EKOM DK50-10 Series, DK50-10 S/M, DK50-10 Z/K, DK50-10 S, DK50-10 Z User Manual

...

DK50-10

EN

User manual

DE

Benutzerhandbuch

FR

RU

Manuel de l’utilisateur

Руководство пользователя

PL

SK

Instrukcja obsługi

Návod na použitie

CS

Návod k použití

CONTENTS................................. 2

INHALT....................................... 30

SOMMAIRE................................ 58

СОДЕРЖАНИЕ.......................... 86

SPIS TREŚCI.............................. 114

OBSAH………............................. 142

OBSAH………............................. 170

Ed. - 1

08/2017 - 1 - NP-DK50-1_08-2017-MD

DK50-10

CONTENTS

IMPORTANT INFORMATION ................................................................................................................. 3

1. CE MARKING ............................................................................................................................ 3

2. WARNINGS ................................................................................................................................ 3

3. WARNINGS AND SYMBOLS ..................................................................................................... 4

4. STORAGE AND TRANSPORT ................................................................................................... 5

5. TECHNICAL DATA ..................................................................................................................... 6

6. PRODUCT DESCRIPTION ......................................................................................................... 9

7. PRODUCT FUNCTIONALITY ................................................................................................... 11

8. PNEUMATIC SCHEMATIC ....................................................................................................... 15

OPERATION .......................................................................................................................................... 16

9. SWITCHING THE COMPRESS OR ON ................................................................................... 16

INSTALLATION ..................................................................................................................................... 17

10. CONDITIONS FOR USE .......................................................................................................... 17

11. PLACEMENT OF THE COMPRESSOR ................................................................................... 18

12.PNEUMATIC CONNECTIONS ................................................................................................. 19

13. ELECTRICAL CONNECTIONS ................................................................................................ 19

14. CONNECTION SCHEMATIC .................................................................................................... 20

15. COMMISSIONING .................................................................................................................... 22

16. SWITCHING THE COMPRESSOR ON .................................................................................... 22

17. COMPRESSOR SHUT-DOWN ................................................................................................. 22

MAINTENANCE .................................................................................................................................... 23

18.EQUIPMENT MAINTENANCE ................................................................................................. 23

TROUBLESHOOTING .......................................................................................................................... 28

19.REPAIR SERVICE .................................................................................................................... 29

20.STORAGE ................................................................................................................................. 29

21.DISPOSING OF THE APPLIANCE ........................................................................................... 29

ANNEX ................................................................................................................................................ 198

22.INSTALLATION RECORD ...................................................................................................... 198

NP-DK50-1_08-2017-MD - 2 - 08/2017

DK50-10

IMPORTANT INFORMATION

1. CE MARKING

Products labeled with the CE mark of compliance meet the safety guidelines (93/42/EEC) of the European

Union.

2. WARNINGS

The product is designed and manufactured to be safe for the user and its surrounding environment when

used in the defined manner. Keep the following warnings in mind. This keeps risks to a minimum.

2.1. General warnings

The user manual aids in correct installation, operation and maintenance of the product. It is included with

the product and must be kept close to it at all times. Careful review of this manual will provide the

information necessary for correct operation of the product.

Original packaging should be kept for the return of the equipment. Only the original packaging ensures

protection of the equipment during transport. If it is necessary to return the product during the warranty

period, the manufacturer is not liable for damages caused by improper packaging.

This warranty does not cover damages originating from the use of accessories or consumables other

than those specified or suggested by the manufacturer.

The manufacturer only guarantees the safety, reliability and function of the equipment if:

- installation, new settings, changes, expansion and repairs are performed by the manufacturer or a

service provider authorized by the manufacturer.

- the product is used pursuant to the user manual.

The user manual corresponds to the configuration of the product and its compliance with applicable

safety and technical standards at the time of its printing. The manufacturer reserves all rights for the

protection of its configuration, methods and names.

Translation of the user manual is performed in accordance with the best available knowledge. The

Slovak version is to be used in the event of any uncertainties.

2.2. General safety warnings

The manufacturer designed and manufactured the product to mitigate all risks when used correctly. Please

note the following safety measures to mitigate residual risks.

Use and operation of the product must comply with all local codes and regulations. The operator and

user are responsible for following all appropriate regulations in the interests of performing work safely.

Only the use of original parts guarantees the safety of operating personnel and flawless operation of the

product itself. Only accessories and parts mentioned in the technical documentation or expressly

approved by the manufacturer may be used.

The operator must ensure the equipment is functioning correctly and safely before every use.

The user must fully understand the operation of the equipment.

Do not use the product in explosive environments.

The user must inform the supplier immediately if any problem occurs during use of the equipment.

08/2017 - 3 - NP-DK50-1_08-2017-MD

DK50-10

2.3. Electrical system safety warnings

The equipment may only be connected to a properly installed socket connected to earth (grounded).

Before the product is plugged in, make sure that the mains voltage and frequency stated on the product

are the same as the power mains.

Check for any damage to the connected compressed air system and electrical circuit before use.

Replace damaged pneumatic and electrical conductors immediately.

Immediately disconnect the product from the mains (remove the power cord from the socket) in

hazardous situations or when a technical malfunction occurs.

Ensure the following during any maintenance and repairs:

- the mains plug is pulled out from the power socket

- pressure is vented from the compressed air lines and the air tank

Only a qualified technician may install the product.

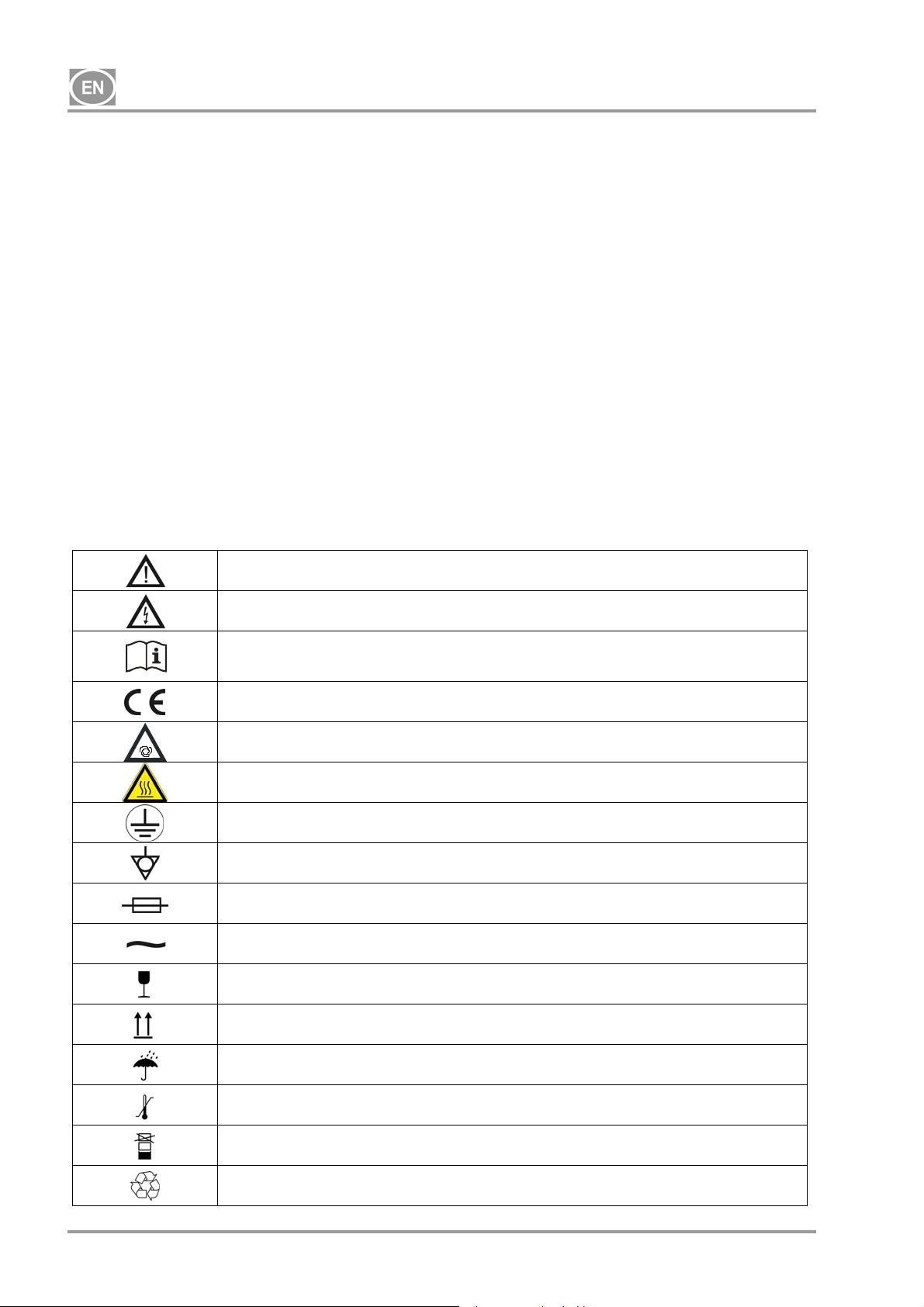

3. WARNINGS AND SYMBOLS

The following labels and symbols are used in the user manual and on the equipment and its packaging to

indicate important details and information:

Information, instructions and cautions for the prevention of damage to health or

materials

Caution! Dangerous electric voltage

Read the user manual!

CE mark of compliance

Caution! Hot surface

Compressor is remote-controlled and may start without warning

Earth (ground) connection

Terminal for ground connection

Fuse

Alternating current

Handling mark on package – FRAGILE

Handling mark on package – THIS SIDE UP

NP-DK50-1_08-2017-MD - 4 - 08/2017

Handling mark on package – KEEP DRY

Handling mark on package – TEMPERATURE LIMITATIONS

Handling mark on package – LIMITED STACKING

Mark on package – RECYCLABLE MATERIAL

DK50-10

4. STORAGE AND TRANSPORT

The compressor is shipped in cardboard that protects the appliance from damage during transport.

Caution! For transport, always use the original packaging and secure the compressor in

the upright position.

Protect the compressor from humidity and extreme temperatures during transport and storage. A

compressor in its original packaging can be stored in a warm, dry and dust-free area. Do not

Ambient conditions for storage and transport

Products may only be stored and transported in vehicles that are free of any traces of volatile chemicals

under the following conditions:

store near any chemical substances.

Keep packaging material if possible. If not, please dispose of the packaging material in an

environmentally friendly way and recycle if possible.

Caution! Before moving or transporting the compressor, release all the air pressure from

the tank and hoses and drain the condensed water.

Temperature: –25°C to +55°C, 24 h at up to +70°C

Relative humidity: 10% to 90% (non-condensing)

08/2017 - 5 - NP-DK50-1_08-2017-MD

DK50-10

5. TECHNICAL DATA

Compressors are designed for dry and ventilated indoor environments with the following conditions:

