EHRLE Series, KD623, 3x3, KD823, KD940 Operating Instruction

...

SERIES 3x3

Serie KD 3X3 / 300781-DE/UK-A

OPERATING INSTRUCTION

KD623 - KD823 - KD940 - KD940-F

OPERATOR

KD623 UK - KD823 UK

High Pressure Cleaner cold water, mobile - Series 3x3

Declaration of Conformity

Manufacturer:

Address:

Product:

High Pressure Cleaner cold water, mobile

Series 3x3

The product given below is in conformity with the European Directives:

Relevant EC Directives:

2000/14/EG

2006/42/EG (+2009/127/EG)

2011/65/EU

2014/30/EU

Applied harmonized standards:

EN 60335–1

EN 60335–2–79

EN 50581

EN 55014–1: 2006+A1: 2009+A2: 2011

EN 55014-2: 2015

EN 62233: 2008

EN 61000–3–2: 2014

EN 61000–3–3: 2013

Ehrle GmbH

Industriestraße 3

D – 89165 Dietenheim

KD623, KD823, KD940, KD940-F

KD623 UK, KD823 UK,

(each Standard and Premium)

Conformity procedures applied:

2000/14/EG: Anhang V

This product is used like

follows marked:

Dietenheim, 01.09.2019

Development

Christoph Nöldner

Head of Development

CE-0085

Reiner Ehrle

CEO

2 von 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

Table of content

1

1.1 General ...............................................................................................................................................5

1.2 Functional device concept ................................................................................................................5

1.3 Terminology ....................................................................................................................................... 6

1.4 Meaning of the emphasis .................................................................................................................6

1.5 Meaning of the symbols ...................................................................................................................7

1.6 Target groups..................................................................................................................................... 9

1.7 Warranty and Liability.......................................................................................................................9

1.8 Environmental protection ...............................................................................................................10

User information

2 Safety

2.1 General safety information ............................................................................................................11

2.2 Authorized persons for device access ............................................................................................11

2.3 Safety instructions for cleaning operation ....................................................................................11

2.4 Accident prevention regulations .................................................................................................... 12

2.5 Lifting and moving loads ................................................................................................................ 12

2.6 Periodic inspections ......................................................................................................................... 13

2.7 Guidelines for liquid sprayers ......................................................................................................... 13

2.8 Design changes to the device ......................................................................................................... 13

2.9 Safety devices ..................................................................................................................................13

Table of content

3 Product description

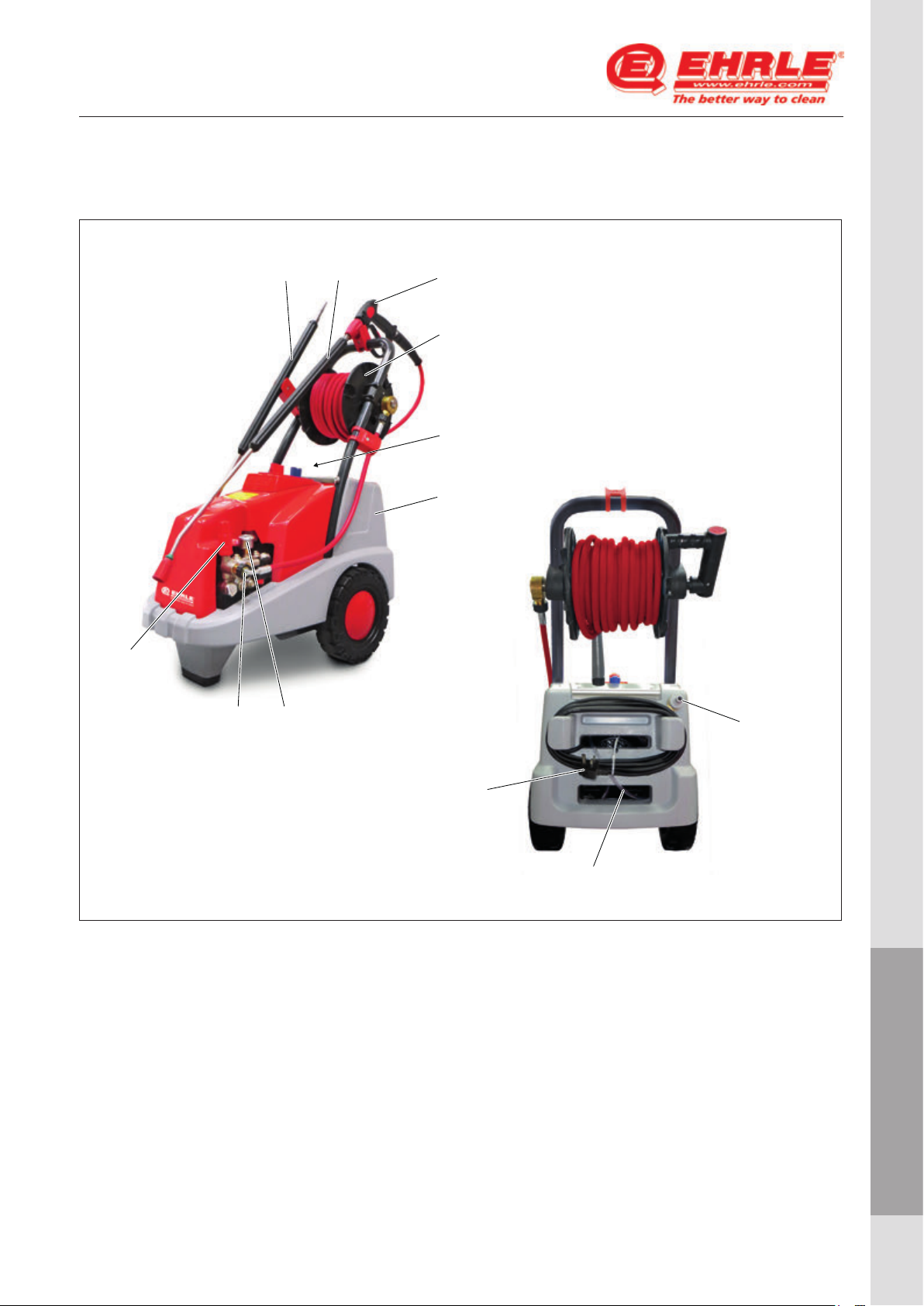

3.1 Device views KD623- and KD823-Standard ....................................................................................14

