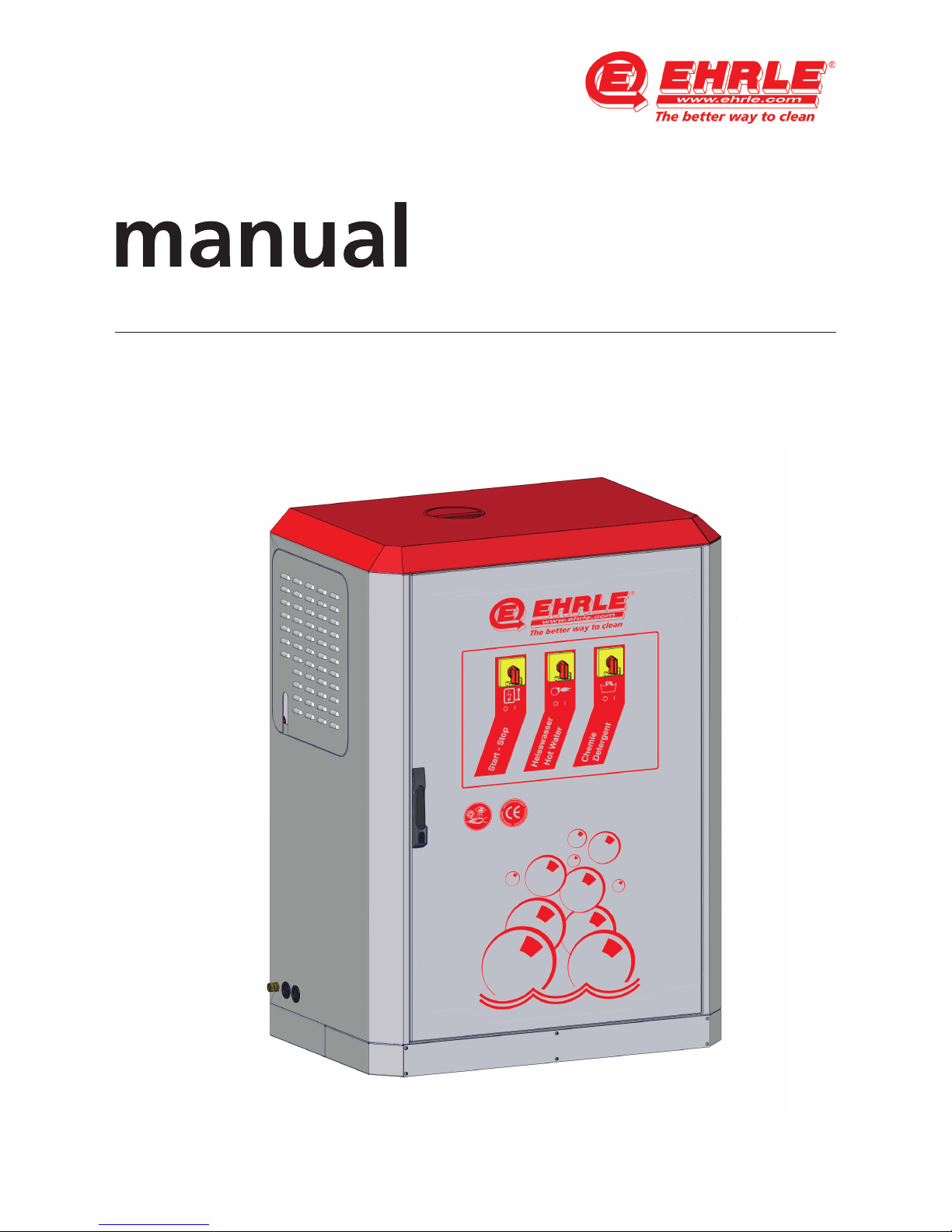

EHRLE HSC1140-INOX Gas Installation And Operating Instructions Manual

High Pressure Cleaner, Hot Water, Stationary HSC1140-INOX Gas

Installation and Operating Instructions

300631 • 1/2018 • H.S.

Authorised Specialists and Operators

HSC1140-INOX Gas / 52701-DE-B

English

2 of 82

Declaration of Conformity

Ehrle GmbH

Industriestraße 3

D – 89165 Dietenheim

HSC1140-INOX Gas

GAD 2009 / 142 / EC

MD 2006 / 42 / EC

LVD 2006 / 95 / EC

EMC 2004 / 108 / EC

CE-0085

Manufacturer:

Address:

Product:

Stationary, Hot Water, High Pressure Cleaner

The product given above is in conformity

with the European Directives:

This product is used like

follows marked:

Development

Christoph Nöldner

Reiner Ehrle

Head of Development

CEO

Illertissen, 01.02.2018

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

300631 • 1/2018 • H.S.

3 of 82

Table of content

Table of Content

1 User information

1.1 General ...............................................................................................................................................5

1.2 Functional system concept ................................................................................................................ 5

1.3 Terminology ....................................................................................................................................... 6

1.4 Meaning of the emphasis .................................................................................................................6

1.5 Meaning of the symbols ...................................................................................................................7

1.6 Target groups..................................................................................................................................... 9

1.7 Warranty and Liability.......................................................................................................................9

1.8 Environmental protection ...............................................................................................................10

2 Safety and security

2.1 General safety information ............................................................................................................11

2.2 Access for persons to the system .................................................................................................... 11

2.3 Safety instructions for cleaning operation for system operators and operating personnel ......12

2.4 Safety instructions for gas-fired systems ........................................................................................13

2.4.1 General information about the gas burner type ..........................................................................13

2.4.2 Note on combustion air ..................................................................................................................14

2.4.3 Behaviour in case of gas odour ......................................................................................................14

2.4.4 Behaviour with exhaust gas odour ................................................................................................14

2.4.5 Gas supply regulations, guidelines and rules ................................................................................14

2.5 Accident prevention regulations .................................................................................................... 15

2.6 Lifting and moving loads ................................................................................................................ 15

2.7 Periodic inspections ......................................................................................................................... 15

2.8 Guidelines for liquid sprayers ......................................................................................................... 16

2.9 Federal Immission Control Act ........................................................................................................16

2.10 Safety regulations Electrical connection ........................................................................................ 16

2.11 Design changes to the system ........................................................................................................16

2.12 Safety devices ..................................................................................................................................16

3 Product description

3.1 System views .................................................................................................................................... 18

3.2 Serial number ..................................................................................................................................20

3.3 Technical data .................................................................................................................................. 21

3.3.1 Technical data of the system........................................................................................................... 21

3.3.2 Selection of spray nozzles ............................................................................................................... 23

4 Installation

4.1 Selection of the operating location ...............................................................................................25

4.2 Operating location inside buildings for type B23 .........................................................................27

4.3 Installation material ........................................................................................................................ 28

4.4 Installation of flue gas pipes for gas-fired .....................................................................................30

4.5 Installation of gas connection ........................................................................................................31

4.6 Installation of the electrical connection ........................................................................................32

4.7 Establishing the water connection ................................................................................................ 33

4.8 Assembly of the condensation water drain hose .......................................................................... 34

4.9 Assembly of washing station equipment .......................................................................................34

4.10 Set up internal cleaning detergent container ............................................................................... 35

300631 • 1/2018 • H.S.

