Page 1

Page 2

MODEL Hf -

general description

GENERAL

The EICO Model HF-

phonic control center and a pair of 14watt amplifiers,

on one

chassis. With it

control accurately any stereophonic source (tape, discs, or

broadcasts) and feed it through the

watt amplifiers to a stereo pair of speaker systems.

you playa monophonic

channe I adds up to a total of

systems. If you desire,

in parallel and driven byone

whi Ie the other preampl

an external power amplifier. In this way your old ampli-

fier can be put to use in a stereophonic

tion is of the "Iow silhouette

dispense with cabinetry if desired.

FEATURES

81 is a complete high fidelity stereo-

you can select preamplify, and

self-contained dual 14

When

source, the 14 watts available per

28 watts for your two speaker

both amplifiers can be connected

preamp I ifier-control section

ifier-control section is free to drive

system. Construc-

" type that permits you to

all

DUAL 14

STEREO AMP

channel) and two auxil iary B

Input Selector switch on front panel has positions for

ing FM tuner output to one

, or FM tuner to one

other

WATT HI-

- PREAMP

inputs (one in each channel).

channel and AM tuner to

channel and FM Multiplex

adapter output to other.

3. May be

preamplifiers,

set free to operate an external

other preampl ifjer-control section used to drive

ternal power

speaker connection terminals. A top -

switch permits choice of operation.

4. Ganged

used as either two independent amplifier-

or one preamplifier-control section may be

power amplifier and the

both in-

ampl ifiers

level controls and a separate focus (balance)

connected in parallel at

of-chassis sl ide

control.

5.

Independent full-range bass and treble tone controls

in each channel. Tone

controls of the low

distortion

variable cross-over feedback type.

feed-

the

1. Separate low

phono, tape head, and microphone. Circuitry

level input in each

channel for mag.

carefully

designed to provide the high gain required by tape heads

and high quality, low output mag. cartridges without

hum

and noise problems. A front panel switch permits choice

of the proper

NARTS tape head equalization for

7 1/2 & 15 or 3 3/4ips tape

2. Separate

Multiplex. Also two

high level inputs

auxiliary A

speeds.

for AM,

inputs (one in each

either

FM, and FM

6. Identical

Williamson type, push-

plifiers with high quality output

7. Hum balance

convenience outlets.

8. EICO "

zontal chassis for proper layout and component separation.

Easy console installation,

ing and adapatability to any panel thickness.

control, panel-mounted fuse, pi lot

low silhouette

Copy,;ght I1d 1958 Electronic Instrument Company, Inc.

" construction employing hori-

if desired

pull EL84power am-

transformers.

lamp,

, with complete shield-

Page 3

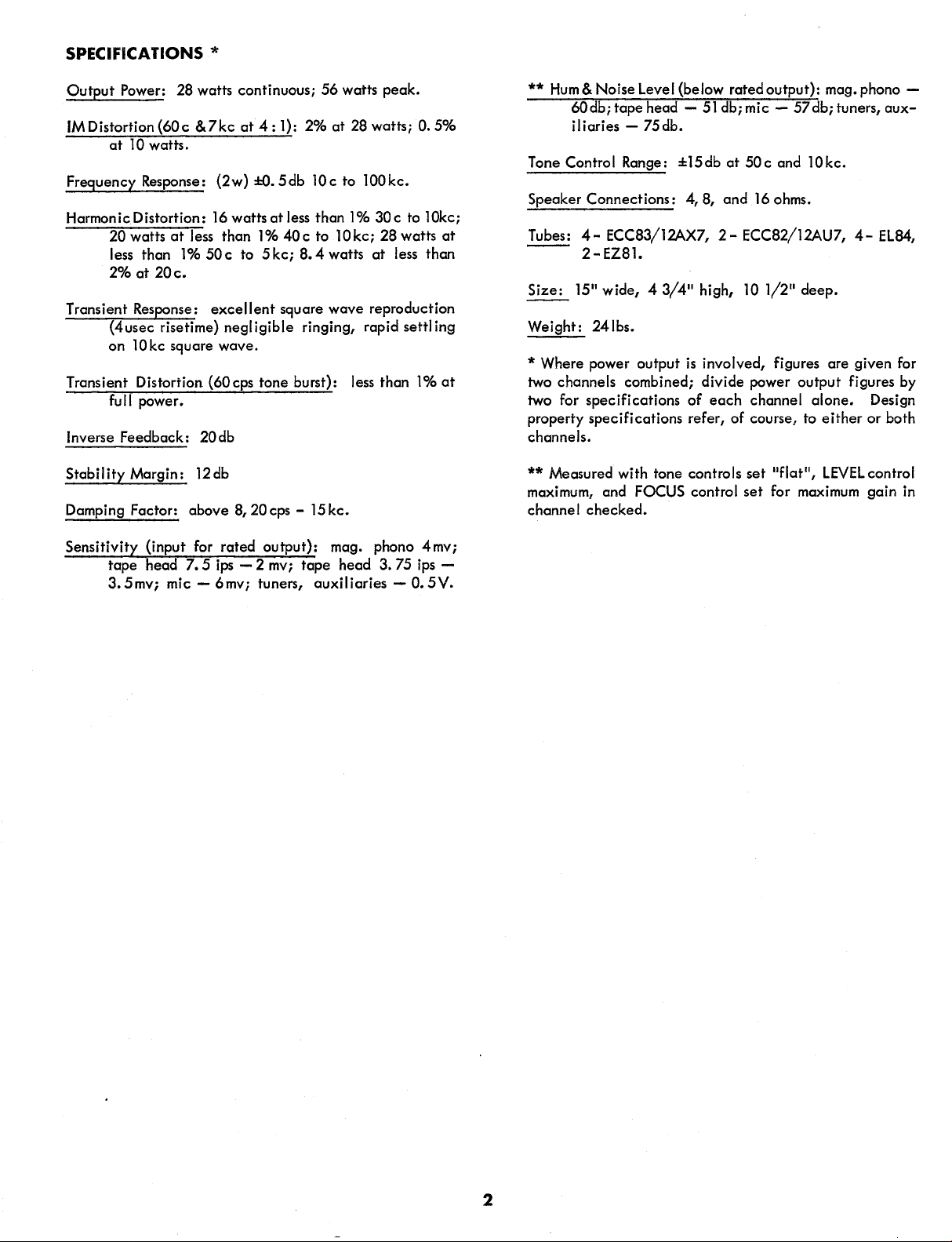

SPECIFICATIONS *

Output Power:

1M Distortion

at 10 watts.

Frequency Response:

HarmonicDistortion:

20 watts at I

less than

28 watts continuous; 56 watts peak.

(60c &7kc at 4:

: 2% at 28 watts; 0.

(2w):I:O. 5db 10c to 1O0kc.

16 watts at less than 1% 30c to lOkc;

ess than 1 % 40 c to 10 kc; 28 watts at

1% 50c to

5kc; 8.

4 watts at

2% at 20c.

Transient Response

(4usec rise time) negligible ringing,

on 10kc square wave.

: excellent square

wave reproduction

Transient Distortion (60cps tone burst)

fu II power.

Inverse Feedback: 20db

Stability Margin:

Damping Factor: above 8, 20 cps - 15 kc.

12db

less than

rapid settl ing

less than 1% at

** Hum & Noise Level (below

60db; tape head - 51

iI iaries

Tone Control Range:

Speaker Connections: 4 8, and 16 ohms.

- 75 db.

::I:15db at

rated output): mag. phono

db; mic

db; tuners, aux-

- 57

50c and 10kc.

Tubes: 4 - ECC83/12AX7, 2 - ECC82/12AU7, 4- EL84,

2 - EZ81.

Size:

Weight:

15" wide, 4 3/4" high, 10 1/2" deep.

241bs.

* Where power output is involved, figures are given for

two channels combined; divide power output figures by

two for specifications of each

channel alone. Design

property specifications refer, of course, to either or both

channels.

flat"

** Measured with tone controls set "

maximum, and

FOCUS control set for maximum gain in

, LEVEL control

channe I checked.

Sensitivity (input for rated output):

tape head 7.

5mv; mic

5 ips - 2 mv; tape head 3.

- 6mv;

tuners, auxiliaries - 0.

mag. phono 4mv;

75 ips

5V.

Page 4

mechanical installation

GENERAL

a) HEAT DISSIPATION (VENTILATION): In common with

other electronic equipment

able heat in normal operation. Unless continuous and

quate air flow is

obtained around the heat producing ele-

ments, these elements will over-

, the HF-Sl produces consider-

ade-

heat and their useful life

will be greatly curtailed.

It is useful to understand the process of convection where-

by heat is removed in judging the

Air heated by the heat-

producing elements expands and

suitability of a location.

rises; cool air is drawn from beneath to take the place of

the heated air. In

motion which continually

fier. (In particular,

major heat-

producing elements; the four EL84 output tubes

this manner, a

removes heat from the ampli-

we are mainly

and the two EZSl rectifier tubes.

ment to or constriction of the airflow, the essential

stream of air is set in

concerned with the

) If there is any impedi-

process

of heat removal will be adversely affected.

Adequate ventilation will be

installed in an open-

back console provided that the top

of the amplifier is spaced at least

shelf mounted above it.

rear, provide several large holes or

as high up in the cabinet back

nate, holes

of the cabinet.

effective ventilation requires provision for cool air

ter at the bottom and hot air to leave at the top.

may be provided in the sides, bottom, or top

The important thing to

If the amplifier is not

situated on an open surface or on a shelf of a

provided if the amplifier is

two inches below any

If the cabinet is enclosed at the

slots as low down and

as possible. As an alter-

remember is that

to en-

installed in a console, it

may be

boakcase~

Four rubber feet are also provided so that the amplifier will

not mar the surface of furniture on which it is placed.

b) EASY ACCESS TO CONTROLS: Mount the amplifier

at a height which will permit easy manipulation of the

trols. Tuner controls should be located nearby.

c) ACCESSIBILITY TO PARTS: . Tubes are the most fre-

quently replaced items in electronic equipment. If

con-

the

amplifier is installed in a console, sufficient space should

be alloted to reach and

Furthermore, input and output

should be accessible to permit easy

tem components for

connection of a portable tape recorder which is

way when not in use.

back of the console in which the amplifier is

arrange them so they will not

remove any tube in the amplifier.

terminals of the ampl ifier

interchanging of sys-

comparison, and connection or dis-

stored a-

If antennas are strung around the

installed,

interfere with access to the

amplifier.

d)

ACOUSTICAL ISOLATION:

are installed in the

same cabinet (not recommended))' pro-

If amplifier and speaker

vide sufficient separation to minimize mechanical speaker

vibration reaching the amplifier. The

minimum separation

is about one foat.

CONSOLE MOUNTING

a) 0 erationsonconsolefront anel

fier mounting:

the face of the console so that the top of the mounting sur-

face line on the template

amplifier mounting shelf. Note:

Tape the panel template provided to

is level with the top of the

reliminar to am li-

When shelf is not avail-

able, tape the template atanyconvenientspot on the face

of the console. (2) Use an awl

centers of the four extreme outer

or a nai I to pierce the

holes for mounting the

control plate, to transfer their locations to the console

panel beneath. (3) Trace out the rectangular cutout with

an awl or nail and then pierce the centers of the

holes)' one in each corner of the cutout.

panel template. (5) Drill the

sole panel, one in each corner of

area. Cut out the rectangular piece with a keyhole sawl

four 1/2" holes in the con-

the rectangular cutout

four 1/2"

(4) Remove the

using the four 1/2" holes as starting holes.

b) Am lifier mounting in console: (1) Pull off the control

knobs. 2 Remove the four screws that fasten

to the side pieces and

two screws and nuts that fasten the

bezel. The bezel

Fasten the control plate to the console panel with the two

#4x3/S wood screws supplied. (5) If the rubber feet

been inserted irwhe bottom plate, remove them. (They

be pried out with a thin screwdriver. ) (6) Place the unit -

remove the bezel. (3) Remove the

control plate to the

is not used in

console mounting. ~)

the bezel

have

may

on the mounting shelf and slide it forward until the slide

switch

slide switch accessible from the front; the control shafts

should be approximately centered in the

holes in the control plate.

the outline of the side and rear

sl,lpport bracket is

up against the panel and the

corresponding

(7) With a sharp penci!l draw

bottom edges on the chassis

shelf. As the bottom plate falls short of the full width by

3/16" on each side, draw new side edge

side the original side edge

lines. (S)

knobs and take the chassis off the shelf.

6screws which fasten the bottom plate to

Place the bottom plate exactly in the outl

shelf and mark the position of the center hole on the left

side and the center hole on the right side. (11)

lines 3/16" in-

Now remove the

(9) Remove the

the chassis. (10)

ine drawn on the

Remove

the bottom plate and dril! each of the marked holes on the

shelf to a diameter of 1/4"

plate to the chassisl withthefourof the six

previously removed, using the two holes at the

two holes at the front of the

chassis on the shelf

previously drawn, and restore the knobs. This time

l positioning

sure that the indicator dot on each

control position. (14) From the bottom side of

insert a #S

xl" screw, with a 1/2" flat

the head, through both the left and right side

These screws engage the stamped nut over each hole on

the chassis flange and when tightened secure the

to the shelf.