3.2 Device views KD623 UK- and KD823 UK-Standard ........................................................................15

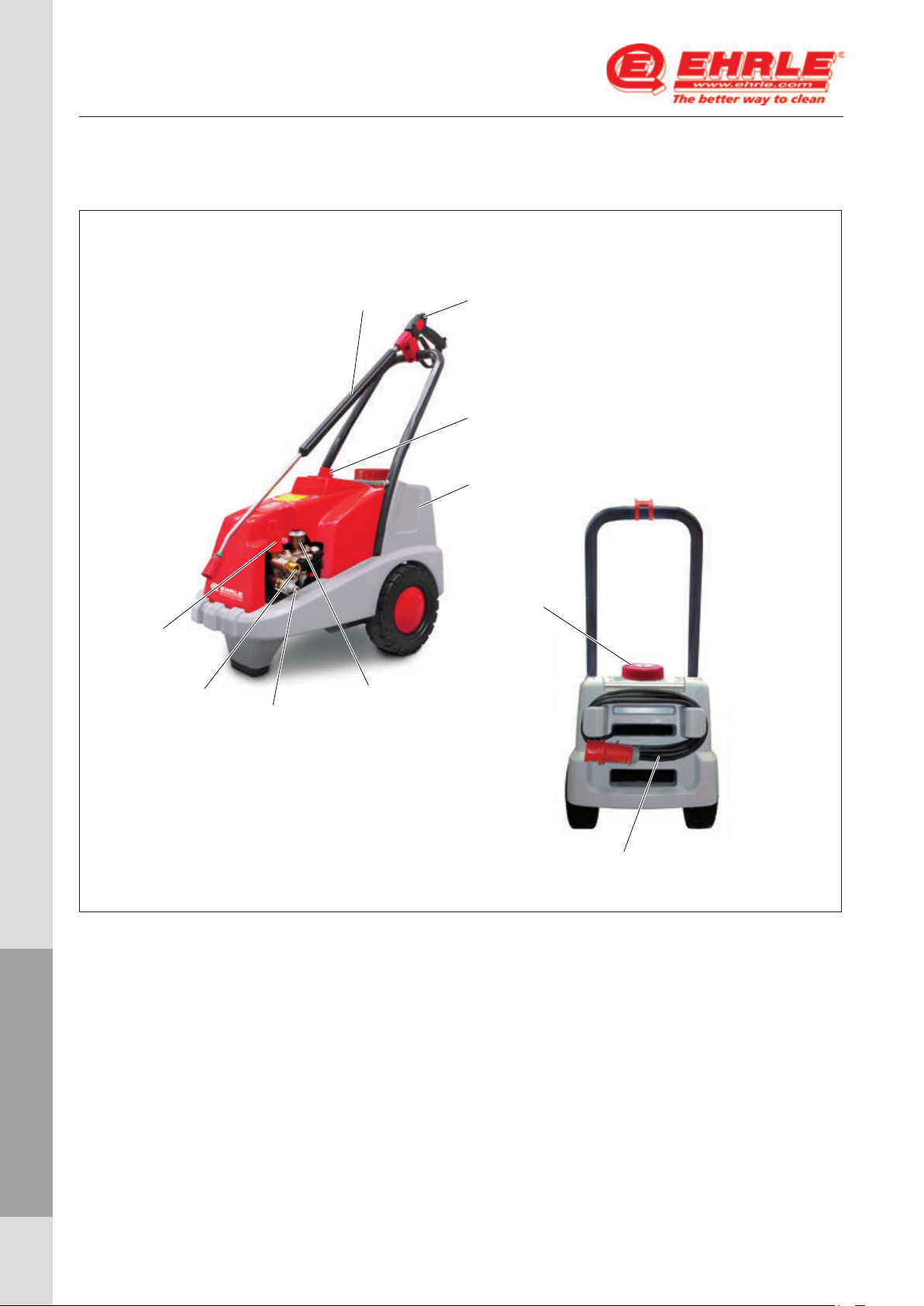

3.3 Device views KD623- and KD823-Premium .................................................................................... 16

3.4 Device views KD623 UK- and KD823 UK-Premium ........................................................................ 17

