EKOM DK50 DE User Manual

CONTENTS

CONTENTS

1. GENERAL INFORMATION ...................................................................................................... 5

INTENDED USE .................................................................................................................. 5

CONTRAINDICATIONS AND SIDE-EFFECTS ................................................................... 5

OPERATOR'S RESPONSIBILITY FOR PATIENT SAFETY ................................................ 5

MARKINGS ......................................................................................................................... 5

WARNINGS ........................................................................................................................ 5

General safety warnings ............................................................................................ 6

Electrical system safety warnings .............................................................................. 6

WARNING NOTICES AND SYMBOLS ................................................................................ 7

USE ..................................................................................................................................... 8

STORAGE AND TRANSPORT ........................................................................................... 8

2. EQUIPMENT DESCRIPTION ................................................................................................... 9

3. TECHNICAL DATA .................................................................................................................11

4. OPERATION ...........................................................................................................................13

INSTALLATION AND FIRST OPERATION ........................................................................13

Removal of transport stabilizers ...............................................................................13

Wheel installation .....................................................................................................14

Compressed air connection ......................................................................................14

Electrical connection.................................................................................................14

First operation ..........................................................................................................15

Accessories ..............................................................................................................16

OPERATION ......................................................................................................................16

Switching the compressor on ....................................................................................16

Running the compressor ..........................................................................................17

Cleaning and replacing filters ...................................................................................17

Cleaning the compressor ..........................................................................................17

5. MAINTENANCE ......................................................................................................................18

REPAIRS AND SERVICE...................................................................................................18

Cover removal ..........................................................................................................18

MAINTENANCE SCHEDULE .............................................................................................18

Safety valve check ...................................................................................................19

Checking tightness of joints and inspecting the equipment .......................................20

Replacing filter elements ..........................................................................................20

Setting output air pressure .......................................................................................21

Cleaning the pressure regulator ...............................................................................21

Replacing the suction filter (18) ................................ ................................................21

Stabilizing the compressor before shipping ..............................................................22

SHUTDOWN ......................................................................................................................22

EQUIPMENT DISPOSAL ...................................................................................................22

6. TROUBLESHOOTING.............................................................................................................23

7. SPARE PARTS .......................................................................................................................24

8. ELECTRIC AND PNEUMATIC DIAGRAMS ............................................................................25

WIRING DIAGRAM ............................................................................................................25

PNEUMATIC DIAGRAM .....................................................................................................26

9. ELECTROMAGNETIC COMPATIBILITY DECARATION ........................................................27

NUTZUNGSBESTIMMUNG ...............................................................................................31

10. ANNEX .................................................................................................................................. 111

INSTALLATION RECORD................................................................................................ 111

4 NP-DK50 DE-18_02-2019

GENERAL INFORMATION

1. GENERAL INFORMATION

INTENDED USE

The EKOM DK50 DE is a medical air compressor that supplies clean, oil-free

compressed air for use with medical ventilators.

CONTRAINDICATIONS AND SIDE-EFFECTS

There are no contraindications or side-effects known.

OPERATOR'S RESPONSIBILITY FOR PATIENT SAFETY

The Installation, Operation and Maintenance Manual is an integral part of the

equipment and must be kept with the compressor. Careful review of this

manual will provide information necessary for correct operation of the

equipment.

Rx only

US Federal law restricts the sale of this device by or on the order of a

physician.

MARKINGS

WARNINGS

Products marked with the CE mark of compliance meet the safety

requirements of the European Union (93/42/EEC).

The safety of operating personnel and trouble-free operation of the

equipment are ensured only if original parts are used. Only accessories

and spare parts mentioned in the technical documentation or expressly

approved by the manufacturer can be used.

If any other accessories or consumable materials are used, the

manufacturer cannot be held responsible for the safe operation and

functionality of the equipment.

The warranty does not cover damages resulting from the use of

accessories or consumable materials other than those recommended by

the manufacturer.

The manufacturer assumes responsibility for the safety, reliability and

function of the equipment only if:

- Installation, calibration, amendments, extensions and repairs are

performed by the manufacturer, one of its representatives or a service

provider authorized by the manufacturer

- The equipment is used in accordance with the Installation, Operation and

Maintenance Manual

NP-DK50 DE-18_02-2019 5

GENERAL INFORMATION

The Installation, Operation and Maintenance Manual accurately describes

the design of the compressor and its compliance with safety and technical

standards. The manufacturer reserves all rights to its wiring diagrams,

procedures and names.

General safety warnings

The equipment is designed to operate safely when used correctly. Please

note the following safety measures to avoid injury or damage.

Equipment operation must comply with all local codes and regulations.

Original packaging should be kept for the possible return of the unit. Only

original packaging ensures optimal protection of the equipment during

transport. If it is necessary to return the equipment during the warranty

period, the manufacturer is not liable for damages caused by incorrect

packaging.

The user must immediately notify the supplier if any problem occurs during

the use of the equipment.

This product is not intended for use in areas where there is a risk of an

explosion. Do not operate the compressor in the presence of flammable

anesthetics.

Never feed oxygen or nitrous oxide into the compressor. Compressor

components are not approved for oxygen or nitrous oxide use.

Electrical system safety warnings

The equipment must be connected to ground. I order to assure proper

grounding, connect the compressor to a receptacle marked "hospital

grade."

Before the compressor is plugged in, make sure that the voltage and

frequency of the mains specified on the equipment are the same as the

power mains.

Before operating, check for possible damage to the equipment and any

connections. Damaged pneumatic and electrical lines must be replaced

immediately.

If a technical failure occurs, immediately disconnect the equipment from

the mains (pull out the main power plug).

During repairs and maintenance, ensure that:

- The main power plug is removed from the power socket

- Compressed air lines are disconnected

- All pressure has been released from the air tank

Only a qualified technician can install this equipment.

6 NP-DK50 DE-18_02-2019

WARNING NOTICES AND SYMBOLS

Attention, see instructions for use

Caution, risk of electric shock

Consult instructions for use

CE mark of compliance

Caution, hot surface

Handling mark on package – FRAGILE

Handling mark on package – THIS SIDE UP

Handling mark on package – KEEP DRY

Handling mark on package – TEMPERATURE LIMITATIONS

Handling mark on package – LIMITED STACKING

Mark on package – RECYCLABLE MATERIAL

Alternating current

Ground connection

Equipotentiality

Fuse

Condensate drain

The following symbols are used for important information in the Installation,

Operation and Maintenance Manual and on packaging and the product:

GENERAL INFORMATION

NP-DK50 DE-18_02-2019 7

GENERAL INFORMATION

USE

The equipment can be installed and operated only in a dry, ventilated and

dust-free area. Climatic conditions for operation - see Technical data.

