Ehrhorn Technological Operations Alpha 76CA, Alpha 76A, Alpha 76PA Service manual

OPERATING AND TE CHN IC AL M ANU AL

HIGH FREQUENCY LINEAR POWER AMPLIFIERS

ALPHA 76A, 76PA, and 76CA

[0 E H R H O R N T E C H N O L O G IC A L O P E R ATIO N S , I NC.

CAÑON CITY, COLORADO 81212

TABLE OF CONTENTS

jr 1

....

...........

-

--------------

-

SECTION 1 - General Description and Sp ec ific atio ns

.....................

.

1

SECTION 2 - INSTALLATION

Interconnections with other equipment . .

Preparing blower fo r operation .................................

...........................................................

...............

.

.

.

2

3

3

SECTION 3 - OPERATION

I ni t i al tune-up ..................................................... 5

Operation at 1 kW and 2 kW input............................6

.............................................................. 4

i

Operating notes ..................................................... 7

Troubleshooting hints

...............

........................... 8

SECTION 4 - THEORY OF O P E R A TIO N .......................................

..

9

SECTION 5 - ILLUSTRATIONS . .

Transformer access and location 11

Rear panel view o f am plifier 11

...............................................

11

Top view showing major component locations

Schematic d i agra ms .................................

Front panel view.......................................Front cover

............

12

..............

13

SECTION 6 - STANDARD ELECTRICAL PARTS LIST .............................. 16

ET0/"ALPHA" PRODUCTS WARRANTY .................................... Back cover

EHRHORN TECHNOLOGICAL OPERATIONS, INC,

CANON CITY, COLORADO 81212

0180 U.S.A.

- 2 -

I

SECTION 2

INSTALLATION

1. Unpacking: Carefully remove am plifier and transformer from cartons; SAVE

PACKING MATERIAL FOR RE-USE - - SHIPMENT OF YOUR ALPHA IN OTHER THAN FACTORY

PACKING MAY RESULT IN DAMAGE NOT COVERED UNDER WARRANTY!

Inspect c lo se ly for evidence o f shipping damage; if found, no tif y d e liv erin g

c a r ri e r and s el ler at once. Complete warranty r e g ist ra t io n form and mail

it to ETO promptly.

2. Transformer Instal lati on: The cover of the am plifier i s e a s il y removed.

Remove the three f l a t head Phi l li ps screws from the front edge on top, the

two pan head screws from the rear flange of the top cover, one f l at head

from the center of the top cover, and f ive pan head screws from each end o f

the cover — then lift it c a re fu lly o ff, dir e c t ly upward.

Orient the transformer so that both m u lti-pin, molded plugs on the transformer

harness point toward the front of the am plifier; move the corresponding

mating connectors in the am plifier itself temporarily out of the way. Care

f ul l y lower the transformer into p osition so that the 1/4-20 tapped holes in

i ts base l ine up with the corresponding clearance holes in the a mp lifier

base plate. I nst al l the 1/4-20 bolts and washers provided, and tighten.

Check both p airs o f connectors vi s ual l y for proper mating orienta tio n (avoid

excessive harness bending or tw ist in g, as it may cause damage to wires, or

connector pins) and mate them firm ly , pushing until the integral latches

engage.

3. E le ct rica l I nstal l ati on: The am plifier i s normally shipped from the factory

wired fo r 220-250V operation. If it i s to be operated instead on 110-130V

l ine s , change over the connections as described below before replacing the

cabinet cover.

