E Instruments EXPERT-1-C-V2, EXPERT-1-C, EXPERT-1-C-C2-F, EXPERT-1-O-N-H, EXPERT-1-N User manual

...

INSTRUCTION & OPERATIONS

MANUAL

AQ EXPERT

PORTABLE MULTIFUNCTIONAL

INDOOR AIR QUALITY MONITOR

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 2 of 52

TABLE OF CONTENTS

CHAPTER 1 ..............................................................................................................................3

TECHNICAL SPECIFICATIONS & SAFETY GUIDELINES.................................................3

CHAPTER 2 ..............................................................................................................................8

INTRODUCTION ......................................................................................................................8

CHAPTER 3 ............................................................................................................................ 12

BASIC INSTRUMENT OPERATION .................................................................................... 12

CHAPTER 4 ............................................................................................................................ 15

POWER REQUIREMENTS ................................................................................................... 15

CHAPTER 5 ............................................................................................................................ 16

SENSORS - TECHNICAL ..................................................................................................... 16

CHAPTER 6 ............................................................................................................................ 22

AQ EXPERT SETUP.............................................................................................................. 22

CHAPTER 7 ............................................................................................................................ 25

INTERNAL DATA STORAGE ............................................................................................... 25

CHAPTER 8 ............................................................................................................................ 27

WIRELESS REMOTE PRINTER .......................................................................................... 27

CHAPTER 9 ............................................................................................................................ 29

ZERO & SPAN CALIBRATION ............................................................................................. 29

CHAPTER 10 .......................................................................................................................... 37

AQ GAS SOFTWARE

CHAPTER 11 .......................................................................................................................... 43

MAINTENANCE ..................................................................................................................... 43

CHAPTER 12 .......................................................................................................................... 46

AQ EXPERT OPTIONS ................................................................ ......................................... 46

CHAPTER 13 .......................................................................................................................... 49

TM

........................................................................................................ 37

BASIC TROUBLESHOOTING .............................................................................................. 49

CHAPTER 14 .......................................................................................................................... 51

REPLACEMENT PARTS ....................................................................................................... 51

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 3 of 52

CHAPTER 1

TECHNICAL SPECIFICATIONS & SAFETY GUIDELINES

AQ EXPERT - AIR QUALITY MONITOR

1. PHYSICAL:

Material: White ABS plastic case with internal aluminum shielding

Dimensions (monitor): 11.42” X 10.24” X 4.88”

Weight: (monitor): 7.6 lbs. / 3.5 kg

Shipping Dimensions & Weight (monitor & all accessories): 15 lbs. / 7 kg

19” x 17” x 15” / 48.2 cm x 43.1 cm x 38.1 cm

2. POWER:

12 Volt, 8 AH rechargeable Li-Ion battery pack

Operating time: 6 – 8 hours continuous use

110/240 VAC input, 12 V/2.5A fast charger

Charging time: 3 hours maximum

3. DISPLAY:

2.6” x 1.4” 128 x 64 graphic, chip on glass (white backlit) LCD display.

Rotating display depending on monitor case orientation

Small and large fonts, plus inverted background color for help messages

Battery condition & charger operation indicator

4. WIRELESS REMOTE PRINTER

2” high resolution, high speed, graphic thermal printer, with charger, prints:

A. current set of data

B. stored data

C. periodic data printouts

D. calibration history and external messages

5. INSTRUMENT PUMP

Continuous Air sample pump: high quality diaphragm pump with long life motor

6. STORAGE

1000 Internal memory storage tags, each tag stores one complete set of data

7. COMMUNICATIONS

Bluetooth wireless: Class 1 (100m)

USB Cable

8. SOFTWARE

AQ GAS™ Windows PC Software

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 4 of 52

SENSOR

RANGE

RES.

ACCURACY

CARBON MONOXIDE (CO)

Std Range

0 - 200 ppm

0.1 ppm

+/- 1 ppm of rdg,

+/- 0.2 ppm

CARBON MONOXIDE (CO)

High Range

0 - 2000 ppm

1 ppm

<300ppm, 10ppm

To 2000ppm, 4%

OXYGEN (O2)

Std Range

0 – 25%

0.1%

0.1% Vol.

NITRIC OXIDE (NO)

Std. Range

0 - 250 ppm

0.1 ppm

+/- 2 ppm of rdg

NITRIC OXIDE (NO)

High Range

0 - 2000 ppm

1 ppm

<100ppm, 5ppm

To 2000ppm, 4%

NITROGEN DIOXIDE (NO2)

Std. Range

0 - 20 ppm

0.1 ppm

+/- 0.5 ppm of rdg

NITROGEN DIOXIDE (NO2)

High Range

0 - 1000 ppm

1 ppm

<100ppm, 5ppm

To 1000ppm, 4%

SULFUR DIOXIDE (SO2)

Std. Range

0 - 20 ppm

0.1 ppm

+/- 0.5 ppm of rdg

SULFUR DIOXIDE (SO2)

High Range

0 - 2000 ppm

1 ppm

<100ppm, 5ppm

To 2000ppm, 4%

HYDROGEN SULPHIDE

(H2S)

Std. Range

0 - 100 ppm

1 ppm

+/- 4 % of rdg,

+/- 0.5 ppm

OZONE (O3)

Std. Range

0 - 5 ppm

1 ppb

FORMALDEHYDE (CH2O)

Std. Range

0 - 10 ppm

1 ppb

2% ± 30 ppb

SENSOR

RANGE

RESOLUTION

ACCURACY

CARBON DIOXIDE (CO2)

Std Range

0 – 5000 ppm

10 ppm

2% of Rdg. + 10 ppm

CARBON DIOXIDE (CO2)

High Range

0.0% - 20.0%

0.1%

+ 3% rdg.

SENSORS

1. AIR QUALITY SENSORS – ELECTROCHEMICAL

*Note: All Accuracies indicated above are under Laboratory Conditions

2. AIR QUALITY SENSORS – NON-DISPERSIVE INFRARED (NDIR) SENSORS

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 5 of 52

SENSOR

RANGE

RESOLUTION

Min Detection

ACCURACY

VOCs

Std Range

0 – 20 ppm

(0-46 mg/m3)

1 ppb

(2.3 µg/m3)

5 ppb

10% of Rdg.

+ 20 ppb

VOCs

High Range

0 – 200 ppm

1 ppb

25 ppm

10% of Rdg.

+ 50 ppb

SENSOR

RANGE

RESOLUTION

ACCURACY

Temperature Type K (T1)

0 – 2000 ºF

(0 – 1100ºC)

0.1 ºF

(0.1 ºC)

+/- 0.5 ºC 0-100ºC

+/- 5% >100ºC

Ambient

Temperature

-40 – 257 ºF

(-40 – 125 ºC)

0.1 ºF

(0.1 ºC)

+/- 0.4 ºC (0-60 C)

Barometric Pressure

260 – 1260 mbar

1 mbar

+/- 2 mbar

Relative Humidity

0 -100 %

0.1%

+/- 2% RH

Pressure

+/- 80 mbar

0.1 mbar

+/- 2 mbar

Air Velocity

0 – 300 ft/sec

1 ft/sec

3. AIR QUALITY SENSORS – PHOTO IONIZATION DETECTOR (PID) SENSORS

4. OTHER SENSORS

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 6 of 52

NOTE: Please take special care when performing Span Calibration of the

monitor. You cannot revert back to the factory setting after any adjustments!

NOTE: CO2 should ALWAYS be Calibrated or Zeroed with a Cylinder of ZERO

AIR. Do Not Use Ambient Air for CO2 sensor calibration.

MODEL AQ EXPERT – SAFETY GUIDELINES

This section provides general rules which must be followed for product safety, avoiding

personal injury, damage to equipment and preserving the manufacturer’s warranty.

Please take care to carefully observe the following instructions.

A. PRODUCT SAFETY INSTRUCTIONS:

Follow the instructions in the AQ Expert Manual

Do not operate the instrument outside of the parameters specified in the

technical specifications

Never use the instrument without the disposable fiber soot line filter or the

condensation disk filter, which are located inside the monitor connected to

the “Sample In” input. Operating the instrument without the filters will put

the monitor at high risk to damage the pump and sensors. These filters

should be replaced as needed. See maintenance chapter for filter

changing.

It is recommended to keep the AQ Expert horizontal using the included

swivel handle as its stand with the LCD display facing the user

Do not use or store the instrument together with any solvents

Do not block the exhaust port in the back of the instrument

Do not expose the monitor to extreme hot or cold temperatures outside of

the stated range in this manual

Do not abuse the charger cord. Do not use power cord for carrying,

pulling. Keep cord away from heat, oil, sharp edges, or moving parts.

