Page 1

Operating Instructions

1. Elektric connection

three-phase motor 380 V - 50 Hz

(alternative 220 V - 60 Hz)

Pay attention to correct sense of rotation!

The abrasive wheels have to run one to the other

(see arrow at the machine casing!)

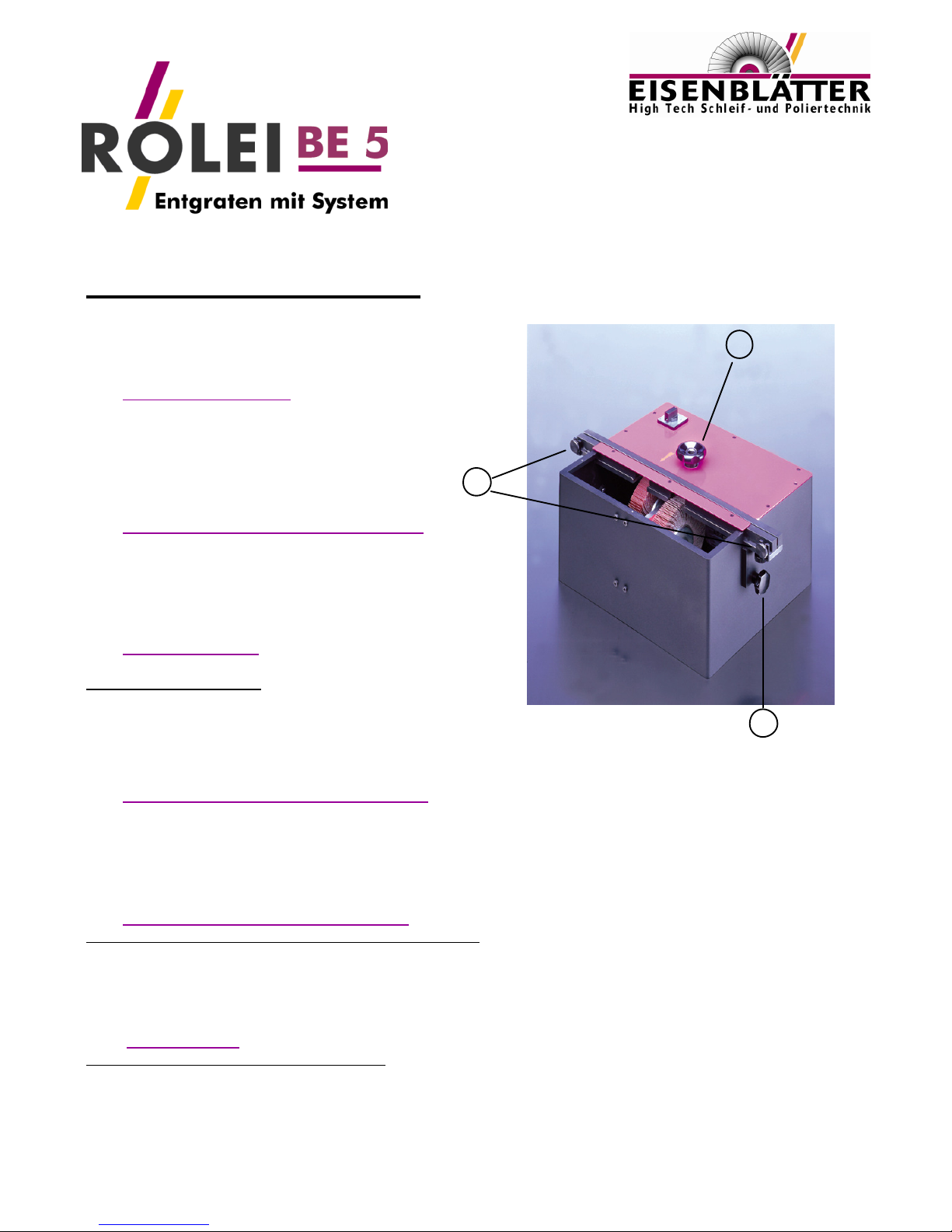

2. Adjustment of the sheet thickness

Release locking screws at the bottom of the guide plate (1),

adjust slot width by means of the setting screws (2) in a

manner that the workpiece can be moved easily –

retighten then locking screws (1).

