Eicher EE483TC, EE483TCI Operation And Maintenance Manual

Pub. No : M190456 : 01

Nov 2012

OPERATION AND MAINTENANCE MANUAL

EE483TCI Power Generation EngineEE483TC &

1

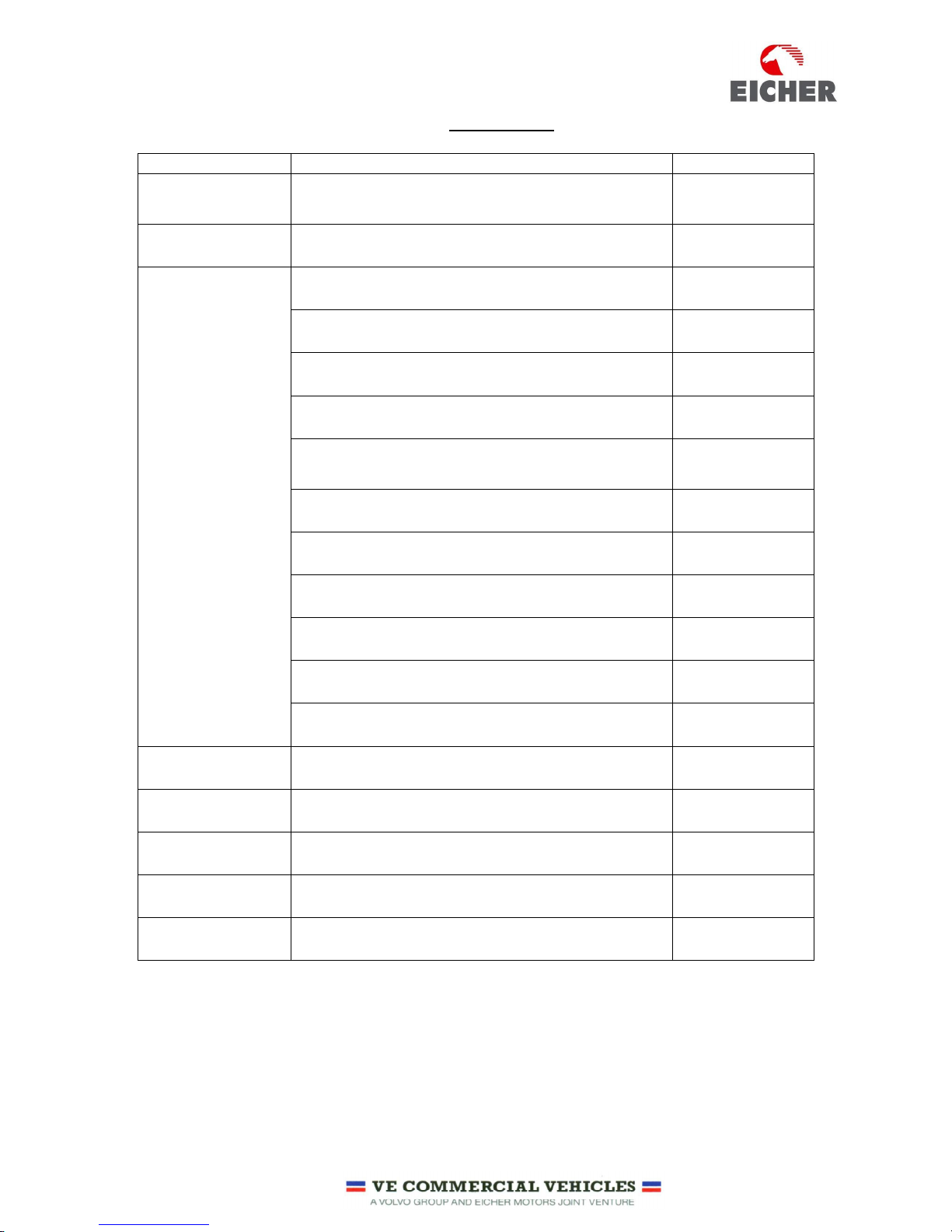

CONTENTS

Section

Details

Page No

Part I

Introduction-Operation & Maintenance

Manual

2

Part II Eicher Engine - General Information 3

Part III

Engine Familiarization

3 General Information 4

3.1- Engine Identification 4

3.2- Engine Nomenclature 5

3.3- Engine orientation and Parts

Illustration

6 to 8

3.4- Technical Specification- Engine 9 to 10

3.5- Engine Systems and Function 11

3.5.1- Air Intake and Exhaust System 11 to 13

3.5.2- Lubrication System 14 to 17

3.5.3- Fuel System 17 to 19

3.5.4- Cooling System 20 to 21

Part IV Engine Electrical System 22 to 23

Part V Safety Guidelines 24 to 25

Part VI Recommended Routine Checks By user 26 to 28

Part VII Engine Inspection and Maintenance 29 to 38

Part VIII Trouble Shooting Guidelines 39 to 47

2

PART I-INTRODUCTION - OPERATION & MAINTENANCE MANUAL

We are glad to introduce us as VE Commercial Vehicles Ltd (VECV), manufactures of EICHER EE483TC and

EE483TCI Power Generation Engine owned by you. VECV is committed to being the leader in customer

satisfaction in India and emerging markets. We put our best efforts to maintain global quality levels by

understanding and fulfilling customer needs.

This manual presented to you gives a comprehensive understanding on Construction, operation and

Maintenance aspects of Engine for the intended application.

These Engines meets current prevailing emission norms.

Due care has been taken in preparing this manual. However due to Continuous improvements product

specifications and illustrations are likely to undergo change without any prior notice.

For any further information, please write to:

PRODUCT SUPPORT

NON AUTOMOTIVE ENGINES

VE Commercial Vehicles Limited

(A Volvo Group and Eicher Motors Joint Venture)

102, Industrial Area No. 1 Pithampur 454775 Dist. Dhar (M.P.) India

Phone: (07292) 402633

Fax: (07292) 402611

PUBLICATION NO: M190456:00 REVISION NO: 01

PUBLICATION MONTH: NOVEMBER’2012 REVISION DATE: 01/11/2012

3

PART II: EICHER ENGINE GENERAL INFORMATION:

Eicher EE483TC Engines manufactured by VE Commercial Vehicles Ltd (VECV) are direct injection, four

Strokes, Water cooled, and Turbo charged Diesel Engines designed to suit Power Generation application.

Eicher EE483TCI Engines manufactured by VE Commercial Vehicles Ltd (VECV) are direct injection, four

Strokes, Water cooled, Turbo charged, Intercooled Diesel Engines designed to suit Power Generation

application.

