EKOM DK50 D, DK50 DM User Manual

GENERAL INFORMATION

NP-eVENT-16_10-2018 1

CONTENTS

1. GENERAL INFORMATION ............................................................................................... 2

INTENDED USE................................................................................................................... 2

CONTRAINDICATIONS AND SIDE-EFFECTS .................................................................... 2

OPERATOR'S RESPONSIBILITY FOR PATIENT SAFETY ................................................. 2

MARKINGS .......................................................................................................................... 2

WARNINGS ......................................................................................................................... 2

General safety warnings ............................................................................................. 3

Electrical system safety warnings ............................................................................... 3

WARNING NOTICES AND SYMBOLS ................................................................................. 5

USE ...................................................................................................................................... 6

STORAGE AND TRANSPORT ............................................................................................ 6

2. EQUIPMENT DESCRIPTION ............................................................................................. 7

3. TECHNICAL DATA .......................................................................................................... 9

FAD efficiency correction for differences in elevation ............................................... 10

4. OPERATION .................................................................................................................. 11

INSTALLATION AND FIRST OPERATION ........................................................................ 11

Preparing the compressor for use ............................................................................ 11

Compressed air connection ...................................................................................... 12

Electrical connection ................................................................................................ 12

First operation .......................................................................................................... 13

Accessories .............................................................................................................. 13

OPERATION ...................................................................................................................... 14

Switching on the compressor.................................................................................... 14

Running the compressor .......................................................................................... 15

Cleaning the suction filter ......................................................................................... 15

Cooling failure alarm ................................................................................................ 15

Cleaning the compressor .......................................................................................... 15

5. MAINTENANCE ............................................................................................................. 16

REPAIRS AND SERVICE .................................................................................................. 16

MAINTENANCE SCHEDULE ............................................................................................. 17

NOTICE ............................................................................................................................. 17

Safety valve check ................................................................................................... 18

Replacing the suction filter ....................................................................................... 18

Replacing the blow down filter .................................................................................. 18

Replacing the pressure regulator filter ...................................................................... 19

Capacity check ......................................................................................................... 19

Stabilizing the compressor before shipping .............................................................. 20

SHUTDOWN ...................................................................................................................... 20

EQUIPMENT DISPOSAL ................................................................................................... 20

6. TROUBLESHOOTING .................................................................................................... 21

7. SPARE PARTS .............................................................................................................. 22

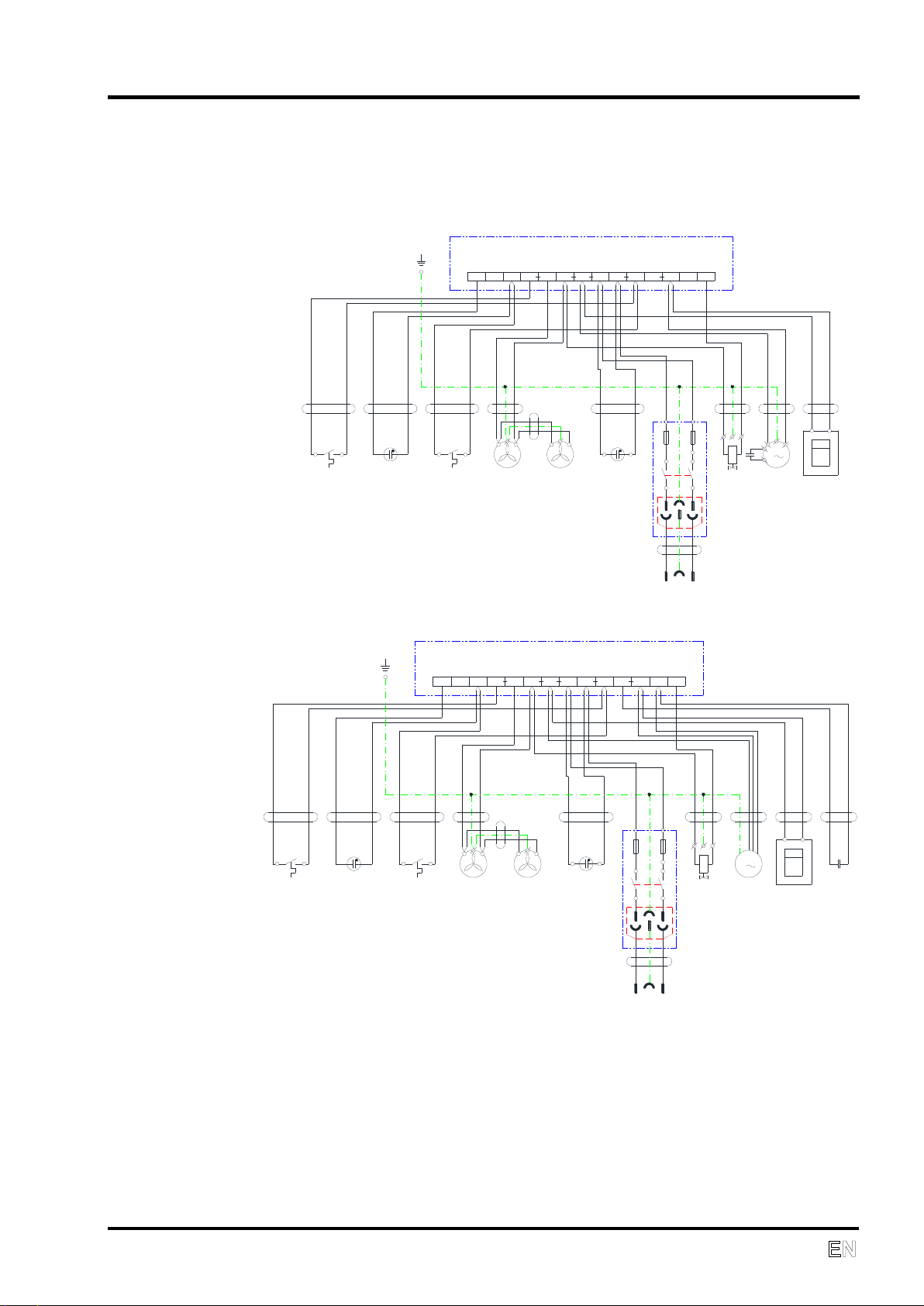

8. ELECTRIC AND PNEUMATIC DIAGRAMS ...................................................................... 23

WIRING DIAGRAM ............................................................................................................ 23

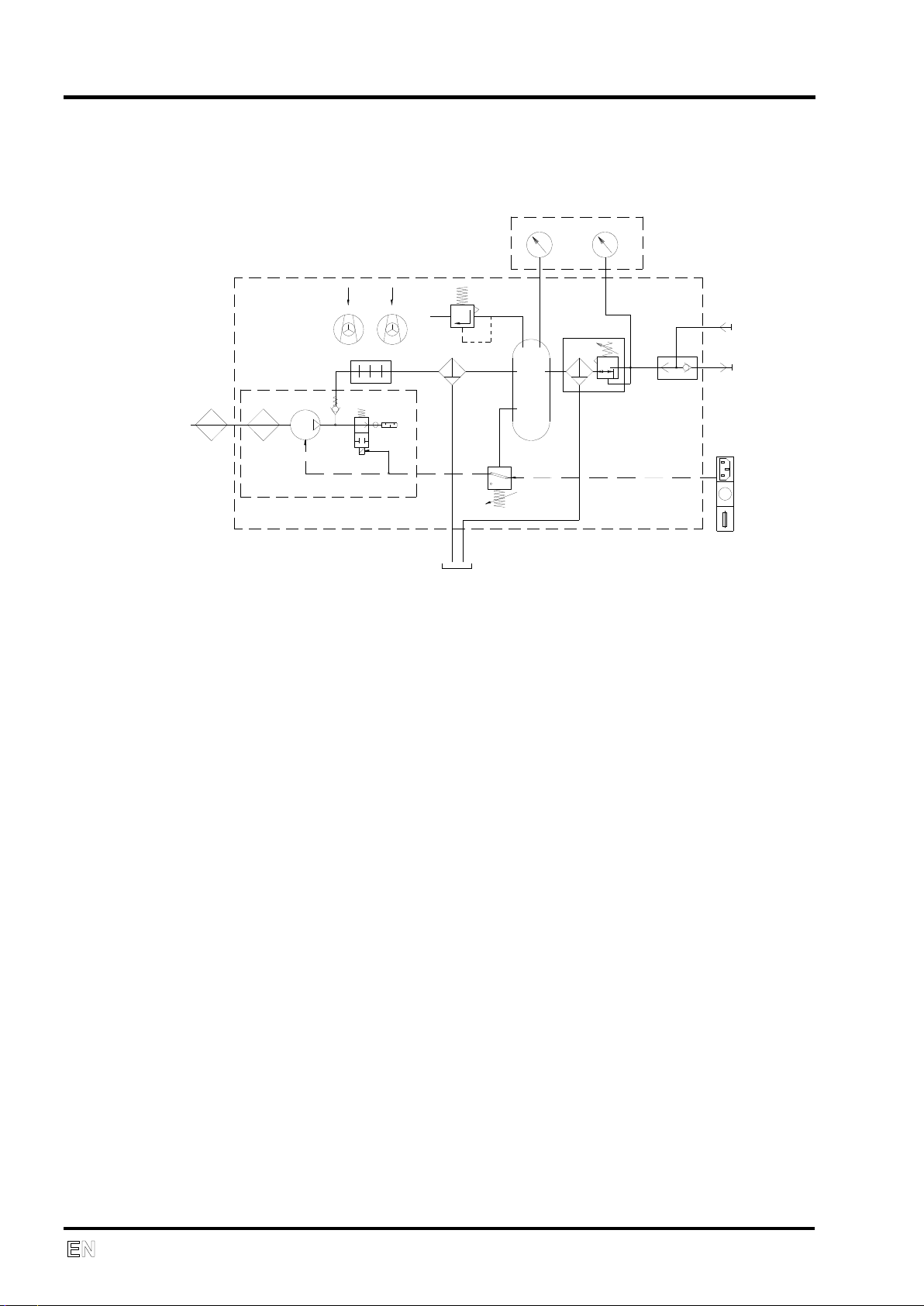

PNEUMATIC DIAGRAM ..................................................................................................... 24

9. ANNEX .......................................................................................................................... 92

INSTALLATION RECORD ................................................................................................. 92

GENERAL INFORMATION

2 NP-eVENT-16_10-2018

1. GENERAL INFORMATION

INTENDED USE

The EKOM DK50 D, DK50 DM is a medical air compressor that supplies

clean, oil-free compressed air for use with medical ventilators.

