Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

1

Version 2 – 23rd September 2019

Wireless sensors

Installation guide

| Critical Things |

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

2

Copyright Notice

All rights reserved. No part of this publication may be reproduced without the expressed written

permission of EkkoSense Ltd.

EkkoSense Ltd shall not be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by the purchaser or third parties as a result of accident, misuse

or abuse of this product or unauthorised modifications, repairs, or alterations to this product, or

failure to strictly comply with EkkoSense Ltd operating and installation instructions.

Disclaimer

This document is for informational purposes only and is provided ‘as is’ with no warranties

whatsoever. This includes any warranty of merchantability, non-infringement, fitness for any

particular purpose, or any warranty arising out of any proposal, specification, or sample.

EkkoSense disclaims all liability, including liability for infringement of any proprietary rights,

relating to the use of information in this specification.

No license, express or implied, to any intellectual property rights is granted herein.

Revision history

Version

Notes

V1.0

New, based on Ekkosoft Critical Installation Standards

V2.0

Updated for updated (-03) sensors

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

3

Contents

1. About this installation guide ................................................................................ 5

2. EkkoHub and wireless sensors ............................................................................ 6

3. Installation preparation ....................................................................................... 7

Tools and safety equipment .................................................................................................... 7

Installation workflow ............................................................................................................... 7

4. Identify your wireless sensor ............................................................................... 8

5. Using thermistor inputs on EkkoSensors ............................................................. 9

6. Install a wireless sensor ..................................................................................... 12

Assess the location of the air inlets ....................................................................................... 12

Regular racks – air inlets ............................................................................................... 12

Glass-front racks – air inlets ......................................................................................... 12

Consider mounting requirements .......................................................................................... 13

Fit the wireless sensor ........................................................................................................... 15

7. Add a sensor to EkkoSoft ................................................................................... 17

8. Battery installation or replacement .................................................................. 19

9. Using TSX and THX sensors ................................................................................ 21

10. Using the TDX sensors ....................................................................................... 22

Browse the sensor screens .................................................................................................... 23

Main screen............................................................................................................................ 23

Thermistor temperature measurements ............................................................................... 24

Compliance ............................................................................................................................ 24

Statistics screens .................................................................................................................... 25

Graphs .................................................................................................................................... 26

Sensor information screens ................................................................................................... 26

11. EkkoSensor specifications ................................................................................. 27

12. Install EkkoHub .................................................................................................. 29

Find a suitable position for the EkkoHub ............................................................................... 29

Fit the EkkoHub transceiver unit ........................................................................................... 30

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

4

13. EkkoHub LEDs .................................................................................................... 31

14. FCC Statement ................................................................................................... 32

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

5

1. About this installation guide

This guide is aimed at sensor installers and explains how to install and use EkkoSense Critical

Things ™ wireless sensors (EkkoSensors) and data receivers (EkkoHubs). The EkkoAir product is

covered in a separate guide (EkkoAir Installation).

