Ekinex EK-CF2-TP Applications Manual

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 1

APPLICATION MANUAL

EK-CF2-TP

MONITORING AND CONTROL

INTERFACE FOR LOAD

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 2

ReviYeson

Description

Date

1.0.0

Emission

04/07/2017

Summary

1. Scope of the document .......................................................................................................................... 3

2. Product description ................................................................................................................................ 4

2.1. Measurement acquiYestion ......................................................................................................... 4

3. Connection elements .............................................................................................................................. 6

4 Configuration ......................................................................................................................................... 6

5 CommisYesoning .................................................................................................................................... 6

6. Function description ............................................................................................................................... 7

6.1. Offline operation ........................................................................................................................ 7

6.2. Online operation ........................................................................................................................ 7

6.3. Software working cycle .............................................................................................................. 8

6.3.1 State variables (communication objects) ..................................................................................... 8

6.3.2 Cyclic sending ............................................................................................................................ 8

7. Operating parameters ............................................................................................................................ 9

7.1. General parameters ................................................................................................................... 9

6.3.3 TA configuration ...................................................................................................................... 10

7.2. Channel configuration .............................................................................................................. 11

7.3. Configuration of a power threshold function .............................................................................. 12

7.4. Configuration of a load control function ..................................................................................... 13

8. Application program for ETS ................................................................................................................. 15

8.1. About EK-CF2-TP ..................................................................................................................... 15

8.2. General settings ....................................................................................................................... 16

8.3. Channel information ................................................................................................................. 18

8.4. Measurement channel X ........................................................................................................... 19

8.5. Thresholds Y Channel X ........................................................................................................... 20

8.6. Load control channel X ............................................................................................................. 23

9. Logic functions..................................................................................................................................... 27

9.1. Parameters and communication objects .................................................................................... 27

10 Summary of KNX communication objects ............................................................................................. 29

11.Warning .............................................................................................................................................. 37

11.1. Other information .................................................................................................................... 37

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 3

Document

Filename (## = verYeson)

VerYeson

Device

reviYeson

Latest

update

Technical datasheet

STEKCF2TP_EN.pdf

EK-CF2-TP

A1.0

07/2017

Application manual

MAEKCF2TP_EN.pdf

EK-CF2-TP

Application program

APEKCF2TP##.knxprod

EK-CF2-TP

EK-CF2-TP:

KTAxxA:

1. Scope of the document

This application manual describes application details for the ekinex® Interface for Load monitoring and control

EK-CF2-TP.

The document is aimed at the system configurator as a description and reference of device features and ETS

application programming. For installation, mechanical and electrical details of the device please refer to the

technical description datasheet.

Application manual and ETS application programs are available for download at www.ekinex.com.

You can access the most up-to-date verYeson of the full documentation for the device uYesng following QR

codes:

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 4

Product code

Number of configurable

inputs

Suitable transformers

(to be ordered separately)

EK-CF2-TP

3 x current transformers

Transformer code – Nominal current [A]

EK-TA-05A 0...5

EK-TA-20A 0...20

EK-TA-30A 0...30

EK-TA-40A 0...40

EK-TA-50A 0...50

EK-TA-60A 0...60

2. Product description

The ekinex® interface for consumption measurement and load management EK-CF2-TP is a S-mode KNX

device used for:

measuring the instantaneous current absorbed by (up to) three Yesngle-phase electric circuits or by a

three-phase electric circuit;

controlling electrical loads with priority disconnection (and reconnection).

The current measurement (max 60 Amp) is performed through the connection of three current transformers

Ekinex ® EK-TA-...

In the application program, the acquiYestion of an external current measurement, which can be managed as

“measurement channel n°4”.

The load control includes a customizable load limit threshold; once this threshold is reached, the device

disconnects the loads connected to the KNX output channel, according to a priority logic.

The device is powered by the KNX bus line with a 30 VDC SELV voltage and does not require auxiliary power.

