EKOM DK50 9x4VRT/M, DK50 9x4VRTS/M User Manual

DK50-9x4VRT/M

EN

User manual

October 2018

Z_2195/2018

Chap. 3 – pgs.5

COMPRESSOR

DK50 9x4VRT/M

EKOM spol. s r. o.

Priemyselná 5031/18

SK-921 01 Piešťany

Slovak Republic

tel.: +421 33 7967255

fax: +421 33 7967223

www.ekom.sk

email: ekom@ekom.sk

DATE OF LAST REVISION

10/2018

NP-DK50-9x4VRTM_ED-EN-

2_10-2018

112000370-0001

DK50 9x4VRT/M

CONTENTS

IMPORTANT INFORMATION .......................................................................................................... 5

1. CONFORMITY WITH THE REQUIREMENTS OF EUROPEAN UNION DIRECTIVES ..................... 5

2. INTENDED USE .................................................................................................................................. 5

3. CONTRAINDICATIONS AND SIDE-EFFECTS ................................................................................... 5

4. WARNINGS AND SYMBOLS .............................................................................................................. 5

5. NOTICE ............................................................................................................................................... 6

6. STORAGE AND TRANSPORT ........................................................................................................... 7

7. TECHNICAL DATA .............................................................................................................................. 8

8. PRODUCT DESCRIPTION ............................................................................................................... 12

9. EQUIPMENT FUNCTION .................................................................................................................. 14

10. PNEUMATIC DIAGRAM .................................................................................................................... 16

INSTALLATION .............................................................................................................................. 17

11. CONDITIONS FOR USE ................................................................................................................... 17

12. PLACEMENT OF THE COMPRESSOR ........................................................................................... 18

13. PNEUMATIC CONNECTIONS .......................................................................................................... 20

14. ELECTRICAL CONNECTIONS ......................................................................................................... 21

OPERATION ................................................................................................................................... 25

15. INITIAL START UP OF THE DEVICE ............................................................................................... 2 5

16. SWITCHING THE COMPRESSOR ON ............................................................................................ 25

17. COMPRESSOR SHUT-DOWN ......................................................................................................... 3 0

MAINTENANCE ............................................................................................................................. 30

18. PRODUCT MAINTENANCE .............................................................................................................. 30

TROUBLESHOOTING AND REMEDYING PROBLEMS ............................................................... 39

19. TROUBLESHOOTING COMMON PROBLEMS ................................................................................ 39

20. REPAIR SERVICE ............................................................................................................................. 41

21. DISPOSAL OF THE DEVICE ............................................................................................................ 41

ANNEX ........................................................................................................................................... 42

22. MAPPING PARAMETERS ............................................................................................................... 42

23. INSTALLATION RECORD ................................................................................................................. 44

NP-DK50-9x4VRTM_ED-EN-2_10-2018 - 4 - 10/2018

DK50 9x4VRT/M

IMPORTANT INFORMATION

1. CONFORMITY WITH THE REQUIREMENTS OF EUROPEAN UNION DIRECTIVES

This product confirms to the requirements of Directives 93/42/EEC (Medical Device Directive) and

2006/42/EEC and is safe for the intended use when all safety instructions are followed.

2. INTENDED USE

The compressor is used as a central source of

clean, oil-free compressed air to power

individual devices and equipment with

compressed air used in large dental clinics

and laboratories, in hospitals wards and other

settings where the parameters and properties

of the compressed air are suitable to the

specific application.

3. CONTRAINDICATIONS AND SIDE-EFFECTS

There are no contraindications or side-effects known.

4. WARNINGS AND SYMBOLS

The following labels and symbols are used in

the Installation, Operation and Maintenance

Manual and on the equipment and its

packaging to indicate important details and

information:

Compressed air supplied by the

compressor is unsuitable for use

with artificial lung ventilation

devices without further filtration.

Any use of the product outside the framework

of its intended use is considered improper

use. The manufacturer is not liable for any

damages or injury resulting from misuse.

Terminal for ground connection

Alternating current

General warnings

Danger, electrocution hazard

Read the user manual

CE conformity marking

Handling mark on package –

FRAGILE

Handling mark on package – THIS

WAY UP

Handling mark on package – DO

NOT EXPOSE TO RAIN

Handling mark on package –

TEMPERATURE RANGE

Compressor is remote-controlled

and may start without warning

Warning! Hot surface

Earth (ground) connection

Handling mark on package –

LIMITED STACKING

Mark on package – RECYCLABLE

MATERIAL

Manufacturer

10/2018 NP-DK50-9x4VRTM_ED-EN-2_10-2018

- 5-

5. NOTICE

DK50 9x4VRT/M

The product is designed and manufactured to

be safe for the user and its surrounding

environment when used in the defined

manner. Keep the following warnings in mind.

This keeps risks to a minimum.

5.1. General warnings

READ THE USER MANUAL CAREFULLY

BEFORE USING THE DEVICE AND KEEP IT

FOR FUTURE USE!

The user manual aids in the correct

installation, operation and maintenance of

the product. It is included with the product

and must be kept close to it at all times.

Careful review of this manual will provide

the information necessary for the intended

use and correct operation of the product.

Equipment containing the condensing dryer

is provided with a separate manual for

these components.

