eisfink varithek acs 1100 d3, varithek acs 600 ec, varithek acs 1000 ec, varithek acs 1500 d3 User Manual

Issue: 2018-06-07

varithek® acs® 1100 d3

varithek® acs® 1500 d3

varithek® acs® 600 ec

varithek® acs® 1000 ec

varithek

air-cleaning-system

acs

®

With integrated side extraction and circulating-air cleaning for food delivery

With electronic fan control

The illustrations show configuration examples, which do not necessarily have to be included in the scope of delivery.

Observe the operating instructions

Translation of the Original Operating Instructions

DOWNLOAD: USER MANUAL

QR code on type plate

Contents

2

Eisfink Max Maier GmbH & Co. KG

Our solutions guarantee high quality, safety and, above all,

excellent energy efficiency and cost effectiveness.

The basic task of the patented air-cleaning-system

®

is to collect the vapour and steam that occur

acs

during cooking at the point of origin, clean them in a sophisticated filter system and then pass them back

into the room free from odours.

Contents

1 Revision Index ................................................................................................................................................. 3

2 Important Information ..................................................................................................................................... 4

2.1 Use of this guide ................................................................................................................................................ 4

2.2 Reference to trademark rights granted for these appliances .............................................................................. 5

2.3 Representation conventions in the text .............................................................................................................. 5

2.4 Structure of safety instructions ........................................................................................................................... 5

3 General Safety Instructions ............................................................................................................................ 6

3.1 General behaviour ............................................................................................................................................. 6

3.2 On use of electrical appliances .......................................................................................................................... 6

3.3 Operator's obligations ........................................................................................................................................ 7

3.4 Qualification of personnel ................................................................................................................................... 8

3.5 Provision of protective equipment for personnel ................................................................................................. 8

3.6 Appliance-specific safety instructions ................................................................................................................. 9

3.7 Information about regulations to be followed .................................................................................................... 13

3.8 Instructions on behaviour in an emergency ...................................................................................................... 14

4 Purpose .......................................................................................................................................................... 14

5 Description of the Equipment ...................................................................................................................... 16

5.1 Designation ...................................................................................................................................................... 16

5.2 Technical data.................................................................................................................................................. 19

6 Before First Use ............................................................................................................................................. 21

6.1 Transport ......................................................................................................................................................... 21

6.2 Observe when commissioning/recommissioning .............................................................................................. 23

7 Use .................................................................................................................................................................. 24

7.1 Only equip the appliances with suitable accessories ........................................................................................ 25

7.2 Ensure undisturbed extraction of steam and vapours ...................................................................................... 27

7.3 Freshly prepare food on the cutting board ........................................................................................................ 28

7.4 Switch appliance on and off electrically ............................................................................................................ 28

7.5 Electronic fan control (option)........................................................................................................................... 29

7.6 Clean the appliance after use .......................................................................................................................... 32

Contents

Eisfink Max Maier GmbH & Co. KG 3

Revision

Change

2013-10-01

New edition

2013-11-19

Potential equalisation system, damaged supply line

2014-04-11

Index

2015-06-15

General modification, adaptation to acs 1600 O3, ISO 82079,

VDE requirement, electronic fan control

2016-08-05

New Eisfink active carbon filter, plus electronic control

2018-06-07

Entfall 800 ec; Absaugung

8 Cleaning, Maintenance and Care ................................................................................................................. 33

8.1 Safety information relating to cleaning, maintenance and care ........................................................................ 33

8.2 Cleaning agents for stainless steel ................................................................................................................... 34

8.3 Overview of maintenance measures and intervals ........................................................................................... 35

8.4 Choose the correct cleaning method ................................................................................................................ 36

8.5 Clean and service stainless steel parts ............................................................................................................ 36

8.6 Clean casters ................................................................................................................................................... 37

8.7 Clean and service plastic parts ........................................................................................................................ 37

8.8 Appliance type ‘ec’ .......................................................................................................................................... 38

8.9 Clean cooking area and splash guard .............................................................................................................. 40

8.10 Clean high-performance grease separator, grease drip trays … ...................................................................... 43

8.11 Inspect technical compartment; clean if necessary .......................................................................................... 48

8.12 Disinfect the appliance as required .................................................................................................................. 52

8.13 Keep ready for next use in dry condition .......................................................................................................... 52

8.14 Ensure preservation of the product identification .............................................................................................. 52

9 Troubleshooting ............................................................................................................................................ 52

9.1 Notes on troubleshooting ................................................................................................................................. 52

9.2 Disposing of your product ................................................................................................................................. 54

10 Warranty and Liability ................................................................................................................................... 55

11 Excerpt from EC Declarations of Conformity ............................................................................................. 55

12 Index ............................................................................................................................................................... 56

13 Contact address ............................................................................................................................................ 56

1 Revision Index

Important Information

4

Eisfink Max Maier GmbH & Co. KG

► It is essential that you read the user guide before using the product for the first

time.

► Keep this guide in a safe place and pass it onto the next owner should you

wish to part with the product.

2 Important Information

2.1 Use of this guide

This guide contains important information about how you can use the appliance safely and correctly.

Our customers often express the wish to have one compact guide instead of a number of different

guides for these product variants, which have similar functions.

If there are any shortcomings in your opinion, please do not hesitate to let us know. With your help, we

will try to become even better.

Please add your notes here

Important Information

Eisfink Max Maier GmbH & Co. KG 5

ATTENTION

indicates potential damage to property without any personal injury.

Failure to follow these instructions may cause damage to property.

User tip

► Useful information or tip

DANGER

indicates imminent danger.

Failure to follow these warning instructions will result in serious bodily injury or even

death.

WARNING

indicates a potentially hazardous situation.

Failure to follow these warning instructions may cause serious bodily injury or even

death.

CAUTION

indicates a potentially harmful situation.

Failure to follow these warnings may cause minor bodily injury.

2.2 Reference to trademark rights granted for these appliances

DE – Design patent no. 202 05 642.2 and no. 201 17 490.1

International patent application no. PCT/EP01/04469/ (WO 01/81831 A 1)

European Patent no. 1 194 721

2.3 Representation conventions in the text

Instructions on certain actions are represented in this way.

Lists are represented in this way.

See ‘. . . ’ cross-references are represented in this way

Notes

2.4 Structure of safety instructions

The signal words DANGER - WARNING - CAUTION classify the degree of risk of bodily injury in an actual

situation. You can avoid injury by complying with the behavioural rules provided.

The warning triangle symbol indicates a "General Danger".

General Safety Instructions

6

Eisfink Max Maier GmbH & Co. KG

3 General Safety Instructions

This section covers residual risks and hazards associated with the intended use of the appliance. We have

provided a list of all generally valid safety instructions which must be followed.

In the following section, safety information relating to a particular operation or situation is placed before the

appropriate operation step or description of the situation.

The information provided here such as ‘Basic rules of conduct’, ‘Operator's obligations’ etc. only refers to the

legally required observance of requirements such as the Workplaces Ordinance (ArbStättV) according to

German law.

3.1 General behaviour

This appliance meets the current state of the art and complies with all acknowledged technical safetyrelated regulations. Nevertheless hazards may still arise.

Only use this appliance when it is in fault-free condition and according to the instructions in this

user guide.

During all phases of the appliance's life please ensure that the appliance is safely integrated into

its environment.

Do not make any conversions or modifications to the appliance.

3.2 On use of electrical appliances

Safety instructions according to EN 60745-1:

Work area

Keep your work area clean and tidy. A messy or unlit work area can cause accidents.

Keep children and other persons at a distance when using the product.

Electrical safety The plug on the unit must fit in the socket. Do not modify the plug in any way. Never use

an adapter in combination with earthed appliances. Using an unmodified plug and a

suitable socket will reduce the risk of an electric shock.

Keep the appliance away from rain or damp. Allowing water to get into an electric

appliance will increase the risk of electric shock.

Do not misuse the cable by using it to remove the plug from the socket. Always remove

whilst holding onto the plug. Keep the cable away from heat, oil, sharp edges or the

moving parts of other appliances. Using damaged or tangled cables increases the risk of

electric shock.

Potential risk of fire due to heat build-up. Unwind the cable from the spool to prevent any

heat build-up or cable fire. The coupling must have splash protection, must be made of

rubber or be rubber-coated.

Safety guidelines for persons Be attentive and pay attention to what you are doing, act rationally when working with an

electrical appliance. Do not use the appliance when tired or under the influence of drugs,

alcohol or medication.

Just one moment of inattention whilst using the appliance can result in serious injury.

Make sure the appliance cannot be switched on unintentionally. Double check that the

main switch is in the "OFF" position before inserting the plug in the socket. Connecting

the appliance to the power supply while it is switched on can cause an accident.

General Safety Instructions

Eisfink Max Maier GmbH & Co. KG 7

Careful handling and use of electrical appliances Never use an electrical appliance with a faulty switch. An electrical appliance which can

no longer be switched on or off is dangerous and must be repaired.