The compressor must stand on a flat and stable base.

The compressor must not be exposed to rain. The equipment must not be

used in humid or wet environments. Never use the compressor in the

presence of flammable liquids or gases.

Before connecting the compressor to respiration equipment, make sure

that it meets the requirements of the respiration equipment. Refer to the

Technical data for this purpose.

Any use other than the compressor‘s intended use is not considered to be

safe. The manufacturer is not responsible for any damages that result if

the compressor is used for any other purpose. Risk is exclusively

assumed by the operator/user.

STORAGE AND TRANSPORT

The compressor is shipped from the factory in transport packaging with the

pump stabilized, protecting it from damage during transport.

For transport, always use the original packaging and secure the compressor

in the upright position.

Protect the compressor from humidity, contamination and extreme

temperatures during transport and storage. A compressor in its original

packaging should be stored in a warm, dry and dust-free area.

Keep the packaging material, if possible. If not, dispose of the packaging

material in an environmentally-friendly way. Cardboard can be recycled.

Before moving or transporting the compressor, the pressure in the air tank

and hoses must be released and any condensed water must be drained.

Secure the motor to prevent movement before shipping.

Prior to transport it is necessary to secure the motor inside the

compressor (Chapter 5).

8 NP-DK50 DE-18_02-2019

EQUIPMENT DESCRIPTION

2. EQUIPMENT DESCRIPTION

1. Switch, main connector, fuses

2. Hour counter

3. OUT – compressed air output

4. Outlet pressure gauge (accuracy ± 5%)

5. WALL – input of compressed air from central distribution (Auxiliary

equipment)

6. Suction filter

7. Equipotential (ground) pin

8. Condensate tank

9. Power indicator

10. Socket for the electrical cord

11. Compressor

12. Safety valve

13. Air tank

14. Filter (40 μm) and water trap

15. Pressure regulator

16. Filter (5 μm) and water trap

17. Control electronics

18. Suction filter

19. Cooler

The compressor contains an oil-free piston (11) driven by a low-maintenance single-phase

electric motor. Compressed air is cooled in the cooler (19) where condensed water is

separated into a separate tank (8). Incoming air passes through two filters (6,18)

undergoing double filtration as it passes through the system (14,16). Constant pressure at

the output is maintained by the pressure regulator (15). The built-in air tank (13) enables

peak air consumption of 200 L/min.

The following applies to products with additional equipment – WALL coupling (5):

If the device is equipped with a WALL quick coupling (5), it can be used as a back-up air

source. In this configuration, the respiratory equipment is supplied with compressed air

from the central air distribution of the medical facility. Air pressure in the central distribution

line is sensed by a pressure sensor. If the pressure is sufficient, the compressor stays in

STANDBY mode. If the pressure falls, the control unit automatically places the compressor

into operation.

When the compressor is used as the main source of air, the control unit determines its

operation based on current demand for air. If air consumption is zero, the device switches

to STANDBY mode.

NP-DK50 DE-18_02-2019 9

EQUIPMENT DESCRIPTION

10 NP-DK50 DE-18_02-2019

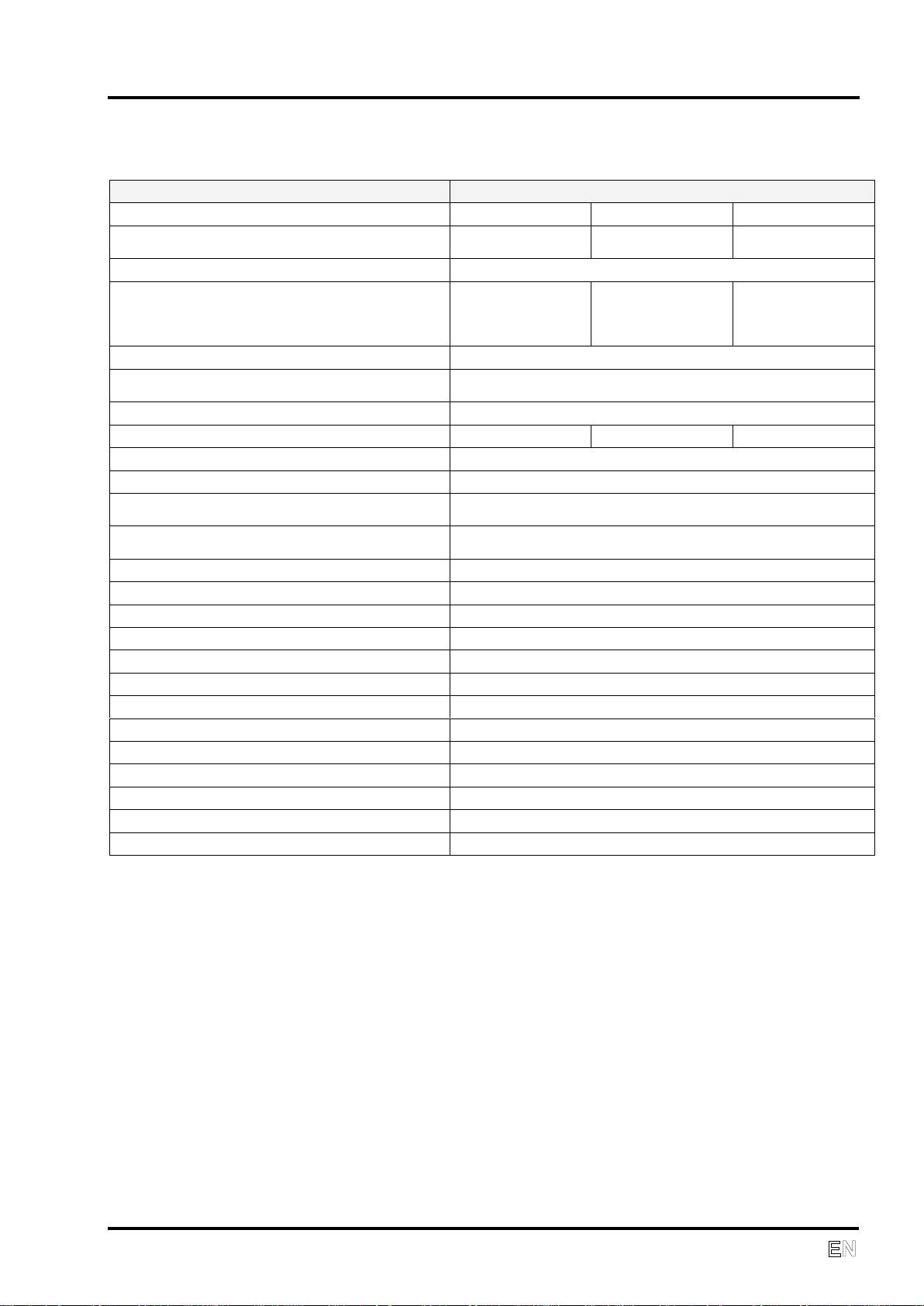

3. TECHNICAL DATA

TYPE

DK50 DE

VERSION basic

standard

advanced

Output flow at pressure

3.5 bar (51 psig)

