Eisys iMove-C, iMove-F Assembly Manual

eisysDESKING

iMove-C Assembly Manual

(Pneumatic Version-H1/H2)

eisys, inc. 112 28th Street South • Birmingham, Alabama 35233 • 205.941.1942 • www.eisys-inc.com

eisysDESKING

Table of Contents

2

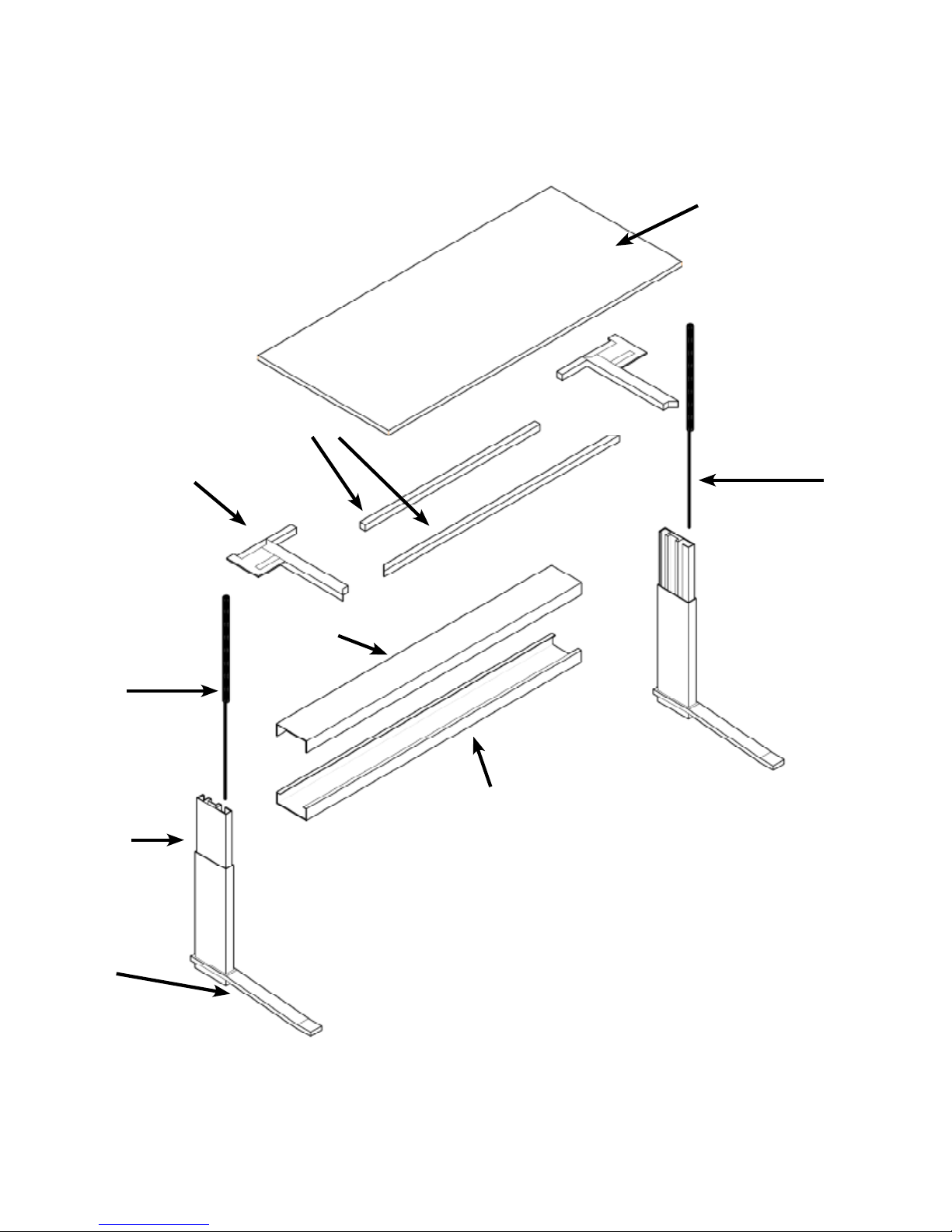

Exploded Desk Diagram

Hardware & Tools

Section 1: Basic Assembly of Desk

Shipped “KD” (knock down)