Keep unused electrical appliances in places where children are not able to reach them.

Do not allow the appliance to be used by persons who are not familiar with it or persons

who are not familiar with this user guide. Electrical appliances are dangerous when in the

hands of inexperienced persons.

Treat the device with care. Check that moving parts are functioning properly and do not

block; check whether parts are broken or damaged and impairing the functioning of the

device. Have any damaged parts repaired before using the appliance. Many accidents

are caused by poorly-maintained electrical appliances.

Use electrical appliances, accessories etc. in accordance with these guidelines and in a

manner that is specified for this particular appliance type. When using the appliance,

please take into account the working conditions and the work being carried out. Using

electrical appliances for other uses than that intended can lead to hazardous situations.

Service Only have the device repaired by qualified and authorised staff. Only use original spare

parts. In this way you can ensure that the appliance remains safe.

3.3 Operator's obligations

Operator

The operator is the person who operates the appliance for commercial or economic purposes either

himself/herself or lets others use it and bears the legal appliance responsibility for protection of the

user, staff or any third parties during operation.

Operator's obligations

The appliance is used in commercial applications. For this reason, the operator of the appliance must

meet all legal duties relating to work safety.

In addition to the safety instructions in this guide, the safety, accident prevention and environmental

protection regulation applying to the application of the appliance must be complied with.

In particular, the following shall apply:

The operator must be familiar with the applicable work safety regulations and identify, by

carrying out a risk analysis, any additional hazards which are due to the place where the

appliance is used. These hazards must be addressed in the form of operating instructions

governing the operation of the appliance.

During the whole service life of the appliance, the operator must verify if the operator's

operating instructions reflect the current versions of the applicable regulations. If necessary,

the operator must update the operating instructions accordingly.

The operator must define and assign the responsibilities for installation, operation, repair,

maintenance and cleaning clearly.

The operator must make sure that all personnel working with the appliance have read and

understood this guide. In addition, the operator must train the personnel and inform them of

the hazards involved at regular intervals.

The operator must provide the personnel with the necessary protective equipment and

make sure that they wear it.

General Safety Instructions

8

Eisfink Max Maier GmbH & Co. KG

In addition, the operator must ensure that the appliance is always in a perfect technical condition. For

this reason, the following shall apply:

The operator must ensure that the maintenance intervals defined in this guide are obeyed.

The operator must have all safety equipment checked regularly for completeness and

proper function.

The operator must ensure that the required media connections are available.

The operator must ensure that all safety-relevant measures required on site are taken.

3.4 Qualification of personnel

Safe operation requires certain technical skills and personal qualification of each person.

The responsibility for organization lies with the ‘Designated Representative’ (operator).

According to EN 50110-1, the Designated Representative is a 'person assigned the direct

responsibility for the performance of the work. If necessary, this responsibility can be

assigned partly to other persons. [...] The designated representative must instruct all

persons involved in the work on all hazards which may not be obvious for them’.

The work may only be performed by ‘instructed persons’ who have been trained

accordingly. Training, instructions must be repeated, proper understanding must be verified

(ideally by way of an appropriate test).

Only ‘Qualified Staff’ are allowed to carry out repair work.

IEC 60204-1 defines qualified personnel as "persons who, on account of their training and

relevant experience are in the position to recognise risks and avoid potentially dangerous

situations."

Electrical work may only be carried out by trained and experienced electricians.

Electro-technically instructed persons may only work under the supervision of a qualified

electrician.

Any repairs and/or overhaul during the warranty period may only be carried out by the

manufacturer´s service department.

Chapter ‘Warranty and Liability’, page 55

3.5 Provision of protective equipment for personnel

Ensure that the personnel wear the personal protective equipment appropriate to the relevant

situation.

Wear safety shoes to prevent injuries when transporting or moving the appliance.

Wear protective gloves to prevent burns to hands and arms when using the cooking accessories.

Eisfink Max Maier GmbH & Co. KG 9

WARNING

Breathing difficulties, lacrimal irritation, mucosal irritations in throat, neck and lungs,

headache, strong tickle in the throat, cannot be excluded in the case of human error.

► Only use with Eisfink active carbon filters, which are correctly mounted.

► Do not interfere with the extraction and circulating-air cleaning: Do not place any

objects on the Eisfink active carbon filter in the technical compartment. Only operate

with a dry Eisfink active carbon filter.

Risk of fire

Risk of fire due to missing or incorrectly mounted filter components.

► Only use with original filter components and grease drip trays, which are correctly

fitted.

► Clean filter area daily.

3.6 Appliance-specific safety instructions

This chapter describes general, appliance-specific safety instructions. In the following section, additional safety

information relating to a particular operation or situation is placed before the appropriate operation step or

3.6.1 Risks due to cooking accessories

description of the situation.

All kinds of risks may occur if the wrong cooking accessories are selected.

User tip

The cooking modules in the Rieber varithek® range are recommended. Baking, grilling, cooking,

wok cooking and frying.

Observe the instructions in the relevant operating manuals.

# Deep-fryer

For the deep-fryer, use an insertion mask that prevents slipping into the system carrier.

General Safety Instructions

3.6.2 Risks due to ventilation, circulating-air cleaning

The unit's extraction and circulating-air cleaning is not a replacement for an air-conditioning system.

Always ensure an adequate supply of fresh air.

Risks due to human error when using the Eisfink active carbon filter for odour and

contaminant absorption and odour elimination using plasma technology

Fire risks

Chapter ‘Cleaning, Maintenance and Care’, page 33 ff.

General Safety Instructions

10

Eisfink Max Maier GmbH & Co. KG

3.6.3 Risks due to opened technical compartment

The technical compartment contains a rotating fan wheel. Keep the technical compartment closed. Use

a suitable tool to open and close the technical compartment.

Before opening the technical compartment

Switch off the ‘ON/OFF pushbutton with indicator light’ and

Switch off the electrical power to the unit by unplugging the main plug.

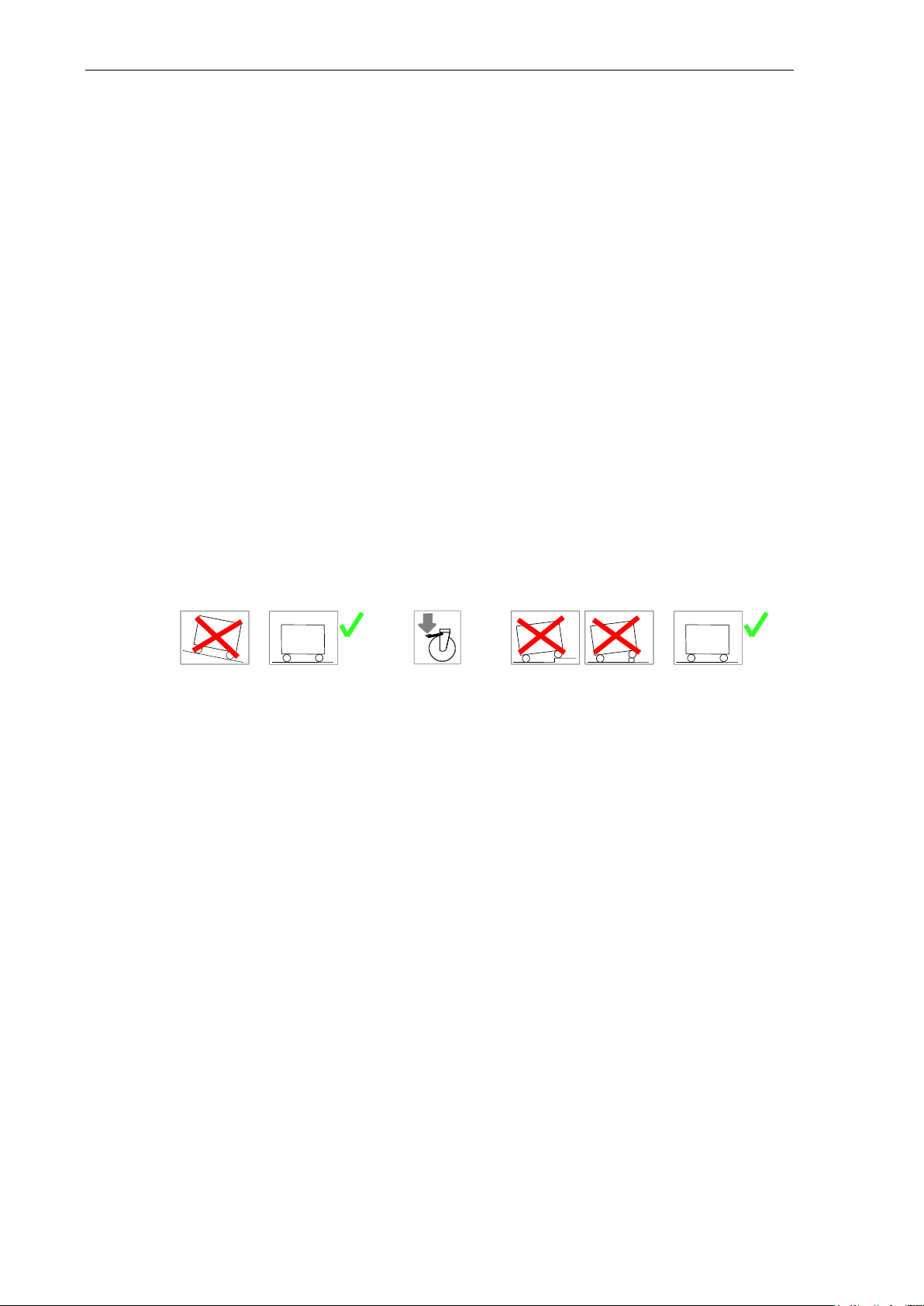

3.6.4 Risks due to transport of mobile appliance

Numerous hazards such as crushing can arise when transporting this heavy product 110 to 160 kg.