3. Setting to work

Switch-on the machine:

Step I for slight burrs

step II for heavy burring

4. Adjustment of the abrasive wheels

Turn abrasiv e wheels (mop) upwards by means of the hand-wheel (right-hand rotation) until a grinding noise is heard,

turn then hand-wheel (3) to the left until the wheels are

"running free" without any noise (the machine is correctly adjusted now). The sheet parts can be pushed now from one

side through the guide prism to burr them neatly at both sides.

CE-tested – is corresponding to the directions 89/392 and 93/68 EEC

5. Changing of the abrasive wheels

Attention: Both driving shafts are left-hand threaded!

Release the nuts and take off the abrasive wheels with the clamping covers.

Pay attention to sense of rotation when new wheels are mounted. Retighten the nuts!

6. Maintenance

The machine (gear) is maintenance-free!

Wheel dust should be removed from the machine daily!

If necessary removal by suction.

1

2

3

Page 2

Page 3

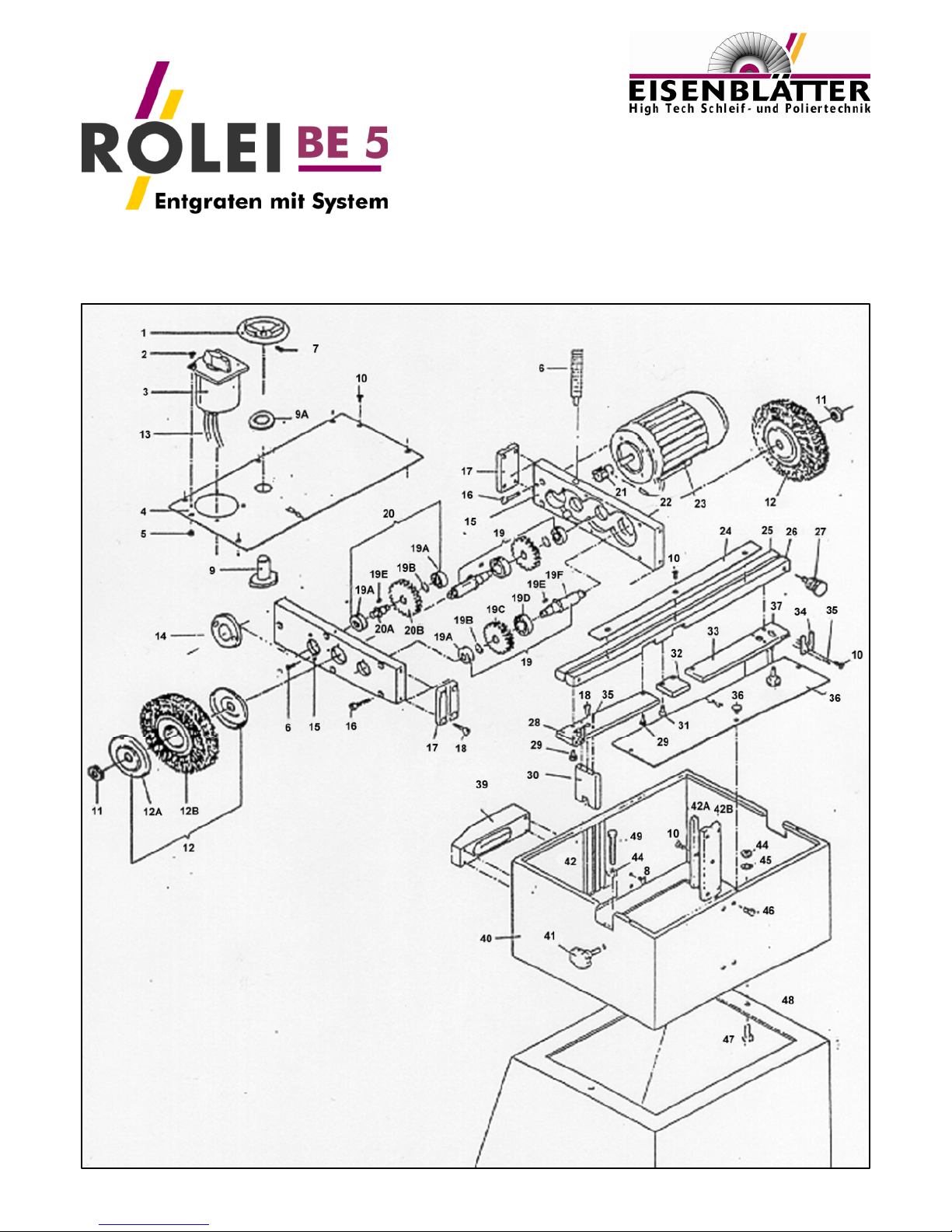

Pos. Art-no. description Pos. Art-no. description

1

54001 hand wheel

20

54020 countershaft complete

2

54002 screw

20A

54020A countershaft

3

54003 Switch

20B

54020B gear wheel

5

54005 nut

21

54021 motor bevel

6

54006 threat

22

54022 screw for motor bevel of ROLEI BE5

9

54009 adjustment nut

23

54023 motor 380 volts

10

54010 knurled screw

24

54024 protection rail

11

54011 nut

25/26

54025 guidance rail 700 mm (part 25 + 26)

12A 54012A clampi ng cover 27 54027 adjustment screw

13

54013 cable

28/32/33

54028 guidance rail 700 mm

14 54014 sealing cover 30 54030 fixing plate

15 54015 gear box 34 54034 adjustment brac ket

16 54016 screw 36 54036 knurled screw 4x8

17

54017 guide

37

54037 knurled screw 6x20