Unpack and Identify Parts

Assemble Cross Rail to Columns

Connecting Desktop Supports

to Columns

Assemble Work Surface

Support Frame

Attach Work Surface to

Support Frame

Replace Cross Rail Cover

and Trim

Attach Hand Lever

10

11

12

3

4

5

6

6

8

9

Section 2: Attaching the Desk 14

to the Lowboard/Pedestal

Attaching Desk to LowboardPedestal

Section 3: Accessories

Section 4: Care & Maintenance

FAQ & Troubleshooting

Section 5: Contact Us

15

17

19

22

Leveling and Calibrating Desk

eisys, inc. 112 28th Street South • Birmingham, Alabama 35233 • 205.941.1942 • www.eisys-inc.com

13

Support Frame Spanners

3

eisysDESKING

Work Surface

Support Frame

Gas Cylinder

Leg

Gas Cylinder

Cross Rail Cover

Cross Rail

Foot

eisys, inc. 112 28th Street South • Birmingham, Alabama 35233 • 205.941.1942 • www.eisys-inc.com

pic.1

eisysDESKING

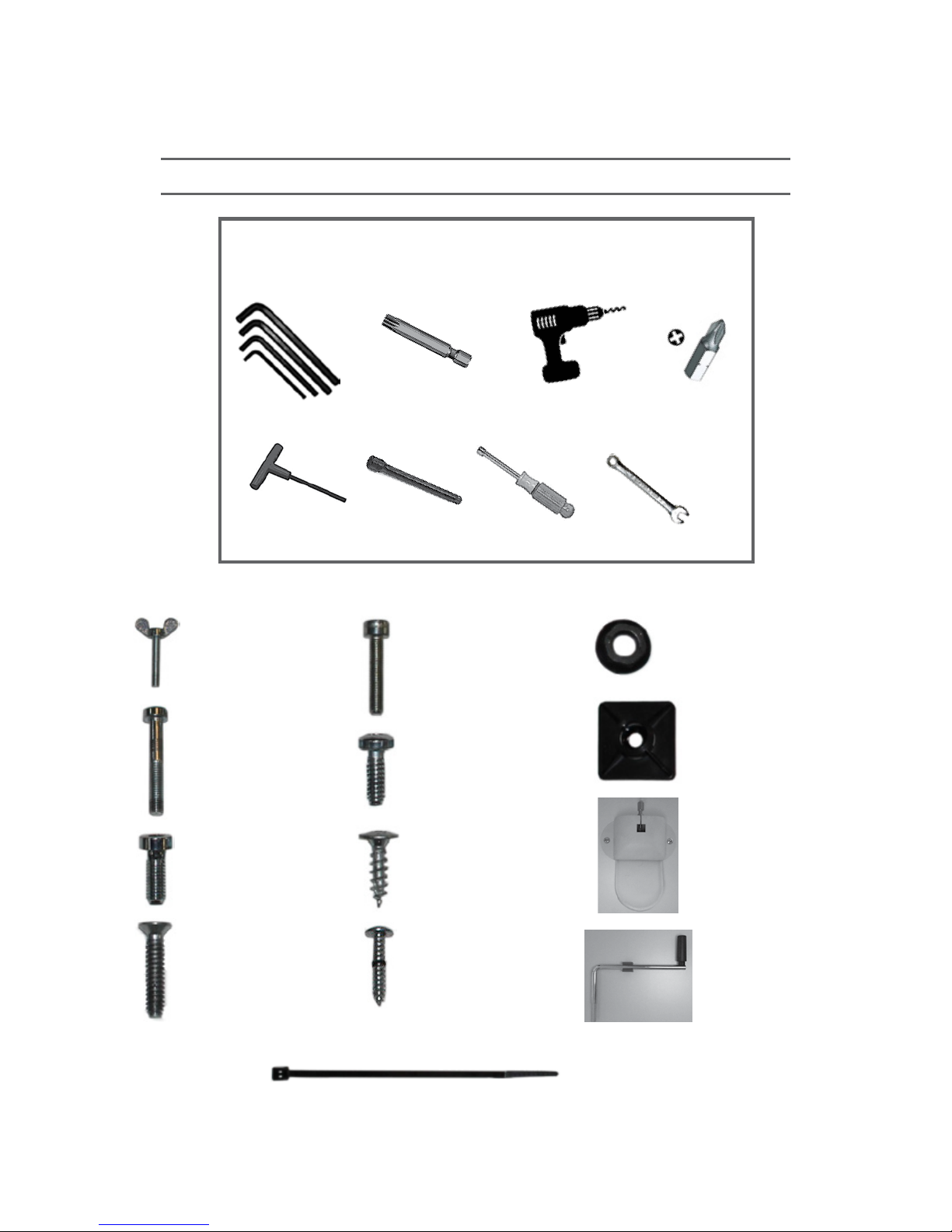

Tools and Hardware

