Page 1

www.kimo-instruments.com

USER MANUAL

E500 Combustion analyzer

E Instruments, a member of Sauermann Group

Page 2

Page 3

TABLE OF CONTENTS

3

1.0 IMPORTANT INFORMATION 06

1.1 Information about this manual 06

1.2 Danger levels and other symbols 06

2.0 SAFETY 07

2.2 Safety check 07

2.2 Intended purpose 07

2.3 Improper use of the product 07

2.4 Precautions for the usage of the Li-Ion battery package 07

3.0 WORKING PRINCIPLE 08

3.1 General overview of the analyzer 08

4.0 DESCRIPTION OF THE PRODUCT 09

4.1 Working principle 09

4.2 Measurement cells 09

4.3 Fuel types 09

4.4 Sample treatment 09

4.5 Pressure sensor, piezoelectric, temperature compensated 09

4.6 Suction pump 09

4.7 Draft measurement with sensor automatic autozero 09

4.8 Bluetooth® connection 10

4.9 IR connection 10

4.10 Available software and applications 10

5.0 COMPONENTS DESCRIPTION 11

5.1 Instrument interface 11

6.0 TECHNICAL SPECIFICATIONS 13

6.1 Technical specifications 13

6.2 Measurement and Accuracy Ranges 14

7.0 USING THE FLUE GAS ANALYZER 15

7.1 Preliminary operations 15

7.2 Warning 15

7.3 Analyzer Power supply 15

7.3.1 Internal battery charge level 15

7.3.2 Use with external power pack 16

7.4 QR code generation 16

7.5 Connection diagram 17

8.0 FLUE GAS ANALYSIS 18

8.1 Flue gas Analysis 18

8.1.1 Switching on the instrument and out-calibration 18

8.1.2 Preliminary Operations 19

8.1.3 Inserting the probe inside the stack 19

8.1.4 Performing the combustion analysis 20

8.1.5 End of the Analysis 21

Page 4

TABLE OF CONTENTS

4

9.0 MENU 23

9.1 Setting Menu 23

9.2 Menu→Measurements 24

9.2.1 Menu→Measurements→Draft 25

9.2.2 Menu→Measurements→CO air 26

9.2.3 Menu→Measurements→Pressure 27

9.4 Menu→Configuration 28

9.4.1 Menu→Configuration→Analysis 29

9.4.1.1 Menu→Configuration→Analysis→Fuel 30

9.4.1.2 Menu→Configuration→Analysis→Condensation 31

9.4.1.3 Menu→Configuration→Analysis→O2 Reference 32

9.4.1.4 Menu→Configuration→Analysis→Measure units 33

9.4.1.5 Menu→Configuration→Analysis→Autozero 34

9.4.1.6 Menu→Configuration→Analysis→Air temp 35

9.4.1.7 Menu→Configuration→Analysis→NOx/NO Ratio 36

9.4.2 Menu→Configuration→Instrument 37

9.4.2.1 Menu→Configuration→Instrument→Display 38

9.4.2.2 Menu→Configuration→Instrument→On site calib. 39

9.4.2.3 Menu→Configuration→Instrument→Clock 44

9.4.2.4 Menu→Configuration→Instrument→Bluetooth 45

9.4.3 Menu→Configuration→Alarm 46

9.4.4 Menu→Configuration→Print 47

9.4.4.1 Menu→Configuration→Print→Pairing 48

9.4.5 Menu→Configuration→Language 49

9.4.6 Menu→Configuration→Reset 50

9.5 Menu→Diagnostic 51

9.5.1 Menu→Diagnostic→Sensors 52

9.5.2 Menu→Diagnostic→Gas probe 53

9.5.3 Menu→Diagnostic→Hardware 54

9.6 Menu→Info service 55

10.0 SENSORS 56

10.1 Sensors arrangement 56

10.2 Sensor types and relevant positioning 56

10.3 Gas sensor life 56

10.4 Gas sensors life table 56

11.0 MAINTENANCE 57

11.1 Routine maintenance 57

11.2 Preventive maintenance 57

11.3 Replacing the gas sensors 58

11.4 Replacing the battery pack 60

12.0 TROUBLESHOOTING 61

12.1 Troubleshooting guide 61

13.0 SPARE PARTS AND SERVICING 63

13.1 Spare parts 63

13.2 Accessories 63

13.3 Service Centers 63

Page 5

TABLE OF CONTENTS

5

ANNEX A - Analysis report examples 64

ANNEX B - Heading of the printed report with the PC Software “Easy2print” 66

ANNEX C - Optional Measurements list /

Measurement units matching → abbreviations 67

ANNEX D - Coefficients of the fuels and Formulas 69

ANNEX E - Declaration of Conformity 71

Page 6

6

1.0

IMPORTANT INFORMATION

Symbol Meaning Comments

The magnets in the back of the instrument can damage credit cards, hard drives, mechanical

It is recommended to keep the instrument at a distance of at least 10 inches (25 cm) away

10:00

Info ser. [1/2]

Sauermann Group EInstruments/KIMO

Zone industr

Montpon FR

Tel.

kimo

1.1 Information about this manual

This manual describes the operation and the characteristics and the maintenance of the Combustion Analyser

model E500.

Read this operation and maintenance manual before using the device. The operator must be familiar with the

manual and follow the instructions carefully.

This use and maintenance manual is subject to change due to technical improvements - the manufacturer

assumes no responsibility for any mistakes or misprints.

1.2 Danger levels and other symbols

watches, pacemakers, defibrillators and other devices proven sensitive to magnetic fields.

from these devices.

+33(0)5.53.80.85.00

-fr.custhelp.com

15/04/19

ielle BP16 24700

WARNING

Information on LCD

Disposal Indications

Read information carefully and prepare safety appropriate action!

To prevent any danger from personnel or other

goods. Violating the information in this manual

may cause danger to personnel, the plant or the

environment and may lead to liability loss.

Dispose of the battery pack at the end of its

working life only at the dedicated collecting bin.

The customer takes care, on his own costs, that

at the end of its working life the product is

collected separately and it gets correctly

recycled.

Keyboard with preformed keys

with main control functions.

Page 7

7

2.0

SAFETY

2.1 Safety check

• Use the product according to what is described in chapter “Intended purpose”.

• During the instrument operation, comply with the current standards.

• Do not use the instrument if damaged on the outer cover, on the power supply plug or on the cables.

• Do not take measures on non-isolated components / voltage conductors.

• Keep the instrument away from solvents.

• For the maintenance of the instrument, strictly comply with what’s described in this manual at the

“Maintenance” chapter.

• All the interventions not specified in this manual, may be performed exclusively by E instruments assistance

centres. Otherwise, E instruments declines every responsibility about the normal operation of the instrument and

on the validity of the several homologations.

2.2 Intended purpose

This chapter describes the areas of application for which the E500 is intended.

Using the E500 in other application areas is on the risk of the operator and the manufacturer assumes no

responsibility and liability for loss, damage or costs which could be a result. It is mandatory to read and pay attention

to the operating/maintenance manual.

All products of the series E500 are handheld measuring devices in professional flue gas analysis for:

•

Small furnaces (burning oil, gas, wood, coal)

•

Low-temperature and condensing boilers

•

Gas heaters

2.3 Improper use of the product

E500 should not be used:

•

As safety alarm instrument

•

In classified zones with explosion risk (ATEX or equivalent)

2.4 Precautions for the usage of the Li-Ion battery package

Pay attention while handling the battery package inside the instrument; a wrong or improper usage may lead to

heavy physical injuries and/or damages:

•

Do not create a short circuit: make sure that the terminals are not in contact with metal or other conductive

materials during transportation or storage.

•

Do not apply with inverted polarities.

•

Do not make the batteries come in contact with liquid substances.

•

Do not burn the batteries nor expose to temperature higher than 140 °F (60°C).

•

Do not try to disassemble the battery.

•

Do not provoke collisions or pierce the batteries. Improper use can cause damages and internal short circuits not

always externally visible. If the battery package has fallen or has been hit with an hard surface, regardless the

external shell condition:

•

Stop operation;

•

Dispose of the battery in compliance with the disposal instructions.

•

Do not use batteries with leaks or damages.

•

Charge the batteries only inside the instrument.

•

If a malfunction occurs or if over heating signs occur, immediately remove the battery package from the

instrument. Warning: the battery may be hot.

Page 8

8

3.0

WORKING PRINCIPLE

3.1 General overview of the Analyzer

E500 is a portable industrial analyzer for flue gas and emissions monitoring.

The instrument is equipped with:

-

Pneumatic line able to manage up to 2 sensors.

-

Easy and immediate user interface so it could be used without the manual support.

-

Wide and bright graphic display, White / Black (128x128 mm), thanks to an efficient backlighting.

-

Rechargeable 'Li-Ion' battery.

-

Supplied with the device is a feeder with output 5V , 2A to charge the internal batteries.

When needed, it is possible to recharge the instrument battery using a power bank, as long as it is equipped

with 5 volts output and 1A minimum current.

Main functions:

-

Combustion analysis in manual.

-

Comes with the 12 most used fuel parameters (such as natural gas, LPG, gas oil and fuel oil).

-

Generation and visualization of a QR code with the purpose of downloading the data of the acquired measures,

having installed the App E instruments “E-Instruments QR Code App” which can be downloaded form the

AppStore (if the version of the instrument foresees it).