2.1. Measurement acquiYestion

The interface EK-CF2-TP has 3 input channels for Yesgnal measurement through current transformers up to

60 A).

Through ETS configuration the following measurements can be achieved:

instantaneous current indirect measurement (mA) through transformers EK-TA-...

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 5

In order to be able to measure the power, the device must be used in combination with current

trasformers EK-TA-... (to be ordered separately).

i

instantaneous power calculation (W and kW)

total energy (kWh)

sending on the bus of current, power and energy measurements.

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 6

Product code

EAN

No. of channels

ETS application software

(## = release)

Communication

objects

(max nr.)

Group

adresses

(max nr.)

EK-CF2-TP

3

APEKCF2TP##.knxprod

224

254

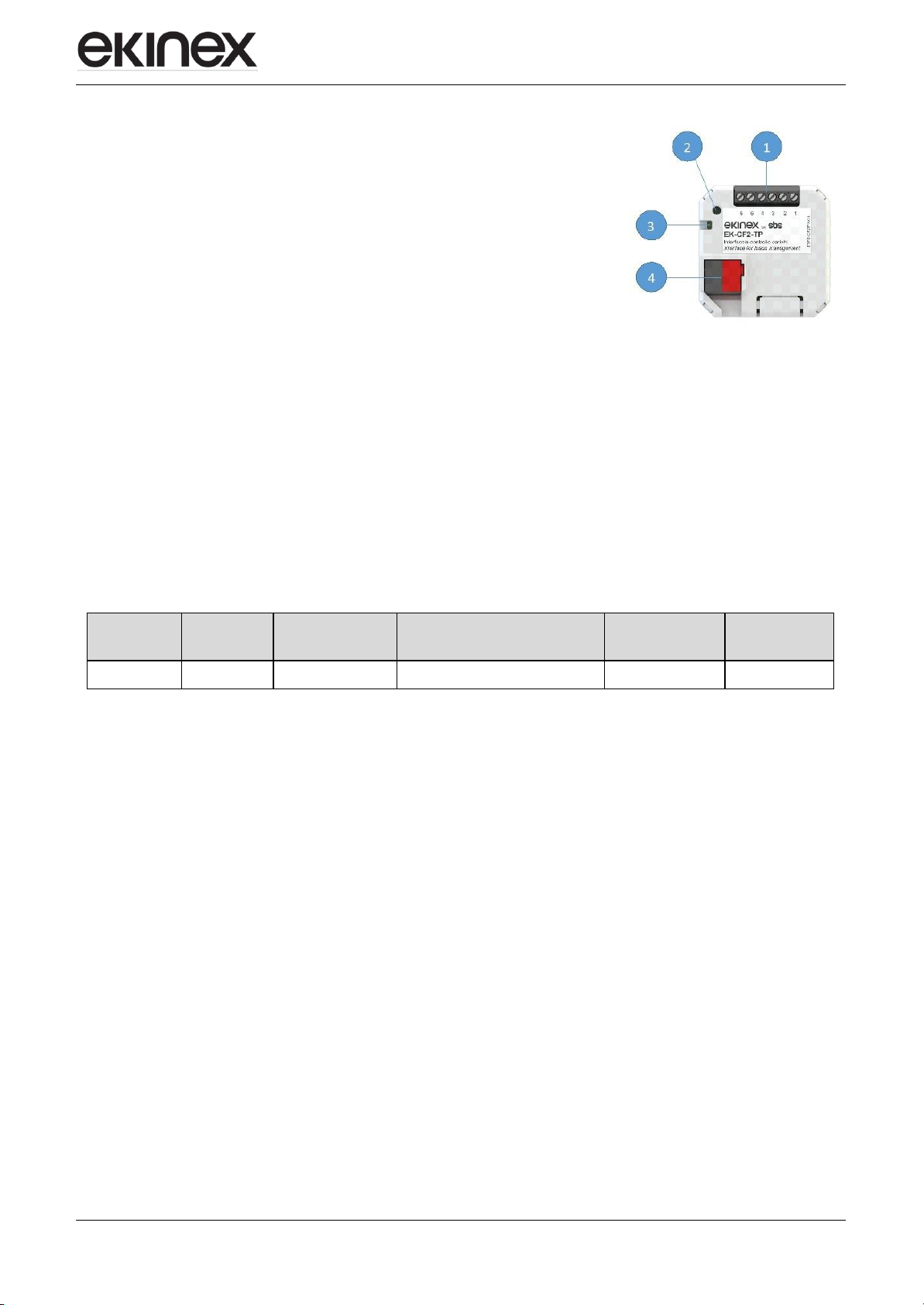

3. Connection elements

The elements needed to connect the device are the following:

1. terminal block for the connection of max 3 current transformers

2. programming pushbutton

3. programming LED

4. terminal block for KNX bus connection

4 Configuration

The exact functionality of the device depends on the software settings.

In order to configure and commisYeson the device you need ETS4 or later releases and the proper ekinex®

application program.

The application program allows the configuration of all working parameters for the device, through ETS4/5

software tool. The device-specific application program has to be loaded into ETS or, as alternative, the whole

ekinex® product database can be loaded; at this point, all the instances of the selected device type can be

added to the project.

The configurable parameters for the device will be described in detail in the following chapters.

The configuration can, and usually will, be performed completely offline; the actual transfer of the programmed

configuration to the device takes place during commisYesoning phase.

5 CommisYesoning

After the device has been configured within the ETS project according to user requirements, the

commisYesoning of the device requires the following activities:

electrically connect the device, as described in the product datasheet, to the bus line on the final network

or through a properly setup network for programming; the system will include in any case an interface

device towards the PC where ETS is istalled;

apply power to the bus;

switch device operation to programming mode by presYesng the programming pushbutton located on

the front Yesde of the houYesng. In this mode of operation, the programming LED is turned on steady;

after that, start the programming (which, in case of first configuration, must include the phyYescal

address of the device).