The user manual corresponds to the

configuration of the product and its

compliance with applicable safety and

technical standards at the time of its

printing. The manufacturer reserves all

rights for the protection of its configuration,

methods and names.

Translation of the user manual is

performed in accordance with the best

available knowledge. The Slovak version is

to be used in the event of any

uncertainties.

5.2. General safety warnings

The manufacturer designed and manufactured

the product to minimise all risks when used

correctly for the intended purpose. The

manufacturer considers it responsible for

specifying the following general safety

precautions.

Only the original packaging ensures

optimal protection of the equipment during

transport. Save this packaging should you

ever have to return the equipment. The

manufacturer is not liable for damages

caused by faulty packaging when returning

a product for transport during the warranty

period.

Use a fork lift truck or similar hoisting

equipment for any movement or handling of

the product.

This warranty does not cover damages

originating from the use of accessories or

consumables other than those specified or

suggested by the manufacturer.

The manufacturer only guarantees the

safety, reliability and function of the

equipment if:

- installation, new settings, changes,

modifications and repairs are performed

by the manufacturer or its

representative, or a service provider

authorized by the manufacturer..

the product is used pursuant to the user

manual.

Use and operation of the product must

comply with all local codes and regulations.

The operator and user are responsible for

following all appropriate regulations in the

interests of performing work safely.

Only the use of original parts guarantees

the safety of operating personnel and

reliable operation of the product itself. Only

use accessories and parts mentioned in the

technical documentation or expressly

approved by the manufacturer.

The manufacturer assumes no liability for

any damages or other risks if any

accessories or parts other than mentioned

in the technical documentation or expressly

approved by the manufacturer are used.

This warranty does not cover damages

originating from the use of accessories or

consumables other than those specified or

suggested by the manufacturer.

The user must make sure that the

equipment is functioning correctly and

safely every time it is used.

The user / operator must be capable of

safely using and properly operating the

NP-DK50-9x4VRTM_ED-EN-2_10-2018 - 6 - 10/2018

DK50 9x4VRT/M

product. The user must be trained to

operate the product and must be

experienced.

Create operating regulations for the person

operating the product.

Wear hearing protection when starting the

product, during operation and any time it is

in operation.

Operating the product in operating

premises that may contain mixtures of

flammable gases such as operating rooms

or in areas that may contain explosive

mixtures of particulate, such as coal dust,

is prohibited.

Flammable materials pose an explosion

hazard!

Use of the product in wet or damp

environments is prohibited.

The user shall inform the supplier

immediately if any problem occurs in direct

connection with the operation of the

equipment.

5.3. Electrical system safety warnings

The equipment may only be connected to a

properly installed socket connected to earth

(grounded).

Before the product is plugged in, make

sure that the mains voltage and frequency

stated on the product are the same as the

power mains.

Check for possible damage to the product

and the connected air distribution system

before use. Replace damaged pneumatic

and electrical conductors immediately.

Immediately disconnect the product from

the mains in hazardous situations or when

a technical malfunction occurs.

During repairs and maintenance, ensure

that:

product is disconnected from the

mains

pressure is released from all lines

Only the manufacturer, or a qualified

specialist trained by the manufacturer may

install, modify or upgrade the product itself.

Only a qualified electrician may install

electrical components!

6. STORAGE AND TRANSPORT

The compressor is shipped from the factory in

a transport packaging. This protects the

device from damage during transport.

The original compressor

packaging must be used for

transport whenever possible. The

compressor is to be shipped in a

vertical position and must be

secured using transport straps.

Protect the compressor from humid

and dirty environments and extreme

temperatures during transport and

storage. Store a compressor in its

original packaging in a warm, dry and

dust-free area. Do not store near any

chemical substances.

Keep packaging material if possible.

If not, please dispose of the

packaging material in an

environmentally-friendly way.

Packaging cardboard can be

recycled with old paper.

The compressor must be

transported only when all air has

been vented. Before moving or

transporting the compressor,

release all the air pressure from

the tank and hoses and drain the

condensed water.

Ambient conditions for storage and

transport

Products may only be stored and transported

in vehicles that are free of any traces of

volatile chemicals under the following

conditions :

