eka EKF 711UD–EKF 664UD–EKF 664 UD-HTEKF 664 UD/003, EKF 664 UD/003, EKF 616 U, EKF 616 UD-HT Use And Instruction Manual Use And Instruction Manual

Page 1

USE AND INSTRUCTION MANUAL

USE AND INSTRUCTION MANUALUSE AND INSTRUCTION MANUAL

USE AND INSTRUCTION MANUAL

MOD

MODMOD

MODDDDD.... EEEEKF

KF KF

KF 711

711711

711 UD

UDUD

UD –––– EEEEKF

KF KF

KF 664

664664

664 UD

UDUD

UD –––– EKF

EKF EKF

EKF 664 UD

664 UD664 UD

664 UD----HT

HT HT

HT

EKF 664 UD/003

EKF 664 UD/003EKF 664 UD/003

EKF 664 UD/003 –––– EKF

EKF EKF

EKF 616 UD

616 UD616 UD

616 UD –––– EKF

EKF EKF

EKF 616 UD

616 UD616 UD

616 UD----HT

HTHT

HT

rev.

rev.rev.

rev. 2222

TECNOEKA S.r.l.

Via Marco Polo, n.11 - 35010 Borgoricco (Padova) Italy

Tel. +39.049.9300344 – +39.049.5791479 Fax 049.5794387

www.tecnoeka.com E-mail: info@tecnoeka.com

Page 2

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 2 __________________________________________________________________________________________

X:\Sgq\PRODOTTI\1 - FORNI\FORNO ELETTRICO\LEka\MANUALI D'USO - Forno Elettrico 40 60 90 -

LEka\Lingua Inglese\NUOVA GAMMA EF\Instruction manual EKF 711 UD - EKF 664 UD (-HT) - EKF 664

UD_003 - EKF 616 UD (-HT) - GB - rev. 2.doc

Page 3

Electric Oven rev. 2 ____________________EKF 711 UD – EKF 664 UD (-HT) – EKF 664 UD/003 – EKF 616 UD (-HT)

___________________________________________________________________________________________ page 3

CE

DECLARATION OF CONFORMITY

Annexed document II A, of directive 2006/42/EC

Annexed document II A, of directive 2006/42/ECAnnexed document II A, of directive 2006/42/EC

Annexed document II A, of directive 2006/42/EC

Manufacturer’s name TECNOEKA Srl

TECNOEKA SrlTECNOEKA Srl

TECNOEKA Srl

Manufacturer’s address Via

Via Via

Via Marco Polo

Marco PoloMarco Polo

Marco Polo, 1

, 1, 1

, 11111 ---- 3501

35013501

35010000 Borgoricco

BorgoriccoBorgoricco

Borgoricco (PD)

(PD)(PD)

(PD)

Manager’s name of technical file Minotto Lorenzo

Minotto LorenzoMinotto Lorenzo

Minotto Lorenzo

Manager’s address of technical file Via

Via Via

Via Marco Polo

Marco PoloMarco Polo

Marco Polo, 1

, 1, 1

, 11111 ---- 3501

35013501

35010000 Borgoricco

BorgoriccoBorgoricco

Borgoricco (PD)

(PD)(PD)

(PD)

Type of product Electronic oven

Electronic ovenElectronic oven

Electronic oven

Purpose of the product Cooking fo

Cooking foCooking fo

Cooking food

odod

od

Model EEEEKF

KF KF

KF 711 UD

711 UD 711 UD

711 UD –––– EKF 664 UD

EKF 664 UDEKF 664 UD

EKF 664 UD –––– EKF 664 UD

EKF 664 UDEKF 664 UD

EKF 664 UD----HT

HTHT

HT

EKF 664 UD/003

EKF 664 UD/003EKF 664 UD/003

EKF 664 UD/003 –––– EKF 616 UD

EKF 616 UDEKF 616 UD

EKF 616 UD –––– EKF

EKF EKF

EKF 616 UD

616 UD616 UD

616 UD----HT

HTHT

HT

TECNOEKA Srl declares that the mentioned above products meet the following safety

regulations:

Low voltage directive 2006/95/CE

Electromagnetic compatibility Directive 2004/108/CE.

TECNOEKA Srl declares that the mentioned above products meet the following harmonised

standards:

CEI EN 60335-1 ; CEI EN 60335-2-42

CEI EN 55014-1 ; CEI EN 61000-3-2 ; CEI EN 61000-3-3 ; CEI EN 62233

TECNOEKA Srl declares that the mentioned above products meet the following directives:

Machine Directive 2006/42/CE;

Directive on the general safety of products 2001/95/CE;

Directive on the restriction in the use of dangerous substances in electrical and electronic

appliances 2011/65/CE;

Directive on waste from electrical and electronic appliances 2002/96/CE (RAEE).

TECNOEKA Srl declares that the mentioned above products meet the

CE 1907/2006 (REACH) Regulation

Borgoricco, 16/03/2015.

________________________________

________________________________________________________________

________________________________

Signature of a Representative of the Board of directors

(CRISTINA LORA)

Page 4

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 4 __________________________________________________________________________________________

Index

IndexIndex

Index

1. Technical service

2. General warnings

3. Technical specifications

4. Instructions for the installer

5. Use instructions (for the user)

6. Residual risks (for the user)

7. How to use the control panel

8. Oven cooking

9. Cleaning

10. Maintenance

11. Technical service

12. Information to the consumers

13. Wiring layout

14. The Warranty

Page 5

Electric Oven rev. 2 ____________________EKF 711 UD – EKF 664 UD (-HT) – EKF 664 UD/003 – EKF 616 UD (-HT)

___________________________________________________________________________________________ page 5

1111.