Measured values:

-

O2

-

CO

-

NO

-

Combustion air temperature

Gas pressure in the piping, pressure in the burning chamber and check of the pressure switches, using the

measurement range up to 200hPa.

- Pressure measurement

- Pressure measurement of the gas alimentation line

-

CO environment measurement (via the internal sensor)

-

Draft measurement

Calculated values:

-

Stack leaks

-

Combustion efficiency

-

CO

2

-

NOX

Maintenance:

-

Sensors can be replaced by the user without having to ship the instrument to the service center, because the

spare sensors delivered are pre-calibrated.

-

The instrument requires annual calibration.

Certificate of calibration

The instrument is accompanied with a calibration certificate, according to the ISO/EN 17025 standard.

Page 9

9

300 hPa MAY CAUSE A

PERMANENT DEFORMATION OF THE MEMBRANE, THUS DAMAGING IRREVERSIBLY THE

4.0 DESCRIPTION OF THE PRODUCT

4.1 Working principle

The gas sample is taken in through the gas probe, by a diaphragm suction pump inside the instrument.

The measuring probe has a sliding cone that allows the probe to be inserted in holes with a diameter of 11 mm to

16 mm and to adjust the immersion depth: it is recommended to have a gas sampling point roughly in the

center of the flue/stack.

The gas sample is cleaned of humidity and impurities by a condensate trap and filter located inside the

instrument.

The gas is then analyzed in its components by electrochemical.

The electrochemical cell guarantees high precision results in a time interval of up to about 60 minutes during

which the instrument can be considered very stable.

When measurement is going to take a long time, we suggest auto-zeroing the instrument again and flushing the

inside of the pneumatic circuit with clean air.

During the zero calibrating phase, the instrument aspirates clean air from the environment and detects the cells’

drifts from zero (20.95% for the O2 cell), then compares them with the programmed values and compensates them.

4.2 Measurement cells

The instrument takes advantage of pre-calibrated gas sensors for the measurement of Oxygen (O2), Carbon

Monoxide (CO) and Nitric Oxide (NO) if available.

The sensors do not need particular maintenance yet they have to be replaced periodically when exhausted.

If sensors of toxic gases are submitted to concentrations higher than 50% of their measurement range for more

than 10 minutes continuously, they can show up to ±2% drift as well as a longer time to return to zero.

In this case, before turning off the analyzer, it is advisable to wait for the measured value be lower than 20ppm by

in taking clean air.

Anyway, the instrument is intended to have a cleaning cycle of the pneumatic circuit, which duration depends on

what has been set in the menu Configuration→Analysis→Autozero.

Exhausted cells can be easily replaced by the user without depriving himself of the instrument and without

complicated calibration procedures with certified mixtures as they are pre-calibrated before being supplied.

E instruments certifies the accuracy of the measurements only upon a calibration certificate issued by its

laboratory or other approved laboratory.

4.3 Fuel types

The device is provided with the technical data of the most common types of fuels stored in its memory.

For more details see Annex D.

4.4 Sample treatment

The gas sample to be analyzed must be delivered to the measuring sensors properly dried and cleaned of solid

residues of combustion; actually for this reason it is usually named ‘dry analysis’.

For this purpose, on the gas suction line, is mounted an anti-condensation trap with dust filter.

4.5 Pressure sensor, piezoelectric, temperature compensated

The instrument is internally provided with a piezoresistive differential pressure sensor which can be used for

measuring the draft (vacuum) in the stack for differential pressure measurement and possibly for other

measurements (pressure of gas in the piping, pressure loss across a filter, etc.).

The measurement range is -10.000 Pa .. +20.000 Pa.

Any potential drift of the sensor are nulled thanks to the autozeroing system.

WARNING

ANY PRESSURE APPLIED TO THE SENSOR GREATER THAN ±

SENSOR ITSELF.

4.6 Suction pump

This diaphragm pump, located inside the instrument, is operated with a DC engine powered by the instrument in

order to obtain the optimal suction flow rate of the flue gas for the ongoing analysis.

4.7 Draft measurement with sensor automatic autozero

E500 performs the draft measurement.

The sensor Autozero allows to make the zeroing of the sensor and must be done with the gas probe NOT

inserted in the stack.

Page 10

10

4.8 Bluetooth® connection (if the version of the instrument foresees it)

The E500 analyzer is internally equipped with a Bluetooth® module, which allows the communication with a

remote Bluetooth

The maximum transmission range in open field is 100 meters (Class 1 Bluetooth

communication companion is equipped with a Class1 Bluetooth

This solution allows great freedom of movement for the operator who is no longer bound directly to the instrument

for acquisition and analysis, with significant advantages for many applications.

®

printer

®

interface.

®

module), provided that also the

4.9 IR connection

The E500 analyzer is internally equipped with an infrared light interface which uses the HP-IR protocol, which

allows the communication with a remote IR printer.

4.10 Software and available applications

Easy2print

PC Software for systems provided with Windows XP or later versions, downloadable from the web site www.einst.com, allows to insert and to store in the instrument the heading of the ticket.

E-Instruments QR Code App

This APP, allows to scan the QR code generated by the instrument, aiming to download the data of the

performed analyses and/or measures.

Page 11

11

>

>

>

>

>

5.0 COMPONENTS DESCRIPTION

5.1 Instrument interface

DESCRIPTION:

Polyester keyboard with preformed keys and main command functions:

KEYS FUNCTION

Activates the context keys shown on the display.

-

Turns on and off the instrument.

-

ESC

If pressed briefly, accesses the instrument menu.

-

If pressed for at least 2 seconds, turns off the instrument.

Exits the current screen.

OK

Confirm settings.

Select and/or Modify.

Page 12

12

ANALYSIS [1/5]

Text 01

Text 02

Text 03

Text 04

Text 05

Text 06

LCD backlit Display, White/Black 128 x 128 pixel with white LEDs.

CAUTION:

If the instrument is exposed to extremely high or extremely low temperatures, the quality of the display

may be temporarily impaired. Display appearance may be improved by acting on the contrast key.

Display

15/06/18 10:00

Print

B-Type USB connector

Connector to connect the device to a personal computer or to the battery charger.

The device comes with a wall charger with 5V , 2A output to charge the internal batteries.

Date, time and battery status.

Selected menu.

Parameters relative to the selected menu.

Context keys. In the various menus the functions vary depending on

the type of operation being carried out.

'T1' Connector

Used to connect the Tc-K male connector of the gas temperature probe.

'P-' pneumatic connector

Negative input (P-) to be used for the connection of the gas aspiration probe; to this input, must be connected

the second branch (with the largest pneumatic connection) of the gas probe for the measurement of the draft

and the combustion analysis.

'IN' pneumatic connector

Input for the connection of the branch of the gas sampling probe with the condensation separating and

anti-dust filter assembly.

'P+' pneumatic connector

Positive input (P+): used for the pressure measurements values.

Gas output

Magnets

Instrument data label.

Page 13

13

6.0 TECHNICAL SPECIFICATIONS

6.1 Technical specifications

Power: Li-Ion battery pack with internal protection circuit.

Average life of the battery package: 500 empty / full charge cycles.

Battery charger: External 5Vdc 2A battery charger with female A-type USB connector +

connection to the device with the same serial communication cable

supplied.

Charging time: 5 hours to charge from 0% to 90% (6 hours for 100%). The device can also

be charged by connecting it to the PC, the device must be turned off, the

charging time depends on the output current from the PC and may be more

than 12 hours.

Instrument working time: 8 hours of non-stop operation with display brightness at 50%.

——————————————————————————————————————————————————

Display: Graphic white LED backlit White / Black, 128 x 128 pixel

——————————————————————————————————————————————————

Connectivity:

Communication port: USB connector type B.

Bluetooth

(if the version of the

instrument foresees it): Class 1. Communication distance <100 meters (in open field)

Infrared interface: For external printer (optional) using protocol HP-IR.

——————————————————————————————————————————————————

Autozero: Settable (30 .. 600 seconds)

——————————————————————————————————————————————————

Gas measurement sensors: Up to 2 electrochemical sensors

Type of combustible: 12 predefined by the factory.

————————————————————————————————————————–——————--——-Self-diagnosis: Checks all functions and internal sensors and reports any abnormal

Temperature measurement: Input for thermocouple type K with mignon connector (ASTM E 1684-96) for the

Room temperature measurement: Through the internal sensor and/or acquisition through the gas probe

——————————————————————————————————————————————————

Suction pump: 1.0 l/min heads at the flue up to 80hPa.

——————————————————————————————————————————————————

Condensate trap:

Type: Outside the instrument.

Line filter: With replaceable cartridge, 99% efficient with 20um particles.

——————————————————————————————————————————————————

Condensing boiler efficiency: Automatic recognition of the condensing boiler, with calculation and printout

Environmental gases: Measurement and separate printout of the ambient CO values.

Draft test: By using the internal sensor connected to the port P+.

——————————————————————————————————————————————————

Operating temperature range: 23°F .. 113°F (-5°C .. +45°C)

Storage temperature range: -4°F .. 122°F (-20°C .. +50°C)

Humidity limit: 20% .. 80% RH

Protection grade: IP42

Air pressure: Atmospheric

Outer dimensions: Analyzer: 2,8 x 2,4 x 6,7 inches (7 x 6 x 17 cm) (Width x Depth x Height)

Weight: Analyzer: ~ 12,3 Oz (~ 0,35 Kg)

——————————————————————————————————————————————————

Compliant with the European standard EN50379-1 and EN50379-2.