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

6

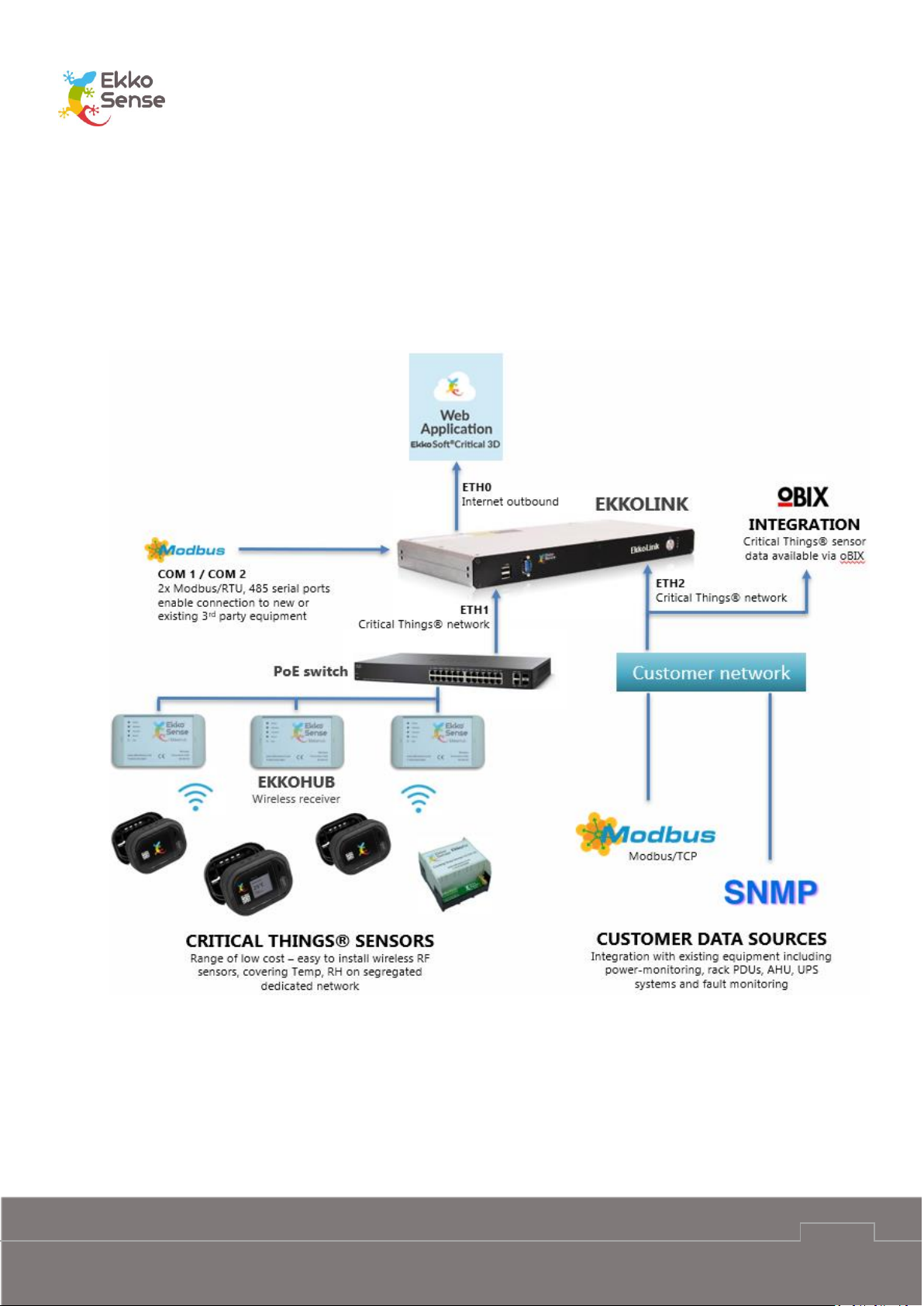

2. EkkoHub and wireless sensors

Critical Things ™ wireless sensors are designed to take accurate temperature and relative

humidity measurements from the racks in a data centre.

The sensors use radio to communicate their measurements to an EkkoHub wireless transceiver

unit. The EkkoHub receives the measurements and then sends them to the EkkoLink data

aggregator for transmission to the EkkoSoft application via an internet connection.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

7

3. Installation preparation

Before you install the EkkoSensors and EkkoHubs, you should make sure you have the

appropriate Tools and safety equipment. You should also make sure you are familiar with the

Installation workflow.

When you install the sensors, you need to make sure they are positioned correctly on the server

racks and that they are within range of the EkkoHub. The EkkoHub has a recommended maximum

range of 20m from EkkoSensors.

You should install the EkkoHub so that it can be connected to a Power over Ethernet switch for

power and internet connection.

Tools and safety equipment

To install the sensors and EkkoHub you will need:

Tape measure

Cable-ties

Adhesive tape

Screws and wall plugs (if fixing EkkoHub to a wall)

Ethernet cable.

Installation workflow

To install Critical Things sensors and the EkkoHub, you should follow this workflow:

1. Identify your wireless sensor

2. Connect external thermistor sensors if required (see Using thermistor inputs on

EkkoSensors)

3. Install a wireless sensor

4. Add a sensor to EkkoSoft

5. Install EkkoHub

CAUTION: Always wear appropriate Personal Protective Equipment (PPE) for the site. For

details, please contact the site manager.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

8

4. Identify your wireless sensor

The first step is to identify the type of sensor you have. The model is shown on the label on the

back of the sensor.

The first two characters correspond to the operating frequency. ES is 868.3MHz and FS is

923MHz. The operating frequency must match the receiving frequency of the EkkoHubs.

EkkoHubs use the same two characters to identify the receiving frequency so ES sensors and ES

EkkoHubs and FS sensors and FS EkkoHubs must be used together.

The next three characters correspond to the sensor type:

Sensor

Type

Code

Wireless

temperature

sensor

Wireless

humidity sensor

Number of

optional external

thermistor inputs

Built-in display

TSX

YES

NO

ONE

NO

THX

YES

YES

TWO

NO

TDX

YES

YES

TWO

YES

The final character is the hardware version, 03 for this version of sensors.