Temperature : +0°C až +50°C,

Max. relative humidity: 90%,

10/2018 NP-DK50-9x4VRTM_ED-EN-2_10-2018

- 7-

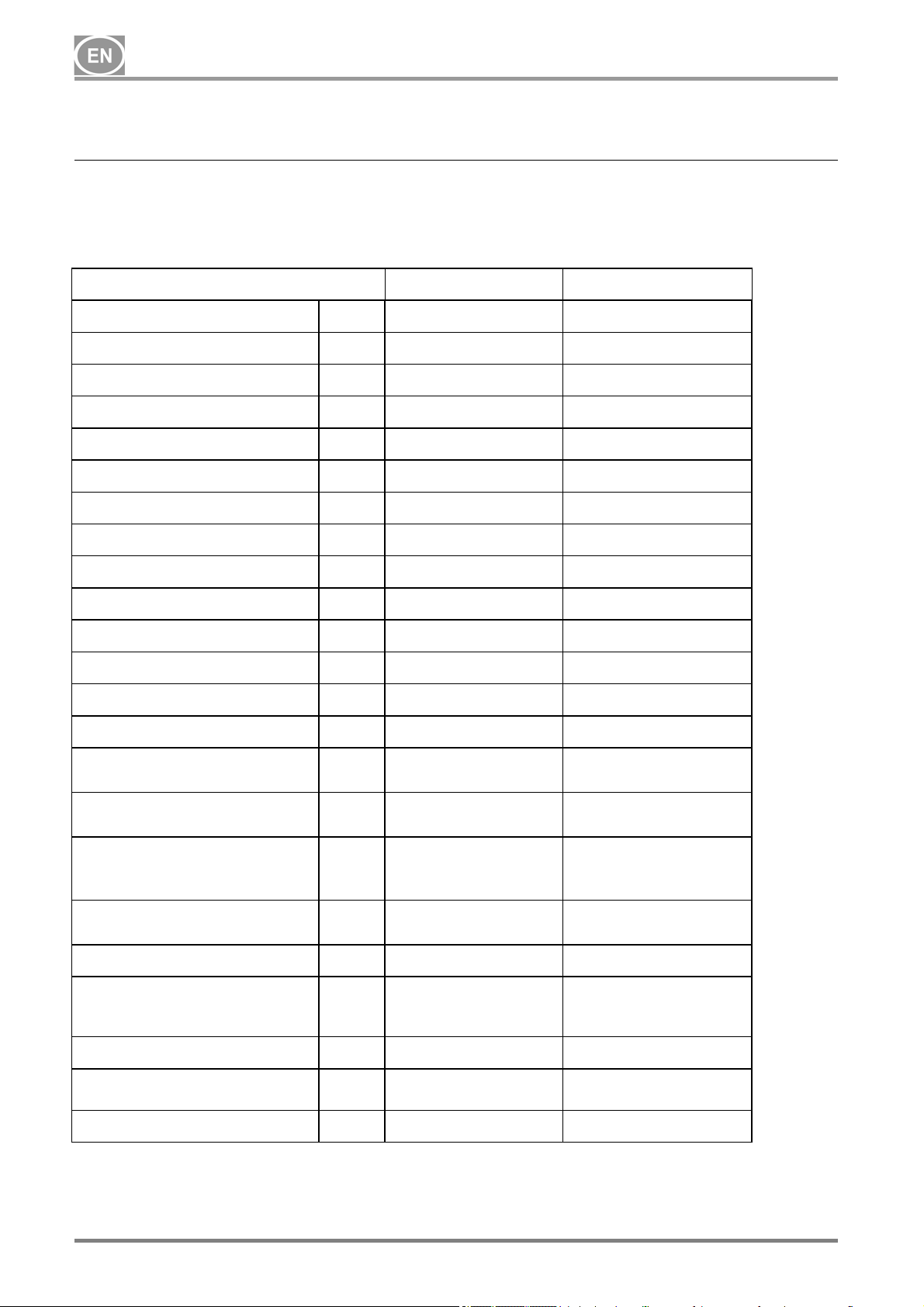

7. TECHNICAL DATA

DK50 9x4VRT/M

Compressors are designed for dry and wellventilated indoor environments with the

following conditions:

Tab.1

Type

Output at 6 bar

Voltage / frequency

Current draw (max.)

Main circuit breaker

Main feeder gauge

Enclosure

Air tank capacity

Working pressure

Safety valve

Noise level

l/min 2380 2380

V / Hz

A 45 45

A

2

mm

l 500 500

bar

bar 10 10

dB 85 74

DK50 9x4VRT/M DK50 9x4VRTS/M

Temperature : +5°C to +40°C,

Max. relative humidity.: 70%,

Max. absolute humidity.: 15 g/m

3 x 400 / 50 3 x 400 / 50

50 50

10 10

IP10 IP30

6 8 6 8

3

.

Total weight of compressor (net)

Weight - compressor module

Weight - dryer module

Weight of air tank

Compressor dimensions, total

(w x d x h)

Dimensions - compressor module

(w x d x h)

Dimensions – ED108 dryer

module

(w x d x h)

Air tank dimensions

(w x d x h)

Operating mode

Dryer performance with

condensation dryer (ED108)

(PDP*)

Time to fill air tank from 0 to 7 bar

Recommended cooling air

changes in space

Electrical class

kg 747 817

kg 540 610

kg 80 80

kg 127 127

mm 3800x705 x2100 3800x705 x2100

mm 1840x630 x1730 1860x705 x1760

mm 760x580x1050 760x580x1050

mm 770x705 x2100 770x705 x2100

+3°C +3°C

s 50 50

3

m

/h 3250 3250

class I.

S1 – 100% S1 – 100%

class I.

