Page 1

k

Originalbetriebsanleitung

Säulenbohrmaschine

t

Original operating instructions

Pillar Drill

p

Mode d’emploi d’origine

Perceuse à colonne

C

Istruzioni per l’uso originali

Trapano a colonna

lL

Original betjeningsvejledning

Søjleboremaskine

U

Original-bruksanvisning

Pelarborrmaskin

Bf

Originalne upute za uporabu

Stupna bušilica

Art.-Nr.: 42.505.30 I.-Nr.: 11061

BT-BD 501

Page 2

2

1

6

16

8

15

9

5

2

11

17

10

13

4

1

7

2

3

12

15

4

18

19

20

5

1

3

4 5

21

23

22

24

13

Page 3

3

8

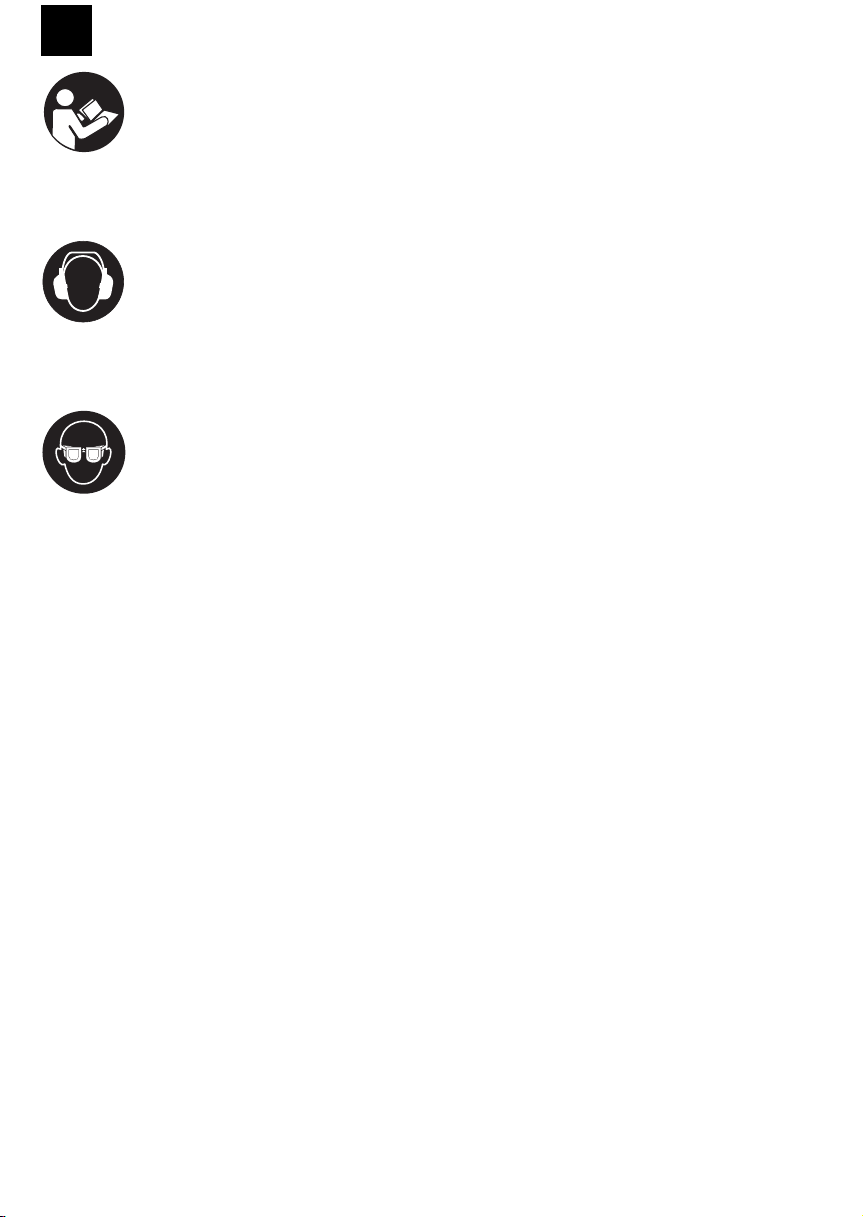

Pos. min

-1

A-4 280

C-4 620

C-2 1550

Pos. min

-1

B-4 450

A-2 720

B-1 1700

Pos. min

-1

A-3 540

B-3 870

C-1 2350

9

10

15

8

7

17

9

25

16

7

4

26

6

13

10

Page 4

4

D

“WARNUNG - Zur Verringerung des Verletzungsrisikos Bedienungsanleitung lesen”

Tragen Sie einen Gehörschutz.

Die Einwirkung von Lärm kann Gehörverlust bewirken.

Tragen Sie eine Schutzbrille.

Während der Arbeit entstehende Funken oder aus dem Gerät heraustretende Splitter, Späne

und Stäube können Sichtverlust bewirken.

Page 5

5

D

Achtung!

Beim Benutzen von Geräten müssen einige

Sicherheitsvorkehrungen eingehalten werden, um

Verletzungen und Schäden zu verhindern. Lesen Sie

diese Bedienungsanleitung / Sicherheitshinweise

deshalb sorgfältig durch. Bewahren Sie diese gut auf,

damit Ihnen die Informationen jederzeit zur

Verfügung stehen. Falls Sie das Gerät an andere

Personen übergeben sollten, händigen Sie diese

Bedienungsanleitung / Sicherheitshinweise bitte mit

aus. Wir übernehmen keine Haftung für Unfälle oder

Schäden, die durch Nichtbeachten dieser Anleitung

und den Sicherheitshinweisen entstehen.

1. Sicherheitshinweise

Die entsprechenden Sicherheitshinweise finden Sie

im beiliegenden Heftchen!

WARNUNG

Lesen Sie alle Sicherheitshinweise und

Anweisungen. Versäumnisse bei der Einhaltung der

Sicherheitshinweise und Anweisungen können

elektrischen Schlag, Brand und/oder schwere

Verletzungen verursachen.

Bewahren Sie alle Sicherheitshinweise und

Anweisungen für die Zukunft auf.

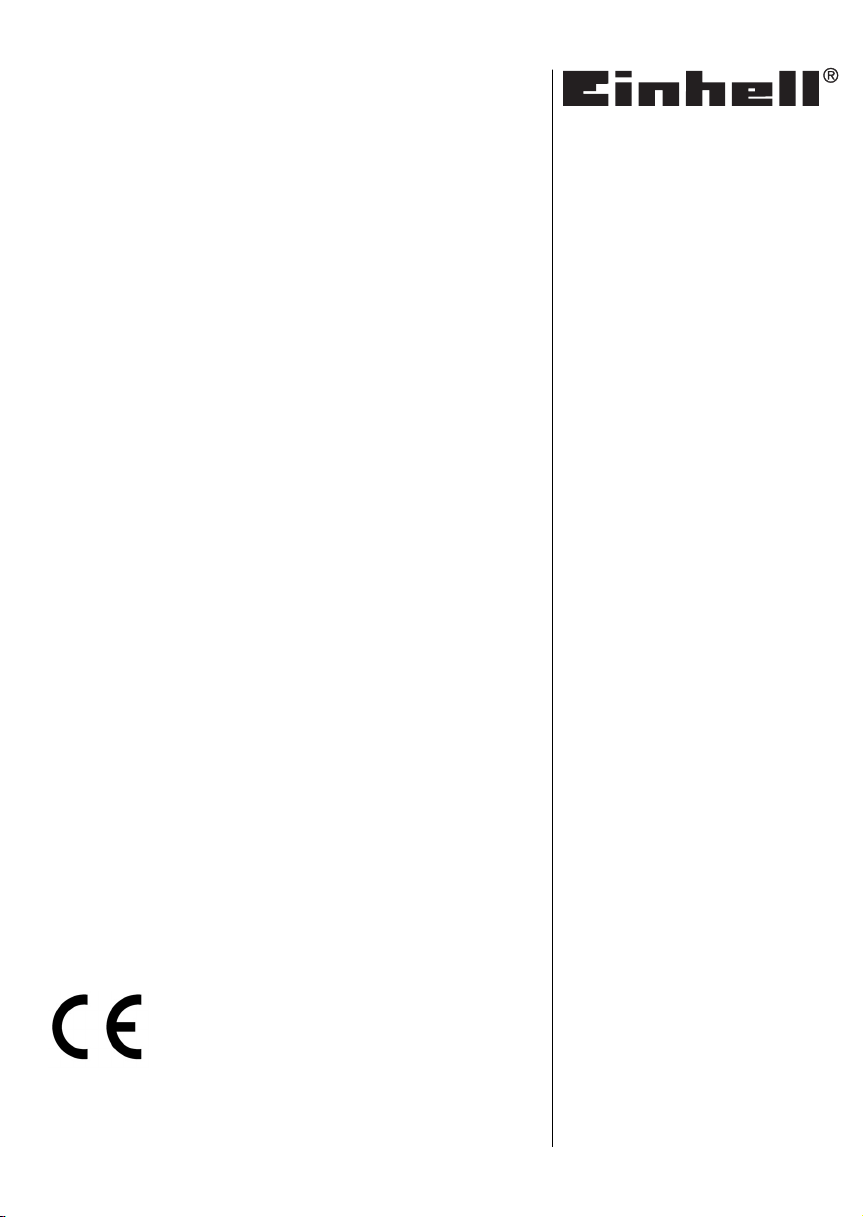

2. Gerätebeschreibung (Abb. 1)

1. Maschinenfuß

2. Säule

3. Befestigungsschrauben

4. Bohrtisch

5. Klemmschraube

6. Maschinenkopf

7. Keilriemenabdeckung

8. Motor

9. Griffe

10. Zahnkranzbohrfutter

11. Spindel

12. Befestigungsbohrungen

13. Klappbarer Späneschutz

15. Spannschraube

16. Schraube

17. Klemmschraube

18. Einschalter

19. Ausschalter

20. Madenschraube

3. Lieferumfang

Öffnen Sie die Verpackung und nehmen Sie das

Gerät vorsichtig aus der Verpackung.

Entfernen Sie das Verpackungsmaterial sowie

Verpackungs-/ und Transportsicherungen (falls

vorhanden).

Überprüfen Sie, ob der Lieferumfang vollständig

ist.

Kontrollieren Sie das Gerät und die Zubehörteile

auf Transportschäden.

Bewahren Sie die Verpackung nach Möglichkeit

bis zum Ablauf der Garantiezeit auf.

ACHTUNG

Gerät und Verpackungsmaterial sind kein

Kinderspielzeug! Kinder dürfen nicht mit

Kunststoffbeuteln, Folien und Kleinteilen spielen!

Es besteht Verschluckungs- und

Erstickungsgefahr!

Säulenbohrmaschine

Zahnkranzbohrfutter

Bohrfutterschlüssel

Klappbarer Späneschutz

Bohrtisch

Originalbetriebsanleitung

Sicherheitshinweise

4. Bestimmungsgemäße Verwendung

Diese Säulenbohrmaschine ist zum Bohren von

Metall, Kunststoff, Holz und ähnlichen Werkstoffen

bestimmt und darf nur im privaten Haushaltsbereich

verwendet werden.

Lebensmittel und gesundheitsgefährdende

Materialien dürfen mit der Maschine nicht bearbeitet

werden. Das Bohrfutter ist nur für die Verwendung

von Bohrern und Werkzeugen mit einem Schaftdurchmesser vom 1,5-16 mm und zylindrischen

Werkzeugschaft geeignet. Darüberhinaus können

auch Werkzeuge mit Kegelschaft verwendet werden.

Das Gerät ist zum Gebrauch durch Erwachsene

bestimmt.

Die Maschine darf nur nach ihrer Bestimmung

verwendet werden. Jede weitere darüber

hinausgehende Verwendung ist nicht

bestimmungsgemäß. Für daraus hervorgerufene

Schäden oder Verletzungen aller Art haftet der

Benutzer/Bediener und nicht der Hersteller.

