®

®

e-mail: orlanski@eko-vimar.com.pl

www.eko-vimar.com.pl

tel.: +48 77/ 400 55 80÷81, 400 55 91

fax: +48 77/ 439 05 03, 400 55 96

EKO-VIMAR ORLAÑSKI ul. Nyska 17b

48-385 Otmuchów / woj. opolskie

POLSKA

2

19

Boiler connected in cascade enables heating of bigger buildings. Boilers should be of

the same output. Such system gives better possibilities of heat source dynamics than

system with one boiler only. Particularly in .transition period. (springtime or autumn)

boilers may be serviced alternately. Boilers with such connection enables for its

exploitation with the output close to nominal, what warrants boiler longer durability.

Heat accumulation tanks allows for boilers' better adjustment according to actual

weather conditions. In transition period (the spring, autumn) any boiler without heat

accumulation set is switched on and off very often. If the set is connected, the boiler

works constantly and the energy is cumulated into the vessels.

Each boiler switching on and off means fuel losses. It may be avoided if the heat

accumulation set is used. Simultaneously, in transition period (the lowest temperature

in winter time) the accumulation set helps to reheat the whole central heating system.

Also it should be mentioned that few heat sources such as solar collector , heating

pump or similar may be connected to the heat accumulation set.Boiler connected in

cascade enables heating of bigger buildings.

Boilers should be of the same output. Such system gives better possibilities of heat

source dynamics than system with one boiler only. Particularly in .transition period.

(springtime or autumn) boilers may be serviced alternately. Boilers with such

connection enables for its exploitation with the output close to nominal, what warrants

boiler longer durability. Heat accumulation tanks allows for boilers' better adjustment

according to actual weather conditions. In transition period (the spring, autumn) any

boiler without heat accumulationset is switched on and off very often. If the set is

connected, the boiler works constantly and the energy is cumulated into the vessels.

Each boiler switching onand off means fuel losses. It may be avoided if the heat

accumulation set is used. Simultaneously, in transition period (the lowest temperature

in winter time) the accumulation set helps to reheat the whole central heating system.

Also it should be mentioned that few heat sources such as solar collector , heating

pump or similar may be connected to the heat accumulation set.

