EKOM DK50 2V/50, DK50 2V/50S Installation, Operation & Maintenance Manual

DK50 2V/50

DK50 2V/50

NP-DK50 2V50-7_02-2016 MD - 2 - 02/2016

CO

NTENTS

IMPORTANT INFORMATI

ON ................................................................................................................. 3

1. CE MARKING ............................................................................................................................ 3

2. WARNINGS ................................................................................................................................ 3

3. ALERT NOTICES AND SYMBOLS ............................................................................................ 4

4. STORAGE AND TRANSPORT .................................................................................................. 4

5. TECHNICAL DATA ..................................................................................................................... 5

6. PRODUCT DESCRIPTION ........................................................................................................ 6

7. FUNCTION ................................................................................................................................. 6

INSTALLATION ....................................................................................................................................... 8

8. USE ............................................................................................................................................. 8

9. INSTALLATION .......................................................................................................................... 9

10.WIRING DIAGRAMS ................................................................................................................ 11

11. PNEUMATIC DIAGRAM .......................................................................................................... 13

12.FIRST OPERATION ................................................................................................................. 14

OPERATION .......................................................................................................................................... 14

13.SWITCHING THE COMPRESSOR ON ................................................................................... 15

MAINTENANCE .................................................................................................................................... 15

14.MAINTENANCE SCHEDULE ................................................................................................. 15

15.MAINTENANCE ........................................................................................................................ 15

16.STORAGE ................................................................................................................................ 17

17.DISPOSING OF THE APPLIANCE .......................................................................................... 17

18.REPAIR SERVICE .................................................................................................................... 17

19.SOLVING PROBLEMS ............................................................................................................. 18

DK50 2V/50

02/2016 - 3 - NP-DK50 2V50-7_02-2016 MD

IMPORTANT INFORMATION

1. CE MARKING

Produ

cts labeled with the CE mark of compliance meet the safety guidelines (93/42/EEC) of the European

Union.

2. W

ARNIN

GS

2.1.

General warnings

This Installation, Operation and Maintenance Manual is a part of the appliance and must be kept with the

compressor. Careful review of this manual will provide the information necessary for correct

operation of the

appliance.

The safety of operating personnel and trouble-free operation of the appliance are guaran

teed only if

origin

al parts are used. Only accessories and parts mentioned in the technical documentation or expressly

approved by the manufacturer can be

used.

If any other accessories or consumable materials are used, the manufacturer cannot be held respon

sible

for the safe o

peration of the appliance. This guarantee does not cover damages originating from the use

of

acce

ssories or consumable material other than those specified or suggested by the manufacturer.

The manufacturer guarantees the safety, reliability and function of the appliance on

ly if:

- Installation,

new settings, amendments, extensions and repairs are performed by the manufacturer or

its repre

sentative, or a service provider authorized by the manufacture

r

- The applia

nce is used in accordance with this Installation, Operation and Maintenance Man

ual

The manufacturer reserves all rights for the protection of its wiring diagrams, methods and names.

Translation of Manual for Installation, Operation and Maintenance is carried out in accordance with the

best knowledge. In the case of ambiguities, the Slovak version of the text prevails.

2.2. General safety warnings

The manufacturer developed and designed the equipment in such a way so that any risks were excluded if it

is used according to intention. The manufacturer considers it to be its obligation to describe the following

safety measures in order to exclude residual damages.

Operation of the appliance must be in compliance with all local codes and regul

ations.

Original packaging should be kept for the return of the appliance. Only the original packaging ensure

s

prote

ction of the appliance during transport. If it is necessary to return the appliance during the guarante

e

perio

d, the manufacturer is not liable for damages caused by improper packaging

.

Each time the appliance is used, the operator must make sure that it is functioning correctly and sa

fely.

The user must fully understand the operation of the applianc

e.

The product is not intended for operation in areas with a risk of explosion.

If any problem occurs during use of the appliance, the user must inform his supplier immediately.

2.3. Electrical system safety warnings

The appliance must be connected to earth (grounded

).

Before the appliance is plugged in, make sure that the mains voltage and mains frequency

stated on the

applia

nce are the same as the power ma

ins.

Prior to putting into operation it is necessary to check for possible damage of the equipment and

connected air and electric distributions. Damaged pneumatic and electric lines must be immediatel

y

r

eplaced

.

Immediately disconnect the appliance from the mains (pull out mains plug) if a tech

nical failure occurs.

During repairs and maintenance, en

sure that:

- The mains plu

g is pulled out from the socket

- Pressure pipe

s are vented and pressure is released from the

air tank.

The appliance must be installed by an approved, qualified technician.

DK50 2V/50

NP-DK50 2V50-7_02-2016 MD - 4 - 02/2016

3.