See the declaration of conformity (ANNEX E).

®

operation.

temperature measurement.

positioned in air.

of efficiency (>100%) on the LHV (Lower Heating Value).

Case: 15,7 x 11,4 x 4,7 inches (40 x 29 x 12 cm) (Width x Depth x Height)

Page 14

14

Electrochemical

Electrochemical

Electrochemical

±5 ppm

±10% measured value

0 .. 100 ppm

Air temperature

TcK sensor

-20.0 ..

120.0°C

0.1 °C

±1 °C

hPa

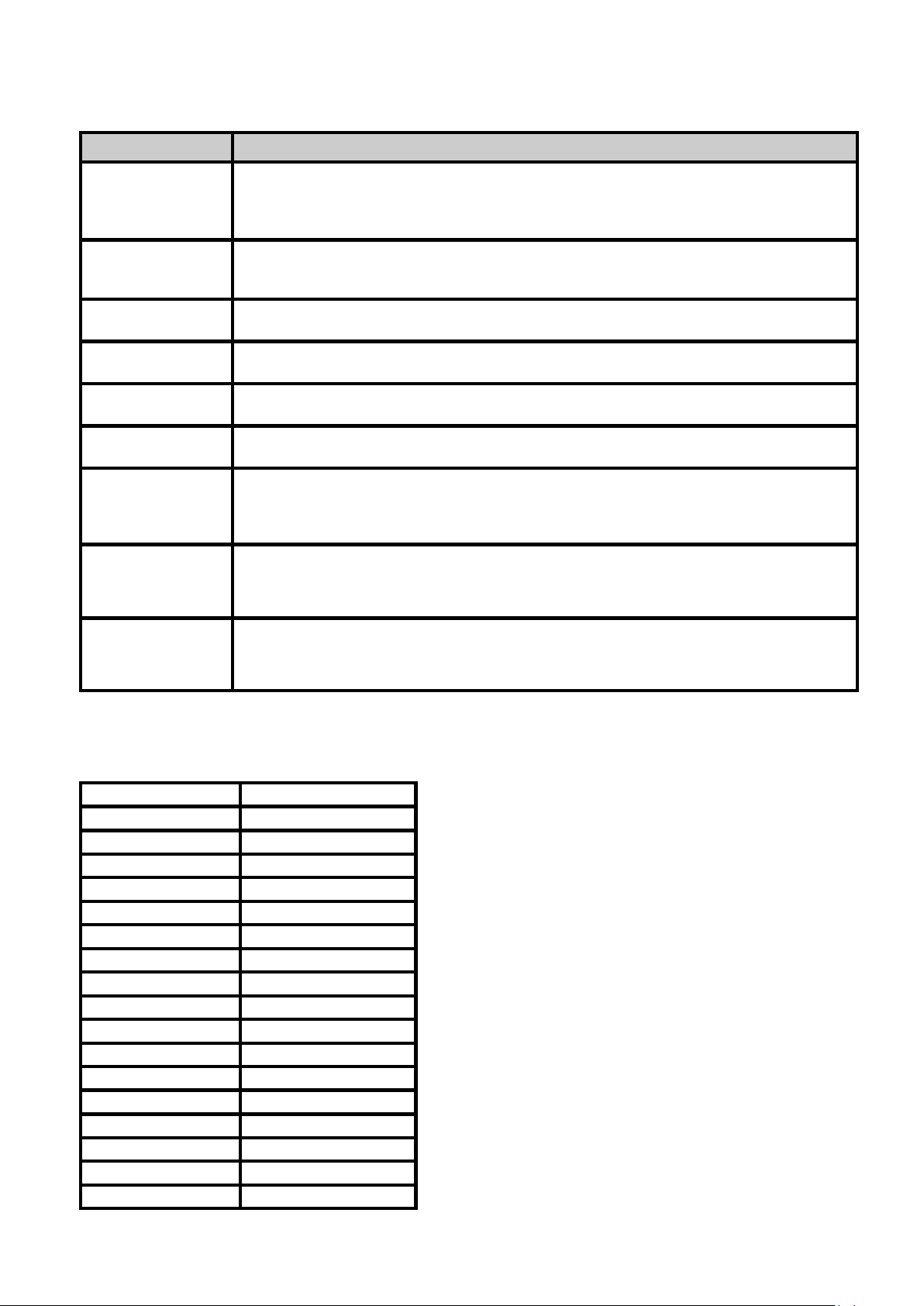

6.2 Measurement and Accuracy Ranges

MEASUREMENT SENSOR RANGE RESOLUTION ACCURACY

RESPONSE

TIME T90

O2

CO

with NOx filter

NO

sensor

sensor

sensor

0 .. 25.0% vol 0.1% vol ±0.2% vol <20 sec.

0 .. 4000 ppm

0 .. 2000 ppm

CO2 Calculated 0 .. 99.9% vol 0.1% vol

Flue gas

temperature

Pressure

(Draft & differential)

Differential

temperature

TcK sensor -20.0 ..

800.0°C

Piezoelectric

sensor

-100 ...

200 hPa

Calculated -20 to 800°C 0.1 °C

Excess air Calculated 0 .. 850 % 1 %

Stack loss Calculated 0.0 .. 100.0 % 0.1 %

Efficiency

Efficiency

(condensing)

Calculated 0.0 .. 100.0 % 0.1 %

Calculated 0.0 .. 120.0 % 0.1 %

1 ppm

1 ppm

0.1 °C

0.01 hPa

±20 ppm

±5% measured value

±5% measured value

±1 °C

±1% measured value

±1% measured value

±0.002 hPa

±1% measured value

0 .. 400 ppm

401 .. 4000 ppm

101 .. 1000 ppm

1001 .. 2000 ppm

0 .. 100 °C

101 .. 800 °C

-100 .. -2.01 hPa

-2.0 .. +2.0 hPa

+2.01 to +200.0

<30 sec.

<40 sec.

Page 15

15

20%

Blinking

THE INSTRUMENT IS SHIPPED WITH THE 30% OF BATTERY LIFE, ACCORDING TO

TRANSPORTATION STANDARDS. IT IS ADVISABLE TO RECHARGE IT

IT IS ADVISABLE TO CHARGE THE BATTERY AT AN AMBIENT TEMPERATURE RANGING

IF THE INSTRUMENT HAS BEEN KEPT AT VERY LOW TEMPERATURES (BELOW

WAITING A WHILE (1 HOUR) BEFORE

SWITCHING IT ON TO HELP THE SYSTEM’S THERMAL BALANCE AND TO PREVENT

7.0 USING THE FLUE GAS ANALYZER

7.1 Preliminary operations

Remove the instrument from its packing and check it for damage. Make sure that the content corresponds to the

items ordered. If signs of tampering or damage are noticed, notify the E INSTRUMENTS service center or agent

immediately and keep the original packing. A label at the rear of the analyzer bears the serial number. This serial

number should always be stated when requesting technical assistance, spare parts or clarification on the product

or its use. E instruments maintains an updated database for each and every instrument.

Before using for the first time we recommend you charge the batteries completely.

7.2 WARNING

• Use the instrument with an ambient temperature between -5 and +45°C.

• Do not extract flue gas samples directly without using a particulate/water trap.

• Do not use the instrument if the filters are clogged or damp.

• Do not exceed sensor overload thresholds.

• When it has finished being used, before turning the instrument off remove the probe and let is aspirate ambient

clean air for at least 30 seconds to purge the pneumatic path from all traces of gas.

• Before putting the measuring probe back in its case after use, make sure it is has cooled down enough and there

is no condensate in the tube. It might be necessary to periodically disconnect the filter and the condensate

separator and blow compressed air inside the tube to eliminate all residues.

• Remember to have the instrument checked and calibrated once a year in order to comply with the existing

standards.

7.3 Analyzer power supply

The instrument contains a high-capacity Li-Ion rechargeable battery.

The battery powers up the instrument and any other probes or remote devices that may be connected. The

instrument runs for approximately 8 hours if the printer is not used and with display brightness at 50%. Should the

battery be too low to effect the necessary measurements, the instrument can be hooked up to the mains via the

power pack provided, allowing operations (and analysis) to proceed.

The battery will be recharged whilst the instrument is being used.

The battery charging cycle takes up to 8 hours for a complete charge and finishes automatically.

ATTENTION: If the instrument is not going to be used for a long time (for example summertime) we suggest recharging it completely at least once every 4 months.

7.3.1 Internal battery charge level

The display constantly shows the internal battery charge level shown with the symbol in the upper left corner of the display.

OPERATING TEMPERATURES) WE SUGGEST

CONDENSATE FORMING IN THE PNEUMATIC CIRCUIT.

SYMBOL BATTERY CHARGE LEVEL

100%

80%

60%

40%

It’s advisable to recharge the battery.

Dead battery

Recharge the battery - The instrument may not function correctly.

CURRENT AIR

COMPLETELY BEFORE USE, TAKING 8 HOURS (ONE NIGHT).

BETWEEN 50°F AND 86°F (10°C AND 30°C).

Page 16

16

BATTERY CHARGE

TYPE PLUG.