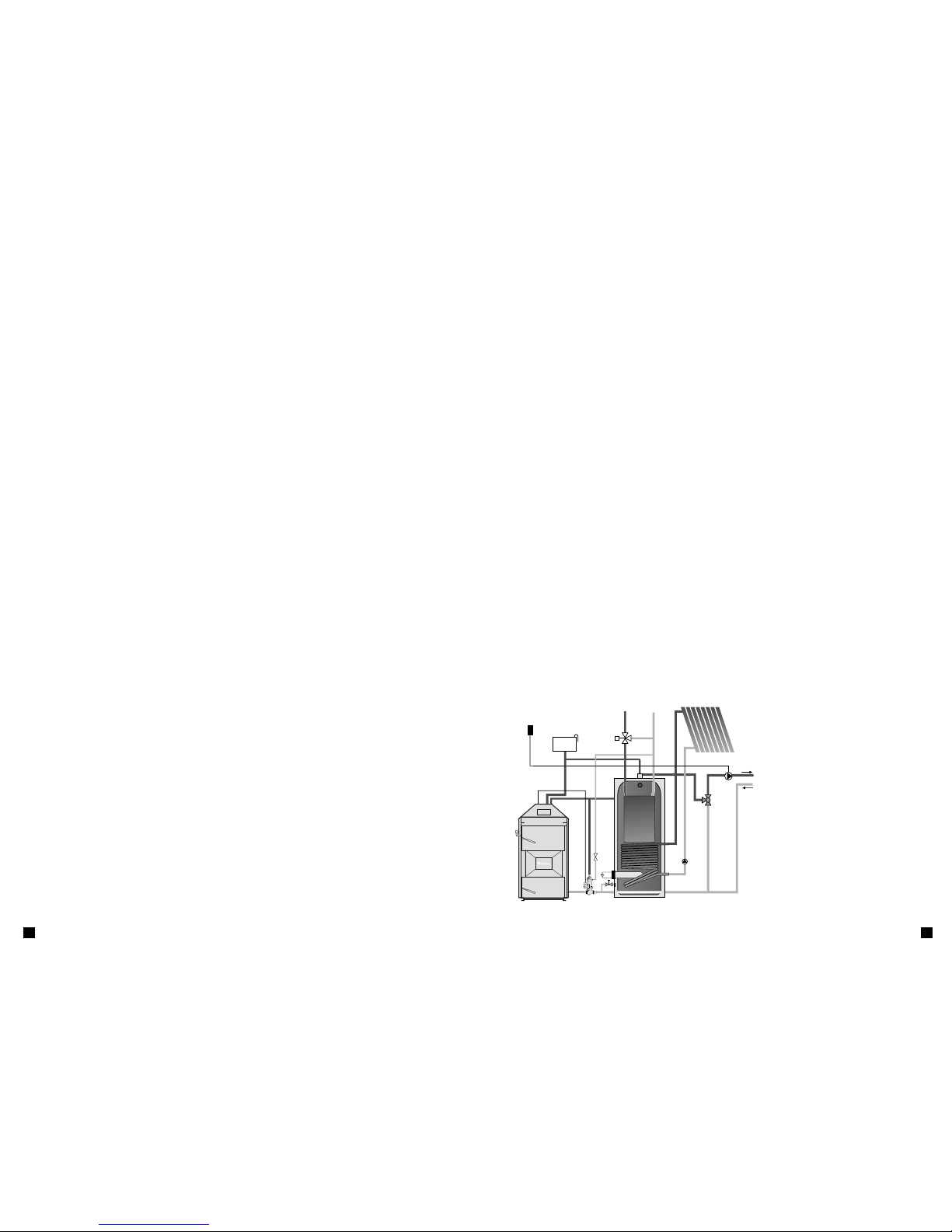

Connection scheme of the heat

accumulation set with one vessel and the solar panel.

Programmable

room thermostat

1 ORLAN STANDARD or

SUPER 1 with RK 2001

regulator

2. LADDOMAT 21 thermoregulator

3. Accumulation tank

NADO 2

4. Electrical heater

5. Three-way mixing valve MIX C

6. Circulating pump

7. Room temperature sensor

8. Theating system exit

9. Opened compensating vessel

10. Mixing value DHW.

11. Coil

12. Solar panel

13. Heating medium pump

8

7

2

CWU

9

6

5

LADDOMAT 21LADDOMAT 21

220V

380V

10

3

4

11

12

13

1

3

18

MANUAL CONTENS:

1. Appropriation.....................................................................................4

2. General requirements ....................................................................... 4

3. Boiler technical specification .......... .............................. ......................6

4. Technical data....................................................................................8

5. Start-up ............................................................................................8

6. Programming .....................................................................................9

7. Regulator characteristic......................................................................9

8. Regulator set-up ................................................................................9

9. Service ............................................................................................9

10. Regulator working description .................. ................................... .....10

fuel shortage.......... .............................. .............................. ..........10

boiler overheating ...................... ......................................... .........11

11. Room thermostat setting-up. .............................. ..............................12

12. Regulator damage .... .............................. .............................. ..........12

13. Regulator technical data...... .............................. ..............................12

14. Fan working characteristic... .............................. ..............................12

15. Boiler exploitation................ .............................. ..............................13

boiler fire-up ........................... ....................... ..............................13

fuel filling-up .......... .............................. ............................... .........13

switching off........... .............................. .............................. ..........14

cleaning ................ .............................. .............................. ..........14

tightness assertion .......... ......................................... ...................15

most favorable temperature assertion .. .............................. ..........15

feeding shortage.... .............................. .............................. ..........16

fan .................... .............................. .............................. ..........16

16. Boiler preservation ........................ .............................. ....................16

17. Faults caused by improper boiler use

and their removing ........... .............................. ..............................17

18. ......................................................................18Orlan Super appendix

18. ORLAN SUPER APPENDIX

ADDITIONALLY IN ORLAN SUPER

ORLAN SUPER is additionally equipped with mechanical clearing system of the

smoke tube exchanger and thermal safety device built into the boiler body.