The engines are eco-friendly, reliable and fuel efficient meets prevailing statutory emission standards.

While we, at manufacturing and testing have taken due care to ensure trouble free performance, as an

engine owner and user, proper up keep of engine, use of genuine parts, use of Genuine oil and Lubricants,

use of Genuine Coolant and adherence to scheduled and preventive maintenance shall derive the best out of

your engine resulting in Value for investment.

4

PART III: ENGINE FAMILIARIZATION

3. GENERAL

This part provides details about engine identification, engine Sl No nomenclature, Orientation, technical

specifications and various Systems of engine.

3.1 ENGINE IDENTIFICATION.

Engine is identified with the engine nameplate fitted on flywheel housing on left hand side of the engine

when viewed from front. Engine name plate contains the information as shown in the figure 1, 2 and 3.

Engine Sl No is also punched on the Cylinder block as shown in the figure 4.

Fig-

1- EE483TC-38 Kw

Fig 2 – EE483TC-48 Kw

Fig-3-EE483TCI-59 Kw

Engine Sl No Punched on Cylinder Block

Fig-4

5

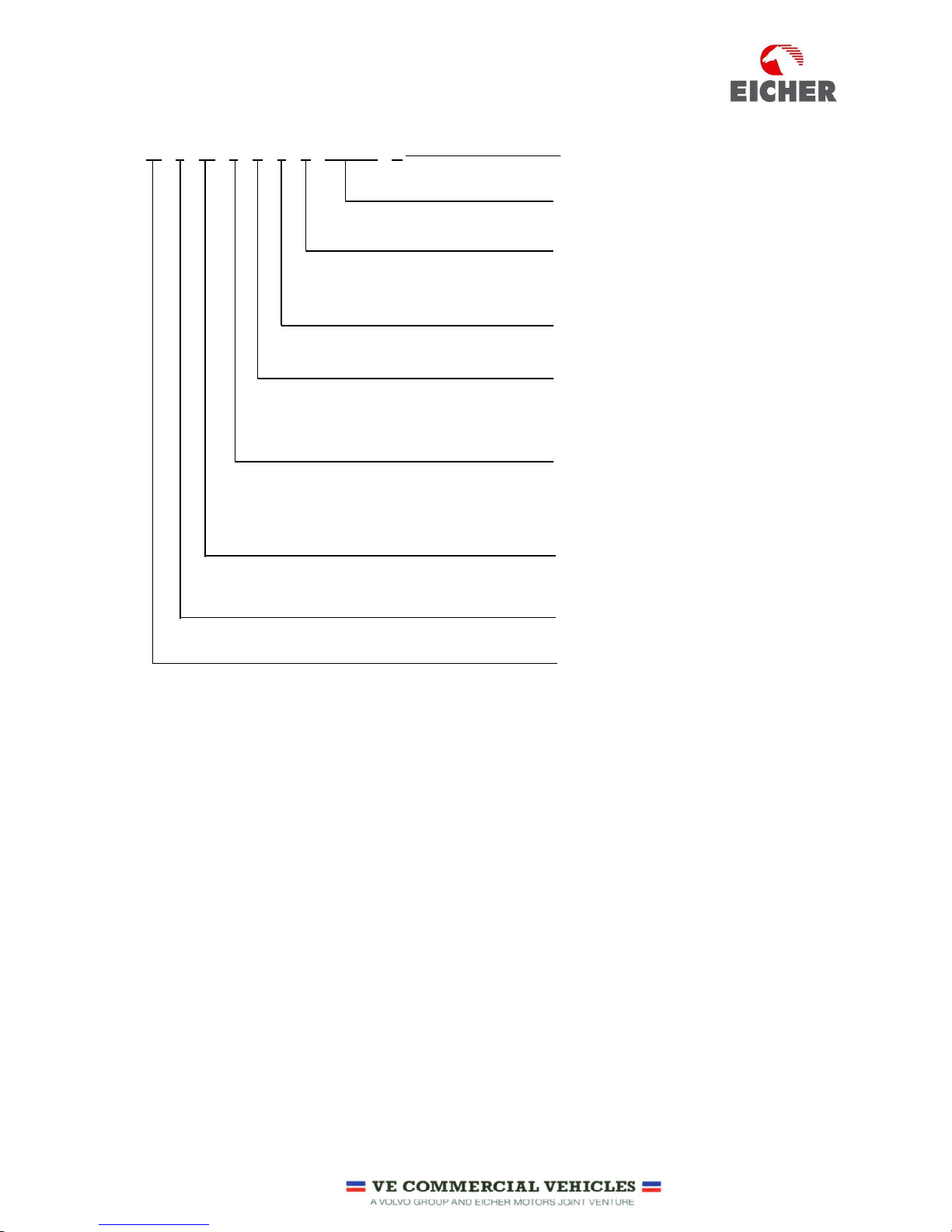

3.2 ENGINE NOMENCLATURE:

EE 4 83 C D B A 100000 G

Running Serial number

Month of production (A to M), A= Jan

& M = Dec.

Note: “I” is omitted

Year of production (A to W), A= 2010

W=2028.

Note: “I” is omitted

Type of fuel used

(D=Diesel)

Version: N=NA (Naturally aspirated)

C= TCI (Turbo Charged intercooled)

T=TC (Turbo Charged)

Swept Volume per cylinder

83=0.83 Litres

No. of Cylinders (4 or 6)

