Page 1

TM 11-6625-3031-14

.

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL,

DIRECT SUPPORT,

AND

GENERAL SUPPORT MAINTENANCE MANUAL

COUNTER, PULSE, ELECTRONIC

TD-1338(V)1/USM

(NSN 6625-01-120-7832)

HEADQUARTERS, DEPARTMENT OF THE ARMY

6 MAY 1983

Page 2

SAFETY STEPS TO FOLLOW IF SOMEONE

IS THE VICTIM OF ELECTRICAL SHOCK

DO NOT TRY TO PULL OR GRAB THE INDI-

VIDUAL

IF POSSIBLE, TURN OFF THE ELECTRICAL

POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL

POWER, PULL, PUSH, OR LIFT THE PERSON

TO SAFETY USING A WOODEN POLE OR A ROPE

OR SOME OTHER INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF CONTACT WITH THE SOURCE OF ELECTRICAL

SHOCK, MOVE THE PERSON A SHORT

DISTANCE AWAY AND IMMEDIATELY START

ARTIFICIAL RESUSCITATION

Page 3

TM 11-6625-3031-14

TECHNICAL MANUAL

NO. 11-6625-3031-14

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual.

you know of a way to improve the procedures, please let us know.

Mail your letter,

tions and Blank Forms),

this manual direct to:

Electronics Command and Fort Monmouth, ATTN:

Fort Monmouth, NJ 07703.

DEPARTMENT OF THE ARMY

WASHINGTON, D.C. 6 May 1983

OPERATOR’S,

AND GENERAL SUPPORT MAINTENANCE MANUAL

ORGANIZATIONAL, DIRECT SUPPORT

FOR

COUNTER, PULSE, ELECTRONIC

TD-1338(V)1/USM

(NSN 6625-01-120-7832)

If you find any mistakes or if

DA Form 2028 (Recommended Changes to Publica-

or DA Form 2028-2 located in the back of

Commander, US Army Communications-

DRSEL-ME-MP,

HEADQUARTERS

Chapter

Section I.

In either case,

INTRODUCTION

1.

General Information . . . . . . . . . . . . . . .

Scope. . . . . . . . . . . . . . . . . . . . 1-1

Reports of maintenance forms, records and

reports. . . . . . . . . . . . . . . . . . . . . 1-2

Administrative storage . . . . . . . . . . . . . 1-3

Destruction of Army electronics materiel. . . . . 1-4

Reporting equipment improvement recommendations

(EIR'

S

). . . . . . . . . . . . . . . . . . . . . 1-5

Warranty information . . . . . . . . . . . . . . 1-6

II.

Equipment Description . . . . . . . . . . . . . .

Equipment characteristics, capabilities and

features . . . . . . . . . . . . . . . . . . . . 1-7

Equipment data . . . . . . . . . . . . . . . . . 1-8

III.

Technical Principles of Operation . . . . . . . .

Counter functional operation . . . . . . . . . . 1-9

a reply will be furnished direct to you.

TABLE OF CONTENTS

Para

Page

1-1

1-1

1-1

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-4

1-4

i

Page 4

TM 11-6625-3031-14

TABLE OF CONTENTS - Continued

Chapter

Section I.

2.

II.

III.

Para

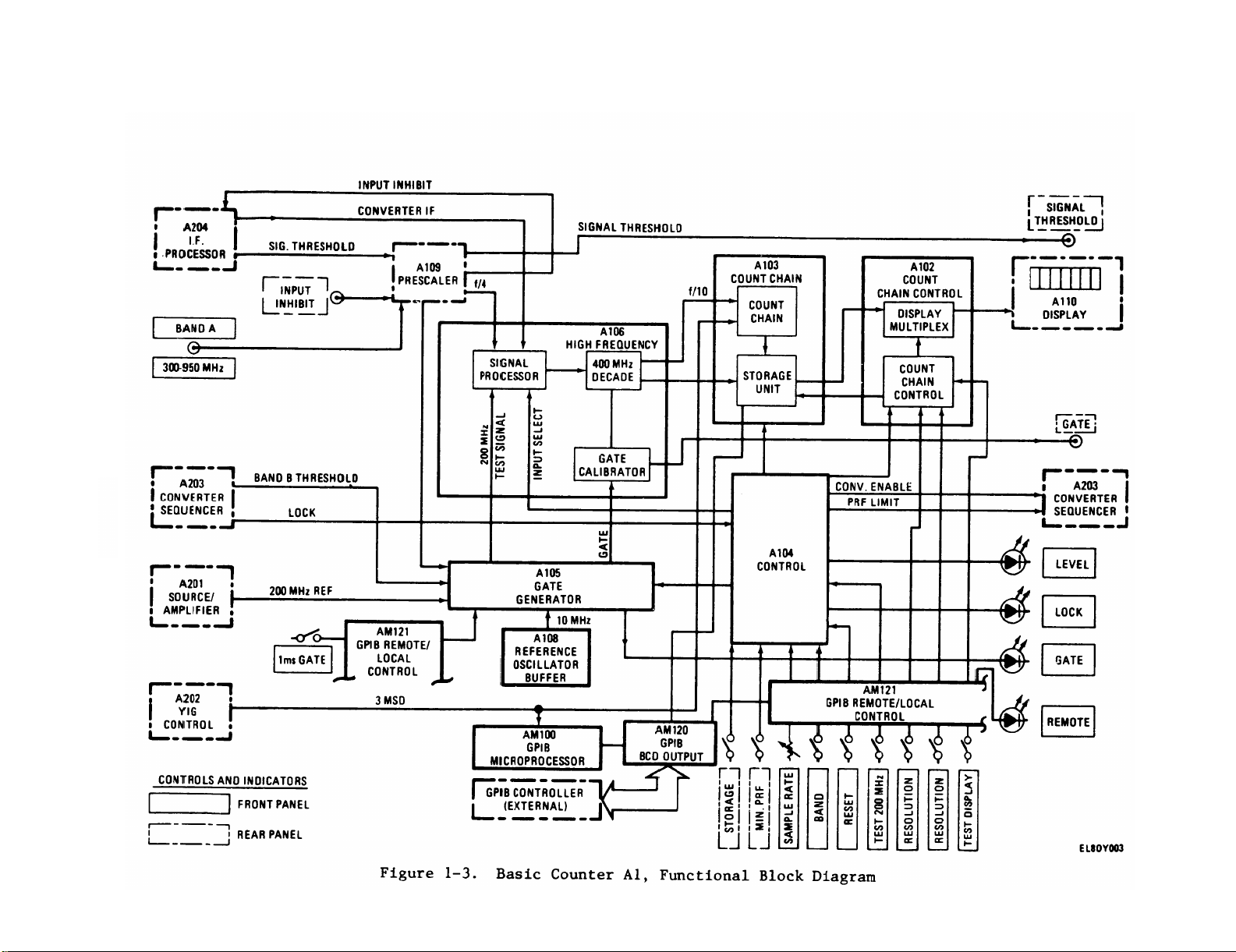

Basic counter A1 . . . . . . . . . . . . . ...1-10

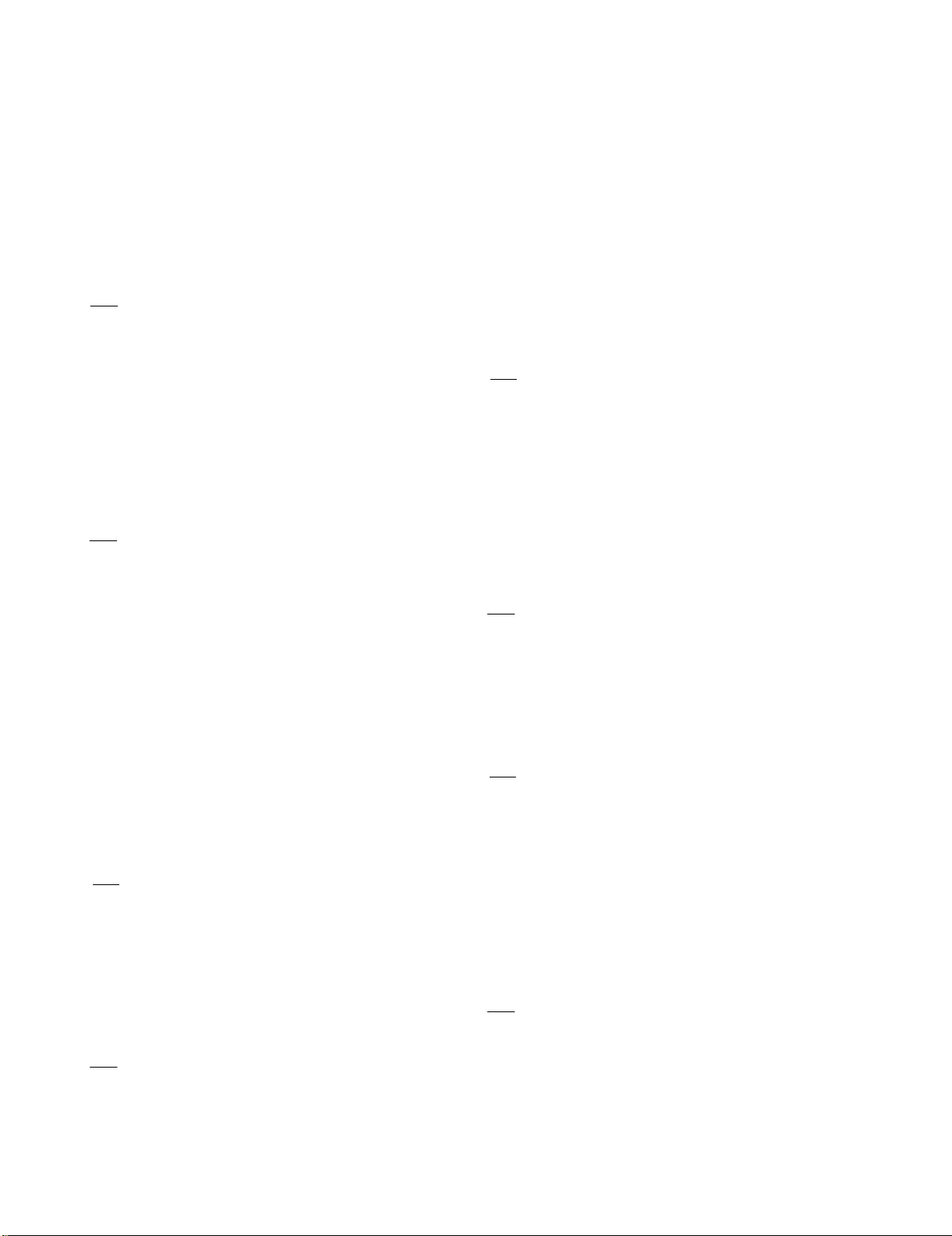

Converter A2 . . . . . . . . . . . . . . . . . . 1-11

OPERATING INSTRUCTIONS

Description and Use of Operator’s Controls and

Indicators . . . . . . . . . . . . . . . . . . .

Front-panel controls, connectors and

indicators . . . . . . . . . . . . . . . . . . .

Rear-panel controls and connectors. . . . . . . .

Preventive Maintenance Checks and Services . . .

General instructions. . . . . . . . . . . . . . .

PMCS procedures. . . . . . . . . . . . . . . . .

Cleaning instructions . . . . . . . . . . . . . .

Operation Under Usual Conditions . . . . . . . .

Assembly and preparation for use . . . . . . . .

Operation as stand-alone instrument . . . . . . .

Externally enabled operation . . . . . . . . . .

Pulse profile measurements. . . . . . . . . . . .

Dynamic characteristics of time varying signals .

Multiple pulse signal measurements . . . . . . .

Timing considerations . . . . . . . . . . . . . .

Accuracy . . . . . . . . . . . . . . . . . . . .

Techniques for improving accuracy . . . . . . . .

Operation using General Purpose Interface Bus . .

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-15

Page

1-6

1-8

2-1

2-1

2-1

2-5

2-5

2-5

2-6

2-7

2-7

2-8

2-10

2-10

2-11

2-11

2-11

2-12

2-13

2-13

Chapter

Section I. Lubrication . . . . . . . . . . . . . .

III. Maintenance Procedures . . . . . . . . . . . . . . . . .

Chapter

Section I.

III.

OPERATOR AND ORGANIZATIONAL

3.

II.

Troubleshooting Procedures . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . .

Inspection. . . . . . . . . . . . . . . . . . . . . . . .

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement . . . . . . . . . . . . . . . . . . . . . . .

Test. . . . . . . . . . . . . . . . . . . . . . . . .

4.

DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE

Repair Parts, Special Tools; Test Measurement,

and Diagnostic Equipment (TMDE); and Support

Equipment. . . . . . . . . . . . . . . . . . . . . . . . .

Common tools and equipment . . . . . . . . . .

Special tools, TMDE,

Repair parts . . . . . . . . . . . . . . . . . . . . . .

II.

Service Upon Receipt . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . .

Reference diagrams . . . . . . . . . . . . . .

IV.

Maintenance Procedures . . . . . . . . . . . .

Disassembly, replacement, and reassembly . . .

Adjustments. . . . . . . . . . . . . . . . . .

Performance test . . . . . . . . . . . . . . . . .

and support equipment . .