THERMAL SAFETY DEVICE ( COOLING COIL )

Cooling coil together with thermal safety drain are to protect the boiler against its

overheating during operation. The cooling coil shall be connected to the cold

water installation by thermal safety drain ( e.g. STS 20 WATTS ). Coil outlet shall

be connected to the sewage system.

BOILER CLEANING

Mechanical cleaning system helps to keep smoke tube heat exchanger clean.

Cleaning elements are produced of springs, axially placed into exchanger tubes.

And they are moved up and down by outside handle.

Cleaning handle should be used after each boiler feeling with wood to protect

them from wood tar or carbon deposit which is accumulated inside of exchanger

tubes.

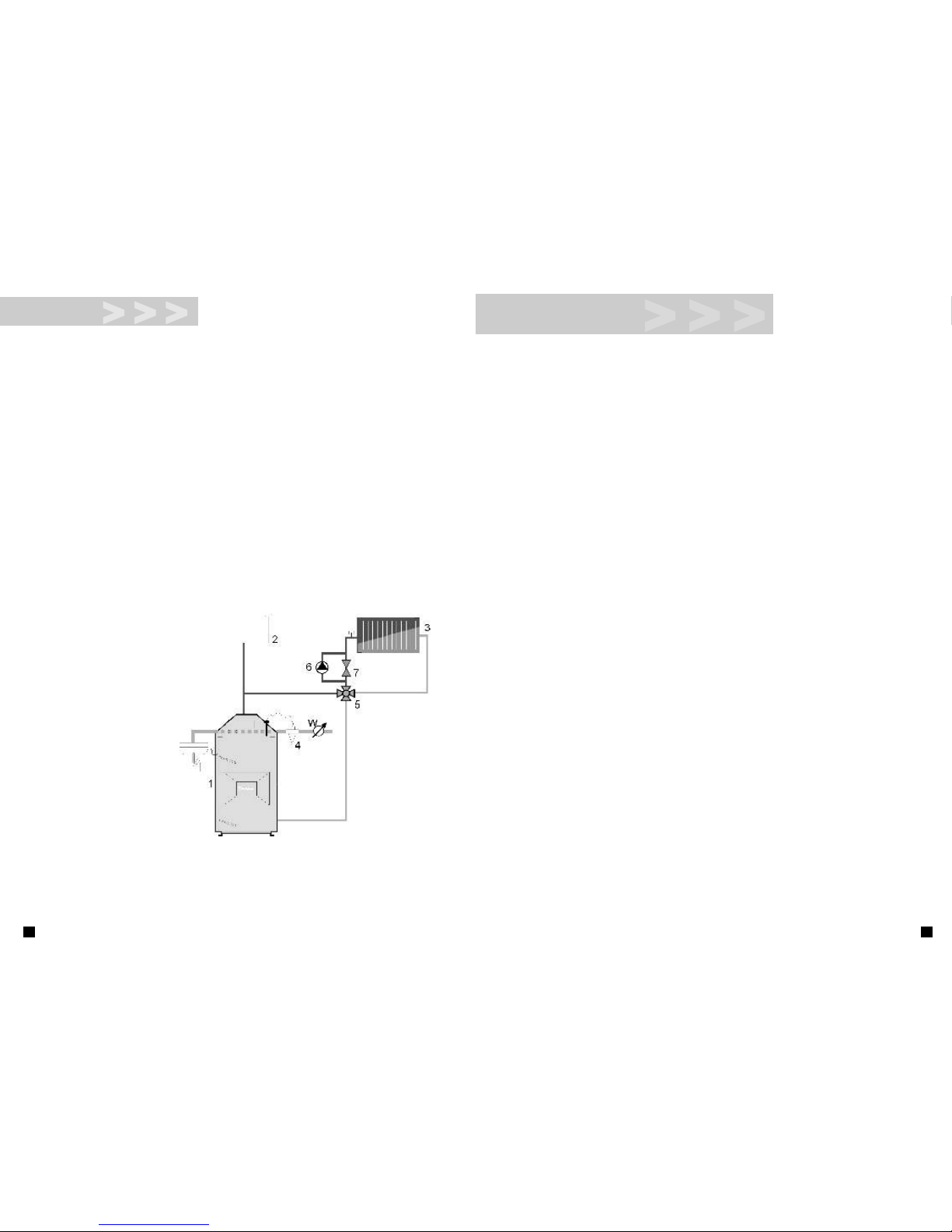

1. ORLAN BOILER

with RK 2001 regulator

2. Compensating vessel

3. Radiator

4. Thermal safety drain

5. Four-way mixing valve

6. Circulating pump

7. Differential valve

Boiler connection

with thermal safety device.

1. BOILER APPROPRIATION

Low temperature water boilers (up to 95ºC) are produced as 18, 25, 40, 60 and|

80 kW units. They can work on gravitation and in forced (pump) circulation. It is not

necessary to change the whole existing system especially for the boiler.

2. GENERAL REQUIREMENS REFERRED TO THE ORLAN BOILERS

Boiler start-up, programming and first setting up should be carried out by qualified

staff, being familiar with this operating manual.

Main requirements:

a) Boiler can be placed on the heating room level or at the basement

b) There should be enough space foreseen for fuel storage; fuel can be stored in

the same boiler room or in separate room but special care should be taken with

fire-fighting rules

c) Floor, ceiling and walls should be made of nonflammable materials according to

the obligatory rules. In case of flammable floor it should be covered by the metal

sheet with 0,7 mm thickness at least 0,5 m around the boiler

4

17

1.1 Chimney assortment on DIN 4705

Required chimney draught [Pa]

Chimney height (m)

Boiler Power

17. FAULTS CAUSED BY IMPROPER BOILER USE AND THEIR REMOVING

If boiler temperature achieves 90ºC safety device will switch of the fan. To burn