EICHER

G- Identification for Power

Generation Engine

6

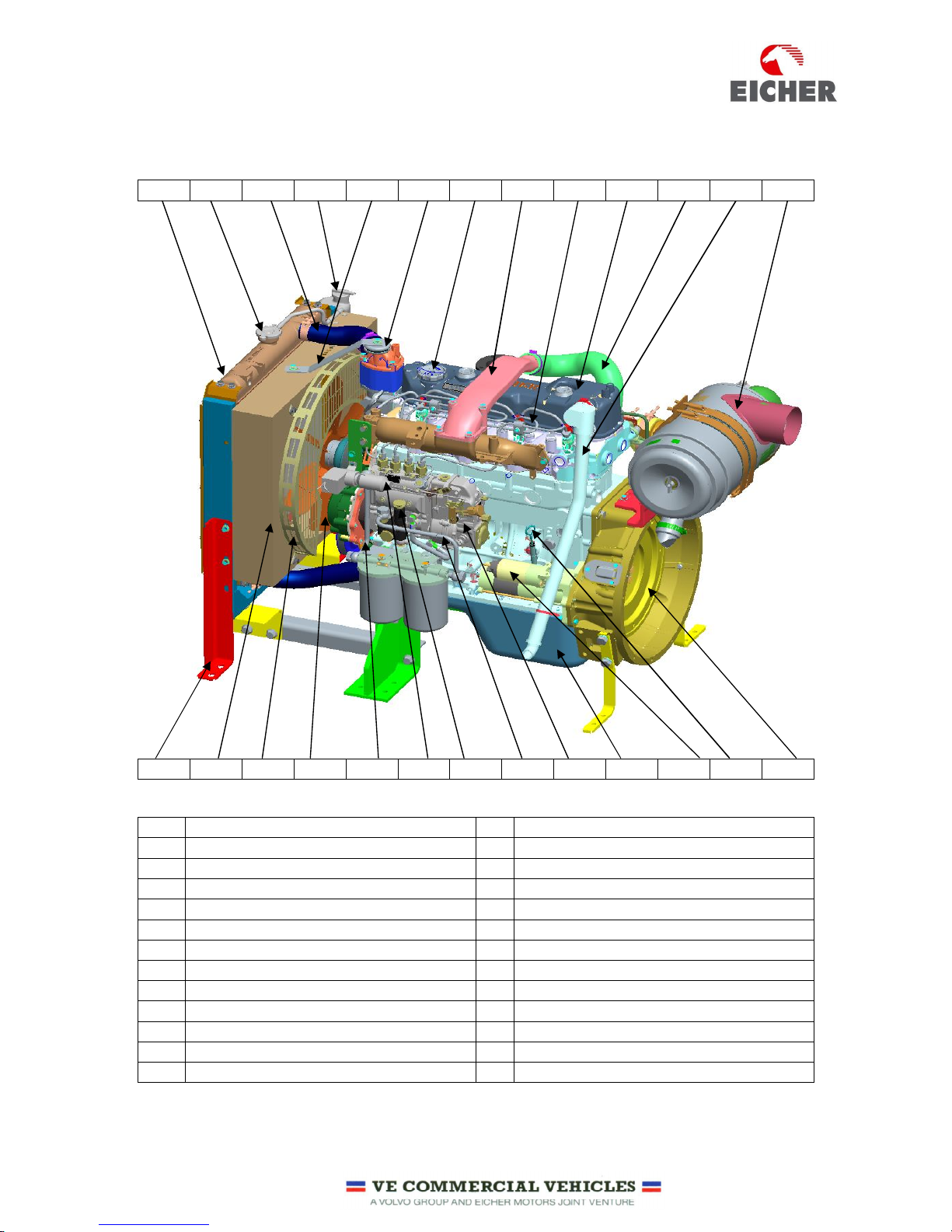

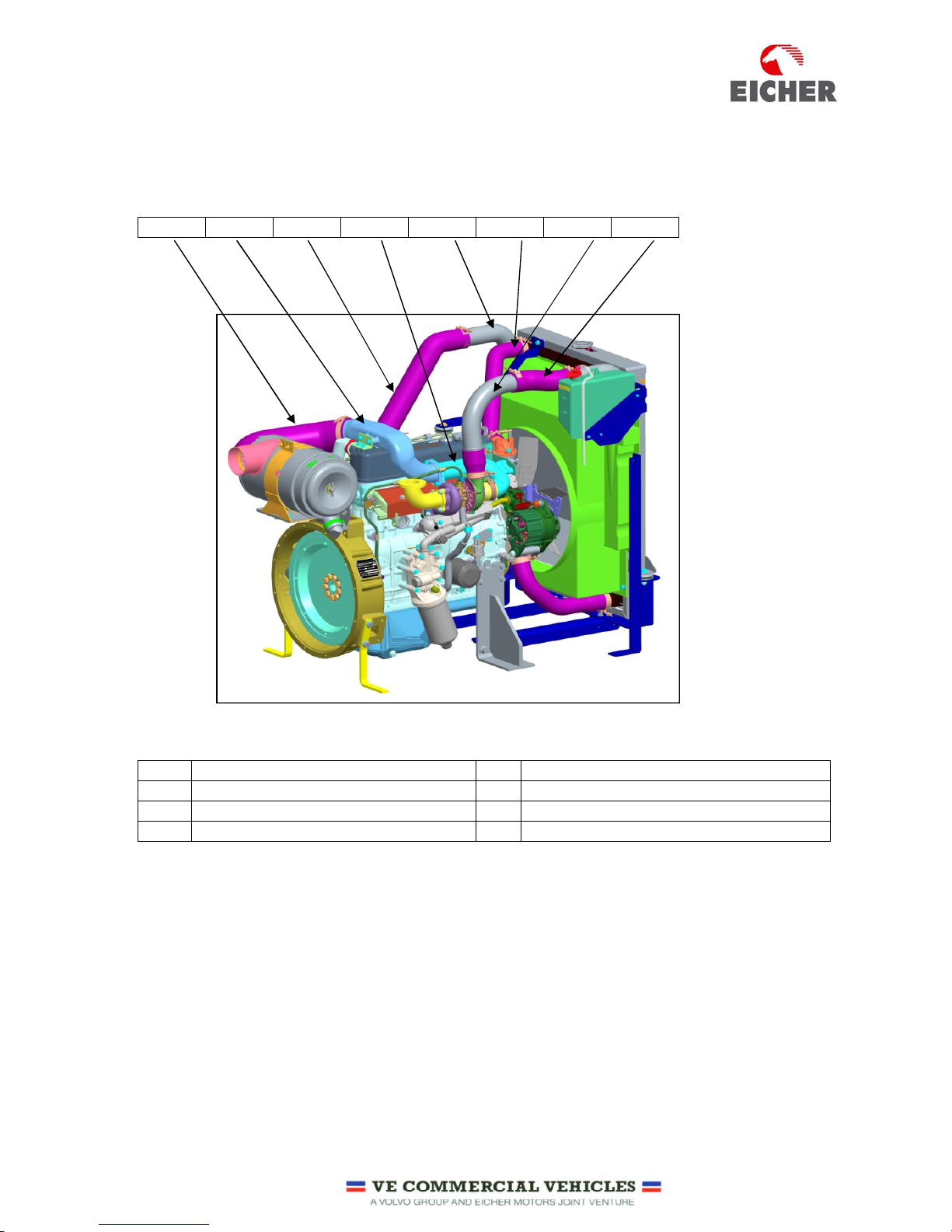

3.3 ENGINE ORIENTATION AND PARTS ILLUSTRATION (EE483TC -TURBO CHARGED ENGINE):

1 2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25 26

1 Radiator

14

Strip-Support radiator

2

Radiator Cap

15

Shroud Radiator

3

Hose

- Radiator In

16

Guard Fan Radiator

4

Tank Condenser

17

Fan Cooling Radiator

5

Bracket

– Radiator Support

18

Pipe-

Fuel filter to Fuel injection pump

6

Cushion

-

Radiator Support Bracket

19

Stop Solenoid

7

Cap Oil Filler

20

Feed pump

8

Pipe-

Turbo to Intake Manifold

21

Pipe fuel

- Feed Pump to fuel filter

9

High Pressure Pipe

22

Fuel injection Pump

10

Rocker Cover

23

Oil Sump

11

Hose

- Turbo out

24

Starter Motor

12

Hose

Breather

25

Dip

Stick 13 Air cleaner Assembly

26

Flywheel

7

ENGINE ORIENTATION AND PARTS ILLUSTRATION (EE483TC -TURBO CHARGED ENGINE) CONTD:

27 28 29 30 31 32 33

34 35 36 37 38 39 40 41 42 43 44 45 46

27 Hose

– Air cleaner

37

Pedestal

- Rear

for Transportation

28

Switch

-

Choke Air Cleaner

38

Hose

- turbo charger in

29

Pipe-

Lubrication Turbocharger

39

Turbo charger

30

Manifold

- Exhaust

40

Filter Oil

– Main

31

Cooler

- Oil 41 Bend Exhaust

32

Manifold

- Intake

42

Filter

- By Pass

33

Switch Cum

Sensor

- Water Temperature

43

Pedestal

– Front

34

Pipe-

Air Cleaner to Turbo

44

Sensor

-

oil Pressure

35

Housing flywheel

45

Alternator

- Battery charging

36

Engine Identification plate

46

V Belt

- Engine/Alternator/Water

pump

8

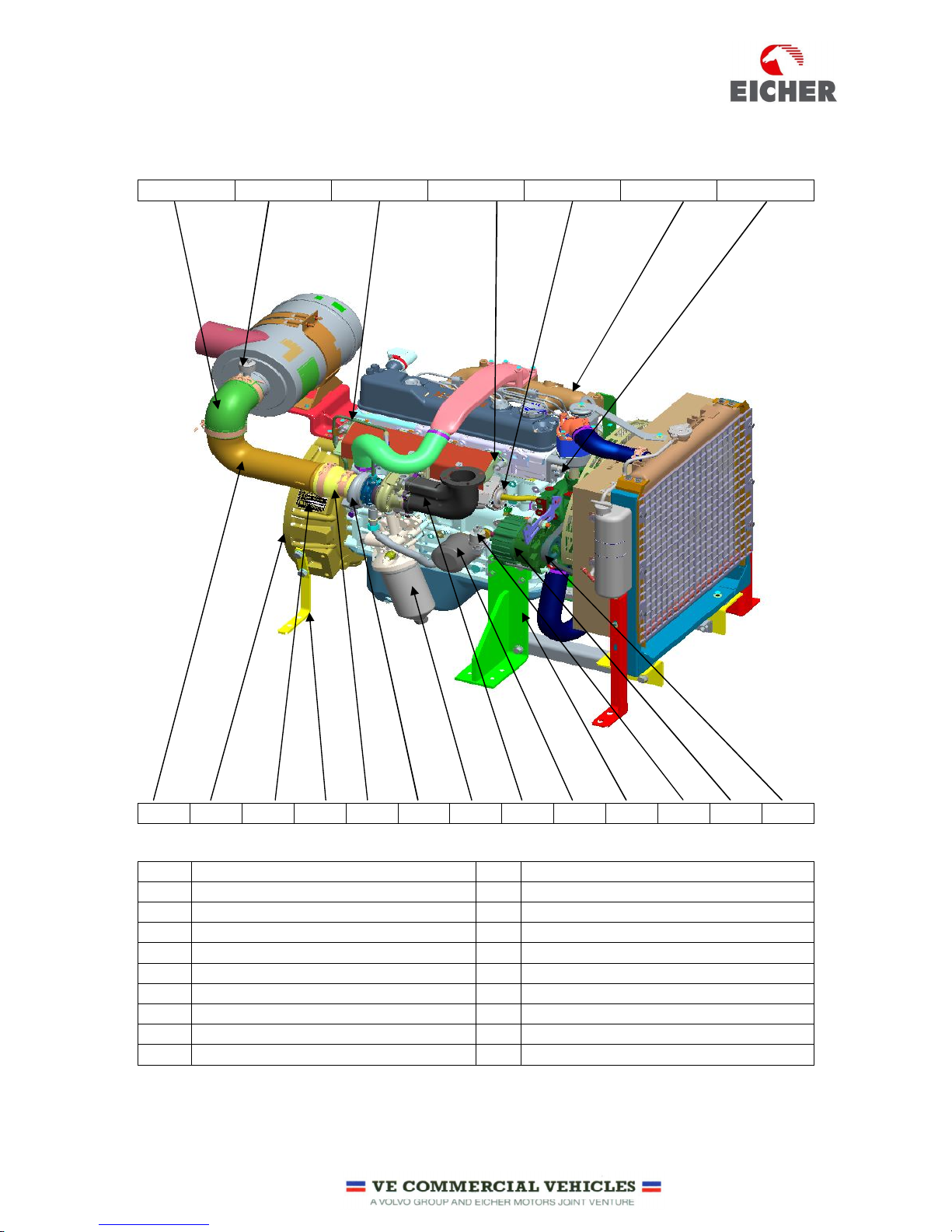

ENGINE ORIENTATION AND PARTS ILLUSTRATION (EE483TCI -TURBO CHARGED INTERCOOLED ENGINE):