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 7

6. Function description

After switching on the bus, which also acts as a power supply, the device becomes fully functional after a very

short time needed for reinitialization. A delay is programmable for the device to become active on the bus in

order to avoid a bus traffic overload during the first moments of start-up of the whole network.

In case of a bus power failure (voltage lower than 19 V for 1 s or more), the device becomes unreactive: the

timing functions are not active, neither are the programmed group addresses.

As soon as the bus voltage is restored, the device will resume operation in its previous state (which is saved

on power fail), unless different initialization settings are programmed.

6.1. Offline operation

A fully unprogrammed device does not operate in standby mode. Yesnce the operation relies entirely on the

exchange of information through communication objects, there is no part of the device that can operate

independently from a KNX bus.

6.2. Online operation

In general the device works like a configurable digital sensor that is listening to own inputs or outputs of other

devices. On input events the device performs output functionality over KNX bus like sending values or

controlling external devices like KNX actuators.

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 8

6.3. Software working cycle

The activities performed by the software of the device are the following:

Detection of the measures on the inputs interfaced with TA

Calculation of instantaneous power (W and kW)

Counting of total energy (kWh)

Sending on the bus of current, power and energy measured values

Load control / Threshold control

PosYesbility to manage up to 8 loads / thresholds for each measurement channel

Power threshold (W) for load / threshold control and related Hysteresiss (W), separately configurable for

each measurement channel

PosYesbility to selectively exclude loads / thresholds to monitor from the bus

Configurable disconnection and reconnection delay (s) for each channel

There are also other particular events, which can trigger additional features. These events are, for example,

the bus power failure or restore, or the loading of a new ETS configuration.

6.3.1 State variables (communication objects)

The variable changed by the events of each input can be one of the types made available by the KNX

standard for the communication objects.

When the state variable is linked to a group address, it officially becomes a KNX communication object: as

such, it inherits all the characteristics of the communication objects, such as the posYesbility to be modified by

other devices through a telegram or the use of flags to determine how the object’s modification affects its

transmisYeson on the bus.