CONTRAINDICATIONS AND SIDE-EFFECTS

There are no contraindications or side-effects known

OPERATOR'S RESPONSIBILITY FOR PATIENT SAFETY

The Installation, Operation and Maintenance Manual is an integral part of the

equipment and must be kept with the compressor. Careful review of this

manual will provide information necessary for correct operation of the

equipment.

Rx only

US Federal law restricts the sale of this device by or on the order of a

physician.

MARKINGS

Products marked with the CE mark of compliance meet the safety

requirements of the European Union (93/42/EEC).

WARNINGS

• The safety of operating personnel and trouble-free operation of the

equipment are ensured only if original parts are used. Only accessories

and spare parts mentioned in the technical documentation or expressly

approved by the manufacturer can be used.

• If any other accessories or consumable materials are used, the

manufacturer cannot be held responsible for the safe operation and

functionality of the equipment.

• The warranty does not cover damages resulting from the use of

accessories or consumable materials other than those recommended by

the manufacturer.

• The manufacturer assumes responsibility for the safety, reliability and

function of the equipment only if:

- Installation, calibration, amendments, extensions and repairs are

performed by the manufacturer, one of its representatives or a service

provider authorized by the manufacturer

- The equipment is used in accordance with the Installation, Operation and

Maintenance Manual

GENERAL INFORMATION

NP-eVENT-16_10-2018 3

• The Installation, Operation and Maintenance Manual accurately describes

the design of the compressor and its compliance with safety and technical

standards. The manufacturer reserves all rights to its wiring diagrams,

procedures and names.

General safety warnings

The manufacturer developed and constructed the equipment so that damage

would not occur when the equipment is used for its intended purpose. The

manufacturer considers it its obligation to describe the following safety

measures in order to avoid further damages.

• Equipment operation must comply with all local codes and regulations. In

order to ensure safe work, the operator and user are responsible for

following all applicable regulations.

• Original packaging should be kept for the possible return of the unit. Only

original packaging ensures optimal protection of the equipment during

transport. If it is necessary to return the equipment during the warranty

period, the manufacturer is not liable for damages caused by incorrect

packaging.

• The user must immediately notify the supplier if any problem occurs

during the use of the equipment.

• This product is not intended for use in areas where there is a risk of an

explosion. Do not operate the compressor in the presence of flammable

anesthetics.

• Never feed oxygen or nitrous oxide into the compressor. Compressor

components are not approved for oxygen or nitrous oxide use.

• This device can be used only with ventilators equipped with a low

pressure alarm.

Electrical system safety warnings

• The equipment must only be connected to an appropriate power source

that has correct grounding. In order to assure proper grounding, connect

the compressor to a receptacle marked "hospital grade".

• Before the compressor is plugged in, make sure that the voltage and

frequency of the mains specified on the equipment are the same as the

power mains.

• Before operating, check for possible damage to the equipment and any

connections. Damaged pneumatic and electrical lines must be replaced

immediately.

• If a technical failure occurs, immediately disconnect the equipment from

the mains (pull out the main power plug).

• During repairs and maintenance, ensure that:

- The main power plug is removed from the power socket,

- Compressed air lines are disconnected,

GENERAL INFORMATION

4 NP-eVENT-16_10-2018

- All pressure has been released from the air tank.

• Only a qualified technician can install this equipment.

GENERAL INFORMATION

NP-eVENT-16_10-2018 5

WARNING NOTICES AND SYMBOLS

The following symbols are used for important information in the Installation,

Operation and Maintenance Manual and on packaging and the product:

Attention, see instructions for use

Caution, risk of electric shock

Consult instructions for use

CE mark of compliance

Caution, hot surface

Handling mark on package – FRAGILE

Handling mark on package – THIS SIDE UP

Handling mark on package – KEEP DRY

Handling mark on package – TEMPERATURE LIMITATIONS

Handling mark on package – LIMITED STACKING

Mark on package – RECYCLABLE MATERIAL

Alternating current

Ground connection

Equipotentiality

Fuse

GENERAL INFORMATION

6 NP-eVENT-16_10-2018

USE

• The equipment can only be installed and operated in a dry, ventilated and

dust-free area. Climatic conditions for operation - see Technical data.

• The compressor must stand on a flat and stable base.

• The compressor must not be exposed to rain. The equipment must not be

used in humid or wet environments. Never use the compressor in the

presence of flammable liquids or gases.

• Before connecting the compressor to respiration equipment, make sure

that it meets the requirements of the respiration equipment. Refer to the

Technical data for this purpose.

• Any use other than the compressor‘s intended use is not considered to be

safe. The manufacturer is not responsible for any damages that result if

the compressor is used for any other purpose. Risk is exclusively

assumed by the operator/user.

STORAGE AND TRANSPORT

The compressor is shipped from the factory in transport packaging with the

pump stabilized, protecting it from damage during transport.

For transport, always use the original packaging and secure the compressor

in the upright position.

Protect the compressor from humidity, contamination and extreme

temperatures during transport and storage. A compressor in its original

packaging should be stored in a warm, dry and dust-free area.

Keep the packaging material, if possible. If not, dispose of the packaging

material in an environmentally-friendly way. Cardboard can be recycled.

Before moving or transporting the compressor, the pressure in the air tank

and hoses must be released and any condensed water must be drained.

Secure the motor to prevent movement before shipping.

Prior to transport it is necessary to secure the motor inside the

compressor (Chapter 5)

EQUIPMENT DESCRIPTION

NP-eVENT-16_10-2018 7

2. EQUIPMENT DESCRIPTION

1. PRESSURE - output air pressure gauge (accuracy ± 5%)

2. HUMIDITY - humidity indicator (performance)

3. Cooling failure indicator

4. Power indicator

5. Hour meter

6. Main input, power switch, primary fuses

7. Equipotential (ground) pin

8. Socket for the electrical cord

9. WALL - inlet air coming from an outside compressed air source

10. OUT - output air from compressor

11. Air tank

12. Suction filter

13. Pressure regulator with filter

14. Filter and water trap

15. Cooler

16. Control electronics

17. Safety valve

18. Internal back cover

19. Tube for supporting equipment

The equipment consists of an oil-free piston compressor driven by a single-

phase electric motor, filtering and drying equipment, an air tank and a

pressure regulator. The compressor is placed in a box lined with noise

absorbing insulation. The equipment produces filtered compressed air

without any traces of oil with reduced water content (dry air).

The air compressor has an input air connector labeled WALL (9) that allows

the connection of an outside air source. When an outside compressed air

source is connected to the WALL inlet fitting supplies air above the adjusted

output pressure, the compressor will not be activated even though the power

switch is in the ON position. Instead, the air from the outside source will be

directed to the compressor's air output. When the outside air source pressure

is less than the adjusted output pressure (or is not connected) and the power

switch is in the ON position, the compressor is activated and supplies

compressed air through the air output.

The compressor pulls in atmospheric air through the suction filter (12).

Compressed air is cooled in the cooler (15), continues to the filter (14) and

condensed liquid from the water trap is automatically released to the

evaporation tray. The air continues through the check valve to the air tank

(11) and through the pressure regulator with the output filter (13) to the OUT

connector (10). Fans operate during compressor operation and when not

operating when the temperature in the cabinet is over 40°C (104°F). If the

temperature in the cabinet is over 80°C (176°F), a cooling failure is signaled

by the red indicator (3) and an acoustic alarm. Control electronics (16) control

compressor operation based on the pressure in the air tank (11). A safety

valve (17) ensure the maximum allowed tank pressure is not exceeded.