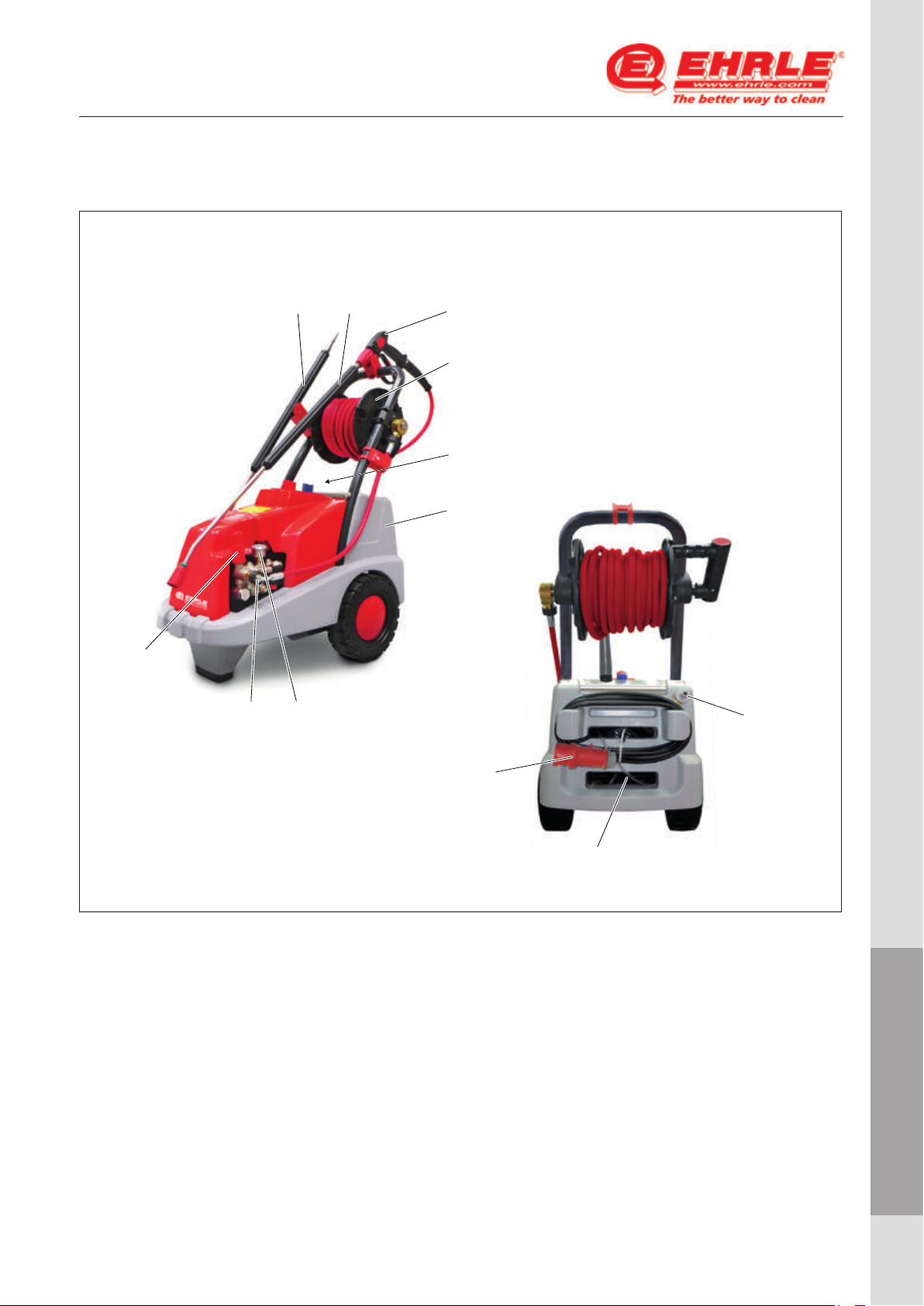

3.5 Device views KD940-Standard ........................................................................................................18

3.6 Device views KD940-Premium ........................................................................................................19

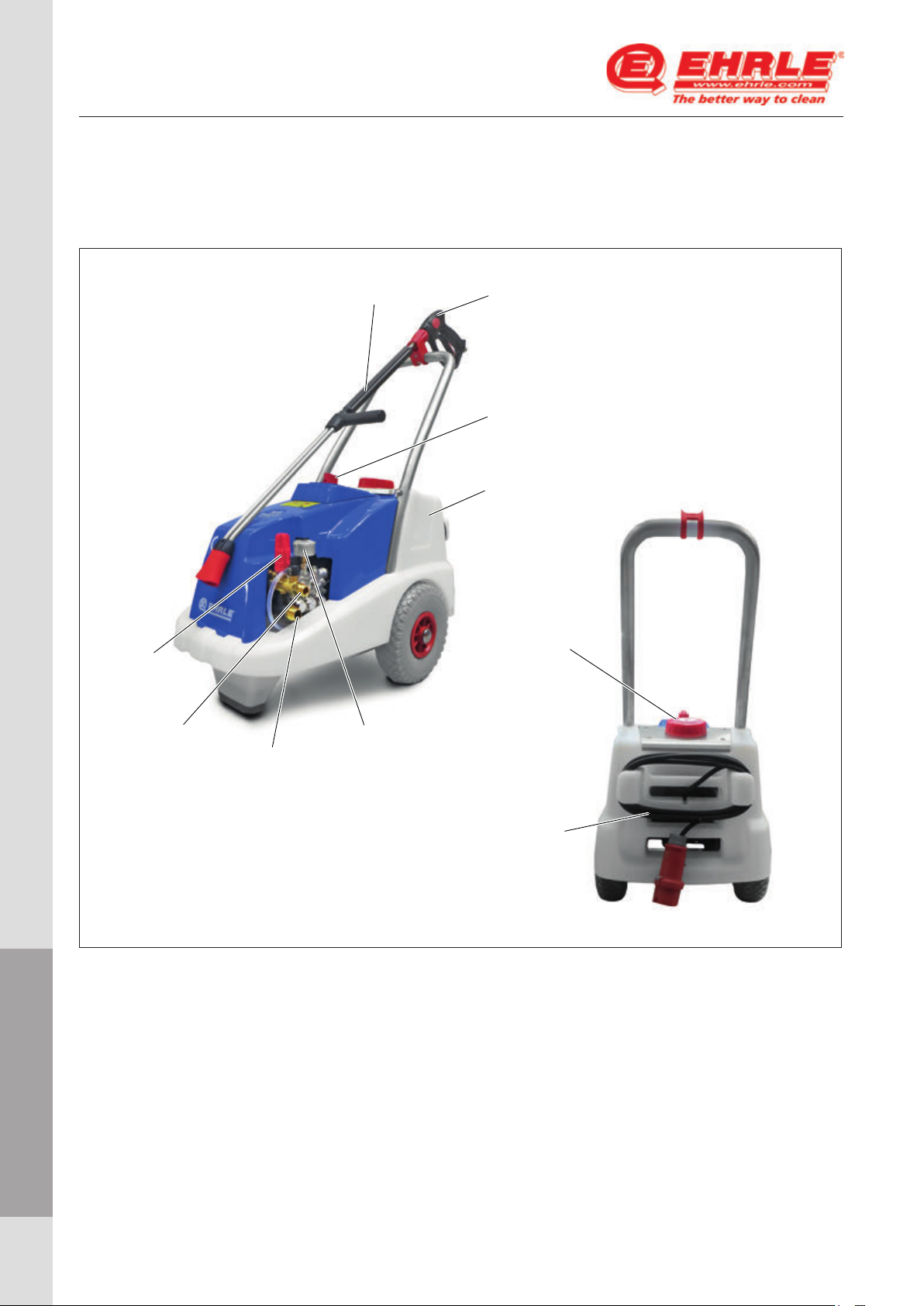

3.7 Device views KD940-F-Standard (food appliance) .........................................................................20