. .

. Technical service

Technical serviceTechnical service

Technical service

A technical check-up once or twice a year helps prolong the life of the appliance and

guarantees better operation.

Make sure that assistance is carried out solely and exclusively by qualified personnel.

For any spare parts orders or for any information about the appliance, always mention the serial

number and model (data indicated on the "technical data" plate at the rear of the oven).

2.

2. 2.

2. General warnings

General warningsGeneral warnings

General warnings

Very important!: keep this instruction book together with the appliance for future consultation.

These warnings were drafted for your safety and for that of others. Please read them carefully

before installing or using the appliance:

- If, on receipt of the goods, the packaging

packagingpackaging

packaging is damaged, write the following on the delivery

note: “I REVERSE THE RIGHT TO CONTROL THE GOODS

I REVERSE THE RIGHT TO CONTROL THE GOODSI REVERSE THE RIGHT TO CONTROL THE GOODS

I REVERSE THE RIGHT TO CONTROL THE GOODS”, specify the damage and get

the driver to sign in acceptance; send a claim in writing to the seller within 4 calendar

days from the date of receipt. No claim shall be accepted after such period.

- The appliance is intended for professional use and must be utilised by qualified personnel

trained to use it.

- Any modification which may be necessary on the electrical system to enable installation

of the appliance, must be carried out solely by competent personnel.

- It is dangerous to modify or attempt to modify the characteristics of this appliance.

- Never clean the appliance with direct water jets, because, if any water enters, it could

limit the machine's safety .

- Before doing any maintenance or cleaning jobs, disconnect the appliance from the

electrical mains and allow it to cool.

- Do not attempt to carry out the periodic controls or any repairs by yourself. Contact the

nearest Service Centre and use only original spare parts.

N.B.:

N.B.:N.B.:

N.B.: Improper or incorrect use and failure to observe the installation instructions shall release

Improper or incorrect use and failure to observe the installation instructions shall release Improper or incorrect use and failure to observe the installation instructions shall release

Improper or incorrect use and failure to observe the installation instructions shall release

the manufacture from all responsibility.

the manufacture from all responsibility.the manufacture from all responsibility.

the manufacture from all responsibility. In this connection, the directives in the "POSITIONING"

In this connection, the directives in the "POSITIONING" In this connection, the directives in the "POSITIONING"

In this connection, the directives in the "POSITIONING"

paragr

paragrparagr

paragraph must be strictly observed.

aph must be strictly observed.aph must be strictly observed.

aph must be strictly observed.

3.

3. 3.

