EIM HQ Series, HQ-200, HQ-015, HQ-120, HQ-300 Installation & Maintenance Manual

HQ Series ¼ Turn Actuator

HQ-015 thru HQ-300

IInnssttaallllaattiioonn && MMaaiinntteennaannccee MMaannuuaall

HQ Series I&M Manual HQ-400-1005 1

Table of Contents:

General 1.0

Actuator Mounting 2.0

External Construction 3.0

Wiring Diagrams 4.0

Power Requirements 5.0

Duty Cycle

Manual Override

6.0

7.0

Mechanical Travel Stops 8.0

Electrical Connection 9.0

Limit Switch Setting Instructions 10.0

Torque Switch Adjustment 11.0

Reverse Acting (Counter Clockwise to close) 12.0

Lubrication 13.0

MDPI (Mechanical Dial Position Indicator) 14.0

Maintenance 15.0

Storage 16.0

Mounting Base Details 18.0

Drive Bushing Details

19.0

Trouble Shooting 20.0

Standard Specifications

EIM Office Locations

HQ Series I&M Manual HQ-400-1005 2

21.0

22.0

1.0 General

HQ series electric actuators are design to provide reliable and efficient operation of 90 degree quarter turn

valves, dampers, etc

Pre-Installation Inspection

.

Warning: Use caution when working in, with, or around valves and

actuators. High pressures, forces, voltages and flammable media can be

present

Warning: Failure to follow instructions for proper electrical wiring, storage,

set-up and maintenance may cause serious injury, damage equipment, or

void warranty.

Verify the actuator nameplate to insure correct model number, torque, operating speed, voltage

and enclosure type before installation or use.

It is important to verify that the output torque of the actuator is appropriate for the torque

requirements of the valve and that the actuator duty cycle is appropriate of the intended application

2.0 Actuator Mounting

Do not lift the actuator by the handwheel

The actuator may be mounted in any position

The HQ- Series actuators are supplied with a female drive output. ISO5211. Bolt patterns are provided for

actuator mounting. The actuator drive bush is removable for ease of machining.

It is mandatory that the actuator be firmly secured to a sturdy mounting bracket or directly mounted to the

valve’s ISO mounting pad. High tensile bolts or studs with spring locking washers must be used.

The valve output shaft must be in line with the actuator output drive to avoid side-loading the shaft.

To prevent backlash, no flexibility in the mounting bracket or mounting should be allowed.

HQ Series I&M Manual HQ-400-1005 3

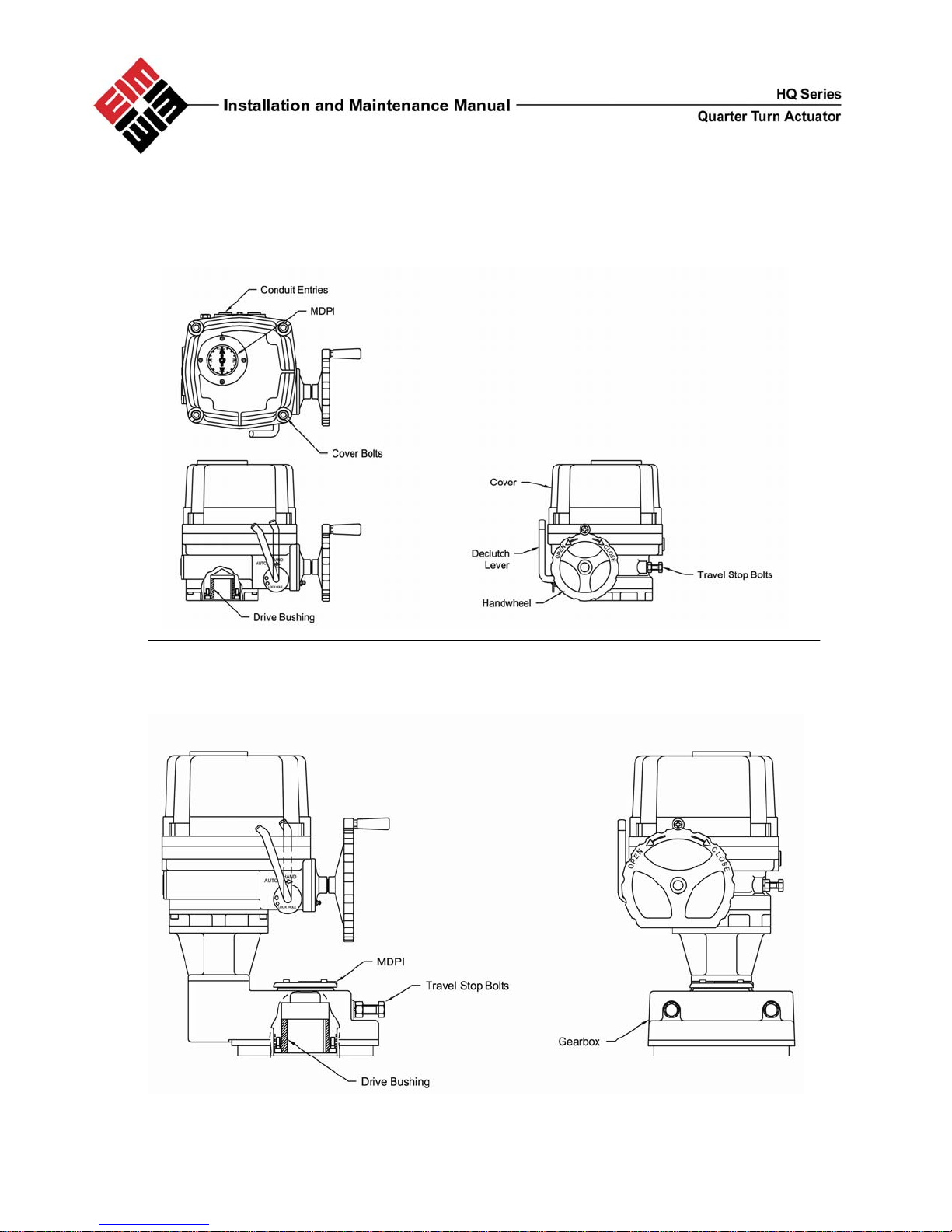

3.0 External Construction

HQ-008 ~ HQ-120

HQ-200 ~ HQ-300

HQ Series I&M Manual HQ-400-1005 4

Loading...

Loading...