Temperature : +5°C až +40°C,

Max. relative humidity.: 70%,

Max. absolute humidity. 15 g/m

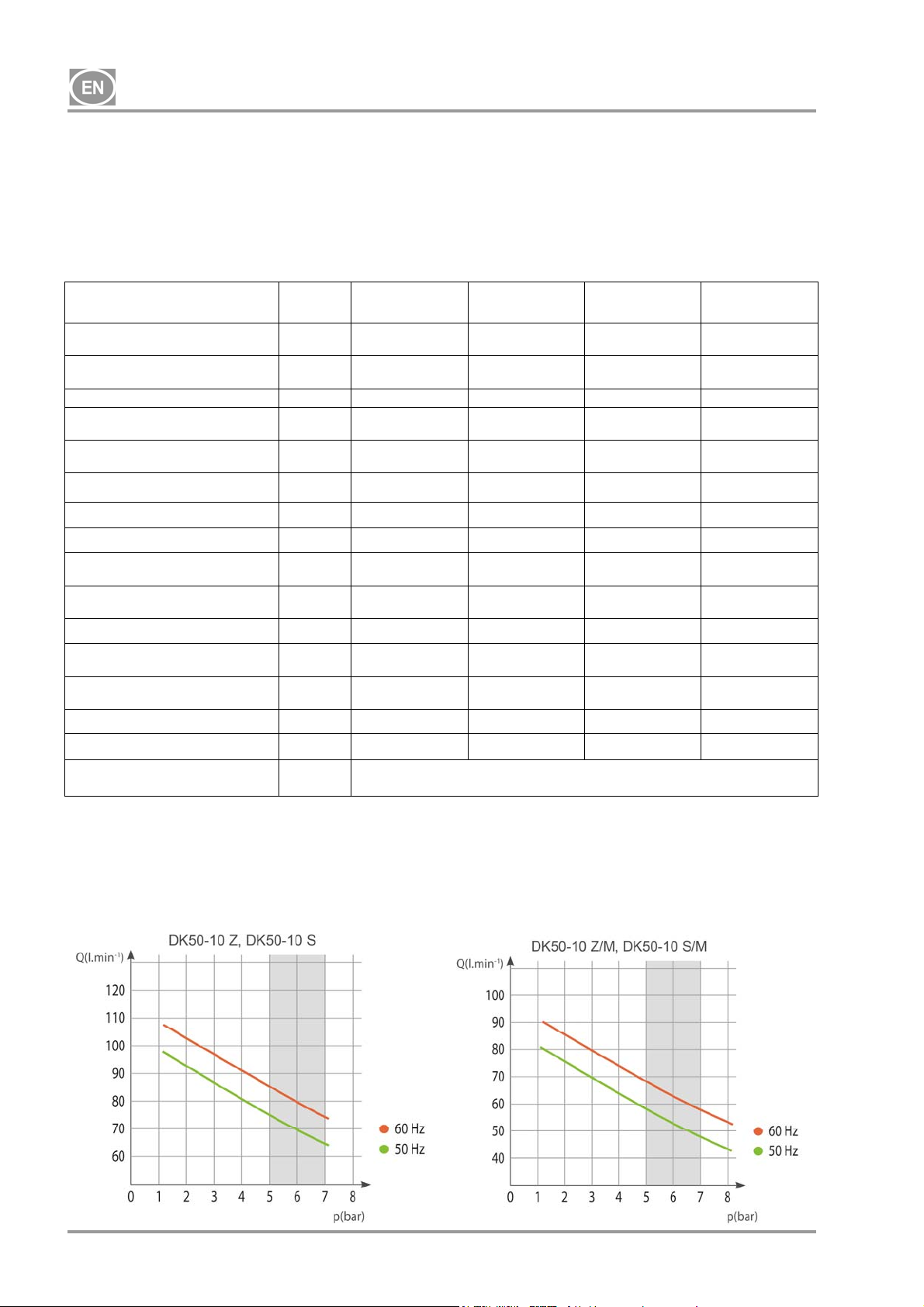

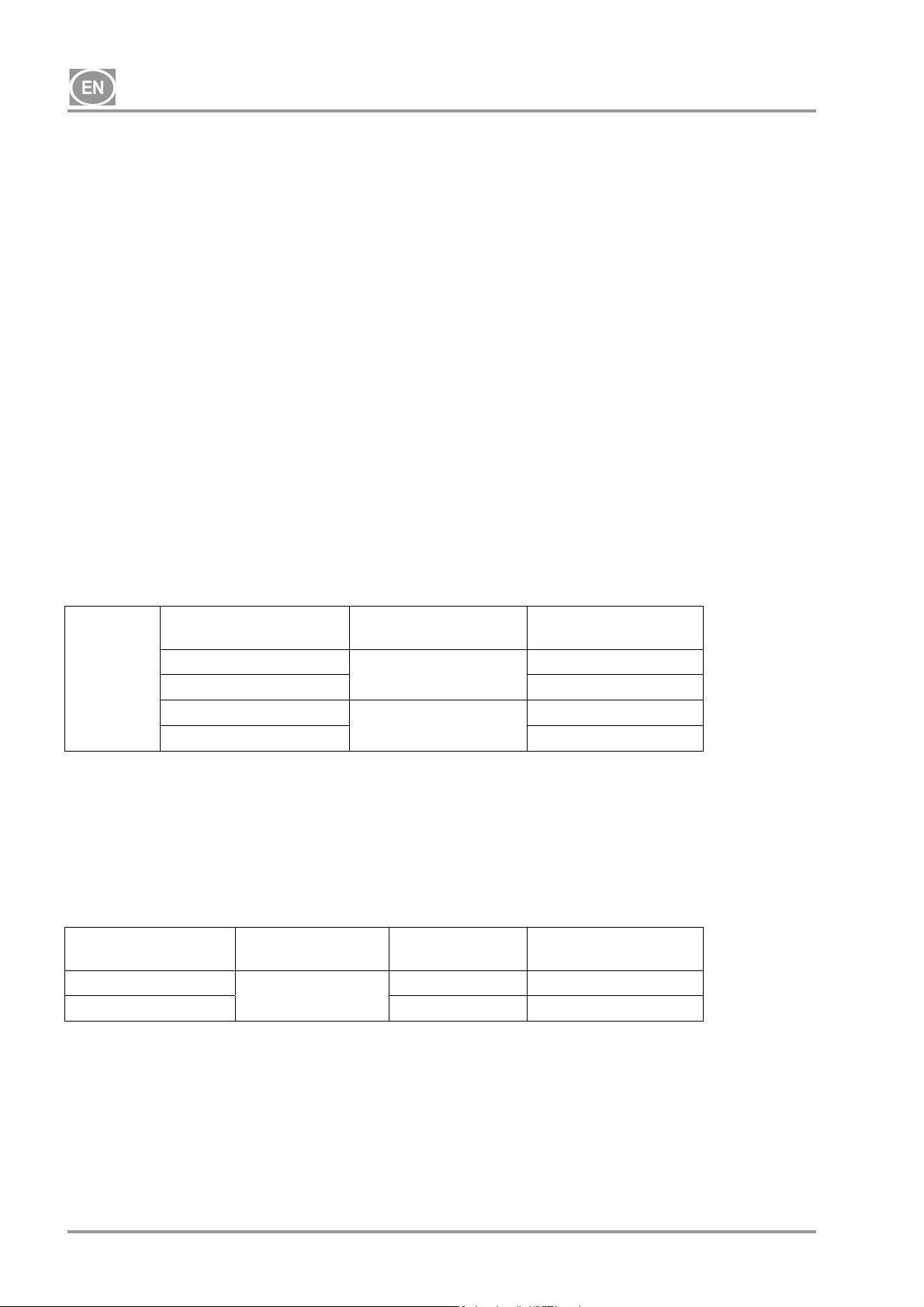

Tab.1

3

5 – 7 bar

Nominal voltage / frequency (*) V / Hz

Output

at 5 bar

Working pressure (**) bar 5.0 – 7.0 5.0 – 7.0 5.0 – 7.0 5.0 – 7.0

Output with KJF-1

at 5 bar

Max. current A

Motor output kW 0.55 0.55 0.55 0.55

Air tank volume Lit. 10 10 10 10

Air quality – filtration

Maximum operating pressure of

safety valve

Noise level at 5 bar LpfA [dB]

Operating mode 100% - S 1 100% - S 1 100% - S 1 100% - S 1

PDP - drying performance at 7

bar

Time to fill air tank from 0 to 6

bar

Dimensions (net) w x d x h mm 485x350x553 580x440x655 544x350x553 649x440x655

Net weight kg 38 (***) 53 (***) 44

Configuration per

EN 60601-1

Lit.min-1

Lit.min-1

m

bar 8.0 8.0 8.0 8.0

- -

s

Type B, class I.

DK50-10 Z DK50-10 S DK50-10 Z/M

230 / 50/60

115 / 60

75 / 85

85

75 / 85

85

3.8 / 4.8

9.5

- - 0.3 0.3

65 / 66.5

66.5

50 / 44

44

230 / 50/60

115 / 60

75 / 85

85

75 / 85

85

3.8 / 4.8

9.5

49.5 / 51

51

50 / 44

44

230 / 50/60

115 / 60

58 / 68

68

- -

4.1 / 5.1

10

67 / 68.5

68.5

+3°C

70/60

60

DK50-10 S/M

230 / 50/60

115 / 60

58 / 68

68

4.1 / 5.1

10

51.5 / 53

53

+3°C

70/60

60

61

Notices:

(*) When ordering, state the version of compressor

(**) Range of pressure: consult with contractor

(***) Weight of compressors with a KJF1 unit _add 3 kg

(****) The permitted operating pressure of the safety valve can also be set to another value, e.g. 9 bar /

the setting shall be specified in the order.

NP-DK50-1_08-2017-MD - 6 - 08/2017

DK50-10

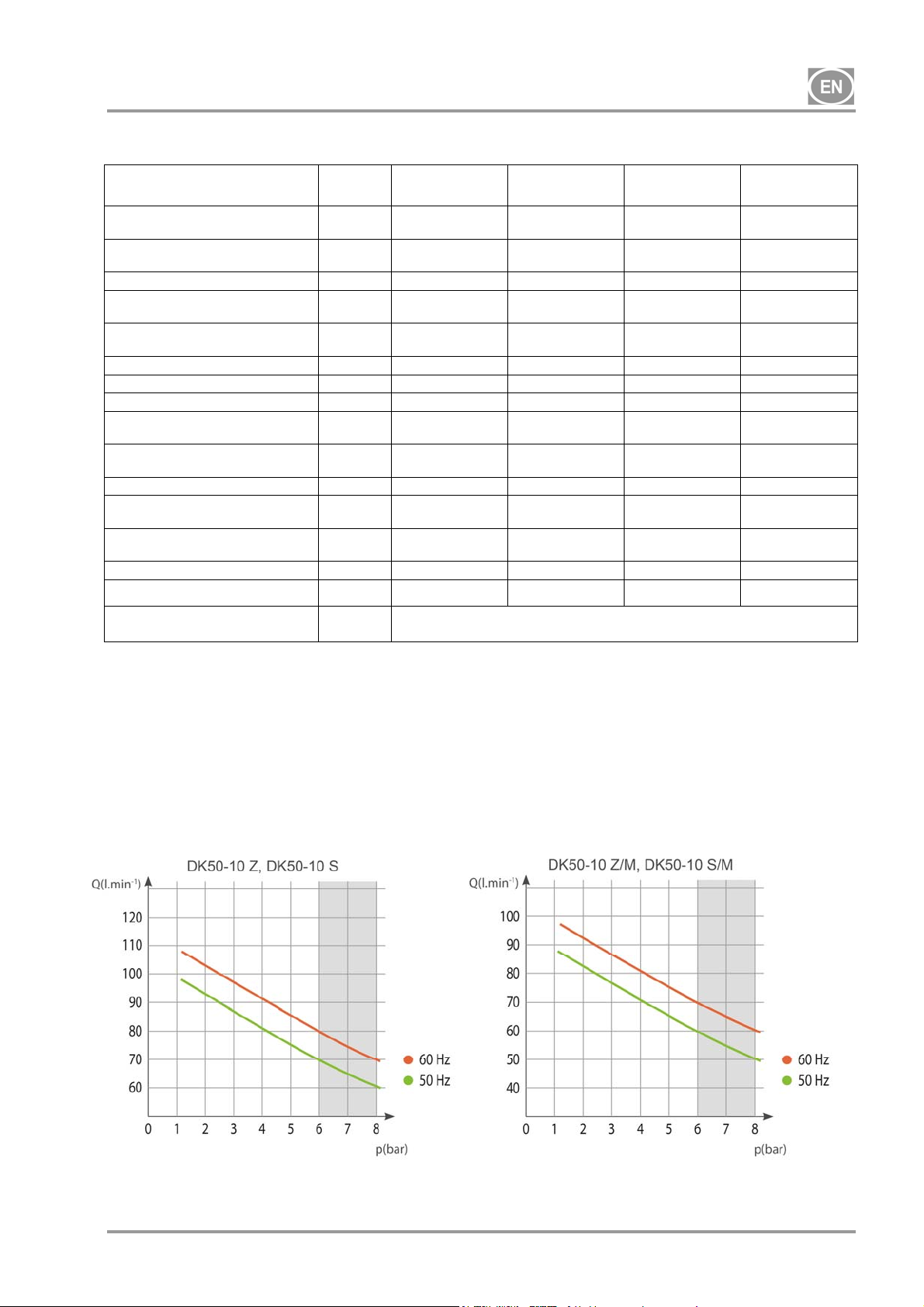

Tab. 2

6 – 8 bar

Nominal voltage / frequency (*) V / Hz

Output

at 6 bar

Working pressure (**) bar 6.0 – 8.0 6.0 – 8.0 6.0 – 8.0 6.0 – 8.0

Output with KJF-1

at 6 bar

Max. current A

Motor output kW 0.55 0.55 0.55 0.55

Air tank volume 10 10 10 10

Air quality – filtration

Maximum operating pressure of

safety valve

Noise level at 5 bar LpfA [dB]

Operating mode

PDP drying performance at 7

bar

Time to fill air tank from 0 to 7

bar

Dimensions (net) w x d x h mm 485x350x553 580x440x655 544x350x553 649x440x655

Net weight kg 38 (***) 53 (***) 44

Configuration per

EN 60601-1

Lit.min-1

Lit.min-1

m

bar 12.0 12.0 12.0 12.0

- -

s

DK50-10 Z DK50-10 S DK50-10 Z/M

230 / 50/60

115 / 60

70 / 80

80

70 / 80

80

3.9 / 4.9

9.8

- - 0.3 0.3

65 / 66.5

66.5

100% - S 1 100% - S 1 100% - S 1 100% - S 1

60 / 51

51

230 / 50/60

115 / 60

70 / 80

80

70 / 80

80

3.9 / 4.9

9.8

49.5 / 51

51

60/51

51

Type B, class I.

230 / 50/60

115 / 60

60 / 70

70

- -

4.1 / 5.1

10.2

67 / 68.5

68.5

+3°C

72/61

61

DK50-10 S/M

230 / 50/60

115 / 60

60 / 70

70

4.1 / 5.1

10.2

51.5 / 53

53

+3°C

72/61

61

61

Notices:

(*) When ordering, state the version of compressor

(**) Range of pressure: consult with contractor

(***) Weight of compressors with a KJF1 unit _add 3 kg

(****) The permitted operating pressure of the safety valve can also be set to another value, e.g. 9 bar /

the setting shall be specified in the order.

08/2017 - 7 - NP-DK50-1_08-2017-MD

DK50-10

Tab. 3

8 – 10 bar

Nominal voltage / frequency (*) V / Hz

Output

at 8 bar

Working pressure (**) bar 8.0 – 10.0 8.0 – 10.0 8.0 – 10.0 8.0 – 10.0

Output with KJF-1

at 8 bar

Max. current A

Motor output kW 0.55 0.55 0.55 0.55

Air tank volume 10 10 10 10

Air quality – filtration

Maximum operating pressure of

safety valve

Noise level at 5 bar LpfA [dB]

Operating mode

PDP drying performance at 7

bar

Time to fill air tank from 0 to 9

bar

Dimensions (net) w x d x h mm 485x350x553 580x440x655 544x350x553 649x440x655

Net weight kg 38 (***) 53 (***) 44

Configuration per

EN 60601-1

Lit.min-1

Lit.min-1

m

bar 12.0 12.0 12.0 12.0

- -

s

DK50-10 Z DK50-10 S DK50-10 Z/M

230 / 50/60

115 / 60

60 / 70

70

60 / 70

70

4.1 / 5.1

10.2

- - 0.3 0.3

65 / 66.5

66.5

100% - S 1 100% - S 1 100% - S 1 100% - S 1

85/75

75

230 / 50/60

115 / 60

60 / 70

70

60 / 70

70

4.1 / 5.1

10.2

49.5 / 51

51

85/75

75

Type B, class I.

230 / 50/60

115 / 60

50 / 60

60

- -

4. / 5.3

10.5

67 / 68.5

68.5

+3°C

96/82

82

DK50-10 S/M

230 / 50/60

115 / 60

50 / 60

60

4.4 / 5.4

10.5

51.5 / 53

53

+3°C

96/82

82

61

Notices:

(*) When ordering, state the version of compressor

(**) Range of pressure: consult with contractor

(***) Weight of compressors with a KJF1 unit _add 3 kg

(****) The permitted operating pressure of the safety valve can also be set to another value, e.g. 9 bar /

the setting shall be specified in the order.