ALERT NOTICES AND SYMBOLS

In the Installation, Operation and Maintenance Manual and on packaging and product, the following labels or

symbols are used for important information:

Attention, see

instructions for use

Cautio

n, risk of electric shock

C

onsult instructions for use

CE mark of compliance

Comp

ressor is remote-controlled and may start without warning

Cautio

n! Hot surface

Ea

rth (ground) connection

Termin

al for ground connection

Fuse

Alternating cu

rrent

Han

dling mark on package – FRAGILE

Han

dling mark on package – THIS SIDE UP

Handling mark

on package – KEEP DRY

Han

dling mark on package – TEMPERATURE LIMITATIONS

Han

dling mark on package – LIMITED STACKING

Mark on pa

ckage – RECYCLABLE MATERIAL

4.

STORAGE AND TRANSP

ORT

The co

mpressor is shipped in cardboard that protects the appliance from damage during transp

ort.

Cau

tion! For transport, always use the original packaging and secure the compressor

in the upright position.

Protect the compressor from humidity and extreme temperatures during transport and storage.

A compressor in its original packaging can be stored in a warm, dry and dust-free area. Do not

store near any chemical substances.

Keep packaging material if possible. If not, please dispose of the packaging material in an

environmentally friendly way and recycle if possible.

Caution! Before moving or transporting the compressor, release all the air pressure

from the tank and hoses and drain the condensed water.

DK50 2V/50

02/2016 - 5 - NP-DK50 2V50-7_02-2016 MD

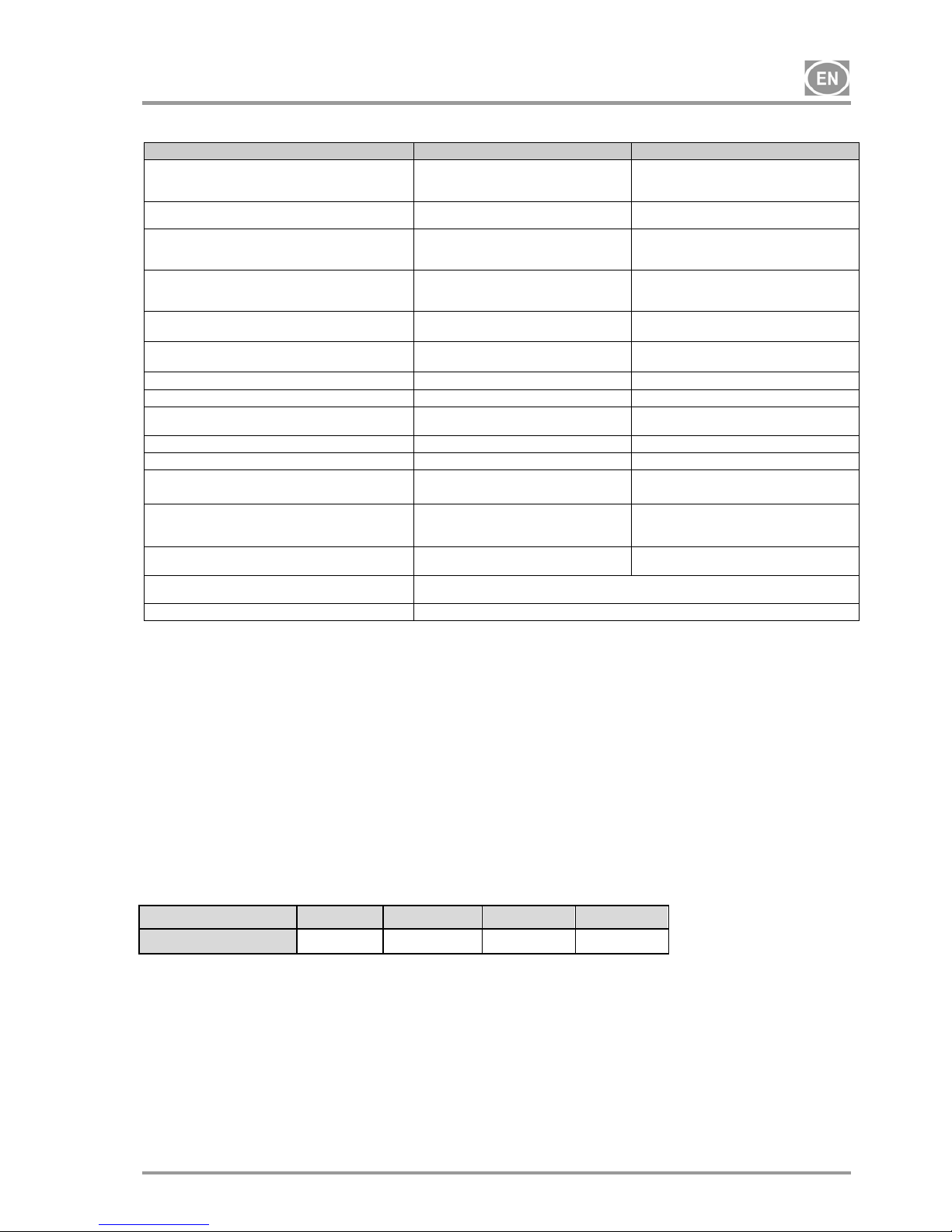

5. TECHNICAL DATA

DK50 2V/50 DK50 2V/50S

Nominal voltage /

frequency

V / Hz

230 / 50

3x400/50

230 / 50

3x400/50

Efficiency of compressor at over-pressure 6 bar

Lit.min

-1

134 134

Efficiency of compressor with dryer at overpressure 6 bar

Lit.min

-1

110 110

Maximal current

A

7.4

4.5

7.6

4.7

Maximal current of compressor with dryer

A

7.6

4.7

7.8

4.9

Motor performance kW

1.1

1.2

1.1

1.2

Air tank capacity Lit.