3.8 Device views KD940-F-Premium (food appliance) ......................................................................... 21

3.9 Type plates device version Standard .............................................................................................. 22

3.10 Type plates device version Premium............................................................................................... 23

3.11 Type plates device version UK-Standard ........................................................................................ 24

3.12 Type plates device version UK-Premium ........................................................................................ 25

3.13 Type plates ....................................................................................................................................... 25

3.14 Technical data .................................................................................................................................. 26

3.14.1 High Pressure Cleaner cold water, mobile - Series 3x3 .................................................................. 26

3.14.2 High Pressure Cleaner cold water, mobile - Series 3x3

KD623 UK- and KD823 UK-Standard and Premium ......................................................................27

4 Device assembly

4.1 Device packaging and accessories .................................................................................................. 30

4.2 Accessories for KD623-, KD823-, KD940-Standard ........................................................................32

4.3 Accessories for KD623-, KD823-, KD940-Premium .........................................................................33

4.4 Accessories for KD940-F-Standard .................................................................................................. 34

4.5 Accessories for KD940-F-Premium .................................................................................................. 35

300781 • 1/2019 • H.S.

3 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

4.6 Device assembly ............................................................................................................................... 36

4.6.1 Device version Standard ..................................................................................................................36

4.6.2 Device version Premium .................................................................................................................. 38

5 Commissioning

5.1 Select location for device operation ..............................................................................................41

5.2 Establishing the water connection ................................................................................................. 42

5.3 Establishing the electrical mains connection ................................................................................. 43

5.4 Commissioning the device ..............................................................................................................44

Table of content

6 Operation

6.1 Control and indicator elements of device .....................................................................................45

6.2 Control elements of the trigger gun ..............................................................................................46

6.3 EMERGENCY STOP - switch-off in case of danger .........................................................................47

6.4 Cleaning operation .........................................................................................................................47

6.5 Operation with cleaning detergent (chemistry) ............................................................................50

6.5.1 General Informationen ...................................................................................................................50

6.5.2 Cleaning detergent operation with version Standard .................................................................. 51

6.5.3 Cleaning detergent operation with version Premium .................................................................. 52

6.5.4 Special application of detergent agents for food appliance (only version Premium) ................ 53

7 Decommissioning

7.1 Temporary decommissioning .......................................................................................................... 55

7.1.1 Device version Standard ..................................................................................................................55

7.1.2 Device version Premium .................................................................................................................. 56

7.2 Decommissioning for a longer period of time ..............................................................................57

8 Maintenance

8.1 General Information .......................................................................................................................58

8.2 EHRLE Maintenance and Inspection Contract ...............................................................................58

8.3 Maintenance work ..........................................................................................................................58

8.3.1 Frost Protection ..............................................................................................................................60

8.3.1.1 Drain water from high pressure cleaner ........................................................................................ 60

8.3.1.2 Rinse high pressure cleaner with antifreeze agent ......................................................................60

8.3.2 Cleaning the filter in the water inlet ............................................................................................. 60

8.3.3 Checking the HP-Hoses ..................................................................................................................61

9 Troubleshooting

9.1 Troubleshooting table ..................................................................................................................... 62

300781 • 1/2019 • H.S.

4 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

1 User information

1.1 General

General information

For a comprehensive advice and information on the High Pressure

Cleaner cold water, mobile - Series 3x3 please contact the EHRLE

Customer Service.

With the purchase of a EHRLE High Pressure Cleaner cold water,

mobile - Series 3x3 you are the owner of a quality product, which is

characterised by:

● user-friendliness,

● reliability,

● environmental friendliness.

1 User information

These operating instructions are part of the High Pressure Cleaner cold

water, mobile - Series 3x3 and must be kept at the operating site and

available at all times.

For the High Pressure Cleaner cold water, mobile - Series 3x3, the manual

contains information on

● User information

● Safety

● Product information

● Device assembly

● Commissioning, Decommissioning

● Operation

● Maintenance

● Troubleshooting

1.2 Functional device concept

Due to the specific constructive properties the high pressure cleaners can

be used in all conceivable industries, for example:

● Industry

● Agriculture and forestry

● Painting companies (e.g. facades, floors)

● Construction companies (structural engineering, underground

construction and road construction

● Forwarding companies, vehicle and rental parks

● Local government

● Hotels and restaurants, as well as food industry

300781 • 1/2019 • H.S.

5 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

1.3 Terminology

In this manual the terminology listed below is replaced by the relevant

short terms whenever possible

● High Pressure Cleaner

cold water, mobile - Series 3x3 high pressure cleaner or device

● Operating Instruction manual

● High pressure hose HP-Hose

If a clear reference to a subject is required in the description parts, the

terminology „High Pressure Cleaner cold water, mobile - Series 3x3“ is used.

1.4 Meaning of the emphasis

The emphasis used in this manual have the following meanings:

1 User information

WARNING

Warning precedes operating procedures, instructions, etc., which, if not

strictly observed, could result in personal injury or loss of life. Warning

precedes also, when device misuse could result in personal injury or loss of

life.

CAUTION

Caution precedes operating procedures, instructions, etc., which, if not

strictly observed, could result in damage to the high pressure cleaner.

Caution precedes also, when device misuse could result in damage to the

high pressure cleaner.

This symbol indicates additional information.