(12) Refasten the bottom

#8x3/Sscrews

rear and the

chassis. (13) Replace the

it exactly in the outline

make

knob agrees with the

the shelf

washer against

center holes.

chassis

Page 5

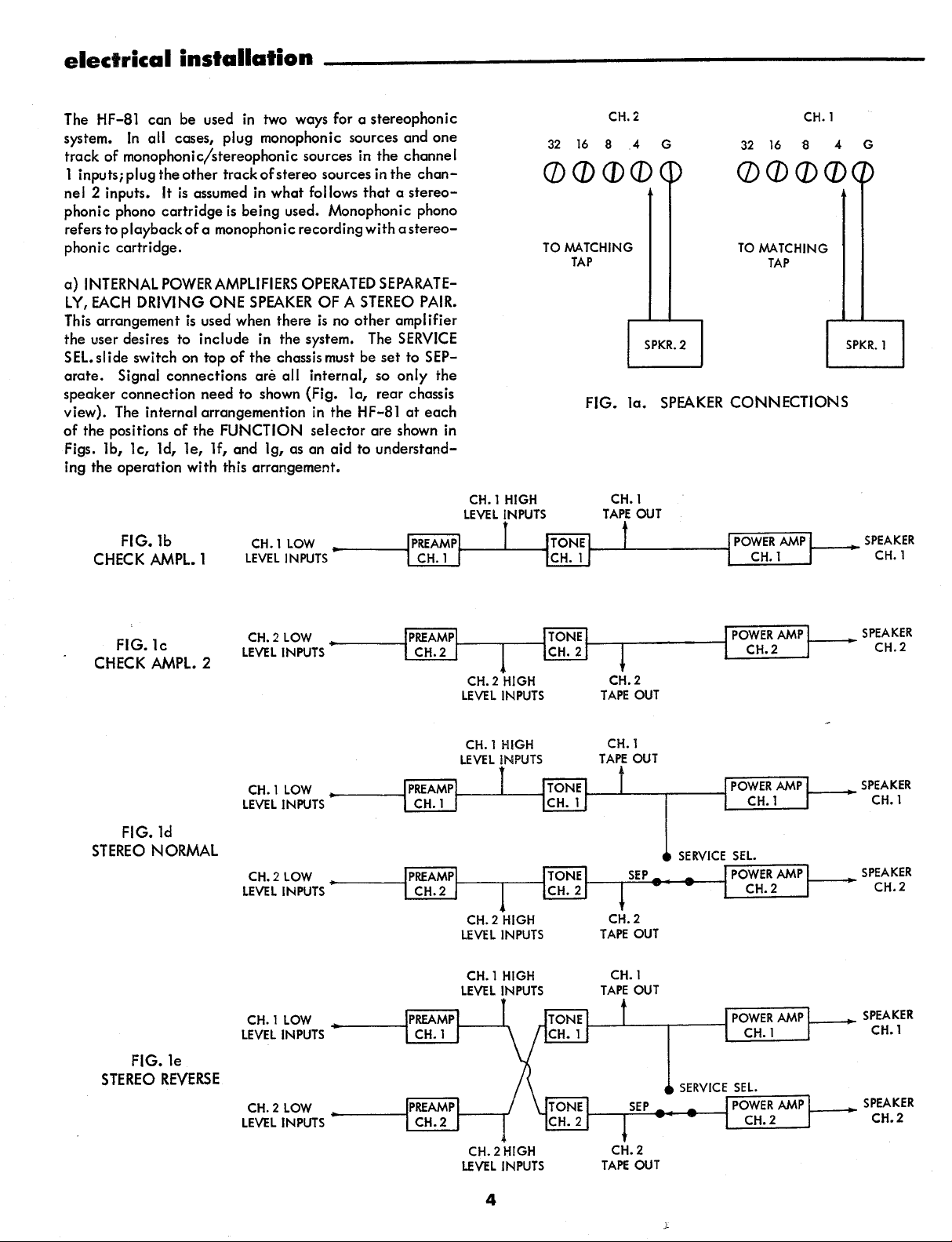

electrical installation

The HF-

81 can be used in two ways

system. In all

cases, plug monophonic sources and one

for a stereophonic

track of monophonic/stereophonic sources in the channel

1 inputs; plug the other track of stereo sources in the

nel 2 inputs. It is assumed in what follows that a

phonic phono cartridge is being used. Monophonic

refers to playback of a monophonic recording with a stereo-

chan-

stereo-

phono

phonic cartridge.

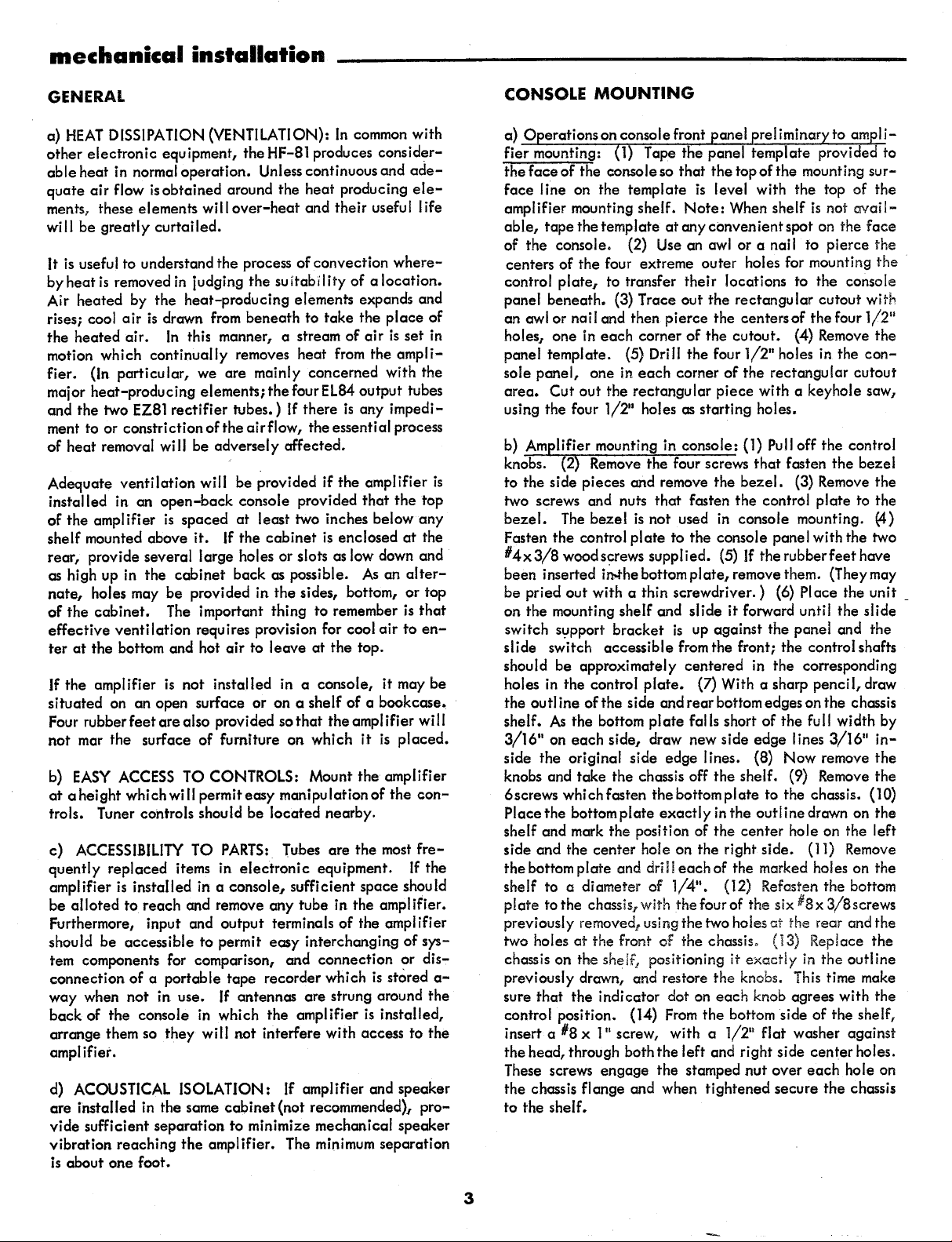

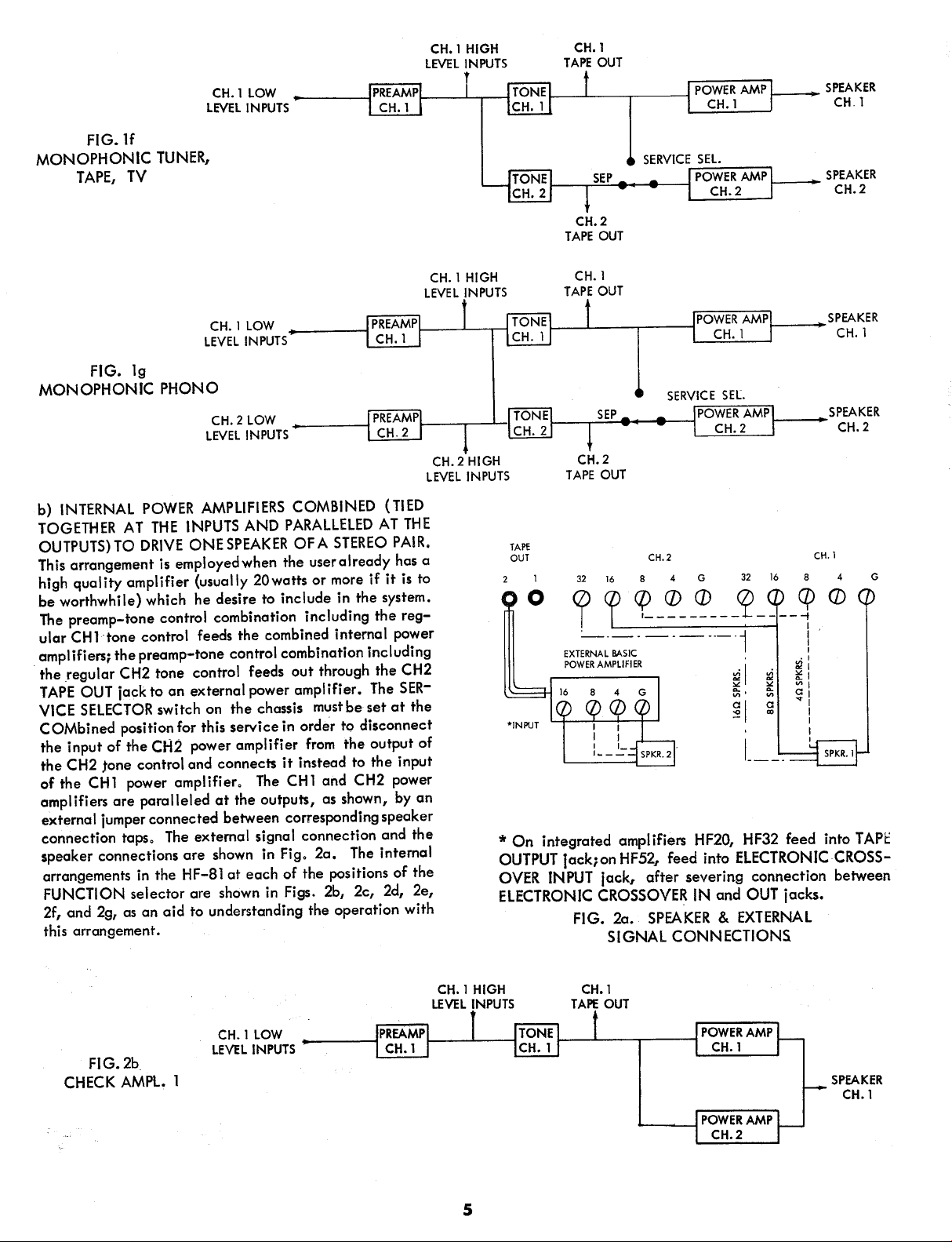

a) INTERNAL POWER AMPLIFIERS OPERATED SEPARATE-

LY, EACH DRIVING ONE

SPEAKER OF A STEREO PAIR.

This arrangement is used when there is no other amplifier

the user desires to include in the system. The

SEL. sl ide switch on top of the chassis must be set

arate. Signal connections are all internal, so only

speaker connection need to shown (Fig.

la, rear chassis

SERVICE

to SEP-

the

view). The internal arrangement ion in the HF-81 at each

of the positions of the FUNCTION selector are

Figs. Ib, lc, Id

, Ie, If

, and 19, as an aid to understand-

shown in

ing the operation with this arrangement.

FIG.

CHECK AMPL. 1

CH. I LOW

LEVEL INPUTS

CH.

IPREAMP~

16 8

32

(J) (J) (f)

TO MATCHING

TAP

FIG. la. SPEAKER CONNECTIONS

CH. 1 HIGH

LEVEL INPUTS

CH.

CH.

SPKR.

CH. 1

TAPE OUT

CH.

32

(J)

TO MATCHING

TAP

POWER AMP

CH.

SPKR.

SPEAKER

CH.

FIG.

CHECK AMPL. 2

FIG. Id

STEREO NORMAL

FIG. Ie

STEREO REVERSE

CH. 2 LOW

LEVEL INPUTS

CH. 1 LOW

LEVEL INPUTS

CH. 2 LOW

LEVEL INPUTS

CH. 1 LOW

LEVEL INPUTS

CH. 2 LOW

LEVEL INPUTS

PREAMP

CH.

~:'~P

CH.

2HIGH CH.

CH.

LEVEL INPUTS T APE OUT

CH. 1 HIGH

LEVEL INPUTS

2 HIGH CH.

CH.

LEVEL INPUTS

CH. 1 HIGH

LEVEL INPUTS

CH.

TAPE OUT

SEP ..

TAPE OUT

CH.

TAPE OUT

SEP

POWER AMP

SERVICE SEL.

I PO

CH.

AMP

SPEAKER

CH.

