Page 1

installation and user instructions

All instructions must be handed to user for safekeeping

Revision A - 08/09

Country(s) of destination - GB/IE

eko 4010

eko 4020

high efficiency fuel effect gas fire

Page 2

Eko 4020

Please note : Except where otherwise stated, all rights, including copyright in the

text, images and layout of this booklet is owned by Focal Point Fires plc. You are

not permitted to copy or adapt any of the content without the prior written permission of Focal Point Fires plc.

Eko 4010

Manufactured by :

Focal Point Fires plc.

Christchurch, Dorset BH23 2BT

Tel: 01202 588 638 Fax: 01202 588 639

www.ekofires.co.uk

e-mail: sales@ekofires.co.uk

© 2009 Focal Point Fires plc.

Page 3

[1] GB - Gas SafeTMregistered operatives (Northern Ireland only- CORGI registered operatives) are the only class of person considered as competent by the HSE under the Gas Safety (Installation and Use) Regulations 1998.

• This fire is an Inset Live Fuel Effect Gas Fire providing radiant warmth. It is designed to operate on Natural Gas only

at the pressure stated on the appliance data plate.

• The appliance incorporates a combustion monitoring system (Oxygen Depletion System). It must not be adjusted

or put out of operation. If replaced then manufacturer’s original parts must be used.

• It is the LAW that all gas appliances and fittings are installed by a competent

[1]

person and in accordance with the

Gas Safety (Installation and Use) Regulations 1998, the relevant British Standards for Installation, Codes of Practice

and in accordance with the Manufacturers’ Instructions.

• In the event of gas leakage from the appliance, the gas supply must be turned off at the nearest isolating valve.

• The appliance must be installed in accordance with the following:

• Failure to comply with the above could lead to prosecution and deem the manufacturer’s warranty invalid.

• This appliance must be installed in accordance with the rules in force and used only in a sufficiently ventilated space.

The appliance is designed to fit various types of situations as described in sections 3.0 and 4.0.

• It should be noted that heaters create warm air currents. These currents move heat to surfaces next to the heater.

Operating the heater where impurities in the air (such as tobacco smoke, candle smoke etc.) exist, may cause surfaces

to become discoloured.

• On first light up of a new appliance, burning off of high temperature paint and lubricants may occur for the first few

hours of operation. During this period some smoke may be emitted, this should be no cause for concern. Accordingly,

the room should be well ventilated with all windows and doors open during this period. During this period the appliance may cause smoke alarms to sound. If this happens, reset the alarms, but do not remove the batteries.

• WARNING: Due to the nature of this product the area around the top of the appliance (i.e. the hood) gets very hot.

Care should be taken when operating the appliance. The manufacturer of this appliance considers all surfaces as

working surfaces with the exception of the control knob. The guard (glass front) is to prevent risk of fire or injury

from burns and no part of it should be permanently removed. It Does Not Give Full Protection For Young Children

Or The Infirm. Where young children, pets, the elderly or infirm are concerned, a suitable fireguard should be used.

• Consult ALL instructions before installation and use of this appliance. This appliance is free from any asbestos

material.

• Manufacturers' Instructions.

• The Building Regulations issued by the Department for Communities and Local Government, the Building Standards

(Scotland) (Consolidation) Regulations issued by the Scottish Development Department.

• Relevant British standards :

• BS 5871 part 2

• BS 5440 part 1, part 2

• BS 1251

• BS 6891

• BS 6461 part 1

• BS EN 1806

• BS EN 1856 part 1

• BS EN 1858

• For Republic of Ireland, reference should be made to the relevant standards governing installation, particularly

in regard to flue sizing and ventilation. See IS813, ICP3, IS327 and any other relevant rules in force.

1.0 IMPORTANT NOTES

1

©

2009 Focal Point Fires plc.

INSTALLATION INSTRUCTIONS

Section

1.0

2.0

3.0

4.0

4.1

5.0

6.0

7.0

7.1

8.0

8.1

8.2

8.3

Contents

Important Notes

Appliance Data

Installation Requirements

Site Requirements

Debris Collection Space

Ventilation

Pre Fabricated Flue Boxes

Unpacking the Appliance

Component Checklist

Preparing the Appliance

Preparing the Opening

Gas Supply

Cable fixing

Page No.

1

2

2

2

3

4

4

4

4

5

5

5

6

Section

8.4

9.0

9.1

9.2

9.3

9.4

9.5

9.6

9.7

10.0

11.0

12.0

Contents

Fitting the Burner

Final Assembly, Testing and Commissioning

Spark gap

Fuel bed layout

Final assembly

Operating the appliance

Setting Pressure

Flue Spillage Monitoring System

Testing for Spillage

Briefing the customer

Servicing

Troubleshooting Guide

Page No.

6

6

6

7

8

8

9

9

9

10

10

11

Page 4

The efficiency of this appliance has been measured as specified in BS 7977-1:2002 and the result is 81%. The gross

calorific value of the fuel has been used for this efficiency calculation. The test data from which it has been calculated

has been certified by GL Industrial Services (0087). The efficiency value may be used in the UK Government’s Standard

Assessment Procedure (SAP) for energy rating of dwellings.

This appliance MUST NOT be installed into a room containing a bath or shower, or where steam may be present. The fire

has been designed to fit into a builders’ opening or fireplace conforming to BS 1251 (and meeting certain dimensional

requirements), or a suitable flue box complying with the constructional requirements of BS 715. The flue box must be

installed onto a suitable non-combustible insulating surface at least 12mm thick, covering the entire base area of the box.

The flue must have an effective height of at least three metres, as measured from the hearth to the top of the flue. Any

flue damper plates or restrictors should be removed and no other restriction fitted to the flue. Where removal is not

practical, the restriction must be fixed in the fully open position.

A natural draught flue system is required, and if previously used for solid fuel or oil burning, the flue and chimney must

be swept prior to appliance installation. The flue must be checked before installation by using a smoke pellet or similar to ensure proper draw and that leakage is not evident at any joints. Repair and re-test as necessary before the appliance is installed.