NP-DK50-1_08-2017-MD - 8 - 08/2017

DK50-10

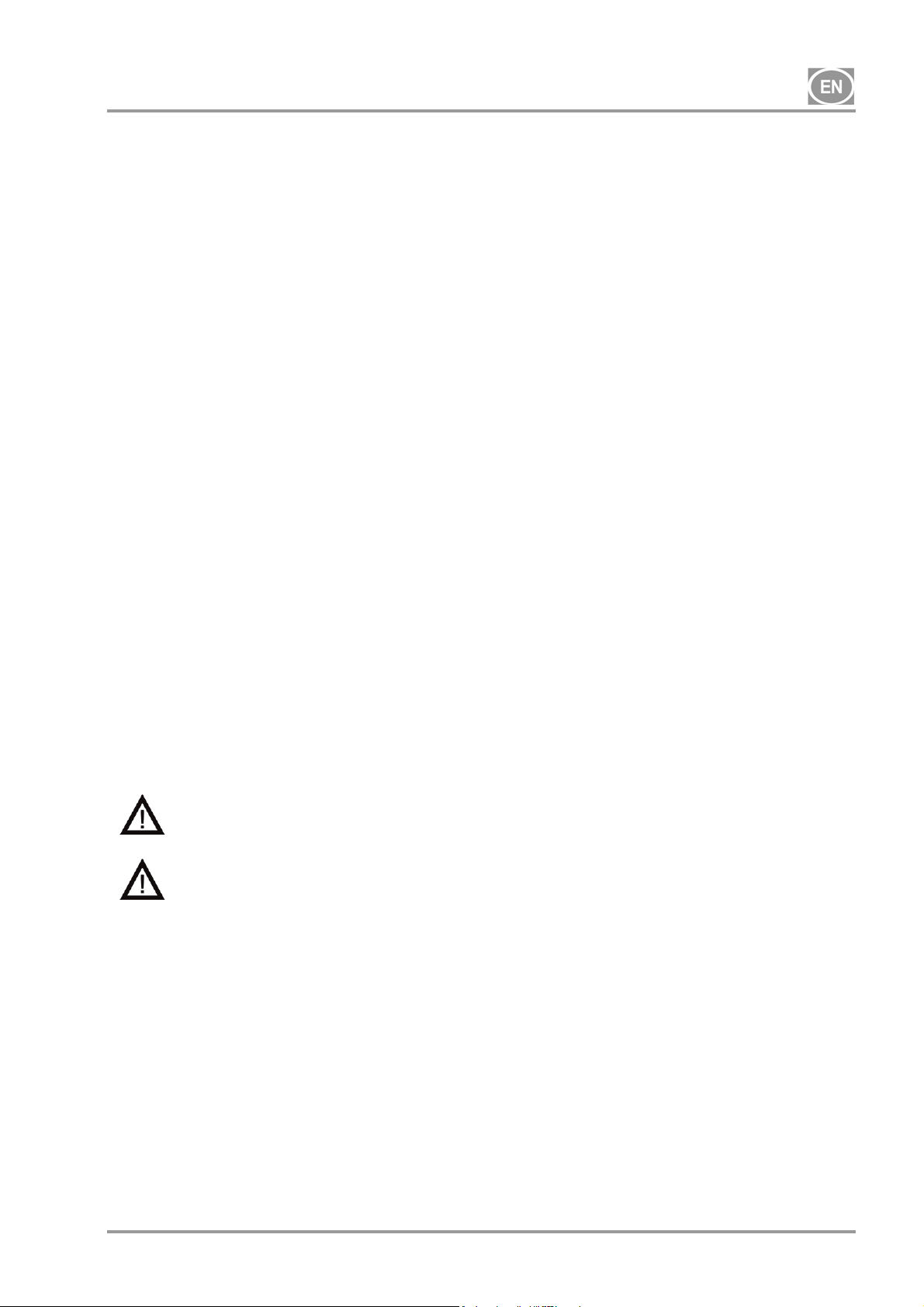

5.1. Free air delivery (FAD) correction due to elevation

FAD correction table

Elevation [mamsl] 0 - 1500 1501 - 2500 2501 - 3500 3501 - 4500

FAD [l/min] FAD x 1 FAD x 0.8 FAD x 0.71 FAD x 0.60

FAD output related to conditions:

Elevation: 0 MASL Temperature : 20°C

Atmospheric pressure : 101325 Pa Relative humidity : 0%

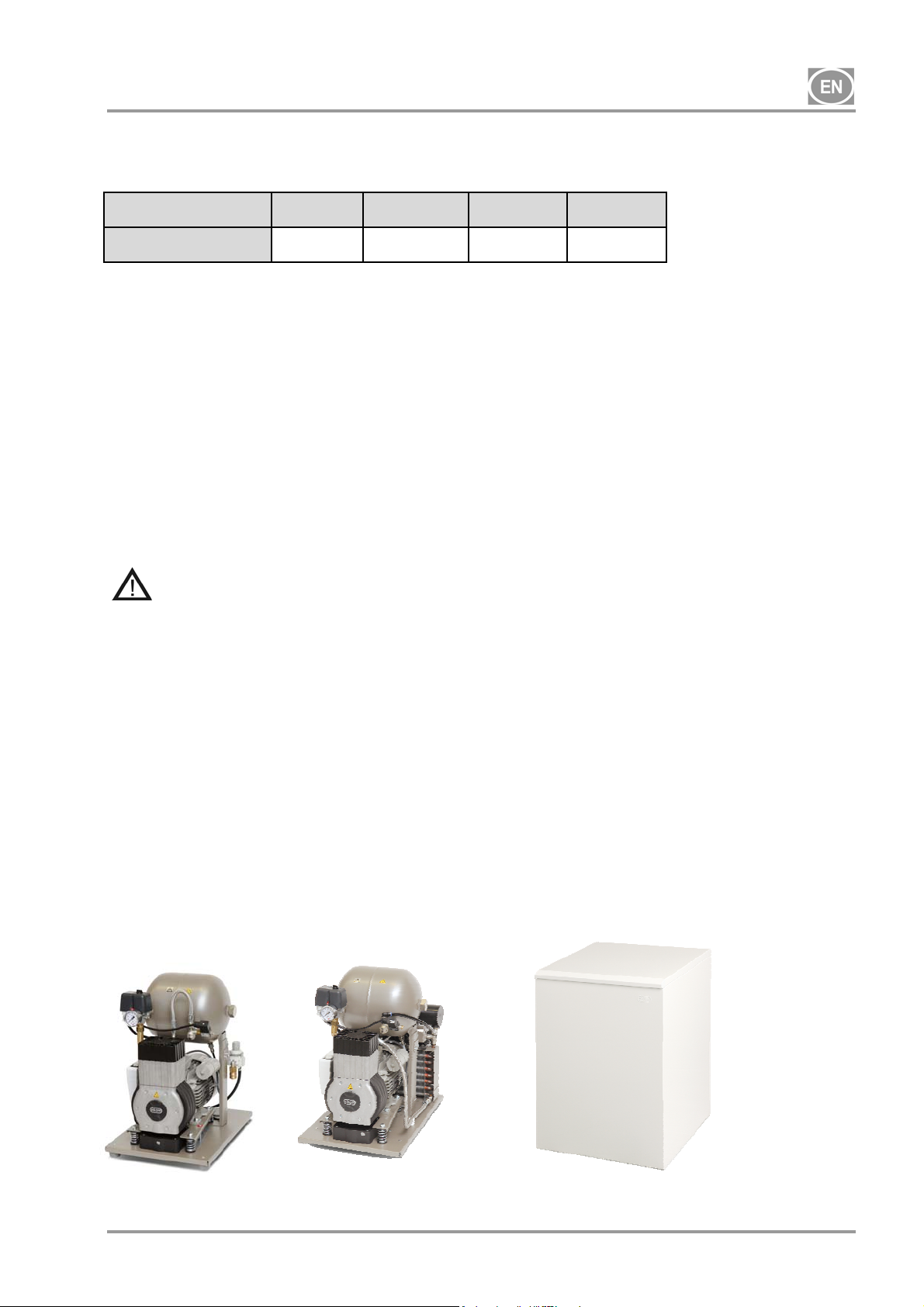

6. PRODUCT DESCRIPTION

6.1. Model variations and their uses

The compressor is used as a source of clean, oil-free compressed air to power dental equipment,

instruments and devices in laboratories where the parameters and properties of the compressed air are

suitable to the specific application.

Compressed air supplied by the compressor is unsuitable for use with artificial lung

ventilation devices without further filtration

Any use of the equipment outside the framework defined herein is considered inappropriate use. The

manufacturer is not liable for any damages or injury occurring as a result of inappropriate use.

6.2. Description

Compressor models are designed for the following uses:

DK50-10 Z compressor - a base-mounted compressor for stand-alone installation in a given space

DK50-10 Z/K compressor - a base-mounted compressor with a condensate and filtration unit (KJF1)

DK50-10 Z/M compressor - a base-mounted compressor with an air dryer

DK50-10 S compressor - an enclosed compressor with effective noise dampening for in-office installations

DK50-10 S/K compressor - an enclosed compressor with a condensate and filtration unit (KJF1)

DK50-10 S/M compressor - an enclosed compressor with an air dryer

DK50-10 Z

DK50-10 Z/M

DK50-10 S

DK50-10 S/M

08/2017 - 9 - NP-DK50-1_08-2017-MD

DK50-10

6.3. Accessories

Accessories not included in the standard order must be ordered separately!

6.3.1 Automatic condensate drain

The automatic condensate drain (AOK) automatically drains condensate from the compressor’s air tank

based on a pre-set time interval. The condensate drain (AOK) is a suitable accessory for compressor

models without dryers.

6.3.2 Set of filters

Compressors may be equipped with a set of filters on the compressed air outlet if specified. The set of filters

may be equipped with a pressure regulator. Sets of filters are suitable accessories for all the compressors

specified above.

NOTE : If a higher level of air filtration is required, this specification must be agreed upon with the supplier

and made clear in the order.

Level of filtration Pressure regulator Kit article no.

SET OF

FILTERS

6.3.3 Condensation and filtration unit (KJF)

The compressor may additionally be fitted with a condensation and filtration unit (KJF-1 or KJFR-1). The

KJF-1 or KJFR-1 ensure that the compressed air from the air tank is cooled in the cooler and the

condensate is captured in the filter and automatically separated from the compressed air circuit. The

compressed air is filtered at the same time.

Condensation and

filtration unit

KJF-1

KJFR-1 Yes 450001011-002

-

5µm 604013233-000

0,3µm

0,01µm 604013235-000

Level of filtration

5µm

Yes

No

Pressure

regulator

No 450001011-001

604013245-000

604013234-000

Kit article no.

NP-DK50-1_08-2017-MD - 10 - 08/2017

DK50-10

7. PRODUCT FUNCTIONALITY

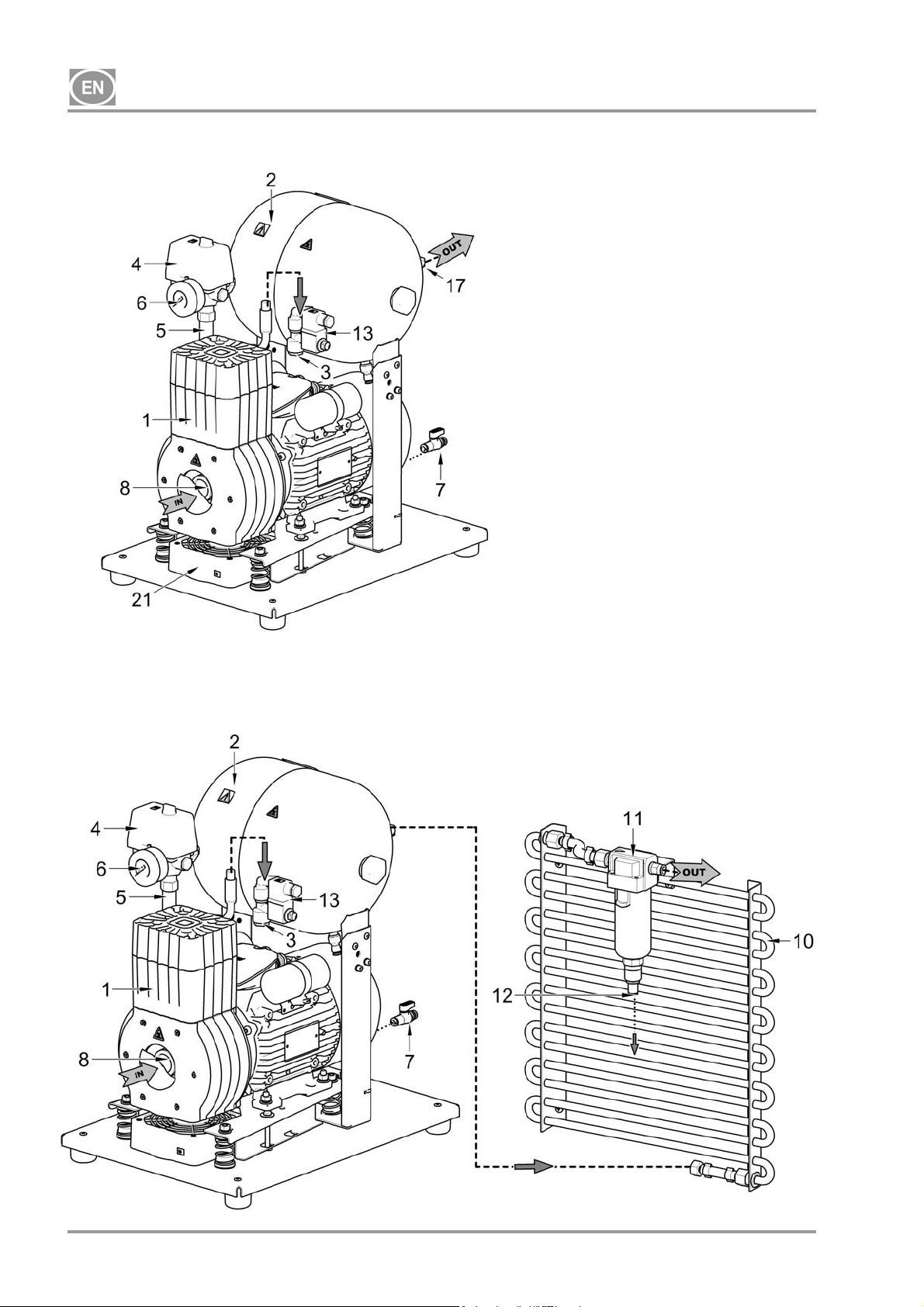

Compressor (Fig. 1)

The compressor aggregate (1) draws in air through an inlet filter (8) and compresses it through a check

valve (3) into an air tank (2) from which the appliance draws compressed air. If the pressure in the air tank

drops to the switching pressure, the pressure switch (4) turns on the compressor and the compressor

supplies compressed air to the air tank until it reaches the switch off pressure, at which time the compressor

switches off. The pressure hose is vented through the relief solenoid valve (13) once the compressor unit is

shut off. The safety valve (5) prevents the pressure in the air tank from rising above the maximum allowed

value. The drain valve (7) drains condensate from the air tank. Compressed, oil-free filtered air is stored in

the air tank ready for use.