4 of 82

Table of content

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

5 Commissioning

5.1 Activities prior to initial commissioning ........................................................................................37

5.2 First switching-on after installation ...............................................................................................38

5.3 Burner setting values for gas-fired systems ................................................................................... 40

6 Operation

6.1 System indicator and control elements ..........................................................................................42

6.1.1 Control elements on the cabinet door front ................................................................................. 42

6.1.2 Control elements of the trigger gun ..............................................................................................43

6.1.3 Indicator and control elements in the cabinet .............................................................................. 44

6.2 Measures for system operators before operation ......................................................................... 45

6.3 Notes on operation for specialist and operating personnel .........................................................46

6.3.1 EMERGENCY STOP - switch-off in case of danger .........................................................................47

6.3.2 System setting and operation for skilled personnel .....................................................................48

6.3.3 System operation for operating personnel ...................................................................................50

6.4 Use of detergents (chemistry) .........................................................................................................52

6.4.1 Adjust the amount of detergent to be added ..............................................................................53

6.4.2 Add detergent ................................................................................................................................. 53

7 Decommissioning

7.1 Temporary decommissioning by operating personnel .................................................................. 54

7.2 Temporary decommissioning by qualified personnel ................................................................... 54

8 Maintenance

8.1 General Information .......................................................................................................................56

8.2 EHRLE Maintenance and Inspection Contract ...............................................................................56

8.3 Maintenance work ..........................................................................................................................56

8.3.1 Antifreeze ....................................................................................................................................... 59

8.3.1.1 Drain water from high pressure cleaner ........................................................................................ 59

8.3.1.2 Rinse high pressure cleaner with antifreeze agent .......................................................................59

8.3.2 Cleaning the filter in the water inlet ............................................................................................. 60

8.3.3 Oil change ........................................................................................................................................ 60

8.3.4 Decalcification of the high pressure cleaner .................................................................................60

8.3.5 Checking the high pressure hoses ................................................................................................. 61

9 Troubleshooting

9.1 Troubleshooting table ..................................................................................................................... 62

9.2 Replacement of components and parts ........................................................................................ 65

10 Spare parts

10.1 System cabinet (exterior view) .......................................................................................................67

10.2 System cabinet (interior) ................................................................................................................. 68

10.3 Components on the chassis middle section ...................................................................................69

10.4 Gas burner with boiler system ........................................................................................................ 70

10.4.1 System version with Weishaupt gas burner ................................................................................... 70

10.4.2 System version with Baltur gas burner ..........................................................................................72

10.5 Drive unit Motor and pump ...........................................................................................................74

10.6 Trigger gun with spray lance .......................................................................................................... 76

11 Circuit diagram

11.1 HSC1140-INOX Gas ..........................................................................................................................78

300631 • 1/2018 • H.S.

5 of 82

1 User information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

1 User information

1.1 General

General information

For a comprehensive advice and information on the High Pressure

Cleaner, Hot Water, Stationary, HSC1140-INOX Gas please contact the

EHRLE Customer Service.

With the purchase of a Stationary EHRLE High Pressure Cleaner you are the

owner of a quality product, which is characterised by:

● user-friendliness,

● reliability,

● environmental friendliness.

These installation and operating instructions are part of the stationary hot

water high pressure cleaner and must be kept at the operating site and

available at all times.

For the stationary hot water high pressure cleaner, the manual contains

information on

● installation

● adjustment of system and operating parameters

● operation

● maintenance

● repair.

1.2 Functional system concept

The stationary hot water high pressure cleaners are designed for two

separate operating levels with different access rights:

● Level 1 for system operators with access to

○ controls and indicator elements inside the cabinet via the lockable

door

○ three main switches at the cabinet door front.

The control elements in the cabinet are used to set operating

parameters such as

○ operating pressure

○ water temperature

○ detergent quantity.

● Level 2 for operating personnel with exclusive access to the three main

switches on the cabinet door front. On the cabinet door front, the three

main switches can be switched on/off:

○ system operation

○ hot water mode

○ admixture of detergents.

300631 • 1/2018 • H.S.

6 of 82

1 User information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

1.3 Terminology

The terminology „High Pressure Cleaner, Hot Water, Stationary,

HSC1140-INOX Gas“ is replaced by the short general term „system“ or

„high pressure cleaner“ in the manual.

If a clear reference to a subject is required in the description parts, the

terminology „High Pressure Cleaner, Hot Water, Stationary,

HSC1140-INOX Gas“ is used.

For the terminology „Installation and Operating Instructions“, the short

general term „Manual“ is used in the description sections wherever

possible.

1.4 Meaning of the emphasis

The emphasis used in this manual have the following meanings:

WARNING

Warning precedes operating procedures, instructions, etc., which, if not

strictly observed, could result in personal injury or loss of life. Warning

precedes also, when device misuse could result in personal injury or loss of

life.

CAUTION

Caution precedes operating procedures, instructions, etc., which, if not

strictly observed, could result in damage to the high pressure cleaner.

Caution precedes also, when device misuse could result in damage to the

high pressure cleaner.

This symbol indicates additional information.

300631 • 1/2018 • H.S.

7 of 82

1 User information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

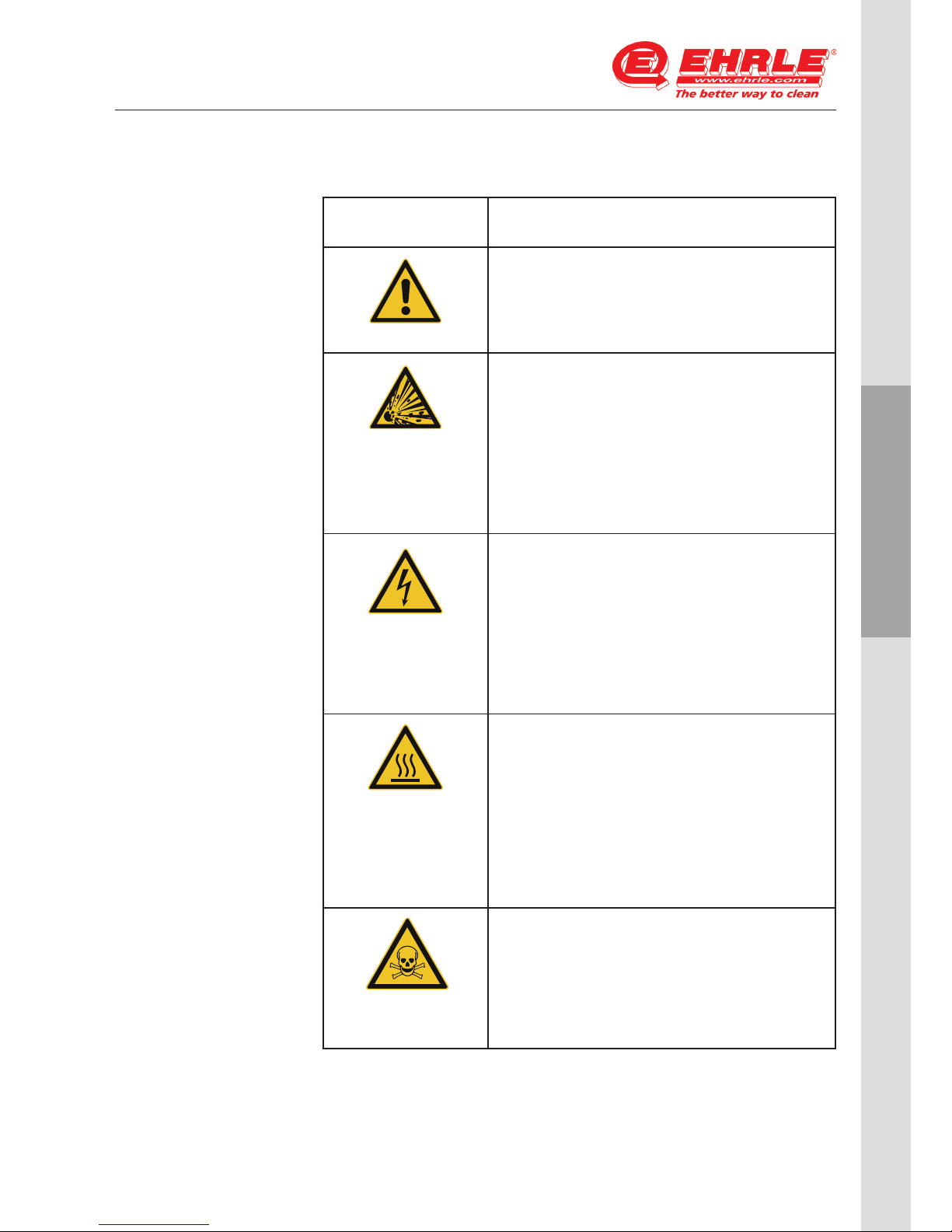

1.5 Meaning of the symbols

Symbol Meaning

WARNING

Follow instructions!

Non-observance or neglecting of prescribed instructions, incorrect operation or misuse of the

system may endanger life and limb of persons.

WARNING

Danger of explosion due to escaping gas.

An ignition source can cause a gas-air mixture

or solvent vapours to explode and cause fatal

injury to persons.

Improperly carried out work on the burner can

lead to gas leakage and explosion. Do not add

solvents to the high pressure jet. Observe all

safety instructions and work instructions.

WARNING

Danger of death due to electric shock.

Switch off the high pressure cleaner and disconnect it from the power supply before starting installation, maintenance and repair work.

Protect the system against unintentional restarting.