According to the charging level of the battery, the instrument can be left in stock for a time correlated to the

battery level itself. Below, a table that explains the correlation between battery charging level and stock time.

LEVEL

STOCK TIME

100% 110 days

75% 80 days

50% 45 days

25% 30 days

7.3.2 Use with external power pack

The instrument can work with the batteries fully discharged by connecting the external power pack provided.

THE POWER SUPPLY/BATTERY CHARGER IS A SWITCHING TYPE ONE.

THE APPLICABLE INPUT VOLTAGE RANGES BETWEEN 90Vac AND 264Vac.

INPUT FREQUENCY: 50-60Hz.

THE LOW VOLTAGE OUTPUT IS 5 VOLT WITH AN OUTPUT CURRENT GREATER THAN

1.5A.

LOW VOLTAGE POWER CONNECTOR: A-TYPE USB CONNECTOR + CONNECTION CABLE WITH B-

7.4 QR code generation (if the version of the instrument foresees it)

The instrument offers the possibility to generate and display a QR code with the purpose to download the data of

the acquired measures, activating the interactive function “Print” visible on the display in the menu configuration,

having installed the “E Instruments QR Code App” downloadable from the AppStore.

Minimum requirements for the App installation “E Instruments QR Code App”

Operating systems: Android from version 4.1

Apple (iOS)

THE INSTRUMENT WILL GENERATE THE QR CODE ONLY IF ON THE DISPLAY THE

INTERACTIVE FUNCTION “PRINT” IS SHOWN.

Page 17

17

7.5 Connection diagram

AA AL05

AAC KP02

AACTA03A

AA SF7-A

Page 18

18

Repeat

Keep

10:00

HARDWARE

►Memories KO

Calibration KO

voltages

ADC channels

WARNING!

When the instrument is turned on, an hardware check

is performed on the memories and on the instrument

calibration. If some error occurs, they will be shown

screen. In this

. If the

problem keeps on appearing or frequently occurring

please contact the Seitron Service Center,

E500

SOME IMPORTANT WARNINGS TO CONSIDER DURING THE COMBUSTION ANALYSIS

GAS SAMPLING PROBE AND OF THE CONDENSATION FILTER

MUST BE WELL CONNECTED TO THE INSTRUMENT. KEEP THE CONDENSATION TRAP ON VERTICAL

POSITION DURING THE ANALYSIS; A WRONG POSITIONING MAY CAUSE CONDENSATE

NSORS. AFTER EACH ANALYSIS

CHECK FOR ANY PRESENCE OF WATER IN THE CONDENSATE COLLECTION BOWL AND REMOVE IT

IF ANY. PUT THE PROBE BACK IN THE CASE ONLY AFTER YOU HAVE ELIMINATED CONDENSATE

'). REPLACE THE FINE

MEASUREMENT WHEN THE FILTER IS REMOVED OR DIRTY IN ORDER TO AVOID ANY RISK OF

BEFORE TURNING ON THE INSTRUMENT:

CONDENSING BOILERS / FURNACES: UPON COMPLETION OF THE AUTOZERO IN FRESH

OUTDOOR AIR, PRESS THE “KEEP” BUTTON TO STORE THE OUTDOOR TEMPERATURE

ATMOSPHERIC BOILERS / FURNACES: UPON COMPLETION OF THE AUTOZERO IN FRESH

AND

“KEEP”

GAS SAMPLING PROBE BEFORE STARTING THE

TEMPERATURE

VALUE. IF THE CONNECTOR IS NOT PLUGGED IN, THE TEMPERATURE WILL NOT BE

ACQUIRED.

15/06/18 10:00

AUTOZERO

60

Fresh

15/06/18 10:00

AUTOZERO

AutoZero in Fresh

Repeat

8.0 FLUE GAS ANALYSIS

8.1 FLUE GAS ANALYSIS

To perform complete flue gas analysis, follow the instructions below.

ARE LISTED BELOW:

FOR A CORRECT ANALYSIS NO AIR MUST FLOW INTO THE PIPE FROM OUTSIDE DUE

TO A BAD TIGHTENING OF THE POSITIONING CONE OR A LEAK IN THE PIPELINE.

THE GAS PIPE MUST BE CHECKED IN ORDER TO AVOID ANY LEAKAGES OR OBSTRUCTIONS ALONG

THE PATH. THE CONNECTORS OF THE

INFILTRATIONS IN THE INSTRUMENT AND THUS DAMAGE THE SE

FROM THE TUBE AND THE EXPANSION TANK (SEE CHAPTER 'MAINTENANCE

DUST FILTER IF IT IS VISIBLY DIRTY OR WET (SEE CHAPTER 'MAINTENANCE'). DO NOT PERFORM ANY

IRREVERSIBLE DAMAGES TO SENSORS AND ANALYZER ITSELF.

8.1.1 Switching on the instrument and auto-calibration

Keep

pressed for

a few

seconds

S.n.:0

Fw:1.00

11/12/17

AutoZero in

Air

with the activation of the Hardware

case, it is advisable to restart the instrument

communicating the shown error.

Air

T: 21.5°C

Keep

When the autozero phase is complete, push the key related to the interactive function “ “, to proceed

with the combustion analysis or push the key related to the interactive function “ “, to repeat the autozero

phase.

CONNECT THE GAS SAMPLING PROBE TO THE INSTRUMENT.

STORING OF THE AMBIENT TEMPERATURE:

BEING USED FOR PRIMARY AIR.

OUTDOOR AIR, MOVE THE E500 INDOORS TO THE EXACT LOCATION OF THE APPLIANCE

ONCE THE TEMPERATURE STABILIZES TO THE INDOOR TEMPERATURE, PRESS THE

BUTTON TO STORE THE INDOOR TEMPERATURE BEING USED FOR PRIMARY AIR.

INSERT THE TCK CONNECTOR OF THE

INSTRUMENT AND LET IT DRAW CLEAN AIR, IN ORDER TO GET A CORRECT

Page 19

19

>

15/06/18 10:00

ANALYSIS [1/3]

O2 4.2 %

CO 23 ppm

CO2 2.9 %

Eff ---%

Loss ---%

Tf ---%

MENU

►Measurements

Configuration

Diagnostic

Service Info.

CONFIGURATION

►Analysis

Instrument

Print

Language

Restore

8.1.2 Preliminary Operations

Following are reported the parameters to set before performing the combustion analysis:

15/06/18 10:00

OK

15/06/18 10:00

Print

BEFORE PERFORMING THE COMBUSTION ANALYSIS, SET THE NECESSARY

PARAMETERS (SEE CHAPTER 9.4.1

).

OK

8.1.3 Inserting the probe inside the stack

When the autozero is over, insert in the stack the gas sample probe, previously connected to the instrument.

In order for the probe to be inserted at the right point within the stack, its distance from the boiler has to be twice

the diameter of the stack pipe itself or, if this is not possible, must comply with the boiler manufacturer’s instructions.

In order to position the probe correctly drill a 13/16 mm hole in the manifold (unless already present), and screwing

in the positioning cone provided with the probe - in this way no air is drawn from the outside during sampling.

The screw on the cone allows the probe to be stopped at the right measuring depth - this usually corresponds to

the center of the flue pipe. For greater positioning accuracy, the user may insert the probe gradually into the pipe

until the highest temperature is read.

The exhaust pipe must be inspected before carrying out the test, so as to ensure that no constrictions or losses

are present in the piping or stack.

Page 20

20

15/06/18 10:00

ANALYSIS [1/5]

O2 4.2 %

CO 23 ppm

CO2 2.9 %

Tf 190.1 C

Ta 15.4 C

Es 91.4 %

B 15/06/18 10:00

WARNING

Printing

in progress ...

PRINT

Curr. analysis

►Copy number 1

Printer IR

QR Code ON

Pairing BT

Print

THE BLUETOOTH PRINTER AND /OR THE QR CODE ARE

INSTRUMENT

Print

Print

8.1.4 Performing the combustion analysis

Print

15/06/18 10:00

AVAILABLE IF THE VERSION OF THE

FORESEES IT .

SCAN THE QR CODE USING THE E INSTRUMENTS APP “E-Instruments

QR Code App”, TO DOWNLOAD THE DATA.

Page 21

21

WHEN THE GAS SAMPLING PROBE IS TAKEN OUT OF THE STACK, THE FORMATION OF

CONDENSATION TRAP

IT IS ADVISED TO ACCURATELY CLEAN EVERY PART BEFORE PUTTING AWAY THE

IN ORDER NOT TO DAMAGE THE CASE MAKE SURE THAT THE METALLIC PROBE PIPE IS

8.1.5 End of the Analysis

-

At the end of the combustion analysis, carefully remove the sample probe and remote air temperature probe, if

used, from their relative ducts, taking care not to get burnt.

-

Switch off the instrument.

Then, proceed to turn off the instrument.

The instrument execute a cleaning cycle, according to what’s set in the menu

“Configuration→Analysis→Autozero→Purging”, during which the pump sucks clean air until reducing the

concentration of CO. The instrument automatically turns off within max. 10 minutes.

Note: It is always advisable to purge the instrument with clean air for at least 5 - 10 minutes before turning it

off.

SOME CONDENSATION IN THE PROBE TUBE AND IN THE ANTIMAY OCCUR.

PROBE AND THE ANTI-CONDENSATION TRAP IN THE CASE.

AT AN INFERIOR TEMPERATURE THAN 60°C.