Condensate must be drained from the air tank at regular intervals (see Chapter 18).

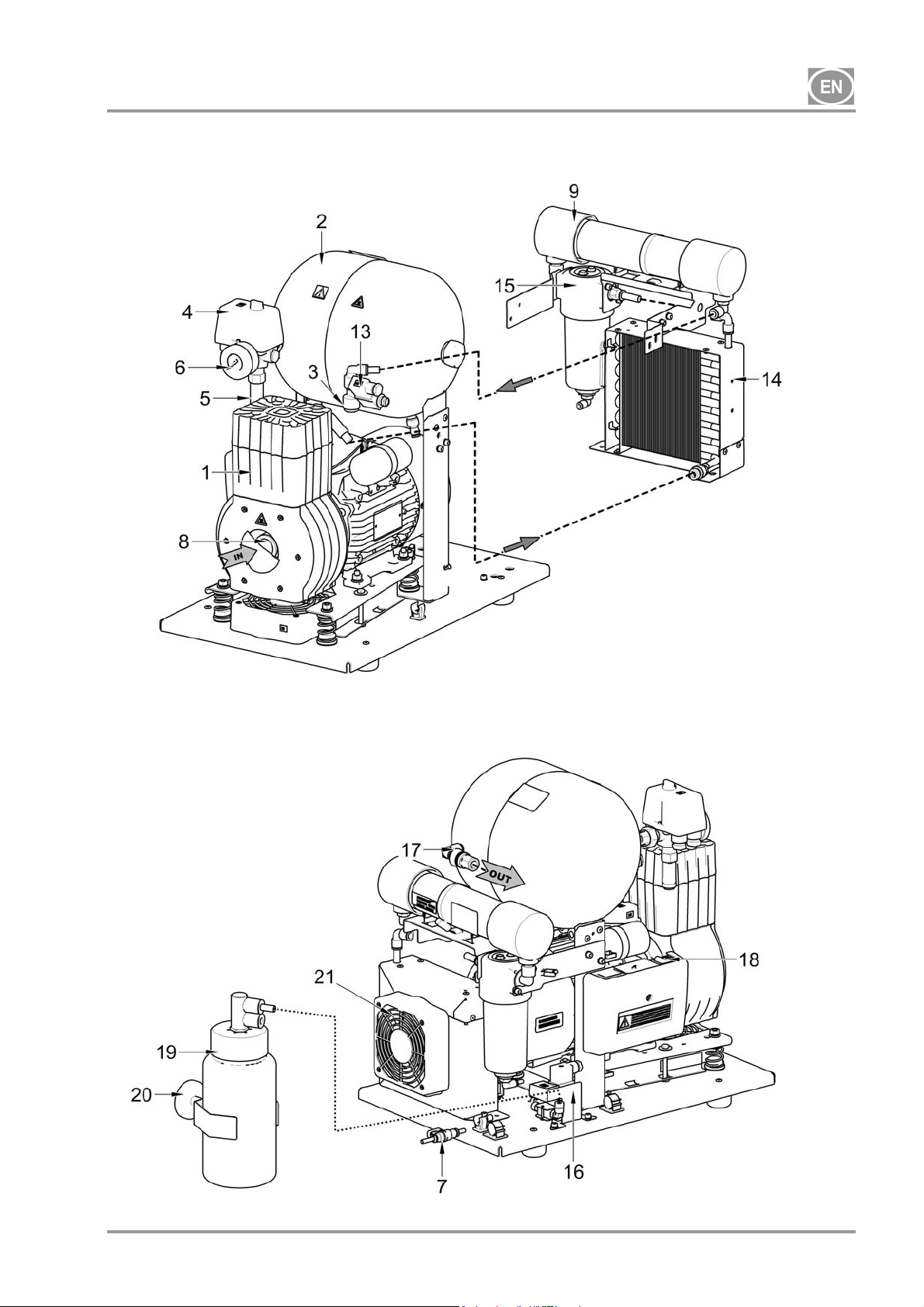

Compressor with membrane dryer. (Fig. 3)

The compressor aggregate (1) draws in air through an inlet filter (8) and compresses it, feeding it to the

cooler (14) through the filter (15) to the dryer (9) and the dry, clean air is then fed through the check valve

(3) into the air tank (2). A portion of the air bypasses the dryer with the captured moisture, which is

manifested as a gentle stream of air along the body of the dryer (9). Condensate from the filter is

automatically drained at regular intervals into the vessel via the condensate drain solenoid valve (16). The

dryer ensures continuous drying of the compressed air. The drain valve (7) drains condensate from the air

tank when drying performance is checked. Compressed, oil-free filtered air is stored in the air tank ready for

use.

The compressor with dryer requires no operator. The pressure vessel does not need to be drained.

Compressor with condensate and filtration unit (Fig. 2)

The compressor aggregate (1) draws in air through an inlet filter (8) and compresses it through a check

valve (3) into an air tank (2). Compressed air from the air tank flows through a cooler (10) that cools the

compressed air. The condensed moisture is trapped in the filter (11) and automatically separates as

condensate (12) into the vessel. Compressed, oil-free filtered air is ready for use.

Condensate must be drained from the air tank at regular intervals (see Chapter 18).

Compressor enclosure

The soundproof enclosure is compact and allows sufficient cooling air exchange. The design makes it

suitable for in-office installations in a way that blends in with other furniture. The fan under the compressor

aggregate ensures sufficient cooling for the compressor and runs with the compressor motor or when the

temperature switch is activated at temperatures above 40 °C.

Make sure that nothing impedes the free flow of air under and around the compressor.

Never cover the hot air outlet on the top back side of the case.

If placing the compressor on a soft floor such as carpet, create space for ventilation

between the base and floor or the box and floor, e.g. underpin the footings with hard

pads.

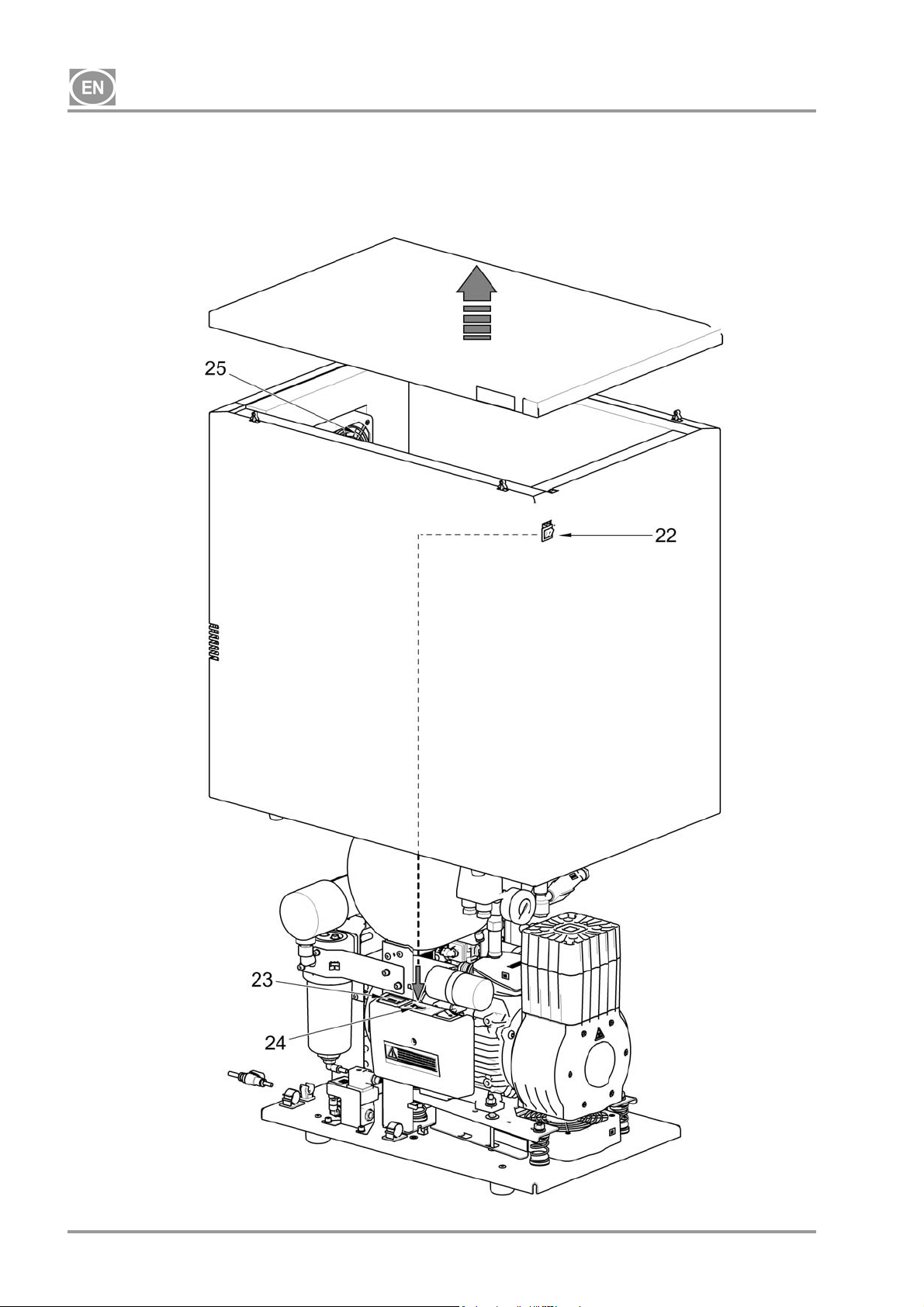

The 10 bar compressor model is equipped with an hour meter (Fig. 4).

08/2017 - 11 - NP-DK50-1_08-2017-MD

DK50-10

Fig. 1 - DK50-10 Z - Compressor

Description for Figures 1-4

1. Compressor aggregate

2. Air tank

3. Check valve

4. Pressure switch

5. Safety valve

6. Pressure gauge

7. Drain valve

8. Inlet filter

9. Dryer

10. Pipe cooler

11. Filter

12. Condensate outlet

13. Solenoid valve

14. Dryer cooler

15. Filter

16. Valve with timer

17. Compressed air outlet

18. Breaker switch

19. Vessel

20. Magnetic bracket

21. Fan

22. Switch

23. Hour Meter

24. Connector

25. Box fan

Fig. 2 – DK50-10 Z/K - Compressor with KJF1 condensate and filtration unit

NP-DK50-1_08-2017-MD - 12 - 08/2017

DK50-10

Fig. 3 - DK50-10 Z/M - Compressor with dryer

08/2017 - 13 - NP-DK50-1_08-2017-MD

DK50-10

Fig. 4 - Compressor DK50-10 S/M - 10bar

NP-DK50-1_08-2017-MD - 14 - 08/2017

DK50-10

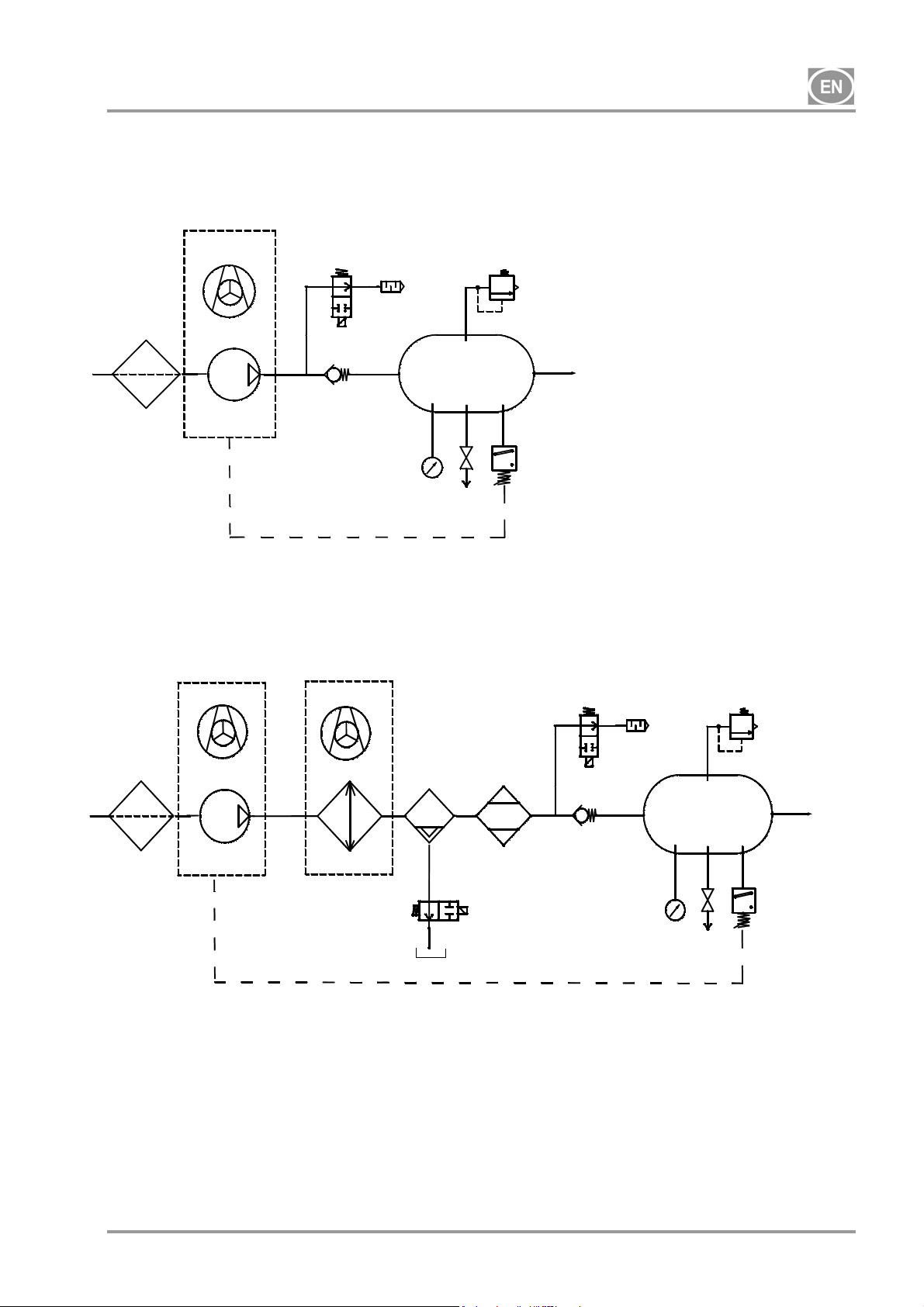

8. PNEUMATIC SCHEMATIC

DK50-10Z, DK50-10S

1

DK50-10Z/M, DK50-10S/M

1

Legend for compressed air schematics

1. Inlet filter

2. Compressor

3. Fan

4. Relief valve

5. Noise muffler

6. Check valve

7. Pressure gauge

8. Pressure switch

3

4

2

3

2

6

3

12

14

9

8

4

6

5

10

11

7

9

8

5

10

11

7

13

16

15

9. Safety valve

10. Air tank

11. Drain valve

12. Cooler

13. Coalescence filter

14. Membrane dryer

15. Condensate tank

16. Condensate drain solenoid valve

08/2017 - 15 - NP-DK50-1_08-2017-MD

DK50-10

OPERATION

In case of emergency, disconnect the compressor from the mains (pull out the mains

plug).

