPPLY

The power terminal is located to the right of the module terminal strip.

Fig. 17 Connecting LSK to power supply

To connect to power supply, draw the

supply cable through gland no. 6, then

press the terminal levers with a flatblade screwdriver (width 3-4mm) and

insert the separate cable cores into the

right slot (see the table below).

.

IDENTIFICATION DESCRIPTION WIRE COLOR TERMINAL COLOR

Page 27 of 78

L

N

PE

Phase Other than blue and yellow-green Red

Neutral Blue White

Protective Yellow-green Green

NOTE: For your own safety, this operation should be performed after shutting down ~230V, 50Hz power supply.

7.4.2. CONNECTING FIRE DAMPERS

The LSK module is designed to operate with dampers fitted

with MP-BUS actuators. Connect the MP-Bus control cable

on LSK side to the interface identified as MP-BUS.

To do this, draw the fire damper connection cable through

gland no. 3, then press the MP-BUS, GND and SHIELD

terminal levers with a flat-blade screwdriver (width 3-4mm)

and insert the separate cable cores into the corresponding

terminals. Terminal colors correspond to YnTKSY cable core

colors to facilitate the connection (blue to blue, white to

white).

Fig. 18 Connecting fire dampers to LSK

7.4.3. CONNECTING ELA-BUS COMMUNICATION BUS LINES

Page 28 of 78

To connect several LSK modules, use ELA-BUS. An LSK

controller features two ELA-BUS ports identified as ELABUS/1 and ELA-BUS/2.

To connect ELA-BUS lines to a module, draw the bus cables

(two cables must reach every module) through glands 1 and

Fig. 19 Connecting ELA-BUS lines in LSK

7.4.4. CONNECTING WE1-WE4 TRIGGER INPUTS

2 (with the cables entering the housing separately), then

press the A, B and SHIELD terminal levers with a flat-blade

screwdriver (width 3-4mm) and insert the separate cable

cores into the corresponding terminals. Terminal colors

correspond to YnTKSY cable core colors to facilitate the

connection (blue to blue, white to white, shielding to green).

Fig. 20 Connecting WE1-WE4 trigger inputs in LSK

Trigger inputs are connected according to the instructions given in section 4.