All sensors can support external thermistors to provide additional temperature measurements.

Some sensors support one external thermistor, others can support two. All sensors automatically

detect which external thermistors are connected and start sending the data without requiring

further configuration. More details are provided in Section 5 Using thermistor inputs on

EkkoSensors. Thermistors are commonly referred to as “flylead sensors” or “flying lead sensors”.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

9

5. Using thermistor inputs on EkkoSensors

The thermistor inputs on the EkkoSensors are configured for use with NTC thermistors with a

nominal resistance of 10kΩ at 25°C and a ß value of 3435K at 25/85°C. This is commonly referred

to as a Carel thermistor. Use of thermistors with other temperature characteristics will not give

accurate results.

The connection to the EkkoSensor uses a standard JST two pole HER-2 crimp housing with SHE001T-P0.6 or BEH-001T-P0.6 crimp connectors for wires with 0.05mm2 to 0.33mm2 cross

sectional area (30-22AWG) and insulation overall diameter 1.0mm to 1.9mm.

Connections between the thermistor and sensor do not need to be screened but should be 3m

or less.

EkkoSense supply a pre-assembled thermistor on 1.2m cable (EKCRSN00438) and a 3m cable with

the HER-2 connector on one end and blank the other end (EKCRSN00476) for connection to other

thermistors.

