EKOM DK50 2x4VR/110, DK50 2x4VR/110S, DK50 2x4VR/110/M, DK50 2x4VR/110S/M Installation, Operation And Maintenance Manual

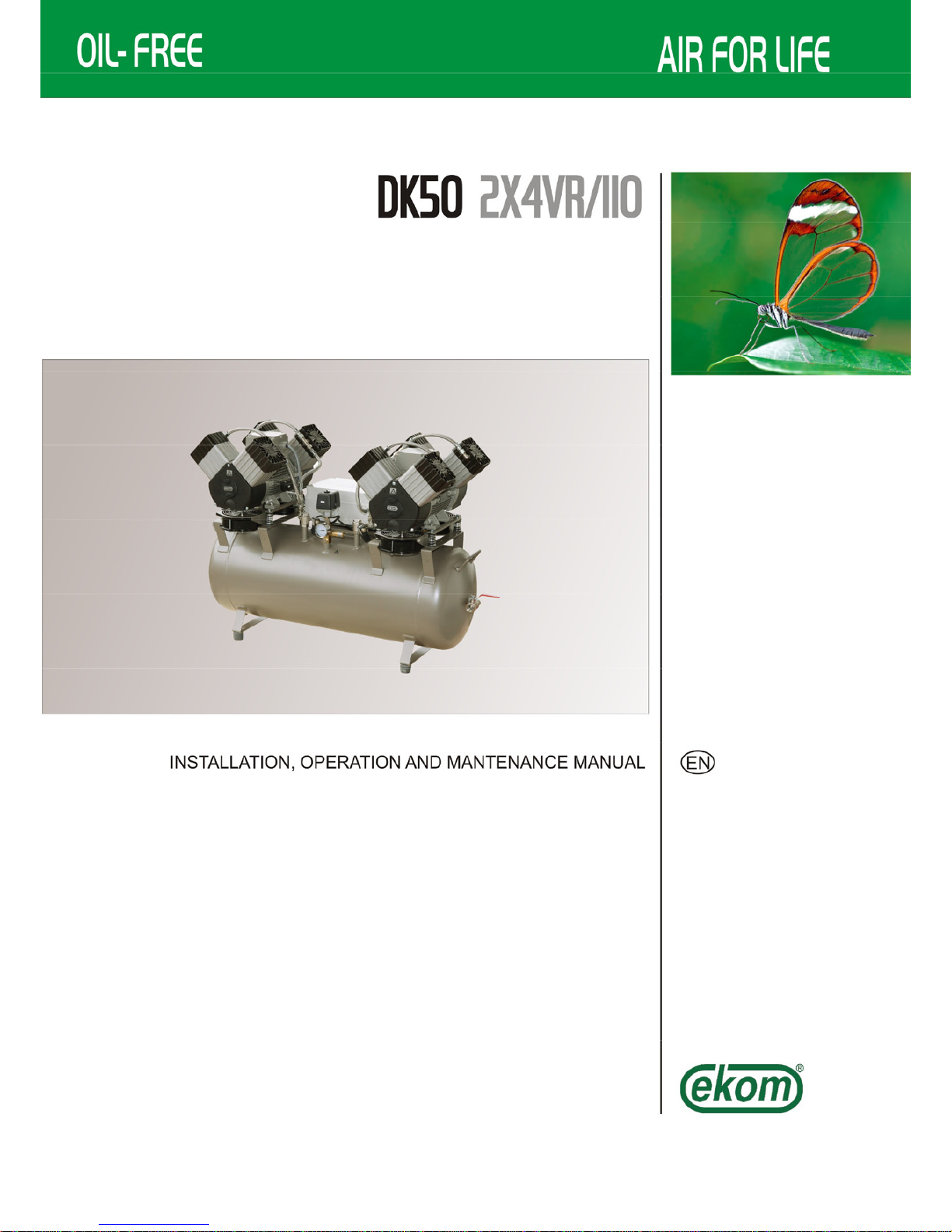

DK50 2x4VR/110

NP-DK50 2x4VR110-12_10-2016 - 2 - 10/2016

CONTENTS

IMPORTANT INFORMATION ................................................................................................................. 3

1. CE MARKING ............................................................................................................................ 3

2. WARNINGS ................................................................................................................................ 3