MAINTENANCE

3-4

3-5

3-6

3-7

3-8

4-1

4-2

4-3

4-5

4-6

4-7

4-8

4-9

3-1

3-1

3-3

3-3

3-3

3-3

3-3

3-3

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-2

4-17

4-17

4-20

4-28

ii

Page 5

TABLE OF CONTENTS - Continued

TM 11-6625-3031-14

Section

Preparation for Storage or Shipment . . . . . . .

V.

Preparation of equipment. . . . . . . . . . . . . 4-10

Packing instructions. . . . . . . . . . . . . . . 4-11

Appendix A. REFERENCES. . . . . . . . . . . . . . . . . . . .

Appendix B.

Appendix C.

MAINTENANCE ALLOCATION . . . . . . . . . . . . .

COMPONENTS OF END ITEM AND BASIC ISSUE

ITEMS LISTS. . . . . . . . . . . . . . . . . . .

Appendix D.

Appendix E.

ADDITIONAL AUTHORIZATION LIST . . . . . . . . . .

EXPENDABLE SUPPLIES AND MATERIALS LIST . . . . .

Para

Page

4-33

4-33

4-33

A-1

B-1

C-1

D-1

E-1

iii

Page 6

TM 11-6625-3031-14

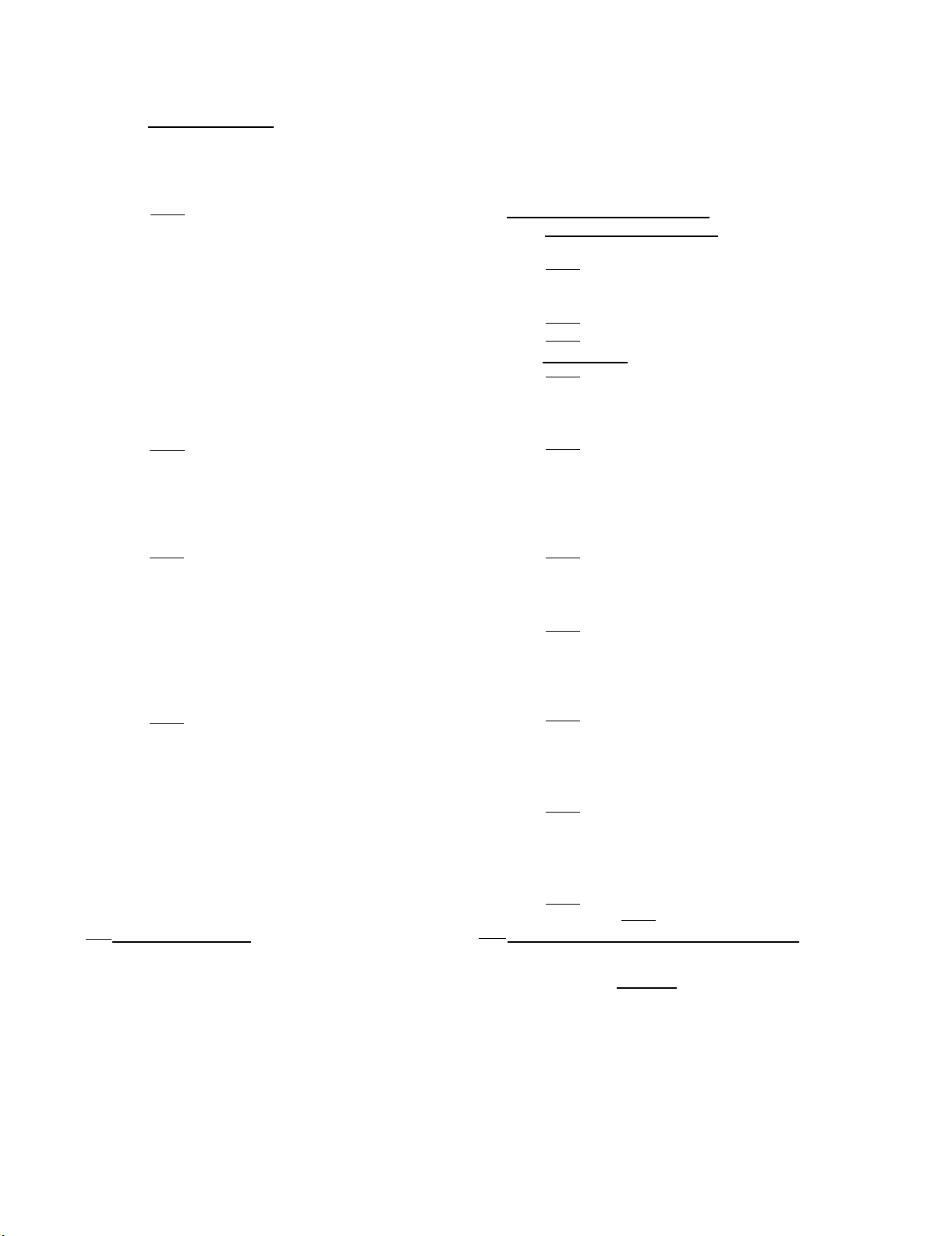

LlST OF ILLUSTRATIONS

Figure

1-1

1-2

1-3

1-4

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

4-12

Title

Counter,

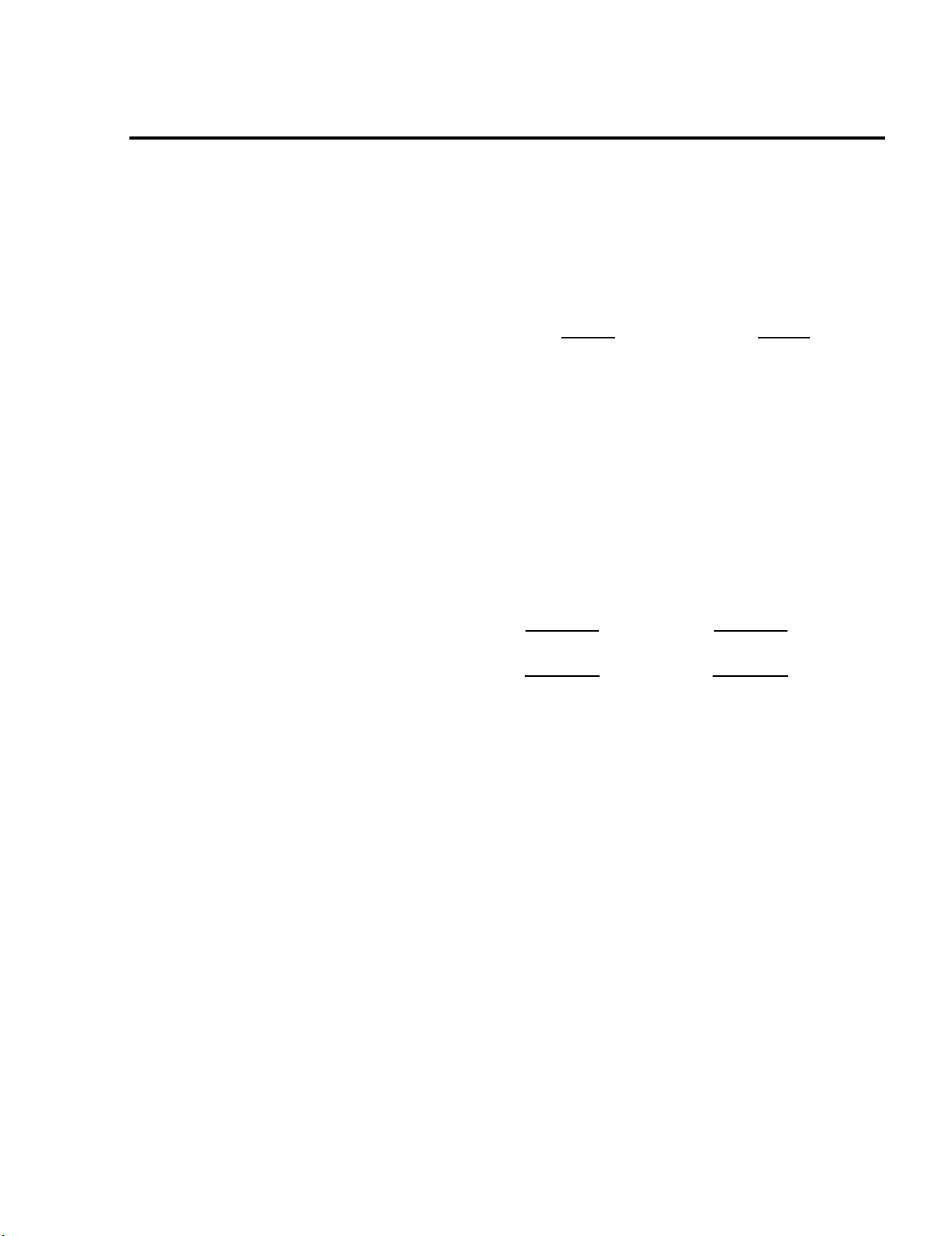

Counter,

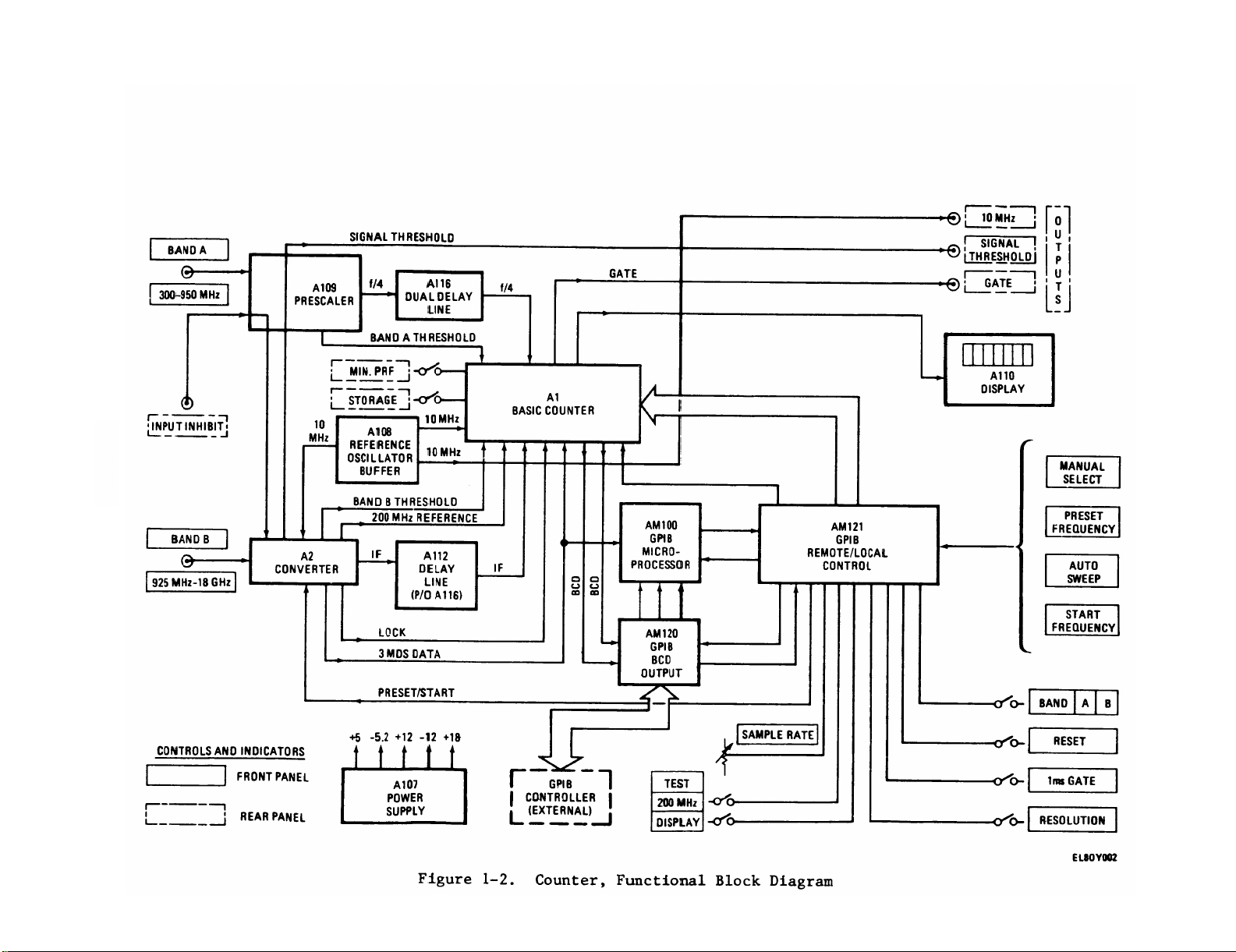

Basic Counter A1,

Converter A2, Functional Block Diagram . . . . . . . . . . . . . . 1-9

Counter Front Panel. . . . . . . . . . . . . . . . . . . . . . . .2-1

Counter Rear Panel. . . . . . . . . . . . . . . . . . . . . . . .2-4

Pulse Profile Measurement Test Setup . . . . . . . . . . . . . . . 2-10

Pulse Profile Measurement . . . . . . . . . . . . . . . . . . . . 2-10

Time Varying Signal Measurement Test Setup . . . . . . . . . . . . 2-11

Internal Timing Delays . . . . . . . . . . . . . . . . . . . . . . 2-12

GPIB Capabilities and Structure . . . . . . . . . . . . . . . . . 2-15

GPIB IEEE STD 488/1975 ADDRESS SWITCH Positions . . . . . . . . . 2-16

Subassembly and Cable Locations . . . . . . . . . . . . . . . . . 4-3

Counter Interconnect A100, Connector and Switch Locations . . . . 4-17

Counter, Partial Exploded View . . . . . . . . . . . . . . . . . . 4-18

Adjustment Locations. . . . . . . . . . . . . . . . . . . . . . . 4-21

Pulse Generator Output . . . . . . . . . . . . . . . . . . . . . . 4-23

YIG Control A202, Adjustment and Test Point Locations . . . . . . 4-24

Detected Modulation and 20 kHz Reference Pulse Timing . . . . . . 4-24

Converter Sequencer A203, Adjustment and Test Point

Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Return Loss Measurement Setup . . . . . . . . . . . . . . . . . . 4-26