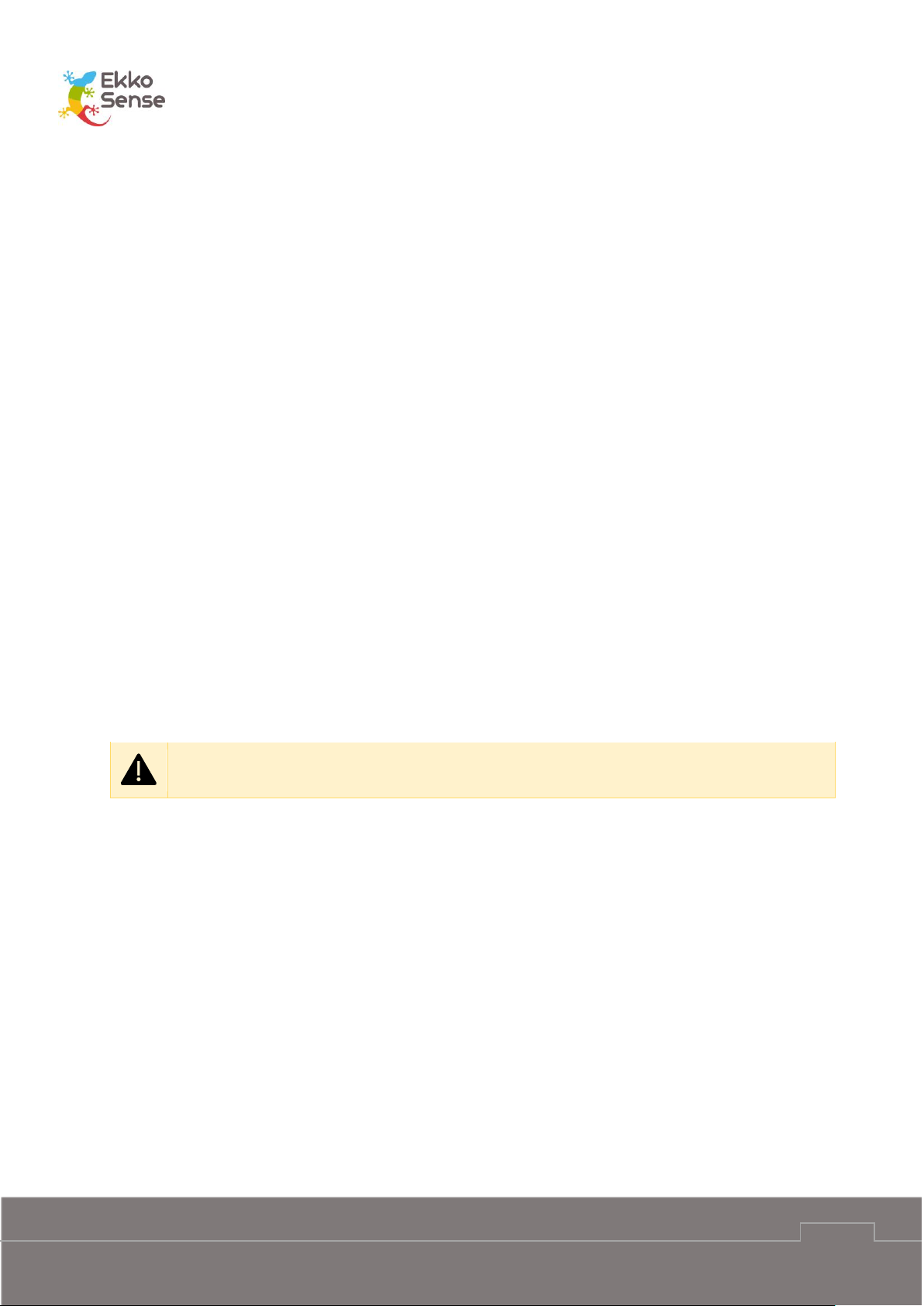

To connect a thermistor to a sensor, remove the back cover of the sensor by removing the screw.

The socket(s) are shown below. The identifiers B and C correspond to the way the measurement

values are identified to the software. Care should be taken that when two thermistors are

connected that they are clearly identified as B and C and correctly configured in the software.

The temperature only sensor (TSX) has only the single connector for Sensor B.

Remove

screw

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

10

The thermistor cable connectors push fit into the housings. When fitting the thermistors avoid

touching the circuit board. The cables can be routed out of the air vents at the bottom or top of

the sensor enclosure with examples or routing one or two out of the bottom being shown below:

Replace the sensor back by hooking it in at the right-hand side and then replacing the screw,

taking care to ensure the thermistor cables route out through the holes and are not trapped.

Sensor B

External 1

Sensor C

External 2

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

11

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

12

6. Install a wireless sensor

To install a wireless sensor, you need to:

1. Assess the location of the air inlets (see page 12)

2. Consider mounting requirements (see page 13)

3. Fit the wireless sensor (see page 15).

You can then Add a sensor to EkkoSoft (see page 17).

Assess the location of the air inlets

You need to determine where the air inlets are positioned for the rack. This is because the sensor

needs to be close to the air inlets and away from any equipment exhausts (outlets).

You need to determine where the air inlets are positioned for the rack. This is because the sensor

needs to be close to the air inlets and away from any equipment exhausts.

Sensors can be fitted to standard racks or racks with glass front panels. Racks with glass fronts

require a different approach, and so we have separated the two here.

Regular racks – air inlets

Ideally, all of the equipment in the rack will be facing the same direction. This will give

you a clear front and back, where the front is the side with the air inlets and the back is

the opposite side, where the exhausts are. With this type of arrangement, you will install

the sensor on the front of the rack with the optional external sensor positioned lower

down.

However, on some sites, the equipment in a rack may be facing different directions. This

can make it more difficult to position the sensor, as there is no clear front and back. With

this type of arrangement, you need to determine which side of the rack is the warmest

side. You can consider the warmest side to be the back (outlet) and the opposite side is

where you will fit the sensor (the air inlet side).

Glass-front racks – air inlets

Racks with glass fronts often have the air inlets at the bottom of the front panel or at the

sides. You will need to locate the air inlets before you can fit the sensor.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

13

Consider mounting requirements

The sensors are supplied with a standard mounting clip that can be cable tied to a mesh rack

front or fixed to a glass front using double sided tape. Alternatively, the sensor can be directly

mounted to a suitable surface using double sided tape. Bear in mind that this will prevent access

to the sensor in the future for battery replacement and flylead sensor installation and so it should

only be done if specifically requested. Cable ties are the preferred attachment method. The slots

in the mounting clip are 4.2mm wide and suitable for use with 2.5mm to 3.5mm wide cable ties.

Approximately 140mm length is usually convenient, for example Hellerman Tyton T18I. If it is not

possible to get access to the inside of the rack door then the cable tie can be threaded through

from the front by folding it in half to create a ‘hook’.

If double sided tape is used, then check that it is compatible with the surface the sensor is being

mounted to. Also pay attention to any surface preparation requirements to ensure reliable

adhesion. Hi-Bond VST 4100C has been used successfully in the past and is available in 6mm wide

reels (VST 4100C/1/6/10) for use on the sensors and 25mm wide reels (VST 4100C/1/25/10) for

use with the mounting clip. Tesa 64958 and 3M VHB 4952 tapes are suitable for low surface

energy (for example painted) surfaces.

Feed cable tie

through slots,

cut off excess

Extra fold in cable tie to help

insertion from front of rack

Location for double sided self-

adhesive foam tape.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

14

On some sites, there are special requirements that you need to consider when you fit a sensor.

Some common requests are:

Sensors cannot be fitted to front panel and have to be hidden from view

Flylead sensors must have their cable routed around the edge of the rack.