Bitte beachten Sie, dass unsere Geräte bestimmungsgemäß nicht für den gewerblichen, handwerk-

Page 6

6

D

lichen oder industriellen Einsatz konstruiert wurden.

Wir übernehmen keine Gewährleistung, wenn das

Gerät in Gewerbe-, Handwerks- oder Industriebetrieben sowie bei gleichzusetzenden Tätigkeiten eingesetzt wird.

5. Technische Daten

Nenneingangsspannung 230V ~ 50 Hz

Nennleistung 500 Watt

Betriebsart S2 15 min.

Motordrehzahl 1400 min

-1

Ausgangsdrehzahl 280 - 2.350 min

-1

Geschwindigkeitsstufen 9

Bohrfutteraufnahme B 16

Zahnkranzohrfutter Ø 1,5 - 16 mm

Max. Schaftdurchmesser 16 mm

Ausladung 115 mm

Bohrtiefe 50 mm

Säulendurchmesser 46 mm

Höhe 650 mm

Gewicht 21,5 kg

Schalldruckpegel L

pA

61,5 dB(A)

Schallleistungspegel L

WA

74,5 dB(A)

Unsicherheit K

pA

3 dB

Unsicherheit K

WA

3 dB

Geräusch und Vibration

Die Geräusch- und Vibrationswerte wurden

entsprechend EN 61029 ermittelt.

Einschaltdauer:

Die Einschaltdauer S2 15 min (Kurzzeitbetrieb) sagt

aus, dass der Motor mit der Nennleistung 500 Watt

nur für die auf dem Datenschild angegebene Zeit (15

min) dauernd belastet werden darf. Andernfalls

würde er sich unzulässig erwärmen. Während der

Pause kühlt sich der Motor wieder auf seine Ausgangstemperatur ab.

Beschränken Sie die Geräuschentwicklung und

Vibration auf ein Minimum!

Verwenden Sie nur einwandfreie Geräte.

Warten und reinigen Sie das Gerät regelmäßig.

Passen Sie Ihre Arbeitsweise dem Gerät an.

Überlasten Sie das Gerät nicht.

Lassen Sie das Gerät gegebenenfalls

überprüfen.

Schalten Sie das Gerät aus, wenn es nicht

benutzt wird.

Tragen Sie Handschuhe.

Restrisiken

Auch wenn Sie dieses Elektrowerkzeug

vorschriftsmäßig bedienen, bleiben immer

Restrisiken bestehen. Folgende Gefahren

können im Zusammenhang mit der Bauweise und

Ausführung dieses Elektrowerkzeuges auftreten:

1. Gehörschäden, falls kein geeigneter Gehörschutz

getragen wird.

6. Vor Inbetriebnahme

6.1.Montage der Maschine

Maschinenfuß (1) aufstellen

Befestigungsflansch mit Säule (2) mit drei

Schrauben (3) und Unterlegscheiben auf dem

Maschinenfuß (1) befestigen.

Bohrtisch (4) mit Bohrtischhalter auf die Säule (2)

schieben (Abb. 3). Arretieren Sie den Bohrertisch

mit der Klemmschraube (5) in der gewünschten

Position.

Bohrkopf (6) mit Keilriemenabdeckung (7) und

Motor (8) auf die Bohrsäule aufsetzen und mit

den Inbusschrauben (20) befestigen.

Drei Griffe (9) am Vorschubhandkreuz

anschrauben.

Hinweis: Zum Schutz vor Korrosion sind alle blanken

Teile eingefettet. Vor dem Aufsetzen des Bohrfutters

(10) auf die Spindel (11) müssen beide Teile mit

einem umweltfreundlichen Lösungsmittel vollkommen

fettfrei gemacht werden, damit eine optimale

Kraftübertragung gewährleistet ist.

6.2. Aufstellen der Maschine (Abb. 1)

Vor der Inbetriebnahme muss die Bohrmaschine

stationär montiert werden. Verwenden Sie dazu die

beiden Befestigungsbohrungen (12) in der Bodenplatte. Achten Sie darauf, dass die Maschine für den

Betrieb und für Einstell- und Wartungsarbeiten frei

zugänglich ist.

Hinweis: Die Befestigungsschrauben dürfen nur so

fest angezogen werden, dass sich die Grundplatte

nicht verspannt oder verformt. Bei übermäßiger

Beanspruchung besteht Gefahr des Bruches.

Page 7

7

D

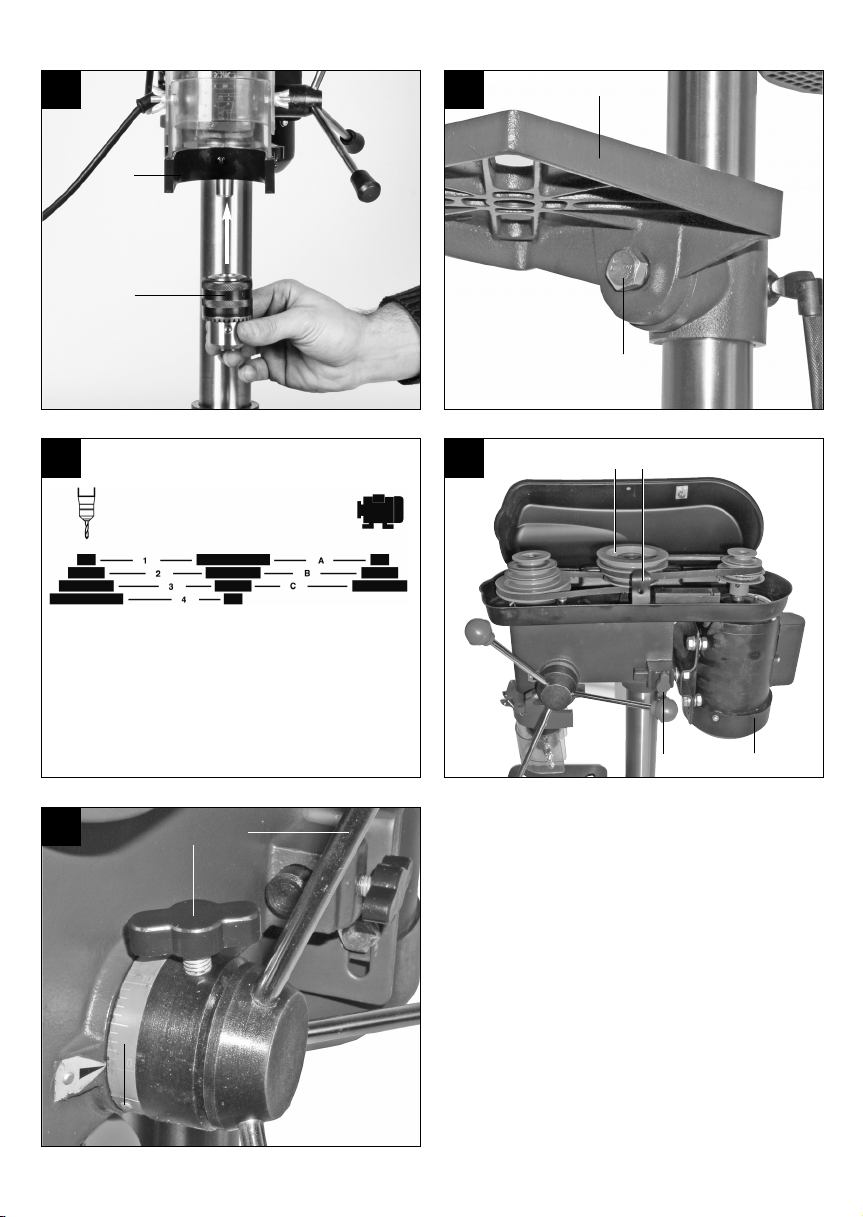

6.3.Klappbarer Späneschutz (Abb. 4-6)

Die drei Schrauben (21) herausschrauben.

Transparenten Abdeckung (23) in den Schlitz des

roten Aufnahmerahmens (24) schieben und mit den

Schrauben (21) wieder fixieren.

Dann den klappbaren Späneschutz (13) mit der

Klemmschraube an der Maschine befestigen.

Anschließend den Späneschutz nach oben klappen

und das Zahnkranzbohrfutter (10) ruckartig auf den

Konus schieben und festen Sitz des Werkzeuges

kontrollieren.

Die Höhe der Abdeckung (23) ist stufenlos einstellbar und über die beiden Flügelschrauben (22) zu

fixieren.

Zum Bohrerwechsel kann der Späneschutz (13)

nach oben geklappt werden, vor dem Einschalten

der Maschine ist der Späneschutz (13) aber wieder

in seine Ausgangsposition zu bringen.

6.4.Vor Inbetriebnahme beachten

Achten Sie darauf, dass die Spannung des Netzanschlusses mit dem Typenschild übereinstimmt.

Schließen Sie die Maschine nur an eine Steckdose

mit ordnungsgemäß installiertem Schutzkontakt an.

Die Bohrmaschine ist mit einem Nullspannungsauslöser ausgestattet, der die Bediener vor ungewolltem Wiederanlauf nach einem Spannungsabfall

schützt. In diesem Fall muss die Maschine erneut

einschaltet werden.

7. Betrieb

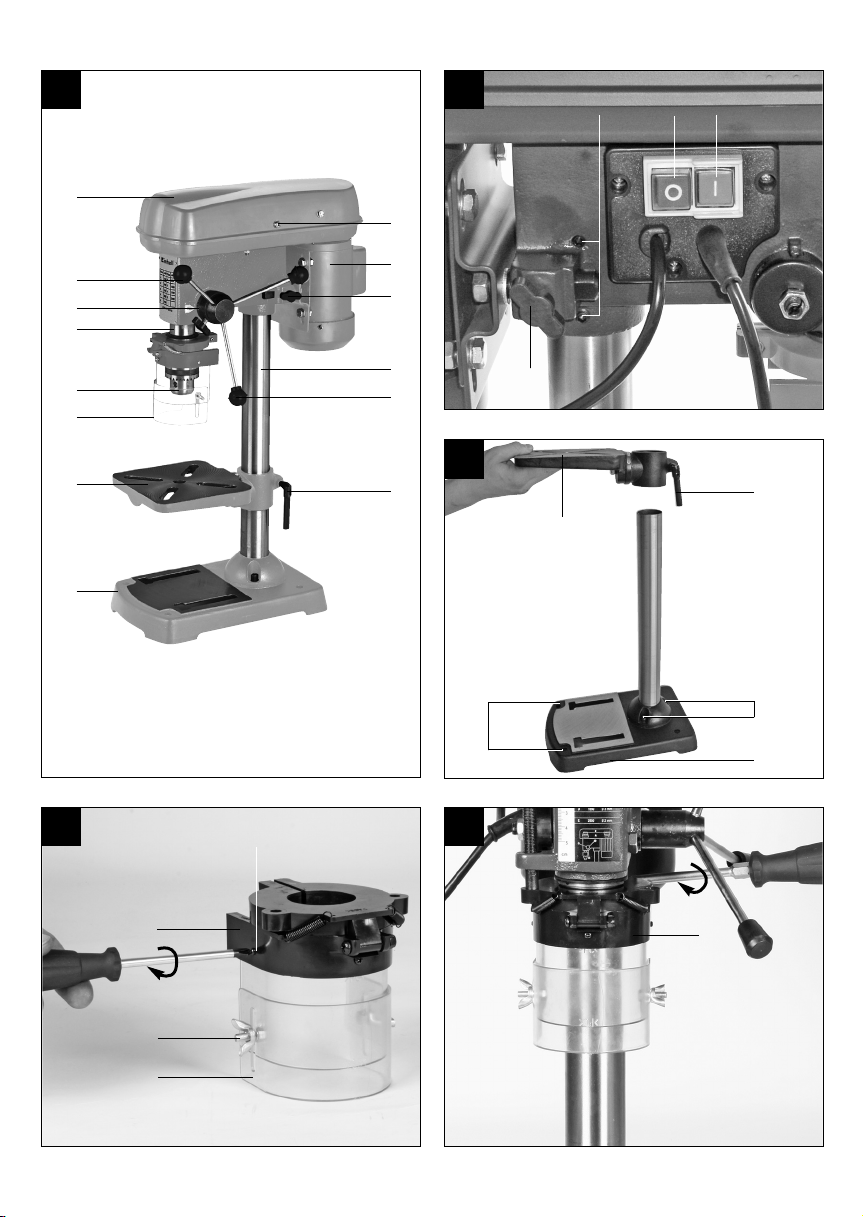

7.1.Allgemein (Abb. 2)

Zum Einschalten betätigen Sie den grünen EinSchalter „I“ (18), die Maschine läuft an. Zum Ausschalten drücken Sie die rote Taste „O“ (19), das Gerät schaltet ab.