EQUIPMENT DESCRIPTION

8 NP-eVENT-16_10-2018

TECHNICAL DATA

NP-eVENT-16_10-2018 9

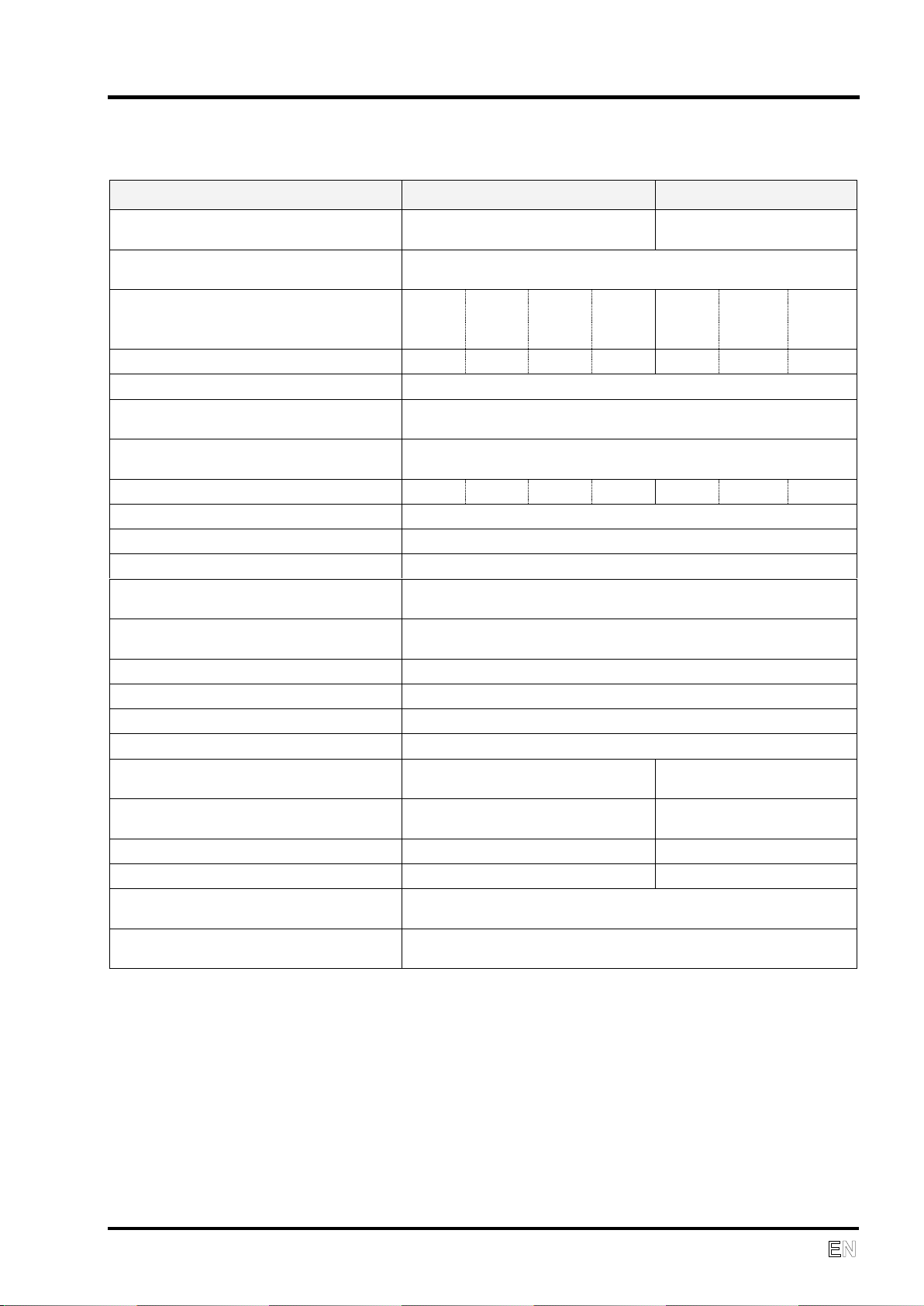

3. TECHNICAL DATA

TYPE

DK50 D

DK50 DM

Output flow at pressure

3.5 bar (51 psig)

Liters/min

40

60

Output flow max.

at pressure 3.5 bar (51 psig)

200 L/min for 2 s *

Rated voltage / Frequency

V/Hz

230/50

230/60

USA

Model

120/60

100

/50-60

230/50

230/60

USA

Model

120/60

Nominal current

A

2.8

2.8

5.6

5,6

3.4

4.3

8.6

Filtration of air to

m

5

Dew point depression at 40 L/min,

3 bar (43.5 psig), 20°C (68°F)

5°C (9°F) under the ambient temperature

Outlet connection

RECTUS 21KS KS08 MPC

Or DISS 1160-A (3/4"-16 UNF)

Sound level

dB(A)

49

51

51

51

50

52

52

Mode of operation

Continuous - S1

Release of condensed water

Automatic

Indication of cooling failure

Acoustic and visual at 80°C (176°F)

Output pressure

3.0 bar (43 psi)

Adjustable to max. 3.5 bar (51 psi)

Automatic start-up

pressure (backup)

3.0 bar (43 psig)

Adjustable to max. 3.5 bar (51 psi)

Air tank capacity

L

5

Pressure range

5.0 - 7.0 bar (72.5 - 101.5 psi)

Safety valve setting

8.0 bar (116 psi)

Adjustment of the output air pressure

Pressure regulator

Dimensions of compressor

w x d x h

400x430x780 mm (16x17x31 in)

400x500x780 mm

(16x20x31 in)

Dimensions of packaging

w x d x h

480x530x835 mm (19x20x33 in)

480x580x835 mm

(19x23x33 in)

Net weight

46 kg (101 lbs)

59 kg (130 lbs)

Gross weight

60 kg (132 lbs)

73 kg (161 lbs)

Implementation pursuant to

EN 60601-1, EN 12021

Class I.

Classification acc. to MDD 93/42

EEC, 2007/47 EC

II b

* With 0.6 bar pressure drop (8.7 psi)

Climatic conditions for storage and transport

Temperature –25°C to +55°C (-13°F to +131°F), 24 hrs +70°C (+158°F)

Relative air humidity 10% to 90% (no condensation)

Relative air humidity for seaworthy packing 10% to 100% (with condensation)

Climatic conditions for operation

Temperature +5°C to +40°C (+41°F to +104°F)