L/min

40 / 32*

50 / 40*

60 / 50*

Peak flow

200** L/min ( 7 Cft/min )

Voltage / Frequency / Nominal current

V/Hz/A

230/50 / 2.8

230/60 / 2.8

120/60 / 5.6

100/50-60 / 5.6

230/50 / 2.8

230/60 / 2.8

120/60 / 5.6

100/50-60 / 5.6

230/50 / 3.3

230/60 / 3.9

120/60 / 6

100/50-60 / 6

Air filtration

m

5

Pressure dew point at 40 L/min

( 1.4 Cft/min ), 3 bar( 43.5 psig ), 20°C (68°F)

5°C (9°F) below the ambient temperature

Outlet connection DISS 1160-A (3/4"-16 UNF)

Sound level dB(A) @50Hz

≤49

≤50

≤51

Mode of operation

Continuous - S1

Separation of condensed water

Automatic

Output pressure

3.0 bar (43 psig)

Adjustable to max. 3.5 bar (51 psig)

Automatic start up pressure (backup***)

Decrease in pressure in the central distribution line under

2.8 bar ( 40.6 psig)

Air tank capacity

2 L (0.61gall UK)

Pressure range

5 bar ( 72.5 psig ) – 6.5 bar ( 94 psig)

Operating pressure of safety valve

7 bar ( 101.5 psig )

Adjustment of output air pressure

Pressure regulator

Dimensions of compressor

w x d x h

440 x 350 x 420 mm (17.5 x 14x 16.5 in )

Dimensions of compressor with wheels

w x d x h

470 x 380 x 505 mm (18.5 x 15x 20 in )

Dimensions of packaging

w x d x h

510 x 480 x 470 mm ( 20 x 19 x 18.5 in )

Net weight

34 kg ( 75 lbs )

Net weight of compressor with wheels

36 kg ( 79 lbs )

Gross weight

42 kg ( 93 lbs )

Gross weight of compressor with wheels

43 kg ( 95 lbs )

Implementation according to EN 60601-1, EN 12021

Class I.

Classification acc. to MDD 93/42 EEC, 2007/47 EC

II b

TECHNICAL DATA

* ) With membrane dryer (optional)

**) With 0.6 bar drop (8.7 psig)

***) Extra equipment

NP-DK50 DE-18_02-2019 11

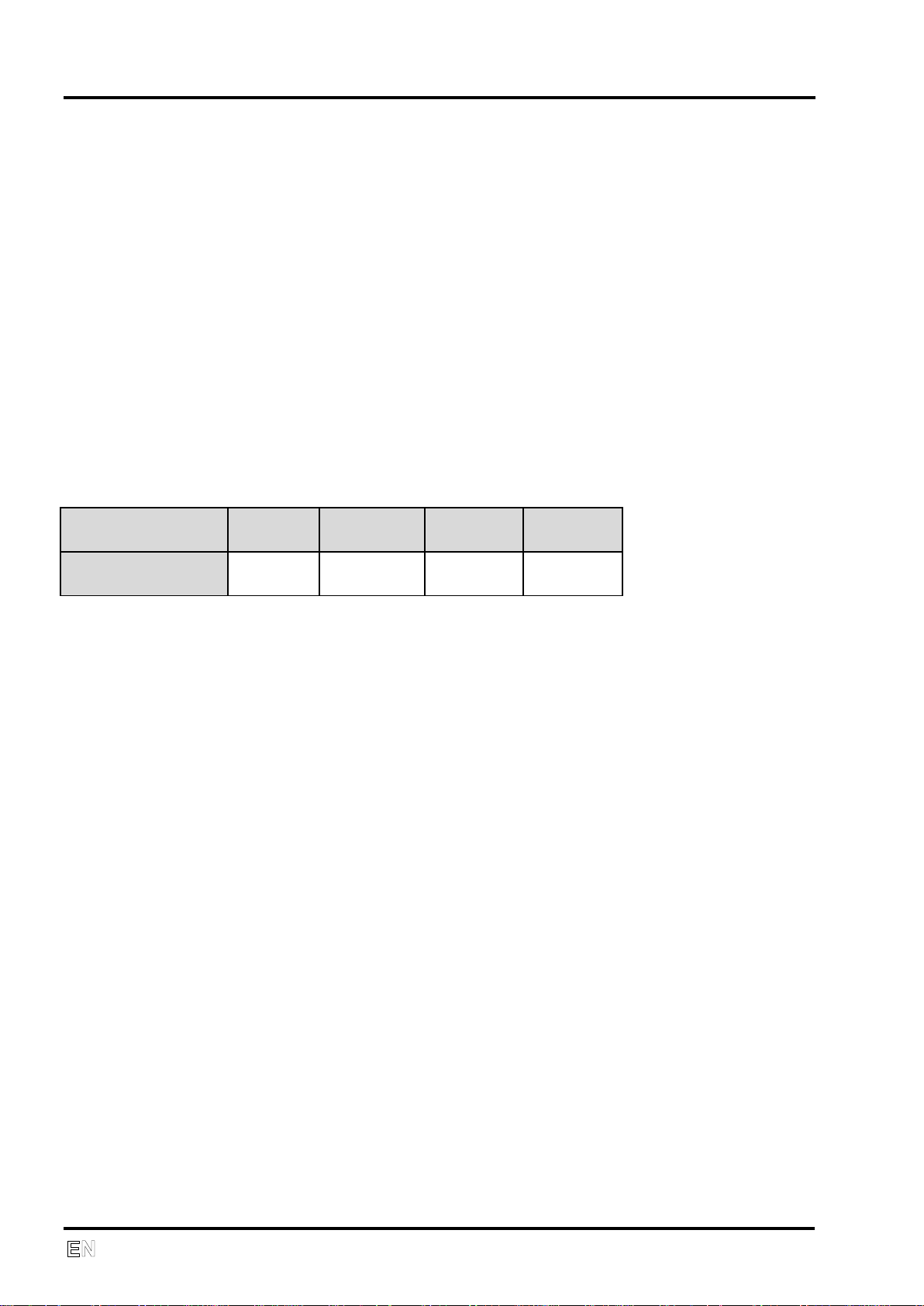

TECHNICAL DATA

Elevation [mamsl]