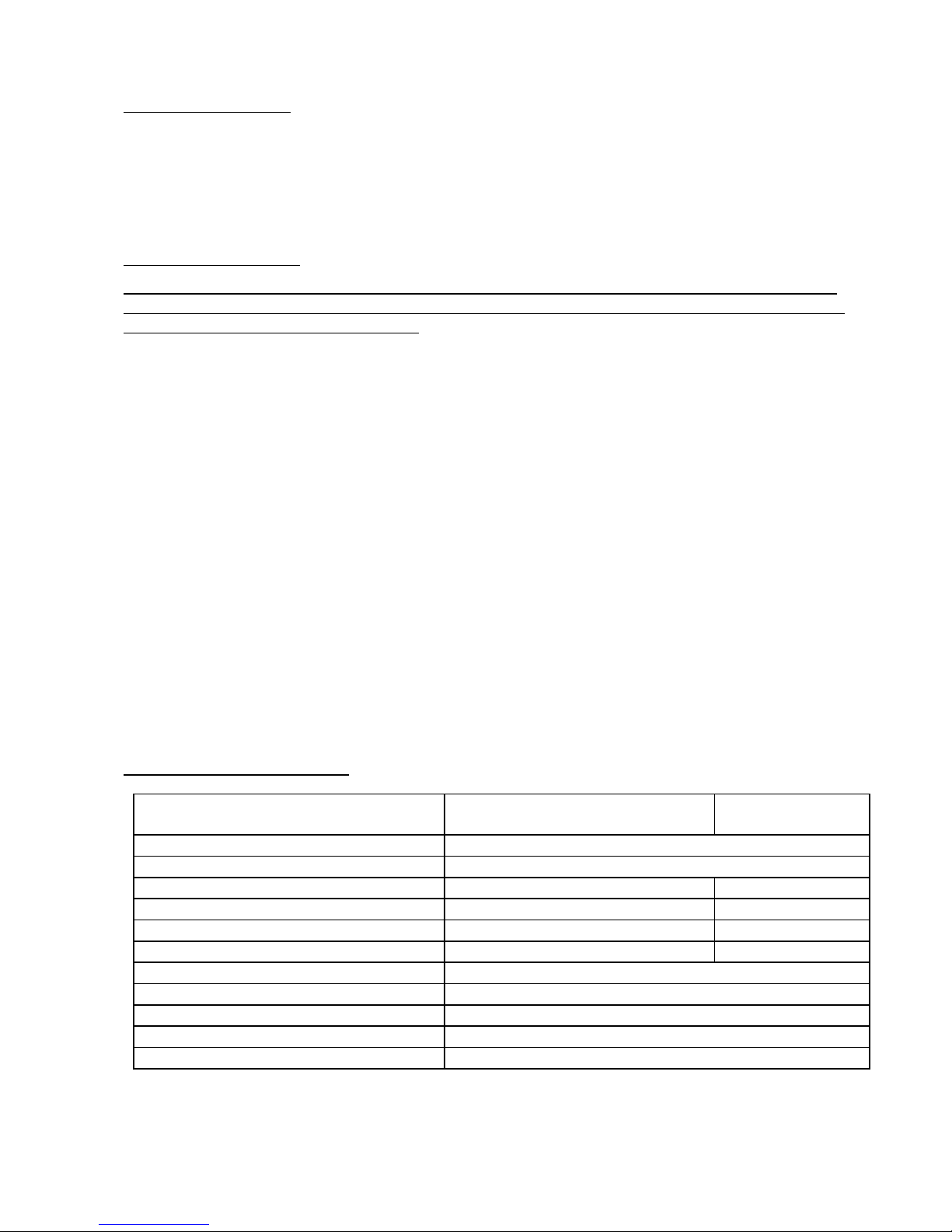

3. Technical specifications

Technical specificationsTechnical specifications

Technical specifications

Models

ModelsModels

Models

EKF 711 UD

– EKF 664 UD

(-

HT)

EKF 616 UD (-HT)

EKF 664 UD/003

Dimensions of appliance LxDxH (mm)

Dimensions of appliance LxDxH (mm)Dimensions of appliance LxDxH (mm)

Dimensions of appliance LxDxH (mm)

935x930x825

Weight (Kg)

Weight (Kg)Weight (Kg)

Weight (Kg)

96,4

Convection heating element (kW)

Convection heating element (kW)Convection heating element (kW)

Convection heating element (kW)

4

(x2) 3 (x2)

Max. absorbed power (kW)

Max. absorbed power (kW)Max. absorbed power (kW)

Max. absorbed power (kW)

8,4 6,4

Power supply voltage (V)

Power supply voltage (V)Power supply voltage (V)

Power supply voltage (V)

AC 400V 3N (50Hz)

230 V (50Hz)

Power cable diameter

Power cable diameterPower cable diameter

Power cable diameter

5x2,5 mm

2

3x4 mm2

Type of cable

Type of cableType of cable

Type of cable

H07RN

-F

Connecting electric cable

Connecting electric cableConnecting electric cable

Connecting electric cable

Tipo Y

Class

ClassClass

Class

I

Degree of protection against humidity

Degree of protection against humidityDegree of protection against humidity

Degree of protection against humidity

IPX3

Water pressure

Water pressure Water pressure

Water pressure

(kPa)

100-200

TTTThe noise level of the appliance in operation is below 70 dB (A).

he noise level of the appliance in operation is below 70 dB (A).he noise level of the appliance in operation is below 70 dB (A).

he noise level of the appliance in operation is below 70 dB (A).

The "technical data" plate is positioned on the rear panel of the appliance.

The "technical data" plate is positioned on the rear panel of the appliance.The "technical data" plate is positioned on the rear panel of the appliance.

The "technical data" plate is positioned on the rear panel of the appliance.

Page 6

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 6 __________________________________________________________________________________________

4.

4. 4.

4. Instructions for the installer

Instructions for the installerInstructions for the installer

Instructions for the installer

The following instructions are aimed at the qualified installer, to ensure that he carries out the

installation, adjustment and maintenance operations as correctly as possible and according to

current legal regulations. Any operation must be performed with electrical power cut to the

appliance. Before using the appliance, carefully remove the special adhesive film protecting the

parts in stainless steel. Do not leave any glue residues on the surfaces. If necessary, remove

them at once, with an appropriate solvent.

Positioning

PositioningPositioning

Positioning - Position the appliance perfectly horizontally on a table or similar support (the table

or support must be at least 85 cm above the floor). Position it at a distance of not less than 10

cm from the side and rear walls, to enable natural ventilating air to circulate freely around it.

The appliance is ventilated through specific openings on the metal walls of the outer housing ,

and ensures efficiency and long-life. For this reason it is strictly forbidden to obstruct these

ventilation openings, even partially or for short periods. Failure to observe this specific

Failure to observe this specific Failure to observe this specific

Failure to observe this specific

prohibition releases the manufacturer of the appliance from all responsibility and immediately

prohibition releases the manufacturer of the appliance from all responsibility and immediately prohibition releases the manufacturer of the appliance from all responsibility and immediately

prohibition releases the manufacturer of the appliance from all responsibility and immediately

voids any guarantee rights for the said appliance,

voids any guarantee rights for the said appliance,voids any guarantee rights for the said appliance,

voids any guarantee rights for the said appliance, because its constructive conformity has been

voluntarily compromised. Furthermore, the appliance is not suitable for embedding and for

grouped positioning with other identical appliances.