Touching live parts can lead to life-threatening

injuries.

WARNING

Danger of burns.

During operation, the cleaning objects, the hot

water emerging from the trigger gun, surfaces

of system components, assemblies or parts can

become hot. Touching hot surfaces or hot water

can cause burns or scalding on the skin surface.

Make sure that the hot surfaces and the water

from the trigger gun have cooled down before

starting maintenance and repair work.

WARNING

Toxic substances.

Inhalation, contact and/or ingestion of toxic

substances through the food chain may endanger the health of persons and can lead to death.

Observe the relevant safety regulations when

handling toxic substances.

300631 • 1/2018 • H.S.

8 of 82

1 User information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

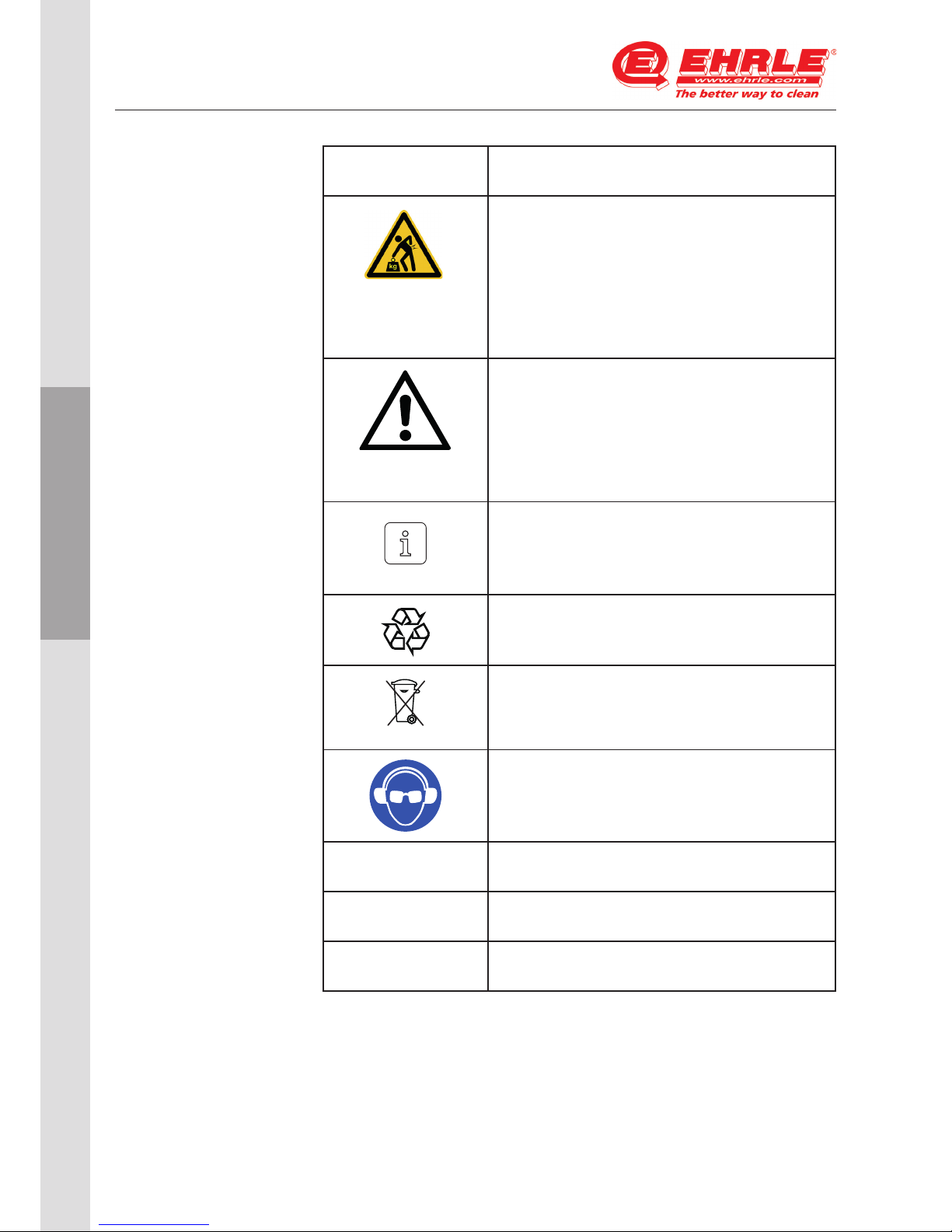

Symbol Meaning

WARNING

Danger with heavy loads.

A person is not allowed to lift and move loads

more than 23 kg. Otherwise the health of persons may be endangered (e.g. overload of the

spinal column, injuries from falling loads).

For loads of more than 23 kg, use suitable lifting equipment (e.g. forklift truck, lift truck).

CAUTION

Observe instructions for installation, system

adjustment, operation, maintenance and repair.

Non-observance or neglecting prescribed

instructions, incorrect operation or misuse of

the system may result in damage to system

parts, assemblies or components.

General Information

General additional information.

Information on recycling

General information on recycling.

Information on disposal

General information on the proper and environmentally sound disposal of materials and

consumables.

Information on hearing protection

General information on hearing protection.

Calls for a direct action.

Result after an action.

•

Enumeration

300631 • 1/2018 • H.S.

9 of 82

1 User information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

1.6 Target groups

This installation and operating manual contains information and

instructions for:

● Authorised, instructed and trained operating personnel for carrying out

cleaning work.

● Authorized, qualified and trained personnel for the installation,

operation, maintenance, repair and adjustment of the system.

1.7 Warranty and Liability

The EHRLE High Pressure Cleaner, Hot Water, Stationary, HSC1140-INOX

Gas may only be used for its intended purpose.

Intended use includes:

● Operation only by authorized, instructed and trained operating

personnel.

● Installation, operation, maintenance, repair and adjustment of the

system only by authorized, trained and qualified personnel. For

installation, maintenance, repair and adjustment of the system, the

relevant specialist personnel can be consulted and commissioned by the

EHRLE Customer Service.

● The information and instructions contained in this installation and

operating manual must be observed.

● If the safety and protective devices are faulty, the system must not be

put into operation.

● The system may only be operated with fully functional safety and

protective devices. In the event of functional failures during operation,

the system must be taken out of operation immediately.

● Faulty, insufficient or defective systems must not be put into operation.

Before commissioning, carry out a visual inspection for faulty, defective

or defective

○ System parts, assemblies or components

○ Electrical cables

○ High pressure hoses.

● The system must be switched off immediately and taken out of

operation if defects, faults or deficiencies occur on

○ System parts, assemblies or components

○ Electrical cables

○ High pressure hoses.

● No constructive changes may be made to the system.

● The system may only be operated in the configuration certified by

the manufacturer. Operation with subsequently installed modules,

components or additional devices is not permitted and may endanger

life and limb of persons or lead to damage to the system.

● Only original parts from the manufacturer or consumables approved by

the manufacturer may be used for maintenance and repair work.

300631 • 1/2018 • H.S.

10 of 82

1 User information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

● Only fuels approved by the manufacturer and operating materials

(engine oil, cleaning agents, etc.) may be used to operate the system.

Any warranty and liability claims for personal injury and damage to the

system are void if the system is not used for its intended purpose.

1.8 Environmental protection

Note on recycling

The packaging materials are recyclable. Please do not throw the

packaging into the household waste, but recycle it.

Note on disposal

Old appliances contain valuable recyclable materials which should be

recycled. Batteries, oil and similar materials must not be discharged into

the environment. For this reason, please dispose of old appliances using

suitable collection systems.

Dispose of used materials in an appropriate and environmentally friendly

manner. Observe the local regulations.

According to environmental regulations, waste water containing mineral

oil, fuels for hot water heating or lubricants such as oils and greases must

not enter the soil, water or sewerage system.

Do not allow engine oil, fuel oil or petrol to escape into the environment.

Protect the soil and dispose of used oil in an environmentally friendly

manner.

Engine cleaning or underbody washing of all types of vehicles may only be

carried out at washing stations equipped with oil separators in accordance

with environmental regulations (environmental protection).

300631 • 1/2018 • H.S.

11 of 82

2 Safety

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

2 Safety and security

2.1 General safety information

Observe the respective national regulations of the legislator for liquid

sprayers.

Observe the relevant national regulations of the legislator on accident

prevention. Liquid sprayers must be inspected regularly and the result of

the inspection must be recorded in writing.