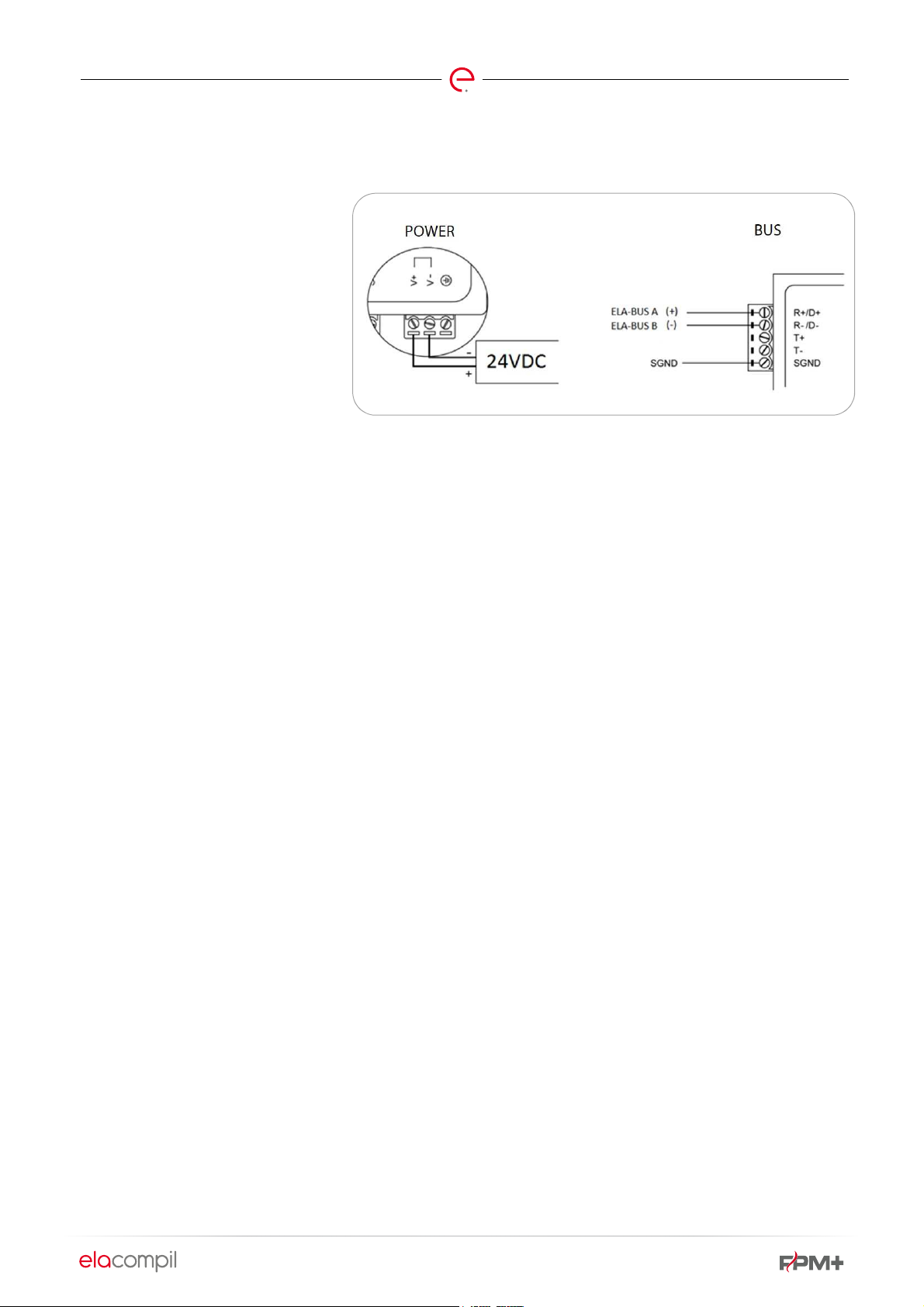

7.5. E.LSK

e.LSK modules are installed in

multiple-module housings (FPM-X-YYZZ) on a DIN bus bar, or in a plastic

housing and on a DIN bus bar as well.

Page 29 of 78

An e.LSK module is fitted with two

control unit bus inputs (at the bottom

of the housing, on both sides) and two

MP-BUS bar inputs (left upper section

of the housing).

Module power supply is connected to

the two terminals in the right upper

section of the housing.

Fig. 21 e.LSK module in a plastic housing

Fig. 22 Connection of e.LSK module

7.6. SKC-A

The diagrams below present the main methods of connecting SKC-A modules to power supply and to the control unit.

Page 30 of 78

Fig. 23 SKC-A to control unit

and power supply wiring

diagram

Fig. 24 SKC-A to control unit

and power supply wiring

diagram

Page 31 of 78

Fig. 25 SKC-A to control unit

and power supply wiring

diagram

7.7. FPM+ BUS REPEATER

An FPM+ bus repeater module is

powered with 24VDC voltage. It is

fitted with two ports for connecting

ELA-BUS.

Page 32 of 78

Fig. 26 FPM+ bus repeater module connection diagram

8. MAIN HOUSINGS FOR CONTROL UNIT MODULES

According to actual needs on site, the designer is able to

choose housing types and sizes, and therefore the number

of modules in a single location.

8.1. EPSCUS

Page 33 of 78

An EPSCUS module can be housed in an ABS housing for a single module.

EPSCUS modules are also installed in multiple-module housings on a DIN bus bar.

The choice of the specific housing and

number of modules in a housing

depends on the building design and the

need to build a control system for fire

safety equipment.

The EPSCUS model is designed for 1248VDC. Power can be supplied from a

certified fire rated power supply.

In the selection of cable thickness for

connections, power consumption and

voltage drops should be considered.

Power can be supplied from a certified

fire rated power supply.

Follow the guidelines for installation to

maintain a proper level of security and

to avoid interference with the

protection level.

Each module must be permanently

attached to building structure

components or to other items

permanently affixed to the building

structure.

Fig. 27 EPSCUS module in housing.

8.2. LSK

LSK module is enclosed in a plastic

ABS housing and is fit for user

installation on site.

8.3. SKC

Follow the guidelines for installation to maintain a proper level of security and to

avoid interference with the protection level.

The module needs to be affixed permanently.

Page 34 of 78

SKC module is enclosed in a plastic ABS housing and is fit

for user installation on site.

Follow the guidelines for installation to maintain a proper

level of security and to avoid interference with the

protection level.

Considering its low output powers, it is recommended to

use supply cables with as small core diameter as possible.

The module needs to be affixed permanently.

8.4. SKC-A

SKC-A module is enclosed in a plastic ABS housing and is

fit for user installation on site.

Follow the guidelines for installation to maintain a proper

level of security and to avoid interference with the

protection level.

The thinnest possible wire (3x0.75) should be used when

the module is powered with 230V voltage.

The module needs to be affixed permanently.