Remove accessories and transport them separately.

Disconnect the connection cable.

Only transport unit on a straight surface. Do no transport on a sloping surface.

Carry out transport with an adequate number of people, at least two.

Transport only permissible using the casters.

Secure the appliance against inadvertently rolling away with the ‘parking brake’.

Wear safety shoes to prevent injuries.

ATTENTION

Observe the permissible step height of maximum 4 mm, otherwise the ‘casters with parking brake’

could be damaged.

Do not push or pull the appliance over sharp edges; Otherwise the casters could sustain damage.

Do not use this appliance with poor floor conditions.

We are not able to rule out the possibility of marks appearing on the floor due to friction with

casters or the formation of scratches due to split cracks in the casters, for example.

We are not able to rule out the possibility that the casters may be damaged or become unusable

due to swelling or sharp edges on the floor.

Mobile appliances may only be moved manually. Machine-aided transport, e.g. using fork lift trucks

or lift trucks, is not permissible. Risk of injury and risk of damaging the appliance.

Eisfink Max Maier GmbH & Co. KG 11

3.6.5 Dangers due to electricity

Before each use, inspect the product, the connecting plug and electric cable for any visible signs

of damage.

The cable must be routed so that it cannot be squeezed or overheated.

The socket outlet must be easily accessible so that the unit can be disconnected from the power

supply at any time.

Compare the connection data on the type plate with the data of the electrical network before

connecting (voltage and frequency, power rating).

3.6.6 Risks due to power interruption possible

Possibility of malfunction after power interruption.

Disconnect the unit from the mains completely after a power failure.

Then switch back on.

General Safety Instructions

3.6.7 Warnings concerning the use of the appliance by children

This appliance may be used by children over 12 and by persons with limited physical,

sensory and intellectual abilities or a lack of experience and/or knowledge if they are

supervised or if they were instructed in the safe use of the appliance and have understood

the resulting dangers.

When using the appliance with ‘accessories’, other risks may arise.

Children may not play with the appliance.

Cleaning and user maintenance may not be carried out by children without supervision.

3.6.8 Safety and monitoring devices

High-performance grease separator (100% flame propagation proof) with Cyclone® blade

profile (separation efficiency approx. 95%)

In addition to protection against electric shock and in order to ensure that the frames of

electrical equipment and any external conductive components are at an equal (or practically

equal) potential, the appliance must be connected to the potential equalisation system.

The connection of all conductive bodies (housing) of electrical equipment to an earthed

protective conductor and the main earthing bar is the basic principle for protection against

electric shock.

For variant with odour elimination using plasma technology:

Pressure sensor monitors the pressure conditions in the technical compartment; in the

event of a fault the plasma generator is switched off

General Safety Instructions

12

Eisfink Max Maier GmbH & Co. KG

Equipotential bonding on the underside of the appliance. Note the symbol.

3.6.9 Product identification

Product identification at the housing, outside

The type plate bears the legally required product data.

The technical compartment is identified.

High-performance grease separators are marked with raised points. These markings can

also be found on the counterpart or frame.

‘Clean filter area daily’.

Product identification, especially 600 ec, 1000 ec, 1100 d3

(Variant with 16 A)

Only connect varithek® appliances with the same voltage, i.e. 400 V or 230 V.

Product identification in technical compartment for all appliance types

‘ WARNING

Unplug mains plug before removing the fan device.’

General Safety Instructions

Eisfink Max Maier GmbH & Co. KG 13

WARNING

Health risks, respiratory disorders

► Only use Eisfink active carbon filter, install correctly.

► Do not place any objects on the

Eisfink active carbon filter.

► All interference with the plasma generator is forbidden.

Product identification in technical compartment for variant with Eisfink active carbon

filter for odour and contaminant absorption and odour elimination using plasma technology

Product identification in technical compartment for appliance type ‘ec’ ‘Setting mark’

In the technical compartment, the bottom opening on the left in the floor of the technical compartment

set by the manufacturer is to be left as is.

3.7 Information about regulations to be followed

In addition to this user guide there are a range of health and safety and other regulationsthat are

relevant for the operation of this cooking station; these include HACCP food hygiene regulations for

example.

# Fulfillment of standards and guidelines VDI directive 2052 Air-conditioning systems. The unit's extraction system is not a

replacement for an air-conditioning system.

Purpose

14

Eisfink Max Maier GmbH & Co. KG

User tip

► Inform yourself in details by reading the in-house operating instructions.

► We recommend that half-yearly emergency training sessions should be carried out.

WARNING

Breathing difficulties, lacrimal irritation, mucosal irritations in throat, neck and lungs,

headache, strong tickle in the throat, cannot be excluded in the case of human error.

► Only use with Eisfink active carbon filters, which are correctly mounted. Replace active

carbon filters after at least 500 operating hours.

► Do not interfere with the extraction and circulating-air cleaning. Do not place any

objects on the active carbon filter in the technical compartment, for example. Only

operate with a dry Eisfink active carbon filter.

► Seek medical treatment if necessary. Ozone-containing air can trigger complaints.

3.8 Instructions on behaviour in an emergency

In an emergency always interrupt the power connection immediately, by disconnecting the

electrical connector.

First aid in the case of burns and scalding or electric shock:

Inform yourself on this before commissioning the appliance.

Store the emergency equipment, including the relevant instructions, at a readily accessible place

near the place of use.

First aid in the case of unaccountable irritations of the mucous membranes, strong urge to

cough when using appliances with additional odour elimination using plasma technology

4 Purpose

This chapter describes the intended use and contains warnings against misuse, for your safety.

Generally, the following are intended uses for the product:

For mobile service in the catering, hotel, and food processing industry; also suitable for the

care and school catering sectors.

Use correctly sized cooking units, like the cooking modules in the Rieber varithek® range.

Baking, grilling, cooking, wok cooking and frying. The relevant operating instructions must

be observed.

The patented air-cleaning-system® (acs®) collects the vapour and steam that occur during

cooking at the point of origin, cleans them in a sophisticated filter system and then passes

them back into the room free from odours.

To prevent persons from burning themselves on hot surfaces, use of the product in

public/for self-service should only be allowed under constant supervision.

Purpose

Eisfink Max Maier GmbH & Co. KG 15

The variant with Eisfink active carbon filter for odour and contaminant absorption and odour

elimination using plasma technology is intended for applications requiring a high level of

odour neutralisation.

The intended use includes compliance with the technical data. Note the information on the

rating plate as well as the product identification.

Equipotential bonding must be carried out by a qualified electrician.

For use only by appropriately trained and suitable operating personnel.

Prevent any potential misuse in advance:

Only use with original filter components, which are correctly mounted.

Only Use correctly sized cooking units, such as the cooking modules in the Rieber varithek®

range.

Provide the unit with electrical fuse connection on site.

The integrated air-cleaning-system acs® ensures that the extracted air is passed back into

the room odour-free. This is not a replacement for an air-conditioning system.

For variants with Eisfink active carbon filter and odour elimination using plasma technology:

Any inference in the ‘plasma generator’ is forbidden.

In appliance type ‘ec’: in the technical compartment, do not adjust the bottom opening

which has been correctly set by the manufacturer. Can be recognised by product

identification with ‘Setting mark’.

Only use one deep-fryer per the appliance, as otherwise the extraction and circulating air

cleaning system may be overloaded and odours may develop.

Do not use gas cooking units, as this can be dangerous.

Do not flambé, as this can be dangerous.

Never operate the appliance unsupervised. To prevent persons from burning themselves on

hot surfaces, use of the product in public, e.g. for self-service, should only be allowed under

supervision.

Front cooking is only admissible with the sneeze guard that can be closed on four sides.

Observe the Food Hygiene Regulations under German law.

Not intended for private use at home.

Do not lean against or sit on the appliance.

Incorrect cleaning can substantially and irreparably damage the stainless steel surfaces.

Do not push or pull the appliance over sharp edges; Otherwise the casters could sustain

damage.

Do not use this appliance with poor floor conditions.

We are not able to rule out the possibility of marks appearing on the floor due to friction with

casters or the formation of scratches due to split cracks in the casters, for example.