the boiler again - see point “BOILER OVERHEATING”. In case of power shortage in

regulator please check the safety device on his back wall if is damaged, change it

for the same one (2A). If the smoke gets out of the boiler see point “Tightness

assertion” or change the insulation cord.

1.Four-way mixer DUOMIX-C 6.OKCV operational water heater

7.Differential valve

(DUOMAX-AP, DUOMIX-A0, DUOMIX-Z)

8.compensating vessel

2.circulating pump

9.exit for warm operational water

3.CP1 room temperature sensor

10.cold water entry

4.Standard ORLAN BOILER

5.heater

Boiler with mixer connecting to the heating system.

5

16

d) Boiler room should be equipped with both natural and artificial light

2

e) Boiler room must be equipped with unclosed supply ventilation 400 cm

2

channel (min. permissible section 300 cm )

f) The exhaust ventilation channel should have 50% surface of the supply

2

ventilation surface (200 m ). The exhaust ventilation and supply ventilation

outlet should be of the same dimensions and be placed close ceiling. Both

ventilation outlets should be performed of non-flammable materials and cannot

be closed

g) Mechanical exhaust ventilation is inadmissible

h) Flue channel should be of 20 x 20 cm section and should be high enough to

assure proper chimney draught. The system should be prepared accordingly

to the environmental protection rules.

I) The boiler room should be large enough to assure the boiler cleaning and

should be minimum 2,2 m high

j) There should be enough space around the boiler surface to get to the boiler

parts :

· 1,5 m from the boiler front

· 0,8 m from the boiler sides

· 1,0 m from the boiler back to be able to easily clean the boiler

k) There shouldn't be any cables or wiring system inside boiler room, not destined

for the boiler operating

l) The central heating system shouldn't be directly connected in any way to the

water supply system

Before combustion duct connection to the main collecting pipe in the living quarters

a special chimney sweep permission is required

Boiler service rules and other important indications concerning central heating

system should be placed in a noticeable place.