3. ALERT NOTICES AND SYMBOLS ............................................................................................ 4

4. STORAGE AND TRANSPORT .................................................................................................. 4

5. TECHNICAL DATA ..................................................................................................................... 5

6. PRODUCT DESCRIPTION ........................................................................................................ 6

7. FUNCTION ................................................................................................................................. 8

INSTALLATION ..................................................................................................................................... 11

8. USE ........................................................................................................................................... 11

9. INSTALLATION ........................................................................................................................ 11

10. WIRING DIAGRAMS ............................................................................................................... 16

11. PNEUMATIC DIAGRAM .......................................................................................................... 18

12.FIRST OPERATION ................................................................................................................. 19

OPERATION .......................................................................................................................................... 19

13.SWITCHING THE COMPRESSOR ON ................................................................................... 20

MAINTENANCE .................................................................................................................................... 21

14.MAINTENANCE SCHEDULE ................................................................................................. 21

15.MAINTENANCE ........................................................................................................................ 21

16.STORAGE ................................................................................................................................ 25

17.DISPOSING OF THE APPLIANCE .......................................................................................... 25

18.REPAIR SERVICE .................................................................................................................... 25

19.SOLVING PROBLEMS ............................................................................................................. 2 5

DK50 2x4VR/110

10/2016 - 3 - NP-DK50 2x4VR110-12_10-2016

IMPORTANT INFORMATION

1. CE MARKING

Products labeled with the CE mark of compliance meet the safety guidelines (93/42/EEC) of the European

Union.

2. WARNINGS

2.1. General warnings

This Installation, Operation and Maintenance Manual is a part of the appliance and must be kept with the

compressor. Careful review of this manual will provide the information necessary for correct operation of the

appliance.

The safety of operating personnel and trouble-free operation of the appliance are guaranteed only if

original parts are used. Only accessories and parts mentioned in the technical documentation or expressly

approved by the manufacturer can be used.

If any other accessories or consumable materials are used, the manufacturer cannot be held responsible

for the safe operation of the appliance. This guarantee does not cover damages originating from the use of

accessories or consumable material other than those specified or suggested by the manufacturer.

The manufacturer guarantees the safety, reliability and function of the appliance only if:

- Installation, new settings, amendments, extensions and repairs are performed by the manufacturer or

its representative, or a service provider authorized by the manufacturer

- The appliance is used in accordance with this Installation, Operation and Maintenance Manual

The manufacturer reserves all rights for the protection of its wiring diagrams, methods and names.

Translation of Manual for Installation, Operation and Maintenance is carried out in accordance with the

best knowledge. In the case of ambiguities, the Slovak version of the text prevails.

2.2. General safety warnings

The manufacturer developed and designed the equipment in such a way so that any risks were excluded if it

is used according to intention. The manufacturer considers it to be its obligation to describe the following

safety measures in order to exclude residual damages.

Operation of the appliance must be in compliance with all local codes and regulations.

Original packaging should be kept for the return of the appliance. Only the original packaging ensures

protection of the appliance during transport. If it is necessary to return the appliance during the guarantee

period, the manufacturer is not liable for damages caused by improper packaging.

Each time the appliance is used, the operator must make sure that it is functioning correctly and safely.

The user must fully understand the operation of the appliance.

The product is not intended for operation in areas with a risk of explosion.

If any problem occurs during use of the appliance, the user must inform his supplier immediately.

2.3. Electrical system safety warnings

The appliance must be connected to earth (grounded).

Before the appliance is plugged in, make sure that the mains voltage and mains frequency stated on the

appliance are the same as the power mains.

Prior to putting into operation it is necessary to check for possible damage of the equipment and

connected air and electric distributions. Damaged pneumatic and electric lines must be immediately

replaced.

Immediately disconnect the appliance from the mains (pull out mains plug) if a technical failure occurs.

During repairs and maintenance, ensure that:

- The mains plug is pulled out from the socket

- Pressure pipes are vented and pressure is released from the air tank.

The appliance must be installed by an approved, qualified technician.