We are not able to rule out the possibility that the casters may be damaged or become

unusable due to swelling or sharp edges on the floor.

Mobile appliances may only be moved manually. Machine-aided transport, e.g. using fork

lift trucks or lift trucks, is not permissible. There is a risk of injury and substantial damage to

the appliance.

Description of the Equipment

16

Eisfink Max Maier GmbH & Co. KG

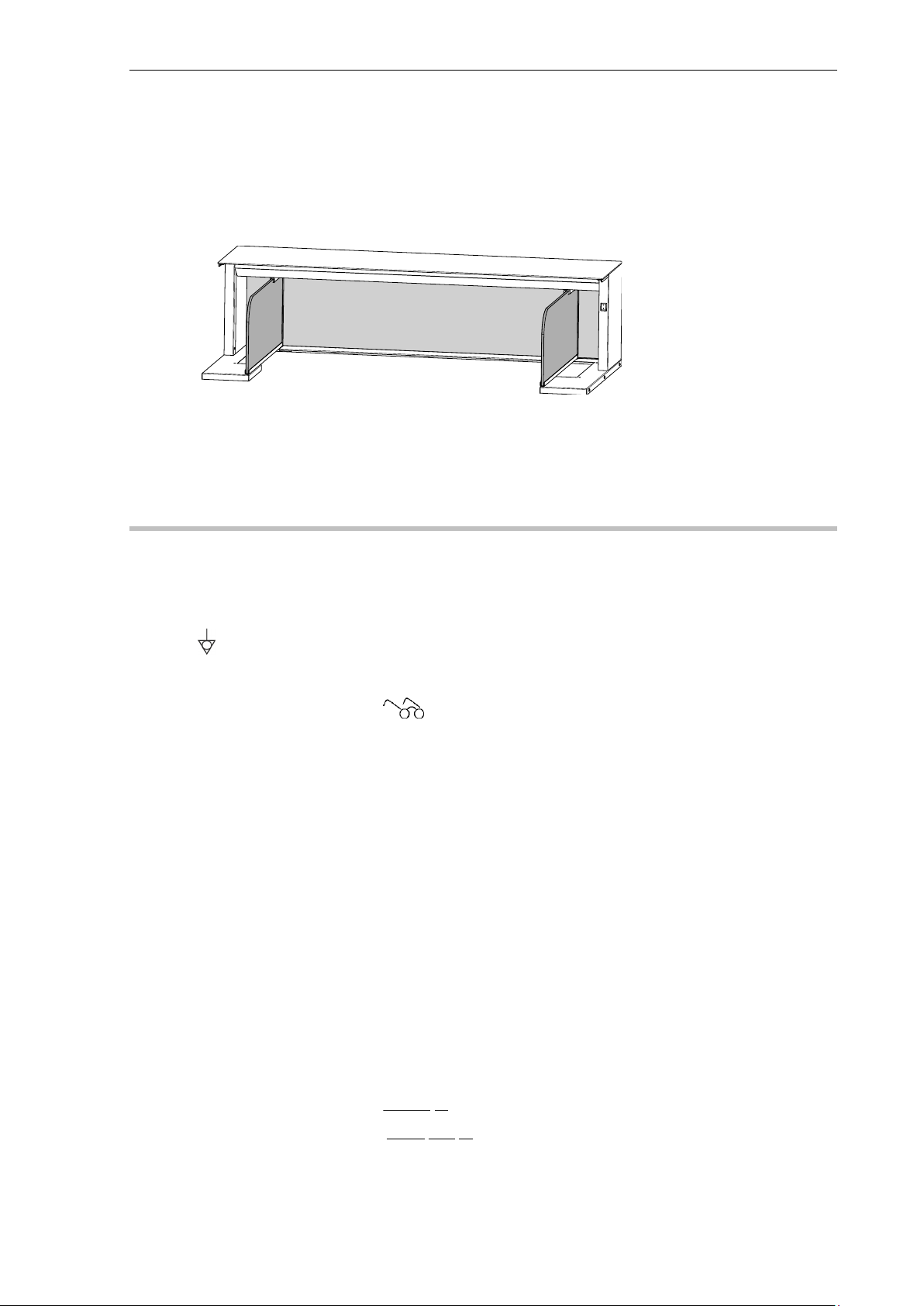

Example

1500 d3

1 4 swivel casters, including 2 ‘swivel casters with parking brakes’ on the operator side

→ Always secure the position of the appliance with the parking brakes.

2 Technical compartment

3 Power connections for cooking units

4 Extraction areas → three-sided extraction of steam and vapour

5 Splash guard; removable for cleaning → option

6 Sneeze guard attachment, including shelf for serving food → option

7 Operating elements, power connections for cooking units

The electrical connection with cable and plug is located at the back of the product.

5 Description of the Equipment

This chapter provides useful information on the structure and function of the equipment.

5.1 Designation

The illustration shows a configuration example which does not necessarily have to be included in the scope of

5.1.1 Appliance type ‘d3’

delivery.

Appliance type ‘d3’ means three- sided extraction Extraction of steam and vapour.

Extraction at front left / right or on both sides and at the back.

Eisfink Max Maier GmbH & Co. KG 17

Appliance type ‘ec’

Example

600 ec

1 4 swivel casters, including 2 ‘swivel casters with parking brakes’ on the operator side

→ Always secure the position of the appliance with the parking brakes.

2 Technical compartment

3 Operating elements, power connections for cooking units

4 sided extraction of vapour and steam

4.1 Air supply area → from radial fan

4.2 Extraction area → one-sided extraction of steam and vapour

5 Splash guard; removable for cleaning

6 Cutting board → fresh preparation of food on the cutting board.

The electrical connection with cable and plug is located at the back of the product.

User tip

Only use correctly sized cooking units.

► Use cooking modules from the Rieber varithek

®

range. Baking, grilling, cooking, wok

cooking and frying.

Appliance type ‘ec’ means ‘EasyClean’, German ‘Einfach reinigen, one- sided extraction of steam

and vapour. The extraction system (push & pull system) is designed in such a way that the vapour

created when cooking and roasting is collected by a transversally running air stream and is extracted

into the side flank.

Description of the Equipment

5.1.2 Cooking units

Description of the Equipment

18

Eisfink Max Maier GmbH & Co. KG

Schematic

diagrams

↑ Appliance type ‘d3’

↑ Appliance type ‘ec’

1 High-performance grease separator

2 Grease drip trays, removable

3 Radial fan

4 # Model type A: Eisfink active carbon filter

# Model type B: Eisfink active carbon filter for odour and contaminant absorption and odour

elimination using plasma technology

The plasma generator converts odorous substances into odourless substances.

Germs and odour-causing bacteria are also killed in the process.

Active carbon filter. Adsorbed substances accumulate in the carbon. Substances to

be filtered are physically absorbed by means of the active carbon filter. When the

capacity is exhausted, the filter must be replaced.

A wet active carbon filter is unusable. Never dry a wet Eisfink active carbon filter in the

oven or dryer, as there is a risk of fire. Let the active carbon filter dry in dry ambient air.

5.1.3 Extraction and circulating-air cleaning

Appliance type ‘d3’: The acs®side extraction systems in appliance type ‘d3’ are designed in such a

way that the generated steam is extracted on three sides; Extraction at front left / right or on both sides

and at the back.

The variant "Eisfink active carbon filter for odour and contaminant absorption and odour elimination

using plasma technology" is intended for applications requiring a high level of odour neutralisation.

Appliance type ‘ec’: In appliance type ´ ec´, the extraction system (push & pull system) is designed in

such a way that the vapour created when cooking and roasting is collected by a transversally running

air stream and extracted into the side flank.

Eisfink Max Maier GmbH & Co. KG 19

5.1.4 Sneeze guard attachment /Option

Standard:

3-sided splash guard made of stainless steel.

Option:

Sneeze guard attachment, including storage space for food delivery made of composite

safety glass and lighting.

Option

Rated voltage / mains

frequency

3N AC 400V 50/60Hz,

Equipotential bonding on the underside of the appliance. This protective

measure serves for additional safety. Standard-compliant

implementation with subsequent inspection of the system is carried out

by a qualified electrician.

IEC 60364-5-54:2011;

for Germany DIN VDE 0100:540:2012-06

Protection class

IPX4 according to DIN EN 60529

→ Unit offers protection against water splashes on all sides.

→ Only use unit inside buildings. Protection against penetrating

moisture is required.

Ambient temperature

+5 °C to +40 °C

3-sided splash guard

Detachable splash guard made of chromium-nickel steel

CNS 1810 (WN 1.4301). Laminated safety glass optional

Rustproof casters

In accordance with DIN 18867, Part 8. 4 height-adjustable swivel

casters made from chromium-nickel steel CNS 1810 (WN 1.4301),

wheel diameter 80 mm.