1 2 3 4 5 6 7 8

1 Hose

-

Air Filter to Pipe TC in B

5

Intercooler Assy

2

Pipe TC in B

6

Hose

– Thermostat to Radiator

3

Hose

- Intercooler Outlet

7

Pipe-Turbo

Charger to Intercooler inlet

4

Pipe TC in A

8

Hose

-

Pipe Intercooler inlet to Intercooler in

9

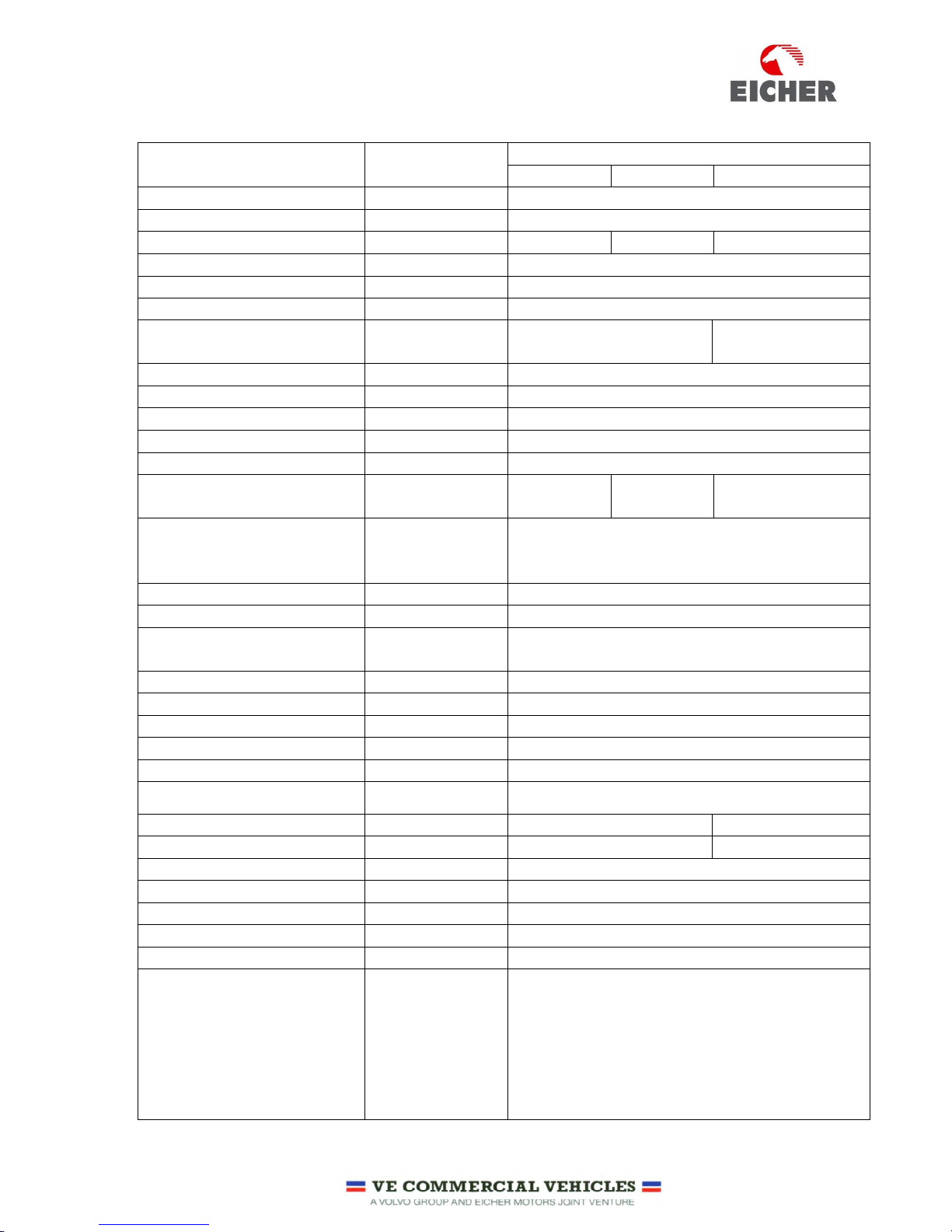

3.4 ENGINE TECHNICAL SPECIFICATIONS:

Parameters Unit

Details

40 Kva 50 Kva 62.5 Kva

Engine Manufacturer Name VE Commercial Vehicles Ltd

Engine Make Make EICHER

Engine Model Model EE483TC EE483TC EE483TCI

Emission Compliance Standard CPCB1 – As Per GSR 448 (E) 12.07.2004

No of Cylinders Nos. 4

Engine Configuration Configuration Inline / 4 Stroke

Engine Aspiration Type Turbo Charged

Turbo Charged

Inter cooled

Engine Fuel Type High Speed Diesel

Combustion Chamber Type Type Direct injection

Cylinder Bore X Stroke Mm 100 X 105

Engine Displacement Litres 3.3

Compression ratio Ratio 17:1 ± 0.5 mm

Engine Rated Output Kw ( HP) @ RPM

38 (52) @

1500

48 (65) @

1500 RPM

59 (80) @ 1500

Standard Operating

Conditions

Ambient /

Relative Humidity

/ Altitude

25°C / 40 % / 1000 mbar

Engine Deration Applicability Above 4000 feet

Rating Standard Standard IS10000

Overload Permissibility

10 % over load Permissible for 1 Hour in Every

12 Hours of Operation

Governing Standard Standard BS5514 / IS 10000

Governing Class Class A 1

Engine Low Idling Speed RPM 700 ± 50

Engine Fly Up Speed RPM 1560 ± 10

Engine Firing order Sequence 1-3-4-2

Direction of Rotation Direction Anti Clock wise when viewed from Flywheel End

Flywheel Standard SAE J 620 SAE 10 SAE 11.5

Flywheel Housing Standard SAE J 620 SAE 3 SAE 2

Lubrication Method Method Oil Pump Forced feed system

Oil Pump Type Gear Type

Oil Filter-Main Type / Nos. Paper Type / Single

Oil Filter-By Pass Type Spin on Type Paper

Oil Cooler Type Shell Type

Engine Lubricating Oil