SPEAKER

CH.

~~~~R

SPEAKER

CH.

SPEAKER

CH.

CH. 2 HIGH

LEVEL INPUTS

CH.

TAPE OUT

Page 6

FIG.

MONOPHONIC

TAPE, TV

TUNER,

CH. 1 LOW

LEVEL INPUTS

CH. 1 HIGH

LEVEL INPUTS

CH.

TAPE OUT

SEP

CH.

TAPE OUT

SPEAKER

CH 1

SPEAKER

CH.

CH. 1 LOW

LEVEL INPUTS

FIG. Ig

MONOPHONIC PHONO

2 LOW

CH.

LEVEL INPUTS

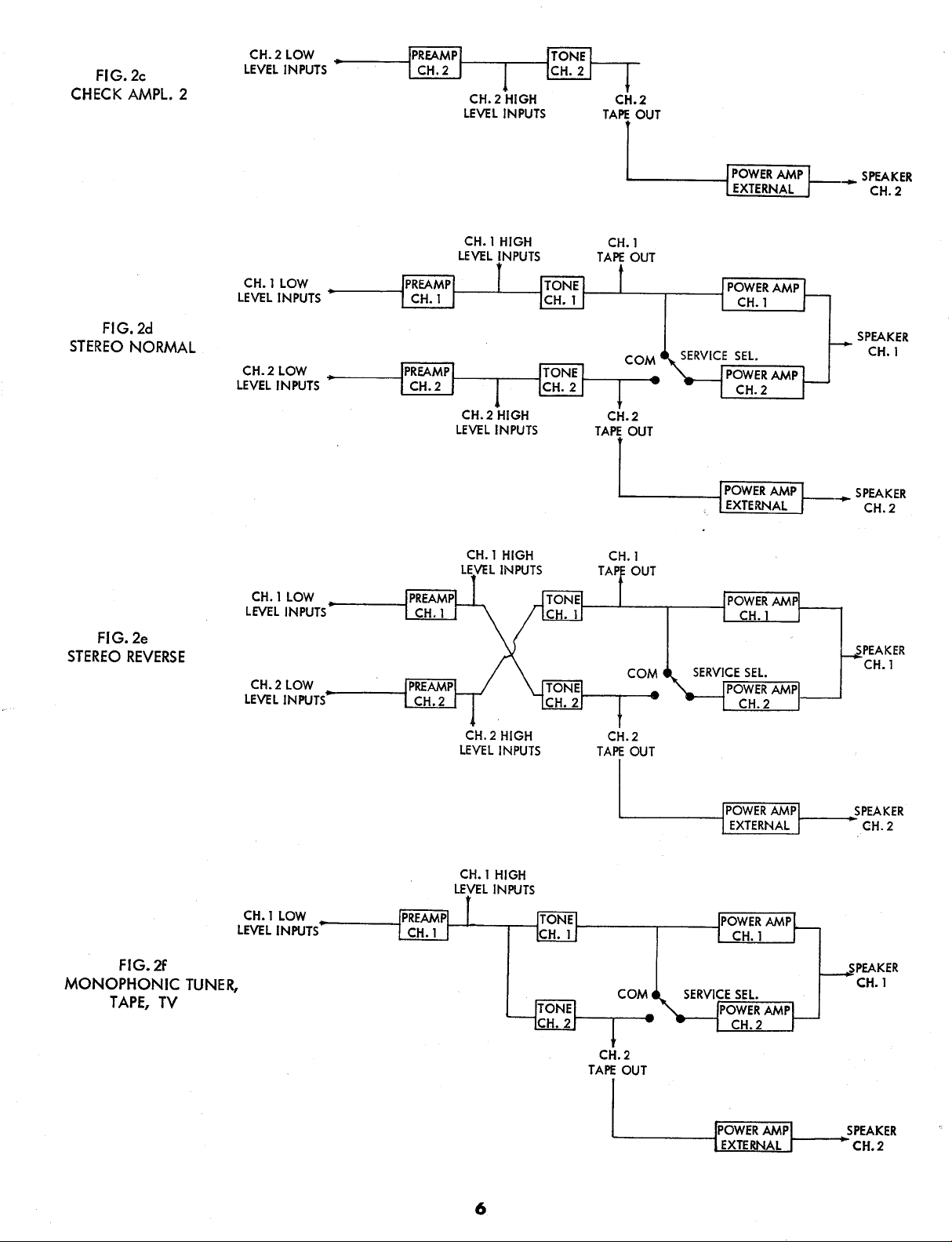

b) INTERNAL

TOGETHER AT THE INPUTS AND

OUTPUTS) TO DRIVE ONE SPEAKER OF A STEREO PAIR.

This arrangement is employedwhen the useralready has a

high quality amplifier (usually 20watts or more if it is to

be worthwhile) which he desire to include in the

The preamp-

ular CHI tone control feeds the

amplifiers; the preamp-tone control combination including

the regular CH2 tone control feeds out

TAPE OUT jack to an external power

VICE SELECTOR switch on

COMbined position for this service in order to disconnect

the input of the CH2 power amplifier

the CH2 tone control and connects it instead to the input

of the CHl

amplifiers are paralleled at the outputs

external jumper connected between corresponding speaker

connection taps, The external

speaker connections are shown in Fig,

arrangements in the HF-

FUNCTION selector are

, and 2g, as an aid to

this arrangement.

POWER AMPLIFIERS COMBINED (TIED

PARALLELED AT THE

system.

tone control combination including the reg-

combined internal power

through the CH2

amplifier. The SER-

the chassis must be set at the

from the output of

power amplifier, The CHI and

CH2 power

, as shown

, by an

signal connection and the

2a. The

81 at each of the positions of the

shown in Figs. 2b,

understanding the operation with

internal

2c, 2d, 2e,

CH. 1 HIGH

LEVEL INPUTS

2HIGH CH.

CH.

LEVEL INPUTS

TAPE

OUT

.INPUT

* On integrated

OUTPUT lack; on HF521 feed into

OVER INPUT jack,

ELECTRONIC CROSSOVER IN and

CH.

T APE OUT

SERVICE SEL

SEP

T APE OUT

CH.

BASIC

~RNA

EXT

POWER AMPLIFIER

~~~:MP

amplifiers HF20,

after severing

FIG. 2a. SPEAKER &

SIGNAL CONNECTIONs.

SPEAKER

CH.

SPEAKER

CH.

CH.

(f)

. I

::! I

:Q it

~ i

~ I

'" I

a I

"" I

1___-

HF32 feed into

ELECTRONIC CROSS-

connection between

OUT jacks.

EXTERNAL

TAPE

FIG.

CHECK AMPL.

CH. 1 LOW

LEVEL INPUTS

CH. 1 HIGH

LEVEL INPUTS

CH.

TAPE OUT

SPEAKER

CH.

Page 7

FIG.

CHECK AMPL. 2

CH. 2 LOW

LEVEL INPUTS

CH. 2 HIGH

LEVEL INPUTS

CH.

TAPE OUT

SPEAKER

CH.

FIG.

STEREO NORMAL

FIG.

STEREO REVERSE

CH. I LOW

LEVEL INPUTS

CH. 2 LOW

LEVEL INPUTS

CH. I LOW

LEVEL INPUTS

CH.

2 LOW

LEVEL INPUTS

CH. I HIGH

LEVEL INPUTS

CH.

2 HIGH

LEVEL INPUTS

CH.

TAPE OUT

SPEAKER

CH.

CH.

TAPE OUT

SPEAKER

CH.

SPEAKER

CH.

FIG.

MONOPHONIC

T APE,

TUNER,

CH. I LOW

LEVEL INPUTS

CH. 2 HIGH

LEVEL INPUTS

CH. I HIGH

LEVEL INPUTS

CH.

TAPE OUT

SPEAKER

CH.

SPEAKER

CH.

CH.

TAPE OUT

SPEAKER

CH.

Page 8

FIG.

MONOPHONIC PHONO

CH. 1 LOW

LEVEL INPUTS

2 LOW

CH.

LEVEL INPUTS

CH. l HIGH

LEVEL INPUTS

CH.

T APE OUT

SPEAKER

CH.

COM

c) INPUTS: There are identical pairs of MAG. PHONO,

TAPE HEAD

ILIARY B inputs -one of each pair in

MICROPHONE, AUXILIARY A, and

channell and chan-

AUX-

nel 2 - and each is identified accordingly by the suffix

1 or 2. The MAG. PHONO,

TAPE HEAD

PHONE pairs of inputs are all II low level" inputs, mean-

ing that they all feed through a preamplifier/equalizer

stage in either channel

AUXILIARY Bpairsofinputs are

ing that they enter either channel

the preampl ifier/equalizer stages.

FM Multiplex inputs are also "

are internally selected in pairs

- by the

INPUT SEL. switch.

l or 2. The AUXILIARY A and

high level" inputs, mean-

l or 2 at a point after

The AM, FM and FM-

high level inputs , which

- one for each channel

At the MONAURAL posi-

tion of the FUNCTION SEL., AM only is selected at

FMposition of the INPUT SEL., and FMonlyis select-

AM-

ed at the FM - FM MULTI. position of the

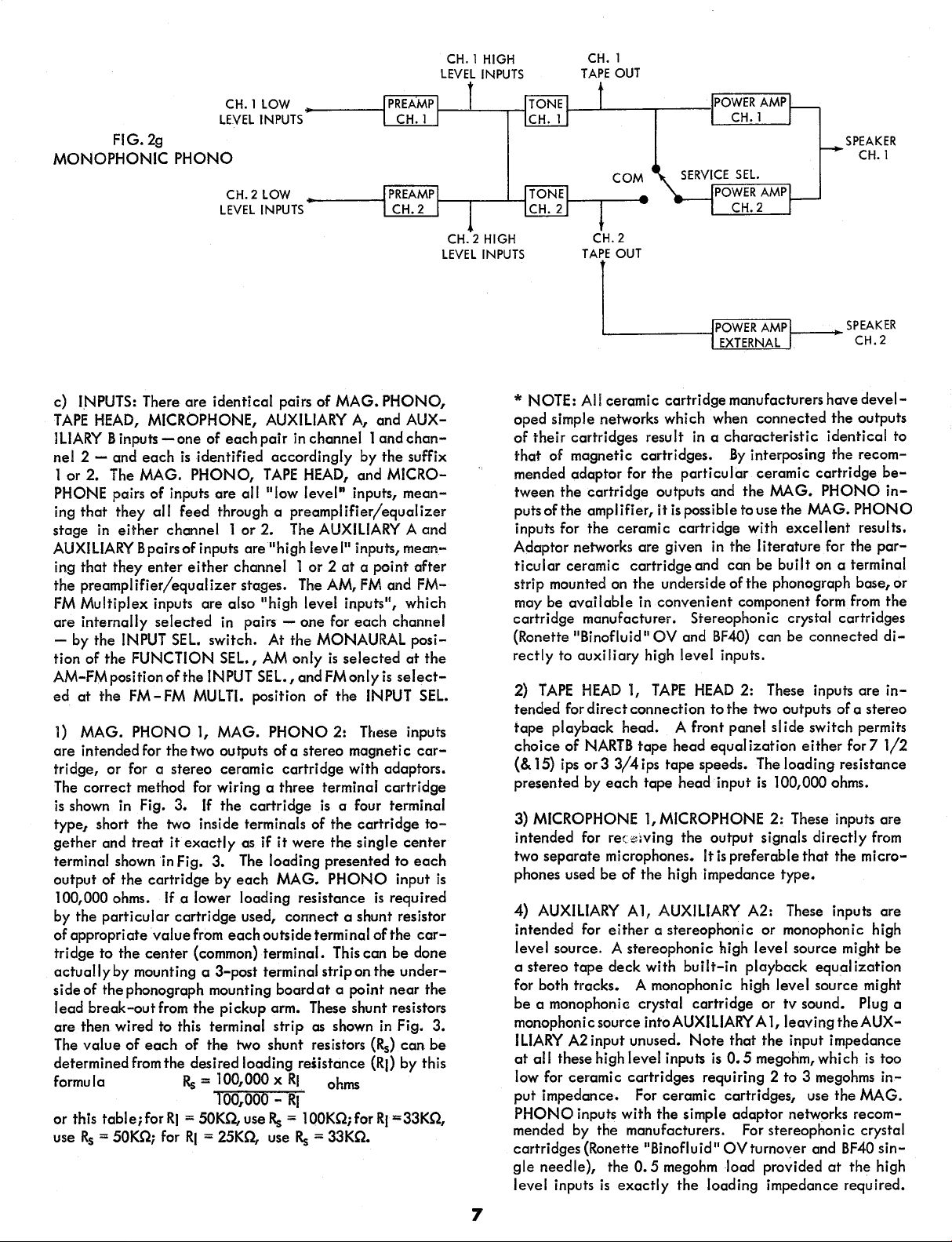

l) MAG.

are intended for the two outputs of a stereo magneti c car-

tridge, or for a stereo

The correct method for wiring a three terminal cartridge

is shown in Fig. 3. If the cartridge is a four terminal

type)' short the two inside

PHONO 1, MAG. PHONO 2: These inputs

ceramic cartridge with adaptors.

terminals of the cartridge to-

MICRO-

, and

INPUT SEL.

the

gether and treat it exactly as if it were the single center

terminal shown in Fig. 3.

The loading presented to each

output of the cartridge by each MAG. PHONO input is

100,000 ohms. If

by the particular cartridge used, connect a shunt

of appropriate value from each outside terminal of the car-

tridge to the center

actually by mounting a 3-

side of the phonograph mounting board at a

lead break-out from the pickup arm.

are then wired to this terminal strip as

The value of each of the

a lower loading resistance is

(common) terminal. This can be done

post terminal strip on the under-

These shunt resistors

shown in Fig. 3.

two shunt resistors (Rs) can be

determined from the desired loading resistance (RI) by this

100,

formula

Rs =

or th is tabl e; for RI = 50KQ, use

use Rs = 50KQ; for

RI = 25KQ, use

000 x RI

00)' - RI

Rs = 1 OOKQ; for RI

ohms

Rs = 33KQ.

required

resistor

point near the

:: 33KQ,

2 HIGH

CH.

LEVEL INPUTS

CH.

T APE OUT

SPEAKER

CH.

* NOTE: All ceramic cartridge manufacturers have devel-

oped simple networks which when

connected the outputs

of their cartridges result in a characteristic identical to

that of magnetic

mended adaptor for the

cartridges. By interposing

particular ceramic cartridge be-

tween the cartridge outputs and the MAG.

puts of the ampl ifjer, it is possible to use the MAG.

inputs for the ceramic cartridge

Adaptor networks are given in

ticular ceramic cartridge

and can be built on a terminal

strip mounted on the underside of the

may be available in convenient

with excellent

the literature for the par-

phonograph base, or

component form from the

cartridge manufacturer. Stereophonic

(Ronette "

rectly to auxiliary high level inputs.

2) TAPE HEAD

Binofluid II OV and BF40) can be connected di-

1, TAPE HEAD 2: These inputs are in-

the recom-

PHONO in-

PHONO

results.

crystal cartridges

tended for direct connection to the two outputs of a stereo

tape playback head. A front panel slide switch permits

choice of NARTB tape head equalization

(& 15) ips or3

presented by each tape head input is 100,000 ohms.

3) MICROPHONE 1, MICROPHONE 2: These inputs are

314

ips tape speeds. The loading resistance

either for71/2

intended for rec~~:ving the output signals directly from

two separate microphones. It is preferable that the microphones used be of the high impedance type.

4) AUXILIARY AI, AUXILIARY A2: These inputs are

intended for either a stereophonic or monophonic high

level source. A stereophonic high level source might be

a stereo tape deck with built-

for both tracks.

A monophonic high level source might

be a monophonic crystal cartridge or tv sound.

monophonic source intoAUXJLlARY A 1, leaving

ILIARY A2 input unused. Note that the input

at all these high level inputs is 0.

low for ceramic cartridges requiring 2 to 3 megohms in-

put impedance. For

ceramic cartridges, use the MAG.

PHONO inputs with the simple adaptor networks recom-

mended by the manufacturers. For

cartridges (Ronette "Binofluid" OVturnover and BF40 sin-

gle needle), the 0.

5 megohm load provided at the high

level inputs is exactly the loading impedance required.

in playback equal ization

Plug a

theAUX-

impedance

5 megohm, which is too

stereophonic crystal

Page 9

STEREO MAG.

CARTRIDGE

5) AUXILIARY Bl, AUXILIARY

ILIARY A 1, AUXILIARY A2 above.

6) AM: This input is intended for AM tuner or the AM

output of an FM-AM tuner where the FM

are independent.

B2: Same as for AUX-

and AM sections

FIG. 3

TO MAG.

INPUT

TO MAG. INPUT 2

mentioned sources to the correspondmg

jack. Unless the source has a low-impedance output such

as a cathode follower (with which up to 50ft.

can be used), use the shortest possible connection and

low - capacity shielded cable (cable having

amplifier input

of cable

as low as

25mmfd capacitance per foot is available).

7) FM:

where the FM and AM sections are independent.

8) FM MULTIPLEX: This input is intended to receive the

This input is intended for an FMor FM-

AM tuner

output from an FM Multiplex adaptor.