Return Loss Measurement Waveform . . . . . . . . . . . . . . . . . 4-27

Typical Attenuator Control Ramp Offset . . . . . . . . . . . . . . 4-27

Comb Line . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Pulse, Electronic TD-1338(V)1/USM . . . . . . . . . . . . 1-0

Functional Block Diagram. . . . . . . . . . . . . . . . . 1-5

Functional Block Diagram . . . . . . . . . . . . 1-7

Page

FO-1

FO-2

FO-3A

FO-3B

FO-4A

FO-4B

FO-5A

FO-5B

FO-6A

FO-6B

FO-7A

FO-7B

FO-8A

FO-8B

FO-9A

FO-9B

FO-10A

FO-10B

iv

Counter Interconnection Schematic Diagram

Interconnection Diagram,

Component Locator Counter Interconnect (A100)

Schematic Diagram Counter Interconnect (A100)

Component Locator and Descriptive Information Count Chain Control (A102)

Schematic Diagram Count Chain Control (A102)

Component Locator and Descriptive Information Count Chain (A103)

Schematic Diagram Count Chain (A103)

Component Locator and Descriptive Information Control (A104)

Schematic Diagram Control (A104)

Component Locator and Descriptive Information Gate Generator (A105)

Schematic Diagram Gate Generator (A105)

Component Locator and Descriptive Information High Frequency (A106)

Schematic Diagram High Frequency (A106)

Component Locator and Descriptive Information Power Supply (A107)

Schematic Diagram Power Supply (A107)

Component Locator and Descriptive Information Reference Oscillator

Buffer (A108)

Schematic Diagram Reference Oscillator Buffer (A108)

Detailed Technical Schematic

Page 7

TM 11-6625-3031-14

Figure

FO-11A

FO-11B

FO-12A

FO-12B

FO-13A

FO-13B

FO-14A

FO-14B

FO-15A

FO-15B

FO-16A

FO-16B

LIST OF ILLUSTRATIONS

Title

Component Locator and Descriptive Information Display (A110)

Schematic Diagram Display (A110)

Component Locator Converter Interconnect (A200)

Schematic Diagram Converter Interconnect (A200)

Component Locator and Descriptive Information Source/Amplifier (A201)

Schematic Diagram Source/Amplifier (A201)

Component Locator and Descriptive Information Yig Control (A202)

Schematic Diagram Yig Control (A202)

Component Locator and Descriptive Information Converter Sequencer (A203)

Schematic Diagram Converter Sequencer (A203)

Component Locator and Descriptive Information IF Processor (A204)

Schematic Diagram IF Processor (A204)

(Continued)

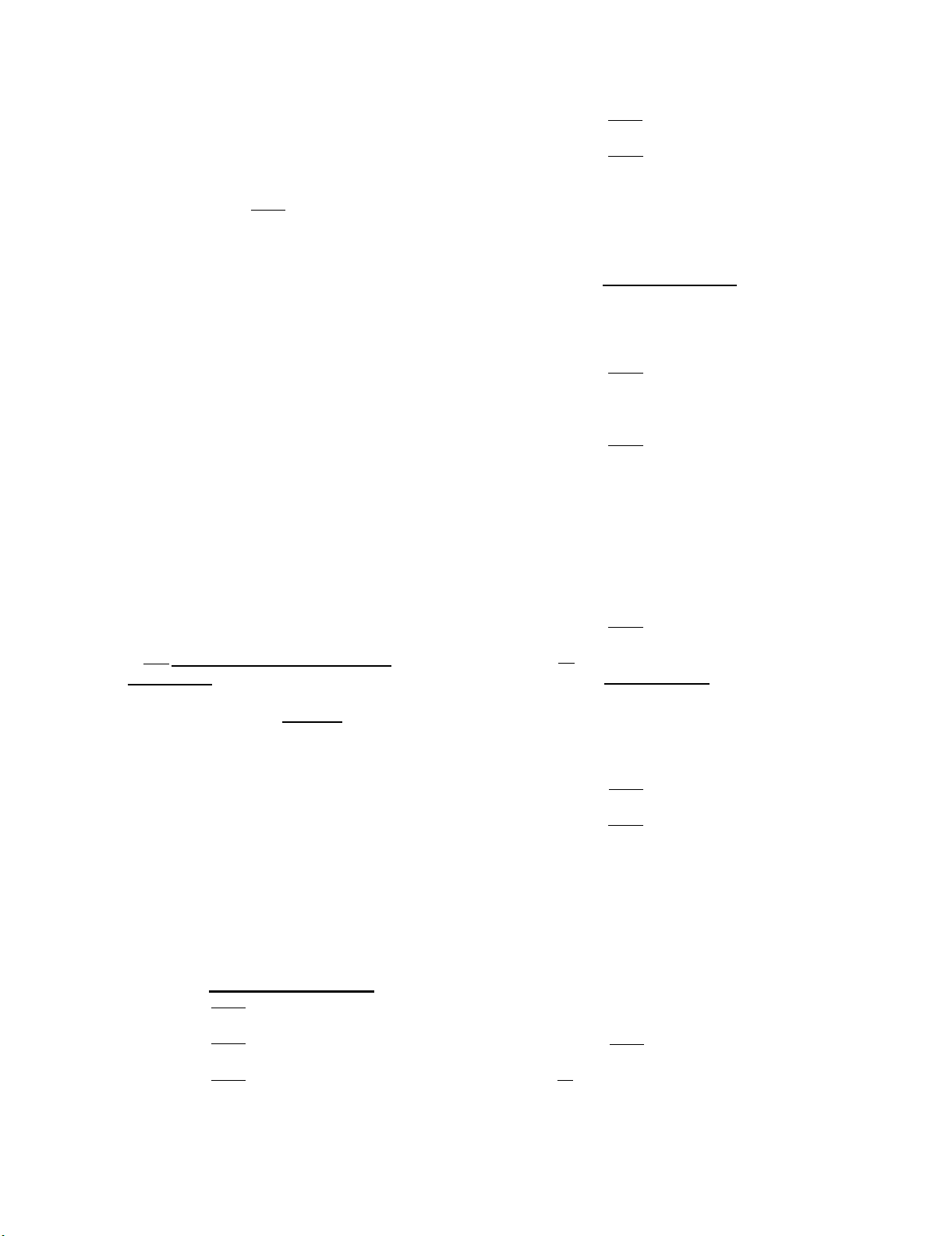

Table

1-1

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

3-1

4-1

4-2

4-3

4-4

4-5

4-6

4-7

LIST OF TABLES

Title

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . .

Front-panel Controls, Connectors and Indicators . . . . . . . . .

Rear-panel Controls and Connectors . . . . . . . . . . . . . . . .

Operator Preventive Maintenance Checks and Services . . . . . . .

Counter GPIB Capability Identification Codes . . . . . . . . . . .

GPIB IEEE STD 488/1975 Connector Pin Assignments . . . . . . . . .

On Line and Off Line ADDRESS SWITCH Settings . . . . . . . . . . .

ADDRESS SWITCH Settings vs ASCII Characters . . . . . . . . . . .

Programming Summary. . . . . . . . . . . . . . . . . . . . . . . .

Typical Program Using Hewlett-Packard 9815 Calculator as

Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator and Organizational Troubleshooting . . . . . . . . . . .

Symptom Index . . . . . . . . . . . . . . . . . . . . . . . . . .

Direct Support and General Support Troubleshooting . . . . . . . .

Power Supply Voltages and Adjustments . . . . . . . . . . . . . .

Band B Response Tests . . . . . . . . . . . . . . . . . . . . . .

Preset Frequency Tests . . . . . . . . . . . . . . . . . . . . . .

Control Sequence. . . . . . . . . . . . . . . . . , . . . . . , .

Converter Sequence Functions . . . . . . . . . . . . . . . . . . .

Page

1-1

2-1

2-5

2-6

2-14

2-16

2-17

2-18

2-20

2-26

3-1

4-2

4-4

4-22

4-29

4-31

4-45

4-65

v

Page 8

TM 11-6625-3031-14

1-0

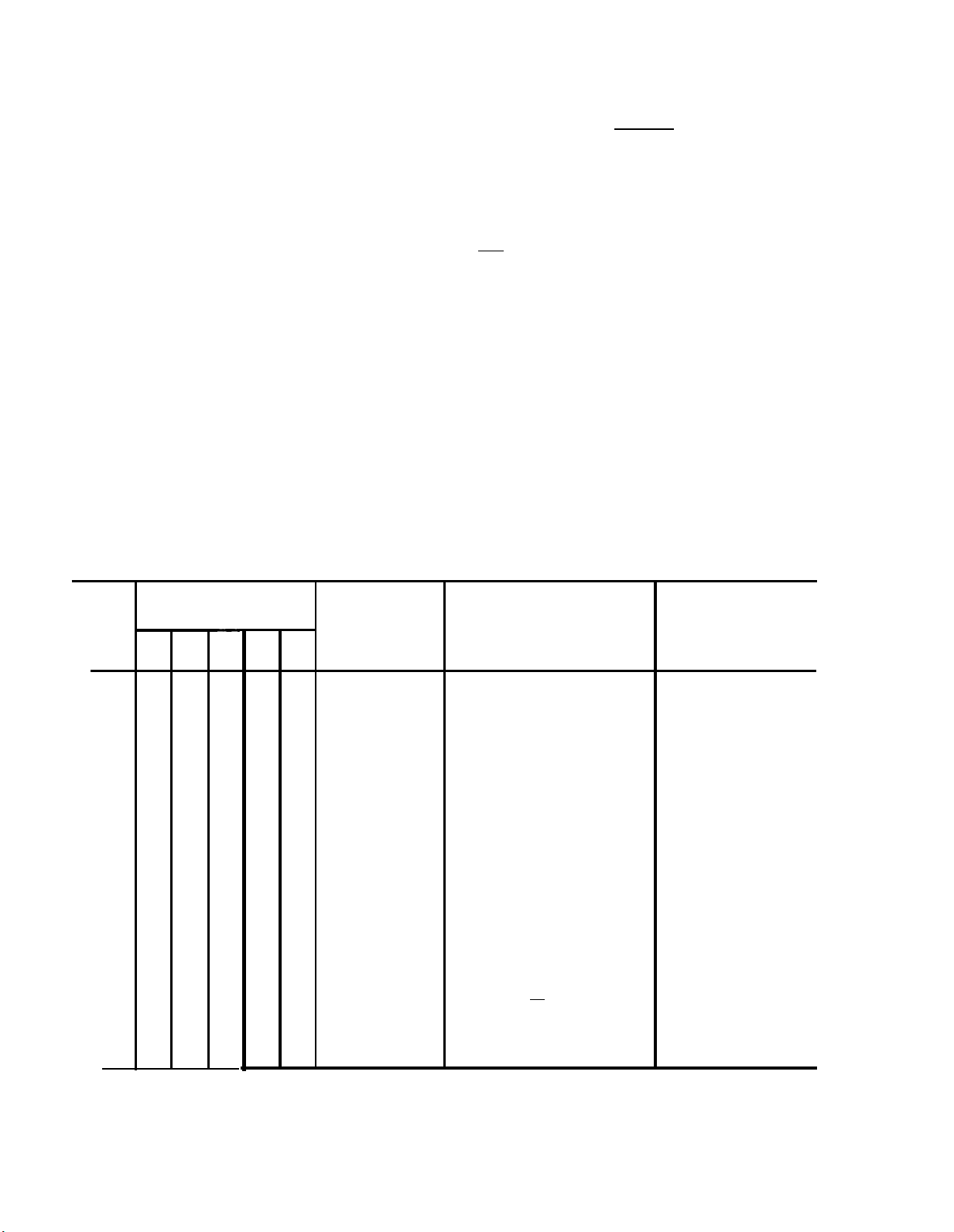

Figure 1-1.

Counter, Pulse, Electronic TD-1338(V)1/USM

Page 9

CHAPTER 1

INTRODUCTION

Section I. GENERAL INFORMATION

TM 11-6625-3031-14

1-1.

tion and maintenance of Counter, Pulse,

Electronic TD-1338(V)1/USM. Throughout

this manual it is referred to as the

counter.

measure the frequency of cw, pulsemodulated, or frequency-modulated

microwave signals between 300 MHz and

18 GHz.

as 100 nanoseconds, with a maximum

pulse repetition frequency of 2.5 MHz.

Peak-to-peak deviation of FM signals

may be as great as 40 MHz at 10 MHz

modulation rates.