50 50

Pressure range bar

6,0 – 8,0 6,0 – 8,0

Maximum operating pressure of safety valve

bar

12,0 12,0

Sound level L

pfA

[dB]

71 56

Mode of operation of compressor

CONTINUAL S 1 CONTINUAL S 1

Mode of operation of compressor

with dryer

CONTINUAL S 1 CONTINUAL S 1

Dimensions of compressor /

of compressor with dryer

w x l x h

mm

595x475x770 /

580x585x775

750x715x1015

Weight of compressor /

of compressor with dryer kg

56 / 61 108 / 114

Drying point of compressor Atmospheric

condensation point

-20°C

Version EN 60 601-1

Appliance of type B, class I

Climat

ic conditions during storage and transport

Temperature : –25°C to +55°C, 24 h to +70°C

Relative air humidity : 10% to 90 % (no condensation)

Climatic operation conditions

Temperature : +5°C to +40°C

Relative air humidity : 70%

5.1. FAD efficiency correction for differences in elevation

FADcorrectiontable

FAD efficiency refers to conditions at an elevation of 0 mamsl: Temperature: 20°C

Atmospheric pressure: 101325 Pa

Relative humidity: 0%

Elevation[mamsl] 0‐1500 1501‐2500 2501‐3500 3501‐4500

