SWISS MADE

E1 & ES1 / ASSEMBLY INSTRUCTIONS

enjoy sports

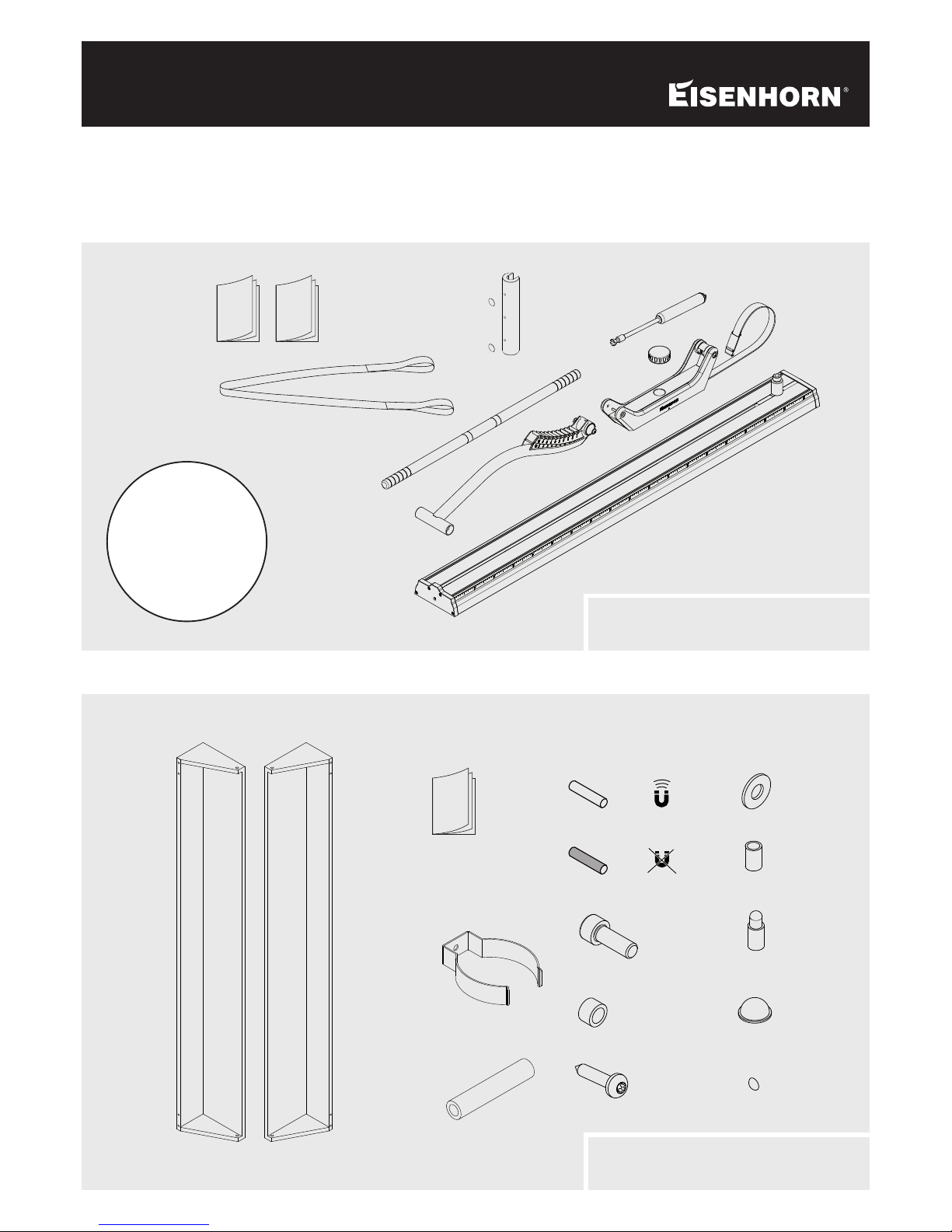

2 PRODUCT OVERVIEW

EISENHORN ES1EISENHORN E1

3 SCOPE OF DELIVERY

2x

2x

2x

6x

4x

4x

4x

3x

2x

2x

2x

1x

EISENHORN ES1

EISENHORN E1 & ES1

+

Screw set for wall

mounting

(see page 9)