1-2.

Records and Reports.

Unsatisfactory Equipment.

of the Army forms and procedures used

for equipment maintenance will be

those prescribed by TM 38-750, The

Army Maintenance Management System

(Army) .

AFM 66-1 for maintenance reporting and

TO 00-35D54 for unsatisfactory equipment reporting.

Deficiencies.

SF 364 (Report of Discrepancy (ROD)) as

prescribed in AR 735-11-2/DLAR 4140.55/

NAVMATINST 4355.73/AFR 400-54/MCO

4430.3E.

(DISREP) (SF 361). Fill out and forward

Discrepancy in Shipment Report (DISREP)

(SF 361) as prescribed in AR 55-38/

NAVSUPINST 4610.33B/AFR 75-18/MCO

P4610.19C/DLAR 4500.15.

Scope.

a. This technical manual covers opera-

b. The counter (fig. 1-1) is used to

Pulse widths can be as narrow

Reports of Maintenance Forms,

a. Reports of Maintenance and

Department

Air Force personnel will use

b. Report of Packaging and Handling

Fill out and forward

c. Discrepancy in Shipment Record

1-3.

issued to and used by Army activities

will have preventive maintenance per-

formed in accordance with the PMCS

charts before storing.

the equipment from administrative

storage, the PMCS should be performed

to assure operational readiness.

1-4.

Materiel.

materiel to prevent enemy use shall be

in accordance with TM 750-244-2.

1-5.

Recommendations (EIR’s).

let us know.

user,

what you don’t like about your equipment.

the design or performance.

SF 368 (Quality Deficiency Report).

Mail it to:

Communications-Electronics Command and

Fort Monmouth, ATTN: DRSEL-ME-MP,

Fort Monmouth, New Jersey 07703. We’ll

send you a reply.

1-6.

Microwave, Inc. for 12 months. It

starts on the date, found in block 23,

DA Form 2408-9, in the logbook.

all defects in material or workmanship

to your supervisor, who will take appropriate action through your organizational maintenance shop.

Administrative Storage.

Administrative storage of equipment

When removing

Destruction of Army Electronics

Destruction of Army electronics

Reporting Equipment Improvement

If your counter needs improvement,

Send us an EIR. You, the

are the only one who can tell us

Let us know why you don’t like

Put it on an

Commander, US Army

Warranty Information.

The counter is warranted by EIP

Report

1-1

Page 10

TM 11-6625-3031-14

Section II. EQUIPMENT DESCRIPTION

1-7.

Equipment Characteristics, Capa-

bilities and Features.

The counter is a portable test

instrument usable as either selfcontained frequency measurement or

monitoring indicator, or as part of a

programmable automatic test equipment

(ATE) system.

readout of frequency from 300

through 18 MHz.

It provides a direct

MHZ

Capabilities and

features include:

a. Measures pulse-modulated microwave

signals.

b. Measures frequency-modulated

microwave signals.

c.

Measures cw microwave signals.

d. Front panel self-test of digital

display.

Table 1-1. Specifications

Frequency Range:

Band A

e. Front panel self-test of internal

circuits.

f. Automatic and selectable resolution

of—readout display.

g. Overload protection built in at

input connector.

h.

Simple change to cover different

power line voltages.

i. Front-panel selection of frequency

scanning limits.

j. Comparable with IEEE STD 488

General Purpose Interface Bus (GPIB).

1-8.

Equipment Data.

Table 1-1 lists the electrical

and physical characteristics of the

counter.

300 MHz to 950 MHz

Band B

Pulse Characteristics:

Pulse width

Pulse repetition frequency

Accuracy:

CW or pulse > 100 µsec

Pulse < 100 µsec

Averaging Error (kHz rms):

100 µsec gate

1 msec gate

Gate error (max)

925 MHz to 18 GHz

100 nsec min, measured at 3-dB points

Minimum 50 Hz or 0 Hz, rear panel

selectable. Maximum 2.5 MHz. Minimum

time between pulses 300 nsec.

Time base accuracy ± 1 count

Time base accuracy ± averaging error

± gate error

Band A Band B

NOTE

PW =

pulse width in µsec

1-2

Page 11

TM 11-6625-3031-14

Table 1-1.

Time Base:

Crystal frequency

Stability:

Aging rate

Temperature

Line voltage

Sensitivity

Input Impedance

Connector Types

Maximum Input Peak Level:

Operating

Burnout level

Specifications - Continued

Temperature compensated crystal

oscillator

(TCXO)

10 MHz

<|3 X 10

<|2 X 10

<|1 X 10

-7

|

per month

-6

|

, 0 to 50°C

-7

|

for ± 10% change

Band A

300

- 950 MHz:

-10 dBm peak

50 ohms nominal

BNC

+10 dBm

+27 dBm

Band B

925 MHz - 10 GHz:

-10 dBm peak

10 GHz - 18 GHz:

-5 dBm peak

50 ohms nominal

N (precision)

+10 dBm

+30 dBm

Reading Time (sec):

100 µsec gate

1 msec gate

Display

Band B Minimum FM Tolerance:

CW

Pulse

Frequency profile

400

(PW) (PRF)

4000

(PW)(PRF)

100

(PW) (PRF)

1000

(PW) (PRF)

NOTE

PW =

PRF =

pulse width in µsec

pulse repetition frequency

in Hertz

7-digit light emitting diode (LED)

Fixed decimal point

Leading zero suppression

40 MHz p-p deviation for modulation

rates dc to 10 MHz

Without input inhibit:

20 MHz maximum

frequency shift across pulse

With input inhibit:

20 MHz maximum

frequency shift during input inhibit

pulse

1-3

Page 12

TM 11-6625-3031-14

Table 1-1.

Specifications - Continued

Band B Acquisition Time:

PRF > 100 H

Z

PRF < 100 Hz

Resolution

General Purpose Interface Bus (GPIB)

Power

Operating Temperature

Warm up Time

Weight

Dimensions (inches)

100 msec + 50 msec/GHz

100 msec +

sec/GHz

10 kHz, 100 kHz, 1 MHz

IEEE Standard Digital Interface for

Programmable Instrumentation, IEEE

STD 488-1975

115 or 230 Vac ± 10%, 50/60 Hz;

115 Vac ± 10%, 400 Hz; single phase;

100 watts nominal

0-

50°C

None Required

30 lb

3.5 H x 16.75 W x 19.0 D

Section Ill. TECHNICAL PRINCIPLES OF OPERATION

1-9.

Counter Functional Operation.

(Fig. 1-2.)

a. The counter automatically measures

and displays the frequency of cw or

pulse-modulated signals from 300 MHz

through 18 GHz. With accessory equip-

ment,

the counter can make dynamic

frequency measurements; measurement

windows as narrow as 20 nanoseconds are

possible.

Two primary input connectors

on the front panel, BAND A 300 - 950 MHz

and BAND B 925 MHz - 18 GHz, are used to

connect the counter to the external frequency source.

An auxiliary INPUT

INHIBIT connector on the rear panel can

be used to control the time during

which an actual reading is made.

Control of the counter can be accomplished

by front-panel switches or by a General

Purpose Interface Bus (GPIB) from an

external GPIB controller.

The output

of the counter is displayed on a 7digit, fixed decimal, light emitting

diode (LED) display and can be transmitted through the GPIB for other

purposes.

controlled by Reference Oscillator Buffer A108 with outputs to Basic Counter

Al and Converter A2; a third output is

connected to a rear-panel 10 MHz OUTPUT

connector.

divide-by-four circuit in Prescaler

A109, whose output is directed to Basic

Counter A1 through Dual Delay Line

A116.

counted in the basic counter for either

a 400 microsecond or 4 millisecond

period to obtain 10 kHz resolution readout on Display A110.

in A1 is enabled by the input signal and

is open only when a signal is present.

verter A2, converted to an IF signal by

heterodyning the input signal against a

200 MHz harmonic,

through Delay Line A112.

gate in A1 is enabled by the Input

signal and is open only when a signal

is present.

inversely proportional to the measurement

Accuracy of the counter is

Band A signals are fed into a

b.

The divide-by-four frequency is

The counter gate

Band B signals are fed into Con-

c.

and directed to A1

The counter

In A1, resolution is

1-4

Page 13

Figure 1-2.

1-5

TM 11-6625-3031-14

Page 14

TM 11-6625-3031-14

time.

For example:

a 1 microsecond

gate time will give 1 MHz resolution.

To get 10 kHz resolution, the counter

threshold comes from Prescaler A109

while the Band B threshold comes from

I.F. Processor A204 in Converter A2.

automatically averages as many input

pulses as necessary to obtain a total

gate time of 100 microseconds or 1 millisecond.

The required number of

pulses is a function of input pulse

width.

The intermediate frequency from

A2 is processed and counted in A1 and

displayed on A110.

d.

Three rear-panel connectors provide

10–MHz, SIGNAL THRESHOLD, and GATE OUT-

PUTS .

The 10 MHz OUTPUT is a service

convenience for adjusting the temperature compensated crystal oscillator

(TCXO) on Reference Oscillator Buffer

A108.

The other two signal outputs may

be used for dynamic frequency measurements such as pulse profile measurements

or time varying signal measurements.

e.

Power Supply A107 provides +5,

-5.2, +12,

counter circuits.

-12, and +18 volts dc for the

The +18 Vdc output is

unregulated; the other four voltages are

regulated.

processed into the range below 360 MH

and applied to the 400 MHz decade, the

frequency of the signal is determined by

accumulating the number of signal cycles

occurring within a precisely determined

time interval (gate). The gate period

is dependent on the 200 MHz reference

frequency.

gates are 100 microseconds and 1 milli-

second for Band B, or 400 microseconds

and 4 milliseconds for Band A. In order

to measure narrow pulses to a resolution

of 10 kHz, it is necessary to add the

number of cycles counted in each of a

large number of pulses until the

required total time interval is

obtained.

precision interval gate. This function

is considerably more difficult for

pulsed signals than it is for cw signals,

the overall accuracy of the counter

1-10.

Basic Counter A1.

(Fig. 1-3.)

depends.

it supplies a gate to A106 only when an

a. Input signals from either the low

range (300 -

(925 MHz -

950 MHz) or high range

18 GHz) sources, or both,

are applied to the signal processor

circuits on High Frequency Circuit

Card A106.

The signal from Prescaler

input signal is present, and it accumulates the total time of gate application

for periods of either 100 microseconds

or 1 millisecond for Band B, or either

400 microseconds or 4 milliseconds for

Band A.

A109 is the BAND A input frequency,

divided by four (f/4). The signal

from I.F. Processor A204 is the BAND B

input frequency minus the reference

frequency identified as the converter

IF signal.

Selection of which signal

to display is controlled by the front

panel BAND selection switches or by

GPIB selection.

Only one of the signal

inputs can be displayed even though

both may be connected to the counter.

The f/4 and the IF signal inputs are

360 MHz or lower and are directed to the

400 MHz decade circuits on A106.

Two threshold (Band A and/or

b.

Band B) control levels are applied to

Gate Generator A105 to provide a gate

output to the 400 MHz decade through

the gate calibrator.

The Band A

requires that the gate begin after the

signal is present at A106 and to end

before the end of signal. This is done

by generating a gate approximately 30

nanoseconds shorter than the RF signal

start as determined by the associated

Band A or Band B threshold level.

arrival time at A106 of the converter

IF or the prescaler f/4 signal is con-

trolled by delay lines in A116, in

series with the signals, so that the

gate will fall entirely within the signal pulse application.

counting clock pulses when the gate is

open until a total period of 100 micro-

seconds or 1 millisecond for Band B, or

400 microseconds or 4 milliseconds for

When an input signal has been

c.

Z

Total time intervals of the

d. Gate Generator A105 provides a

and it is on this function that

A105 performs two functions;

e. The first function or operation

The

f. The second function is done by

1-6

Page 15

Figure 1-3.

1-7

TM 11-6625-3031-14

Page 16

TM 11-6625-3031-14

Band A, is accumulated.

that each gate opening is for an exact

integral number of clock pulses.

MHz clock is used, causing the gate

width to increase in 5 nanosecond steps

until a total of 20,000 steps for

100 microseconds, 80,000 steps for

400 microseconds, 200,000 steps for

1 millisecond, or 800,000 steps for

4 milliseconds is accumulated.

g. The signal passes through the

counter gate and is accumulated in the

counting-chain first decade, the 400

MHz decade on A106.

(f/10) of the 400 MHz decade is fed to

the storage unit through the 6-decade

count chain of A103. The storage unit

on A103 holds all of the digital information from the previous reading.

put from the storage unit is fed to the

display multiplexer which is controlled

by count chain control circuits on the

Count Chain Control A102.

h. Output of the display multiplexer

on A102 is fed to Display A110.

mounted on the front panel along with

LEVEL, LOCK, and GATE status indicators.

The front-panel REMOTE indicator is used

with GPIB controller operations.

all control of the counter is performed

by Control Circuit Card A104. Frontpanel selection switching is routed to

A104 through GPIB Remote/Local Circuit

Card AM121.

REMOTE mode of operation, front-panel

controls and switches are inoperative

except for the SAMPLE RATE control, and

then only under certain programming

instructions from the GPIB controller.

1-11.

input microwave frequencies down to

frequencies between 100 and 360 MHz.