Electrical connection

Electrical connectionElectrical connection

Electrical connection - The appliance must be connected to the electrical mains according to

current legal regulations. Before making the connection, make sure of the following:

- the voltage and frequency values of the power supply system match the values on the

"technical data" plate affixed on the appliance;

- the limiting valve and the system are able to support the appliance's load (see the

"technical data" plate);

- the power sup

the power supthe power sup

the power supply system has an adequate earth connection according to current legal

ply system has an adequate earth connection according to current legal ply system has an adequate earth connection according to current legal

ply system has an adequate earth connection according to current legal

regulations;

regulations;regulations;

regulations;

- a omnipolar switch with minimum between-contacts aperture of the overvoltage

category III (4000 V), sized to the load and conforming to current legal regulations, is

fitted between the appliance and the mains in the direct connection to the mains;

- the omnipolar switch used for connection is easy to reach when the appliance is

installed;

- the yellow/green earth wire is not interrupted by the switch;

the yellow/green earth wire is not interrupted by the switch;the yellow/green earth wire is not interrupted by the switch;

the yellow/green earth wire is not interrupted by the switch;

- the power supply, when the appliance is operating, must not deviate from the rated

voltage value by ±10%.

- make sure that after inserting the power supply cord into the terminal block it does not

come into contact with any of the cooking range's hot parts.

- if the supply cable is dama

if the supply cable is damaif the supply cable is dama

if the supply cable is damaged then it must be replaced by the manufacturer or by your

ged then it must be replaced by the manufacturer or by your ged then it must be replaced by the manufacturer or by your

ged then it must be replaced by the manufacturer or by your

technical support or by a qualified person to avoid any risk

technical support or by a qualified person to avoid any risktechnical support or by a qualified person to avoid any risk

technical support or by a qualified person to avoid any risk

Connection to the water mains

Connection to the water mainsConnection to the water mains

Connection to the water mains - The appliance must be fed with softened drinking water, with

hardness from 0.5°F to 5°F (it is obligatory to use a softener to reduce the formation of lime

inside the cooking chamber) and pressure in the range from 150 to 250 kPa (1.5 - 2.5 bar).

Connection to the water mains should be made through the threaded 3/4" solenoid-valve on

the rear of the appliance, fitting in between a mechanical filter and an on/off tap (before you

connect the filter, allow a certain quantity of water to flow out in order to drain any waste from

the pipe).

Page 7

Electric Oven rev. 2 ____________________EKF 711 UD – EKF 664 UD (-HT) – EKF 664 UD/003 – EKF 616 UD (-HT)

___________________________________________________________________________________________ page 7

Water drainage

Water drainageWater drainage

Water drainage

A drain pipe (see Fig. 1) comes out from the rear of the appliance, to drain the oven cavity. This

pipe must be connected up to a pipe made to resist steam temperatures (90°C-100°C) with an

internal diameter of 30 mm (DN 30). To prevent choking, it is best to use a rigid pipe and make

sure there are no "elbow" bends anywhere along the drain line. Furthermore, the drain line

must slope down (minimum slope 5%) along its full length (the length in question is from the

appliance's drain pipe to the drain point and must not exceed 2 metres). The drain line must run

into an open floor drain (Fig.2). In addition, there must be a free air gap of at least 25 mm

(distance between the drain line coming from the appliance and the funnel on the drain

standpipe). Whatever the case, in order to comply with current hygiene standards, the line

connected to the appliance's drain pipe must not come into direct contact with the drain point.

It is advisable to include a suitable trap in the line connecting the appliance's drain outlet to the

grey water waste system, thus stopping the steam coming back out of the drain.

FIG.

FIG. FIG.

FIG. 1111 FIG.

FIG. FIG.

FIG. 2222

Connecting the power cable

Connecting the power cableConnecting the power cable

Connecting the power cable (for modd. EKF 711 UD – EKF 664 UD(-HT) – EKF 616 UD(-HT)) - To

reach the power terminal board remove the left side of the appliance. Loosen the cable-clamp

on the back (at the bottom) of the appliance and pass the cable through up to near to the

terminal board. Locate the leads against the terminal board so that the earth lead is the last to

detach from its terminal in the event of reverse pulling. Connect the 3 phase

phase phase

phase leads to the

terminals marked “1” “2”

“1” “2”“1” “2”

“1” “2” and “3”

“3”“3”

“3”, the neutral

neutral neutral

neutral lead to the terminal marked “4”

“4”“4”

“4” or “5”

“5”“5”

“5” and

the earth

earth earth

earth lead to the terminal marked as shown in the following layout:

(this electrical connection lay-out is located near the power supply terminal board ). Tighten the

cable gripper and re-fit the left side-panel of the appliance.

The appliance must be connected to an equipotential system

equipotential systemequipotential system

equipotential system whose efficiency must first be

checked according to current legal regulations.

This connection must be made between different appliances by using the appropriate terminal

marked with the symbol . The equipotential conductor must have a minimum diameter of 2,5

mm

2

The equipotential terminal is at the rear of the appliance.

Page 8

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 8 __________________________________________________________________________________________

Connecting th

Connecting thConnecting th

Connecting the power cable

e power cablee power cable

e power cable (for mod. EKF 664 UD/003)- To reach the power terminal board

remove the left side of the appliance. Loosen the cable-clamp on the back (at the bottom) of

the appliance and pass the cable through up to near to the terminal board. Locate the leads

against the terminal board so that the earth lead is the last to detach from its terminal in the

event of reverse pulling. Connect the phase

phase phase

phase lead to the terminal marked ““““L”

L”L”

L”, the neutral

neutral neutral

neutral lead to

the terminal marked “N”

“N”“N”

“N” and the earth

earth earth

earth lead to the terminal marked . Tighten the cable

gripper and re-fit the left side-panel of the appliance.