NP-DK50-9x4VRTM_ED-EN-2_10-2018 - 8 - 10/2018

DK50 9x4VRT/M

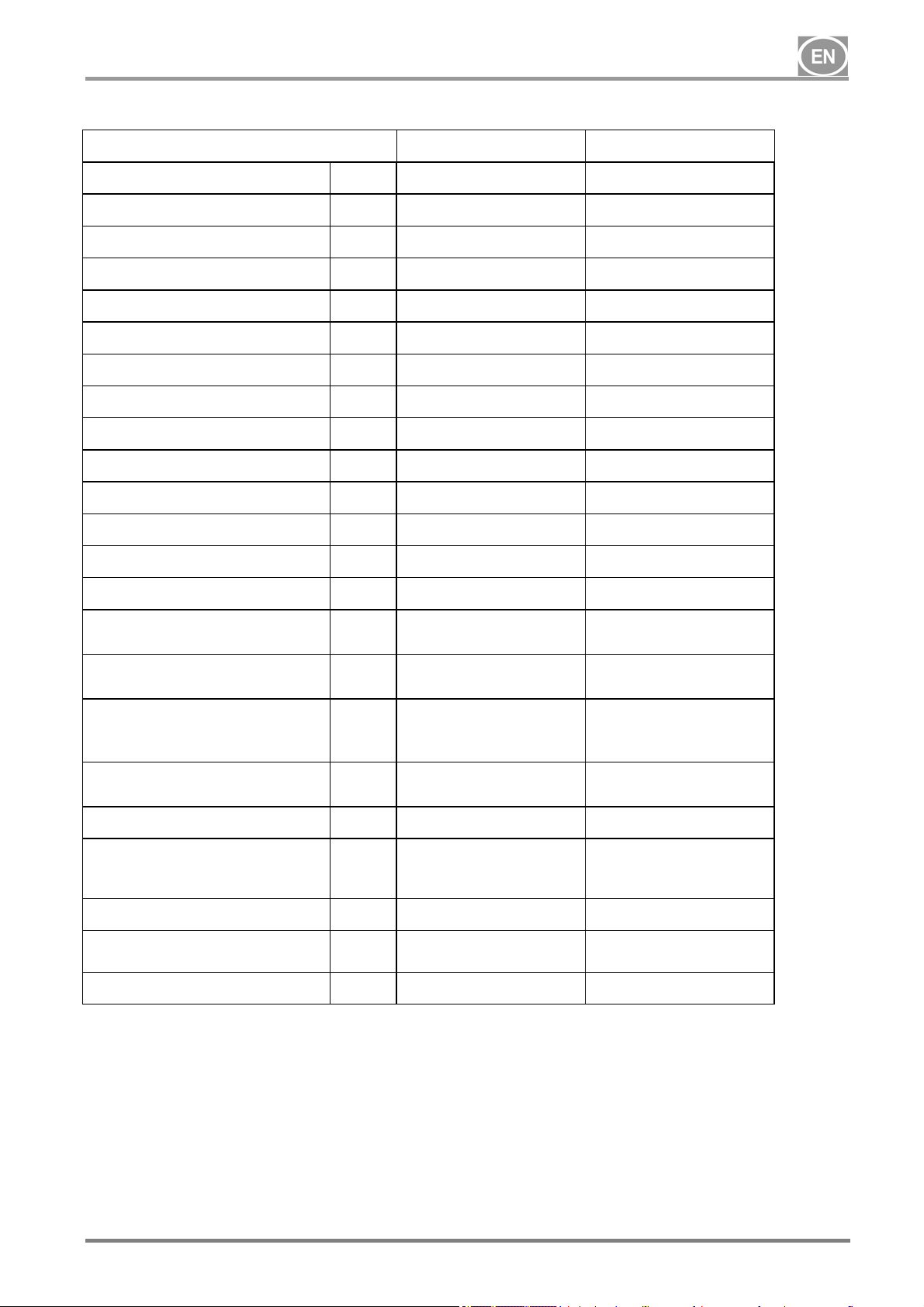

Tab.2

Type

DK50 9x4VRT/M DK50 9x4VRTS/M

Output at 8 bar

Voltage / frequency

Current draw (max.)

Main circuit breaker

Main feeder gauge

Enclosure

Air tank capacity

Working pressure

Safety valve

Noise level

Total weight of compressor (net)

Weight - compressor module

Weight - dryer module

Weight of air tank

Compressor dimensions, total

(w x d x h)

Dimensions - compressor module

(w x d x h)

Dimensions – ED108 dryer

module

(w x d x h)

Air tank dimensions

(w x d x h)

Operating mode

l/min 1780 1780

V / Hz

A 47 47

A

2

mm

l 500 500

bar

bar 11 11

dB 80 69

kg 747 817

kg 540 610

kg 85 74

kg 127 127

mm 3800x705 x2100 3800x705 x2100

mm 1840x630 x1730 1860x705 x1760

mm 760x580x1050 760x580x1050

mm 770x705 x2100 770x705 x2100

3 x 400 / 50 3 x 400 / 50

50 50

10 10

IP10 IP30

8 10 8 10

S1 – 100% S1 – 100%

Dryer performance with

condensation dryer (ED108)

(PDP*)

Time to fill air tank from 0 to 7 bar

Recommended cooling air

changes in space

Electrical class

+3°C +3°C

s 50 50

3

m

/h 3250 3250

class I.

class I.