Translation is done by mixing the input

frequencies with a reference frequency

to produce, by heterodyne action, an

amplified intermediate frequency.

IF is then fed to A106 through Delay

Line A112 for counting and processing in

Basic Counter A1.

b. Generation of the heterodyning ref-

erence frequency starts by generating a

Converter A2.

a. Converter A2 translates the Band B

When the counter is in the

This requires

A 200

The signal output

Out-

A110 is

Over-

(Fig. 1-4.)

The

200 MHz reference signal in Source/

Amplifier A201. The 200 MHz reference

in A201 is generated by an L-C oscilla-

tor phase-locked to 10 MHz from Reference Oscillator Buffer A108.

MHz outputs from A201 are directed to

YIG (Yttrium-Iron-Garnet) Comb Generator

A207 and to Gate Generator A105 in

Basic Counter A1.

section on A201 amplifies the 200 MHz

signal before it is applied to A207.

The 200 MHz output to A105 is used to

generate a Band B gate or may be used

for a TEST 200 MHz self-test.

harmonic, frequency is generated in YIG

Comb Generator A207 by taking the 200

MHz signal from A201 and converting it

to a train of narrow pulses containing

all harmonics of 200 MHz up to 18 GHz.

This conversion is done by the YIG comb

generator and a two-stage YIG filter,

which selects the desired 200 MHz

harmonic. The YIG filter is tuned by

varying the current through a pair of

coils, which change magnetic fields in

the assembly.

to Limiter/Attenuator A206.

diode limiter protects Mixer A205 from

power levels in excess of one watt peak

(+30 dBm).

diode attenuator section controls the

RF signal level to the mixer and

switches off the input signal during

portions of converter operation.

wave circuit assembly consisting of a

hybrid coupler, termination, mixer

diode, and dc return. The mixer produces two output signals on a common

line:

ence frequency between the incoming RF

signal from A206 and the reference frequency harmonic from A207, and a video

signal resulting from rectification

(detection) of either the RF or reference inputs. The mixer output is fed to

I.F. Processor A204.

A205 are separated in A204. The IF signal is amplified by the IF amplifier and

sent on as the converter IF signal to

A106, through Delay Line A112, for

The 200

A power amplifier

c.

The local oscillator, or reference

d. Band B input signals are applied

A passive

A multistage matched PIN

e.

Mixer A205 is an integrated micro-

an IF signal equal to the differ-

f. The IF and video signals from Mixer

1-8

Page 17

Figure 1-4.

1-9

TM 11-6625-3031-14

Page 18

TM 11-6625-3031-14

counting.

The video signal is amplified

in the video amplifier to produce three

video outputs: (1) a threshold signal

is directed to the rear-panel SIGNAL

THRESHOLD connector through Prescaler

A109;

(2) a threshold signal, identified as attenuator control, is sent to

an attenuator control circuit on Con-

verter Sequencer A203; and

(3) an

analog output is applied to the power

level control portion of A203.

g.

On A203, inputs from the lock

section of I.F. Processor A204 are

sequenced and timed to produce a lock

level signal for Control A104 and a

Band B threshold signal for Gate Gen-

erator A105.

The attenuator control

threshold signal from the video section

of A204 is combined with an input from

the converter sequencer in the attenu-

ator control to give two outputs:

(1) an attenuator control signal, activated at a level approximately 7 dB

above signal threshold, sent to the PIN

attenuator of A206, to reduce signal

level into Mixer A205; and (2) a reduce

signal level sent to the front-panel

REDUCE SIGNAL indicator when the

attenuator control is sending a signal

to the PIN attenuator.

The power level

control circuit receives an analog input

from the video section of A204 and a

digital signal from the converter

sequencer of A203, and provides a signal

to the tuning circuits of A202 to set

the comb line amplitude.

The converter

sequencer function is to control the

sensing, leveling, and control of Converter A2.

YIG Control A202 contains circuits

h.

to step the YIG filter to the proper

comb line, and is controlled by input

lines from Converter Sequencer A204.

On-board circuits include a YIG driver

to supply the required current, a

digital-to-analog converter (DAC) to set

the approximate center frequency, and a

centering circuit to precisely center

the YIG filter passband on a comb line.

The centering process is done by modulating the YIG center frequency by an

auxiliary modulation coil in YIG Comb

Generator A207.

The modulation control

circuit is on A202.

1-10

Page 19

TM 11-6625-3031-14

CHAPTER 2

OPERATING INSTRUCTIONS

Section I. DESCRIPTION AND USE OF OPERATORS CONTROLS

AND INDICATORS

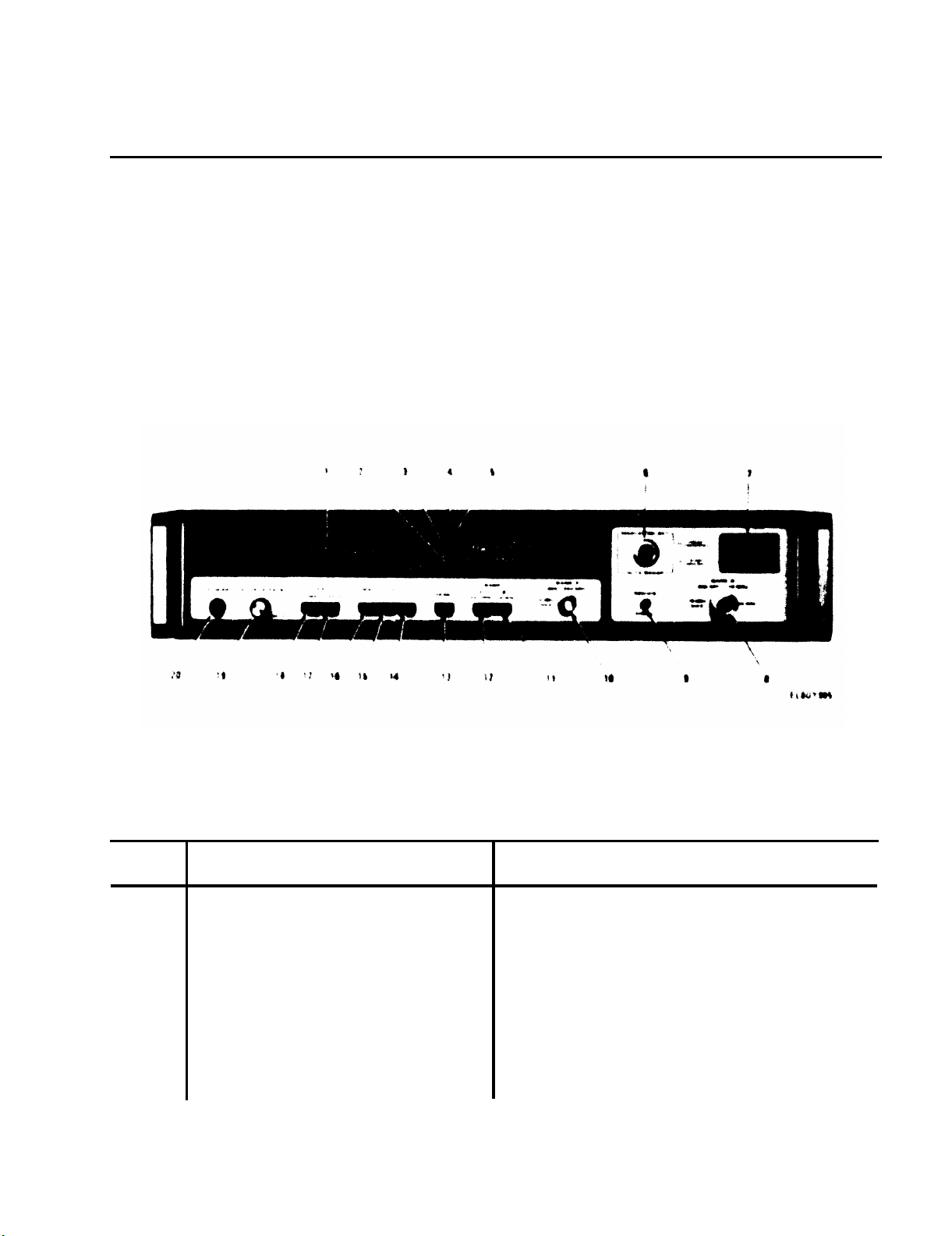

2-1.

and Indicators.

nectors and indicators are shown in fig-

ure 2-1 and are keyed to table 2-1,

which describes their functions.

Front-Panel Controls, Connectors

Operator’s front-panel controls, con-

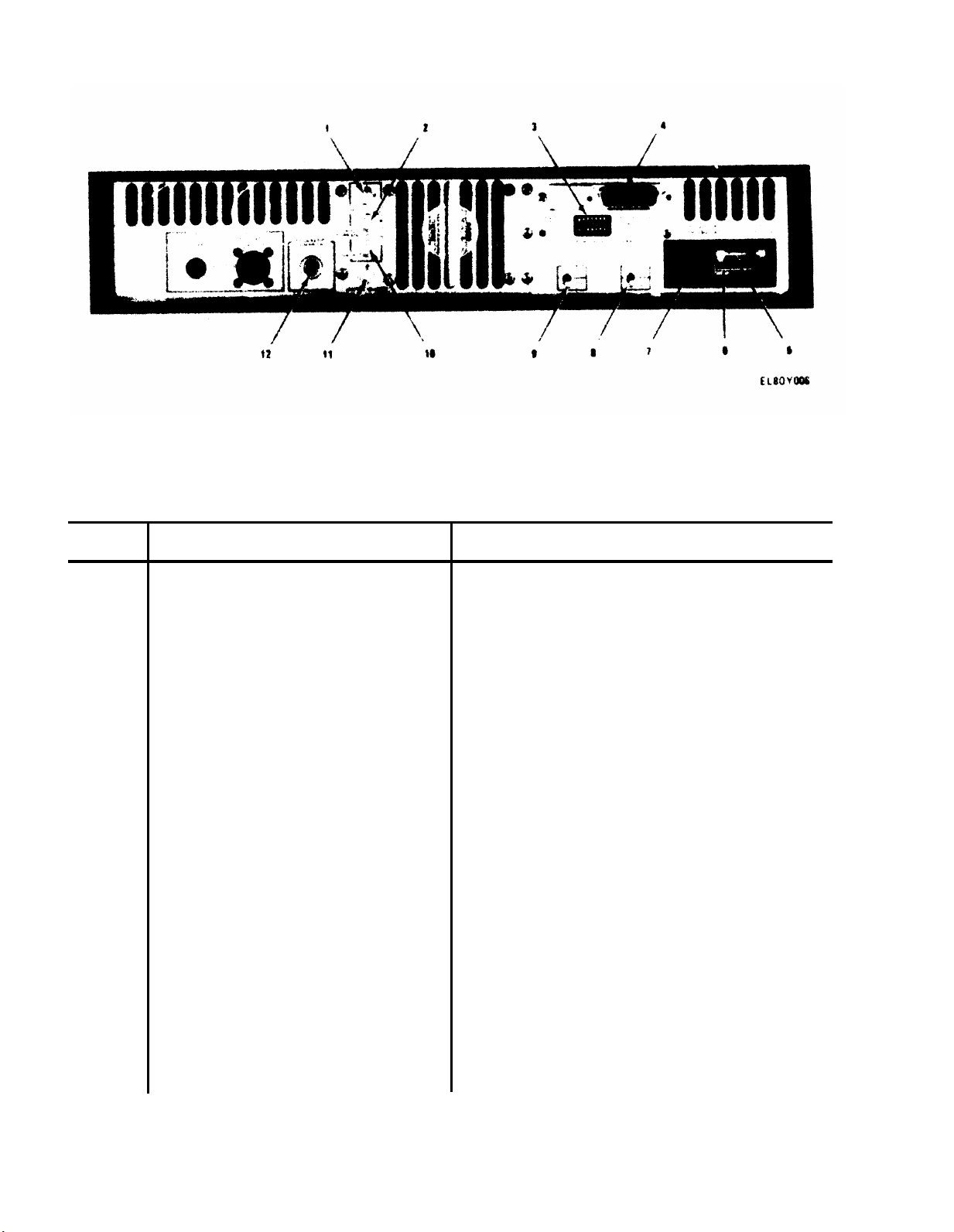

2-2.

Connectors.

connectors are shown in figure 2-2 and

are keyed to table 2-2, which describes

their functions.

Rear-panel Controls and

Operator’s rear-panel controls and

Key

1

2

Figure 2-1.

Table 2-1.

Control, connector

or indicator

Display

REMOTE indicator

Front-panel Controls,

Counter Front Panel

Connectors and Indicators

Functional operation

Seven-digit LED display provides

direct numerical readout of input

frequency in GHz and MHz.

When lighted, indicates that all

front-panel controls are disabled

except SAMPLE RATE. This indicator

is controlled by digital programmed

data on the General Purpose Interface Bus (GPIB) and by rear-panel

ADDRESS SWITCH.

2-1

Page 20

TM 11-6625-3031-14

Table 2-1.

Key

3

4

5

6

7

Front-panel Controls,

Control, connector

or indicator

GATE indicator

LEVEL indicator

LOCK indicator

MANUAL SELECT/AUTO SWEEP

switch

PRESET FREQUENCY/START

FREQUENCY thumbwheel

switch

Connectors and Indicators - Continued

Functional operation

Lights when counter is in measurement portion of cycle.