The appliance must be connected to an equipotential system

equipotential systemequipotential system

equipotential system whose efficiency must first be

checked according to current legal regulations.

This connection must be made between different appliances by using the appropriate terminal

marked with the symbol . The equipotential conductor must have a minimum diameter of 2,5

mm2 The equipotential terminal is at the rear of the appliance.

Safety ther

Safety therSafety ther

Safety thermal breaker

mal breakermal breaker

mal breaker - The appliance has a manually reset safety thermal breaker. It protects

against excessive dangerous over-temperatures which could be accidentally generated inside the

appliance. If the device is tripped, it interrupts electrical power to the appliance and thus

prevents it from operating. To access this device, remove the left side-panel of the appliance.

5.

5. 5.

5. Use instructions (for the user)

Use instructions (for the user)Use instructions (for the user)

Use instructions (for the user)

This appliance is not intended for use by persons (including children) with reduced phycal,

sensory or mental capabilities, or lack of experience and knowledge. Unless they have

beengiven supervision or instruction concerning use of appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

For first use, we advise you to let the appliance to run load-free at maximum temperature for

about one hour. In this way, any unpleasant smells due to thermal insulation and residual work

grease are eliminated. This appliance must be used solely for the purpose for which it was

expressly designed, i.e. cooking foods in the oven. Any other use is considered unsuitable.

The appliance can be used: for all oven cooking of deserts, pizzas, meat, fish, vegetables, as

well as for gratinating, and for re-conditioning cooled and frozen foods. When placing food in

the cooking compartment, leave a space of at least 40 mm between pans in order not to overobstruct air circulation. Do not use pans with higher than necessary edges: edges are barriers

which prevent the circulation of hot air. Warm up the oven before every cooking operation to

obtain maximum uniformity. Do not salt foods in the cooking compartment.

6.

6. 6.

6. Residual risks (for the user)

Residual risks (for the user)Residual risks (for the user)

Residual risks (for the user)

After a cooking operation, open the door cautiously, to avoid a violent outflow of heat which

could cause burns. While the oven is in operation, pay attention to the hot zones (marked on

the appliance) of its external surfaces. Place the machine on a bench or similar support, at a

height of at least 85 cm from the floor. The bench or support must be able to support the

weight of the machine and house it correctly. The appliance contains electrical parts and must

never be washed with a jet of water or steam. The appliance is electrically connected: before

attempting any cleaning operation, cut power to the appliance. To prevent incorrect connection

of the appliance, the relevant electrical and water connections are marked by identification

plates. If the internal glass panel of the door has to be cleaned, it must be dismantled with the

help of a second operator: one operator supports the glass panel, while the other unscrews its

securing screws.

Page 9

Electric Oven rev. 2 ____________________EKF 711 UD – EKF 664 UD (-HT) – EKF 664 UD/003 – EKF 616 UD (-HT)

___________________________________________________________________________________________ page 9

7.

7. 7.

7. How to use the control panel

How to use the control panelHow to use the control panel

How to use the control panel

1. "End of cooking" programming knob

2. Control thermostat knob

3. Automatic humidifier knob

4. "End of cooking" programmer indicator

light

5. Control thermostat indicator light

6. Automatic humidifier indicator light

1

2

3

4

5

6

Page 10

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 10 __________________________________________________________________________________________

Fig. 3 Fig. 4

Fig. 5

Programming cooking time

Programming cooking timeProgramming cooking time

Programming cooking time - To run the oven, turn the programmer knob (Fig. 3) in line with

symbol (continuous operation) or in line with the selected cooking time (up to 120 minutes).

In the second case, end of cooking is signalled by the oven switching OFF automatically.

Programming cooking temperature

Programming cooking temperatureProgramming cooking temperature

Programming cooking temperature - Turn the knob of the adjustment thermostat (Fig. 4) in line

with the temperature selected for cooking.

Programming vapour quantity

Programming vapour quantityProgramming vapour quantity

Programming vapour quantity - To generate vapour while the oven is in operation (cooking

compartment hot), turn the knob of the automatic humidifier (Fig. 5) in line with the required

value (from 1 to 5). If you turn the knob to position • (OFF) the humidifier will stop operating.

Remember

RememberRemember

Remember

-

If you turn the knob to positions “1” to “4”, the humidifier operates by generating vapour

“1” to “4”, the humidifier operates by generating vapour “1” to “4”, the humidifier operates by generating vapour

“1” to “4”, the humidifier operates by generating vapour

(water is introduced into the cooking compartment) at automatically adjus

at automatically adjusat automatically adjus

at automatically adjusted, cyclically

ted, cyclically ted, cyclically

ted, cyclically

repeated time intervals

repeated time intervalsrepeated time intervals

repeated time intervals (The higher the number the higher the humidifier operating time and

thus a higher quantity of vapour is produced).

-

If you turn the knob to position "5", automatic control of the humidifier is disabled

"5", automatic control of the humidifier is disabled "5", automatic control of the humidifier is disabled

"5", automatic control of the humidifier is disabled - it now

operates by continuously introducing water into the cooking compartment (continuous

production of vapour).