0 - 1500

1501 -

2500

2501 -

3500

3501 -

4500

FAD [l/min]

FAD x 1

FAD x 0.8

FAD x

0.71

FAD x

0.60

Climatic conditions for storage and transport

Temperature –25°C to +55°C (-13°F to +131°F), 24 hrs +70°C (+158°F)

Relative air humidity 10% to 90% (no condensation)

Relative air humidity for seaworthy packing 10% to 100% (with condensation)

Climatic conditions for operation

Temperature +15°C to +40°C (+59°F to +104°F)

Relative air humidity up to +95%

IPX0 Rating

FAD efficiency correction for differences in elevation

FAD correction table

FAD efficiency refers to conditions at an elevation of 0 mamsl:

Temperature: 20°C

Atmospheric pressure: 101325 Pa

Relative humidity: 0%

12 NP-DK50 DE-18_02-2019

4. OPERATION

INSTALLATION AND FIRST OPERATION

Do not use the compressor immediately after unpacking as it will not

adjust to the ambient temperature.

Only qualified personnel can install the compressor and put it into

operation for the first time. The installer shall train the operating

personnel in the use and routine maintenance of the equipment.

Installation and training of personnel should be acknowledged by the

installer‘s signature on the installation certificate.

Prior to start-up, the four screws for transport stabilization must be

removed. If the compressor is switched on without removing the

stabilizers, the compressor could be permanently damaged.

The compressor does not contain a backup power supply.

Never block the suction filter on the backside or the vent outlets on the

top of the equipment.

If the compressor is equipped with a main source of air, the standby air

source must be available.

OPERATION

ANY MODIFICATION OF THIS EQUIPMENT IS FORBIDDEN!

If this equipment is used nearby other instruments, the equipment must

be observed in order to verify normal operations in the configuration it

will be used.

Instruments may be affected electro-magnetically!

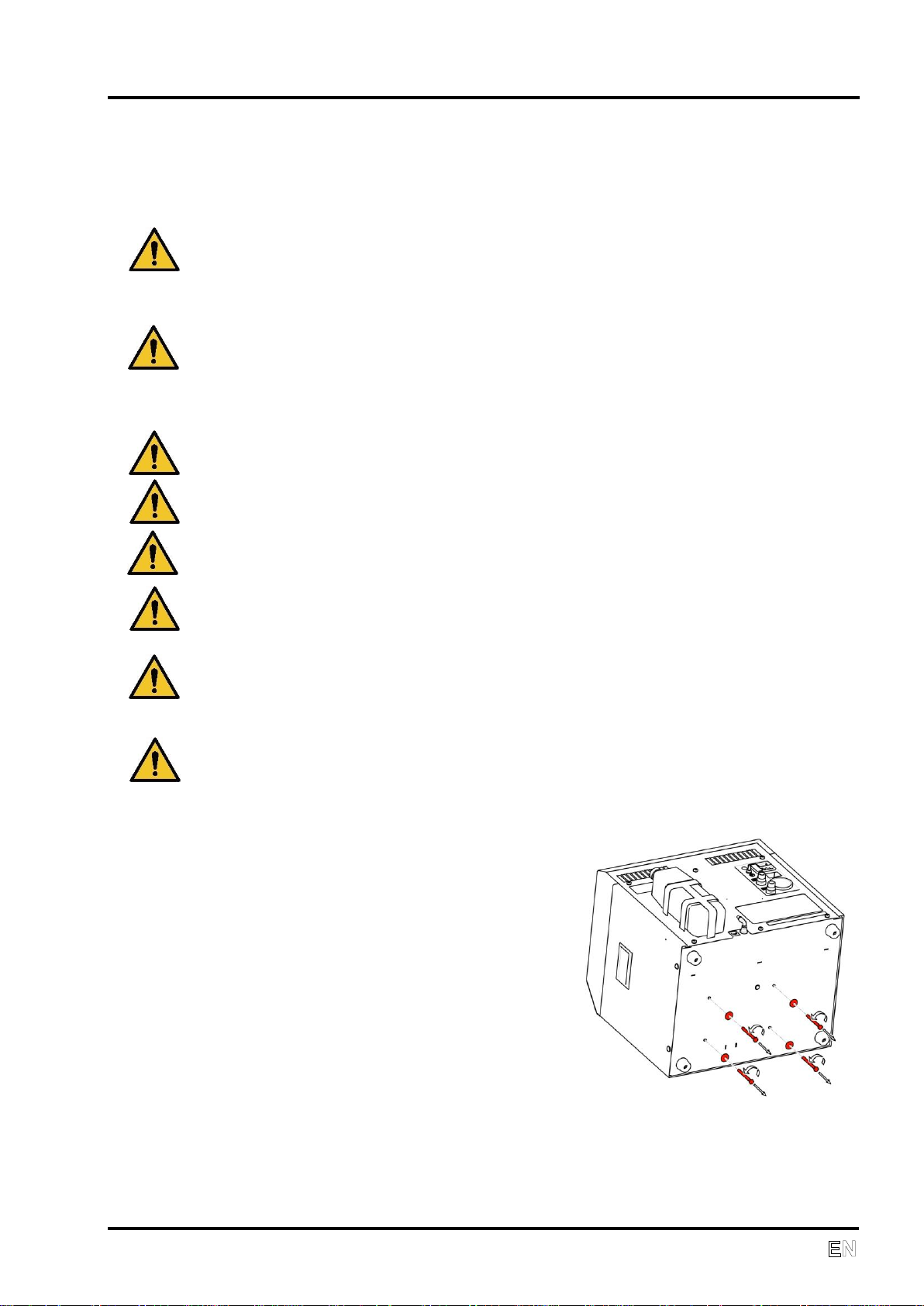

Removal of transport stabilizers

On the bottom of the unit are four M6

stabilizing screws that must be removed

before start-up. They are marked with a

red warning washer.

Please retain the stabilizing screws for

future transport of the compressor.

