EHC NDIR120L, NINDSL120L, NDIR150L, NDIR180L, NDIR210L Installation & Maintenance Instructions Manual

...

Installation & Maintenance

Instructions

MARCH 2017

The Electric Heating Company Ltd

Unit 40 Block 5 Third Road

Blantyre Industrial Estate

Blantyre Glasgow

G72 0UP

Tel: 01698 820533

Fax: 01698 825697

email: info@electric-heatingcompany.co.uk

www.electric-heatingcompany.co.uk

01

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

PAGE CONTENT

1 Introduction

2 Storage, Handling & Supply Requirements

3 Component Table

4 Siting the unit

5 General Installation

7 Discharge Arrangement

9 Technical Specifications: Slimline -

Direct & Indirect

10 Technical Specifications: Direct & Indirect

11 Technical Specifications: Solar Indirect

12 Solar Coil Installation

13 S-Plan Wiring Schematics

14 Commissioning & Servicing

15 Fault Finding & User Instructions

16 - 17 Specification & Performance

18 Commissioning Record

19-24 Service Record

25-26 Guarantee - Terms & Conditions

27 Gaurantee Card

INTRODUCTION

The EHC Neptune Unvented cylinder is made from

Duplex Stainless Steel for excellent corrosion resistance.

The EHC Neptune has a strong rust-resistant steel case

and is highly insulated with environmentally friendly

foam.

The EHC Neptune is supplied complete with all the

necessary safety and control devices needed to connect

to the cold water mains. All are pre-adjusted. High

quality controls have been selected to combine high flow

rate performance with minimum pressure drop to make

the EHC Neptune perform well in all areas, even those

with poor water pressure.

IMPORTANT NOTE TO

THE INSTALLER

Read these instructions before commencing installation. Unvented cylinders are a controlled service as defined in the

latest edition of the building regulations and should only be fitted by a competent person.

The relevant regulations are: England and Wales – Building Regulation G3, Scotland – Technical Standard P3, N Ireland –

Building Regulation Part F

After installation the commissioning record must be completed and left, with these instructions, with the householder for

future reference.

IMPORTANT NOTE TO THE INSTALLER

Read these instructions before commencing installation. Unvented cylinders are a controlled

service as defined in the latest edition of the building regulations and should only be fitted

by a competent person.

The relevant regulations are: England and Wales – Building Regulation G3, Scotland – Technical

Standard P3, N Ireland – Building Regulation Part F

After installation the commissioning record list must be completed and left, with these

instructions, with the householder for future reference.

02

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

STORAGE PRIOR TO INSTALLATION

The EHC Neptune should be stored in its original packaging

in an upright position in an area free from excessive damp.

Regulations G3+L.

HANDLING PRODUCT

The EHC Neptune should be carried upright where possible.

Assessments of risks for carrying the cylinder should be

conducted. Use more than 1 person for carrying where

appropriate. Always follow latest guidelines for lifting

techniques, to avoid injury and damage to the product.

WATER SUPPLY

The EHC Neptune operates at 3 bar (controlled by the inlet

control set) and is capable of delivering over 50 litres per

minute. The high quality inlet control set has been designed

to make the most of the flow rates available, however the

performance of any unvented system is only as good as the

mains water supply. The maximum possible water demand

should be assessed, taking into consideration that both

hot and cold services are supplied simultaneously from the

mains.

The water supply should be checked to ensure it can

meet these requirements. If necessary, consult the local

water company regarding the likely pressure and flow rate

availability.

If measuring the water pressure, note that a high static

(no flow) mains pressure is no guarantee of good flow

availability. In a domestic installation 1.5 bar and 25 l/min.

should be regarded as the minimum. The maximum mains

pressure that the inlet control set can accept is 12 bar.

Consideration should be given to upgrading existing

½” (15mm) cold mains pipework to a larger size if the

recommended minimum pressure/flow rate is not being

achieved.

ELECTRIC SUPPLY

The EHC Neptune requires 240 Volt electrical supply for

the immersion elements. The electrical supply to each

immersion heater must be fused at 13A via a double pole

isolating switch to BS 3456. The cable must be at least

2.5mm2 heat resistant (85°C HOFR) sheathed flex complying

to BS 6141:1981 Table 8.

UNPACKING THE UNIT

The EHC Neptune comes complete with the fittings required

to complete the installation. Please see over for component

content list.