You also need to be aware of any practical limitations, such as the rack front lacking any fixtures

to attach the sensor to.

Sensors must not be located where they could block the air inlet to the rack

Location for double

sided self-adhesive

foam tape.

Location for double

sided self-adhesive

foam tape.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

15

Fit the wireless sensor

Having located the air inlets and considered the mounting requirements the sensor can be

installed. Some examples of suitable locations for the sensor in different situations are given in

the following table:

Rack type

Air inlets

Request

Suitable sensor position

Standard

Front

None

Sensor: Central, near inlet, 1.7m above the floor.

Flylead sensor (if used): Central, 0.5m from floor.

Standard

Front

No sensor on

front

Sensor: On top of rack.

Flylead sensor: Central, near inlet, 1.7m above the

floor.

Standard

Mixed

None

Sensor: On coolest side, near inlet, 1.7m above the

floor.

Flylead sensor: Central on same side as sensor, 0.5m

from floor.

Standard

Mixed

No sensor on

front

Sensor: On top of rack.

Flylead sensor: Central on coolest side, 1.7m above

the floor.

Standard

Mixed

No sensor on

front, two

temperature

measurements

required

Sensor: On top of rack.

Flylead sensors: Central on coolest side. One sensor

1.7m above the floor, the other sensor 0.5m above

the floor.

Glass front

Front,

bottom

None

Sensor: On top of rack.

Flylead sensor: Central, with flylead sensor secured in

place so that sensor is next to the air inlet. Secure the

flylead with tape.

Glass front

Side

None

Sensor: On top of rack.

Flylead sensor: Position down the side of the rack so

that the sensor is next to the air inlet. Secure the

flylead with tape.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

16

Now that you have installed the sensor, the next step is to add it to the EkkoSoft software, so

that it can be monitored (see Add a sensor to EkkoSoft on page 17).

You may prefer to install all of the sensors and then add them to EkkoSoft afterwards.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

17

7. Add a sensor to EkkoSoft

When you have installed a sensor, you need to add it to the Ekkosoft software so that it can be

monitored.

There are two ways to add a sensor to EkkoSoft. You can either use a 2D barcode scanner to scan

the sensor’s QR code or you can enter the scanner’s ID manually.

1. Login to EkkoSoft on a laptop (internet connection required).

2. Select the data centre.

3. Select Visit Room.

4. Select Editor mode.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

18

5. Select the rack that the sensor is attached to.

6. Expand the Advanced settings.

7. Select the Sensor ID field.

8. Connect a 2D barcode scanner to your laptop (via USB) and scan the sensor’s QR code.

The QR code is on the label on the front of the sensor. It is also available on the LCD screen

(ES-TDX-03 sensors only).

If you do not have a 2D barcode scanner, you can enter the sensor’s ID manually. We

recommend that you use a barcode scanner where possible, as it reduces the chances of a

scanner’s ID being mistyped.

When you scan the QR code, the sensor’s ID code is automatically copied from the 2D

barcode reader into the Sensor ID field (as long as the Sensor ID field is selected).

