Installation, Operation and Maintenance Manual

Series 2000LP

Low Pressure Pneumatic Actuator

Part Number: E7K-400-0413

Release: April 2013

When communicating with EIM for replacement parts or for technical questions, we MUST have

actuator nameplate information, including Job, Serial, and Model numbers. This allows us to check

records of EIM equipment furnished.

When ordering parts, specify repair part by EIM part number and description from drawings

furnished with actuator.

Installaton, Operation and Maintenance Manual

Part Number: E7K-400-0911, Rev. 0

Table of Contents

Section 1: Introduction ..................................................... 1

Section 2: Storage Instructions ......................................... 3

Section 3: Product Data .................................................... 4

Section 4: Lubrication and Maintenance ........................... 5

Section 5: Mounting Dimensions ...................................... 7

Section 6: Assembly to Valve ............................................ 8

6.1 Multi-Turn Valve Stem Nut Installation .......................................................... 8

6.2 Lockpin Installation ....................................................................................... 9

6.3 Thrust Spool Installation (Multi-Turn) ............................................................ 9

6.4 Spline Bushing (Quarter Turn) ....................................................................... 9

6.5 Quarter Turn Gearbox Stop Setting Procedure ............................................. 10

Table of Contents

April 2013

Section 7: Pneumatic Hookup ..........................................11

Section 8: Travel and Torque Limits ..................................13

8.1 General Information .................................................................................... 13

Section 9: Setting Travel Limit Valves ...............................15

Section 10: Setting Torque Limit Valves

10.1 Opening Torque .......................................................................................... 17

10.2 Closing Torque ............................................................................................ 18

Section 11: Optional Electric Limits ................................... 19

11.1 General Information .................................................................................... 19

11.2 Standard Wiring Diagram ............................................................................20

Section 12: Typical LP Control Package .............................. 21

Section 13: Typical Control Diagram .................................. 22

Table of Contents

I

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0911, Rev. 0

Section 14: Gast Pneumatic Motor .................................... 24

14.1 Installation .................................................................................................. 24

14.2 Lubrication .................................................................................................. 24

14.3 General Information .................................................................................... 24

14.4 Servicing ..................................................................................................... 25

Section 15: Troubleshooting ............................................. 26

Table of Contents

April 2013

II

Table of Contents

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 1: Introduction

This installation and operation manual explains how to install, operate, and maintain the

2000LP valve actuator.

Carefully follow the instructions in this manual and make sure you install the actuator correctly

and according to your requirements.

Safety notices in this manual detail precautions the user must take to reduce the risk of

personal injury and damage to the equipment. The user must read these instructions in their

entirety. Failure to observe these safety notices could result in serious bodily injury, damage to

the equipment, voiding of the warranty, or create operational difculty.

Safety notices are presented as follows:

WARNING:

Alerts user of potential danger; failure to follow the warning notice could result in serious

personal injury or death.

Section 1: Introduction and Safety Information

April 2013

CAUTION:

Identies precautions the user must take to avoid personal injury or equipment damage.

NOTE:

Highlights information critical to the user’s understanding of the 2000LP valve actuator

installation or operation.

WARNING:

Read this manual in its entirety before installing, operating, or performing

maintenance on the 2000LP actuator.

WARNING:

Use caution when working on, with, or around valves and actuators. High

pressures, forces, voltages and flammable media can be present.

WARNING:

Failure to follow instructions for proper electrical wiring, storage, setup, and

maintenance may cause serious injury, damage equipment, or void warranty.

Introduction and Safety Information

1

Section 1: Introduction and Safety Information

April 2013

WARNING:

If the actuator is being installed within a hazardous area, take into account that:

• Improper installation in hazardous areas can cause an explosion.

• Assembly, disassembly and maintenance are only allowed at the actuator

when, at the time of the activity, an explosive mixture is not present.

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

2

Introduction and Safety Information

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 2: Storage Instructions

If your actuator cannot be installed immediately, the following procedures are to be followed.

This will ensure optimum performance from your 2000LP actuator.

Failure to comply with recommended procedures could lead to actuator malfunction and will

void the warranty.

The 2000LP actuator is an inherently weatherproof unit when shipped from the factory,

providing that all compartment covers and entry plugs remain intact. The actuator should

be immediately stored in a clean, dry warehouse, free from vibration and rapid temperature

changes, until it can be installed and commissioned.

If the actuator must be stored outside, it should be stored off of the ground, at an elevation

sufcient to prevent it from being immersed in water or buried in snow, and covered to prevent

damage from site debris.

If not attached to a valve, the preferred orientation is with the motor and control compartment

horizontal.

Section 2: Storage Instructions

April 2013

If the actuator is mounted on a valve and the valve stem protrudes from the unit, a suitable

stem protector must be installed to prevent drive sleeve corrosion. Stem protectors may be

purchased from your local EIM distributor.

CAUTION:

Condensation or moisture that enters the actuator can damage internal components, which

may ultimately result in failures.

(1) Ensure integrity of gaskets and O-rings.

(2) Seal all conduit openings, whether used or not.

(3) Replace any plastic conduit plugs with pipe plugs appropriate for the application.

(4) Place a packet of dessicant in the control housing to absorb excessive moisture.

For storage procedures exceeding one year, contact your local EIM representative for

recommendations.

Contact information is located on the last page of this manual.

Storage Instructions

3

Section 3: Product Data

April 2013

Section 3: Product Data

The EIM 2000LP pneumatic actuator from Emerson is a multi-turn air driven actuator that

is perfect for applications using linear stem, rising stem or rotating stem valves. It can be

powered by air, nitrogen, or natural gas at pressures between 60 and 100 psi. Manual controls

and/or a number of remote pneumatic or electric control options can be provided as shown in

the table below.

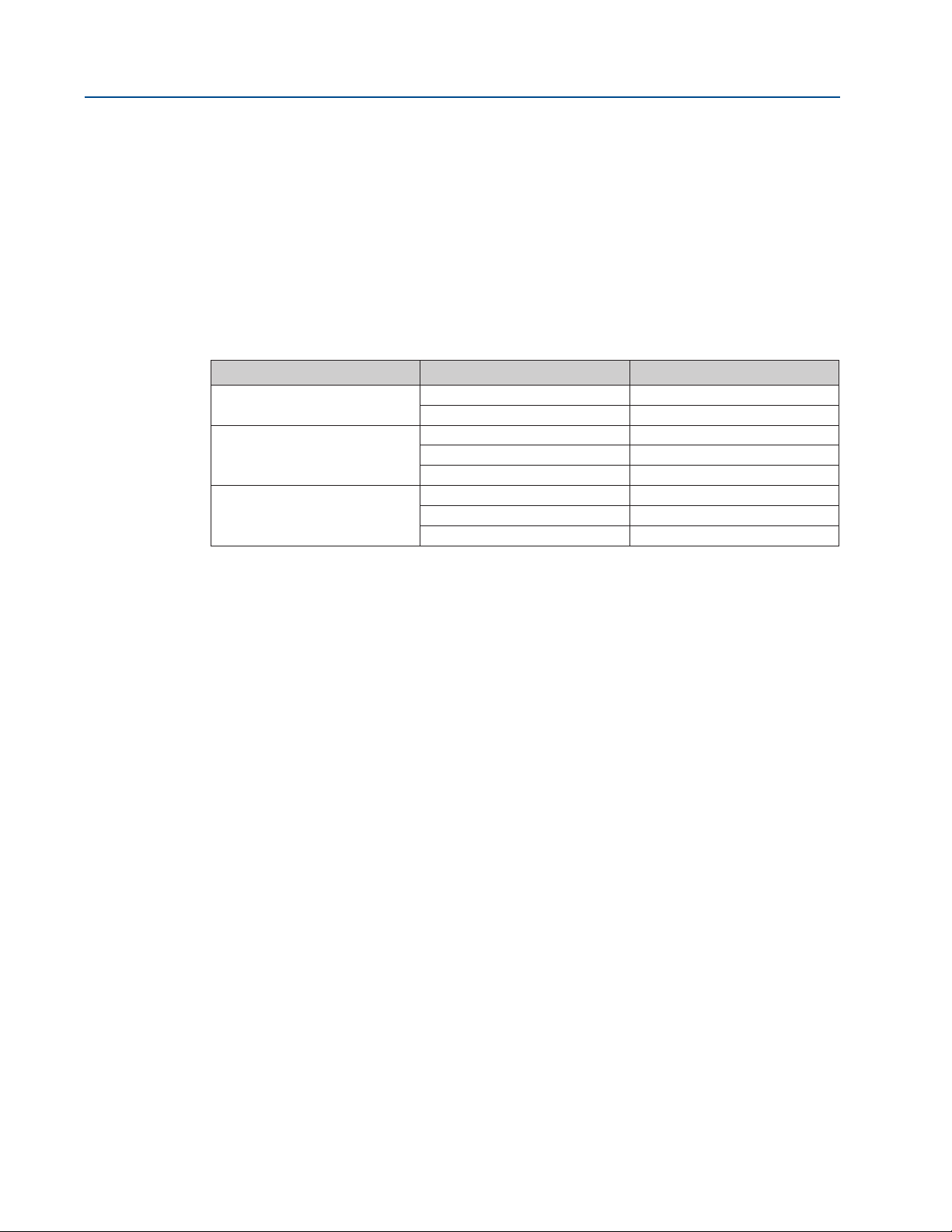

Table 1. Standard Control Diagrams

Typ e Description Diagram

Manual

Pneumatic

Electric

No Controls PD-100

Local 2-Way PD-101

Fail Close PD-102

Fail Open PD-103

Double Acting PD-104

Fail Close PD-105

Fail Open PD-106

Double Acting PD-107

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

There is a ve digit alpha-numeric code used to describe basic actuator features for computer

assisted order entry. This number appears on the actuator nameplate afxed to the actuator

gear housing. The most signicant designators for a sample 2CLG-AF actuator are shown

below.

2 C L G - A F

Frame Size Motor Size Motor Gears Worm Gears Control System Special Services

1 = 1000 X = 6AM A = No controls

2 = 2000 Y = 8AM B = Local Manual

3 = 3000 Z = 16AM C = Remote

The 2000LP is based on the proven EIM Series 2000 platform and shares many of its distinctive

features and benets such as direct mounting and handwheel operation during power loss or

emergency situations.

The three most common frame sizes of EIM actuators, the 1000, 2000 and 3000, establish the

foundation for the 2000LP. Subsequently, most major 2000LP mechanical components are

interchangeable with standard EIM electric actuators, which facilitates the acquisition of spare

parts.

The control housing is also a shared EIM electric component, resulting in NEMA 4, 4X and IEC

IP66 product ratings for the 2000LP. Working temperature range is listed at -20 / +150°F (-29 /

+66°C).

4

Product Data

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 4: Lubrication and Maintenance

Section 4: Lubrication and Maintenance

An annual check of the following items should be made of your EIM 2000LP actuator.

1. Check for any external leaks and tighten ttings appropriately and/or replace failed

components.

2. Check for internal component leakage by testing for the presence of air exiting the

exhaust port(s) while the actuator is not moving.

3. Open the control housing to inspect and tighten any loose connections.

4. Visually inspect for any mechanical damage. Replace worn or damaged components.

5. Replace any seals that permit oil leakage or water ingress.

6. Lubrication consistency and quantity needs to be checked only after 3000 cycles

unless the actuator has been leaking oil or making excessive noise. Fill or replace with

recommended uid if required .

Lubrication – EIM actuator gear housings are factory lled with a high quality lubricant carefully

selected to ensure proper performance under specied operating conditions. Refer to EIM JOB

SPEC SHEET to identify the lubricant provided. Normal operation may not require lubricant

replacement.

April 2013

Lubricant level in the gear housing should be maintained at the following quantity. Do not

overfill.

• 1000 and 2000 Frame Sizes

(See “product data” section of this manual for determining frame size)

— Oil: 54 oz (1.54 Liters). Oil is recommended for all drive sleeve speeds over

51RPM.

— Grease: 3.5 lbs (1.58 Kg.). Grease is adequate for drive sleeve speeds under

51RPM.

• 3000 Frame Size

— Oil: 62 oz (1.83 Liters). Grease is not recommended for use in the 3000 Frame

Size

Lubrication and Maintenance

5

Section 4: Lubrication and Maintenance

April 2013

The following recommended lubricants are manufactured by Schaeffer Manufacturing

Company, but may be replaced with equivalent products manufactured by other reputable

companies. Lubricant selection must be made based upon ambient temperature and

application.

Table 2. Schaeffer Manufacturing Cpmpany Lubricants / Temperature for EIM

Products

Product Continuous Operating Range Part Number

#158 (ISO 68) Low Temp Oil -65 / +400°F (-54 / 204°C) 3000100228

#267 EIM Std. Oil -20 / +350°F (-29 / 177°C) 3000100227

#229 EIM Std. Grease -25 / +350°F (-32 / 177°C) 3000100222

#200 SUG (Special for EIM) -40 / +400°F (-40 / 204°C) 3000100212

#197 Low Temp, Grease -60 / +500°F (-51 / 260°C) 3000100219

#271 Food Grade -15 / +500°F (-26 / 260°C) 3000100216

#276 Food Grade Oil -15 / +300°F (-26 / 149°C) 3000100218

#286 High Temp *Na / +900°F (*Na / 482°C) 3000100220

#167 (Gear Oil) 75-140 Wt. -50 / +350°F (-45 / 177°C) 3000100230

#238 EP 1 Grease -10 / +350°F (-23 / 177°C) 3000100226

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

NOTE:

During operation of this actuator, gear housing temperature increase in combination with

variations of outdoor temperature may cause a small pressure build-up within the actuator gear

box. EIM furnishes Pressure Relief Vent Fitting Part No. 83385 to prevent excessive pressure

build-up. Pressure Relief Vent Fitting placement on the actuator can be determined after eld

location and position of the valve have been determined. Select the highest 1/2NPT vent

location of the actuator gear box; remove the ½ NPT plug and replace with Part No. 83385.

6

Lubrication and Maintenance

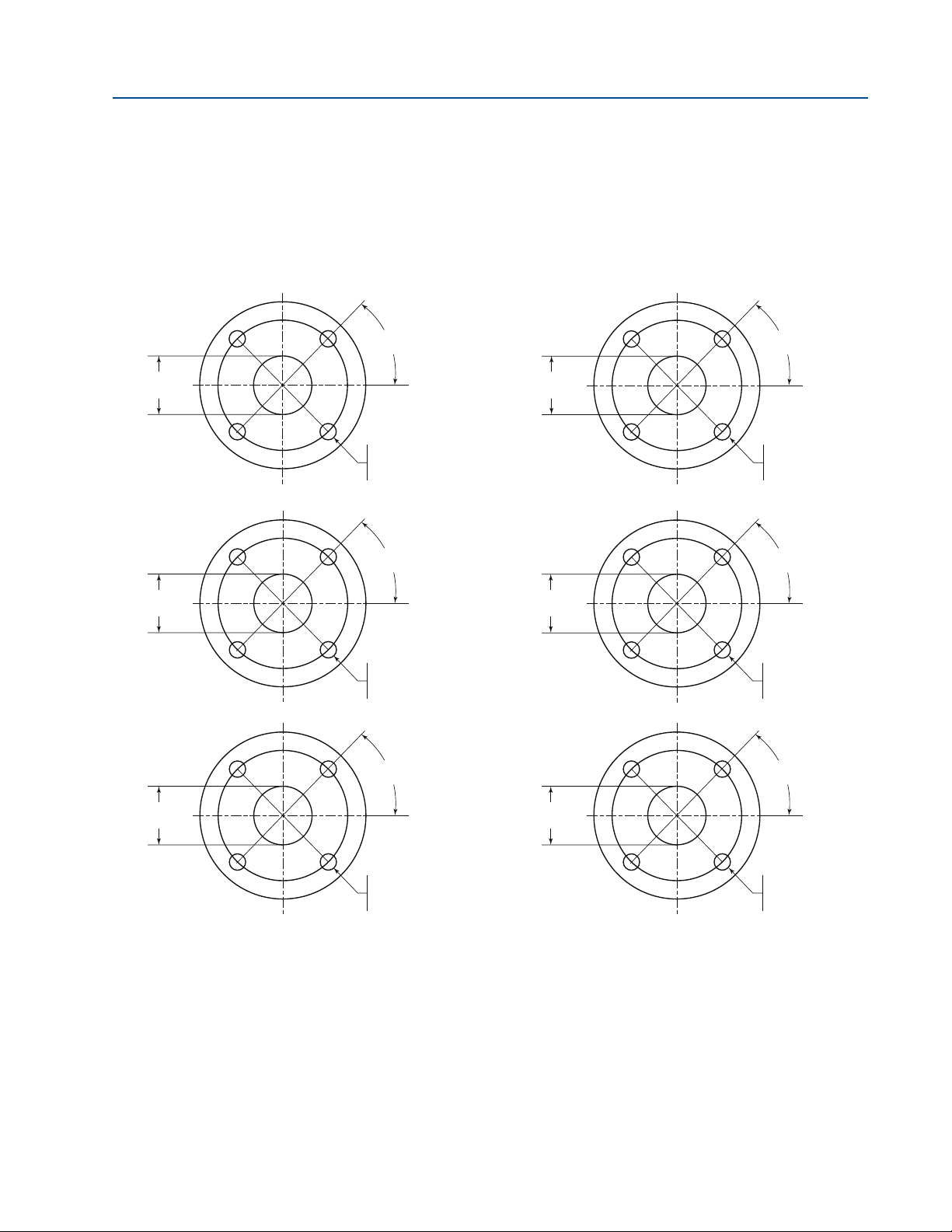

45°

45°

45°

45°

45°

45°

2.308”/2.305”

Pilot Dia.

(4) 3/8”-16 Holes

Tapped 0.8” (20) Deep

on 4.00” (102) B.C.

69.98mm/69.90mm

Pilot Dia.

(4) M10 Holes

Tapped 0.8” (20) Deep

on 4.00” (102) B.C.

3.745”/3.742”

Pilot Dia.

(4) 5/8”-11 Holes

Tapped 1.32” (33) Deep

on 5.50” (140) B.C.

99.98mm/99.90mm

Pilot Dia.

(4) M16 Holes

Tapped 1.32” (33) Deep

on 5.50” (140) B.C.

129.95mm/129.87mm

Pilot Dia.

(4) M20 Holes

Tapped 1.52” (38) Deep

on 6.50” (165) B.C.

4.994”/4.990”

Pilot Dia.

(4) 3/4”-10 Holes

Tapped 1.32” (33) Deep

on 6.50” (165) B.C.

FA10/F10

FA14/F14

FA16/F16

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 5: Mounting Dimensions

EIM Standard mounting is MSS SP-102 (FA) – Left column

ISO (F) Mounting can be supplied if requested – Right column

Section 5: Mounting Dimensions

April 2013

Mounting Dimensions

7

Section 6: Assembly to Valve

52

5556

54

April 2013

Installation, Operation and Maintenance Manual

Section 6: Assembly to Valve

6.1 Multi-Turn Valve Stem Nut Installation

Figure 1

Part Number: E7K-400-0913

1. Unscrew Locknut (55) holding Bronze Stem Nut (54) and remove Stem Nut and Key

(52).

2. Lubricate Stem and run Stem Nut (54) down stem to check acme thread t, then

remove Stem Nut and set aside.

3. Lower actuator over stem onto valve ange. After ensuring proper ange mating and

valve actuator orientation, insert Grade 5 mounting screws thru valve ange into

actuator. Screws must engage a minimum of one full screw diameter into bottom base

and be torqued to the following value:

• 3/8-16 = 50 lbf-ft (M10 = 68 Nm)

• 5/8-11 = 225 lbf-ft (M16 = 305 Nm)

• 3/4 -10 = 400 lbf-ft (M20 = 542 Nm)

NOTE:

If EIM supplied adaption, the mounting screws are included. If the adaption to the

valve was the responsibility of others, the mounting screws are not furnished by

EIM. Screws thru adapter MUST engage a minimum of one screw diameter into EIM

actuator base.

4. Screw Stem Nut (54) onto valve stem until it enters the Drive Sleeve. Align Nut Key (52)

with Drive Sleeve keyway and insert Stem Nut Key (52).

5. Turn handwheel in Open direction, pulling the Stem Nut into Drive Sleeve until it

bottoms out (valve will begin to open).

6. Place Locknut (55) over Valve Stem and screw into place rmly against top of Stem Nut

(54). Tighten Locknut by tapping ears with brass drift.

8

Locknut must be screwed very tightly against stem nut.

Assembly to Valve

CAUTION:

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 6: Assembly to Valve

6.2 Lockpin Installation

1. Using a number 30 (.1285) drill; drill a hole 3/4 inch deep into the Drive Sleeve

assembly threads for the Locknut Lockpin(56). Use groove in Stem Nut Locknut threads

as a guide.

2. Install Locknut Lockpin (56) into drilled hole to prevent the Stem Nut Locknut from

working loose and turning.

NOTE:

When installing, the Lock-nut Lockpin should extend 1/4 inch above the Drive Sleeve Assy to

allow for easy removal.

6.3 Thrust Spool Installation (Multi-Turn)

1. Locate Thrust Mounting bolts.

2. Remove the eight mounting bolts and separate the Spool from the actuator.

3. Position the Spool over the valve stem. Thread the Spool onto the valve stem until it

meets the valve plate.

4. Bolt and secure Spool onto valve.

5. Position actuator above Spool. Lower actuator onto Spool while manually rotating the

unit until ears on the stem nut and ears on main Drive Sleeve mesh.

6. Grease ange face before securing unit to Spool.

7. Re-install thrust plate mounting bolts. Tighten to proper torque.

April 2013

NOTE:

Reverse procedure if the stem nut needs to be replaced. Actuator does not need to be returned

to factory for this procedure.

6.4 Spline Bushing (Quarter-Turn)

EIM removable Spline Bushing allows easy adaption to valve shaft diameter and key. Actuator

may be rotated with respect to the valve shaft for unex-pected or awkward eld installations.

1. Move valve to full Open or Close.

2. Place Splined Bushing on valve shaft with key and tighten set screw.

3. Using the handwheel on actuator, move the Gear position indicator ar¬row to full Open

or full Close (duplicating the position in Step 1).

4. Position actuator so the Splined Bore is correctly aligned with the Splined Bushing on

stem shaft.

5. Lower the actuator onto the shaft until the ange faces properly mate. Se¬cure with

screws thru the adapter ange into the base of the actuator.

Assembly to Valve

9

Section 6: Assembly to Valve

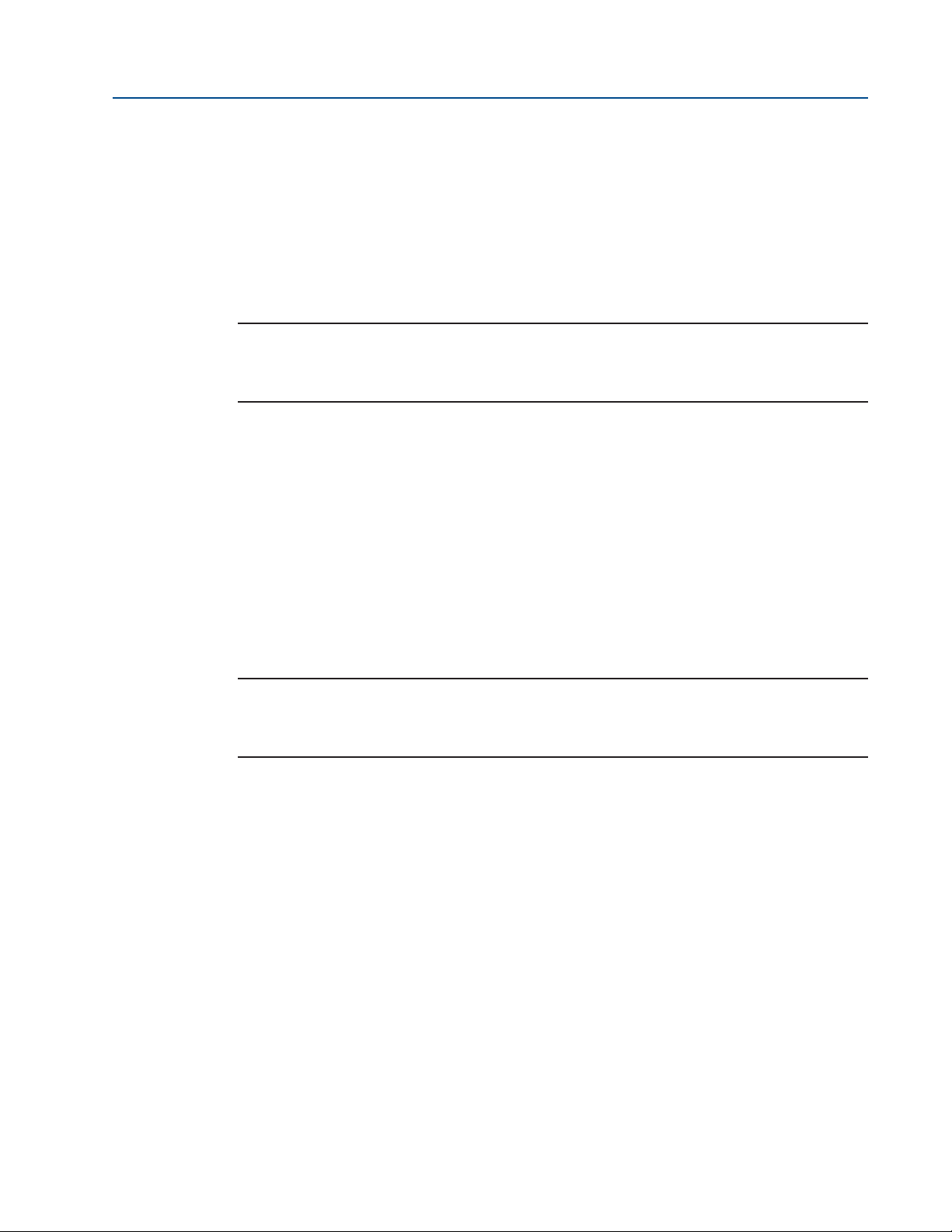

8786

46

48

April 2013

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

6.5 Quarter Turn Gearbox Stop Setting Procedure

Built-in mechanical stops are provided in the gearbox to prevent operation beyond total valve

travel of 90° (± 6°).

End of travel stops are independently adjusted, locked in place and sealed.

Figure 2

Loosen both LOCKNUTS (46) and back out two STOPBOLTS (86 & 87) to allow valve to close and

open fully. Ensure Travel Limit Valves have been properly adjusted (see appropriate section of

this manual), and then proceed as follows:

1. Run actuator pneumatically to full closed position.

2. Screw CLOSE STOPBOLT (86) in until it seats, then back off 1/2 TURN. Install WASHER

(48) and tighten LOCKNUT (46).

3. Run actuator pneumatically to full open position.

4. Screw OPEN STOPBOLT (87) in until it seats, then back off 1/2 TURN. Install WASHER

(48) and tighten LOCKNUT (46).

CAUTION:

Do not set Actuator Travel Limit valves to drive into mechanical stops. Damage can occur if

actuator is allowed to repeatedly stall into end stops.

10

Assembly to Valve

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 7: Pneumatic Hookup

1. When mounting is complete, per previous instructions in Assembly to Valve, move the

valve position to mid-stroke with the actuator’s Handwheel. This will provide sufcient

time to stop actuator operation in case of incorrect pneumatic connection(s).

2. Identify a means of removing power from the actuator during hook up and check out.

3. Be sure no erroneous remote signal can be received that would cause the actuator to

energize.

4. Each pneumatic actuator is supplied with a directional valve that is sized to deliver an

air volume at the necessary required to achieve design performance for each actuator.

The following criteria should be used when selecting your air system. The air motor

size can be found on the unit ID (serial number) tag.

See Product Data Section of this manual to determine motor size.

Table 3. Motor Pressure Consumption

Section 7: Pneumatic Hookup

April 2013

Port Size (PSIG) (SCFM) SIZE

X 100 130 1/2" NPT

Y 100 180 1/2" NPT

Z 100 280 1" NPT

5. Consumption at a lower pressure is proportional to the data shown. Consideration

must be given to your piping system. At a normal 100 psi supply, schedule 40 piping,

or tubing with an equal internal diameter is recommended. A lter and lubricator

MUST have threaded connections equal to port sizes shown. Piping size should be

the same as that shown and connected to a larger header as close to the actuator as

possible.

Depending on the condition of the air supply, a lter may be required to maintain

ltration in a 40-50 micron range. Filter selection must meet this operating criteria.

6. Install an automatic lubricator in the air line leading to the motor. It should be

mounted in a horizontal pipe run as near as possible to the actuator.

NOTE:

Refer to “typical control diagrams” in this manual to determine proper piping location for

accessory connections.

NOTE:

Do not hang pipe loads on the actuator. Use external support or exible connections to the

actuator.

Pneumatic Hookup

The lubricator should be adjusted to feed one drop of oil for every 50-75 SCFM of air going to

the actuator. For example, an “X” motor running for one minute would require a minimum of

three drops of oil from the lubricator.

11

Section 7: Pneumatic Hookup

April 2013

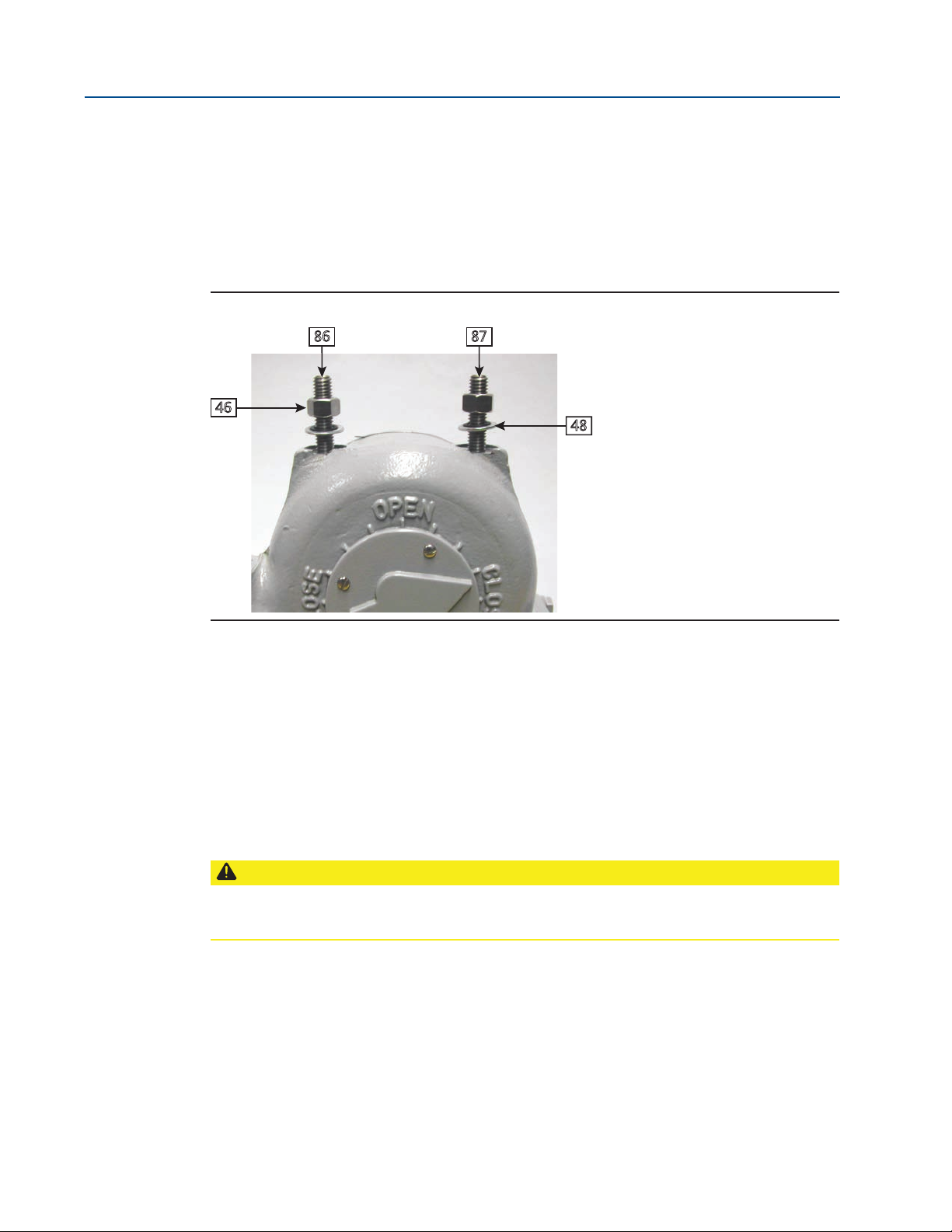

Figure 3 TYPICAL FILTER, REGULATOR AND LUBRICATOR PACKAGE

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

7. A lubricant is required for all internal moving parts of the air motor and air control

valves. This is intended to reduce wear and prevent rust. Brand name oils are suitable

if they are mineral base, wax free & aniline point in the range of 200-220°F. Oils must

be thin enough to atomize in the lubricator. This should be in the range of Group D,

Turbine Light with a viscosity of 32 at 100°F. Listed below is a representative group of

suitable light oils that may be considered for use.

• Chevron - GTS OIl 32

• Exxon - Teresstic T32

• Mobil - Light

• Shell - Turbo 32

• Texaco - Capella 32 WF

NOTE:

Do not use penetrating oils or detergent type oils as they will damage seals and thicken in cold

weather.

NOTE:

Any temperature below 32°F may require the addition of small amounts of pure ethylene glycol

into the air system to prevent freezing. Do not concede the volume of oil normally used.

NOTE:

This product, as well as similar devices such as cylinders, solenoid valves, ESD valves, etc. emit

air to atmosphere in their normal operating mode. Confer with established codes and safety

regulations.

12

CAUTION:

Use of the product on any power medium other than compressed air or nitrogen may establish

a potential hazard.

Pneumatic Hookup

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 8: Travel and Torque Limits

Section 8: Travel and Torque Limits

8.1 General Information

All Series 2000LP pneumatic actuators are provided with 3-way pneumatic travel limit valves

(LVO and LVC). They are activated at each end of stroke to neutralize the control and stop the

actuator in the proper position.

See gure 4 for location in control housing.

Series 2000LP actuators are also provided with 3-way pneumatic torque limit valves (TVO and

TVC). They are activated when an over-torque condition is detected in either the opening or

closing direction and will neutralize the control in order to prevent valve damage. They may

also be set to provide the correct amount of torque for torque seated valves.

See gure 4 for location in control housing.

Figure 4

April 2013

LVC LVO

TSC TVC

NOTE:

All position and torque limit valves must be set according to the instructions on the following

pages of this manual after mounting the actuator to the valve.

The control assembly can also be tted with auxiliary pneumatic limit valves for remote

indication or other logic circuits as desired. These valves are mounted on top of the travel limit

valves (LVO - LVC) and are actuated by the same cams as the travel limit valves. Consequently

they cannot be adjusted to operate at any valve position other than full open and full closed

with the travel limits. These valves can be used as 3-way normally closed, 3- way normally open

or selector valves depending on port selection.

TSO

TVO

Travel and Torque Limits

13

Section 8: Travel and Torque Limits

April 2013

Pneumatic valve details:

• Maximum operating pressure rating - 125 psig

• Flow coefcient – 0.1 (20 CFM at 125 psig)

• Port size – 1/8 NPT

• With the roller actuator out (extended), the NO port is Open to Cylinder. This blocks

the NC port on the valve.

• When the roller actuator depressed, the NC port is open to Cylinder and the NO port is

blocked.

NOTE:

Optional electrical contacts are also available as needed. See pages 19 and 20 of this manual

for electrical limit switch information and wiring diagram. It must also be recognized that

auxiliary pneumatic limit valves and electrical limit switches cannot both be supplied on the

same unit.

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

14

Travel and Torque Limits

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 9: Setting Travel Limit Valves

Section 9: Setting Travel Limit Valves

Before setting limits it must be noted that actuators ordered specically for torque-seated valve

applications are assembled at the factory without tubing on the closing side limit valve. The

close side limit valve is physically installed but the tubing bypasses it and runs directly to the

torque limit.

1. Determine full-open valve position

Open the valve completely using the handwheel. Observe the rotational direction

of the adjusting shaft (1) during opening. When the valve is fully open, close several

turns (clockwise) to prevent overtravel.

2. Disengage drive pinion

Push the spring loaded shaft (2) down and rotate it 90° to the captured position. This

disengages the gear drive from the G/L pinion. The shaft (1) will now rotate freely.

3. Rotate adjustment shaft

Observe position of limit valve roller cam for one of two positions.

April 2013

• Position One - if the cam has not actuated the LVO valve, rotate the adjusting

shaft (1) in the same direction noted in step one until the rotating cam

actuates the limit valve.

• Position Two – if the cam has actuated the LVO valve, rotate the adjusting

shaft (1) in the opposite direction until the rotating cam actuates the limit

valve.

Note – Limit valves are actuated when the cam is pointing at the center of the limit

valve roller.

NOTE:

Many turns maybe required to set travel limits. It may be convenient to use a reversible

variable speed drill to rotate the adjusting shafts instead of a screwdriver.

4. Re-engage drive pinion

Rotate the spring-loaded shaft (2) 90°. The shaft will rise when locked in place.

5. Important

Lightly jiggle all adjusting shafts back and forth with a screwdriver to ensure correct

engagement: shafts should not turn when locked in place.

Setting Travel Limit Valves

15

Section 9: Setting Travel Limit Valves

3

1

3

April 2013

6. Determine full-close valve position

Close the valve completely using the handwheel. Observe rotational direction of

adjusting shaft (3) during closing. Once the valve is closed, open it several turns

(counterclockwise) to prevent overtravel.

Repeat steps 2 thru 5 for LVC limit valve.

Figure 5

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

16

Setting Travel Limit Valves

Installation, Operation and Maintenance Manual

Set Opening Value

Operating

Point

Part Number: E7K-400-0413

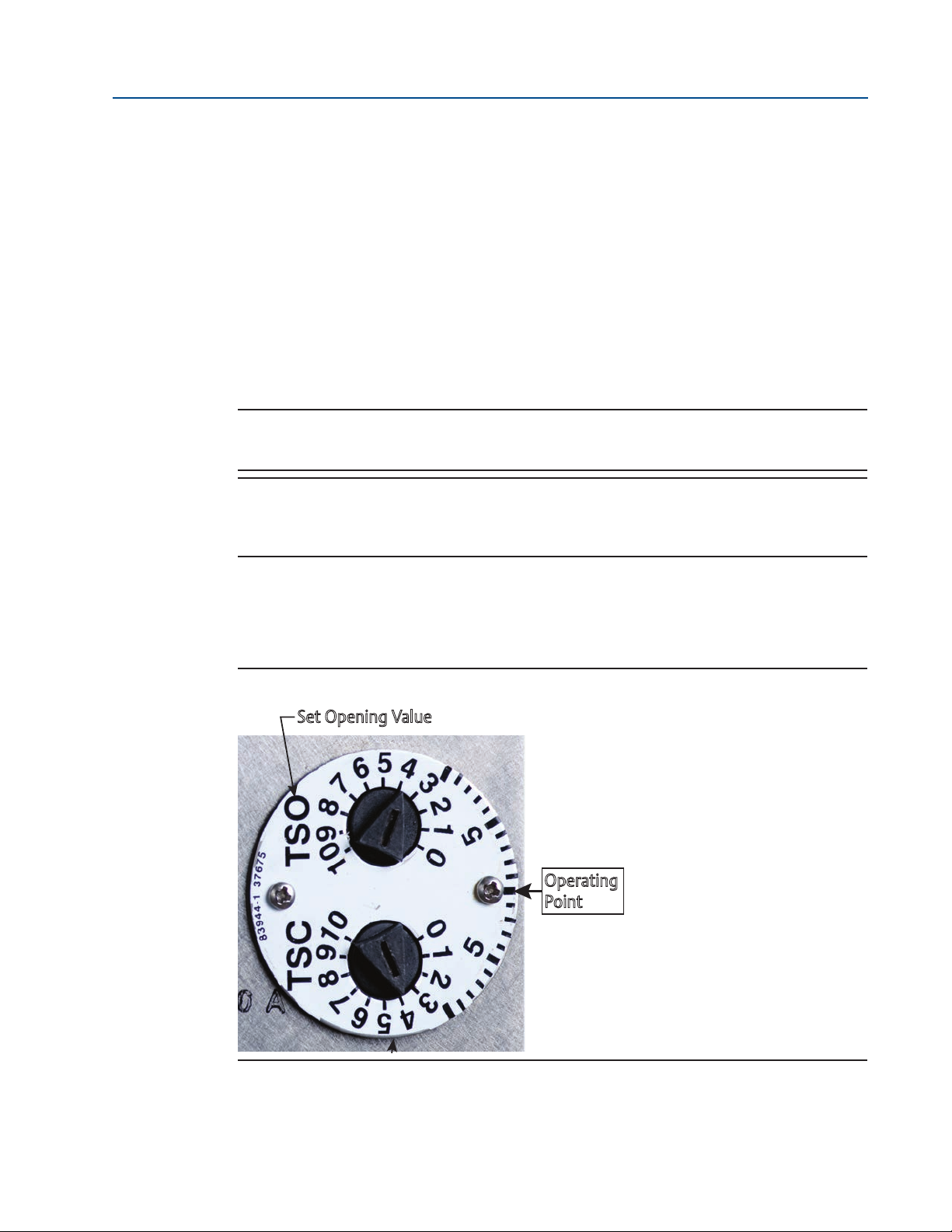

Section 10: Setting Torque Limit Valves

Section 10: Setting Torque Limit Valves

Torque limit valves prevent mechanical overload in the Closed (TVC) and Open (TVO) positions.

The torque limit valves are mounted in a stacked conguration. The top torque limit valve

(TVO) controls the actuator opening torque and the bottom limit valve (TVC) controls the

actuator closing torque.

Refer to the EIM Job Specication Sheet supplied with each actuator to review the customer-

provided valve torque requirement shown at the top of the sheet. The bottom of the

specication sheet shows numerous torque switch dial settings relative to output torque trip

point limits. All actuators are shipped from the factory at minimum torque dial setting unless

otherwise specied by customer.

NOTE:

Closing torque limits for torque-seated valve applications are factory set.

NOTE:

The customer supplied torque values on EIM Job Specication Sheets already includes a safety

factor.

April 2013

10.1 Opening Torque

Using the handwheel, open the valve completely while observing the Torque Dial rotation for a

reference operating point.

Figure 6

Refer to the EIM Job Specication Sheet for additional suggested setpoints. Determine

appropriate setpoint and press down on the TSO dial indicator approximately 1/16” with a at

blade screwdriver and position the arrow for the desired setting. Release to secure in place.

Partially open the valve and reseat with the Handwheel to ensure the set point is accurate.

Setting Torque Limit Valves

17

Section 10: Setting Torque Limit Valves

April 2013

10.2 Closing Torque

Using the handwheel, close the valve completely while observing the Torque Dial rotation for a

reference operating point.

Figure 7

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0913

Set Closing Value

Refer to the EIM Job Specication Sheet for additional suggested setpoints. Determine

appropriate setpoint and press down on the TSC dial indicator approximately 1/16” with a at

blade screwdriver and position the arrow for the desired setting. Release to secure in place.

Partially open the valve and reseat with the Handwheel to ensure the set point is accurate.

18

Setting Torque Limit Valves

Installation, Operation and Maintenance Manual

LSC

LSO

ETS 1

Part Number: E7K-400-0413

Section 11: Limit Switch and Wiring Information

Section 11: Optional Electric Limits

11.1 General Information

Two optional limit switches are available for Series 2000LP pneumatic actuators, one for open

position (LSO) and one for the close position (LSC) – see Figure 8.

The 12 point electrical terminal strip (ETS) for customer connection is mounted on the

backplate - see Figure 8.

Figure 8

April 2013

Limit Switch and Wiring Information

Limit switches LSO and LSC are mounted to a bracket located on top of the limit valves. They

are actuated by the same cam that actuates the limit valves and may be independently

adjusted by loosening the mounting screws (1) and repositioning the switch in the slotted

mounting bracket.

NOTE:

Electrical limit switches cannot be installed if auxiliary pneumatic limit valves are required.

19

Section 11: Limit Switch and Wiring Information

April 2013

Installation, Operation and Maintenance Manual

11.2 Standard Wiring Diagram

Limit switches are supplied with a potted exible connecting cable containing four wire leads;

one blue lead, one black lead, one brown lead and one gray lead. These leads are factory

prewired to the terminal strip (ETS) for each end of travel limit – see Figure 9.

NOTE:

When provided, solenoids will be wired to terminals 9, 10, 11 and 12, as shown in Figure 9.

Table 4. Rated Switching Capacity

AC DC

Resistive Inductive Resistive Inductive

400V 3A 2A

250V 5A 3A 0.4A 0.03A

30V 7A 5A 7A 5A

Part Number: E7K-400-0913

Figure 9

20

NOTE:

Limit switches are always wired to terminals #1 through #8 as shown, even when solenoids are

not provided.

Limit Switch and Wiring Information

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Section 12: Typical Control Package

Section 12: Typical LP Control Package

April 2013

Typical Control Package

21

Section 13: Manual Control Schematic

April 2013

Installation, Operation and Maintenance Manual

Section 13: Typical Control Diagram

Example One - Local Manual Control

Part Number: E7K-400-0913

22

Manual Control Schematic

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

Example Two - Double Acting Electric

Section 13: Manual Control Schematic

April 2013

Manual Control Schematic

23

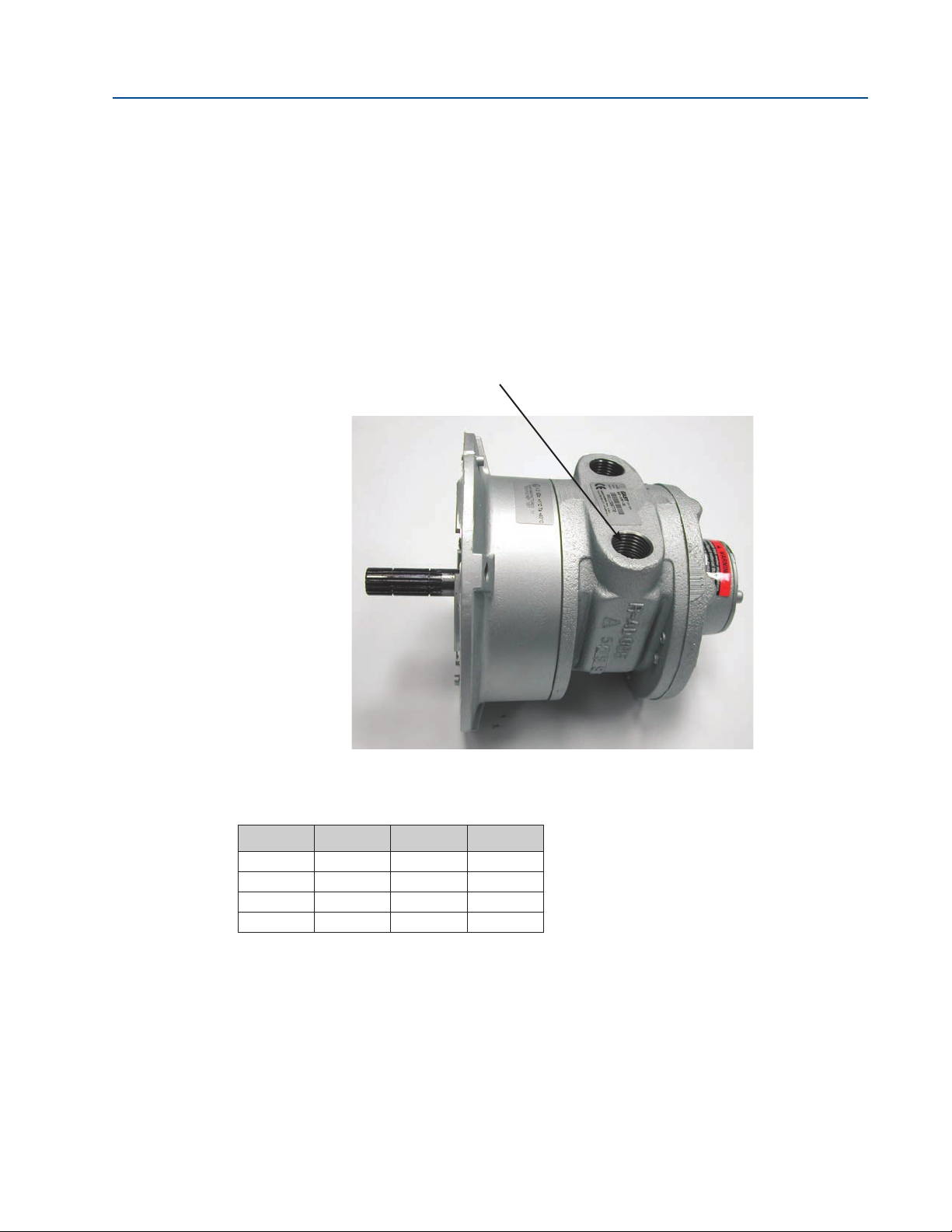

Section 14: Gast Air Motor Information

April 2013

Installation, Operation and Maintenance Manual

Section 14: Gast Pneumatic Motor

The air motor supplied is a precision built rotary vane type. Internal components take up their

own wear & will last approximately 5 to 15 thousand hours of use. This depends on motor

speed, method of oiling, operating air pressure and plant preventative maintenance practices.

MOTOR SIZES

4AM 6AM 8AM 16AM

14.1 Installation

Install a moisture trap and lter in the air line ahead of the actuator’s air motor. For efciency

of output and speed control, use air lines the same size or in the next pipe size larger than the

intake port of the motor.

Part Number: E7K-400-0913

The motors are piped up to work equally well in both directions of operation. The control valve

makes reversing possible (refer to typical control diagram).

When coupling or connecting the motor to a driven member, avoid any end or side thrust on

the motor shaft. Do not hammer on the shaft itself.

14.2 Lubrication

Lubrication is necessary for all internal moving parts and rust prevention. An auto-matic air line

lubricator must be installed in the air line just ahead of the air motor. The lubricator should

be adjusted to feed one drop of oil for every 50 – 75 SCFM of air going through the motor. Oil

specications can be found in the Pneumatic Hookup section of this manual.

Excessive moisture in the air line can cause rust formation in the motor and might also cause ice

to form in the mufer due to expansion of air through the motor.

The moisture problem can be corrected by installing a moisture separator in the line & by

installing an aftercooler between the compressor and air receiver.

14.3 General Information

The air motor is designed to be driven by compressed air. Under no circumstances should it

be driven by uids, particles, solids or any substance mixed with air, particularly combustible

substances likely to cause an explosion.

24

WARNING:

Do not drive with ammable or explosive gases.

WARNING:

Do not allow corrosive gases or particulate material to enter the motor. Water vapor, oil-based

contaminants, or other liquids must be ltered out.

Gast Air Motor Information

Installation, Operation and Maintenance Manual

Part Number: E7K-400-0413

14.4 Servicing

If the motor is sluggish or inefcient, try ushing with an approved solvent:

• To ush, disconnect air line and mufer, add several teaspoons or spray solvent directly

into the motor.

• Rotate the shaft by hand in both directions for a few minutes, reconnect the air line

and slowly apply pressure until there is no trace of solvent in exhaust air.

• Flush unit in a well ventilated area.

• Re-lubricate the motor with a squirt of oil in the chamber.

Section 14: Gast Air Motor Information

April 2013

Table 5. Air Motor Consumption (SCFM)

Gast Air Motor Information

8AM SHOWN ABOVE

Motor 60 psi 80 psi 100 psi

4AM 40 50 62

6AM 70 90 110

8AM 95 120 145

16AM 135 175 220

25

Section 15: Troubleshooting

April 2013

Installation, Operation and Maintenance Manual

Section 15: Troubleshooting

SYMPTOM PROBABLE CAUSE CORRECTION

No power to actuator Check Air Supply

MOTOR WILL NOT RUN

HANDWHEEL HARD TO TURN

VALVE ONLY OPENS OR CLOSES

PARTIALLY WITH MOTOR

TORQUE VALUE IS CORRECTLY SET, BUT

ACTUATOR TORQUES OUT IN

MID-TRAVEL

HANDWHEEL WILL NOT OPERATE VALVE

MOTOR RUNS BUT WILL NOT OPERATE

THE VALVE

MOISTURE IN CONTROL ENCLOSURE

GREASE [OIL] IN CONTROL ENCLOSURE

Low Air Pressure – Filter is clogged in

power or control circuit or

Motor Vanes are Worn Check worn motor vanes

Valve stem improperly lubricated Lubricate with grease

Actuator lubrication has broken down

Valve Packing Gland too tight Loosen packing gland nuts

Drive Sleeve Bearing Failure Replace bearing

Jammed Valve Refer to Valve Maintenance

Torque Setting too Low Check setting & recalibrate

Limit Improperly Set Check actuation & reset

Damaged or bent valve stem Refer to Valve Maintenance

Valve Packing too Tight Refer to Valve Maintenance

Jammed Valve (obstruction in line) Refer to Valve Maintenance

Handwheel shaft bearing assembly

malfunction

Sheared gear key or stripped gearing Replace

P/S shifter in wrong position or malfunc-

tioning

Broken Handwheel shaft Repair or replace

Broken valve stem or stripped stem nut Replace as required

Motor Bearing assembly malfunction Repair/Replace

Sheared gear key [fastener, pin] Replace

Stripped gearing Replace

Broken valve stem or stripped stem nut Repair/Replace

Leakage through conduit entry Tighten all conduit plugs

Enclosure is not correctly sealed Inspect & replace o-ring

Pressure relief tting not installed Install pressure relief tting

Bad Torque Limit or Gear Limit assembly Replace assembly

Bad Torque Limit or Gear Limit seal Replace seal

Part Number: E7K-400-0913

Clean or replace lter

Clean out old grease and replace with

new

Repair or replace

Shift into proper position

Replace parts as required

26

Troubleshooting

Contact Us: Emerson Process Management, Valve Automation facilities at your nearest location:

NORTH & SOUTH AMERICA

13840 Pike Road

Missouri City, Texas 77489 USA

T +1 800 679 1561 (Toll Free USA)

T +1 281 499 1561

F +1 281 499 8445

info: missouricity@emerson.com

MIDDLE EAST & AFRICA

P. O. Box 17033

Dubai

United Arab Emirates

T +971 4 811 8100

F +971 4 886 5465

P. O. Box 105958

EUROPE

Asveldweg 11

7556 BR Hengelo (O)

The Netherlands

T +31 74 256 1010

F +31 74 291 0938

Via Montello 71/73

20038 Seregno (Milan)

Italy

T +39 0362 2285 207

F +39 0362 2436 55

ASIA PACIFIC

No. 9 Gul Road

#01-02 Singapore 629361

T +65 6501 4600

F +65 6268 0028

1277 Xin Jin Qiao Road

Jin Qiao Export Processing Zone

Shanghai 201206

P.R.China

T +86 21 2892 9000

F +86 21 2892 9001

Please visit our web site for up to date product data.

www.EmersonProcess.com/EIM.

©2013 Emerson Process Management. All Rights Reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Brand name is a mark of one of the Emerson Process Management

family of companies. All other marks are the property of their respective owners.

The contents of this publication are presented for information purposes only, and while effort has been made to ensure their accuracy, they

are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or

applicability. All sales are governed by our terms and conditions, which are available on

Loading...

Loading...