NOTE: A shielded cable with a shielded "

plug should be used to connect from each of the above-

HF 81

phono-type

TAPE

OUT

cgJ

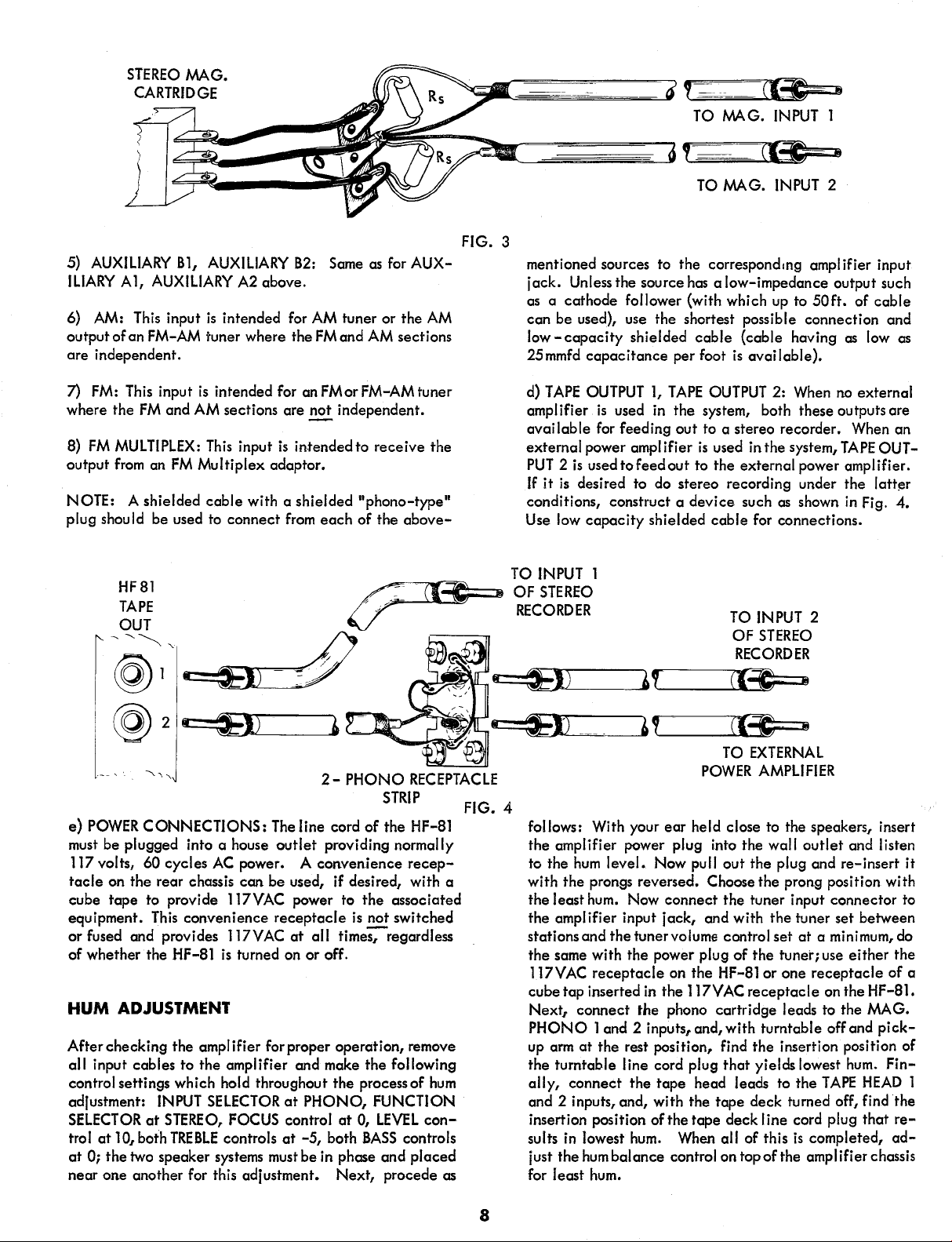

e) POWER CONNECTIONS: The line

must be plugged into a house outlet providing normally

117 volts, 60 cycles AC power.

tacle on the rear chassis can be used, if desired

cube tape to provide

equipment. This convenience receptacle is not switched

or fused and provides 117VAC at all time'S""rregardless

of whether the HF-81 is turned on or off.

HUM ADJUSTMENT

After checking the ampl ifier for proper operation, remove

all input cables to the amplifier and make the following

control settings which hold throughout the process of hum

adJustment: INPUT

SELECTOR at STEREO, FOCUS control at 0,

trol at 10)' both TREBLE controls at -5, both BASS controls

at 0; the two speaker systems must be in phase

near one another for this

-=8

2 - PHONO RECEPTACLE

STRIP

cord of the HF-

A convenience recep-

, with a

117VAC power to the associated

SELECTOR at PHONO, FUNCTION

LEVEL con-

and placed

adJustment. Next, procede

FIG. 4

d) TAPE OUTPUT 1, TAPE OUTPUT 2: When no

amplifier is used in the system,

available for feeding out to a stereo recorder. When an

external power ampl ifier is used in the system,

PUT 2 is used to feed out to

the external power amplifier.

If it is desired to do stereo

conditions, construct a device such as

both these outputs are

recording under the latter

shown in Fig. 4.

external

TAPE OUT-

Use low capacity shielded cable for connections.

TO INPUT

OF STEREO

RECORDER

6 ,

TO INPUT 2

OF STEREO

RECORDER

TO EXTERNAL

POWER AMPLIFIER

follows: With your ear held close to the speakers, insert

the amplifier power plug into the wall outlet and listen

to the hum level. Now pull out the plug and re-insert it

with the prongs reversed. Choose the prong position with

the least hum. Now connect the tuner input connector to

the amplifier input jack, and with the tuner set

stations and the tuner volume control set at a minimum, do

between

the same with the power plug of the tuner; use either the

117VAC receptacle on the HF-

cube tap inserted in the 117V AC receptacle on the HF-

Next)' connect the phono cartridge leads to the MAG.

PHONO 1 and 2 inputs, and, with turntable

up arm at the rest position, find the insertion position of

the turntable line cord plug that yields lowest hum. Fin-

81 or one receptacle of a

off and pick-

ally, connect the tape head leads to the TAPE HEAD

and 2 inputs, and, with the tape deck turned

insertion position of the tape deck line cord plug that

sults in lowest

just the hum balance control on top of the amplifier chassis

for least hum.

hum. When

all of this is completed, ad-

offl find the

81.

re-

Page 10

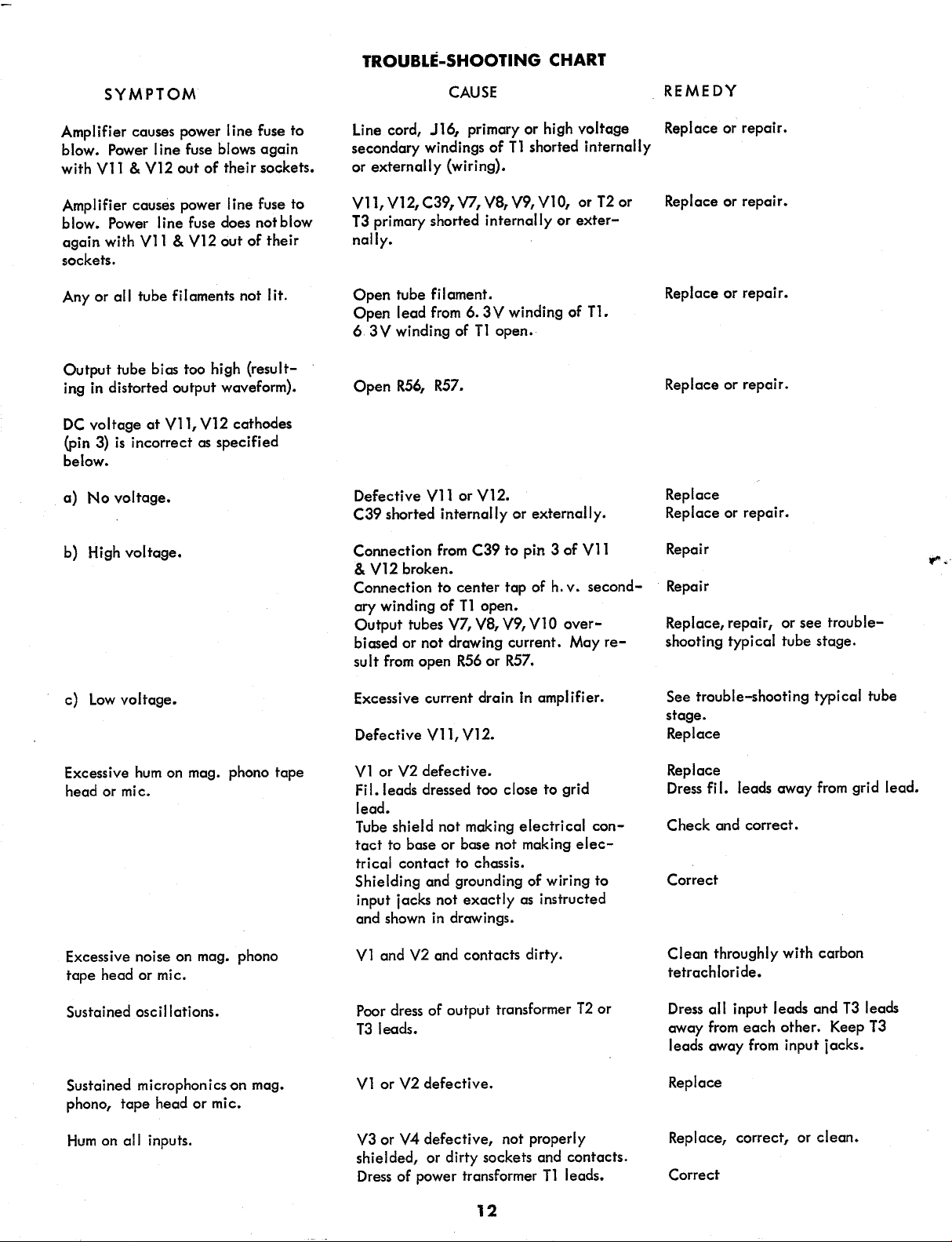

operation

PRELIMINARY: Be sure all tubes are

sockets and that the tube shields are making good contact

firmly seated in their

with their baSes. As initial adjustments, set these controls

as follows: LEVEL at 0, FOCUS at

at O. Turn the amplifier on by turning the

trol clockwise from AC OFF and set it at zero

Also set the

TREBLE 1 control

0)' both BASS controls

TREBLE 2 con-

initially.

at zero. Please note that

in the instructions that follow, it is assumed that a stereo

pick-

up and/or a stereo tape head is being

the system.

LISTEN IN G TO

TOR to PHONO if you

PHONOGRAPH: Set the IN

have a megnetic cartridge or a

employed in

PUT SELEC-

ceramic cartridge with adaptors interposed between the

cartridge outputs and the MAG. PHONO

(The RIAA equalization provided at the PHONOposition

is now the international standard in the recording industry

for both monophonic and stereophonic records and is also

a very good compromise for the most important of

monophonic recording characteristics.

SELECTOR to AUX Aor AUX B if you are using a stereo-

1 and 2 inputs.

) Set

the INPUT

the older

phonic crystal cartridge (Ronette) connected to eitherAUX

A or AUX B inputs. Set the FUNCTION

either STEREO position.

channels, playa conventional monophonic

To balance levels between the

cording on the changer or turntable and turn the

control up until you have

that the action of the

normal listening level.

FOCUS control (sometimes called a

SELECTOR at

(lateral) re-

LEVEL

Note

balance" control) is to simultaneously raise the level in

one channel while lowering the level in the other as it is

turned in anyone

FOCUS control)' equal sound volumes would

channels only if the ideal conditions of identically effi-

cient loudspeakers and identical overall gains in both

direction. At the zero

setting of the

obtain on both

channels existed. With the conventional monophonic re-

cording being played

volume from each speaker system.

, adjust the FOCUS control for equal

With the

FOCUS set-

ting properly made, any stereo recording played back will

have close to the same balance as actually exists in the

recording. The

manent adjustment in that

FOCUS control setting can be a semi-

, at any given time, the setting

per-

achieved as described above will usually be satisfactory

for tape stereo, and

may also be for broadcast

stereo, if

it means exist of adjusting for equal output levels from the

stereo broadcast rece iving equ ipment. As

a shift of the

normal FOCUS control setting may be nec-

components age,

essary. Note that there are a concentricpairofbass con-

trois, one in each channel and a concentric pair of treble

controls, one in each channel. Use the

treble controls to

of the recording from the standard recording characteristic,

as well as to

of your audio system (including room acoustics). Set the

FUNCTION SELECTOR to

REVERSE for

compensate for any audible deviation

compensate for the over-

STEREO NORMAL or STEREO

stereophonic records and to MONOPHONIC

PHON 0 for CONVENTIONAL MON OPHON IC records.

LISTENING TO TAPE DECK

(direct connection to tape

separate bass and

all characteristics

head): Set the INPUT SELECTOR to TAPE. NARTB tape

head equalization is provided in both channels for

tape speed selected with the

~nel'- One position is

for71/2and

TAPE switch on the front

15ips tapes and the

the

other for 3 3/4 ips tapes. These equalizations are the

industry standard for pre-recorded stereophon i

phonic tapes.

described in the preceding paragraph

satisfactory for this function also.

If the FOCUS' control has been set as

, it will usually be

Otherwise, it may be

set in a similar manner using a test tape or

Set the FUNCTION SELECTOR to STEREO NORMAL

REVERSE for

TUNER

TREBLE tone controls as described above.

LISTENING

ED TO AUXILIARY AI, AUXILIARY Bl

PHONIC AM BROADCAST, OR

BROADCAST: Set the

AUX.

FUNCT10N SELECTOR to MO~OPHONIC

Use the BASS and TREBLE controls as described previous

LISTENING TO A STEREOPHONIC SOURCE CONNECT-

ED TO AUXILIARY Al and

stereophonic tapes or to

, AUX for

monophonic tapes. Use the BASS

TOAMONOPHONIC

, AM-FM, or FM-

SOURCE CONNECT-

TO MONOPHONIC FM

INPUT SELECTOR to AUX. A,

MUL TI.

A2, AUXILIARY B1 and B2,

respectively and the

AM and FM, FM and FM MULTIPLEX: Set the INPUT

SELECTOR to AUX A,

respectively. Set the

AUX B, AM-FM, or FM-MUL TI

FUNCTION SELECTOR

NORMAL or STEREO REVERSE. The FOCUS, BASS and

TREBLE controls are set as described previously.

MAKING

by connecting the recorder to the

See "TAPE OUTPUT 1,

TRICAL INSTALLATION. Please

cannot be made on tape decks

RECORDINGS: Tape recordings may be made

TAPE OUTPUT jacks.

TAPE OUTPUT 2" under ELEC-

note that recordings

unless those decks are

c and mono-

simply by ear.

MONOPHONIC

and

, TO

MONO-

TUNER, AUX.

at STEREO

I y.

equipped with the electronics required for recording.