18 54018 screw 41 54041 hand grip screw 8x20

19 54019 driveshaft complete 42 54042 gear guide

19A 54019A bearing 43 54043 cable connection

19B

54019B circlip

50

54050

complete gear with drive cover and gear

wheels with motor

19C 54019C gear wheel 51 54051

complete gear with drive cover and gear

wheels without motor

19D 54019D bearing 52 54052 1 set of cr own wheels 2x19C/1x20B/1 x21

19E 54019E fitting key 53 54053 1 set ball bearings 4x19A/2x17D

19F

54019F driveshaft

54

54054 cable guidance

380 V version

12B

37040 ROLEI spare flap wheel 165 x 30 mm grit 40

12B

37080 ROLEI spare flap wheel 165 x 30 mm grit 80

12B

37060 ROLEI spare flap wheel 165 x 30 mm grit 60

12B

37120 ROLEI spare flap wheel 165 x 30 mm grit 120

Spare flap wheels

Attention: Use only Original EISENBLÄTTER s pare flap wheels because the polyester fibre

residues of spare flap wheels with polyester material can seriously damage the bearing bush of the

gear!

A warranty claim is only possible by using the Original Eisenblätter spare flap wheels!

Page 4

Gerd Eisenblätter GmbH Jeschkenstr. 10 DE-82538 Geretsried

CE 94 Anlage zur ROLEI BE 5 -

Bedienungsanleitung

ENGLISH NEDERLA NDS

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product is in conformity

with the following standards or standardization documents: EN 60745, EN 5 5014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3 according to the provisions of the regulations 2006/42/ EG, 2 004/108/EG.

EC-KONFORMITEITSVERKLARING

Wij verklaren op eigen verantwoording, dat dit produkt voldoet aan de

volgende normen of normatieve dokumenten: EN 6 0745, EN 55014-1,

EN 55014-2, EN 61000-3-2, EN 61000-3- 3 volgens de bepalingen van

de richtlijnen 2006/42/EG, 2004/108/EG.

