Page 1

ORIGINAL OPERATING AND INSTRUCTION MANUAL

MODELS EKF 464 TC – EKF 511 TC

rev. 5

TECNOEKA S.r.l.

Via Marco Polo, n.11 - 35010 Borgoricco (Padova) Italy

Tel. +39.049.9300344 – +39.049.5791479 Fax +39.049.5794387

www.tecnoeka.com E-mail: info@tecnoeka.com

Page 2

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 2 _____________________________________________________________________________________________

EU DECLARATION OF CONFORMITY

Annex II A, of Directive 2006/42/EC

Manufacturer's name

TECNOEKA Srl

Manufacturer's address

Via Marco Polo, 11 - 35010 Borgoricco (PD)

Name of the person in

charge of the technical file

Lorenzo Minotto

Address of the person in

charge of the technical file

Via Marco Polo, 11 - 35010 Borgoricco (PD)

Product type

Electronic oven

Purpose of the product

Cooking food

Model

EKF 464 TC… – EKF 511 TC…

TECNOEKA Srl declares that the above mentioned products comply with all provisions

pertaining to the following directives:

Machinery directive 2006/42/EC;

Electromagnetic compatibility directive 2014/30/EU

TECNOEKA Srl declares that the above mentioned products comply with the following

harmonised directives:

EN 60335-1 ; EN 60335-2-42

EN 55014-1 ; EN 55014-2 ; EN 61000-3-2 ; EN 61000-3-3 ;

EN 62233

TECNOEKA Srl declares that the above mentioned products also comply with the

following directives:

General product safety directive 2001/95/EC;

Directive restricting the use of hazardous substances in electrical and electronic equipment

2011/65/EU;

Directive on waste of electrical and electronic equipment 2012/19/EU.

TECNOEKA Srl declares that the above mentioned products comply with

(EC) Regulation 1907/2006

Borgoricco, 06/07/2016.

_________________________________

Board Representative Signature (Lora Cristina)

X:\Sgq\PRODOTTI\1 - FORNI\FORNO ELETTRICO\LEka\MANUALI D'USO - Forno Elettrico 40 60 90 - LEka\Lingua

Inglese\NUOVA GAMMA EF\Instruction manual EKF 464 TC - EKF 511 TC - GB - rev. 5.doc

Page 3

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 3

Contents

1

Technical service

2

General information

3

Instructions for the installer

4

Instructions for the user

5

Settings menu

6

Accessories menu

7

Oven-user communication

8

Cleaning

9

Maintenance

10

Possible faults

11

Possible alarms

12

Electrical diagrams

13

Technical support

14

Information to users

15

Recipe book

16

The warranty

17

Availability and supply of spare parts

Page 4

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 4 _____________________________________________________________________________________________

1. Technical service

For periodic maintenance checks and repairs, contact your nearest Support Centre and only use

original spare parts. Failure to comply with this provision shall forfeit the warranty right.

2. General information

It is essential for this instruction manual to be stored together with the appliance for future

referencing; in the event of misplacing it, a copy must be obtained directly from the manufacturer.

This information has been prepared for your safety and that of others; therefore we kindly ask you

to read it carefully before installing and using the appliance.

If upon reception of the goods the packaging should not be intact or should it be damaged, affix

the following wording: “GOODS SUBJECT TO CHECK”, with the specification of the damage and

countersigned by the driver; file a written complaint with the seller within 4 calendar days (not

business days) from the date of delivery, after which no complaints shall be accepted.

The appliance is intended for professional use in institutional and professional kitchens and must

only be used by skilled personnel who have been trained on its proper use. For safety reasons the

appliance must be supervised during operation.

The appliance is not intended to be used by children and/or persons with impaired physical,

sensory or mental abilities, or who lack experience or knowledge, unless they are supervised by a

person responsible for their safety, or who has been instructed on using the appliance.

It is hazardous to modify or attempt to modify the features of this appliance.

The appliance must never be cleaned with direct water or steam jets, since any ingress of water

might affect its safety.

Before maintenance or cleaning disconnect the appliance from the power supply mains and let it

cool. In the event of failure or poor operation, switch off the appliance, close the water supply

cock, disconnect the power supply and contact an authorised Service Centre.

Any modification to the electrical system that might be required to be able to install the appliance

must be carried out by competent personnel only.

All installation and commissioning operations must be exclusively be performed by technically

skilled installers, according to the manufacturer's instructions and in compliance with national

standards in force.

For periodic maintenance checks and repairs, contact your nearest Support Centre and only use

original spare parts. Failure to comply with this provision shall forfeit the warranty right.

Note: The inappropriate or incorrect use and failure to comply with installation rules shall

invalidate any liability by the Manufacturers. In this connection, the instructions laid out under

“POSITIONING” (paragraph 3.6) must be strictly complied with.

Page 5

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 5

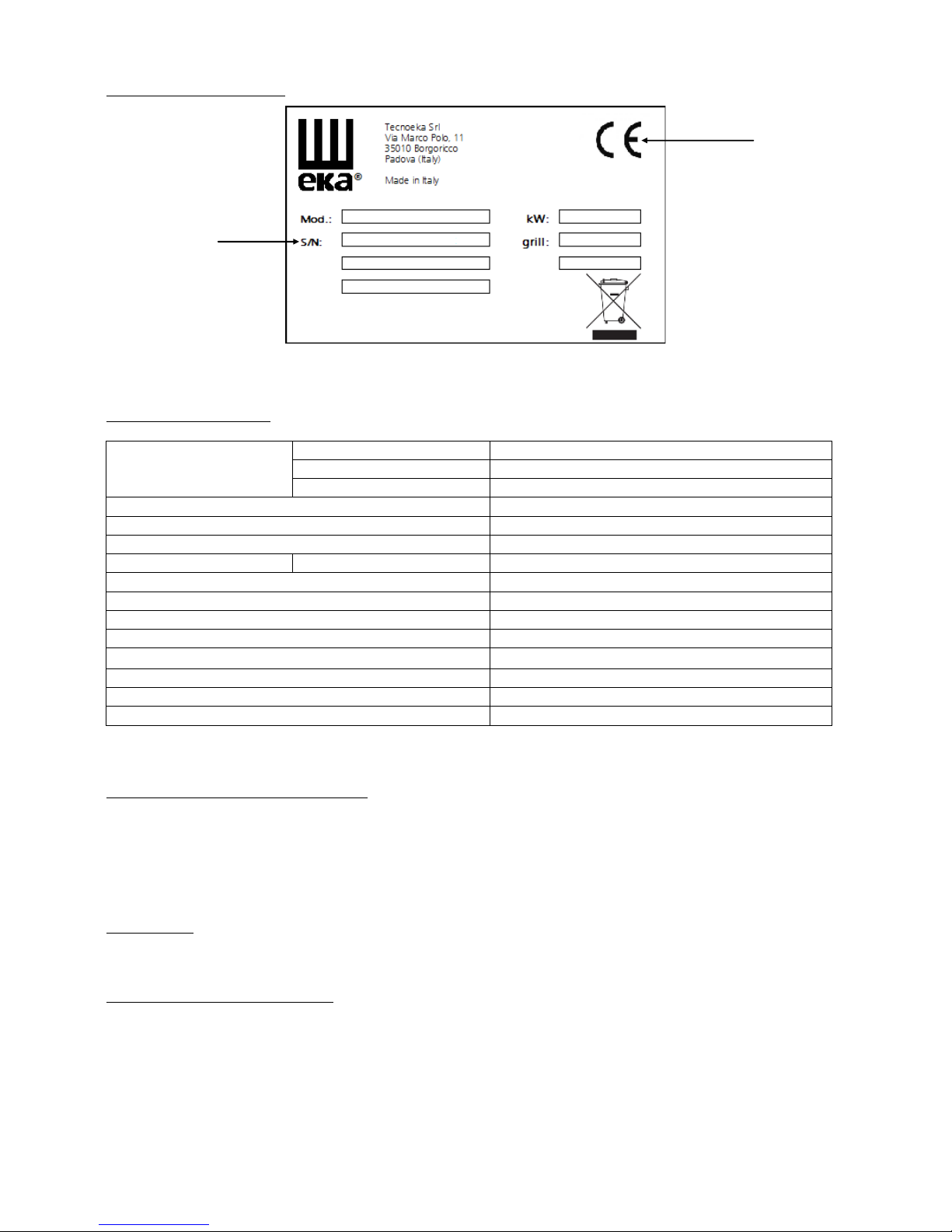

2.1 Technical data plate (example)

The “technical data” plate is located on the side of the appliance.

2.2 Technical features

Overall dimensions:

Height (with feet)

cm 74,5

width

cm 93,5

depth

cm 93

Weight:

kg 85

Maximum load per tray GN1/1-600x400mm

kg 4 - 2

Maximum load GN1/1-600x400mm

kg 20 - 8

Electrical power:

Convection resistors

kW 7,5

Maximum electrical power:

kW 8

Electrical insulation class:

I

Casing protection degree:

IPX5

Water pressure:

kPa 100 – 200

Power supply voltage:

400V 3N 50/60 Hz

Power supply cable section:

5G 2,5 (5 x 2,5 mm2)

Power supply cable type:

H07RN-F

Power supply cable connection:

Tipo : Y

The noise level of the appliance in operation is less than 70 dB (A).

3. Instructions for the installer

The following instructions are aimed at the skilled installer for them to perform installation,

electrical and water connection operations in the most correct manner and according to the safety

regulations in force in the place of installation of the appliance. The manufacturer shall not be

liable for damage or harm to persons, pets or property arising from installation errors. Nor are they

responsible for any appliance breakage caused by faulty installation.

