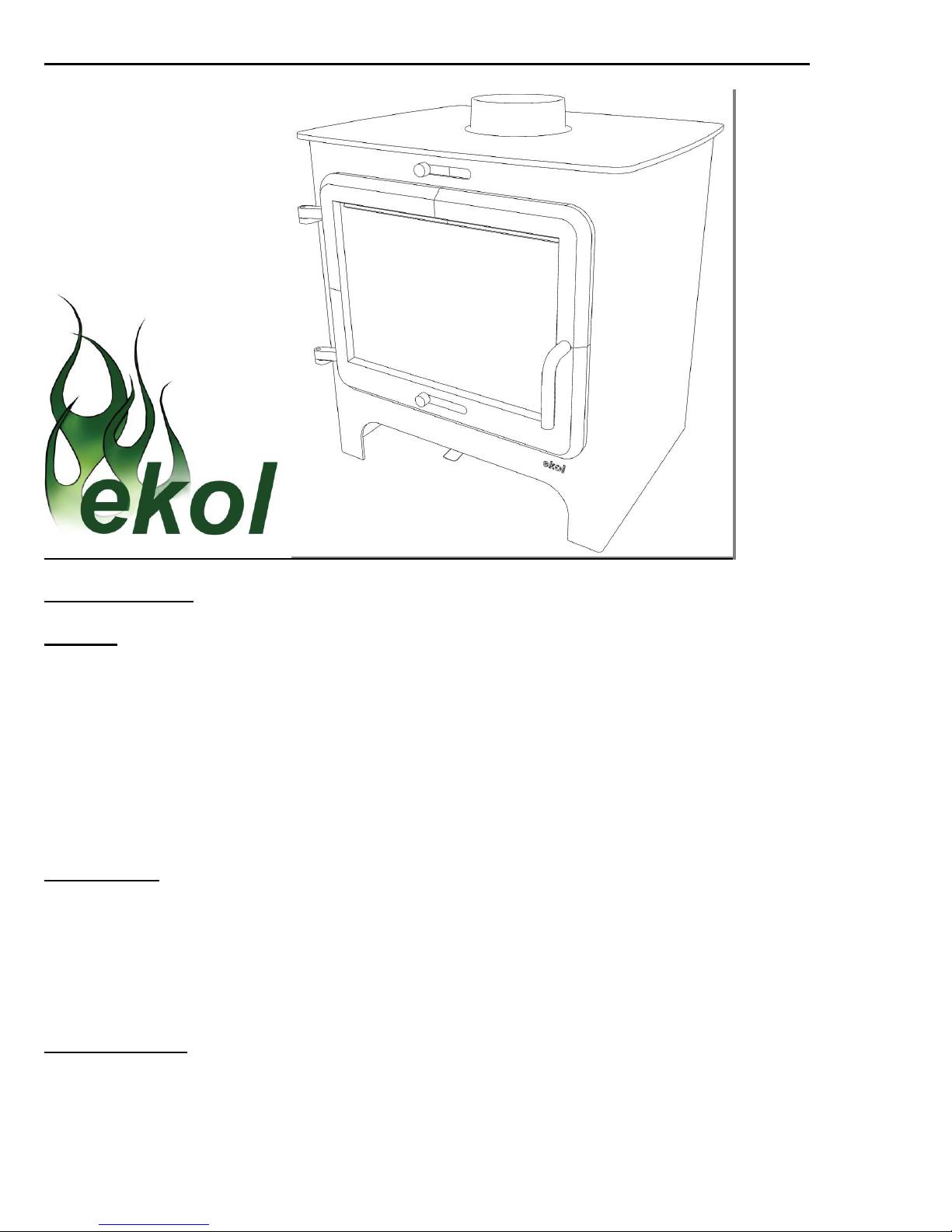

Ekol Clarity Double Sided Installation And Operating Instructions Manual

EKOL CLARITY DOUBLE SIDED – INSTALLATION AND OPERATING INSTRUCTIONS.

INTRODUCTION

SAFETY

Safety is the most important consideration when using and installing your stove. If not installed and used correctly,

a house fire could result. Installation must comply with relevant national and local Building Regulations and fire

safety standards.

IN THE EVENT OF CHIMNEY FIRE, EVACUATE THE PROPERTY AND CALL THE EMERGENCY

SERVICES.

Your stove will be heavy and care needs to be taken when lifting - 2 people will normally be required to lift.

UNPACKING

Your stove will have several of its components stored inside the stove itself for transportation.

Do NOT drag the stove on its legs – it must be carefully lifted into place.

The flue spigot must be bolted to the flue outlet on the top of the stove.

Inside the stove you will find a glove which must be used when opening the door or when adjusting air vents when

the fire is hot.

INSTALLATION

Installation of your stove must comply with relevant local and national Building Regulations and fire safety

standards.

TECHNICAL

Model; “Ekol Clarity Double Sided”

Nominal heat output – 12.3 kW

Maximum Heat Output – 14kW

Gross Weight of Stove (inclusive of packaging) - 160 kg.