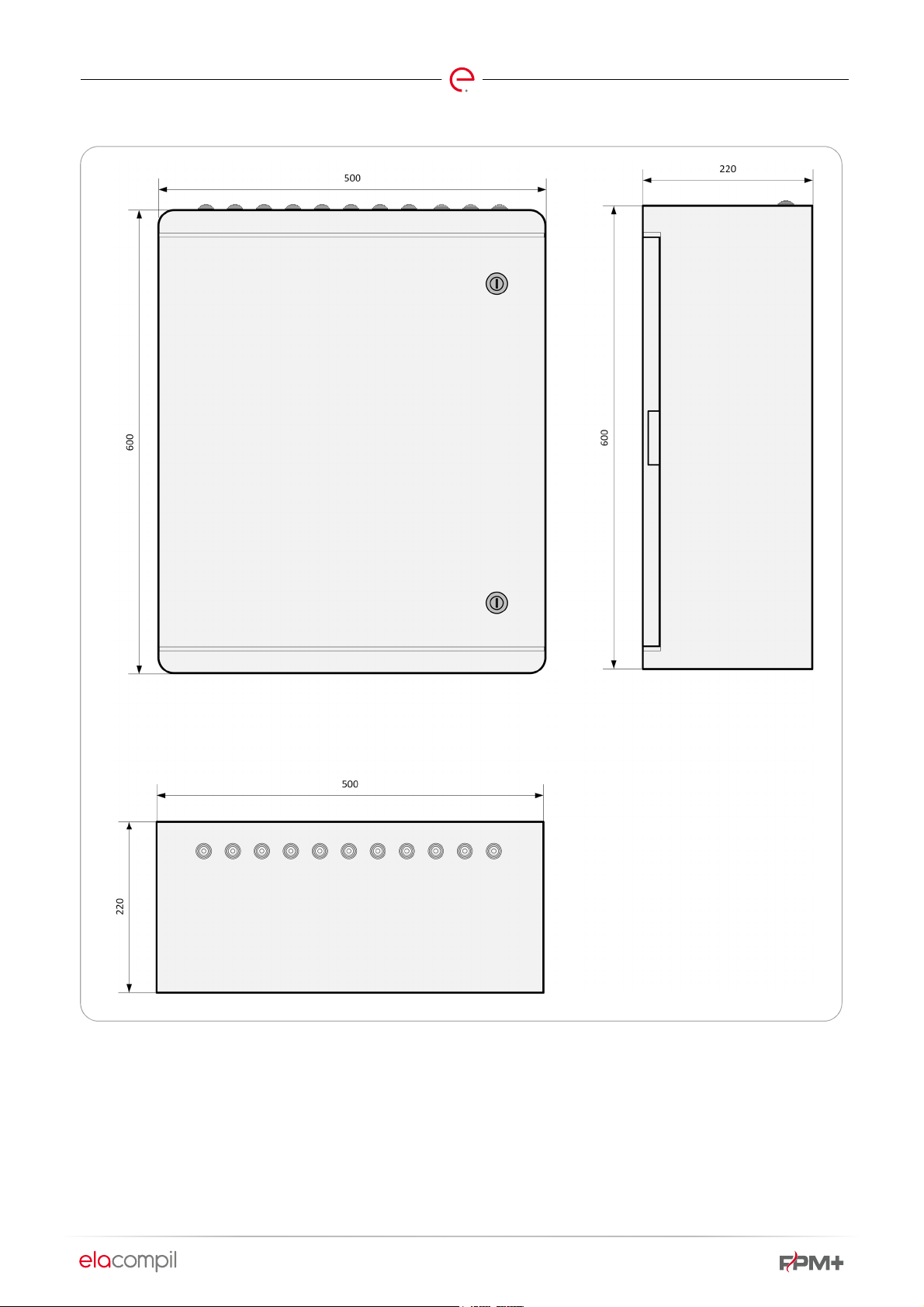

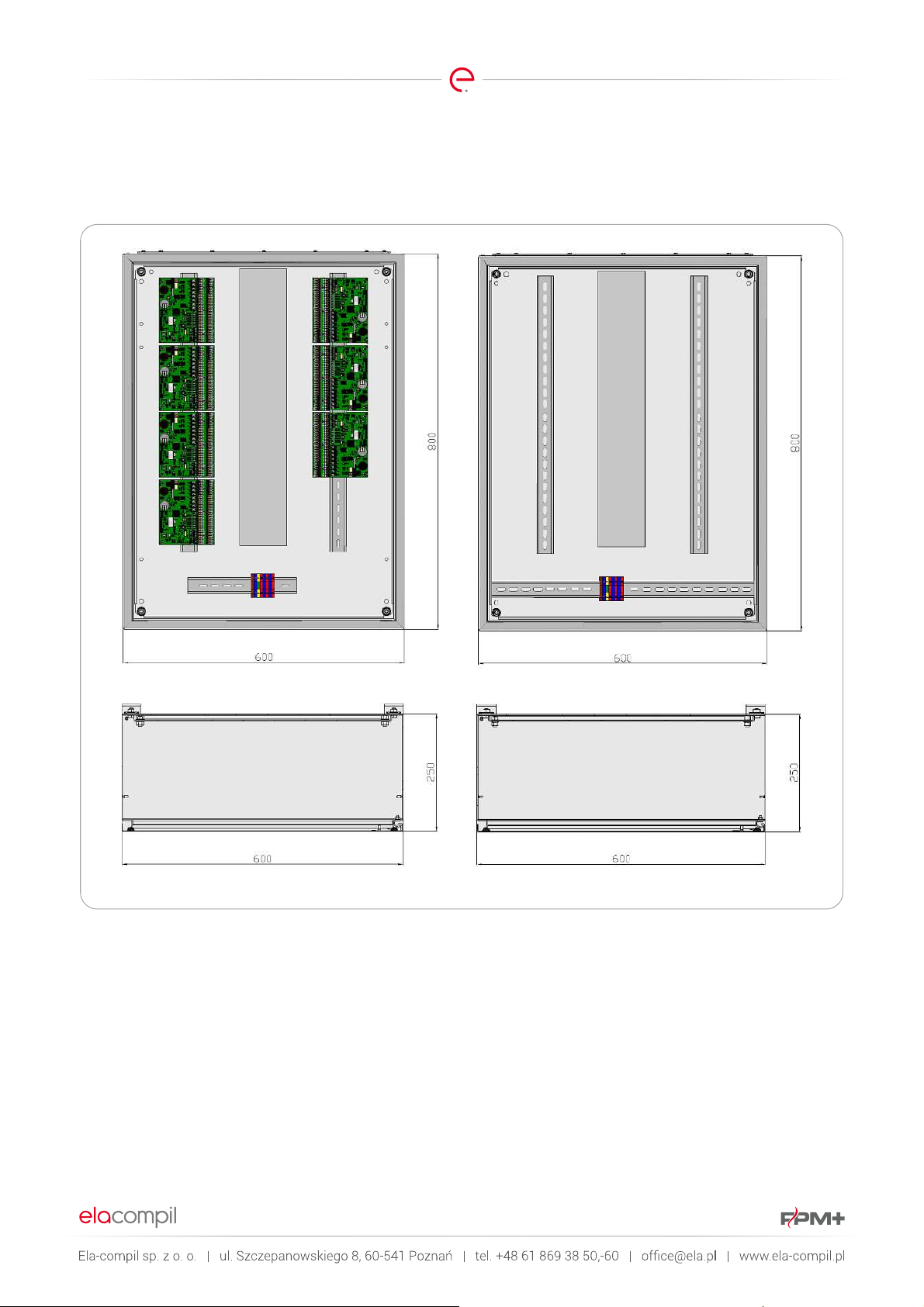

8.5. MAIN HOUSING OF THE CONTROL UNIT, TYPE FPM-M-YY-ZZ

The main housing of the control unit and the basic multiplemodule housings are designed on the basis of single range

steel cabinets. This ensures identical housing attachment

technique, connection tightness and effective installation of

fixtures.

The differences between the specific types of housings are

concerned with dimensions (5 basic dimensions) and

housing fixtures. The fixtures include: cable penetrations,

equipment mounting bars, cable trays.

The main enclosure of a control unit type FPM-M-YY-ZZ is