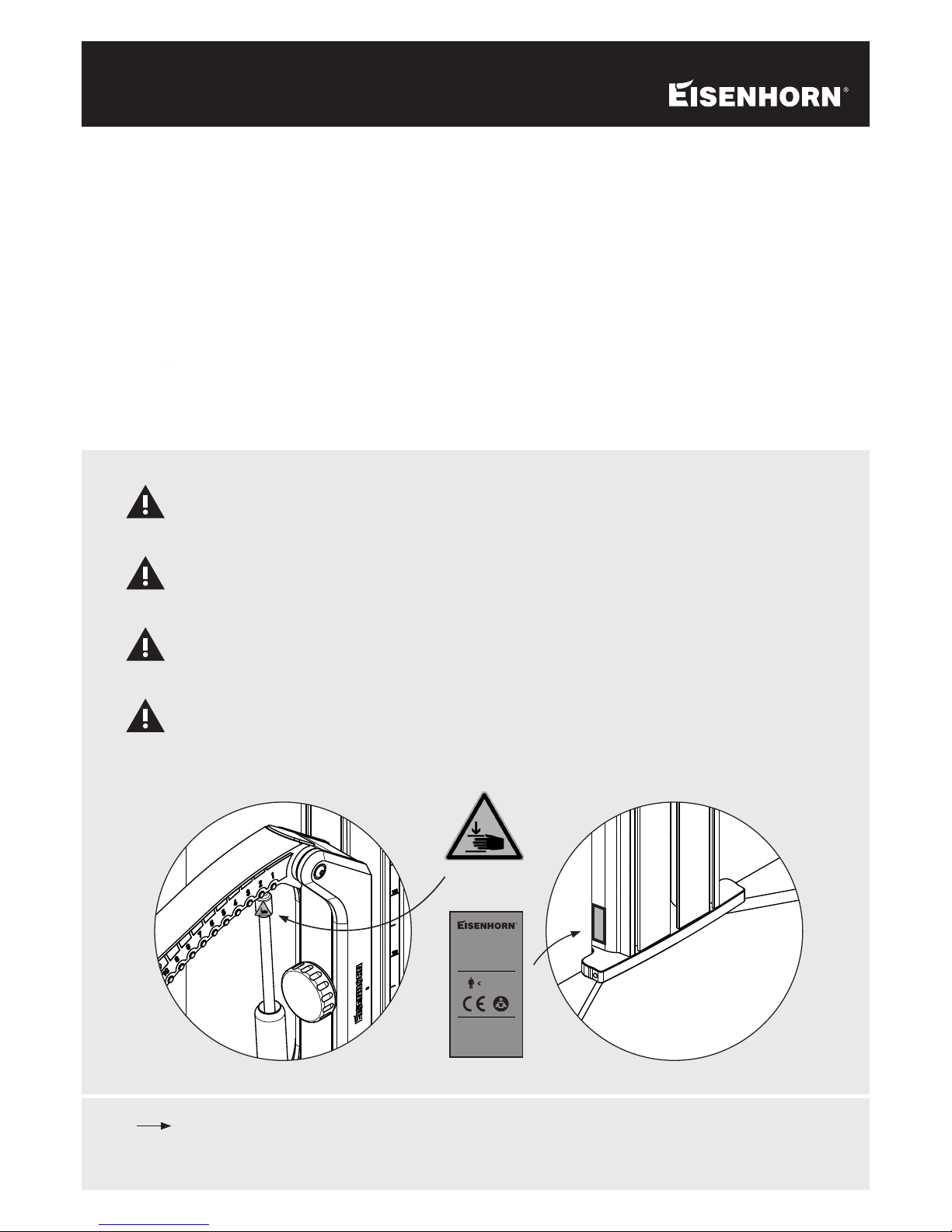

4 SAFETY INSTRUCTIONS

For setting up the device and the training itself, a separate user manual is

included in the delivery. Carefully read all the instructions for installation and

use, particularly those in the „SAFETY INSTRUCTIONS“ sections, before

starting the installation and using the device. Keep in mind that incorrect

installation or improper use may result in injury, and no liability or warranty

claims can be asserted.