The heating equipment of the system is a combustion system. Firing

systems must be regularly inspected in accordance with the respective

national regulations of the legislator.

If the system is operated in rooms, the exhaust gases must be safely

discharged (flue gas pipe without draught interrupter). Furthermore, a

sufficient supply of fresh air must be ensured.

Observe the safety instructions provided with the cleaning agents used

(usually on the packaging label).

Keep cleaning agents out of the reach of unauthorized persons. Risk of

poisoning or caustic burns from cleaning agents! Observe the instructions

on the cleaning agents.

Perform prescribed adjustment, maintenance and inspection work in due

time (see Section 8, Maintenance).

Safety-relevant defects must be rectified immediately. Keep all signs on the

system legible.

2.2 Access for persons to the system

The cabinet door for access to the interior of the cabinet must be kept

locked. Only authorised persons may have access to the inside of the

cabinet.

Ensure that access to the system is only possible for the following persons:

● Operating personnel authorised, instructed and trained by the system

operator and specially trained for general cleaning tasks. Operation is

limited to the three main switches on the front of the cabinet door.

● Authorised, qualified and specially trained personnel for the

installation, operation, maintenance, repair and adjustment of the

system. Access to the key for the cabinet door in order to be able to

carry out appropriate measures inside the cabinet.

Keep the key for the cabinet access door in a place accessible only to

authorised personnel.

300631 • 1/2018 • H.S.

12 of 82

2 Safety

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

2.3 Safety instructions for cleaning operation for

system operators and operating personnel

During cleaning work, the personnel at the workplace must wear the

necessary protective clothing. This includes waterproof protective suits,

rubber boots, protective goggles, headgear, ear protection if necessary, etc.

No cleaning work may be carried out in the presence of persons without

sufficient protective clothing.

Before switching on, carry out a visual inspection of the system parts from

the outside for damage (high pressure hose, electrical or mechanical parts).

Systems with damaged system parts, assemblies or components must not

be put into operation.

The water jet leaving the trigger gun must not be directed at

● persons

● animals

● live electrical installations (building mains connections, sockets,

electrical wiring, etc.)

● live electrical installations, machines, devices, assemblies or components

● system, machinery or equipment in operation.

Under the influence of the high pressure jet, parts can be separated from

the cleaning object and thrown away. Persons can be injured as a result.

Never aim the high pressure jet at fragile or loose objects.

When cleaning tyres and their valves, keep a minimum distance of 30 cm

from the high pressure nozzle. Otherwise damage may occur.

Before cleaning the High Pressure Cleaner, Hot Water, Stationary,

HSC1140-INOX Gas itself, take the system out of operation and disconnect

it from the electrical mains connection. Secure the system against

unintentional or unauthorised restarting (e.g. lock main switch, warning

sign indicating work on the system, etc.).

Never operate the system unattended.

During hot water operation, parts of the cabinet interior, water-carrying

parts (e.g. non-insulated pipes, metal parts of the trigger gun and jet pipe)

and cleaning objects become hot and can cause burns if touched. Keep

the cabinet door closed during operation. Before touching heated system

parts, water-carrying parts or cleaning objects, wait until they have cooled

down.

Do not close or block the exhaust opening of gas-fired high pressure

cleaners, do not bend over it or reach into it during operation. The

escaping exhaust gases are very hot and must not be inhaled. The exhaust

gases and system components become very hot and can lead to severe

burns.

Do not inhale the exhaust gases. Inhalation of exhaust fumes may

endanger life and limb of persons.

For high pressure cleaners operated in rooms, a safe discharge of the flue

gases must be ensured. It must also be ensured that sufficient ventilation is

available (combustion air).

Asbestos-containing and other materials containing substances hazardous

to health must not be sprayed off.

300631 • 1/2018 • H.S.

13 of 82

2 Safety

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

Information on hearing protection

If the sound levels exceed the permissible values, the personnel and

persons in the area of exposure must wear hearing protection.

The sound level for EHRLE high pressure cleaners under maximum load is

82 dB (A). A high sound level can cause hearing loss over a longer period

of time. If the noise produced by the application of the emerging high

pressure jet to noise-enhancing objects exceeds the permissible values,

the operating personnel and any persons affected must wear hearing

protection.

Do not operate the system if electrical lines or other safety-relevant parts

(pressure relief valve, high pressure hose, trigger gun, etc.) are defective.

2.4 Safety instructions for gas-fired systems

2.4.1 General information about the gas burner type

The High Pressure Cleaner, Hot Water, Stationary, HSC1140-INOX Gas is

equipped with a gas burner of the company

● Weishaupt, gas burner type WG5

or

● Baltur, gas burner type BPM90

The technical manual „Installation and Operating Instructions“ of

Weishaupt or Baltur is included in the scope of delivery of every gasheated stationary hot water high pressure cleaner and must be observed.

The gas-fired high pressure cleaners are subject to certification by the

DVGW (Deutscher Verein des Gas- und Wasserfaches).

The CE number is: CE-0085AR0179

SVGW Certificate No. 09-034-8 SVGW/VKF

300631 • 1/2018 • H.S.

14 of 82

2 Safety

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

2.4.2 Note on combustion air

The combustion air must be free of aggressive substances (e.g. halogens).

If the combustion air in the installation room is contaminated, increased

cleaning and maintenance is required. In this case, operate the system

independently of the room air.

If the system is operated in a closed room, the installation room must

comply with local regulations.

Improper use may cause:

● endanger life and limb of the user or third parties,

● affect the installation or other tangible assets.

2.4.3 Behaviour in case of gas odour

With gas odour:

Immediately refrain from any operation or switching on/off of

infrastructure equipment (supply voltage switches or circuit breakers for

internal building infrastructure, light switches, etc.).

Immediately refrain from operating or switching on/off any electrical

device (e.g. work lamps for illuminating a work area for maintenance

and repair, fan heaters, etc.) or electronic device (e.g. mobile

telephones, laptops, etc.).

Do not remove any plugged in mains plugs from the sockets.

Open windows and doors to ensure sufficient air exchange.

Close the gas ball valve.

Warn house inhabitants (do not activate doorbell).

Leave building.

Notify from outside the building, heating company or gas supplier.

2.4.4 Behaviour with exhaust gas odour

With exhaust odour:

Switch off the system and take it out of operation.

Open windows and doors to ensure sufficient air exchange.

Notify customer service.

2.4.5 Gas supply regulations, guidelines and rules

Before installing the gas-fired system, coordination with the gas supply

company and the district chimney sweep master is required.

During installation, the regulations of building law, trade law and

immission control must be observed.

For the gas supply observe:

● The gas-fired system may only be installed by a specialist company in

accordance with the relevant national regulations.

● Observe local regulations and guidelines during installation (e.g.

DVGW-TRGI, Worksheet G 600; TRF Volume 1 and Volume 2).

300631 • 1/2018 • H.S.

15 of 82

2 Safety

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

● The installation of the gas pipes, as well as the gas-side connection of

the system, may only be carried out by a specialist company approved in

the gas and water trade.

● Only the gas supplier or a contracted installer may carry out adjustment,

maintenance or repair work on gas installations in buildings and

premises.

● Line systems must be subjected to a load and leak test or a serviceability

test in accordance with the operating pressure (e.g. DVGW-TRGI,

Worksheet G 600).

● Depending on the type and quality of the gas, gas supply must

be carried out in such a way that no liquid substances are formed

(e.g. condensate). For liquid gas, observe evaporation pressure and

evaporation temperature.

● When planning a chimney, the locally valid guidelines must be observed

● Only use tested sealing materials and observe the processing

instructions.

● When switching to a different type of gas, reset the condensing boiler

system. The changeover between liquid and natural gas requires a

conversion.

● Carry out leak test after every maintenance and troubleshooting.

2.5 Accident prevention regulations

Observe the applicable national regulations of the legislator on accident

prevention.

2.6 Lifting and moving loads

The High Pressure Cleaner, Hot Water, Stationary, HSC1140-INOX Gas

weighs 300 kg (with packaging 317 kg).

Lifting and moving loads is permitted for one person up to 23 kg. If the

load exceeds 23 kg (e.g. system units, assemblies) use suitable lifting

equipment (e.g. forklift, lift trucks).

Observe the international standard „ISO 11228-1 Ergonomie - Manuelles

Handhaben von Lasten - Teil 1 Heben und Tragen 05/2003“.