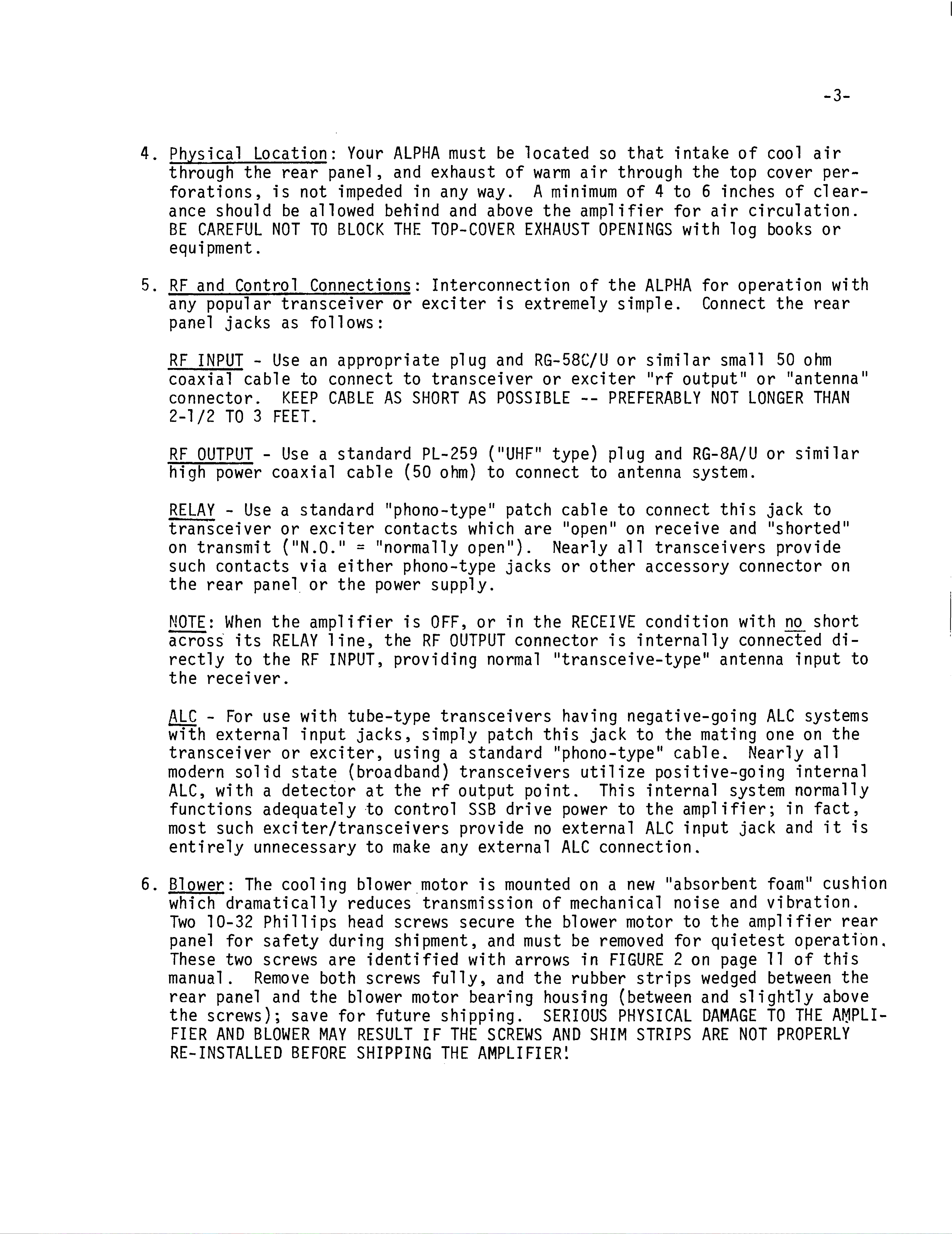

Changeover to 110-130V Operation - Locate the six-terminal ba rr ie r s t r ip on

the r ig h t side of the center c ha ssis p a r ti ti on , above and to the l e f t o f the

transformer. With short jumper wires between lugs #2 and #3 only, the ampli

f i er i s connected for 240V power supply. Su b stitu ting instead one jumper

between terminals #1 and #2, another between #3 and #4, and a th ird between

#5 and #6, re-connects for 120V power source. (See sketches below.)

CONNECTIONS FOR 2^0V CONNECTIONS FOR 1 2 OY

Power Cable Connection - The green wire of the am plifier power cable i s a

ch assis safety ground, and must always (and o n ! v) be connected to the safety

ground o f the a-c mains - - NEVER to one o f the "hot" power wires. The black

and white wires are interchangeable and connect to the two "hot" service

conductors.

3

4. Physical Lo cation: Your ALPHA must be located so that intake o f cool ai r

through the rear panel, and exhaust of warm air through the top cover per

fo ra tio ns , i s not impeded in any way. A minimum of 4 to 6 inches of c le ar

ance should be allowed behind and above the am plifier for ai r c ir cu la tio n.