Ensure that small children have no access to the installation materials. Swallowing small parts poses a choking hazard.

The piston is under high pressure and should not be exposed to temperatures

above 70 degrees. Select the installation location accordingly.

After installation, regularly check all screw connections to make sure they are

tight. See maintenance instructions.

Warning symbol and nameplate must be affixed as follows. If they are missing,

they must be re-ordered from EISENHORN and affixed to the device.

The device is built for indoor use (0 - 40 degrees Celsius and 30 - 75% humidity).

Trainingsgerät E1 / ES1

Seriennummer:

000 00051

Baujahr: 2015

100kg

EISENHORN AG

Rüttistrasse 49

CH-1716 Plaffeien

www.eisenhorn.com

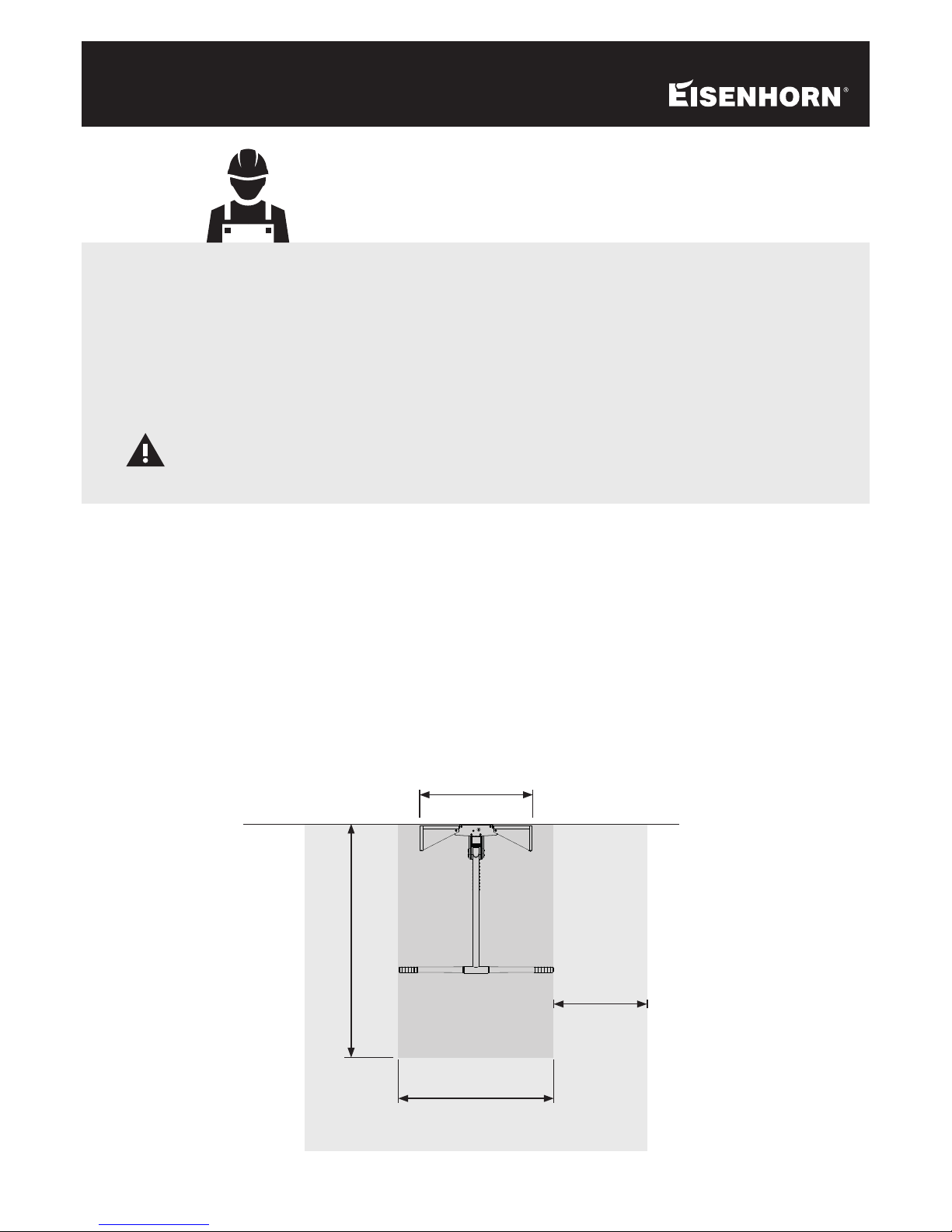

5 IMPORTANT INFORMATION

Choose the position on the wall so that you have enough room available later

for the different exercises. In particular, allow for sufficient distance to lamps,

light switches, electrical sockets, doorframes and window frames etc. for the

opened cabinet. For the main standard exercises, a minimum floor area of 1 x

1.5 m is sufficient. Ideally, there should be additional clearance of a good half

metre all around for optimal accessibility. A wall height of 2.12 m is sufficient

for mounting the device. For an unrestricted workout, a height of 2.25 m or

more is recommended.

A precondition for safe use of EISENHORN is a flat wall and professional wall

mounting. With the standard installation using 5 screws, each connection point

must withstand a tensile load of 800 Newtons. Screw and dowel materials must

be selected according to the wall (see page 9).

For the above reasons, we strongly recommend that you have the unit

installed by a competent professional.

1 m

0.73m

min. floor area

Ideal

clearance

0.5m

1,5 m

6 WALL MOUNTING

2

1

3

4

5

6

7

8

9

Mark the screw insertion points as per the dimensions on the drawing. Make

sure the holes are precisely vertical one above the other. If cavities, pipes, joints

between tiles or the like make it impossible to drill at this point, all holes except

the top one may be slightly offset in height (max. 5 cm).