The compressor has hot surfaces.

Burns or fire may result if contact is made.

During prolonged operation of the compressor, the temperature in the box may increase

The working pressure settings for the pressure switch set by the manufacturer cannot be changed.

Compressor operation at a working pressure below the switching pressure indicates high air usage by the

attached appliance (see the Malfunctions chapter)

9. SWITCHING THE COMPRESSOR ON

to over 40°C. At this point the cooling fan automatically switches on. After cooling the

space to under 32°C, the ventilator switches off.

Automatic start: when pressure in the tank drops to the pressure switch’s lower limit

level, the compressor automatically switches on. The compressor automatically switches

off after reaching the pressure switch’s upper limit level.

Required drying performance can only be achieved when following the defined operating

conditions!

Drying performance will decline and the achieved dew point will drop if the dryer is

operated at any pressure below the minimum working pressure!

The dryer will suffer damage if operated at ambient temperatures above the maximum

working temperature!

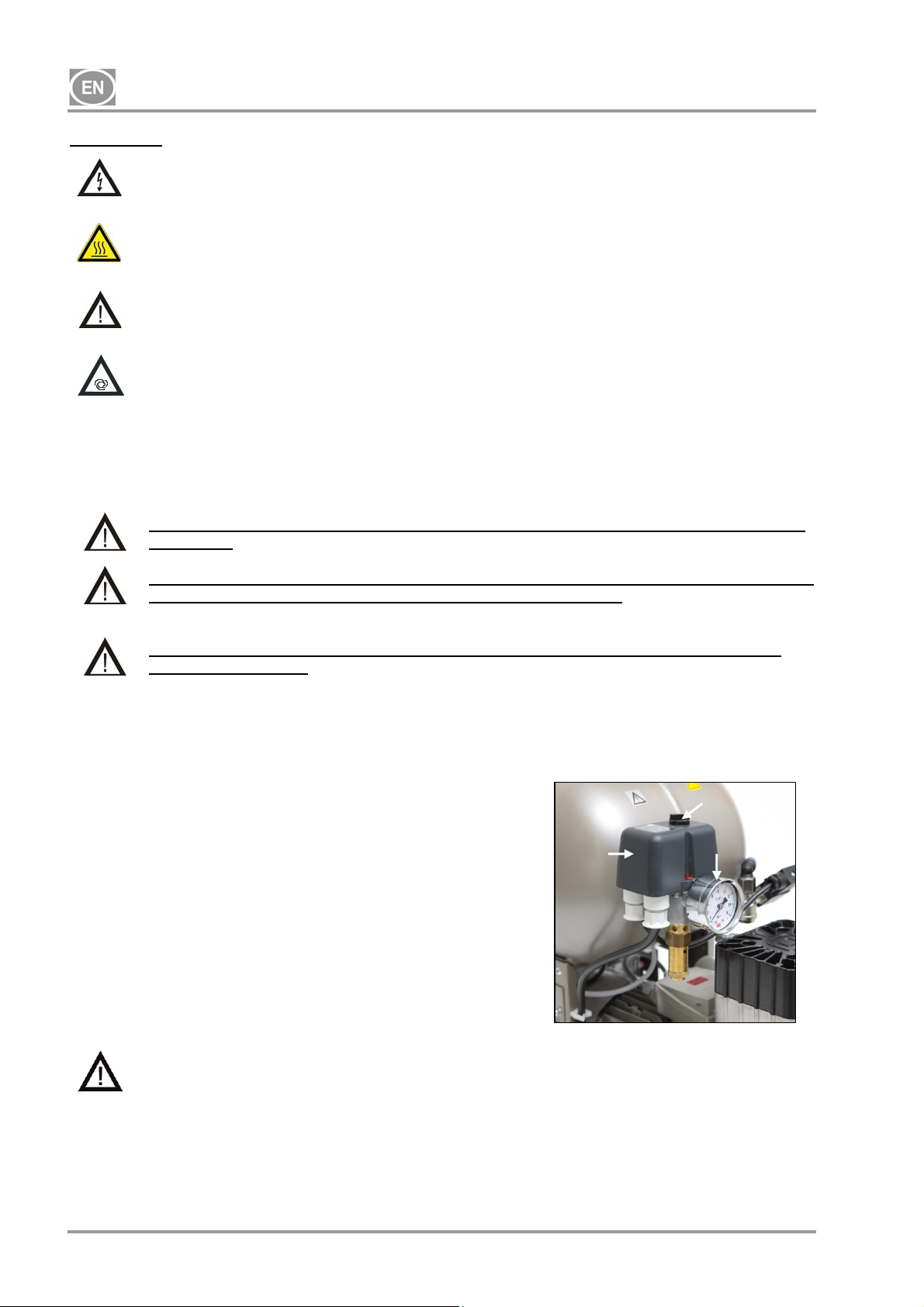

(Fig. 5)

Turn the compressor on at the pressure switch (2) by rotating the

main switch (3) to the “I” position. Check the position of the breaker

switch, it must be in the “I” position. If it is in the “0” position, turn

the switch to the “I” position (Fig.3 – position 18). The switch (Fig. 4

– position 22) in the case of DK50-10 S/M 10bar compressors is on

the front side of the enclosure; the indicator lights up green. The

compressor switches on and begins to fill the air tank until the

pressure reaches the switching pressure and the pressure switch

turns the compressor off. The compressor then operates in

automatic mode and is controlled by the on and off pressure

settings on the pressure switch based on compressed air usage.

This pressure may be monitored on the pressure gauge (5). A

tolerance of 10% is acceptable. The pressure in the air tank may

not exceed the permitted operating pressure.

Changing the switching pressures on the pressure

switch is prohibited on any compressor.

The pressure switch (2) has been set by the manufacturer and further setting of switching on and off

pressure may be carried out only by a qualified expert trained by the manufacturer.

2

Fig. 8

Fig.5

3

5

NP-DK50-1_08-2017-MD - 16 - 08/2017

DK50-10

INSTALLATION

10. CONDITIONS FOR USE

Compressors may only be installed and operating in dry, well-ventilated and clean environments with

environmental parameters that meet the requirements specified in Chapter 5, Technical data. The

compressor must be installed so that it is accessible at all times for operating and maintenance. Please

ensure that the nameplate on the device is readily accessible.

The compressor must stand on a flat, sufficiently stable base (be aware of the weight of the compressor,

see Chapter 5, Technical data).

Compressors may not be operated outdoors or in otherwise wet or damp environments. Do not use the

compressor in the presence of explosive gases, dust or flammable liquids.

Before connecting the compressor to medical equipment, the supplier must confirm that it meets all

requirements for its use. Refer to the technical data of the product for this purpose. When a unit is to be

built-in, classification and evaluation of compatibility must be done by the manufacturer or supplier of the

product to be used.

Any use other than that described in this manual is not covered by the guarantee, and the manufacturer is

not liable for any damages that may result. The operator/user assumes all risk.

Only a qualified professional may install the compressor and place it into operation for

the first time. This professional is obliged to train operating staff as to the use and

maintenance of the equipment. Installation and training of all operators shall be confirmed

by the installer’s signature on the certificate of installation.

Prior to installation, ensure that the compressor is free of all transport packaging and

stabilizers to avoid any risk of damage to the product.

Caution! When in operation, the compressor is hot. Burns or fire may result if contact is

made by the operator or any flammable material.

Ambient operating conditions

Temperature: +5°C to +40°C,

Max. relative humidity: 70%,

Max. absolute humidity: 15 g/m

3

.

08/2017 - 17 - NP-DK50-1_08-2017-MD

DK50-10

11. PLACEMENT OF THE COMPRESSOR

The equipment shall only be installed by a qualified professional.

Unwrap the compressor from the packaging.

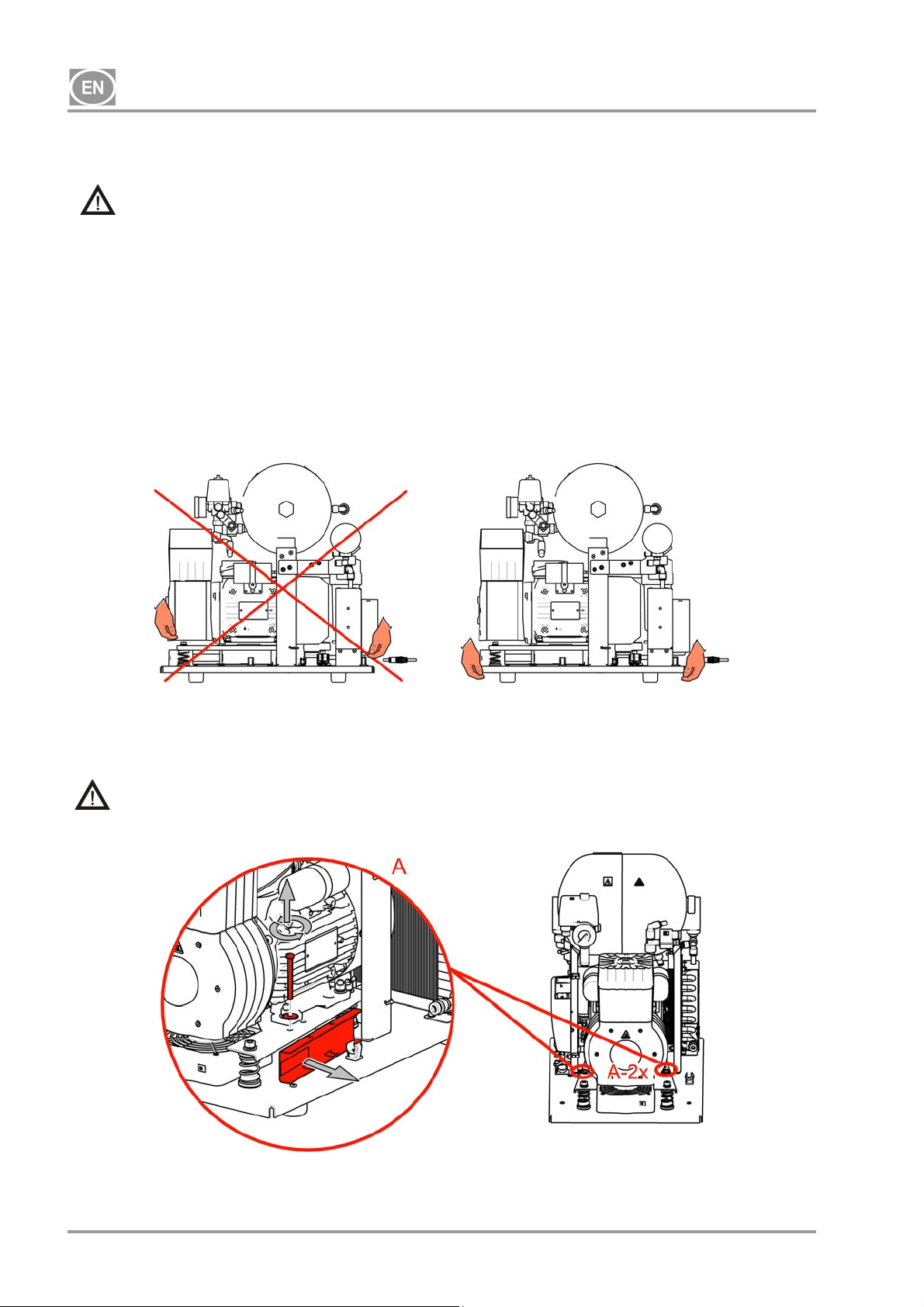

11.1. Handling and releasing the compressor

Position the compressor at the site of future operation (Fig. 6)

Fig.6

Remove the transport stabilisers from the aggregates. (Fig. 7)

Remove all devices used to secure the compressors once the compressor set has been installed

and mounted at the site of final installation!