Relative air humidity up to +95%

IPX0 Rating

TECHNICAL DATA

10 NP-eVENT-16_10-2018

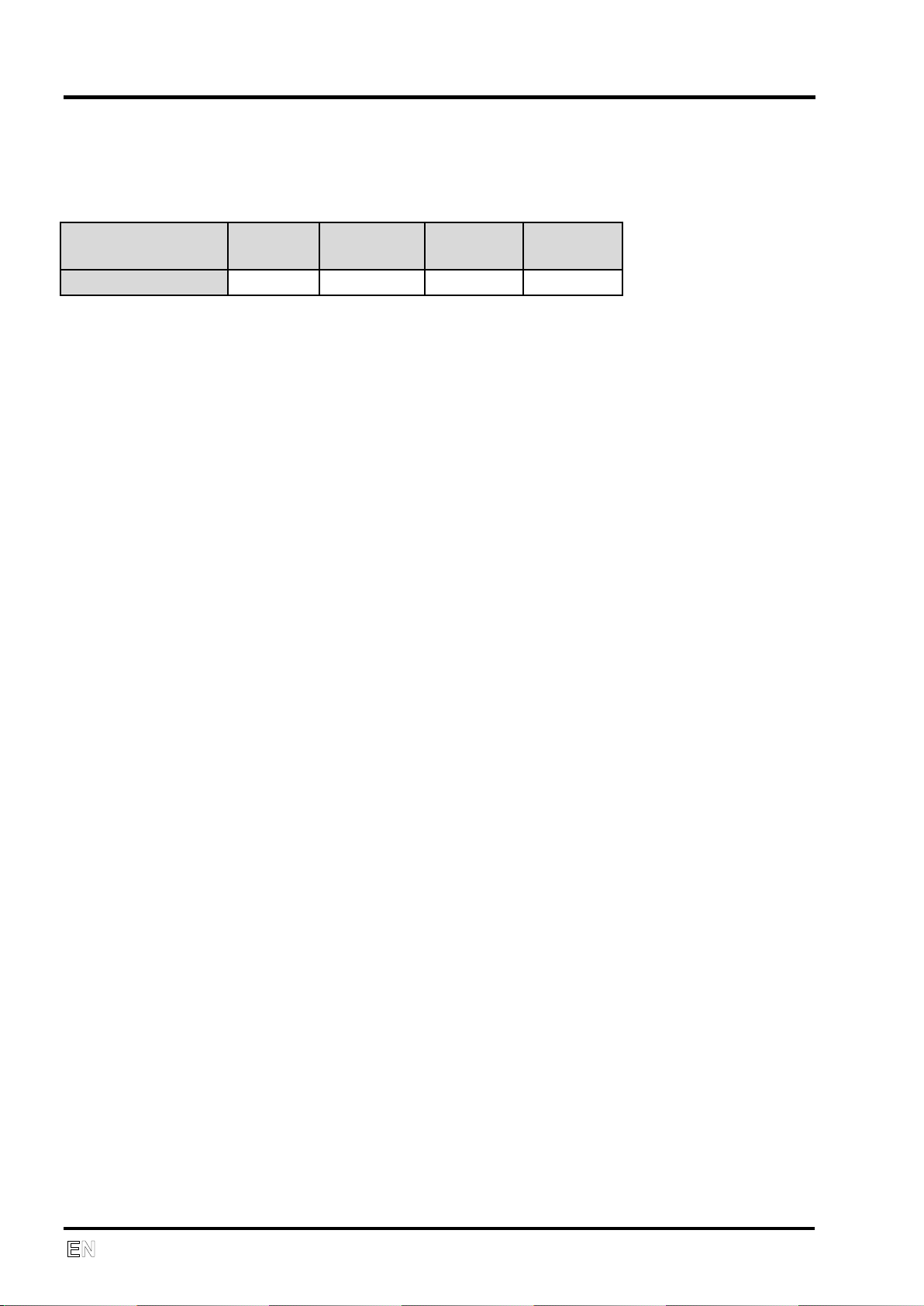

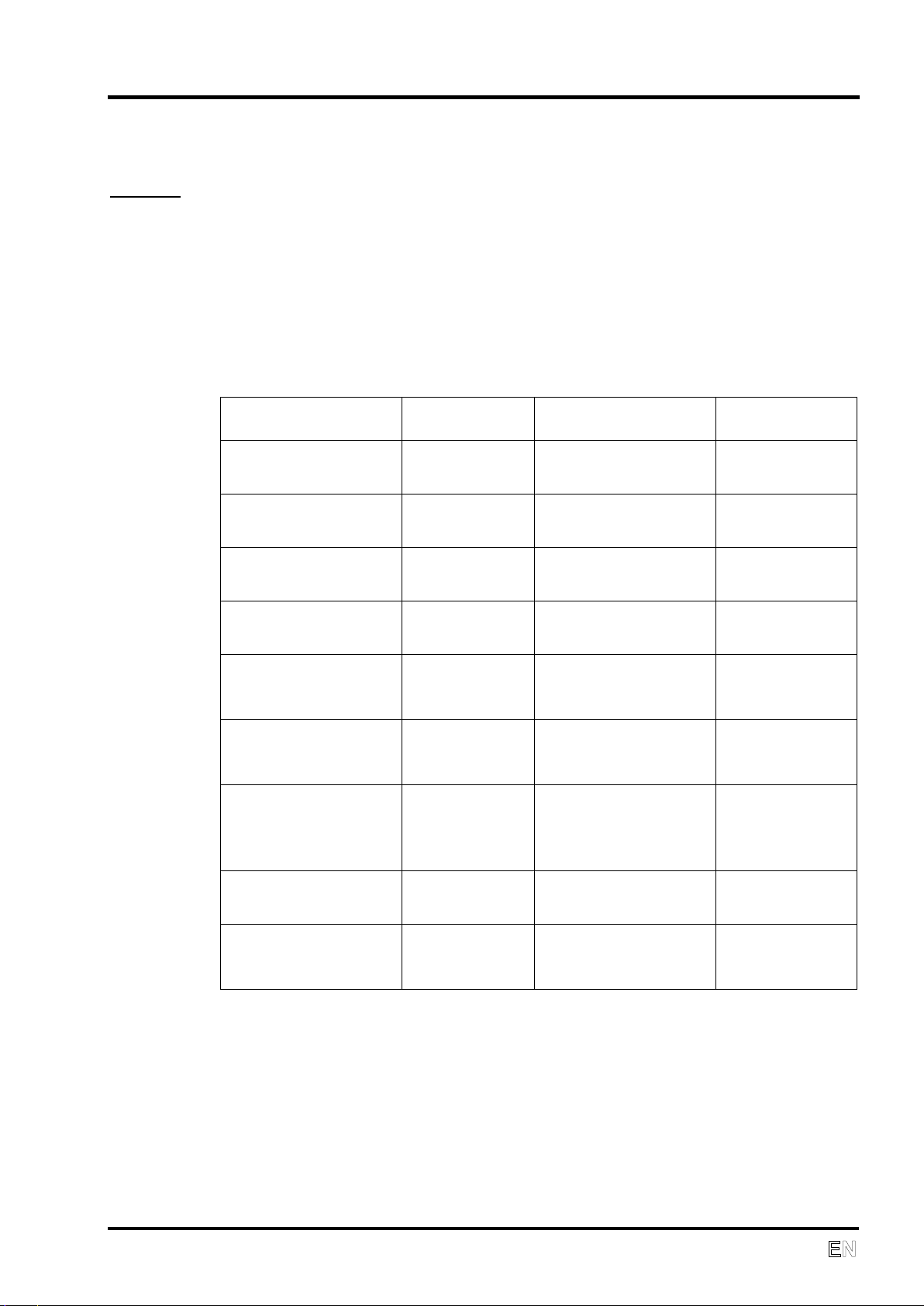

FAD efficiency correction for differences in elevation

FAD correction table

FAD efficiency refers to conditions at an elevation of 0 mamsl:

Temperature: 20°C

Atmospheric pressure: 101325 Pa

Relative humidity: 0%

Elevation [mamsl]

0 - 1500

1501 - 2500

2501 -

3500

3501 -

4500

FAD [l/min]

FAD x 1

FAD x 0.8

FAD x 0.71

FAD x 0.60

OPERATION

NP-eVENT-16_10-2018 11

4. OPERATION

INSTALLATION AND FIRST OPERATION

Do not use the compressor immediately after unpacking as it will not

adjust to the ambient temperature.

Only qualified personnel can install the compressor and put it into

operation for the first time. The installer shall train the operating

personnel in the use and routine maintenance of the equipment.

Installation and training of personnel should be acknowledged by the

installer‘s signature on the installation certificate.

Prior to start-up, the four screws for transport stabilization must be

removed. If the compressor is switched on without removing the

stabilizers, the compressor could be permanently damaged!

The compressor does not contain a backup power supply.

This compressor can only be used with ventilators equipped with low

pressure alarms.

Never block the suction filter and the vent outlets on the lower part of

equipment. Never lift the unit by the handle! The handle is to be used to

move a compressor on the floor with the brakes released.

If the compressor is equipped with a main source of air, the standby air

source must be available.

ANY MODIFICATION OF THIS EQUIPMENT IS FORBIDDEN!

If this equipment is used nearby other instruments, the equipment must

be observed in order to verify normal operations in the configuration it

will be used.

Instruments may be affected electro-magnetically!

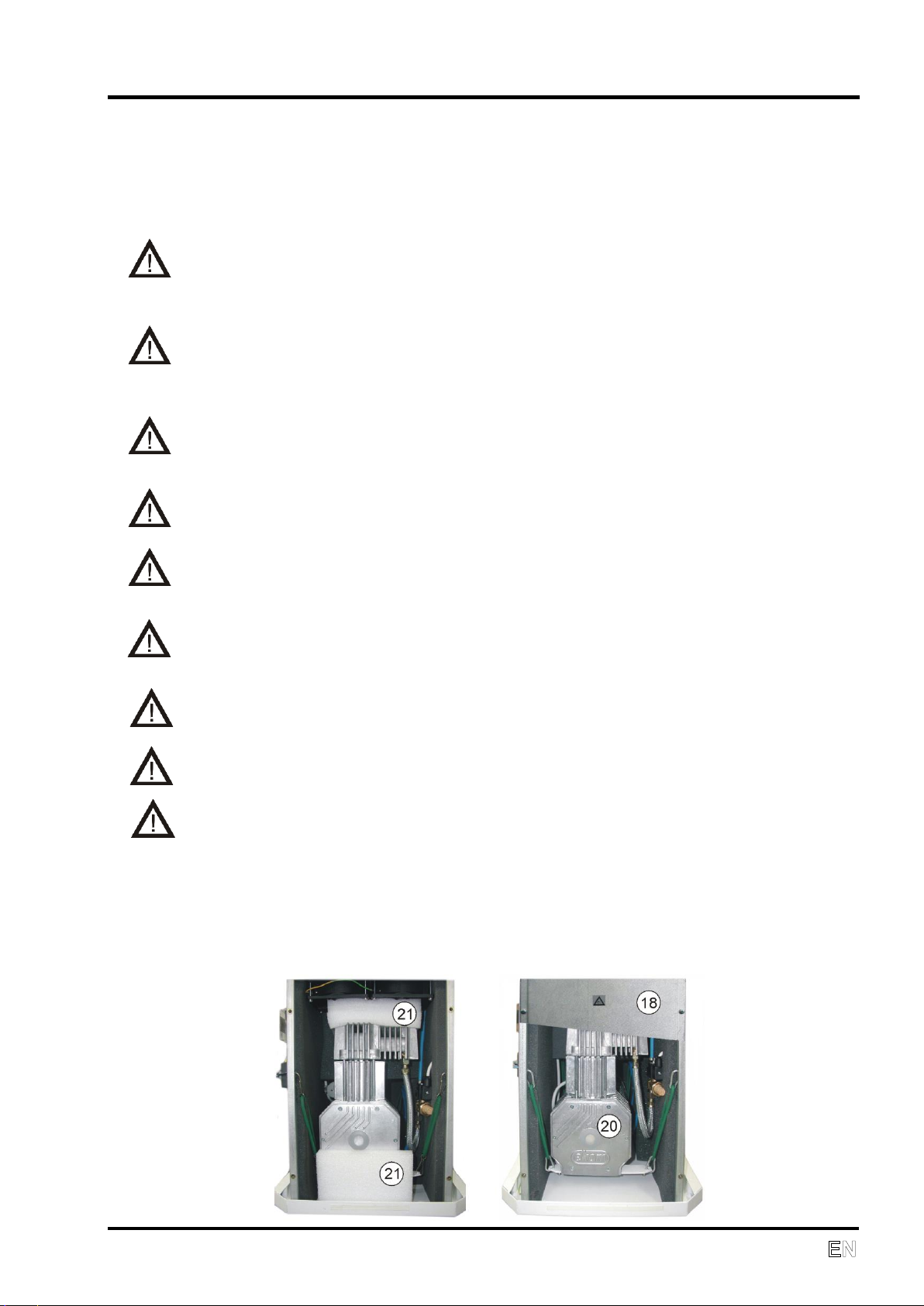

Preparing the compressor for use

After unpacking, place the compressor upright with the castor wheels firmly

on the ground.