3.1 Storage

In the event the appliance has been warehoused at temperatures below 0°C (maximum allowed –

5°C), it must be brought back to a temperature of at least +10°C before operating it.

3.2 Transport of the appliance

During transport the appliance must be left in its packaging in order to protect it from any

external damage.

The weight of the appliance must also be taken into account in order to prevent overturning.

CERTIFICATION

SERIAL NUMBER

EKF 464 TC

5214010500

8 kW

IPX5

400V 3N 50/60 Hz

kPa 100 - 200

Page 6

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 6 _____________________________________________________________________________________________

3.3 Unpacking the appliance

Remove packaging before installation. It consists of a wooden pallet supporting the appliance and

a cardboard casing protecting it. Ensure the appliance has not undergone any damage during

transport; otherwise immediately alert your dealer and/or carrier.

3.4 Removal of the protecting film

Before using the appliance accurately remove the special film protecting the stainless steel

components, avoiding to leave glue residues on the surfaces; if required, immediately remove

them using an appropriate solvent of non flammable type.

3.5 Disposal of packaging

The packaging must be disposed of in strict compliance with the regulations in force in the place

of installation of the appliance. The various materials (wood-paper-cardboard-nylon-metal staples)

the packaging consists of must be suitably separated and delivered to the suitable collection

centres. In any case adhere to environmental protection regulations.

3.6 Placement

Check the place of installation ensuring transit areas (any doors and corridors) are sufficiently wide

(the dimensions of the appliance without pallet are shown in Fig.1).

The appliance must be installed in a well-aerated room with permanent vents.

The maximum working height, referred to the highest surface level, must be 1.6 metres from the

floor. After installing the appliance apply the suitable adhesive symbol (supplied) at a height of 1.6

metres. To assure accessibility and air circulation around the appliance, leave at least 50cm of

space between the left side and the wall (or other appliance), and at least 10 cm between the

back and the wall and between the right side and the wall (see Fig.1). It is strictly forbidden to

obstruct, even partially, the forced aeration vents on the left side, even for short periods of time.

Failure to comply with this explicit prohibition shall void any liability from the appliance's

manufacturer and immediately forfeit any warranty rights on the same, since its constructive

conformity has been deliberately impaired. For the same reason, do not place any appliances that

might produce heat sources and/or spray hot liquids (fryers) near the left side.

Should the appliance be installed near walls, shelves, tops and the like, these must be of the non

flammable or heat-insensitive type; otherwise, they must be protected by adequate fire retardant

coating. In this connection it is indispensable to act in compliance with the fire prevention

regulations in force.

Cooking produces hot smoke and smells which are expelled from the suitable vent device at the

top of the appliance. It is recommended to place the appliance under an extraction hood or to use

the suitable TECNOEKA hoods, in order to convey the smoke to the outside.

3.6.1 Table top oven placement

The appliance must be placed in a perfectly horizontal position on a table or similar support; never

on the floor.

For safety reasons it is recommended to use the support produced by the manufacturer; otherwise

the weight of the appliance must be taken into account. The appliance is unsuitable for recessing.

Warning

In the event the appliance is positioned on a wheeled table/support, ensure the permissible

movement does not damage electrical wires, water pipes, drain pipes or anything else.

3.7 Electrical connection

Connection to the power mains must be performed according to regulations in force. Before

performing the connection ensure that:

- the voltage and frequency of the power supply system match with

the specifications on the "technical data" plate affixed on the side of the appliance;

Page 7

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 7

- the limiting valve and the system are able to withstand the appliance's load (see "technical

data" plate);

- the power supply system is fitted with effective earthing connection according to the

regulations in force;

- In the permanent connection to the mains, a protective pole switch must be provided

between the appliance and the mains with minimum opening between the contacts of

overvoltage category III (4000V), sized for the load and complying with applicable

regulations (e.g. automatic magnetic circuit breaker);

- the pole switch used for the connection is easily accessible with installed appliance;

- the yellow/green earthing cable is not interrupted by the switch;

- The appliance must be connected to an equipotential system the effectiveness of which

must be suitably assessed according to applicable regulations. This connection must be

performed with the suitable terminal located on the rear and marked with the symbol .

The equipotential conductor must have minimum section 2.5mm².

- when the appliance is operating, the power supply voltage does not deviate from the

nominal voltage value by ±10%;

- ensure the power supply cable does not enter in contact with the appliance's hot parts

after inserting it in the terminal board.

- if the power supply cable is damaged it must be replaced by the manufacturer or their

technical support service, or in any case by a person with similar qualifications, to prevent

any risk.

Installation and connection drawings

Fig. 1 (Dimensions are expressed in mm )

1

USB PORT

3

SOCKET FOR CORE PROBE CONNECTION

4

WATER DRAIN PIPE (DN30)

5

WASHING WATER INLET

6

SOFTENED WATER INLET (THREADED SOLENOID VALVE¾”)

8

STEAM VENT

9

POWER SUPPLY CABLE RETAINER

10

WARNING HOT SURFACE

11

DO NOT OBSTRUCT AERATION VENTS

12

WATER INLET MAX.200kPa

13

SOFTENED WATER INLET MAX. 200kPa

Page 8

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 8 _____________________________________________________________________________________________

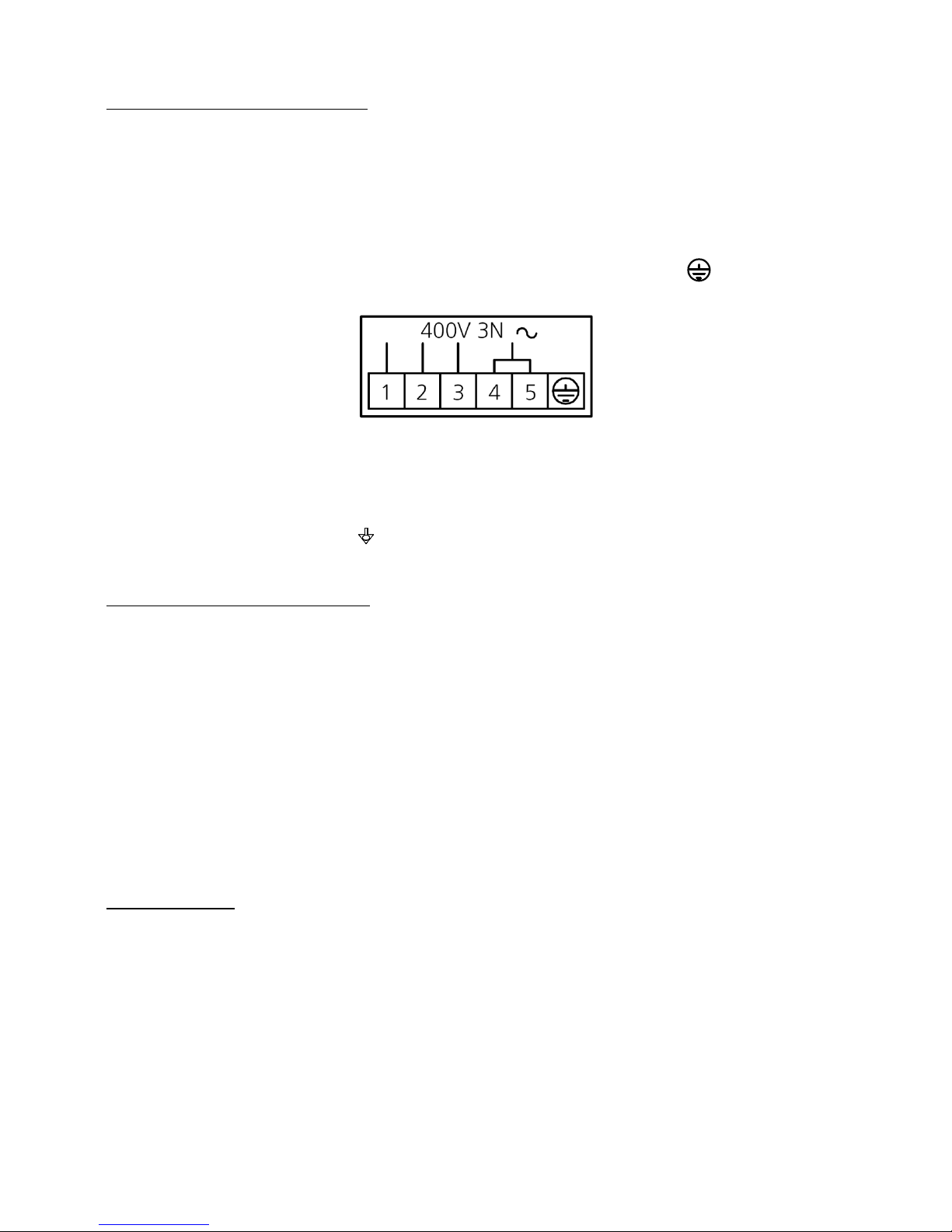

3.8 Power supply cable connection

Remove the back and left side of the appliance to access the power supply terminal board.

Loosen the cable retainer at the rear (bottom) of the appliance (see Fig.1) and run the cable

through it until reaching the terminal board. Prepare conductors for connection with the terminal

board so that the earth conductor is the last to be extracted from its terminal in the event the

cable should be abnormally pulled. Connect the 3 phase conductors (L1, L2, L3) of the cable to

the terminals marked with “1”(brown conductor) “2”(black conductor) and “3”(grey conductor)

of the terminal board, the neutral conductor (blue) to the terminal marked with “4” or “5” and

the earth conductor (yellow/green) to the terminal marked with the symbol (see diagram also

available by the terminal board):

Tighten the cable retainer on the rear of the appliance; fit the left side and back on again. The

cable must be as per specifications in the "Technical features" table (paragraph 2.2). The

appliance must be connected to an equipotential system the effectiveness of which must be

suitably assessed according to applicable regulations.