In case of exploitation of two boilers or more the following should be concerned:

a) The boiler room should be equipped with a sink and a bib-valve

b) Catch basin should be of one boiler volume

c) Boiler room entry door should be performed of non-flammable material and

shall be opened externally

d) The boiler room ceiling should be performed of gas-tight material with heat

and sound insulation and meet the requirements of the refractoriness rules

e) Boiler room outside thermometer is recommended

(gasification process totally fade). In result a wood tar seats on the boiler walls.

To avoid a/m situation we recommend to install the four-way mixing valve on boiler

outlet. This valve mixes hot water with return water from installation. If hot and return

water jets, flowing through the valve have proper water temperature on boiler return,

then any drastic temperature decrease has no place in gasification chamber and

whole gasification process is on expected level. In spite of it, water temperature

difference 15 - 20ºC does not affect in boiler materials, then boiler exploitation is

longer.

Feeding shortage

Sometimes a power deficiency can take place during boiler exploitation. Then

boiler fuel filling should be stopped. If boiler works - an opened chimney flap is

forbidden. The wood may burn very fast and boiler will get overheated.

In forced (pump) system, in case of power deficiency, fan and circulating pump will

be switched off automatically. Insufficient heat reception from the boiler by radiators

may cause water boiling into the boiler. To avoid this situation, we recommend

connecting an additional heat receiver, for example operational water heater.

Warning! To protect the boiler regulator or other boiler electrical wiring of voltage

excess in network, use some constant-voltage regulator (e.g. computer

strip).

Fan

Fan is very important boiler part. Its blades shall always stay clean. Fan should be

cleaned periodically using of small brush with soft horse hair.

16. BOILER PRESERVATION

Boiler should be exactly preserved for unserviceable season. Boiler inside

chamber, exchanger, and chimney flap should be carefully cleaned. After cleaning,

boiler should stay opened for its better ventilation.

6

15

Schematic dimensions of the ORLAN boiler

3. BOILER TECHNICAL SPECIFICATION

ORLAN boilers are designed to be used as a source of heat in central heating

system either in gravitation or in forced (pump) system. The boilers are adapted for

burning any kind of waste wood, ranging from sawdust to chunks of wood. The boiler

casing is made of welded metal sheets that form a water jacket. The internal boiler

walls, which are exposed to the flue gas, are made of metal sheets that are 6 mm

thick, whereas the remaining walls are only 4 mm thick. The boiler convection

surface is made of vertical smoke tubes measuring 57 x 4 mm where the flue gas is

transported to the chimney via the chimney flue. The external casing consists of

metal sheet panels that are 0,8 mm thick. The thermal insulation is composed of

glass wool of the NOBASIL type that is 20 mm thick.

All boilers nozzles are made of steel tubes. The chimney flue is made of

4mm thick steel tube. The chimney flap is produced of the high constructional sheet.

The accurate chimney flap adhesion to the combustion duct assures the

combustion chamber tightness.

The fan is placed in front of the boiler. Fan casing is made of 0,8 mm metal

sheet. Boiler control panel is located on the boiler's upper cover.

Tightness assertion

The boiler tightness is very important especially if we are thinking of boiler's door,

heat exchanger lid and chimney flap. If one of these is leaky the smoke can come

out of the boiler room but first of all it may be the reason of uncontrolled burning into

the boiler what may also overheat the boiler. That's why the insulation cord should

be lubricated (every second week) with graphitic oil (or any other machine oil). The

cord fibre is more flexible and adheres better to the surface.

After some time of boiler working (e.g. one season) the cord may be pressed. That

is why a special boiler door regulation is foreseen.

Please remember to clean up the chimney flap!

All threaded elements shall be lubricated with some lubricant before

each bolt unscrewing. The boiler hinges and locks should be also

lubricated periodically.

Most favourable temperature assertion

Water temperature is important due to boiler capacity. Outer water temperature

should be around 75ºC then the boiler works most favourable.