The flue must be connected to only one fireplace, and the flue must not vent more than one appliance (i.e. not shared

with a gas back boiler). There must be no opening in the flue apart from the one that the appliance is installed into,

and the one venting the gases into the air. A suitable terminal may be fitted, such as class GC1, as regulations allow.

This appliance has been tested for use in a pre-cast block flue complying with BS 1289. In accordance with BS 1289 part

1, pre-cast flues built with directly plastered faces (front or rear) are not correctly installed as to ensure proper operation with any type of gas fire. In some instances of this flue construction, temperature cracking of the surface plaster

may occur through no fault of the appliance. An air gap or some form of insulation material should be installed to prevent normal flue temperatures from damaging wall surfaces. Pre-cast flues must be checked for mortar fangs and correct installation of joints, flue sections in loft space and terminals.

This appliances has been tested for use with circular flues of a minimum internal diameter of 125mm.

This appliance MUST be installed into a non combustible back panel capable of withstanding 150

o

C.

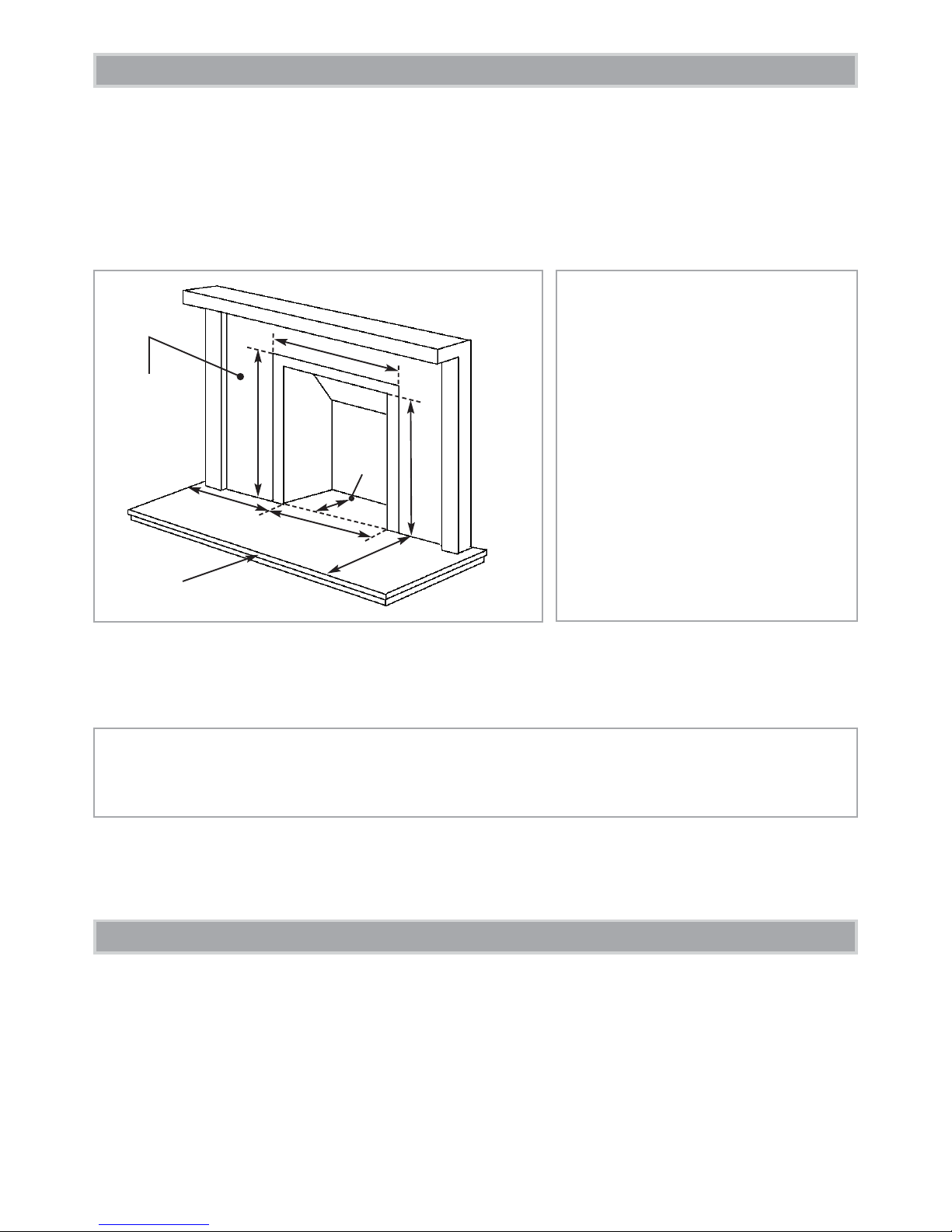

The fireplace opening should be inspected and repairs made where necessary. Any chair brick or fireback may be left

in situ, providing that the dimensional requirements for debris collection space and spigot clearances are met. See figure 1. The opening WIDTH and HEIGHT dimensions should be between 385mm and 440mm wide, and 545mm to

575mm high. For flues used with solid fuel, minimum WIDTH is 380mm.

Opening DEPTH should be 145mm or greater for a clay/cement lined or pre-cast flue which is new, unused or previously only used with a gas fire. DEPTH should be 185mm or greater for a flue which has previously been used for a

solid fuel or oil burning appliance. Opening DEPTHS include any plaster or infill panels which form part of the installation. Any existing under grate draught device must be sealed off. WARNING This fire is designed to get very hot! The

fireplace opening wall or back panel must be non-combustible and rated to withstand 150

o

C.

2.0 APPLIANCE DATA

3.0 INSTALLATION REQUIREMENTS

4.0 SITE REQUIREMENTS

Efficiency 90% (net), 81% (gross)

NOx Class 2

Pilot Energy Input (gross) 166 W

Oxypilot (ODS) SIT 9082

Main Injector Burner Stereo 65

Gas Inlet Connection 8mm Inlet Restrictor Elbow

Gas Control Valve Dungs BM 733/NGC6802

Ignition Integral Piezo spark

Spark Gap (± 1.0mm) 4.0mm

Weight 20 Kg

Please see Data Badge affixed to appliance for current data.

This appliance is for use only with the gas type, and at the pressure stated on the appliance Data Badge.

