Eimac 3CX1500D7 Datasheet

TECHNICAL DATA

AIR-COOLED

HIGH-MU

POWER TRIODE

3CX1500D7

The Eimac 3CX1500D7 is a compact power triode with an anode dissipation rating of 1500 watts. This tube

features a filament designed to operate at 5 volts, a value that is common to other power grid tubes and allows

a single 3CX1500D7 to replace two 3-500Z in many applications. The high-Mu grid employed in this tube

permits operation as a linear amplifier in class AB with zero or minimal bias voltage. The 3CX1500D7 may also

be used in class B or C with additional bias voltage where it provides good efficiency, making it ideal as an rf

amplifier for industrial and scientific applications.

GENERAL CHARACTERISTICS

ELECTRICAL

Filament: Thoriated Tungsten

Voltage..................................…... 5.0

Current @ 5.0 volts…………................… 30 A

Direct Interelectrode Capacitances (grounded grid)

Cin.................................................…….. 18.6 pF

Cout............................................……… 7.2 pF

Cpk..................................................…… 0.4 pF

Amplification Factor, Average….................…200

Frequency of Maximum Rating (CW).......... 100 MHz

± 0.25 V

2

MECHANICAL

1

Characteristics and operating values are based upon performance tests. These figures may change without notice as the result of additional

data or product refinement. CPI Eimac Division should be consulted before using this information for final equipment design.

2

Capacitance values are for a cold tube as measured in a special shielded fixture in accordance with Electronic Industries Association

Standard RS-191.

Overall Dimensions:

Length ................................….. 5.6 in; 143 mm

Diameter ……………..……….... 3.42 in; 86.9

mm

Weight (approx.) ....................……. 2.4 lb; 1.1 kg

Operating Position...............Vertical, base up or down

Maximum Operating Temperatures:

Ceramic/Metal Seals & Envelope............... 250°C

Anode Core ……………………………….…250°C

Cooling ........................................………. Forced Air

Base................................................. Special, Five

Pin

Recommended Socket …….…………EIMAC SK–410

1

3CX1500D7

RADIO FREQUENCY LINEAR AMPLIFIER

Class AB2, Cathode-Driven

ABSOLUTE MAXIMUM RATINGS:

Anode Voltage............……….. 6.0 Kilovolts dc

Anode Current............………... 0.8 Ampere dc

Anode Dissipation.................... 1.5 Kilowatts

Grid Voltage……………………-500 Volts dc

Grid Dissipation ..................… 50 Watts

TYPICAL OPERATION*, under 30 MHz:

Anode Voltage...................... 3.0 4.5 kVdc

Cathode Bias Voltage............. 0 12 Vdc

Zero-Signal Anode Current . 168 98 mAdc

Anode Current (max signal) 0.72 0.64 Adc

Grid Current*

Driving Power*

Anode Dissipation*

Anode Output Power*

1...................................

1....................................

1 ......................

1................

247 180 mAdc

80 70 W

660 930 W

1.5 1.95 kW

Input Impedance.................... 73 72 Ohms

Resonant Anode Load Z*.. 2650 2900 Ohms

Intermodulation Distortion

Products2 , 3rd order ... -29 -34 dB

5th order......-43 -37 dB

* Measured data

1. Approximate Values

2. Referenced against one tone of a two-equal tone signal

RADIO FREQUENCY POWER AMPLIFIER TYPICAL OPERATION, under 30 MHz:

Class B, Cathode-Driven

Anode Voltage....................................5.0 kVdc

ABSOLUTE MAXIMUM RATINGS: Anode Current.................................. 0.71 Adc

Cathode Bias Voltage.......................... 25 Vdc

Anode Voltage.............................6.0 Kilovolts dc Grid Current *

Anode Current.............................0.8 Ampere dc Driving Power*

1

.................................. 0.20 Adc

1

...................................95 W

Anode Dissipation .......................1.5 Kilowatts Anode Dissipation...........................1220 W

Grid Voltage…………………..… -500 Volts dc Anode Output Power....................... 2400 W

Grid Dissipation.............................50 Watts Input Impedance..................................85 Ohms

Resonant Anode Load Impedance.. 3760 Ohms

1. Approximate Values

NOTE: TYPICAL OPERATION data are obtained from direct measurement or by calculation from

published characteristic curves. Adjustment of the rf grid voltage to obtain the specified anode current at

the specified bias and anode voltages is assumed. If this procedure is followed, there will be little

variation in output power when the tube is changed.