Including 2 ‘swivel casters with parking brakes’ on the operator side;

Option: 4 stands, height-adjustable

Material

Stainless steel CNS 18/10, WN 1.4301

Circulating air cleaning

Radial fan,

High-performance grease separator (100% flame propagation proof)

with Cyclone

®

blade profile (separation efficiency approx. 95%),

Grease drip trays. In addition

Version A: Eisfink active carbon filter

Model type B: Eisfink active carbon filter for odour and contaminant

absorption and odour elimination using plasma technology

Description of the Equipment

5.2 Technical data

5.2.1 Generally applicable data

Description of the Equipment

20

Eisfink Max Maier GmbH & Co. KG

varithek® acs® 1100 d3

varithek® acs® 1500 d3

Power consumption

Maximum 11 kW / 22 kW

maximum 22 kW

Electrical fuse

Connect the unit on site to a socket with a series-connected residual

current operated device (RCD) with a tripping current of 30 mA.

16 A: Only connect appliances that have the same voltage, i.e.

400 V or 230 V.

32 A: Automatic circuit breaker for integrated power outlets in the

device, right installation compartment.

Permissible loading

maximum 80 kg

maximum 120 kg

Air capacity in accordance with

DIN 61591

Circulating air 1150 m3 per hour

Circulating air 1250 m3 per hour

External dimensions

(L x W x H) approx.

1100 x 722 x 900 (1100) mm

1500 x 770 x 900 (1100) mm

Placement niche (L x W x H)

approx.

805 x 615 x 260 mm

1205 x 660 x 260 mm

Weight approx.

115 kg

155 kg

Emitted sound pressure level

Lpa ≤ 70 dB(A)

Lpa ≤ 70 dB(A)

Electrical connection

Approx. 3 m cable / CEE plug 3x 16 / 32 A / L1 / L2 / L3 / N / PE

varithek® acs® 600 ec

varithek® acs® 1000 ec

Power consumption

Maximum 11 kW

Maximum 11 kW

Electrical fuse

16 A. Connect the unit on site to a socket with a series-connected

residual current operated device (RCD) with a tripping current of 30 mA.

Only connect appliances that have the same voltage, i.e. 400 V or 230 V.

Permissible loading

maximum 40 kg

maximum 80 kg

Air capacity in accordance

with DIN 61591

Circulating air 750 m3 per hour

External dimensions

(L x W x H) approx.

600 x 720 x

900 (1000 1) mm

1000 x 720 x

900 (1000 1) mm

Placement niche

(L x W x H) approx.

405 x 690 x 260 mm

805 x 690 x 260 mm

Weight approx.

110 kg

140 kg

Emitted sound pressure

level

Lpa ≤ 70 dB(A)

Connected load

3N AC 230 V / 400 V, 50 Hz, 16 A, maximum 11 kW

Electrical connection

Approx. 3 m cable / CEE plug 3x 16 A / L1 / L2 / L3 / N / PE

1

5.2.2 Concerning appliance type ‘d3’

5.2.3 Relating to appliance type ‘ec’

For detailed information on dimensions, order number, accessories, circuit diagrams, spare and

wearing parts:

see type plate, catalogue, brochure

Complete with splash guard

Eisfink Max Maier GmbH & Co. KG 21

WARNING

Heavy appliance, 110 to 160 kg. See type plate.

► Wear protective gloves and safety shoes.

► Lift the appliance using at least 4 people. Another person quickly pulls the pallet

together with the 2 profiles away. Only appropriately trained personnel are permitted.

Transport with high physical demands should be avoided where possible, as the

risk of an accident or injury is always higher.

Lift / deposit a heavy load evenly with your knees bent and your upper body

straight and upright. Your feet should be at least hip-width apart and your

abdominal muscles braced. Breathe out. Do not twist your spine.

6 Before First Use

Before First Use

6.1 Transport

6.1.1 Check/handle transport damage

Immediately after delivery, visually check the appliance for any transport damage.

Document any potential transport damage on the consignment note in the presence of the haulage

contractor, and have the damage confirmed by the haulage contractor (with signature).

Decide if you wish to keep the appliance and report the defect using the consignment note, or if

you wish to reject the appliance.

This chapter describes the measures to be taken before use.

6.1.2 Unpack

▌ By following this procedure you will ensure proper claim settlement.

Open the transport packaging at the positions provided for this purpose. Do not tear or cut.

Remove any packaging remnants.

6.1.3 Unload appliance from the pallet

Before First Use

22

Eisfink Max Maier GmbH & Co. KG

ATTENTION

Do not unload from the pallet using a fork-lift truck, as this could cause substantial damage.

6.1.4 Scope of delivery

1x wrench for the adjustment and/or setting of the installation height:

Swivel casters or stands, fixed

6.1.5 Note on packaging material

Disposable packaging or Euro-pallet

Decide whether to: Keep the Euro-pallet for subsequent transport or return?

Dispose of the disposable packaging with respect for the environment.

6.1.6 Clean the appliance

Clean the appliance thoroughly before using for the first time.

Clean with a damp cloth and rub dry with a clean cloth.

See ‘Cleaning, Maintenance and Care’, page 33

Eisfink Max Maier GmbH & Co. KG 23

ATTENTION

Protective foils or heat-sensitive objects at/in the appliance might damage the appliance

during heating.

► Ensure that there are no protective foils on the inside or outside of the appliance.

Equipotential bonding must be carried out by a qualified electrician.

6.2 Observe when commissioning/recommissioning

Preconditions

The appliance has no defects or visible damage.

The appliance is at room temperature and is dry.

Wear safety shoes to prevent injuries.

Comply with the mechanical installation conditions

The place of installation must be horizontal.

The casters must be secured by 'parking brakes' to prevent accidental running away.

Before First Use

Maintain a minimum distance from walls, to prevent fingers, clothes, etc. from getting caught when

putting food in/taking food out.

Do not use the appliance as a means of transport.

If necessary, adjust the height-adjustable swivel casters

For this, loosen the locking nut with the wrench and adjust the axle.

▌ When turning clockwise, the installation height is reduced.

User tip. Use a spirit level for lengthwise and transversal adjustment.

Comply with the applicable electrical requirements

Before commissioning, check the mains voltage and type of current.

Check that these match the specifications on the type plate.

Connect this electrical appliance to an outlet with an upstream ground fault circuit interrupter with a

tripping current of 30 mA.

The electrical requirements of VDE 0100 ff. and the technical connection requirements of the local

electricity company must be met.

The socket outlet must be easily accessible so that the unit can be disconnected from power

supply at anytime.

Use

24

Eisfink Max Maier GmbH & Co. KG

Equipotential bonding must be carried out by a qualified electrician.

7 Use

Keep to the basic rules for operating the product

Before each use, check the appliance for any visible damage.

Only use in dry rooms in the building.

Never operate the appliance unsupervised.

Only operate the appliance with adequate lighting.

This chapter provides information on the use and operation of the appliance.

For version with 16 A, acs® 600 ec, acs® 1000 ec, acs® 1100 d3:

Connect varithek® appliances with the same voltage, i.e. 400 V or 230 V.

Avoid risks when transporting the mobile appliance

Numerous hazards can arise when transporting this relatively heavy product, 110 to 160 kg.

Disconnect the connection cable. Only transport the product on straight surfaces using the

required number of people. Always secure the position with the parking brakes. Wear safety shoes

to avoid injuries.

Do not use the appliance as a means of transport. Remove accessories and transport them

separately.

ATTENTION

Note the permissible step height, maximum 4 mm, otherwise the casters might be damaged.

Prevent risks due to electricity

Danger of electric shock. Risk of death

Before each use, inspect the product, the connecting plug and electric cable for any visible signs

of damage. Only connect to a socket with series-connected residual current operated device

(RCD) with a tripping current of 30 mA. Never direct a jet of water at electrical components such

as heater, controller or ventilation grille.

Avoid malfunctions after a power interruption

Disconnect the unit from the mains completely after a power failure. Then switch on the electrical

appliances again.

Eisfink Max Maier GmbH & Co. KG 25

User tip

Only use correctly sized cooking units.

► Use cooking modules from the Rieber varithek

®

range. Baking, grilling, cooking, wok

cooking and frying. Use

varithek® functional components.

varithek® functional elements

in system unit

1/1 – gp

AST 255 (high)

1/1 – ck, ik

AST 155 (low)

AST 255 (high)

Ensure that the upper edge of the cookware does not

protrude over the upper edge of the ATS 255. Ensure

uninterrupted extraction.

400 – ik, iw, gp

varithek® functional elements

in system unit

Position in the acs®

1/1 – gp

AST 255 (high)

right in connection with ck,

ik, iw

1/1 – ck, ik

AST 155 (low)

left in connection with gp

AST 255 (high)

Ensure that the upper edge of the cookware does not

protrude over the upper edge of the ATS 255. Ensure

uninterrupted extraction.

400 – gp

right in connection with ck,

ik, iw

400 – ik, iw

left in connection with gp

800 – gp

Keep the technical compartment closed

Danger of electric shock. Risk of death. Rotating parts.

Keep the technical compartment closed. Switch off the electrical power to the unit before opening

the technical compartment.