fitted by default with a MASTER module and an indicator

panel with LEDS and pushbuttons.

Depending on actual needs, it can be fitted with a power

supply unit complete with batteries. This housing can

accommodate a maximum of two EPSCUS modules

together with the MASTER.

The dimensions of the housing are: (HxWxD) 600x500x250;

available colors: RAL3000

Fig. 28 FPM+ unit housing

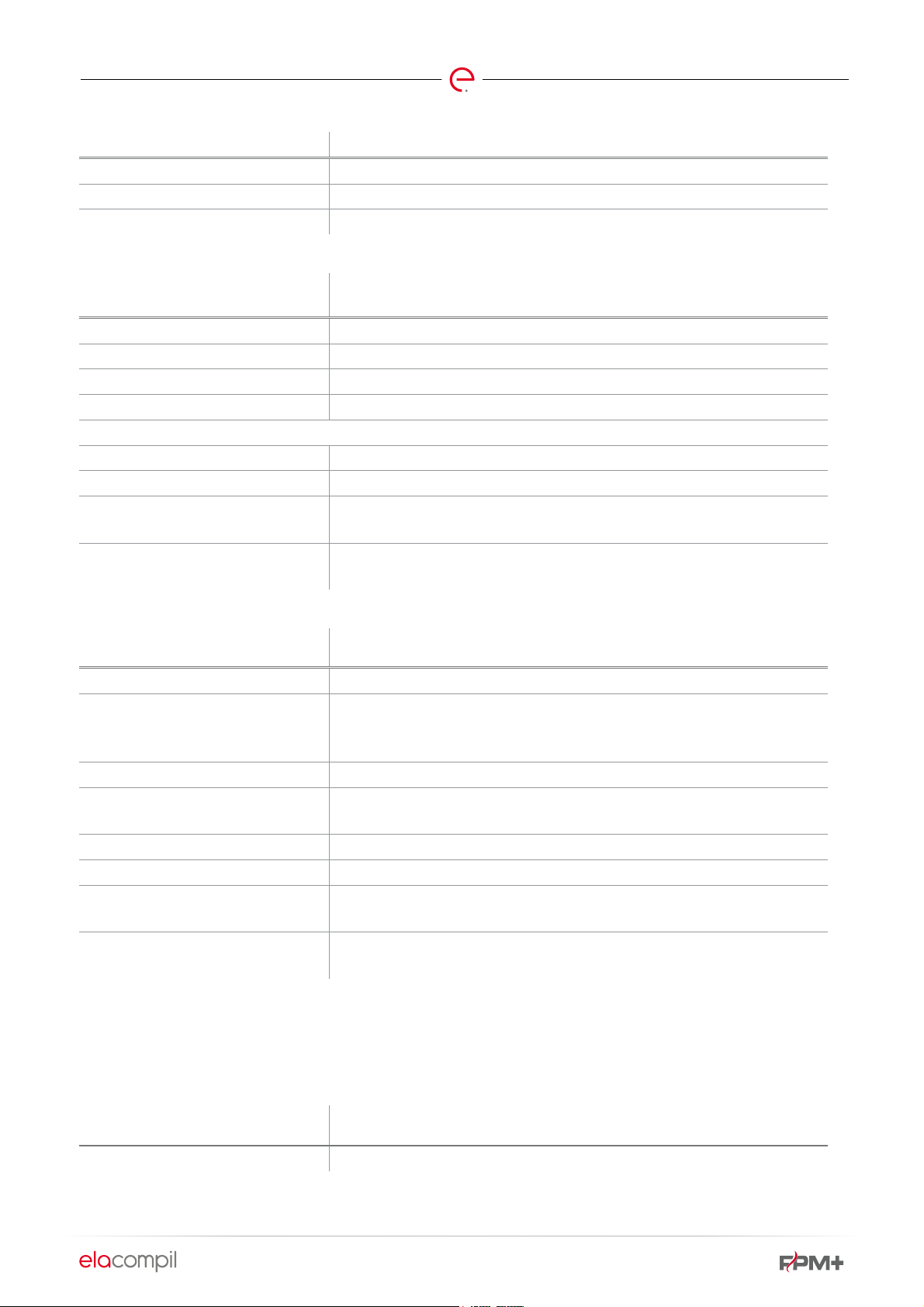

8.6. FPM-X-YY-ZZ

Page 35 of 78

The main housing of the control unit and the basic multiplemodule housings are designed on the basis of single range

steel cabinets. This ensures identical housing attachment

technique, connection tightness and effective installation of

fixtures.