FUNCTION SELECTOR: The STEREO NORMAL and STER-

EO REVERSE positions

production. At the

are both used for stereophonic re-

STEREO REVERSE

position, the chan-

nel 1 and channel 2 amplifiers from the tone controls to

the speaker connections are interchanged.

These two

positions permit interchanging the signals fed to the two

speakers so that the correct

orchestra can be achieved on all recordings or broadcasts.

The CHECK AMPL. 1 and CHECK AMPL. 2 positions per-

mit hearing either channell alone or

comparison or balancing purposes during stereophoni

left to right display of the

channel 2 alone for

c use.

The MONOPHONIC TUNER, AUX position is used for

monophonic FM, AM, tv

ridge monophonic pre-

nel 1 inputs. At this

are unused in this type of operation, are disconnected

from t

he active channel so that they cannot

interference. At the MONOPHONIC PHONO

the channell and 2

is useful when playing monophonic records with

phonic cartridge to cancel vertical rumble

sound)' monophonic phono

amplified tape etc., fed into chan-

position)' the channel 2 inputs which

contribute

position,

corresponding inputs are mixed

, which

a stereo-

components.

cart-

Page 11

BASS CONTROL 1,

The plus sign on the right side of the dial indicates that

clockwise rotation from the mid-

increases (boosts) _

side indicates that counter-

BASS CONTROL 2 (CONCENTRIC):

point (0) of either control

bas~ response; the minus sign on the

clockwise rotation from the

left

mid-point decreases (cuts) bass response. There is no in-

teraction with the

TREBLE

control.

with this control set at the mid-

the "flat" position since bass response

Start all adjustments

point (0), which is called

is neither cut nor

boosted at this position.

maintenance

TREBLE CONTROL

TRIC): The plus sign on the right side of the

that clockwise rotation from the mid-

1, TREBLE CONTROL 2

(CONCEN-

dial indicates

point (0) of either

control increases (boosts) treble response; the

indicates that counter-

point decreases (cuts) treble

action with the

this control set at the mid-

flat" position since treble response

BASS control.

clockwise rotation from the mid-

response. There is no inter-

Start all

point (0), whi ch

adjustments with

is called the

is neither cut nor

boosted at this position.

minus sign

GENERAL

Your amplifiershou Id require I ittle

mal tube replacement. We

recommend no substitutions for

service except for nor-

the tube types used in this amplifier except as stated. All

the tube types used are distributed national Iy, but

ments can be obtained directly

To facil itateservicing, remedial and trouble-

cedures have been provided in the TROUBLE-

CHART that follows.

CHART is also provided

A VOLTAGE AND

from EICO if desired.

as an aid in

locating defective

replace-

shooting pro-

SHOOTING

RESISTANCE

components. DC operating voltages are given both at no

signal and signal developing 14 watts

output, as well as

the corresponding 1 kc signal voltages.

TROUBLE-SHOOTING PROCEDURES

Connect the leads from the

two speakers to the amplifier.

as described in the section "

stereo cartridge and from the

These connections are made

Electrical Connections "

the Input Selector control at PHONOand the Function Se-

lector at

STEREO. Playa known high quality stereo

record-

ing on the phonograph. If there is no output to the speaker

of if the output is

low or audibly distorted

checks for those symptoms. If there is

. the output

ampl ifier and short the phono input

, disconnect the phono input cable

hum disappears, the trouble is not

, procede to the

excessive hum in

from the

jack to chassis. If the

in the amplif.er but in

the phonograph or in the connection to the amplifier.

each case, check for the trouble in the amplifier which

seems defective. If both

the power supply.

The cause of phonograph hum may be a

not grounded to the cable shield (try a good single ground

amplifiers are defective, check

metal pick-up arm

connection to the cable shield from turntable frame, pick-

up arm, and cartridge case), direct

hum pick-up by the

magnetic cartridge from the record player motor(tryusing

a rubber mat on the turntable to increase the separation of

the pick-up from the motor), or pick-up from a power

transformer or other magnetic

moving phonograph away from suspected source). Check

also that the phono input cable shielding is

the ampl !fier chassis at one point only, through

of the input connector where it

Finally, try a good building ground

field in the vicinity

grounded to

the skirt

plugs into the ampl ifier.

such as a connection

from a cold water pipe terminated under speaker terminal

. Set

(try

G" on the amplifier

to other

components in the system

channel be connected to the amplifier

shielded cable to the ampl ifier

that the ground leads on both cables not be

gether at any point

ever, with some

this. In this case, just disregard this last instruction.

Excessive hum on other inputs may be checked in

Do not connect such a ground wire

If possible, let each

using a separate

input. It is

- not even at the cartridge. How-

cartridges, it will not be possible to do

also desirable

connected to-

a similar

manner. Disconnect the input cable in question and short

the particular input jack to the chassis. If the hum dis-

appears, the trouble is external to the amp!

that on all

nect to the ampl ifier only

connector. The cause and remedies for the following

symptoms are then based on the

inputs, the braid of th;;; input cable shou Id con-

through the skirt of the input

assumption that checks

ifier.

Note

made in the manner described above have eliminated the

possibilityof the trouble being external to the amplifier.

If the trouble is no output or low output

, check AC signal

voltages and DC operating voltages starting at the input

and work step_

fier. Set the

FOCUS, BASS and

(0), the INPUT SELECTOR to PHONO and

TION SELECTOR

wave signal

Square Wave Audio Generator In addition, use a pre-

cision 100: 1 attenuator to permit obtaining a

0035 volt fed into MAG. PHONO

erator output of 0.

onthelowestACvolts range ofyourVTVM

signal to hum from generator). Use a high

ance VTVM for all

VTVM or 20,

. If the trouble

replacement, signal tracing, or procede

tage and resistance measurements.

When the defective stage is local ized, procede

by-step toward the output in each ampl i-

VOLUME control to

TREBLE controls

to STEREO

, such as supplied by the EICO 377 Sine &

maximum (10), the

to their mid-points

the FUNC-

. Use a 1000cycle sine-

level of

from an audio gen-

35 volts, which can easily be measured

(also improves

input imped-

AC signal voltage

OOOQ/v

YOM

for DC volts measurements.

measurements; a

is an excessively distorted output, try tube

directly to vol-

to a resist-

ance and voltage check of the stage, using the data in the

VOLTAGE and

RESISTANCE chart.

Disconnect theampli-

fier from the power line and discharge capacitors prior to

making any resistance check and prior to removing any or

all of theEL84output tubes.

with any of the output tubes

Do not turn the amplifier on

remove

Page 12

CHECKING A

1. Check tube.

2. Check plate and cathode resistor.

3. Check

4. For output stage, check dc

TYPICAL TUBE STAGE

coupl ing capacitors for leakage or short.

resistance of transformer

windings.

5. Check grid leak resistor for open.

6. Check cathode

7. If

no or

path for open or defective R60,

by-pass capacitors for short.

low B+ voltage on tube, check decoupling

R61, R62, R63 and fiI ter

capacitor C37, C38 or C39.

8. . If wiring and circuit

check O. K. and B+

coupl ing path for short or

Suspected trouble in the

volume controls and networks should lead to specific

components including the tube

voltage is

excessive)' check the de-

defective R60, R61,

R62and R63.

equalization)' tone, focus, and

re-

sistance and capacitance checks to localize the trouble.

In general, if the user suspects poor frequency response,

defective equal ization)' or defective operation of the tone

controls, the amplifier should be tested thoroughly

audio generator, vtvm, and scope.

with

SPEAKER PHASING

IMPORTANT NOTE ON

loudspeaker systems must be

in phase, meaning that corresponding cones or diaphragms

SPEAKER PHASING:

connected so that they operate.

in the systems move in and out together when

The two

actuated by

the same or similar signals. A simple method of checking

this is to playa conventional monophonic (lateral)

record-

ing having considerable bass program material, setting the

FUNCTION SELECTOR at MONAURAL. After listening

for a few minutes, reverse the connections of the speaker

leads at only one of the speaker

systems - not both

- and

listen again to the same program material. Normally, you

wi II noti ce that one of these connections seems to give

bass re-inforcement and the other bass cancellation. The

connection that gives bass re-inforcement is the in-phase

connection and should be used.

Another criterion for the in-phase connection is that of

blending, which can be best applied if the speaker

are identical or at

frequency range reproducers. With the in-

least have similar middle

nection and both speakers operating at approximately the

same volume level, a monophonic

emanating from a point mid-

speakers will blend. With the out-of-

source will appear to be

way between and the two

phase connection,

systems

and high

phase con-

the two sources will appear to remain separate.

SERVICE

If trouble developes in your instrument which

remedy yourself, write to our service

all possible indications that might be helpful.

you can;.,t

department listing

If desired

you may return the instrument to our factory where it wi

be placed in operating condition for $12.

of parts replaced due to their being damaged in the

of construction.

sure all parts are securely

instrument, giving your home address and the trouble with

the unit. Pack very carefully in a rugged

NOTE: Before returning .

mounted. Attach a tag to the

ing sufficient packing material (cotton,

50 plus the cost

course

this unit, be

container)' us-

shredded news-

paper, or excelsior), to make the unit completely immov-

able within the container.

is satisfactory, providing the original

sufficient packing material

ment immovable.

possible, to Electronic Instrument Co.,

ern Blvd., Long Island City I,

mentwill be made byexpress collect. Note that a

Ship by prepaid Railway

cannot be held liable for

The original shipping carton

inserts are used or

inserted to keep the instru-

Express, if

Inc., 33-

New York.

00 North-

Return ship-

carrier

damages in transit if packing

IN HIS OPINION)' is insufficient.

Page 13

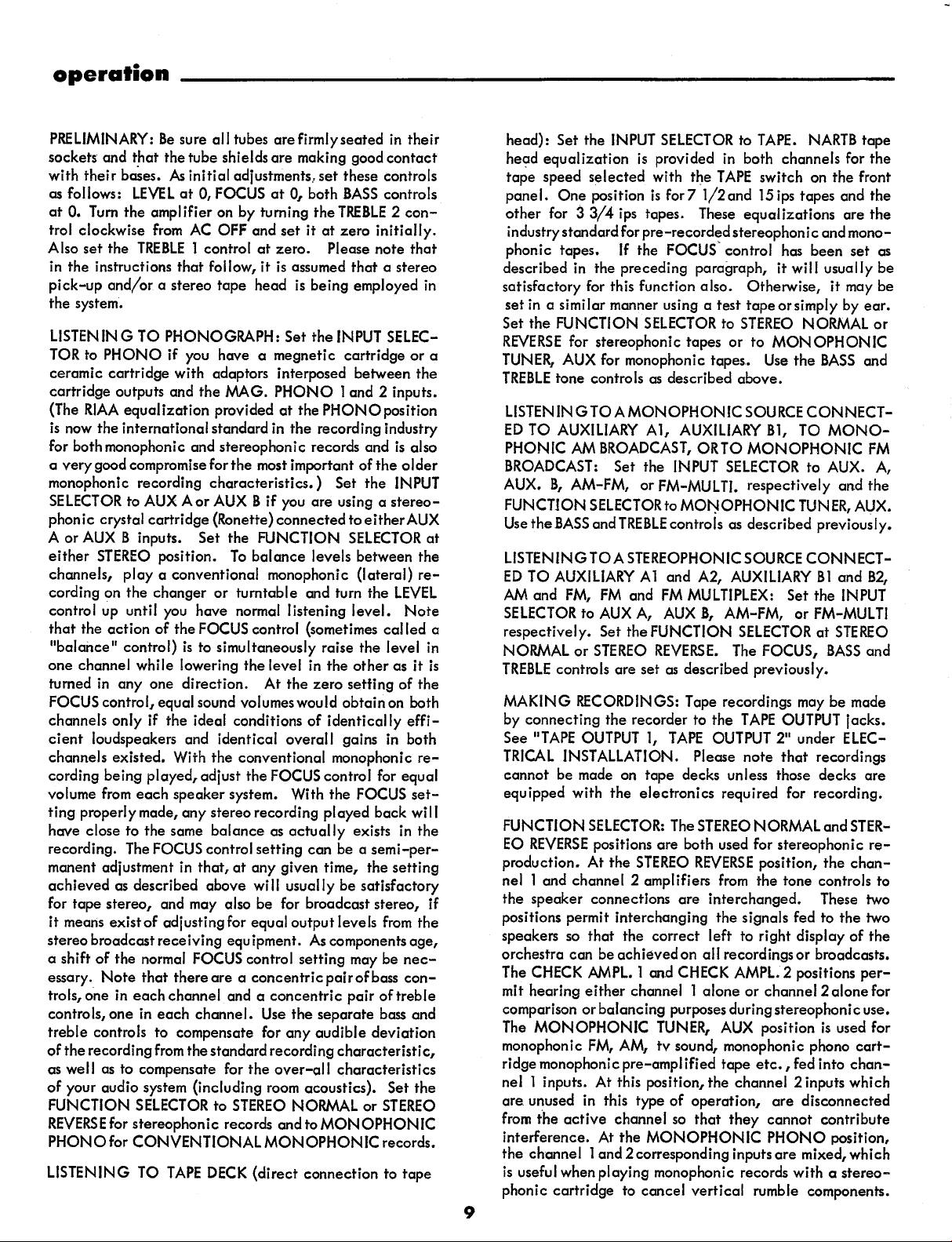

TROUBLE-

SHOOTING CHART

SYMPTOM

Amplifier causes power line fuse to

blow. Power line

with VII &

fuse blows again

V12 out of their sockets.

Amplifier causes power line fuse to

blow. Power line fuse

again with VII &

does not blow

V12 out of their

sockets.

Any or all tube filaments not lit.

Output tube bias too high (result-

ing in distorted output waveform).

DC voltage at Vl1, V12 cathodes

(pin 3) is incorrect as specified

below.

a) No

voltage.

CAUSE

Line cord, J16, primary or high voltage

secondary windings of T1 shorted internally

or externally (wiring).

VII, V12, C39)' V7, va, V9,

T3 primary shorted internally or

VI0, or T2

exter-

nally.

Open tube fil ament.

Open lead from 6. 3V winding of T1.

6 3 V winding of T1 open.

R56, R57.

Open

Defective VII or V12.

C39 shorted internally or externally.

REMEDY

Replace or repair.

Replace or repair.

Replace or repair.

Replace or repair.

Replace

Replace or repair.

b) High voltage.

c) Low voltage.

Excessive hum on mag. phono tape

head or mic.

Excessive noise on mag. phono

tape head or mic.

Connection from C39 to pin 3 of VII

& V12 broken.

Connection to center tap of h. v. second-

ary winding of T1 open.

Output tubes V7, VS,

V9, VI0 over-

biased or not drawing current. May re-

sult from open

R56 or R57.

Excessive current drain in amplifier.

Defective VII, V12.

VI or V2 defective.

leads dressed toa close to grid

FiI.

lead.