RANGE VALUES FOR EQUIPMENT DESIGN

Min. Max.

Filament Current @ 5.0 Volts................................................................... 29.5 32 A

Interelectrode Capacitances

1

(grounded grid)

Cin .............................................................................................….. 16.5 21 pF

Cout ................................................................................................ 5.8 8.9 pF

Cpk.................................................................................................. --- 0.6 pF

1

Capacitance values are for a cold tube as measured in a shielded fixture in accordance with Electronic Industries Association

Standard RS-191.

Zero-Signal Anode Current (Ec = 0, Eb = 4.0 kV) ……………………… 0.305 0.375 A

Cut-off Bias (Eb = 3 kV, Ib = 1.0 mA) …………………………………. --- - 24.0 V

2

3CX1500D7

APPLICATION

HANDLING – This product contains a thoriatedtungsten filament and should be protected from

shock and vibration. It is recommended that the

tube be removed from equipment that is being

shipped, to prevent damage that may occur in

transit.

The center “pin” in the base of this tube is hollow

and is a part of the filament support structure and

is at the same potential as the filament; no

electrical contact to this pin is necessary or

desirable. The vacuum “nip-off” or seal is located

at the end of this center “pin”; the edge on it is

very sharp and can cut. Do not touch or contact

this seal as any mechanical damage to it may

cause loss of vacuum integrity.

MOUNTING & SOCKETING – The tube must be

operated with its primary axis vertical. The base of

the tube may be up or down at the option of the

equipment designer. The Eimac SK-410 socket is

ideal for use with this tube; other sockets may

restrict airflow or increase pressure-drop and are

therefore not recommended. Sockets other than

the Eimac SK-410 may also apply excessive

lateral force to the connecting pins on the base,

and this can result in mechanical failure of the

metal/ceramic seals. An air chimney is necessary

to assure that air flows through the fins in the

anode cooler. A cylindrically-shaped Teflon™ or

Pyrex chimney around the outside of the cooler is

recommended for this purpose. Connection to the

anode should be made by use of a band around

the anode cooler.

STORAGE – If a tube is to be stored as a spare

it should be kept in its original shipping carton with

the original packing material to minimize the

possibility of handling damage. Before storage a

new tube should be operated in the equipment for

100 to 200 hours to establish that it has not been

damaged and operates properly. If the tube is still

in storage 6 months later it should be operated in

the equipment for 100 to 200 hours to make sure

there has been no degradation. If operation is

satisfactory the tube can again be stored with

great assurance of being a known-good spare.

COOLING - The maximum temperature rating for

the anode core and the ceramic/metal seals of

this tube is 250°C and sufficient forced-air cooling

must be provided to assure operation at safe tube

temperatures. Tube life is usually prolonged if

cooling in excess of the absolute minimum

requirements is provided.

