EKOM DK50 Operation Manual

OIL-FREE COMPRESSOR DUPLEX DK50 4x2V/M

OPERATION MANUAL

EKOM spol. s r.o.

Priemyselná 5031/18

921 01 Piešť any

Slovak republic

Tel.:+421 33 7967 255

Fax.:+421 33 7967 223

E-mail: ekom@ekom.sk

OPERATION MANUAL DK 50 4x2V/M

NP-DK50 4x2V-M-EN-16_11-2015 11/2015

2

CONTENTS

1. WARNINGS ................................................................................................................................ 3

1.1. General warnings ................................................................................................................... 3

1.2. General safety warnings ....................................................................................................... 3

1.3. Safety warnings regarding the protection against electric current ......................................... 3

2. PRODUCT INFORMATION ....................................................................................................... 5

2.1. Purpose and use .................................................................................................................... 5

2.2. Product description ................................................................................................................ 5

3. TECHNICAL DATA.................................................................................................................... 6

4. RANGE OF DELIVERY ......................................... CHYBA! ZÁLOŽKA NIE JE DEFINOVANÁ.

5. INSTALLATION AND ASSEMBLY ........................................................................................... 6

6. PUTTING THE PRODUCT INTO OPERATION ......................................................................... 7

7. PRODUCT MAINTENANCE ...................................................................................................... 8

7.1. Replacement of the input filter and prefilter ........................................................................... 8

7.2. Replacement / cleaning of filter in air dryer ........................................................................... 8

7.3. Check of safety valve ............................................................................................................. 9

7.4. Replacement of filter element in filter ..................................................................................... 9

7.5. Regulation output pressure air regulator ............................................................................... 9

7.6. Intervals of maintenance ...................................................................................................... 10

8. INFORMATION ON REPAIR SERVICE .................................................................................. 11

9. TROUBLESHOOTING AND SOLVING COMMON PROBLEMS ........................................... 11

10. ENCLOSURES ......................................................................................................................... 13

11. PNEUMATIC SCHEMA ........................................................................................................... 14

12. LIST OF COMPONENTS ......................................................................................................... 15

OPERATION MANUAL DK 50 4x2V/M

NP-DK50 4x2V-M-EN-16_11-2015 11/2015

3

1. WARNINGS

1.1. General warnings

The installation, operation and maintenance manual is an integral part of the appliance. It is

necessary to always keep this document close to the appliance. Strict observance of this manual

is a prerequisite for the correct operation of the appliance.

The safety of operating personnel and failure-free operation of the appliance are ensured only

when using the original components of the appliance. Only accessories specified in the technical

documentation or approved by the manufacturer must be used.

When used with non authorized accessories or consumable material, the manufacturer cannot

assume responsibility for the safe operation and functionality of the device.

The Guarantee does not cover damages that originate due to the use of non authorized

accessories or consumable material other than those recommended by the manufacturer.

The manufacturer assumes responsibility regarding safety, reliability and function only if

- The installation, calibration, amendments, extensions and repairs are made by the

manufacturer or his representative or a service organization authorized by the

manufacturer,

- The appliance is used in accordance with the installation, operation and maintenance

manual.

1.2. General safety warnings

The manufacturer developed and constructed the appliance so that damage would not occur

when the appliance is used for its intended purpose. The manufacturer considers it his obligation

to describe the following safety measures in order to avoid further damages.

When operating the appliance, it is necessary to observe laws and regional regulations valid in the

place of usage. In order to ensure safe course of works, the operator and user are responsible for

the observation of regulations.

The original packaging should be kept for the possible return of the unit. Only original packaging

guarantees an optimal protection of the appliance during transportation. If it would be necessary to

return the appliance during warranty period, the manufacturer is not responsible for damages

caused by incorrect packing.

It is necessary that the user ensures the appliance is safe to use prior to usage.

The user must familiarize himself with the correct operation of appliance.

If an undesirable event occurs in the operation of appliance, the user is obliged to immediately

inform his supplier to this event.

This product is not intended for use in areas with the risk of explosion.

1.3. Safety warnings regarding the protection against electric current

The appliance must only be connected to an appropriate power source that has correct grounding.

Prior the connecting the compressor, verify whether the mains voltage and frequency specified on

the apparatus are in accordance with the local supply.

Prior to putting into operation, check for possible damages on the appliance and the air

connectors. Damaged cables and sockets/plugs must be replaced immediately.

In the case of a dangerous situation or a technical failure, immediately disconnect the appliance

from mains supply.

During all repairs and maintenance:

- ensure that the mains plug is removed from the power socket

- pressure pipes must be air vented

- pressure must be released from pressure tank.

This appliance can only be installed only by a qualified expert.