Tube shield not making electrical con-

tact to base or base not

trical contact to chassis.

making elec-

Shielding and grounding of wiring to

input jacks not exactly as instructed

and shown in drawings.

VI and V2 and contacts dirty.

Repair

Repair

Replace, repair, or see troubleshooting typical tube stage.

See trouble-shooting typical tube

stage.

Replace

Replace

Dress fit. leads

Check and correct.

away from grid lead.

Correct

Clean throughly with carbon

tetrachloride.

Sustained oscillations.

Sustained microphonicson mag.

phono, tape head or mi c.

Hum on all inputs.

Poor dress of output transformer T2 or

T3 leads.

VI or V2 defective.

V3 or V4 defective, not properly

shielded, or dirty sockets and contacts.

Dress of power transformer T1 leads.

Dress all input leads and T3 leads

away from each other. Keep T3

leads away from input jacks.

Replace

Replace, correct

, or clean.

Correct

Page 14

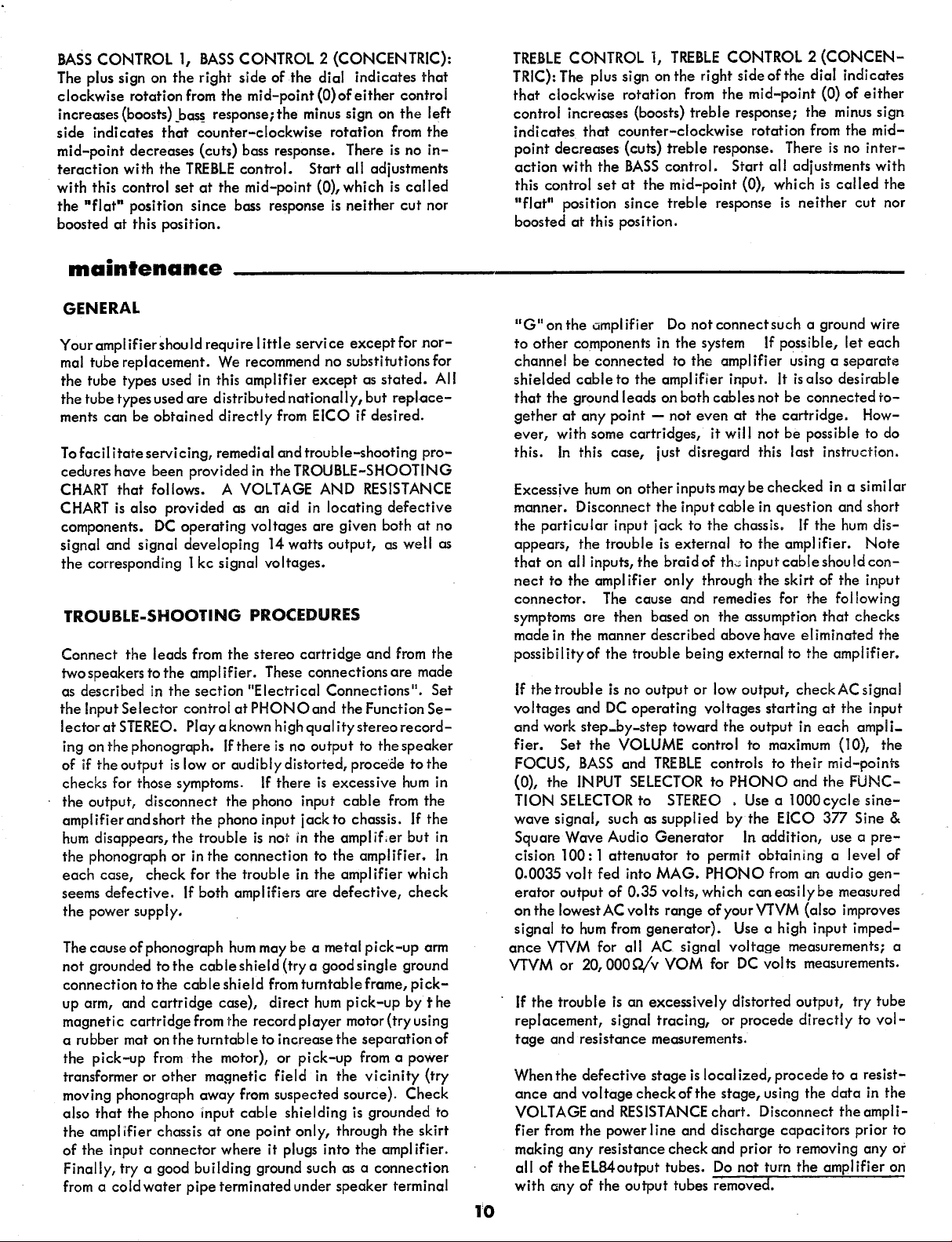

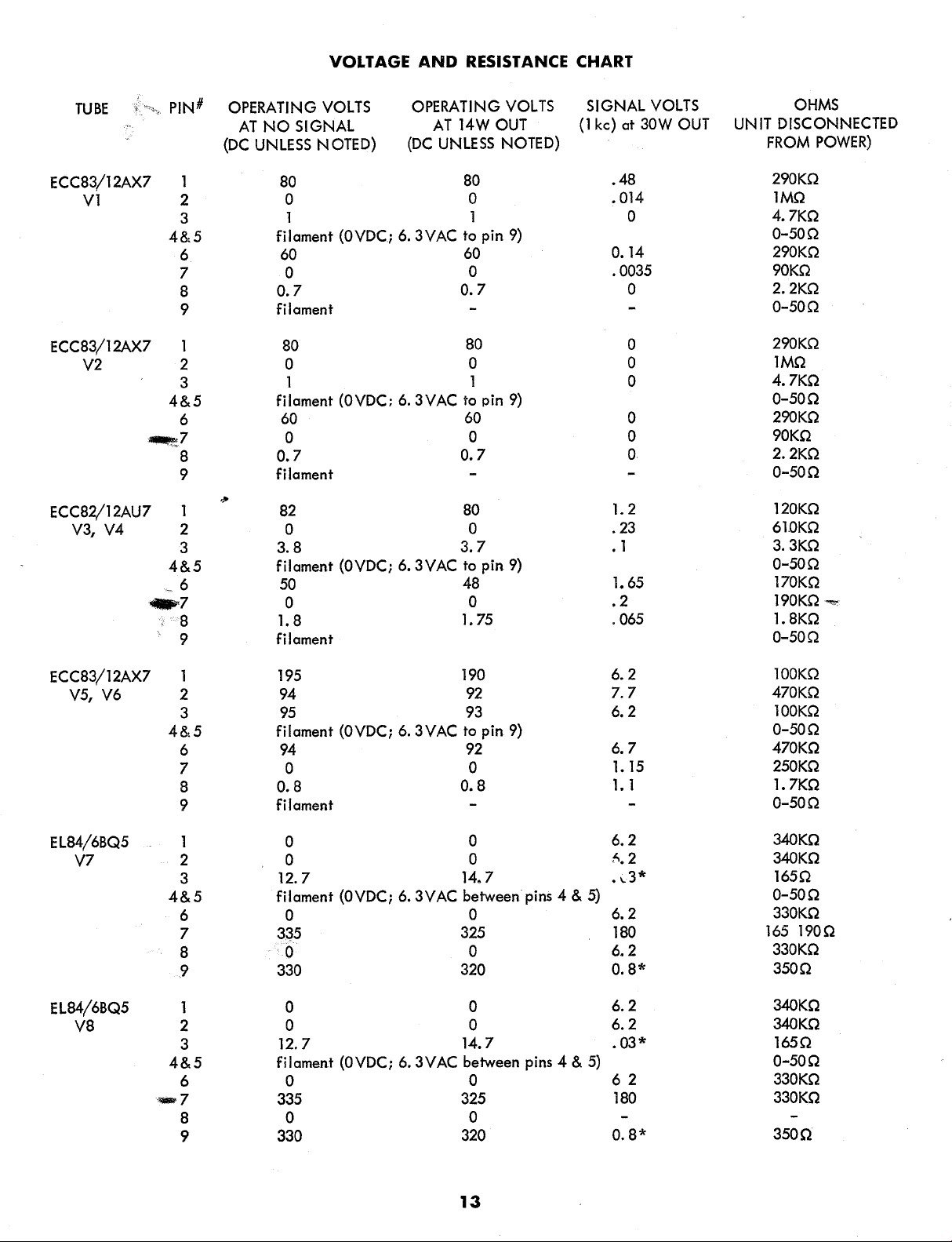

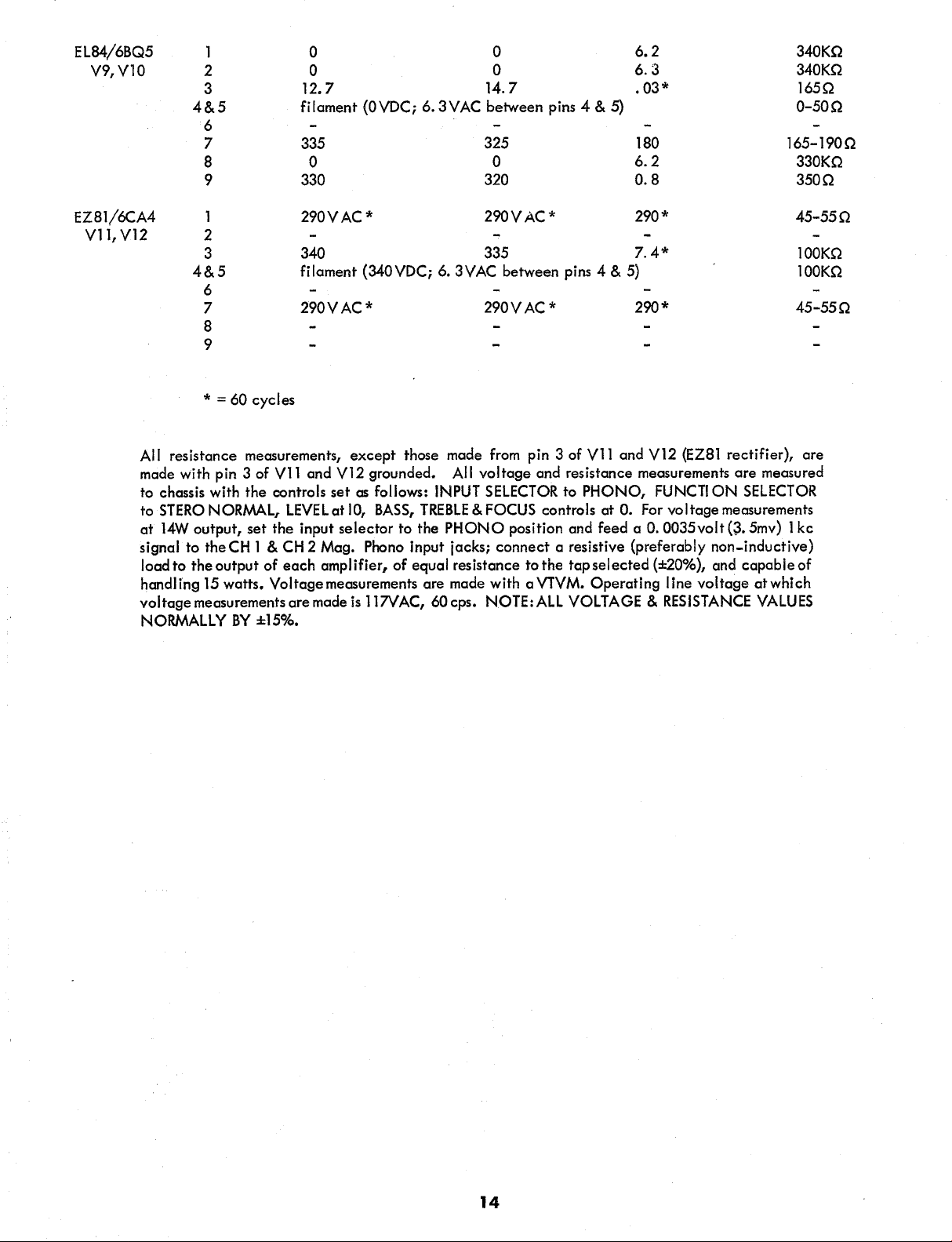

VOLTAGE AND RESISTANCE CHART

TUBE

CC83(12AX7

ECC83/12AX7

ECC82/12AU7

V3, V4

PIN# OPERATING VOLTS

AT NO SIGNAL

(DC UNLESS NOTED)

4&5

filament (OVDC; 6. 3VAC to pin 9)

filament

4&5

4&5

filament (OVDC; 6. 3VAC to pin 9)

fi lament

filament (OVDC; 6.

1. 8

filament

OPERATING VOLTS

AT 14W OUT

(DC UNLESS NOTED)

3VAC to pin 9)

1. 75

SIGNAL VOLTS

(1 kc) at 30W OUT UN IT DISCONNECTED

014

OHMS

FROM POWER)

290KO

IMO

7KO

500

290KO

0035

90KO

2KO

500

290KO

IMO

7KO

500

290KO

90KO

2KO

500

1. 2

. 1

120KO

61OKO

3KO

500

170KO

190KO

065

8KO

500

ECC83/12AX7

V5, V6

EL84(6BQ5

EL84(6BQ5

195

4&5

filament (OVDC; 6. 3VAC to pin 9)

filament

12.

4&5

filament (OVDC; 6. 3V AC between pins 4 & 5)

335

330

12.

4&5

filament (OVDC; 6. 3V AC between pins 4 & 5)

-,7 335

190

1. 15

1. 1

,1,

14.

325

320

14. 03*

325

180

6 2

180

100KO

470KO

100KO

500

470KO

250KO

7KO

500

340KO

340KO

1650

500

330KO

165 1900

330KO

3500

340KO

340KO

1650

500

330KO

330KO

330

320

3500

Page 15

EL84/6BQ5

V9, V10

4&5

0 6.

12. 7

filament (OVDC; 6. 3VAC between pins 4 & 5)

14. 7 . 03 *

340KQ

340KQ

165Q

50 Q

EZ81/6CA4

VII, V12

All resistance measurements, except those

made with pin 3 of V11 and V12 grounded.

to chassis with the controls set as follows:

to STERO NORMAL)' LEVEL at

at 14W output

signal to the CH 1 &

load to the output of each amplifier, of equal resistance to the tap selected

handling 15 watts. Voltage measurements are made with a

voltage measurements are made is 117VAC, 60cps.

NORMALLY BY::I:15%.

335

330

290 V AC *

340 335 7.