Specification /

Grade /

Recommendation

API CH4-SAE 15W40 / EICHER Premium Diesel

Engine Oil

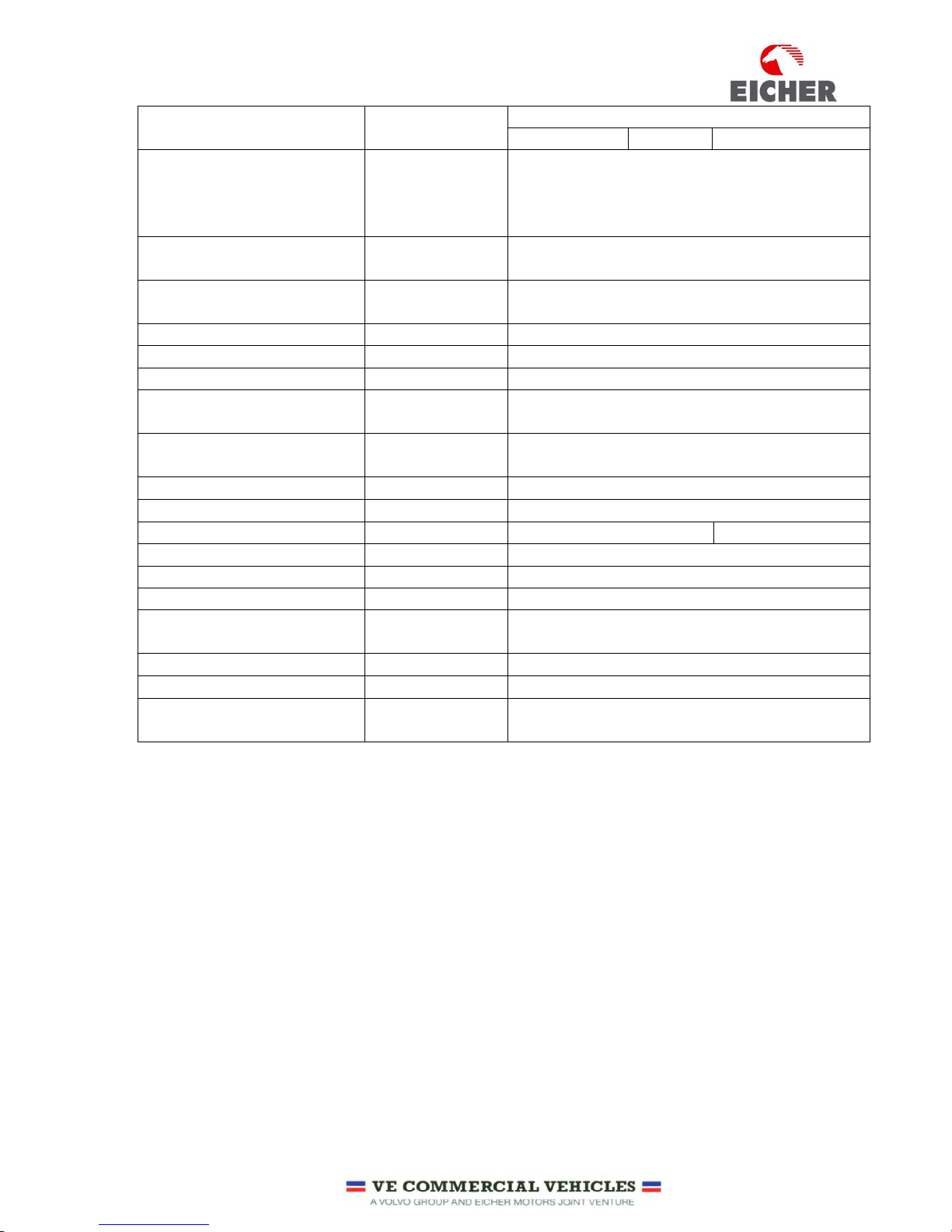

10

Parameters Unit

Details

40 Kva 50 Kva 62.5 Kva

Lubricating Oil Consumption

% of Fuel

Consumption

< 0.15 %

Minimum Lubricating Oil

Pressure @ Low Idle

Bar 1.5

Max Lubricating Oil Pressure

@ Fly up Speed

Bar 5.5

Fuel Injection Pump Make/Type Bosch / Inline

Fuel Filter Type / Nos. Cartridge type / 2 Nos.

Cooling Method Method Liquid Cooling / Forced Circulation

Water Pump Type

Centrifugal

Coolant

Specification /

Recommendation

JIS-K-2234-94 / EICHER GENUINE RADIATOR

COOLANT

Engine Cooling Fan Type Pusher

Electrical System V 12

Starter Motor Make / V / Kw Bosch / 12 / 1.9 Kw Bosch / 12 / 3.2

Battery Charging Alternator Make / V / Amps Bosch / 14 / 49

Shut off Solenoid Type Energise to Stop

Switch – Low Oil Pressure Applicability Yes

Switch – High Coolant

Temperature

Applicability Yes

Switch- Air Cleaner Choke Applicability Yes

Sensor-Water temperature Applicability Yes (Integral Design with Switch)

Sensor-Lubricating Oil

Pressure

Applicability Yes

11

3.5 ENGINE SYSTEMS AND ITS FUNCTION:

As we all know, Diesel engine is a prime mover developing useful power. Air and fuel is required to produce

power. Lubrication is necessary for the moving parts of the engine. Continuous cooling is required to

dissipate heat generated during combustion. Electrical system is required for engine starting, battery

charging and sensing of critical engine operating parameters.

The construction of Eicher diesel engine is divided in to five parts as below.

1 Air intake and Exhaust System

2 Lubrication System

3 Fuel System

4 Cooling System

5 Electrical System

The below section provides details of function, key components and working principle of respective system

to understand better about Engine aspects.