7.1 Only equip the appliances with suitable accessories

Use

7.1.1 Examples for the configuration of the acs® 600 ec

7.1.2 Examples for the configuration of the acs® 1000

Only connect varithek ® appliances with the same voltage, i.e. 400 V or 230 V.

Use

26

Eisfink Max Maier GmbH & Co. KG

varithek® functional elements

in system unit

1/1 – gp

AST 255 (high)

1/1 – ck, ik

AST 155 (low)

AST 255 (high)

Ensure that the upper edge of the cookware does not

protrude over the upper edge of the ATS 255. Ensure

uninterrupted extraction.

400 – ik, iw, gp

800 – gp

7.1.3 Examples for the configuration of the acs® 1100 d3 and 1500 d3

7.1.4 Observe the rules for using the deep-fryer

Only use one deep-fryer per product, otherwise odours may develop.

Use an insertion mask (EM AST FT 6) for the deep-fryer, to prevent slipping in the system module.

7.1.5 Instructions for griddle on the acs® 600 ec, acs® 1000 ec

Position griddle to the right.

Do not position a ceramic hob next to the griddle, as otherwise odours may develop due to

splashes of grease.

‘Ensure undisturbed extraction of steam and vapours’, page 27

Eisfink Max Maier GmbH & Co. KG 27

User tip

If the extraction is interrupted, unpleasant odours can develop.

► Ensure that suitable cooking units are selected. See illustrations below.

► Ensure that the parts of the upper extraction area are completely assembled.

► Ensure that the cutting board is in position.

Appliance

type

‘d3’

↑ CORRECT

↑ INCORRECT

The acs®side extraction systems in appliance type ‘d3’ are designed in such a way that the

generated steam is extracted on three sides; Extraction at front left / right or on both sides and at the

back.

Appliance

type

‘ec’

↑ CORRECT

↑ INCORRECT

In appliance type ´ ec´, the extraction system (push & pull system) is designed in such a way that the

vapour created when cooking and roasting is collected by a transversally running air stream and

extracted into the side flank.

7.2 Ensure undisturbed extraction of steam and vapours

Use

Use

28

Eisfink Max Maier GmbH & Co. KG

Example

‘ec’

User tip

If the cutting board is not in place unpleasant odours can develop, due to interrupted

extraction.

► Ensure that the cutting board is in position. Briefly removing the cutting board for

cleaning will not interrupt the extraction.

Example

1500 d3

1 ON/OFF push- button switch with light indicator

2 230 V — grounded socket

3 400 V — CEE power outlet

User tip

► We recommend letting the extraction system run for another 10 minutes at the

end of the cooking process, so that the vapour caused by residual heat cannot

disperse into the environment.

7.3 Freshly prepare food on the cutting board

Freshly prepare food on the cutting board.

7.4 Switch appliance on and off electrically

Switch the device ‘ON/OFF at the rocker switch with indicator light'.

▌ Green indicator light illuminates.

Eisfink Max Maier GmbH & Co. KG 29

Button

1 ON/OFF

2 RESET

3 TURBO

4 Decrease ventilation intensity, levels 4 to 1

5 Increase ventilation intensity, levels 1 to 4

Display

6 LED display

7 LED fan fault, red = alarm

8 LED plasma fault, red = alarm

9 LED filter usage time exceeded, red = alarm

10 LED OK, green = fault-free

7.5 Electronic fan control (option)

7.5.1 Operating panel

Use

Use

30

Eisfink Max Maier GmbH & Co. KG

Switch the ON/OFF pushbutton with indicator light on the air-cleaning-system

acs® to ON.

▌

Control is in STANDBY.

Press ON/OFF button (1).

▌

During normal operation the OK LED shows a green light.

▌

The extraction system starts at the lowest fan speed, level 1.

Allow the ventilation to run on briefly if necessary, so that the vapours rising due to

residual heat cannot spread to the surrounding environment.

Press the ON/OFF button to switch off.

▌

The display goes out. The display is black.

Adjust intensity, levels 1 to 4

Press the PLUS button (5), to increase the level.

Press the MINUS button (4), to decrease the level.

▌

The selected level and the fan icon appear in the display.

TURBO is the highest ventilation intensity level.

Adjust TURBO

Press the TURBO button (3).

▌

The fan icon and TURBO appear in the display.

▌

After 5 minutes the fan switches back to the last selected ventilation

intensity.

7.5.2 Switching on / Switching off

7.5.3 Adjust ventilation intensity

Eisfink Max Maier GmbH & Co. KG 31

WARNING

Danger of electric shock. Dangerous electrical voltage.

► Repairs may only be carried out by specialists

► Any interference in the ‘plasma generator’ is forbidden.

In the event of a fault a continuous acoustic tone is emitted.

Press ON/OFF button (1).

▌

The fan control is switched off.

Press the RESET button.

▌

The continuous tone stops.

Eliminate the fault or arrange for repair by a specialist.

Check for possible errors:

Is the technical compartment closed?

Are the filters in the technical compartment free from objects?

Are the Eisfink active carbon filters correctly inserted?

Are the high-performance grease separators, grease drip trays and filter mats

correctly mounted in the air supply area?

Is the fan defective? No air flow?

Check for possible errors:

Is the technical compartment closed?

Is the plug of the radial fan / plasma generator inserted?

Are the active carbon filters correctly positioned?

7.5.4 Notes on troubleshooting

Use

7.5.5 Messages and measures for fault elimination

A fault is indicated in the display. If several faults are present at the same time, the fault with the

highest priority is displayed. The fault display replaces the fan operating state display. Faults (7), (8),

(9) remain illuminated until they have been eliminated and acknowledged.

Use

32

Eisfink Max Maier GmbH & Co. KG

If the usage time is exceeded:

The red usage time LED lights up.

A continuous acoustic tone is emitted.

The text shown on the display indicates the necessary measure.

The time intervals for cleaning the high-performance grease separators are no

more than 12 operating hours.

Clean grease filters

Risk of fire

Clean the high-performance grease separators and reinsert them correctly with

the other filter components.

Replace filter mat if necessary.

The time intervals for replacing the Eisfink active carbon filters are no more than

500 operating hours. Only use the filter type specified in the display.

Replace Eisfink active carbon filters

Replace the Eisfink active carbon filters in the technical compartment.

Reset the usage time counters to ‘0’

Carry out the maintenance work correctly as indicated in the display. Only then

should you reset the message. To do this:

Still in off mode, press the TURBO and RESET buttons simultaneously for at

least 10 seconds.

▌

The counters are set to ‘0’ counter status.

Display operating hours

Press the TURBO button and hold it pressed for at least 10 seconds.

▌

The total number of operating hours is shown in the display. This is

the time during which the fan control is switched on. The display

cannot be reset.

7.5.6 Messages due to exceeded usage times

7.5.7 Reset usage times, display operating hours

7.6 Clean the appliance after use

Risk of fire

Clean the appliance daily after use.

See ‘Cleaning, Maintenance and Care’, page 33

Cleaning, Maintenance and Care

Eisfink Max Maier GmbH & Co. KG 33

WARNING

Danger of electric shock. Risk of death.

► Disconnect the appliance from the mains; disconnect the power supply unit.

► Protect the appliance against moisture. Never direct a jet of water at electrical

components such as heater, controller or ventilation grille.

► Check the heating and connecting cable for any damage.

► Do not use a steam cleaning unit to clean electrical appliances. Doing so may allow

moisture to get into the electrical system and cause a short circuit. Do not expose to

spray water. To clean the electrical part, use a damp cloth and dry the surface using a

dry cloth.

► Have electrical equipment inspected at least every 6 months

2

by a qualified

electrician.

WARNING

Breathing difficulties, lacrimal irritation, mucosal irritations in throat, neck and lungs,

headache, strong tickle in the throat, cannot be excluded in the case of human error.

► Only use with Eisfink active carbon filters, which are correctly mounted.

► Do not interfere with the extraction and circulating-air cleaning: Do not place any

objects on the Eisfink active carbon filter in the technical compartment. Only operate

with a dry Eisfink active carbon filter.

Risk of fire

Risk of fire due to missing or incorrectly mounted filter components.

► Only use with original filter components and grease drip trays, which are correctly

fitted.

► Clean filter area daily.

2

8 Cleaning, Maintenance and Care

This chapter will help you to meet the hygiene requirements. Before reading this section, please read through

the "General safety instructions" section thoroughly first.

8.1 Safety information relating to cleaning, maintenance and care

Avoid dangers due to electricity

Risks due to human error when using the Eisfink active carbon filter for odour and

contaminant absorption and odour elimination using plasma technology

Fire risks

Source: DGUV Regulation 3. Electrical Systems and Equipment

Cleaning, Maintenance and Care

34

Eisfink Max Maier GmbH & Co. KG

Cleaning agent

Suitable

Brush products

Brushes with natural or synthetic bristles

Textiles

Textile material comprising natural and chemical cleaning fibres and textile

fabrics (knitted and woven fabric, cleaning cloths, floor cloth, fringed

material, fleece). Microfibre cleaning textiles are ideal for removing finger

marks from stainless steel surfaces.