300781 • 1/2019 • H.S.

6 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

1.5 Meaning of the symbols

Symbol Meaning

WARNING

Follow instructions!

Non-observance or neglecting of prescribed

instructions, incorrect operation or misuse of

the device may endanger life and limb of

persons.

WARNING

Danger of death due to electric shock.

Do not open the device. During operation,

dangerous voltages are present on live parts of

the device.

Touching live parts can lead to life-threatening

injuries.

1 User information

WARNING

Danger of burns and scalds.

When operating with a water inlet temperature of up to 45 °C (device version Standard

and Premium) resp. up to 80 °C (device version

Standard and Premium for food appliance) the

cleaning objects, the hot water emerging from

the trigger gun, surfaces of the cleaning objects

or device components can become hot.

Touching hot surfaces or hot water can cause

burns or scalding of the skin surface. Make sure

surfaces have cooled before touching.

The hot water escaping from the trigger gun

must not come into contact with the skin.

WARNING

Danger with heavy loads.

A person is not allowed to lift and move loads

more than 23 kg. Otherwise the health of persons may be endangered (e.g. overload of the

spinal column, injuries from falling loads).

For loads of more than 23 kg, use suitable lifting equipment (e.g. forklift truck, lift truck).

300781 • 1/2019 • H.S.

CAUTION

Observe instructions for installation, device

adjustment, operation, maintenance and repair.

Non-observance or neglecting prescribed

instructions, incorrect operation or misuse of

the device may result in damage to device parts,

assemblies or components.

7 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

Symbol Meaning

General Information

General additional information.

Information on recycling

General information on recycling.

Information on disposal

General information on the proper and environmentally sound disposal of materials and

consumables.

Information on hearing protection

General information on hearing protection.

1 User information

•

Calls for a direct action.

Result after an action.

Enumeration

300781 • 1/2019 • H.S.

8 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

1.6 Target groups

This Operating Instruction contains information and instructions for

operating personnel for carrying out general cleaning work.

1.7 Warranty and Liability

The EHRLE High Pressure Cleaner cold water, mobile - Series 3x3 may only

be used for its intended purpose.

Intended use includes:

● Operation only by authorised persons who

○ are instructed and trained on the device, or

○ have completely read and understood the information and

instructions in this Operating Instruction and can therefore

guarantee safe handling of the device.

● The information and instructions contained in this Operating Instruction

must be observed.

● If the safety and protective devices are faulty, the high pressure cleaner

must not be put into operation

● The high pressure cleaner may only be operated with fully functional

safety and protective devices. In the event of functional failures during

operation, the high pressure cleaner must be taken out of operation

immediately.

● Faulty, insufficient or defective high pressure cleaners must not be put

into operation. Before commissioning, carry out a visual inspection for

faulty, defective or defective

○ Device parts, assemblies or components

○ Electrical cables

○ HP-Hoses.

● The high pressure cleaner must be switched off immediately and taken

out of operation if defects, faults or deficiencies occur on

○ Device parts, assemblies or components

○ Electrical cables

1 User information

300781 • 1/2019 • H.S.

○ HP-Hoses.

● No constructive changes may be made to the device.

● The device may only be operated in the configuration certified by the

manufacturer. Operation with subsequently installed modules, components or additional devices is not permitted and may endanger life and

limb of persons or lead to damage to the device

● Only original parts from the manufacturer or consumables approved by

the manufacturer may be used for maintenance and repair work.

Any warranty and liability claims for personal injury and damage to the

device are void if the high pressure cleaner is not used for its intended

purpose.

9 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

1.8 Environmental protection

Note on recycling

The packaging materials are recyclable. Please do not throw the

packaging into the household waste, but recycle it.

Note on disposal

Old appliances contain valuable recyclable materials which should be

recycled. Batteries, oil and similar materials must not be discharged into

the environment. For this reason, please dispose of old appliances using

suitable collection systems.

Dispose of used materials in an appropriate and environmentally friendly

manner. Observe the local regulations.

1 User information

According to environmental regulations, waste water containing mineral

oil, fuels for hot water heating or lubricants such as oils and greases must

not enter the soil, water or sewerage system.

Do not allow engine oil, fuel oil or petrol to escape into the environment.

Protect the soil and dispose of used oil in an environmentally friendly

manner.

Engine cleaning or underbody washing of all types of vehicles may only be

carried out at washing stations equipped with oil separators in accordance

with environmental regulations (environmental protection).

300781 • 1/2019 • H.S.

10 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

2 Safety

2.1 General safety information

Observe the respective national regulations of the legislator for liquid

sprayers.

Observe the relevant national regulations of the legislator on accident

prevention. Liquid sprayers must be inspected regularly and the result of

the inspection must be recorded in writing.

Observe the safety instructions provided with the cleaning agents used

(usually on the packaging label).

Keep cleaning agents out of the reach of unauthorized persons. Risk of

poisoning or caustic burns from cleaning agents! Observe the instructions

on the cleaning agents.

Perform prescribed maintenance and inspection work in due time (see

Section 8, Maintenance).

Safety-relevant defects must be rectified immediately. Keep all signs on the

device legible.

2.2 Authorized persons for device access

Ensure that access to the device is only possible for the persons who

● have completely read and understood the information and instructions

in this Operating Instruction and can therefore guarantee safe handling

of the device or

● are instructed and trained on the device.

Children as well as persons with reduced physical, sensory or mental

abilities are not allowed to operate the device.

2.3 Safety instructions for cleaning operation

During cleaning work, the personnel at the workplace must wear the

necessary Personal Protective Equipment (PPE). This includes waterproof

protective suits, rubber boots, protective goggles, headgear, ear protection

if necessary, etc

No cleaning work may be carried out in the presence of persons without

sufficient PPE.

2 Safety

300781 • 1/2019 • H.S.

Before switching on, carry out a visual inspection of the device parts from

the outside for damage (HP-Hose, electrical or mechanical parts). Devices

with damaged parts, assemblies or components must not be put into

operation.