Achten Sie darauf, das Gerät nicht zu überlasten.

Sinkt das Motorgeräusch während des Betriebes,

wird der Motor zu stark belastet.

Belasten Sie das Gerät nicht so stark, dass der

Motor zu Stillstand kommt.

7.2.Werkzeug in Bohrfutter einsetzen (Abb. 1)

Achten Sie unbedingt darauf, dass beim Werkzeugwechsel der Netzstecker gezogen ist. Im Bohrfutter

(10) dürfen nur zylindrische Werkzeuge mit dem

angegebenen maximalen Schaftdurchmesser gespannt werden. Nur einwandfreies und scharfes

Werkzeug benutzen. Keine Werkzeuge benutzen,

die am Schaft beschädigt sind oder sonst in irgendeiner Weise verformt oder beschädigt sind. Setzen

Sie nur Zubehör und Zusatzgeräte, die in der

Bedienungsanleitung angegeben oder vom

Hersteller freigebeben sind, ein.

7.3.Handhabung des Schnellspannbohrfutters

Ihre Tischbohrmaschine ist mit einem Zahnbohrfutter

(10) ausgestattet. Um einen Bohrer einzusetzen, ist

zuerst der Späneschutz (13) nach oben zu klappen,

anschließend der Bohrer einzusetzen und das

Bohrfutter mit dem mitgelieferten Futterschlüssel

festzuziehen.

Futterschlüssel wieder abziehen. Achten Sie auf

festen Sitz der eingespannten Werkzeuge.

Achtung! Futterschlüssel nicht steckten lassen.

Verletzungsgefahr durch Wegschleudern des

Futterschlüssels.

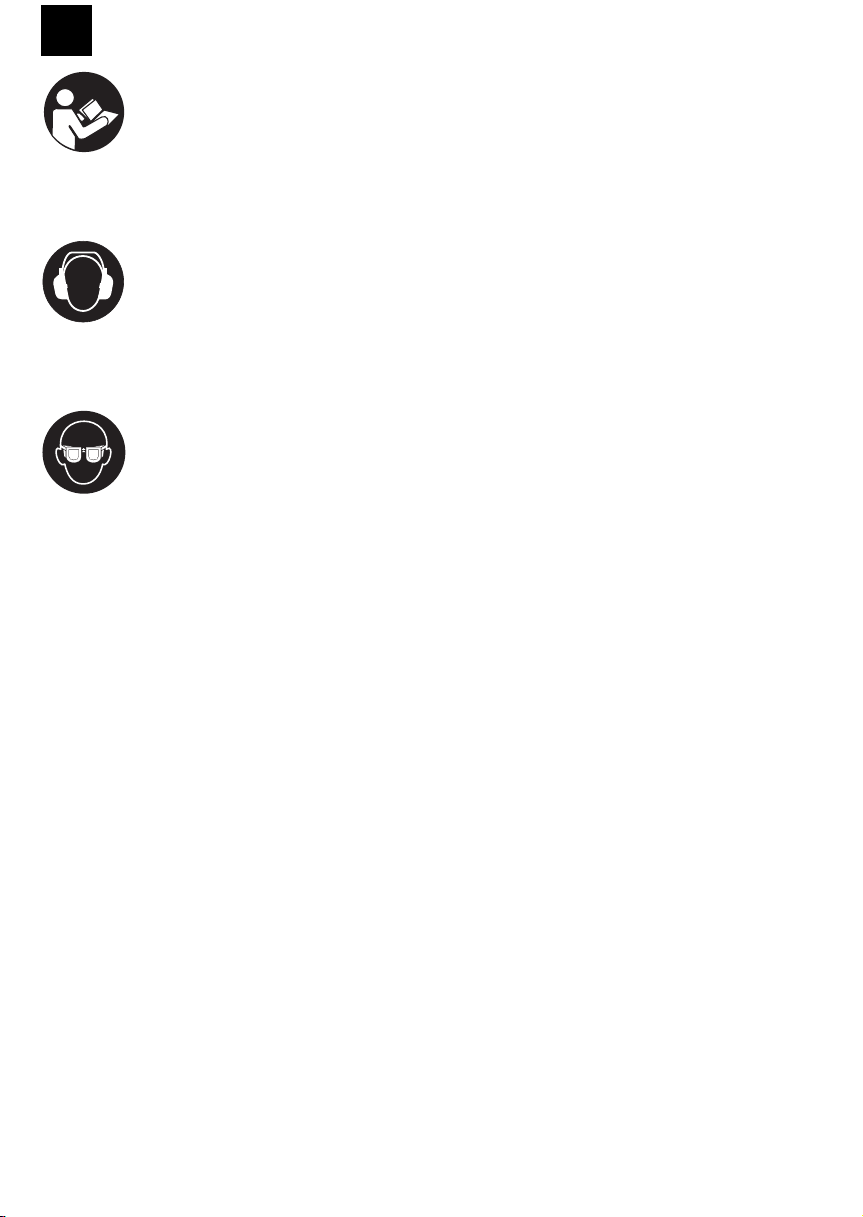

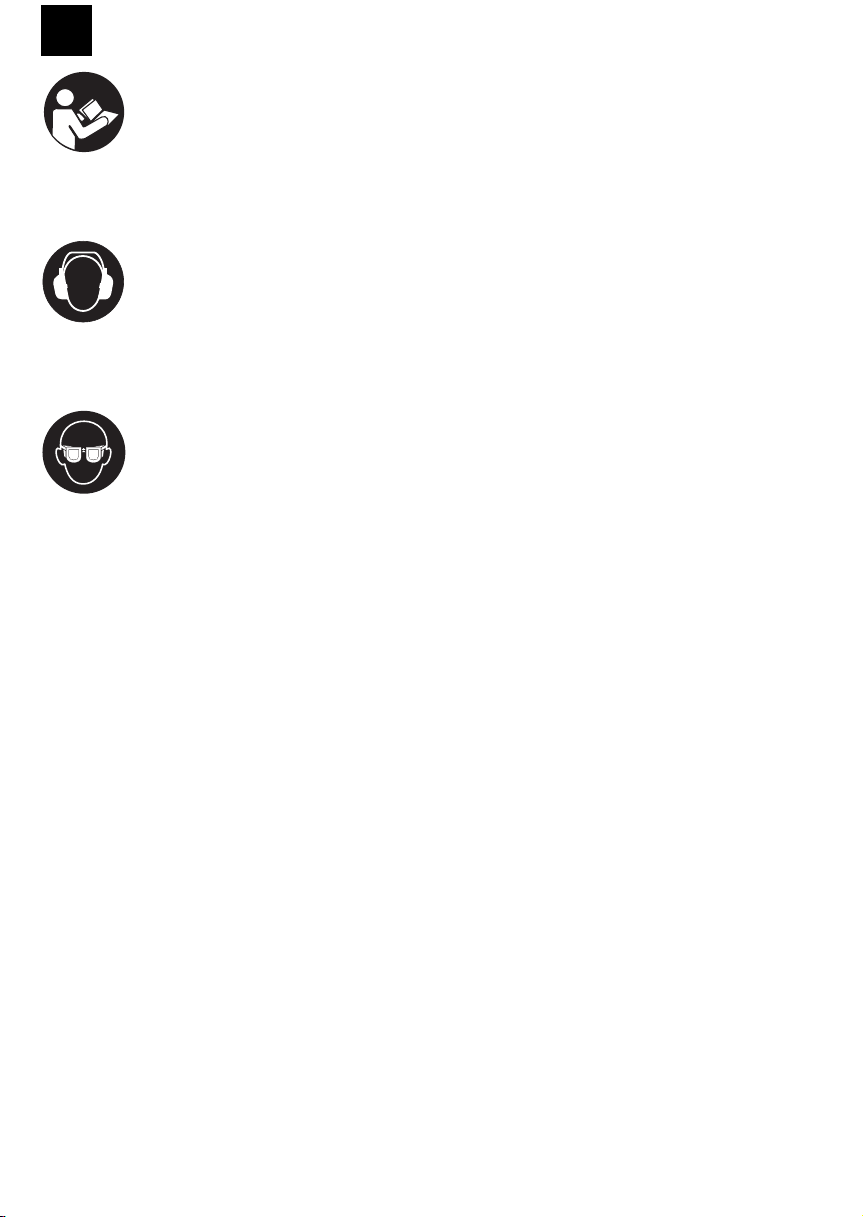

7.4.Drehzahleinstellung (Abb. 1/8/9)

Schalten Sie zuerst die Maschine aus und ziehen Sie

den Netzstecker.

Die verschiedenen Spindeldrehzahlen können durch

Umsetzen des Keilriemens eingestellt werden.

Gehen Sie wie folgt vor:

Lösen der Schraube (16) um die

Keilriemenabdeckung (7), öffnen zu können.

Spannschrauben (15) lösen und den Motor (8) in

Richtung Maschinenkopf schieben.

Keilriemen auf die gewünschte Position

umsetzen.

Die entsprechenden Drehzahlen entnehmen Sie

der Tabelle (Abb. 8).

Keilriemen spannen, indem Sie den Motor (8)

entgegen des Maschinenkopfes (6) schieben.

Spannschrauben (16) wieder festziehen. Die

Spannung ist richtig eingestellt, wenn sich der

Keilriemen in der Mitte ca. 1 cm durchdrücken

lässt.

Keilriemenabdeckung schließen und mit der

Schraube (16) festschrauben. Die

Keilriemenabdeckung (7) muss immer fest

verschlossen sein, da die Maschine mit einem

Sicherheitsschalter ausgestattet ist und somit nur

bei geschossener Keilriemenabdeckung (7)

eingeschaltet werden kann.

Achtung! Niemals die Bohrmaschine mit geöffneter

Keilriemenabdeckung laufen lassen. Vor dem Öffnen

des Deckels immer den Netzstecker ziehen. Niemals

in laufende Keilriemen greifen.

Page 8

8

D

7.4.1 Bohrtiefenanschlag (Abb. 10)

Die Bohrspindel besitzt einen verdrehbaren Skalenring (25) zum Einstellen der Bohrtiefe. Einrichtarbeiten nur im Stillstand vornehmen.

Bohrspindel (11) nach unten drücken bis die

Bohrerspitze auf dem Werkstück anliegt.

Klemmschraube (17) lockern und Skalenring (25)

nach vorne drehen bis zum Anschlag.

Skalenring (25) um die gewünschte Bohrtiefe

zurückdrehen und mit der Klemmschraube (17)

fixieren.

Achtung! Beim Einstellen der Bohrtiefe einer zylindrischen Bohrung, müssen Sie die Länge der

Bohrerspitze hinzurechnen.

7.5 Neigung des Bohrtisches einstellen

(Abb. 7)

Schlossschraube (26) unter dem Bohrtisch (4)

lockern.

Bohrtisch (4) auf das gewünschte Winkelmaß

einstellen.

Schlossschraube (26) wieder fest anziehen um

den Bohrtisch (4) in dieser Position zu fixieren.

7.6 Höhe des Bohrtisches einstellen (Abb. 1)

Spannschraube (5) lockern

Bohrtisch (4) durch drücken oder heben und

gleichzeitiges leichtes drehen nach links und

rechts auf die gewünschte Höhe einstellen.