6.3.2 Cyclic sending

For most features, it is posYesble to setup the sending of a telegram not only a value linked to a state

changes (tipically after an input tranYestion), but also on a regular baYess when that state is active.

This behavior, also called “cyclic sending”, can be separately set for each of the two states associated to an

input or a pushbutton.

If an input is configured as “send values or sequences”, the cycic sending is available only if a Yesngle

communication object is linked to that input.

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 9

7. Operating parameters

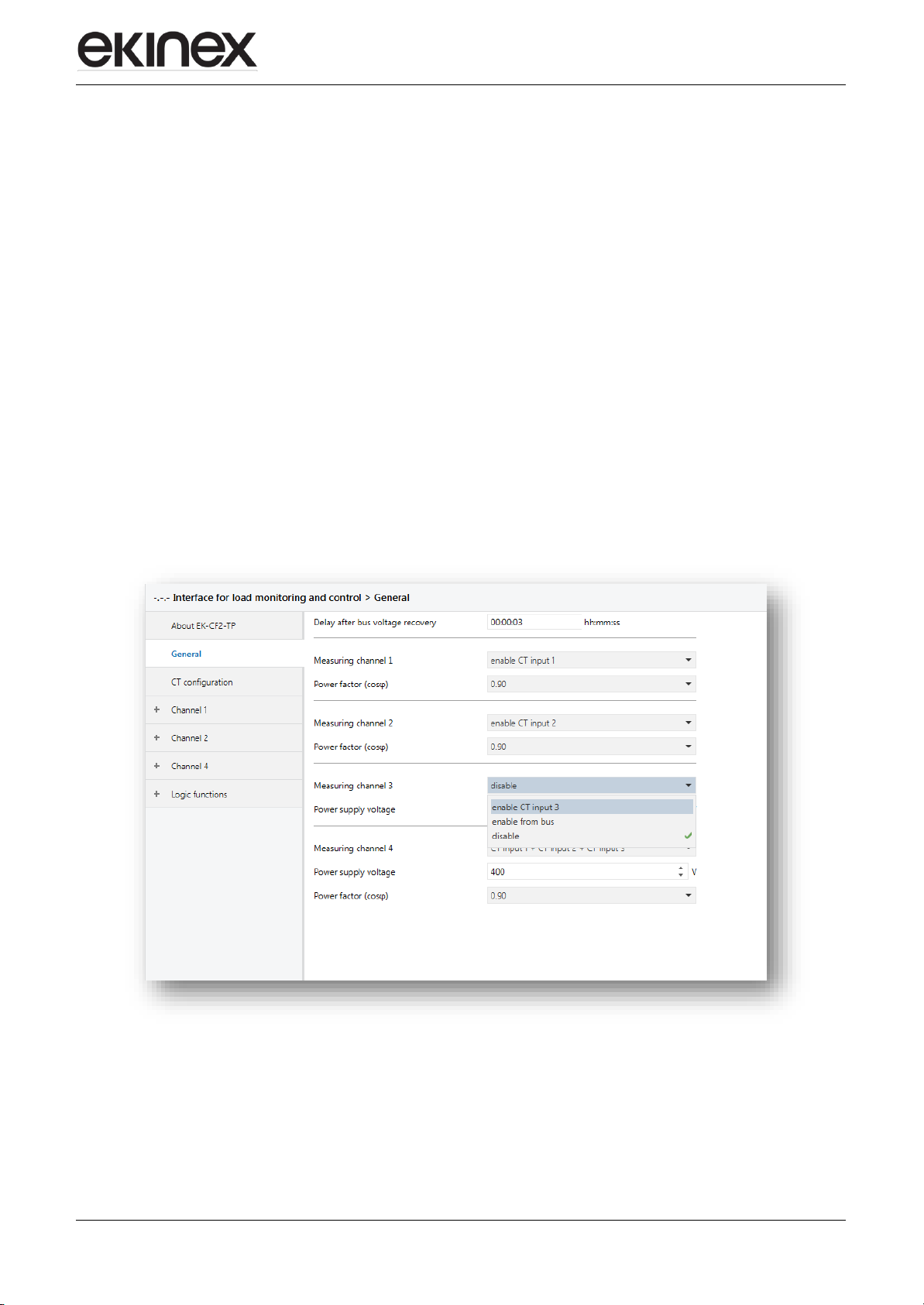

7.1. General parameters

The formula for calculating the absorbed power (in W) for every Yesngle channel, and to sum the input

channels, is the following: W = I x V x cos φ

It takes into conYesderation:

The nominal network voltage (V), to be defined in the parameters;

The cos φ phase difference between current and voltage, to be defined in the parameters.

As previously stated, you can connect up to 3 TA to their related channels, in order to control 3 Yesngle-phase

and 1 three-phase loads, uYesng the channel no.4 as sum of the channels no.1-2-3. The result will be both

communication objects indicating the power of the Yesngle channels in W and/or in kW, and communication

objects indicating the power in W and/or in kW as result of the sum of the channels.

Moreover, you can use channel no.4 as an independent channel, to acquire via bus an external power

measurement, which can be useful for load and/or threshold control.

Every channel can be enabled both at the acquiYestion of the nominal input measurement, both from bus.

If not used, it can be disabled.

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 10

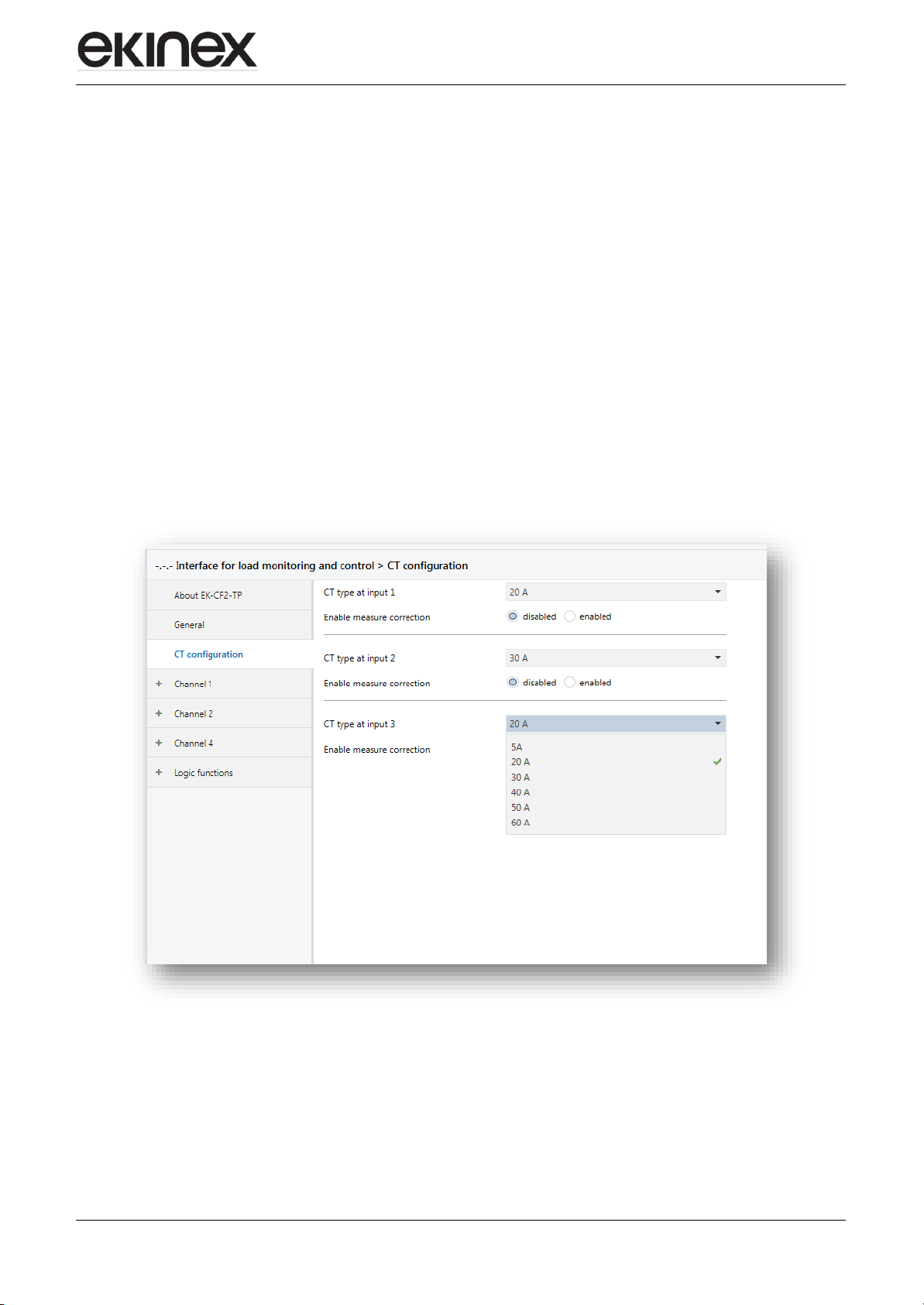

6.3.3 TA configuration

In this section, the TAs to be connected to channels 1-2-3 can be parametrized, by inserting the measurement

range characteristics (5, 20, 30, 40, 50 and 60 A).

Moreover, it is posYesble to perform a calibration for a more precise and linear measurement.

If the parameter “Enable measurement correction” is enabled, you can proceed to insert the requested values

in the windows called “current point x measured by input and channel”.

Pratically, you must proceed like this:

Through ETS > Diagnostics, verify the current measurement detected in a point with low absorption,

inserting the detected value in the window called “Current point 1 measured by input”.

Without changing load or conditions, with a current clamp, measure the current and insert the value in

the window called “current point 1 measured by user”.

Increase the load, according to the maximum measurement of the TA, and repeat the two measurements

inserting them in the windows called respectively “Current point 2 measured by input” and “Current point

2 measured by user”.

This way, the device will perform an auto-calibration of the absorbed current linearization curve, in order to

obtain measurements that are more precise.