In the heat demand period, temperature decrease of return water from

installation is sometimes possible. If return water temperature is lower than feeding

water temperature more than 20ºC, there is a possibility of partial gasification

chamber pre-cooling, and consequently decreasing of gasification efficiency

Conservation

Door hinge regulation

1.. take off the door

2.. release the nut

3.. turn lower hinge part by 360°

4.. turn on the nut

!

ATTENTION!

Door regulation shall be done parallel

on lower and upper hinge.

Cleaning elements

7

14

The system works by:

- water temperature setup on the boiler exit ( wide temp. range 65 - 80º C)

- signaling of excessive water increase and also excessive water drop

- fan switching off when the water temperature on the boiler achieves the

assigned value

- reduction of fan rotations when water temperature approaches the assigned

value (modulation)

The boiler is also equipped with additional safe guard thermometer (sensor)

needed for entire fan switching off when water temperature on the boiler exit

achieves 90ºC.

Drying and gasifying of wood takes place in the boiler container. Wood glows in

the air-tight loading chamber; the chimney exit is closed, while the fan is feeding

only a scarce amount of air; all gas components released during the pyrolysis

process reach the elongated burner of refractory concrete placed under the

container. The burner (nozzle) is also fed some secondary air which mixes with the

wood gas in such a way that the burning process is perfect. The burning of wood

gas in the lower chamber achieves 1200ºC.

The steel bottom of the combustion chamber (ash pit) is covered

by refractory concrete which protect the steel of the high temperature. The

chamber bottom and internal side of the boiler's door are also covered with the

refractory concrete. The boiler nozzle is made of refractory concrete as

a whole.

Above mentioned elements can work even in 1600ºC.

All boilers' door is sealed with a heat-resisting, glass wool cord.

To fill the boiler up:

1.switch off the fan using boiler master switch

2.open chimney flap

3.open upper door and fill up the boiler with wood

4.close chimney flap, door, and wood switch on the master switch

Remark! Boiler fuel shortage is indicated by yellow indicator

Boiler switching off

Boiler is switched off by pressing of master switch or automatically during fuel

shortage. See above.

Boiler cleaning

Boiler ash pit should be cleaned of every 3- 5 days. Loading (gasification)

chamber should be cleaned before each boiler burning. The ash shall be swept out

by the boiler nozzle of refractory concrete special care should be taken not to

damage of the boiler bottom. Onyl original cleaning tools shall be used (always

delivered together with the boiler).

A wood tar is produced during gasification process. Its issuing degree depends

on: wood type, its humidity but also inlet and outlet water temperature. Gasification

chamber should be cleaned of wood tar once a month by using of delivered scraper.

Also, inside exchanger tubes a carbon deposit is settled. It causes tubes diameter

decrease. Due to this, exchanger tubes should be cleaned every second week to

assure their permeability.

To clean out the exchanger you should:

1.Take off the boiler back upper casing

2.Turn on the nuts with M13 - M17spanners (depending on boiler type). Important!

Before nuts turning on and turning off the thread should be preserved with a

special anticorrosion agent; do not turn on nuts with exertion.

3.Precisely clean out each tube with cleaning shield (disk, target) up and down to

avoid setting of the furnance black down in the tube.

4.Sweep all of the furnance black settled on the boiler back wall.

8

13

4. Technical specification of the Orlan boilers

Boiler dimensions

5. BOILER START-UP

1.The boiler room should meet the rules shown in GENERAL BOILER

REQUIREMENTS (see point 2).

2.The boiler should be connected to the central heating system whose heating

capacity is equal of the boiler power range.

3.If the boiler is connected into the forced (pump) system it has to be protected in

case of power deficiency (boiler and pump disconnection) min. power

collection must be assured, e.g. for boiler 25 kW ca. 5 kW.

4.Boiler has to be connected to the chimney duct as shortly as possible,

a straight tube is preferred.

5.The tube connection flue with chimney should slightly rise over the chimney side

to reduce the pressure drop ( lift min. 5º ).