DK50 2x4VR/110

NP-DK50 2x4VR110-12_10-2016 - 4 - 10/2016

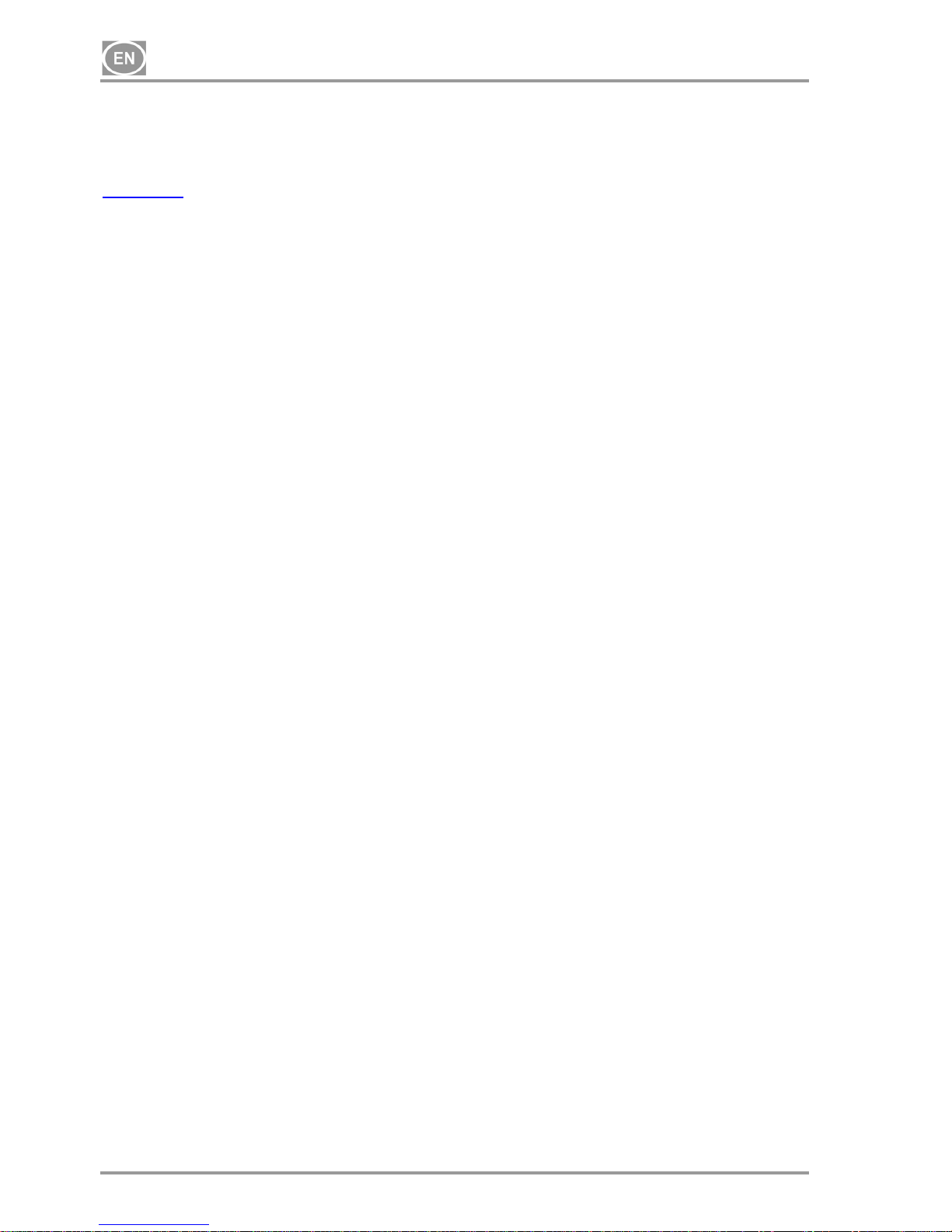

3. ALERT NOTICES AND SYMBOLS

In the Installation, Operation and Maintenance Manual and on packaging and product, the following labels or

symbols are used for important information:

Information, instructions and cautions for the prevention of damage to health or

materials

Caution! Dangerous electrical voltage

Read the user manual!

CE mark of compliance

Compressor is remote-controlled and may start without warning

Caution! Hot surface

Earth (ground) connection

Terminal for ground connection

Fuse

Alternating current

Handling mark on package – FRAGILE

Handling mark on package – THIS SIDE UP

Handling mark on package – KEEP DRY

Handling mark on package – TEMPERATURE LIMITATIONS

Handling mark on package – LIMITED STACKING

Mark on package – RECYCLABLE MATERIAL

4. STORAGE AND TRANSPORT

The compressor is shipped in cardboard that protects the appliance from damage during transport.