The water jet leaving the trigger gun must not be directed at

● persons

● animals

● live electrical installations (building mains connections, sockets,

electrical wiring, etc.)

● live electrical installations, machines, devices, assemblies or components

● system, machinery or equipment in operation.

11 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

Under the influence of the high pressure jet, parts can be separated from

the cleaning object and thrown away. Persons can be injured as a result.

Never aim the high pressure jet at fragile or loose objects.

When cleaning tyres and their valves, keep a minimum distance of 30 cm

from the high pressure nozzle. Otherwise damage may occur.

Before cleaning the High Pressure Cleaner cold water, mobile - Series 3x3

itself, take the device out of operation and disconnect it from the electrical

mains connection. Secure the device against unintentional or unauthorised

restarting (e.g. lock main switch, warning sign indicating work on the high

pressure cleaner, etc.).

Never operate the device unattended.

The device is designed for a water inlet temperature of up to 45 °C (device

version Standard and Premium) resp. up to 80 °C (device version Standard

and Premium for food appliance). When operated with hot water, watercarrying parts (for example pump housing, uninsulated pipes, metal parts

of the trigger gun and spray lance) as well as cleaning objects may become

hot. Touching hot surfaces can cause burns or scalding of the skin surface.

Make sure surfaces have cooled before touching. The hot water escaping

from the trigger gun must not come into contact with the skin.

2 Safety

Asbestos-containing and other materials containing substances hazardous

to health must not be sprayed off.

Information on hearing protection

If the sound levels exceed the permissible values, the personnel and

persons in the area of exposure must wear hearing protection.

The sound level for EHRLE high pressure cleaners under maximum load is

82 dB (A). A high sound level over a long period can cause hearing loss. If

the noise produced by the application of the emerging high pressure jet

to noise-enhancing objects exceeds the permissible values, the operating

personnel and any persons affected must wear hearing protection.

Do not operate the device if electrical cables or other safety-relevant parts

(pressure relief valve, HP-Hose, trigger gun, etc.) are defective.

2.4 Accident prevention regulations

Observe the applicable national regulations of the legislator on accident

prevention.

300781 • 1/2019 • H.S.

2.5 Lifting and moving loads

The High Pressure Cleaner cold water, mobile - Series 3x3 weighs from

48 to 60 kg depending on the type (with packaging from approx. 66 kg to

approx. 78 kg).

Lifting and moving loads is permitted for one person up to 23 kg. If the

load exceeds 23 kg use suitable lifting equipment (e.g. forklift, lift trucks).

Observe the international standard „ISO 11228-1 Ergonomie - Manuelles

Handhaben von Lasten - Teil 1 Heben und Tragen 05/2003“.

12 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

2.6 Periodic inspections

The periodic inspections are listed in Section 8 (Maintenance).

2.7 Guidelines for liquid sprayers

High pressure cleaners must be inspected by an expert in accordance with

the „Guidelines for liquid sprayers“, if necessary or at least every

12 months. The result of the test must be recorded in writing.

In the appendix of this manual there is a test sheet (proof of customer

service) to record the tests carried out.

EHRLE service technicians are experts and can be consulted and

commissioned by EHRLE service for this prescribed inspection.

2.8 Design changes to the device

Design changes to the high pressure cleaner are not permitted.

When operating a device which has been modified or changed in design,

the device will not be used for its intended purpose. If the device is not

used for its intended purpose, no liability or warranty will be accepted (see

Section 1.7, Warranty and Liability).

2.9 Safety devices

Safety devices serve to protect the user and must not be suspended or

circumvented in their function.

The high pressure cleaner has the following safety devices listed below:

● Pressure switches:

Device functions are switched on or off (safety functions) based on type

of construction and intended use.

● Unloader valve and non-return valve:

The first serves to adjust the operating pressure and the second valve

keeps the pump head depressurised when the trigger gun is deactivated.

● TSS system with pump-off delay:

After deactivating the trigger gun, the pump continues operation for

approx. 30 s in the pressureless bypass mode (avoidance of too high

pressure build-up in the pump); after 30 s the high pressure cleaner

automatically switches into the stand-by mode.

● Total Switch-off:

Automatically switches the high pressure cleaner off in the event of

prolonged interruption of operation or unused trigger gun for more

than 20 minutes.

● Overload protection switch:

When the motor current load is too high the switch releases and the

device is switched off.

● Mechanical arrest for trigger gun:

Prevents unintentional or unconscious activating the trigger gun.

2 Safety

300781 • 1/2019 • H.S.

13 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

3 Product description

3.1 Device views KD623- and KD823-Standard

7

6

5

8

1

2

3

9

4

1 Trigger gun 6 High pressure outlet (pump)

2 Device switch 0/I 7 Unloader valve

3 Detergent container 8 Spray lance with adjustable nozzle

4 Pressure gauge 9 Filler neck for cleaning detergent

5 Connection water inlet 10 Mains cable connection 230 VAC

with adapter

Fig. 3 - 1 KD623- and KD823-Standard, total and rear view

3 Product information

300781 • 1/2019 • H.S.

10

14 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

3.2 Device views KD623 UK- and KD823 UK-Standard

7

6

5

8

1

2

3

9

4

1 Trigger gun 6 High pressure outlet (pump)

2 Device switch 0/I 7 Unloader valve

3 Detergent container 8 Spray lance with adjustable nozzle

4 Pressure gauge 9 Filler neck for cleaning detergent

5 Connection water inlet 10 Mains cable connection 240 VAC

with adapter

Fig. 3 - 2 KD623 UK- and KD823 UK-Standard, total and rear view

300781 • 1/2019 • H.S.