BE CAREFUL NOT TO BLOCK THE TOP-COVER EXHAUST OPENINGS with log books or

equipment.

5. RF and Control Connections: Interconnection o f the ALPHA for operation with

any popular tran sceive r o r exciter i s extremely simple. Connect the rear

panel jacks as follow s:

RF INPUT - Use an appropriate plug and RG-58C/U or s imila r small 50 ohm

coaxial cable to connect to transceiver or exciter "rf output" or "antenna"

connector. KEEP CABLE AS SHORT AS POSSIBLE - - PREFERABLY NOT LONGER THAN

2-1/2 TO 3 FEET.

RF OUTPUT - Use a standard PL-259 ("UHF" type) plug and RG-8A/U or simila r

high power coaxial cable (50 ohm) to connect to antenna system.

RELAY - Use a standard "phono-type" patch cable to connect t h i s jack to

trans ceive r or exciter contacts which are "open" on receive and "shorted"

on transmit ("N.O." = "normally open"). Nearly a ll transceive rs provide

such contacts via either phono-type jacks or other accessory connector on

the rear panel or the power supply.

NOTE: When the a mplifier i s OFF, or in the RECEIVE condition with no^ short

across i t s RELAY l in e , the RF OUTPUT connector i s in t e rn a ll y connected di

re c tly to the RF INPUT, providing normal "transceive -typ e" antenna input to

the receiver.

ALC - For use with tube-type tra nsceivers having negative-going ALC systems

with external input jacks, simply patch t h i s jack to the mating one on the

trans ceive r or exciter, using a standard "phono-type" cable. Nearly all

modern s o li d state (broadband) tran sceive rs ut i l i ze p os it iv e-go in g internal

ALC, with a detector at the rf output point. This internal system normally

functions adequately to control SSB drive power to the am p lifier; in fact,

most such e xcite r/ tran sc eive rs provide no external ALC input jack and it i s

e n t ir e ly unnecessary to make any external ALC connection.

6. Blower: The cooling blower motor is mounted on a new "absorbent foam" cushion

which dramatically reduces transmission o f mechanical noise and vib ra tion.

Two 10-32 Phi l l ips head screws secure the blower motor to the am plifier rear

panel for safety during shipment, and must be removed fo r quietest operation.

These two screws are id e nt ifie d with arrows in FIGURE 2 on page 11 o f th is

manual. Remove both screws f ul l y , and the rubber str ips wedged between the

rear panel and the blower motor bearing housing (between and sl i ghtl y above

the screws); save fo r future shipping. SERIOUS PHYSICAL DAMAGE TO THE AMPLI

FIER AND BLOWER MAY RESULT IF THE SCREWS AND SHIM STRIPS ARE NOT PROPERLY

RE-INSTALLED BEFORE SHIPPING THE AMPLIFIER!

OPERATION

4

SECTION 3

1. Control Functions:

BAND - Selects tuning range o f am plifier, in dic atin g the nominal center o f

the band in MHz.

TUNE - Controls the operating frequency. In general, higher frequency bands

(14 & 21 MHz, etc.) tune toward the "0 " end o f the vern ier d ial scale,

while lower frequency bands tend to tune toward the 50-100 end.

LOAD - Controls am plifier plate loading ... the power input level at which

best e ffic ie nc y and l i near i t y i s achieved. Higher bands tend to load

normally toward the 70-100 end of the vernier scale, while lower bands

t y p i c a l ly vary across most of the dial depending on exact frequency

and the load impedance or VSWR. In general, higher dial numbers tend

to r e su lt in heavier lo a d in g , but v a ria tio n s to t h i s rule may occur,

p a r ti c u la r ly on 160 meters.

PUSH BUTTONS -

ON: Depressing momentarily applies a-c power to am plifier. Press also

to restore power a fte r overcurrent relay has tripped.

OFF: Depress momentarily to remove a-c power from a mplifier.

HV: Multimeter monitors high voltage - 3000V d-c f u l l scale.

GRID: Multimeter monitors g rid current - 150 mA f u l l scale.

FWD: Multimeter monitors forward RF power - 2000W f u l l scale.

REFL: Multimeter monitors reflected RF power - 200W f u ll scale.