Destination

Country

Cat

Inlet Pressure

(±2.0 mbar)

Max Energy Input

(kW)

Min Energy Input

(kW)

High Burner

Pressure

(±1.5 mbar)

Low Burner

Pressure

(±0.75 mbar)

G20 G25

G30 G31

Gross Net Gross Net Hot Cold Hot Cold

GB - IE I2H 20

-

- -

5.0 4.5 3.5 3.15

18.6 18.1

9.1 8.8

2

©

2009 Focal Point Fires plc.

Page 5

This appliance requires a natural draught flue system which may be one of the following;

225mm x 225mm (9in x 9in) brick or stone.

125mm (5in) minimum diameter lined brick or stone.

125mm (5in) minimum diameter twin wall flue conforming to BS 715.

Pre-cast block flue complying with BS 1289.

The appliance requires a hearth with non-combustible surface of at least 12mm thick. The top surface must be at least

50mm above the surrounding floor level, or be surrounded by a raised edge or fender 50mm high.

To enable the products of combustion to be cleared properly up the flue, the outlet at the back of the appliance must

have a 50mm minimum clearance between it and the back wall of the opening or any other obstruction. The area immediately above the outlet must form a smooth path into the flue.

Any type of fire surround used with this appliance must be adequately sealed to the wall and floor.

A combustible shelf may be fixed to the wall above the fire, providing that it complies with the dimensions given below.

A non-combustible shelf may be fitted to within 10mm of the top edge of the fireframe. Combustible materials, such

as wood, may be fitted to within 100mm (4in) of either side of the fireplace opening, providing the forward projection

does not exceed 100mm (4in). Any combustible side walls must be at least 500mm to the side of the radiant heat

source. As with all heating appliances, any decorations, soft furnishings, and wall coverings (i.e. flock, blown vinyl

and embossed paper) positioned too close to the appliance may discolour or scorch.

The mounting depth of this appliance is 180mm. In accordance with BS 5871 part 2, minimum debris collection volumes are required behind the installed appliance. These are shown in the table below and as dimension X on the fireplace diagram shown previously.

CLAY/CEMENT LINES OR BLOCK FLUE WHICH IS NEW, UNUSED, OR PREVIOUSLY ONLY USED WITH A GAS FIRE.

X Dimension = 20mm

UNLINED FLUE OR CHIMNEY WHICH HAS BEEN PREVIOUSLY USED FOR A SOLID FUEL OR OIL BURNING APPLIANCE

X Dimension = 60mm

4.0 SITE REQUIREMENTS (continued)

A. Opening height: 545mm min/575mm max.

B. Opening width: 350mm min/440mm max.

C. Mounting depth: 125mm

D. Hearth must extend minimum of 150mm

either side of the opening.

E. Hearth must extend minimum of 300mm in

front of the fuelbed.

F. Non-combustible hearth must be a minimum

of 50mm in height, or be surrounded by 50mm

high fender.

G. 470mm: This area must be flat and vertical

to allow good frame sealing.

H. 585mm: This area must be flat and vertical

to allow good frame sealing.

X. See section 4.1.

A

C

D

B

E

F

G

H

X

Figure 1

Maximum depth of shelf Minimum distance from finished hearth

surface to underside of shelf

100mm (4in) 745mm (29

1/4

in)

150mm (6in) 845mm (33

1/4

in)

203mm (8in) 895mm (35

1/4

in)

4.1 DEBRIS COLLECTION SPACE

3

©

2009 Focal Point Fires plc.

Non combustible

back panel

capable of

withstanding

150

o

C.

Page 6

No purpose provided ventilation is normally required for this appliance. The requirements of other appliances operating in the same room or space must be taken into consideration when assessing ventilation.

If spillage is detected when commissioning the appliance, then amongst other problems there may be insufficient natural ventilation for correct operation of the flue. If the appliance does not spill with the windows open, but spillage is

detected with the windows closed, this demonstrates a lack of natural ventilation. If spillage is still detected with the

windows open, the flue is at fault. Installation of an air brick is the best solution to lack of ventilation. Any ventilation

fitted must comply with BS 5871 part 2 and BS 5440 part 2. Vents fitted under or within the immediate vicinity (1 metre)

of the appliance must not be used as adverse effects to the operation of the ODS may occur.

Spillage detected during commissioning is almost always a result of poor flue performance that cannot be corrected by

any amount of ventilation.

For Republic of Ireland ventilation may be required, see IS 813, ICP3, IS 327, and any other rules in force.

This appliance can be fitted into a number of proprietary flue

boxes provided that the minimum dimensions given in figure 2

are complied with.

Constructional Note: The frame of the fire, any back panel or

other infill panels, and the flue box must be sealed together so

that there is no possibility of leakage between them. Adequate

clearances to combustible materials (e.g. false chimney breast construction) must be maintained.

The manufacturers’ instructions for fitting the prefabricated

box shall be complied with at all times.

To fit the fire using the cable fixing kit, some minor adaption may

be necessary for certain flue boxes. A check should be made to

ensure the firebox does not obscure the flue box outlet. The firebox, base of the flue box, and hearth below may be drilled to allow

plugs and screws to secure installation. It is important that the

sealing requirements of the appliance are met at all times and that

the flue box is well sealed to any back or infill panel. Note: The

DEPTH dimension is inclusive of any back or infill panel.

Stand the carton the right way up, cut the strapping bands and remove the top endcap. Read all the instructions before

continuing to unpack or install this appliance.

Remove the box containing the firefront, and the bags containing the ceramic components. Remove the cardboard packing pieces, and any other bags or boxes containing fittings or other parts. When all loose parts have been removed, the

outer sleeve may be lifted off to reveal the appliance. Check that the components supplied correlate with the component checklist given in section 7.1. Please dispose of all the packaging materials at your local recycling centre.