15 of 70

10

3 Product information

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

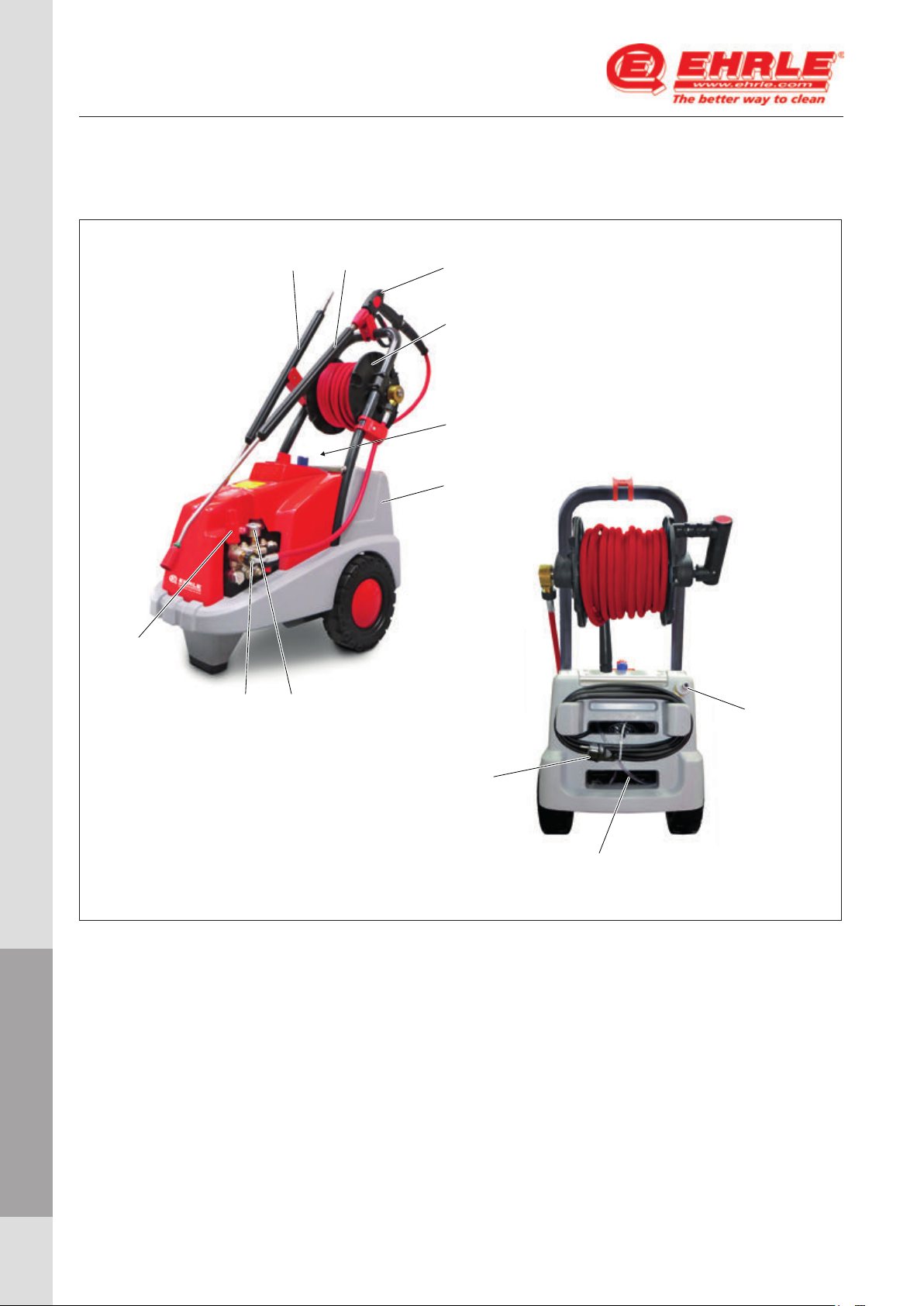

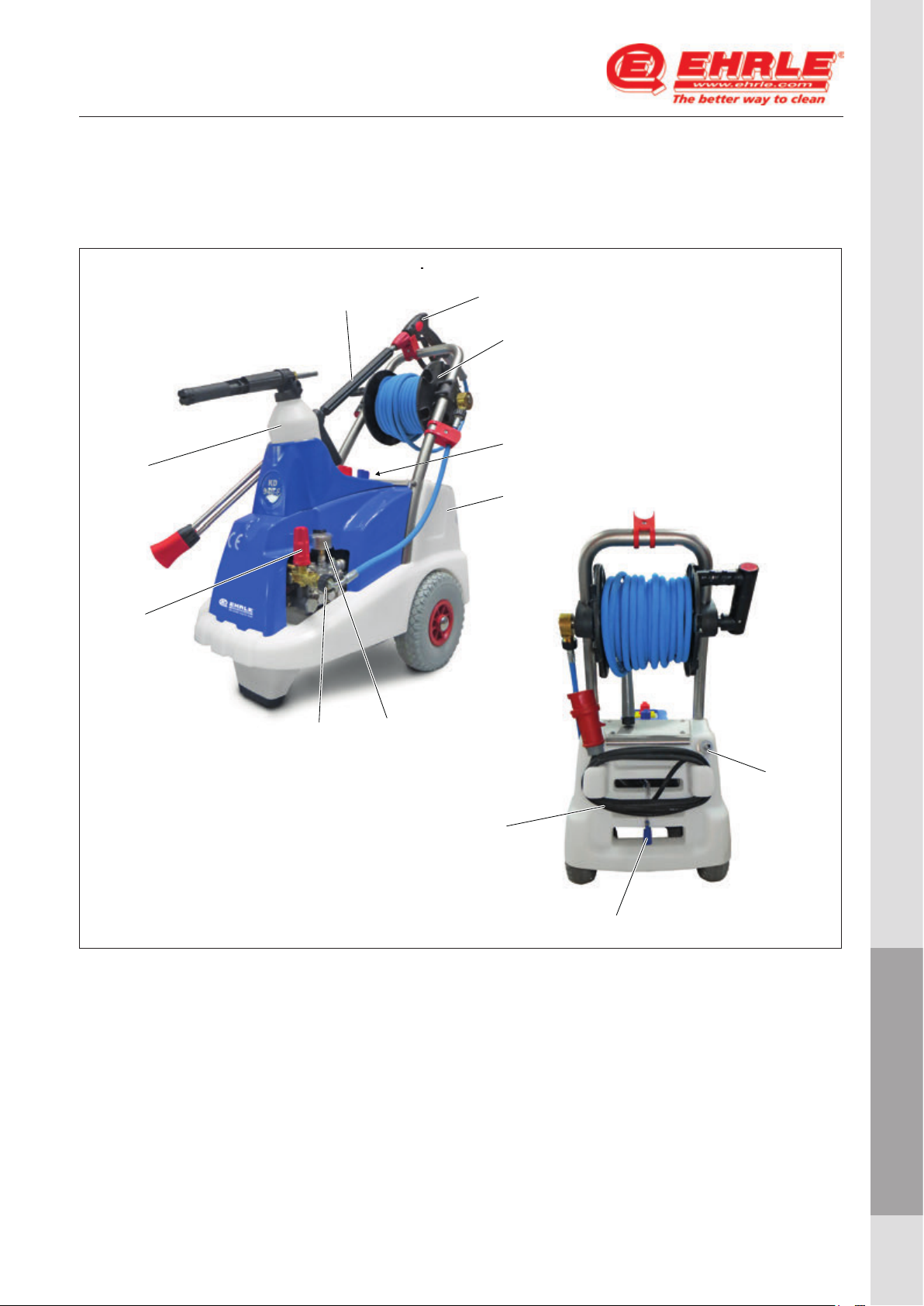

3.3 Device views KD623- and KD823-Premium

7

8

9

1

2

3

4

6

5

10

1 Trigger gun 6 High pressure outlet (pump)

2 Hose reel 7 Unloader valve

3 Control panel with 8 Spray lance with rotary nozzle

Detergent control valve (blue) and 9 Spray lance with nozzle protection

Device switch 0/I (red) 10 Mains cable connection 230 VAC

4 Water supply separation tank 11 Detergent suction hose with filter

5 Pressure gauge 12 Connection water inlet with adapter

Fig. 3 - 3 KD623- and KD823-Premium, total and rear view

12

11

3 Product information

300781 • 1/2019 • H.S.

16 of 70

Operating Instruction

High Pressure Cleaner cold water, mobile

Series 3x3

3.4 Device views KD623 UK- and KD823 UK-Premium

7

8

9

1

2

3

4

6

5

10

1 Trigger gun 6 High pressure outlet (pump)

2 Hose reel 7 Unloader valve

3 Control panel with 8 Spray lance with rotary nozzle

Detergent control valve (blue) and 9 Spray lance with nozzle protection

Device switch 0/I (red) 10 Mains cable connection 240 VAC

4 Water supply separation tank 11 Detergent suction hose with filter

5 Pressure gauge 12 Connection water inlet with adapter

Fig. 3 - 4 KD623 UK- and KD823 UK-Premium, total and rear view

12

11

3 Product information

300781 • 1/2019 • H.S.

17 of 70

Operating Instruction

1

2

3

4

5

9

7

8

6

10

High Pressure Cleaner cold water, mobile

Series 3x3

3.5 Device views KD940-Standard

1 Trigger gun 6 High pressure outlet (pump)

2 Device switch 0/I 7 Unloader valve

3 Detergent container 8 Spray lance with adjustable nozzle

4 Pressure gauge 9 Filler neck for cleaning detergent

5 Connection water inlet 10 Mains cable connection 3x400 VAC

with adapter

Fig. 3 - 5 KD940-Standard, total and rear view

3 Product information

300781 • 1/2019 • H.S.