This connection must be performed between different appliances through the suitable terminal

which is marked with the symbol . The equipotential conductor must have minimum section

2.5mm². The equipotential terminal is at the rear of the appliance.

3.9 Connection to the water mains

The appliance must be supplied with softened drinking water, with hardness between 0.5°F and

5°F. and maximum temperature 30°C. It is obligatory to use a softener to reduce the formation

of limescale inside the cooking chamber. The water pressure must be between 100 and 200 kPa

(1.0 -2.0 bar). If the mains pressure exceeds 2.0 bar, install a pressure reducer upstream of the

appliance. If the value is lower than 1.0 bar use a pump to raise the pressure. The appliance is

equipped with flexible hose (1.5 metres) with threaded ¾” female fittings and relevant gaskets.

The old joints must not be used. Connection to the water mains must be performed through the

¾” threaded solenoid valve located at the rear (bottom) of the appliance (see Fig.1), interposing a

mechanical filter and a stopcock (before connecting the filter drain off a certain amount of water

to flush the pipe from any dirt).

Warning

Any damage caused by limescale or other chemicals contained in the water are not covered by

warranty.

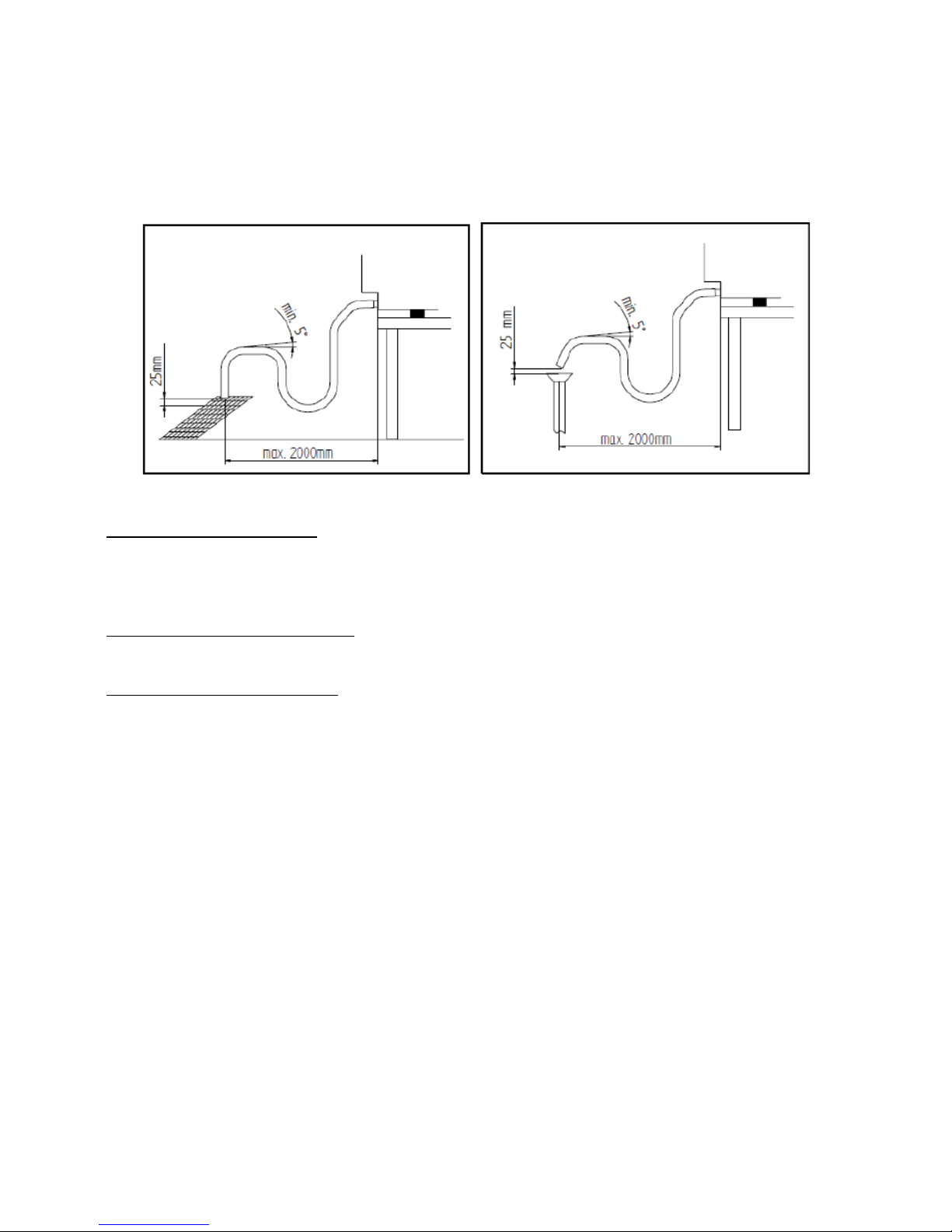

3.10 Water drain

A drain pipe comes out of the rear of the appliance (see Fig.1) to drain the cooking chamber.

This pipe must be connected to piping with 30 mm inner diameter (DN 30) resistant to steam

temperature (90°C-100°C).

To avoid choking the pipe should be stiff and there should be no "elbows" along the drain path.

The pipe must also maintain constant slope (min. 5%) along its entire length (the length

considered is that of the appliance's drain pipe at the drain point and must not exceed 2 metres).

The drain piping must be conveyed into an open floor drain (Fig.2); otherwise, there must be at

least 30 cm height difference between the drain pipe of the appliance and the drain point in order

to assure regular water drainage.

Furthermore, the minimum "air gap" must be 25 mm (distance between the drain pipe from the

appliance and the cup of the drain duct pipe).

Page 9

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 9

In any case, for reasons of compliance with health regulations in force, the piping connected to

the drain pipe of the appliance must not be in direct contact with the drain point.

It is recommended to connect the appliance's drain to the grey water network through an

adequate syphon, in order to stop steam from coming out of the drain.

The connection to drain water must be done separately for each appliance; in case of several

appliances connected to the same drain pipe, ensure the pipe is suitably sized to assure regular

drainage with no hindrances.

FIG. 2 FIG. 3

3.11 Safety thermal devices

The appliance is equipped with a manually reset safety thermostat, to protect against excessive

and hazardous overheating which might accidentally occur inside it. In the event of tripping the

device interrupts power supply to the appliance.

3.12 Electronic circuit protection

The electronic circuit housed inside the electrical components compartment is protected by fuse.

3.13 Disposal of the appliance

The appliance is constructed with recyclable raw materials and does not contain toxic or

hazardous substances for persons and environment. Eventual disposal of the appliance and its

packaging must be carried out strictly following the regulations in force in the place of installation.

The different materials it is made up of must be separated by type of disposal and delivered to the

suitable collection centres. In any case adhere to environmental protection regulations.

Page 10

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 10 _____________________________________________________________________________________________

4. Instructions for the user

4.1 General information

- Use the appliance at room temperature between +5°C and +25°C. 35°C may be reached

occasionally.

- The temperature of the appliance's external surfaces may exceed 60°C, only touch control

elements. Burn hazard!

- When the appliance is first used it is recommended to operate it unladen for 40/50 minutes at

a temperature of 220/230°C. In this way all unpleasant and wholly normal smells due to

heating the thermal insulation enveloping the cooking chamber and the silicone used for its

external sealing are dissipated.

- Supervise the oven during operation.

- This appliance must only be used for the use it has been especially designed for, that is

cooking food in the oven; any other use is to be deemed improper.

- The appliance may be used for all types of baking of pastries, baked goods and food: fresh and

frozen; for reconditioning chilled and frozen food, for steam cooking of meats, fish and

vegetables.

- No foods containing easily flammable substances must be cooked, such as alcohol-based

foods; self-combustion phenomena might occur leading to fires and explosions in the cooking

chamber.

Pay attention to handling food containers during and after cooking: they might be very hot.

Wear appropriate protective thermal clothing to prevent burns

- In placing the food in the cooking chamber, maintain a space of at least 40 mm between trays

in order not to excessively obstruct air circulation.

- Do not use trays with sides higher than necessary: the sides form barriers that prevent hot air

circulation.

- Preheat the oven every time before cooking to achieve top performance.

- For cooking as consistently as possible, spread the food evenly in every tray taking into account

its size, layer or thickness.

- Avoid adding salt to food in the cooking chamber.

- To check correct progress of the cooking cycle use the chamber's internal lighting: avoid

uselessly opening the door, which causes wastes of energy and longer cooking times.

Warnings

To prevent boiling, do not use containers filled with liquids or food that liquefy with heat, in

excessive amounts that cannot be easily kept under control. For this reason, only use trays that let

you see inside the container.

When extracting a tray containing hot liquid pay attention not to spill any liquid: burn hazard!

4.1.1 Residual risks

After baking open the door with caution, to avoid the violent outflow of heat which might cause

burns. During oven operation pay attention to hot areas of its outer surfaces (marked on the

appliance). Do not use the door handle to move the appliance (possible glass breakage).

The supporting bench must be able to withstand the weight of the machine and house it

correctly. The appliance is fitted with electrical parts and must never be washed with a water or

steam jet. The appliance is electrically connected: disconnect the power supply before performing

any type of cleaning. To avoid incorrect connections of the appliance, the relevant electrical/water

connections are marked on the appliance by suitable identification plates.