FAD[l/min] FADx1 FADx0.8 FADx0.71 FADx0.60

DK50 2V/50

NP-DK50 2V50-7_02-2016 MD - 6 - 02/2016

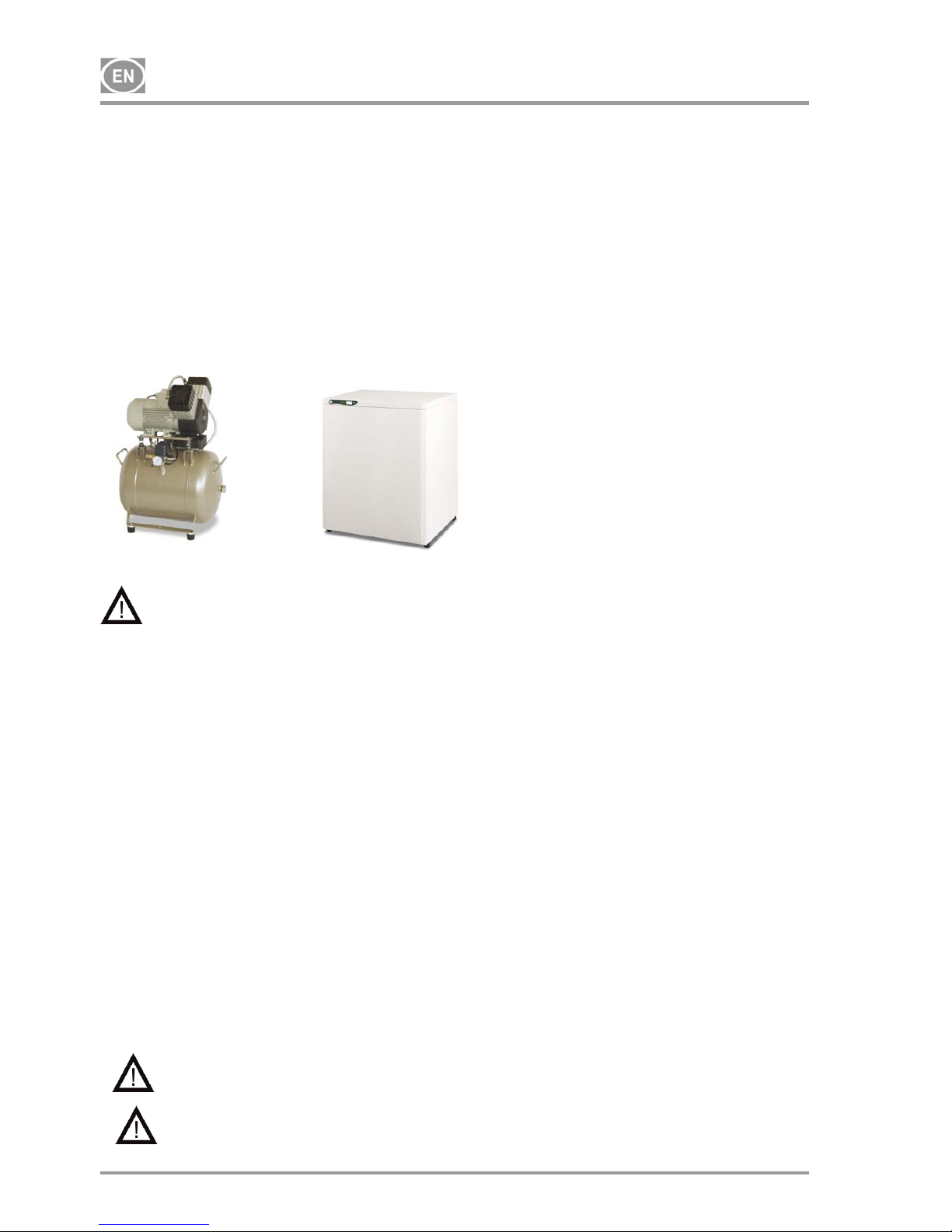

6. PRODUCT DESCRIPTION

6.1. Model variations and their uses

Compressors are the source of clean, oil-free compressed air used to drive dental appliances and

equipment.

Compressors models are designed for the following uses:

Dental compressors DK50

2V/50 - are designed for independent placement of the compressor in any

area.

Dental compressors DK50 2V/50/M - are designed for independent placement of the compressor in any

area and feature a membrane dryer.

Dental compressors DK50 2V/50S - feature soundproof boxes suitable for placing in the dentist‘s

surgery.

Dental compressors DK50 2V/50S/M - feature soundproof boxes and a membrane dryer.

DK50 2V/50 SKRINKA

Withou

t additional filtration equipment, the compressed air from a compressor is not suitable

for the operation of breathing appliances or similar equipment.

7. FUNCTIO

N

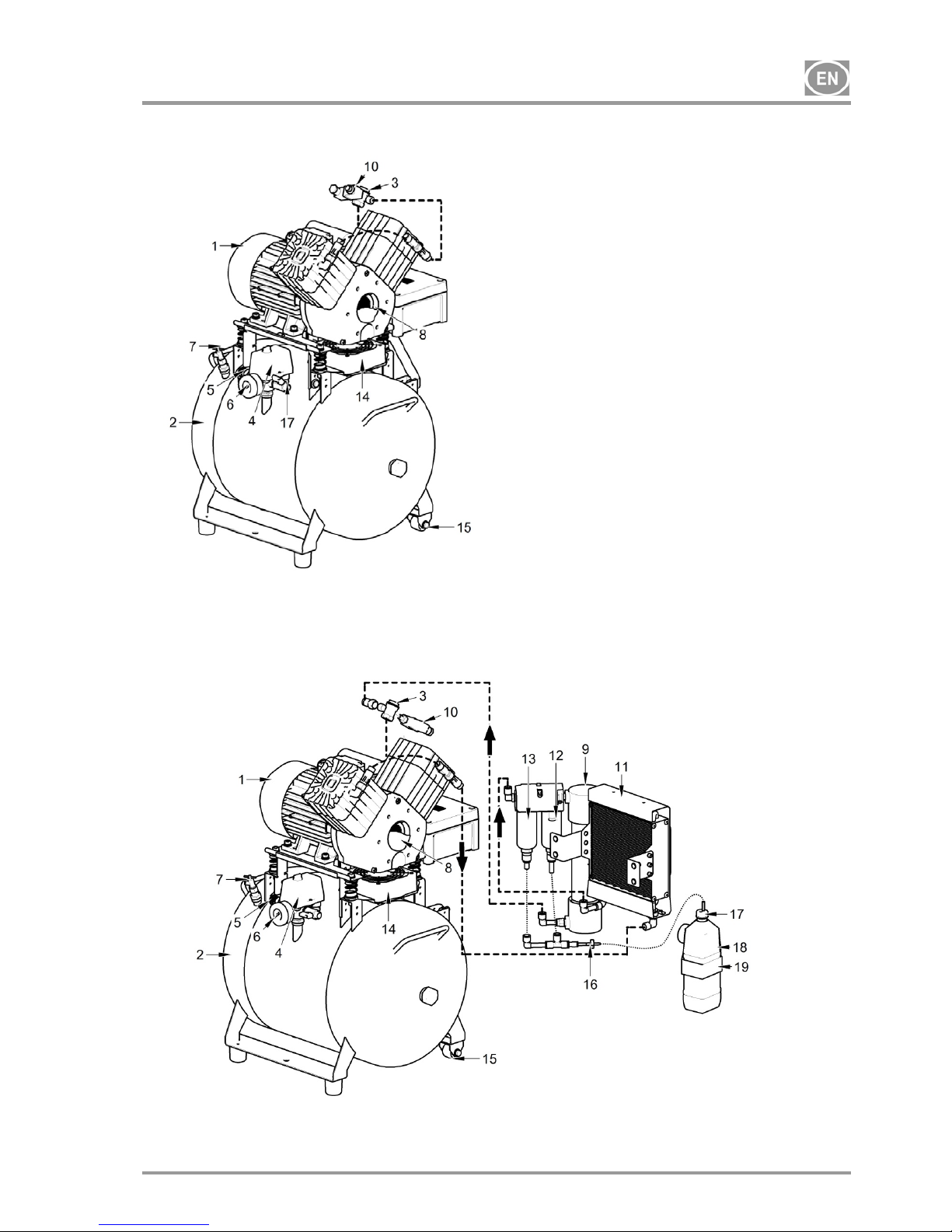

Compressor (Fig.1)