(*) Apply the correction factor for the ED180 dryer

10/2018 NP-DK50-9x4VRTM_ED-EN-2_10-2018

- 9-

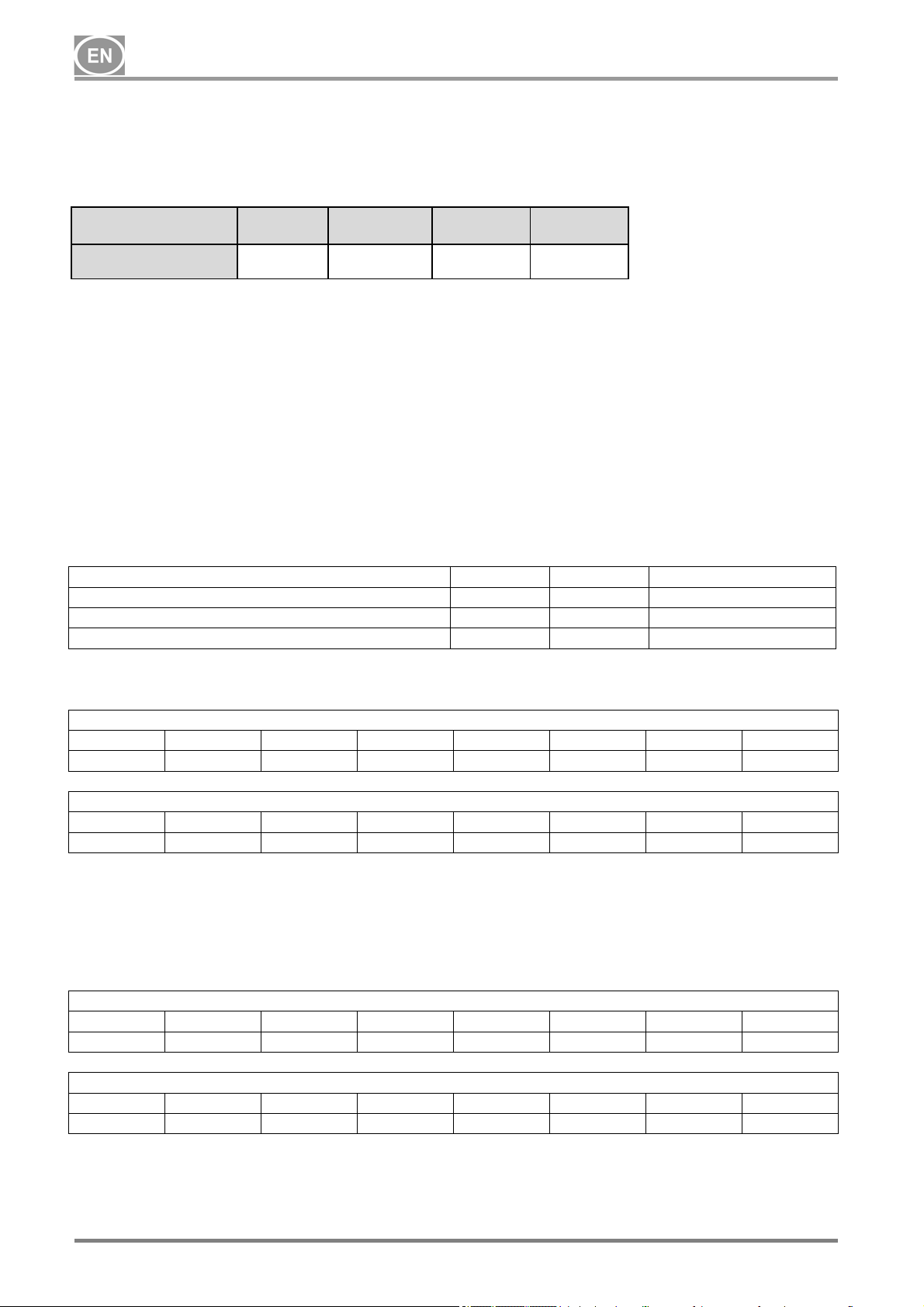

7.1. Free air delivery (FAD) correction due to elevation

FAD correction table

DK50 9x4VRT/M

Elevation [MASL]

FAD [l/min] FAD x 1 FAD x 0.8 FAD x 0.71 FAD x 0.60

0 - 1500 1501 - 2500 2501 - 3500 3501 - 4500

FAD reference conditions:

Elevation: 0 MASL

Temperature: 20°C

Atmospheric pressure: 101 325 Pa

Relative humidity: 0%

7.2. Dryer performance correction

ED180 dryer reference values

Temperature of air entering the dryer t

°C 35 (max.55)

inlet

Ambient temperature t0 °C 25 (max.45)

Working pressure p bar 7 (max.16)

Pressure dew point PDP °C +3 (-22 atm.)

ED180 dryer correction factors

Correction factor for working pressure

p (bar) 4 5 6 7 8 9 10

FC1

Correction factor for temperature of compressed air entering the dryer

t

(°C) 30 35 40 45 50 55

inlet

FC2

The cooler cools the compressed air to a temperature of ~19

temperature. Therefore:

t

= to + 19oC

inlet

It means E.G. at ambient temperature of t

Dew point correction factor

PDP (°C) 3 4 5 6 7 8 9

FC3

Correction factor for ambient temperature

to (°C) 25 30 35 40

FC4

0.78 0.85 0.93 1.0 1.06 1.11 1.15

1.2 1.0 0.85 0.71 0.58 0.49

o

C higher than the ambient

= 16oC, t

o

= 16o + 19o = 35oC → FC2 = 1,0

inlet

1 1.04 1.09 1.14 1.18 1.25 1.3

1 0.96 0.92 0.88

NP-DK50-9x4VRTM_ED-EN-2_10-2018 - 10 - 10/2018

DK50 9x4VRT/M

Calculation to determine dryer pressure dew point value:

Q

F

3

C

skut

FFFQ

421

CCCn

= actual airflow

Q

skut

Q

= nominal dryer flow (1800lit/min)

n

F

= working pressure correction factor

C1

F

= correction factor for air entering the dryer

C2

F

= dew point correction factor

C3

= ambient temperature correction factor

F

C4

See the user manual for the dryer on the CD for more information

10/2018 NP-DK50-9x4VRTM_ED-EN-2_10-2018

- 11-

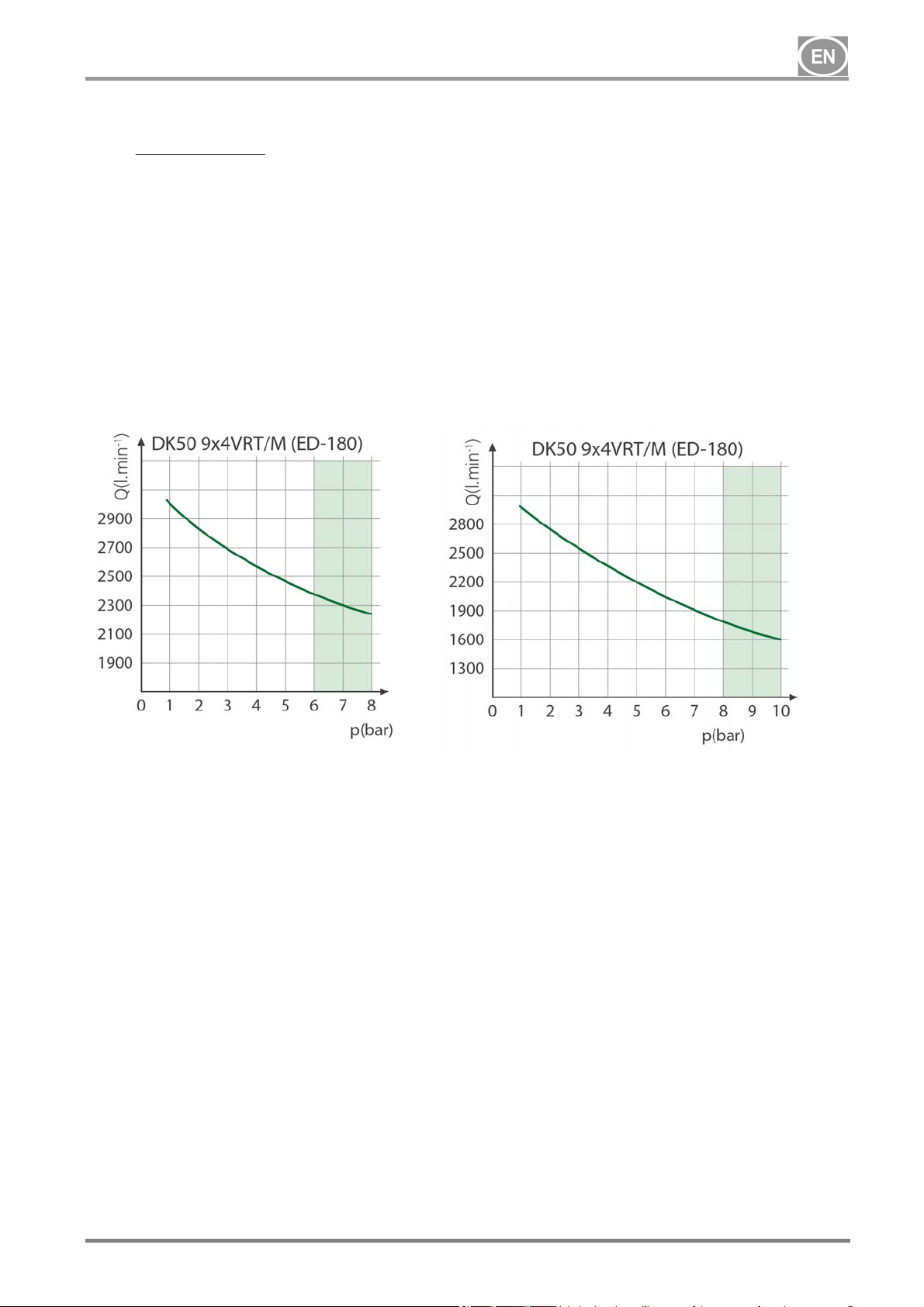

8. PRODUCT DESCRIPTION

DK50 9x4VRT/M

8.1. Variants

DK50 9x4VRT/M compressor comprised of

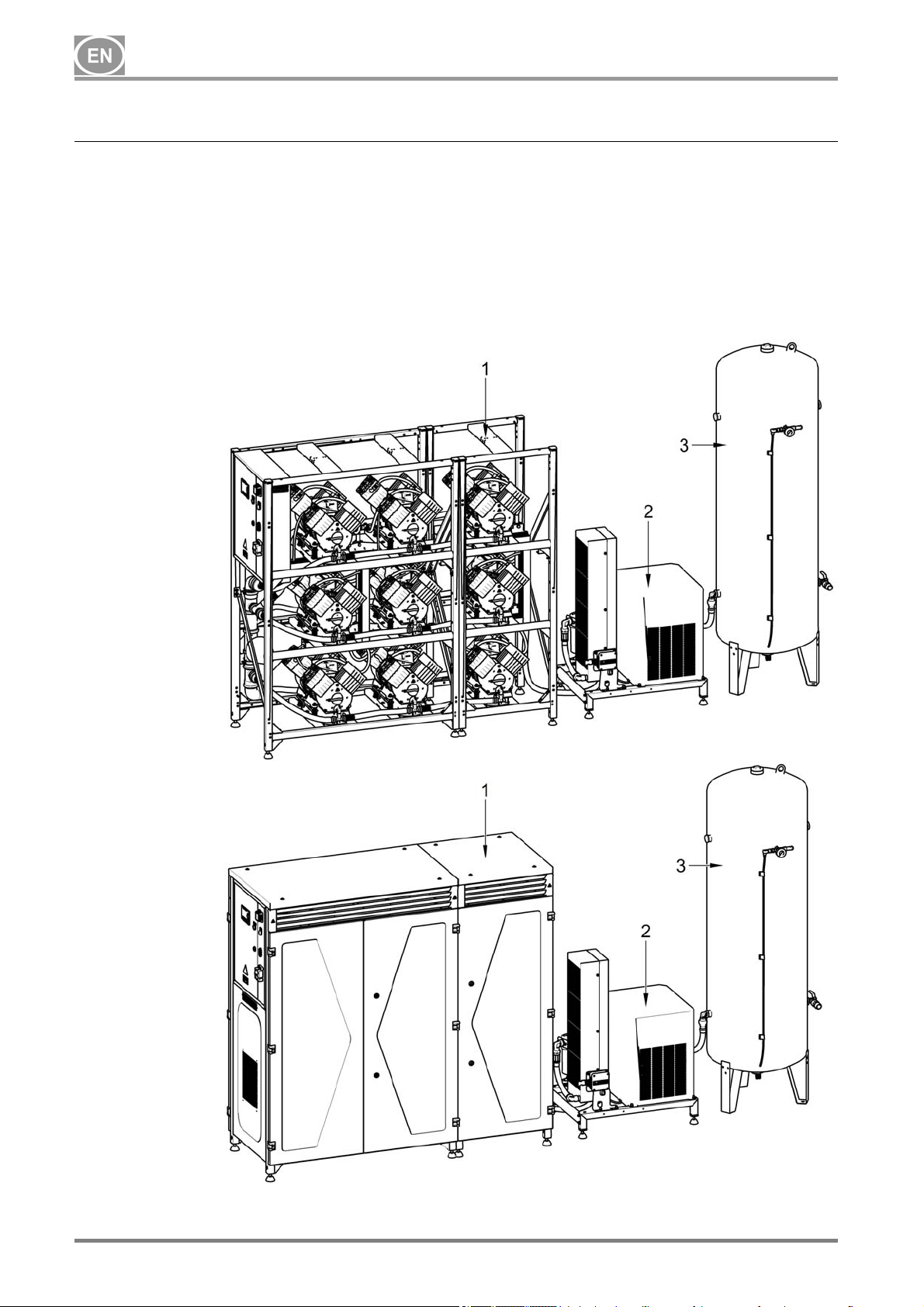

the following modules (Fig.1a):

- compressor module with 9 compressor

air pumps and controls

- a (condensing) dryer module with

connection hoses

- air tank module

Fig. 1a Compressor without enclosure

Fig.1b Compressor with enclosure

DK50 9x4VRTS/M compressor comprised of

the following modules (Fig. 1b):

- a compressor module with 9 compressor

air pumps and controls along with a

soundproof enclosure

- a (condensing) dryer module with

connection hoses

- air tank module

1. Compressor module

2. Dryer module

3. Air tank module

NP-DK50-9x4VRTM_ED-EN-2_10-2018 - 12 - 10/2018

DK50 9x4VRT/M

8.2. Accessories

Accessories are available for compressor

directly from the manufacturer (by special

request in an order) or may be ordered

directly from the manufacturer at a later time,

see below. Individual accessories may be

combined.

Accessories not included in the standard