Caution! For transport, always use the original packaging and secure the compressor

in the upright position.

Protect the compressor from humidity and extreme temperatures during transport and storage.

A compressor in its original packaging can be stored in a warm, dry and dust-free area. Do not

store near any chemical substances.

Keep packaging material if possible. If not, please dispose of the packaging material in an

environmentally friendly way and recycle if possible.

Caution! Before moving or transporting the compressor, release all the air pressure

from the tank and hoses and drain the condensed water.

DK50 2x4VR/110

10/2016 - 5 - NP-DK50 2x4VR110-12_10-2016

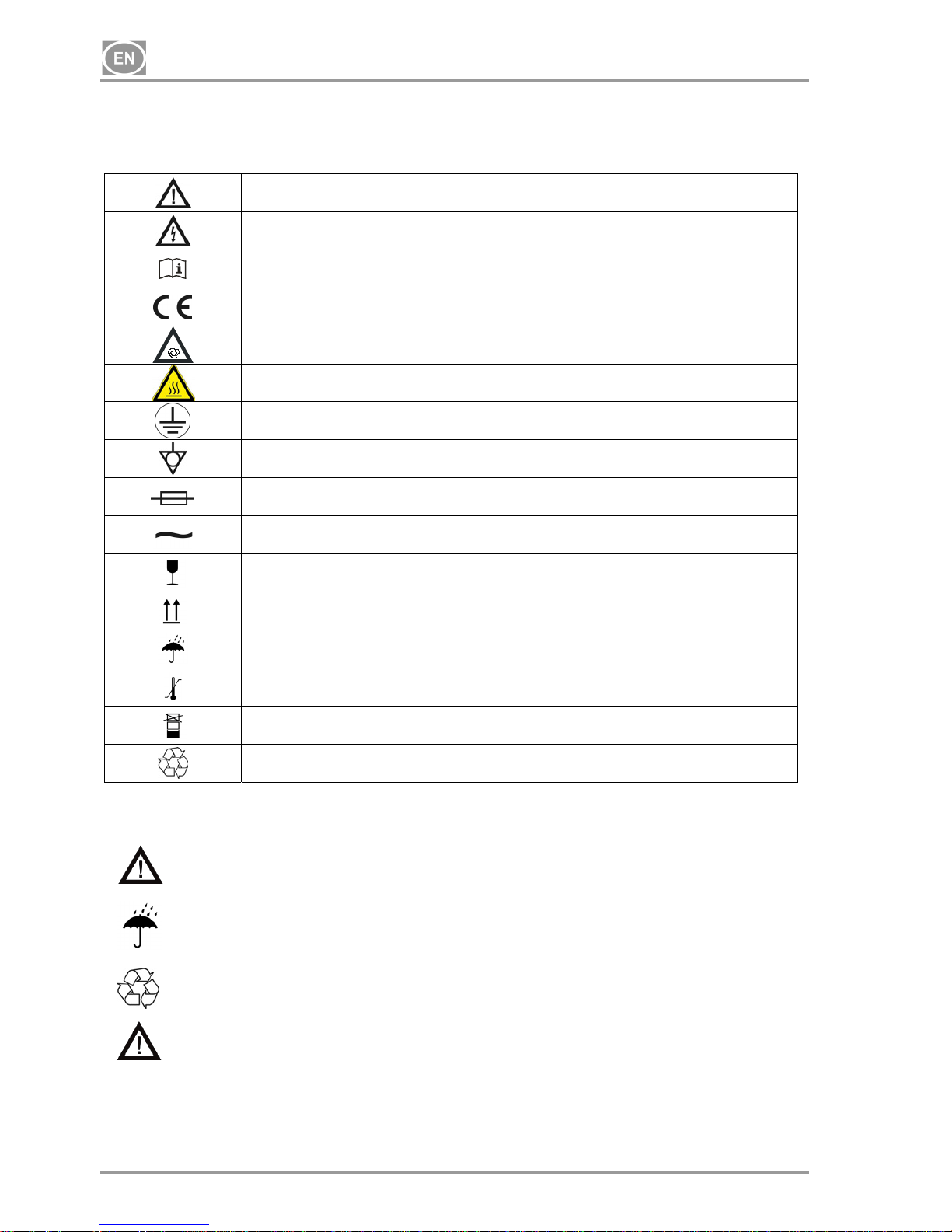

5. TECHNICAL DATA

DK50 2x4VR/110

DK50 2x4VR/110S

Rated voltage /

frequency

V / Hz

3x400/50 3x400/50

Compressor output

at pressure of 6 bar

Lit.min-1

520 520

Compressor output at 6 bar with

dryer

MD

Lit.min

-1

430 430

NDL

400 400

Maximum compressor current

A

9.4 10.2

Maximum compressor current with dryer A

10.1 10.6

Motor output kW

2x2.2 2x2.2

Air tank capacity Lit.

110 110

Working pressure bar

6.0 – 8.0

6.0 – 8.0

Maximum operating pressure of safety valve bar

9.0 9.0

Noise L

pfA

[dB]

77 58

Mode of operation

Continuous S1 Continuous S1

Mode of operation with dryer

Continuous S1 Continuous S1

Compressor dimensions W x L x H

mm

1090x500x830 1260x795x1025

Dimensions

with dryer

W x L x H

MD

mm

1210x670x830

1550x795x1240

NDL 1210x770x1240

1550x795x1240

Weight

kg

136 218

Weight

with dryer

MD

kg

158 240

NDL

172 252

Air dryer performance

Atmospheric dew point

MD

°C

-20

Pressure dew point

NDL

- 35

Configuration pursuant to EN 60 601-1

Type B, class I.

Climatic conditions during storage and transport

Temperature : –25°C to +55°C, 24 h to +70°C

Relative air humidity : 10% to 90 % (no condensation)

Climatic operation conditions

Temperature : +5°C to +40°C

Relative air humidity : 70%

5.1. FAD efficiency correction for differences in elevation

FADcorrectiontable

FAD efficiency refers to conditions at an elevation of 0 mamsl: Temperature: 20°C

Atmospheric pressure: 101325 Pa