The differences between the specific types of housings are

concerned with dimensions (6 basic dimensions) and

housing fixtures. The fixtures include: cable penetrations,

equipment mounting bars, cable trays.

Item

1

2

3

ENCLOSURE

SYMBOLS

MAX. EPSCUS CONTROLLERS

FPM-2-YY-ZZ 2 12 x O/C outputs

FPM-4-YY-ZZ 4 24 x O/C outputs

FPM-6-YY-ZZ 6 36 x O/C outputs

FPM-X-YY-ZZ line housings, designed to accommodate

multiple modules, are available in five basic sizes. They can

be fitted with power supplies with different power ratings

and batteries with different capacities. Depending on the

size of a specific housing, it can accommodate different

numbers of modules, and therefore it offers different

numbers of unit inputs and outputs.

MAX. INPUTS/OUTPUTS

16 x relay outputs

16 x analog or digital inputs

32 x relay outputs

32 x analog or digital inputs

48 x relay outputs

48 x analog or digital inputs

4

5

FPM-8-YY-ZZ 8 48 x O/C outputs

FPM-10-YY-ZZ 10 60 x O/C outputs

A detailed description of the housing versions is presented

in Appendix 2.

64 x relay outputs

64 x analog or digital inputs

80 x relay outputs

80 x analog or digital inputs

On special order, control unit housings with different

capacity or dimensions can be produced. The housings

must meet the isolation criteria (min. IP42). The range of

housings and ranges are presented in Appendix E.

8.7. FPM-U-X-X-X-X-X AND FPM-L-X-X-X-X-X

Page 36 of 78

The main housing of the control unit and the basic multiplemodule housings are designed on the basis of single range

steel cabinets. This ensures identical housing attachment

technique, connection tightness and effective installation of

fixtures.

FPM-U-x-x-x-x-x and FPM-L-x-x-x-x-x line housings are the

extension of line FPM-X-YY-ZZ housings. The primary

difference between the particular lines of housings is the

layout of cable trays inside the housing, and the cable exit

pattern. FPM-U-x-x-x-x-x and FPM-L-x-x-x-x-x line housings

are primarily fit for installation of e.LSK and e.USP modules.

Detailed specifications of the housings are presented in

Appendix 3 and assembly drawings of the housings are

given in Appendix D.