order must be ordered separately!

8.2.1. Central air pump intake kit

This kit provides a properly sized central filter

located on the compressor module with intake

ducts to the individual compressors. This

extends the central filter replacement interval

(now every 2,000 hours) and eliminates the

need to replace filters on individual

compressors with simple and fast replacement

of the central filter.

Compressor type Kit article no.

DK50 9x4VRT/M 447000001-067

DK50 9x4VRTS/M 447000001-066

8.2.2. Set of compressed air outlet filters

The compressor may be equipped with a set

of filters if needed. A pressure regulator may

be added to the set of filters. The set of filters

is fully compatible with all compressors listed

above.

If a higher level of air filtration is

required, this specification must be

agreed upon with the supplier and

made clear in the order.

Level of filtration Pressure regulator Kit article no.

3µm

3µm – 0.3µm 447000001-060

SET OF

FILTERS

8.2.3. Compressor module enclosure (soundproofing)

Enclosing the compressor module reduces the

noise generated by the compressor by up to

11 dB(a) compared to the existing module

3µm – 0.01µm 447000001-062

1µm – AC/HC 447000001-064

3µm – 0.3µm

3µm – 0.01µm 447000001-063

1µm – AC/HC 447000001-065

Compressor type With central intake Kit article no.

DK50 9x4VRT/M yes 447000001-068

yes

no

while ensuring sufficient cooling for the air

pumps themselves for S1 class continuous

operations.