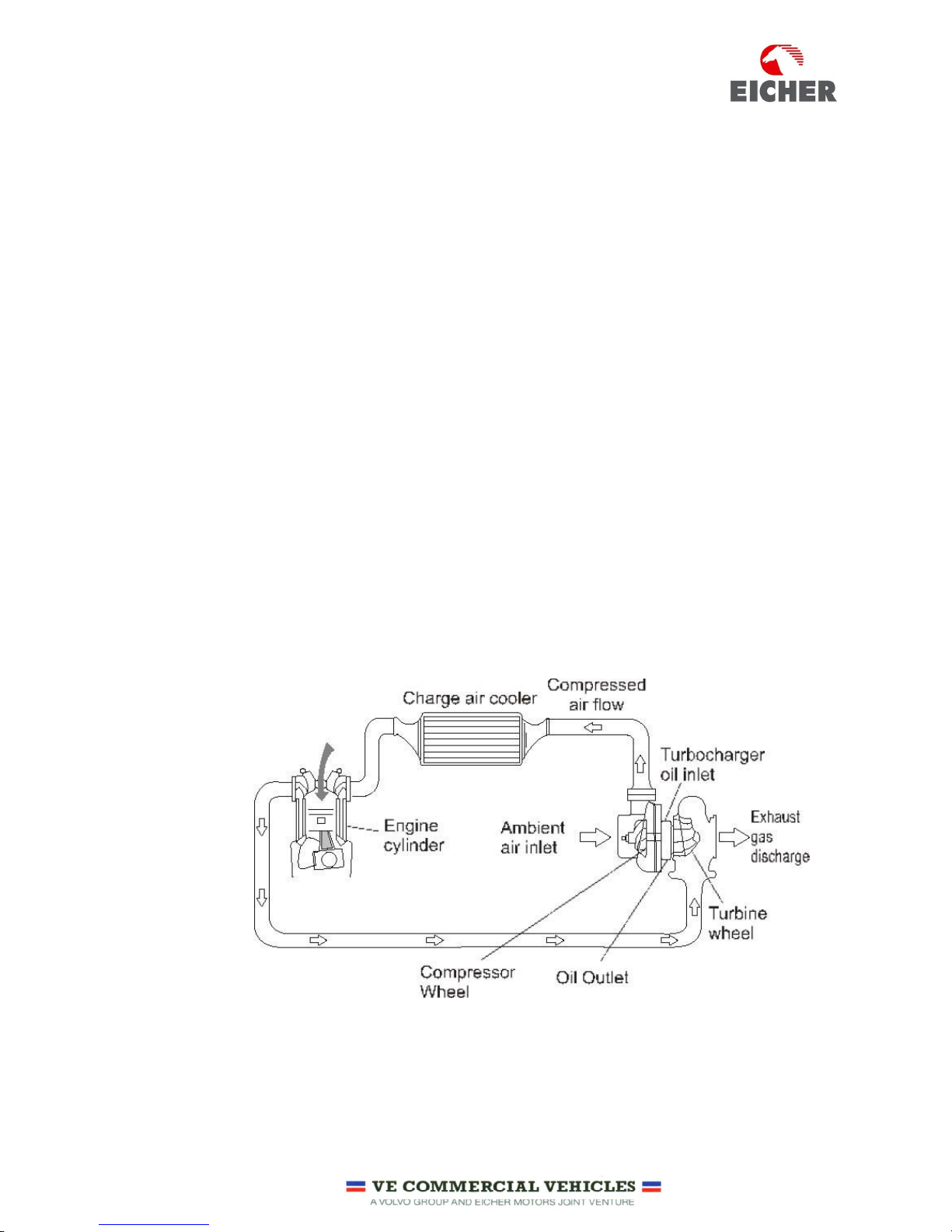

3.5.1 AIR INTAKE AND EXHAUST SYSTEM

TURBO CHARGED INTERCOOLED ENGINES:

The function of air system is to supply clean, cool and sufficient quantity air required for proper combustion

of the fuel which results in designed power output of the engine and maintains emissions as per statutory

norms.

Air intake system facilitates cleaning of air, induction of air, compression of air through turbocharger and

cooling by intercooler.

Air is sucked from atmosphere and passed through the Air filter to restrict dust and other foreign particles

from entering into air intake system. Clean air is then induced and compressed by the turbocharger

compressor wheel. Turbocharger increases the temperature of the air. This high temperature air is then

passed through an intercooler which decreases its temperature. As air inducted cools down its density is

12

further increased. Due to more air with desired density of air inducted into the engine there will be complete

combustion resulting in:

• Increase in power and torque without increasing the size of the engine.

• Improves fuel economy.

• Reduce engine noise.

• More complete combustion resulting in cleaner emission

TURBO CHARGED ENGINES:

In turbo charged engines, intercooler will not be present. The Compressed air from turbo charger will be

directly inducted into the combustion chamber. The combustion parameters will be designed to suit the air

temperature inducted in to the combustion chamber and accordingly desired quantity of fuel will be

supplied to ensure better fuel economy and complete combustion to achieve emission characteristics.

AIR FILTER:

Air filter is fitted on the Suction Side. It is paper cartridge dry type air filter comprising of inner and outer

element. Air filter prevents dust and other foreign particles entering into the air inlet system. The restriction

Indicator fitted on the filter gives indication when air filter gets clogged.

Do not run the engine with clogged air filter. Clogged air filter reduces

power output, fuel efficiency; higher exhaust emissions and affects

engine performance.

Air filter outer element shall be cleaned whenever the restriction

indicator gives indication. There are limitations for cleaning as

frequent cleaning affects air filter filtration efficiency. Follow the

recommendation for cleaning procedures and permissible number of

cleaning.

The inner element should not be cleaned and it should be replaced.

Never run the engine without air filter. Running without air filter will cause foreign object entering into air

system and results in turbocharger and engine failures.

TURBO CHARGER:

The exhaust gases discharged from the combustion chamber are driven out through the exhaust manifold

into the turbo charger and accelerated in the turbine housing to turn the turbine wheel driving away the

Exhaust gases through the muffler to the atmosphere.

Simultaneously, the compressor wheel mounted on the same shaft spins at the designed speeds. The

centrifugal action draws air from air cleaner and builds up the boost pressure in the intake system.

13

SILENCER:

Silencer is used to reduce the noise of exhaust gas /

Smoke.

The exhaust gas is sent through a number of small holes

provided inside the silencer which results in sudden

expansion of exhaust gases.

This results in reduction in exhaust noise.

For specific applications like Power Generation residential

mufflers are used to achieve reduction in noise levels.