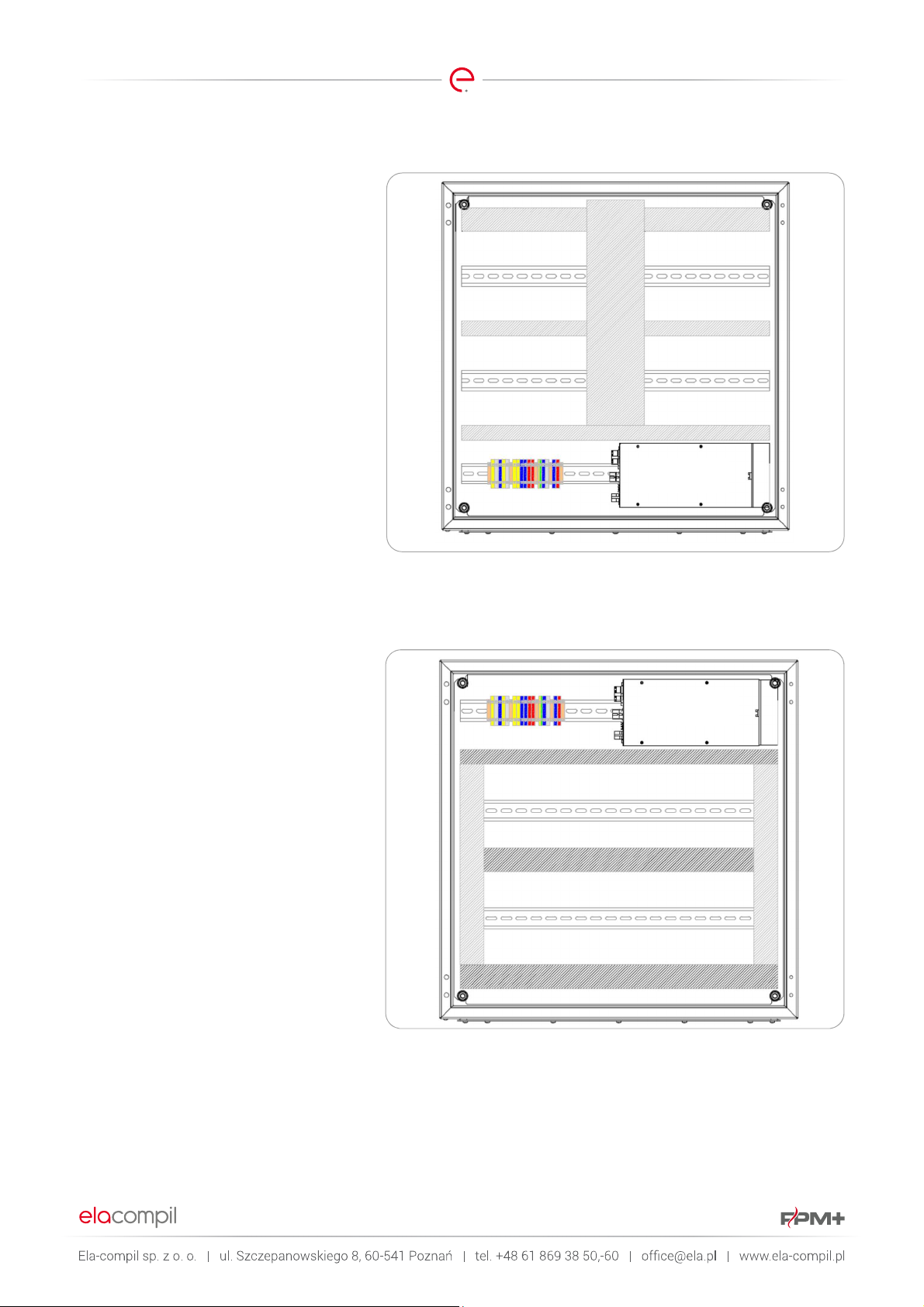

8.8. PLASTIC MULTIPLE-MODULE HOUSINGS

Multiple-module plastic housings are designed to

accommodate multiple modules and are available in three

basic sizes. They can be fitted with power supplies with

different power ratings and batteries with different

HOUSING

OUTER DIMENSIONS

CP5004 400 x 500 x 175 mm 350 x 455 x 150 mm 3 kg

CP5005 400 x 600 x 200 mm 355 x 550 x 175 mm 4 kg

CP5008 500 x 600 x 220 mm 455 x 550 x 195 mm 5 kg

capacities. Depending on the size of a specific housing, it

can accommodate different numbers of modules, and

therefore it offers different numbers of unit inputs and

outputs.

INNER DIMENSIONS

WEIGHT

Page 37 of 78

Fig. 29 CP5004 type housing

Page 38 of 78

Fig. 30 CP5005 type housing

Page 39 of 78

Fig. 31 CP5008 type housing

9. ASSEMBLY INSTRUCTIONS

9.1. BUS

Page 40 of 78

A single section of bus line between modules can reach

1200m length. The acceptable MP-Bus length is 600m

(determined as the sum of the lengths of cable sections

within the bus and not the largest distance between

appliances.

Bus cables should not be laid near power cables.

If the system is used for smoke extraction, the bus line,

motor line and the terminal rooms must be designed to E90.

9.2. SHIELDING

In order to comply with the interference immunity

requirements as per PN-EN 61000-6-2:2008

Electromagnetic compatibility (EMC), Part 6-2: General Immunity requirements for the industrial environment”, all

bus connections (control unit bus, MP-BUS) must be made

of shielded cables (e.g. YnTKSYekw, HTKSHekw).

It is further recommended to connect input signals (to

EPSCUS module inputs) using shielded cables.

9.3. EXTERNAL POWER SUPPLIES

Moreover, make sure that the bus incoming and outgoing

cables are laid as separate routes. In this case, construction

laws must be specifically complied with.

LSK, EPSCUS and MASTER modules must be connected

into a single loop. No other connections can be established

(additional branch lines from the main loop).

MP-Bus modules cannot be designed in a loop layout. Linear

or star topology is acceptable.

Shielding should be continuous, connected to shared PE

potential. It is recommended to join ELA-BUS shields

together (e.g. by twisting or connecting to appropriate

terminals in the modules).

All steel housings (FPMPLUS-M-xx-xx, OBZ-FPMPLUS-xx

and OZ-FPMPLUS-xx) should be connected to PE potential.

It is recommended to establish a direct connection with the

building structure earthing (hoop iron).

If external power supplies are used, each power supply

should be located as close as possible to the control unit

10. TYPES OF INPUTS IN THE UNIT

Unit inputs can vary in terms of type and function (a

description of their functions is given in section 6). Both

these properties are assigned in FPM+ Configurator.

Type of input indicates the electrical characteristics of the

input.

housing with modules. In addition to power, power supply

failure signal should be connected to the unit as well.

Inputs differ in terms of response and auxiliary external

pieces (if any).

Input types are defined for LSK, EPSCUS and EPSCUS(A)

controllers.

Not all the types enumerated below are available for every

controller.

10.1. INPUT TYPE: UNUSED

Page 41 of 78

Unused inputs are present in LSK, EPSCUS and EPSCUS(A)

modules.

10.2. INPUT TYPE: DIGITAL NO

Digital NO inputs are present in LSK and EPSCUS modules.

A digital NO input is a digital input without line state

supervision, for direct connection of relay contact.

Fig. 32 Digital NO input diagram

An unused input is not utilized in the system and does not

report any state, irrespective of the connected alarm.

Open state is alerted as idle, shorting means an alarm.

10.3. INPUT TYPE: DIGITAL NC

Digital NC inputs are present in LSK and EPSCUS modules.

A digital NC input is a digital input without line state

supervision, for direct connection of relay contact.