2.7 Periodic inspections

The periodic inspections are listed in Section 8 (Maintenance).

300631 • 1/2018 • H.S.

16 of 82

2 Safety

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

2.8 Guidelines for liquid sprayers

High pressure cleaners must be inspected by an expert in accordance

with the „Guidelines for liquid sprayers“, if necessary or at least every 12

months. The result of the test must be recorded in writing.

In the appendix of this manual there is a test sheet (proof of customer

service) to record the tests carried out.

EHRLE service technicians are experts and can be consulted and

commissioned by EHRLE service for this prescribed inspection.

2.9 Federal Immission Control Act

The heating device is a combustion system which, according to the first

regulation for the implementation of the Federal Immission Control Act,

must be checked once a year by your responsible district chimney sweep

for compliance with the ejection limit values.

The first check must be carried out within the first four weeks after

commissioning. The operator of the high pressure cleaner must initiate the

measurement.

2.10 Safety regulations Electrical connection

When working on electrically live parts:

● Observe accident prevention regulations DGUV V3 (previously BGV A3)

and local regulations,

● Use tools according to DIN EN 60900.

2.11 Design changes to the system

Design changes to the high pressure cleaner are not permitted.

When operating a system which has been modified or changed in design,

the system will not be used for its intended purpose. If the system is not

used for its intended purpose, no liability or warranty will be accepted (see

Section 1.7, Warranty and Liability).

2.12 Safety devices

Safety devices serve to protect the user and must not be suspended or

circumvented in their function.

The high pressure cleaner has the following safety devices listed below:

● Various pressure switches:

System functions are switched on or off (safety functions) based on type

of construction and intended use.

● Low-water cut-off:

The system does not switch on, respectively in case of operation off, if

the water level in the float container is insufficient.

● Unloader valve and non-return valve:

The first serves to adjust the operating pressure and the second valve

keeps the pump head depressurised when the trigger gun is deactivated.

300631 • 1/2018 • H.S.

17 of 82

2 Safety

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

● Safety valve:

Opens when a preset pressure is exceeded and diverts the water stream.

● Thermostat and overload protection switch:

Releases when the pump current load is too high, the system is switched

off.

● TSS system with pump-off delay:

After deactivating the trigger gun, the pump continues operation for

approx. 30 s in the pressureless bypass mode (avoidance of too high

pressure build-up in the pump); after 30 s the high pressure cleaner

automatically switches into the stand-by mode.

● Total Switch-off:

Automatically switches the high pressure cleaner off in the event of

prolonged interruption of operation or unused trigger gun for more

than 20 minutes.

● Leakage recognition:

Switches off the high pressure cleaner automatically after detection of a

leakage

○ at the high pressure hose

○ with the trigger gun or

○ in the system.

● Optical flame monitoring:

Switches off the heating after the flame in the combustion chamber has

extinguished.

● Mechanical arrest for trigger gun of the trigger gun:

Prevents unintentional or unconscious activating the trigger gun.

300631 • 1/2018 • H.S.