OPERATION MANUAL DK 50 4x2V/M

NP-DK50 4x2V-M-EN-16_11-2015 11/2015

4

2. ALERT NOTICES AND SYMBOLS

In the Installation, Operation and Maintenance Manual and on packaging and product, the following

labels or symbols are used for important information:

Information, instructions and cautions for the prevention of damage to health or

materials

Caution! Dangerous electrical voltage

Read the user manual!

CE mark of compliance

Compressor is remote-controlled and may start without warning

Caution! Hot surface

Earth (ground) connection

Terminal for ground connection

Fuse

Alternating current

Handling mark on package – FRAGILE

Handling mark on package – THIS SIDE UP

Handling mark on package – KEEP DRY

Handling mark on package – TEMPERATURE LIMITATIONS

Handling mark on package – LIMITED STACKING

Mark on package – RECYCLABLE MATERIAL

3. STORAGE AND TRANSPORT

The compressor is shipped in cardboard that protects the appliance from damage during transport.

Caution! For transport, always use the original packaging and secure the

compressor in the upright position.

Protect the compressor from humidity and extreme temperatures during transport and

storage. A compressor in its original packaging can be stored in a warm, dry and dust-free

area. Do not store near any chemical substances.

Keep packaging material if possible. If not, please dispose of the packaging material in an

environmentally friendly way and recycle if possible.

Caution! Before moving or transporting the compressor, release all the air pressure

from the tank and hoses and drain the condensed water.

OPERATION MANUAL DK 50 4x2V/M

NP-DK50 4x2V-M-EN-16_11-2015 11/2015

5

4. PRODUCT INFORMATION

4.1. Purpose and use

Oil-free compressor DK50 4x2V/M - DUPLEX with dryer MONZUN serves as the source of dry, clean,

oil-free compressed air for driving pneumatic appliances and equipment. With its performance,

operational pressures, but also economic operation, it is suitable for the use in large dental

laboratories, dental clinics, with another auxiliary device even as the source of compressed air for

driving devices for support of respiration, for departments of hospitals, as well as in further areas of

medical practice, in food industry, and everywhere clean and dry compressed air is necessary and

where compressor with its version, performance and operational pressure meets the given

requirements.

The device is construed for environment of interior spaces, where temperature of air is within the

scope of +5°C to +35°C, relative humidity does not exceed 80% and absolute humidity of air does not

exceed 15 g/m

3

.

Oil-free compressor DK 50 4x2V - DUPLEX (without dryer) serves as the source of oil-free

compressed air for driving pneumatic appliances and equipment.