QUANTITY DESCRIPTION

1 Firebox and burner assembly

1 Decorative frame (either of three-piece design or one-piece dependant on exact model)

1 Firefront

1 Black moulded ceramic fibre combustion matrix

4 Moulded ceramic coal pieces

1 Front ceramic decorative strip

1 Ceramic rear panel

1 Cable fixing kit; 2 cables, 2 tensioners, 2 cable clamps, 4 fixing eyes

1 Sealing grommet

1 Screw pack; 7 x No8 x 5/16 Self tapping type, 2 x M4x12 Machine screw type.

1 Spigot restrictor

1 Deflector baffle/burner heatshield (shown in fig.9)

1 Smoke match tube

1 Set of manufacturers instructions

4 Wall Plugs

5.0 VENTILATION

125mm min internal

dia twin wall flue

540mm

min

opening

height

140mm

min depth

380mm min

opening width

6.0 PREFABRICATED FLUE BOXES

Figure 2

7.0 UNPACKING THE APPLIANCE

7.1 COMPONENT CHECKLIST

4

©

2009 Focal Point Fires plc.

Page 7

The fireplace opening and environment must be in compliance with specifications laid down in the appropriate sections of these instructions. Remove the

appliance from it’s carton as described previously and stand upon a dust sheet

or similar. Place the decorative frame, coals, ceramics and fixings safely to one

side. Remove the glass panel assembly by removing the retaining screws.

Remove the burner from the assembly by removing the retaining screws. The

tray is now free, and may be lifted away.

Spigot restrictor : The appliance is supplied with an optional spigot restrictor.

The spigot restrictor may be fitted when the fire is to be installed in a good

class 1 flue, a conventional brick chimney, or a 175mm (7”) circular flue. The

spigot restrictor is not recommended for pre-cast and 125mm (5”) circular flues

as it may cause spillage. If required, fit the spigot restrictor using three No8 x

5/16 Self tapping screws (supplied loose) as shown in figure 3.

If spillage is detected during the commissioning of the appliance, the spigot restrictor should be removed immediately.

Supply pipe entry : Knockout holes are provided in the rear and sides of the firebox for use where concealed pipework

is required. Where necessary, knock out the appropriate hole with a sharp tap from a hammer, and fit the rubber grommet supplied. A small incision can now be made in the rubber to slip snugly around the outside of the pipe and sleeving. Do not install or use the appliance without the seals in place. If a hole is inadvertently opened, reseal with an

intact grommet. Failure to fit the seal correctly will cause flue suction to act upon the area under the burner, resulting

in poor performance and intermittent cutting out of the burner. Some possible pipe routes are shown in figure 5.

The appliance is supplied with a high temperature rope sealing strip factory fitted to the firebox.

Before installing the fire, check the flue for correct operation using a smoke pellet. All of the smoke should be drawn

up the flue and exit correctly from the terminal. If problems are found

DO NOT fit the fire until corrective action is completed.

Protect the decorative hearth whilst pushing the convector box in and

out of the opening. Part of the packaging is an ideal hearth saver pad.

Before running the gas supply into the opening, offer up the convector

box to the fireplace to check the fit is good. Ensure that it slides in correctly, the sealing face sits flat and square to the wall or infill panel, and

that the base is firm in the floor of the opening as no leaks are permissible here. At this stage it is essential to ensure that the spigot outlet of

the fire is not obstructed in any way. Remove the convector box and take

any necessary measurements before making good and preparing for

final installation.

Cable fixing: Drill four holes as shown in figure 4 and fit the wall

plugs. If the fireplace does not allow for the exact layout shown, the

eyebolts should be fixed to give a similar configuration as possible. To

complete the cable fixing of the convector box, refer to section 8.3.

Fixing by screw: Mark and drill the fireframe or base, and relevant

points in the opening or on the wall. Additional screws will be required for this method of fixing.

When the opening is ready for installation of the fire, the gas supply can be routed. Some possible supply pipe routes are shown in

figure 5.

Select the supply route most relevant to the entry point of the gas

supply into the fireplace opening. If using an across the hearth

connection, then the firefront is notched and the supply pipe can

be routed through this.

The gas pipe must be suitably protected where it passes through

fireplace openings. Any sleeving should be sealed to the pipe at its

ends.

The open end of the gas supply pipe should be temporarily sealed

to prevent ingress of dust and dirt during installation.

8.0 PREPARING THE APPLIANCE

Figure 3

Inlet restrictor elbow

Grommets

Fireplace opening

Firebox

Figure 5

8.1 PREPARING THE OPENING

A

B

C

A. 250 mm

B. 330 mm

C. 70 mm

All dims

+/-10mm

Figure 4

8.2 GAS SUPPLY

5

©

2009 Focal Point Fires plc.

Page 8

Thread both tensioning cables through the holes at

the top of the firebox, both eyelets, and back

through the lower holes in the firebox in the positions indicated in figure 6.

Push the appliance back into the fireplace, centralise

and pull the loose cables through the holes into the

firebox.

Thread the cable tensioners onto the cables as

shown, with the nuts screwed down close to the tensioner head.

Slide the screwed nipple onto the cable, pull cable

taut and tighten nipple.

Adjust tensioner using suitable spanners to pull the

appliance back into position, to allow an even seal

around the fireplace opening. See figure 7.

Visually inspect the seal and reseat if necessary.

Surplus tension cable MUST NOT be cut off as this will prevent proper installation after servicing. Coil up the surplus

cable as shown in figure 8.

Temporarily fit the burner tray and ensure a suitable gas route can

be achieved. Place the burner tray into the firebox making sure

that the rear lugs locate properly on to the ledge in the firebox. Fit

the two securing screws through the tray legs to secure the assembly.

Connect the gas supply and tighten the gas connections. Fit the

data/control plate to the tray using the two screws provided.

Ensure that the control knob can be pushed fully in and does not

touch the plate.

Fit the deflector baffle to the two locations on the front face of the

firetray. Screws are provided for this purpose. The baffle should be

level with the lower edge of the tray. Place contemporary firefront in

front of the fire temporarily to check the angle of the baffle. The front should fit well and the control devices beneath

should not be visible to the eye. Realign the baffle slightly if necessary to achieve the correct fit.

Purge the gas supply thoroughly to remove air and dirt/debris BEFORE connection. Now disconnect the inlet restrictor

elbow from the inlet pipe. Connect the previously installed gas supply to inlet restrictor elbow, and re-fit the restrictor

elbow to the inlet pipe of the appliance.

If using an across hearth connection, ensure the decorative fireframe and firefront will clear the supply route.