Gas sampling probe cleaning

-

When you finish using the sample probe clean it thoroughly as described below before returning it to its case:

- Disconnect the sample probe from the instrument and from the water trap (Fig. a-b) then blow a jet of clean air

into the hose of the probe (refer to Fig. b) to remove any residual condensate that may have formed within.

Fig. a

Page 22

22

Blackened particulate filter

Cleaning hose

Maintaining the water trap / filter unit

To remove the water trap, just rotate the cover and unhook the filter holder body; remove the internal cup and

then replace the filter (see figure on the side).

Clean all the filter parts using water only, dry the components and reassemble the filter.

Fig. b

Replacing the particulate filter

If the particulate filter appears black, especially on the inner surface (see adjacent example), it has to be replaced

immediately. In this way gas flow is not obstructed.

Page 23

23

>

SUB-MENU

FUNCTION

Measurements

Through this menu, it is possible to execute the draft, ambient CO and pressure

Configuration

Diagnostic

The user can verify any anomalies of the instrument.

Info service

MENU

►Measurements

Configuration

Diagnostic

Info service

>

9.0 MENU

9.1 Menu

15/06/18 10:00

KEY

FUNCTION

ESC

OK

Measurements.

SEE CHAPTER 9.2.

The user can set the different reference parameters of the instrument in order to

perform the combustion analysis.

SEE CHAPTER 9.3.

SEE CHAPTER 9.4.

Display the info about the current condition of the instrument.

SEE CHAPTER 9.5.

Returns to the previous screen.

Selects the available parameters.

Enters in the selected parameter setting.

Page 24

24

>

SUB MENU

FUNCTION

Draft

CO air

the user measure the CO value present in the environment, with the

scope of checking the personal safety conditions of a specific working environment. The

exposure limit (REL) stipulated by the National Institute for

and calculated as

It is compulsory to perform the autozero in the clean air, so that the

ient CO measurement is correct. It is advisable to turn on the

instrument and wait for the autozero completion outside the area where

Pressure

Through the use of the external flexible pipe made in RAUCLAIR (supplied) is possible to

measure a pressure value within the range stated in the technical features (connect the pipe

10:00

MEASUREMENTS

►Draft

CO air

Pressure

KEY

FUNCTION

>

9.2 Menu→Measurements

15/06/18

ESC

OK

The DRAFT menu gives access to the stack draft measurement.

NOTE: The measurement may not be accurate due to condensation inside the gas

probe. Should you notice an inaccurate or unstable reading on the instrument, it is

advisable to disconnect the gas probe from the instrument itself, and purge pipes by

blowing with a compressor. In order to be sure there is no humidity, it is suggested to

perform the measurement by means of the transparent rubber pipe supplied on issue.

SEE CHAPTER 9.2.1.

This type of analysis lets

instrument leaves our factory with the following pre-set threshold values:

COmax: 35 ppm Recommended

Occupational Safety and Health (NIOSH), equivalent to 40 mg/m3

an 8-hour Time-Weighted Average (TWA).

Returns to the previous screen.

Selects the available parameters.

Enters in the selected parameter setting.

amb

the test is being performed.

SEE CHAPTER 9.2.2.

to P+ input).

SEE CHAPTER 9.2.3.

Page 25

25

Print

Print

10:00

DRAFT

Inlet P+

Draft 0.00 h

►Zero sensor

KEY

FUNCTION

>

>

15/06/18 10:00

DRAFT

Inlet P+

Draft --- P

►Zero

Save

Print

15/06/18 10:00

DRAFT

5

15/06/18 10:00

DRAFT

Inlet P+

Draft 3.02 P

►Zero

Save

Print

15/06/18 10:00

PRINT

Curr. analysis

►Copy number 1

Printer BT

QR Code ON

Pairing BT

B 15/06/18 10:00

WARNING

Printing

in progress ...

9.2.1 Menu→Measurements→Draft

15/06/18

Activate the context keys shown on the

display.

Save Print

INTERACTIVE OPERATION FUNCTION

Save

Print

To measure the draft proceed as follows:

Connect the probe pressure input hose to the instrument P+ input.

Before starting the pressure zeroing sequence pay attention to remove the gas probe from the

stack.

Having carried out the pressure zeroing sequence, insert the probe in the stack and measure the

draft.

Example:

The measure will be printed on the ticket of the current combustion analysis

According to the version of the instrument and/or according with the related

setting, it is possible to print or visualize the QR code

ESC

OK

Returns to the previous screen.

Starts the pressure sensor autozero.

OK

Zero

Print

Page 26

26

It is compulsory to perform the autozero in the clean air, so that the ambient CO

measurement is correct. It is advisable to turn on the instrument and wait for the autozero

Print

Print

15/06/18 10:00

CO AIR

CO 412 p

CO Max 413 p

KEY

FUNCTION

>

>

15/06/18 10:00

CO AIR

CO 412 p

CO Max 413 p

15/06/18 10:00

PRINT

Curr. analysis

►Copy number 1

Printer BT

QR Code ON

Pairing BT

Print

B 15/06/18 10:00

WARNING

Printing

in progress ...

9.2.2 Menu→Measurements→CO air

Activate the context keys shown on the

display.

Save Print

INTERACTIVE OPERATION FUNCTION

Save

Print

The measure will be printed on the ticket of the current combustion analysis

According to the version of the instrument and/or according with the related

setting, it is possible to print or visualize the QR code

completion outside the area where the test is being performed.

ESC

Returns to the previous screen.

Example:

Save Print

Page 27

27

Print

Print

15/06/18 10:00

PRESSURE

Press. 0.00 h

►Zero Sensor.

>

>

15/06/18 10:00

PRESSURE

Press. 0.00 h

►Zero

Save

Print

15/06/18 10:00

PRESSURE

5

15/06/18 10:00

PRESSURE

Press. 0.00 h

►Zero

Save

Print

10:00

PRINT

Pressure

►Copy number 1

Printer BT

QR Code ON

Pairing BT

Print

WARNING

Printing

in progress ...

9.2.3 Menu→Measurements→Pressure

KEY FUNCTION

Activate the context keys shown on the

display.

Save Print

INTERACTIVE OPERATION FUNCTION

Save

Print

The measure will be printed on the ticket of the current combustion analysis

According to the version of the instrument and/or according with the related

setting, it is possible to print or visualize the QR code

Example:

ESC

OK

Returns to the previous screen.

Perform the Zero Sensor of the pressure sensor.

15/06/18

OK

Zero

B 15/06/18 10:00

Page 28

28

>

Analysis

Instrument

Alarm

of

the

The Minimum alarm type will ring when

measured gas drops below the set threshold, while the Maximum alarm type

will ring when the measured gas goes above the set threshold. If the alarm is in

Print

This menu allows the user to set the printing parameters, such as copy number,

code so to download

Language

Reset

CONFIGURATION

►Analysis

Instrument

Alarm

Print

Language

Reset

KEY

FUNCTION

>

9.4 Menu→Configuration

15/06/18 10:00

ESC

OK

Returns to the previous screen.

Selects the available parameters.

Enters in the selected parameter.

SUB MENU FUNCTION

Through this menu the user, can set the different reference parameters of the

instrument in order to perform the combustion analysis.

SEE CHAPTER 9.4.1

Through this menu the user, can set the different reference parameters of the

instrument.

SEE CHAPTER 9.4.2

Alarm management - In this menu it is possible to set and store only one alarm

which it is possible to define the observed gas, the intervention threshold and

kind of alarm: Minimum, Maximum or Off.

the

Off mode, it is deactivated.

Gas Concentration

Measured

Value

Maximum Alarm

SEE CHAPTER 9.4.3

Minimum Alarm

printer type (OFF, BT or IR) and the visualization of the QR

the data of the performed analysis.

SEE CHAPTER 9.4.4

Select the desired language of the instrument.

SEE CHAPTER 9.4.5

Reset default data.

SEE CHAPTER 9.4.6

Alarm Alarm

Threshold

Threshold

Time

Alarm

Page 29

29

>

Fuel

Condensation

mospheric pressure and humidity of the combustion air. As the atmospheric

culated at the combustion air temperature as measured from the instrument; in

case this value is unknown the operator is recommended to enter 50% for this

O2 reference

Measure units

Autozero

Air temp.

Nox/NO Ratio

(If the version of

the instrument

foresees it)

NOx/NO: all the nitrogen oxides which are present in the flue emissions (Nitric

). In

percentage contained in

the gas is not far from very low values (3%); hence it is possible to obtain the NOx

r

percentage value contained in the gas can be however set

ANALYSIS

►Fuel

Condensation

O2 reference

Measure units

Autozero

Air temp.

KEY

FUNCTION

>

9.4.1 Menu→Configuration→Analysis

15/06/18 10:00

ESC

OK

Returns to the previous screen.

Selects the available parameters.

Enters in the selected parameter.

SUB MENU FUNCTION

Lets the user select the type of fuel to be used during analysis.

SEE CHAPTER 9.4.1.1.

The burner efficiency figure when condensation takes place is influenced by at-

pressure is hardly precisely known, the operator is asked to enter a related parameter, i.e. the altitude of the place above the sea level, from which the pressure is then derived once the dependency from atmospheric conditions is neglected. In calculations the value of 101325 Pa is assumed as atmospheric pressure at sea level. Further the air relative humidity input is allowed, being this cal-

value.