Lights when input signal level is

high enough to be counted. Light

will blink if signal pulse repeti-

tion frequency is too low.

Lights when input signal has been

acquired.

Selects either manual or automatic

operation of counter for BAND B.

When MANUAL SELECT/AUTO SWEEP switch

(6) is set to MANUAL SELECT, thumb-

wheel switch sets PRESET FREQUENCY;

input signal frequency must be 105

to 325 MHz higher.

SELECT/AUTO SWEEP switch is set to

AUTO SWEEP, thumbwheel switch sets

sweep START FREQUENCY; input signal

frequency must be at least 105 MHz

higher than sweep start.

When MANUAL

8

9

10

11

12

13

14

BAND B 925 MHz - 18 GHz

connector

REDUCE SIGNAL indicator

BAND A 300 - 950 MHz

connector

BAND B pushbutton switch

BAND A pushbutton switch

RESET pushbutton switch

1 ms GATE pushbutton

switch

Type N precision input connector

for Band B operation.

Lights when Band B input power

approaches maximum safe operating

level.

Type BNC input connector for Band A

operation.

Selects Band B operation for frequencies between 925 MHz and 18 GHz.

Selects Band A operation for frequen-

cies between 300 and 950 MHz.

When pushed and released, overrides

SAMPLE RATE control, resets display

to zeros,

reading.

When pushed in, provides 10 kHz

resolution with 1 millisecond gate

time on Band B or 4 millisecond gate

time on Band A for reduced pulse

averaging error.

and initiates a new

2-2

Page 21

TM 11-6625-3031-14

Table 2-1.

Key

15

16

17

18

Front-panel Controls, Connectors and Indicators - Continued

Control,

or ind

connec

icator

tor

Right RESOLUTION pushbutton

switch

Left RESOLUTION pushbutton

switch

TEST DISPLAY pushbutton

switch

TEST 200 MHz pushbutton

switch

Functional operation

Provides blanking of least signifi-

cant digit for resolution of 100 kHz

with 100 microsecond gate time on

Band B or 400 microsecond gate time

on Band A.

Provides blanking of two least significant digits for resolution of

1 MHz with 100 microsecond gate time

on Band B or 400 microsecond gate

time on Band A.

When pushed and held in, provides

test of all segments of display

LEDS.

Display should read

88 888.88.

When pushed and held in, provides

check of counting circuits.

Display

should indicate 200.00 MHz.

19

20

SAMPLE RATE control

POWER pushbutton switch

Continuously variable control which

varies display time from 0.1 to 10

seconds per reading.

Rotating con-

trol to its switched HOLD position

will cause display to hold last

reading without an update until

RESET switch (13) is pushed in.

When pushed in and released, power

counter is turned on or off.

power is on,

a green indicator is

When

visible in switch.

2-3

Page 22

TM 11-6625-3031-14

Key

1

2

3

Figure 2-2.

Table 2-2.

Rear-panel Controls and Connectors

Control or connector

10 MHz OUTPUT connector

SIGNAL THRESHOLD OUTPUT

connector

GPIB IEEE STD 488/1975

ADDRESS SWITCH

Counter Rear Panel

Functional operation

Provides output of internal 10 MHz

clock; 1 Vp-p minimum into 50 ohms.

Provides pulse output representing

signal threshold level of input

pulse.

Output pulse typically

delayed 20 nanoseconds from input

pulse.

Used for frequency profile

measurements.

Address switches of counter when

General Purpose Interface Bus (GPIB)

is used.

Setting of various combi-

nations of seven switches permits

the counter to be operated in Talk,

Listen,

or Monitor modes when external GPIB controller is connected

to counter.

2-4

4

GPIB IEEE STD 488/1975

connector

5

Fuse

Provides connection to external

GPIB controller.

Slow-blow line fuse; 1.5 A at

115 Vac or 0.75 A at 230 Vac.

6

Line voltage selector

card

Selects either 115 or 230 Vac line

voltage.

Selected voltage printed

on card is visible when card is

installed.

Page 23

TM 11-6625-3031-14

Key

7

8

9

10

Table 2-2.

Control or connector

AC power connector

MIN. PRF switch

STORAGE switch

GATE OUTPUT connector

Rear-panel Controls and Connectors - Continued

Functional operation

Three-prong male connector for ac

power cable.

grounding meets NEC and UL

requirements.

Selects minimum prf.

to 50 Hz position.

counter will measure very low prf

signals but reading will not auto-

matically reset when signal is

removed.

Controls display update.

ON; in OFF position front-panel

display updates continuously during

measurement cycle.

Provides gate pulse representing

actual time at which measurement is

being made. Used in frequency

profile measurements.

Third conductor

Normally set

In 0 position,

Normally

11

12

INPUT INHIBIT connector

ACCESSORY POWER OUT

connector

Connector for external pulse input

for use in frequency profile

measurements.

Provides +5, -5.2, +12, and -12 Vdc

for accessories used with counter,

such as EIP Model 400 Delay

Generator.

Section II. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

2-3.

mind

your

mind

your

form

Troubleshoot with proper equipment.

Report any deficiencies using the proper

forms.

General Instructions.

Before you operate.

a.

the CAUTIONS and WARNINGS. Perform

before (B) PMCS.

b.

While you operate.

the CAUTIONS and WARNINGS.

during (D) PMCS.

After you operate.

c.

your after (A) PMCS.

d.

If your equipment fails to operate.

See TM 38-750.

Always keep in

.

Always keep in

Perform

Be sure to per-

2-4.

be performed at specific intervals.

These checks and services are to maintain Army electronic equipment in a

combat serviceable condition; that is,

in good general (physical) condition

and in good operating condition. To

assist operators in maintaining combat

serviceability, the chart indicates what

to check.

"Equipment is not ready/available if:"

column,

PMCS Procedures.

Table 2-3 outlines the functions to

If any entry appears in the

appropriate corrective

2-5

Page 24

TM 11-6625-3031-14

maintenance

restore the

condition.

2-5.

table 2-3, remove dust and loose dirt

with a clean soft cloth.

Cleaning Instructions.

a. At the interval specified in

—

action must be taken to

counter to an operational

Table 2-3.

Operator Preventive Maintenance Checks and Services

Within designated interval, these checks are

to be performed in the order listed.

B-

Before

D

- During

A

- After

NOTE

CAUTION

Do not use any solvent except

water or a mild detergent to

clean the plastic front panel of

the counter.

damage the panel.

b.

Clean external surfaces with a

clean soft cloth moistened with clean

water.

more effective cleaning.

A mild detergent may be used for

W-

Weekly

M-

Monthly

Other solvents may

Item

No.

1

2

3

4

5

6

B

x

x

Interval

DxA

WxM

Item to be

inspected

Completeness

Power cable

.

Controls and

hardware

Exterior

x

surfaces

Nameplate

x

Operational

capability

Procedures -

check for and have

repaired or adjusted

as necessary

Power cable connected

to counter.

Cuts or cracks in

outside jacket;

damage to connector

pins.

Missing or loose

knobs or hardware

Clean exterior

surfaces.

Legibility.

Perform self-test,

para 2-7 b (2).

Equipment

is not ready/

available if:

Power cable is

missing.

Power cable is

defective.

Self-test

indications

are incorrect.

2-6

Page 25

TM 11-6625-3031-14

Section III. OPERATION

2-6.

carton for signs of damage before opening.

request that the shipper’s agent be pres-

ent when the counter is unpacked.

Visible and concealed damage claims

against the carrier or shipper can only

be filed if the agent is present or

waives his rights.

instrument supports and packing

materials.

counter.

Without applying power, check the mechan-

ical operation of all controls and

switches.

are selection of either 115 Vac or 230

Vac line voltage and connecting the

power cable to the instrument.

ready for operation from a 115 Vac power

line, with a 1.5 ampere slow-blow fuse

installed.

voltage selector card (6, fig. 2-2),

visible through the window in the fuse

cover,

volts.

Assembly and Preparation for Use.

a. Unpacking.

—

(1) Visually inspect the shipping

If there is any apparent damage,

(2) Open the carton, removing

Carefully lift out the

Inspect the counter for damage.

b. Assembly

—

(1) The only assembly requirements

Be sure only the specified power

cable is used.

is provided with a 3-wire cable

which grounds the instrument

cabinet.

be inserted in a socket outlet

provided with a protective ground

contact.

should not be negated by the use

of an extension cord without a

protective ground conductor.

(2) The counter is normally shipped

to be certain that it reads 115

The FUSE FULL lever attached to

the body of the power module

housing does not come off.

This cable should only

This protective action

Check the marking on the line

The instrument

CAUTION

Firm

UNDER USUAL CONDITIONS

lifting up on the FUSE PULL lever and

check that it is a 1.5 ampere fuse.

with one of the correct value and con-

nect the power cable to the ac power

connector.

operation,

slide the fuse cover to the left and

remove the fuse by lifting up on the

FUSE PULL lever; see CAUTION above.

selector card.

appropriate marking (115 or 230 volts)

will be visible when the card is

inserted into the card slot.

but firmly insert the card into the

slot, being careful not to cant or tilt

the card while inserting.

seating by sliding the fuse cover from

left to right.

seating, slide the fuse cover back to

the left to gain access to the fuse

clip.

the correct value (1.5 amperes for 115

Vat, 0.75 ampere for 230 Vac) in the

fuse clip;

puller does not obstruct the fuse cover

by sliding the fuse cover to the right.

the ac power connector.

special procedures are necessary if the

counter is used as a stand-alone test

instrument.

ing the signal to the selected connector and selecting the desired switches

and controls is all that is required.

but careful rotation of the fuse

puller will lift up one end of the

fuse so that finger force can re-

move the fuse. Failure to heed

this caution by exerting too much

force may damage the plastic pivot

of the built-in fuse puller.

(3) Remove the installed fuse by

(4) Reinstall or replace the fuse

(5) To change the line voltage

proceed as follows:

(a)

On the rear of the counter,

(b)

Extract the line voltage

(c)

Rotate the card so that the

Carefully

Check the

After checking the card

(d) Insert a slow-blow fuse of

check that built–in fuse

(e)

Connect the power cable to

c. Preparation for Use.

—

(1) Stand-alone Operation. No

Applying power and connect-

2-7

Page 26

TM 11-6625-3031-14

(2) GPIB Operation. Installation

of the counter in a GPIB-controlled

system will vary with console or rack

hardware.

cedures can be suggested.

counter are 3.5 inches high by 16.75

inches wide by 19 inches deep.

mounting kits are available from the

manufacturer of the counter to mount

the instrument in a standard 19 inch

width rack-mount cabinet or console.

Ventilation of the counter is through

the rear panel so it is not necessary

or desirable to remove the top and bot-

tom covers for cooling.

covers should remain in place secured

by screws to retain RFI integrity.

required to control selector switches

and the GPIB address switches.

panel ventilating louvers and blower

should not be blocked off from free air

flow.

sources to—the counter front-panel con-

nectors should be as short as possible.

A common ground bus should tie the

counter to other instruments and the

GPIB controller.

cable is not critical but the supplied

cable should be retained and plugged

into a powerline strip.

interface cable should be as short as

feasible and should be shielded against

RFI to reduce data transmission con-

tamination.

program controller may be connected,

provided that the controller meets IEEE

Standard 488/1975.

2-7.

Instrument.

a. Operating Modes.

three principal modes of operation:

automatic, manual, and externally enabled.

MHz) is automatic;

(925 MHz matic or manual.

operation covers specific measurement

techniques.

Therefore only general pro-

(a)

The dimensions of the

Rack

Top and bottom

(b)

Access to the rear panel is

The rear

(c) Leads from frequency

The length of power

(d)

The length of the GPIB

Any keyboarding or fixed

Operation as Stand-alone

The counter has

Operation on Band A (300 - 950

operation on Band B

18 GHz) may be either auto-

Externally enabled

Signals may be connected to

both the BAND A and BAND B inputs at the

only the input frequency selected by the

appropriate BAND pushbutton switch on

panel switches as follows.

ADDRESS SWITCH 7 to 0 (top of switch

depressed).

light and the internal cooling fan

should operate.

of the two RESOLUTION switches and

release it, so that neither switch

remains in a depressed position.

digits in the display should indicate

zero.

switch.

88 888.88 while the switch is held in.

Release the switch.

switch.

200.00, with the two leading zeros

blanked (unlighted), while the switch is

held in.

switch and again hold the TEST 200 MHz

switch in.

200.0, with the two leading zeros

blanked.

digit immediately above the switch

which has been depressed, and any digit

by repeating step (b).

same time,

the front panel.

b. Preliminary Procedures.

—

(1) Rear-panel Switches. Set rear-

(2) Self-test.

turn on the counter. The display should

switch in turn and note that the display

to the right, is blanked.

c. Band A (300 -

Peak power applied to the BAND A

input connector should be between

-10 and +10 dBm for normal operation.

but the counter will display

(a)

GPIB IEEE STD 488/1975

(b)

MIN. PRF switch to 50 Hz.

(c)

STORAGE switch to ON.

(a) Press the POWER switch to

(b)

Partially depress either

All

(c) Press the TEST DISPLAY

The display should indicate

(d)

Press the TEST 200 MHz

The display should indicate

Release the switch.