If the data/control plate is not already fitted, attach with two screws, ensuring the control knob is free to be depressed

fully.

Turn on and test the gas supply up to the fire for any leaks, in accordance with current edition of BS6891.

When the appliance is first used, protective oils coating the firebox may burn off. It is advisable to ventilate the room

during this period for at least one hour.

The spark gap (shown in figure 10) between the spark electrode and the thermocouple should be 3.5 - 4.5mm to produce a good spark.

There should be no need to adjust this.

If under any circumstances the electric spark fails, the pilot may be lit manually by

proceeding with the ignition sequence as previously described, and after turning the

control knob through the spark position, the knob should be held in and the pilot lit

with a taper.

8.3 CABLE FIXING

Cable Route

Fireplace

opening

Eyebolts

Figure 6

1. Tighten nipple onto cable

2. Hold tensioner steady

3. Tighten nut

Figure 7

Figure 8

8.4 FITTING THE BURNER

9.0 FINAL ASSEMBLY, TESTING AND COMMISSIONING

Figure 9

6

©

2009 Focal Point Fires plc.

9.1 SPARK GAP

Figure 10

Spark gap

Page 9

9.2 FUEL BED LAYOUT

2. Place the moulded coal piece marked on the

underside ‘A’ onto the matrix as shown in figure 11.

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15

1. Remove the ceramic components from their protective packaging, and place the brick panel against

the rear of the firebox.Place the ceramic combustion

matrix onto the burner.

3. Place the moulded coal piece marked on the

underside ‘B’ onto the matrix as shown in figure 12.

4. Place the moulded coal piece marked on the

underside ‘C’ onto the matrix as shown in figure 13.

5. Place the moulded coal piece marked on the

underside ‘D’ onto the matrix as shown in figure 14.

6. With pieces ‘A’ to ‘D’ correctly in position, the fuel

bed should appear as shown in figure 15.

Note : The fire is designed to operate correctly with

only the ceramic coal pieces supplied when assembled according to these instructions. Never add

extra ceramics, or change them for a different type.

Never throw rubbish or other matter onto the

fuelbed.

7

©

2009 Focal Point Fires plc.

Note: Pilot viewing hole

Page 10

Refit the glass panel ensuring that the unsupported edge of

the glass is facing downwards. Take care not to damage the

ceramic fuel bed when fitting. Secure using four M6 screws

previously removed.

Now fit the hood. This is provided separately. Remove all protective packaging materials. Carefully attach using two No8 x

5/16 self tapping screws (also provided within loose parts) in

the positions shown in figure 16. Do not overtighten.

Now fit the decorative front coal piece. This is intended to sit

flush in front of the glass panel in order to complete the realistic coal fuel effect.

Attach the strip using two M4 screws in the positions shown

in figure 17. Take care not to damage the ceramic part of the

component.

The appliance is supplied either with a one piece or three

piece decorative frame.

For one piece frames : The appliance is supplied with a one

piece decorative frame that is attached to the front of the firebox with the magnets provided.

Place the decorative firefront in front of the fire and slide the

ashpan door into place. The firefront shown in these instructions may be different to the one supplied with the appliance.

For three piece frames : The side pieces of the clip on

assembly should be pushed into position first, followed by

the top bar (shown in figure 18), which should overlap the

sides.

IMPORTANT NOTE: Due to the possibility of sharp edges,

care should be taken when handling the three piece frame

components. The use of protective gloves is recommended.

Place the firefront into position in front of the fire and slide

the ashpan door into place. Do not use any other firefront

other than the one supplied with this appliance. The firefront shown in these instructions may differ from the one

supplied with the appliance.

The pilot is visible through the viewing hole (see figure 15) which is located at

the lower left hand side of the fuel bed.

Push in and turn the control knob to the SPARK position, and hold there for a few

seconds.

Continue turning anti-clockwise through the spark click to the PILOT light position, ensuring the pilot has lit. If not, return the knob clockwise, and repeat.

When the pilot lights after the spark, keep the knob depressed for approximately ten seconds. Now release the knob and the pilot should stay alight. If the pilot

is extinguished during use, wait three minutes before repeating the ignition procedure.

To achieve the HIGH setting, push the control knob in slightly and continue turning anti-clockwise to the high position.

The main burner should light after a few seconds.

To decrease the setting to low, turn the control knob clockwise to the LOW setting.

To turn to the PILOT position from the HIGH or LOW positions, press the control knob in, and return to the pilot position and release.

To turn the fire off, keep the knob pressed in, return to the OFF position and release.

8

©

2009 Focal Point Fires plc.

9.3 FINAL ASSEMBLY

Figure 16

Figure 17

Figure 18

9.4 OPERATING THE APPLIANCE

Figure 19

Page 11

The pressure test point is located on the left hand side of the

appliance, on the main burner pipe, next to the brass restrictor/connector. Release the setting pressure test point screw

(shown in figure 20), and attach a pressure gauge. Light the fire

on the HIGH setting.

To commission the appliance, the burner pressure must be in

accordance with the figures stated in section 2.0 of these instructions. The fire is factory set to achieve these pressures and any

significant variation could indicate a supply problem.

If the pressure is too high, the gas supply meter may be set incorrectly. This should be checked with the fire running and if necessary reset by the gas supplier. If the burner pressure is too low,

then check the inlet pressure with the appliance running. If this is less than the inlet pressure stated in section 2.0 of

these instructions it will need to be reset by the gas supplier. If the setting pressure is too low, but the meter pressure

is acceptable, then a problem in the supply pipework is to be suspected. Upon satisfactory checking of the burner pressure, turn the fire off, disconnect the pressure gauge and refit the test point screw. Light the fire and check for gas

soundness. In the event that the burner pressure is not in accordance with the figures stated in the data section of these

instructions, the appliance must not be commissioned, and the manufacturer should be contacted for guidance.

This fire is fitted with a flue spillage safety device (ODS).

If the fire shuts down during use for no apparent reason then several things may be suspected. If a door or window has

been opened creating a draught, then pilot disturbance is the problem, and removal of the draught should resolve this.

The gas pressure reaching the fire must also be checked (again, recall your installer to check and rectify any problem).