Page 11

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 11

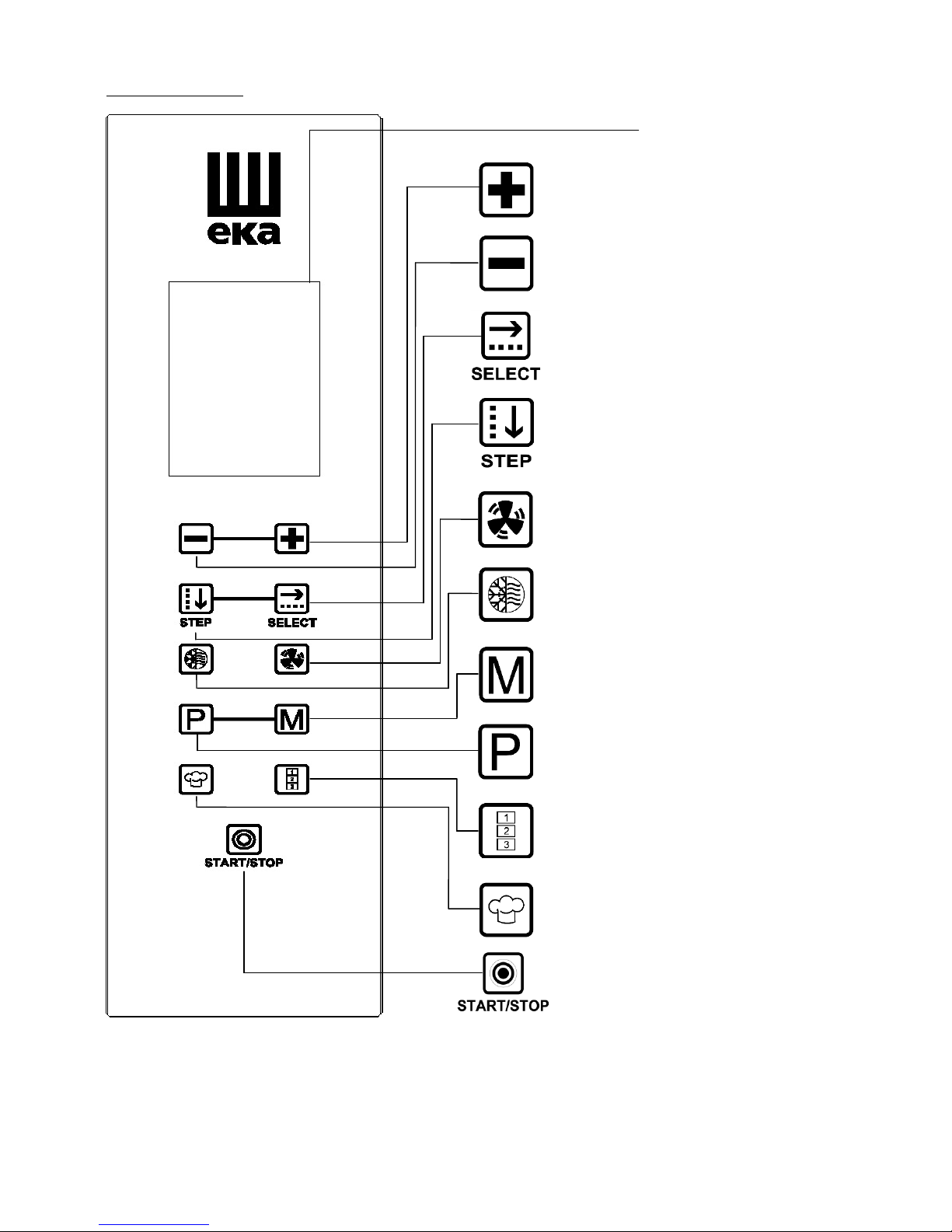

4.2 Control panel

LCD DISPLAY

INCREASE PARAMETER VALUE

DECREASE PARAMETER VALUE

CONFIRM PARAMETER VALUE

STEP/PARAMETER SELECTION

AIR FLOW SPEED SETTING

"PRE-HEATING" SETTING

GENERAL SETTINGS MENU

PROGRAMMING

ACCESSORIES

RECIPE BOOK

START/STOP

Page 12

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 12 _____________________________________________________________________________________________

4.3 “Touch” control operation

The “TOUCH” control works by touching the screenprinted key (exclusively use your fingers and

no other utensils such as knives, forks, or other objects in general).

All oven functions are activated in this way. To make use of the control panel easier, only the keys

that may be activated are lit.

4.3.1 Switching on/off

Keep your finger on the “START/STOP” key for a few seconds and the display will show

the screen with the “EKA” logo, DATE/TIME. After 5’’ the screen dissolves and the oven

automatically readies for programming the cooking cycle: the “TIME” parameter screen is

displayed.

After 10 minutes if no key is activated, the “Touch” control goes into STAND-BY mode and only

the “START/STOP” key remains lit on the control panel.

To reactivate the “Touch” control, just touch the “START/STOP” key with your finger for

a few seconds. To activate the STAND-BY mode hold your finger on the “START/STOP”

key for a few seconds.

4.3.2 Manual operation

4.3.2.1 General information

The cooking cycle may be programmed by using the PARAMETER SCREEN (displays the value of

each individual parameter of the cooking cycle), or using the OVERVIEW SCREEN (simultaneously

displays all the cooking cycle parameter values). The PARAMETER SCREEN is displayed

automatically only when the cooking cycle is first set, after the oven is first switched on. In this

case the values of the parameters set must be confirmed by acting on the “SELECT” key.

In the OVERVIEW SCREEN the individually displayed parameter may also be selected. Choose the

parameter to be displayed with the “STEP” key, then touch the “SELECT” key and the

PARAMETER SCREEN is displayed.

The set value is automatically confirmed after 5’’ both in the OVERVIEW SCREEN and in the

PARAMETER SCREEN.

The RED SCREEN indicates WARNING when, while setting a step of the cooking cycle, the

parameter required to activate the step is missing (symbol in the direction of the number of

the step where the

operative parameter is missing) or the oven door is opened during the cooking cycle.

The RED SCREEN indicates ALARM (sound) when faults occur during oven operation that prevent

cooking cycle continuation or automatic washing cycle (the type of fault is described and

represented by a symbol).

For the various types of alarm see the relevant paragraph 11.

Page 13

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 13

4.3.2.2 Selection of cooking parameters

The following parameters may be set for each step of the cooking cycle (up to 9 steps):

1. Cooking time

2. Cooking chamber temperature

3. Core temperature

4. Delta T

5. Percentage (%) of humidity/steam activation

To confirm the set parameter and move to the next one, act on the “SELECT” key. The

airflow speed inside the cooking chamber may be modified (3 available speeds) by acting on

key .

Warning

A complete cooking cycle does not obligatorily require all 9 available steps, therefore it is possible

to set only the desired ones without affecting correct oven operation.

4.3.2.3 Cooking time or core temperature settings

Each cooking step is controlled by the cooking time parameter or core temperature parameter.

The time and core temperature parameters are mutually exclusive: if the core temperature

parameter is set, the time parameter is automatically deleted even if it has been previously set.

Warnings

Setting excessively short cooking times or excessively low core temperatures with respect to

correct values may lead to incomplete cooking.

Setting excessively long cooking times or excessively high core temperatures with respect to

correct values may result in excessively dry food, with the risk of burning the surface.

4.3.3 Parameter setting

4.3.3.1 Cooking TIME setting (Parameter screen)

With the “STEP” key the following may be set:

1. TIME

2. PAUSE

3. MAINTENANCE

1. TIME

The parameter is settable from a minimum of 0h 01’ to 9h 59’ maximum. In the event of

MANUAL mode cooking cycle, in STEP 1 it is possible to also set an “INF” time (INFINITE):

The oven continues working until it is switched off by the operator.

2. PAUSE

This option may be set for a time between 0h 01’ and 23h 59’.

If the PAUSE is entered in STEP 1, it allows “DELAYED START” of the cooking cycle, which

is useful for foodstuff that needs to raise before cooking.

If the PAUSE is entered after STEP 1, it allows “thermal pressure” on the product to be

limited.

3. MAINTENANCE

This option makes it possible to maintain a constant temperature of 75°C within the

cooking chamber until the oven is switched off by the operator.

Page 14

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 14 _____________________________________________________________________________________________

The PARAMETER SCREEN reads: “OFF”

use the key to enable this option (the display then reads ”ON”) which is

confirmed with the “SELECT” key;

use the key to disable this option (the display reads “OFF” again) which is confirmed

with the “SELECT” key.

When this option is active, at the end of the cooking cycle the display reads: “OVEN IN

MAINTENANCE”.

When the cooking cycle is active the display reads: “COOKING IN PROGRESS”

When the cooking cycle is in “PAUSE” the display reads: “BAKING STARTS IN” (count-down)

With “BAKING IN PROGRESS” : the display shows the count-down of the set time in the direction

of the symbol and on the right the total time set of the cooking cycle (of 1 or more STEPS).

Important

The value of the set parameter may be confirmed immediately in the PARAMETER SCREEN

with the “SELECT” key; otherwise, the value is confirmed automatically after 5”.

4.3.3.2 TEMPERATURE setting (Parameter screen)

With the “STEP” key the following may be set:

1. TEMPERATURE IN COOKING CHAMBER

2. CORE TEMPERATURE (

The core probe is not standard supplied but is an optional accessory)

3. DELTA T Value (

The core probe is not standard supplied but is an optional accessory)

1. TEMPERATURE IN COOKING CHAMBER

Use the keys and to increase or decrease the temperature (from 30°C to 260°C). After

that confirm the choice with the “SELECT” key.

With “BAKING IN PROGRESS”: the display shows the set temperature in the direction of the

symbol and the actual temperature detected in the cooking chamber in the direction of the

symbol .