Relative humidity: 0%

Elevation[mamsl] 0‐1500 1501‐2500 2501‐3500 3501‐4500

FAD[l/min] FADx1 FADx0.8 FADx0.71 FADx0.60

DK50 2x4VR/110

NP-DK50 2x4VR110-12_10-2016 - 6 - 10/2016

6. PRODUCT DESCRIPTION

6.1. Model variations and their uses

Compressors are the source of clean, oil-free compressed air used to drive dental appliances and

equipment.

Compressors models are designed for the following uses:

Dental compressors DK50 2x4VR/110 - are designed for independent installation in a suitable

environment.

Dental compressors DK50 2x4VR/110/M - are designed for independent installation in a suitable

environment and are equipped with an air dryer.

Dental compressors DK50 2x4VR/110S - are installed in cabinets with efficient noise mufflers and are

suitable for use in office environments.

Dental compressors DK50 2x4VR/110S/M - are installed in cabinets and are equipped with air dryers.

DK50 2x4VR/110 DK50 2x4VR/110/M (NDL) DK50 2x4VR/110S/M

DK50 2x4VR/110/M (MD) S110R

DRYER MD WITH COOLER DRYER NDL COOLER

Without additional filtration equipment, the compressed air from a compressor is not

suitable for the operation of breathing appliances or similar equipment.

DK50 2x4VR/110

10/2016 - 7 - NP-DK50 2x4VR110-12_10-2016

6.2. Optional accessories

Products may be equipped with optional accessories that are not

included with the basic product and must be ordered separately:

Filter regulator / set 604012967-000 /

The filter regulator filters out impurities in the compressed air down to a size

of 5 m. The use of this accessory on a compressor without a dryer partially

reduces moisture content in the supplied compressed air. Filtered

compressed air is suitable for use anywhere its parameters meet the

stipulated requirements. The regulator ensures a supply of output air at a

constant pressure (so long as the pressure value set on the regulator is not

higher than the switching pressure set on the pressure switch).

Regulator / set 604022073-000 /

The regulator ensures a supply of output air at a constant pressure (so long

as the pressure value set on the regulator is not higher than the switching

pressure set on the pressure switch).