NP-DK50 DE-18_02-2019 13

OPERATION

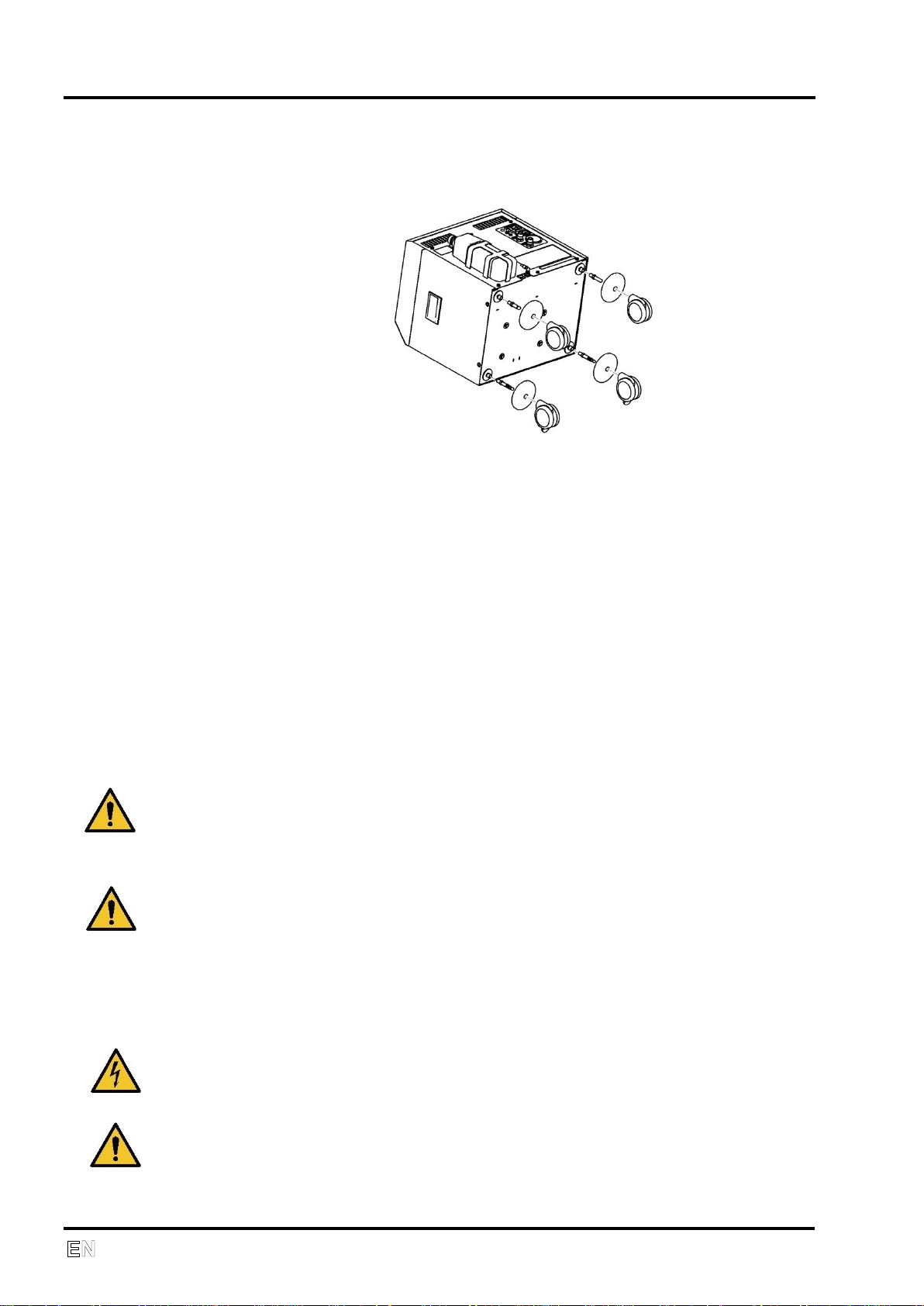

Wheel installation

Wheels must be installed following the figure below for versions of the

compressor with wheels.

Compressed air connection

The given appliance or respiratory apparatus should be connected to the

OUT (3) quick coupler, as this is the outlet for compressed air.

The following applies for equipment with additional equipment – WALL (5)

coupling:

Compressed air from the central distribution line is connected via the WALL

(5) quick coupling as this is the inlet for compressed air, if applicable. Air

from the distribution system is automatically connected through the

compressor to the OUT outlet port. In this configuration, the compressor

serves as a backup source of compressed air. If the air pressure from the

central distribution system is reduced, the compressor automatically switches

on and there is no interruption in the supply of continuously pressurized air at

the outlet of the compressor.

Please note that the air supply from the central distribution line

entering the compressor must be medical grade air (particulate size,

humidity.) The compressor does not modify the air from the central

distribution line.

The hose connecting the compressor to the respiration equipment

must not pass through a cold environment i.e. placed on the ground. It

should be as short as possible with no kinks (this may cause water to

condense inside the hose).

Electrical connection

The compressor comes with a plug containing an appropriate

protective contact (ground.) Adhere to local electrical regulations. The

voltage and frequency of the mains must comply with the

specifications on the data label.

The electrical cord must not be stressed or have any tension exerted

upon it, and must always be free.

14 NP-DK50 DE-18_02-2019

The socket must be accessible for safety reasons so that the equipment

The relevant current circuit must be protected.

Connection of the ground connection (7) to other equipment must adhere

Fasten the electrical cord through the holder (10).

First operation

Make sure that the stabilizing screws used during transport were

Check that the connection to the compressed air supply is correct.

Check for proper connection to the main power supply.

Switch on the pressure switch (1) to position “I”.

The compressor will be operational once it is put into operation. If there is no

air consumption at the output, the device switches to STANDBY mode. When

air consumption resumes, the compressor automatically switches on.

During operation, the device drains off the entrapped condensed water from

pneumatic circuits via automatic filter separators into a tank.

The following applies to device with additional equipment – WALL (5)

coupling:

After the compressor is put into operation, it shall work in one of the following

modes depending upon the pressure level in the central distribution and upon

air consumption.

STANDBY – When there is sufficient pressure in the central air distribution

line, the main switch is on, the compressor is idle. The device operates as a

standby source of air as it checks the pressure in the central air distribution

line and, if the pressure falls, the compressor switches on.

OPERATION

can be safely disconnected from the power supply in case of an

emergency.

to local electrical regulations.

removed.

When pressure is low in the central air distribution line, or if the device is

not connected to the central distribution line, the compressor is running. If

there is no air consumption at the outlet, the device switches to STANDBY

mode. When air consumption resumes, the compressor automatically

switches on.

During operation, the device drains the trapped condensed water from

pneumatic circuits via automatic filter separators into a separate tank.