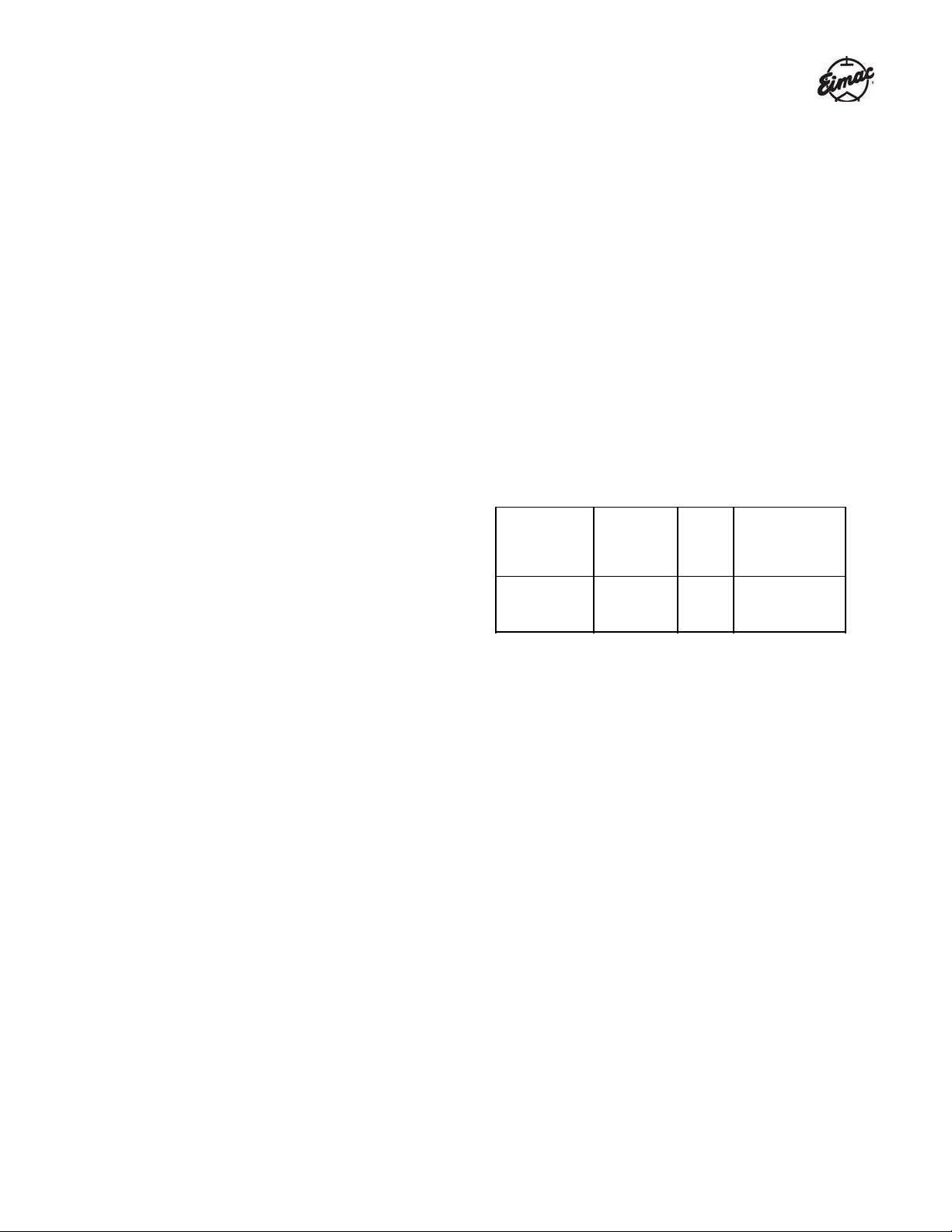

The table below shows minimum airflow requirements necessary to keep the anode temperature

below 225°C with an inlet air temperature of 25°C

at sea level. Air-flow is specified to be in the baseto-anode direction. This data applies to operation

below 30 MHz; if the tube is used above this

frequency additional cooling may be required

because of increased rf losses that occur at VHF.

Airflow Anode Airflow Approximate

Direction Dissipation CFM Pressure Drop

Watts in H

Base to Anode 500 15 0.09

“ 1000 34 0.22

“ 1500 65 0.45

At higher altitudes increased airflow is required; in

this case both the airflow and pressure drop

values shown must be increased by the following

factors: 5000 feet x 1.24; 10,000 feet x 1.46.

Additional cooling of the tube base may be

required especially if the anode cooling air is not

directed past the base first. The preferred

configuration is airflow supplied in the base-toanode direction; cooling air may be supplied in the

alternate direction, but the flow rate must be

substantially higher to provide proper cooling.

The designer is cautioned that the cooling

recommendations shown are absolute values for

inlet air and temperature rise conditions shown

with no safety factor; it is considered good

engineering practice to allow additional air flow for

conservatism and to make allowance for variables

such as dirty air filters, dirty anode cooling fins,

and pressure losses in air ducting; other factors

for additional airflow are the increased anode

temperature that occurs during adverse load

conditions and reduced anode efficiency that may

occur during amplifier tuning and loading.

O

2

3

Loading...

Loading...