Damaged or entangled cords can increase risk of electric shock

Only use the supplied, appropriate AC Charger

If the monitor enclosure is ever unscrewed and taken apart, avoid over-

tightening the screws that hold the two main enclosure pieces together.

Do not store or operate in dusty, dirty areas

Always use the monitor with care and use the instrument properly

Do not use force when disconnecting and reconnecting the Black external

Temp, RH and Pressure Sensor (see photo below)

Do not use instrument in the rain or high moisture areas to prevent water

droplets on the black external Temp, RH, and Pressure Sensor.

Remember to have the monitor checked and calibrated at least once a

year to ensure sensor accuracy and compliance with existing standards

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 7 of 52

DO NOT LIFT OR HANDLE THE INSTRUMENT BY THE BLACK

EXTERNAL TEMP, RH, PRESSURE SENSOR HOUSING! See photo

below

B. ELECTROMAGNETIC COMPATIBLITY

Complies with EN61326-1, Portable Equipment

The E Instruments AQ EXPERT Indoor Air Quality Monitor is a battery operated

Portable device designed to be used by a qualified engineer/technician to make

measurements in buildings and residential facilities. For long-term testing, you may

operate the unit connected to the supplied charger by carefully following the product

safety instructions in Section A above.

C. ESD Protection

In extreme cases or abnormal applications, Electrostatic Discharge can

potentially cause serious and immediate damage to the electronic circuits of the

instrument.

D. BATTERY DISPOSAL & RECYCLING

Recycle all applicable material properly. Take faulty/depleted batteries to

proper collection/recycling centers

Dispose of batteries and the monitor according to statutory regulations.

Do not dispose of with regular household items. After the monitor’s useful

life, please return to your local authorized E Instruments’ distributor or

send back to E Instruments directly. We will ensure that it is disposed of

in an environmentally friendly manner

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 8 of 52

CHAPTER 2

INTRODUCTION

A. UNPACKING THE INSTRUMENT

Every E INSTRUMENTS AQ EXPERT includes as standard equipment:

• IAQ Monitor Model AQ Expert with CO2, Temp, %RH, DPt, WBT, BP, Velocity,

Differential Pressure and Differential Temperature

• Internal Continuous Sampling Pump

• Swivel Handle

• Battery charger / AC adaptor for the monitor

• USB Thumb Drive includes:

• AQ GAS TM Software for Windows TM

• Instruction Manual

• USB Cable for Software Kit

• Internal Wireless Bluetooth

• Bluetooth Dongle for PC

• Calibration Certificate

The instrument can have up to six (6) electrochemical gas sensors, one (1) infrared gas

sensors and one (1) PID sensor installed. The AQ Expert has three temperature

sensors in total. All sensor readings are single range readings with ranges listed in

Chapter 1.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 9 of 52

B. INSTALLING/REMOVAL OF SWIVEL HANDLE INSTRUCTIONS

1. Depress BOTH of the Grey Push-Release buttons on the Left & Right circular

ends of the handle (Photo B)

2. With the handle angled AWAY from the front face of the instrument and with the

buttons depressed, position the circular ends OVER the Gray circular holders ON

the side of the instrument until it falls into place (Photos C & D)

3. Depress the Grey Push-Release buttons and rotate the Handle down below the

Front Face (Photo E) of the instrument until it locks into place under the

instrument holding it upright in place. (Photo F)

4. To Remove the handle, repeat steps 1-3 in reverse

PHOTO A PHOTO B PHOTO C

PHOTO D PHOTO E PHOTO F

C. REPACKING UNIT IN OPTIONAL VINYL CARRYING CASE

1. With the AQ Expert powered OFF, turn the instrument on its side with the

FRONT FACE of the unit to the LEFT. See photo A below.

2. Place the carrying case on a supported surface (desk, floor, etc) with the Front

Logo facing the user.

3. With the AQ Expert powered OFF, turn the instrument on its side with the

FRONT FACE of the unit to the LEFT. See photo A below.

4. Carefully place the AQ Expert in the Case, taking SPECIAL PRECAUTION to

NOT damage the External Temp, RH, Pressure sensor. See Photo B below

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 10 of 52

PHOTO A PHOTO B

INSTRUCTIONS: DO NOT LIFT OR HANDLE THE INSTRUMENT BY THE BLACK

EXTERNAL TEMP, RH, PRESSURE SENSOR HOUSING!

D. AQ EXPERT STARTING INSTRUCTIONS

1. Make sure the instrument is in a clean-air, room-temperature environment and

turn it on by pressing the POWER key on the keypad. The instrument will begin

to draw in air from the SAMPLE IN inlet at a rate of about 500 cc/minute.

2. If needed or in doubt of the contaminants in the Ambient Air, you can initiate the

ZERO CAL on ALL of the GAS sensors on the AQ Expert. Please refer to

CHAPTER 8 of this manual for ZERO & SPAN calibration on the AQ Expert.

3. Press the MEASURE key to view the ambient temperature, barometric pressure,

relative humidity and dew point. The toxic gas readings are also displayed: CO,

CO2, NO, NO2, SO2, H2S, O3, & VOCs.

4. If, at the end of the ZERO countdown, if the display shows an error message for

a particular sensor, see the troubleshooting table in section D of this chapter. The

instrument will measure correctly all sensors that do not show an error message.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 11 of 52

LIST OF ABBREVIATIONS

PARAMETERS

CO2 Carbon Dioxide – NDIR measurement

CO Carbon Monoxide

Ta Ambient (room) Air Temperature

RH Percentage of Relative Humidity

DPt Dew Point Temperature

WBT Wet Bulb Temperature

BP Barometric Pressure

O2 Oxygen

O3 Ozone

VOCs Volatile Organic Compounds

FMH Formaldehyde

H2S Hydrogen Sulfide

NO Nitric Oxide

NO2 Nitrogen Dioxide

NOX Oxides of Nitrogen

SO2 Sulfur Dioxide

VEL Air / Gas Velocity (measurement with pitot tube)

∆P Differential Pressure (with Velocity Probe turned OFF)

T1 Thermocouple Type K Temperature (T1 Input)

T2 Thermocouple Type K Temperature (T2 Input)

BAT Battery Life / Voltage

NA Parameter Not Available

UNITS

PPM Parts (of pollutant) per million

PPB Parts (of pollutant) per billion

mg/m3 Milligrams per Cubic meter

µg/m3 Micrograms per Cubic meter

°F Temperature Measurement in Fahrenheit

°C Temperature Measurement in Celsius

"WC Inches of water (pressure measurement)

mmHg Millimeters of Mercury (pressure measurement)

"Hg Inches of Mercury (pressure measurement)

PSI Pounds per Square Inch (pressure measurement)

mmWC Millimeters of water (pressure measurement)

kPa KiloPascals (pressure measurement)

mbar Millibars (pressure measurement)

FPS Feet per second (gas / air velocity measurement)

MPS Meters per second (gas / air velocity measurement)

CMM Cubic meters per minute (gas / air velocity measurement)

CFM Cubic feet per minute (gas / air velocity measurement)

V Voltage (battery)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 12 of 52

SETUP

Controls all customization parameters, such as measurement

units, for the monitor

CALIB

Controls calibration settings and zeroing of the monitor’s

sensors.

STORE

Controls operation of the monitor’s internal data storage

PRINT

Executes print commands for the monitor’s optional remote

Bluetooth printer

CHAPTER 3

BASIC INSTRUMENT OPERATION

The AQ EXPERT is operated by the 11 button keyboard located on the front of the

monitor.

The POWER key turns the instrument on and off.

The MEASURE key shows the currently measured parameters.

Displays the monitor’s currently measured data in either of two (2) fonts:

A. Small fonts (all data displayed simultaneously plus range indicated, battery

condition and time)

B. Large fonts (four data parameters displayed simultaneously)

Note: The AQ Expert allows the user to ZOOM in and out of the screen by changing

from Small to Large Fonts using the MEASURE key.

Four keys will bring up a menu: SETUP, CALIB, STORE, & PRINT.

The menus are navigated with the UP, DOWN, LEFT, RIGHT, & OK keys.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 13 of 52

CO2: 520PPM O2: 20.9%

CO: 0PPM NO2: 0PPM

Ta: 79.1°F SO2: 0PPM

RH: 46.9% H2S: 0PPM

DPt:57.0°F O3: 0PPB

BP: 1012mb VOC: 0PPB

_____________________

Sampling 12:45:00

NOTE: Depending on the options

enabled for your AQ EXPERT some of

the entries in one or more of the

displays shown above will be blank if

that option is not available.

APR 1 ‘14 12:45:00

Temperature Units: F

Measure Units: PPM

Pressure Units: inWC

Pumps: AUTO 1000cc/m

Velocity Probe: OFF

Velocity Units: FPS

Duct Size: 0 in2

Display Contrast: 24

Baudrate: 115 kbps

Version: 1.00Li

Fast-Charge Mode

Battery Charger Connected

Battery Empty

Battery Full

INSTRUMENT OPERATION OVERVIEW

1. Turn the AQ Expert on by pressing the POWER key. The instrument’s internal

pump will immediately turn on and the E INSTRUMENTS logo will appear.

2. If applicable, attach the optional probe and sampling line to the monitor.

3. Press the MEASURE key and check the unit’s battery condition.

The MEASURE key allows the user to toggle between a small

font and a large font screen. Select the small font screen.

The battery icon is displayed in the middle of the bottom line of

the display. Its condition is marked by the shaded fraction of the

icon. If the unit is powered by the battery charger a small “plug”

icon will replace the battery icon.

NOTE: When connecting the battery charger to the monitor

make sure that the “plug” icon appears on the MEASURE screen.

This ensures a proper power connection and charging of the

batteries.

4. If you are using the monitor for the first time, press the

SETUP key to set the appropriate parameters (i.e.: measurement units) for your

application. See Chapter 5 for an explanation of each parameter.

5. All sensor readings shown on the screen indicate Ambient measurements. To

ZERO the gas sensors, please see Maintenance Chapter 11 of this manual.

6. To obtain a printout of the data displayed, press the PRINT key. The cursor

Find Quality Products Online at: sales@GlobalTestSupply.com

(reverse color) will point to:

Print Test Record

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 14 of 52

Press the OK key to execute a printout on the AQ Expert’s optional remote

printer.

7. Measured data can be stored in the monitor’s internal memory. Please refer to

Chapter 7 for more details about data storage.

8. When you are finished with your measurements allow the monitor to draw clean

ambient air for several minutes before turning the monitor off. If you are using

the optional probe, please disconnect and let the instrument run in clean ambient

air before turning the instrument off.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 15 of 52

Battery Charger Connected

Battery Full

Battery Empty

Fast-Charge Mode

CHAPTER 4

POWER REQUIREMENTS

The AQ Expert can run off of AC power or the internal Li-Ion rechargeable battery pack.

It is recommended to run the AQ Expert off AC power as often as possible for maximum

operating time.

Power is supplied by a Li-Ion rechargeable battery pack. The battery pack will supply

power to the monitor for approximately 6-8 hours of continuous operation.

A 110 – 240 Volt AC charger having a 12 Volt DC / 2.5A output is supplied with the

instrument. The battery charger will fully charge the battery pack in three hours.

You can check the condition of the batteries at any time:

1. By pressing the MEASURE key, (small font screen) and observing the battery

icon, located at the bottom of the display.

2. 2. By pressing the MEASURE key, (large font screen), the user can scroll all the

way to the end using the DOWN arrow key to observe the battery life shown in

voltage. When the unit is operating on its internal batteries, the voltage

displayed will vary from an initial 8.0 to 8.4 volts (fully charged) dropping slowly to

approximately 7 volts (batteries nearly empty). When the battery voltage drops to

7.1 volts a “low battery” warning will appear on the display. Within a few minutes

later the instrument will automatically turn off, to preserve the remaining battery

power for the sensor bias voltages.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 16 of 52

SENSOR

LIST:

CO2

CO

VOC

NO

NO2

SO

2

H2S

CH2O

O2

O3

CHAPTER 5

SENSORS - TECHNICAL

The great versatility of the AQ Expert Air Quality monitor is partly due to the large

number of sensors available within a single monitor.

These sensors are primarily gas sensors and can be grouped into four categories based

on their principle of operation:

1. Six (6) electrochemical gas sensors*

2. One (1) NDIR (infrared gas sensors) – CO2

3. One (1) Photo ionization detector (PID gas sensor) - VOC

4. Non-gas sensors (Temperature, Velocity, Humidity, Pressure, and

Barometric pressure) sensors

*NOTE: When O3 (Ozone) sensor is installed the AQ Expert can include O3 + NO2 OR

O3 + SO

together simulatenously.

The main section of the monitor that houses all the electrochemical, NDIR, and PID gas

sensors, battery pack, and PC board. On the face of the unit, the external sampling

system or Ambient Temperature, Relative Humidity, and Barometric Pressure.

The figure below shows the location of the gas sensors on their housing:

. The unit can NOT have all three (3) sensors (O

2

+ NO2 + SO2)

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 17 of 52

1. ELECTROCHEMICAL SENSORS

All electrochemical sensors are mounted on bayonet style fittings for easy removal.

The electrochemical sensors are described below:

A. Nitrogen Dioxide sensor (NO2)

This is a three electrode sensor that responds to nitrogen dioxide gas. Nitrogen dioxide

is a “sticky” gas and this sensor’s response is usually the slowest of all sensors.

B. Sulfur Dioxide sensor (SO2)

It is a three electrode sensor that responds to sulfur dioxide gas. It is equipped with an

inboard filter to remove interference from H2S gas and other acidic gases.

C. Nitric Oxide sensor (NO sensor)

This is also a three electrode sensor that responds to nitric oxide. It is equipped with an

inboard filter to remove any interference from other acidic gases.

The nitric oxide sensor requires a constant bias-voltage for proper operation. This is

supplied by the monitor’s battery. If the battery voltage drops below a certain value the

monitor will turn off automatically to maintain the sensor bias. If, however, the battery

voltage further drops to near zero, one must wait 24 hours after connecting the battery

charger, for the sensor bias to recover.

D. Oxygen sensor (O2 sensor)

This sensor measures the oxygen concentration in the sample. It is a two-electrode

electrochemical cell. It has a silver cathode and a lead anode. Oxygen diffuses through

a tiny hole and reacts with the lead anode. The reaction produces an electric current.

The unit software linearizes the current vs. oxygen response. The cell becomes

exhausted when all the lead is consumed.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 18 of 52

E. Hydrogen Sulfide sensor. (H2S)

This is a 4-series three-electrode micro sensor with low methanol interference. It

measures the concentration of hydrogen sulfide, which is a highly toxic gas. Special

precautions must be taken during calibration.

F. Carbon Monoxide sensor (CO)

This is also a three electrode sensor that responds to carbon monoxide. It is equipped

with an inboard filter to remove any interference from other acidic gases.

The optional High Range CO sensor has four electrodes. One measures the

concentration of carbon monoxide gas and the other the concentration of any interfering

hydrogen gas (It is hydrogen compensated).

G. Ozone sensor (O3)

This is also a three electrode sensor that responds to ozone.

H. Formaldehyde Sensor (CH2O)

This is also a three electrode sensor that responds to formaldehyde. It is equipped with

an inboard filter to remove any interference from other acidic gases.

2. NDIR (INFRARED) SENSOR (CO2)

A non-dispersive infrared (or NDIR) sensor is a simple spectroscopic device most

commonly used to measure CO2 in indoor air quality applications. The main

components are an infrared source (lamp), a sample chamber or light tube, a

wavelength sample chamber, and the CO2 gas concentration is measured electrooptically by its absorption of a specific wavelength in the infrared (IR).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 19 of 52

GAS

RANGE

ACCURACY

CARBON DIOXIDE

(CO2)

0 – 5000 ppm

2% of reading

+ 10 ppm

CARBON DIOXIDE

(CO2)

0.0% - 20.0%

3% of reading

GAS

RANGE

ACCURACY

VOCs*

0 – 20 ppm

+ 10 % of reading

VOCs*

0 – 200 ppm

+ 10 % of reading

The AQ Expert Air Quality Monitor is equipped with one standard NDIR infrared sensor

capable of CO2 measurement (standard range: 0 – 5000 ppm). This infrared sensor

can be substituted for higher CO2 ranges upon special request.

The NDIR options have the following specifications:

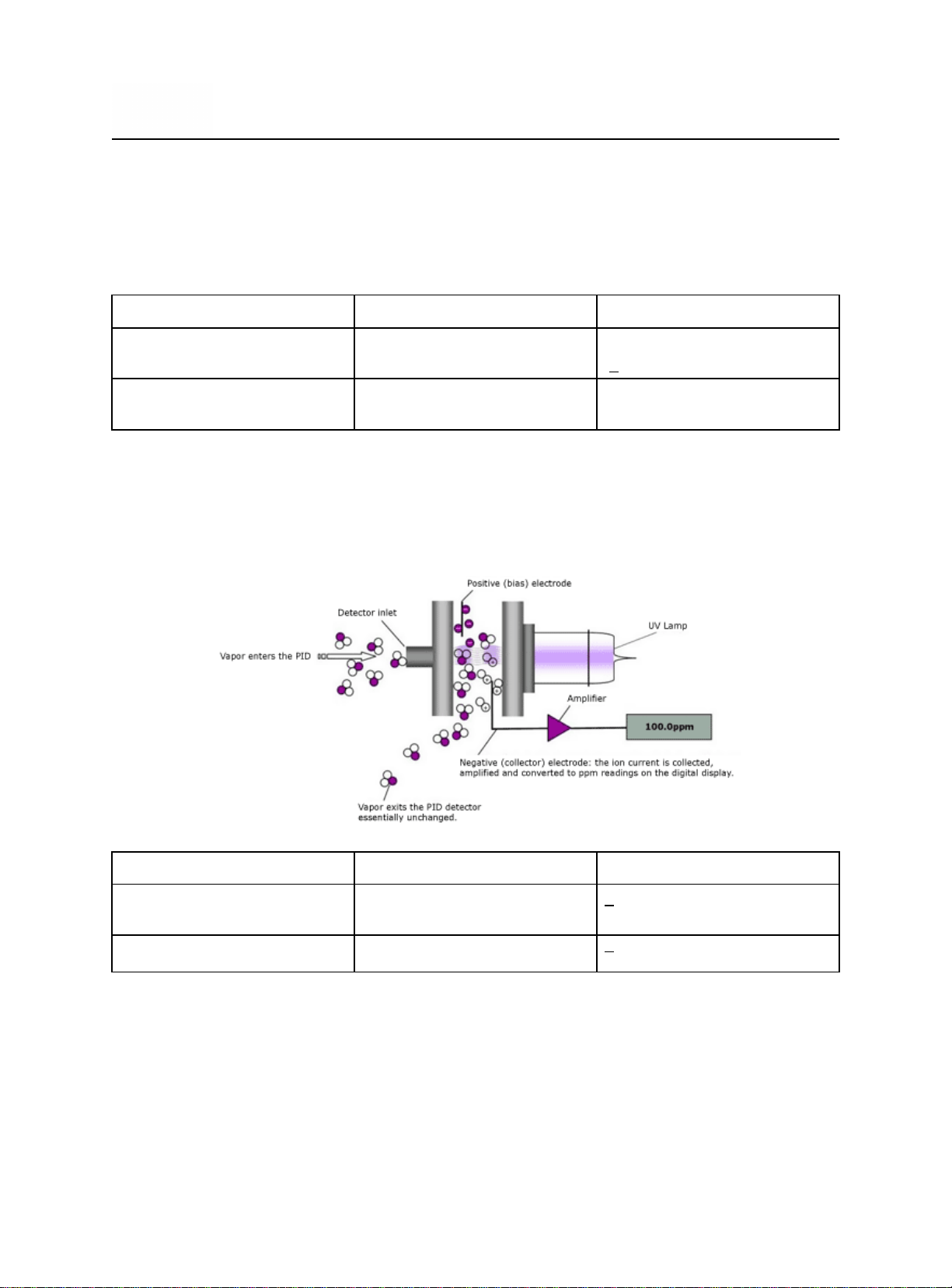

3. PHOTO IONIZATION DETECTOR (PID) - VOCs

Photo ionization detectors are the most common method to measure volatile organic

compounds (VOCs) and other gases in indoor air quality in concentrations in parts per

billion (PPB) and parts per million (PPM).

The PID options have the following specifications:

*VOC sensor will not measure Formaldehyde. The ionization potential of the sensor is outside of the VOC sensor

range. If you need Formaldehyde, you need to use the direct CH2O sensor.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 20 of 52

4. NON-GAS SENSORS

A. Ambient Temperature sensor

This is a solid state sensor located on the front panel of the monitor. The

ambient temperature is displayed on the MEASURE screen in either °F or °C.

The dew point is calculated from the ambient temperature and relative humidity.

The dew point is displayed on the Small and Large Font MEASURE screens as

DPt.

B. Humidity sensor

This is a solid state sensor located on the front panel of the monitor. The

relative humidity is displayed on the MEASURE screen in %RH (% Relative

Humidity). The Wet Bulb is calculated from the ambient temperature, relative

humidity, and barometric pressure. The wet bulb is displayed on the Large

Font MEASURE screen only as WBT.

C. Barometric Pressure sensor

This is a solid state sensor located at the front panel of the monitor. The

barometric pressure is displayed on the Small and Large Font MEASURE

screens as BP.

D. External temperature sensor (T1 & T2)

The thermocouple is located at the tip of any optional or separate Type K

thermocouple probe and/or wire. The T1 & T2 temperature measurements are

displayed on the Large Font MEASURE screen only as T1, T2.

E. Differential Pressure / Air Velocity sensor.

If the monitor comes with the Differential Pressure option and/or the air velocity

option (optional separate S-type pitot tube and pressure tubing), the internal

pressure sensor is a very low range pressure sensor. The Velocity

measurements are displayed on the MEASURE screen only as VEL.

Differential Pressure are displayed on the MEASURE screen only as ∆P.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 21 of 52

Connecting Differential Pressure Hoses:

1. Connect White Connector to either P+ or P- Connection as shown in photo

below

2. Once connected, turn White Connector CLOCKWISE to lock. Do NOT

Over tighten.

3. To Disconnect, turn White Connector COUNTER-CLOCKWISE to unlock and

pull hose off to remove

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 22 of 52

APR 1 ‘14 12:45:00

Temperature Units: F

Measure Units: PPM

Pressure Units: mbar

Pumps: AUTO 1000cc/m

Velocity Probe: OFF

Velocity Units: FPS

Duct Size: 0 in2

Display Contrast: 24

Baudrate: 115 kbps

Version: 1.00Li

CHAPTER 6

AQ EXPERT SETUP

The SETUP MENU allows the operator to change the instrument’s parameters.

Every parameter listed on the SETUP MENU screen can be changed as follows:

a. Use the UP / DOWN keys to move the highlighted line to the parameter you wish

to change.

b. Press OK to edit the value. The arrow will disappear as the current line shifts to

the left by one character and a cursor appears over the value. This indicates that

you are in edit mode.

c. Use the UP / DOWN keys (keys displaying the triangles) until the desired value

of the selected parameter appears on the display.

d. Press the OK key to execute the change.

A more detailed explanation of each parameter follows:

1) DATE & TIME: The monitor’s internal clock is displayed in the format month-dayyear, hour-minute-second. Hours are always displayed using a 24-hour clock

format.

Find Quality Products Online at: sales@GlobalTestSupply.com

2) TEMPERATURE UNITS: The UP / DOWN keys toggle between °F (Fahrenheit) and

°C (Celsius). Stack temperature and ambient temperature will be displayed, printed,

and saved in the selected units.

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 23 of 52

3) GAS MEASURING UNITS: When the cursor is blinking on this line, you can select

any of the following units of measurement for the toxic gas sensors:

PPM : Parts per million (volumetric)

PPB : Parts per billion (volumetric)

MGM: Milligrams per cubic meter (weight)

µGM: Micrograms per cubic meter (weight)

Note: Formaldehyde, Ozone and VOCs will always read in PPB (parts per billion)

4) PRESSURE UNITS: Pressure measurements can be shown in millibar (mbar),

inches of water (inWC), millimeters of water (mmWC), millimeters of mercury

(mmHG), inches of mercury (inHG), pounds per square inch (psi) or kilopascal

(kPa).

1 mbar = 0.10 kPa = 0.40 inWC = 10.2 mmWC = 12.95 inHg = 0.75 mmHg = 1.45 PSI

5) VELOCITY UNITS: (Velocity Option) Select between feet per second (FPS), meters

per second (MPS), cubic feet per minute (CFM), or cubic meter per minute (CMM).

AIR VELOCITY AND DIFFERENTIAL PRESSURE CAN NOT BE MEASURED

SIMULTANEOUSLY. USER MUST CHOOSE ONE OR THE OTHER.

To change the selection, hit the SETUP key. Using the DOWN arrow key, scroll

Down to VELOCITY PROBE and hit OK. The OFF/ON selection will be highlighted.

Use the Up & Down arrow keys to change the selection from OFF to ON or vice versa.

With the Velocity Probe Selection OFF, the AQ Expert will measure Differential

Pressure (∆P) automatically. With the Velocity Probe Selection ON, the AQ Expert will

measure Air Velocity (VEL) automatically. When you have your selection chosen, hit

the OK button and the entire Velocity Probe will be highlighted again. Hit the

MEASURE Button to get back to the Main Measurement screen once you are complete.

6) DUCT SIZE: (Velocity Option). Estimate the cross-section area of your Ducts in

square inches (in2) and set this value to obtain automatic & accurate Air Flow

measurements in CFM or CMM.

NOTE: When using the Velocity Feature on the AQ Expert it is recommended to ZERO

the readings BEFORE using the Pitot tube to ensure proper Velocity measurements.

See Chapter 9 for instructions on Zeroing the AQ Expert. (Zero Gas Sensors)

Connecting Pitot Tube: In air conditioning, heating and ventilating work, it is helpful to

understand the techniques used to determine air velocity. In this field, air velocity

(distance traveled per unit of time) is usually expressed in feet per minute (FPM). By

multiplying air velocity by the cross section area of a duct, you can determine the air

volume flowing past a point in the duct per unit of time. Volume flow is usually measured

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 24 of 52

in cubic feet per minute (CFM). To make Air Velocity measurements using the AQ

Expert, you will need to use the Optional 12” Pitot tube. Follow Steps #5 & #6 above to

(1) turn the Velocity Probe option ON (VEL will appear on the unit’s main screen) and

(2) set up your Duct Size. Connect the supplied hoses from the Pitot tube to the WHITE

(-) and/or (+) PRESSURE connections on the Front of the AQ Expert.

7) PUMP: Pump status is displayed:

a) AUTO - Automatic sample mode is selected

b) OFF – The internal Pump is turned off.

8) DISPLAY CONTRAST: Select the best value for viewing the LCD screen.

9) BAUDRATE: The communication speed for both the USB port and the Bluetooth

connection is set here. The default setting is 115 kbps.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 25 of 52

Store Current Buffer

Select Buffer

Start Average Test

Start Periodic Store

Select Interval: 1m

Review Buffer

Name Buffers

Erase Buffers

00: TAG#00

CHAPTER 7

INTERNAL DATA STORAGE

The STORE MENU allows the operator to store data and manage the internal storage

tags.

The AQ Expert has 1000 internal storage tags. Each tag stores one complete set of air

quality data. There are two ways to store air quality data to the monitor’s buffer. You can

either store data by selecting the option STORE CURRENT DATA after pressing the

STORE key, or alternatively you can make use of the monitor’s capability of storing data

automatically on a periodic basis. You can set the time period between data storage.

The STORAGE MENU shows the relevant display lines for the storage options.

1. STORE CURRENT BUFFER: The monitor will store one set of data into the tag

currently selected. The index number and the name of this tag appear at the

bottom of the screen.

2. SELECT BUFFER: Selecting this item will display an index of the monitor’s 1000

internal storage tags. Tags that are used have an icon next to their index

number. The selected storage tag is indicated by the reverse color line. When

data is stored, this pointer will automatically advance to the next available tag. If

you want to store data in a different location, use the UP, DOWN, & OK keys to

select a new tag. As you scroll up and down, tags containing data show their

date and time at the bottom of the display. Empty tags show the word empty.

3. START AVERAGE TEST: This will begin a period of data averaging, with the

average values stored periodically in successive memory tags. The interval

between each storage cycle is displayed below and can be set by the user. Once

enabled, this line will read: STOP AVERAGE TEST.

4. START PERIODIC: This will turn on the periodic store function. In this mode, the

Find Quality Products Online at: sales@GlobalTestSupply.com

unit will continuously store data at an interval displayed on the next line. Once

enabled, this line will read: STOP PERIODIC.

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 26 of 52

*** NAME BUFFERS ***

Starting Tag: 00

Ending Tag: 00

Name:xxxxxxxxxxxxxxxx

1 2 3 4 5 6 7 8 9 0 ◄

A B C D E F G H sym ►

I J K L M N O P shift

Q R S T U V W X Y Z

5. SELECT INTERVAL: The time between each store is set here. This can range

from 10 seconds to 60 minutes.

6. REVIEW BUFFER: This choice allows you to view previously saved data. Press

OK. The display will switch to the data screen, with the data in the first tag

displayed. The time and date when the data was saved will appear at the bottom

of the display. Use the UP / DOWN keys to scroll through the tags.

7. NAME BUFFERS: This choice will take you to

another screen where you can rename one or

more tags. This is useful if you use several tags

together to form a test series. Select the starting

test index with the UP / DOWN / LEFT / RIGHT

keys and press OK. Next, select the ending test

index. The cursor will move to the first character

of the first tag’s name, and the alphanumeric

keyboard will appear. Use the UP / DOWN /

LEFT / RIGHT keys to navigate around the keyboard, and press OK to select the

letter or number. For lower-case letters, highlight shift and press OK, for

symbols, highlight sym and press OK. The arrows in the corner will move the

cursor forward or backward through the tag’s name.

8. ERASE BUFFER: This option is used to erase stored data. Data that has been

stored in the monitor’s memory will be retained even after the instrument has

been shut off and its batteries removed. To erase the contents of a specific tag,

use the UP / DOWN keys to move the arrow to the desired tag. As you scroll up

and down, tags containing data show their date and time at the bottom of the

display. Empty tags show the word empty. If you wish to erase all 1000 of the

monitor’s stored data, move the arrow to the entry ALL TAGS and press OK.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 27 of 52

Print Test Record

Start Test Log

Log Interval: 60s

Print Buffer

Configure Record

Edit Customer Name

Calibration Record

Paper Feed On/Off

Mobile Printer...

Seri al # : 00 0000

Comp any Name

TEST RECORD

AUG 1 ‘14 12:45:00

CO2: XX. X %

CO: XXX X PP M

T am bien t: XXX ºF

RH: XX. X %

DP t: X XX ºF

WBT: XXX X ºF

BP: XXX X ps i

Oxyg en: XX.X %

NO: X XXX P PM

N O2: X XXX P PM

N Ox: X XXX P PM

S O2: X XXX P PM

H 2S: X XXX P PM

O3: XX X PP M

VOC: XX X PP M

* WIRELESS PRINTERS *

Scan for printers

Press OK to search

* WIRELESS PRINTERS *

Device Found

Press OK to Connect

Device 1:001122334455

* WIRELESS PRINTERS *

Device Connected

Press OK to Continue

Device 1:001122334455

CHAPTER 8

WIRELESS REMOTE PRINTER

The AQ Expert uses a wireless Bluetooth remote printer. The

printer is powered by a rechargeable battery. An AC charger is

supplied with the printer. The printer is optional with the

AQ Expert.

First you must turn the printer on. Then press PRINT to scan and

connect with your wireless printer to establish communications

between the monitor and the printer.

When you have connected successfully the printer’s green status light will turn on.

Pressing the PRINT key will now display the PRINT MENU.

The PRINT MENU allows the user to print test records.

Find Quality Products Online at: sales@GlobalTestSupply.com

PRINT TEST RECORD: This option will print a test record of

the current air quality parameters.

PRINT TEST LOG: This option begins a log of the following air

quality parameters: CO2, Temperature, %RH, Wet Bulb, Dew

Point, Barometric Pressure, Oxygen, Carbon Monoxide, VOCs,

etc.

LOG INTERVAL: This selects the interval between each log

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 28 of 52

** EDIT HEADER INFO *

E INSTRUMENT AQ EXPERT

1 2 3 4 5 6 7 8 9 0 ◄

A B C D E F G H sym ►

I J K L M N O P shift

Q R S T U V W X Y Z

entry. The interval can be set between 1 and 60 seconds.

PRINT BUFFER: This option is used to print data stored in the monitor’s memory. Each

line corresponds to one storage tag. Tags containing data show an icon next to the

index number. When you scroll up and down, the date (mm/dd) and time (hh/mm) when

the data was stored appear at the bottom; empty tags show the word “empty”. To print

the contents of a specific tag, use the UP / DOWN keys to move the arrow to the

desired tag and press OK. If you wish to print the entire monitor’s stored data in

sequence, move the arrow to the entry ALL TAGS and press OK.

CONFIGURE RECORD: This option allows the user to add, delete, or change the order

of the parameters that appear on the paper print out.

EDIT CUSTOMER NAME: This will display a screen

where you can change the information printed at the top of

each printout. Usually the customer’s name or the

operator’s name appears here. To edit this information,

use the UP / DOWN / LEFT / RIGHT keys to navigate

around the keyboard, and press OK to select the letter or

number. For lower-case letters, highlight shift and

press OK, for symbols, highlight sym and press OK. The

arrows in the corner will move the cursor forward or

backward through the name.

CALIBRATION RECORD: This option will print a record of each sensor’s last

calibration, including the date of calibration and span gas value used.

PAPER FEED: This toggles the printer’s motor on and off, advancing the paper out the

top of the printer as needed. The motor will not turn on if there is no paper present.

MOBILE PRINTER: The WIRELESS PRINTERS screen will appear. You can

disconnect your current Bluetooth connection and connect to another printer in range.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 29 of 52

**** CALIBRATION ****

Zero Gas Sensors

Zero CO2 Sensor

Zero Thermocouples

Zero Errors

Zero Time: 60sec

Span Time: 120sec

** Span Lockout **

Sensor History

Span CO: xxxx PPM

Span H2: xxxx PPM

Span CO2: xxxx PPM

Span NO: xxxx PPM

Span NO2: xxxx PPM

Span SO2: xxxx PPM

Span H2S: xxxx PPM

Span FMH: xxxx PPB

Span Ozone:xxxx PPB

Span VOC: xxxx PPB

Span Velocity: xx "

Span ∆P: xx "

Span AmbT: xx.x C

Span BP: xxxx mbar

Span RH: xx.x %

Cal Thermcple1:xxxF

Cal Thermcple2:xxxF

NOTE: CO2 should ALWAYS be Span Calibrated or Zeroed with a Cylinder of

ZERO AIR. Do Not Use Ambient Air for CO2 sensor calibration.

NOTE: Please take special care when performing Calibration of the monitor.

You cannot revert back to the factory setting after any adjustments!

CHAPTER 9

ZERO & SPAN CALIBRATION

Every instrument must occasionally be tested against some known value or standard in

order to make sure that its accuracy has not deteriorated. If the instrument is reading

outside of the stated accuracies in this manual, the unit should be calibrated by

following the procedures described in this chapter.

This chapter will contain all of the information on calibrating and adjusting the AQ Expert

IAQ Monitor. The term Span Calibration means comparing the AQ Expert’s readings to

a standard concentration (i.e.: calibrated gas bottles) and adjusting/changing the AQ

Expert’s individual sensor’s readings to match the standard concentration for the most

accurate measurements. The term ZERO calibration refers to the user’s ability to

calibrate each sensor with zero concentration of the targeted gas. See Chapter 11,

Maintenance, for recommended frequencies of each procedure.

If the unit is returned to E Instruments for Span Calibration, the unit will be shipped back

after Calibration with a new Calibration Certificate valid for one (1) year. If the unit is

Span Calibrated in the field, the original calibration certificate is no longer valid.

The CALIBRATION MENU lets you set span calibration

values for each sensor and performs all sensor

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

calibrations. The CALIBRATION MENU is shown below

A brief explanation of the parameters shown follows

below:

ZERO GAS SENSORS: This will set the zero point of

CO, NO, NO2, SO2, H2S, CH2O, O2, VOCs, Pressure &

Velocity values.

ZERO CO2 SENSOR: This will set the zero point of CO2.

ZERO THERMOCOUPLE: This calibrates the external

thermocouple input (T1) to ambient temperature.

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 30 of 52

ZERO ERRORS: This will display a list of sensors that were out of the monitor’s

acceptable range during the last zero countdown.

ZERO TIME: This is the countdown time for the zero procedure. The zero cycle time

should set at 20-60 seconds.

SPAN TIME: When carrying out a span calibration, you must introduce the span gas for

an appropriate amount of time before the monitor executes the span calibration. This

setting, which is the same for all sensors, controls this time interval. The span time is

indicated in seconds.

SPAN LOCKOUT: This controls access to the remaining span calibration menu

options. Span lockout prevents accidental or mistaken calibrations. Span lockout is

enabled and disabled by entering a 4-digit code.

SENSOR HISTORY: The date that each sensor was installed is displayed, along with

the date the sensor was last calibrated and the span gas concentration used.

SPAN XXXX: The remaining lines of the CALIBRATION MENU are used for carrying

out span calibrations of the CO, CO2, NO, NO2, SO2, H2S, Ozone, Formaldehyde,

VOCs, and Velocity sensors. For detailed use of these settings, please refer below.

A. ZEROING THE AQ EXPERT

Select CALIB key to go into Calibration Mode

There are two (2) methods to Field-Calibrate the GAS & CO2 Sensors on the AQ Expert.

(i) ZERO Gas Sensors using the ZERO AIR Cylinder (to zero all gas sensors)

(ii) Using Outside fresh Air to Calibrate the gas sensors (except the CO2 sensor)

1. ZEROing ALL GAS Sensors using a certified Cylinder of ZERO AIR

If you have a gas cylinder/bottle of ZERO AIR you can use this for Zeroing ALL of the

gas sensors in the AQ Expert. If you do not have this cylinder, please contact

E Instruments to purchase our optional Calibration Kit consisting of ZERO AIR &

regulator for proper calibration of the AQ Expert (part #: AQCAL).

ZERO GAS SENSORS: This will set the zero point of CO, NO, CH2O, NO2, SO2, H2S,

O2, and VOCs values. Connect Cylinder to the “A” inlet connection on the bottom of the

AQ Expert using the optional accessories included in the CALIBATION KIT (Part #:

AQCAL). See CALIBRATION APPARATUS section below for how to connect.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 31 of 52

Have the cursor (reverse color) point to the line:

Zero Gas Sensors

Press the OK key to execute a zero cycle of all the gas sensors. This procedure should

last 60 seconds.

At the end of the zero period, the AQ Expert reads the output of all gas sensors (with

the exception of the CO2 sensor) and sets them all to zero, and the Oxygen (O2) that it

sets to 20.9%.

If no error messages appear at the end of the countdown, proceed with your

measurements.

ZERO CO2: This will set the zero point of CO2. You must use cylinder of ZERO AIR

for CO2 ZERO CALIBRATION. Connect Cylinder to the “A” inlet connection on the

bottom of the AQ Expert using the optional accessories included in the CALIBATION

KIT (Part #: AQCAL). See CALIBRATION APPARATUS section below for how to

connect.

Scroll down using down arrow key and have the cursor (reverse color) point to

the line

Zero CO2 Sensors

Press the OK key to execute a zero cycle of the CO2 Sensor. This procedure should

last 60 seconds.

If no error messages appear at the end of the countdown, proceed with your

measurements.

2. ZEROing Sensors using OUTDOOR FRESH AIR (with the exception of CO2)

If you are not using bottled ZERO AIR, it is important to select a location where the

ambient environment of the monitor is clean from traces of carbon monoxide or other

toxic gases. The user should be at least 20-30 feet (6-10 meters) away from any

buildings, parking lots, highways, and any other possible exhaust sources. If in doubt of

the ambient air, please use the ZERO AIR cylinder.

When you turn the instrument on in clean ambient air, wait at least one (1) minute to

allow the monitor to warm up before carrying out the zero calibration.

ZERO GAS SENSORS: This will set the zero point of CO, NO, CH2O, NO2, SO2, O2,

H2S, and VOCs values based on the clean ambient conditions.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 32 of 52

NOTE: You must always span calibrate the instrument when a sensor is replaced.

Have the cursor (reverse color) point to the line:

Zero Gas Sensors

Press the OK key to execute a zero cycle of all the gas sensors. This procedure should

last 60 seconds.

At the end of the zero period the AQ Expert reads the output of all gas sensors (with the

exception of the CO2 sensor) and sets them all to zero, with the exception of the

Oxygen (O2) that it sets to 20.9%.

If no error messages appear at the end of the countdown, proceed with your

measurements.

ZERO THERMOCOUPLE: This calibrates the one external thermocouple input (T1) to

ambient temperature.

Be sure the Thermocouples being testing are at room temperature before Calibrating

To start the zero procedure, press the CALIB key and select ZERO Thermocouples.

B. SPAN CALIBRATION

E Instruments recommends performing a span calibration of the instrument once every

6 months for maximum accuracy, or at a minimum of once per year. The parameters

that require a span calibration are: carbon monoxide, carbon dioxide, nitric oxide,

nitrogen dioxide, sulfur dioxide, hydrogen sulfide, oxygen, formaldehyde, and VOCs.

You can carry out all span calibrations in sequence.

Span calibration using your own gas

If you wish to use your own span gas to perform span calibrations you must take certain

precautions and follow the instructions below carefully in order to calibrate the sensors

properly.

Notice that you will need a number of certified gas cylinders. Make sure that you use a

bypass flow meter as shown below in the CALIBRATION APPARATUS section, in order

to supply an adequate flow of span gas without developing excessive or insufficient

pressure on the sensors.

Make sure the concentration of the calibration gas is within the range of each sensor.

Do not use gas that will over-range the sensor.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 33 of 52

TO SPAN CALIBRATE THE MONITOR, IT IS BEST TO USE ONLY SINGLE GAS

MIXTURES WITH EITHER NITROGEN OR AIR BALANCE.

The CO span gas can be in the range of 30 - 200 PPM, 2% accuracy with balanced

nitrogen, preferably.

The NO span gas can be in the range of 10 - 200 PPM, 2% accuracy with balanced

nitrogen, required.

The NO2 span gas can be in the range of 10 - 20 PPM, 2% accuracy with balanced

nitrogen or air.

The SO2 span gas can be in the range of 10 - 20 PPM, 2% accuracy, with balanced

nitrogen, preferably.

The VOC (Isobutylene) span gas can be in the range of 0 - 10 PPM, 2% accuracy with

balanced air.

The CH2O (Formaldehyde) span gas can be in the range of 0 - 2 PPM, with balance

nitrogen, preferably.

The H2S span gas can be in the range of 10 - 20 PPM, 2% accuracy, with balance

nitrogen, preferably.

The CO2 span gas can be in the range of 2500 PPM, 2% accuracy, with balance air

Make sure the concentration of the calibration gas is within the range of each

sensor. Do not use gas that could over-range the sensor.

For greatest accuracy, it is recommended that you use a span gas value close to

the gas concentration you expect to measure.

C. CALIBRATION APPARATUS

During calibration an adequate flow of span gas must be supplied without developing

excessive pressure on the sensors. A compressed cylinder of span gas must be

equipped with a primary pressure regulator. Connect the regulator of the bottled gas to

the AQ Expert “Sample In”. A simple way to feed the span gas to your monitor is by an

open T-connection that will ensure that gas is fed at ambient pressure. The regulator

valve is used to control the flow of gas to the monitor. To ensure that the span gas is fed

properly and as efficiently as possible, connect a bypass flow-meter at the outlet. Adjust

the regulator to maintain approximately 750 cc/min of flow at the outlet.

You must not feed gas to the AQ EXPERT under pressure and you must not starve the

AQ EXPERT's pump for gas. When feeding the gas, you must maintain a reasonably

constant pressure, near ambient pressure.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 34 of 52

ZERO AIR Gas Bottle Calibration:

D. CALIBRATION PROCEDURE

The following page illustrates the sequence of key strokes to carry out a span

calibration of the AQ Expert. It is assumed that the instrument has been zeroed and

there have been no error messages.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 35 of 52

NOTE: Please take special care when performing Calibration of the monitor.

You cannot revert back to the factory setting after making any adjustments!

Electrochemical Gas & PID VOC Sensors

1. Turn the AQ Expert on and press OK to perform a zero. Allow the instrument to

warm up for 15 minutes, and repeat the zero.

2. Connect the outlet from the tee fitting of the gas calibration fixture to the

connector on the front of the monitor labeled “SAMPLE IN” using the set up

shown on the following figure:

3. Turn on the gas flow and observe the gas readings on the instrument. If the gas

reading for the sensor being calibrated does not increase after a few seconds,

turn off the gas flow until the problem is found. Otherwise, press OK.

4. Press the key labeled “CALIB” to enter the calibration menu.

5. Scroll down to the SPAN TIME and set the value to 20 seconds.

6. Scroll down to the sensor to be calibrated. If the calibration lock is on, enter the

password 1315.

7. Use the arrow keys to enter the span value printed on the calibration cylinder.

Press OK.

8. Turn on the gas flow and observe gas readings. If the gas reading for the sensor

being calibrated does not increase after a few seconds, turn off the gas flow until

the problem is found. Otherwise, press OK.

9. When the countdown reaches 3 seconds, there will be a series of beeps. Verify

that the reading for the sensor being calibrated matches the value entered in the

calibration menu, and that the reading for all of the other sensors is zero. Turn off

the gas flow.

10. Repeat this procedure for each electrochemical sensor to be calibrated.

11. After all of the sensors are calibrated, turn the unit off and back on again, and

perform a zero.

Temperature, Humidity and Barometric Pressure

Please contact E Instruments for proper Calibration Procedure

Pressure and Air Velocity Calibration Procedure

1. Connect a pressure calibration standard to the pressure (+) connector on the

front of the instrument.

2. In the SETUP menu, make sure the velocity sensor is off.

3. Press the “CALIB” key to enter the calibration menu.

4. Scroll down to SPAN ∆P and press OK.

5. Using the calibration standard, generate a pressure value near the maximum

stated value for the scale being used, for instance 80 mbar if using the mbar

range.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 36 of 52

6. Enter the value generated as the span value using the arrow keys, and press the

enter key.

7. Verify that the reading on the instrument matches the reading on the calibration

standard.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 37 of 52

CHAPTER 10

AQ GAS SOFTWARE

1. COMMUNICATIONS

The AQ Expert Monitor communicates with a PC either using the USB cable or

wirelessly using its internal Bluetooth (BT) module. If your computer does not have

internal BT capabilities, use the external BT module that is supplied with the AQ Expert

The communication protocol is as follows:

BAUD RATE: 115000 baud

FORMAT: 8 bits, 1 stop bit, no parity

HANDSHAKE: None

USB CONNECTION

For USB connections, use the A-to-B type USB cable supplied with the instrument. To

establish a USB connection, the FTDI USB driver must first be installed on your

computer. The USB drivers for Windows computers are located on the E

INSTRUMENTS USB Thumb Drive:

When you plug the USB cable from the computer to the monitor, you should hear

a small “da-ding” sound indicating that the USB connection has been made.

If you have the FTDI USB driver already installed in your computer the computer

will know and will NOT initialize the “New Hardware Wizard”.

If the New Hardware Wizard appears you need to install the FTDI USB driver. To

install this driver:

1. Locate the FTDI USB driver on the CD or download it from the

E INSTRUMENTS website and save it to your desktop.

2. The downloaded file is zipped. Double-click the zipped folder and choose

Extract All Files. Extract the files to a folder on the Desktop. The driver files

are in the FTDI_USB folder.

3. Follow the instructions in the New Hardware Wizard

4. You will have to go through the wizard twice, once to install the ftdiport.inf file

and once for the ftdibus.inf file.

BLUETOOTH CONNECTION

For Bluetooth connections, the connection process varies with different Bluetooth

devices. Follow your manufacturer’s instructions for adding a device. The

E INSTRUMENTS’ Bluetooth modem is a Class 1 device, with a maximum range of

100m. Obstacles such as walls and equipment will reduce the effective range.

The AQ Expert is supplied with a Bluetooth Dongle to make connections to PC’s without

internal Bluetooth capabilities.

TM

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 38 of 52

1. Connect the USB Bluetooth Dongle adapter to your PC, the drivers will begin to

install automatically.

2. In order to establish communications between the PC and your E Instruments’

monitor, navigate to the following path:

Start –> Control Panel –> Hardware and Sound –> Add a Bluetooth device (listed

in Devices & Printers area)

3. Turn your instrument on, and it will appear on the screen after a few moments.

Select it from the list and click Next.

4. On the next screen, select “Enter the device’s pairing code” and click Next.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 39 of 52

5. Enter the pairing code “0000” (four zeros) into the empty field and click Next.

6. Paring will complete and the PC to instrument communication drivers will be

automatically installed.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 40 of 52

ALL CONNECTIONS

When you connect your monitor to your

computer for the first time, the connection will

be assigned a unique comport number.

Remember the comport number as it will be

needed to open an AQ GAS session.

You can find the comport associated with your

E INSTRUMENTS in the Windows Device

Manager.

To open the Device Manager:

Go to the Windows “START” menu,

click “RUN” and type devmgmt.msc

(Or go to the Control Panel, choose the

System icon, then the Hardware tab,

and click the Device Manager Key).

A window will open that will list

“PORTS” among other items. Click on

“PORTS”.

The comport will be listed as:

o USB Serial Port (USB)

o Standard Serial over Bluetooth link (Bluetooth)

AQ GAS SOFTWARE

You can enhance the performance and versatility of the E INSTRUMENTS AQ EXPERT

by using the AQ GAS software program. AQ GAS is available for most Windows

operating systems.

The AQ GAS software is a robust package that allows you to:

1. Monitor all Air Quality

parameters.

2. Record maximum,

minimum, average for all

Air Quality parameters.

3. Select a variety of saving

and printing options.

4. Retrieve stored data.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 41 of 52

5. Set alarms for every air quality parameter including recording the time duration

that alarms have been exceeded.

6. Plot bar graphs and time plots of all air quality parameters.

The AQ GAS software can be downloaded from the included USB Thumb Drive.

Consult the AQ GAS manual for details on installing and operating the program. The

manual can be accessed by clicking on “Help” and then “How Do I…” in the AQ GAS

software program

STARTING AQ GAS

1 Before starting AQ GAS, have your monitor turned on and connected via USB

or Bluetooth.

2 Start AQ GAS. If you have connected before, the monitor icon will appear. If

this is the first time you are connecting you will need to add a new port.

3 On the AQ GAS window click on “Connections”, then click on “Add Port”.

4 Enter the COM port number which appeared in the Device Manager, and click

“OK”.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 42 of 52

5 The COM port with its number should appear on the left side of the AQ GAS

window. AQ GAS will look for an monitor on this port. After a moment the E

INSTRUMENTS monitor icon should appear. You are now connected to your

monitor.

6 Click on the E INSTRUMENTS icon. A menu will appear. Choose “Monitor”

from the menu. (Follow the AQ GAS manual for further instructions).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 43 of 52

INTERVAL

ITEM

PROCEDURE

Weekly

ZERO Check of ALL Gas Sensors

Perform using ZERO AIR

Weekly

ZERO Check of the CO2 Sensor

Perform using ZERO AIR

6 Months

Inlet & Moisture Filters

Check and/or Replace

Annually

SPAN Calibration of ALL Gas Sensors

Perform or send to Factory

CHAPTER 11

MAINTENANCE

The AQ Expert Indoor Air Quality Monitor is a sophisticated analytical instrument

designed to perform accurate air quality measurements. However, because the monitor

is a portable, field/lab used instrument that can be used in many environments, care

must be taken to prevent physical and environmental abuse to help maintain troublefree operation.

There are some of the components that will require periodic inspection or replacement.

These are:

1. The disposable fiber line filter for particulates, located inside the of the monitor

2. The disposable round disk condensation filter for moisture, also located inside

the of the monitor

3. Gas sensor periodic replacement / Calibration

4. Printer paper replacement (separate optional wireless printer)

*Note: These stated intervals are dependent on the unit’s usage and applications

A. Fiber Line Filter and Condensation Disk Filter Replacement

The disposable fiber line filter is located inside the monitor located right in line with the

sampling pump. Its function is to prevent dirt & dust particles from reaching the

monitor’s pump and sensors. The disk condensation filter is also located in the same

area directly behind the fiber line filter. Its function is to prevent any residual

water/moisture from penetrating into the sensor area.

You must replace the filters when they become discolored or show any signs of cracks.

Never operate the AQ Expert without these filters.

Frequency of filter replacement depends on the application this instrument is being used

in and the hours of active use.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 44 of 52

NOTE: You must always span calibrate the instrument every time

you replace a sensor.

NOTE: CO2 should ALWAYS be Calibrated or Zeroed with a Cylinder of ZERO

AIR. Do Not Use Ambient Air for CO2 sensor calibration.

To replace the filters, remove the top section of the instrument case (see section B

below for more details on how to remove top section of the instrument) and disconnect

the two pieces of flexible tubing that hold the respective filters in place. If you are

replacing the disk filter make sure that the filter’s lettering is facing the front face of the

instrument.

B. Sensor Replacement

This should be an infrequent operation, since the sensors have a typical life of a few

years.

If you receive an error message for one of the sensors during instrument operation you

may have to replace the sensor. Please contact E Instruments for replacement

sensors. The user can send the unit back to the factory for sensor installation and recalibration of the instrument or the sensors can be replaced in the field. The

replacement sensors will be supplied with installation instructions.

To access the sensor compartment you must remove the top section of the instrument

case. The top section of the monitor case is held to the bottom section by a total of four

retaining screws. With both hands, slide off the vent covers on each side. Use a Philips

screwdriver to remove both pairs of retaining screws (one pair on each side of the

case). It is best to remove the bottom pair of screws first. Carefully lift the top of the

instrument case together with the attached aluminum mounting shielding plate

especially since the top & bottom cases pieces are connected with cables/wires. When

the plastic case is open, be careful when near the main board because some of the

resistors on the board can get significantly hot. The location of the gas sensors on the

manifold is shown in the figure in Chapter 5.

To replace a sensor locate its correct position on the manifold. Carefully lift the small PC

board that is mounted on top of the sensor. Grab the sensor with your fingers and lift it

twisting it out of its bayonet fitting.

Take a new sensor. Remove any springs that may be shorting the sensor pins. Install it

on its mount and connect the small PC board on top of it.

Replace the top section of the case and secure it with the four screws.

Wait 30 minutes before zeroing the monitor:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 45 of 52

Span calibrate the sensor as explained in Chapter 8. If you are installing a precalibrated sensor, use the following procedure:

1) While holding the SETUP key, press the MEASURE key three times. The display

will show the sensor factors.

2) Press the DOWN key until you reach the appropriate sensor then press OK.

3) Use the UP / DOWN keys to enter the correct factor, digit by digit starting with the

hundreds digit, press OK to move through the tens, ones, and tenths digits.

C. Printer Paper Replacement

The external printer uses a high quality 2" thermal paper. Keep any spare paper rolls in

a cool dark place to prevent paper discoloration.

1) Press the open key on the printer to open the paper cover

2) Insert the paper as shown in the image. Remove any

remaining core of a used paper roll.

3) Make sure to align the paper roll properly.

4) Pull the paper out as shown in the image, and close the

cover.

5) Tear off any excess paper in the direction of the side of the

printer.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

AQ EXPERT Instruction & Operations Manual Version 1.08

Page 46 of 52

CHAPTER 12

AQ EXPERT OPTIONS

The E INSTRUMENTS’ AQ EXPERT is an extremely versatile Indoor Air Quality (IAQ)

measurement system that meets practically all Air Quality measurement requirements.

It has been designed as a modular system, permitting the installation, in the field, of

most of the various available options. This manual describes the complete instrument

equipped with all the options.

The AQ Expert’s standard capabilities include (1) NDIR CO2 sensor (0-5,000 ppm),

Ambient Temperature, Relative Humidity, Wet Bulb, Dew Point, Barometric Pressure,

two (2) separate Type K (TcK) thermocouple temperature measurement inputs, Air

Velocity measurements, differential pressure measurements, 1000 internal storage

tags, Bluetooth wireless PC communications, REAL-TIME Data Logging capabilities

using the included AQ GAS WindowsTM software, USB Cable, and extensive userfriendly help screens. The available additional gas sensor options and accessories are:

1. AIR QUALITY MONITOR SENSORS*

Carbon Dioxide (CO2) – non-dispersive infrared (NDIR) sensor (0-20%)

Carbon Monoxide (CO) – electrochemical sensor (0-200 ppm OR 0-2000 ppm)

Oxygen (O2) - electrochemical sensor (0-25%)

Nitrogen Dioxide (NO2) - electrochemical sensor (0-20 ppm OR 0-1000 ppm)

Nitrogen Oxide (NO) - electrochemical sensor (0-250 ppm OR 0-2000 ppm)

Sulfur Dioxide (SO2) – electrochemical sensor (0-20 ppm OR 0-2000 ppm)

Hydrogen Sulfide (H2S) – electrochemical sensor (0-100 ppm)

Formaldehyde (FMH-CH2O) – electrochemical sensor (0-10 ppm)

Ozone (O3) – electrochemical sensor (0-5 ppm)

Isobutylene (VOC) sensor – Photo ionization detector (PID Sensor) (0-20 ppm)

Isobutylene (VOC) sensor – Photo ionization detector (PID Sensor) (0-200 ppm)

*Note: When O

The unit can NOT have all three (3) sensors (O3 + NO2 + SO2) together simulatenously.