Fig.7

NP-DK50-1_08-2017-MD - 18 - 08/2017

DK50-10

12. PNEUMATIC CONNECTIONS

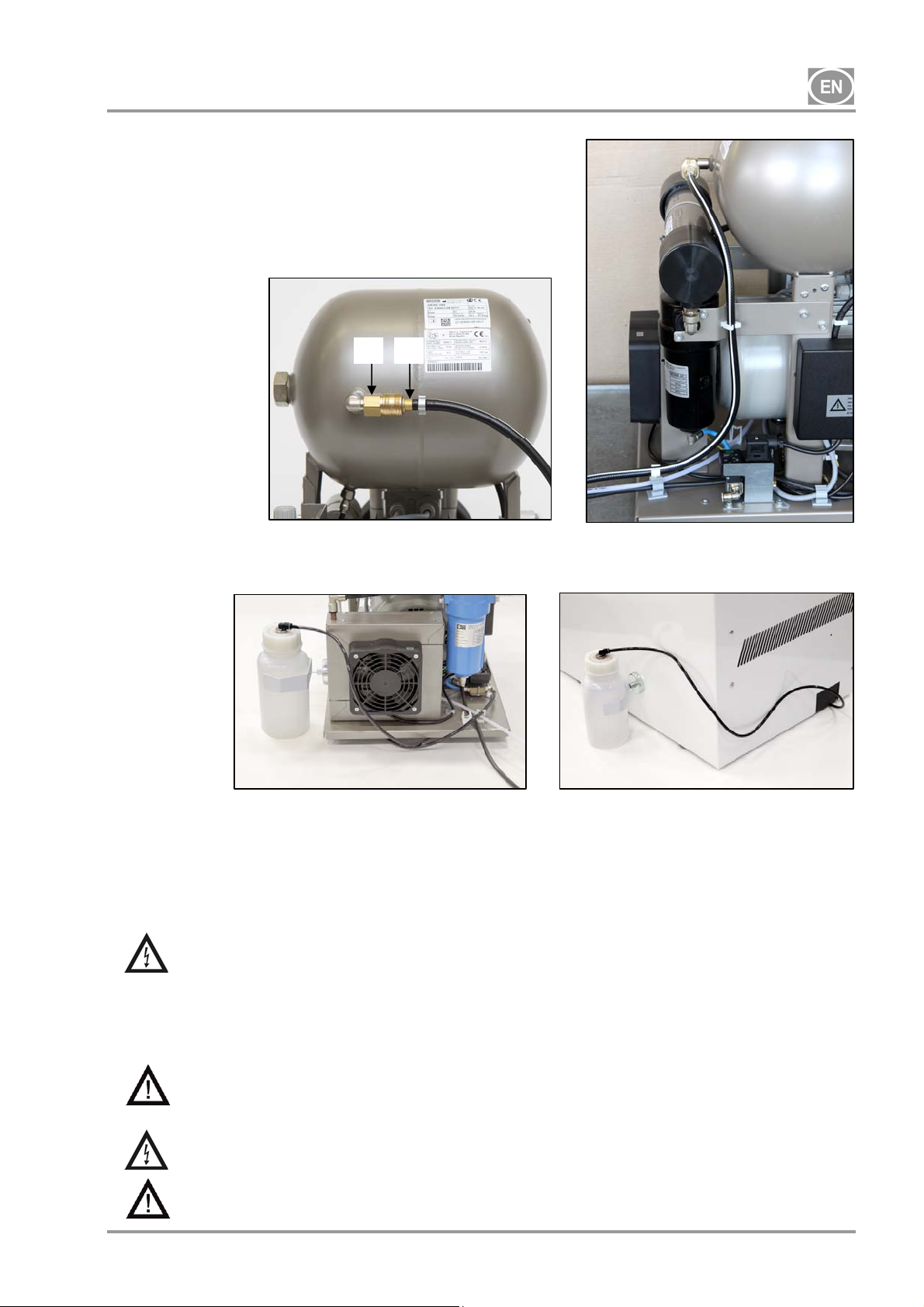

12.1. Compressed air outlet (Fig. 8)

Connect a pressure hose terminated at one end with a sliding

quick connector (1) to the compressed air outlet (2) on the

compressor and connect the hose to the compressed air

system or directly to the appliance, in this case dental

equipment.

Fig.8

12.2. Condensate outlet (Fig. 9)

2 1

Connect the condensate drain hose to the condensate vessel on compressors with dryers.

Fig. 9

Route the hose through the opening in the rear wall of the enclosure for other compressors (without

dryers).

13. ELECTRICAL CONNECTIONS

The product is equipped with a grounded plug. Insert the mains plug into a rated mains socket.

Ensure full compliance with all local electrical codes. The mains voltage and frequency

must comply with the data stated on the device's label.

Keep the socket easily accessible to ensure that in an emergency the appliance can be safely

disconnected from the mains.

Connection to the power distribution box must be max.16 A.

The enclosure for the DK50-10S/M 10 bar model compressor is equipped with a cooling fan

and a switch. The enclosure must be connected using the provided cord with connector to the

matching connector on the compressor’s electrical panel. (Fig. 4)

Ensure the electrical cable does not touch hot compressor components. Risk of electric

shock!

If any electrical cord or air hose is damaged it must be replaced immediately.

08/2017 - 19 - NP-DK50-1_08-2017-MD

DK50-10

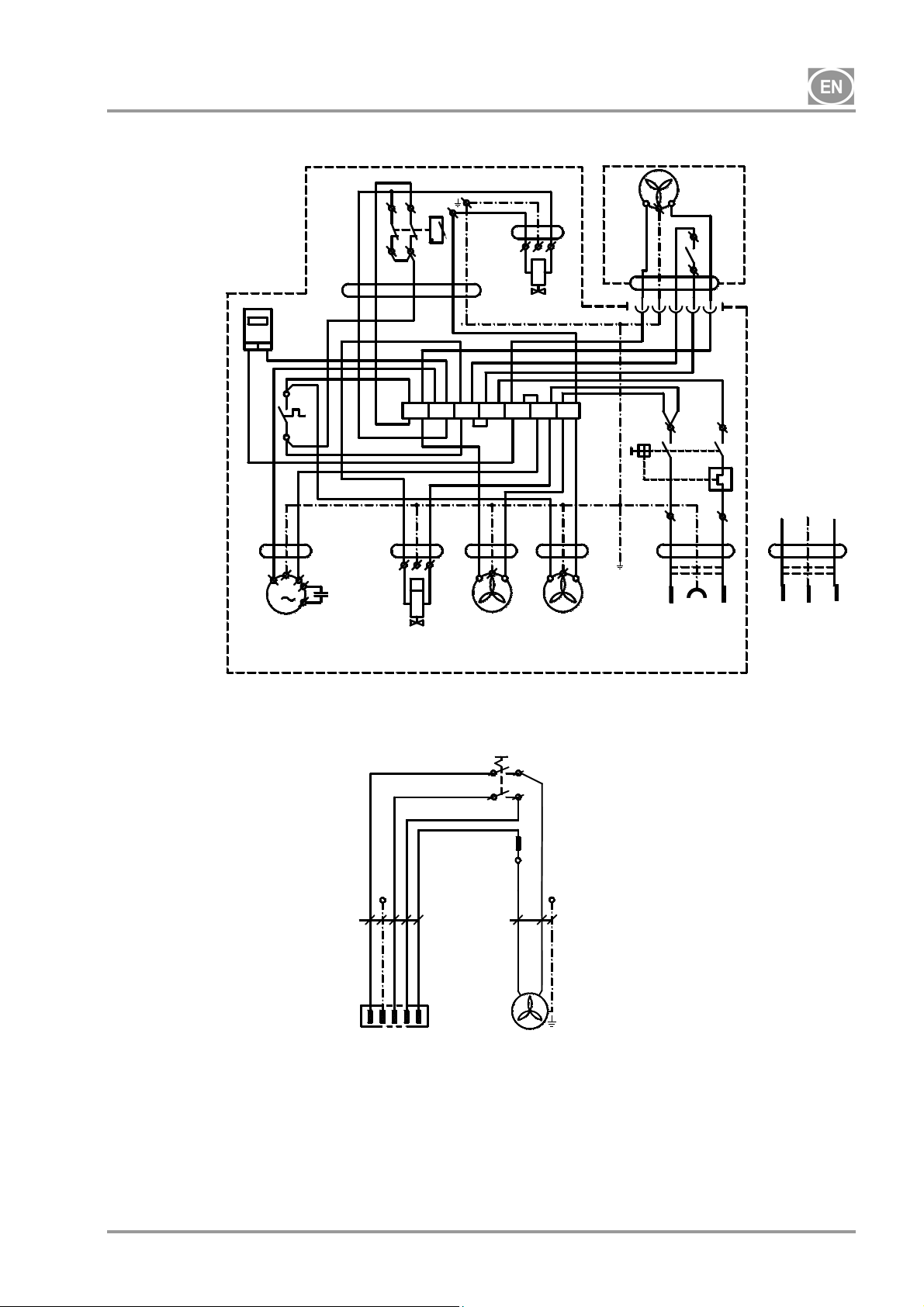

14. CONNECTION SCHEMATIC

DK50-10 Z, DK50-10 S - 5-7bar, 6-8, 8-10 bar

1/N/PE ~ 115V / 60 Hz

~ 230V / 50/60 Hz

00000

bk bu

P1*

bk

B2

5G1

bn gy

40°C

bk

3G1

1

bk-1bk-2

M

C1

M1

DK50-10 Z/M, DK50-10 S/M 5-7bar, 6-8 bar

1/N/PE ~ 115V / 60 Hz

~ 230V / 50/60 Hz

5G1

bn gy

bk

B2

40°C

bk

3G1

M

1

M1

bk-1bk-2

3G0,75

C1

X1

X1

bk

1

bk

bn

B1

p >

bu

2

U

B1

p >

bu

2

1

T

U

bu bu

bn

3G0,5

M4

N

3G0,75

3G0,75

N

bu

N

E2

bn

M3

* - only for 8-10bar version

bu bk

bu

P1

P2

F1

gnye

4

8

bu bu

bn

3G0,5

bn

bu

E1

3G1,5

CE

gnye

PE

bn

UN

gnye

bu bn

3G1,5

UK

PE

UN

M3

bu bk

F1

3G1,5

bu

bu

CE

P2

8

gnye

PE

P1

4

gnye

bn

UN

bu bn

3G1,5

PE

UN

UK

N

gnye

bu

bn

3G0,5

E1

NP-DK50-1_08-2017-MD - 20 - 08/2017

DK50-10

DK50-10 Z/M, DK50-10 S/M - 8-10 bar

1/N/PE ~ 230V 50..60Hz

Box for DK50-10 S/M - 10bar

Legend for electrical schematics

~ 115V 60Hz

bn gy

5G1

00000

P1

bkbu

bk

3G1

B2

40°C

bk

bk-1bk-2

M

1

X1

bn

3G0,75

C1

M1

* - only for DK50-10 Z/M version

1/N/PE ~ 230V 50..60Hz

bn

bu

PE

5G1

-X10

1

N23PE

M1 Compressor motor

E1 Compressor fan

E2 Dryer fan

M3 Solenoid valve

B2 Temperature switch

E3,E10 Box fan

X10, X2 Connector

B1

p >

3G0,75

bk

bu

2

1

U

U

bn

bu

M3

N

N

N

*

gnye

bu bu bu

T

bk

gy

M4

3G0,5

-S10

bn

E2

2

2a

1

1a

1

bn

3G0.5

3G0,5

bu

bu

bn

E1

PE

-E10

C1 Capacitor

B1 Pressure switch

X1 Terminal strip

F1 Protected switch

M4 Condensate drain valve

P1 Hour meter

S1 Switch

2

E3

S1

gy

5G1

bu

N

bu

F1

bu bk

3G1,5

bk

bn

1

32

bk

bk

bk

X2

bu

P1

P2

4

8

gnye

PE

bn

UN

bu bn

3G1,5

CE UK

1

1 - Compessor

2 - Box

gnye

PE

UN

08/2017 - 21 - NP-DK50-1_08-2017-MD

DK50-10

15. COMMISSIONING

(Fig. 10)

Make sure all transport stabilizers were removed.

Check that all pressurized air line connections are secure.

Check to ensure power is connected correctly to the compressor.

Check the position of the main switch; it should be in the “I” position; if the switch remains in the “0”

position, turn the main switch to the “I” position. (Fig. 3)

Check to see if the DK50-10S/M enclosure (8-10 bar models only) is connected to the compressor using

the cable with the connector.

The compressor is not equipped with a backup power supply.

16. SWITCHING THE COMPRESSOR ON

(Fig. 10)

3

Turn the compressor on using the pressure switch (2) by rotating

the selector (3) to the “I” position. Check the position of the

breaker switch, it must be in the “I” position. If it is in the “0”

position, turn the switch to the “I” position (Fig.3 – position 18).

2

5

The switch (Fig. 4 – position 22) in the case of DK50-10S/M 10bar

compressors is on the front side of the enclosure; the indicator

lights up green. The compressor switches on and begins to fill the

air tank until the pressure reaches the switching pressure and the

pressure switch turns the compressor off. The compressor then

operates in automatic mode and is controlled by the on and off

pressure settings on the pressure switch based on compressed air

usage. This pressure may be monitored on the pressure gauge

(5). A tolerance of 10% is acceptable. The pressure in the air

tank may not exceed the permitted operating pressure.

Fig. 10

Adjustments to the pressure range on the compressor’s pressure switch are prohibited.

The pressure switch (2) was set up by the manufacturer and only a qualified technician

trained by the manufacturer may make any changes to its settings.

Compressor – when first started and placed into service, the compressor fills the air tank until the switching

pressure and the pressure switch turn off the compressor. The compressor operates in automatic mode,

switched on and off by the pressure switch, depending on compressed air usage.

Compressor with dryer – the compressor operates in the same manner as above, only the compressed air

passes through a cooler to remove moisture from the compressed air.

Compressor with a condensate and filtration unit (KJF-1) - during usage by the appliance, the

compressed air passes through the KJF-1 unit, where the air is cooled, filtered and condensed liquid is

captured and automatically drained into a vessel.

17. COMPRESSOR SHUT-DOWN

Compressor shut-down for service or any other reason is performed at the pressure switch (2) by turning the

selector (3) to the “0” position and pulling the mains plug from the socket. This disconnects the

compressor from power. Then open the drain valve (Fig. 1) to vent the pressure in the air tank to zero.

NP-DK50-1_08-2017-MD - 22 - 08/2017

DK50-10

MAINTENANCE

18. EQUIPMENT MAINTENANCE

Warning!

The operator shall ensure completion of repeated testing of the equipment at least once every 24

months (EN 62353) or at intervals defined by applicable national legal regulations. A record of these

test results shall be completed (e.g. per EN 62353, Annex G) together with the measurement

methods.

The equipment has been designed and manufactured to keep maintenance to a minimum. The following

work must be performed to preserve the proper and reliable operation of the compressor.

Before starting compressor maintenance work, check to ensure the compressor is

disconnected from the appliance to ensure the person using the appliance is not at risk

and there is no risk of any other material damages!

Aggregate components (head, cylinder, pressure hose, etc.) are very hot during and

shortly after compressor operation – do not touch these components!