18 of 82

3 Product information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

3 Product description

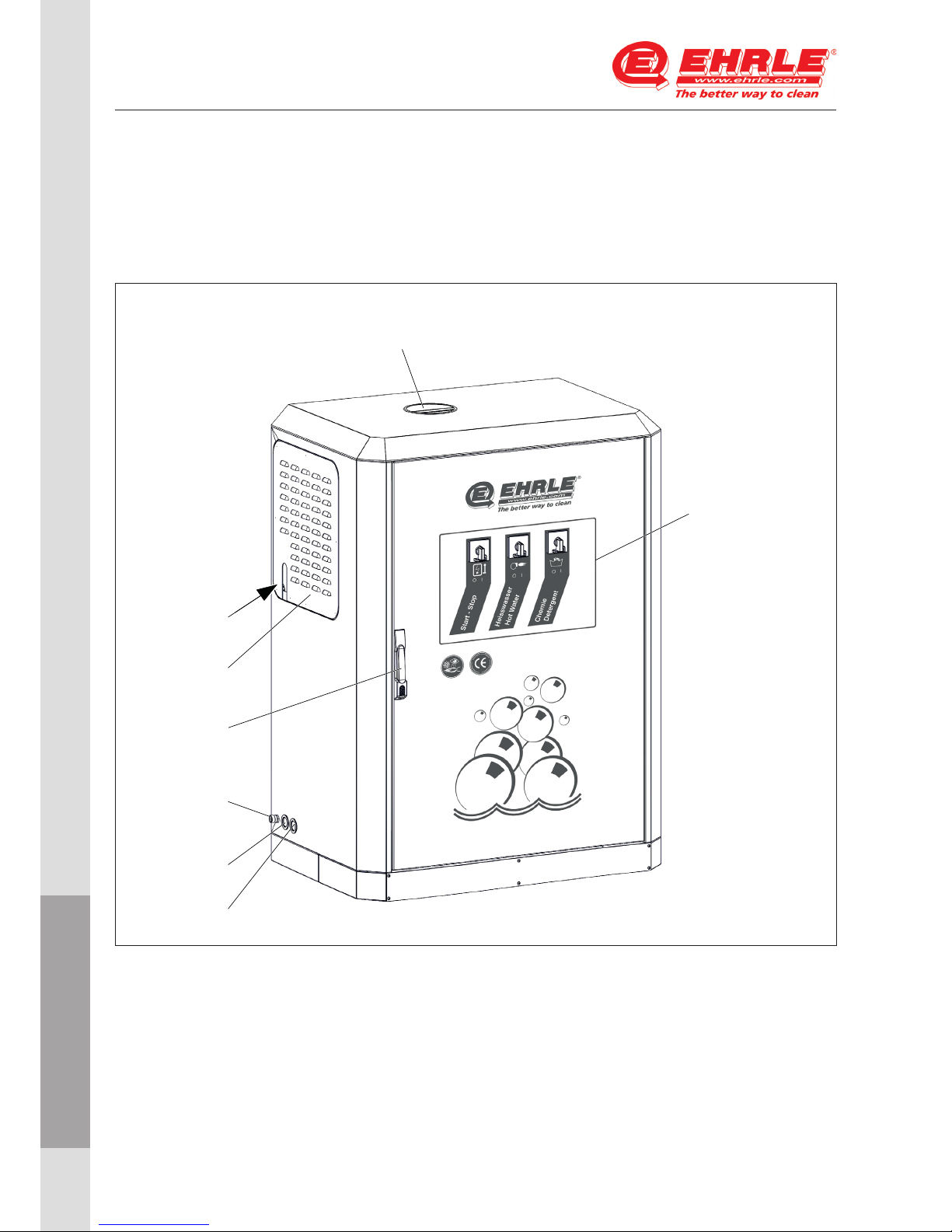

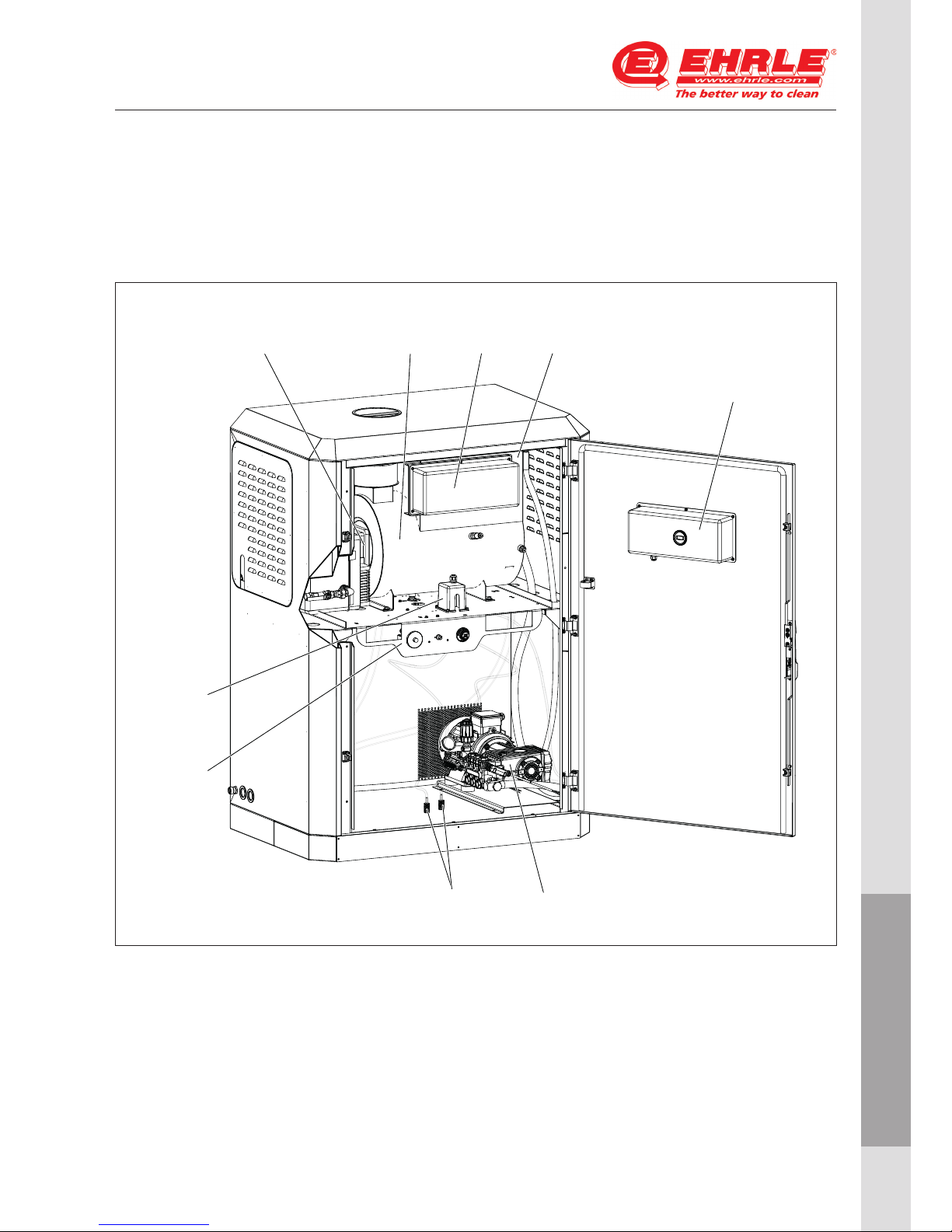

3.1 System views

The two following figures show a general example for the High Pressure

Cleaner, Hot Water, Stationary, HSC1140-INOX Gas.

1

3

4

5

6

7

8

2

1 Exhaust pipe feed-through 5 Water connection

2 Shut-off fitting Gas supply 6 High pressure pipe feed-through

at gas burner 7 Feed-through electrical connection

3 Cover Maintenance opening 8 Control panel, cabinet door front

4 Door latch with lock

Fig. 3 - 1 High Pressure Cleaner, Hot Water, Stationary, HSC1140-INOX Gas, total view

300631 • 1/2018 • H.S.

19 of 82

3 Product information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

1

7

9

6

2

3 4

5

8

1 Gas burner 6 Pump unit with driving motor

2 Boiler 7 Filter for suction hose detergents

3 Electrical terminal strip and 8 Panel with control elements (temperature,

Electronics with protective cover Manual reset, chemical control valve)

4 Float container 9 Chemical pump

5 Protective cover (terminal contacts)

Fig. 3 - 2 High Pressure Cleaner, Hot Water, Stationary, HSC1140-INOX Gas, Cabinet interior

(door opened)

300631 • 1/2018 • H.S.

20 of 82

3 Product information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

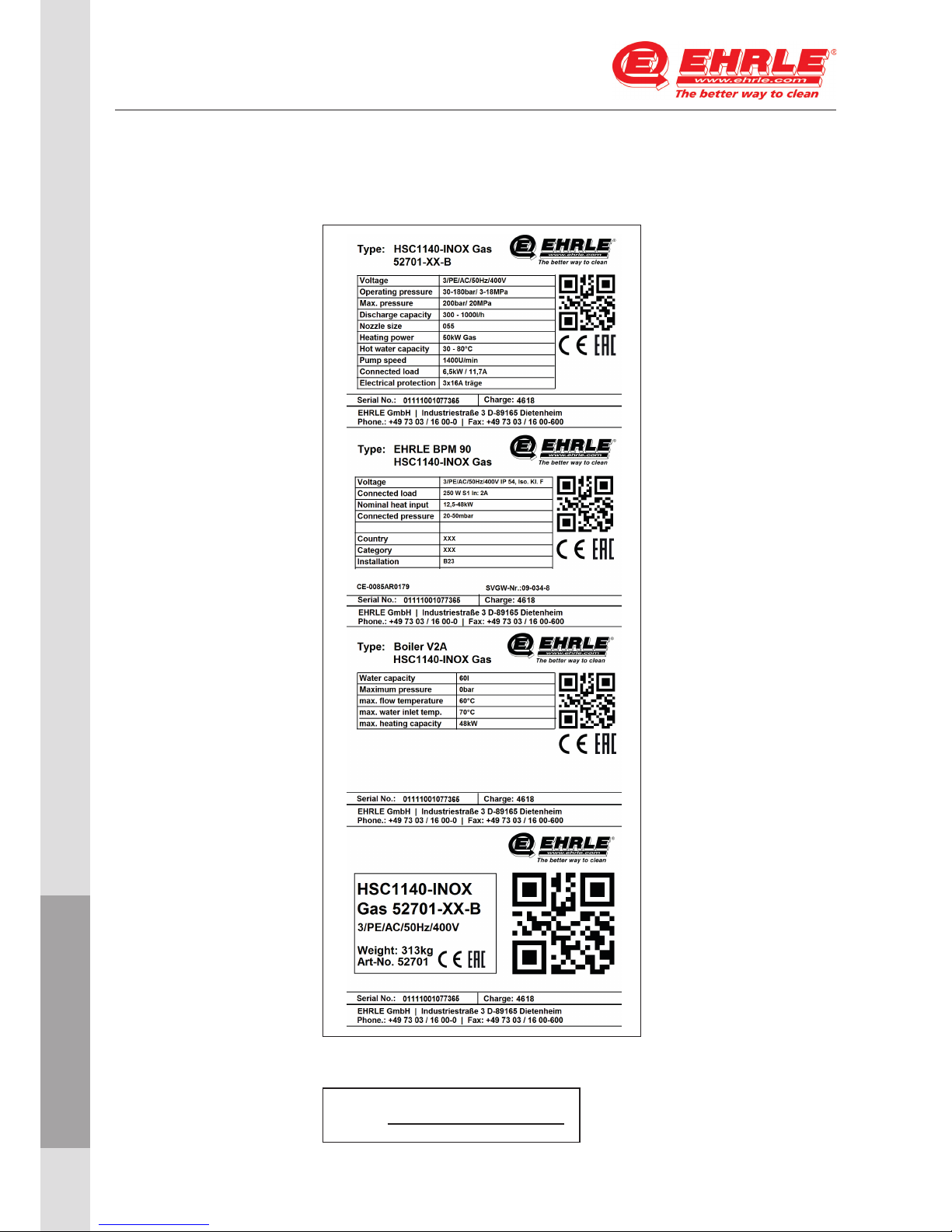

3.2 Serial number

The serial number on the nameplate uniquely identifies the product. It is

required for Ehrle customer service.

Fig. 3 - 3 Nameplate for HSC1140-INOX Gas

Ser. Nr.

300631 • 1/2018 • H.S.