NP-DK50 DE-18_02-2019 15

OPERATION

Accessories

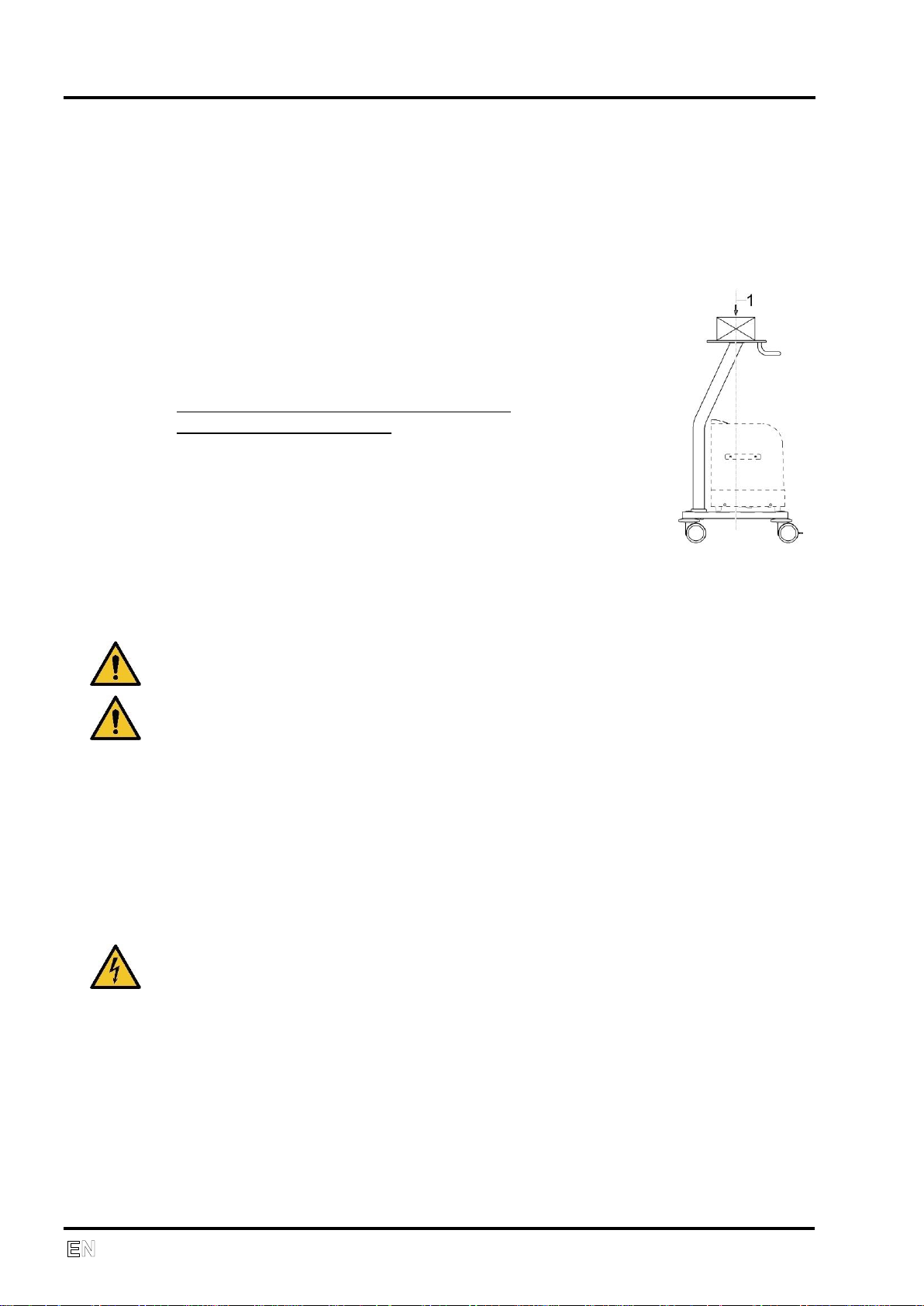

Trolley SD 30 (24)

The trolley accommodates the compressor, a fan and a humidifier. Large

casters allow for mobility and braking, guided by means of an ergonomic

handle. A wide base ensures the stability of the entire assembly.

Specifications

Supply No.: 602021222

Dimensions: 535x575x1070

Maximal load-carrying capacity with load

in the upper plate axis (1):

Trolley without compressor - 25kg

Trolley with compressor - 30kg

The manufacturer is not liable for any damage

resulting from excessive loads on the equipment!

The supplier is obliged to ensure the acceptability of a load delivered

by a supplied accessory.

It is forbidden to lean or press against an installed accessory for

support!

The equipment must be lifted when travelling over an obstacle!

Supporting equipment must be disassemble before transport!

The maximum load on the upper trolley plate is 30 kg!

Humidifier holder (25)

This clamp is used to attach the Fischer & Paykel humidifier to the trolley in

its proper position.

Supply No. 604031175

OPERATION

In case of emergency, switch the equipment off at the switch and pull

out the main power plug.

Switching the compressor on

The compressor is switched on at the main power switch (1) by putting it in

position "I".

16 NP-DK50 DE-18_02-2019

Running the compressor

Compressor operation is automatic. The compressor runs permanently,

when air consumption is lower than the set point; once set point is reached

the operation is switched to idle run. The pressure gauge displays the value

of output pressure. When air consumption stops, the compressor shall switch

off after around 30 seconds and switch on after air consumption is restored.