OPERATION

12 NP-eVENT-16_10-2018

• Remove the front and back cover unscrewing the six screws on the

cabinet side.

• Unscrew the four screws and remove the internal back cover (18).

• Remove all packing elements above (21) and under the compressor (20).

• Screw the internal back cover back on, connect the ground wire, screw

the front and back cover and insert the suction filter.

Please retain the packing elements for future compressor transportation.

Compressed air connection

The medical compressor is equipped with quick couplings WALL (9) and

OUT (10) to the rear of the cabinet.

Connect the pressure hose from the given equipment/respiration equipment

to the quick coupling OUT (10) -outlet compressed air.

Connect the compressed air line from the central distribution line o the quick

coupling WALL (9) -inlet compressed air. Air from the distribution system is

automatically connected through the compressor to the OUT outlet port. In

this configuration, the compressor serves as a backup source of compressed

air. If the air pressure from the central distribution system is reduced, the

compressor automatically switches on and there is no interruption in the

supply of continuously pressurized air at the outlet of the compressor.

Please note that the air supply from the central distribution line

entering the compressor must be medical grade air (particulate size,

humidity.) The compressor does not modify the air from the central

distribution line.

The hose connecting the compressor to the respiration equipment

must not pass through a cold environment i.e. placed on the ground. It

should be as short as possible with no kinks (this may cause water to

condense inside the hose).

Electrical connection

The compressor comes with a plug containing an appropriate

protective contact (ground.) Adhere to local electrical regulations. The

voltage and frequency of the mains must comply with the

specifications on the data label.

The electrical cord must not be stressed or have any tension exerted

upon it, and must always be free.

• The socket must be accessible for safety reasons so that the equipment

can be safely disconnected in case of an emergency.

• The relevant current circuit must be protected.

OPERATION

NP-eVENT-16_10-2018 13

• Connection of the ground connection (7) to other equipment must adhere

to local electrical regulations.

• Fasten the electrical cord through the holder (8).

First operation

• Make sure the stabilizing screws used during transport were removed.

• Check that the connection to the compressed air supply is correct.

• Check for proper connection to the main power supply.

• Switch on the pressure switch (6) to position “I”.

After the compressor is first put into operation, the air tank of the compressor

is pressurized to a ‘switching-off’ pressure and the compressor will then be

automatically switched off. During the following time period the compressor

works in an automatic mode, i.e. according to the consumption of

compressed air; the pressure switch controls compressor operation.

During operation, the equipment releases condensed water from the

condenser (filter) automatically to the evaporation tray.

Accessories

Holder for supporting equipment - Item 604011346-000

The holder (19) is suitable for supporting a respiratory apparatus with

accessories. Please remove the plug in the middle of the upper side before

installation. Screw the holder into the socket and tighten it fast.

Technical data:

Diameter 25 mm

Height 1100 mm above the floor

The maximum holder load is 28 kg. The centre of gravity of supporting

equipment must be in the axis of the holder, max. 1100 mm above the floor.

Consult the manufacturer regarding any other connections.

The manufacturer is not liable for any damage resulting from excessive

loads on the equipment!

The supplier is obliged to ensure the acceptability of a load delivered

by a supplied accessory.

It is forbidden to lean or press against an installed accessory for

support!

The equipment must be lifted when travelling over an obstacle!

Supporting equipment must be disassemble before transport!

OPERATION

14 NP-eVENT-16_10-2018

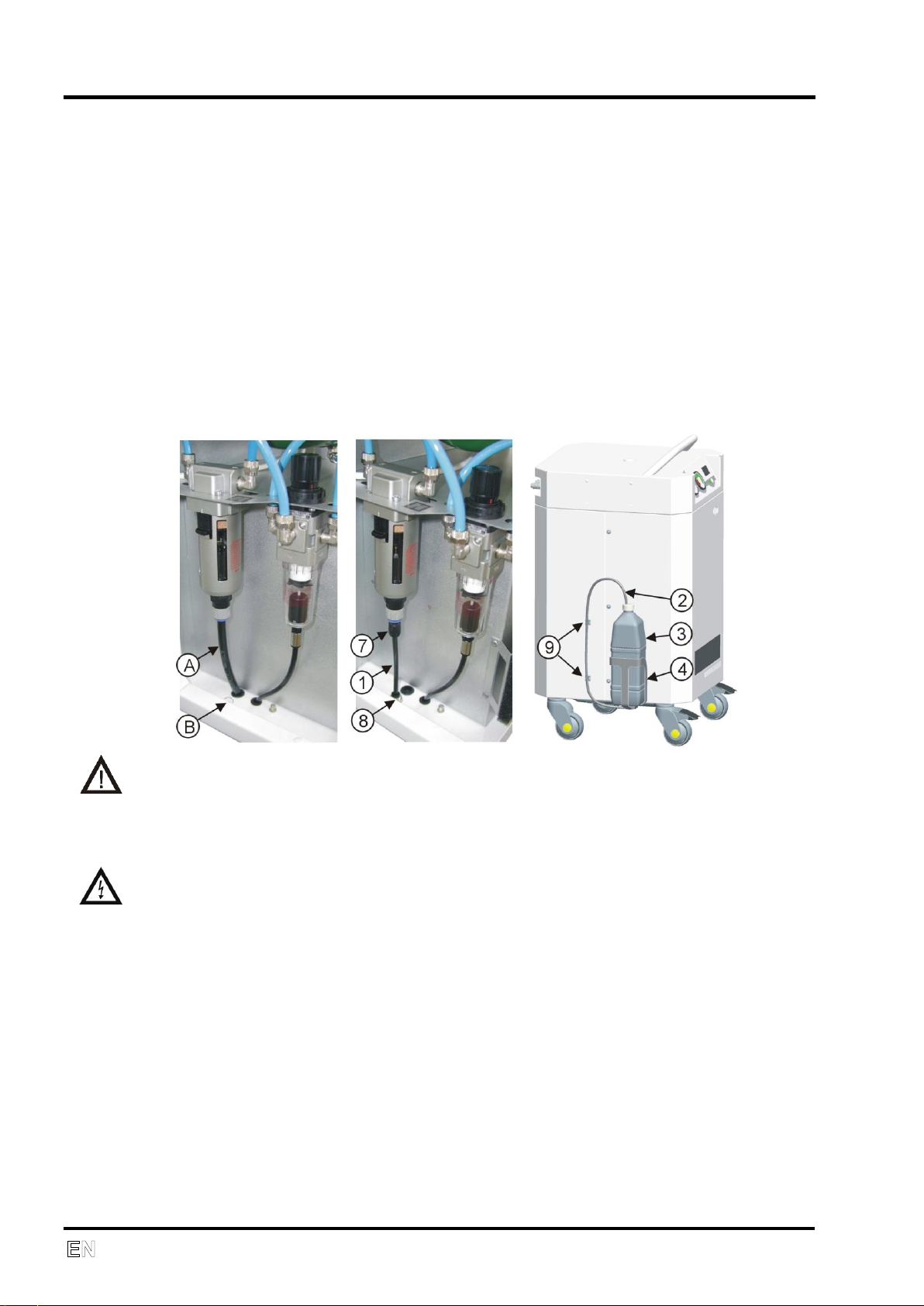

Kit for higher relative air humidity - Item 604011497-000

1. Hose PUR 6/4-130 062000337-000 1

2. Hose PUR 6/4-700 062000357-000 1

3. Tank LUH-1 062000333-000 1

4. Holder 3KB-972 023000564-000 1

5. Washer D5 043000002, 043000005-000 4

6. Screw M5 041000131-000 4

7. Reducer 10/6 062000339-000 1

8. Connector L6/6 025400153, 025400154-000 1

9. Clamp self-adhesive 033400011-000 2

Dismount the hose (A) and plug (B). Install the reducer (7), connector (8) and

plug-in hose (1). Screw holder (4), plug-in hose (2) and install tank (3). Fix

hose with two clamps (9).

Empty tank regularly.

OPERATION

In case of emergency, switch the equipment off at the switch and pull

out the main power plug.

Automatic operation. When the pressure in air tank falls to the ‘switch on’

pressure, the compressor is automatically switched on. The compressor is

automatically switched off when the pressure increases to the ‘switch off’

pressure in the air tank.

Switching on the compressor

The compressor is switched on at the main power switch (6) by putting it in

position "I". Switching on is signaled by the green indicator (4).

OPERATION

NP-eVENT-16_10-2018 15

Running the compressor

When the pressure of the air at the ‘Inlet’ port is reduced or if there is a

reduction of pressure in the air tank, the compressor is switched on and the

air tank is filled with compressed air. After the ‘switch-off’ pressure is

reached, the compressor is automatically switched off. Pressure of the output

air from compressor is indicated on the pressure gauge (1).

During compressor operation, the pointer of the humidity indicator (2) should

be in the green zone. If equipment air consumption is higher than maximum

output, the pointer of indicator will move from the green zone and the air from

compressor will not reach the declared parameters (see Technical data).

The hour meter (5) indicates total running time of the compressor.

Cleaning the suction filter

At least once a week take out and clean the suction filter (12) located on the

front side. Wash the filter in warm soapy water, rinse thoroughly and allow it

to dry. Insert the clean filters so that the suction openings are completely

covered by the filters.

