Page 1

EIM 2000 Series E796 M2CP

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

August 2017

Page 2

Page 3

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Table of Contents

Section 1: Introduction

1.1 DO ................................................................................................................ 1

1.2 DON'T ........................................................................................................... 1

1.3 Lubrication ....................................................................................................2

1.4 Maintenance ................................................................................................. 2

1.5 Pressure Relief ............................................................................................... 2

1.6 Short Term Storage ....................................................................................... 3

1.7 Long Term Storage ........................................................................................ 3

Section 2: M2CP Electical Hook Up

2.1 Electrical Hook Up ......................................................................................... 5

Section 3: Assembly to Valves

3.1 Threaded Valve Stem .................................................................................... 6

3.1.1 Locknut Lockpin Installation ............................................................... 6

3.1.2 Stem Nut Installation (Multi-turn) ....................................................... 6

3.2 Mounting Screws ..........................................................................................7

3.2.1 Thrust Spool (Model 4000 & 5000) ..................................................... 7

3.2.2 Spline Bushing (Quarter-Turn) ............................................................ 8

3.3 Quarter-Turn Valve ........................................................................................ 8

3.3.1 Stop Setting Procedure....................................................................... 8

Table of Contents

August 2017

Section 4: Limit Switch Setting Instructions

4.1 Before making limit switch setting .............................................................. 10

4.2 To set Open Limit Switch (LSO) .................................................................... 10

4.3 Set (LSC) Close Limit Switch ........................................................................ 12

4.4 To set Intermediate Switch (LSA or LSB), if included ..................................... 13

4.5 Torque Seated Valves .................................................................................. 13

4.6 Torque Switch Calibration ........................................................................... 13

4.7 To set Open Torque Switch (TSO) ................................................................14

4.8 Torque Switch Rotation Limit ......................................................................14

Section 5: Multi-turn Actuators

5.1 Calibration .................................................................................................. 15

5.2 Quarter-Turn Model P, Q, R & M ................................................................... 16

Section 6: M2CP Wiring Diagram Symbols

6.1 Description ................................................................................................. 17

Section 7: Troubleshooting .................................................21

Table of Contents

I

Page 4

Section 1: Introduction

August 2017

Section 1: Introduction

1.1 DO

1. DO follow proper storage procedures. Improper storage will voidwarranty.

2. DANGER: DO check for proper motor rotation. If valve goes wrong direction

when button is pushed, you have no torque or limit protection.

3-Phase incoming power voltage must have 2 wires reversed.

3. DO read and follow procedures before attempting to energize actuator.

4. DO cut off electric power before opening switch compartment.

5. DO install relief vent in highest point of gearbox.

6. DO use valve stem covers of sufcient length.

7. DO clean electrical enclosure ange thoroughly & lightly grease before closing.

8. DO secure electrical enclosure bolts (10-12 ft-lbs).

9. DO follow an annual maintenance procedure.

10. DO use caution when working on, with, or around valves and actuators.

You can be dealing with high pressures, forces, voltages and ammable media.

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

1.2 DON'T

1. Don’t Start-up without reading this manual.

2. Don’t stack actuators.

3. Don’t store actuator on the ground unprotected.

4. Don’t lift the unit by clutch lever or handwheel.

5. Don’t lift a valve assembly by electrical actuator.

6. Don’t operate electrically without rst checking proper phase rotation, torque

and position limit switch adjustments (follow instructions on pgs 2, 4 and 5).

7. Don’t plug actuator motor by starting and stopping repeatedly to move a too

stiff valve. Check for cause.

8. Don’t jumper torque switches except as recom- mended by Wiring Diagram or

Valve Manufacturer.

9. Don’t use oversize thermal motor overloads to eliminate tripping problem.

Find cause and correct.

10. Don’t use a cheater to force the handwheel. You can damage gearing and shafts.

Find cause and correct.

11. Don’t torque seat valve, sluice gate or damper unless the valve manufacturer

recommends.

1

Introduction

Page 5

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

1.3 Lubrication

EIM Actuators are factory lled with a high quality lubricant carefully selected to insure

actuator performance under specied operating conditions. Refer to EIM JOB SPEC

SHEET to identify the lubricant provided. Normal operation may not require lubricant

replacement.

1.4 Maintenance

At least once a year a check should be made of your EIM actuator.

a. Disconnect all electrical power to actuator.

b. Open electrical enclosure. Inspect & tighten all electrical connections.

c. Visually inspect for any electrical or mechanical damage.

Replace worn or damaged components.

d. Check lubrication consistency and level. Fill or replace if required.

Section 1: Introduction

August 2017

1.5 Pressure Relief

During operation of electric actuator, the gear temperature increase in combination with

variations of outdoor temperature will cause a small pressure build-up within actuator gear

box. EIM furnishes Pressure Relief Vent Fitting Part No. 83385. Placement on Actuator can

be determined only after eld location and position of valve has been determined. Select

the highest 1/2 NPT vent location on actuator gear box; remove 1/2 NPT plug and replace

with 83385. The possible locations of vent are shown on EIM Outline Drawing.

Introduction

2

Page 6

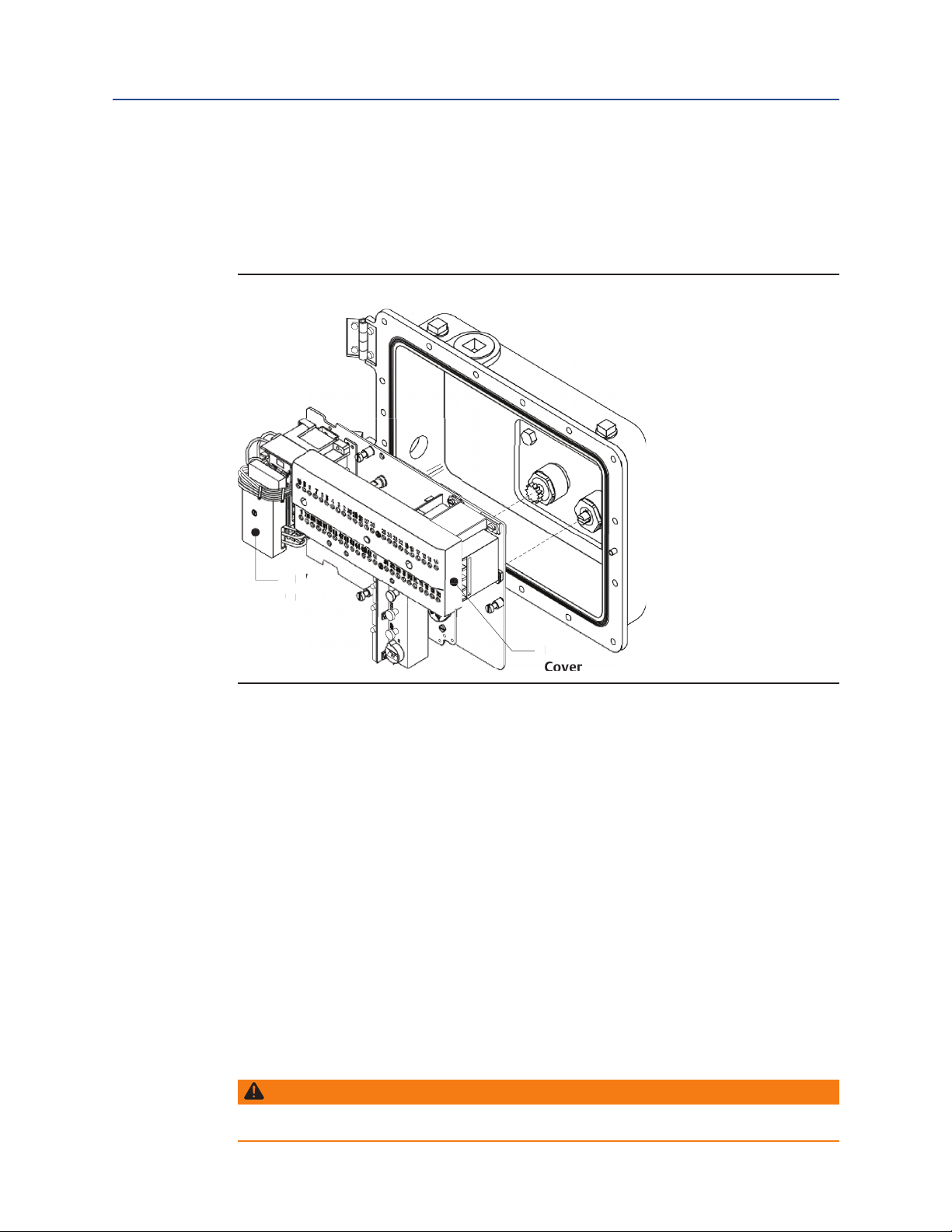

Cover

r

Section 1: Introduction

August 2017

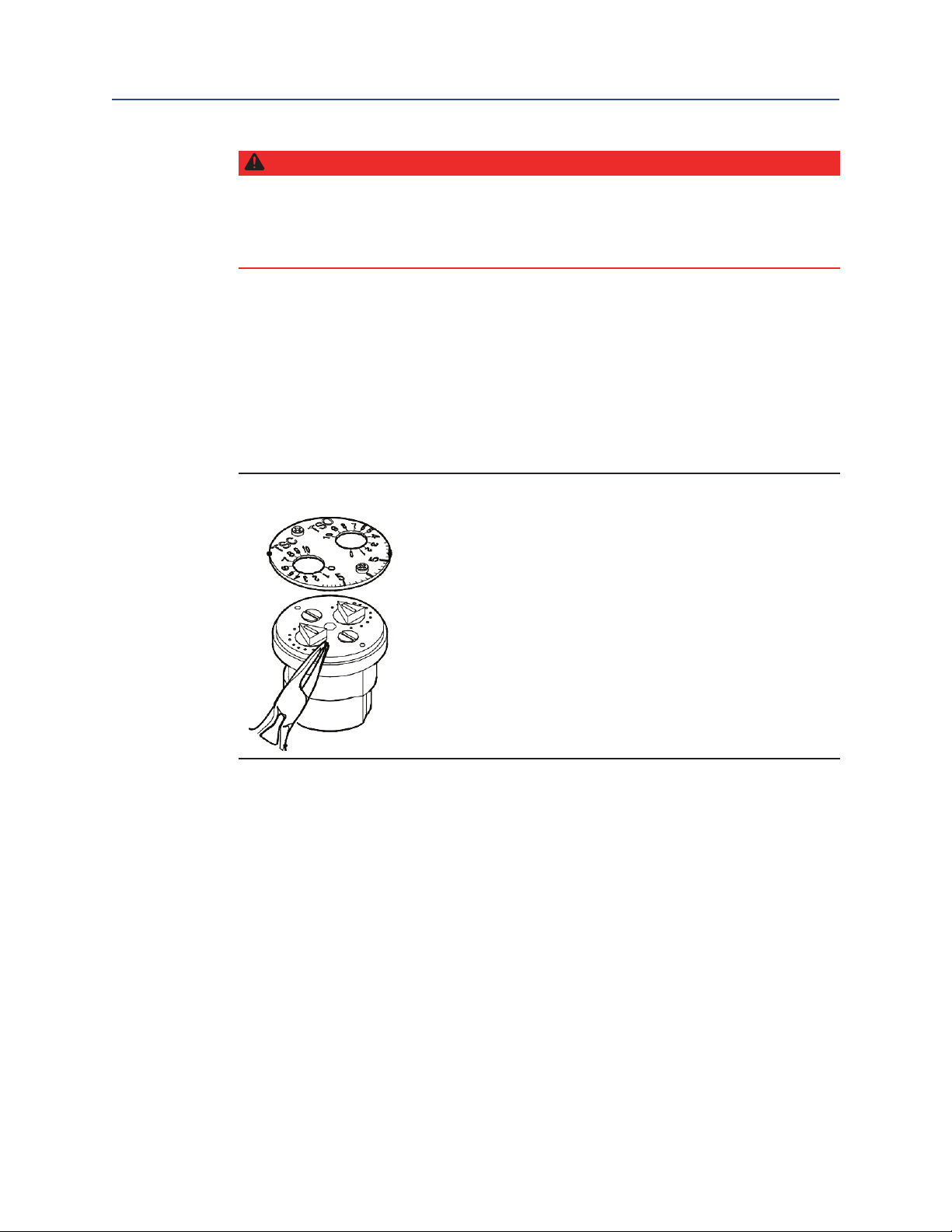

1.6 Short Term Storage

(Stored at Job Site less than one year from shipment)

1. Actuator should be stored with motor shaft in horizontal position and electrical

enclosure in either the horizontal or vertical position.

Figure 1

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

PWR

Coe

Cover

2. Actuator should be stored indoors free from job site dirt, mud, moisture and

temperature changes.

3. If indoor storage is not possible, the actuator must be stored off the ground above

possible water or snow level. Remove M2CP and store with other electrical and

electronic equipment in protected warehouse. If M2CP is not removed, Space

heater MUST be energized to protect electrical controls.

4. EIM supplies NPT plugs in each conduit entry. Do not remove until electrical hookup. The customer conduit should be routed to enter electrical enclosure at 1-1/2

(1.50) NPT located at lowest point, so condensation does not drain into enclosure

and damage parts.

5. Cover units loosely with a plastic sheet. This serves as partial protection from rain.

1.7 Long Term Storage

(Stored more than one year from shipment)

1. Store indoors or M2CP should be removed and stored in a protected area. Follow

procedures of short term storage.

LSM

LSM

WARNING:

Failure to store actuator properly ill void warranty of electical & electronic components.

3

Introduction

Page 7

Installation and Maintenance Manual

)

.315

12 AWGmax

375

AWx

0

E2K-402-0817 Rev. 2

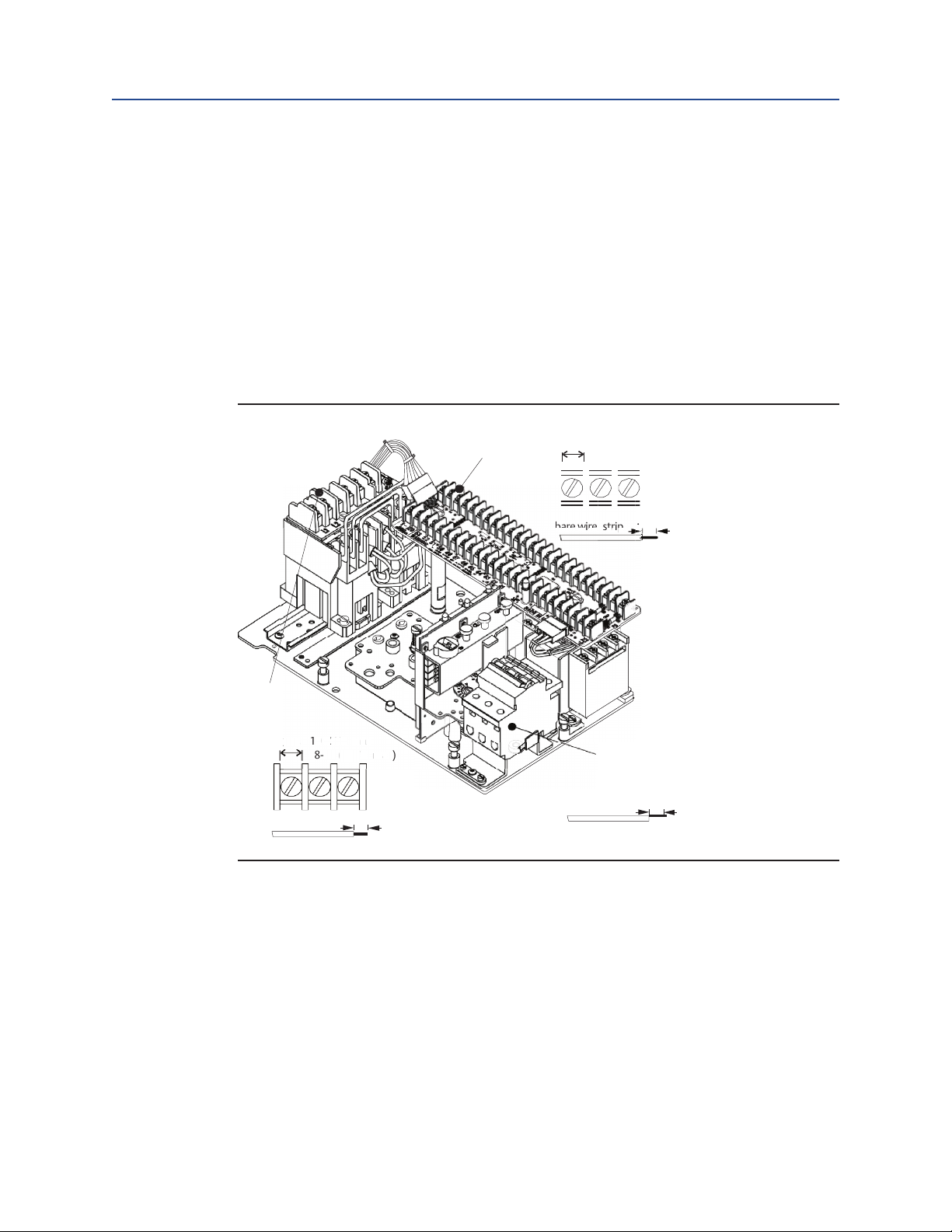

Section 2: M2CP Electrical Hook Up

Section 2: M2CP Electical Hook Up

Remove PWR and TBM covers to expose terminals for customer wiring. EIM Modular

Modular Control Package (M2CP) is available congured in many combinations of electrical

and electronic parts. Refer to WIRING DIAGRAM and EIM JOB SPEC SHEET for components

provided by EIM. Connect control wires to TBM and Power (motor) Voltage to PWR terminals.

If optional M2CP mounted circuit breaker was specied, connect power voltage leads to

circuit breaker. EIM terminal blocks are furnished with wire binding screw connectors with

rising captive plates, allowing eld connection by several methods: 1) strip and connect bare

wire, 2) strip and install wire ferrule, 3) strip and install crimp-on insulated or non-insulated

ring tongue or similar terminal. Circuit Breaker accepts 1) bare wire strip, or 2) wire ferrule.

Figure 2

August 2017

PWR

Terminal s

.375

bare wire strip

10 AWGmax

60

#8-32 (600V max)

.400

TBM

#6-32 (230Vmax

Terminal s

bare wire strip

.315

Circuit

Breaker

bare wire strip .450

18-8 AWG (600V max)

M2CP Electrical Hook Up

4

Page 8

Section 2: M2CP Electrical Hook Up

August 2017

2.1 Electrical Hook Up

Step 1. Move valve to mid-position by handwheel. This will allow sufcient time to

stop actuator in case of improper hook-up or reversed incoming power

voltage phases.

Step 2. Identify a means of removing power from actuator during check out.

Be sure no erroneous remote control signal can be received causing

actuator to energize.

Step 3. Energize Open control to check operation of contactor and pushbuttons.

Open controls must move valve in Open direction. If valve Closes, actuator

must be stopped and any

CAUTION:

If voltage is improperly phased, Torque and Position Limit Switches are not in circuit to

protect valve.

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Step 4. Seal all eld conduit entries in accordance with National Electric Code.

5

M2CP Electrical Hook Up

Page 9

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Section 3: Assembly to Valves

Section 3: Assembly to Valves

3.1 Threaded Valve Stem

3.1.1 Locknut Lockpin Installation

Figure 3

(56)

(55)

(52)

(54)

August 2017

1. With actuator in place on valve, ensure proper ange mating and valve actuator

orientation.

2. Use a number 30 (.1285) drill bit to drill a hole 3/4 inch deep into the Drive Sleeve

assembly threads for the Locknut Lockpin (56) using groove in Stem Nut Locknut

as drill guide.

3. Install Locknut Lockpin (56) into drilled hole to prevent Stem Nut Locknut from

working loose and turning.

NOTE:

Install Locknut Lockpin (56) into drilled hole to prevent Stem Nut Locknut from working

loose and turning. When installing, the Locknut Lockpin - it should extend 1/4 inch above

the Drive Sleeve assembly to allow for future removal.

3.1.2 Stem Nut Installation (Multi-turn)

1. Unscrew Locknut (55) holding Bronze Stem Nut (54) and remove the Stem Nut and

Key (52).

2. Lubricate Stem and run Stem Nut down Stem to check acme thread t, then

remove Stem Nut and set aside.

Assembly to Valves

6

Page 10

Section 3: Assembly to Valves

August 2017

3. Lower actuator over Stem onto valve ange. The screws thru valve ange into

actuator must engage a minimum of one full screw diameter deep into bottom

base and be tightened to a preload. See assembly drawing for screw size and

torque to tighten properly.

4.

3.2 Mounting Screws

If EIM supplied adaptation, the mounting screws are included. If adaptation to valve was

the responsibility of others, the mounting screws are not furnished by EIM. Screws thru

adapter MUST engage a minimum of one screw diameter deep into EIM actuator base.

1. Screw Stem Nut on Stem until it enters Drive Sleeve. Line (52) Key and (54) Drive

Sleeve keyway and insert (52) Key.

2. Turn handwheel in Open direction, pulling Stem Nut into Drive Sleeve until it

bottoms out (valve will begin to open).

CAUTION:

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Locknut must be tight against stem nut.

3. Lower Locknut (55) over Valve Stem and screw into place rmly against top of

Stem Nut. Tap Locknut ears using brass drift until tight.

3.2.1 Thrust Spool (Model 4000 & 5000)

1. Locate Thrust Mounting bolts.

2. Remove eight mounting bolts and separate Spool from actuator.

3. Position Spool over Valve Stem. Thread Spool onto Valve Stem until it meets valve

plate.

4. Bolt and secure Spool onto valve.

5. Position actuator above Spool. Lower actuator onto Spool while manually rotating

the unit until ears on Stem Nut and ears on main Drive Sleeve mesh.

6. Grease ange face before securing unit to Spool.

7. Re-install thrust plate mounting bolts. Tighten to proper torque.

NOTE:

Reverse procedure if Stem Nut needs to be replaced. Actuator does not need to be

returned to factory for this procedure.

7

Assembly to Valves

Page 11

Installation and Maintenance Manual

(86)

(46)

(48)

E2K-402-0817 Rev. 2

Section 3: Assembly to Valves

3.2.2 Spline Bushing (Quarter-Turn)

EIM removable Spline Bushing allows easy adaptation to valve shaft diameter and Key.

Actuator may be rotated with respect to valve shaft for unexpected or awkward eld

installations.

1. Move valve to full Open or Close.

2. Place Spline Bushing on valve shaft with Key and tighten set screw.

3. Using handwheel on actuator, move gear position indicator arrow to full Open or

Close (the position in Step 1)

4. Position actuator so Spline Bore is correctly aligned with the Spline Bushing on

stem shaft.

5. Move actuator onto shaft until ange faces properly mate. Secure with screws thru

the adapter ange into base of actuator.

3.3 Quarter-Turn Valve

August 2017

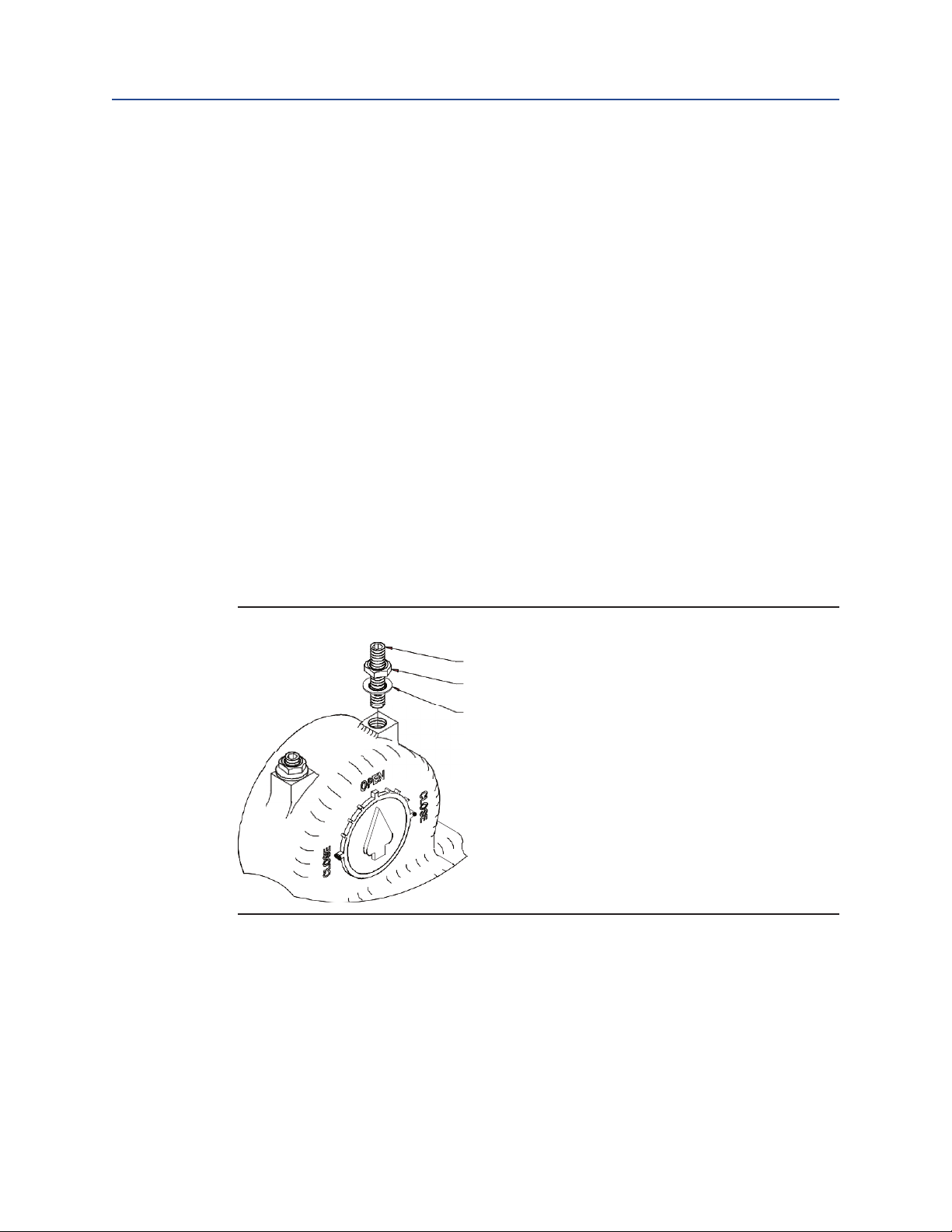

3.3.1 Stop Setting Procedure

Built-in mechanical stops are provided to prevent handwheel operation beyond total valve

travel (90 ± 6°). End of travel stops are independently adjusted, locked in place and sealed.

Figure 4

Type P, Q and R

(top mount)

Loosen both Locknuts (46) and back out two Stopbolts (86) to allow valve to close and

open fully. Ensure Electrical Travel Limit Switches have been adjusted (see appropriate

section of this manual), proceed as follows:.

1. Run actuator electrically to full Close.

2. Screw Close (86) Stopbolt in until it seats, then back off 1/2 turn. Install (48)

Washer and tighten (46) Locknut.

3. Run actuator electrically to full Open.

4. Screw Open (86) Stopbolt in until it seats, then back off 1/2 turn. Install (48)

Washer and tighten (46) Locknut.

Assembly to Valves

8

Page 12

Section 3: Assembly to Valves

August 2017

Figure 5 Full MCP Frame

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

(4)

(3)

(2)

(1)

Type M/MG

(side mount)

EIM Modular Control Package (MCP) is available congured in thousands of possible

combinations of electrical and electronic parts. Refer to WIRING DIAGRAM and EIM JOB

SPEC SHEET provided by EIM with each actuator.

Back out two Stopbolts (1) to allow valve to close and open fully.

Set Travel Limit Switches (see pg. 4).

1. Run actuator electrically to full Close.

2. Screw Close (1) Stopbolt in until it seats, then back off 1/2 turn. Tighten (2)

Lockscrew.

3. Run actuator electrically to full Open.

4. Screw Open (1) Stopbolt in until it seats; back off 1/2 turn. Tighten Locknut.

5. Install (3) & (4) Seal Washer & Screw.

CAUTION:

Do not set actuator position Limit Switches to drive into mechanical stops.

Damage can occur if unit is repeatedly stalled into end stops.

9

Assembly to Valves

Page 13

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Section 4: Limit Switch Setting Instructions

August 2017

Section 4: Limit Switch Setting Instructions

4.1 Before making limit switch setting

1. Move valve to mid-position (use handwheel).

2. Phase the power (motor) voltage and make sure that open contactor moves valve

Open and close contactor moves valve Closed.

DANGER:

Improper power voltage phasing eliminates protection of both position limit switch and

torque switches, risking valve damage.

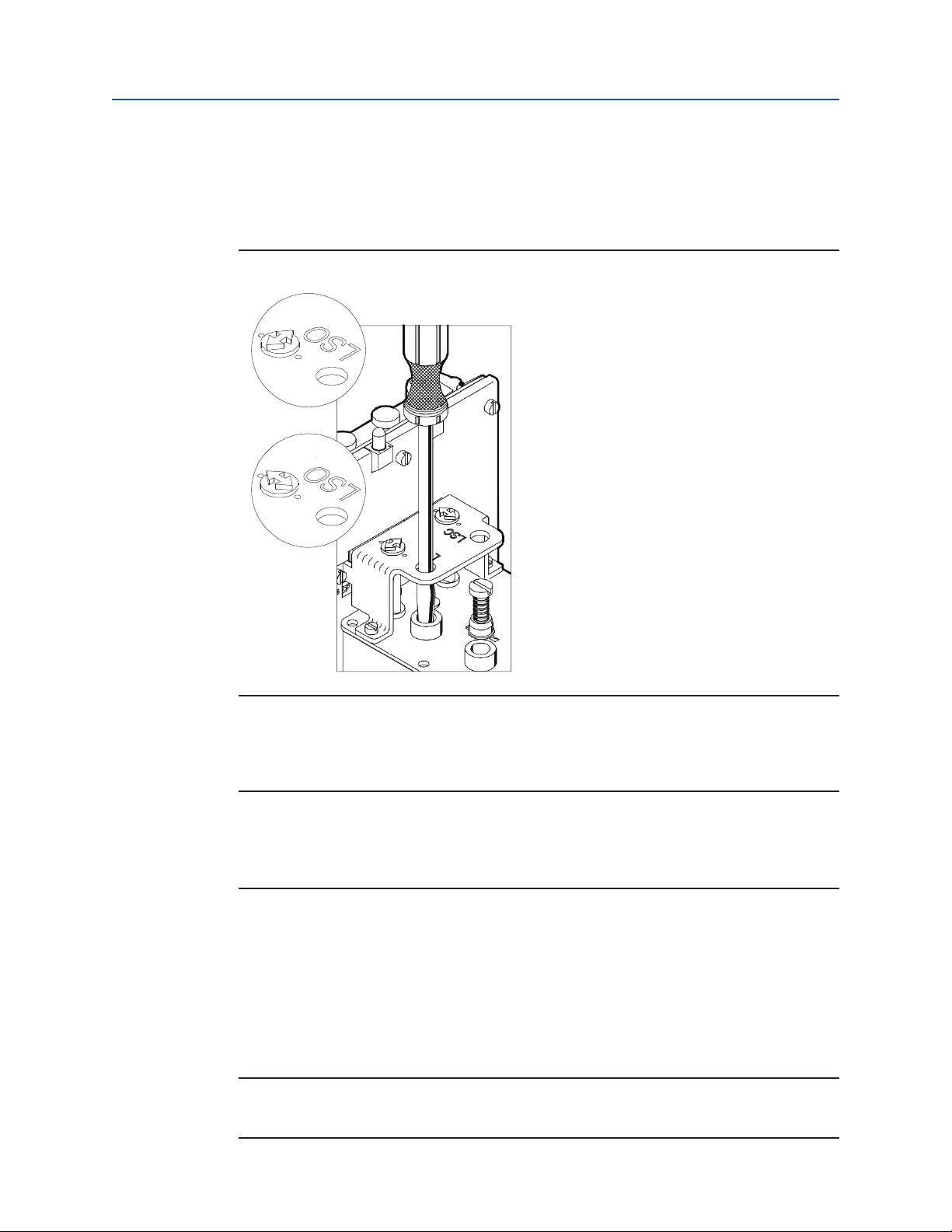

4.2 To set Open Limit Switch (LSO)

1. Open valve during handwheel operation note rotation direction of screwdriver

(Fig. 6) in LSO Adjusting Shaft. After valve is fully Open, Close it three handwheel

turns to allow for coasting when motor is actuated.

Figure 6

Limit Switch Setting Instructions

10

Page 14

Section 4: Limit Switch Setting Instructions

August 2017

2. Disengage spring loaded gear: Push Disengage Shaft in (Fig. 7a) down, then rotate

90° so shaft is captured down. This will disengage limit switch gears from spring

loaded drive gear.

Figure 7

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Fig. 7a

Push

Down

Rotate 90°

NOTE:

Many turns may be required to set limit switches; it may be convenient to use a reversible

variable speed drill to rotate the adjusting shafts instead of a screwdriver.

11

Limit Switch Setting Instructions

Page 15

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

3. Line up LSO indicator: If switch rotor arrow does not line with round holes

(within ± 15°) on plate as shown in Fig. 8a, rotate screwdriver in same direction

noted in Step 1 until switch just rotates. If arrows line up as shown in Fig. 8b, rotate

screwdriver in the opposite direction until switch just rotates.

Figure 8

Fig. 8a

Fig. 8b

Section 4: Limit Switch Setting Instructions

August 2017

4. Re-engage the spring-loaded drive gear by rotating disengage shaft in Fig. 8a.

Spring loaded disengage shaft will rise.

IMPORTANT:

To insure limit switch gears have re-engaged properly with spring loaded drive gear, rmly

“jiggle” (rotate) all adjusting shafts with screwdriver back and forth. Proper engagement

has been made if all shafts (LSC, LSO, LSA & LSB) will not turn with screwdriver.

4.3 Set (LSC) Close Limit Switch

1. Close valve, using handwheel. During handwheel operation note rotation direction

of screwdriver in LSC adjusting shaft. After valve is fully Closed,

Open it three handwheel turns to allow for coast.

2. Repeat steps 2 through 5 of LSO setting instructions with screwdriver in LSC cavity.

IMPORTANT:

“Jiggle” adjusting shafts.

Limit Switch Setting Instructions

12

Page 16

Section 4: Limit Switch Setting Instructions

August 2017

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

4.4 To set Intermediate Switch (LSA or LSB), if included

1. Open Valve to desired position, then repeat steps 2 thru 5 of LSO.

NOTE:

“Jiggle” adjusting shafts.

4.5 Torque Seated Valves

If valve is a torque seated valve, and the geared limit contacts are used for indication only,

the LSC switch should be set several handwheel turns ahead of torque switch contact

action. This gives proper valve position Lamp indication in spite of minor position variations

which might occur due to torque seating.

4.6 Torque Switch Calibration

Figure 9

To set Close Torque Switch (TSC)

13

a. Close valve using handwheel. Set valve to the desired torque. Observe

rotating dial for number that corresponds to desired Close Torque.

b. Insert screwdriver in TSC slot. Press down to disengage and turn arrow to

setting determined in a). Release at this point and it will re-engage and

remain set.

c. Back the valve away from Close position and reseat by handwheel to

verify torque trip point is at desired setting. The trip point of switch is a

distinctive click as it breaks contact.

Limit Switch Setting Instructions

Page 17

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Section 4: Limit Switch Setting Instructions

DANGER:

Reverse power voltage phasing removes torque switch protection from reversing contractor coil circuits. Valve damage could occur. If phasing has not been checked, do so before

proceeding. Back valve away from Close position with handwheel and test torque electrically, using Close controls. Readjust as required.

4.7 To set Open Torque Switch (TSO)

a. Follow procedure as for TSC at TSO dial.

4.8 Torque Switch Rotation Limit

Adjustment rotation may be limited, Remove dial to expose anti-rotation pins. Remove

pins from position 10 and insert into the desired hole.

Figure 10

August 2017

Limit Switch Setting Instructions

14

Page 18

Section 5: Multi-turn Actuators

August 2017

Installation and Maintenance Manual

Section 5: Multi-turn Actuators

Multi-turn top-mounted and side-mount bevel gear actuators require use of Gear

Reduction Assembly part no. 84055-0000 for Mechanical Dial Position Indication MDPI and

1-turn Pot. N-number replaces -0000 to complete part no. For 1-turn Pot only without Dial

Indication part no. is 84117-0000. Refer to EIM JOB SPEC SHEET for MDPI furnished.

MDPI Mechanical Dial Position Indication is a gear reduction assembly to convert multi-turn

valve stem nut turns to 270 degrees (.75 turn) for viewing position indication arrow thru

glass window on actuator electric switch compartment cover. Point of rotation reference

has been designated as N-number. N is the total number of electric actuator 12-tooth gear

limit spring-load pinion rotations for full valve stroke.

Figure 11

E2K-402-0817 Rev. 2

5.1 Calibration

MDPI & POT Drive is calibrated after LSC and LSO are properly set (Pg. 4). Move valve to

Close position. Manually rotate MDPI arrow to indicate Close. Calibration is now complete.

Open valve to check that MDPI arrow goes to Open, indicating that N is correct for full

valve travel. Potentiometer, if included, has been calibrated. Mechanical dial travel is 270°.

Approximately 5% of total Pot resistance is left on each end for total valve travel.

15

Multi-turn Actuators

Page 19

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

5.2 Quarter-Turn Model P, Q, R & M

Top-mount P, Q and R and several models of M/MG’s side-mount do not require MDPI gear

reduction assembly for 1-turn Pot. If multi-turn Pot is required, EIM JOB SPEC SHEET will list

84131-0000 or the correct assembly. Spec Sheet will list,(1) Pot clutch gear, (2) Pot input

gear and (3) potentiometer.

Figure 12

(1) Clutch Gear

(2) Pot Input

Gear

Section 5: Multi-turn Actuators

August 2017

(3) Potentiometer

Multi-turn Actuators

16

Page 20

1K Ohm

Section 6: M2CP Wiring Diagram Symbols

August 2017

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Section 6: M2CP Wiring Diagram Symbols

6.1 Description

Refer to EIM JOB SPEC SHEET and EIM WIRING DIAGRAM for components furnished.

Figure 13 Potentiometer

CLOSE

Potentiometer slider is geared to Valve Position and "in-step" at all times.

Figure 14 Transformer

18V

H2

115V 12V

H1

Outputs: 120, 12 and 18Vac.

Figure 15 Pilot Lamps - LED Indicators

Actuated by position limit switches.

Figure 16 Position Limit Switch

LSC LSO

LSC shows open. LSO shown made.

Figure 17 Torque Limit Switches

TC1

TC2

17

N.C. Double Break Contacts Open when overload occurs. N.O. contacts make.

Figure 18 Fuse

F3

M2CP Wiring Diagram Symbols

Page 21

Installation and Maintenance Manual

STOP

E2K-402-0817 Rev. 2

Figure 19 Pushbuttons N.C.

Momentary N.C. Contact

Figure 20 Pushbuttons N.O.

Section 6: M2CP Wiring Diagram Symbols

August 2017

R3

C

14 13

14

13

R1

R1

R6

7

6

8

5

OPEN

Momentary N.O. contacts connects control voltage to reversing contactor 8 coils.

Seal-in contacts C and O (14,13) on contactor allow travel without continued holding down

of pushbutton.

Figure 21 Terminal Points

X1

Factory wired by EIM.

Figure 22 Space Heater

SPACE

HEATER

Heater in Switch. Compartment is standard

Figure 23 Circuit Plug & Receptacle

Figure 24 Grounds

Chassis

GROUNDS

M2CP Wiring Diagram Symbols

Earth

18

Page 22

Section 6: M2CP Wiring Diagram Symbols

August 2017

Figure 25 Reversing Contactor

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

ZR3C1

9

R2

R5

10

ZR4C2 R6

22 21

C

22 21

R5

R4

C

Interlock

Mechanical

O

Showing Open and Close coils, Mechanical Interlock, and Electrical Interlock Contacts O

(21, 22) & C (21, 22)

Figure 26 Nuisance Trip

C2

TO1

To prevent (TSO) contact tripping when valve has been jammed closed - LSC contact allows

valve to open slightly. Contact then open, ensuring torque protection for remaining travel

Figure 27 Circuit Breaker

21L1

43L2

65L3

Figure 28 Selector Switch N.C. & N.O. Double Break

OFF

Local

(hand) (auto)

16

D

CS2

S1

S3

S5

S6

S7

Remote

15

14

17

18

19

S4

19

M2CP Wiring Diagram Symbols

Page 23

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Figure 29 3 Phase Motor with overload relay heaters & contractor contacts

211C2 21

4334 43

6556 65

T1

T2

T3

Figure 30 SS Table

Auto

Off

Hand

S1 XOO

S2 OO X

OX X

S3

S4 XX O

S5 XOO

S6

OO X

S7 XXO

8)

L1

L2

L3

MOTOR

Thermal

Protector

Section 6: M2CP Wiring Diagram Symbols

August 2017

Figure 31 Contact N.C.

Figure 32 Contact N.O.

M2CP Wiring Diagram Symbols

20

Page 24

Section 7: Troubleshooting

August 2017

Section 7: Troubleshooting

Symptom Probable Cause Corrective Action

Blown Control Fuse

Motor will not Run

No Power available

to Actuator

Handwheel Hard to Turn

Valve only opens or closes

partially with motor

Torque switch is properly

set, but actuator

Torque’s out in mid-travel,

open or closed direction

Handwheel will not

operate valve

Open in Control Circuit

Insulation Resistance

Breakdown in Motor

Tripped Circuit Breaker Reset Circuit Breaker

Valve Stem improperly

Lubricated

Actuator Lubrication has

broken down

Valve packing gland

too tight

Drive Sleeve Bearing Failure Replace Bearing

Jammed Valve Refer to Valve Maintenance

Torque Switch Setting

too low

Limit Switch Improperly Set

Damaged or bent valve stem Refer to Valve Maintenance

Valve packing too tight Refer to Valve Maintenance

Jammed Valve

(obstruction in line)

Handwheel shaft bearing

assembly malfunction

Sheared gear key or Stripped

Gearing

PS Shifter Position or

Malfunction

Broken Handwheel Shaft Repair or replace as necessary

Broken Valve Stem or

Stripped Stem Nut

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Check Fuse and Replace

as necessary

Refer to appropriate wiring

diagram and check

for continuity

Perform Megger Test

Lubricate with Grease

Clean out old grease and

replace with recommended

lubricant

Loosen packing gland nuts

as necessary

Check Setting and Reset

if necessary

Check Switch Actuation and

recalibrate if necessary

Refer to Valve Maintenance

Repair or replace as necessary

Replace as necessary

Replace Gear(s)

Repair or replace as necessary

21

Troubleshooting

Page 25

Installation and Maintenance Manual

E2K-402-0817 Rev. 2

Section 7: Troubleshooting

August 2017

Motor runs but will not

operate the valve

Moisture in Electrical

Enclosure

Gear (Oil) in Electrical

Enclosures

Motor Bearing Assembly

Malfunction

Repair or replace as necessary

Sheared gear key

(fastener pin)

Stripped Gearing Replace

Broken Valve Stem or

Stripped Stem Nut

PS shifter position or

malfunction

Repair or replace as necessary

Replace PS Assembly

Install an approved Seal-off or

Leakage through Conduit

Entry

Electrical Enclosure is not

re-route conduit to enter

Enclosure from the bottom of

Inspect and replace O-ring

properly sealed

Space Heater Inoperable

Pressure Relief Fitting not

installed

Bad Seal on T/L or G/L

Assembly

Check Circuit continuity

Install Pressure Relief Fitting

Replace Stat-O-Seals or O-Rings

Rotate Actuator Mounting

Replace

enclosure

if necessary

for Heater

Troubleshooting

22

Page 26

Page 27

World Area Configuration Centers (WACC) offer sales support, service,

inventory and commissioning to our global customers.

Choose the WACC or sales office nearest you:

NORTH & SOUTH AMERICA

19200 Northwest Freeway

Houston TX 77065

USA

T +1 281 477 4100

F +1 281 477 2809

Av. Hollingsworth

325 Iporanga Sorocaba

SP 18087-105

Brazil

T +55 15 3238 3788

MIDDLE EAST & AFRICA

P. O. Box 17033

Dubai

United Arab Emirates

T +971 4 811 8100

F +971 4 886 5465

P. O. Box 10305

Jubail 31961

Saudi Arabia

T +966 3 340 8650

F +966 3 340 8790

F +55 15 3228 3300

24 Angus Crescent

ASIA PACIFIC

Longmeadow Business Estate East

P.O. Box 6908 Greenstone

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6777 8211

F +65 6268 0028

No. 1 Lai Yuan Road

1616 Modderfontein Extension 5

South Africa

T +27 11 451 3700

F +27 11 451 3800

EUROPE

Wuqing Development Area

Tianjin 301700

P. R. China

T +86 22 8212 3300

F +86 22 8212 3308

Berenyi u. 72- 100

Videoton Industry Park

Building #230

Székesfehérvár 8000

Hungary

T +36 22 53 09 50

F +36 22 54 37 00

For complete list of sales and manufacturing sites, please visit

www.emerson.com/actuationtechnologieslocations or contact us at

info.actuationtechnologies@emerson.com

www.emerson.com/eim

©2017 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co.

TM

is a mark of one of the Emerson family of companies.

EIM

All other marks are property of their respective owners.

The contents of this publication are presented for information purposes

only, and while every effort has been made to ensure their accuracy,

they are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which

are available on request. We reserve the right to modify or improve the

designs or specifications of our products at any time without notice.

Loading...

Loading...