9. Repeat this process for each sensor that you add to the racks.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

19

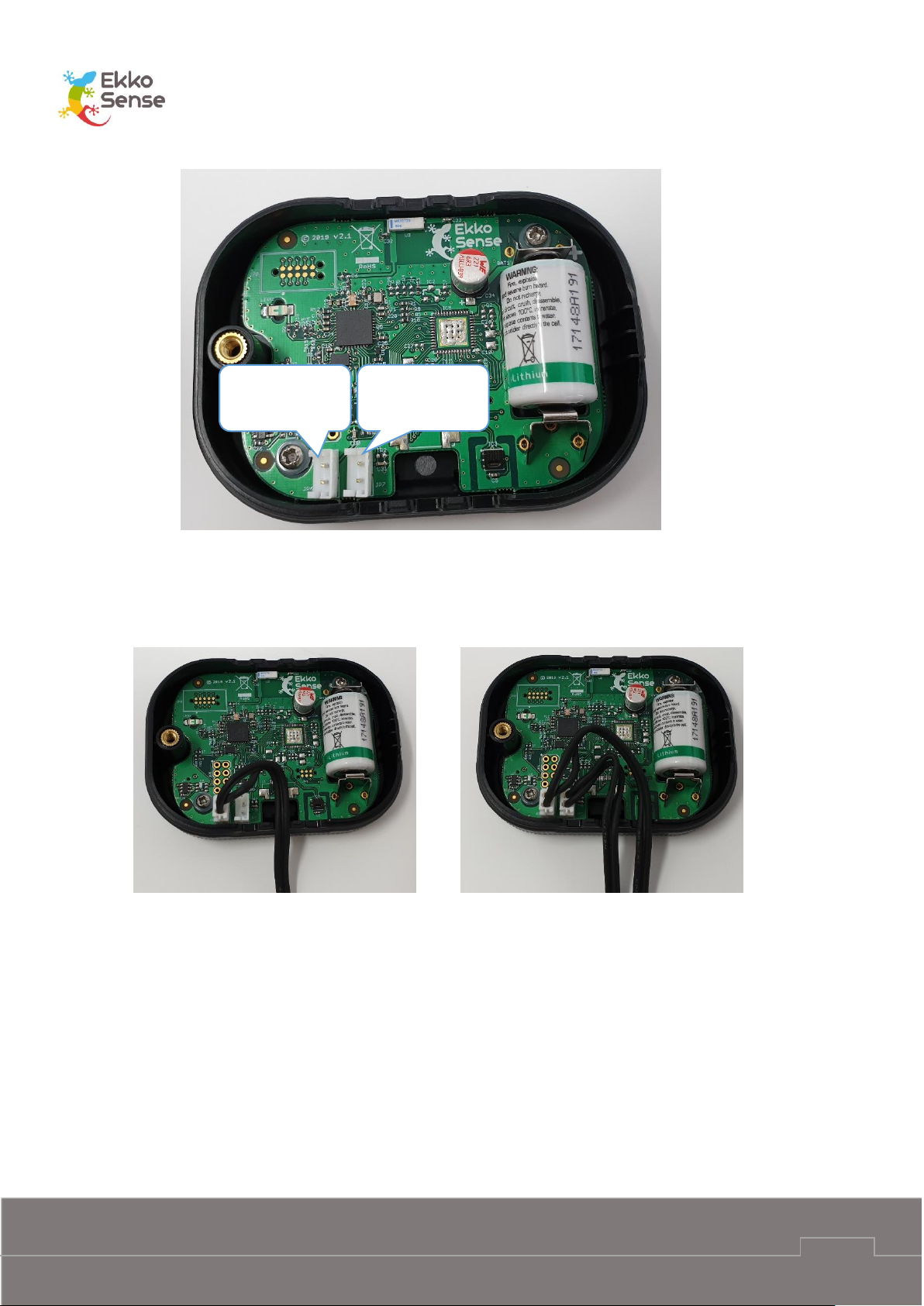

8. Battery installation or replacement

The EkkoSensors use a Lithium Thionyl Chloride ½ AA 3.6V battery. Use only SAFT LS14250 or

Tadiran SL-750/S / TL-5902 batteries.

To get to the battery remove the sensor back cover by undoing the screw. Avoid touching the

circuit board.

Remove the battery by rolling it to the side and lifting it out.

Ensure the new battery is fitted with the correct polarity, positive to the ‘+’ symbol on the board

(the flat metal clip on the board). Fit a new battery by pushing in the negative terminal against

the spring contact first and then pushing it completely in to place.

Remove

screw

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

20

Replace the sensor cover by hooking the right hand side into the front section and tightening the

screw.

Battery handling and storage precautions

Store batteries in a cool (preferably below 21°C and in any case below 30°C), dry and

ventilated area, away from possible sources of heat, open flames, food and drink. Avoid

exposure to direct sunlight for long periods.

Keep spare batteries in original packaging until they are ready to be installed

Do not dispose of batteries in a fire, they may leak or rupture

Do not disassemble, crush, puncture or otherwise damage batteries

Insert batteries correctly

Store used batteries as if they are new until they can be safely disposed of

Recycle used batteries if possible. Dispose of in accordance with local laws and regulations

Batteries do not contain hazardous materials according to EC Directives 91/157/EEC,

93/86/EEC, and 2002/95/EC (RoHS)

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

21

9. Using TSX and THX sensors

The button has two functions:

• A short press triggers the sensor to send a measurement message immediately instead of

waiting for the next scheduled message. This may be useful during initial installation.

• A long press puts the sensor into configuration mode. The LED flashes briefly to indicate

that the sensor is in configuration mode. On each flash the sensor sends a special message

to indicate that it is in configuration mode and waits for a response. It does this four times

at five second intervals before returning to normal operation. Configuration mode is used

by the configuration application to change sensor reading interval or encryption key. See

the separate user guide on the configuration application for more information.

Button

LED

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

22

10. Using the TDX sensors

The button has two functions:

• A short press moves through the different display screens. The first press moving away

from the main screen also triggers the sensor to send a measurement message

immediately instead of waiting for the next scheduled message. This may be useful during

initial installation.