The compressor (1) draws in air through a filter (8) and compresses it through a check valve (3) into an air

tank (2). The connected apparatus draws the compressed air from the air tank until the pressure drops to a

default preset level on the air-pressure switch (4) switching the compressor on. The compressor again

compresses air into the nozzle until the maximum pressure is reached and the compressor switches off.

After compressor aggregate is switched off, pressure hose shall be pressure-release solenoid valve (10).

Safety valve (5) prevents the pressure in air chamber from rising above the maximal allowed value. The

drain valve (7) releases the condensate from the air nozzle. Compressed, clean air free from oil traces is

stored in the air tank ready for use.

Compressor with membrane dryer (Fig.3)

The compressor unit (1) pulls in outside air through the inlet filter (8) and compresses it through the cooler

(11), filter (13) and micro-filter (12) to the dryer (9) and on through the check valve (3) as dry clean air in the

air tank (2). Condensate from the filter and micro-filter is automatically drained into the collection vessel. The

dryer provides continuous drying of the compressed air. Dry, clean compressed air free from oil traces is

stored in the air tank ready for use.

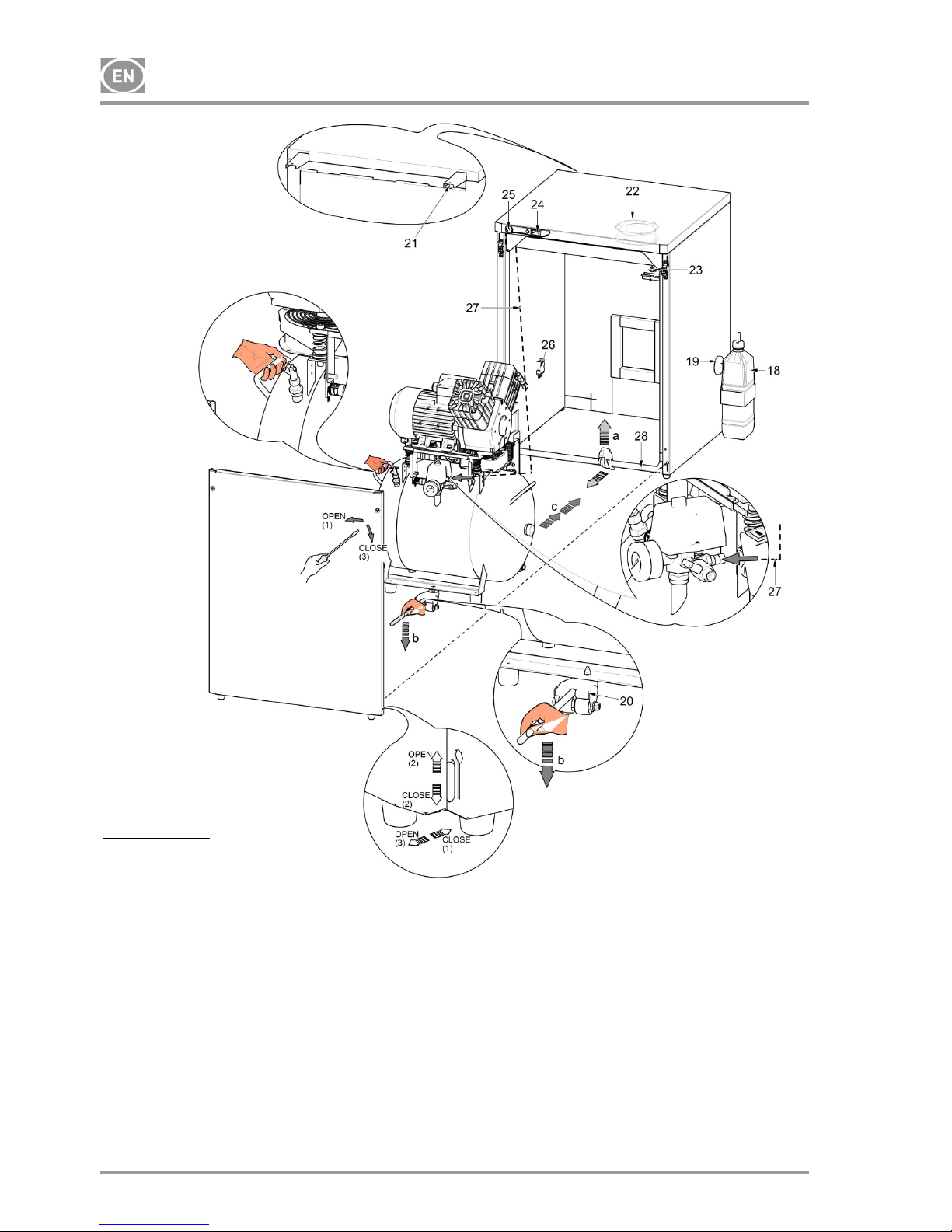

Compressor box (Fig.4)