Repair work beyond normal maintenance can be performed only by qualified personnel or

he manufacturer’s representative.

Use only spareparts and accessories approved by the manufacturer.

Wear eye protection, i.e. goggles, when venting compressed air from the compressed air

circuit (air tank).

The work below may only be performed by trained personnel as follows:

BEFORE STARTING ANY MAINTENANCE WORK, IT IS NECESSARY to switch the

compressor off, disconnect it from the mains (pull out the mains plug) and vent the

compressed air from the air tank.

The 10 bar compressor model is equipped with an hour meter (Fig. 4), used to check the total hours of

operation.

08/2017 - 23 - NP-DK50-1_08-2017-MD

DK50-10

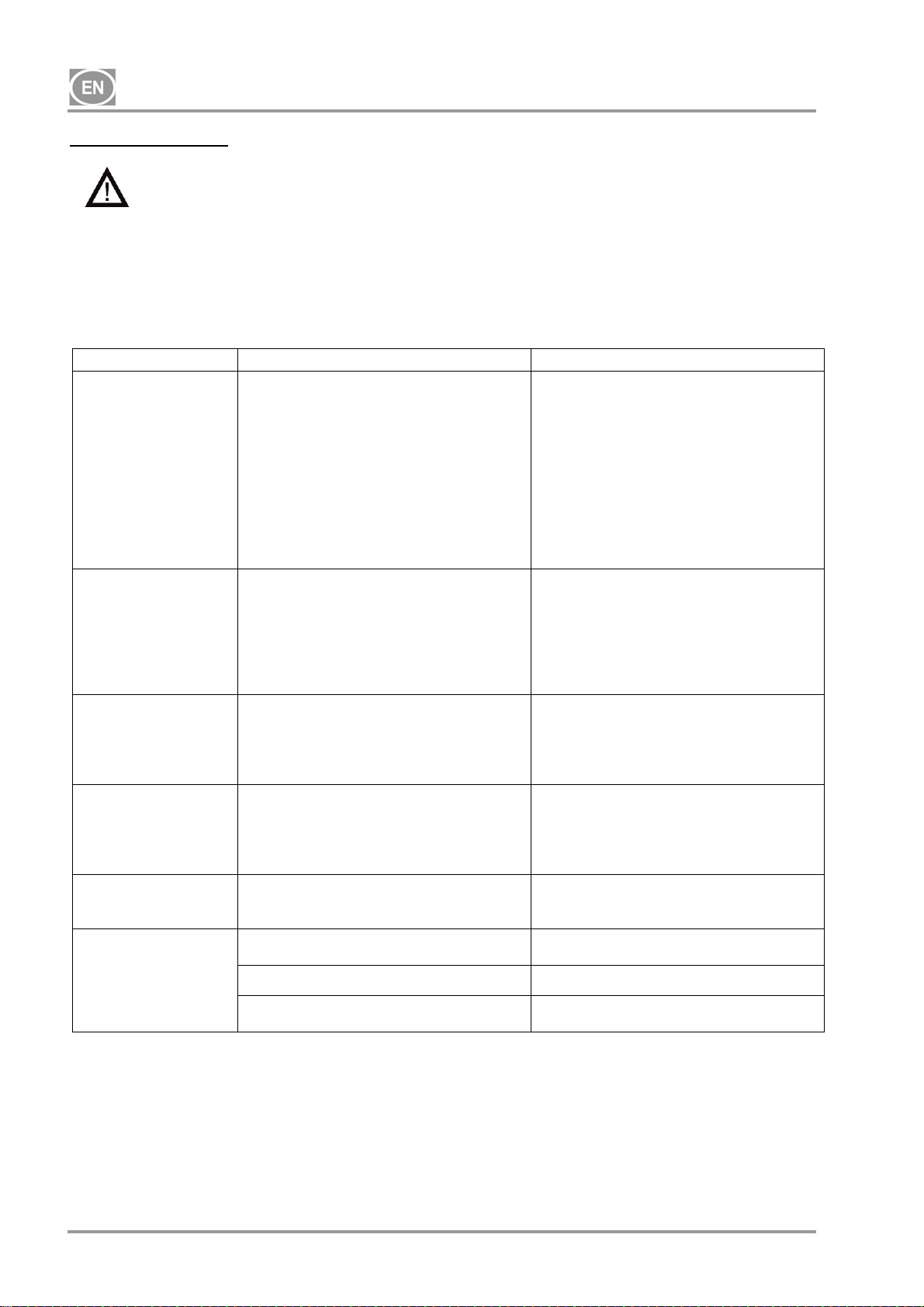

18.1. Maintenance intervals

Time interval

once

a day

once

a week

once

a year

once

every 2

years

2000 4000 6000 8000 10000 12000 Chapter

Set of spare

parts

Performed by

Produkto operational checks

Drain condensate from the air

tank )**

- At high humidity

Drain condensate from the air

tank )**

- At normal humidity

Product function check x

Leak check connections and

inspect equipment

Inspection of electrical

connections

Cooler and fan check

Filter element replacement

in the dryer filter

Filter element replacement in

theKJF-1

Safety valve check x

Conduct a “repeated test” per

EN 62353

Aggregate inlet filter

replacement )*

x 18.2 -

x

x

x

x

x

x

x

x 18 -

x x

)* data is presented in hours; if not possible, then the data is considered in years

)** only for compressors without dryers

18.5 - user

18.5 - user

7 - user

18.3 -

18.4 -

18.10 -

18.8 025200304-000

18.9 025200061-000

18.6 -

x x 18.7 025200126-000

user

qualified

professional

qualified

professional

qualified

professional

qualified

professional

qualified

professional

qualified

professional

qualified

professional

qualified

professional

NP-DK50-1_08-2017-MD - 24 - 08/2017

DK50-10

18.2. Operational checks

Check aggregate condition – the aggregates should be operating normally without excessive vibration

or noise. Troubleshoot any problem or call in service personnel if trouble is detected

Visually inspect fan operation – the fans must be operating when the aggregates are running.

Troubleshoot any problem or call in service personnel if trouble is detected

Check to ensure the power cable and pneumatic hoses are undamaged. Replace damaged

components or call in service personnel.

Check the ambient temperature – the ambient temperature must be below the temperature limit (40

°C). Cool the space if the temperature is high.

On the compressor with dryer – open the plug on the condensate vessel to drain the condensate

18.3. Leak check compressed air connections and inspect the equipment

Leak check:

Leak check the compressed air lines when the compressor is running and under pressure (not during

regeneration venting).

A Use a leak analyser or soapy water to check all joints and connections for leaks. Tighten or reseal

the connection where leaks are found.

Equipment inspection:

Check the condition of the compressor aggregate for normal operation and noise levels.

Fan operation check - the fans must be running during the defined compressor work cycles

Check of temperature switch operation (B2) – heat the temperature switch to a temperature above

40°C (e.g. using a heat gun, being careful not to warp any plastic pieces nearby). Fan EV1 (and EV2

for a compressor with dryer) will start up once the temperature reaches 40°C so long as power is

connected to the compressor.

Check filter condition – the filters must be undamaged and sufficiently clean.

Check the condition of the aggregate itself and ensure there is no contamination inside the crankcase

or play in the crankshaft

Replace any defective parts as needed.

18.4. Inspection of electrical connections

Check all electrical connections on the equipment with the mains disconnected!

Inspection

Check the mechanical function of the main switch.

Check to ensure the power cable and connected wires are undamaged.

Visually inspect the connection of individual cables to the terminal strip.

Inspect all screw terminals for the protective green and yellow PE grounding conductor.

08/2017 - 25 - NP-DK50-1_08-2017-MD

g

DK50-10

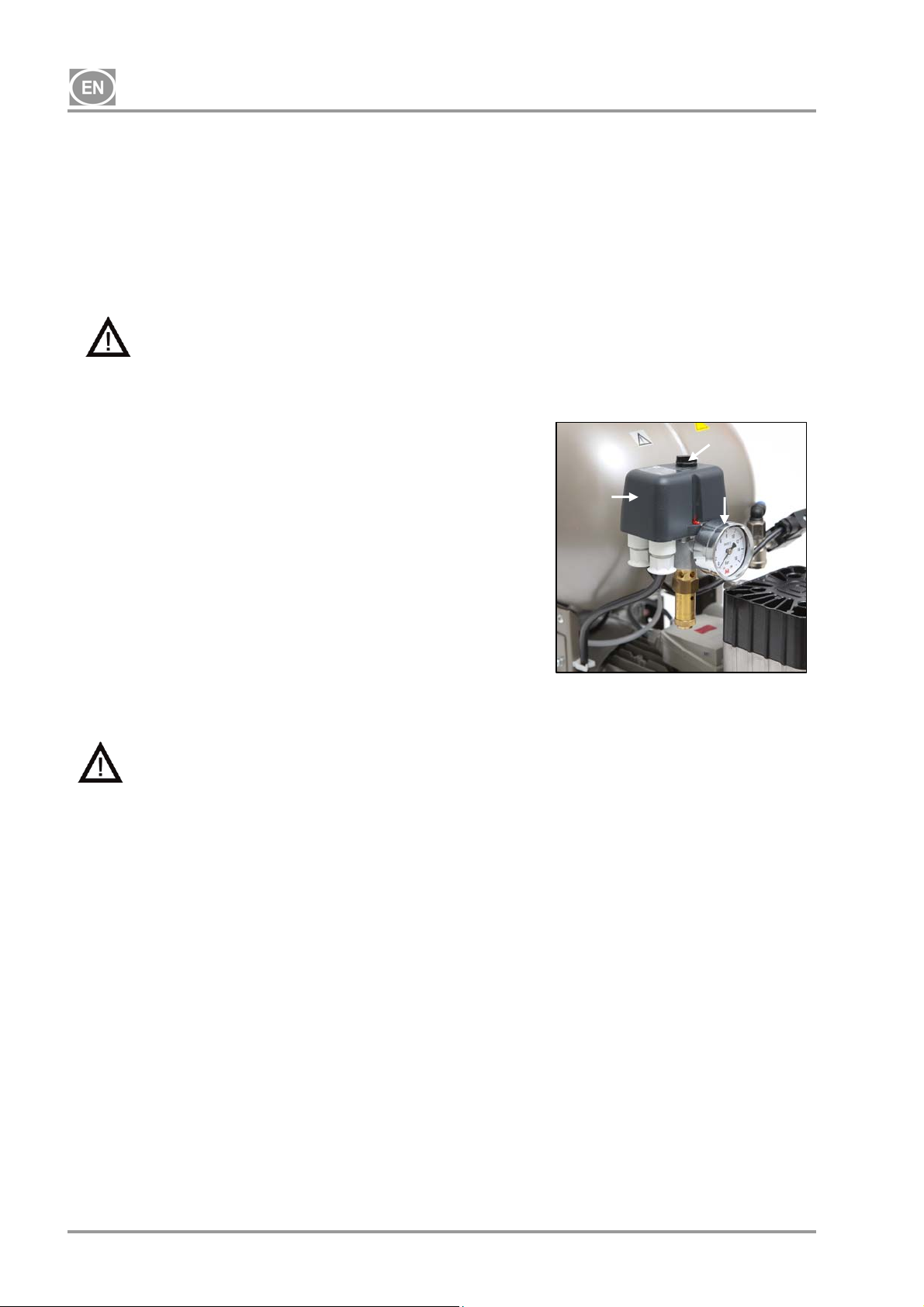

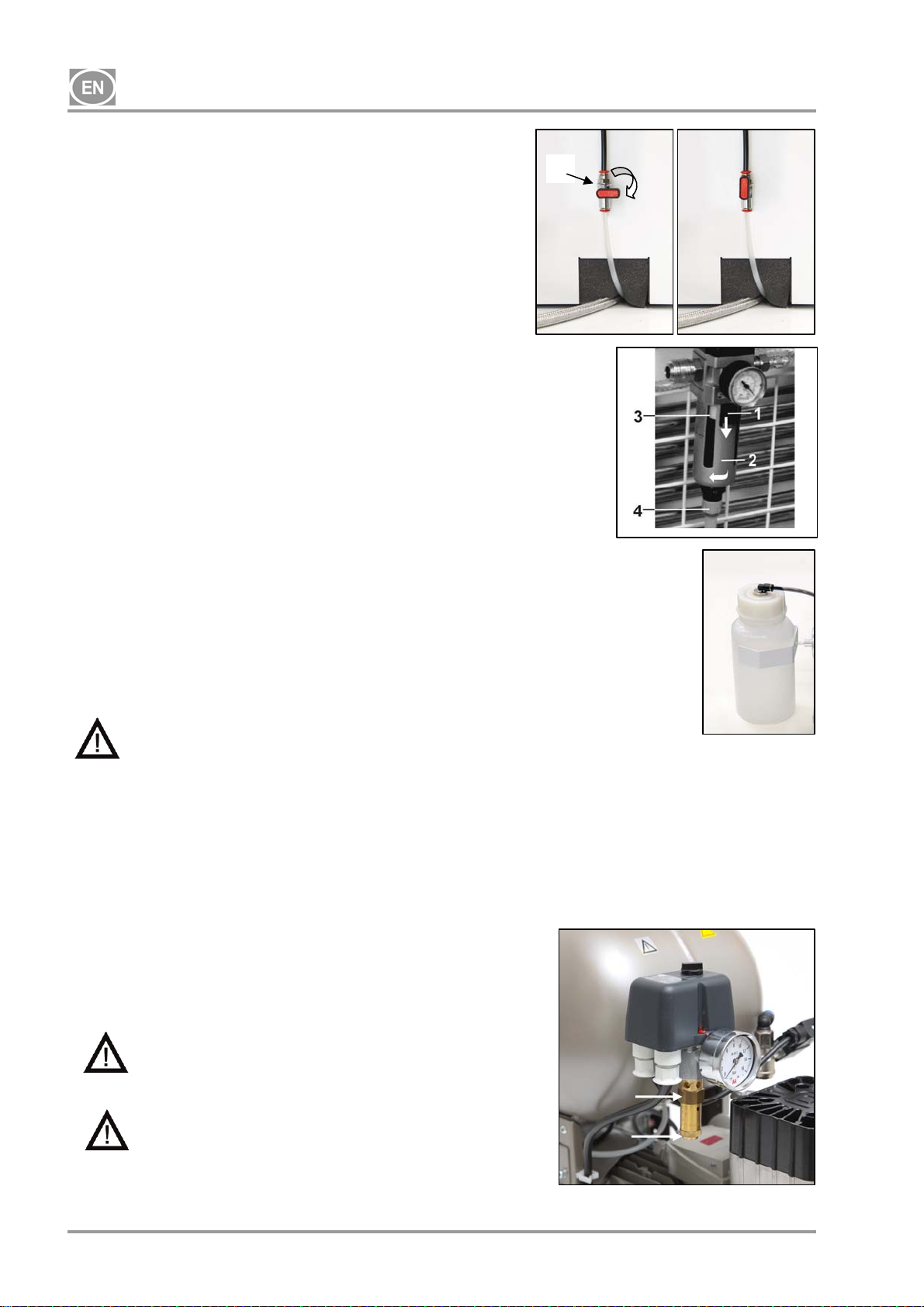

18.5. Condensation drain valve

Compressors (Fig. 11)

1

Draining the condensate from the pressure vessel is

recommended during regular operation. Switch off the

compressor at the mains and lower the pressure to a maximum

of 1 bar, for instance, by venting air through the connected

equipment. Place the hose with the drain valve into a vessel

prepared in advance and open the drain valve (1) to remove the

condensate from the tank.