CM: Selects lower plate voltage optimum for CW/FSK/SSTV and other types

of emission, including SSB, up to 1 kW d-c plate input.

SS B: Selects high plate voltage for up to 2+ kW PEP SSB plate input.

OUT = STANDBY: When both the CW and SSB buttons are out (as evidenced

by black colo r windows), the a m plifie r i s placed in the STANDBY

condition. Antenna changeover relay i s disabled, permitting

"st raig ht- thro ugh " operation o f the exc iter/tra nsceiver while the

am plifier remains ready for immediate use if desired.

ALC - Rear panel screwdriver adjustment sets the drive power level at which

ALC voltage begins to increase (negatively) from zero — the ALC "thre sh

old " le vel. Use a small, insulated screwdriver to avoid a cciden tally

shorting the ci r c u it .

2. Tune-Up Procedure:

(a) GENERAL - The objective of tune-up i s to adjust the a m plifier to d eliv er

maximum power output at the desired level o f plate d-c power input, or at

the a vailable level o f rf drive power, whichever i s lower.

When the am plifier i s adjusted for maximum attainable rf power output

with a s p e c if ic , fixed level of rf c a rrie r drive power, i t i s automatic

al l y set up properly for the best combination of e ffic ie nc y and l i nearity

possible at that drive 1 e ve!.

If the drive power i s increased beyond the tune-up level a fter fina l TUNE/

LOAD adjustments, flattopping and undesirable d i st o rt io n (on SSB) w ill

re s u lt, along with grid current grea tly in excess of normal.

4

If drive power i s reduced below the tune-up level without further ad just

ment o f TUNE and LOAD co ntro ls, am plifier e ff ic ie n cy w ill be reduced.

Both o f these statements are applicable equally to any lin e a r am plifier

of the types used for high power amateur and s imila r service.

I t i s therefore essential that the a mp lifier be adjusted for maximum rf

output at the drive and d-c input powers which are to be employed in

normal operation, WITH ONE IMPORTANT EXCEPTION: if the plate voltage i s

changed without also changing the TUNE and LOAD adjustments, the re su lt in g

power input level which w ill y i e ld optimum performance at the new plate

voltage w il l vary in proportion to the square o f the plate v olta ge . For

example, if the ALPHA 76A i s tuned up for maximum output with 1400 VDC

plate voltage (typical LV) and with the drive level set so that the

resu lta nt maximum rf output is about 700 watts (equivalent to a d-c input

of roughly 1000 watts), THEN when the plate voltage i s increased to 2000

VDC the a mplifier w i ll inherently perform optimally when driven to about

700 X (2000/1400)2 = 1400 watts rf output, corresponding to approximately

2000 watts d-c plate input.

In general, the final operating adjustment after basic tune-up should be

to set excitation (drive) from the exciter or tra nsceiv er so that the

GRID current meter ind ica tio n j u st reaches about 50 mAdc (1/3 scale) key-

down or on SSB voice peaks.

(b) IN ITIAL TUNE-UP - Place a mplifier in STANDBY (both CW and SSB buttons out:

if one i s already depressed, par t i al l y depress the other and release, so

that both pop out and show bl a c k ).

(1) Press HV button and watch MULTIMETER HV scale (0-3 KV).

(2) Press ON button and release. Panel meters should immediately illu mi

nate amber or red and the MULTIMETER should swing promptly to i ndi

cate 1.5 KV +_ 100V (mid-scale). (If t his does not occur, press OFF

immediately and locate the problem.) The blower should s ta rt immedi

ate ly and exhaust air should be detectable flowing from cover vents.

(3) When tube warm-up delay i s completed in approximately 60 seconds,

the meters w ill change to pale green or blue, in dic atin g "ready" to

transmit. Set controls to the preliminary points indicated in

Table I below, depending on the desired operating frequency.