After drilling, remove the drilling dust from each hole.

Now place the column against the wall. Distance between bottom edge and

floor is 21 cm.

Tip: Put the column on the packaging carton.

Start by mounting the third screw connection from the top.

Select the fastening components depending on the type of wall (see pages 9-14).

Mount the screw from the front through the groove in the column (see page 8).

Mount the two lower screw connections in the same way.

Make sure the sliding surfaces of the carriage and the front panel of the

column are clean.

Mount the carriage on the trolley, drag it down to half the column height and

attach it securely using the turning knob.

Now mount the top two screw connections.

Place the Eisenhorn in the corresponding bearing of the carriage and tighten the

two lateral screws with 15Nm torque.

Screw the piston into the rotary base of the carriage.

By rotating clockwise, align the clipper (e.g. using a screwdriver) parallel to the

locking pins.

Test whether the trolley can be moved along the whole length of the column

easily and without jamming. If the trolley jams at a particular point, the screw

connections in this area must be checked and adjusted (possibly screwed too

tight, or wall is uneven).

4

3

4

5

6

7

8

2

21cm

330

630

1680

1980

2070

7 WALL MOUNTING

9

1

Make sure the cylindrical surfaces of the clipper and the 10 pins for the

resistance levels are always clean. Otherwise, paintwork defects or noise

(squeaking) may occur due to the high loading pressure.

8 IMPORTANT INFORMATION

TIGHTENING THE SCREWS

Mount the screw from the front through the groove in the column into the

mounting bracket and screw it tight until the bracket deforms slightly.

PLEASE NOTE: Do not screw too tight. The bracket should not bend all the

way to the wall!

Right!Wrong!

Column Column

Wall Wall

9 SCREW SET FOR WALL MOUNTING

SCREW MATERIALS

It must be determined at the installation spot whether the screw material provided is suitable for the selected wall.

EISENHORN offers no guarantee for the use of unsuitable mounting parts or

installation not undertaken by a professional.