The soundproof box is compact yet allows sufficient exchange of cooling air. It can be placed in a dentist’s

office. The ventilator (14) under the aggregate of a compressor provides cooling of compressor and it is in

operation at the same time with an engine of the compressor. After a prolonged operation of the compressor,

when temperature in a casing rises above 40°C, the cooling ventilator of the casing (22) shall be switched

on automatically. After the area in housing is cooled down under ca 32°C, the ventilators shall be

automatically switched off.

Make sure that nothing impedes the free flow of air under and around the compressor.

Never cover the hot air outlet on the top back side of the case.

If placing the compressor on a soft floor such as carpet, create space for ventilation

between the base and floor or the box and floor, e.g. underpin the footings with hard pads.

DK50 2V/50

02/2016 - 7 - NP-DK50 2V50-7_02-2016 MD

Fig.1 - Compressor

Fig.2 – Compressor with dryer

1. Compressor motor

2. Air tank

3. Check

valve

4. Pr

essure sw

itch

5. Safet

y

valve

6. Manometer

7. Condenser

ou

tlet

8. Input filter

9. Dr

ye

r

10. Solenoid valve

11. Cooler

12. Micro-filter

13. Filter

14. Compres

sor fan

15. Wheels

16. Check

valve

17. Stopper

18. Bottle

19. Magnetic bottle holder

20. Pulling

system

21. Wall stopper

22. Box fan

23. Thermo

switch

24. Sw

itch

25. Manometer

26.

Connector of casi

ng

27.

Hose of manomet

er

28. Connecting

reinfo

rcement

DK50 2V/50

NP-DK50 2V50-7_02-2016 MD - 8 - 02/2016

Fig.3 - Box

INSTALLATION

8. USE

The appliance must be installed and operated in a dry, well ventilated and dust-free area where ambient

temperature is within the range of +5°C to +40°C and relative air humidity does not exceed 70%. Otherwise,

failure-free operation of the compressor cannot be guaranteed. The compressor must be installed so that it

is accessible at all times for operation and maintenance. Please ensure that the appliance label is

accessible.

The appliance must stand on a flat, sufficiently stable base. See paragraph 5 (Technical data) when

positioning or lifting the compressor.

Compressors cannot be exposed to outdoor environments. The appliance cannot be used in moist or wet

environments. Do not use the compressor in the presence of explosive gases, dust or combustible liquids.

Before connecting the compressor to medical equipment, the supplier must confirm that it meets all

requirements for its use. Refer to the technical data of the product for this purpose. When a unit is to be

built-in, classification and evaluation of compatibility must be done by the manufacturer or supplier of the

product to be used.

Any use other than that described in this manual is not covered by the guarantee, and the manufacturer is

not liable for any damages that may result. The operator/user assumes all risk.