21 of 82

3 Product information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

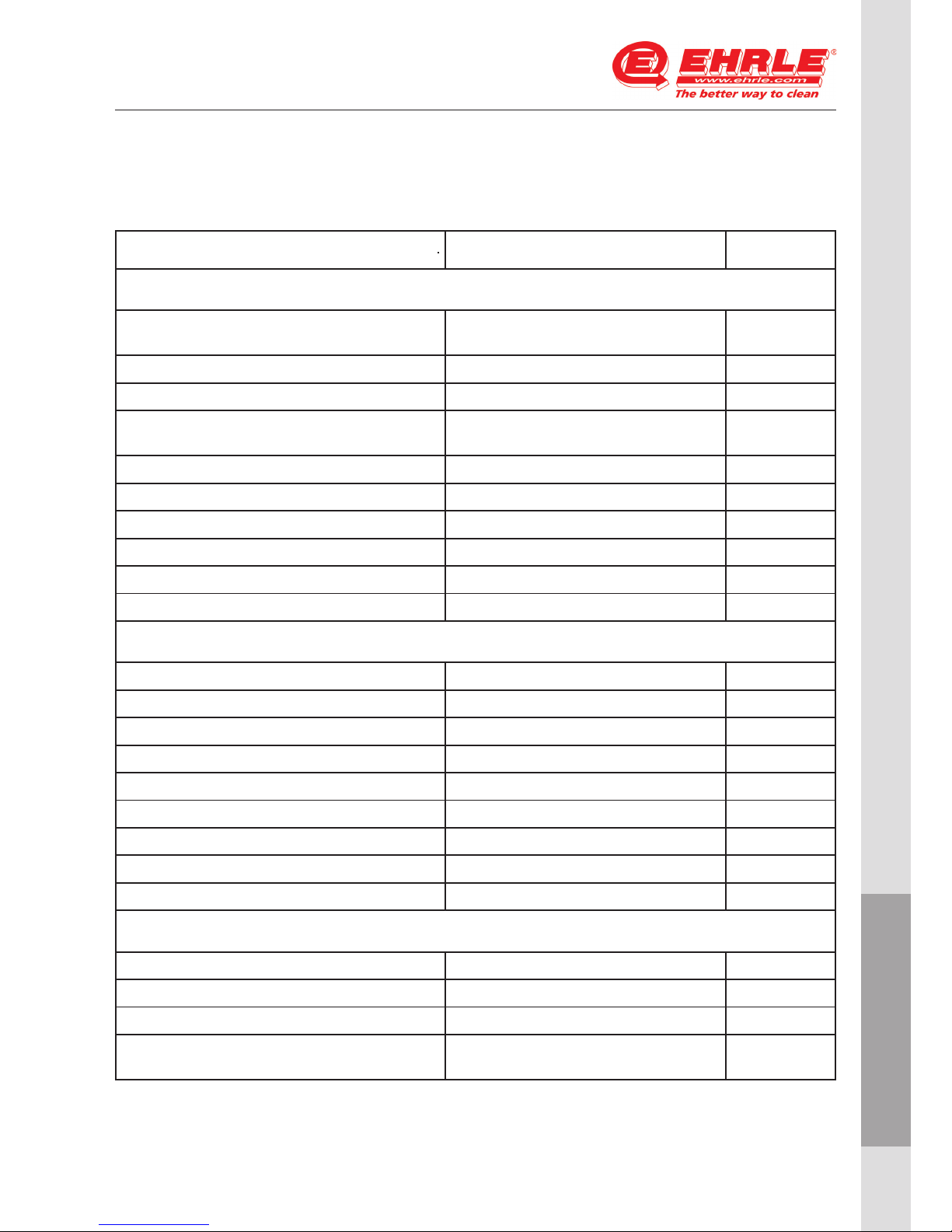

3.3 Technical data

3.3.1 Technical data of the system

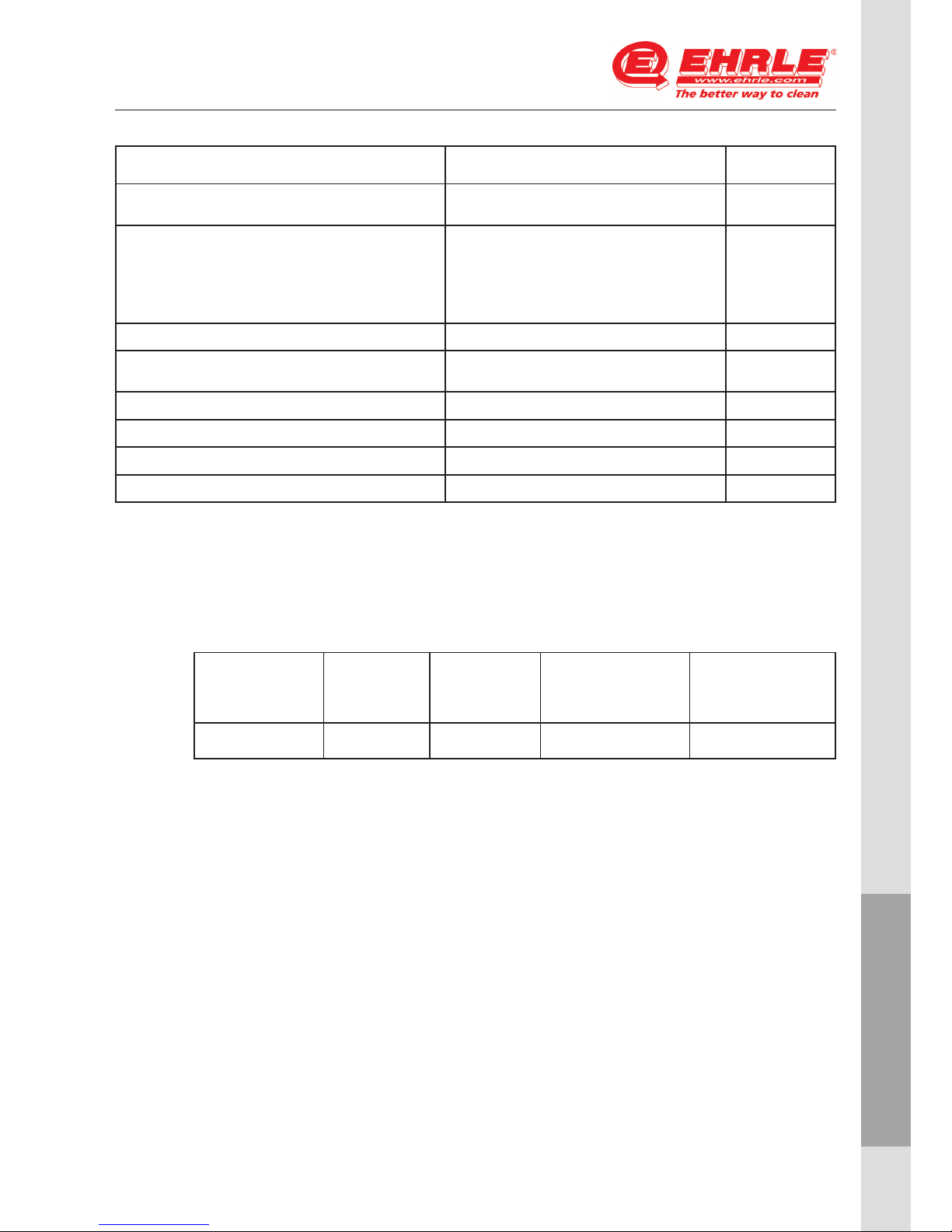

Designation

Technical value Unit

Performance data

Operating pressure water (with standard

nozzle)

3 ... 18 (30 ... 180)

MPa (bar)

Max. operating overpressure (safety valve) 20 (200) MPa (bar)

Water flow rate (continuously adjustable ) 300 ... 1000 (5 ... 16,6) l/h (l/min)

Detergent suction

(continuously adjustable )

0-50 (0 ... 0,8) l/h (l/min)

Pump speed 1400 rpm

Heating power 50 kW

Water connection

Inlet flow rate (min.) 1100 (18,3) l/h (l/min)

Inlet pressure (min.) 0,1 (1) MPa (bar)

Inlet pressure (max.) 0,6 (6) MPa (bar)

Electrical connection

Voltage 3 / 400 - 415 V

Frequency 50 Hz

Current 11,7 A A

Connected power 6,5 kW

Electrical protection (slow blow) 3 x16 A

Protection type IPX5 -

Protection category I -

Maximum permissible mains impedance (0,381+j 0,238) Ohm

Electrical supply cable H07 - RNF 5 x 1,5 mm

2

Temperature

Inlet temperature (max.) 30 - 70 °C

Max. operating temperature hot water 98 °C

Max. temperature safety thermostat 110 °C

Temperature increase at max.

water flow rate

60 ... 65 °C

Table 3 - 1 Technical data for HSC1140-INOX Gas

300631 • 1/2018 • H.S.