Automatic condensate drain / set 604011998-000 /

The automatic condensate drain automatically drains condensate from the compressor's air tank based on a

pre-set time interval.

The drain automatically opens a solenoid valve at a pre-set time interval to drain condensate from the air

tank.

A timer is used to set the time between actuation of the solenoid valve (approximately 30 minutes).

The time between actuations of the solenoid valve can be adjusted to a lower value if excessive amount

of condensate is generated.

- The TEST button (2) is used to check the actuation of the solenoid valve, and when pushed the

solenoid valve should open (ON) and the time between actuations of the solenoid valve begins from this

point.

- The LED (1) lights up to signalize the valve is open(ON).

1

2

DK50 2x4VR/110

NP-DK50 2x4VR110-12_10-2016 - 8 - 10/2016

7. FUNCTION

Compressor (Fig.1)

The compressor (1) draws in air through a filter (8) and compresses it through a check valve (3) into an air

tank (2). The connected apparatus draws the compressed air from the air tank until the pressure drops to a

default preset level on the air-pressure switch (4) switching the compressor on. The compressor again

compresses air into the nozzle until the maximum pressure is reached and the compressor switches off.

After compressor aggregate is switched off, pressure hose shall be pressure-release solenoid valve (9).

Safety valve (5) prevents the pressure in air chamber from rising above the maximal allowed value. The

drain valve (7) releases the condensate from the air nozzle. Compressed, dry and clean air is then ready for

additional use in the air tank.

Compressor with membrane dryer (MD) (Fig. 2)

The compressor (1) draws in air through an inlet filter (8) and compresses it through a check valve (3) into a

cooler (10). The air then passes through a filter (33) and micro-filter (34) into the dryer (35) with the dry and

clean air passing through a check valve (3) to the air tank (2). Condensate from the filter and micro-filter is

automatically released into a drainage vessel. The dryer ensures continuous drying of the compressed air.

Compressed, dry and clean air is then ready for additional use in the air tank.

Compressor with NDL dryer (Fig. 3)

The compressor (1) draws in air through an inlet filter (8) and compresses it through a check valve (3) into

the cooler (10). The air then proceeds through the condensate separator (15) and the drying chamber (11)

with the adsorbent media where moisture is removed and then on to the air tank (2). The adsorbent media

regenerates when the drying chamber is being evacuated, always after the compressor is switched off by the

pressure switch. The air is then released from the adsorption chamber via the open solenoid valve as it is

evacuated using dry compressed air. Air drying occurs in one chamber while regeneration occurs in the

other chamber. The mode of each chamber changes in regular cycles and the drying and regeneration

processes are then performed in the alternate chamber. Compressed, dry and clean air is then ready for

additional use. Constant output pressure is maintained by the pressure regulator (12).

The pressure switch (13) protects the dryer from damage if the compressor operates for an extended period

of time at low pressure (less than 5 bar)