SEE CHAPTER 9.4.1.2.

In this mode the user can set the oxygen percentage level to which pollutant

emission values detected during analysis will be referenced.

SEE CHAPTER 9.4.1.3.

Through this submenu the user can modify the units of measurement for all the

analysis parameters, depending on how they are used.

SEE CHAPTER 9.4.1.4.

In this sub menu it is possible to modify the auto zero cycle duration and the duration of the sensor cleaning cycle.

SEE CHAPTER 9.4.1.5.

In this submenu there is a possibility to acquire or manually enter the combustion air temperature.

SEE CHAPTER 9.4.1.6

oxide = NO, Nitrogen dioxide = NO2); total nitrogen oxides = NOx (NO + NO2

the combustion processes, it is found out that the NO2

value by a simple calculation without using a direct measurement with a furthe

NO2 sensor. The NO2

at a value other than 3% (default value).

SEE CHAPTER 9.4.1.7

Page 30

30

>

>

>

15/06/18 10:00

FUEL [1/2]

►Natural gas

Propane

#2 Oil

#4 Oil

#6 Oil

Diesel

Wood/Pel. 8%

15/06/18 10:00

FUEL [2/2]

Coal

►Bio-fuel 5%

Bagasse

L.P.G.

Butane

9.4.1.1 Menu→Configuration→Analysis→Fuel

KEY FUNCTION

ESC

OK

Returns to the previous screen.

Scrolls through the pages.

Confirms the choice of fuel to be used during the analysis.

Page 31

31

15/06/18 10:00

CONDENSATION

►Altitude 0 m

R.H. air 0 %

>

> >

>

15/06/18 10:00

CONDENSATION

►Altitude 0 m

R.H. air 0 %

15/06/18 10:00

CONDENSATION

►Altitude

0

m

R.H. air 0 %

15/06/18 10:00

CONDENSATION

►Altitude

100

m

R.H. air 0 %

9.4.1.2 Menu→Configuration→Analysis→Condensation

KEY FUNCTION

ESC

OK

Altitude above sea level

Relative humidity of air

When pressed in modify mode cancels the selection made, otherwise returns to the previous screen.

The arrows select each line displayed. In edit mode, it scrolls through the

suggested values.

Enters the modify mode for the selected parameter, then confirms the

modification.

Example:

OK

OK

Page 32

32

>

>

>

>

15/06/18 10:00

02 REFERENCE

►CO 0.0 %

15/06/18 10:00

02 REFERENCE

►CO 0.0 %

10:00

02 REFERENCE

►CO

0

.0 %

02 REFERENCE

►CO 1.0 %

9.4.1.3 Menu→Configuration→Analysis→O2 Reference

Percentage of Oxygen in CO measurement

KEY FUNCTION

Example:

ESC

OK

When pressed in modify mode cancels the selection made, otherwise

returns to the previous screen.

The arrows select each line displayed. In edit mode, it scrolls through the

suggested values.

Enters the modify mode for the selected parameter, then confirms the

modification.

15/06/18

OK

15/06/18 10:00

OK

Page 33

33

MEASURE UNITS

►CO ppm

Pressure hPa

Draft mmH2O

Temperature oC

Altitude ft

>

> >

>

15/06/18 10:00

MEASURE UNITS

►CO ppm

Pressure hPa

Draft mmH2O

Temperature oC

Altitude ft

15/06/18 10:00

MEASURE UNITS

►CO

ppm

Pressure hPa

Draft mmH2O

Temperature oC

Altitude ft

15/06/18 10:00

MEASURE UNITS

►CO

mg/m3

Pressure hPa

Draft mmH2O

Temperature oC

Altitude ft

9.4.1.4 Menu→Configuration→Analysis→Measure units

15/06/18 10:00

KEY FUNCTION

ESC

OK

Measurement unit can be set as: ppm - mg/m3 - mg/kWh - g/GJ - g/m3 ng/J - g/kWh - %

Measurement unit can be set as: ppm - mg/m

Measurement unit can be set as: hPa - Pa - mbar - mmH

Measurement unit can be set as: °C - °F

Measurement unit can be set as: m - ft

When pressed in modify mode cancels the selection made, otherwise returns to the previous screen.

The arrows select each line displayed. In edit mode, it scrolls through the

suggested values.

Enters the modify mode for the selected parameter, then confirms the

modification.

3

- mg/kWh - g/GJ - g/m3 ng/J - g/kWh - %

2O - mmHg - inH2O - psi

Example:

OK

OK

Page 34

34

AUTOZERO

►Autozero 30 s

Purging 0 s

> >

> >

>

15/06/18 10:00

AUTOZERO

►Autozero 60 s

Purging 0 s

15/06/18 10:00

AUTOZERO

►Autozero 060 s

Purging 0 s

9.4.1.5 Menu→Configuration→Analysis→Autozero

15/06/18 10:00

KEY FUNCTION

ESC

OK

Duration of autozero, expressed in seconds.

Duration of the cleaning cycle, expressed in seconds.

When pressed in modify mode cancels the selection made, otherwise returns to the previous screen.

When in modify mode, sets the desired value.

Enters edit mode of the selected element and then confirms the change.

Example:

OK

Page 35

35

15/06/18 10:00

AUTOZERO

►Autozero 065 s

Purging 0 s

OK

Page 36

36

>

>

15/06/18 10:00

AIR TEMP.

T probe --- F

►T air 32.0 F

KEY

FUNCTION

>

INTERACTIVE OPERATION

DESCRIPTION

T probe

T probe

AIR TEMP.

T probe 77.0 F

►T air 0.0 F

15/06/18 10:00

AIR TEMP.

T probe 77.0 F

►T air 77.0 F

9.4.1.6 Menu→Configuration→Analysis→Air temp

T probe

OK

ESC

Example with probe connected to the instrument:

15/06/18 10:00

Enters edit mode of the selected element and then confirms the change.

When in modify mode, sets the desired value.

When pressed in modify mode cancels the selection made, otherwise returns to the previous screen.

Acquires the detected temperature by the Tc-K probe connected to the instrument and uses it as primary air temperature.

T probe

T probe

Page 37

37

>

>

15/06/18 10:00

NOx/NO RATIO

►NOx/NO 1.05

>

>

>

15/06/18 10:00

NOX/NO RATIO

►NOx/NO 1.05

15/06/18 10:00

NOX/NO RATIO

►Nox/NO 1.05

10:00

NOX/NO RATIO

►NOx/NO 1.08

9.4.1.7 Menu→Configuration→Analysis→NOx/NO Ratio (if the version of the instrument foresees it)

KEY FUNCTION

Example:

15/06/18

OK

ESC

Enters edit mode of the selected element and then confirms the change.

When in modify mode, sets the desired value.

When pressed in modify mode cancels the selection made, otherwise returns to the previous screen.

OK

OK

Page 38

38

>

Display

On site calib.

) sensor is not

Clock

Bluetooth

(if the version of

the instrument

foresees it)

INSTRUMENT

►Display

On site calib.

Clock

Bluetooth

>

9.4.2 Menu→Configuration→Instrument

15/06/18 10:00

KEY

FUNCTION

ESC

OK

SUB MENU FUNCTION

With the arrow keys it is possible to increase or decrease the brightness and the

contrast of the display.

SEE CHAPTER 9.4.2.1.

It is possible to make a recalibration of the instrument’s gas sensors with suitable known concentration gas cylinders. Recalibration of Oxygen (O2

available since it is already recalibrated during every autozero sequence.

The access to the sensor recalibration is password protected, the password is ' 1111 '.

SEE CHAPTER 9.4.2.2.

Returns to the previous screen.

Selects the available parameters.

Enters in the selected parameter.

This allows the current time and date to be set. The user can select the date and

hour format either in EU (European) or USA (American) mode.

SEE CHAPTER 9.4.2.3.

In this sub menu it is possible to turn on and off the Bluetooth® communication

of the instrument and to visualize the related codes.

SEE CHAPTER 9.4.2.4.

Page 39

39

>

15/06/18 10:00

DISPLAY

►Brightness 80

Contrast 55

KEY

FUNCTION

>

>

>

15/06/18 10:00

DISPLAY

►Brightness 80

Contrast 55

15/06/18 10:00

DISPLAY

►Brightness

80

Contrast 55

15/06/18 10:00

DISPLAY

►Brightness

85

Contrast 55

9.4.2.1 Menu→Configuration→Instrument→Display

Example:

ESC

OK

When pressed in modify mode cancels the selection made, otherwise returns to the previous screen.

The arrows select each line displayed. In edit mode, it scrolls through the

suggested values.

Enters the modify mode for the selected parameter, then confirms the

modification.

OK

OK

Page 40

40

15/06/18 10:00

ON SITE CALIB.

0

000

> >

> >

9.4.2.2 Menu→Configuration→Instrument→On site calib.

FUNCTION KEY

Sets the password.

Selects line; in modification sets the value or the desired mode.

Once password is entered, gives access to the 'On site calibration' menu.

Returns to the previous screen.

When in modify mode cancels the modification just made.

Page 41

41

10

password

>

>

' 1111 '

E500

15/06/18 10:00

AUTOZERO

60

Fresh

15/06/18 10:00

AUTOZERO

AutoZero in Fresh

Repeat

15/06/18 10:00

INSTRUMENT

►Display

On site calib.