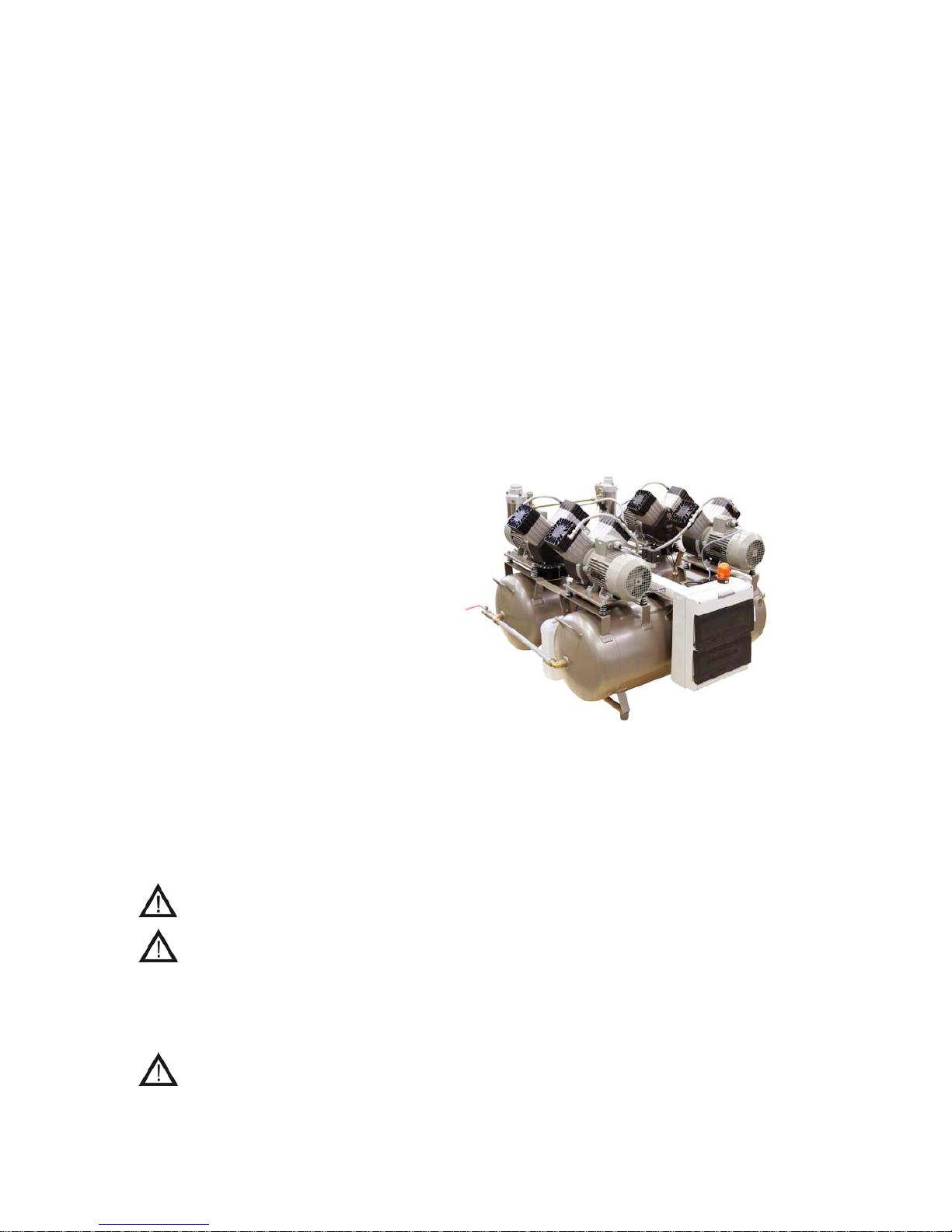

4.2. Product description

The assembly consists of four oil-free,

piston, two-cylinder compressors driven

by three-phase electric motors located

on two air chambers with fittings for

input of compressed air, check valves,

pressure meter, safety valves, pressure

switch and sludge valves. Air chambers

are mechanically connected via

stabilizing consoles and at both

rounded sides of air chambers are

connected by direct pipes. The output

of compressed air from entire unit is

created by ball valve with internal

G3/4“ thread.

Valid for DK50 4x2V/M

There is mechanically fixed air dryer

MONZUN with cooling unit.

New type of the safety valve (PRV) is

included into the pneumatic distribution

between the compressor aggregates

and the dryer.

The safety valve for the air (PRV) is intended for the prevention of pressure increase in the pressure

circuit of the compressor over the permissible value, providing for the protection of individual

pneumatic parts, above all for the compressor aggregates against an adverse influence of inadequate

pressures. The opening pressure of PRV is set to 11 bar.

It is forbidden to deliberately reset the opening pressure on the safety valve; the

resetting should always be agreed on with the manufacturer!

The outlets on the safety valve may neither be closed, nor the pressure air exit

therethrough limited.

When the pressure in the pressure circuit of the compressor increases to the value of set opening

pressure, the PRV automatically starts letting the air from the system through. When the pressure

drops, the PRV will close.

The pressure increase in the pressure circuit can only occur due to the increase of

flow resistances of the pneumatic distributions or in case of the dryer failure (e.g.

non-functional solenoid valves, increased flow resistance of a drying material and

similar) and therefore if a repeated opening of the safety valve occurs, it is

unavoidable to check the dryer function, possibly to repair it

!

OPERATION MANUAL DK 50 4x2V/M

NP-DK50 4x2V-M-EN-16_11-2015 11/2015

6

5. TECHNICAL DATA

Compressor performance: 560 l.min

-1

at overpressure 0,5MPa.

Compressor performance with dryer: 480 l.min

-1

at overpressure 0,5MPa.

Rated voltage / frequency: 3 x 400 V (10%) / 50 Hz

Rated current: 14,5 A

Air chamber capacity: 220 lit.

Working pressure of compressor: 0,6 MPa 0,8 MPa.

Safety valve - opening pressure: 1,2 MPa.

Noise level(dist. 1m, at 480 l.min

-1

a 0,5 Mpa): 73 dB [A]

Weight of device: 240 kg

Dimensions and shape: according to picture

Operation mode: permanent operation – S1

Version: appliance of B type, class I.

(podľa STN EN 60 601-1)

Drying grade of comp.: (only for DK50 4x2V/M) atmospheric dew point - 20

o

C

Advised capacity for exchange of cooling air: 2 297 [m3/hod]