Cooling failure alarm

Problems with compressor cooling are signaled by the red indicator (3) and

the acoustic alarm.

If a cooling failure alarm is signaled, secure an alternate air pressure

source and disconnect the compressor.

Cleaning the compressor

The product can be cleaned using normal detergents. To clean the

compressor, use a detergent that contains no abrasives, chemical solvents

or other corrosive agents.

MAINTENANCE

16 NP-eVENT-16_10-2018

5. MAINTENANCE

REPAIRS AND SERVICE

Warranty and extended warranty repairs are to be completed by the

manufacturer or a service provider authorized by the manufacturer.

The manufacturer reserves the right to modify the equipment in any

way that will not alter the function or the operation of the equipment.

Only a qualified technician or the Customer Service Department of the

manufacturer may perform repairs that go beyond routine maintenance.

Use only spare parts and accessories approved by the manufacturer.

Prior to any maintenance or repairs, switch off the compressor and

disconnect it from the mains (pull out the main power plug).

MAINTENANCE

NP-eVENT-16_10-2018 17

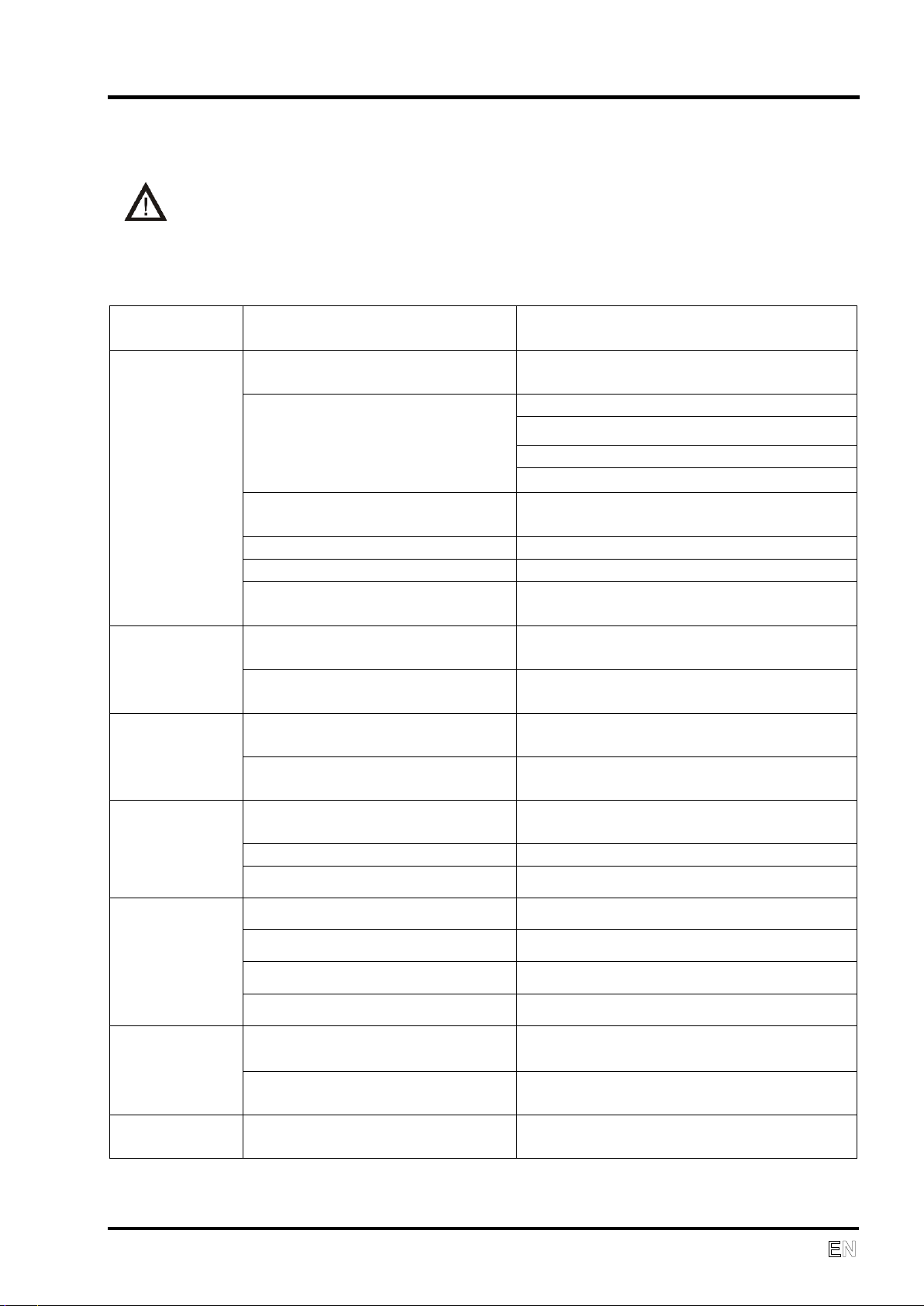

MAINTENANCE SCHEDULE

NOTICE

The operating entity is obliged to ensure that all tests of the equipment are carried

out repeatedly at least once within every 24 months (EN 62353) or in intervals as

specified by the applicable national legal regulations. A report must be prepared on

the results of the tests (e.g.: according to EN 62353, Annex G), including the

measurement methods used.

Maintenance range

Page

Time interval

To be

performed by

Clean suction filter

13

At least once a

week

Staff

Safety valve check

16

Once per year

Qualified expert

Replace filter (B)

16

Every 8000 hours

Qualified expert

Replace filter in

blow down filter (C)

16

Every 2000 hours

Qualified expert

Replace filter in the

pressure regulator

(D)

17

Every 2000 hours

Qualified expert

Test the tightness of

joints and inspect

the equipment

Service

documentation

After two years

Qualified expert

Replace piston

complete with piston

rings, O-rings and

bearing

Service

documentation

Every 4000 hours

Qualified expert

Bearing

replacement

Service

documentation

Every 4000 hours

Qualified expert

Perform “Repeated

Test” according to

EN 62353

15

1 x 2 years

Qualified expert

MAINTENANCE

18 NP-eVENT-16_10-2018

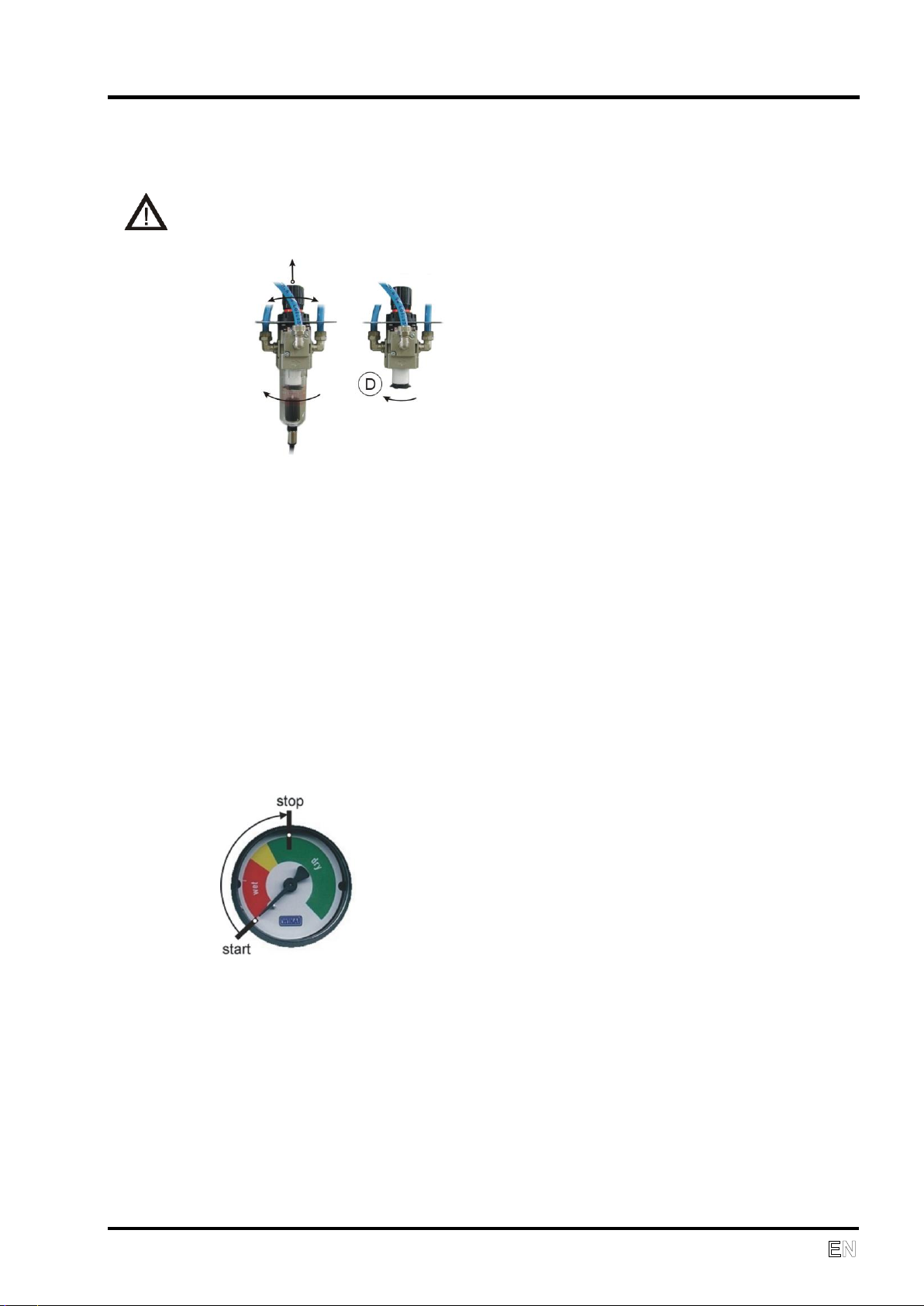

Safety valve check

The safety valve is adjusted to 8 bar (116 psig) by the manufacturer,

then tested and marked. It must not be readjusted.