Spannschraube (5) wieder festziehen.

7.7 Werkstück spannen

Spannen Sie Werkstücke grundsätzlich mit Hilfe

eines Maschinenschraubstocks oder mit geeignetem

Spannmittel fest ein. Werkstücke nie von Hand

halten! Beim Bohren sollten das Werkstück auf dem

Bohrtisch (4) beweglich sein, damit eine Selbstzentrierung stattfinden kann. Werkstück unbedingt gegen

Verdrehen sichern. Dies geschieht am besten durch

Anlegen des Werkstückes bzw. des

Maschinenschraubstocks an einen festen Anschlag.

Achtung! Blechteile müssen eingespannt werden,

damit sie nicht hochgerissen werden können. Stellen

Sie den Bohrtisch je nach Werkstück in Höhe und

Neigung richtig ein. Es muss zwischen Werkstückoberkante und Bohrerspitze genügend Abstand

bleiben.

7.8 Arbeitsgeschwindigkeiten

Achten Sie beim Bohren auf die richtige Drehzahl.

Diese ist abhängig vom Bohrerdurchmesser und dem

Werkstoff.

Unten aufgeführte Liste hilft ihnen bei der Wahl von

Drehzahlen für die verschiedenen Materialien.

Bei den angegebenen Drehzahlen handelt es sich

lediglich um Richtwerte.

Ø Bohrer Grauguss Stahl Eisen Aluminium Bronze

3 2550 1600 2230 9500 8000

4 1900 1200 1680 7200 6000

5 1530 955 1340 5700 4800

6 1270 800 1100 4800 4000

7 1090 680 960 4100 3400

8 960 600 840 3600 3000

9 850 530 740 3200 2650

10 765 480 670 2860 2400

11 700 435 610 2600 2170

12 640 400 560 2400 2000

13 590 370 515 2200 1840

14 545 340 480 2000 1700

16 480 300 420 1800 1500

18 425 265 370 1600 1300

20 380 240 335 1400 1200

22 350 220 305 1300 1100

25 305 190 270 1150 950

7.9 Senken und Zentrierbohren

Mit dieser Tischbohrmaschine können Sie auch

Senken oder Zentrierbohren. Beachten Sie hierbei,

dass das Senken mit der niedrigsten Geschwindigkeit durchgeführt werden sollte, während zum Zentrierbohren eine hohe Geschwindigkeit erforderlich

ist.

7.10 Holzbearbeitung

Bitte beachten Sie, dass beim Bearbeiten von Holz

eine geeignete Staubabsaugung verwendet werden

muss, da Holzstaub gesundheitsgefährdend sein

kann. Tragen Sie bei stauberzeugenden Arbeiten

unbedingt eine geeignete Staubschutzmaske.

8. Austausch der Netzanschlussleitung

Wenn die Netzanschlussleitung dieses Gerätes

beschädigt wird, muss sie durch den Hersteller oder

seinen Kundendienst oder eine ähnlich qualifizierte

Person ersetzt werden, um Gefährdungen zu

vermeiden.

Page 9

9

D

9. Reinigung, Wartung und

Ersatzteilbestellung

Ziehen Sie vor allen Reinigungsarbeiten den

Netzstecker.

9.1 Reinigung

Die Tischbohrmaschine ist weitgehend

wartungsfrei. Halten Sie das Gerät sauber.

Ziehen Sie vor allen Reinigungs- und

Wartungsarbeiten den Netzstecker. Verwenden

Sie zum Reinigen keine scharfen Lösungsmittel.

Achten Sie darauf, dass keine Flüssigkeiten in

das Gerät gelangen. Fetten Sie blanke Teile

nach Beendigung der Arbeiten wieder ein.

Besonderes die Bohrsäule, blanke Teile des

Ständers und der Bohrtisch sollten regelmäßig

gefettet werden. Benützen Sie zum Fetten ein

handelsübliches säurefreies Schmierfett.

Achtung: Öl- und fetthaltige Reinigungstücher

sowie Fett- und Ölrückstände nicht in den

Hausmüll geben. Entsorgen Sie diese

umweltgerecht. Kontrollieren und reinigen Sie

regelmäßig die Lüftungsöffnungen. Lagern Sie

das Gerät in einem trockenen Raum. Sollte das

Gerät beschädigt sein, versuche Sie nicht, es

selbst zu reparieren. Überlassen Sie die

Reparatur einer Elektrofachkraft.

Wir empfehlen, dass Sie das Gerät direkt nach

jeder Benutzung reinigen.

Reinigen Sie das Gerät regelmäßig mit einem

feuchten Tuch und etwas Schmierseife.

Verwenden Sie keine Reinigungs- oder

Lösungsmittel; diese könnten die Kunststoffteile

des Gerätes angreifen. Achten Sie darauf, dass

kein Wasser in das Geräteinnere gelangen kann.

9.2 Wartung

Im Geräteinneren befinden sich keine weiteren zu

wartenden Teile.

9.3 Ersatzteilbestellung:

Bei der Ersatzteilbestellung sollten folgende

Angaben gemacht werden;

Typ des Gerätes

Artikelnummer des Gerätes

Ident-Nummer des Gerätes

Ersatzteilnummer des erforderlichen Ersatzteils

Aktuelle Preise und Infos finden Sie unter

www.isc-gmbh.info

10. Lagerung

Lagern Sie das Gerät und dessen Zubehör an einem

dunklen, trockenen und frostfreiem sowie für Kinder

unzugänglichem Ort. Die optimale Lagertemperatur

liegt zwischen 5 und 30 ˚C. Bewahren Sie das

Elektrowerkzeug in der Originalverpackung auf.

11. Entsorgung und Wiederverwertung

Das Gerät befindet sich in einer Verpackung um

Transportschäden zu verhindern. Diese Verpackung

ist Rohstoff und ist somit wieder verwendbar oder

kann dem Rohstoffkreislauf zurückgeführt werden.

Das Gerät und dessen Zubehör bestehen aus

verschiedenen Materialien, wie z.B. Metall und

Kunststoffe. Führen Sie defekte Bauteile der

Sondermüllentsorgung zu. Fragen Sie im

Fachgeschäft oder in der Gemeindeverwaltung nach!

Page 10

10

GB

“Caution - Read the operating instructions to reduce the risk of inquiry”

Wear ear-muffs.

The impact of noise can cause damage to hearing.

Wear safety goggles.

Sparks generated during working or splinters, chips and dust emitted by the device can cause

loss of sight.

Page 11

11

GB

Important.

When using the equipment, a few safety precautions

must be observed to avoid injuries and damage.

Please read the complete operating instructions and

safety information with due care. Keep this manual in

a safe place so that the information is available at all

times. If you give the equipment to any other person,

hand over these operating instructions and the safety

information as well. We cannot accept any liability for

damage or accidents which arise due to a failure to

follow these instructions and the safety information.

1. Safety information

Please refer to the booklet included in delivery for the

safety information.

CAUTION

Read all the safety information and instructions.

Failure to follow the safety information and

instructions may result in an electric shock, fire and/or

serious injury.

Keep all the safety information and instructions

in a safe place for future use.

2. Layout (Fig. 1)

1. Machine base

2. Pillar

3. Fixing screw

4. Drill table

5. Clamping screw

6. Machine head

7. V-belt

8. Motor

9. Grip knobs

10. Scroll chuck

11. Spindle

12. Mounting holes

13. Folding chip guard

15. Tightening screw

16. Screw

17. Clamping screw

18. ON switch

19. OFF switch

20. Grub screw

3. Items supplied

Open the packaging and take out the equipment

with care.

Remove the packaging material and any

packaging and/or transportation braces (if

available).

Check to see if all items are supplied.

Inspect the equipment and accessories for

transport damage.

If possible, please keep the packaging until the

end of the guarantee period.

IMPORTANT

The equipment and packaging material are not

toys. Do not let children play with plastic bags,

foils or small parts. There is a danger of

swallowing or suffocating!

Pillar drill

Scroll chuck

Drill chuck key

Folding chip guard

Drill table

Original operating instructions

Safety instructions

4. Intended use

This pillar drill is designed for drilling metal, plastic,

wood and similar materials. It is intended for use in

the private sector only.

Food and harmful materials may not be processed

with the equipment. The drill chuck is only designed

for use with drill bits and tools with a shaft diameter of

1.5 to 16 mm, and for cylindrical tool shanks. Tools

with a tapered shank can also be used. The

equipment is intended for use by adults only.

The equipment is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse. The user / operator and not the manufacturer

will be liable for any damage or injuries of any kind

caused as a result of this.

Please note that our equipment has not been

designed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

equipment is used in commercial, trade or industrial

businesses or for equivalent purposes.

Page 12

5. Technical data

Nominal input voltage 230V ~ 50 Hz

Power rating 500 W

Operating mode S2 15 min.

Motor speed 1,400 rpm

Output speed 280 – 2,350 rpm

Speed levels 9

Drill chuck mount B 16

Scroll chuck Ø 1,5 - 16 mm

Max. shaft diameter 16 mm

Reach 115 mm

Drill depth 50 mm

Pillar diameter 46 mm

Height 650 mm

Weight 21.5 kg

LpAsound pressure level 61.5 dB(A)

LWAsound power level 74.5 dB(A)

KpAuncertainty 3 dB

KWAuncertainty 3 dB

Sound and vibration

Sound and vibration values were measured in

accordance with EN 61029.

Load factor:

A load factor of S2 15 min (intermittent periodic duty)

means that you may operate the motor continuously

at its nominal power level (500 W) for no longer than

the time stipulated on the specifications label (15

minutes ON period).

If you fail to observe this time limit the motor will

overheat. During the OFF period the motor will cool

again to its starting temperature.

Keep the noise emissions and vibrations to a

minimum.

Only use appliances which are in perfect working

order.

Service and clean the appliance regularly.

Adapt your working style to suit the appliance.

Do not overload the appliance.

Have the appliance serviced whenever

necessary.

Switch the appliance off when it is not in use.

Wear protective gloves.

Residual risks

Even if you use this electric power tool in

accordance with instructions, certain residual

risks cannot be rules out. The following hazards

may arise in connection with the equipment’s

construction and layout:

1. Damage to hearing if no suitable ear protection is

used.

6. Before starting the equipment

6.1. Assembling the machine

Position the machine base (1).

Fasten mounting flange with pillar (2) using three

screws (3) and washers to drill base (1).

Push the drill table (4) with drill table clamp shaft

onto the pillar (2) (Fig. 3). Lock the drill table into

the desired position using the clamping screw (5).

Place drill head (6) with V-belt cover (7) and

motor (8) onto the drill pillar and fasten using the

Allen screws (20).

Screw the three ball-shaped handles (9) onto the

feeder cross handle.

Note: All bare parts are greased in order to protect

them from corrosion. Before mounting the drill chuck

(10) onto the spindle (11), both parts must be

completely degreased using an environmentally

friendly solvent. This ensures optimal transmission of

power.

6.2. Installing the machine (Fig. 1)

Before you use the drill for the first time it must be

permanently fixed in position. Use both mounting

holes (12) in the base plate to do this. Ensure that the

equipment is freely accessible for operation,

adjustment and maintenance.

Note: The fixing screws may only be tightened to a

point where they do not distort or deform the base

plate. Excessive tension can lead to fracture.

6.3. Hinged chip guard (Fig. 4-6)

Unscrew the three screws (21). Push the transparent

cover (23) into the groove of the red mounting frame

(24) and fasten it again with the screws (21).

Then use the clamping screw to fasten the folding

chip guard (13) to the machine. Finally swing up the

chip guard, push the scroll chuck (10) with a jerk onto

the taper and check that the tool is securely seated.

The height of the cover (23) is infinitely adjustable

and can be locked using both thumb screws (22).

The chip guard (13) can be flipped upwards to

change drill bits, however ensure that the chip guard

(13) is back in its initial position before restarting the

equipment.