Required and Recommended Tools

4

Metric Hex Wrenches

(3,4 & 5mm)

6” 4mm T-Handle

Hex Driver

Thumb Bolts —2 ea.

T25 Torx

Driver Bit

8” Driver

Extension

M5 x 20

Socket Cap Bolts —8 ea.

Cordless Driver

Drill

8mm Nut Driver or Box Wrench

#1 Phillips

Driver Bit

8mm Hex Nuts—8 ea.

Zip Tie Base—3ea.

M6 x 1.0 x 40

Socket Cap Bolts —4 ea.

M6 x 1.0 x 16

Socket Cap Bolts —4 ea.

M5 x 25

Flat Head Screws —8 ea.

eisys, inc. 112 28th Street South • Birmingham, Alabama 35233 • 205.941.1942 • www.eisys-inc.com

M5 x 16 TORX

Button Head s—8 ea.

20mm SPAX

Wood Screws—12 ea.

#4 x 16

Wood Screws —3 ea.

Hand Lever Control

Hand Crank (H2 only)

4” Zip Ties—3ea.

eisysDESKING

Section 1: Basic Assembly of Desk

Shipped “KD” (knock down)

-Pneumatic Version-

[H1-no calibration H2-weight compensation]

5

eisys, inc. 112 28th Street South • Birmingham, Alabama 35233 • 205.941.1942 • www.eisys-inc.com