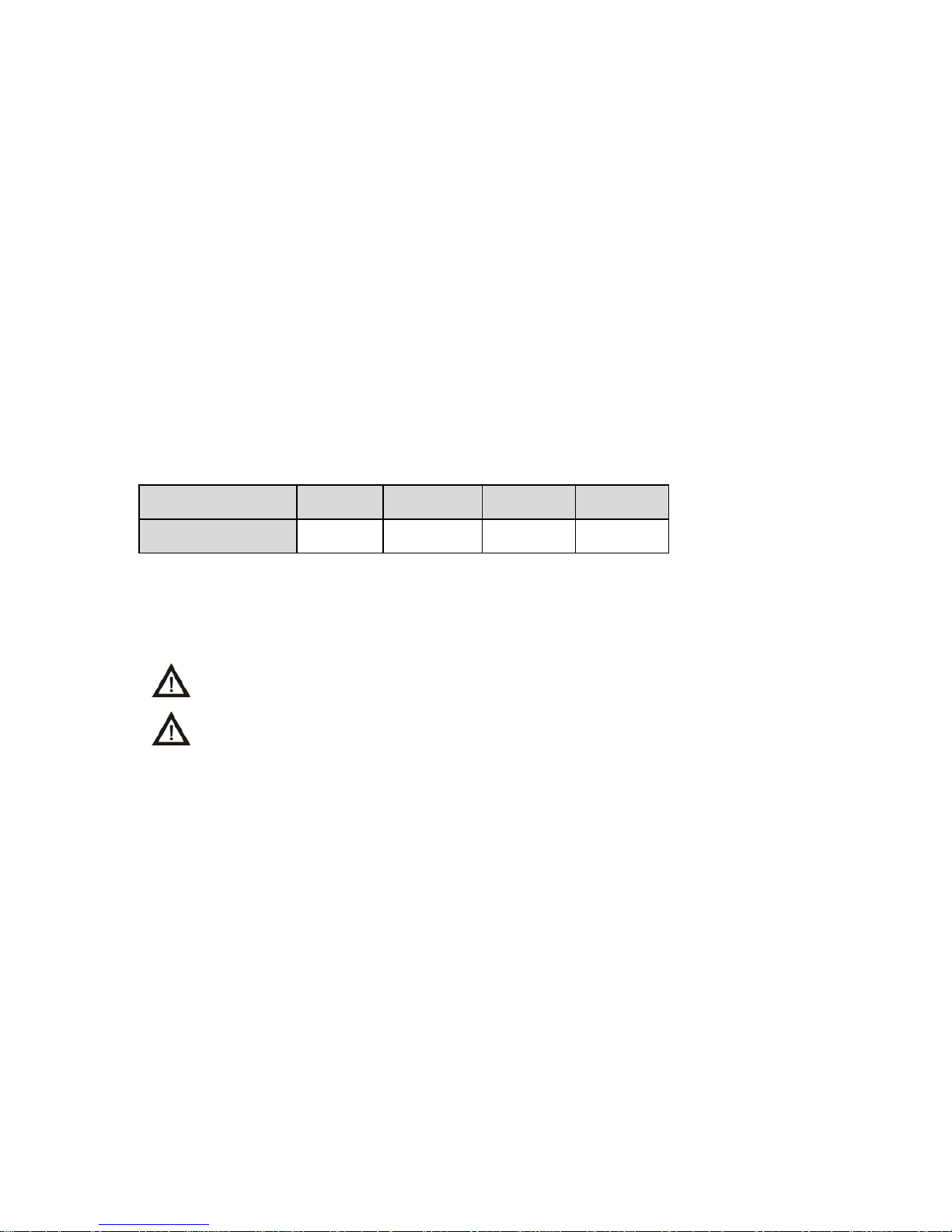

FAD efficiency correction for differences in elevation

FADcorrectiontable

FAD efficiency refers to conditions at an elevation of 0 mamsl: Temperature: 20°C

Atmospheric pressure: 101325 Pa

Relative humidity: 0%

6. INSTALLATION AND ASSEMBLY

Remove fixing elements after unpacking the compressor!

The installation can be performed only by an qualified expert trained by producer

with corresponding electrotechnical qualification!

Air chambers with compressors and dryer after unpacking and unscrewing of screws from transport

pallet are to be placed onto a floor in a room, in which the device shall be operated. Connect

distribution of compressed air to the output of ball valve with internal G3/4“thread.

In the case of installation in the room, which has lower entrance than the exterior dimensions of

device, it is necessary to proceed as follows:

Disassembly of electric part:

Release terminal board cover X4, disconnect wires from terminals PE, N, 1, 2,...,5 and release

cords from clamps.

Mechanically release plastic groove from air chamber with engines M3, M4.

Release wires from terminals of engines M3, M4.

Disassembly of mechanical part:

Disconnect pressure hoses from engines M3, M4.

Release cap nuts with cutting ring at both rounded sides of air chambers and disconnect PE

interconnecting pipes 22 mm.

Release screws on connecting consoles at the sides of air chambers and disconnect consoles.

Assembly of the device:

Separated air chambers should be placed onto the specified place and using the reversal

procedure for disassembly, make assembly of mechanical and electric parts.

Elevation[mamsl] 0‐1500 1501‐2500 2501‐3500 3501‐4500

FAD[l/min] FADx1 FADx0.8 FADx0.71 FADx0.60

Loading...

Loading...