2. CORE TEMPERATURE

Use the keys and to increase or decrease the temperature (from 0°C to 100°C). After

that confirm the choice with the “SELECT” key.

With “BAKING IN PROGRESS”: the display shows the set temperature in the direction of the

symbol and the actual temperature detected by the core probe in the direction of the

symbol .

Page 15

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 15

When the OVERVIEW SCREEN shows the TEMPERATURE IN CHAMBER parameter and the

CORE TEMPERATURE parameter , to go back to setting the TIME parameter :

- Use the “STEP” key to select the CORE TEMPERATURE parameter .

- Use the “SELECT” key (the display shows the PARAMETER SCREEN);

- Use the “STEP” key to select the TEMPERATURE IN COOKING CHAMBER parameter ;

- Use the “SELECT” key.

At the end of these operations the display will show the red OVERVIEW SCREEN (if the

PREHEATING function is not set) to indicate the TIME parameter is missing (“00.00”).

3. DELTA T VALUE

Use the keys and to increase or decrease the temperature (from 0°C to 100°C). After that

confirm the choice with the “SELECT” key.

With “BAKING IN PROGRESS”: the display shows the set temperature in the direction of and

the actual temperature detected by the core probe in the direction of the symbol .

The display shows the set temperature in the direction of the symbol and the actual

temperature detected in the cooking chamber in the direction of the symbol .

When the OVERVIEW SCREEN shows the CORE TEMPERATURE parameter and the DELTA T

parameter , to go back to setting the TIME parameter :

- Use the “STEP” key to select the DELTA T parameter ;

- Use the “SELECT” key (the display shows the PARAMETER SCREEN);

- Use the “STEP” key to select the TEMPERATURE IN COOKING CHAMBER parameter ;

- Use the “SELECT” key.

At the end of these operations the display will show the red OVERVIEW SCREEN (if the

PREHEATING function is not set) to indicate the TIME parameter is missing (“00.00”).

4.3.3.3 HUMIDITY/STEAM setting(Parameter screen)

Use the keys e to increase or decrease the humidity/steam value (from 10% to

100%). After that confirm the choice with the “SELECT” key.

Page 16

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 16 _____________________________________________________________________________________________

4.3.3.4 “PREHEATING” setting (Overview screen)

Use the key and the display shows the relevant PARAMETER SCREEN.

Use the key (“ON”) to activate the function or the key (“OFF”) to deactivate it. In both

cases use the “SELECT” key to confirm the choice, otherwise it is confirmed automatically

after 5”.

During the preheating stage, the display reads “PREHEATING IN PROGRESS” and no value is

shown in the direction of the TIME parameter (---).

This means that the preheating time is not included in the cooking time.

When the preheating temperature is reached (temperature set in cooking chamber increased by

40°C: this temperature is maintained if the door is not opened), and intermittent buzzer goes off

and the words “PREHEATING OK OPEN THE DOOR” flashes on the display. Open the door, put

the food in the oven, close the door again: the cooking cycle starts automatically.

4.3.3.5 AIR FLOW SPEED setting (Overview screen)

The possibility to set 3 speed levels of air flows inside the cooking chamber makes it possible to

bake any type of food, from the most delicate and lightest to that needing higher heat

conveyance.

Use key and the relevant PARAMETER SCREEN is displayed;

Use the keys and to set the desired speed level:

minimum speed ( )

medium speed ( )

maximum speed ( )

Use the “SELECT” key to confirm the choice, otherwise the choice is confirmed automatically

after 5”.

Important

The maximum speed is already pre-set for every cooking cycle ( ).

The key

may be used even during the cooking cycle to modify the speed level of fans.

Should this operation need to be performed during an already programmed cooking cycle, the fan

speed values will go back to those originally set upon creating the program.

“SEMI-STATIC” MODE

“Semi-static” baking is a mode that allows motors to be activated only when the heating

elements are operating.

The fans are activated for a few seconds, in order to distribute the heat generated by the heating

elements and make the temperature inside the cooking chamber even.

In this way static oven operation is reproduced.

To activate the “semi-static” baking mode operate as follows (from OVERVIEW SCREEN):

touch the key and the display shows the screen “AIR FLOW SPEED SETTING”.

Touch the key “STEP” to activate the “semi-static” baking mode: the words “ST OFF” turn

into “ST ON” which indicate successful activation.

Page 17

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 17

Touch the key “SELECT” to confirm the selection: “ST” is displayed in the overview screen in

the direction of the icon indicating motor speed.

Fan speed may be modified also while baking in “semi-static” mode.

Operate as follows (from OVERVIEW SCREEN):

touch the key and the display shows the screen “AIR FLOW SPEED SETTING”.

Touch keys and to set the desired speed.

Touch key “SELECT” to confirm the selection.

4.3.4 Selection of cooking steps (Overview screen)

Each cooking cycle may consist of up to 9 STEPS. The desired parameters may be set for each step.

To move from one step to the next one, after setting STEP 1, act as follows:

touch key “STEP” to select STEP 1 (word highlighted on dark box);

touch key . The red OVERVIEW SCREEN is displayed reading STEP 2 (the red background warns

that the TIME parameter has not been set and therefore the selected step cannot be operative).

Touch key “STEP” to select the TIME parameter then touch keys and to set the

desired value.

As soon as the TIME parameter is set, the background of the OVERVIEW SCREEN turns blue to

indicate that STEP 2 has become operative. Complete setting the values of the other desired

parameters. To move to the following steps (STEP 3, STEP 4 ...) repeat the same operations

described for STEP 2.

Upon completing step setting, start the cooking cycle with the “START/STOP” key.

The display shows the OVERVIEW SCREEN of STEP 1 of the cooking cycle and the overall number

of steps it consists of. (E.g. 1/5 means that STEP 1 of the total 5 set is active).

Next to the TIME parameter: the “count-down” of the active step is shown on the left and the

overall time of all cooking cycle steps is shown on the right.

In the event of “manual” baking the display shows the word “MANUAL”, in case of

“programmed” baking, the name of the stored recipe (program) is displayed.

4.3.5 Starting/stopping the cooking cycle

Once the desired cooking parameters are set, to start the cycle touch the “START/ STOP”

key.

To stop the cooking cycle at any time touch the “START/ STOP” key again for a few

seconds.

When a cooking cycle is completed ( in “manual” mode or in “programmed” mode) a buzzer

goes off (“beep”) for 30’’ and at the same time the words flash on the screen : “COOKING

COMPLETED”.

If during this period the key is activated, the OVERVIEW SCREEN

of the cooking cycle just ended is displayed again. The cooking cycle is automatically reactivated

for 1 MINUTE. To lengthen the cooking time just touch the “STEP” key and select the TIME

parameter ; then touch the key to set the desired value.

Page 18

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 18 _____________________________________________________________________________________________

The 30’’ “cooking completed” buzzer may be interrupted at any time by touching the “STEP” key

or the “START/STOP” key.

The OVERVIEW SCREEN of the cooking cycle just ended is displayed again.

4.3.6 Cooking cycle setting

4.3.6.1 Cooking cycle with time and temperature in chamber

From "TIME" PARAMETER SCREEN

Use the keys and to set the desired value:

TIME (“INF” or between 0h 01’ and 9h 59’)

Touch the “STEP” key to set the desired option:

PAUSE (from 0h 01’ to 23h 59)

MAINTENANCE (“ON” or “OFF”)

Touch the “SELECT” key to confirm the set values.

From OVERVIEW SCREEN

Touch the “STEP” key to select the TIME parameter and touch keys and to set

the desired value. The value is automatically confirmed after 5”.

From PARAMETER SCREEN "TEMPERATURE IN CHAMBER"

After setting the TIME parameter, touch the “SELECT” key: the screen concerning the 3

different TEMPERATURE parameters is displayed (Temperature in cooking chamber/Core

temperature/Delta T). For the operator's convenience a 180°C TEMPERATURE IN COOKING

CHAMBER is already set. To modify the set value use the keys and . Touch the “SELECT”

key to confirm the set values.

From OVERVIEW SCREEN

Touch the “STEP” key to select the TEMPERATURE parameter and touch keys and

to set the desired value. The value is automatically confirmed after 5”.

From PARAMETER SCREEN “% HUMIDITY/STEAM” (optional function)

After setting the value of the parameter “TEMPERATURE IN CHAMBER”, use the “SELECT”

key: the parameter screen “% HUMIDITY/STEAM” is displayed.

Use the keys and to set the desired value. Touch key “SELECT” to confirm the set

value.

Page 19

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 19

From OVERVIEW SCREEN

Touch key “STEP” to select the TIME parameter then touch keys and to set the

desired value. The value is automatically confirmed after 5”. Use the “START/STOP” key

to activate the cooking cycle.

4.3.6.2 Cooking cycle with core temperature and temperature in chamber

From "TIME" PARAMETER SCREEN

If the CORE TEMPERATURE is set it is not required to set the TIME parameter.

By using the “STEP” key there is in any case the possibility to choose the options “PAUSE”

and “MAINTENANCE”.

Touch the “SELECT” key to confirm the set values.

From PARAMETER SCREEN TEMPERATURE IN CHAMBER

Use the keys and to set the desired value.

Touch the “STEP” key to select the "CORE TEMPERATURE" parameter and touch keys

and to set the desired value. Touch the “SELECT” key to confirm the set values.

From OVERVIEW SCREEN

Touch the “STEP” key to select the “TEMPERATURE IN CHAMBER” parameter and touch

keys and to set the desired value. Touch the “SELECT” key to confirm the set value

(the screen of the 3 different temperature parameters is displayed). Touch the “STEP” key to

select the "CORE TEMPERATURE" parameter and touch keys and to set the desired

value. The value is automatically confirmed after 5”.