Synthetic fleece

Without abrasives.

Mainly produced in the colours white, beige, yellow.

Other

Natural leather (chamois), synthetic leather, synthetic fleece, sponges,

sponge cloths

Cleaning agent

Areas of application

All-purpose cleaners

Particularly for lighter grease stains.

Neutral cleaners

For surfaces soiled with grease and oil (fingerprints); also suitable as a

dishwashing detergent.

Alcohol cleaners

As all-purpose cleaner

Alkaline cleaners

Especially for heavy grease and oil stains (dried-in oils).

Observe the manufacturer's dosage instructions.

Solvent cleaners

Depending on the type, particularly good for the removal of grease, oil, wax,

tar, adhesives, paints and lacquers.

Not suitable for plastics.

Disinfectant cleaners

Effect on pathogenic germs differs depending on active disinfectant

ingredient.

Long-term exposure to sodium hypochlorite can cause damage to the

material. It should not be used if possible. Products should be used, which

are specified in the list of the German Society of Hygiene and Microbiology

(DHGM).

8.2 Cleaning agents for stainless steel

# The following applies for all cleaning agents:

Observe the instructions for use provided by the cleaning agent manufacturer.

# Chemical cleaners for stainless steel

# Mechanical cleaners for stainless steel

Cleaning, Maintenance and Care

Eisfink Max Maier GmbH & Co. KG 35

Interval

Activity to be performed

Page

After use, at least daily

Clean generally

Page 36

Clean upper area of air extraction

system:

Clean grease drip trays,

Clean high-performance grease separator

Inspect filter mat

Page 38

Page 40 ff.

Every 7 working days or weekly

Inspect technical compartment; clean if

necessary

Page 48

After at least 500 hours of

operation

Replace Eisfink active carbon filter

Page 48, 51

Monthly

Ensure preservation of the product

identification

Page 12, 52

Every 6 months

Have electrical equipment inspected by a

qualified electrician in accordance with

DGUV regulation 3,

Also have the residual current operated

device inspected

Page 33

After at least 3000 hours of

operation

For version with ‘plasma generator’:

Clean plasma generator

Page 51

8.3 Overview of maintenance measures and intervals

Cleaning, Maintenance and Care

36

Eisfink Max Maier GmbH & Co. KG

ATTENTION

Incorrect cleaning can damage the surface or even destroy the appliance. Please note:

► Do not scratch the surface with sharp-edged objects. Do not use any abrasive or

aggressive cleaning agents, such as oven spray or a sponge with an abrasive surface.

► Remove dirt with cleaning and care products that are suitable for stainless steel.

► Do not mix standard cleaning agents; do not produce your own cleaning agent.

► Do not use steel wool or steel brushes.

► Avoid extended exposure of stainless steel to liquid containing salt, as this can lead to

surface discolouration and corrosion.

► Avoid direct, extended contact of stainless steel with corroding iron parts, e.g. cast iron

pans or steel kitchen sponges.

User tip

► We recommend Rieber cleaning agent for stainless steel for cleaning stainless

steel.

▌

It is an especially tough yet gentle cleaner, produces a dazzling shine,

cleans and protects in one.

Order no.: 72 10 24 08

8.4 Choose the correct cleaning method

# Note on regular cleaning

Abrasive-free cleaning agents are primarily used for regular cleaning.

Grease stains or grease-bound pigment dirt can generally be easily removed with

All-purpose cleaners

Neutral cleaners

Alkaline cleaners.

Solvent cleaners or non-abrasive emulsions are helpful for very heavy grease stains (dried-in oil and

grease) and tar marks (but not on painted surfaces).

8.5 Clean and service stainless steel parts

Clean the stainless steel surfaces withwarm, mild soapy water. After cleaning, rub the surfaces

dry with a soft cloth.

‘Cleaning agents for stainless steel’, page 34

Eisfink Max Maier GmbH & Co. KG 37

8.6 Clean casters

ATTENTION

Cleaning the casters incorrectly can damage them.

► Never clean the casters with a steam-jet blower, as this may cause lubricating grease

to escape from the wheel bearings.

► Clean the casters with mild washing up detergent diluted in hot water. After

cleaning, rub surfaces dry with a soft cloth.

Example

‘ec’

User tip

If the cutting board is not in place unpleasant odours can develop, as the extraction is

interrupted.

► Ensure that the cutting board is in position. Briefly removing the cutting board for

cleaning will not interrupt the extraction.

8.7 Clean and service plastic parts

Clean the plastic parts with mild washing up detergent diluted in hot water. After cleaning, rub

the surfaces dry with a soft cloth.

Cleaning, Maintenance and Care

# Clean technical compartment seal

The seal can be removed for cleaning if necessary.

Clean the dirty seals with mild washing up detergent diluted in hot water. Then rub dry with a

soft cloth.

Reinsert removed seals correctly in the cover of the technical compartment.

# Clean cutting board

Remove, rinse with lukewarm water, and rub dry.

If necessary, clean the cutting board in the dishwasher.

Cleaning, Maintenance and Care

38

Eisfink Max Maier GmbH & Co. KG

‘ec’

‘ec’

‘ec’

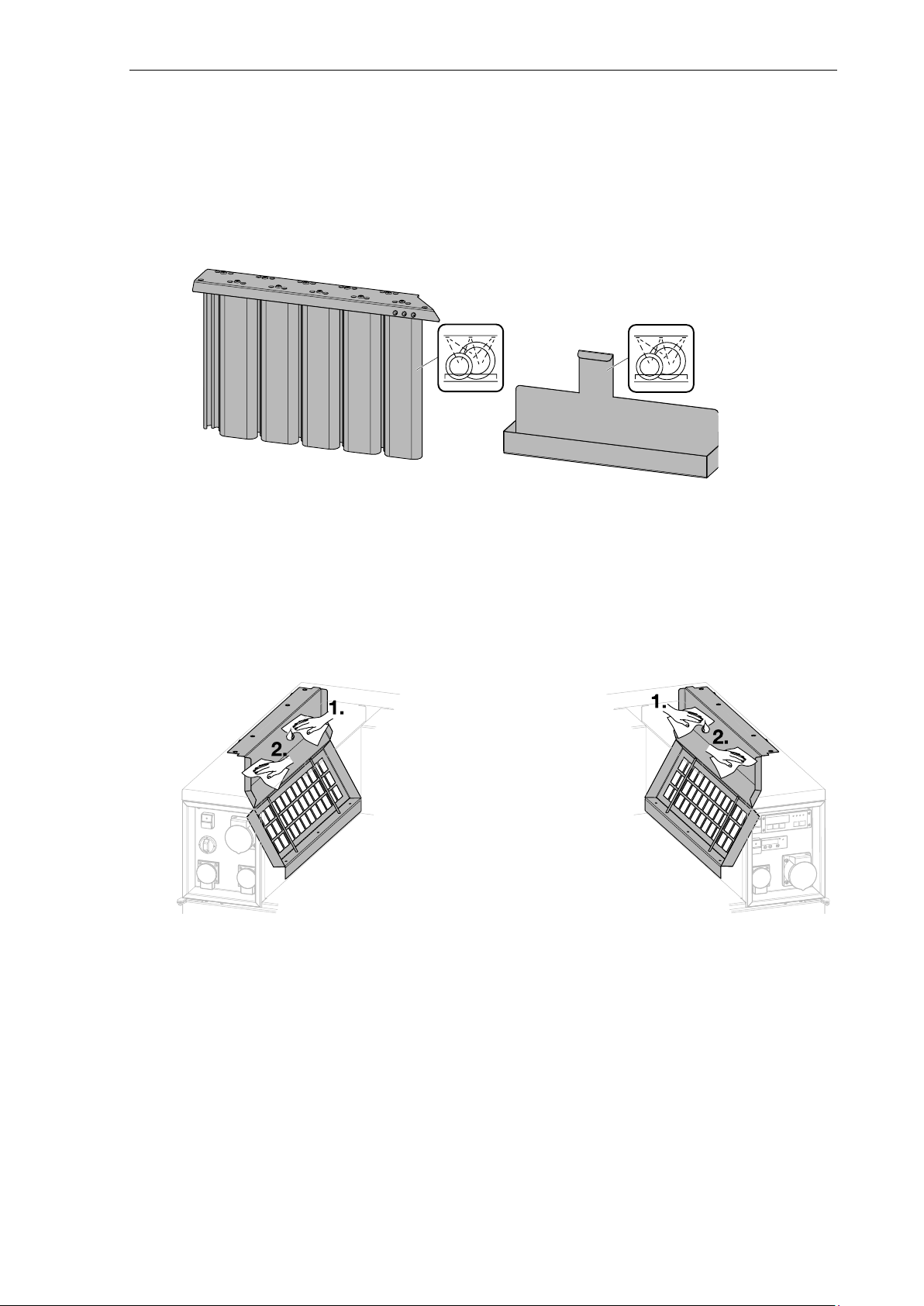

↑ High-performance grease separator

↑ Grease drip tray

User tip

Note the arrangement of the parts. Installation is then easier to carry out.