DEUTSCH DANSK

CE-KONFORMITÄTSERKLÄRUNG

Wir erklären in alleiniger Verantwortung, d ass dieses Produkt mit den

folgenden Normen oder normativen Dok umenten übereinstimmt: EN

60745, EN 55014-1, EN 55014- 2, EN 6 1000-3-2, EN 61000-3-3 gemäß

den Bestimmungen der Richtlinien 2006/42/EG, 2004/108/EG.

CE-KONFORMITETSERKLÆRING

Vi erklæerer under almindeligt ansvar, at dette produkt er i overensstemmelse med følgende normer eller normative dokumenter: EN

60745, EN 55014-1, EN 55014- 2, EN 6 1000-3-2, EN 61000-3-3 i henhold til bestemmelserne i direktiverne 2006/42/EG, 2004/108/EG.

FRANÇAIS NORGE

DÈCLARATION "CE" DE CONFORMITÉ

Nous déclarons sous notre propre responsa bilité que ce produit est en

conformité avec les normes ou documents normalisés: EN 60745, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3- 3 conformément aux

termes des réglementations 2006/42/EG, 2004/108/EG.

CE-ERKLÆRING AV KONFORMITET

Vi overtar ansvaret for at dette produktet er i overenst emmelse med følgende standar der eller standard-dokumenter: EN 60745,

EN 55014-1, EN 55014-2, E N 61000-3-2, EN 61000-3-3 i s amsvar med

bestemmelsene i direktivene 2006/42/EG, 2004/108/EG.

ITALIANO SVENSKA

DICHIARAZIONE DI CONFORMITÀ CE

Ass umendone la piena responsabilità, dichiariamo che il prodotto è conforme alle seguenti normative ed ai relativi documenti: EN 60745, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3- 3 in base alle prescrizioni delle direttive 2006/42/EG, 2004/108/EG.

CE-KONFORMITETSFÖRKLARINGEN

Vi intygar och ansvarar för att denna produkt överenss tämmer med

följande norm och dokument: EN 60745, EN 55014-1, EN 55014-2, EN

61000-3-2, EN 61000-3-3 enligt bestämmels erna i riktlinjerna 2006/42/

EG, 2004/108/EG.

ESPAÑOL SUOMI

DECLARACION DE CONFORMIDAD CE

Declaramos bajo neustra sola responsabilidad que este producto está en

conformidad con las normas o docu-mentos normalizados siguientes : EN

60745, EN 55014-1, EN 55014- 2, EN 6 1000-3-2, EN 61000-3-3 de acuerdo con las regulaciones 2006/42/EG, 2004/108/EG.

TODISTUS CE-STANDARDINMUKAISUUDESTA

Todistamme täten ja vastaamme yksin siitä, että tämä tuote en allalueteltujen standardie n ja standardoimisasiakirjojen vaatimusten mukainen: EN 60745, EN 55014-1, E N 55014-2, EN 61000- 3-2, EN 61000-3-3

seuraavien ohjeiden määräysten mukaisesti: 2006/42/EG,

2004/108/EG.

PORTUGUES GREEK

DECLARAÇÃ0 DE CONFORMIDADE CE

Declaramos sob nossa exclusiva responsabilidade que este producto

cumpre as seguintes normas ou documentos normativos : EN 60745, EN

55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3- 3 de acordo com as

disposições das directivas 2006/42/EG, 2 004/108/EG.

∆΄HΛΩ∑Н ∑ΥМΒΑΤΙΚ΄ОΤΗΤОΣ

∆ηλώvoυµε υттεuθύvως óтı тo проїóv αuтó εіvαı καтασκεuασµ έvo

ơúµφωvα µε тоuς εξής καvovισµ οúς ή καтαơкεuασтıκές σuσтάσεıς: EN

60745, EN 55014-1, EN 55014- 2, EN 6 1000-3-2, EN 61000-3-3

σúµφωνα µε тıς

δıαтάξεıς тων Οδηуıών: 2006/42/ EG, 2004/108/EG.

Gerd Eisenblätter GmbH

Loading...

Loading...