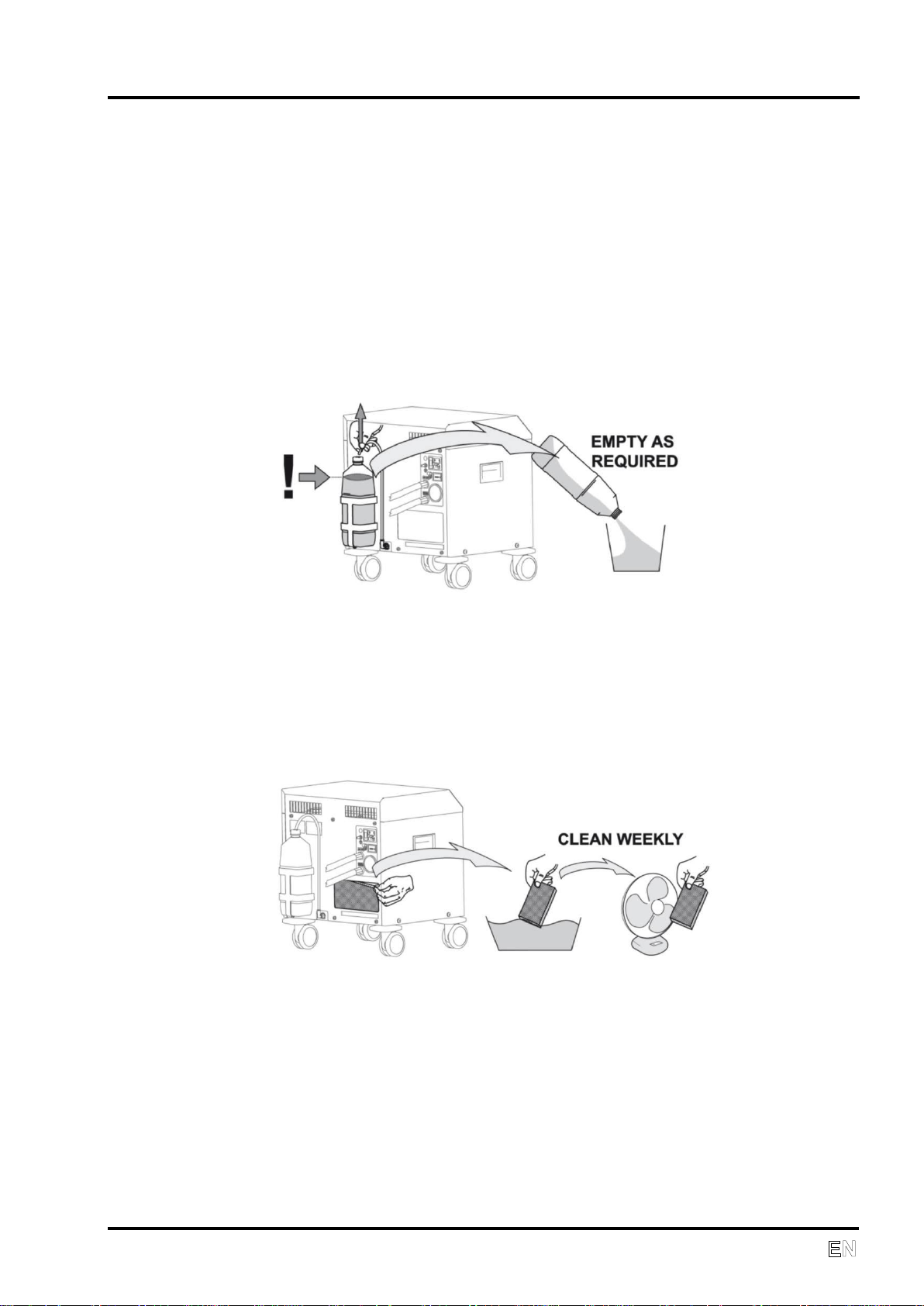

The condensed liquid drains into a tank (8) at the back of the device. When

the tank fills up, it must be emptied.

OPERATION

Cleaning and replacing filters

At least once a week take out and clean the suction filter (6) located on the

back side. Wash the filter in warm soapy water, rinse thoroughly and allow it

to dry. Insert the clean filters so that the intake openings are completely

covered by the filters. A replacement suction filter (6) No. 025000018 is

included in the basic equipment for the product.

Cleaning the compressor

To clean the compressor, use a detergent that contains no abrasives,

chemical solvents or other corrosive agents.

NP-DK50 DE-18_02-2019 17

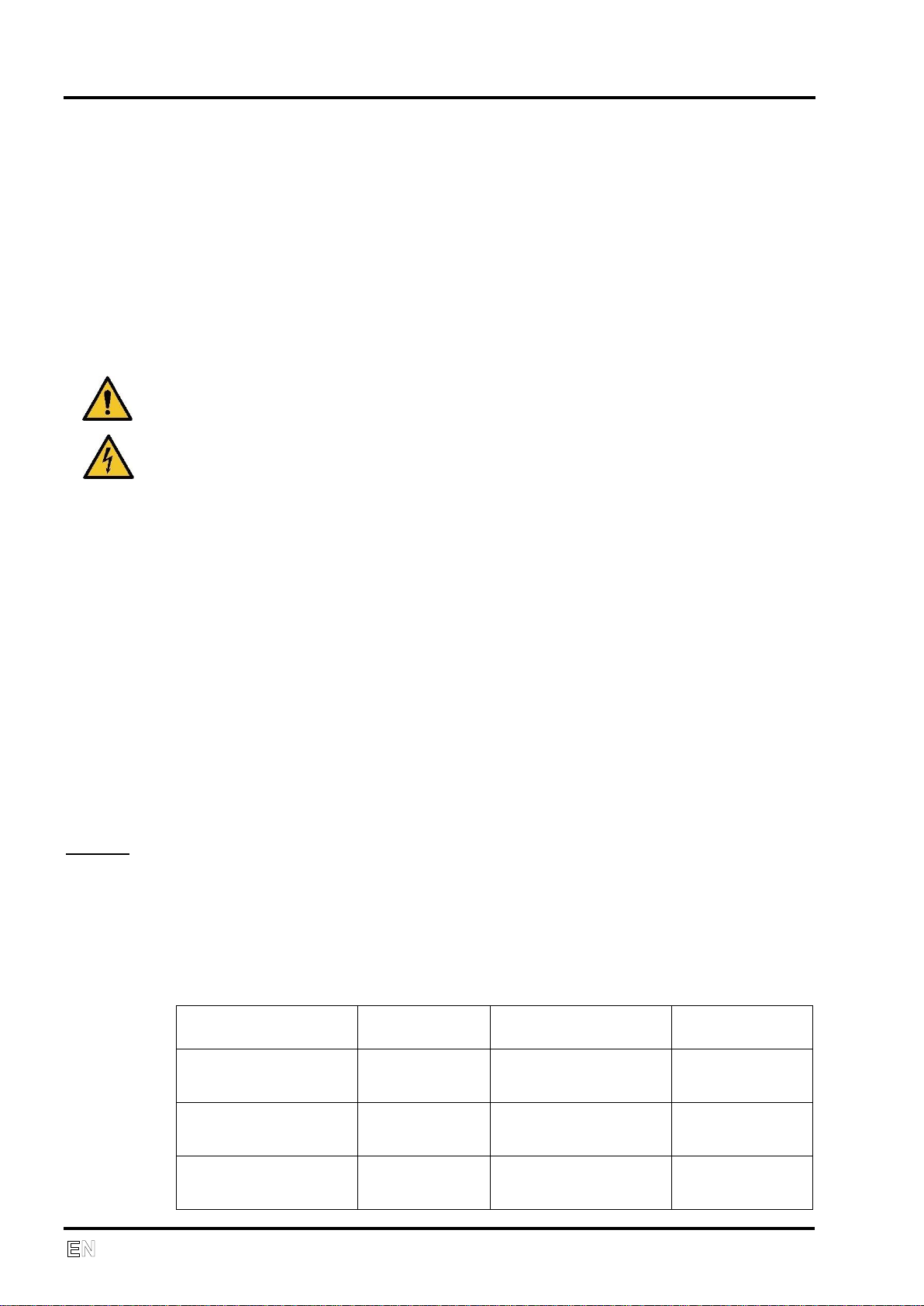

MAINTENANCE

Maintenance

Page

Time interval

To be

performed by

Clean suction filter

13

At least once a

week

Staff

Safety valve check

15

Once per year

Qualified expert

Replace filters in

filter

16

Every 4000 hours

Qualified expert

5. MAINTENANCE

REPAIRS AND SERVICE

Warranty and extended warranty repairs are to be completed by the

manufacturer or a service provider authorized by the manufacturer.