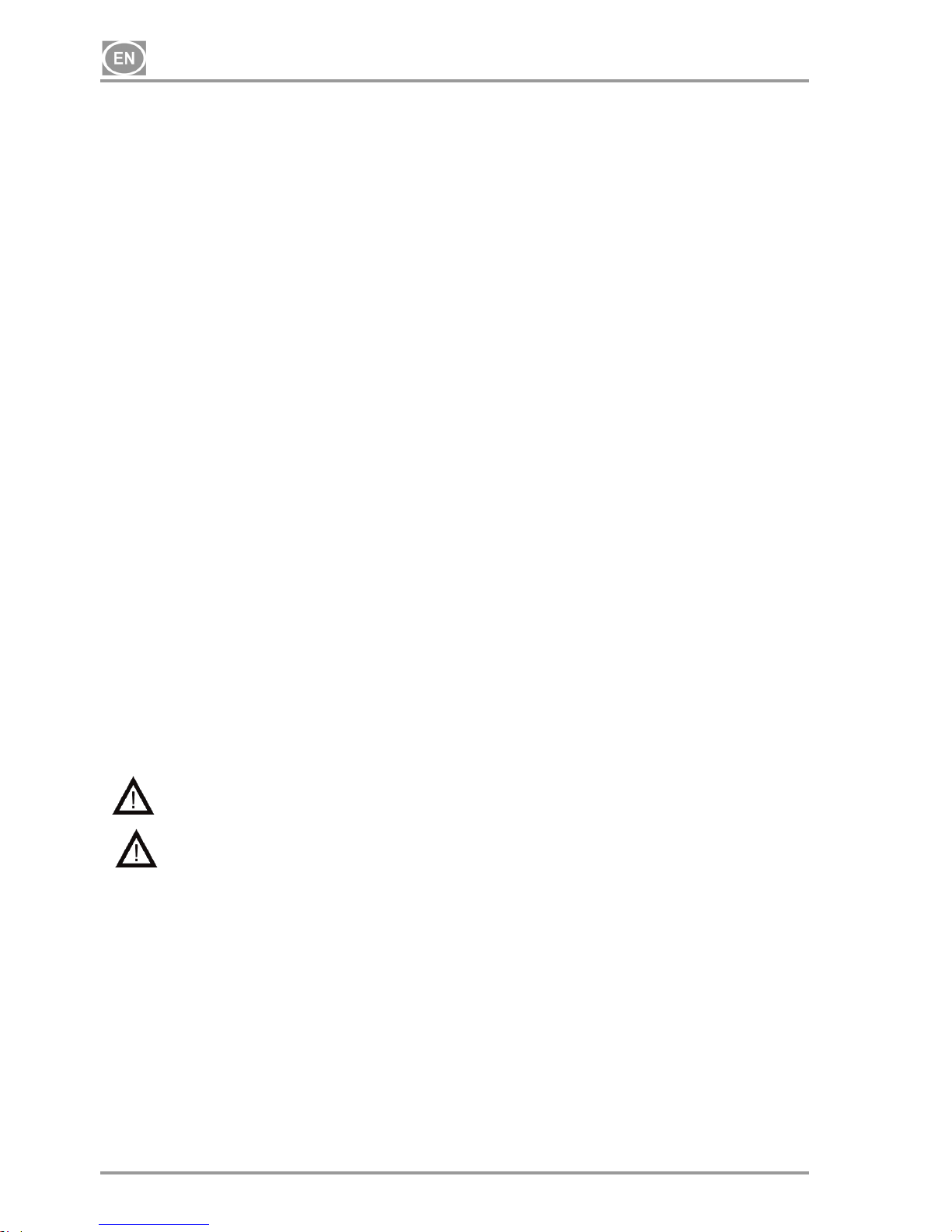

Compressor cabinet (Fig. 4)

The soundproof cabinet itself is compact yet allows sufficient exchange of cooling air.

The fan (18) underneath the compressor aggregate and the cabinet fans (26) cool the compressor and the

space inside the cabinet. The fans operate when the compressor motor is running. The cooling fans

automatically start if the temperature in the cabinet reaches over 40°C, even when the compressor is not

running. The fans automatically switch off once the cabinet temperature drops to around 32°C.

An indicator (29) located on the front of the cabinet indicates maintenance is needed on the compressor with

the NDL dryer unit (see the Maintenance Interval chapter)

Make sure that nothing impedes the free flow of air under and around the compressor.

Never cover the hot air outlet on the top back side of the case.

If placing the compressor on a soft floor such as carpet, create space for ventilation

between the base and floor or the box and floor, e.g. underpin the footings with hard pads.

DK50 2x4VR/110

10/2016 - 9 - NP-DK50 2x4VR110-12_10-2016

Fig. 1 - Compressor

Fig.2- Compressor with membrane dryer (MD)

1. Compressor

2. Air tank

3. Check valve

4. Pressure switch

5. Safety valve

6. Pressure gauge

7. Condensate drain valve

8. Inlet filter

9. Solenoid valve

10. Dryer cooler

11. Adsorption dryer (NDL)

12. Pressure regulator (Optional accessories)

13. Pressure switch 2

14. Pressure relief valve

15. Condensate separator

16. Control valve

17. Check valve

18. Compressor fan

19. Box gas springs

20. Wall bump stop

21. Power supply cord

22. Pressure gauge hose

23. Angular screwing

24. -

25. Compressor wheel

26. Cabinet fan

27. Handle

28. Switch

29. Maintenance indicator

30. Cabinet pressure gauge

31. Temperature switch

32. Positioning truck

33. Filter

34. Micro-filter

35. Membrane dryer (MD)

36. Hour meter

17

Loading...

Loading...