12

GB

Page 13

13

GB

6.4. Prior to using the machine for the first time

Ensure that the voltage of the mains supply complies

with the specifications on the rating plate. Connect

the equipment only to a socket with the properly

installed earthing contact. The drill is equipped with a

no-volt trip that is designed to protect the operator

from an undesired restart following a drop in voltage.

Should this happen, the equipment must be

physically restarted.

7. Operation

7.1. General (Fig. 2)

To switch on the equipment, push in the green On

button “I” (18); the drill starts up. To switch off, press

the red Off button “O” (19); the drill shuts down.

Ensure that you do not overload the equipment.

If the sound of the motor drops in pitch during

operation, it is being overloaded.

Do not overload the equipment to the point where the

motor comes to a standstill.

7.2. Fitting tools to the drill chuck (Fig. 1)

Make sure that the power plug is removed from the

socket-outlet before changing tools. Only cylindrical

tools with the stipulated maximum shaft diameter may

be clamped in the drill chuck (10). Only use a tool that

is sharp and free of defects. Do not use tools whose

shaft is damaged or which are deformed or flawed in

any other way. Use only accessories and

attachments that are specified in the operating

instructions or have been approved by the

manufacturer.

7.3. Using the quick-change drill chuck

Your drill is equipped with a gear-toothed drill chuck

(10). In order to insert a drill bit, flip up the chip guard

(13), insert the drill bit, then tighten down the drill

chuck using the supplied chuck key.

Pull out the chuck key. Ensure that the clamped tool

is firmly seated.

Important. Do not leave the chuck key in the clamp

hole. Doing so will cause the chuck key to be

catapulted out, which could cause injury.

7.4. Setting the speed (Fig. 1/8/9)

First switch the equipment off, then pull the power

plug.

The various spindle speeds can be set by moving the

V-belt.

Proceed as follows:

Remove the screw (16) in order to open the V-

belt cover (7).

Slacken the tightening screw (15) and push the

motor (8) in the direction of the machine head.

Move the V-belt to the desired position.

Refer to table (Fig. 8) for the recommended

speeds.

Tighten the V-belt by pushing the motor (8) away

from the drill head (6). Screw the tightening screw

(16) back down again. The tension is properly set

when the V-belt flexes in the middle by approx. 1

cm when pressed.

Close the V-belt cover and screw down using the

screw (16). The V-belt cover (7) must always be

locked tight, as the equipment is equipped with a

safety switch that only allows the equipment to be

turned when the V-belt cover (7) is closed.

Important. Never let the pillar drill run when the Vbelt cover is open. Always pull power plug before

opening the cover. Never touch the V-belt when it is

rotating.

7.4.1 Drill depth stop (Fig. 10)

The drilling spindle has a swivelling scale ring (25) for

setting the drill depth. Only adjust the setting when

the equipment is at a standstill.

Press the drilling spindle (11) downwards until the

tip of the drill bit touches the workpiece.

Slacken the clamping screw (17) and turn the

scale ring (25) forwards until it stops.

Turn the scale ring (25) back to the desired drill

depth, then lock this setting into place using the

clamping screw (17).

Important. When setting the drill depth of a

cylindrical hole you must add the length of the drill tip.

7.5. Setting the angle of the drill table (Fig. 7)

Slacken the carriage bolt (26) under the drill table

(4).

Set the drill table (4) to the desired angle.

Tighten down the carriage bolt (26) in order to

lock the drill table (4) into this position.

7.6. Setting the height of the drill table (Fig. 1)

Slacken the tightening screw (5).

Set the drill table (4) to the desired height by

pressing down or lifting up and simultaneously

(gently) pushing to the left or right.

Screw the tightening screw (5) back down again.

7.7 Clamping the workpiece

As a general rule, use a machine vice or another

suitable clamping device to lock a workpiece into

position. Never hold the workpiece in place with

your hand! When drilling, the workpiece should be

able to travel on the drill table (4) for self-centering

purposes. Ensure that the workpiece cannot rotate.

This is best achieved by placing the

Page 14

workpiece/machine vice on a sturdy block.

Important. Sheetmetal parts must be clamped in to

prevent them from being torn up. Properly set the

height and angle of the drill table for each workpiece.

There must be enough distance between the upper

edge of the workpiece and tip of the drill bit.

7.8 Working speeds

Ensure that you drill at the proper speed. Drill speed

is dependent on the diameter of the drill bit and the

material it is made from.

The table below acts as a guide for selecting the

proper speed for drill bits made from various

materials.

Note: The rotational speeds shown are merely

suggested values.

Drill bit Ø Cast iron Steel Iron Aluminum Bronze

3 2550 1600 2230 9500 8000

4 1900 1200 1680 7200 6000

5 1530 955 1340 5700 4800

6 1270 800 1100 4800 4000

7 1090 680 960 4100 3400

8 960 600 840 3600 3000

9 850 530 740 3200 2650

10 765 480 670 2860 2400

11 700 435 610 2600 2170

12 640 400 560 2400 2000

13 590 370 515 2200 1840

14 545 340 480 2000 1700

16 480 300 420 1800 1500

18 425 265 370 1600 1300

20 380 240 335 1400 1200

22 350 220 305 1300 1100

25 305 190 270 1150 950

7.9 Countersinking and center-drilling

With this drill you can also perform countersinking

and center-drilling jobs. Please observe that

countersinking should be performed at the lowest

speed, while a high speed is required for centerdrilling.

7.10 Woodworking

Please note that sawdust must be properly evacuated

when working with wood, as it can be a health

hazard. Ensure that you wear a suitable dust mask

when performing work that generates dust.

8. Replacing the power cable

If the power cable for this equipment is damaged, it

must be replaced by the manufacturer or its aftersales service or similarly trained personnel to avoid

danger.

9. Cleaning, maintenance and ordering

of spare parts

Always pull out the mains power plug before starting

any cleaning work.

9.1 Cleaning

The drill is maintenance-free to a large extent.

Keep the equipment clean. Pull the power plug

before doing any cleaning and maintenance work

on the appliance. Do not use any harsh, abrasive

solvents to clean. Ensure that no liquid seeps into

the equipment. Regrease all bare parts when the

work is finished. The drill pillar, blank parts of the

column, and the drill table especially should be

regreased at regular intervals. Use a standard,

acid-free lubricating grease to do this.

Important: Do not use your household trash can

as a receptacle for oil and grease-soaked

cleaning rags or grease and oil sludge. Dispose

of these toxic materials in an environmentallyfriendly fashion. Regularly check and clean the

ventilation holes. Store the equipment in a dry

room. Should the equipment become damaged,

do not try to repair it yourself. Leave this work to

the hands of a qualified electrical technician.

We recommend that you clean the equipment

immediately after you use it.

Clean the appliance regularly with a damp cloth

and some soft soap. Do not use cleaning agents

or solvents; these may be aggressive to the

plastic parts in the appliance. Ensure that no

water can get into the interior of the equipment.

9.2 Servicing

There are no parts inside the equipment which

require additional maintenance.

14

GB

Page 15

15

GB

9.3 Ordering replacement parts:

Please provide the following information on all orders

for spare parts:

Model/type of the equipment

Article number of the equipment

ID number of the equipment

Spare part number of the required spare part

For our latest prices and information please go to

www.isc-gmbh.info

10. Storage

Store the equipment and accessories out of children’s

reach in a dark and dry place at above freezing

temperature. The ideal storage temperature is

between 5 and 30 °C. Store the electric tool in its

original packaging.

11. Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in

this packaging can be reused or recycled. The

equipment and its accessories are made of various

types of material, such as metal and plastic. Defective

components must be disposed of as special waste.

Ask your dealer or your local council.

Page 16

16

F

« Avertissement – Lisez ce mode d’emploi pour diminuer le risque de blessures »

Portez une protection de l’ouïe.

L’exposition au bruit peut entraîner une perte de l’ouïe.

Portez des lunettes de protection.

Les étincelles générées pendant travail ou les éclats, copeaux et la poussière sortant de

l’appareil peuvent entraîner une perte de la vue.

Page 17

Attention !

Lors de l’utilisation d’appareils, il faut respecter

certaines mesures de sécurité afin d’éviter des

blessures et dommages. Veuillez donc lire

attentivement ce mode d’emploi/ces consignes de

sécurité. Veillez à le conserver en bon état pour

pouvoir accéder aux informations à tout moment. Si

l’appareil doit être remis à d’autres personnes, veillez

à leur remettre aussi ce mode d’emploi/ces

consignes de sécurité. Nous déclinons toute

responsabilité pour les accidents et dommages dus

au non-respect de ce mode d’emploi et des

consignes de sécurité.

1. Consignes de sécurité

Vous trouverez les consignes de sécurité

correspondantes dans le petit manuel ci-joint !

AVERTISSEMENT

Veuillez lire toutes les consignes de sécurité et

instructions. Toute omission lors du respect des

consignes de sécurité indiquées plus loin peut

entraîner des décharges électriques, un incendie

et/ou de graves blessures.

Conservez toutes les consignes de sécurité et

toutes les instructions pour l’avenir.

2. Description de l’appareil (fig. 1)

1. Pied de la machine

2. Mât

3. Vis de fixation

4. Table de perçage

5. Vis de serrage

6. Tête de la machine

7. Recouvrement de courroie trapézoïdale

8. Moteur

9. Poignées

10. Mandrin à couronne dentée

11. Broche

12. Trous de fixation

13. Dispositif de protection anti-copeaux rabattable

15. Vis de serrage

16. Vis

17. Vis de serrage

18. Contacteur

19. Interrupteur

20. Vis sans tête

3. Volume de livraison

Ouvrez l’emballage et prenez l’appareil en le

sortant avec précaution de l’emballage.

Retirez le matériel d’emballage tout comme les

sécurités d’emballage et de transport (s’il y en a).

Vérifiez si la livraison est bien complète.

Contrôlez si l’appareil et ses accessoires ne sont

pas endommagés par le transport.

Conservez l’emballage autant que possible

jusqu’à la fin de la période de garantie.

ATTENTION

L’appareil et le matériel d’emballage ne sont pas

des jouets ! Il est interdit de laisser des enfants

jouer avec des sacs et des films en plastique et

avec des pièces de petite taille. Ils risquent de

les avaler et de s’étouffer !

Perceuse à colonne

Mandrin à couronne dentée

Clé du mandrin

Dispositif de protection anti-copeaux rabattable

Table de perçage

Mode d’emploi d’origine

Consignes de sécurité

4. Utilisation conforme à l’affectation

Cette perceuse à colonne est destinée à percer le

métal, les matières plastiques, le bois et autres

matériaux semblables et doit uniquement être utilisée

dans le secteur des ménages privés.

Les produits alimentaires et matériaux nocifs à la

santé ne doivent pas être traités avec cette machine.

Le mandrin convient exclusivement à l’emploi de

forets et d’outils d’un diamètre de tige de 1,5 à 16 mm

et de tiges d’outils cylindriques. Vous pouvez

également utiliser des outils à tige conique. L’appareil

est conçu pour être utilisé par des adultes.

La machine doit exclusivement être employée

conformément à son affectation. Chaque utilisation

allant au-delà de cette affectation est considérée

comme non conforme. Pour les dommages en

résultant ou les blessures de tout genre, le

producteur décline toute responsabilité et

l’opérateur/l’exploitant est responsable.

17

F

Page 18

18

F

Veillez au fait que nos appareils, conformément au

règlement, n’ont pas été conçus pour être utilisés

dans un environnement professionnel, industriel ou

artisanal. Nous déclinons toute responsabilité si

l’appareil venait à être utilisé professionnellement,

artisanalement ou par des sociétés industrielles, tout

comme pour toute activité équivalente.