447000001-058

447000001-061

DK50 9x4VRT/M no 447000001-069

10/2018 NP-DK50-9x4VRTM_ED-EN-2_10-2018

- 13-

9. EQUIPMENT FUNCTION

DK50 9x4VRT/M

The compressor produces oil-free, dry,

filtered compressed air to power pneumatic

devices and equipment used in dental clinics

and laboratories, hospital departments and

more.

Compressor air pumps (11) draw in

atmospheric air through the inlet filters and

compress it through check valves and into the

compressed air system. From there, the

compressed air proceeds to the cooler (8), in

which the compressed air is cooled for the first

time and condensate is produced. The air

then passes through a water separator and

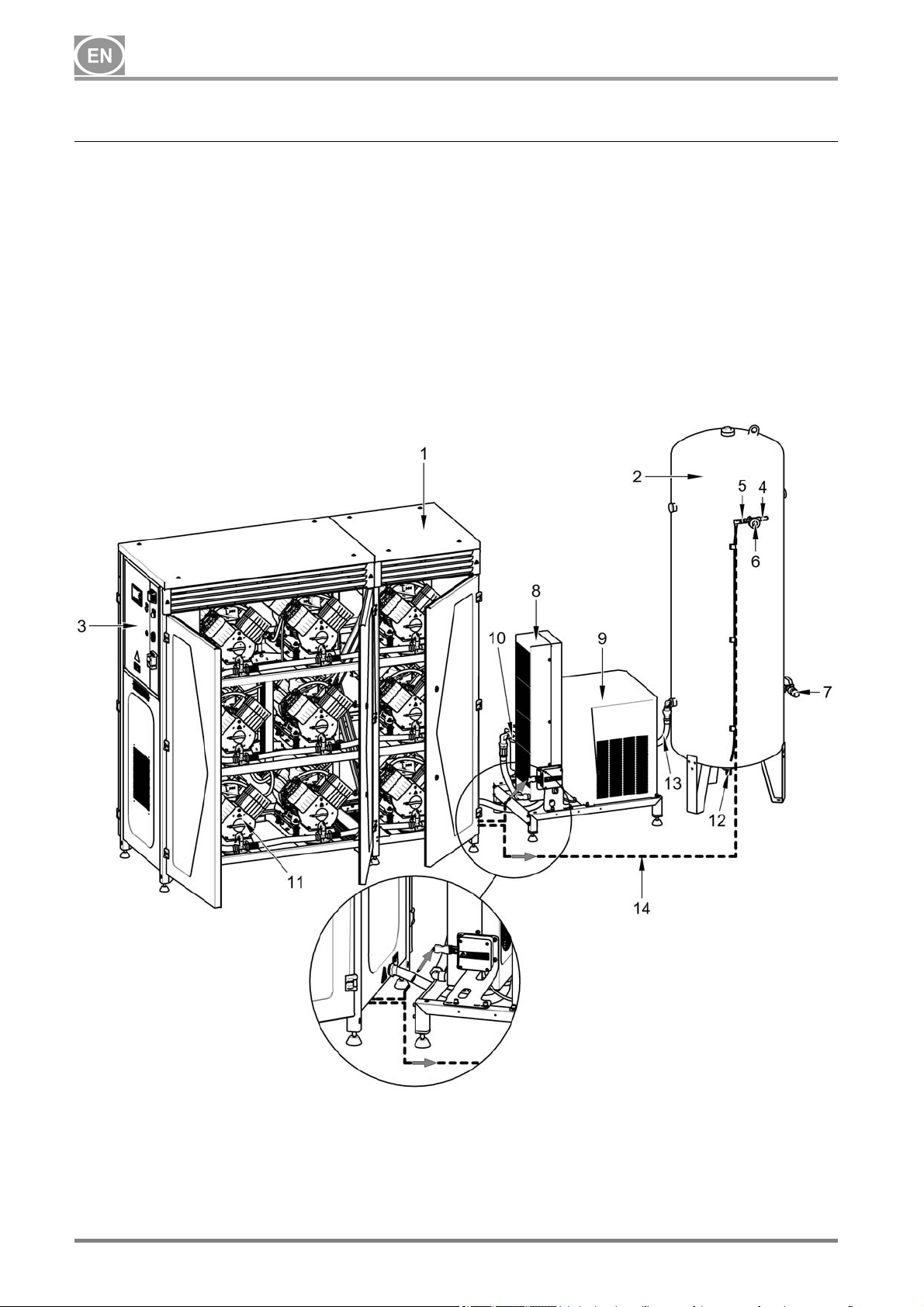

Fig. 2 Equipment function

into the condensing dryer (9). This continues

to lower the temperature of the air and

produces more condensate. The temperature

then rises to reduce the relative humidity. The

clean, dry air then passes through a check

valve and enters the air tank (2). Condensate

from the water separator and the dryer is

drained off into a 10 l vessel in the

condensate drain kit. The dryer ensures the

continuous and no-loss drying of the

compressed air. The treated compressed air

is then ready for additional use in the air tank.

1. Compressor module

2. Air tank

3. Switchboard

4. Safety valve

5. Pressure sensor

6. Pressure gauge

7. Outlet valve

8. Cooler

9. Condensation dryer

10. Water separator

11. Compressor air pump

12. Drain valve

13. Connecting hoses

14. Electric cables

NP-DK50-9x4VRTM_ED-EN-2_10-2018 - 14 - 10/2018

Loading...

Loading...