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 11

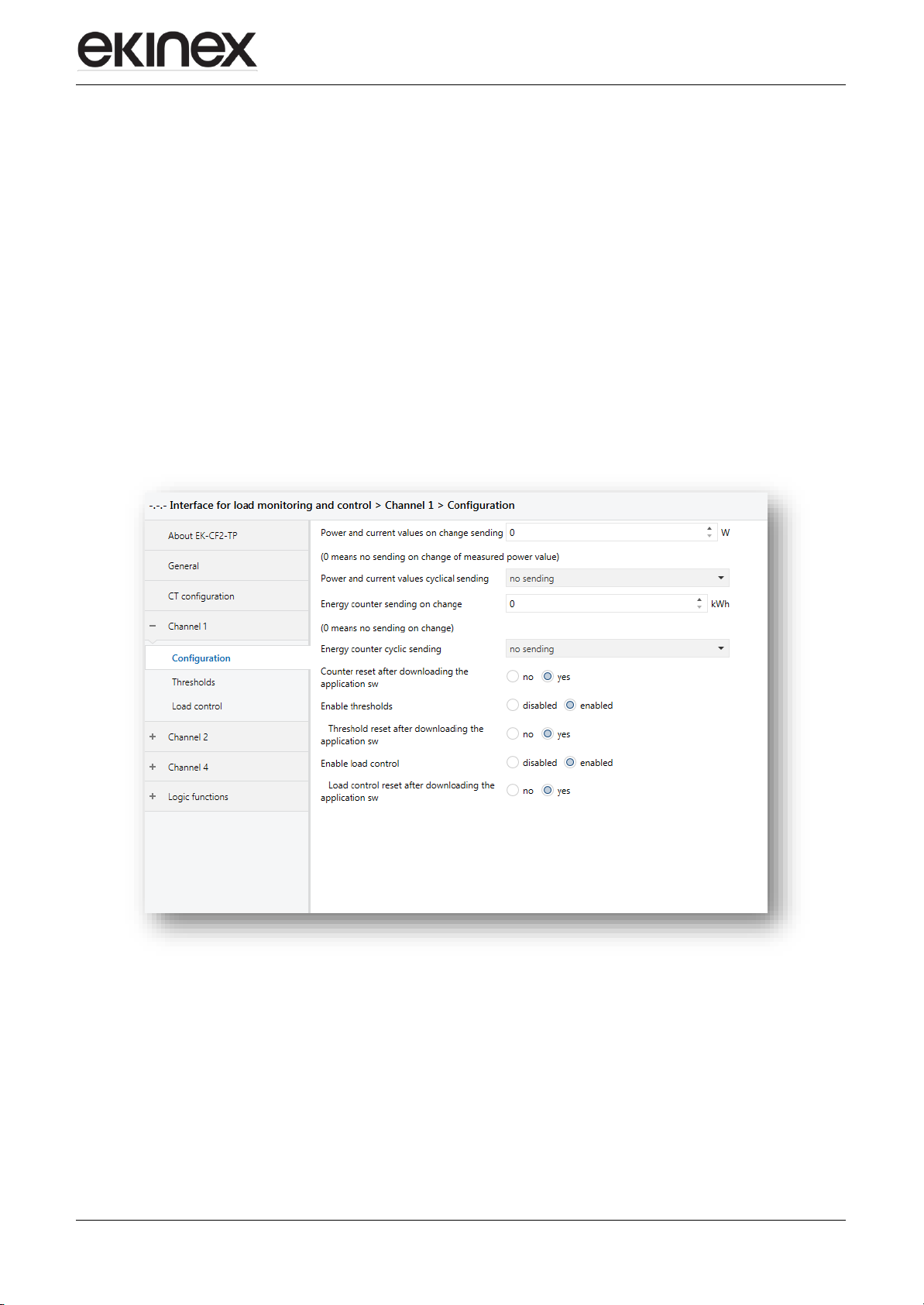

7.2. Channel configuration

For each channel, once configured, we have the posYesbility to setup a series of parameters:

The cyclic and/or on change sending of the measured power and current

The cyclic and/or on change sending of the calculated total energy (kWh)

The posYesbility to reset the calculated total energy counter (kWh), which is particularly useful if

other parameters are modified but you do not want to temper with those settings

The enabling of the “Thresholds” function

The posYesbility to reset the value of the “Thresholds”, which is particularly useful if other parameters

are modified but you do not want to temper with those settings

The enabling of the “Load control” function

The posYesbility to reset the value of the “Load control”, which is particularly useful if o ther

parameters are modified but you do not want to temper with those settings

Application manual

Interface for Load monitoring and control EK- CF2-TP

Revision 1.0.0 - Update: 04/07/2017

© EKINEX S.p.A. – All rights reserved

MAEKCF2TP_IT

Pag. 12

7.3. Configuration of a power threshold function

The use of the “Thresholds” function, independent from the “Load control” function, can be useful to define

some thresholds of those measured power where it is necessary to define a technical alarm, a functional

logic or the disconnection of one or more loads.

It is very useful in case, thanks to a renewable energy contribution controlled by the EK-CF2-TP, the user

sets a series of ACTIVATION thresholds for loads that can be used ONLY with renewable energy systems,

in order to optimize its use and consume less energy.

It is posYesble to send on the bus the value of the power thresholds in Watt.

Up to 8 functions for each channel can be parametrized and used.

For each configured threshold, the following parameters can be parametrized:

Value of intervention in Watt

Mode of operation of the reached threshold status (inverted / not inverted) in order to use the

communication object in negative logic without additional logic objects

Mode of intervention (if the threshold is above or below the set value)

Hysteresiss of intervention

Delay of activation

Cyclic sending of the state

Disable the threshold from bus

Loading...

Loading...