-

Before beginning to run the automatic humidifier, stabilise the temperature inside the

cooking compartment at a value of at least 110°C, order to optimise vapour production.

"End of cooking" programmer indicator light

"End of cooking" programmer indicator light"End of cooking" programmer indicator light

"End of cooking" programmer indicator light - The programmer green indicator light indicate

that the oven is operating and that cooking time is active.

Control thermostat indicator light

Control thermostat indicator lightControl thermostat indicator light

Control thermostat indicator light - The control thermostat orange indicator light goes OFF

whenever the programmed temperature is reached inside the cooking compartment. It lights up

again when the thermostat is tripped to re-establish this temperature.

Automatic humidifier indicator light

Automatic humidifier indicator lightAutomatic humidifier indicator light

Automatic humidifier indicator light - The orange indicator light of the automatic humidifier

indicates that the water solenoid-valve is operating and, therefore, vapour is being produced in

the cooking compartment.

Oven internal light

Oven internal lightOven internal light

Oven internal light - The light is always on when the oven is operating.

To switch off the oven

To switch off the ovenTo switch off the oven

To switch off the oven - Turn OFF the knobs of the "end of cooking" programmer and of the

thermostat. When you have finished using the oven, shut off the water ON/OFF tap upstream of

the appliance and cut out electric power.

8.

8. 8.

8. Oven cooking

Oven cookingOven cooking

Oven cooking

For cooking, before putting food in, warm up the oven to the required temperature. When the

oven reaches the temperature, put the food in and check cooking time. Switch off the oven 5

minutes before the theoretical time in order to recover stored heat.

Convection cooking (dry heat)

Convection cooking (dry heat)Convection cooking (dry heat)

Convection cooking (dry heat) - Operate the oven and turn the thermo state knob to the

desired temperature.

Convection cooking + steam (dry heat + wet heat)

Convection cooking + steam (dry heat + wet heat)Convection cooking + steam (dry heat + wet heat)

Convection cooking + steam (dry heat + wet heat) - Operate the oven and turn the thermo

state knob to the desired temperature and the humidifier know the desired steam quantity.

De freezing

De freezingDe freezing

De freezing - Operate the oven and turn the thermo state knob and the humidifier knob in

correspondence of position OFF (•).

Page 11

Electric Oven rev. 2 ____________________EKF 711 UD – EKF 664 UD (-HT) – EKF 664 UD/003 – EKF 616 UD (-HT)

___________________________________________________________________________________________ page 11

9.

9. 9.

9. Cleaning (WARNING:

Cleaning (WARNING:Cleaning (WARNING:

Cleaning (WARNING: Cut power to the appliance before every operation)

Cut power to the appliance before every operation)Cut power to the appliance before every operation)

Cut power to the appliance before every operation)

General cleaning

General cleaningGeneral cleaning

General cleaning - Clean the oven when it is cold. Wash enamelled parts with lukewarm water

and soap, do not use abrasive products, steel wool, or acids, which could ruin them. To clean

the steel parts, do not use products containing chlorine (sodium hypochlorite, hydrochloric acid,

etc) even if diluted. Use specific off-the-shelf products or a little hot vinegar. Rinse thoroughly

with water and dry with a soft cloth. Clean the glass door of the oven with hot water only, and

do not use rough cloths. Do not allow foods (especially acid foods such as salt, vinegar, lemon,

etc) to stagnate on the stainless steel parts, because they could deteriorate. Do not wash the

appliance with direct jets of water, because if water enters, this could limit the appliance's

safety. Do not use corrosive substances (e.g. hydrochloric acid) to clean the oven' s support

bench.

Cleaning the oven

Cleaning the ovenCleaning the oven

Cleaning the oven - It is good practice to clean the oven interior at the end of every day of duty.

In this way it will be easier to remove cooking residues, preventing them from burning when the

oven is next used. Clean it accurately with hot water and soap or with the appropriate off-theshelf products.

Cleaning the door

Cleaning the doorCleaning the door

Cleaning the door - The glass panel of the door facing inwards toward cooking compartment

can be cleaned with the same type of degreasing product used to clean the compartment.

Otherwise, you can use normal glass cleaning product (non toxic). A common glass detergent

can be used also to clean the glass panel of the door facing outward. In all cases, you may just

use tepid soapy water. After rinsing, thoroughly dry the glass surface with a soft cloth. If

opaque sections form between the two glass panels of the door, they can be eliminated after

dismantling the internal glass panel.

Cleaning the fans

Cleaning the fansCleaning the fans

Cleaning the fans - The fans must be periodically cleaned with specific anti-lime scale products.

All the parts must be carefully cleaned, removing all lime scale deposits. To have access to the

fans remove the fan casing after removing the screws that fix it to the cooking chamber. When

cleaning is complete, replace the casing and screws.

Cleaning the door seal

Cleaning the door sealCleaning the door seal

Cleaning the door seal - For hygiene and good operations, it is good practice to clean the door

seal at the end of each day’s work. It should be carefully washed with warm soapy water, rinsed

and dried with a soft cloth. Any incrustations or food deposits must be carefully removed,

without using sharp metal tools which could irreparably damage the seal.

10.

10. 10.