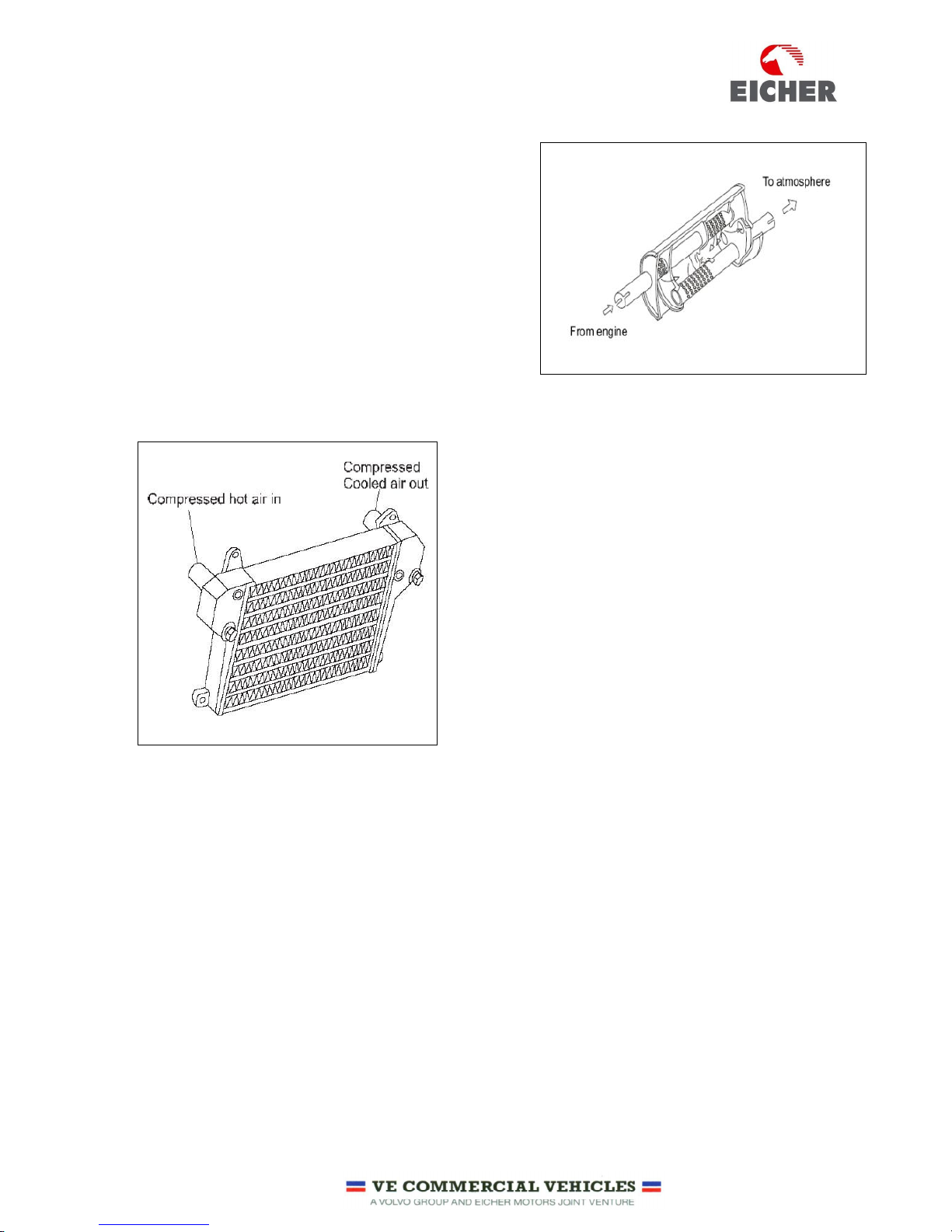

INTER COOLER (APPLICABLE FOR TURBO CHARGED INTERCOOLED ENGINES):

Compressed hot air from turbocharger flows through the

tubes of intercooler.

Pusher type radiator cooling fan charges Cold air through the

intercooler fins carries away the heat from compressed hot air

flowing through the intercooler tubes thereby reducing the

temperature of air to the designed temperature levels. This

compressed cold air rushes in to the combustion chamber.

14

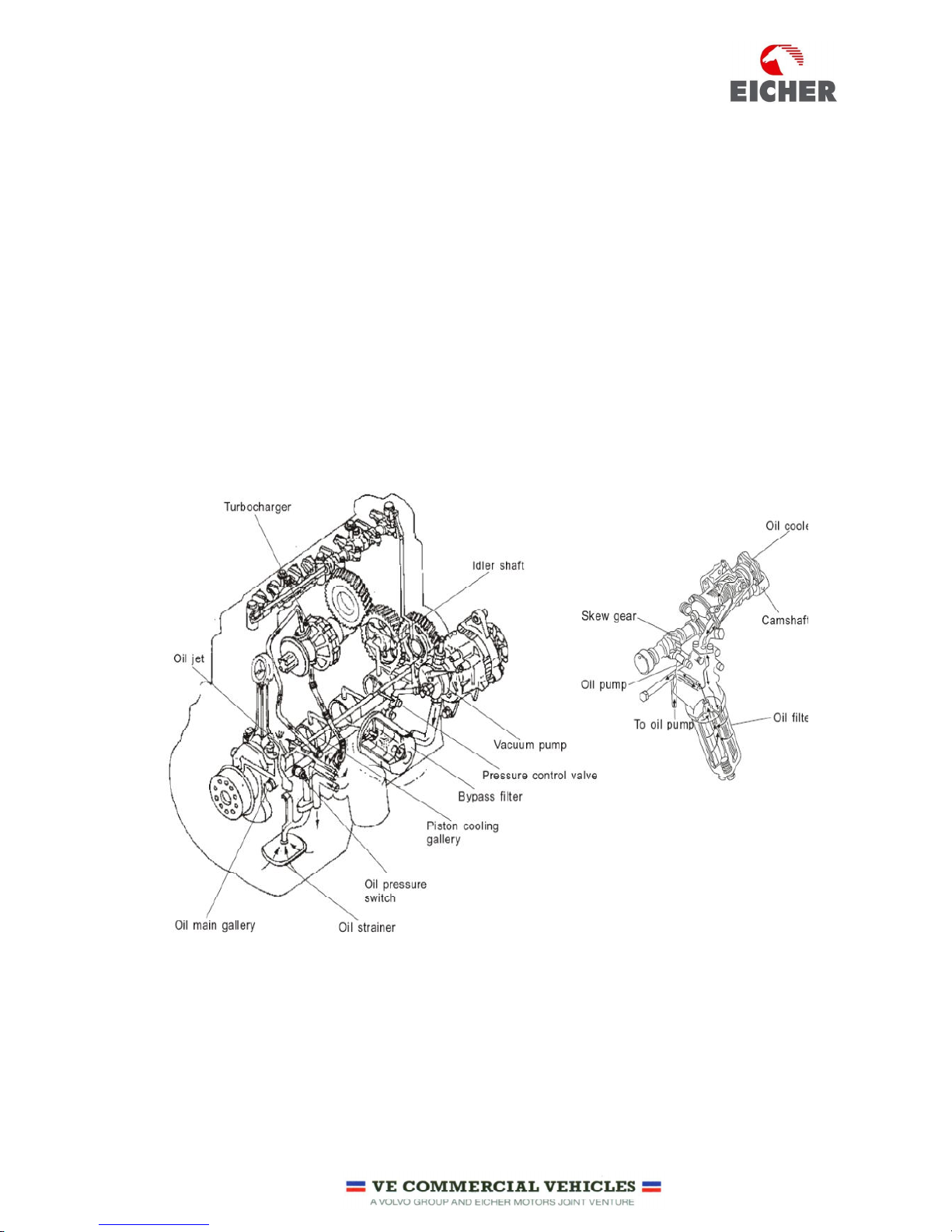

3.5.2 LUBRICATION SYSTEM:

The engine has a forced lubrication system. The main functions of the Lubrication systems are as follows:

• Lubricates moving engine parts by forming a thin film of oil between components and prevents

metal to metal contact

• This oil film is capable of absorbing shocks in Con-rod Bearings and Gear train

• Flowing oil absorbs heat and cools engine parts

• Oil also collects carbon & metal particles formed during engine operation and flows it to the oil pan

• Oil neutralizes the acids and alkali produced during engine operation & prevents corrosion

• Seals compression by forming a thin oil film on cylinder liner walls

ENGINE OIL FLOW PATH:

Loading...

Loading...