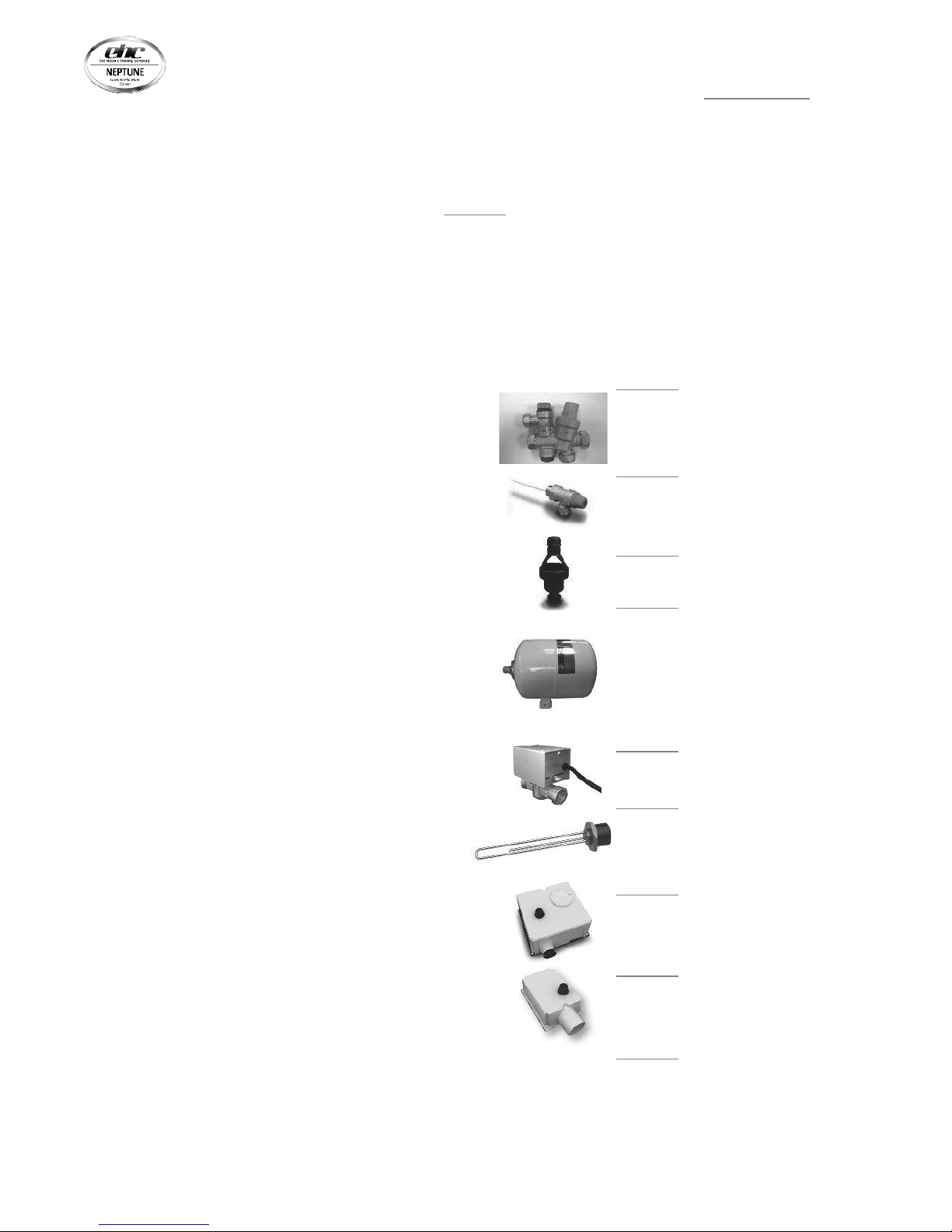

High flow rate inlet control set - 3 bar

PRV 6 bar Expansion Relief

Spare Part No. CB091

Temperature and pressure relief valve

Spare Part No. CB098

Acetal tundish 15 x 22 mm

Spare Part No. CB096

Incoloy long life

3 kW immersion heater

Spare Part No. CB099

Two port valve

Spare Part No. EC10008

Dual thermostat

Spare Part No. CB142

High limit thermostat

Spare Part No. CB135

Expansion Vessel

• 60- 250 ltr units - 18 ltr vessel

Spare Part No. CB144

• 300 ltr units - 25 ltr vessel

Spare Part No. CB145

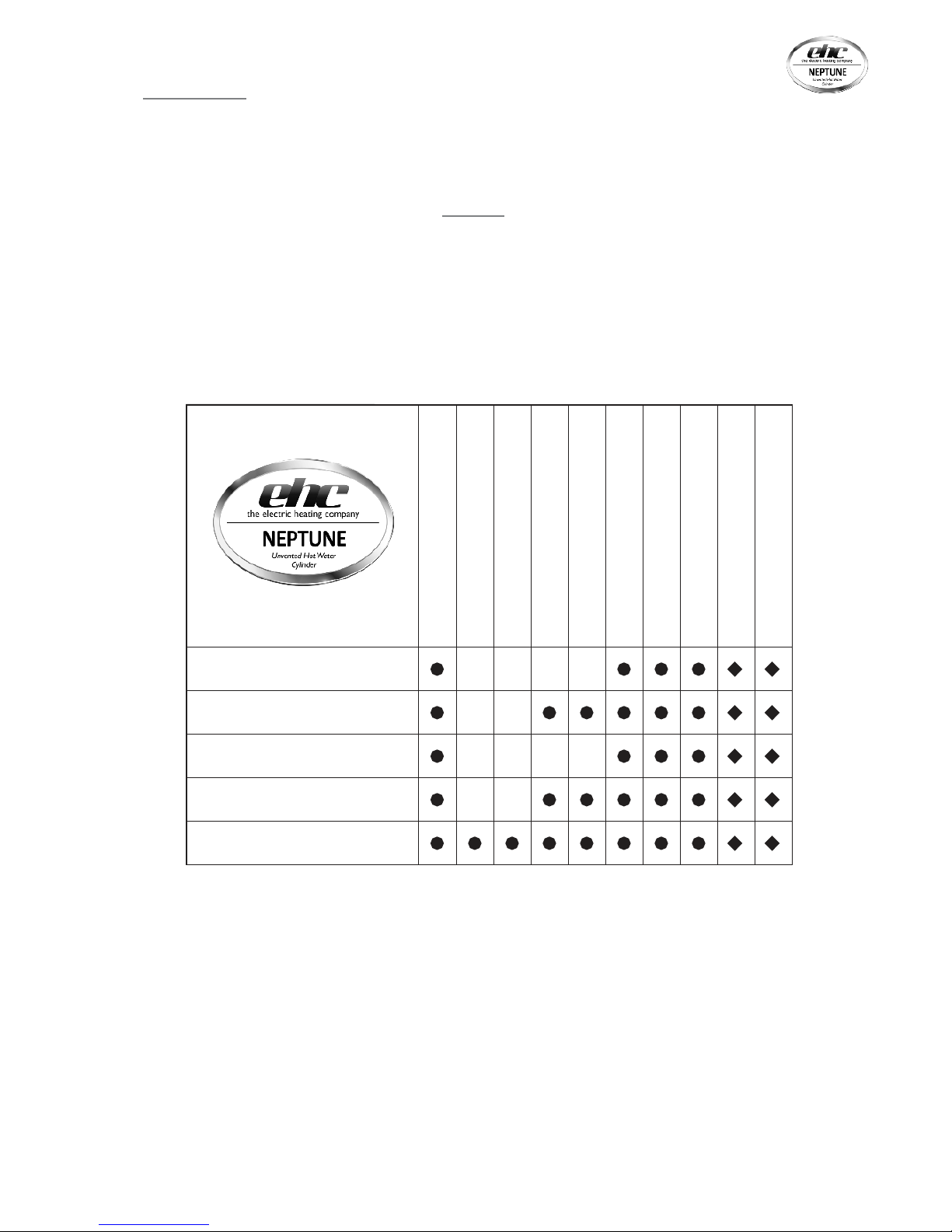

COMPONENT CONTENT TABLE

Inlet Control Set

• • • • •

Temp & Pressure Relief Valve

• • • • •

Tundish

• • • • •

Expansion Vessel

• • • • •

Immersion Heater

• • • • •

Two Port Valve

• • •

Dual Thermostat

• • •

Single High Limit Stat

•

Sensor Pocket Retaining Bungs

•

Installation & Maintenance

Instructions

• • • • •

Slimline Direct Models (Electric)

Slimline Indirect Models

Direct Models (Electric)

Indirect Models

Solar Indirect Models

Direct Models (Electric)

Indire ct Mod els (Single Coil )

Solar I ndirec t Models (Two Coils)

03

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

SITING THE UNIT

The EHC Neptune can supply outlets above it or at some

distance from it. Site the unit to minimise “dead leg”

distances, especially to the point of most frequent use.

Outlets above the EHC Neptune will reduce the outlet

pressure available by 0.1 bar for every 1m of height

difference. The unit should be protected from frost.

Particular care is needed if sitting in a garage or outbuilding.