18 of 70

Operating Instruction

9

1

2

3

4

5

10

7

8

6

11

12

High Pressure Cleaner cold water, mobile

Series 3x3

3.6 Device views KD940-Premium

1 Trigger gun 6 High pressure outlet (pump)

2 Hose reel 7 Unloader valve

3 Control panel with 8 Spray lance with rotary nozzle

Detergent control valve (blue) and 9 Spray lance with nozzle protection

Device switch 0/I (red) 10 Mains cable connection 3x400 VAC

4 Water supply separation tank 11 Detergent suction hose with filter

5 Pressure gauge 12 Connection water inlet with adapter

Fig. 3 - 6 KD940-Premium, total and rear view

3 Product information

300781 • 1/2019 • H.S.

19 of 70

Operating Instruction

1

2

3

4

5

9

7

8

6

10

High Pressure Cleaner cold water, mobile

Series 3x3

3.7 Device views KD940-F-Standard

(food appliance)

1 Trigger gun 6 High pressure outlet (pump)

2 Device switch 0/I 7 Unloader valve

3 Detergent container 8 Double spray lance 900 mm

4 Pressure gauge with nozzle protection

5 Connection water inlet 9 Filler neck for cleaning detergent

with adapter 10 Mains cable connection 3x400 VAC

Fig. 3 - 7 KD940-F-Standard food appliance, total and rear view

3 Product information

300781 • 1/2019 • H.S.

20 of 70

Operating Instruction

9

1

2

3

4

5

10

7

8

6

11

12

High Pressure Cleaner cold water, mobile

Series 3x3

3.8 Device views KD940-F-Premium

(food appliance)

1 Trigger gun 7 Unloader valve

2 Hose reel 8 Soft foam kit with 2 l bottle

3 Control panel with 9 Double spray lance 900 mm

Detergent control valve (blue) and with nozzle protection

Device switch 0/I (red) 10 Mains cable connection 3x400 VAC

4 Water supply separation tank 11 Detergent suction hose with filter

5 Pressure gauge 12 Connection water inlet with adapter

6 High pressure outlet (pump)

3 Product information

Fig. 3 - 8 KD940-F-Premium food appliance, total and rear view

300781 • 1/2019 • H.S.

21 of 70

Loading...

Loading...