(e)

Press the right RESOLUTION

The display should indicate

Release the switch.

(f)

Press each RESOLUTION

(g)

Unblank all display digits

950 MHz) Operation.

CAUTION

Peak input must not

2-8

Page 27

exceed +27 dBm or damage to the

counter may result, even if the

counter is turned off.

(1) Perform the preliminary proce-

dures of step b.,

(2) Connect the signal source to

the BAND A input connector.

(3) Depress the BAND A switch.

(4) Depress the desired RESOLUTION

switch.

(5) If the input signal level is

high enough for counting, both the LEVEL

and LOCK indicators will light, and the

measured frequency will be displayed.

The REDUCE SIGNAL indicator is

inoperative on Band A.

(6) Turn the SAMPLE RATE control to

provide the desired display update rate.

The GATE indicator will flash in accord-

ance with the sample rate.

control is set to its switched HOLD

position,

last reading.

desired, press and release the RESET

switch.

d. Band B (925 MHz - 18 GHz)

Operation.

Peak power applied to the BAND B

input connector should be within

the following ranges for normal

operation:

925 MHz - 10 GHz: -10 to +10 dBm

10 -

The peak input power must not ex-

ceed +30 dBm or damage to the

counter may result, even if the

counter is turned off.

procedures of step b above.

to the BAND B input connector.

the display will retain the

18 GHz:

(1) Initial Procedures.

(a)

(b)

(c)

above.

NOTE

If the

If a new reading is

CAUTION

-5 to +10 dBm.

Perform the preliminary

Connect the signal source

Depress the BAND B switch.

RESOLUTION switch.

is high enough for counting, both the

LEVEL and LOCK indicators will light.

If the REDUCE SIGNAL indicator lights,

the input signal power is approaching

the maximum safe operating level and

should be reduced.

matic mode,

input signal by sweeping from a start

frequency which is 105 MHz above a preset frequency.

SWEEP switch to AUTO SWEEP. For full

search,

switches to 00.0 GHz.

speed, the sweep start frequency may be

set by means of the START SWEEP thumb-

wheel switches.

which can then be acquired and displayed

will be 105 MHz above the switch set-

tings; erroneous readings may be displayed if the frequency of the applied

signal is less than 105 MHz above the

switch settings.

control as described in paragraph

2-7 c (6).

mode,

reducing the acquisition time. However,

the signal frequency to be measured

must be between 105 and 325 MHz above a

preset frequency.

SWEEP switch to MANUAL SELECT.

thumbwheel switches so that they indi-

cate a frequency 105 to 325 MHz lower

than the signal frequency. For example,

if the frequency to be measured is ex-

pected to be 12.35 GHz, the thumbwheel

switches should be set to indicate 12.2

GHz, which places the input frequency

105 to 325 MHz above the preset frequency.

played if the frequency of the applied

signal is outside the preset range.

control as described in paragraph

2-7 c (6).

TM 11-6625-3031-14

Depress the desired

(d)

(e)

If the input signal level

(2) Automatic Mode. In the auto-

the counter searches for the

(a)

Set the MANUAL SELECT/AUTO

set the START SWEEP thumbwheel

(b)

To improve acquisition

The lowest frequency

(c)

Adjust the SAMPLE RATE

(3) Manual Mode. In the manual

the search sweep is inhibited,

(a)

Set the MANUAL SELECT/AUTO

(b)

Set the PRESET FREQUENCY

Erroneous readings may be dis-

(c)

Adjust the SAMPLE RATE

2-9

Page 28

TM 11-6625-3031-14

2-8.

panel INPUT INHIBIT connector makes

possible a class of measurements known

as dynamic frequency

measurements made at a specified point

in time on a signal whose frequency is

some repetitive function of time.

a high emitter-coupled-logic (ECL) level

is applied,

from making a measurement. Thus a signal at the INPUT INHIBIT connector can

be used as an enable signal to make a

measurement at a desired time.

width of the enable signal determines

the duration of the measurement, typi-

cally 30 nanoseconds less than the

applied pulse.

INPUT INHIBIT circuit is designed to be

compatible with either a 50 ohm imped-

ance pulse generator or ECL devices.

An internal termination of 50 ohms

returned to -2 volts makes this dual

compatibility possible.

level signal (-0.8 to -1.1 V) will

inhibit measurement, while an ECL low

level signal (-1.5 to -2.0 V) will

enable measurement.

designed to drive 50 ohm lines without

reflections when the lines are termi-

nated with 50 ohms returned to -2 V.

The direct compatibility with a 50 ohm

pulse generator results from the fact

that zero volts from a 50 ohm source

will produce

(inhibiting the counter), while a -1 V

signal into 50 ohms will produce -1.5 V

at the INPUT INHIBIT thus enabling the

counter.

2-9.

Externally Enabled Operation.

a.

Function.

b.

INPUT INHIBIT Requirements.

Pulse Profile Measurements

The use of the rear-

measurements -

the counter is inhibited

An ECL high

ECL devices are

-1 V at the INPUT INHIBIT

The

When

The

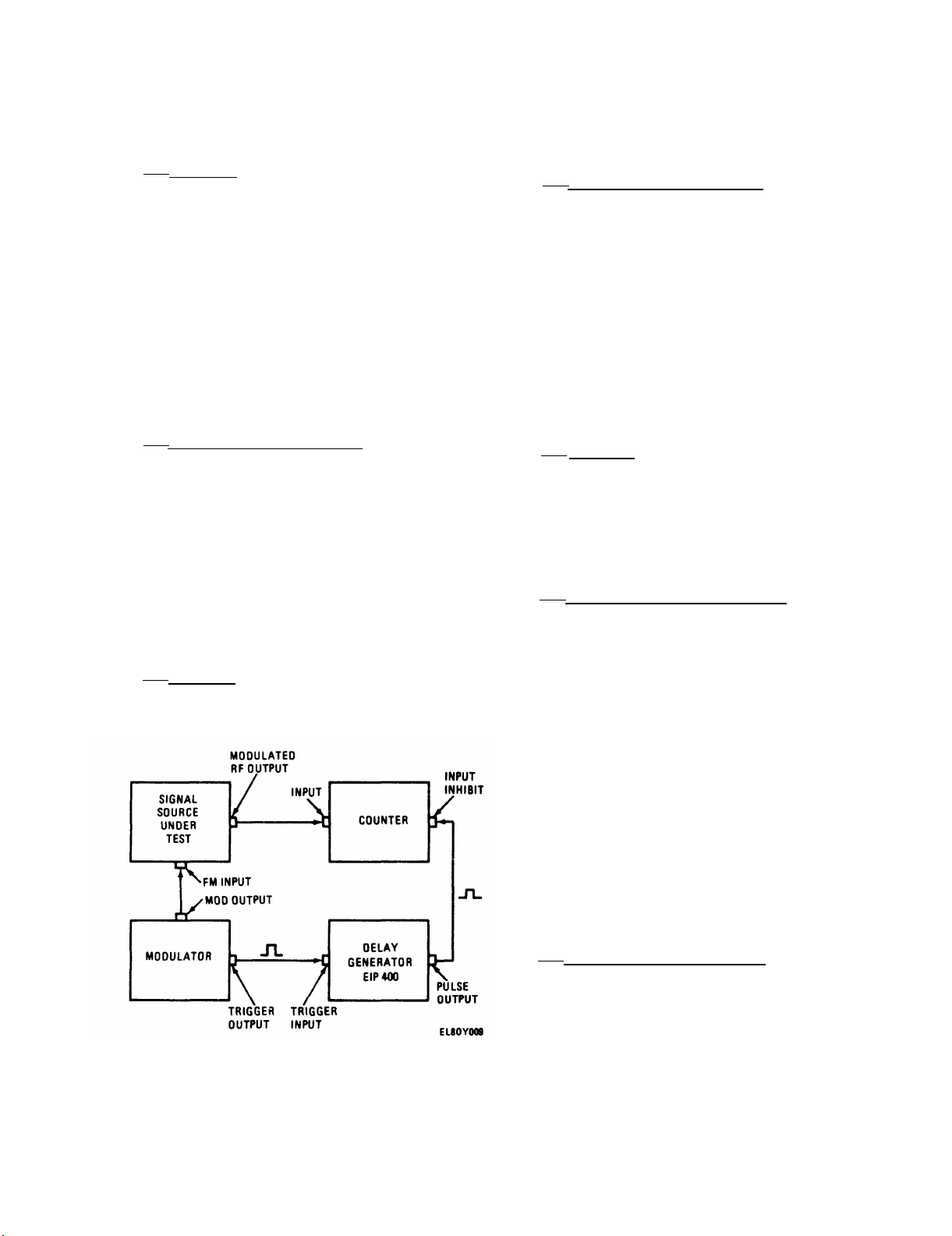

ments of these characteristics are

easily made with the counter and a

delaying pulse generator (see fig. 2-3).

The SIGNAL THRESHOLD OUTPUT of the coun-

ter is used to trigger the pulse genera-

tor. The generator’s output pulse is used

as an enable input to the counter. As the

pulse delay is varied, the measurement

window can be “walked” through the pulse.

A plot of frequency versus delay gives

the frequency-versus-time profile of the

pulse directly as shown in fig. 2-4. The

width of the measurement window is deter-

mined by the width of the pulse genera-

tor output.

nanoseconds or less can be used, although

wider windows yield higher accuracy.

b. Measurement Technique. Measure-

Figure 2-3.

Measurement Test Setup

Measurement windows of 50

Pulse Profile

a. Purpose.

ments can determine the average fre-

quency of a pulse.

however,

necessary.

tron may exhibit substantial frequency

shift near the leading and trailing

edges of the pulse, or a pulsed Gunn

diode oscillator may exhibit frequency

shift during a pulse due to peak power

thermal effects.

2-10

additional information may be

Automatic pulse measure-

In some cases,

For example,

a pulse magne-

Figure 2-4.

Pulse Profile Measurement

Page 29

TM 11-6625-3031-14

2-10.

Varying Signals.

not pulses at all but simply continuous

signals whose frequency varies repetitively with time. One example is the

measurement of the response of a device

such as a voltage-controlled oscillator

(VCO).

tuning voltage will produce a response

curve of frequency versus time, allowing

measurement of various settling times

such as post-tuning drift.

sible application would be the measure-

ment of linearity and amplitude for

frequency-modulated radar altimeter

signals.

shows a test setup designed to make

measurements on time varying signals.

It is similar to the pulse profile test

setup, except that in this case, since

there is always a signal present, a

trigger must be obtained from the modulating source.

pulse generator which controls the

measurement.

2-11.

Measurements.

ment is that of a repetitive sequence of

pulses differing in frequency. In this

Dynamic Characteristics of Time

a.

Purpose.

A square wave applied to the

b. Measurement Technique.

Multiple Pulse Signal

a.

Purpose.

Figure 2-5.

Measurement Test Setup

Many complex signals are

Another pos-

Fig. 2-5

This will trigger the

Another type of measure-

Time Varying Signal

measurement window is the period during

which the gate is actually open to enable the counting of a signal.

gate width will typically be 30 nanoseconds narrower than the pulse applied

width of the gate is always an integral

number of clock periods (5 nanoseconds).

For applications where the measurement

window needs to be known to an accuracy

better than 20 nanoseconds, it is rec-

ommended that the GATE OUTPUT on the

rear panel be observed directly on a

high speed oscilloscope. The desired

gate width may then be set by varying

the INPUT INHIBIT pulse width.

accurate pulse representation, the

oscilloscope input should be terminated

in a 50 ohm load.

necessary to measure the signal frequency at a precise point in time, the

internal delays of the measuring instrument can be significant. The total

delay between the time a signal is

applied to the counter input connector,

and the time it is available to be

case, it is desirable to measure the

frequency of each pulse in the sequence

separately.

b. Measurement Technique. The same

test setup as shown in fig. 2-5 is

required, with the trigger pulse syn-

chronous with the sequence.

measurement,

simply to discriminate between pulses.

The enabling pulse can be slightly

wider than the pulse to be measured.

The counter will automatically restrict

the measurement window entirely within

the pulse.

the enabling pulse,

the sequence can be separately measured.

2-12.

internal timing within the counter is of

no concern to the user.

applications where a few nanoseconds are

significant,

operation are important.

two areas:

and internal timing delays.