DK50 2V/50

02/2016 - 9 - NP-DK50 2V50-7_02-2016 MD

Unpacking

Handling

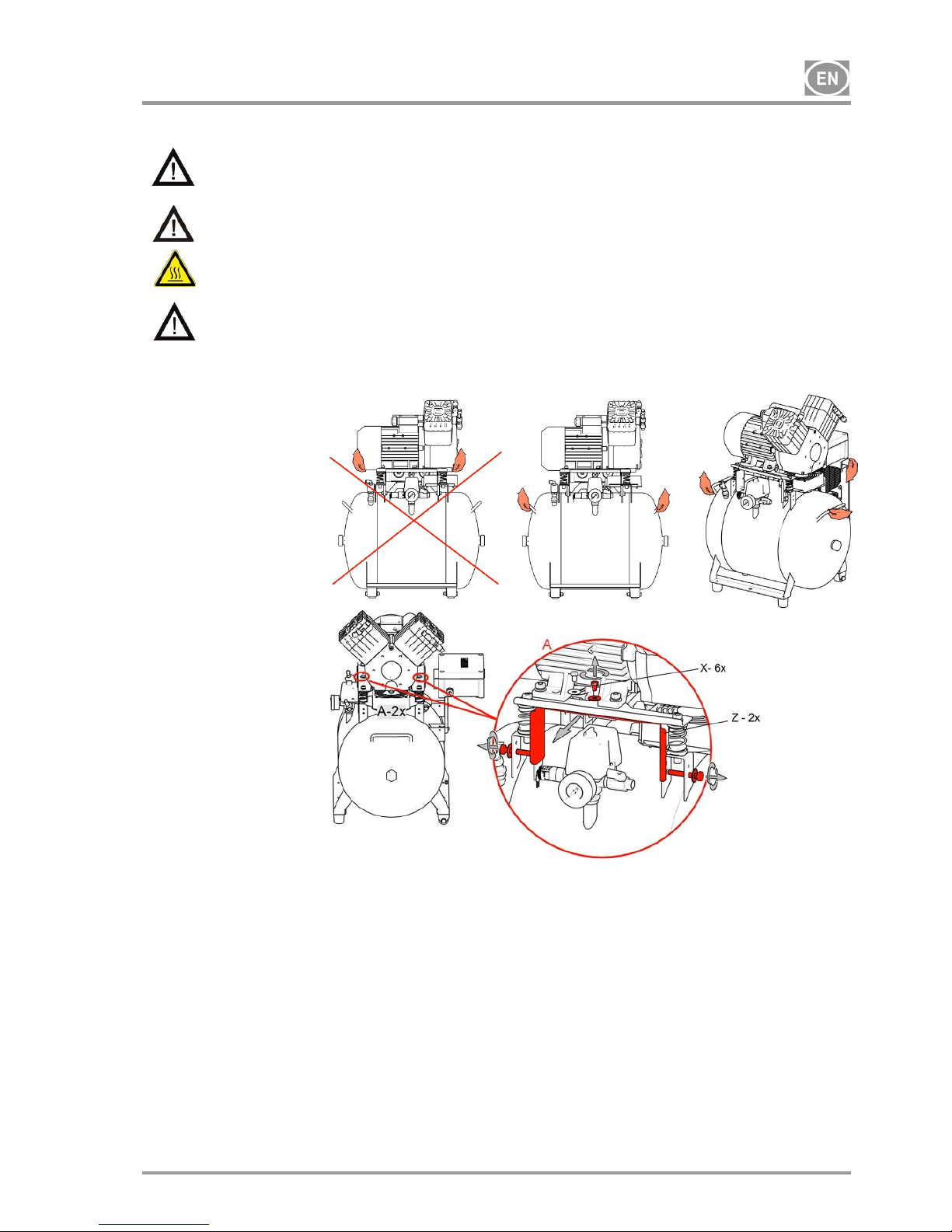

Fig.4

9. INSTALLATION

Only qualified personnel can install and start up the appliance and train operating

personnel in its correct use and maintenance. Installation and training of all operators

shall be confirmed by the installer’s signature on the certificate of installation.

Prior to installation, ensure that the compressor is free of all transport packaging and

stabilizers to avoid any risk of damage to the product.

Caution! When in operation, the compressor is hot. Burns or fire may result if contact is

made by the operator or any flammable material.

Electric cord for connection to electric mains and air hoses may not be broken. The power

cord may not be exposed to pulling, pressure and excessive heat.

9.1. Placement of the compressor

Dental compressor DK50 2V/50, DK50 2V/50/M

(Fig.4)

After removing all packaging material, place the product on the floor and remove stabilization parts Y (Detail

A). Connect output hose with end-piece to the appliance. Plug the mains cord plug into a socket.

Dental compressor in box DK50 2V/50S (Fig.3, Fig.4)

After unpacking, place the product onto the floor in a room, release it from packaging materials and remove

fixation parts (Y) - detail A. Place a wall end stop (21) 2 pcs on compressor casing in the rear, upper part of

the casing and fit in the casing on the required place.The end-stops shall ensure the sufficient distance of the

casing from the wall for thorough ventilation. For fitting the compressor in the place to the casing it is

necessary to disassemble the casing door and take off the connecting reinforcement (28) in the front bottom

part of the casing. Protrude the pressure hose under the casing and fix it to the appliance in a suitable

manner. Grasp the compressor at its handle and using the transport mechanism (20) and the built-in

castors (15) place it to the casing. Embed the hose (27) of manometer (25) of the casing to fast-on coupling

on the compressor, place back the connecting reinforcement (28) and connect output pressure hose to the

compressor.

Connect the connector (26) of casing to the compressor and connect the electric mains plug to mains socket.