Net Weight of Stove – 137kg (low version), 152 kg (tall version).

Max Height - 598 mm (low version), 815 mm (Tall version)

Max Width - 625 mm

Max Depth - 515 mm

Flue Diameter - 150mm (6”)

Mean flue gas temperature directly downstream of the flue spigot – 431 degrees C. (with closed doors).

Flue gas mass flow – 8.4 g/s

Mean CO emission (at 13% Oxygen) –0.14 %

Net Energy Efficiency 73.3 %

The stove must not be installed within the specified minimum distances to combustible materials: A gap of at least

900mm needs to left between the stove and any combustible materials at the sides. Adjacent walls should be of

non-combustible materials and construction, preferably masonry or brickwork.

Your stove will require a constant air supply, and should not be used at the same time and in the same room/space

as extractor fans or any device which may draw air supply away from the stove.

The stove should be installed on a level floor with adequate load bearing capacity.

The stove needs to stand on a hearth of non-combustible materials not less than 12mm thick conforming to

Building Regulations.

NOT suitable for installation in a shared flue system.

If installed in a standard type chimney, a register plate needs to be fitted inside the chimney.

When purchasing flue pipe, 6” diameter is required. The flue pipe must be fitted INSIDE the flue spigot, and sealed

with a generous amount of Fire Cement.

Access should be provided for cleaning the flue gas connector and chimney flue to ensure that the passageways for

exhaust gases remain free from obstruction.

We recommend that you have a qualified fitter install your stove. The British recognised standard for solid fuel

installations is HETAS. You can find a HETAS qualified installer in your area by going to the HETAS website –

www.hetas.co.uk.

OPERATING INSTRUCTIONS

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the authority to be a

smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any fixed

boiler if located in a designated smoke control area. It is also an offence to acquire an "unauthorised fuel" for use

within a smoke control area unless it is used in an "exempt" appliance ("exempted" from the controls which

generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorise smokeless

fuels or exempt appliances for use in smoke control areas in England. In Scotland and Wales this power rests with

Ministers in the devolved administrations for those countries. Separate legislation, the Clean Air (Northern Ireland)

Order 1981, applies in Northern Ireland. Therefore it is a requirement that fuels burnt or obtained for use in smoke

control areas have been "authorised" in Regulations and that appliances used to burn solid fuel in those areas (other

than "authorised" fuels) have been exempted by an Order made and signed by the Secretary of State or Minister in

the devolved administrations.

The “Ekol Clarity Double Sided” has been recommended as suitable for use in smoke control areas when burning

seasoned wood.

Further information on the requirements of the Clean Air Act can be found here : http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision

of smoke control areas and you can contact them for details of Clean Air Act requirements.

FUEL

Wood- All types of wood are suitable provided they are wells seasoned, UNTREATED, and have a moisture level

between 12% and 20%. For soft woods, typically they will need to have been left in suitable storage for 9+ months

in order for the moisture to evaporate. For hardwoods, this will usually be 18 months+. It is recommended that logs

should be no more than 5” or 125mm in diameter. Logs should be no more than 450mm in length. If you are unsure

of the moisture content of your fuel, then you can buy a moisture meter which will indicate the moisture levels in

your fuel.

Liquid fuels must NEVER be used.

WARNING: Wet timber should not be used as this will create excess tar deposits in the chimney and stove and

could increase the risk of chimney fire. Timber which is not of a suitable moisture content will also create more

smoke and harmful emissions.

Manufactured smokeless coals and anthracite can be used and will all have different qualities and effects. – Do

NOT use Petro-Coke based fuels or any petroleum based fuels as this will invalidate the warranty. Never use your

stove as incinerator to burn waste or rubbish. Any coal burned should be coal suitable for a multi-fuel stove (some

coal is only for use on open fires and burns too hot for a stove).

Never use your stove as incinerator to burn waste or rubbish.

AIR INLET CONTROLS

Your stove has four sets of air inlet areas-

The upper vent above each door provides air supply for the air-wash system and allow air into the higher areas of

the fire box – this is called the Secondary air – when this vent is open, the door glass is kept clean by high speed air

rushing downwards across the inside of the glass. By moving the Secondary vent knob to the right, airflow into the

stove is increased. The secondary air vent is set such that the closure plate does not seal fully, thus allowing some

constant air supply into the stove.

The lower vent knob on the bottom of the door controls the provision of Primary air – this is the primary source of

air supply for combustion. Sliding the knob to the right increases the amount of Primary airflow into the stove.

The third (Tertiary) vent control is located underneath the stove and controlled by a lever/ knob tucked under the

bottom shelf. Pulling the lever out increases the airflow into the stove. The air is then channelled through a

chamber on the bottom of the stove and to the sides of the firebox, and enters the firebox via a series of small

holes. Pushing the lever fully in closes of this air intake partially. This intake cannot be fully closed. This ensures

the stove maintains level of combustion not likely to create excessive smoke.

Loading...

Loading...