• Turn the screw of the safety valve

(17) several rotations to left until the

safety valve puffs.

• Only allow the safety valve freely

puff for a short period of time.

• Turn the screw to the right until it is

tight, closing the valve.

Never use the safety valve to release pressure in the air tank. This could

damage the safety valve.

Replacing the suction filter

• Unlock the cover and pull it out.

• Replace the filter

• Lock the cover

Spare part:

Suction filter 05W POLYESTER, Item 025200194-000

Replacing the blow down filter

• Loosen lock on filter (14) by pulling it down.

• Slightly turn the cover of the filter and pull it out.

• Unscrew the filter holder.

• Replace filter (C), screw in the filter holder.

• Place the cover of filter and secure it by turning to right till it locks.

B

MAINTENANCE

NP-eVENT-16_10-2018 19

Replacing the pressure regulator filter

Before working on this equipment all air pressure must be released

from the tank so that pressure is zero and the equipment must be

disconnected from the electrical power mains.

• Unscrew the filter regulator cover (13) and pull it out.

• Unscrew the filter holder.

• Replace filter (D), screw in the filter holder.

• Screw in the regulator cover.

Setting output air pressure

Switch on the compressor and set the output pressure air flow until the

humidity indicator (2) remains in the green area. Unlock the control button of

the filter regulator (13) and rotate to set the demand output pressure. After

setting the pressure, lock the control button of the regulator by pushing down.

Capacity check

Before checking capacity it is necessary to switch off the compressor using

the power switch, vent air pressure out of the air tank and disconnect the

output hose from the OUT (10) fitting. Next switch the compressor on using

the power switch and measure (record) the time between start and stop (2).

Compressor capacity is met when the recorded time is not more than 45

seconds for DK50 D or 30 seconds for DK50 DM.

MAINTENANCE

20 NP-eVENT-16_10-2018

Stabilizing the compressor before shipping

Before shipping, the compressor must be stabilized to prevent movement.

The procedure is illustrated on page 9.

• Remove the front and back covers unscrewing screws on the cabinet side,

disconnect the ground connector on the covers.

• Disassemble the internal back cover (18) unscrewing four screws.

• Insert the shipping elements (21) under and above the compressor.

• Assemble the internal back cover (18), connect the ground connector on

the covers, and insert the covers and the suction filter.

SHUTDOWN

If the compressor is not going to be used for a long period of time,

disconnected it from the main power supply and release the pressure in the

air tank.

EQUIPMENT DISPOSAL

• Disconnect the equipment from the main power supply.

• Release the pressure in the air tank.

• Dispose of the equipment according to local regulations.

• Parts used in this product have no negative impact on the environment

when disposed of properly.

TROUBLESHOOTING

NP-eVENT-16_10-2018 21

6. TROUBLESHOOTING

Prior to servicing the equipment, reduce the pressure in the air tank to

zero and disconnect the equipment from the main power supply.

Only trained service personnel can perform the activities listed in the

troubleshooting guide.

PROBLEM

POTENTIAL CAUSE

TROUBLESHOOTING

Compressor

does not start

No main power voltage

Switched off main breaker in distribution

system

No current from the pressure

switch

Check supply

Replace a defective fuse

Loose wire terminal – tighten

Power cord defective – replace

Interrupted winding of motor,

damaged thermal protection

Replace motor

Defective capacitor

Replace capacitor

Jammed piston or another parts

Replace damaged parts

Pressure switch does not switch

on

Change pressure switch

The humidity

indicator is out

of the green

zone

Leakage of air from pneumatic

distribution system

Inspect pneumatic distribution system –

seal loose connection

Large consumption of

compressed air

Do not exceed max. flow (see Technical

data)

Compressor

often switches

on

Leakage of air from pneumatic

distribution system

inspect pneumatic distribution system –

seal loose connection

Leakage of check valve

Clean check valve, replace seal,

replace check valve

The operation

of compressor

is extended

Leakage of air from pneumatic

distribution system

Inspect pneumatic distribution system –

seal loose connection

Worn out piston rings

Replace worn out piston rings

Dirty filter inserts

Replace the dirty inserts

Red indication

lights – state

of overheating

Dirty suction filter

Clean or replace the dirty suction filter

Dirty filter inserts

Replace the dirty inserts with new ones

Cooling fans don’t work

Replace fans or faulty thermal switch

Unit is hot, unventilated area

Relocate unit

Compressor is

noisy

(knocking,

metal noises)

Damaged piston bearing or

bearing on motor

Replace damaged bearing

Loose (cracked) belt on the

compressor hanger

Replace damaged hanger

Water coming

out of outlets

Water trap (13) or (14) not

working

Clean or replace the water trap

SPARE PARTS

22 NP-eVENT-16_10-2018

7. Spare parts

• Suction filter (12) 4KB-552 025000011-000

• Suction filter (B) 05W POLYESTER 025200194-000

• Filter (C) 111511-40B 025200070-000

• Filter (D) AF20P-060S 025200113-000

• Fuse

• DK50 D 230V T6.3A 038100004-000

• DK50 D 120V, DK50 DM 230V T10A

038100005

• DK50 DM 120V T16A 038100007-000

• Nipple

• RECTUS 21SSTF08MPC 025500131-000

• DISS 1160-A 024000261-000

ELECTRIC AND PNEUMATIC DIAGRAMS

NP-eVENT-16_10-2018 23

EV1 EV2

YV1

1 2 3

40°C

ST1

4 5 6 7 8 9 10 11 12 13 14

HL2

80°C

ST2

HL1

RD

GN

1

gnye

bk

gy

bn

M1

M

Motor Soft Start-Stop

PCB

PE

U N

PH

0000

h

C

B1

1/N/PE ~ 115/230 V 50/60 Hz

ELECTRIC OBJECT OF 1st CAT.

XC

EV1 EV2

YV1

1 2 3

40°C

ST1

4 5 6 7 8 9 10 11 12 13 14

HL2

80°C

ST2

HL1

RD

GN

Motor Soft Start-Stop

PCB

PE

U N

PH

0000

h

1/N/PE ~ 115/230 V 50/60 Hz

ELECTRIC OBJECT OF 1st CAT.

XC

M1

1

M

B1

C

8. ELECTRIC AND PNEUMATIC DIAGRAMS

WIRING DIAGRAM

DK50 D

DK50 DM

Note

Wire entering the terminal should be marked with marking element with corresponding

number.

Des. Name Des. Name

HL1,HL2 Glow lamp M Electric motor

EV1,EV2 Ventilator ST1,ST2 Thermal switch

PH Hour meter XC Socket with fuses

YV Solenoid valve Cb1 Capacitor

ELECTRIC AND PNEUMATIC DIAGRAMS

24 NP-eVENT-16_10-2018

PNEUMATIC DIAGRAM

2

1

19

3

4

6

8

5

18

18

13

14

9

7

17

10

12

WALL

20

OUT

11

15 16

CONTROL PANEL

1. Suction filter

2. Suction filter

3. Compressor

4. Solenoid valve

5. Sound absorber

6. Cooler

7. Micro filter with water trap

8. Check valve

9. Air tank

10. Pressure regulator with filter

11. Air Outlet

12. Air Inlet

13. Main input, power switch, primary fuses

14. Pressure sensor

15. Humidity indicator

16. Pressure gauge

17. Pressure relief valve

18. Fan

19. Water tray

20. Shuttle valve

СОДЕРЖАНИЕ

NP-eVENT-16_10-2018 25

СОДЕРЖАНИЕ

1. ОБЩИЕ CВЕДЕНИЯ .............................................................................................................. 26

ПРИМЕНЕНИЕ СОГЛАСНО НАЗНАЧЕНИЮ ................................................................... 26

ПРОТИВОПОКАЗАНИЯ И ПОБОЧНЫЕ ЭФФЕКТЫ ........................................................ 26

ОТВЕТСТВЕННОСТЬ ПЕРСОНАЛА ЗА БЕЗОПАСНОСТЬ ПАЦИЕНТА ...................... 26

МАРКИРОВКА ................................................................................................................... 26

ПРЕДУПРЕЖДЕНИЯ ........................................................................................................ 26

Общие предупреждения по безопасности ............................................................ 27

Предупреждения по безопасности для защиты от электрического тока ............. 27

ПРЕДОСТЕРЕГАЮЩИЕ ПРЕДУПРЕЖДЕНИЯ И СИМВОЛЫ ........................................ 28

УСЛОВИЯ ПРИМЕНЕНИЯ ............................................................................................... 29

УСЛОВИЯ ХРАНЕНИЯ И ТРАНСПОРТИРОВКИ ............................................................ 29

2. ОПИСАНИЕ ИЗДЕЛИЯ .......................................................................................................... 30