4&5

* = 60 cycles

, set the input selector to the PHONO position

filament (340VDC; 6. 3VAC between pins 4 & 5)

290V AC *

made from pin 3 of Vl1 and V12

All voltage and resistance

INPUT SELECTOR to

10, BASS, TREBLE & FOCUS controls at O. For voltage measurements

CH 2 Mag. Phono Input jacks; connect a resistive (preferably non-

325

320

29OV AC* 290*

290V AC *

PHONO, FUNCTION SELECTOR

and feed a O. 0035volt

VTVM. Operating line voltage atwhlch

NOTE: ALL VOLTAGE &

180

290* 45-

measurements are measured

(::1:20%), and

165- 190 Q

330KQ

350Q

45-55 Q

100KQ

100KQ

(EZ81 rectifier),

(;3. 5mv) 1 kc

inductive)

capable of

RESISTANCE VALUES

55 Q

are

Page 16

INPUT

SELECTOR

SWITCH

S 1

SECTION

AUXA

11- 10-11- 10- 12

10-

AUX B AM-FM FM-

11- 11-

MUL TI MIC

2-6-

PHONO

10- 10- 11-

10-

TAPE

11-

3- 7

4-11 1 -4-

10-

10-

10- 10- 10-

SECTION

FUNCTION

SELECTOR

SWITCH

1) Entries are numbers of those switch contacts

AMPL. 1

4- 10

AMPL. 2

which are connected together by the

NC means no connection.

2) On schematic diagram, all switch wafers shown in the

seen from the front or shaft end.

2-4- 3-4-

3-6-

10-12.

NORMAL

9- 1 0-

REVERSE TUNER AUX.

10- 10- 10-

1":12

10- 10-11

3-4-7

rotors at the

maximum counter_clockwise position (AUXA and CH

TOP VIEW

particular position.

PHONO

1CHECK)as

~~Lhttps://manualmachine.com/6BQ5

~'-'t'~

MODEL HF-

DUAL 14 WATT HIGH FIDELITY 140 WATTS

INTEGRATED AMPL"'ER

ECC83/12AX7V ECC82/12AU7V

3 AMPS 117 VAC

(Q)

ITJJ 10

ECC83/12AX7

ECC83/12AX7

r'\ V-

iUEIiJ.

MODEL HF-

DUAL 14 WATT HIGH FIDELITY

INTEGRATED AMPLIFIER

TAPE OUT SPEAKER CONNECTIONS

84/6BQ5 ~~L~4/6BQ5

r'\ r'\ V-

V V

r'\

FRONT

0 0 001

CH- 2

CH.

CHANNEL 2 CHANNEL 1

~~~84/6BQ5

ECC83/12AX7

r'\V-

VECC82/12AU7

100000\

r'\V-

11 r'\V-

VEZ81 \JEZ81

OAM

OFM

000

MIC PHONO TAPE

CHANNEL 1

AUX A

AUX B

MULTIO

000

MIC PHONO TAPE

CHANNEL 2

OPERATES FROM ""V

SO/6C CYCLE AC LINE

POWER CONSUMPT'ON.

ELECTRONIC INST. '

noo NORTHERN BLVD

L , CITY 1 N Y

CO.. INC.

Page 17

REPLACEMENT PARTS LIST

Stock'

20050

23014

23020

22517

22514

22518

22550.

22506

20039

22520

22529

22543

23007

22533

24005

23016

20043

22519

91005

92000

50020

50018

50011

50016 J16

"'" 29751

10407

10400

11526

10423

10430

11504

11527

10422

11518

_18045

---., 8046

10435

10414

18048

18047

10410

10420

10431

11543

10412

14600

11538

10851'

10952

14302

19009

10421

60057

60065

62000

62002

30021

32013 T2, 3

54516

54002

54001

54014

54003

54006

54013

54008

Symbol

Cl,

C3,

C5,

C7,

C35, 36

C9,

Cl1,

C13,

C15,

CI7, 18,

CI9, 20,41,

C23,

C25, 26, 27, 28

C29,

C31, 32, 43, 44

C37

C38,

C40

C47, 48

JI-

J5-

10.

11-12-

J14-

PCl,

Rl,

R:r,4,

53, 54,

RS, 6, 11

R13

R15,

RI7 18, 44,

46,

20, 60

R19

R2I,

R22, 23

R24, 25

R26,

R28, 29

R30, pot., IMQ, linear

R32, 33, 54

R34, 35

R36,

R38,

R42, 43

R48, 49,

RS6, 57

RS8, 59

R61

R62

R63

R64 pot" 100Q

R70, 71

TB1,

TB3,

T84 terminal strip, IP right

TB5

TB6,7,

TB9, 11, 18

TBIO, 19 terminal strip, lP left w/ground

TBI2, 14

Description

cop. , paper

cop.,

cap.,

cap., disc., . 025mfd, GMV (25K or 25,

33,

, 45, 46

cap.,

cap.,

cap.

cop.

21, cap.,molded,.

cap.,

cap. disc., 150mmf, "'10%

cap.,

cap., elec., 5Omfd, 25V

cap., disc., 47mmf, "'10%

cap.

cap., elec., 30mfd,

cap., molded, .

cap., disc., . 0Imfd,

fuse, 30mp

pilot light, '47

jack, quad,

jack, triple

jack, dual

outlet, convenience

printed circuit

res., IMQ,

res., 10KQ

40, 41,

res., 200KQ,

res., 2. 2KQ,

res., 4.

res., 90KQ,

45, res., 100KQ

res., 68KQ,

res. , 2.2MQ, l('NI, : 5% (red, red,

pot. , 750KQ

pot., 250KQ, audio, dual

res., 150KQ,

res., I. 8KQ,

pot. ,

res", 100KQ,

, 68, 69

res., 3. 3KQ, l(~, %10% (orange,

res., 470KQ,

res. , 1.8KQ, l(~, : 5% (brown,

50, 51" res. , 330KQ, 1/~,

res., 1650,

res., 22KQ, 1/~, % 5% (red

res., 22KQ,

res., 4. 7KQ,~,

res., 3500,

res., 6. 8KQ, 1/~, :10%

switch, Input Selector

switch, Function Selector

switch, slide,

switch, slide, SPOT 81145

transformer, power 81146

transformer, output 81154

terminal board, 5 screw 81903

terminal strip, lP right w/ground 89207

terminal strip, 3P 2 left 89219

13, terminal strip, 2 past

terminal strip, 3P 2 right 97710

25mfd, 200V

elec., lOmfd

, 25mfd, 6V

elec.

disc., 850mmf, "'10%

disc., . 0027mfd, "'10%

disc., 6oommf, "'10%

disc.

02mfd, "'10%

lmfd,

disc., . 0012mfd, "'10% (1.

disc., 225mmf

, elec., 4O-40-

1/~, "'10% (brown,

1/~, "'10% (brown,

1/~, '" 5%

1/'NI, "'lOOk.

7KQ,

1/~, :10% (yellow,

1/'NI

1/'NI,

1/'NI,

linear, dual

1/~, :10% (brown,green,yellow,

1/~, :10%

500KQ, linear

l(ZW,

1/~, :10% (yellaw,

lW, %10"k.

lOW, :10%

DPDT 81144

terminal strip, 4 past 66316

, 6V

"'10%

400V,

, "'10%

20mfd/350- 350-

4O0V

, 600V

03mfd

"'10%

(red, black, yellow, gold) 42029

(red, red,

5% (white, black, orange, gold)

'" 5% (brown,

:10% (blue, grey, orange, silver) 46006

(brown, grey, red, silver)

, concentric 53017

, concentric

%10%

:10% (arange,

!)N, % 5%

(red, red orange,

:10% (yellow,

OOOmmf)

(2. 7K or 2700mmf)

(20K or 20,

000mmf)

2Kor 1200mmf)

400V

(10K or 10,000mmf) 41000

black,green,

black, orange,

red silver)

vi~let

silver)

silver)

red, silver)

black,yellow,gold)

green, gold)

silver)

w/SPST switch 53018

(brown, black, yellow, silver)

, red, orange, gold)

(blue, grey, red, silver)

red, silver) 58004

orange,

violet,yellow,

grey, red, gald) 58302

arOnge, ye

violet,

silver)

ilow, sHver) 58408

silver)

silver)

red,

Stock'

~1\T

54000

90034

90033

90039

90038

97800 XFl

97712 XII

97027 XV1,

...97025

40000

40001

40007

40008

40016

40026

40027

41003

41016

41026

41027

41028

41045

41046

41047

42000

42002

42007

42008

42032

43000

43001

43004

46000

50012

50019

50021

51006

53016

57000

58300

58410

58412

58501

80057

81109

81110

81111

81116

81124

81134

89208

97300

66067

TB15,

TB17

Vl,

V7, 8, 9,

Vll,

2, 3,

XV5, 6, 7, 8,

10,

Description

18

'4-40

32 x 1/4

32 x 3/8

32 x 1

32 brown

ground

2 past right

lP left

bracket

terminal strip,

terminal strip,

tube, 12AX7

tube, 12AU7

tube, EL84

tube, EZ81

fusebolder

pilot assembly

sacket, 9 pin min. w/shield

socket, 9 pin min.

nut, hex, '6-

nut, hex, '3/8-

nut, he",

nut, he", '8-32

nut, for fuse holder

nut, lin., '8-

nut, tin., angle

screw, '6-

screw, '8screw, '4-40 x 1/4

screw, '4-40 x 1/4 brass

screw, '4 wood

screw, '8-

screw, '6 P. K. brown

screw, '8-

screw, '8 P. K.

washer, '3/8 lock

washer, '6 lock

~sher, '4 lock

washer, '8 lock

washer, rubber, forfuseholder

washer, fiAt, '8

lug, '6 ground

lug, '3/8 pot ground

lug,

grommet, 3/8

feet, rubber

insulator for 50011

insulator for 50018

insulator for 50020

pbono plug

knob, outer concentric

knob, inner concentric

knob, duell concentric

line cord

wire, hook...p, thin wall

spoghetti

spaghetti, heavy

cable, 1 conductor

cable, 4 conductor

cable, 3 conductor

wire, bare

panel

bottom plale

brocket, left

bracket, right

bezel

chassis

shield w/spade bolls

perfomled screen

bracket~ Input

bracket far DPDT switch

shield bottom

clamp, wire

label, rear apron

label, tube layout

label, service

tube shield

Jewel, red

manual af instructions (wired)

manual of instructions (kit)

length

length

length

length

length

length

length

Page 18

';'

';'

----

JI4

(g)

R59

C31

JI5

R58

C32

C18

R32

R42

VllVI2

R63

R62

R61

'IV

R60

..1f37C ..1f378 .1f37A ..1f38

1958

PREAMP

:10%

%10%

%10%

I/2N,

8KQ, I/2W, :10%

2AX7

';'

--

R71

4"5

pat., 1O0Q

res., 330KQ, 1/2W,

R66

R65 res., 330KQ, I/2W,

5ym Description

%10% R64

%10%

%IO"k

I/2W,

Description

R39 res" 470KD.

R..uJ res., lOKn, J(2W,

R4l res., 10KQ, I/2W,

%10%

% 5%

I/2N,

, 9OKD.

Descri tion

res., 4.7KD. I/2N,

res.

res., 9OKD. J(2W, % 5%

RJ4

RJ5

R16

res., 2. 2MQ, I/2W, % 5%

res., IOOKQ, I/2W, :10%

res., 1O0KQ,

switch, function selector

switch, slide, DPDT

R67

R70 res., 6,

R71 res. , 6.8KQ, 1/2N, :10%

-51 switch, input selector

:10%

: 5%

% 5%

% 5%

8KD.I/2W, %5% R68

res., 1, 8Kn, I/2W,

R42

R43 res., 1.

I/2N, % 5%

res., lOOKQ,

res., 100KQ,I/2W, % 5%

R17

RJ8

:10%

I/2N,

, 330KQ, I/2W,

, 100KQ, I/2W, : 5% R69

res.

res., lOOKD. I/2W,

R45 res., 100KQ,

R46 res., 100KD. I/2W,

R47

R48 res.

R44

:5%

:10%

J(2N,

2MQ,J(2W,

, 750KQ linear, dual

res., 68KQ, I(2W, :10%

res.,

res., 68KQ,

pot.

pot., 750KQ linear, dual

R19

R20

R2l

R23

;:.oR22

res., 330KD. I/2W,

R49

pat., 250KQ, audio, dual

R24

tube, 12AX7

switch, 5P5T, port of R32,

:10%

R50 res., 33OKQ, 1(2W,

pat., 250KQ, audio, dual

--rt25

tube, 12AU7

tube, 12AX7

tube, I

tube, ELM

--VI tube, 12AX7

.V5

... V3 tube, 12AU7

""V7

-55 switch, slide, 5PDT

"'10%

, 330KD.J(2W, "'10%

R51 res.

R52 res., 1OKD. J(2W,

%10%

res., 150KQ,I/2N,

res., 150KQ,I/2N, "'10%

R26

R27

"-...V6

:10%

%10"k

%10%

I/'M, % 5%

!NI, 5%.

!NI,

I/2N,

, lOKn, I/2W,

res.

res. , 165Q,

res., 165Q,

res. , 22KQ,

R53 res., lOKQ,

R54 res., 10KD. I/2W,

R55

R58

-R56

- R57

%10%

, concentric

, concentric

linear, concentric

I/2N,

500KD.

, IMQ, linear, concentric

res., 8KD.I/2N, "'10%

res., I. 8KQ,

pot.

pat., lMQ, linear

pat.

pot., 500KQ, linear

R28

R29

R31

R32

R33

--R30

tube, ELM

tube, ELM

tube, ELM

tube, EZ81

tube, EZ8J

-VIO

-V9

-V8

....VII

.......VI2

I('M, % 5%

I/2W, :10%

I/'M, :10%

res. , 22Kn,

res., 22KQ, IW, :10%

res., 7KD.

R59

R60 res., 68KQ,

R61

R62

=-R63 res., 350Q, lOW, %10%

"'10%

"'10%

%JO%

"'lO"k

"'IO%

I/2N

I/2N,

I/2N,

3Kn, I/2W,

, lOOKD.

res., lOOKD.

res.

res., 3.

res., 3. 3KQ

res_, 470KQ, I/'M,

R34

R35

R36

R37

R38

STEREO AMP.

WATT HI-

~~~

, .

';' ';'

, .

, .

C13

channel 2

aux A -

DescriJ'tion

%JO%

Description

cap.,disc., 225mmf

C27

200V "'-

Description

cap.,paper, . 25mfd

cap.,paper, . 25mfd

channel I

channel 2

channel I

DUX B -

multiplex

mic -

phono - channel I

tope -

d'l

"JI0

%IO%

25V

25V

%10%

%10%

disc., 225mmf,

elec., 50mfd

cap.,

cap.,

cap.,elec., 50mfd,

cap.,disc., 47mmf,

cap., disc., 47mmf,

C28

C29

"'C31

;;,-C32

,.-C30

200V ~

6V

6V

6V

10mfd 6V -

cap., elec.,

cop., elec., IOmfd,

cap., elec., 25mfd

cap., elec., 25mfd

channel 2

channel 2

mic - channel.

phono -

tope -

tope output - channel 2

tope output - channel I

ac pawer

JI3

:)15

"JI2

,-:Ill

025mfd, GMV

disc., .

cap.,

,C33

025mfd GMV

cap., disc., .