Clock

Bluetooth

15/06/18 10:00

ON SITE CALIB.

0

000

15/06/18 10:00

ON SITE CALIB.

11 1

Calibration procedure

To perform the recalibration the following instruments are needed:

-

Known concentration gas cylinder suitable for the sensor, equipped with a pressure regulator

-

Flow meter

-

Hose with Tee fitting to connect the cylinder to the flowmeter and to the instrument

In the following is described a recalibration example for the CO sensor.

1.

Start the instrument

Air

T: 21.5°C

Keep pressed

for a few

seconds

2.

Once autozero is completed press the button and select the menu Instrument→on site calib.

S.n.:0

Fw:1.00

WARNING

• Make sure autozero is execute in clean air and terminates correctly.

• Do not connect the gas probe to the instrument.

• Check the battery charge level or connect the power adapter to avoid data loss

during recalibration.

OK

AutoZero in

Air

Keep

Insert

OK

Page 42

42

ON SITE CALIB.

►S2:CO OK

S3:CO OK

ON SITE CALIB.

►Calibrate

Status --El. time

App. gas 100.0 p

Meas.gas 100.0 p

Is 2.22

Ia 0.17

3.

Once in the ‘On site calibration’ menu, is shown the list of the installed sensors for which the

recalibration is available. In the recalibration screen all information related to the last performed

calibration is shown, as well as the relevant values.

15/06/18 10:00

15/06/18 10:00

Calibrate: saves new calibration

Status: not active: returns to the factory

calibration

active: returns to the last

calibration made by the

OK

----:

user

no ‘on site calibration’

has been previously

stored

Elapsed time: timer

Applied gas: enters the

concentration of the

applied calibration

gas

Measured gas: Measurements the

concentration of the

applied gas

Is: 'Is' current from the

sensor

Ia: 'Ia' current from the

sensor

4.

In the following is described in detail a recalibration example for CO sensor.

CHOOSE THE SENSOR TO BE RECALIBRATED AND PROCEED AS DESCRIBED (CO SENSOR

EXAMPLE):

•

Connect the known concentration gas cylinder to the instrument as shown in the following diagram:

WARNING!

Adequate ventilation must be provided when working with toxic gases, particularly the flow

meter and instrument outputs must be evacuated by a ventilation system.

GAS CYLINDER FLOW METER COMBUSTION ANALYZER

Page 43

43

0,5 l/m

Page 44

44

>

>

>

>

control the time

15/06/18 10:00

ON SITE CALIB.

Calibrate

►Status ---

El.time

App. gas 100.0 p

Meas.gas 100.0 p

Is 2.22

Ia 0.17

15/06/18 10:00

ON SITE CALIB.

Calibrate

►Status active

El.time

App. gas 100.0 p

Meas.gas 100.0 p

Is 2.22

15/06/18 10:00

ON SITE CALIB.

Calibrate

►Status inactive

El.time

App. gas 100.0 p

Meas.gas 100.0 p

Is 2.22

15/06/18 10:00

ON SITE CALIB.

Calibrate

Status inactive

El.time 00:03:40

App. gas 1018 p

Meas.gas 0 p

Is 2.22

15/06/18 10:00

ON SITE CALIB.

Calibrate

Status inactive

El.time 00:00:00

App. gas 1018 p

Meas.gas 0 p

Is 2.22

15/06/18 10:00

ON SITE CALIB.

Calibrate

Status inactive

El.time 00:03:00

►App. gas 100.0 p

Meas.gas 0 p

Is 2.22

15/06/18 10:00

ON SITE CALIB.

Calibrate

Status inactive

El.time 00:03:50

►App. gas 100.0 p

Meas.gas 0 p

Is 2.22

15/06/18 10:00

ON SITE CALIB.

Calibrate

Status inactive

El.time 00:03:50

►App. gas 1018 p

Meas.gas 0 p

Is 2.22

•

The calibration will be possible only when the status is set to ' ---- ' or 'inactive'.

•

Enter the value of the concentration of the gas applied.

OK OK

OK

•

Apply gas to the instrument and adjust the output pressure of the gas from the cylinder so that the flow meter

indicates a minimum flow of 0.5 l/m: this guarantees that the instrument is taking the exact amount of gas required

by the internal pump.

•

The instrument Measurements the concentration of gas applied; wait at least 3 minutes to allow the reading

to stabilize. The reading is shown in line 'Gas measured'.

OK

OK

Zeroes the timer -

helps to keep under

elapsing during the

stabilization phase.

Page 45

45

15/06/18 10:00

ON SITE CALIB.

►Calibrate

Status inactive

El.time 00:03:00

App. gas 8000 p

Meas.gas 8000 p

Is 2.22

15/06/18 10:00

ON SITE CALIB.

►Calibrate

Status active

El.time 00:03:00

App. gas 8000 p

Meas.gas 8000 p

Is 2.22

•

After the stabilization time, select 'Calibrate' and activate the function ' ' to store the new calibration.

OK

Messages in the 'Status' line:

saving: the instrument is saving the performed

calibration

error: the sensor has NOT been recalibrated

for any of the following reasons:

-

OK

The calibration gas cannot

properly reach the instrument.

-

Concentration for the calibration

gas has not been set in the

relevant line ‘Applied gas’.

-

The user didn’t allow for the

stabilization time to properly

elapse.

-

The sensor could be damaged or

exhausted and must therefore be

replaced.

WARNING

At any time the user can restore the factory calibration in the instrument by setting

the 'Status' line on 'not active'.

In the following are listed the suggested stabilization times for the ‘on site calibration’ of the sensors.

Sensor CO: 3 minutes

Page 46

46

>

>

CLOCK

Time 10:00

Date 15/06/18

Mode EU

Mode 24h

9.4.2.3 Menu→Configuration→Instrument→Clock

15/06/18 10:00

Time, in the chosen format

Date, in the chosen format

Date format: EU (Europe) or USA (America)

Time format: 24h or 12h

KEY FUNCTION

ESC

OK

When pressed in modify mode cancels the selection made, otherwise

returns to the previous screen.

Selects line; in modification sets the value or the desired mode.

Enters the modify mode for the selected parameter, then confirms the

modification.

Page 47

47

>

>

Off

On

BLUETOOTH

Status On

ID --MAC 008025CE0E6E

9.4.2.4 Menu→Configuration→Instrument→Bluetooth (if the instrument version foresees it)

B

15/06/18 10:00

Bluetooth status: On or Off

Device ID

Device MAC address

Off

KEY FUNCTION

Activate the context keys shown on the display.

ESC

INTERACTIVE OPERATIONS DESCRIPTION

Goes back to the previous screen.

Turns off Bluetooth®.

Turns on Bluetooth®.

Page 48

48

9.4.3 Menu→Configuration→Alarm

>

>

>

9.4.3 Menu→Configuration→Alarm

10:00

ALARM

►Measure O2

Mode Min

Limit 18.0 %

11/12/17

Observed parameter: CO - NO - O2

Kind of set alarm: Max / Min / Off

Concentration threshold of the observed gas.

KEY FUNCTION

OK

ESC

Enters the modify mode for the selected parameter, then confirms the

modification.

Selects line; in setting mode, sets the value or the desired mode.

When pressed in modify mode cancels the selection made, otherwise returns to the previous screen.

Page 49

49

>

PARAMETER

DESCRIPTION

Copy number

Sets the number of ticket copy to be printed.

Printer

Select the type of printer with which the ticket is printed:

OFF

Mode

This parameter is visible only if the IR printer has been selected.

QR code

QR code generation (if the instrument version foresees it):

pushing the button related to the interactive function “Print” the instrument

generates a QR code, which can be read with the “E Instruments Analyzer App”

and allows to download the data acquired of the performed combustion analysis

Pairing BT

PRINT

►Copy number 1

Printer IR

Mode fast

QR code ON

Pairing BT

>

When pressed in modify mode cancels

the selection made, otherwise returns to

9.4.4 Menu→Configuration→Print

15/06/18 10:00

KEY

FUNCTION

OK

ESC

This is a valid setting only if a printer has been selected.

BT: Bluetooth® - at the first start up it is necessary to perform the paring

procedure described below. (if the instrument version foresees it)

IR: Infrared.

: none - the printer is turned off.

Selects the printing speed of the IR printer between ‘fast’ and ‘slow’.

Select 'slow' in order to make the printing process compatible when an HP IR

printer is used.

Enters the modification mode of the

selected data and then confirms it.

Selects the available parameters.

In modification mode, scrolls the available values.

the previous screen.

ON:

and the additional measures.

OFF: the QR code will not be shown.

Carry out the instrument association procedure to pair the Bluetooth

(If the instrument foresees

the on-board Bluetooth

interface)

printer.

®

Page 50

50

PAIRING BT

PAIRING BT

Pairing

in progress ...

Pairing

complete

PAIRING BT

Pairing

failed

PRINT

Copy number 1

Printer BT

QR code ON

►Pairing BT

B

PAIRING BT

Turn on the

printer and

start searching

B

PAIRING BT

Printer

detection in

progress ...

10:00

PAIRING BT

► 00025BB3D74E v

9.4.4.1 Menu→Configuration→Print→Pairing

1. When the Bluetooth printer is set, proceed with the following procedure:

15/06/18 10:00

15/06/18 10:00

15/06/18 10:00

B

15/06/18

If the printer is not found,

the following message will

appear:

“No printer was detected”.