Important

The needle-shaped thermal probe (core probe) must be inserted in the centre of the food,

in the thickest area, avoiding contact with any bones. After placing the food in the cooking

chamber, extract the cable of the thermal probe by running it through the lower part of the

cooking chamber and close the oven door. The plug of the probe must be connected into the

suitable socket located on the control panel (see fig.1).

Warnings

Before removing the food from the oven after cooking with the needle shaped thermal probe

(core probe), extract with care the hot probe from the cooked food, paying attention not to let it

hang outside the cooking chamber: burn hazard!

Before reusing it right away it is recommended to cool it (in this way harmful piercing of the food

is also avoided). In order not to irreparably damage the needle shaped thermal probe (core probe),

avoid using it in high temperature cooking (OVER 230°C); also avoid letting the probe cable come

into contact with the hot metal surfaces inside the cooking chamber.

Page 20

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 20 _____________________________________________________________________________________________

From PARAMETER SCREEN “% HUMIDITY/STEAM” (optional function)

After setting the value of the parameter “CORE TEMPERATURE”, use the “SELECT” key: the

parameter screen “% HUMIDITY/STEAM” is displayed.

Use the keys and to set the desired value. Touch the “SELECT” key to confirm the

set value.

From OVERVIEW SCREEN

Touch the “STEP” key to select the % HUMIDITY/STEAM parameter then touch keys

and to set the desired value. The value is automatically confirmed after 5”. Use the

“START/STOP” key to activate the cooking cycle.

4.3.6.3 Cooking cycle with core temperature and Delta T

From "TIME" PARAMETER SCREEN

If the CORE TEMPERATURE and DELTA T value is set it is not required to set the TIME parameter.

By using the “STEP” key there is in any case the possibility to choose the options “PAUSE”

and “MAINTENANCE”. Touch the “SELECT” key to confirm the set values.

From PARAMETER SCREEN "TEMPERATURE IN CHAMBER"

If the CORE TEMPERATURE and DELTA T value is set it is not required to set the TEMPERATURE IN

CHAMBER parameter.

Touch the “STEP” key to select the "CORE TEMPERATURE" parameter and touch keys

and to set the desired value. Touch the “STEP” key again to confirm the set value and

select the “DELTA T” parameter.

Use the keys and to set the desired value. Touch the “SELECT” key to confirm the

set value.

From OVERVIEW SCREEN

Use the “STEP” key to select the "TEMPERATURE IN CHAMBER" parameter .

Touch the “SELECT” key: the screen of the 3 different temperature parameters is displayed.

Touch the “STEP” key to select the "CORE TEMPERATURE" parameter and touch keys

and to set the desired value.

Touch the “STEP” key again to confirm the set value and select the “DELTA T” parameter

. Use the keys and to set the desired value.

The value is automatically confirmed after 5”.

Page 21

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 21

Important

The “DELTA T” parameter makes it possible to maintain constant, throughout the cooking stage,

the difference ( ) between the temperature inside the food (temperature detected by the

needle-shaped thermal probe) and the temperature inside the cooking chamber. This means that

the value of the temperature in the cooking chamber becomes the sum of the temperature inside

the food and a fixed temperature value “ “ set by the operator.

In practical terms there is a slow increase of the temperature in the cooking chamber, with a

constant difference with respect to the internal food temperature which, exactly because of that,

undergoes a prolonged and delicate cooking process (in the case of meat, proteins are protected,

since surface tensions caused by excessively quick crust formation are avoided).

From PARAMETER SCREEN “% HUMIDITY/STEAM” (optional function)

After setting the value of the “DELTA T” parameter, use the “SELECT” key: the “%

HUMIDITY/STEAM” parameter screen is displayed. Use the keys and to set the desired

value. Touch the “SELECT” key to confirm the set value.

From OVERVIEW SCREEN

Touch the “STEP” key to select the % HUMIDITY/STEAM parameter then touch keys

and to set the desired value. The value is automatically confirmed after 5”. Use the

“START/STOP” key to activate the cooking cycle.

4.3.7 How programs work

4.3.7.1 Store programs (recipes)

The user is able to store up to 200 programs/recipes, assigning to each a NAME which may consist

of up to 10 letters of the alphabet.

After setting the cooking parameters for the program (recipe) you intend to store, operate as

follows:

press key to access the “PROGRAMMING MENU” screen.

Press the “STEP” key and select the symbol . Confirm the selection with the “SELECT”

key: the screen with the letters of the alphabet will be displayed.

Keys and are used to make the horizontal movements ( to the left / to the right),

and the “STEP” key for vertical ones (at each “touch” there is a shift down, while if the

“STEP” key is held the shift is up). When the desired letter is found (highlighted on black

background), use the “SELECT” key and the chosen letter will be displayed in the top portion

of the screen. If a letter of the alphabet is wrongly selected while composing the name, move to

(symbol on dark background) and use the “SELECT” key to delete the letter.

After composing the name of the program (recipe), use the “STEP” key to move to “SAVE”

(writing highlighted on dark background).

Page 22

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 22 _____________________________________________________________________________________________

Use the “SELECT” key to bring up the “RECIPE BOOK” screen with 8 different types of

products:

- FIRST COURSES

- SECOND COURSES

- FISH

- GAME

- BREAD

- VEGETABLES

- DESSERTS

- EXTRA

Use the “STEP” key to choose the type of product (icon with box) where to “save” the recipe.

Use the “SELECT” key to confirm.

The overview screen of the cooking cycle with the set name will be automatically displayed.

Important

Programming may be cancelled at any time: use the “STEP” key to move to “CANCEL”

(wording highlighted on dark background) then use the “SELECT” key to confirm the

selection. The OVERVIEW SCREEN concerning the last set cooking cycle is shown again.

4.3.7.2 Delete programs (recipes)

The user is able to delete a program (recipe) set and stored in the “CHEF RECIPE BOOK” at any

time.

Use the key with symbol to bring up the “EKA RECIPE BOOK” screen.

Touch the “STEP” key to select the word “CHEF” (word highlighted on dark background). Use

the “SELECT” key to bring up the “RECIPE BOOK” (8 food type icons). Use the “STEP”

key to select the product icon (e.g.: dessert or main course or vegetable) where the recipe

(program) to be deleted is stored.

Use the “SELECT” key to select the RECIPE BOOK with the NAME of the recipe to be

deleted. Use the “STEP” key to select the recipe to be deleted. Use the “SELECT” key to

confirm the selection. Use the key to enter the “PROGRAMMING MENU” screen.

Use the “STEP” key to select the mark (“DELETE” symbol ) and use the “SELECT” key

to confirm the selection.

The screen reads: “CONTINUE DELETING?”.

Touch the “SELECT” key to confirm the selection .

The recipe is deleted. (the display shows the “TIME” parameter screen to be able to start setting a

new recipe).

Page 23

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 23

4.3.7.3 “Download” programs from oven (onto “USB pen drive”)

With the oven's “USB port” the user is able to “download” into the “USB pen drive” the

programs (recipes) stored in the “CHEF RECIPE BOOK”.

Connect the “USB pen drive” to the oven's port. Use the key with symbol to bring up the

“EKA/CHEF RECIPE BOOK” screen. Touch the “STEP” key to select the word “CHEF” (word

highlighted on dark background). Use the “SELECT” key to bring up the “RECIPE BOOK” (8

food type icons). Use the “STEP” key to select the product icon (e.g.: dessert or main course

or vegetable) where the recipe (program) to be "downloaded" is stored. Use the “SELECT”

key to select the RECIPE BOOK with the NAME of the recipe to be “downloaded”. Use the “STEP”

key to select the recipe (name) to be “downloaded”. Use the “SELECT” key to confirm

the selection (the overview screen of the selected recipe's cooking cycle is displayed).

Use the key to enter the “PROGRAMMING MENU” screen.

Use the “STEP” key to select the symbol .

Use the “SELECT” key to confirm the selection: the recipe is “loaded” into the “USB pen

drive”. The “RECIPE BOOK” screen is displayed again (8 product type icons): to “load” other

recipes (in the “USB pen drive”), repeat all operations for the first recipe in the same way.

4.3.7.4 “Download” all programs in the oven (onto “USB pen drive”)

Through the “USB port” of the oven, the user has the possibility to download all the recipes in the

“CHEF RECIPE BOOK” performing one operation only.

Use the key to enter the screen of the general settings menu.

Use the “STEP” key to select the icon .

Use the “SELECT” key to access the screen with the letters of the alphabet.

Key in the password “CHEF” (see instructions to select letters in paragraph 4.3.7.1).

Touch key “STEP” to go to “SAVE” (word highlighted on dark box).

Use the “SELECT” key: the screen indicating recipe transfer in progress is displayed.

At the end of this process all the oven recipes will also be within the “USB pen drive”.

Warning

During transfer the recipes having the SAME NAME as those transferred from the oven will be

automatically “overwritten” into the “USB pen drive”.

Important

Every operation must be done within 5”; after this time the overview screen of the cooking cycle is

automatically displayed.

Page 24

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 24 _____________________________________________________________________________________________

4.3.7.5 “Load” programs on the oven (from “USB pen drive”)

Through the oven's “USB port”, the user is able to “load” into the “CHEF RECIPE BOOK”, the

programs (recipes) stored in the “USB pen drive”. Connect the “USB pen drive” to the oven's

port. Use the key to enter the “PROGRAMMING MENU” screen.

Use the “STEP” key to select the symbol . Use the “SELECT” key to confirm the

selection: the RECIPE BOOK screen is displayed with the name of the recipes contained in the

“USB pen drive”. Use the “STEP” key to select the recipe (name) to be “loaded” into the

“CHEF RECIPE BOOK”. Use the “SELECT” key to confirm the selection: the recipe (name) is

stored in the RECIPE BOOK under the relevant product type (e.g. Lasagne = FIRST COURSES,

Trout = FISH, Potatoes = VEGETABLES etc.). The RECIPE BOOK screen is displayed again with the

name of the recipes contained in the “USB pen drive”: to "load" other recipes (into the “CHEF

RECIPE BOOK”), repeat all the operations for the first recipe in the same way.

Important

Every operation must be done within 5”; after this time the overview screen of the cooking cycle is

automatically displayed.

4.3.7.6 “Load” all programs in the “USB pen drive” on the oven

Through the oven's “USB port”, the user is able to “load” into the “CHEF RECIPE BOOK”, all the

programs (recipes) stored in the “USB pen drive” with a single operation.

Plug the “USB pen drive” into the suitable socket.

Use the key to enter the programming menu. Use the “STEP” key to select the icon .

Touch the “SELECT” key to confirm the selection

Press the “STEP” key once only to select all recipes.

Use the “SELECT” key to initiate recipe transfer.

During recipe transfer the screen reading “OPERATION IN PROGRESS” will be displayed and the

number of remaining recipes before completing the transfer.

Warning

During transfer the recipes having the SAME NAME as those transferred from the "USB pen drive"

will be automatically “overwritten” into the “CHEF RECIPE BOOK”.

4.3.7.7 Use programs (recipes)

Tecnoeka has inserted in the oven some recipes drawn up by its chefs, which may be selected and

run by you.

The recipe book, which is accessed with the key , includes 40 cooking programs (non

modifiable) in the “EKA RECIPE BOOK” and the same cooking programs in the “CHEF RECIPE

BOOK”, modifiable.

By referencing these recipe books you are able to execute the recipes from the “EKA RECIPE

BOOK” (see paragraph 4.3.7.7.1) or to run and/or modify the parameters of the cooking cycles

from the “CHEF RECIPE BOOK” (see paragraph 4.3.7.7.2).

Page 25

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 25

4.3.7.7.1 Using programs stored in the “EKA RECIPE BOOK”

To use a program/recipe (see paragraph 15 “RECIPE BOOK”):

Use the key with symbol to bring up the “EKA RECIPE BOOK” screen. Use the “SELECT”

key: the “RECIPE BOOK” screen will be displayed (product type icons).

Use the “STEP” key to select the food type the name of the recipe to be used belongs to. Use

the “SELECT” key to confirm the product type. The “RECIPE SELECTION RECIPE BOOK”

screen is displayed.

Use the “STEP” key to select the name of the recipe to be used. Touch key “SELECT” to

confirm the selection. The overview screen of the cooking cycle with the recipe name will be

displayed. Use the “START/STOP” key to activate the cooking cycle.

4.3.7.7.2 Using programs stored in the “CHEF RECIPE BOOK”

To use a program/recipe (see paragraph 15 “RECIPE BOOK”):

Use the key with symbol to bring up the “EKA RECIPE BOOK” screen. Use the “STEP”

key to select the word “CHEF” (the “CHEF RECIPE BOOK” screen is displayed). Use the “SELECT”

key: the “RECIPE BOOK” screen will be displayed (product type icons).

Use the “STEP” key to select the food type the name of the recipe to be used belongs to. Use

the “SELECT” key to confirm the product type. The “RECIPE SELECTION RECIPE BOOK”

screen is displayed.

Use the “STEP” key to select the name of the recipe to be used. Touch key “SELECT” to

confirm the selection. The overview screen of the cooking cycle with the recipe name will be

displayed. Use the “START/STOP” key to activate the cooking cycle.

Important

The values of a stored program (recipe) parameters may be modified either before starting the

cooking cycle or with the cooking cycle in progress.

The original values will still remain in the oven's memory.

4.3.7.8 “NEW RECIPE” option

To store a NEW RECIPE use the key : the “PROGRAMMING MENU” screen is displayed.

Use the “STEP” key and select the icon . Touch the “SELECT” key to confirm the

selection .

The TIME parameter screen is displayed: set the values of the various cooking parameters of the

new recipe (paragraph 4.3.6). Store the new recipe (paragraph 4.3.7.1).

Page 26

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 26 _____________________________________________________________________________________________

4.3.7.9 “COPY RECIPE” option

For a RECIPE to be COPIED the recipe (to be copied) must be in the OVERVIEW SCREEN.

Use the key : the “PROGRAMMING MENU” screen is displayed.

Use the “STEP” key and select the icon .

Touch key “SELECT” to confirm the selection. The screen with the letters of the alphabet is

displayed: type the new recipe name then store it in the RECIPE BOOK (paragraph 4.3.7.1).

4.3.8 Standard functions

4.3.8.1 “LAST” function

It lets you select the last ended cooking cycle: whether it has been executed in “manual” or

programmed mode.

Use the key to bring up the “EKA RECIPE BOOK” screen.

Use the “STEP” key and select “LAST” (word highlighted on dark background).

Use the “SELECT” key to bring up the overview screen of the last executed cooking cycle,

which can be started by pressing the “START/STOP” key.

4.3.8.2 “COOKING CHAMBER COOLING” function

This function lets you quickly cool the cooking chamber after completing a cooking cycle.

Open the oven door (red screen is displayed).

Press the key the “COOLING” screen is displayed, which shows the temperature inside the

cooking chamber in real time, even while the function is running .

The “cooling” function may be disabled at any time by means of the “START/STOP” key;

or it ends automatically when the temperature inside the cooking chamber goes below 45°C.

In both cases, upon completing the function, the display shows the red warning screen with the

words “open door”.

When the door is closed, the overview screen of the cooking cycle that has just ended is displayed,

and a new cycle may be set: use the “STEP” key and choose the parameters to be modified

and with the keys and set their relevant values: open the door, place the food to be

cooked in the oven. To start the cooking cycle, close the door again and press the “START/STOP”

key. To set a new cooking cycle with open door just press the “SELECT” key, the

overview screen of the cooking cycle just ended is displayed.

Within 5’’ press the “STEP” key and select the parameters to be modified and with keys

and select the relevant values. After placing the product to be cooked in the oven, to start the

cooking cycle close the door and touch the “START/STOP” key.

Warning

During open door operation do not remove the fan cover; do not touch the moving fans and

resistors which are still hot.

Page 27

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 27

4.3.8.3 “HACCP” function

The “HACCP” function has the purpose of recording the operative data of cooking cycles

performed, constantly monitoring their progress.

The “HACCP” data are recorded into a “USB pen drive” which must be connected into the

suitable “USB port” of the oven. The USB pen drive is not supplied but is an optional accessory.

“HACCP” FUNCTION ACTIVATION

To activate the “HACCP” function the following operations must be performed:

- connect the “USB pen drive” in the suitable USB “port” of the oven.

- set the cooking cycle (manual or programmed)

- press key to access the “PROGRAMMING MENU” screen

- press the “STEP” key until selecting the word “HACCP”

- press the “SELECT” key to confirm the selection: the “HACCP” function is activated

Use the “START/STOP” key to activate the cooking cycle.

When the cooking cycle is completed the “HACCP” function is automatically disabled.

DISPLAY “HACCP” DATA (ON PC)

To display on the PC the parameters of an executed cookign cycle:

- press the “START/STOP” key for few seconds and switch off the oven

- remove the “USB pen drive” from the oven and insert it in the “USB port” of the PC

- open the desired “file” in the “USB pen drive”

Important

All the data concerning the cooking done on the same day are contained in the same “HACCP”

file. The “HACCP” file is automatically renamed after another “HACCP” file is created on the

following day, highlighting the date when the cooking has been done.

The “HACCP” data must be interpreted with the aid of the following key:

Page 28

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 28 _____________________________________________________________________________________________

KEY

C1

START OF COOKING

C2

COOKING CORRECTLY ENDED

C3

COOKING INTERRUPTED WITH START/STOP KEY OR DUE TO AN ALARM

AL1

ALARM: OPEN DOOR

AL2

ALARM: THE CORE PROBE HAS BROKEN DOWN DURING COOKING

AL3

ALARM: THE TEMPERATURE PROBE IS FAULTY

AL4

ALARM: MOTOR

AL5

ALARM: SAFETY THERMOSTAT

AL9

ALARM: RESISTORS ARE NOT CONNECTED

R

RECIPE NAME

R: MAN

MANUALLY SET RECIPE

F0

TYPE OF MANUAL RECIPE

F1

FIRST COURSES

F2

SECOND COURSES

F3

FISH

F4

GAME

F5

BREAD

F6

VEGETABLES

F7

DESSERTS

F8

EXTRA

T1

TEMPERATURE DETECTED IN THE COOKING CHAMBER

T2

TEMPERATURE DETECTED BY THE CORE PROBE

D1

THE DOOR WAS OPENED DURING COOKING

D2

THE DOOR WAS CLOSED DURING COOKING

POSSIBLE ERRORS OF “HACCP” FUNCTION

Type of error

Cause of the error

Corrective action

Er. 1 IMPOSSIBLE

TO SAVE “HACCP”

- The “USB pen drive” was removed

- Insert the “USB pen drive” to

save the data of the next

cooking cycle

Er. 2 IMPOSSIBLE

TO SAVE “HACCP”

- The “USB pen drive” was removed

and a drive was inserted not in

“FAT” format

- Insert the “USB pen drive” (max

2GB) in “FAT” format to save

the data of the next cooking

cycle

Er. 3 IMPOSSIBLE

TO SAVE “HACCP”

- Incorrect “USB pen drive” format

- The “USB pen drive” must be in

“FAT” (max 2GB) format to be

able to save the following

cooking cycle data

Page 29

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 29

5 . Settings menu

This function lets you view the various available settings.