The manufacturer reserves the right to modify the equipment in any

way that will not alter the function or the operation of the equipment.

Only a qualified technician or the Customer Service Department of the

manufacturer may perform repairs that go beyond routine maintenance.

Use only spare parts and accessories approved by the manufacturer.

Prior to any maintenance or repairs, switch off the compressor and

disconnect it from the mains (pull out the main power plug).

Cover removal

- Unscrew the 6 screws from the rear cover

- Disconnect the grounding wire

- Remove the rear cover

- Unscrew the 4 screws from the rear of the main cover

- Disconnect the grounding wire

- Remove the main cover

- Reassemble using the opposite order

MAINTENANCE SCHEDULE

Notice!

The operating entity is obliged to ensure that all tests of the equipment are carried

out repeatedly at least once within every 24 months (EN 62353) or in intervals as

specified by the applicable national legal regulations. A report must be prepared on

the results of the tests (e.g.: according to EN 62353, Annex G), including the

measurement methods used.

18 NP-DK50 DE-18_02-2019

MAINTENANCE

Test the tightness of

joints and inspect

the equipment

16

After two years

Qualified expert

Replace piston

complete with piston

rings, O-rings and

bearing

Service

documentation

Every 8000 hours

Qualified expert

Replace suction

filter

16

Every 8000 hours

Qualified expert

Perform “Repeated

Test” according to

EN 62353

14

1 x 2 years

Qualified expert

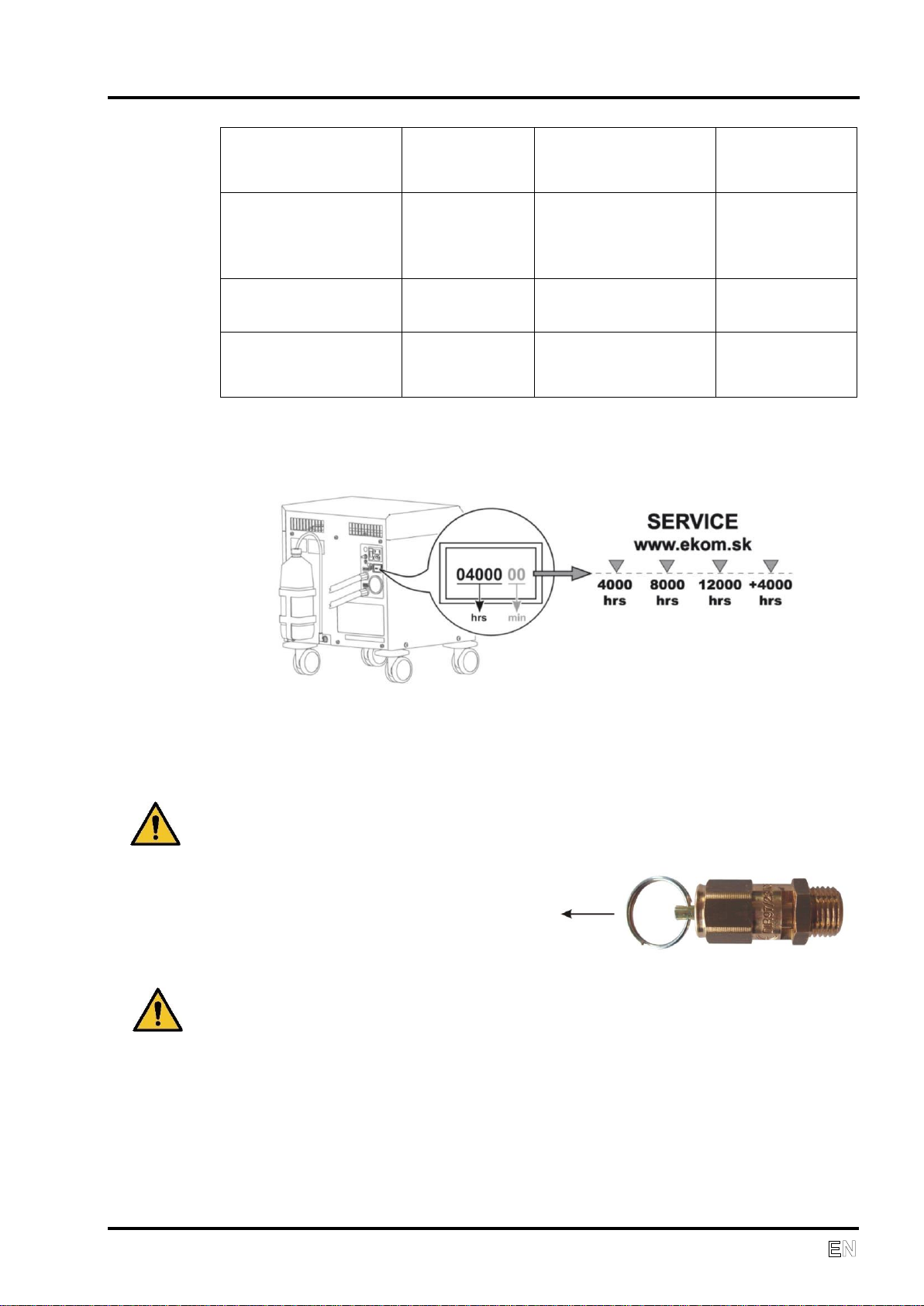

Safety valve check

The safety valve is adjusted to 7 bar by the manufacturer, then tested

and marked. It must not be readjusted.

Only allow the safety valve freely

puff for a short period of time.

Never use the safety valve to release pressure in the air tank. This could

damage the safety valve.

NP-DK50 DE-18_02-2019 19

Loading...

Loading...