-116

..J14

350-400V

GMV

GMV

..uJOV

025mfd,

025mfd,

025mfd, GMV

elec. , 30mfd,

cap., disc., .

cap., disc., .

cap., disc., .

cap.,elec., 40-40-20mfc!/350-

cap.,

C34

C36

""C35

%10% ;"C37

%1O% ...C38

%10%

%10% .

O25mfd, GMV -

0027mfd

850mmf,

, . 0027mfd,

cap., disc., .

cap., disc., 850mmf,

cap., disc.,

cap.,disc.

cap., disc., .

% 5%

%10%

%10%

%JO%

%10%

I/2N,

I/2N,

I/2N,

I/2N,

res., JMQ,

res., IMQ.

res., 1OKD.

res., 10KD.

res., 200KD. I/2N,

%1O%

OOOY

4OQV

03mfd

0012mfd

, . 00 12 mfd, %10%

, 47mmf, %JO%

elec., 3Qmfd,

molded, .

cap.,

cap.,

cap., disc.

cap., disc.

cap., disc.

-C41

"..,c42

......c39

.....,('C..uJ

..uJOV, %IO%-C43

%10%

%10%

%10%

02mfd

02mfd,

600mmf, %10%

molded, . Imfd,

cap., disc.,

cap., disc., 600mmf

cap., disc.

cap., disc., .

cap.,

%10%

% 5%

% 5%

%10%

%10%

I/2N,

I/2N,

I/2N;

2Kn, J(2N, %10%

res., 200KD.J(2N, % 5%

res.,

res., 2.2KD.I/2N,

res., IMQ,

res., JMQ,

res., 200KQ,

res., 200KD. I/2N,

res. 7KD.I/2N, %JO%

RJO

RlI

R12

RI3

025mfd, GMV

OJ mfd,%l0%

0Imfd %10%

O25mfd, GMV

channel I

disc., .

cap.,

cap.,disc., .

"C46

channel I

aux A -

aux B -

cap. , disc.. .

-Jl

-:13

, 47mmf, %10%

cap.,disc.

disc., .

cap.,

.?C45

%1O%-C47

%10%

..uJOV, %IQ%- C44

..uJOV,

..uJOV, %1O%-"'C48

%10% _

%10% '

%10%

1 mfd,

00J2mfd, %IO"k

OOJ2mfd

, . I mfd,

molded, . Imfd,

disc., .

cap.

cap.,

disc.

cap.,

disc. , 225mmf

cap., molded

cap., molded, .

cop., disc. , 150mmf

cap., disc., 150mmf,

cap.,

DUAL 14

MODEL Hf-

~'4

%10% -

disc., 225mmf

cap.,

",,-,

';'

Jl0

J13

J12

Jl1

... Cl

-c4

....c6

~C8

.... C7

=CIO

- ClI

-c13

..:.CJ2

-CJ5

........C14

-'J6

,...CJ7

-CJ8

--C19

--C20

.....C21

-C23

-C22

""C25

~C24

""1:26

Page 19

Page 20

Page 21

JOj jl '

aljt pnpuo::J

SJaWJOjSUOJt pUO '

JadoJd ayt Ot paWwpt aq PlnoljS spoal asalj1 '

aljt paulWJatap

uo!pnJtsuo::J aljt JOj paJ!nbaJ

asn Wu 00

SIOOt

aJO SJots!saJ

toljt oslo alaN

puosnoljt dUO Aq

s6UHOJ puosanloA

lj::J!ljM JOj stJod aljt jO

U! SjOH::Jodo::J JO SJots!saJ uo

P!O 01 '

parlow tOljt oslo

6U!MOIIOj aljt atOU asoald '

puo SJOH::Jodo::J ::Js!pSOaJaljM '

uo!wadaJ AJOSsa::Jauun I

J!M puo 6uHunow datS-

(j) UOHO!AaJqqo

uapp::Jo tuaAaJd Ot

~l

. JaplOS Mau asn ot

patOaljJaAO Alnpun 6u!aq WOJj

111M SJaiid alj1 '

SJOH::Jodo::J '

aJns aq

SJalld asou6uol jO Jlod 0 jO dH aljt

SJOts!saJ uo spoal

tUIO! 0 JaplosaJ O~

tuauodwo::J aljt tuaAaJd

aljt tOljt patou aq oslo Plnoljs

AJOssa::Jau sl t!

pUO AOMO

ljHM paJap

UOSoaJ AUO

sWOJ6OIP aljt U!

aAOlj nOA IHun peal

UMOljS so patnOJ SI peal

aJO

sloat

AUO tn::J tOU 00

paJlnbaJ UOljt Ja6UOI uauo

'AJOssa::Jau ualjM ljt6ual

::J!soq asalj1

V/L ot 11

:G3~lnO3~

aljt ualjM ljt6ual paJ!nbaJ

9L/~ - JaAppMaJ::J5

. Jalj!ldwo aljt jO

51001

apolq "

)ISV'S

toalj

aJO

. L

(SHOM ~~)

. Japlos

UOJ! l!::Juad JO '

aJo::J

xnH ::JHaljtUAS

sa::JuOtswn::JJp AUO Japun

un6Japlos JO '

tualoA!nba JO

apolq ,,

8/L - JaAppMaJ::JS

(SHOM OOL) UOJ!

9 JO t;; -

U!SOJ AHlonb

SJaHn::J

sJa!ld asou6u01 .

6upaplos .

lou060!0

xnH atsod

sJa!ld soD '

JO P!::Jo

lj6!H .

AJotuawalddns Injasn

(jww) SpOJOjOJ::J!W-

%OZ

'AlaA!padsaJ SpOJOj OJ::J!W-

pa!ldHlnwaq tsnw

J!aljt aAoljtnq I

AUOW

AJaA oslo

AJaA

puo (OOOLX) JalldHlnw 0

tDljt atou asoald

papo::J JOlo::J aqtO

aJO Jaddpts aJ!M 0 puo sawu!ds jO tas V'

:NOll V')I:lIlN301 Sl~V'd

anloA

OJ::J!W JO swljo U! anloA aljt U!Otqo Ot

10::J!Jawnu

UAoW uaA!6 S! 6u!po::JJO\0::J

patupd aljt toljt

S! )I Jattal aljl '

~patu!Jd sanloA J!aljt aAolj Jots!saJ %L

puo '

%OL

OJ::J!W ~uo!lI!W

tDljt

PU!W U! daa)j '

auo Ot lonba

UOHo::J!jHuap! p!doJ U!

S! (jw) pOJOjOJ::J!W

SOaJaljM papo::J JOlo::,

'AtPodo::J JO a::JuotSlsaJ ssaJdxa Ot

patupd san

papo::J JOlo::J aq

loA J!aljt aAOlj

pasn sHun aljt

tau AOW

JOAOW SJOt!::Jodo::JJolnqnt

SAOMIO II!M

uaaM,Jaq sd!ljsuoHolaJ

S::JHAloJpala

sato::J!p

patu!Jc.:

auo

(~W) wlj06aw

(jW) SpOJOj

OJ::J!W L :::

L :: (~)I)

(jww) SpOJDj

swljolPI OOOL

OJ::J!W-OJ::J!W

swljo

000

000 000

000

papMoJ::Juns6u!MOJpalj

Aq-

dats ataldwo::J aljl

t d3a)j01 '

:3~nG3)0~d NOI1)n~1SNO)

sMollOj ampa::JoJd 6u!

(papauuo::J uaaq aAolj spoal Jaljto I!tun) Japlos

alj1 :atoN '

S!ssolj::J aljt

paH!WO aq AOW sl!otap 6UP!M

JO 6uHunow jO

pJOMOt sta)j::Jos aljt

Japlos puo pauuo::J suoaw (S)

su!d ta)j::Jos aljt Ot

uo sqOt 6nl punoJ6 aljt puas

taU op tnq pauuo::J suoaw

UOHO!AaJqqo

6UHJoljS lOt

aljt

-)n~1SNI aljt

NOIl)n~15NOJ aljt

pato::Jol SI Uo!pas

)L)

6UIMOilOj sa60d aljt

),, Aq paMolloj sJaqwnu a60d

6ultdnJsap tnoljHM

. tuawnJtSU! S!lj Ul a::Juapuuo::J

JopnJtsuo::J aljt pJOMaJ II!M tuawnJtSU! slljt

Amssa::Jau awH aljt

UMOljS tnOAol StJod pUO aJ!M

aJO saliM uatjO AJaA '

aq II!M JOJJa 6U!J!M 0 6UlpU!j

pataldwo::J aljt jO a::JuoJoaddo aljt Alu!opa::J

pa::Jold

NOIl)n~1SNO) aljt

110 a~ot Ot

SNOUJn'H.1SNI 'V'H:lN:I!)

S! a60d S!ljt ljHM 6uluu!6aq lonuow aljt jO Uo!pas alj1

UMOljS tnoAol s.

uo sawnsaJ uolpas NOI1)n~15NI

H SMOllOj puo H sapa::JaJd

paAOWaJ aq AOW puo )jooq

aAolj Uo!pas S!ljt

toljt atON '

jO Uo!pnJtsuo::J aljt U! ua)jot

uoH::Jas

U! sa60d IIV' '

ljtoq toljt uolpas

NOI1)n~15NO)

alj1 '

aljt Ul AlloJtua::J

('::Jta '

uolpas

)2:

NOll

ale)

JatoaJ6 puo

tnq

uoH::JnJtsuo::J aljt ljsnJ

a::J!AJas AJOPOjSHOS jO SJoaA AUOW

tOU Ot nOA a6Jn aM

ljHM

aljt MOllOj nOA tOljt AI6UOJtS a6m

joAtln::J!H!paljt puopaAoJdw!aq II!M

alq!ssod so

llod puo aJ!M aljt 6u!MOIIOj aljt

Alasol::J so

puo l

. 6UP!M puo Alqwasso JadoJd JOj

uosoaJ po06 0 JOj

SWOJ60!p 10!Jop!d aljt U!

aM aJoWJaljtm::l

Aq pa::JnpaJ

tuawnJtsul

UMOljS so

Jatsa)l so

tSUl060tJod

ape:;. JOlo::J aljt JO

aAolj noA jl '

alqoMollo aljt

puo %OOL+ Allonsn

AUO aJnsoaw AOW Jots!saJ%OL

'Ins aJO SJOH::Jodo::J

~3G10S 3~0) NISO~

NV'1SWn)~I) ON ~30Nn '

lj::Jns saxnH patOA!pO

lj::J09)j::Jalj::J puo AI InjaJo::J

S!ssolj::J aljt Ot

SWOJ6OlP 10pop!d

patunow

aJO

aljt Ot JajaJ StJod

t!)j aljt )j::Jodun :1()I 3H1 DNI)I)V'dNn

toljt stJod asolj

t 6u!pnl::Ju! ts!I stJod aljt

AUO 6U!AjHuapI alqnoJt

U!ljHM

Jadod uo

AJOA

II!M tuauodwo::J 0 jO anloA aljt

S! S::JHAloJpala JOj a::JuoJalot aljt puo '

::10 30V'~D 153S 3H1 3Sn

sa::JuoJal01 . ~)lZ'

=F

I ~)lL'

sadApollwIs JO "

Mau aljt 6UIU!Otuo

aljt '

aldwoxa Jo:l '

~ puo ~)lZ'

toljt pu!j II!M

JatoaJ6 AlloHUOtS

a::JuoJalot

V uaaM,Jaq aJaljM

aJo::JHlnw" U!SJ3 ' "

::J dUO AlqOJajaJd

:SlNIH NOI1)n~lSNO)

aAI:I-u!sa~"

tJolj::J r-

noA

t!n::JJ!::J

%O~-

1NO

ualjM AU!ljS puo ljtoows S! tU!o!

pamdJoaddo II!M tU!o! aljt '

toalj alH!I OCt

aljt IHun

patlaw

-uO::J 10::J!uolj::Jaw po06

-as asno::J UO::J xnlj

SttOM OOL uoljt Jallows ou '

SI Japlos aljt tOljt

UOJ! 6upaplos

~pap!OAO aq Ot sawaJtxa

ppo

0 jO u!otJa::J 0 a)jow

a::Juls Xn1:1

01:)"'1' ~O ~3G10S 3~0) ODV' 35n 53)

6upaplos aJojas '

aljt aAOWaJ tau 00 '

os(UOJ! aljt uo tou) tU!oJ

uoJ!6upaplos pauuHAlljsaJj '

6uHI nsaJ aljt toljt adS Ot

OM,J aJO aJalj1 .

jlasH tUlo! aljt WOJj

aljt uo Japlos aljt

)j::Jalj::J pUO SMOlj Japlos

uoal::J 0 asn ' uo!pau

paloo::J solj Japlos aljt

JaljHa

-IDS am

puolj Jaljto aljt uo

AOW H Ot papauuo::J StJod aljt

nOA jl ' UMOP )joaJq JO

. AJOPOjSHoSun S! lj::JIljM tU!oJ

pa!lddns S! toalj aitHI

'6uHOO::J

tUIO! 0 Ot pal Iddo

aAlpatoJd Jlaljt asool l

UISOJ 0 6UHo::J!PUI ' AaJ6 puo

OOt jl '

S! toalj

toalj lj::Jnw oct puo

UO!SOJJO::J

toalj aljt Aq

a::Jold puo

anlOA a6uolj::J

lj::Jnw oct

snop

-IOS 6u!aq tU!o! aljt puo tJod aljt

uaaM,Jaq peal aljt Plolj

tJod 0 Ot

asol::J

6upap

Page 22

TB19

XV10

XV9

TB 14

TB18

TB5

TB13

TB17

TB4

TB1

TB2

XV8

-Jl11213

.J8910

TB3

XV6

Fig. 1

'-'. ) !'

8 '

-$- -$-

TB20

TB21

XV12 -

XVll

TBll

to.)

Page 23

lock-

U,e two

tighten

C39, as

, line

, TB6;

1eft with

, TB21.

, TB13;

j,

~g.

rubber washer

TB3. Under the re-

shown. Use

chassis. DO NOT

32 hex nuts. Under the

hole next to the fuse-

shown. Use two #6-

wider part of the holder. Slide the

32 hex nuts.

lug.

wew te,mlnall"""d, TB2, '" ,hawn.

the 5

right with ground terminal strip,

rubber grommet into the 3/8"

Mount the fuseholder, XFI, as

1. Mo,nt

Fig. 1.

nut, mount a #6 ground

, mount one post

hlg.

#6-31 screws, two #6 lockwashers and two #6-

9.

washer

10.

maining "

large nut over the fuseholder on the inside of the

against the outside of the chassis under the

11. Fig. 1. Push a