► Remove the 2x high-performance grease separators.

► Remove the 1x grease drip tray.

8.8 Appliance type ‘ec’

ATTENTION

Handle the splash guard with care to prevent surface damage and scratches.

Remove stainless steel splash guard for cleaning.

Ensure exact positioning when mounting; use 2x fixings per pin.

For cleaning, open the cover on the left; for this activate closures.

Clean the stainless steel part and the air supply area.

Cleaning, Maintenance and Care

Eisfink Max Maier GmbH & Co. KG 39

Risk of fire

Risk of fire due to missing or incorrectly mounted filter components.

► Insert the grease drip trays.

► Insert the (dry, unused) filter mat. The visible side is blue.

► Insert the grease separator with 1 raised point , then the one with 3 raised points.

Right side

‘ec’

↑ Order no. 61550346 (1 raised point)

(no further identification available)

↑ Order no. 61550347 (2 raised point)

# Notes on cleaning

The cleaning intervals depend on the intensity of use.

Risk of fire

Clean the filter components in the extraction area daily after use.

Clean the high-performance grease separators and grease drip trays with a fat-soluble detergent,

rinse thoroughly and then dry completely. The parts are dishwasher-safe.

The high-performance grease separators are marked with raised points. These markings can also be

found on the counterpart or frame of the product.

# Notes on assembly

The illustration shows the right side from the operator's viewpoint, as an example.

Ensure that the parts are completely dry and undamaged prior to assembly.

Cleaning, Maintenance and Care

40

Eisfink Max Maier GmbH & Co. KG

Example

‘d3’

8.9 Clean cooking area and splash guard

# Note on preparation

Remove the cooking units and other equipment from the cooking area.

User tip. Place an adequately large, soft surface in the cooking area for placing the parts to be

cleaned.

8.9.1 Clean air ducts

The cover of the air ducts is fixed with pins at the bottom left and clipped in at the top.

Cleaning, Maintenance and Care

Eisfink Max Maier GmbH & Co. KG 41

# Note on removable U-profile on the attachment

The yellow markings, arrow and ‘push’ lettering are engraved on the surface.

To remove the U-profile, push it to the left in the direction of the arrow and remove it on the

operator side.

To insert the U-profile, position the profiles on top of each other and then push the U-profile to

the right into the operating position.

# Notes on removal and installation of the cover

ATTENTION

Incorrect handling can cause scratches.

Grasp the cover with both hands, lift it vertically upwards out of the fixing and remove.

When inserting the part after cleaning, ensure that it is fixed with the pins on both sides

simultaneously.

# Note on cleaning

Clean the casing and air ducts with a hot, mild detergent diluted in water. After cleaning, rub

surfaces dry with a soft cloth.

8.9.2 Clean cooking area

Clean the appliance with a hot, mild detergent diluted in water. After cleaning, rub surfaces dry

with a soft cloth.

Cleaning, Maintenance and Care

42

Eisfink Max Maier GmbH & Co. KG

Remove the splash guard,

holding it with both hands.

When re-inserting, ensure

correct mounting in the guides

at the top and bottom. Simply

push the splash guard into the

guide as far as it will go.

8.9.3 Remove and clean splash guard

ATTENTION

Clean laminated safety glass parts like normal glass surfaces.

ATTENTION

Ensure correct positioning and condition of the plastic profiles, replace if necessary; Order no.

37160605 /bulk goods

# NOTE

Only re-install the splash guard after cleaning the side edge extraction units.

Chapter ‘Insert the parts again’, page 46

Cleaning, Maintenance and Care

Eisfink Max Maier GmbH & Co. KG 43

# Remove cover

Grasp the part in the

centre and pull it out

vertically upwards.

Remove the part.

Place the part on the

prepared surface.

# Remove highperformance grease

separator

Grasp the front filter

centrally at the handle

strip, tilt the part and pull

it out vertically upwards.

Repeat with the rear

filter.

8.10 Clean high-performance grease separator, grease drip trays …

8.10.1 Remove the parts

Danger of electric shock. Risk of death

Disconnect the appliance from the power supply before carrying out repair, maintenance and

cleaning work; Do this by unplugging the power plug.

Cleaning, Maintenance and Care

44

Eisfink Max Maier GmbH & Co. KG

# Remove grease grip trays

NOTE

Do not spill the grease,

as considerable

additional cleaning work

would then be required.

Thorough cleaning of

the technical

compartment would be

necessary.

Grasp the front grease

drip tray by the handle

and pull it out vertically

upwards.

Repeat with the rear

grease drip tray.

Slide forward around

10 cm first of all.

# Remove filter mat

Grasp the filter mat

centrally and pull it out.

Eisfink Max Maier GmbH & Co. KG 45

Clean with a hot, mild

detergent diluted in

water, using a slightly

damp cloth.

After cleaning, rub

surfaces dry with a soft

cloth.

8.10.2 Clean the parts

# Clean removed stainless steel parts

The parts are dishwasher-safe.

Clean the high-performance grease separators and the grease drip trays with fat-soluble cleaning

agents. Rinse thoroughly and then dry completely.

Cleaning, Maintenance and Care

# Inspect Filter mat, replace if necessary

Grease particles are mainly deposited on the blue side of the filter mat. If grease stains have formed

and the filter mat feels greasy, you should replace it immediately.

Dispose of the used filter mat in the household waste.

Order no. 91 70 05 15

# Clean inside of appliance

Cleaning, Maintenance and Care

46

Eisfink Max Maier GmbH & Co. KG

# Feed in filter mat

The visible side is blue.

Feed the filter mat

through the rear wire.

Push it back as far as it

will go.

Make a loop and push

the mat forward through

the front wire as far as it

will go.

Make sure that the filter

mat is positioned

smoothly.

# Install grease drip trays

Grasp the grease drip

tray at the handle edge

and push it down

vertically as far as it will

go.

Then push it back as far

as it will go.

Insert the other grease

drip tray at the front.

8.10.3 Insert the parts again

The parts are inserted in the reverse order to that described for removal.

Cleaning, Maintenance and Care

Eisfink Max Maier GmbH & Co. KG 47

# Install high-performance

grease separators

The high-performance

grease separators are

marked with raised points.

These markings are also

found on the housing in the

cooking area.

Align the grease

separators for the left

and right side with each

other and position like

this.

Hold the rear grease

separator at the handle

edge and insert it. Push

it back as far as it will

go, swing it up and push

it sideways as far as it

will go.

Insert the front grease

separator. Push it

forward, swing it up and

push it sideways as far

as it will go.

Make sure that the

grease separators are

positioned flush.

# Install cover

ATTENTION

Do not scratch the

surface.

Install the cover. Make

sure it is firmly in place.

# Re-install side splash guard

Install the side splash guard, left and right.

Chapter ‘Remove and clean splash guard ’, page 42

Cleaning, Maintenance and Care

48

Eisfink Max Maier GmbH & Co. KG

WARNING

Rotating parts. The impeller wheel of the radial fan rotates when the power to the

appliance is switched on.

► Switch off the electrical power to the appliance and disconnect from the power supply

before opening the technical compartment.

8.11 Inspect technical compartment; clean if necessary

8.11.1 Inspect and clean technical compartment, replace filter

Opening angle around 70 to 90 °, simply remove or insert the cover.

# Notes on opening and closing

# Inspect technical compartments for soiling

The steam and vapour extracted by the radial fans, which contain grease in addition to water vapour,

are also deposited on the surfaces.

Inspect the condition, such as greasy surfaces. Do this by touching several points on the stainless

steel surfaces with your finger and feeling it.

# Note on quick cleaning

Clean the soiled stainless steel surfaces with a hot cloth slightly dampened with a mild

detergent solution. After cleaning, rub the surfaces dry with a soft cloth.

# Note on professional cleaning

Remove active carbon filter.

Remove the radial fan if necessary by pulling it out along the guides and place it on a soft surface.

Clean the surfaces in the technical compartment with a hot, mild detergent diluted in water.

After cleaning, rub the surfaces dry with a soft cloth.

Cleaning, Maintenance and Care

Eisfink Max Maier GmbH & Co. KG 49

DANGER

Danger of electric shock. Dangerous electrical voltage.

► Unplug mains plug before removing the fan device.

User tip

The period of use of the Eisfink active carbon filter depends on the type of vapour and the

amount of grease. The degree of soiling of the active carbon filter cannot be visually

assessed. The active carbon filter cannot be cleaned.

► We recommend replacing the Eisfink active carbon filter at least after 500 operating

hours. Replace the filters early in the case of unwanted odours.

► Always replace the active carbon filters completely.

► Dispose of the active carbon filter with respect for the environment, as domestic waste.

The seals of the covers can be removed for cleaning. Ensure that it is mounted correctly with the

seal ends at the bottom.