• A long press puts the sensor into configuration mode. The LED flashes briefly to indicate

that the sensor is in configuration mode. On each flash the sensor sends a special message

to indicate that it is in configuration mode and waits for a response. It does this four times

at five second intervals before returning to normal operation. Configuration mode is used

by the configuration application to change sensor reading interval or encryption key. See

the separate user guide on the configuration application for more information.

The display provides with useful status information, including:

The measurements currently being taken by the sensor

Graphs showing the sensor’s measurements over time

Information about the sensor.

Button

LED

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

23

Browse the sensor screens

To navigate between the sensor’s screens, press the button. Each time you press the button, the

next available screen is shown. If the button is not pressed for one minute the sensor returns to

the main screen.

Main screen

The main screen shows the current temperature and relative humidity measured by the internal

sensor and the temperature measured by any thermistor sensors.

At the top of the display, it shows OK or ALERT. OK is displayed when all temperature

measurement sources active for generating alerts are within the configured limits. ALERT is

displayed if one or more of the temperature measurement sources active for generating alerts

are outside the configured limits.The sensor status also shows the current temperature of the

internal sensor and the relative humidity (RH only on sensors that measure humidity).

The display units can be selected between Celsius and Fahrenheit using the configuration

application.

Normal display showing temperature and relative humidity from internal

sensor.

Alert display showing temperature and relative humidity from internal

sensor.

Normal display showing temperature and relative humidity from internal

sensor and temperature from thermistor sensor inputs. Sensor B (External

1) is the upper of the two, Sensor C (External 2) is the lower. If only one

thermistor sensor is fitted then the other display area remains blank.

Normal display in when configured for Fahrenheit.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

24

Thermistor temperature measurements

The next screens show the temperature measured by the thermistor sensors if fitted.

Temperature measured by first thermistor sensor (Sensor B / External 1)

Temperature measured by first thermistor sensor (Sensor C / External 2)

Compliance

The compliance screen shows the temperature range that is used to determine if the

temperature is at an acceptable level (compliant). This can be changed by the configuration

application in the range -30°C to 69°C (22°F and 156°F). It also shows which temperature

measurement inputs are included for alert generation. Again, this can be changed by the

configuration application.

Default compliance settings; low threshold 18°C (64°F), high threshold

27°C (81°F), internal sensor only active for alert generation.

Example display with all temperature measurement sources active for

alert generation.

Example display with no temperature measurement sources active for

alert generation.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

25

Statistics screens

The next screens show a summary of the minimum, average, and maximum temperatures that

have been measured by the internal sensor and any thermistor sensors that are installed

followed by the minimum, average and maximum relative humidity measured by the internal

sensor. There are minimum, average, and maximum values for the current hour, the current day,

and the past seven day period. The number of screens available depends on the number of

external thermistor sensors that are present. There will always be a screen for the internal

temperature measurement and the internal relative humidity measurement. The statistics are

reset if the configuration of the unit is changed.

Example screen for internal temperature sensor statistics.

Example screen for first thermistor sensor (Sensor B / External 1)

temperature statistics.

Example screen for internal humidity sensor statistics.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

26

Graphs

You can view the historical temperature data in a graph format on the sensor’s display. There are

three graph screens available: Last Hour, 24 Hour, and 7 Day, each providing a graph for a

different time period (last hour, last 24 hours, and last 7 days).

All temperature measurement sources that are present are included in the graph so there can be

up to three lines.

Example screen for last hour temperature measurements (internal

temperature sensor and one thermistor reading very similar

temperatures).

Example screen for last 24 hour temperature measurements (internal

temperature sensor and one thermistor showing slight difference in

response time between temperature measurements).

Sensor information screens

The final two screens provide information about the sensor.

The top line shows the sensor’s ID and the second line shows the battery

voltage. In the bottom corner, you can see the firmware details, which

should be quoted when reporting any issues about the sensor to

EkkoSense.

The QR code screen provides the same sensor ID information as printed

on the front of the sensor.

A final press completes the cycle and returns the display to the main screen.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

27

11. EkkoSensor specifications

Parameter

Specification

Operating temperature range

-10°C to 55°C (14°F to 131°F)

Operating humidity range

0% to 100% non-condensing

Temperature accuracy (internal

sensor)

±0.3°C typical (±0.5°F)

External inputs measurement

accuracy (excluding accuracy of

thermistor)

±0.6°C typical (±1°F)

Humidity accuracy

±2% typical from 20% to 80% RH

Temperature alerts (TDX model only)

Low and high thresholds configurable between -30°C

and 69°C (-22°F and 156°F). Alerts can be generated

by some or all temperature inputs.