5. Caractéristiques techniques

Tension d’entrée nominale 230V ~ 50 Hz

Puissance nominale 500 Watt

Mode d’exploitation S2 15 min

Régime moteur 1400 tr/min

Régime de départ 280 - 2350 tr/min

Vitesses 9

Logement de mandrin B 16

Mandrin à couronne dentée Ø 1,5-16 mm

Diamètre de tige max. 16 mm

Distance de l’axe de la broche au bâti 115 mm

Profondeur de perçage 50 mm

Diamètre de colonne 46 mm

Hauteur 650 mm

Poids 21,5 kg

Niveau de pression acoustique L

pA

61,5 dB(A)

Niveau acoustique L

WA

74,5 dB(A)

Imprécision K

pA

3 dB

Imprécision K

WA

3 dB

Bruit et vibrations

Le bruit et les vibrations ont été déterminées

conformément à EN 61029.

Duré de mise en circuit :

La durée de mise en circuit S2 15 min (service bref)

indique que le moteur de cette puissance nominale

de 500 Watt ne doit être chargé en continu que pour

le temps (15 min) indiqué sur la plaque signalétique.

Sinon, il se réchaufferait de façon inadmissible.

Pendant la pause, le moteur refroidit jusqu’à sa

température de départ.

Limitez le niveau sonore et les vibrations à un

minimum !

Utilisez exclusivement des appareils en excellent

état.

Entretenez et nettoyez l’appareil régulièrement.

Adaptez votre façon de travailler à l’appareil.

Ne surchargez pas l’appareil.

Faites contrôler l’appareil le cas échéant.

Mettez l’appareil hors circuit lorsque vous ne

l’utilisez pas.

Portez des gants.

Risques résiduels

Même en utilisant cet outil électrique

conformément aux prescriptions, il reste

toujours des risques résiduels. Les dangers

suivants peuvent apparaître en rapport avec la

construction et le modèle de cet outil électrique :

1. Déficience auditive si aucun casque anti-bruit

approprié n’est porté.

6. Avant la mise en service

6.1. Montage de la machine

Mettez le pied de la machine (1) en place

Fixez la bride de fixation avec la colonne (2) sur

le pied de la machine (1) à l’aide de trois vis (3) et

de rondelles.

Poussez la table de perçage (4) sur la colonne (2)

(fig. 3). Arrêtez la table de perçage à l’aide de la

vis de serrage (5) dans la position désirée.

Placez la tête de perçage (6) avec le

recouvrement de la courroie trapézoïdale (7) et le

moteur (8) sur la colonne de perçage et fixez à

l’aide de vis à six pans creux (20).

Vissez trois poignées (9) sur le croisillon

d’avance.

Remarque : Toutes les pièces nues sont graissées

pour les protéger contre la corrosion. Avant de mettre

le mandrin (10) en place sur la broche (11), les deux

pièces doivent être entièrement dégraissées à l’aide

d’un solvant biologique afin de garantir une

transmission de force optimale.

6.2. Mise en place de la machine (fig. 1)

Avant la mise en service, la perceuse doit être

montée de manière stable. Pour cela, utilisez les

deux perçages de fixation (12) dans la plaque du sol.

Veillez à ce que la machine soit bien accessible pour

le service et pour les travaux de réglage et de

maintenance.

Page 19

Remarque : les vis de fixation doivent être serrées

juste pour éviter que la plaque de base ne se tende ni

ne se déforme. En cas de sollicitation trop importante,

il y a un risque de rupture.

6.3. Dispositif de protection anti-copeaux

rabattable (fig. 4-6)

Dévissez les trois vis (21). Introduisez le

recouvrement transparent (23) dans la fente du cadre

de logement rouge (24) et fixez-le à nouveau à l’aide

des vis (21).

Ensuite fixez le capot protecteur de sciures rabattable

(13) sur la machine à l’aide de la vis de fixation. Puis

rabattre le capot protecteur vers le haut et poussez le

mandrin à clé (10) d’un coup sec sur le cône, vérifiez

que l’outil est bien fixé.

La hauteur du recouvrement (23) est réglable en

continu et doit être fixée par l’intermédiaire des deux

vis à oreilles (22).

Pour changer de foret, le dispositif de protection

anticopeaux (13) peut être rabattu vers le haut, il faut

cependant le remettre dans sa position initiale avant

de remettre la machine en circuit.

6.4. Avant la mise en service

Veillez à ce que la tension du raccordement réseau

corresponde bien à celle de la plaque signalétique.

Raccordez la machine uniquement à une prise

disposant d’un contact de protection installé dans les

règles de l’art. La perceuse est équipée d’un

déclencheur de tension sur zéro qui protège

l’opérateur de toute remise en circuit inattentionnée

après une panne de tension. Dans ce cas, la machine

doit être remise en circuit.

7. Fonctionnement

7.1. Généralités (fig. 2)

Pour mettre en service, actionnez l’interrupteur vert «

I » (18), la machine démarre. Pour mettre hors circuit,

appuyez sur la touche rouge « O » (19), l’appareil se

met hors circuit.

Veillez à ne pas surcharger l’appareil.

Si le bruit du moteur se réduit pendant le service, ceci

indique que le moteur est trop surchargé.

Ne sollicitez pas le moteur au point qu’il s’arrête.

7.2. Insertion de l’outil dans le mandrin de

perceuse (fig. 1)

Veillez absolument à ce que la fiche du secteur soit

déconnectée lorsque vous voulez changer d’outil.

Dans le mandrin de perçage (10) il est uniquement

permis de monter des outils cylindriques au diamètre

de tige maximal indiqué. N’utilisez que des outils d’un

état impeccable et aiguisés. N’utilisez aucun outil

endommagé au niveau de leur tige ou déformé, voire

endommagé de quelque manière que ce soit. Utilisez

uniquement des accessoires et appareils

complémentaires indiqués dans ce mode d’emploi ou

recommandés ou indiqués par le producteur de l’outil.

7.3. Manipulation du mandrin à serrage rapide

Votre perceuse à table est équipée d’un mandrin à

couronne dentée (10). Pour enfiler un foret, il faut tout

d’abord rabattre le dispositif de protection anticopeaux (13) vers le haut, ensuite placer le foret, puis

serrer à fond le mandrin à l’aide de la clé jointe à la

fourniture.

Retirez la clé. Veillez à ce que les outils tendus

tiennent correctement.

Attention ! Ne laissez pas la clé enfoncée. Risque

de blessure par expulsion de la clé.

7.4. Réglage de la vitesse de rotation

(fig. 1/8/9)

Mettez tout d’abord la machine hors circuit et retirez

la fiche du secteur.

Les diverses vitesses de rotation peuvent être

réglées en déplaçant la courroie trapézoïdale.

Veuillez procéder comme suit :

Desserrez la vis (16) pour pouvoir ouvrir le capot

de recouvrement de la courroie trapézoïdale (7).

Desserrez les vis de tension (15) et poussez le

moteur (8) en direction de la tête de la machine.

Déplacez la courroie trapézoïdale dans la

position désirée.

Les vitesses de rotation correspondantes sont

indiquées dans le tableau (fig. 8).

Tendez la courroie trapézoïdale en poussant le

moteur (8) contre la tête de la machine (6).

Resserrez les vis de serrage (16) à fond. La

tension est correctement réglée lorsque la

courroie trapézoïdale peut être enfoncée à son

centre d’env. 1 cm.

Fermez le capot de la courroie trapézoïdale et

vissez à fond à l’aide de la vis (16). Le capot de

recouvrement de la courroie trapézoïdale (7) doit

toujours être fixement fermé étant donné que la

machine est équipée d’un interrupteur de sécurité

et qu’elle ne peut donc être mise en service que

lorsque le capot de recouvrement de la courroie

trapézoïdale (7) est fermé.

Attention ! Ne faites jamais marcher la perceuse

lorsque le capot de recouvrement de la courroie

trapézoïdale est ouvert. Avant d’ouvrir le couvercle,

retirez toujours la fiche du secteur. Ne saisissez

jamais la courroie trapézoïdale lorsqu’elle tourne.

19

F

Page 20

7.4.1 Butée de profondeur de perçage (fig. 10)

La broche de perçage est dotée d’un anneau gradué

(25) pour le réglage de la profondeur de perçage.

N’entreprendre des travaux de réglage qu’à l’arrêt.

Enfoncez la broche de perçage (11) vers le bas

jusqu’à ce que la pointe du foret se trouve sur

l’outil.

Desserrez la vis de serrage (17) et tournez

l’anneau gradué (25) vers l’avant jusqu’à la butée.

Tournez en arrière l’anneau gradué (25) de la

profondeur de perçage et fixez avec la vis de

serrage (17).

Attention ! Lors du réglage de la profondeur de

perçage d’une perceuse cylindrique, vous devez

compter en plus la longueur de la pointe du foret.

7.5 Régler l’inclinaison de la table de perçage

(fig. 7)

Desserrez le boulon brut à tête bombée et collet

carré (26) sous la table de perçage (4).

Réglez la table de perçage (4) sur l’angle

souhaité.

Resserrez à fond la vis (26) et fixez la table de

perçage (4) dans cette position.

7.6 Régler la hauteur de la table de perçage

(fig. 1)

Dévissez la vis de serrage (5)

Réglez la table de perçage (4) à la hauteur

désirée en l’appuyant ou la soulevant et en la

tournant simultanément légèrement vers la

gauche et vers la droite.

Resserrez la vis de serrage (5) à fond.

7.7 Serrage de la pièce à usiner

Tendez toujours une pièce à usiner en utilisant un

étau ou à l’aide d’un dispositif à tendre adéquat. Ne

tenez jamais les pièces à usiner à la main ! Lors

du perçage, la pièce à usiner doit être amovible sur la

table de perçage (4) pour qu’un centrage

automatique puisse avoir lieu. Assurez toujours la

pièce á usiner pour qu’elle ne se torde pas. Ceci est

possible pour le mieux en plaçant la pièce à usiner

et/ou l’étau contre une butée fixe.

Attention ! Les pièces en tôle doivent être tendues

de manière à ne pas monter en chandelle. Réglez

correctement la hauteur et l’inclinaison de la table de

perçage en fonction de la pièce à usiner. Il faut garder

suffisamment de distance entre l’arête supérieure de

la pièce à usiner et la pointe du foret.

7.8 Vitesses de travail

Veillez à ce que la vitesse de rotation soit correcte

pendant le perçage. Celle-ci dépend du diamètre du

foret et de la pièce à usiner.

La liste indiquée ci-bas vous aidera à sélectionner les

vitesses de rotation en fonction des matériaux

différents.

Les vitesses de rotation indiquées sont

uniquement des grandeurs de référence.

Ø Foret Fonte grise Acier Fer Aluminum Bronze

3 2550 1600 2230 9500 8000

4 1900 1200 1680 7200 6000

5 1530 955 1340 5700 4800

6 1270 800 1100 4800 4000

7 1090 680 960 4100 3400

8 960 600 840 3600 3000

9 850 530 740 3200 2650

10 765 480 670 2860 2400

11 700 435 610 2600 2170

12 640 400 560 2400 2000

13 590 370 515 2200 1840

14 545 340 480 2000 1700

16 480 300 420 1800 1500

18 425 265 370 1600 1300

20 380 240 335 1400 1200

22 350 220 305 1300 1100

25 305 190 270 1150 950

7.9 Chanfreiner et perçage à centrer

Avec cette perceuse à table, vous pouvez aussi

chanfreiner et effectuer un perçage à centrer. Veillez

ce faisant au fait que le chanfreinage doit être réalisé

à la vitesse la plus basse alors que le perçage à

centrer nécessite une vitesse élevée.

7.10 Usinage du bois

Veuillez veiller au fait que lorsque vous usinez le bois,

il vous faut utiliser une aspiration de poussière

adéquate étant donné que la poussière de bois peut

être nocive à la santé. Portez toujours un masque de

protection anti-poussière lorsque vous effectuez des

travaux générateurs de poussière.

20

F

Page 21

8. Remplacement de la ligne de

raccordement réseau

Si la ligne de raccordement réseau de cet appareil

est endommagée, il faut la faire remplacer par le

producteur ou son service après-vente ou par une

personne qualifiée afin d’éviter tout risque.