The thermocouple connection into the back of the gas control valve may also have worked loose during installation,

simply get the installer to tighten.

If pilot disturbance is not the cause, then the ODS safety system may be in operation. Switch the appliance OFF, check

the flue and carry out any remedial work required. Relight the fire and carry out a spillage test. DO NOT allow the appliance to be used if it continues to fail a spillage test.

The aeration hole of the pilot must be carefully cleaned out on each annual service to ensure continued function of the

ODS.The spillage monitoring system shall not be adjusted, modified, or put out of operation by the installer. Any spare

parts fitted MUST be of a type supplied for the purpose by the appliance manufacturer. If the fire is not spilling, then

further guidance should be sought, using the Troubleshooting section as a guide.

Close all doors and windows to the room containing the appliance. Let the fire run on HIGH for five minutes. Take a

smoke match and put in the smoke match tube provided. Light the smoke match and position the end of the smoke

match tube centrally next to the draught diverter as shown in figures 21 and 22.

All the smoke should be drawn away up the flue.

Any smoke returning into the room indicates that spillage is occurring.

If the spillage test fails and the spigot restrictor is fitted, remove the spigot restrict, re-fit and re-test. If the initial

spillage test fails, run the fire for a further 10 minutes and repeat the test. When the test has been completed satisfactorily, repeat with any extractor fans in the premises running on the highest setting, and any communicating doors

open. Finally, repeat with all doors open.

DO NOT allow the fire to be used until the test is satisfactorily passed.

9.5 SETTING PRESSURE

9.6 FLUE SPILLAGE MONITORING SYSTEM

9

©

2009 Focal Point Fires plc.

Figure 20

9.7 TESTING FOR SPILLAGE

Figure 22

Section view of draft diverter

Figure 21

Note : insert smoke match

tube until end of tube

touches draft diverter baffle

=

=

Note : insert smoke match

tube centrally

Page 12

All instructions must be handed to the user for safekeeping. Show the customer how to light and control the fire. After commissioning the appliance, the customer should be instructed on the safe use of the appliance and the need for regular servicing. Frequency of service depends on usage, but MUST be carried out at least once annually. Advise that cleaning of the fire

may be achieved when the fire is cold using a damp cloth and mild detergent on most surfaces.

Scratched and other superficial damage to the mat black paintwork of the appliance can be covered with matching heatproof

spray. Use only the manufacturers’ recommended spray paint. Paint only when the fire is OFF and cold. Always mask off the

surrounding area to prevent contamination with overspray. Ventilate the room during the use of the spray. DO NOT attempt

to spray paint the coals or ceramics, or wash them in water.

Advise that the fire will emit a “newness” smell for a time after initial commissioning and that extra ventilation may be needed during this time. Advise that the fire is fitted with a spillage safety device (O.D.S.). If the fire shuts down, this system may

be in operation. If spillage is suspected, SWITCH APPLIANCE OFF and call in the installer to investigate any problems.

Isolate the fire from the gas supply. Ensure that the fire is fully cold before attempting service. A suggested procedure for servicing is detailed below.

Remove the firefront and place to one side. Remove the ceramic components. Gently clean in the open air. Be careful not to

create dust from the coals. Where necessary replace damaged components with genuine spares. Seal scrap ceramic components in plastic bags and dispose at proper refuse sites as directed. Re-fit the coals by referring to section 9.2 of these

instructions.

Remove the firefront. Remove the ceramics and the data/control plate and place safely aside.

Remove the two screws securing the tray legs to the firebox. Pull tray forward slightly and lift away.

Refitting is the reverse of above, being sure to engage the tray location lugs on the shelf at the rear of the firebox.

Remove the tray as previously described. The pilot unit can be removed by withdrawing the tubing nut, the thermocouple nut

on the rear of the valve, and the two securing screws, and lifting away. Remove the tubing nut from the valve end of the pilot

pipe, and blow through to dislodge any debris.

Remove the two tubing nuts on the ends of the gas pipe to the injector elbow and blow clear. Release the screw through the

supporting leg and lift assembly clear. The injector pipe can now be checked for debris. Remove the nut retaining the injector

elbow. Blow through the elbow to remove any debris. The valve is not field serviceable, apart from the pilot filter. Remove the

control knob by pulling it forwards, then remove the largest of the three screws on the face of the valve. Slide the filter out

and clean away any debris that may have accumulated. The filter element should also be blown clean. This component should

not require replacement, however if signs of deterioration are evident then a genuine spare part must be used. If a large

amount of debris is present in the filter then the pipework and gas valve should be thoroughly cleaned before re-assembly.

Remove the burner tray as in relevant section and pilot unit as described.

Clean the pilot assembly with a soft brush and blow through. Check the aeration holes are free of any dirt or lint. Clean

thoroughly internally, the connection can be removed from the base of the pilot unit using two spanners to make cleaning

easier. Do not damage or try to remove the pilot injector. The unit is factory set and the only check necessary is to ensure

the spark gap is correct. See section 2.0 Appliance data for gap setting. See section 9.1 for full details of the pilot assembly.

10.0 BRIEFING THE CUSTOMER

11.0 SERVICING

10

©

2009 Focal Point Fires plc.

1. Lay out the dust sheet and tools.

2. Remove the hood, glass panel, and remove the ceramic components.

3. Remove the firefront and decorative trim.

4. Remove the two screws that retain the data/control plate.

5. Disconnect the gas supply, and remove the two securing screws in the tray legs.

6. Remove the burner tray.

7. Remove firebox as described.

8. Check the fireplace opening for rubble accumulation and remove. If debris is excessive, initiate remedial work on the flue.

9. Check the flue with smoke pellet for correct operation.

10. Vacuum clean inside of firebox removing all dust. Refit firebox.

11. Strip off the burner pipes and clean thoroughly.

12. Clean out the injector, pilot assembly and burner tube. DO NOT remove the pilot injector.

13. Vacuum clean tray, especially around the injector/venturi tube removing all dust. Re-assemble and re-fit the burner tray.