22 of 82

3 Product information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

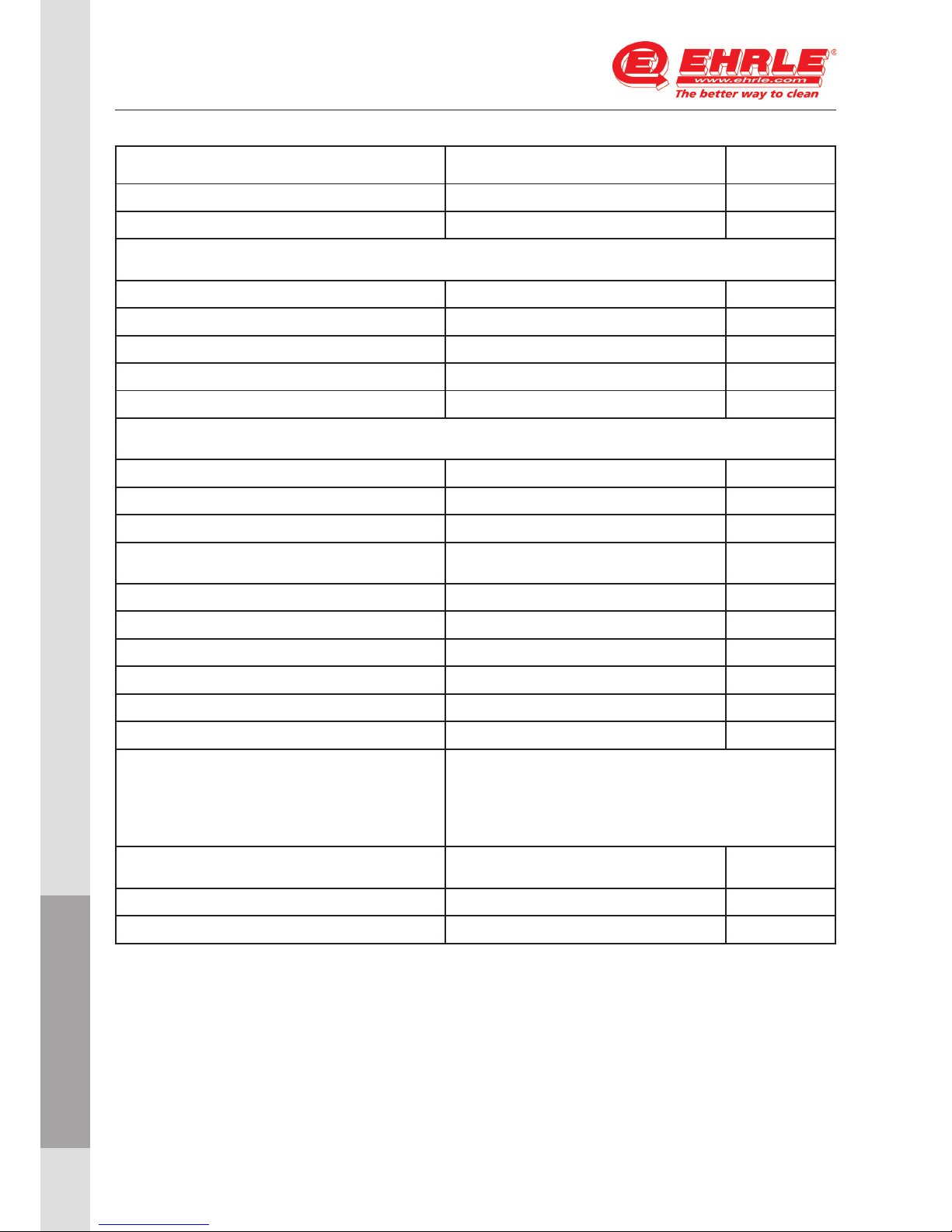

Designation

Technical value Unit

Gross heating capacity 75 kW

Chimney draft 0,01 ... 0,04 kPa

Gas connection values

Natural gas E (G 20) 7,2 m

3

/h

Natural gas LL (G 25) 8,2 m

3

/h

Nominal supply pressure (natural gas) 1,8 ... 5 kPa

Propane - kg/h

Nominal supply pressure (Propane) - kPa

Environmental data

Standard Degree of utilisation 97 %

Standard emission factor NOX (natural gas G 25)

< 40 mg/kWh

Standard emission factor CO (natural gas G 25)

< 40 mg/kWh

Values for chimney dimensioning

Overpressure ability (min.) 0,05 kPa

Pull requirement 0 kPa

Exhaust gas mass flow - full load 130 kg/h

CO

2

(natural gas) 9,5 %

CO

2

(natural gas) - %

Exhaust gas temperature max. 190/150 °C

Combustion air/air supply Max. length: 10 m with two 90° bends (minimum

diameter 100 mm). Length: 10 m with two 90° bends

(minimum diameter 100 mm). According to local

regulations from the installation room or fresh air

from outside.

Condensate drain

Condensate drain (max.) 4 (via siphon in sewerage) l/h

Minimal water column, siphon 300 mm

Table 3 - 1 Technical data for HSC1140-INOX Gas

300631 • 1/2018 • H.S.

23 of 82

3 Product information

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

Designation

Technical value Unit

Licensing EN 60335-2-79

Device category Europe I 2E (r),

I 2ELL,

I 2H,

I 2L,

I2 HE

-

Device type B23 -

Dimensions and mass

Length (with packaging) 1220 (1250) mm

Width (with packaging) 755 (815) mm

Height (with packaging) 1625 (1755) mm

Mass (with packaging) 300 (317) kg

Table 3 - 1 Technical data for HSC1140-INOX Gas

3.3.2 Selection of spray nozzles

Contamination Nozzle Spraying

angle

Part No. Pressure [MPa]

heavy 050 (blue) 25° 25050 max. 20

Table 3 - 2 List of spray nozzles

300631 • 1/2018 • H.S.

24 of 82

4 Installation

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

4 Installation

WARNING

Ensure correct installation.

The installation of the system may only be carried out by qualified and

trained personnel.

WARNING

Danger with heavy loads.

The High Pressure Cleaner, Hot Water, Stationary, HSC1140-INOX Gas

weighs 300 kg (with packaging 317 kg).

A person is not allowed to lift and move loads (e.g. system units, assemblies) more than 23 kg. Otherwise the health of persons may be endangered (e.g. overload of the spinal column, injuries from falling loads).

For loads of more than 23 kg, use suitable lifting equipment (e.g.

forklift, lift truck).

General Information

For detailed advice and information on the installation of the High

Pressure Cleaner, Hot Water, Stationary, HSC1140-INOX Gas, please

contact EHRLE customer service.

If required, EHRLE Customer Service can commission qualified personnel

to carry out a wide variety of installation work.

Depending on the system configuration, the High Pressure Cleaner, Hot

Water, Stationary, HSC1140-INOX Gas is equipped with a gas burner of the

company

● Weishaupt, gas burner type WG5

or

● Baltur, gas burner type BPM90

For installation and operation of the system, observe the information in

the installation and operating instructions of the respective manufacturer.

For lifting and moving loads exceeding 23 kg (e.g. system units, assemblies)

use suitable lifting equipment (e.g. forklift, lift truck).

300631 • 1/2018 • H.S.

25 of 82

4 Installation

Installation and Operating Instructions

High Pressure Cleaner, Hot Water, Stationary

HSC1140-INOX Gas

4.1 Selection of the operating location

WARNING

Select a suitable and permissible operating location for the system.

The local regulations concerning the installation and operation of the

system must be observed.

The standard version systems must not be installed and operated in rooms

or areas subject to fire or explosion hazards.

For use at filling stations or similar hazardous areas, reference is made

to the hazardous areas in accordance with the „Technical Rules for

Flammable Liquids“ (TRGF).

For special applications, e.g. in rooms subject to fire and explosion

hazards, only electrically heated high pressure cleaners with the

corresponding EEx protection class may be used.

WARNING

Observe the regulations for combustion and gas-fired systems.

If gas-fired systems are installed in closed rooms, proper discharge of the

combustion gases and adequate ventilation must be provided.

The heating equipment of the system is subject to the guidelines for

combustion systems. When installing them, the locally applicable

regulations must be observed.

For the installation and operation of the gas-fired system, please observe

the installation and operating instructions of Weishaupt (gas burner WG5)

or Baltur (gas burner BPM90), depending on the system configuration.

When selecting a location, ensure that the following system components

are easily accessible for operation, maintenance, repair and adjustment

work (for dimensions, see Fig. 4 - 1):

● Lateral maintenance cover

● Connections for system supply

○ supply voltage

○ water pipe

○ gas pipe

● The swivel area of the cabinet door must be completely free

● Flue gas pipes

● Washing station equipment such as trigger gun and high pressure hose

Screw the system cabinet firmly to the floor at the location.

Loading...

Loading...