9. Nettoyage, maintenance et

commande de pièces de rechange

Retirez la fiche de contact avant tous travaux de

nettoyage.

9.1 Nettoyage

La perceuse à table est pratiquement sans

maintenance. Gardez l’appareil en bon état de

propreté. Retirez la prise du réseau pour chaque

travail de réglage et de maintenance. N’utilisez

pas de solvant âcre pour le nettoyage. Veillez à

ce qu’aucun liquide ne s’immisce dans l’appareil.

Regraissez les pièces nues après les travaux. La

colonne de perçage, les pièces nues du support

et de la table de perçage doivent particulièrement

être graissées régulièrement. Utilisez une graisse

sans acide commune pour la lubrification.

Attention : Les chiffons de nettoyage

comprenant de l’huile et de la graisse et les

restes de graisse et d’huile ne doivent pas être

éliminés dans les ordures ménagères. Eliminezles dans le respect de l’environnement. Contrôlez

et nettoyez régulièrement les orifices d’aération.

Stockez l’appareil dans une salle sèche. Si

l’appareil est endommagé, n’essayez pas de le

réparer vous-même. Laissez un(e) spécialiste

électricien(ne) effectuer les travaux.

Nous recommandons de nettoyer l’appareil

directement après chaque utilisation.

Nettoyez l’appareil régulièrement à l’aide d’un

chiffon humide et un peu de savon. N’utilisez

aucun produit de nettoyage ni détergent ; ils

pourraient endommager les pièces en matières

plastiques de l’appareil. Veillez à ce qu’aucune

eau n’entre à l’intérieur de l’appareil.

9.2 Maintenance

Aucune pièce à l’intérieur de l’appareil n’a besoin de

maintenance.

9.3 Commande de pièces de rechange :

Veuillez indiquer ce qui suit pour toute commande de

pièces de rechange

Type de l’appareil

Référence de l’appareil

Numéro d’identification de l’appareil

Numéro de la pièce de rechange requise

Vous trouverez les prix et informations actuelles à

l’adresse www.isc-gmbh.info

10. Stockage

Entreposez l’appareil et ses accessoires dans un

endroit sombre, sec et à l’abri du gel tout comme

inaccessible aux enfants. La température de

stockage optimale est comprise entre 5 et 30 °C.

Conservez l’outil électrique dans l’emballage

d’origine.

11. Mise au rebut et recyclage

L’appareil se trouve dans un emballage permettant

d’éviter les dommages dus au transport. Cet

emballage est une matière première et peut donc être

réutilisé ultérieurement ou être réintroduit dans le

circuit des matières premières. L’appareil et ses

accessoires sont en matériaux divers, comme par ex.

des métaux et matières plastiques. Eliminez les

composants défectueux dans les systèmes

d’élimination des déchets spéciaux. Renseignezvous dans un commerce spécialisé ou auprès de

l’administration de votre commune !

21

F

Page 22

22

I

“Avvertimento – Per ridurre il rischio di lesioni leggete le istruzioni per l’uso”

Portate cuffie antirumore.

L’effetto del rumore può causare la perdita dell’udito.

Indossate gli occhiali protettivi.

Scintille createsi durante il lavoro o schegge, trucioli e polveri scaraventate fuori dall’apparecchio

possono causare la perdita della vista.

Page 23

23

I

Attenzione!

Nell’usare gli apparecchi si devono rispettare alcune

avvertenze di sicurezza per evitare lesioni e danni.

Quindi leggete attentamente queste istruzioni per

l’uso/avvertenze di sicurezza. Conservate bene le

informazioni per averle a disposizione in qualsiasi

momento. Se date l’apparecchio ad altre persone,

consegnate anche queste istruzioni per

l’uso/avvertenze di sicurezza insieme all’apparecchio.

Non ci assumiamo alcuna responsabilità per incidenti

o danni causati dal mancato rispetto di queste

istruzioni e delle avvertenze di sicurezza.

1. Avvertenze di sicurezza

Le relative avvertenze di sicurezza si trovano

nell’opuscolo allegato!

ATTENZIONE

Leggete tutte le avvertenze di sicurezza e le

istruzioni. Dimenticanze nel rispetto delle

avvertenze di sicurezza e delle istruzioni possono

causare scosse elettriche, incendi e/o gravi lesioni.

Conservate tutte le avvertenze e le istruzioni per

eventuali necessità future.

2. Descrizione dell’apparecchio

(Fig. 1)

1. Piede dell’apparecchio

2. Colonna

3. Viti di fissaggio

4. Piano di lavoro

5. Vite di bloccaggio

6. Testa dell’apparecchio

7. Copertura per cinghia trapezoidale

8. Motore

9. Impugnature

10. Mandrino per punte da trapano a corona dentata

11. Mandrino

12. Fori di fissaggio

13. Protezione ripiegabile contro i trucioli

15. Vite di serraggio

16. Vite

17. Vite di bloccaggio

18. Interruttore ON

19. Interruttore OFF

20. Grano filettato

3. Elementi forniti

Aprite l’imballaggio e togliete con cautela

l’apparecchio dalla confezione.

Togliete il materiale d’imballaggio e anche i fermi

di trasporto / imballo (se presenti).

Controllate che siano presenti tutti gli elementi

forniti.

Verificate che l’apparecchio e gli accessori non

presentino danni dovuti al trasporto.

Se possibile, conservate l’imballaggio fino alla

scadenza della garanzia.

ATTENZIONE

L’apparecchio e il materiale d’imballaggio non

sono giocattoli! I bambini non devono giocare

con sacchetti di plastica, film e piccoli pezzi!

Sussiste pericolo di ingerimento e

soffocamento!

Trapano a colonna

Mandrino per punte da trapano a corona dentata

Chiave del mandrino per punte da trapano

Protezione ripiegabile contro i trucioli

Piano di lavoro

Istruzioni per l’uso originali

Avvertenze di sicurezza

4. Utilizzo proprio

Questo trapano a colonna è concepito per perforare

metallo, materie plastiche, legno e materiali simili e

deve essere usato solo in ambito privato.

L’apparecchio non deve essere usato per lavorare

generi alimentari e materiali nocivi per la salute. Il

mandrino per punte da trapano è adatto solo per

l’utilizzo di punte ed utensili con un diametro di 1,5-16

mm e di forma cilindrica. Si possono inoltre usare

utensili con gambo conico. L’apparecchio deve

essere usato da persone adulte.

L’apparecchio deve essere usato solamente per lo

scopo a cui è destinato. Ogni altro tipo di uso che

esuli da quello previsto non è conforme.

L’utilizzatore/l’operatore, e non il costruttore, è

responsabile dei danni e delle lesioni di ogni tipo che

ne risultino.

Tenete presente che i nostri apparecchi non sono

stati costruiti per l’impiego professionale, artigianale o

industriale. Non ci assumiamo alcuna garanzia se

l’apparecchio viene usato in imprese commerciali,

artigianali o industriali, o in attività equivalenti.

Page 24

5. Caratteristiche tecniche

Tensione nominale in ingresso 230V ~ 50 Hz

Potenza nominale 500 Watt

Modalità operativa S2 15 min.

Numero di giri del motore 1400 min

-1

Numero di giri in uscita 280 - 2.350 min

-1

Livelli di velocità 9

Attacco delle punte da trapano B 16

Mandrino per punte da trapano a

corona dentata Ø 1,5 - 16 mm

Diametro max. del gambo 16 mm

Sbraccio 115 mm

Profondità di perforazione 50 mm

Diametro colonna 46 mm

Altezza 650 mm

Peso 21,5 kg

Livello di pressione acustica L

pA

61,5 dB(A)

Livello di potenza acustica L

WA

74,5 dB(A)

Incertezza K

pA

3 dB

Incertezza K

WA

3 dB

Rumore e vibrazioni

I valori del rumore e delle vibrazioni sono stati rilevati

secondo la norma EN 61029.

Durata di inserimento

La durata di inserimento S2 di 15 min (esercizio

breve) indica che il motore deve essere sollecitato

con la potenza nominale 500 Watt in modo continuo

solo per il periodo (15 min) riportato sulla targhetta

delle caratteristiche tecniche.

In caso contrario si riscalderebbe eccessivamente.

Durante la pausa il motore si raffredda ritornando alla

temperatura iniziale.

Limitate al minimo lo sviluppo di rumore e le

vibrazioni!

Utilizzate soltanto apparecchi in perfetto stato.

Eseguite regolarmente la manutenzione e la

pulizia dell’apparecchio.

Adattate il vostro modo di lavorare

all’apparecchio.

Non sovraccaricate l’apparecchio.

Fate eventualmente controllare l’apparecchio.

Spegnete l’apparecchio se non lo utilizzate.

Indossate i guanti.

Rischi residui

Anche se questo elettroutensile viene utilizzato

secondo le norme, continuano a sussistere

rischi residui. In relazione alla struttura e al

funzionamento di questo elettroutensile

potrebbero presentarsi i seguenti pericoli:

1. Danni all’udito nel caso in cui non vengano

indossate cuffie antirumore adeguate.

6. Prima della messa in esercizio

6.1. Montaggio dell’apparecchio

Posizionate il piede dell’apparecchio (1)

Fissate la flangia di fissaggio con la colonna (2),

con tre viti (3) e rosette al piede dell’apparecchio

(1).

Spingete il piano di lavoro (4) con il relativo

supporto verso la colonna (2) (Fig. 3). Bloccate il

piano di lavoro nella posizione desiderata con la

vite di bloccaggio (5).

Appoggiate la testa del trapano (6) con la

copertura della cinghia trapezoidale (7) ed il

motore (8) alla colonna del trapano e fissate con

le viti ad esagono cavo (20).

Avvitate le tre impugnature alla crociera di

avanzamento (9).

Avvertenza: tutte le parti lucide sono lubrificate per

proteggerle dalla corrosione. Prima di montare il

mandrino per punte da trapano (10) sul mandrino

(11), le due parti devono essere completamente

sgrassate con un solvente ecologico, in modo da

garantire una trasmissione di forza ottimale.

6.2. Installazione dell’apparecchio (Fig. 1)

Prima della messa in esercizio si deve montare il

trapano in modo fisso. Utilizzate a tal fine i due fori di

fissaggio (12) nella piastra di base. Fate attenzione

che l’apparecchio sia accessibile per l’esercizio e per

i lavori di impostazione e manutenzione.

Avvertenza: le viti di fissaggio devono essere serrate

in modo che la piastra di base non sia serrata

eccessivamente o deformata. In caso di sollecitazioni

eccessive sussiste il pericolo di rottura.

24

I

Page 25

25

I

6.3. Protezione ripiegabile contro i trucioli

(Fig. 4-6)

Svitate le tre viti (21). Spingete la copertura

trasparente (23) nella fessura del supporto rosso (24)

e fissate di nuovo con le viti (21).

Poi fissate alla macchina la protezione ripiegabile

contro i trucioli (13) con la vite di serraggio. Ribaltate

quindi verso l’alto la protezione contro i trucioli e

spingete di colpo il mandrino a corona dentata (10)

sul cono, controllando che l’utensile sia ben serrato.

L’altezza della copertura (23) è regolabile in continuo

e viene fissata mediante le due viti ad alette (22).

Per cambiare il trapano si può ribaltare verso l’alto la

protezione contro i trucioli (13). Tuttavia, prima

dell’inserimento dell’apparecchio occorre riportare la

protezione contro i trucioli nella posizione iniziale.

6.4. Da tenere presente prima della messa in

esercizio

Accertatevi che la tensione della presa di rete

corrisponda ai dati sulla targhetta di identificazione.

Collegate l’apparecchio soltanto ad una presa con

contatto di terra regolarmente installato. Il trapano è

dotato di un interruttore di minima tensione che

protegge l’utilizzatore da indesiderati riavvii dopo una

caduta di tensione. In questo caso si deve inserire di

nuovo l’apparecchio.