Use the key to bring up the “SETTINGS” screen.

Use the “STEP” key to select the desired setting.

Use the “SELECT” key to confirm the desired setting:

- DATE/TIME

- BUZZER

- INFO

- °C / °F

- LANGUAGE SELECTION (

English language pre-set)

- MODIFY FUNCTIONAL PARAMETERS (for “EKA” engineer only)

DATE/TIME

Use the “STEP” key to select one after the other: day/month/year/hour and minutes.

Use the keys and to set the desired value.

Touch the “SELECT” key to confirm the set values.

BUZZER

Use the “SELECT” key to eliminate the buzzer or to reactivate it.

INFO

Use the “SELECT” key to display the “firmware” versions of the electronic boards

the oven is equipped with.

°C / °F

Use the “SELECT” key to change the temperature unit of measure from °C to °F and

vice versa.

LANGUAGE SELECTION (

English language pre-set)

Use the “SELECT” key : the “LANGUAGES” screen is displayed.

Use the “STEP” key to select the desired language. Use the “SELECT” key to

confirm it.

Every operation must be done within 5”; after this time

the overview screen of the cooking cycle is automatically displayed.

6 . Accessories menu

Use the key to bring up the screen of compatible ACCESSORIES with the oven:

1 WASHING

2 HOOD

3 PROVER.

Page 30

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 30 _____________________________________________________________________________________________

Use the “STEP” key to choose the name (type) of accessory to be activated, in case it is

already available and connected to the oven.

Touch key “SELECT” to confirm the selection.

If no choice is made, after 20” the overview screen of the

cooking cycle is displayed automatically.

7 . Oven - user communication

The oven is equipped with an USB port (fig.1) through which it is possible to:

- “Load”/ “Download” cooking programs

- Modify operative parameters

- Store data required for the “HACCP” system

Use the key to bring up the screen with available functions.

Use the “STEP” key to select the desired function. Touch key “SELECT” to confirm it.

8. Cleaning

8.1 General information

Before performing any cleaning on the appliance, disconnect the power supply (act on the safety

magnetic circuit breaker) and water supply (close the water cock). Let it cool completely.

The appliance must be cleaned at regular intervals, even daily, to assure best functionality and

lengthening its life cycle.

The appliance has electrical components inside, for safety reasons it is forbidden to wash it with

water or steam jets especially if aimed at the vents on the metal surfaces of its outer casing

(possible hazardous seepage detrimental to electrical components).

In the event specific detergents (degreasers) are used for cleaning stainless steel, ensure they do

not contain corrosive acid substances (no presence of chlorine even if diluted) or abrasive

substances. Carefully follow the instructions and warnings of the detergent's manufacturer and

take precautions such as using adequate rubber gloves.

Strictly avoid using scouring pads, steel wool and scrapers that may ruin the treated surfaces.

Also avoid prolonged permanence on the steel surfaces of foods containing acidic substances

(lemon juice, vinegar, salt, etc.) which cause corrosive deterioration.

8.2 Cleaning the cooking chamber

8.2.1 Manual cleaning

For hygienic reasons it is good practice to clean the cooking chamber on a daily basis, at the end

of every day the oven is used. Correct cleaning also prevents the formation of corrosive

phenomena inside the chamber, as well as preventing the danger of accidental combustion due to

any grease and food residues accumulated over time.

To aid cleaning remove the side grilles. The cleaning detergents must not contain abrasive

substances or substances of acid/corrosive nature. In case of lack of appropriate detergents it is

sufficient to clean the cooking chamber with a sponge soaked in warm soapy water or warm

water and a little vinegar. Rinse with plenty of water (use the suitable shower if available) and dry

well with a soft cloth. The side grilles must be cleaned separately and fitted back on. When

cleaning is completed leave the oven door slightly open.

Page 31

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 31

8.2.2 Semi-automatic cleaning

- spray specific degreaser for stainless steel on the internal walls of the cooking chamber, on

the side grilles, on the fan covers (do not spray onto the fans through the grille) and on the

internal door glass;

- let the product act for about 20 minutes with closed door;

- switch the oven on adjusting the temperature at 70-80°C;

- run a cycle with maximum steam (100%) for about 15 minutes;

- upon completing the cycle switch off the oven, let the cooking chamber cool and rinse it

with plenty of water (use the suitable shower if available);

- dry by running a heating cycle adjusting the temperature at 150-160°C for about 10 minutes

(repeat the cycle if necessary).

When cleaning is completed leave the oven door slightly open.

8.2.3 Automatic cooking chamber cleaning (optional)

From the “ACCESSORIES MENU” (paragraph 6) it is possible to activate automatic washing

“KWT” for automatic cleaning of the oven's cooking chamber.

The “KWT” washing system offers the following programs:

1. L1 – Short washing

2. L2 – Medium washing

3. L3 – Long washing

4. P – Pre-loading detergent and rinse aid from the peristaltic pumps

5. R – Rinse and dry the cooking chamber without using any chemicals.

The “KWT” washing system may already be available in the cooking chamber, or fitted on at a

later time as optional kit in the oven models that support it.

Important

It is recommended to use the program “P” when first using the “KWT” washing system. In this

way the air inside the peristaltic pumps and the detergent and rinse aid tubes is removed, thus

assuring correct system operation. When cleaning is completed leave the oven door slightly open.

Warnings

Do not open the door during washing operations, as chemical substances used for cleaning and

hot fumes might escape. Danger of corrosion and burns! When the red screen signalling

temperature in the cooking chamber exceeding 100°C, washing cannot be activated. It is possible

to go back to the overview screen by pressing the “SELECT” key.

8.3 Cleaning fans

The fans must be regularly cleaned with appropriate descaling products. All their parts must be

thoroughly cleaned, eliminating any limescale. The fan cover must be removed to access fans.

When cleaning is completed fit the cover back on operating in reverse order.

8.4 Door gasket cleaning

For hygienic and functional reasons it is good practice to clean the door gasket at the end of every

day the oven is used. It must be accurately washed with warm soapy water. It must be rinsed and

dried with a soft cloth. Any scaling or food residue must be removed with special care, without

using sharp metal tools that might irreparably damage the gasket.

Page 32

TECNOEKA Srl ___________________________________________________________ operating and instruction manual

page 32 _____________________________________________________________________________________________

8.5 Door cleaning

The internal glass of the cooking chamber door may be cleaned using the same type of degreaser

used for manually cleaning the cooking chamber; otherwise, a normal (non toxic) glass cleaning

product may be used. A common glass detergent may be used also to clean the external door

glass. In any case one may simply use warm soapy water. After rinsing dry the glass surface well

with a soft cloth. Should opaque spots form between the two glass panes, these may be removed

as they are inspectable.

8.6 Cleaning the external casing

The outer steel surfaces must be cleaned with a cloth soaked in warm soapy water or mixed with

a little vinegar, they must be rinsed well and dried with a soft cloth.

Should you wish to use specific products on the market, these must comply with the cleaning

requirements set out in the “General information” paragraph (paragraph 8.1).

It is worth remembering that the counter supporting the appliance or the floor surrounding the

area where the appliance is should also be cleaned without using acid corrosive substances (e.g.

muriatic acid) since the vapours released by them might corrode and deteriorate the outer steel

shell and cause irreparable damage to the electrical components inside the appliance.

8.7 Inactivity period

Should the appliance not be used for a long extent of time, it is good practice to disconnect it

from the power (act on the safety magnetic circuit breaker located upstream of the appliance) and

water supply. It is recommended to clean it with care internally (cooking chamber) and externally,

paying special attention to removing any salt residues which might lead to corrosion on the steel

surfaces. It is also recommended to protect the appliance with oil-based spray products (e.g.

Vaseline oil) which form an effective protective film when sprayed on the surfaces.

Leave the door of the cooking chamber ajar.

Adequately covering the appliance, finally, allows it to be protected from dust.

9. Maintenance

9.1 General information

A periodic check (at least once a year) of the appliance contributes to extending its life and assures

proper functionality. Any maintenance operation on the appliance must only be done by highly

qualified personnel trained in the operations to be performed.

Before performing any maintenance on the appliance, the power supply must be disconnected

(act on the safety magnetic circuit breaker located upstream of the appliance) and let it cool

down. The components that might require maintenance are all accessible by removing the left side

and back of the appliance.

9.2 Door gasket replacement

The door gasket has a rigid profile with retainer fins. This profile must be inserted in the suitable

guide on the front of the cooking chamber. To replace the gasket just remove the worn one from

the guide (pull hard at the 4 corners). Clean the guide from any dirt and insert the new gasket (it

is advisable to moisten the gasket profile with soapy water to make fitting easier).

9.3 Handle adjustment

Should the door handle not close properly, check and if required adjust the "nose" position as

follows:

1. With oven door open, loosen the fixing screws of the "nose"

2. Move the "nose" vertically and fasten it so that when the door is closed it may be inserted

in the handle, completely open (horizontal position) without rubbing.

3. After adjustment, with closed door the handle must be in vertical position (the end portion

of the "nose" must be perfectly horizontal).

Warning

The door handle must only be adjusted after positioning the oven in the correct way

(paragraphs

3.6.1)

Page 33

Electronic convection oven rev. 5 _________________________________________MODELS EKF 464 TC – EKF 511 TC

_________________________________________________________________________________________ page 33

10 Possible faults