10. Maintenance

MaintenanceMaintenance

Maintenance

General information

General informationGeneral information

General information - A periodic control (at least once a year) of the appliance aids to guarantee

long life and correct operations. Any sort of maintenance work on the appliance must be done

exclusively by technically qualified operators who have been trained in the maintenance work

on this appliance. Before beginning any sort of maintenance work on the appliance, turn the

power supply off (at the magnetothermal safety switch upstream from the appliance) and let it

cool down. Access is gained to the inside components that could require maintenance work by

removing the left side of the appliance.

Changing the lighting lamp in the cooking chamber

Changing the lighting lamp in the cooking chamberChanging the lighting lamp in the cooking chamber

Changing the lighting lamp in the cooking chamber - The lamp is housed between the two

door glasses; to replace it remove the internal glass as described in the paragraph: “Cleaning

the door”. After removing the internal glass, replace the lamp with another with the same

specifications: 12V 35W 300°C (this is a halogen lamp and should not be touched with your

bare hands).

Page 12

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 12 __________________________________________________________________________________________

Changing the door seal

Changing the door sealChanging the door seal

Changing the door seal - The door seal has a rigid profile with 3 fixing tabs. The profile must be

fitted into the guide on the face of the cooking chamber. The rectangular seal fits perfectly into

the frame of the guide and, therefore, the seal profile fits perfectly onto the face of the cooking

chamber. To change the seal, remove the old one from the guide by pulling hard at the four

corners. Clean any dirt from the guide and introduce the new seal (to make this operation

easier, we advise dampening the seal profile with soapy water).

Resetting the thermal breaker safety device

Resetting the thermal breaker safety deviceResetting the thermal breaker safety device

Resetting the thermal breaker safety device - This device is reached by removing the left side of

the appliance and can be reset by pressing the red key right down (which is marked by a special

adhesive label), which is inside the electric components compartment.

Possible faults

Possible faultsPossible faults

Possible faults

Type of fault

Type of faultType of fault

Type of fault

Cause

CauseCause

Cause

Corrective action

Corrective actionCorrective action

Corrective action

Control panel

completely off (the oven

does not work)

- Incorrect electric connections to the

mains

- Check the mains connection

- No mains voltage

- Restore mains voltage

- Thermal break safety device tripped

- Reset the thermal break safety

device

Cooking cycle set: the

oven does not work

- Door open or ajar - Close the door

- Damaged magnetic sensor

- Contact a qualified tec

hnician to

repair the sensor

Automatic humidifier

ON: no steam is

produced in the cooking

chamber

- Incorrect connection to water

mains

- Check the connection to water

mains

- Cut-off cock closed

- Check the cut

-

off cock

- Blocked water inlet filter

- Clean the f

ilter

- Damaged water inlet solenoid

- Contact a qualified technician to

repair the solenoid

Door closed: steam

comes out of the seal

- Seal not fitted correctly

- Check the seal fitting

- Damaged seal

- Contact a qualified technician to

repair the seal

- Handle prong loosened

- Contact a qualified technician to

repair the prong

The oven does not cook

evenly

- One of the motors is blocked or

turns slowly

- Contact a qualified technician to

repair the motor

- The motors do not go into reverse

- Contact a qualified technic

ian to

repair the motor

- Heating element not powered or is

damaged

- Contact a qualified technician to

repair the element

Lighting lamp in the

cooking chamber does

not work

- Damaged lamp - Change the lamp

- Damaged lamp feeder

- Contact a qualified technician t

o

repair the feeder

The thermo safety

device turns on in

continuous

- Device damaged

- Contact a qualified technician to

repair the feeder

- Regulating thermo state damaged

- Contact a qualified technician to

repair the feeder

Page 13

Electric Oven rev. 2 ____________________EKF 711 UD – EKF 664 UD (-HT) – EKF 664 UD/003 – EKF 616 UD (-HT)

___________________________________________________________________________________________ page 13

11. Technical service

11. Technical service11. Technical service

11. Technical service

Before leaving the factory, the appliance was completely regulated and tested by expert

specialised personnel to guarantee the best operating results.

All repairs and settings must be performed with utmost care and attention, respecting national

safety regulations in force. Always contact your retailer or our nearest Service Centre, giving

details of the problem, the appliance model and the serial number (on the rating plate on the

rear panel).

For any maintenance the user can contact Tecnoeka by calling the telephone numbers on the

cover or going to www.tecnoeka.com

www.tecnoeka.comwww.tecnoeka.com

www.tecnoeka.com.

12.

12.12.

12. Informations to the consumers

Informations to the consumersInformations to the consumers

Informations to the consumers

Further to Directive 2002/96/EC, the symbol of the crossed rubbish skip on

the appliance means that at the end of its life, the product must be

disposed of separately from the other rubbish. The user must hand the

appliance to a specialised waste collection centre for electric and electronic

equipment.

The separate collection of the rubbish and subsequent treatme

nt, recovery and disposal help to

produce other equipment using recycled materials, reducing the negative effects on the

environment and public health, which would be caused by incorrect management of the

rubbish.

Should the user dispose of the product abusively, administrative sanctions would be applied.

Page 14

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 14 __________________________________________________________________________________________

13.

13. 13.

13.