Fig. 33 Digital NC input diagram

Open state is indicated as alarm, shorting - idle.

10.4. INPUT TYPE: DIGITAL THREE-STATE

Digital three-state inputs are present in LSK and EPSCUS

modules.

Inputs of this type will indicate either of the three states:

open, closed, or intermediate.

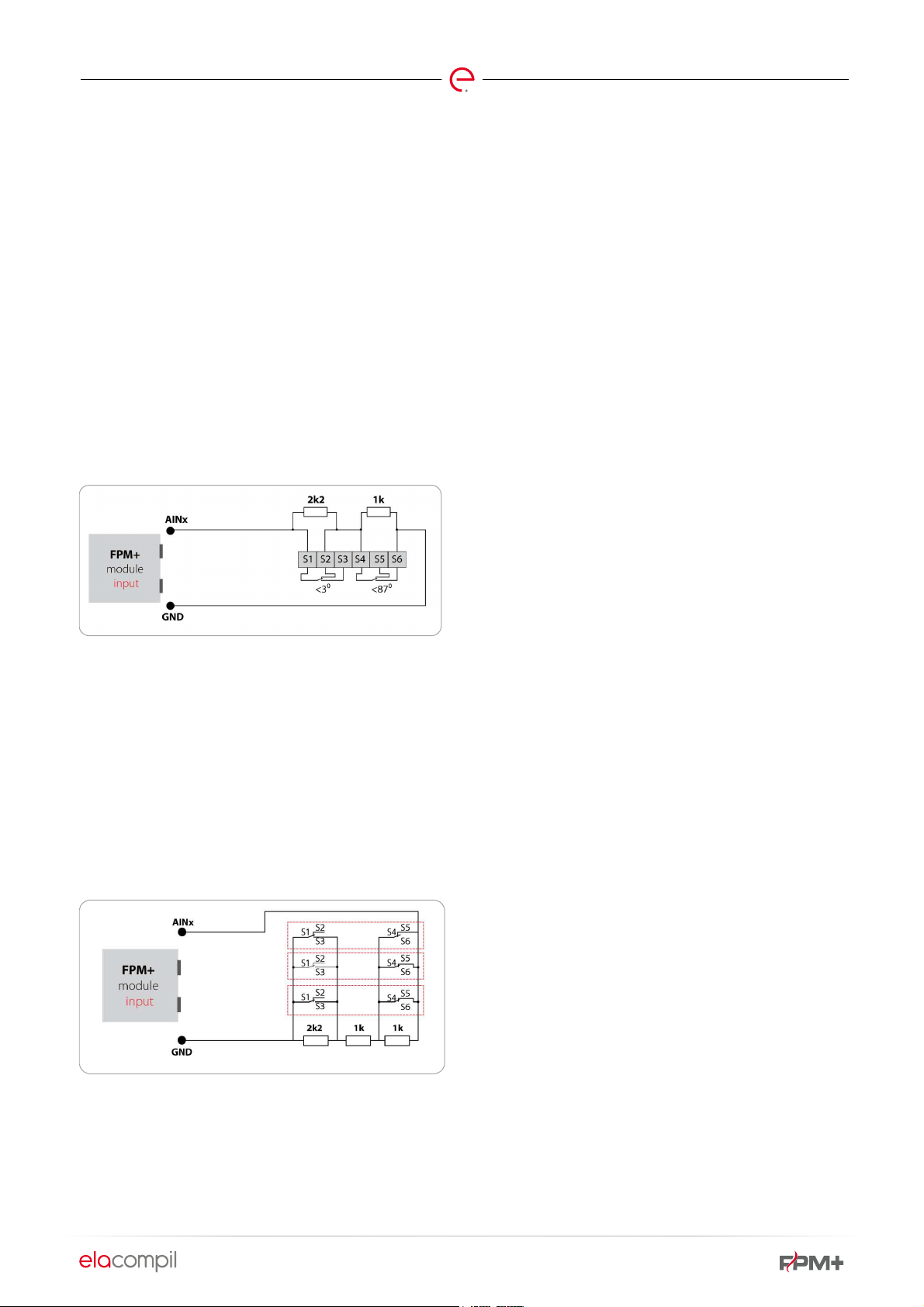

10.5. INPUT TYPE: ANALOG RESISTIVE

Page 42 of 78

It is used for such functions as damper operation, where the

damper status can be verified with the right selection of

resistors.

Analog resistive inputs are present in EPSCUS modules.

They are used to measure the value of connected resistance.