6.The chimney should have the section and height assuring required chimney

draught. Recommended chimney section is 20 x 20 cm.

7.Stable boiler connection to the water supply system is not recommended in case

of valve leakage it does not allow for pressure increase in boiler.

8.Boiler setting up should be carried out by qualified staff.

Each boiler is always delivered with: boiler filling up valve, room temperature

sensor and cleaning up elements.

Cleaning elements are: poker (fire iron), scraper, exchanger tube cleaner (bar ).

Remark! It is your duty to check delivery completeness.

15. BOILER EXPLOITATION

Before first boiler start-up you should check all of threaded connections (if there is

no leakage) and also water level into central heating system - then set-up boiler

working parameters.

It is recommended to be familiar with this instruction manual before boiler

setting-up.

Proper boiler burning:

1. Push the chimney flap (gas pass opened)

2. Place splinters and some bigger wood pieces using boiler upper chamber

3. Burn paper

4. Open lower door (natural draught)

5. Wait about 15 - 20 min for better wood burning

6. Place more wood to cover the boiler bottom (ca. 10 cm)

7. Switch on the master switch

8.fill up the whole boiler with wood

9.close upper and lower door

10. pull the chimney flap (gas pass closed)

11. if boiler temperature achieves 60ºC, fan begins to work

Warning! It is forbidden to switch on the fan if the upper door is opened

Important! Pay attention during boiler filling up with chunk of wood. They should be

of suitable size. Chunks bigger than required may cause door damage.

Maximum chunks dimensions:

Important! Wood has its permissible humidity when is seasoned at least 1 year.

Recommended humidity level is achieved after 2 years of wood seasoning.

Fuel filling up

If boiler is well-chosen, one full loading is sufficient for 6 to 12 hours of heating.

However, to avoid repeating of boiler burning it's good to check the boiler every 5-

7 hours.

Boiler type

Max. chunk diameter mm

Max. chunk length mm

18

200

500

40

200

500

25

200

500

60

300

750

80

300

1000

91 91 9191

9

12

6. PROGRAMMING

2.0 RK 2001 R4E Regulator

1. master switch

2. boiler temperature indicator

3. boiler fire-up mode indicator

4. boiler overheating indicator

5. room thermostat indicator

6. boiler thermostat knob

7. circulating pump indicator

8. fuel shortage indicator

9. room thermostat knob

7. REGULATOR CHARACTERISTIC

The regulator is destined for boiler temperature setting-up. The regulator

continues water temperature measurement then shows it on small screen and

operates the circulating pump as well.

The regulator is also equipped with room thermostat to assure the precise temperature regulation in the heated room space.

8. REGULATOR SET-UP

Before feeding plug connection into the socket (230V/50Hz) it should be decided

if regulator works with circulating pump or not. If first option is chosen the regulator should be taken of the boiler frame and after opening, properly connect the

pump power lead to the place named “CENTRAL HEATING PUMP”.

Before regulator insertion into the casing it should be assured that the temperature

sensor has not came out of the measurement casing.

Warning! Before regulator setting up it should be checked out if the wiring

system is correctly connected to the ground.

Warning! A fan and pump of max. 250W can be connected to one regulator.

9. REGULATOR SERVICE

Connecting strip as well as the safety device socket is placed on the regulator

11. ROOM THERMOSTAT SETTING-UP

RK 2001E regulator is equipped with a special input, placed on its back wall,

enabling room thermostat connecting (always delivered with each boiler). When

room temperature is lower than assigned one then the boiler indicator begins to

shine what means that the boiler should keep ordered temperature. When room

temperature gets assigned value the indicator is switched off and the boiler keeps

the temperature of 65ºC

Warning! Any room thermostat equipped with contact output is to be connected to

the regulator

Warning! If we do not want to use a room thermostat, the input contact should

stay closed

12. REGULATOR DAMAGE

After regulator damage is detected the fan and circulating pump is automatically

switched off; an appropriate note is shown on the regulator screen

In case of your regulator damage, please switch it off and contact service.