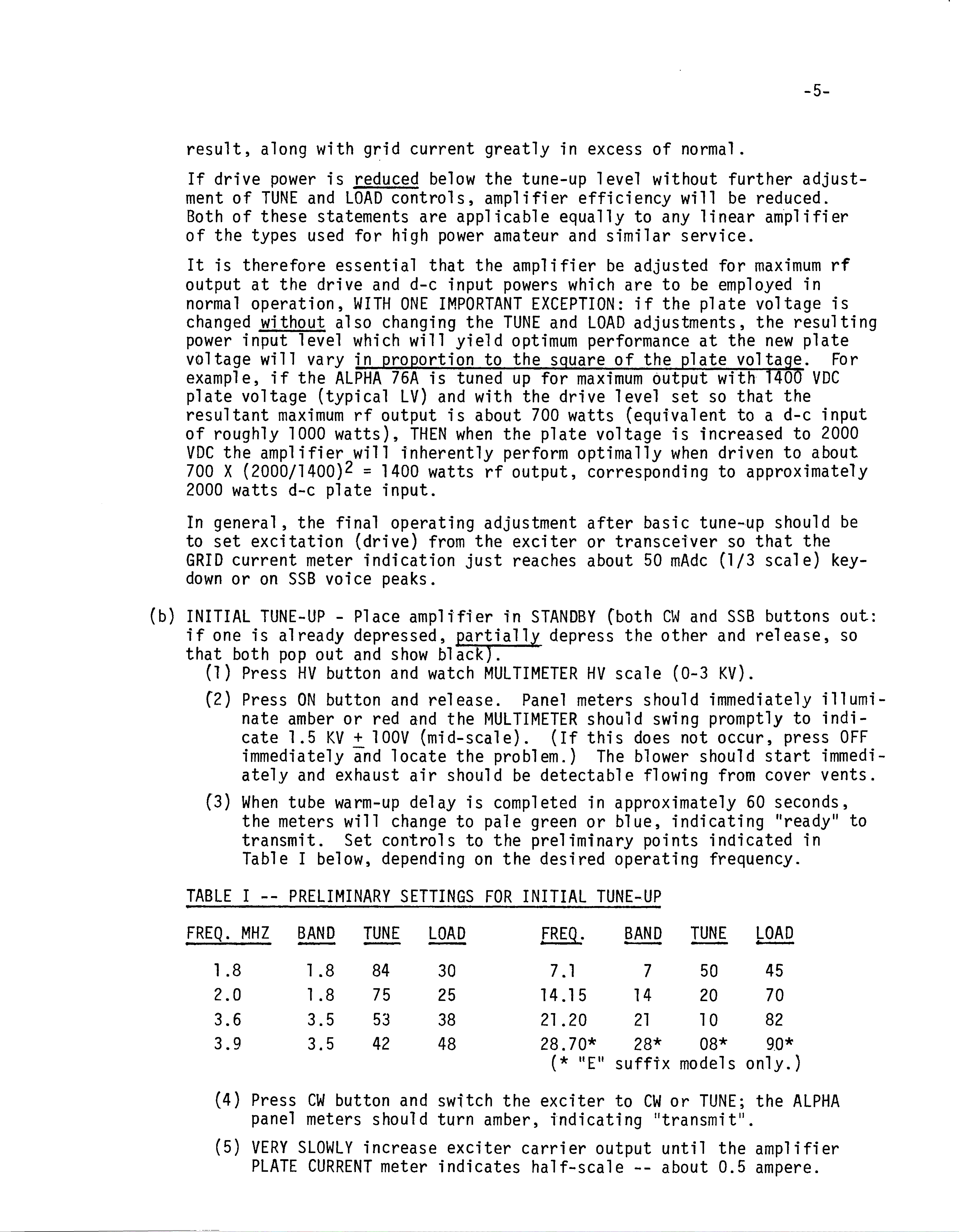

TABLE I — PRELIMINARY SETTINGS FOR INITIAL TUNE-UP

FREQ. MHZ

BAND

TUNE

LOAD

f REQ.

BAND

TUNE LOAD

1 .8

2.0

1 .8

1 .8

84

30

75 25 14.15 14

3.6 3.5 53 38

3.9 3.5 42

48

7.1 7

21.20

28.70*

M£H

s u f f i x

50

20

21 10

45

70

82

28* 08* 9.0*

models only.

(4) Press CW button and switch the exciter to CW o r TUNE; the ALPHA

panel meters should turn amber, in dica ting "transm it".

(5) VERY SLOWLY increase excite r c a r r ie r output u ntil the a mplifie r

PLATE CURRENT meter indicates h a lf- sc ale - - about 0.5 ampere.

Loading...

Loading...