3. ТЕХНИЧЕСКИЕ ДАННЫЕ .................................................................................................... 32

Поправка эффективности потребляемого объема сжатого воздуха (ПОСВ) на

разность подъема .................................................................................................... 33

4. ОБСЛУЖИВАНИЕ .................................................................................................................. 34

УСТАНОВКА И ПЕРВЫЙ ПУСК В ЭКСПУАТАЦИЮ ........................................................ 34

Отфиксирование компрессора .............................................................................. 35

Присоединение сжатого воздуха ........................................................................... 35

Электрическое присоединение .............................................................................. 36

Первый пуск в эксплуатацию ................................................................................. 36

Дополнительное оснащение .................................................................................. 37

ОБСЛУЖИВАНИЕ ............................................................................................................. 38

Включение компрессора ........................................................................................ 38

Работа компрессора ............................................................................................... 38

Очистка и замена входного фильтра..................................................................... 39

Сигнализация помехи охлаждения ........................................................................ 39

Очистка изделия ..................................................................................................... 39

5. УХОД ...................................................................................................................................... 39

СВЕДЕНИЯ О РЕМОНТНЫХ УСЛУГАХ .......................................................................... 39

ИНТЕРВАЛЫ УХОДА ........................................................................................................ 40

УВЕДОМЛЕНИЕ ................................................................................................................ 40

Проверка предохранительного клапана ................................................................ 41

Замена фильтра ................................................................................................ ..... 41

Замена фильтровального вкладыша фильтрa ..................................................... 41

Замена фильтровального вкладыша регулятора ................................................ 42

Контроль мощности компрессора .......................................................................... 42

Фиксация агрегата перед транспортировкой ........................................................ 43

ПРИОСТАНОВЛЕНИЕ ЭКСПЛУАТАЦИИ ........................................................................ 43

ЛИКВИДАЦИЯ УСТРОЙСТВА .......................................................................................... 43

6. ПОИСК НЕИСПРАВНОСТЕЙ И ИХ УСТРАНЕНИЕ............................................................. 44

7. ЗАПЧАСТИ ............................................................................................................................. 45

8. ЕЛЕКТРИЧЕСКИЕ И ПНЕВМАТИЧЕСКИЕ СХЕМЫ ............................................................ 46

ЕЛЕКТРИЧЕСКАЯ СХЕМА ............................................................................................... 46

ПНЕВМАТИЧЕСКАЯ СХЕМА ........................................................................................... 46

9. ПРИЛОЖЕНИЕ ....................................................................................................................... 92

ОТЧЕТ ОБ УСТАНОВКЕ ................................................................................................... 93

ОБЩИЕ СВЕДЕНИЯ

26 NP-eVENT-16_10-2018

1. ОБЩИЕ CВЕДЕНИЯ

УВАЖАЕМЫЙ ПОЛЬЗОВАТЕЛЬ.

ПОЖАЛУЙСТА, ВНИМАТЕЛЬНО ПРОЧТИТЕ ДАННОЕ РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ ДЛЯ

ТОГО, ЧТОБЫ ОБЕСПЕЧИТЬ ОПТИМАЛЬНОЕ И ПРАВИЛЬНОЕ ФУНКЦИОНИРОВАНИЕ ВАШЕГО

МЕДИЦИНСКОГО ОБОРУДОВАНИЯ.

Изделие зарегистрировано и соответствует требованиям Федеральной Службы по

надзору в сфере здравоохранения и социального развития Российской Федерации.

Изделие соответствует системе сертификации ГОСТ Р Госстандарта России.

ПРИМЕНЕНИЕ СОГЛАСНО НАЗНАЧЕНИЮ

Медицинский компрессор DK50 D, DK50 DM в передвижном шкафчике

служит в качестве источника чистого, безмасляного, сжатого воздуха

для дыхательного оборудования.

ПРОТИВОПОКАЗАНИЯ И ПОБОЧНЫЕ ЭФФЕКТЫ

Противопоказания или побочные эффекты неизвестны.

ОТВЕТСТВЕННОСТЬ ПЕРСОНАЛА ЗА БЕЗОПАСНОСТЬ ПАЦИЕНТА

Инструкция по установке, обслуживанию и уходу является составной

частью устройства. Необходимо, чтобы она находилась всегда рядом с

устройством. Точное соблюдение настоящей инструкции является

предпосылкой правильного применения согласно назначению и

правильного обслуживания устройства.

МАРКИРОВКА

Продукты обозначены маркой согласия CE, исполняют директивы

безопасности Европейской унии (93/42/EEC).

ПРЕДУПРЕЖДЕНИЯ

• Безопасность обслуживающего персонала и бесперебойная

эксплуатация устройства гарантированы только при использовании

оригинальных составных частей устройства. Применять только

принадлежности и запчасти, указанные в технической документации

или непосредственно одобренные производителем.

• Если будут применяться иные принадлежности или расходный

материал, производитель не может принять на себя никакую

гарантию за безопасную эксплуатацию и безопасную работу.

• На повреждения, которые возникли при применении иных

принадлежностей или расходного материала, чем тех, которые

предписывает или рекомендует производитель, гарантия не

распространяется.

ОБЩИЕ СВЕДЕНИЯ

NP-eVENT-16_10-2018 27

• Производитель берет на себя ответственность по отношению к

безопасности, надежности и работе только тогда, когда:

- установку, новую настройку, изменения, расширения и ремонты

осуществляет производитель или представитель - сервисная

организация, уполномоченная производителем,

- устройство применяется в соответствии с инструкцией по установке,

обслуживанию иуходу.

• Инструкция по установке, обслуживанию и уходу соответствует при

распечатке варианту устройства и состоянию согласно

соответствующим техническим нормам по безопасности.

Производитель оставляет за собой все права по патентной охране

указанных соединений, методов и названий.

Общие предупреждения по безопасности

Производитель разработал и сконструировал устройство таким

образом, чтобы были исключены повреждения при правильном

применении по назначению. Производитель считает своей

обязанностью описать следующие меры по безопасности, чтобы можно

было исключить остальные повреждения.

• При эксплуатации устройства необходимо принимать во внимание

законы и региональные инструкции, действующие по месту

назначения. В интересах безопасного проведения работ за

соблюдение инструкций несут ответственность эксплуатирующее

лицо и пользователь.

• Оригинальную упаковку необходимо сохранить на случай возможного

возвращения. Только оригинальная упаковка гарантирует

оптимальную защиту устройства во время транспортировки. Если в

течение гарантийного срока необходимо вернуть устройство,

производитель не гарантирует за повреждения, нанесенные в

результате неправильной упаковки.

• Если непосредственно в связи с эксплуатацией устройства настанет

нежелательная ситуация, пользователь обязан без промедления

информировать своего поставщика об этой ситуации.

• Изделие не предназначено для эксплуатации во взрывоопасных

областях. Взрывоопасность угрожает при использовании

компрессора в близости огнеопасных анестезирующих средств.

• Никонда недавайте кислород или закись азота в компрессор.

Електрические компоненты изделия неурочные для их

использование.

• Устройство можно использовать только с аппаратом ИВЛ

оборудованным сигнализацией низкого давления.

Предупреждения по безопасности для защиты от электрического тока

• Оборудование может быть присоединено только к правильно

установленной розетке с защитным соединением. Доверительное

ОБЩИЕ СВЕДЕНИЯ

28 NP-eVENT-16_10-2018

заземление одержите тогда когда ест устройство присоединене в

розетку эквипотенциального соединения.

• Перед присоединением устройства необходимо проверить,

соответствуют ли сетевое напряжение и частота, указанные на

устройстве, значениям сети питания.

• Перед пуском в эксплуатацию необходимо проверить возможные

повреждения устройства и подсоединяемых воздушных

распределительных сетей. Поврежденные проводки и вилки сразу

же необходимо заменить.

• В случае опасных ситуаций или технических неисправностей,

устройство надо сразу же отсоединить от сети ( вытащить сетевой

штепсель).

• Во время всех работ, связанных с ремонтом и уходом, должны быть

сетевой штепсель вынут из розетки, из напорного трубопровода

выпущен воздух и выпущено давление из напорного резервуара.

• Устройство должен устанавливать только квалифицированный

работник.

ПРЕДОСТЕРЕГАЮЩИЕ ПРЕДУПРЕЖДЕНИЯ И СИМВОЛЫ

В инструкции по установке, обслуживанию и уходу, на упаковках и

изделии для особо важных сведений применяются следующие

наименования или знаки:

Внимание! Cмотри инструкции по применению

Внимание! Oпасноcть ранения электрическим током

Читайте инструкцию по применению

CE – обозначение

Внимание! Горячая поверхность

Манипуляционный знак на упаковке – ХРУПКИЙ ПРЕДМЕТ

Манипуляционный знак на упаковке – ЭТОЙ СТОРОНОЙ

ВВЕРХ

Манипуляционный знак на упаковке – БЕРЕЧЬ ОТ ВЛАГИ

Манипуляционный знак на упаковке – ТЕМПЕРАТУРНЫЕ

ОГРАНИЧЕНИЯ

Манипуляционный знак на упаковке – ОГРАНИЧЕННОЕ

СТОГОВАНИЕ

Знак на упаковке – УТИЛИЗИРОВАННЫЙ МАТЕРИАЛ

Присоединение защитного провода

Переменный ток

Клемма для эквипотенциального прямого соединения

Предохранитель

Loading...

Loading...