14. Clean the ceramic components - see section 9.2.

15. Turn on the gas supply, and leak test.

16. Refit the ceramic components, glass panel, hood, decorative frame and cast firefront.

17. Check any purpose provided ventilation is un-obstructed.

18. Light the fire and carry out a spillage test.

19. Check setting pressure and safe operation of the appliance.

For specific servicing instructions, see the relevant sections.

11.1 CLEANING THE CERAMIC PARTS

11.2 REMOVING THE BURNER

11.3 DISMANTLING THE BURNER

11.4 PILOT ASSEMBLY

Page 13

Remove the burner tray as described previously.

Protect the hearth from potential damage. Unroll the coiled tensioner cables from the rear of the firebox. Remove the

securing nipples and tensioner adjusters. The firebox is now released from the opening and can be slid outward onto

the hearth. Inspect the fireplace opening for debris and if excessive rectify the flue before proceeding further. Check

the seal around the fireframe and if necessary replace. Refitting of the firebox is as described in the fitting section of

these instructions.

Fire sparks but pilot does not light • No gas to fire, check isolators are open and gas supply is on.

• Pipework blockage, clean out.

• Air not fully purged, re purge supply or wait longer.

• Spark earthing to metalwork, reset gap correctly.

• Blocked pilot, clean out internally.

Pilot lights but then goes out • Severe restriction in gas supply: clear obstruction.

• Faulty thermocouple, replace pilot unit.

• Blocked pilot, clean out.

• Blocked lint gauze, clean.

• Hold control knob in for longer.

• Check control knob does not foul indicator plate.

• If the pilot will not stay lit there could be a problem with contamination of the

gas supply, drafts, room size and/or ventilation or the thermocouple needs

replacement.

Modifications are dangerous and can have a serious unseen effect on safety.

NEVER MODIFY OR BEND THE THERMOCOUPLE TO MAKE THE PILOT STAY ALIGHT.

Fire does not spark at pilot • HT lead detached, refit.

• Check the spark gap (see section 9.1).

• Faulty piezo unit, replace.

• Debris shorting out electrode, clean.

• Spark shorting to metalwork under tray, check routing of HT lead under burner.

Fire runs for a time • Loose or faulty thermocouple, rectify.

and then cuts off • Blocked pilot, clean out.

• Excessive drafts in the room.

• Excessive flue pull.

• Fire is too close to an air vent.

• Fire is sited on disused chimney breast which has not been adequately sealed up.

• Dirt or lint in pilot aeration hole or on the lint gauze, clean thoroughly.

• If the pilot will not stay lit there could be a problem with contamination of the

gas supply, drafts, room size and/or ventilation or the thermocouple needs

replacement.

Modifications are dangerous and can have a serious unseen effect on safety.

NEVER MODIFY OR BEND THE THERMOCOUPLE TO MAKE THE PILOT STAY ALIGHT.

Pilot flame shrinks when • Poor gas flow to fire, check pressure with fire on high.

fire is on high • If pressure is low, remove any restriction in pipework or valve.

• Check all isolators are adequately sized and fully open.

• Check meter pressure is adequate.

• Firebox grommet seal missing, rectify.

• If the pilot will not stay lit there could be a problem with contamination of the

gas supply, drafts, room size and/or ventilation or the thermocouple needs

replacement.

Modifications are dangerous and can have a serious unseen effect on safety.

NEVER MODIFY OR BEND THE THERMOCOUPLE TO MAKE THE PILOT STAY ALIGHT.

Fire smells when first lit or in use • Newness smell from brand new appliance.

• Spillage occurring. Carry out Spillage test and rectify any problems.

• Combustible materials used in incorrect positions.

• Firebox grommet seal missing, rectify.

• Other airborne contaminants such as dust, tobacco smoke, paint vapours.

11.5 REMOVING THE FIREBOX

11

©

2009 Focal Point Fires plc.

12.0 TROUBLESHOOTING GUIDE

Page 14

The installation of this fire MUST only be carried out by a competent

[1]

person in accordance with the Gas Safety (Installation

and Use) Regulations 1998, the relevant British Standards, Codes of Practice, the Building Regulations and the manufacturers’

instructions.

Failure to comply with the above recommendations could lead to prosecution and invalidate the appliance warranty.

Please ensure you are handed all of the manufacturers documents on completion of the installation. This will include these

instructions. Always keep a note of the installer’s name, address and Gas Safe

TM

registration number, the original purchase

receipt and the date of installation for future reference.

The fire and flue should be serviced regularly to ensure continued safe operation. See the servicing section for further details.

Frequency of service will depend on use, but MUST be carried out at least once annually.

The guard (glass front) is to prevent risk of fire or injury from burns and no part of it should be permanently removed.

It Does Not Give Full Protection For Young Children Or The Infirm. Parts of this appliance become naturally hot during use.

It is recommended that a suitable fire guard conforming to BS 8423 is used, especially where young children, the

elderly, or infirm are concerned.

The manufacturer of this appliance considers all surfaces as working surfaces with the

exception of the control knob and control panel.

Combustible items, such as flooring and furniture, and soft wall coverings (such as blown vinyl or embossed paper) may discolour if fitted too close to the fire. See relevant section for further details on clearances to combustibles. No combustible

material or flooring should protrude onto the hearth. DO NOT burn any foreign material on this fire, the coals must be of the

correct type and laid out in accordance with the relevant section of these instructions. Failure to do so could create a hazard

or lead to sooting. Before the appliance is installed, the chimney should be swept. All flues should be checked by the installer

to ensure there are no defects or obstructions that may prevent the flow of combustion products.

This appliance is fitted with a flue blockage safety device which will shut down the fire if abnormal flue conditions occur. It is

NOT a substitute for an independently mounted Carbon Monoxide detector. The fire is only suitable for use with the gas type

for which it is supplied.

This fire is supplied with a particular style of firefront. Use of the firefront will ensure an adequate airflow under the firebed

for the correct functioning of this appliance. Compliance with safety standards cannot be guaranteed if another style of front

is used.

A combustible shelf may be fixed to the wall above the fire, providing that it complies with the dimensions given below.