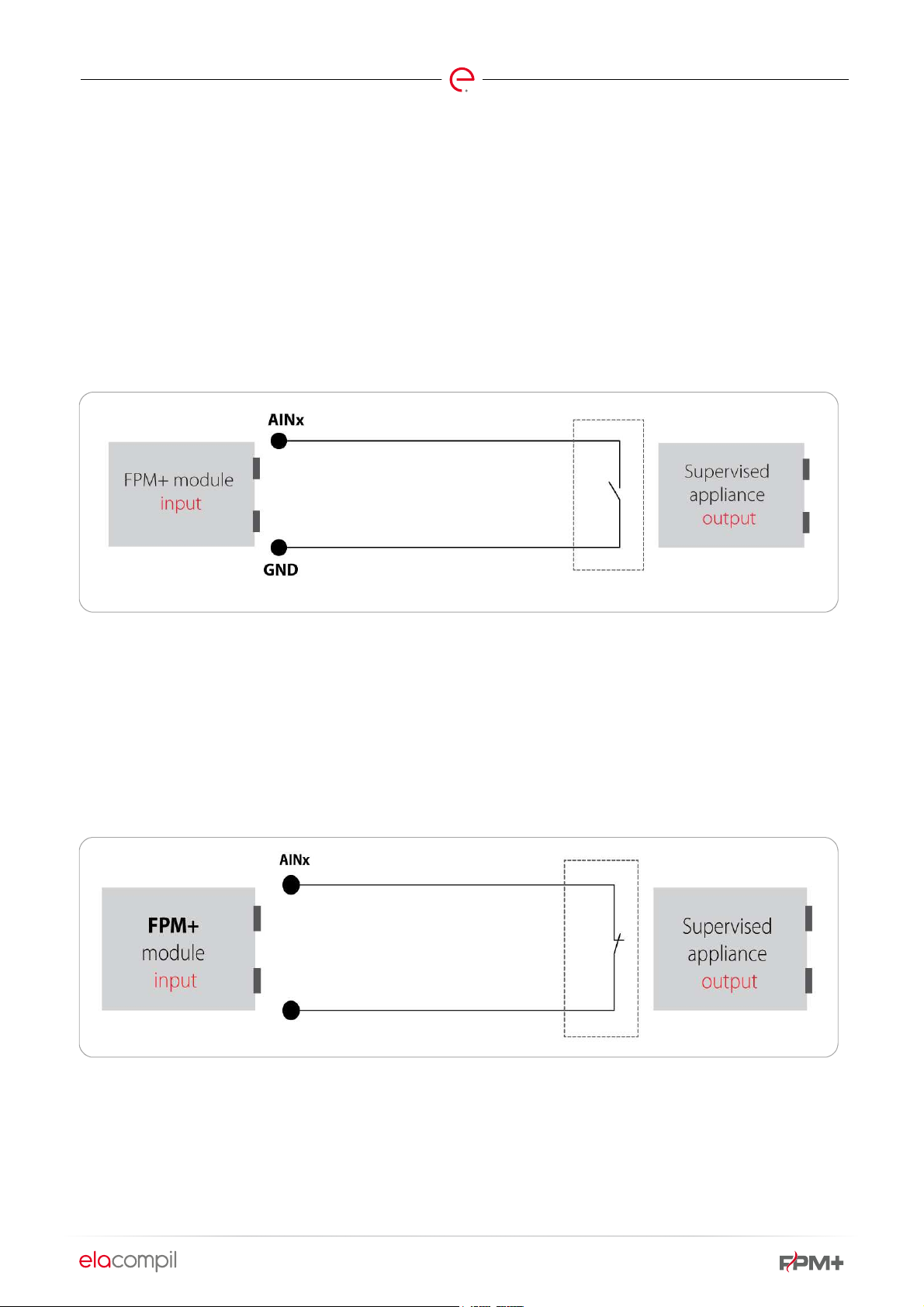

10.6. INPUT TYPE: DIGITAL SUPERVISED NO

Digital supervised NO inputs are present in EPSCUS

modules.

A digital supervised NO input is a digital input with line state

monitoring. Monitoring is done via a connected NO contact

that triggers resistor signal.

Analog resistive inputs do not trigger alarms.

The resistance values are the following: 3.3kOhm for idle,

1kOhm for alarm.

This input indicates line failure if the line resistance value is

outside these two values.

Fig. 34 Digital supervised NO (2EOL/NO) input diagram

10.7. INPUT TYPE: DIGITAL SUPERVISED NC

Digital supervised NC inputs are present in EPSCUS

modules.

A digital supervised NC input is a digital input with line state

monitoring. Monitoring is done via a connected NC contact

that triggers resistor signal.

The resistance values are the following: 1kOhm for idle,

3.3kOhm for alarm.

This input indicates line failure if the line resistance value is

outside these two values.

Fig. 35 Digital supervised NC (2EOL/NC) input diagram

10.8. INPUT TYPE: ANALOG 0-5V

Analog 0-5V inputs are present in EPSUS(A) modules.

Analog 0-5V inputs accept signals from the range of 0-5V.

If monitoring is to cover other voltages than those in 0-5V

range, use a resistor divider so as to avoid exceeding the 5V

threshold.

Page 43 of 78

An additional safeguard is used to protect the system

against the consequences of exceeding the permitted

voltage value.

Example function of an analog 0-5V input is for voltage

supervision.

10.9. INPUT TYPE: ANALOG 4-20MA

Analog 4-20mA inputs are present in EPSUS(A) modules.

Analog 4-20mA inputs accept 4-20mA signal (where an additional 249Ohm resistor is required).

Fig. 36 Analog 4-20mA input diagram

Page 44 of 78

11. TYPES OF OUTPUTS IN THE UNIT

Unit outputs can vary in terms of type and function (description in section 7). Depending on their type, outputs can control

various appliances, such as lifts, escalators, analog actuators, other actuators, or indicator lights.

11.1. OUTPUT TYPE: RELAY

Relay outputs are designed to control external equipment.

An EPSCUS module is fitted with eight relay outputs.

An auxiliary terminal F is located at each relay output, which

can be used for example to connect an external resistor.