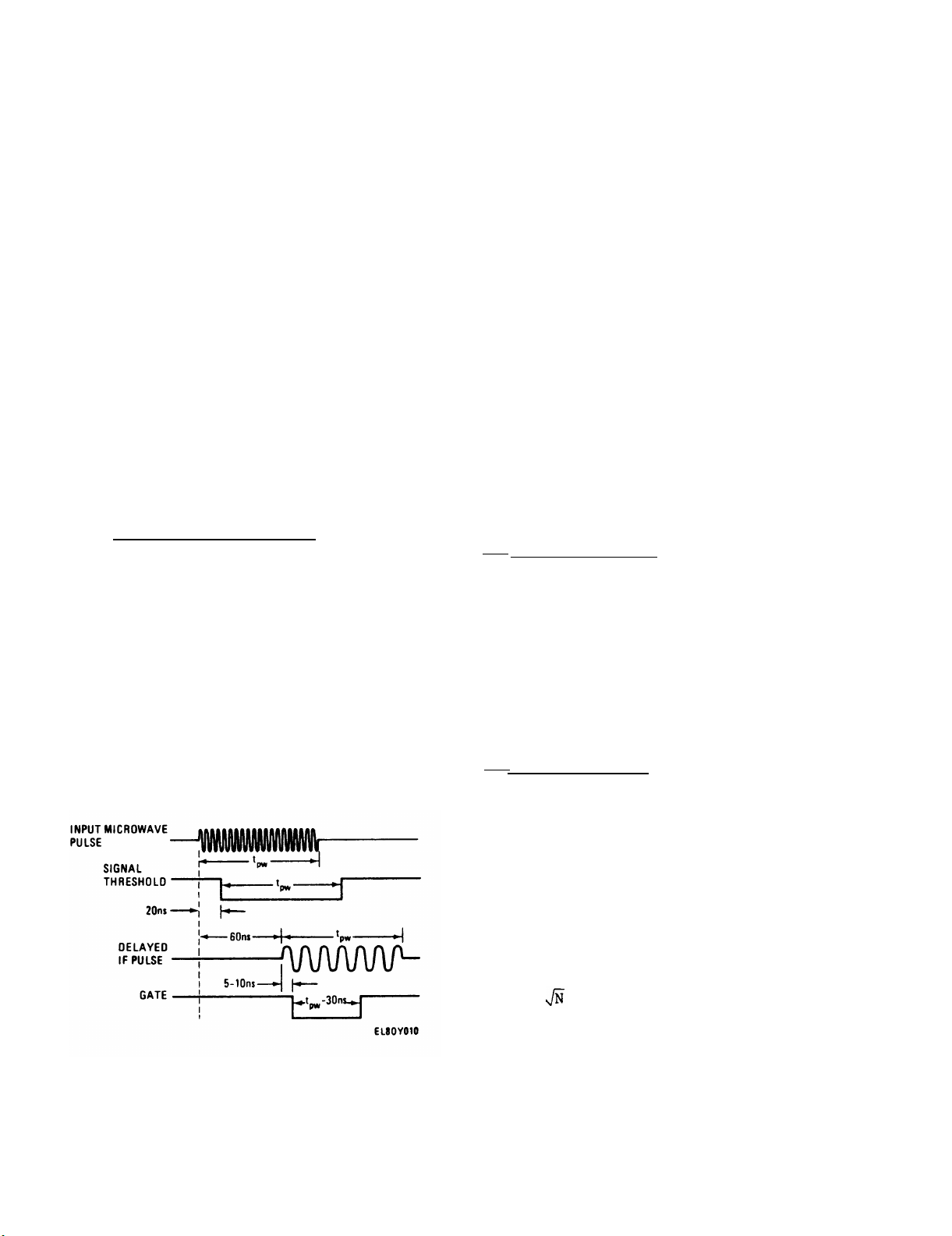

b. Measurement Window Width. The

to the INPUT INHIBIT connector.

c.

Timing Considerations.

a.

General.

Internal Timing Delays.

the INPUT INHIBIT is used

By shifting the delay time of

each input pulse of

Under most circumstances,

some details of internal

measurement window width

In this

However, in

These involve

This

The

For

When it is

2-11

Page 30

TM 11-6625-3031-14

counted,

The SIGNAL THRESHOLD OUTPUT on the rear

panel typically occurs 20 nanoseconds

after the signal is applied.

OUTPUT at the rear panel occurs at the

measurement time with virtually no

delay.

time positioning of a signal is required,

it is necessary to consider that the

GATE OUTPUT signal,

measurement period, is actually making

a measurement of the signal which

appeared at the input connector 60 nano-

seconds earlier. If the SIGNAL THRESHOLD OUTPUT is used as an indication of

input signal, then it occurs 40 nano-

seconds prior to measurement.

shows the relative timing of these signals for a pulsed input signal.

however, is not a function of input signal characteristics.

2-13.

a. General Considerations.

—

measurement accuracy is generally speci-

fied as time base accuracy ±1 count.

This means that the frequency measurement is in error by the same percentage

as the time base reference oscillator.

The maximum error in the time base is

the sum of various possible errors,

such as aging rate, temperature, etc.

count, is derived from the relative

timing of gate and signal.

stated, if an event occurs every 400

milliseconds,

Figure 2-6.

is nominally 60 nanoseconds.

The GATE

In other words, when absolute

which represents the

Fig. 2-6

Timing,

Accuracy.

(1) In a cw frequency counter,

(2) The second type of error, ±1

Simply

a counter could measure

Internal Timing Delays

either 2 or 3 events in a one second

interval,

signal and the gate are asynchronous.

error in a cw counter is gate error.

A gate is supposed to represent a precise number of reference oscillator

cycles.

in the rise and fall times of various

circuits,

be a fixed amount wider or narrower

than desired. If this error is less

than one period of the maximum input

frequency, no counter error will occur.

Thus a 300 MHz counter needs a gate

accurate to about 3 nanoseconds.

error can contribute to the overall

error In pulse frequency measurements.

In fact for narrow pulses, the second

and third sources of error, which are

usually ignored in a cw counter, become

the dominate sources of error in a

pulse counter.

error in the time base reference oscillator results in a proportional frequency measurement error.

sources of time base error are aging

rate and temperature. The temperature

compensated crystal oscillator (TCXO)

reduces temperature instability to less

than 2 x 10-6.

frequency standard, this error can be

made less than one count, and thus

becomes insignificant.

obtain high resolution, the frequency

of a number of measurements is averaged.

Each individual measurement has a ±1

count uncertainty as previously noted.

If N measurements are made, then an

uncertainty of ±N counts is possible,

but very unlikely.

averaged measurement will follow the

rules of statistics, in that succes-

sive measurements will vary randomly

to a certain degree.

of the readings (63 percent) will fall

between ± counts; this is called

the rms averaging error.

number of gates required to accumulate

100 microseconds or 1 millisecond of

gate time.

since the processed input

(3) A third possible source of

Due primarily to differences

the actual gate will usually

(4) Each of these three sources of

b.

Time Base Errors. A frequency

Two main

By calibration against a

c.

Averaging Error. In order to

The resultant

In fact, most

N is the

The gate is typically

2-12

Page 31

TM 11-6625-3031-14

30 nanoseconds

pulse, so that

narrower than the input

determined and corrected. As an

example, the measured time base output

is 10.0001 MHz.

1 x 10

readings will be 1 x 10

quency.

where PW =

F

= 200 kHz with 100 µsec gate,

pulse width in microseconds

Band A; or 60 kHz with

be 10 kHz low.

can be corrected for this error, the

counter should be recalibrated as soon

as possible.

1 msec gate, Band A; or

100 kHz with 100 µsec gate,

Band B; or 30 kHz with

1 msec gate, Band B.

quency and pulse width can be virtually

eliminated.

simulating a pulse input and determining

d.

Gate Error.

(1) When narrow pulses are counted,

the gate is opened many times in order

to obtain a high resolution measurement.

the gate error.

can then be added to, or subtracted

from,

obtain the correct frequency.

Each time the gate opens and closes,

there will be a small but finite error.

The total error is proportional to the

number of times the gate is cycled during a measurement, and is thus inversely

proportional to the gate width.

This

error is also related to both temperature and input frequency.

case error,

including all variables, is

The worst

specified for the counter as:

error using a cw source at approxi-

mately the same frequency (within

25 MHz) as the indicated measurement.

A pulsed input is then simulated by

applying an enable signal, of the same

width as the pulse to be measured, to

the INPUT INHIBIT connector.

error is the difference in reading

between the pulsed and non-pulsed

measurement of the same cw signal.

This procedure provides the true gate

error,

any possible pulling of the signal

source.

-6

high in frequency, and all

The time base is thus

-6

low in fre-

Thus, a reading at 10 GHz will

Although the reading

b. Gate Error.

—

(1) Gate error at any given fre-

This is accomplished by

This calibration factor

the indicated measurement to

(2) First, determine the gate

Gate

and avoids error associated with

where PW =

pulse width in microseconds.

(2) Unlike averaging error, which

is random, gate error is systematic,

and is not reduced by frequency

averaging.

2-14.

Techniques for Improving

Accuracy.

a. Time Base Calibration. A frequency

error in the time base oscillator results in the same percentage error in

the frequency reading for either cw or

pulsed signals.

By directly measuring

the 10 MHz time base frequency at the

10 MHz OUTPUT connector with a standard

of known accuracy, this error can be

2-15.

Operation Using General Purpose

Interface Bus.

a. General.

—

(1) The counter may be operated via

the General Purpose Interface Bus (GPIB)

and may be controlled by, listened to

and talked to by any device or devices

compatible with IEEE STD-488.

Table 2-4

lists the Capability Identification

Codes assigned to the counter.

This

code is also printed on the counter rear

panel adjacent to the GPIB 24-pin connector so that programming instructions

or keyboarding of a controller can be

interfaced with the counter configuration and capabilities.

(2) The IEEE STD-488 GPIB system

(fig. 2-7) consists of 16 signal lines

2-13

Page 32

2-14

Table 2-4.

TM 11-6625-3031-14

Page 33

TM 11-6625-3031-14

used to carry data, control, and

management information.

The 16 lines

are organized into three sets, as

follows:

(a) Data Bus (b)

Control -

3 signal lines

(c)

Management-

Data Byte Transfer

General Interface

5 signal lines.

8 signal lines

(3) The counter is a type B device

able to talk and listen (T1 and L4

codes). Mnemonics assigned to the vari-

ous signal lines are as follows:

(a)

Data Bus lines are:

DIO 1 through DIO 8 (Data Input/Output

line 1 through 8)

- used to transmit

message bytes in bit-parallel, byte-

serial format,

asynchronously and

usually in a hi-directional manner.

(b)

Data Byte Transfer Control

lines are:

DAV (Data Valid) - used to indicate the

condition (availability and validity) of

information on DIO signal lines.

Figure 2-7.

and Structure

GPIB Capabilities

NFRD (Not Ready For Data) - used to indicate the condition of readiness of

device(s) to accept data.

NDAC (Not Data Accepted) - used to indi-

cate the condition of acceptance of data

by device(s).

(c) General Interface Manage-

ment lines are:

ATN (Attention)

- used by a controller

to specify how data on the DIO signal

lines are to be interpreted and which

devices must respond to the data.

IFC (Interface Clear) - used by a controller to place the interface system,

portions of which are contained in all

interconnected devices, in a known

quiescent state.

SRQ (Service Request) - used by a device

to indicate the need for attention and

to request an interruption of the cur-

rent sequence of events.

REN (Remote Enable) - used by a con-

troller (in conjunction with other mes-

sages) to select between two alternate

sources of device programming data.

2-15

Page 34

TM 11-6625-3031-14

EOI (End Or Identify) - used by a talker

to indicate the end of a multiple byte

transfer sequence or, in conjunction

with ATN (by a controller), to execute a

polling sequence.

NOTE

The EOI function is not included

in this counter.

(4) The 16 GPIB lines are connected

to the rear-panel GPIB IEEE STD 488/

1975 connector as shown in table 2-5.

To the left of and below the connector

are seven ADDRESS SWITCHes for setting

the GPIB modes or addresses of the

counter.

b. On Line and Off Line Operation.

(1) The Talk Only On Line and Off

Line operation are summarized in table

2-6.

determines the mode of operation of the

counter. When the switch is set to the

1 position before power is applied to

the counter,

The setting of ADDRESS SWITCH 7

the counter can be a talker

Table 2-5. GPIB IEEE STD 488/1975

Connector Pin Assignments

Pin

10

11

12

Signal

1

DIO 1

2

DIO 2

DIO 3

3

DIO 4

4

EOI

5

(not used)

DAV

6

NRFD

7

NDAC

8

IFC

9

SRQ

ATN

(Shield)

line

Pin

13

14

15

16

17

18

19

20

21

22

23

24

Signal

line

DIO 5

DIO 6

DIO 7

DIO 8

REN

Gnd (6)*

Gnd (7)*

Gnd (8)*

Gnd (9)*

Gnd (10)*

Gnd (11)*

Gnd (Logic)*

only with continuous output from the

GPIB connector.

rate control (either by the front-panel

SAMPLE RATE control or Fast Active) and

output format (either ExponentScientific or Exponent-Four) is set by

ADDRESS SWITCHes 1 and 2.

other ADDRESS SWITCHes, 3 through 6, do

not effect the output when the counter

is being used in the Talk Only mode.

selected, ADDRESS SWITCH 7 is placed in

the 1 position before power is applied

to the counter. After power is applied,

the front-panel controls will be operative unless ADDRESS SWITCH 1 is in the

1 position,

RATE control will be inactive.

selected, ADDRESS SWITCH 7 is placed in

the 0 position before power is applied

to the counter.

the counter is accomplished by placing

ADDRESS SWITCHes 1 through 5 in the

appropriate configuration shown in

table 2-6.

counter will respond to the ASCII Listen

or Talk Address character that has been

set by the ADDRESS SWITCHes 1 through 5,

as indicated in table 2-7. Configura-

tion of the ADDRESS SWITCHes is shown in

fig. 2-8.

Selection of sample

The four

(2) When Off Line operation is

in which case the SAMPLE

(3) When On Line operation is

Address assignment to

After being turned on, the

NOTE

ASCII ? and is reserved for

GPIB Unlisten and Untalk and

therefore cannot be assigned as