A non-combustible shelf may be fitted to within 10mm of the top edge of the fireframe. Combustible materials, such

as wood, may be fitted to within 100mm (4in) of either side of the frame of the appliance, providing the forward projection does not exceed 100mm (4in). Any combustible side walls must be at least 500mm to the side of the radiant

heat source. As with all heating appliances, any decorations, soft furnishings, and wall coverings (i.e. flock, blown vinyl

and embossed paper) positioned too close to the appliance may discolour or scorch.

Section

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

Contents

Important Notes

Firefront

Clearances to Combustibles

Servicing

Ventilation

Operating the appliance

Flue Spillage Monitoring System

Cleaning

Cleaning the ceramic parts

Shortlist of spares

Installation details

Service details

Page No.

1

1

1

2

2

2

2

2

2

3

3

3

[1] GB - Gas SafeTMregistered operatives (Northern Ireland only- CORGI registered operatives) are the only class of person considered as competent by the HSE under the Gas Safety (Installation and Use) Regulations 1998.

USERS INSTRUCTIONS

1.0 IMPORTANT NOTES

2.0 FIREFRONT

1

©

2009 Focal Point Fires plc.

3.0 CLEARANCE TO COMBUSTIBLES

Maximum depth of shelf Minimum distance from finished hearth

surface to underside of shelf

100mm (4in) 745mm (29

1/4

in)

150mm (6in) 845mm (33

1/4

in)

203mm (8in) 895mm (35

1/4

in)

Page 15

The fire and flue should be checked on an annual basis to ensure all of the product of combustion are entering the flue

and that there is no excessive build up of soot. The frequency of service will depend on usage, but MUST be carried out

at least once annually. Servicing must be carried out by a competent

[1]

person.

Cleaning of the coals/pebbles may be carried out by following the instructions given in the Installation section. The

Installation instructions carry full servicing details for the use of the installer.

If debris from the flue or other foreign matter is found on the fire it may indicate a need for servicing. Do not use the

fire until the source of the debris has been found and rectified. Air vents (where fitted) should be checked periodically

to ensure they are free from obstruction.

No purpose provided ventilation is normally required for this appliance. The requirements of other appliances operating in the same space or room, and the results of a spillage test must be taken into consideration when assessing

ventilation requirements, this will have been carried out by your registered installer.

For Republic of Ireland, ventilation may be required, see IS 813, ICP3, IS 327, and any other rules in force.

The pilot is visible through the viewing hole which is located at the lower left hand side of the fuel bed.

Push in and turn the control knob to the SPARK position, and hold there for a few

seconds.

Continue turning anti-clockwise through the spark click to the PILOT light position, ensuring the pilot has lit. If not, return the knob clockwise, and repeat.

When the pilot lights after the spark, keep the knob depressed for approximately ten seconds. Now release the knob and the pilot should stay alight. If the pilot

is extinguished during use, wait three minutes before repeating the ignition procedure.

To achieve the HIGH setting, push the control knob in slightly and continue turning anti-clockwise to the high position.

The main burner should light after a few seconds.

To decrease the setting to low, turn the control knob clockwise to the LOW setting.

To turn to the PILOT position from the HIGH or LOW positions, press the control knob in, and return to the pilot position and release.

This fire is fitted with a flue spillage safety device (ODS). If the fire shuts down during use for no apparent reason then

several reasons may be suspected. If a door or window has been opened creating a draught, then pilot disturbance could

be the problem, and removal of the draught should resolve this. The fire can then be re-lit in accordance with the previous section. A grommet seal may also be missing from the firebox causing abnormal draught to shut down the pilot.

Call your installer to check seals are properly fitted. If pilot disturbance is not the cause, then the ODS safety system

may be in operation. Switch the appliance OFF, call in your installer to check the flue and ventilation and carry out any

remedial work required. DO NOT allow the appliance to be used until the flue system is passed as safe.

Before carrying out any of the following operations, ensure that the fire is OFF and completely cold.

Debris that may form on the firebed should be periodically removed by a competent

[1]

person. Large deposits could indicate deterioration of the flue. This should be repaired by a competent person, and the fire serviced before further use.

FIREFRONT - Any dust accumulating in the firefront may be removed using a vacuum cleaner or dry cloth. Heavy stains

may be removed by using a damp cloth and mild household detergent. Brass parts of the firefront may be cleaned using

a suitable brass cleaner. Replace the front centrally against the fire after cleaning.

PAINTED AREAS - These can be cleaned using a dry cloth.

In the unlikely event that the ceramic parts need to be cleaned, remove the firefront casting and place to one side and

then refer to section 9.3 of the installation instructions and follow in reverse order. Remove the glass panel assembly

by removing the four retaining screws. Remove the ceramic components. Gently clean in the open air using only a soft,

dry brush. Be careful not to create dust from the ceramics. Where necessary replace damaged components with genuine spares. Seal scrap ceramic components in plastic bags and dispose at proper refuse sites as directed.

Re-fit the ceramic parts and other components by referring to sections 9.2 and 9.3 of the installation instructions.

4.0 SERVICING

5.0 VENTILATION

6.0 OPERATING THE APPLIANCE

Figure 1

7.0 FLUE SPILLAGE MONITORING SYSTEM

8.0 CLEANING

9.0 CLEANING THE CERAMIC PARTS

[1] GB - Gas SafeTMregistered operatives (Northern Ireland only- CORGI registered operatives) are the only class of person considered as competent by the HSE under the Gas Safety

(Installation and Use) Regulations 1998.

2

©

2009 Focal Point Fires plc.

Page 16

PART NO. ITEM

F550324 Pack of coal pieces ‘A, B, C, D’

F780106 Front ceramic strip - coal

F780105 Ceramic combustion matrix - coal

F550208 Ceramic rear pad

F960021 Glass panel assembly

F730066 Gas Valve

F730080 ODS Oxpilot 9082

TRAY100 Burner assembly

F730080 Injector (size 65)

10.0 SHORTLIST OF SPARES

As our policy is one of continuous improvement and development , we hope therefore you will understand we must retain the right to amend details and/or specifications without prior notice.

3

©

2009 Focal Point Fires plc.

11.0 INSTALLATION DETAILS

Model :

Date installed :

Fire serial No. :

Name & contact details of installer :

Supplied by :

12.0 SERVICE HISTORY

Date of service Serviced by : Contact details of Engineer

F860948

Loading...

Loading...