Bore diameter 8mm

5x

2

5x

1

Diameter 6mm x 85mm

5x

4

Bore diameter 10mm

5x

Diameter 8mm x 80mm

3

10 INSTALLATION MATERIALS

SOLID WOOD MOUNTING:

It must be determined at the installation spot whether the screw material provided is suitable for the selected wall.

EISENHORN offers no guarantee for the use of unsuitable mounting parts or

installation not undertaken by a professional.

Tighten the screws as per the information on page 8.

1

11 INSTALLATION MATERIALS

DRYWALL POSTS MOUNTING:

It must be determined at the installation spot whether the screw material provided is suitable for the selected wall.

EISENHORN offers no guarantee for the use of unsuitable mounting parts or

installation not undertaken by a professional.

Tighten the screws as per the information on page 8.

1

12 INSTALLATION MATERIALS

4

DRYWALL (GYPSUM FIBREBOARD) MOUNTING:

It must be determined at the installation spot whether the screw material provided is suitable for the selected wall.

EISENHORN offers no guarantee for the use of unsuitable mounting parts or

installation not undertaken by a professional.

Tighten the screws as per the information on page 8.

PLEASE NOTE!

The carrying capacity of

drywalls can vary greatly.

Ensure the recommended

tensile load per point of

connection can be borne

(see page 5).

If possible, choose the

installation method as per

page 11.

3

13 INSTALLATION MATERIALS

CONCRETE / MASONRY MOUNTING

It must be determined at the installation spot whether the screw material provided is suitable for the selected wall.

EISENHORN offers no guarantee for the use of unsuitable mounting parts or

installation not undertaken by a professional.

Tighten the screws as per the information on page 8.

PLEASE NOTE!

After drilling, thoroughly

remove the drilling dust

from each hole. Otherwise

an excessively high screwin force results, which can

lead to shearing-off of the

screw.

2

1

Borehole depth

min. 90mm

14 INSTALLATION MATERIALS

PERFORATED BRICK MOUNTING

It must be determined at the installation spot whether the screw material provided

is suitable for the selected wall. Drilling must not be done with a power tool.

EISENHORN offers no guarantee for the use of unsuitable mounting parts or

installation not undertaken by a professional.

Tighten the screws as per the information on page 8.

2

1

15 ASSEMBLING THE CABINET DOORS (ES1)

ES1 DESIGNER CABINET

If you have purchased an EISENHORN ES1 with designer cabinet, now proceed

with the assembly of the cabinet doors. A separate installation manual is

included with the delivery of the designer cabinet.

The following pages describe how to mount the cabinet doors on the column.

16 MOUNTING THE CABINET DOORS (ES1)

2x

2x 2x

Magnetic

2x

1x

2x

1 2

3

17 MOUNTING THE CABINET DOORS (ES1)

4x

4x

Firmly stick on the rubber pads as shown above.

18 MOUNTING THE CABINET DOORS (ES1)

4x

4x

2x

(top only)

1

1

2

3

2

3

undertake

on both sides

TOP

TOP

BOTTOM

19 MOUNTING THE BLOCKER BRACKET

E1 ES1

90mm

Firmly stick on the metal disks as shown above.

As manufacturer we declare that the training device specified below complies with the directives and standards given below.

Manufacturer: EISENHORN AG, CH-1716 Plaffeien / Authorised representative for the technical documents: EISENHORN AG, Michael

Schrag, CH-1716 Plaffeien / Name of the equipment, trade name: Training device / Model, type: E1/ES1 / Serial number: E1/ES1 xxx xxxxx /

Directives: 2006/42/EC (09.06.2006) Machinery Directive of the European Parliament and of the Council / Standards: EN ISO 20957-1:2013

Stationary Training Equipment – Part 1: General safety requirements and test methods (ISO 20957-1:2013); German version EN ISO 20957-1:2013

Plaffeien, 31.03.2016 / Michael Schrag, Managing Director …………….....……

www.eisenhorn.com Issue status: March 2016

Loading...

Loading...