Support Frame Spanners

Support Frame

Gas Cylinder

Cross Rail Cover

eisysDESKING

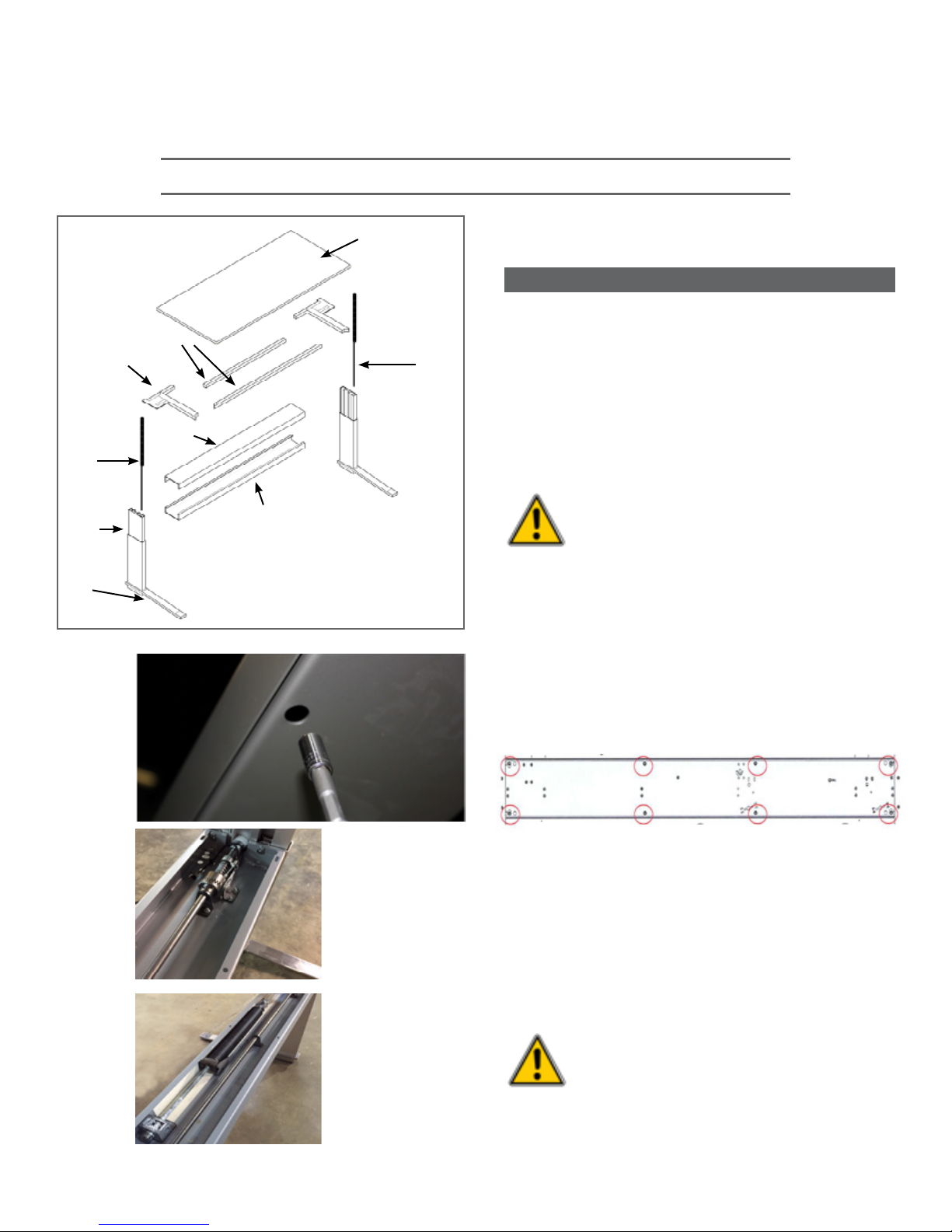

Basic Assembly of Desk Shipped “KD” (knock down)

1.

Work Surface

Gas Cylinder

Identify and uncrate ALL parts

(pic.1 )

NOTE:

1.Not all desks will require two gas cylinders.

The number of gas cylinders will depend on the

size and weight of desk top.

2. If user is providing their own custom top,

determine the weight of the top and contact

eisys to order the appropriate gas cylinders.

(This step should have been completed at

order entry).

6

Leg

Foot

Cross Rail

pic.4

pic.1

pic.2

Use caution when working with

compressed gas cylinders.

An uncontrolled release could

cause severe damage and/or

personal injury.

2.

Assembling Cross Rail to Columns (Legs)

a.

Use the 8mm nut driver or socket to remove

cross rail cover at indicated positions.

(pic.2-3 )

cross rail as seen from below

pic.3

After removing cover, note that H1 does not

b.

have a torsion spring. (pic.4)

H2 only, carefully examine the large torsion

spring to ensure it is in its fully relaxed

position (collapsed). (pic.4a)

eisys, inc. 112 28th Street South • Birmingham, Alabama 35233 • 205.941.1942 • www.eisys-inc.com

pic.4a

(H2 only)

WARNING!!! If torsion spring is

in a tight position (expanded)

STOP! Go to Section 5 and

contact eisys immediately!