7. Esercizio

7.1. Generalità (Fig. 2)

Per l’inserimento azionate l’interruttore verde “I” (18),

l’apparecchio inizia a funzionare. Per il disinserimento

premete il tasto rosso “0” (19), l’apparecchio si ferma.

Fate attenzione a non sovraccaricare l’apparecchio.

Se il rumore del motore diminuisce durante

l’esercizio, ciò significa che è sollecitato

eccessivamente.

Non sovraccaricate l’apparecchio in modo tale da

provocare l’arresto del motore.

7.2. Inserimento della punta nel mandrino (Fig. 1)

Fate assolutamente attenzione che durante la

sostituzione della punta la spina sia staccata dalla

presa di corrente. Nel mandrino per punte da trapano

(10) si devono serrare solo utensili cilindrici con il

diametro massimo indicato per il gambo. Usate solo

utensili affilati ed in perfetto stato. Non utilizzate

utensili con il gambo danneggiato o deformati e

danneggiati in qualsiasi altro modo. Usate solo

accessori ed apparecchi complementari indicati nelle

istruzioni per l’uso o autorizzati dal produttore.

7.3. Uso del mandrino per punte da trapano a

serraggio rapido

Il vostro trapano da banco è dotato di un mandrino

dentato per punte da trapano (10). Per inserire una

punta, si deve prima ribaltare verso l’alto la

protezione contro i trucioli (13), poi inserire l’utensile

e serrare il mandrino per punte da trapano con la

chiave relativa in dotazione.

Estraete di nuovo la chiave. Controllate che gli

utensili siano ben serrati.

Attenzione! Non lasciate inserita la chiave. Se viene

scagliata intorno può provocare lesioni.

7.4. Impostazione del numero di giri

(Fig. 1/8/9)

Disinserite prima l’apparecchio e staccate la spina

dalla presa di corrente.

I diversi numeri di giri del mandrino possono essere

impostati spostando la cinghia trapezoidale.

Procedere nel modo seguente.

Allentate la vite (16) per poter aprire la copertura

della cinghia trapezoidale (7).

Allentate le viti di serraggio (15) e spingete il

motore (8) verso la testa dell’apparecchio.

Portate la cinghia trapezoidale nella posizione

desiderata.

I relativi numeri di giri sono riportati nella tabella

(Fig. 8).

Tendete la cinghia trapezoidale spingendo il

motore (8) verso la testa dell’apparecchio (6).

Serrate di nuovo le viti di serraggio (16). La

tensione è impostata correttamente se la cinghia

trapezoidale cede di circa 1 cm se premuta al

centro.

Chiudete la copertura della cinghia trapezoidale e

serratela con la vite (16). La copertura della

cinghia trapezoidale (7) deve essere ben chiusa

poiché l’apparecchio è dotato di un interruttore di

sicurezza e lo si può dunque inserire soltanto se

la tale copertura (7) è chiusa.

Attenzione! Non fate mai funzionare il trapano con la

copertura della cinghia trapezoidale aperta. Staccate

sempre la spina dalla presa di corrente prima di aprire

la copertura Non mettete mai la mano sulle cinghie

trapezoidali funzionanti.

7.4.1 Asta di profondità di perforazione (Fig. 10)

Il mandrino portapunte è dotato di un anello graduato

(25) per impostare la profondità di perforazione.

Eseguite le regolazioni solo ad apparecchio fermo.

Abbassate il mandrino portapunte (11) finché la

punta del trapano tocchi il pezzo da lavorare.

Allentate la vite di bloccaggio (17) e ruotando

l’anello graduato (25) portatelo in avanti fino alla

battuta.

Page 26

Ruotate all’indietro l’anello graduato (25) fino alla

profondità di perforazione desiderata e fissatelo

con la vite di bloccaggio (17).

Attenzione! Quando impostate la profondità di

perforazione di un foro cilindrico, dovete anche

tenere in considerazione la lunghezza della punta

dell’utensile.

7.5 Impostazione dell’inclinazione del piano di

lavoro (Fig. 7)

Allentate la vite da legno a testa quadra (26) sotto

il piano di lavoro (4).

Regolate il piano di lavoro (4) sull’inclinazione

desiderata.

Serrate di nuovo saldamente la vite da legno a

testa quadra (26) per fissare il piano di lavoro (4)

in questa posizione.

7.6 Impostazione dell’altezza del piano di lavoro

(Fig. 1)

Allentate la vite di serraggio (5).

Impostate il piano di lavoro (4) all’altezza

desiderata spingendolo o sollevandolo e

contemporaneamente ruotandolo verso sinistra e

destra.

Serrate di nuovo la vite di serraggio (5).

7.7 Serraggio del pezzo da lavorare

Serrate saldamente i pezzi da lavorare con l’ausilio di

una morsa a vite dell’elettroutensile o con un mezzo

di serraggio appropriato. Non tenete mai con le

mani i pezzi da lavorare! Durante la perforazione il

pezzo da lavorare dovrebbe potersi muovere sul

piano di lavoro (4) affinché sia possibile

l’autocentramento. Assicurate il pezzo da lavorare in

modo che non giri. Il modo migliore per farlo consiste

nel posizionare il pezzo da lavorare ovvero la morsa a

vite per macchine ad una battuta d’arresto sicura.

Attenzione! Le lamiere devono essere fissate in

modo tale che non possano essere sollevate di colpo.

Impostate correttamente l’altezza e l’inclinazione del

tavolo di lavoro in base al pezzo da lavorare. Fra il

bordo superiore del pezzo da lavorare e la punta del

trapano deve esserci spazio sufficiente.

7.8 Velocità di lavoro

Durante la perforazione badate sempre che il numero

di giri sia corretto. Esso dipende dal diametro della

punta e dal pezzo da lavorare.

La lista sotto riportata vi aiuta nella scelta dei numeri

di giri per i diversi materiali.

I valori del numero di giri riportati sono

solamente indicativi.

Ø trapano Ghisa Acciaio Ferro Alluminio Bronzo

3 2550 1600 2230 9500 8000

4 1900 1200 1680 7200 6000

5 1530 955 1340 5700 4800

6 1270 800 1100 4800 4000

7 1090 680 960 4100 3400

8 960 600 840 3600 3000

9 850 530 740 3200 2650

10 765 480 670 2860 2400

11 700 435 610 2600 2170

12 640 400 560 2400 2000

13 590 370 515 2200 1840

14 545 340 480 2000 1700

16 480 300 420 1800 1500

18 425 265 370 1600 1300

20 380 240 335 1400 1200

22 350 220 305 1300 1100

25 305 190 270 1150 950

7.9 Svasatura e perforazione di centraggio

Con questo trapano da banco potete anche svasare

ed eseguire lavori di centraggio. Nell’eseguire tali

operazioni tenete presente che la svasatura

dovrebbe essere eseguita a velocità minima, mentre

per il centraggio è necessaria una velocità elevata.

7.10 Lavorazione del legno

Tenete presente che per la lavorazione del legno

deve essere utilizzato un dispositivo di aspirazione

della polvere adeguato in quanto la polvere di legno

può essere nociva. Portate assolutamente una

maschera antipolvere in caso di lavori con

produzione di polvere.

8. Sostituzione del cavo di

alimentazione

Se il cavo di alimentazione di questo apparecchio

viene danneggiato deve essere sostituito dal

produttore, dal suo servizio di assistenza clienti o da

una persona al pari qualificata al fine di evitare

pericoli.

26

I

Page 27

27

I

9. Pulizia, manutenzione e ordinazione

dei pezzi di ricambio

Prima di qualsiasi lavoro di pulizia staccate la spina

dalla presa di corrente.

9.1 Pulizia

Il trapano da banco richiede una manutenzione

minima. Tenete l’utensile pulito. Prima di

qualsiasi lavoro di pulizia e di manutenzione

staccate la spina dalla presa di corrente. Per i

lavori di pulizia non fate uso di solventi aggressivi.

Fate attenzione che non penetrino liquidi

all’interno dell’apparecchio. Dopo aver concluso i

lavori, lubrificate di nuovo le parti lucide. In

particolare dovrebbero essere regolarmente

lubrificati la colonna del trapano, le parti lucide

del supporto ed il tavolo di lavoro. Lubrificate con

grasso comune privo di acidi.

Attenzione: non smaltite i panni per pulizia

sporchi di olio e grasso così come i residui di

grasso e olio insieme ai rifiuti domestici. Smaltiteli

in modo rispettoso dell’ambiente. Controllate e

pulite regolarmente le fessure di aerazione.

Conservate l’apparecchio in un luogo asciutto.

Non tentate di riparare da soli l’apparecchio nel

caso in cui sia danneggiato. Affidate la

riparazione ad un elettricista.

Consigliamo di pulire l’apparecchio subito dopo

averlo usato.

Pulite l’apparecchio regolarmente con un panno

umido ed un po’ di sapone. Non usate detergenti

o solventi, perché questi ultimi potrebbero

danneggiare le parti in plastica dell’apparecchio.

Fate attenzione che non possa penetrare

dell’acqua all’interno dell’apparecchio.

9.2 Manutenzione

All’interno dell’apparecchio non si trovano altre parti

che richiedano manutenzione.

9.3 Ordinazione di pezzi di ricambio

In caso di ordinazione di pezzi di ricambio è

necessario indicare quanto segue:

tipo di apparecchio

numero di articolo dell’apparecchio

numero di identificazione dell’apparecchio

numero del pezzo di ricambio richiesto

Per i prezzi e le informazioni attuali si veda

www.isc-gmbh.info

10. Conservazione

Conservate l’apparecchio e i suoi accessori in un

luogo buio, asciutto, al riparo dal gelo e non

accessibile ai bambini. La temperatura ottimale per la

conservazione è compresa tra i 5 e i 30 °C.

Conservate l’elettroutensile nell’imballaggio originale.

11. Smaltimento e riciclaggio

L’apparecchio si trova in una confezione per evitare i

danni dovuti al trasporto. Questo imballaggio

rappresenta una materia prima e può perciò essere

utilizzato di nuovo o riciclato. L’apparecchio e i suoi

accessori sono fatti di materiali diversi, per es.

metallo e plastica. Consegnate i pezzi difettosi allo

smaltimento di rifiuti speciali. Per informazioni

rivolgetevi ad un negozio specializzato o

all’amministrazione comunale!

Page 28

28

DK/N

„Advarsel – Læs betjeningsvejledningen for at reducere risikoen for personskade“

Brug høreværn.

Støjudviklingen fra maskinen kan forårsage høretab.

Brug beskyttelsesbriller.

Gnister, som opstår under arbejdet, eller splinter, spån og støv, som står ud fra maskinen, kan

forårsage synstab.

Page 29

Vigtigt!

Ved brug af denne type produkter er der visse

sikkerhedsforanstaltninger, der skal tages højde for,

så skader på personer og materiel undgås. Læs

derfor betjeningsvejledningen /

sikkerhedsanvisningerne grundigt igennem først.

Opbevar betjeningsvejledningen et praktisk sted, så

du altid har den lige ved hånden. Husk at lade

betjeningsvejledningen / sikkerhedsanvisningerne

følge med produktet, hvis du overdrager det til andre.

Vi fraskriver os ethvert ansvar for skader på personer

eller materiel, der måtte opstå som følge af, at

anvisningerne i denne betjeningsvejledning, navnlig

vedrørende sikkerhed, ikke overholdes.

1. Sikkerhedsanvisninger

Relevante sikkerhedsanvisninger finder du i det

medfølgende hæfte!

ADVARSEL

Læs alle sikkerhedsanvisninger og øvrige

anvisninger. Følges anvisningerne, navnlig

sikkerhedsanvisningerne, ikke korrekt, kan

konsekvensen være elektrisk stød, brand og/eller

svære kvæstelser.

Alle sikkerhedsanvisninger og øvrige

anvisninger skal gemmes.

2. Oversigt over maskinen (fig. 1)

1. Maskinfod

2. Søjle

3. Fastspændingsskruer

4. Boreplan