Repeat the procedure

pushing the button related

to the interactive function

“Restart”.

OK

OK

B

B

Start

15/06/18 10:00

15/06/18 10:00

Start

B

In this case repeat the

Pairing procedure.

15/06/18 10:00

Restart

Page 51

51

> > > >

>

10:00

LANGUAGE [1/2]

►Italiano √

English

Pусский

Español

Français

Hrvatski

Deutsch

LANGUAGE [2/2]

►Polski

LANGUAGE [1/2]

►Italiano √

English

Pусский

Español

Français

Hrvatski

Deutsch

LANGUAGE [1/2]

Italiano √

►English

Pусский

Español

Français

Hrvatski

Deutsch

9.4.5 Menu→Configuration→Language

15/06/18

FUNCTION KEY

Returns to the previous screen.

Scrolls through the available languages.

Sets the selected language.

Example:

15/06/18 10:00

15/06/18 10:00

15/06/18 10:00

OK

Page 52

52

15/06/18 10:00

RESET

Clear memory data

and restore

factory setting?

Push OK to

continue

15/06/18 10:00

RESET

Deleting and

resetting data

9.4.6 Menu→Configuration→Reset

OK

KEY FUNCTION

ESC

OK

Exits the current screen without resetting.

Starts the factory data reset phase.

Page 53

53

>

SUB MENU

DESCRIPTION

Sensors

Gas probe

Hardware

15/06/18 10:00

DIAGNOSTIC

►Sensors

Gas probe

Hardware

>

9.5 Menu→Diagnostic

KEY

FUNCTION

ESC

OK

Displays information on the state and calibration of the electrochemical sensors.

Moreover, accesses to the ID data of the sensor:

Code

Serial number

Manufacturing and calibration date.

Measured currents (to perform a quick diagnosis in case of malfunction).

SEE CHAPTER 9.5.1.

Tests the tightness of the gas probe pneumatic path.

SEE CHAPTER 9.5.2.

Returns to the previous screen.

Selects the available parameters.

Enters in the selected parameter.

If a malfunction happens, before contacting the Customer care service collect and/or send

the data present in this menu.

SEE CHAPTER 9.5.3.

Page 54

54

15/06/18 10:00

SENSORS

►S1: O2 OK

S2: CO OK

S3: NO OK

Sensor measurement range

>

>

SENSORS

►S1: O2 OK

S2: CO OK

S3: NO OK

SENSOR S1

S.N. 00000000

Code AACSE15

Gas O2

Range 0-25 %

Is 101.000 uA

9.5.1 Menu→Diagnostic→Sensors

KEY DESCRIPTION

ESC

OK

Returns to the previous screen.

Selects the available parameters.

Shows the details about the selected sensor.

Example:

15/06/18 10:00

OK

Messages on the state and calibration of the electrochemical sensors:

Ok No problem detected

absent The sensor was not detected

err data Memory data error of the sensor

unknown It is necessary to update the FW of the device

err pos The sensor has been installed in the wrong position

err cal Calibration error (sensor not calibrated)

err curr Currents outside the range

err cfg Do not use this sensor as it has not been accepted on

the screen "types of sensors".

15/06/18 10:00

Sensor serial number

Sensor code

Measured Gas

Is sensor current

Page 55

55

GAS PROBE

Calibration

Probe Test

Result: Tight

Connect the flue gas sampling probe and filter unit

15/06/18 10:00

GAS PROBE

Close the flue

gas probe

Push OK to

continue

GAS PROBE

Calibration

10:00

GAS PROBE

Probe Test

15/06/18 10:00

GAS PROBE

Close the flue

gas probe

Push OK to

continue

9.5.2 Menu→Diagnostic→Gas probe

KEY FUNCTION

assembly to the instrument;

Fully insert the black rubber cap on the gas probe tip, as

shown in the following picture:

Provided black rubber cap

ESC

OK

Tightness test of the probe.

15/06/18 10:00

OK

Returns to the previous screen.

Starts the test to check the tightness of the gas sampling probe.

15/06/18 10:00

15/06/18

→ →

Results:

Tightness: The system is OK

Leak: Make sure that the probe is connected to the input P- or P+, check the seals of the pneumatic

Error: It is not possible to perform the test because the sensor is not calibrated.

connections and/or the seal of the condensation trap and check that the test cap is correctly inserted

on the tip of the probe. WARNING: a damaged probe tip may impair the test.

Page 56

56

>

INTERACTIVE OPERATIONS

DESCRIPTION

mV

Bit

>

15/06/18 10:00

HARDWARE

Memory OK

Calibration OK

►Voltages

ADC channels

>

HARDWARE

Memories OK

Calibration OK

►Voltages

ADC channels

VOLTAGES

VBAT 3001 m

VIN 4712 m

VRTC 2602 m

HARDWARE

Memories OK

Calibration OK

Voltages

►ADC channels

10:00

ADC CH. [1/2]

O2-GAS 1016 m

CO-SEN 58 m

CO-AUX 58 m

NO 60 m

PRESS 225 m

EM-SEL 1499 m

ADC CH. [2/2]

T-FLUE 1499 m

T-SPAN 58 m

T-ZERO 60 m

T-GND 225 m

TCOLDJ 1499 m

9.5.3 Menu→Diagnostic→Hardware

KEY

FUNCTION

ESC

OK

Returns to the previous screen.

Selects the available parameters.

Enters in the selected parameter.

Shows the values in mV.

Shows the values in Bit.

Note: the memory and calibration parameters are not accessible if their condition is OK.

Visualization example:

11/12/17 10:00

11/12/17 10:00

11/12/17 10:00

OK

OK

11/12/17

Bit

11/12/17 10:00

Bit

Page 57

57

Info ser. [1/2]

E instruments

Tel. +33 (0)5 53 80 85 00

Fax. +33 (0)5 53 80 16 81

www.e

09/05/19 10:00

Info ser.

Model

S.N.

FW rev.

FW P.N.

HW rev.

Boot rev.

Boot P.N.

Rev.

9999

9.99

1.00

1379M

> >

>

9.6 Menu→Info Service

09/05/19 10:00

-inst.com

FUNCTION KEY

Returns to the previous screen.

Toggle view between next or previous screen.

Page 58

58

10.0

SENSORS

CODE

POSITION

O2 Sensor

CO Sensor with NOx filter

NO Sensor

CODE

O2 Sensor

Cod. AACSE55

CO Sensor with NOx filter +

Cod. AACSE58

POSITION

POSITION

POSITION

15/06/18 10:00

SENSOR

►S1:O2 OK

S2:CO OK

S3:NO OK

SENSORS ARRANGEMENT INSIDE

THE SENSORS COMPARTMENT

GRAPHICAL DISPLAY OF ARRANGEMENT

10.1 Sensors arrangement

S1 O2

S3 NO

S2 CO

10.2 Sensor types and relevant positioning

S1 S2

Cod. AACSE55

0-4000ppm

Cod. AACSE58

Cod. AACSE60

S3

10.3 Gas sensors life

The gas sensors used in this instrument are electrochemical: thus, when the relative gas is detected, a chemical

reaction takes place inside them that generates an electrical current.

The electrical current acquired by the instrument is then converted into the corresponding gas concentration.

Sensor life is strongly related to the consumption of the reagents within.

Sensor characteristics diminish as the reagents are consumed and when these have been used up completely the

sensor must be replaced. The sensors must be recalibrated on a regular basis to assure measuring accuracy:

recalibration can only be performed by a qualified E INSTRUMENTS service centre.

Table 10.4 illustrates the characteristics inherent to each sensor.

10.4 Gas sensors life table

H2 immunity

0-4000ppm

NO Sensor

Cod. AACSE60

MEASURED GAS AVERAGE LIFE RECALIBRATION

O2

Oxygen

CO

Carbon Monoxide

NO

Nitric Oxide

24 months not necessary

24 months

>36 months

Yearly

Yearly

Page 59

59

11.0

MAINTENANCE

11.1 Routine maintenance

This instrument was designed and manufactured using top-quality components. Proper and systematic

maintenance will prevent the onset of malfunctions and will increase instrument life altogether.

The following basic requisites are to be respected:

•

When the analysis is over extract the sample probe from the stack and let the analyzer draw fresh air for a

few minutes, or at least until the displayed parameters return to their original values:

O2: >20.0%

Toxic gases: <20ppm

•

Clean the filter unit when necessary, replacing the particulate filter and applying a jet of air to the sample

probe hose to eliminate any condensate that may have formed.

Do not clean the instrument with abrasive cleaners, thinners or other similar detergents.

11.2 Preventive maintenance

At least once a year send the instrument to a SERVICE CENTER for a complete overhaul and thorough internal

cleaning.

E INSTRUMENTS’ highly qualified staff is always at your disposal and will provide you with all the sales,

technical, application and maintenance details required.

The service center will always return the instrument to you as new and in the shortest time possible. Calibration is

performed using gases and instruments comparable with National and International Specimens.

Annual servicing is accompanied by a specific calibration certificate that is a guarantee of perfect instrument

performance.

Page 60

60

4

5

2

3

1

11.3 Replacing the gas sensors

The gas sensors of the instrument shall be periodically replaced with new or recalibrated sensors.

The user can easily perform this replacement operation according to the following instructions: