EIM Guide: Network Master User Guide for Allen Bradley Series SLC-500 Programmable Controller Manuals & Guides

Page 1

User’s Guide

AB1746-C

Network Master

(Version 5.21)

For

Allen-Bradley Series SLC-500 Programmable Controllers

(Date: 2004-11-18)

Page 2

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

User’s Guide

Controlinc Network Master … AB1746-C (Version 5.21)

For

Allen-Bradley Series SLC-500 Programmable Controllers

Table of Contents

0. Quick Start Information...............................................................................1

1. Introduction...................................................................................................2

1.1. Overview of 1746-C System ................................................................................... 2

1.2. Overview of Changes in Version 5.21 ................................................................... 4

1.3. Reference Manuals ................................................................................................. 5

1.4. EIM Equipment Compatibility .............................................................................6

1.5. Firmware ................................................................................................................. 6

2. 1746-C Hardware..........................................................................................7

2.1. Hardware Setup ...................................................................................................... 7

2.2. LED Utilization ....................................................................................................... 8

2.2.1. Green (PRT1 & PRT2) and Yellow (LED1 & LED2) LED Usage ........................... 8

2.2.2. Red “BA LOW” LED Usage .................................................................................10

3. Network Setup and Connecting to the NIU ..............................................11

3.1. Field Connections at the Actuator....................................................................... 13

3.1.1. Step 1. Plan the Network Topology ................................................................... 13

3.1.2. Step 2. Select Network Cable............................................................................13

3.1.3. Step 3. Route Cable away from Electrical Interference ..................................... 14

3.1.4. Step 4. Observe Polarity and Network Grounding ............................................. 14

3.1.5. Step 5. Wire Preparation and Connections........................................................ 14

3.1.6. Step 6. Test Network ......................................................................................... 14

3.2. Field Network Cable Connection to the NIU ..................................................... 15

3.3. Cable Connection Between the NIU and the Network Master ........................ 15

4. 1746-C General Theory of Operation .......................................................16

4.1. Operational Overview ..........................................................................................16

4.1.1. Diagram Describing Relationship Between Process Time Slices ........................ 16

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page i

Page 3

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.1.2. Diagram Describing Network Scanning & Actuator Writing Logic........................17

4.1.3. Diagram Demonstrating Adding Additional Valves in Valve Scan Time-Slice...... 18

4.1.4. Diagram Describing Relationship Between Scan Period & Diagnostic Scan....... 19

4.1.5. 1746-C System Operations at Power Up.............................................................20

4.2. Network Interface (Scan) Time-Slice (1746-C ↔ Network Communication) 21

4.2.1. Operation: Network Scanning to Gather Valve Actuator Data ............................ 21

4.2.2. Operation: The Network Communication Diagnostic Scan................................. 22

4.3. PLC Interface Time-Slice (1746-C ↔ PLC Communication)..........................24

4.3.1. Operation: PLC (Write Data Tables To) or (Read Tables From) the 1746-C...... 26

4.3.2. Operation: PLC Commands to Write Data to the Actuators................................ 29

4.3.3. RLL Example … Manually Send New Table … Auto Read Response ................ 31

5. System Tables..............................................................................................33

5.1. Table Arrangement............................................................................................... 35

5.2. Standard Header Format (All Tables) … Words [0 3] ................................37

5.2.1. Word [0]: Table ID............................................................................................. 37

5.2.2. Word [1]: Read / Write Command Indicator ......................................................37

5.2.3. Word [2]: Reserved / Firmware ID..................................................................... 37

5.2.4. Word [3]: Emergency Shut Down (ESD) Command Word & Indication ............ 38

5.3. Table [0] … System Information Table.............................................................. 39

5.3.1. Table [0] Overview............................................................................................... 39

5.3.2. Table [0] Configuration Words … Words [4 17]................................................ 42

5.3.3. Table [0] Run-Time Information Words … Words [47 63] ................................47

5.3.4. Table [0] … RSLOGIX-500 Examples ................................................................. 48

5.3.4.1. Example RSLOGIX-500 Screen: ..........................................................................48

5.3.4.2. Table [0] … The Configuration Values (RSLOGIX-500). .....................................49

5.3.4.3. Table [0] … The Configuration Values – Writing Table [0] (RSLOGIX-500) ........50

5.3.4.4. Table [0] … The Run-Time Feedback Values From 1746-C (RSLOGIX-500).....51

5.4. Tables [1 20] … Actuator Information Tables..............................................52

5.4.1. Table [1]: Communication Error Status............................................................... 52

5.4.2. Table [2]: Actuator Operational Status................................................................ 54

5.4.3. Table [3]: Discrete Control Mode (Open/Close/Stop) .........................................56

5.4.4. Table [4]: Valve Position Indication … 0 – 100.0% ............................................. 58

5.4.5. Table [5]: Valve Position Setpoint … 0 – 4095 ...................................................59

5.4.6. Tables [6 & 7]: User Analog Inputs #1 & 2.......................................................... 61

5.4.7. Table [8]: Analog Output #1................................................................................62

5.4.8. Tables [9 & 10]: Digital Input Accumulators (Totalizers) #1 & 2..........................64

5.4.9. Table [11]: Valve Position Indication … 0 – 4095 ............................................... 66

5.4.10. Table [12]: Discrete Input Statuses................................................................... 67

5.4.11. Table [13]: Solid State Relay (SSR) Configuration Table .................................69

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page ii

Page 4

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

5.4.12. Table [14]: Additional Register Being Polled From Entire Network...................71

5.4.13. Table [15]: Additional Block of Registers Being Polled From 1 Actuator........... 73

5.4.14. Tables [16 & 17]: Monitor & Control Discrete Digital Outputs ........................... 76

5.4.15. Table [18]: Actuator System Type ID................................................................ 81

5.4.16. Table [19]: Actuator Firmware Version ID.........................................................83

5.4.17. Table [20]: Modbus Exception Message Response.......................................... 84

5.4.18. Tables [21-24]: TEC2000 Status Inputs............................................................ 86

6. Application Notes ........................................................................................88

6.1. App Note: Performance Tuning ......................................................................... 88

6.1.1. General Practices to Ensure Better Performance................................................88

6.1.2. Reading Run-Time Information from Table [0]..................................................... 88

6.1.3. Loading Table [0] with Configuration Information ................................................89

6.1.4. Behavior if a Delay in Loading Table [0] Configuration Information ..................... 90

6.1.5. Using the “Scan Period” Value ............................................................................91

6.2. App Note: 1746-C Operation – Additional Detailed Information .................. 92

6.2.1. Scan Operation: Determining & Exiting “Network Down” Condition.................... 92

6.2.2. Detailed Description of 1746-C Operation ........................................................... 93

6.2.3. Time Allocated Process Control (Allocated Time Slices)..................................... 94

6.2.4. Preferred Communication Port Operation............................................................ 96

6.2.5. Communication Failure Indications (Low-Level & High-Level)............................. 97

6.2.6. Bringing Units On-Line After a Power Cycle ...................................................... 100

6.2.7. Toggling the Preferred Port to Assist Diagnostics ............................................. 101

6.3. App Note: For Diagnostics - Know the Physical Network Wiring ...............102

6.4. App Note: Memory Maps ................................................................................. 103

6.4.1. Specific Holding Registers Referenced by the Network Master......................... 103

6.4.2. Specific Coils & Inputs Referenced by the Network Master............................... 104

6.4.3. 320A Memory Map … Table for Coils & Inputs (Version 2.0) ............................105

6.4.4. 320A Memory Map … Addressable Holding Registers (Version 2.0) ................ 106

6.4.5. 320B Memory Map … Table for Coils & Inputs.................................................. 108

6.4.6. 320B Memory Map … Addressable Holding Registers...................................... 109

6.4.7. TEC2000 Memory Map … Table for Coils & Inputs........................................... 111

6.4.8. TEC2000 Memory Map … Table for Holding Registers..................................... 112

6.5. App Note: Modbus Message Formats..............................................................117

6.5.1. Modbus RTU Functions (Command Codes) Implemented ................................ 117

6.5.2. Modbus Function (Command) Code Descriptions ............................................. 118

6.5.2.1. Modbus Function Code 01 … Read Coil Status .................................................118

6.5.2.2. Modbus Function Code 03 … Read Holding Register........................................119

6.5.2.3. Modbus Function Code 05 … Set (Force) Single Coil........................................120

6.5.2.4. Modbus Function Code 06 … Set Single Register .............................................121

6.5.2.5. Modbus Function Code 15 (0x0F) … Set (Force) Multiple Coils ........................122

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page iii

Page 5

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

6.5.3. Modbus Exception Messages Supported .......................................................... 123

6.6. App Note: Install the 1746-C Network Master Firmware............................. 124

6.6.1. Configure the Module for a Firmware Upload .................................................... 124

6.6.2. Upload the 1746-C Firmware............................................................................. 125

6.6.3. Reset the 1746-C Module for Normal Operations.............................................. 126

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page iv

Page 6

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

0. Quick Start Information

1. As a minimum, you should have access to the following reference documents:

• This manual (1746-C User’s Guide)

• Allen-Bradley SLC-500 BASIC User's Manual (1746-BAS & 1746-BAS-T)

Publication No. 1746-UM004A-US-P 2000

• EIM Controlinc 320A Quick Startup Guide, Rev. F or later

• EIM Controlinc 320B Quick Startup Guide, Rev. A or later

2. Refer to Section 2 of this manual on how the jumpers should be set on the BASIC module.

3. The 1746-C module comes from EIM pre-programmed with the network master program in it. However, if

for some reason the module needs to be flashed again (ex: a field upgrade) then refer to Section 5 on

installing the firmware in the module.

Note: Remember, you will need to connect a serial cable between the 1746-C and the computer. The

correct cable is a Null Modem Cable

the module) and the serial communications port on the computer used for the upload.

4. Ensure the PLC rack power is turned off.

Install the module in the correct slot in the PLC rack. Connect all cables and power the system up.

5. The PLC-RLL will start interfacing with the 1746-C after the 1746-C performs initial scans of the network

on power up.

NOTES: To ensure optimal performance, some things the PLC should do …

1. Ensure table [0] is set correctly and repeated in a timely manner. Allow for frequent table [0] read backs.

2. Restrict the rate of data writes to the actuators … only write as fast as required to adequately control the

valve.

(cuts down on the interruptions to scanning the network … gathering data)

3. Expedite responses to M1 transfer requests made by the 1746-C. Delaying them can slow 1746-C

operations.

4. Only activate writing to or reading from tables if actually in use (or when needed).

(ex: do not write to the analog output table if analog outputs are not used)

(ex: do not read totalizer data if its not being used)

(ex: only poll for “static” [non-changing] data one time and stop)

(prevents unnecessary delays to gathering the more important data from the network)

Remember:

The 1746-C uses explicit read/write commanding of the tables such that if word [1] in any table is

zero (0) then it is a table read request by the PLC. Otherwise, the command is a table write

command.

connected between the PRT1 port (top DB9 connector on

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 1

Page 7

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

1. Introduction

1.1. Overview of 1746-C System

This document is intended for end users as a Guide in applying an EIM

AB 1746-C Network Master.

The software that enables network operation is called a communication

driver. It is used in conjunction with an Allen-Bradley 1746-BAS

module thereby creating the 1746-C network master module. The

1746-C allows an AB SLC-500 controller to acquire data from and send

information to an EIM Controlinc Actuator Network.

GENERAL SYSTEM PURPOSE:

The EIM 1746-C network master serves as a data concentrator for

applications that use an AB SLC-500 Programmable Logic Controller

(PLC). The 1746-C module must be located in a slot in the local

chassis (it cannot be mounted in a chassis that is remote from the SLC CPU).

In general, the network master off-loads

network communication and management

tasks from the actual controlling equipment.

The main function of the 1746-C is to provide

the interface between a PLC and its network of

valve actuators. Acting as a Host, the PLC

controls the network by sending data to the

1746-C for routing to a particular actuator.

The 1746-C network master polls the individual

actuators for information and makes it available

to the PLC when requested.

A typical ring topology network and network

master are illustrated in Figure 1. The 1746-C

module serves as a master within this Modbus

(Modbus RTU) master/slave network. The

module will manage network operation by

keeping an orderly cycle of data transfers

between itself and each slave (valve actuator).

SLC-500 with

1746-C installed

1746-C

Figure 1

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 2

Page 8

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

The 1746-C master will handle network communication, error detection, alarming, and network

recovery.

Other features include:

• Reporting of inaccessible actuators

• Reporting of network faults

• Emergency shutdown broadcasting

• Minimal Interfacing with the Relay Ladder Logic (RLL) program in the PLC CPU module

Each 1746-C module can support a single network of up to 60 valve actuators. Multiple modules can

be installed in an SLC-500 system rack to provide support for multiple networks (up to 60 actuators

each).

Note 1: It is important to note that the 1746-C Network Master may be used in any slot of the 1746

rack, not just slot 1 next to the SLC-500 CPU.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 3

Page 9

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

1.2. Overview of Changes in Version 5.21

For the 1746-C system, there is no previous version of the product to reflect functional changes to.

However, any later releases of this document for this version of the product (5.21) are to only correct

entries in this document … primarily grammatical or “typos” that are discovered in the future. Major

ideas will be documented with a separate “line entry”.

Major document changes:

1. This document: 2004-11-18

Previous document: 2004-08-17

Major Change: Memory Maps adjusted.

2. New document: 2004-08-17

Previous document: 2004-08-06

Major Changes: Memory Maps adjusted and this section added.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 4

Page 10

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

1.3. Reference Manuals

• Allen-Bradley SLC-500 BASIC User's Manual (1746-BAS & 1746-BAS-T)

Publication No. 1746-UM004A-US-P 2000

This manual is required for installing the module and for proper uploading of this driver into the

hardware.

• EIM … Controlinc 320A Quick Startup Guide, Rev. F or later

Publication No. ECL-4004-0102

This manual is used for specific information on the Controlinc 320A Controller card located in

the valve actuator. This includes networking, setup and available options.

• EIM … Controlinc 320B Quick Startup Guide

Publication No. ECL-4005-0404

This manual is used for specific information on the Controlinc 320B Controller card located in

the valve actuator. This includes networking, setup and available options.

• EIM … TEC2000 “Document … TBD”

Publication No. ?????????

At the time of this printing, this TEC2000 publication had not been made available.

• Other Allen-Bradley manuals specific to the SLC-500 being applied. These may be required to

implement the necessary Relay Ladder Logic (RLL) for application of the driver. For instance,

this may include:

o Allen Bradley SLC-500 Instruction Set Reference,

Publication 1747-RM001D-EN-P (November-2003)

This reference includes information in Appendix E on the M0 & M1 File Data Transfer

handling.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 5

Page 11

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

1.4. EIM Equipment Compatibility

The 1746-C is compatible with the following EIM equipment:

• 320A … version 1.17 and later.

• 320B … all

• TEC2000 … all

Other points:

• The 1746-C derives the system type of each actuator during the diagnostic scan and stores the

results in table [18].

• The 1746-C derives the firmware Version ID for the 320A & 320B systems during the diagnostic

scan and stores the results in table [19].

• Since the TEC2000 system has several micro-controllers with firmware, a special request must

be made to them to derive the firmware version ID for each controller in the unit.

• The SSR bit is only checked and set on 320A actuators.

Note: For maximum compatibility with the TEC2000 systems, it is recommended that you enable

monitoring the TEC2000 Status Inputs (tables [21-24]). This way, you can ensure you have all

critical status information for any TEC2000 system on the network. For more information,

refer to the section on Tables [21-24].

Note: This document references the addressable memory ranges (“Memory Maps”) of several EIM

actuators (ex: M2CP–320B, TEC2000). This is only for the reader’s convenience. The

specific details in the memory maps are only correct as of the date this manual was published.

Therefore, to ensure you have the most current memory information, please refer to the

technical information for that particular actuator.

1.5. Firmware

The firmware is a “driver program” which is a compiled application program (not an interpreted one). It

is loaded and stored in the module's 32K EEPROM (A-B P/N 1747-M2). The user is required to

provide configuration information from the PLC Relay Ladder Logic (RLL) for each specific application

(the RLL must load table [0] with appropriate configuration information).

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 6

Page 12

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

2. 1746-C Hardware

2.1. Hardware Setup

Refer to Chapter 1 of the 1746-BAS manual. The following hardware jumper settings are required. If the

1746-BAS module was supplied by EIM, jumpers are already set and no other settings are required.

For the 1746-C to run, the jumper

settings should be set as follows:

• JW1 - enable RS232

• JW2 - enable RS232

• JW3 - M2 EEPROM

• JW4 - PRT1 = ASCII

- PRT2 = ASCII

- DH485 = PGM

This jumper configuration is

normally performed by EIM before

shipping the 1746-C.

JW1

JW2

JW1

JW3

JW4

JW2

JW4

JW3

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 7

Page 13

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

2.2. LED Utilization

2.2.1. Green (PRT1 & PRT2) and Yellow (LED1 & LED2) LED Usage

There are 2 “Yellow” LED lights on the front of the 1746-C module

• LED1.

• LED2.

There are currently 3 general functions operating these LEDs:

1. After CPU restart, both LED1 & LED2 are ON until the 1746-C finishes initialization and starts

polling the network.

2. After initialization, LED1 is used as a “starting a new scan” indicator by toggling on/off at the

start of each scan. Ex: Starting scan 1: LED1 is ON.

Starting scan 2: LED1 toggles to the OFF state.

Starting scan 3: LED1 toggles to the ON state.

3. After initialization, LED2 is used as an “entire network is down” indicator. If the 1746-C ever

detects zero (0) actuators on the network, it will turn LED2 on and immediately enter a

diagnostic scan and remain there until an actuator is found to be on-line and communicating.

There are 2 communication LED lights (green LED lights) on the 1746-C module:

• PRT1: Port 1 Transmit … lights up when transmissions are going out port 1.

• PRT2: Port 2 Transmit … lights up when transmissions are going out port 2.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 8

Page 14

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

PRT1 & PRT2 (Green) LED App Note: Green LED Lights & System Initialization with Table [0]

After startup, if table [0] is not initialized shortly after the 1746-C finishes its initial diagnostic

scan, the program starts running with factory default settings. This means that unless the

network actually has 60 actuators on it, the 1746-C will believe the “other valves” are just off

line.

Plus, an operator can often determine when the PLC-RLL actually writes to table [0] (configures

the system) by watching the green LED lights.

For instance …

• On a network that actually has 25 valves on it (addressed 1-25), until table [0] – word [4]

gets initialized with 25, the program thinks that there are still supposed to be 60

actuators on the network … only the last 35 happen to be “off line”.

• Then (if viewing the green LED lights) when a scan starts (LED1 changes state), you will

see the green LEDs “flash” while the 1746-C communicates with valves 1-25.

Then you will observe a “dead space” in time when the program is trying to determine if

any of the final 35 valves “it believes to be connected” are available (

are because the network only has 25 valves on it

).

and of course none

• As soon as a new scan starts (all “60” valves have been checked and ready to scan the

network again … LED1 changes state) then the green LEDs will start flickering again

while the 1746-C communicates with valves 1-25.

Then the “dead space” time will be observed again.

This sequence will repeat until the PLC program initializes the 1746-C by writing to table

[0].

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 9

Page 15

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

2.2.2. Red “BA LOW” LED Usage

The red “BA LOW” LED indicates low battery status. The purpose of the battery in the BASIC module

is to back up portions of RAM and other resources. For guaranteed long-term repeatability of

operations, the EIM 1746-C program does not utilize any of these resources. Therefore, it doesn’t

matter what state the battery is in (installed and fully charged, inline and dead or totally removed from

the unit), the EIM network master program will always run the same.

This also means that a new 1746-C module might run with the BA LOW LED off for a while and then

turn on when the battery dies. This is normal and has NO effect on the system. However, if for

some reason you want to replace the battery, you can order it directly from Allen-Bradley.

“BA LOW”

LED

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 10

Page 16

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

3. Network Setup and Connecting to the NIU

In general, the EIM NIU (“Network Interface Unit”) is a “beefed up” and configurable RS232

converter.

The ports on the 1746-C, Port1 (PRT1) and

Port 2 (PRT2), are configured for serial

communication using RS-232.

SLC-500 with

1746-C installed

1746-C

The network communication parameters are

pre-configured and fixed at 9600 baud – 8 bit

– no parity – 1 stop bit.

The NIU isolates and protects the 1746-C

and the PLC from the network and is

powered by its own 120 AC circuit. Its

primary function is to convert RS232

communications to RS485 communications.

The RS485 connection then communicates

to a ring or ring network.

Note: To help with isolation, there are two

(2) entirely separate boards in the NIU.

However, because of this, there are two (2)

120 VAC connections to the NIU. Ensure

Figure 1

that both are connected (you can jumper the

circuits together).

The Controlinc network is connected to the 1746-C module via the Network Interface Unit (NIU). It

doesn’t matter if you connect:

• Port 2 (PRT2) (bottom DB9 connector): connects to the NIU at the port labeled “HOST A”.

• Port 1 (PRT1) (top DB9 connector): connects to the NIU at the port labeled “HOST B”.

or

• Port 1 (PRT1) (top DB9 connector): connects to the NIU at the port labeled “HOST A”.

• Port 2 (PRT2) (bottom DB9 connector): connects to the NIU at the port labeled “HOST B”.

However, it is recommended that you remain consistent.

NOTE: You can always connect a PC to the network at the NIU if you …

• Disconnect the cable connecting the 1746-C and NIU.

• Connect the PC using a (serial cable + NULL modem) to the DB9 connector on the NIU.

RS485

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 11

Page 17

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

A typical E>Net network connection format is in a ring …

• It starts from Port 1 (PRT1) (the top DB9 connector) on the 1746-C as RS232 and connects to

the NIU at the port labeled “Host A”.

• It exits the NIU at the port labeled “Port A” as an RS485 circuit and proceeds to the first valve

actuator, normally addressed as #1, in port A.

• It exits the actuator from Port B and proceeds to the port A next actuator (address #2) and on

until the last actuator on the network is connected.

• The RS485 network then exits port B on the last actuator returns to the NIU at the port labeled

“Port B”.

• The network connection is then transformed back to an RS232 format and exits the NIU via the

port labeled “Host B”

• It connects to the 1746-C via port2 (PRT2) (the bottom DB9 connector).

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 12

Page 18

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

3.1. Field Connections at the Actuator

Communication connections and wiring are important for the network and the master.

(

3.1.1. Step 1. Plan the Network Topology

Before connecting actuators, the entire network layout should be planned. Topologies may be bus,

redundant bus, E>Net, redundant E>Net, E>Net ring, and redundant E>Net rings. Planning should

include node addressing, wire routing, terminations, and grounding.

3.1.2. Step 2. Select Network Cable

Ensure correct cable is being used.

The following are acceptable Belden or equivalent cables for most network applications.

The following information was primarily derived from the Controlinc Quick Startup Guide)

• Networks require twisted pair and shielded cable with characteristic impedance between 50 and

120 Ohms.

• Capacitance between conductors must be less that 30 pF/Ft (98 pF/M); 10-15pF/Ft is ideal.

• Shielding maybe aluminum foil with drain wire.

• If cable has multiple pairs, then individual pair shielding is required.

• Only cables with stranded conductors are recommended.

• Insulating and outer jacket materials must be selected for the application environment.

AWG 20 18 16 14

Beldon # 8762 8760 8719 8720

Rating 12.8 Pf/fT 12.8 Pf/fT 12.8 Pf/fT 12.8 Pf/fT

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 13

Page 19

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

3.1.3. Step 3. Route Cable away from Electrical Interference

Network cables should enter the electrical enclosures and the

bottom or lowest point (on 320A systems, this is near the

transformer end and normally in a counter clockwise direction

to the topside of the TBM). Never install network cable in the

same conduit with power conductors. Never route the network

cable through the high voltage contactor area. On 320A

systems, the cable should never lie across the TBM or hinder

the protective cover of the TBM. Always use the shortest

distance and keep access cable to a minimum.

See Figure 3-1

3.1.4. Step 4. Observe Polarity and Network

Grounding

Each network connection is polarized + and - on wiring

diagrams. Always use consistency in wiring and the use of

wire colors to track polarity. The cable shield (or “drain wire”)

must be connected to the designated “shield” terminal at each

port of each actuator. The shield must be connected to earth

ground at only one point. Some networks require a jumper

between the shield connections on ports A & B of the actuator

to carry the shielding through the network. The shield

connection of each actuator is isolated from earth ground.

Do not allow the shield to touch other circuits or the metal enclosure.

Figure 3-1

Correct termination of the Network

to a Controlinc 320A Actuator

3.1.5. Step 5. Wire Preparation and Connections

Screw terminal connections on the TBM and in the TEC2000 terminal chamber have wire clamps,

which will accept conductors with out terminals. Wire terminals may be applied if desired but are not

required. Strip conductor insulation back 3/8” when connecting directly to the TBM screw terminals. Do

not allow wire clippings to fall on the TBM or into the enclosure.

Protect the conductors and shield to prevent them from contacting any other circuits or earth ground.

Use plastic electrical tape or heat shrink tubing to prevent bare conductors from contacting other

circuits or earth ground.

See Figure 3-1

3.1.6. Step 6. Test Network

Use EIM’s Configuration and Control Utility (CCU) to test the network prior to connecting to the host or

network master. The CCU is a Windows application, which will run on a laptop. Use a RS232 to RS485

adapter or EIM’s Network Interface Unit (NIU) to connect the laptop to the network. Test each actuator,

one at a time, to determine that all network connections are good and each actuator is functional via the

network in remote.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 14

Page 20

W

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

3.2. Field Network Cable Connection to the NIU

Refer to Figure 3-2 for terminals on the EIM

Network Interface Unit (NIU). The NIU is a dual port

RS232 to RS485 converter specifically designed for

ring networks.

Connect the twisted shielded pair cable of the field

network to NIU Terminals 1 (-), 2 (Shield), 3 (+) of

J1 of Port A.

The network shield must be connected to a good

earth ground at only one shield terminal point on the

NIU.

The network cabling should use recommended

cabling for an RS-485 network able to handle the

distance desired.

There should be little, if any, electrical noise on the

network for the entire length of the network.

Ne twor k

Por t

J1

+

+

Shield

sh

-

-

1

SW1

RXD

TXD

Ground

DB-9 Female

Connector

(1746-C Side)

2

3

5

R S - 2 3 2

R

P

P o r t

2 V A C / D C

1

J3

1

RS232 Cable

J 2

P W R

N I U 8 4 3 2 0

(#37121)

Shield

Figure 3-2

DB-9 Male

Connector

(NIU Side)

Chassis

1

RXD

2

TXD

3

Ground

7

PWR

TxD

RxD

3.3. Cable Connection Between the NIU and the Network Master

Refer to the “

No. 1746-UM004A-US-P 2000”

used for network ports one and two.

Jumpers JW1 & JW2 must be set for RS-232 when connecting with EIM's Network Interface Unit (NIU)

P/N 84320 or a user-supplied modem.

Refer to Figure 3-2 for the pin-out of the DB-9 female connector.

Allen-Bradley SLC-500 BASIC User's Manual (1746-BAS & 1746-BAS-T) Publication

for additional information on the pin-out of the male DB9 connections

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 15

Page 21

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4. 1746-C General Theory of Operation

4.1. Operational Overview

The interface for the PLC with the actuators (through the 1746-C module) is with an array of 25 tables

… 64 words per table with the table number (command) in Word # [0] of each. This is based on the

M0/M1 interface protocol established by Allen-Bradley for the SLC-500 systems.

The 1746-C operates using a “Non-Interruptible Time-Slice Process Allocation

methodology. This means that it must finish executing the process that is executing in its allocated

time-slice before another process can operate. The two processes being scheduled are:

• Scanning the network for data.

• Interfacing with the PLC.

This means that the 1746-C will ignore any new commands from the PLC while scanning the network

(during the network scan time-slice) and no network scanning will take place while processing a

command from the PLC (during the PLC interface time-slice).

” communication

4.1.1. Diagram Describing Relationship Between Process Time Slices

Process time slicing is how the 1746-C divides its time when performing its 2 primary communication

tasks … communicating with the PLC and communicating with the actuator network.

This diagram helps demonstrate the relationship between the two communication processes.

PLC

PLC 1746-C

Communications

(PLC Interface Time Slice)

1746-C

1746-C Actuators on

Network Communications

(Network Scan Time Slice)

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 16

Page 22

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.1.2. Diagram Describing Network Scanning & Actuator Writing Logic

This example demonstrates how a normal scan cycle gets elongated with data writes to the actuators.

The more writes being performed the longer it will take to complete data scans. This is where the

PLC/HMI must make a value decision for the best fit for their application:

• Fast enough repetitive writes to control the system

• Slow enough repetitive to ensure effective feedback to control the system.

Polling

for data

Time to poll 30

actuators for

data … without

any writing to

actuators

Polling

for data

actuators for data …

Performing 3 sets of

interspaced within

the single scan loop

Time to poll 25

data writes

Polling

for data

Polling

for data

Polling data …

“Network Scan

Time-Slice”

Writing

data

Writing data to

the network …

“PLC Interface

Time-Slice”

Writing

data

Writing

data

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 17

Page 23

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.1.3. Diagram Demonstrating Adding Additional Valves in Valve Scan

Time-Slice

This example demonstrates how increasing the additional number of valves to be scanned before

servicing the PLC communication task decreases the total network scan time.

This is where the PLC/HMI must make a value decision for the best fit for their application:

• Increasing the number: Speeds up data collection Lowers PLC control capabilities.

• Decreasing the number: Slows down data collection Increases PLC control capabilities.

Example of scale for time to scan network … different values for Additional valves in scan time slice:

Network size: 8 Network size: 8

Additional valves: 0 Additional valves: 3

(Note the relative time differences are for illustration purposes only … not to any exact scale.)

Poll 1 valve for data

Service PLC cmd

Poll 1 valve for data

Service PLC cmd

Poll 1 valve for data

Service PLC cmd

Poll 1 valve for data

Service PLC cmd

Poll 1 valve for data

Service PLC cmd

Poll 1 valve for data

Service PLC cmd

Poll 1 valve for data

Service PLC cmd

Poll 1 valve for data

Service PLC cmd

Poll 4 valves for data

Service PLC cmd

Poll 4 valves for data

Service PLC cmd

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 18

Page 24

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.1.4. Diagram Describing Relationship Between Scan Period & Diagnostic

Scan

This example demonstrates the relationship between the diagnostic scans, scan periods, the current

scan period, the previous scan period.

This example: a scan period value of 10 and 25 valves on the network. This means that all the valves

on the network will be scanned 10 times before the scan period is over … and before the next

diagnostic scan is performed.

(all 10 network scans of 25

Previous

Scan Period

valves completed)

Diagnostic

scan

Individual

network scans

Diagnostic

scan

Current

Scan Period

(so far, 5 network scans

completed)

Current time History

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 19

Page 25

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.1.5. 1746-C System Operations at Power Up

The 1746-C software boots up on a power up of the 1746-C module. The general sequence is:

1. Illuminate LED1 & LED2 as an indication that the software is initializing itself and the network.

2. Perform basic internal initializations.

3. Perform the initial diagnostic scan of the network and identify all actuators on the network.

4. Finish internal initializations.

5. Turn off LED1 & LED2.

6. Start standard scanning of the network. Initialization is finished. Normal operations

(scanning) have commenced and are allowing PLC communications.

(LED1 toggles ON during the start of this first scan)

Note 1: Remember that the PLC cannot perform any block transfers until after the network master has

finished polling the network for status information and LED2 has been turned off and the

1746-C starts indicating that it is ready for data (after scanning starts).

Note 2: Even though LED1 turns off immediately after the initial scan after power up and then toggles

back on after normal operations start, the user will not normally see this … at the most it

would be a small flicker. Therefore, to the user that is observing the LED behavior after

restart on a system that has actuators communicating, it will appear that …

During the initial scan when the PLC cannot talk to the 1746-C …

LED1 == ON

LED2 == ON.

Immediately after the initial scan when normal operations start (start of 1

LED1 == ON

LED2 == OFF.

st

normal scan):

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 20

Page 26

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.2. Network Interface (Scan) Time-Slice (1746-C ↔ Network

Communication)

4.2.1. Operation: Network Scanning to Gather Valve Actuator Data

The Network Master polls and controls up to 60 valves on the network by sequentially polling

(scanning) each device in sequence from slave actuator address #1 to the last slave address (#n) on its

network.

This polling gathers information from the actuators (including alarms, discrete information and actuator

position) and places it in tables that can be transmitted to the PLC.

The scan operation cannot stop in the middle of a request for data from a particular actuator.

Therefore, the 1746-C can only interface with the PLC once it has finished all required communications

with the actuator it is currently getting data from. Network scanning resumes with the next actuator

after interfacing with the PLC and processing any requests made by the PLC (writes to tables, writes to

actuators, table reads, …).

For example, if the 1746-C is currently scanning actuator [5] and the PLC wants to write a new valve

position setpoint to 22 actuators then the 1746-C will …

1. Finish getting data from actuator [5]

2. Get the new command table from the PLC.

3. Write the new valve position setpoint to all 22 actuators.

4. Restart network scanning where it left off … the next actuator [6] after the last one polled [5].

Standard data is gathered from the actuators by a single Modbus 03 command.

However, a 2

• If requesting totalizer data

• If requesting a specific holding register

• If requesting a block of holding registers from this actuator

• If requesting to monitor the discrete outputs on this actuator

• If requesting TEC2000 input data.

This is one reason why additional data should only be requested when needed … it will slow the entire

scan time of the system (by a minimum of 30-50 ms each time an actuator is polled for this data).

For instance, if all 5 of the above are requested for each actuator, an extra 30-50 ms is required for

EACH … meaning that the scan time could be increased by almost a factor of 5! … dramatically

slowing down the system!

A typical scan time (time to scan all the actuators on the network) to gather “standard” information on

60 actuators is less than 10 seconds … depending upon the 1746-C configuration.

When gathering data, the data is stored in the appropriate tables in the 1746-C. Values in the table

for a particular actuator will not be overwritten if there is an error communicating (on both ports) with the

actuator.

nd

Modbus 03 command is generated if any of the following are true …

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 21

Page 27

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.2.2. Operation: The Network Communication Diagnostic Scan

After a predetermined number of loops through the network scanning the actuators (the “scan period”),

the 1746-C performs a communication diagnostic scan to determine if any “off-line” actuators can come

back on line. If there are any that are ready, the 1746-C will bring them back on line without human

intervention. This is the only time an off-line system can come back on-line.

The number of loops around the network is determined by the “scan period

this value to accommodate site requirements and current operating environments.

Unlike the other operations that access the actuators on the network, the diagnostic scan checks both

ports when communicating with the actuators. Because of this, it also always takes longer to execute

than standard data gathering scans. However, normal data is still gathered during a diagnostic scan.

The only major difference in data gathering between a standard scan and a diagnostic scan is

• In the diagnostic scan, the 1746-C determines actuator system type and actuator firmware

version ID (tables [18 & 19]).

• Both ports are explicitly tested when getting the system type information.

• The diagnostic scan ensures that the hardware ports are set correctly … 9600 - 8N1.

Otherwise, all other data gathering activities are the same as in a normal network scan.

Communication error indications may only be cleared during this scan.

The “scan loop counter

” is always zero (0) during a diagnostic scan … the diagnostic scan does not

count as part of the scans in the scan period. This is the only time the loop counter is zero … during

the diagnostic scan.

The diagnostic scan time increases as you increase the discrepancy between the

(number of valves actually on line and talking

) VS (the number of valves configured to be on line)

Below shows a sample of diagnostic scan times empirically taken on a network when there was no

network “writes to the actuators” (Table [0] was configured for 60 valves). As you can see, as you

increase the number of “off line” units, you increase the diagnostic scan time.

# Nodes “Talking” … On-Line

60 of 60 (#1 – 60) 15

54 of 60 (#7 – 60) 16

48 of 60 (#13 – 60) 17

42 of 60 (#19 – 60) 18

36 of 60 (#25 – 60) 19

30 of 60 (#31 – 60) 20

24 of 60 (#37 – 60) 21

12 of 60 (#49 – 60) 23

6 of 60 (#55 – 60) 23

3 of 60 (#58 – 60) 24

2 of 60 (#59 – 60) 25

1 of 60 (#60) 25

Diagnostic Scan Times (secs)

Version 5.21

” value. The PLC adjusts

The values in this table

“rounded values” and

have a precision of (+/-) 1

second.

Because of this, these

numbers are only

appropriate for estimates

and trend analysis.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 22

Page 28

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

Notes:

• Though not much, the diagnostic scan time can also vary with the number of valves in the valve

scan time slice.

• The greater the number of valves configured to be on line, the longer the diagnostic scan time

… more valves to check.

• During normal operations, an operator can use the HMI to force the system into a diagnostic

scan by temporarily changing the “scan period” value in table [0] to a value lower than the

current scan loop counter. This will cause the program to enter a diagnostic scan as soon as

this scan loop has finished.

• Because the diagnostic scan detects faulty communication ports and flags them, there can be a

perceived increased performance in the normal network scans because “off-line” actuators have

already been flagged and will be skipped.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 23

Page 29

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.3. PLC Interface Time-Slice (1746-C ↔ PLC Communication)

The primary interface for the PLC with the 1746-C module is with an array of 25 tables (labeled 0 24)

stored in the 1746-C RAM. Each table is 64-words long and each word is 16-bits. From the

perspective of the PLC interfacing with the network, some of the tables are “read only” and some are

“read/write” (depending upon a command word).

Relative to M0/M1 transfers, from the 1746-C perspective, there is no difference in handling “table

reads” or “table writes” … they both require a M0/M1 file transfer command.

The Relay Ladder Logic (RLL) in the PLC CPU interfaces with the 1746-C module with the M0/M1 file

transfer mechanism and transferring fixed blocks of 64 words (a table) with the table number

(command) in Word # [0] of each transfer.

• To send a table to the 1746-C (either as a write table command or to indicate a particular table

to read back), the PLC must send the desired table in the data portion of the M0 file.

• To read back a table, the PLC must read the M1 file sent from the 1746-C.

Note: Since the 1746-C must be mounted in the local chassis (in the same chassis as the CPU), the

RLL cannot use the BTR/BTW block transfer command set (BTR/BTW commands cannot be

used over the back plane in the SLC systems). Therefore, the RLL must implement the

transfer using the “copy file” command … copying the M0/M1 files back and forth.

Note: Refer to the following Allen Bradley Documents:

• Allen Bradley SLC-500 Instruction Set Reference,

Publication 1747-RM001D-EN-P (November-2003)

• Allen-Bradley SLC-500 BASIC User's Manual (1746-BAS & 1746-BAS-T)

Publication No. 1746-UM004A-US-P 2000

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 24

Page 30

p

k

uffer (BOB)

r

uffer (

)

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

The interfacing between the PLC and the 1746-C is performed in the 1746-C module in a section of

RAM that is used as an exchange buffer area. To prevent potential overwriting problems when

performing transfers, there are two separate buffers in this exchange area:

• M0 file … Basic Input Buffer (BIB): PLC fills to send 64 words to the 1746-C.

• M1 file … Basic Output Buffer (BOB): 1746-C fills to send 64 words to the PLC.

This is the only address accessed by the PLC when executing the M0/M1 transfer commands (meaning

that all reads & writes by the PLC are to and from these buffers).

PLC must read the

M1 file in timely

manner as to not

slow down networ

scanning

PLC

M0 File Transfer

commands

executed by the

PLC

PLC

The PLC must ensure

the M0 file is there fo

the 1746-C to read in

a timely enough

manner as to not

slow down network

scanning

M1 File Transfer

commands

executed by the

1746-C

64-Word M1 File Transfer

B

The 1746-C looks

for an M0 file

transfer at the start

of the PLC Interface

time slice

64-Word M0 File Transfer

BIB

B

1746-C

1746-C driver

erations

o

Standard RAM

(Tables)

MODBUS RTU

commands

executed by the

1746-C and

actuators

ACTUATOR

Figure 3-1 Concept Diagram of Command Operations

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 25

Page 31

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.3.1. Operation: PLC (Write Data Tables To) or (Read Tables From) the

1746-C

Relative to M0/M1 transfers, from the 1746-C perspective, there is no difference in handling

• Writing a value to any table in the 1746-C memory.

• Writing a value to a table in the 1746-C memory that is also passed on to the specified actuator

on the network.

They both require a M0 file transfer command. The only difference is in the 2

transferred (word [1]).

• If word [1] == 0, then this M0 transfer is a command to read a table from the 1746-C.

• If word [1] =/= 0, then this M0 transfer is a command to write data to a table in the 1746-C.

To perform a transfer of table data:

1. The PLC interface time-slice has now started.

2. The 1746-C looks to see if a new M0 file has arrived from the PLC. If not, this operation

terminates and must be restarted on the next PLC interface time slice. Otherwise, continue.

3. Since a new M0 file is here, the 1746-C copies the table into its own memory.

4. If word [3] indicates an ESD command sequence (start or stop the ESD condition) then that is

outputted to the entire network of actuators on both ports.

5. If word [1] == 0, then a read-only request command was made and the appropriate table is

copied into the M1 exchange buffer.

If word [1] =/= 0, then this was a write command and this table is copied into 1746-C memory.

A final “resultant” table (what will be stored in the 1746-C and potentially sent out onto the

network) is then copied into the exchange buffer to be fed back to the PLC.

6. The new M1 file is prepared to be transferred to the PLC such that if the received M0 file

indicated

• A read command – the data the PLC requested in a read table command.

• A write command – the immediate feedback of the command structure the 1746-C is

about to execute.

7. The 1746-C looks to see if the last M1 file was already read.

8. The new M1 file is transferred after the PLC indicates that the previous M1 file was read or the

1746-C system times waiting for the previous M1 to be read. Note that if the 1746-C times out

waiting, the previous M1 file will be overwritten.

9. After the M1 file is sent, if the command was to write data to the actuators, the 1746-C will now

loop through and write to all “appropriate” actuators on the network.

10. The PLC interface time-slice is now finished.

nd

word in the block being

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 26

Page 32

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

As per affecting network performance,

unless the command is to write data to the actuators, the

PLC does not have to limit the rate in which these commands are sent to the 1746-C because the

1746-C only sends back the table information it already has stored in memory. Conceptually, these

do delay the overall scan time. However, the amount of delay is very minor from a global perspective.

Obviously, the PLC must still ensure all appropriate M0/M1 TRANSFER handshaking is performed)

(

As per writes that send data to the actuators, the rate should be limited. Please refer to the section

that discusses writing data to the actuators on the network.

Note 1: All tables can be read by the PLC. To ensure you only read from a read/write table, access it

with the command word set to “0” (zero).

Note 2: An invalid table ID sent to the 1746-C will default to a read request for table [0] data.

Note 3: If the 1746-C times out waiting for the previous M1 file to be read by the PLC, the previous M1

file will be over-written.

Note 4: On write commands from the PLC, reading the immediate feedback is optional for the PLC. In

other words, if the PLC has no need to inspect this table, then it can read it back but just throw

it out. However, servicing the M1 transfer request is important to overall system throughput.

For instance, the PLC program might be architected such that it treats an output pipe

(“command”) as just that … a one-way pipe that has no feedback. In this case, the PLC would

use other mechanisms for feedback (ex: other tables) and does not require the redundant

feedback on write commands.

Note 5: When a request for an M1 transfer is made by the 1746-C, the 1746-C program waits (in the

respective request function) until either the transfer completes or until a timeout is triggered

(currently set at 2 seconds).

This extended timeout time is to assist a PLC program that is having other (hopefully

temporary) difficulties and might take a while to return to normal behavior.

Therefore, to not slow down 1746-C network scanning activities, the PLC-RLL needs to service

these requests as soon as possible … even if it is to only throw away the table read back.

Servicing the request for an M1 transfer made by the 1746-C is critical for overall timing

efficiency.

Note 6: One main point to remember on M0/M1 transfer timing is that once the 1746-C responds to an

M0 transfer, the 1746-C will not return to process (setup for) another M0 file from the PLC until

it:

• responds with an immediate feedback M1 file transfer request containing the table being

addressed.

• finishes writing the entire table of values to the valves (if a write command).

• completes the set of scans in the next network scan time slice

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 27

Page 33

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

Note 7: Once the 1746-C reads in a table from the M0 file, the 1746-C will always deliver the

feedback table almost immediately … whether or not it was a read or write table command.

Therefore, the best practice to maintain synchronization between the PLC and 1746-C is for the

PLC to “conceptually” wait for a feedback response from the 1746-C before continuing … even

if only to throw away the table.

This will also increase the 1746-C overall speed because it waits for an acknowledgement of

the feedback before continuing with command execution.

REMEMBER … Speed in servicing of the M1 transfer requests expedites system throughput.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 28

Page 34

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.3.2. Operation: PLC Commands to Write Data to the Actuators

When valve control commands (change setpoint, open, stop or close) are generated by the PLC, the

Network Master sends the appropriate command(s) over the network to the addressed slave device

(actuator).

However, if the command for a particular valve has not changed (value in the table is the same as

before), then nothing is sent to the particular valve (it is skipped). Basically, when the 1746-C starts

acting on a command to write data to the actuators, it compares the current value in the table with the

new one. If the values are different, then the actuator is flagged as one to write information to.

When writing discrete output control commands (directly controlling coils [3-5] or [100-1011]),

the 1746-C does NOT compare the value to the last one. When commanded to write to the

coils, it is performed ONE TIME and then turned off for that actuator (however, monitoring the

status of those outputs is left on for that actuator).

When the 1746-C starts writing data to the actuators, is starts with the lowest address number and

proceeds through to the highest address number. This write operation is completed after all

“appropriate” actuators have been written to.

In general, there is one Modbus command/response set issued for EACH PLC command to write data

to a particular actuator (ex: writing analog output data).

However, as per the specification, when a position control command is issued, the 1746-C is required

to ensure that a “SSR” contactor configuration bit is set on any 320A system prior to receiving a control

command. Therefore, there are up to 3 Modbus command/response sets issued for EACH PLC

command to write position data in any particular 320A actuator:

If the actuator is configured to have an SSR in it (table [13]):

1. A Modbus command is sent to the actuator requesting status information to verify the SSR

configuration coil is set.

2. If the coil is not set, a Modbus command is sent to set it.

3. The Modbus command is sent to indicate the new setpoint.

Note 1: Discrete OPEN / CLOSE / STOP commands.

The discrete OPEN / CLOSE / STOP commands (in table 3) are handled exactly the same as if

a setpoint was sent.

• OPEN (send a 100% open setpoint)

• CLOSE (send a 0% open setpoint)

• STOP (send a setpoint matching the last position read)

(For more information on how this works, refer to the actuator’s operation manual)

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 29

Page 35

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

Note 2: If writing to a valve and the write fails, then the internal flag to write the value REMAINS

ACTIVE. This means that even though the communication process will prevent the program

from trying to transmit when there is an error, the program will keep this value identified as one

to send out until it is actually sent out or cleared by the PLC.

This also means that the write to this particular actuator will be attempted the next time the PLC

sends this table in with a “write table” command associated with it.

For example … If this was a value in table [5], the 1746-C will retry writing the value to the

actuator the next time the PLC sends table [5] in as a write command.

The 1746-C cannot “cancel” this command because it is not in its scope of responsibility to

directly change process control commands.

Therefore, it is the PLC’s responsibility to write whatever “safe” value is appropriate for the

particular actuator/application at any time in case the actuator “comes back online”.

Note 3: The PLC should limit the rate in which these commands are sent to the 1746-C … only write

as fast as required to adequately control the valve. The faster the PLC requests changes to

valve setpoint positions in the valves, the longer it takes the 1746-C to complete the write

operation and continue scanning the network for data … decreasing the overall performance

concerning updating status information for all actuators on the network.

For example

: Sending write commands once per second might still afford good control and still

update all status information. However, sending write commands 4 times a second might write

the information out faster but delay the response (status) information for the entire network to a

point where it is too difficult to control.

Warning: If the valve has been moved while the PLC is down or the valve was moved while in local

mode, then as soon as the valve is communicating and accepting remote commands, it will

move according to values in tables [3] and [5]. Please adjust the PLC RLL accordingly.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 30

Page 36

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

4.3.3. RLL Example … Manually Send New Table … Auto Read Response

Below is a simple example of an RLL that will manually send a table in a BTW and read back the

resulting feedback table using a BTR.

On the next page is an example of the M0 & M1 files (tables) sent and received.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 31

Page 37

r

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

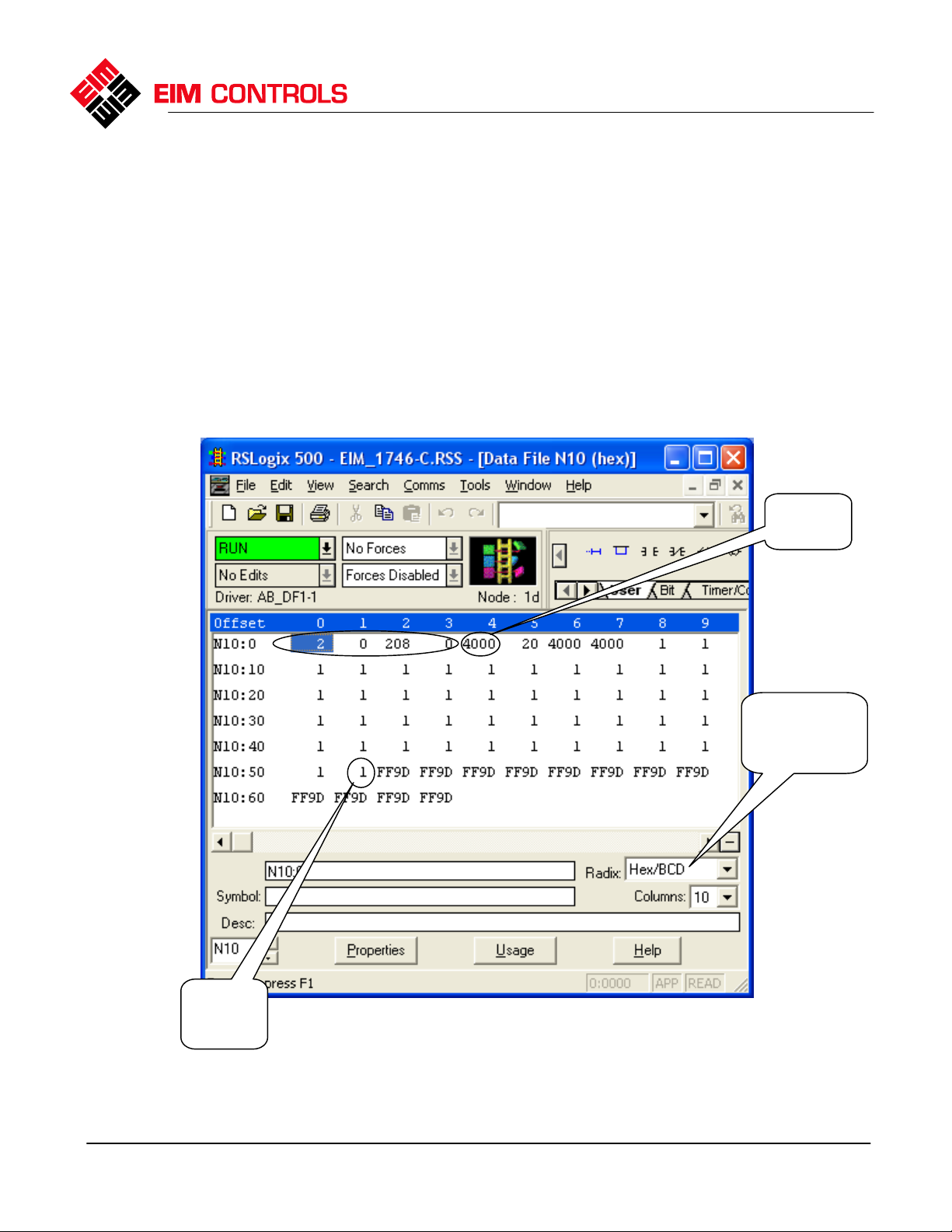

Control & Feedback via the N10 & N11 files … (table [19] requested … only 3 actuators on network)

Table

sent in

with the

M0 file

Table Number

Sent in

Table

read back

with the

M1 file

4-word

heade

3 Nodes on

Network

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 32

Page 38

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

5. System Tables

From the perspective of the PLC, all tables can be read but only some can be written to. If the PLC

attempts to perform a write to a “read-only” table, the 1746-C ignores it and treats it as a read

command/request.

In general, when writing data to be transmitted to the actuators over the network, the Network Master

will differentiate which values change in tables being received from the PLC and will only send new

command information to the actuators that require a change.

The tables have the following PLC (“user”) access:

• Table [0]: read / write

• Table [1]: read only

• Table [2]: read only

• Table [3]: read / write

• Table [4]: read only

• Table [5]: read / write

• Table [6]: read only

• Table [7]: read only

• Table [8]: read / write

• Table [9]: read / write

• Table [10]: read / write

• Table [11]: read only

• Table [12]: read only

• Table [13]: read / write

• Table [14]: read / write

• Table [15]: read / write

• Table [16]: read / write

• Table [17]: read / write

• Table [18]: read only

• Table [19]: read only

• Table [20]: read / write

• Table [21]: read / write

• Table [22]: read / write

• Table [23]: read / write

• Table [24]: read / write

Table [0] is a “system focused” table. It is focused on information about the network system and

network master. All the rest of the tables are focused on information about individual actuator “units”.

NOTE: In tables [1 24 … except 15], the last 60 words hold information for particular actuators.

Words [4

actuator is represented by its

end of the header). For instance, Word [7] in all tables will always have valve #4

information.

63] are in sequence with valve actuator network node addresses. A particular

POSITION in the table as an offset starting from word [3] (the

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 33

Page 39

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

There are two parts to a table:

• General Header Information: Words [0 3]

• Table Specific Information: Words [4 63]

In table [0], words [4

63] are divided into three parts:

• Words [4 17]: System Configuration Information

• Words [18 46]: -reserved- … currently not used.

• Words [47 63]: Run-time information inserted by the 1746-C.

Copyright © 2004 EIM COMPANY, INC. • 13840 PIKE ROAD • MISSOURI CITY, TX. 77489

Page 34

Page 40

Controlinc 1746-C (Version 5.21) Network Master Users Guide (2004-11-18)

5.1. Table Arrangement

Table [0]

System

Info Table

Word

offset

into

table

Read /

Write

Table #

0

R / W

1

Command

Reserved

2

(F/W ID

3 ESD ESD ESD ESD ESD ESD ESD ESD ESD ESD ESD ESD ESD ESD ESD ESD

# Valves

4

Network

5

Period

6

Totalizers

7

~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

See table [0]

63

Command to Monitor

Word

offset into

&/or Control Discrete

table

0

1 R / W 0 0 0 R / W R / W R / W R / W R / W

2

3 ESD ESD ESD ESD ESD ESD ESD ESD ESD

4

Discrete Output Cmd

5

Discrete Output Cmd

6

Discrete Output Cmd

7

Discrete Output Cmd

~ ~ ~ ~ ~ ~ ~ ~ ~ ~

63

Discrete Output Cmd

Table [1]

---Comm.

----

Status

Table #

0x00

Reserved

(F/W ID)

Valve #1

on

Comm

Status

Scan

Valve #2

Comm

Size

Status

Valve #3

Poll

Comm

Status

Valve #4

Comm

Status

Run-Time

Valve #60

Information

Comm

Configuration &

Status

Table [16]

----

Digital Outputs

Read / Write

Table #

0x10

Reserved

(F/W ID)

Valve #1

Valve #2

Valve #3

Valve #4

Valve #60

Table [2]

---Interpreted

Error

Status Bits

---Reg [06]

Read

Only

Table #

0x01

0 0 R / W 0 R / W 0 0 R / W R / W R / W 0 0 R / W R / W R / W

Reserved

(F/W ID)

Valve #1

Valve #2

Valve #3

Valve #4

Status of Discrete

Discrete Out Status

Discrete Out Status

Discrete Out Status

Discrete Out Status

Discrete Out Status

Table [3]

----

Valve

Read

Status

Status

Status

Status

Valve

Status

Digital Outputs

Discrete

---(O / C / S)

Only

Table #

0x02

Reserved

(F/W ID)

Valve #1

Valve #2

Valve #3

Valve #4

#60

Table [17]

----

…

Read / Write

Table #

0x11

Reserved

(F/W ID)

Valve #1

Valve #2

Valve #3

Valve #4

Valve #60

Control

Control

Read /

----

Valve

----

----

----

Write

0x03

AOCS

AOCS

AOCS

AOCS

Valve

#60

AOCS

Table [4]

----

Valve

Position

Feedback

----

0 – 100%

in 0.1%

increments

----

Read

Only

Table #

0x04

Reserved

(F/W ID)

Valve #1

POS

0 – 100.0%

Valve #2

POS

0 – 100.0%

Valve #3

POS

0 – 100.0%

Valve #4

POS

0 – 100.0%

Valve

#60

POS

0 – 100.0%

Table [18]

----

System Type

Read Only

Table #

0x12

Reserved

(F/W ID)

Valve #1

System Type

Valve #2

System Type

Valve #3

System Type

Valve #4

System Type

Valve #60

System Type

Table [5]

----

Valve

Control

----

Valve

Setpoint

----

0 - 4095

----

Read /

Write

Table #

0x05

Reserved

(F/W ID)

Valve #1

STPT

Valve #2

STPT

Valve #3

STPT

Valve #7

STPT

Valve

#60

STPT

Table

[6]

----

Analog

Input #1

----

Read

Only

Table #

0x06

Reserved

(F/W ID)

Valve #1

AIN-1

Valve #2

AIN-1

Valve #3

AIN-1

Valve #4

AIN-1

Valve

#60

AIN-1

Table [19]

----

Firmware

Version ID

Read Only

Table #

0x13

Reserved

(F/W ID)

Valve #1

Firmware ID

Valve #2

Firmware ID

Valve #3

Firmware ID

Valve #4

Firmware ID

Valve #60

Firmware ID

Table

Table [8]

[7]

----

----

Analog

Analog

Output #1

Input #2

Read

Only

Table #

0x07

Reserved

(F/W ID)

Valve #1

AIN-2

Valve #2

AIN-2

Valve #3

AIN-2

Valve #4

AIN-2

Valve

#60

AIN-2

Table [20]

Modbus Exception

Response

Indications

Read / Write

Reserved

Exception Code

Exception Code

Exception Code

Exception Code

Valve #60

Exception Code

----

----

Table #

0x14

(F/W ID)

Valve #1

Valve #2

Valve #3

Valve #4

----

Read /

Write

Table #

0x08

Reserved

(F/W ID)

Valve #1

AOUT

Valve #2

AOUT

Valve #3

AOUT

Valve #4

AOUT

Valve

#60

AOUT

Table [9]

----

Totalizer

#1

----

Read /

Write

Table #

0x09

Reserved

(F/W ID)

Valve #1

TTL - 1

Valve #2

TTL - 1

Valve #3

TTL – 1

Valve #4

TTL - 1

Valve

#60

TTL - 1

Table [21]

TEC2000 Inputs

[1000 – 1015]

Reg [1000]

Read / Write

Table #

0x15

Reserved

(F/W ID)

Valve #1

Inputs [1000-1015]

Valve #2

Inputs [1000-1015]

Valve #3

Inputs [1000-1015]

Valve #4

Inputs [1000-1015]

Valve #60

Inputs [1000-1015]

----

…

Table [10]

----

Totalizer

#2

----

Read /

Write

Table #

0x0A

Reserved

(F/W ID)

Valve #1

TTL - 2

Valve #2

TTL - 2

Valve #3

TTL - 2

Valve #4

TTL - 2

Valve

#60

TTL - 2

Table [11]

Reserved

TEC2000 Inputs

[1016 – 1031]

Inputs [1016-1031]

Inputs [1016-1031]

Inputs [1016-1031]

Inputs [1016-1031]

Inputs [1016-1031]

----

Valve

Position

0 – 4095

reg [14]

----

Read

Only

Table #

0x0B

(F/W ID)

Valve #1

POS

0 – 4095

Valve #2

POS

0 – 4095

Valve #3

POS

0 – 4095

Valve #4

POS

0 – 4095

Valve

#60

POS

0 – 4095

Table [22]

----

Reg [1001]

…

Read / Write

Table #

0x16

Reserved

(F/W ID)

Valve #1

Valve #2

Valve #3

Valve #4

Valve #60

Table [12]