eisysDESKING

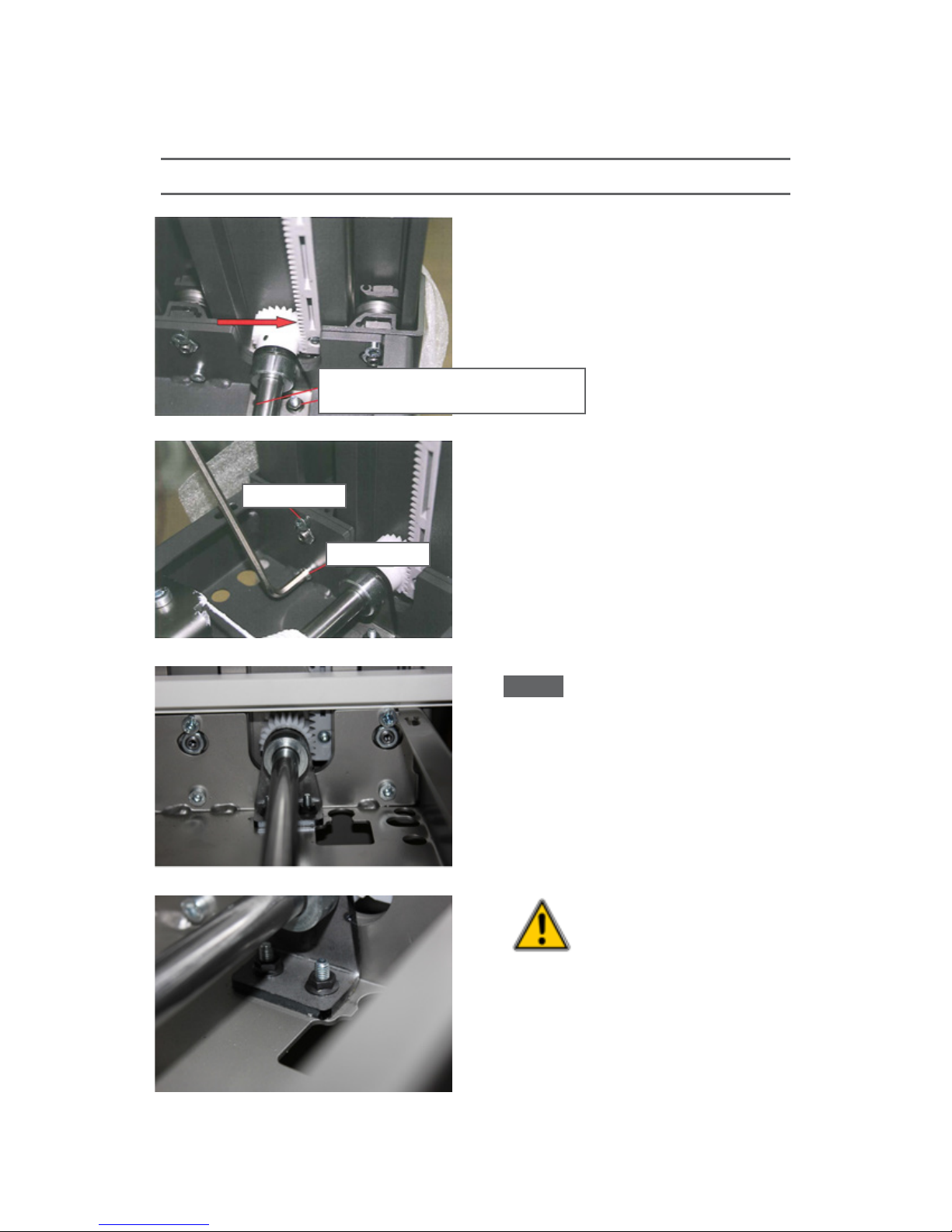

Basic Assembly of Desk Shipped “KD” (knock down)

2.

Assembling Cross Rail to Columns (Legs)

(continued)

Using the 3mm & 8mm wrenches,

c.

loosen/remove the two drive shaft support

bracket bolts at each end of cross rail.

(pic.5 & pic.6)

screws for shaft support

screw from below cross rail

pic.5

long bolt

7

short bolt

pic.6

pic.7

d.

With the “inner leg” FULLY extended join

the cross rail to the leg and carefully insert

the gear into the track. (pic.5) Make sure the

inner leg is FULLY extended and the gear is

properly engaged with the track.

*TIP: The screw head at the end of the

*TIP:

geared track should be aligned with the

approximate center of the drive shaft/gear

when the leg is at max height. (pic.7)

Once cross rail is secured to legs, make sure

e.

the gear is seated with the geared track then

tighten shaft support bracket bolts. (pic.8)

CRITICAL!!! Make sure the

gears in both columns (legs)

are aligned at the exact same

position in each gear track per

above *TIP and picture 7.

eisys, inc. 112 28th Street South • Birmingham, Alabama 35233 • 205.941.1942 • www.eisys-inc.com

pic.8

Loading...

Loading...