Fig.11

Compressors with condensation and filtration unit (Fig.12)

During regular use, condensation is automatically released via

the release valve of the condensation unit filter. To check that

the automatic drain is working properly, open the valve (4) of the

drain vessel (2) by turning to the left. Release a small amount of

condensate from the vessel. Close the valve (4) by turning to

the right.

Both types of compressors may be equipped with an automatic

Fig.12

condensate drain on the air tank condensate drain to allow the

condensate to drain without operator intervention (see the

Scope of Delivery – Accessories chapter).

Compressors with air dryer (Fig.13)

Condensate from compressors with air dryers is automatically

drained into a vessel. The vessel must be drained regularly, see

Chapter 18.2

Fig.13

THE FOLLOWING IS REQUIRED BEFORE ANY FOLLOW-UP CHECKS:

For DK50-10S and DK50-10S/M compressors with an enclosure - remove / lift up the enclosure.

For the DK50-10S/M 10 bar compressor model with an enclosure - remove the cover of the

enclosure, disconnect the enclosure connector from the compressor connector and remove / lift up

the enclosure.

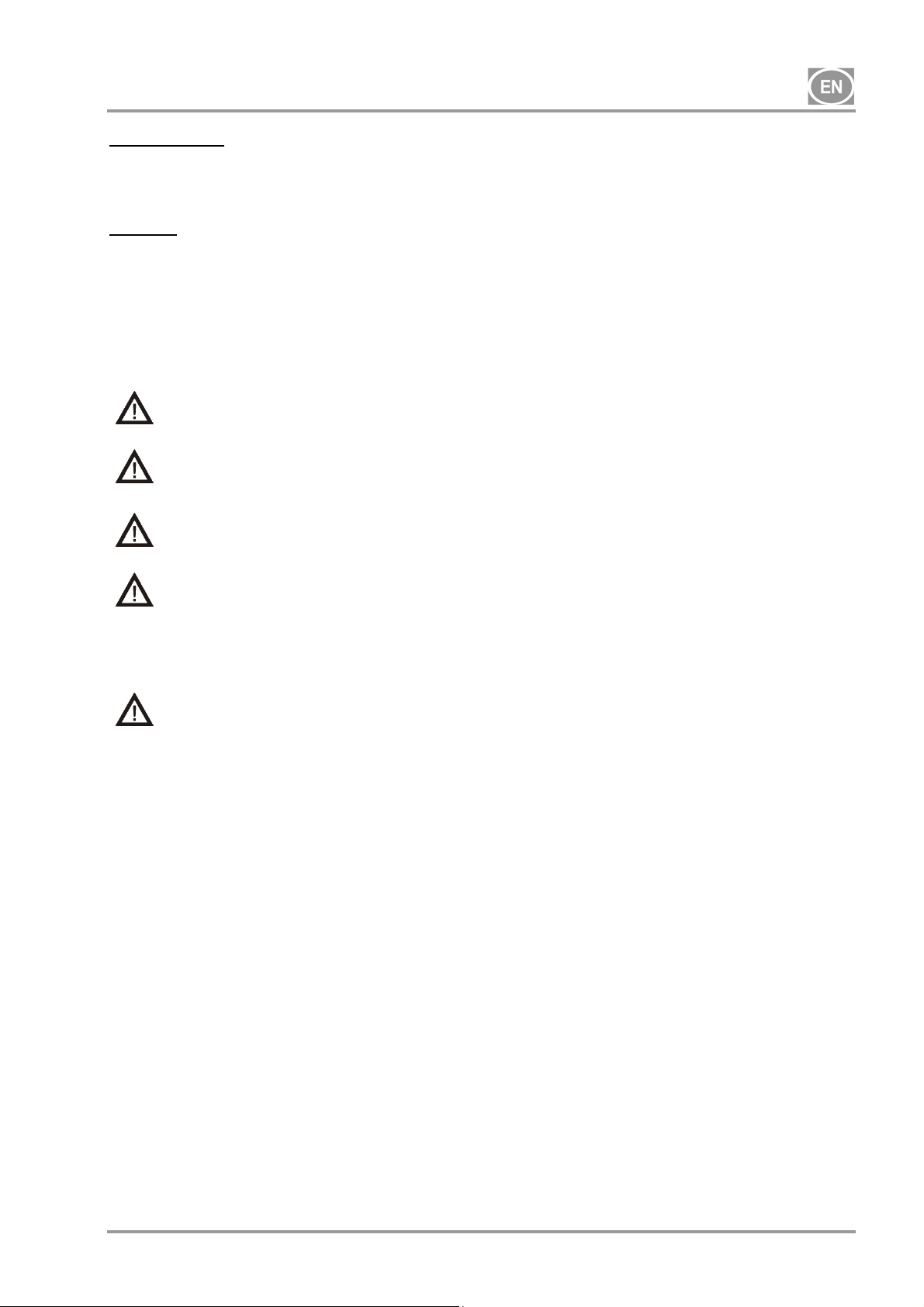

18.6. Safety valve check

(Fig. 14)

When the compressor is operated for the first time, make sure that

the safety valve is working properly. Turn the screw (2) on the

safety valve (1) several rotations to the left until the safety valve

releases air. Let the safety valve vent for only a few seconds. Turn

the screw (2) to the right until it seats, closing the valve.

Never use the safety valve to vent air pressure in

the air tank. It could damage the safety valve. The

valve is set to the maximum permitted pressure by

the manufacturer. Adjustments are not permitted!

Warning! Compressed air can be dangerous. Wear

eye protection when venting any air. Compressed

1

2

air may damage the eyes or cause vision

problems.

NP-DK50-1_08-2017-MD - 26 - 08/2017

Fi

.14

DK50-10

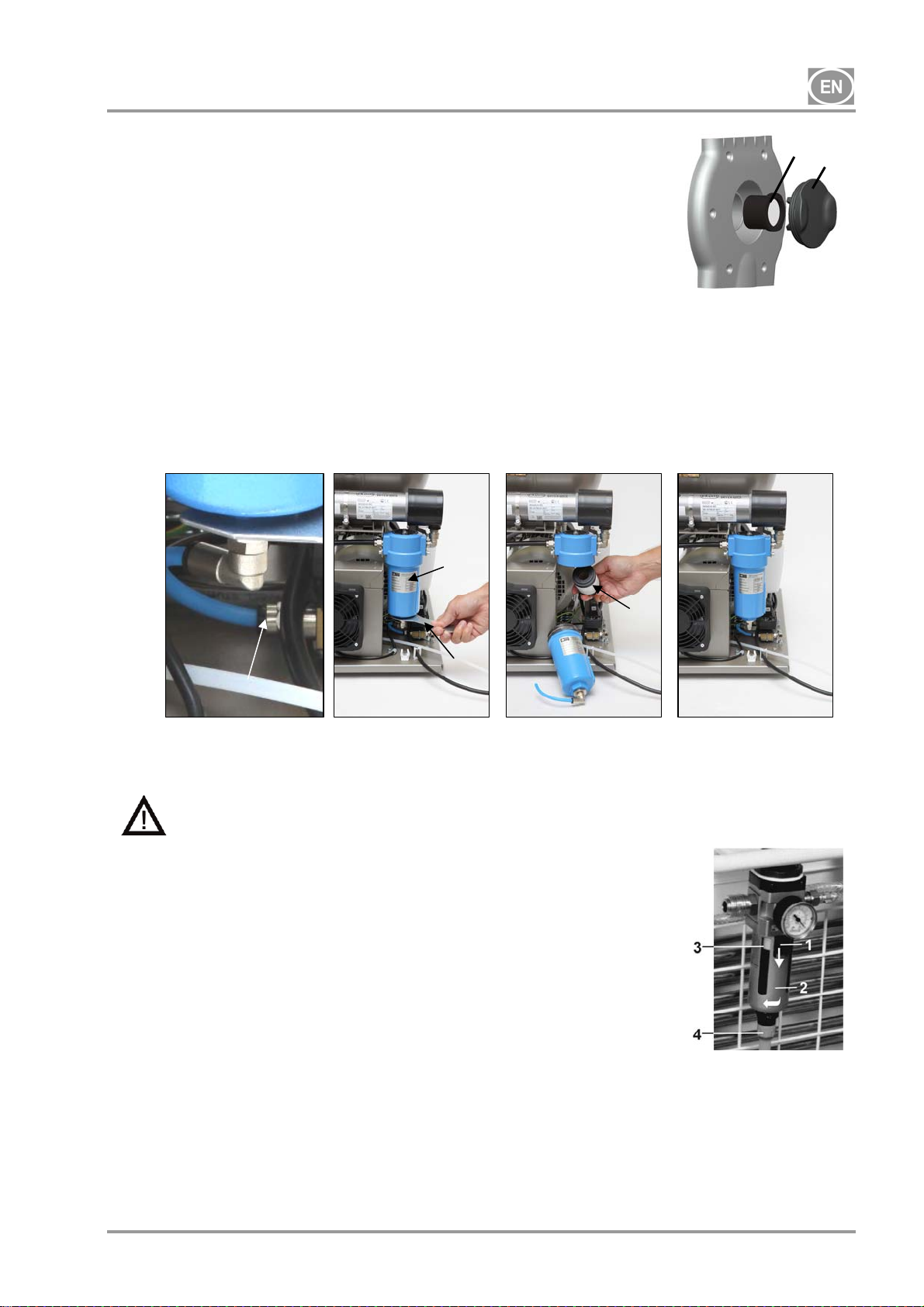

18.7. Inlet filter replacement

(Fig.15)

Pull out the rubber plug (2) by hand.

Remove the dirty inlet filter (1).

Insert a new filter and replace the rubber plug.

18.8. Filter element replacement

Fig.15

(Fig.16)

Remove the hose (1) from the quick connector.

Use a wrench (2) to release the filter vessel (3) and remove.

Pull down on the filter element (4) to remove.

Insert a new filter element.

Re-install the filter vessel.

Gently tighten the filter vessel with the wrench.

Install the hose back on the quick connector.

Fig.16

1

3

2

18.9. Filter element replacement in the KJF-1 unit

4

Before proceeding, vent the air tank to zero pressure and disconnect the equipment from

power.

(Fig.17)

Replace the filter inside the automatic condensate drain when

the condensate unit is in regular operation.

Release the catch (1) on the filter vessel by pulling

downward, rotate the filter cover (2) to the left and remove.

Unscrew the filter bracket (3) by turning it to the left.

Replace and secure the new filter by rotating the filter

bracket to the right back against the filter body.

Replace the filter cover and secure it by turning to the right

until the catch locks.

Fig.17

18.10. Cooler and fan check (Fig.3)

The equipment altogether, and especially the compressor fan, cooler fan (21) and cooler (14), must be kept

clean to ensure efficient drying performance; vacuum or blow down the cooling fins and fans with

compressed air to remove any dust from the surface.

08/2017 - 27 - NP-DK50-1_08-2017-MD

DK50-10

TROUBLESHOOTING

Caution! Before proceeding, depressurize the air tank to zero and disconnect the

appliance from the mains.

For permanently high efficiency of drying, it is necessary to maintain the whole appliance, and

mainly ventilator clean – regularly clean the surface of ventilator and cooling fins of cooler.

Troubleshooting can be performed only by qualified personnel.

MALFUNCTIONS POSSIBLE CAUSE REMEDY

Compressor does not

start

Compressor often

switches on

Low pressure in air

tank (compressor

running constantly)

Prolonged operation

of the compressor

Compressor is noisy

(knocking, metal

noises)

Dryer doesn't dry

(condensed water in

the air) *

No voltage at the pressure switch

Check voltage in socket

Check the circuit breaker – switch into the

“I” on position

Loose conductor at terminal – tighten

Check the electrical cord – replace

defective cord

Motor winding failure, damaged

thermal overload protection

Faulty capacitor

Seized piston or other rotating part

Pressure switch does not switch

Air leak in compressed air distribution

system

Leaking check valve

Large volume of condensed liquid in

pressure vessel

Replace motor or windings

Replace capacitor

Replace damaged parts

Check the function of the pressure switch

Check compressed air distribution

system – seal loose joints

Clean solenoid valve, replace seals,

replace solenoid valve

Drain condensed liquid

Check the time to fill the air tank

Low compressor performance

High air usage by appliance, Leak in

compressed air system, Low aggregate

output

Aggregate malfunction

Dryer malfunction

Air leak in compressed air distribution

system

Worn piston ring

Inlet filter is plugged

Defective solenoid valve

Damaged piston bearing, piston rod,

motor bearing

Loose or cracked spring

Check compressed air distribution

system – seal loose joint

Replace worn piston ring

Replace old filter with a new filter

Repair or change the valve or coil

Replace damaged bearing

Replace damaged spring

Cooling fan not working Replace the fan

Check the power source

Damaged dryer Replace the dryer

Non-functioning automatic condensate

Clean / replace

drain - clean / replace on the filter

)* After a dryer malfunction, the interior surfaces of the air tank must be thoroughly cleaned and all

condensed liquid removed.

Check the dew point of the air leaving the air tank (see Chapter 5 - Technical data) to protect the

equipment from damage!

NP-DK50-1_08-2017-MD - 28 - 08/2017

Loading...

Loading...