13. REGULATOR TECHNICAL DATA

14. FAN WORKING CHARACTERISTIC

The fan adapts its capacity to water temperature into the boiler. 10ºC before

assigned temperature, fan works in modulation mode, decreasing of its rotation

together with temperature increase.

Feeding

230V+/- 10%

Power input

< 4 VA

Temperature measurement range

0

0-99 +/- 1 C

Temperature measurement indicator

K

TY 81 - 210

Temperature regulation range

0

65 - 80 C

Current -carring cappacity

1A / 220V

THERMOSTAT

TEMPERATURE

15

20

22

25

27

10

75

65

80

o

C

o

C

o

C

! !

1 2 3 4 5 6

9 8 7 10

10

11

back wall. On the same wall there is also placed room thermostat socket and time

regulation handwheels

10. REGULATOR WORKING DESCRIPTION

Regulator's work is based on suitable controlling of the fan and heating system

circulating pump to achieve assigned boiler and room temperature. After regulator

switching on or after switching off the boiler overheating indicator, the regulator

begins boiler burning; it is shown by green indicator.

The burning process is finished if boiler temperature achieves assigned value and

green indicator will switch off.

If boiler temperature does not achieve 65ºC during 2 hours of boiler working, the

regulator will switch on the fan and shows fuel shortage indicator.

During its work regulator shows an actual boiler temperature and controls fan

speed as below:

Ø If during of the burning process boiler temperature is lower than 60ºC

the fan works in 40 - 100% ; if temperature is higher than 60ºC the fan

works in 100% of its power

Ø If boiler temperature during its normal work is lower than assigned value more

than 10ºC then fan works in 100% of its power

Ø If boiler temperature during its normal work is lower than assigned value less

than 10ºC then regulator reduce the fan speed but not less than 40% of its

power

Ø If boiler temperature is higher or equal of assigned thermostat tempe-rature the

fan switches off

Ø The fan will switch on again when boiler temperature gets down about 5ºC of

assigned value

Ø To avoid gasses accumulation during boiler outage, the regulator makes 5-

secunds blows through the boiler every 1÷9 minute. The blows can be set-up

after regulator switching on when you can see (P1….P9, P-) on the regulator

screen; pressing (P-) you will switch off the blows.

If circulating pump works:

Ø during boiler burning , until boiler achieves 65ºC, pump is switched off

Ø if, boiler temperature is higher than 65ºC pump starts to work and works until

boiler temperature gets down to 60ºC to avoid excessive boiler pre-cooling

Ø if, during boiler operation the temperature temporarily gets down to 60ºC the

pump starts to work again after temperature achieves 65ºC

FUEL SHORTAGE

If boiler temperature gets down under 65ºC and it is continued by 30 min., then

regulator switch off the fan and switch on the fuel shortage indicator.

In case of regulation repeated switching off, you should:

Ø fill up the boiler with wood or to burn the boiler again if necessary

Ø turn the thermostat handweel to the left as much as possible

Ø wait until the fuel shortage indicator starts to blink

Ø set-up boiler temperature using of thermostat handwheel

BOILER OVERHEATING

If boiler temperature achieves over 85ºC, the regulator switches off the fan and

switch on the boiler overheating indicator. Then you should:

Ø wait until boiler temperature gets down

Ø remove boiler overheating reason (e.g. water shortage )

Ø wait until the overheating boiler indicator begins to blink

Ø set-up of boiler assigned temperature turning the thermostat handweel to the

right

Warning! Filling up with water should be done if boiler temperature gets

under 40ºC

Warning! If boiler temperature gets under 60ºC before cancelling of boiler

overheating - regulator begins boiler burning

Warning! Regulator is equipped with additional internal protecting thermostat

avoiding the boiler high temperature excess. When water temperature

in the boiler increase10ºC more than assigned one - regulator

automatically disconnect the fan then disconnecting of protection

follows after temperature gets down lower than assigned value.

Loading...

Loading...