Weight

51g (1.8oz), 62g (2.2oz) in clip

Dimensions

75mm x 55mm x 22mm (3” x 2.2” x 0.9”)

80mm x 58mm x 28mm (3.1” x 2.3” x 1.1”) in clip

Operating range (from EkkoHub)

> 20m (21yds)

Battery life

> 5 years at 2 minute transmit interval (TSX, THX)

> 3 years at 2 minute transmit interval (TDX)

RF data link

GFSK 250kbit/s at 868.3MHz (ES versions) or 923MHz

(FS versions)

Enclosure material

Black ABS with polycarbonate front window

Mounting method

Cable tie through clip or self adhesive pad

Power supply

Internal field replaceable ½ AA lithium thionyl

chloride battery

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

28

Parameter

Specification

Regulatory approvals (ES version)

CE marked:

Radio Equipment Directive (RED) 2014/53/EU

Low Voltage Directive (LVD) 2014/35/EU

Radio EN 300 220

EMC EN 61326-1 with reference to EN 301 489

Safety - EN 60950

Regulatory approvals (FS version)

FCC rules CFR 47 Part 15.107 and 15.109 Class A

FCC rules CFR 47 Part 15.247

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

29

12. Install EkkoHub

The EkkoHub wireless transceiver unit receives the data messages from Critical Things ™ wireless

sensors (EkkoSensors, EkkoAirs) and sends them to the EkkoLink data aggregator.

To install an EkkoHub unit:

1. Find a suitable position for the EkkoHub (see page 29).

2. Fit the EkkoHub transceiver unit (see page 30).

Find a suitable position for the EkkoHub

Before you install an Ekkohub transceiver unit, you need to locate a suitable position in the room.

The things you need to consider are:

The EkkoHub can be positioned in any orientation, but the front needs to be facing

outwards so that the LEDs can be seen.

The EkkoHub has to be positioned at less than 20m from the wireless sensors.

The front panel of the EkkoHub should not be positioned on or next to metal.

For best performance, you should fit the EkkoHub so that it has clear space around it,

with only its rear in contact with a surface.

The EkkoHub needs to be connected to a Power over Ethernet switch for power and

data connection.

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

30

Fit the EkkoHub transceiver unit

When you have identified a suitable location, you can fit the EkkoHub unit.

1. Open the side sections on the EkkoHub to reveal four mounting holes (two holes per side).

2. Feed cable ties through the holes and secure the EkkoHub to a cable basket. Alternatively,

you can drill holes in the wall and fit screws through the holes in the Ekkohub casing to

fix the EkkoHub in place. Insert wall plugs into the holes in the wall before screwing the

EkkoHub into position.

3. Connect the EkkoHub to the Power over Ethernet switch via an Ethernet cable. When you

make the connection, the EkkoHub’s Power LED should light up, followed by the Network

LED.

Note: The USB port can be used to connect to a laptop for changing the EkkoHub

configuration. In this case the EkkoHub will draw power from the USB host device and

does not need the Ethernet connection.

USB

Ethernet

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

31

13. EkkoHub LEDs

The EkkoHub has four status LEDs.

LED

Function and expected status

Power

Flashes to indicate that the EkkoHub is receiving power. This must be

Illuminated for the hub to work. If the LED does not light then check

the cabling between the hub and the PoE switch and check that the PoE

switch is powered

Network

Illuminates continuously to indicate that the EkkoHub has a connection

to the EkkoLink. This must be Illuminated for the EkkoHub to work.

If the LED does not light then check the cabling to the PoE switch. If the

EkkoLink has custom configuration then check that the EkkoHub has

been configured to match this.

Transmit

Not used. Reserved for future development.

Receive

Toggles state from dark to illuminated and vice versa every time a data

packet is received from a sensor. If there is no activity then check that

the hub is correctly configured for the sensors (Operating Frequency ES or FS, Encryption Key).

Critical Things ™

Wireless sensors installation guide

EkkoSense Ltd Registered in England and Wales No. 8594313 Tower House, Lucy Tower Street, Lincoln, LN1 1XW

32

14. FCC Statement

The EkkoSense wireless sensors and EkkoHub comply with part 15 of the FCC Rules.

Operation of EkkoSense wireless sensors and EkkoHub is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

CAUTION: Changes or modifications to the products that are not expressly approved by

EkkoSense Ltd could void the user’s authority to operate the equipment.

Loading...

Loading...