DK50 2V/50

NP-DK50 2V50-7_02-2016 MD - 10 - 02/2016

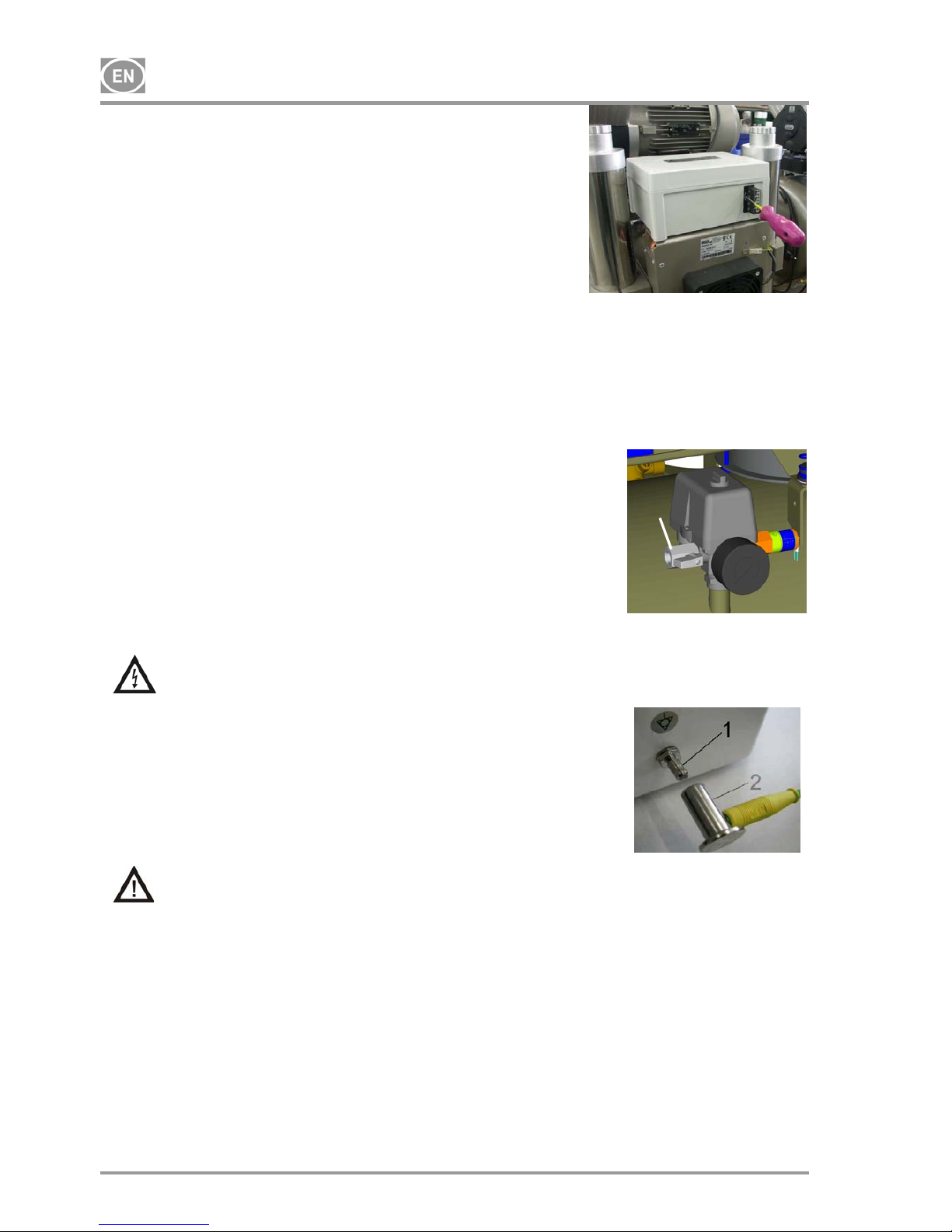

Fig.6

Fig.7

In case of disassembling the compressor it is necessary to

disconnect the connector of soundproofing box by using the

screwdriver.

(

Fig.5)

Dental compressor in DK50 2V/50S/M, (Fig.3, Fig.4)

After removing all packaging material, place the product on the floor and remove stabilization parts Y (Detail

A). Place the compressor into housing similarly as in the previous paragraph. Prior to placing the

compressor into housing, protrude house for condensate drain via hole in housing and connect it to a bottle

(18). Magnetic holder (19) with a vessel (18), for entrapping the condensate from the dryer may be fitted

onto any vertical part of casing, or from front on its door. When fixing the holder with a vessel at the housing

side it is necessary to consider a space of at least 11 cm between the housing and furniture. Distance

smaller than the specified one may cause problem with handling of the vessel.

9.2. Compressed air outlet

(Fig.6)

Lead the pressure hose from the output of compressed air (1) to the

appliance – dental set.

9.3. Electrical connection

Plug the electrical cord into the mains.

The appliance is equipped with a grounded plug. Make sure this connection complies

with local electrical codes. The mains voltage and frequency must comply with the data

stated on the appliance label.

(Fig.7)

Keep the socket easily accessible to ensure that in an emergency the

appliance can be safely disconnected from the mains.

Connection to the power distribution box must be max.16 A.

The connection of the earth ground pin 6mm (1) with other

appliances must be completed in accordance with local electrical

codes. The female socket (2), which is not included in the standard

set, is an optional accessory.

Electrical cable may not contact the hot parts of a compressor. Insulation could be

damaged!

If any electrical cord or air hose is damaged it must be replaced immediately.

Fig.5

Loading...

Loading...