Wiring layout

Wiring layoutWiring layout

Wiring layout

MODELS EKF 711 UD

MODELS EKF 711 UD MODELS EKF 711 UD

MODELS EKF 711 UD –––– EKF 664 UD

EKF 664 UDEKF 664 UD

EKF 664 UD((((----HT)

HT)HT)

HT) –––– EKF 616 UD

EKF 616 UDEKF 616 UD

EKF 616 UD((((----HT)

HT)HT)

HT)

Key

KeyKey

Key

M Power terminal board

Pr "End of cooking" programmer

T1 Safety thermostat

T2 Oven thermostat

U Automatic humidifier

S1 Programmer indicator light

S2 Thermostat indicator light

S3 Automatic humidifier indicator light

IM Operating direction reversing element

MI

Door microswitch

E Solenoid-valve for automatic humidifier

B1-B2-B3-B4 Contactor coil

B-R Contactor Relais

T Transformer for oven lamp

L Oven lighting lamp

V1-V2 Radial motoventilators

V3 Tangential motorised ventilator

R1-R2 Circular heating elements

C1-C2 Capacitors

Page 15

Electric Oven rev. 2 ____________________EKF 711 UD – EKF 664 UD (-HT) – EKF 664 UD/003 – EKF 616 UD (-HT)

___________________________________________________________________________________________ page 15

MODEL EKF 664 UD

MODEL EKF 664 UDMODEL EKF 664 UD

MODEL EKF 664 UD/003

/003/003

/003

Key

KeyKey

Key

M Power terminal board

Pr "End of cooking" programmer

T1 Safety thermostat

T2 Oven thermostat

U Automatic humidifier

S1 Programmer indicator light

S2 Thermostat indicator light

S3 Automatic humidifier indicator light

IM Operating direction reversing element

MI

Door microswitch

E Solenoid-valve for automatic humidifier

B1-B2 Contactor coil

B-R Contactor Relais

T Transformer for oven lamp

L Oven lighting lamp

V1-V2 Radial motoventilators

V3 Tangential motorised ventilator

R1-R2 Circular heating elements

C1-C2 Capacitors

Page 16

TECNOEKA Srl ______________________________________________________________ use and instruction manual

page 16 __________________________________________________________________________________________

14.

14. 14.

14. The Warranty

The WarrantyThe Warranty

The Warranty

Your appliance is covered by warranty. The seller will replace or repair (and his decision will be final), free

of charge for the customer, only those parts that are defective due to a manufacturing fault on condition

that, under penalty of forfeiture:

− for domestic equipment, the customer notifies the fault within two months from the date when

he/she discovered it and anyway within 2 years form the date of purchase;

− for professional equipment, the customer notifies the fault within 8 days from the date when

he/she discovered it and anyway within 12 months from the date of purchase,

by registered letter with acknowledgement of receipt and enclosing the invoice or receipt proving the

purchase.

Apart from the case when the customer cannot produce the invoice or receipt proving the purchase or

when the above-mentioned terms are not complied with, the warranty is expressly excluded

warranty is expressly excluded warranty is expressly excluded

warranty is expressly excluded in the

following cases:

1) faults or breakage caused by the transport;

2) wrong or incorrect installation of the product (for instance because of insufficient draught of the

flue or exhausts) in light of the instructions given in the user’s handbook supplied with the

product;

3) inadequate or abnormal electrical, hydraulic and/or gas supplies;

4) carelessness, negligence or incompetence in using the product in light of the instructions given in

the user’s handbook supplied with the product;

5) use of the product for uses different from the one for which it was built or anyway in a manner

not compliant with the instructions given in the user’s handbook supplied with the product;

6) tampering with the product;

7) adjustments and/or maintenance and/or repairs carried out by unauthorised personnel and/or

with non original spare parts;

8) inadequate or careless maintenance of the product in contrast with the user’s handbook supplied

with the product;

9) damages caused by fire, natural disasters and accident as well as by any cause not attributable to

TECNOEKA SRL.

The warranty explicitly excludes

The warranty explicitly excludesThe warranty explicitly excludes

The warranty explicitly excludes: varnished or enamelled parts, knobs, handles, movable or removable

plastic parts, bulbs, glass parts, refractories and any accessories.

TECNOEKA SRL cannot be held responsible for any damages, either direct or indirect, caused by the

product breaking down or following its non-use.

Any repairs carried out during the warranty do not cause said warranty to be extended or renewed.

Nobody is authorised to modify the terms and conditions of the warranty or to issue new verbal or

written warranties.

The warranty is valid only for appliances installed in the European Union.

The warranty is valid only for appliances installed in the European Union.The warranty is valid only for appliances installed in the European Union.

The warranty is valid only for appliances installed in the European Union.

Any dispute shall be settled by the competent Court in Padua.

Warning for the Buyer:

Warning for the Buyer:Warning for the Buyer:

Warning for the Buyer:

1. the cooking appliance is designed only for cooking purposes while the heating appliance is

designed only for heating domestic environments;

2. TECNOEKA S.r.l. does not install the appliances; the seller shall be responsible for any installation

carried out;

3. TECNOEKA S.r.l. cannot be held responsible for any damages, either direct or indirect, to people,

pets or property caused by the appliance breaking down or following its non-use.

The Manufacturer cannot be held responsible for any inaccuracies due to misprints or mistakes in

copying in this handbook. The Manufacturer reserves the right to modify the products as he deems fit,

also in the interest of the user, without affecting the vital characteristics of functionality and safety.

Loading...

Loading...