All exposed pipework should be insulated. EHC Neptune

must be installed VERTICALLY on a flat base capable

of supporting the weight of the cylinder when full. See

technical specification section (page 16) for weights. The

minimum recommended cupboard size is 650mm square.

NOTES:

The pressure reducing

valve, non-return valve

and expansion relief valve

are combined together in

the inlet control set.

On 60 – 180 litre sizes

there is no dedicated

secondary return boss

and the secondary return

circuit should be tee’d into

the cold feed pipe just

above the drain elbow.

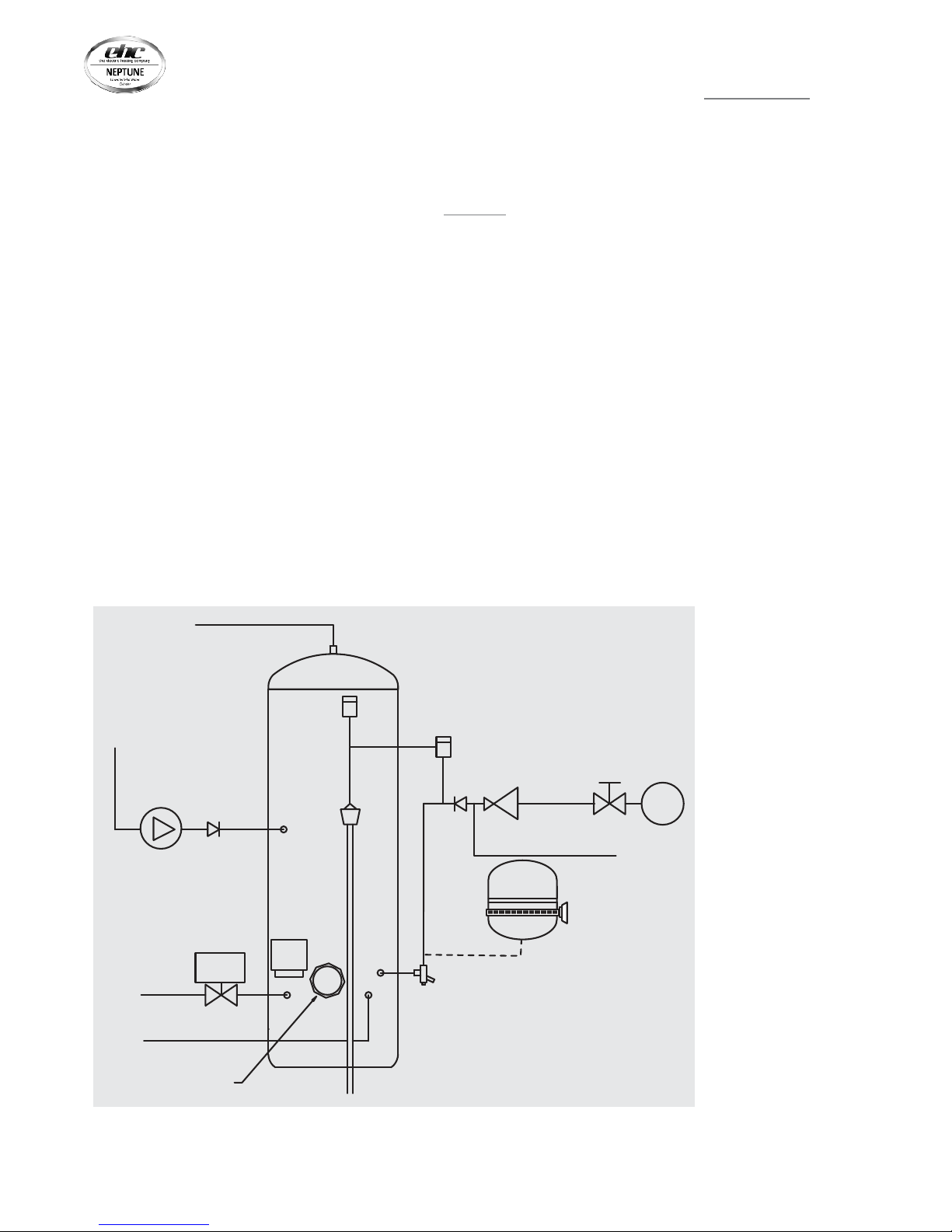

SCHEMATIC DIAGRAM

Access for maintenance of the valves should be considered.

Consideration should be given to position of discharge

pipes (tundish), drain valves - shall be positioned away from

electrical components.

The immersion heaters are 375mm long and care should be

taken to ensure that they can be withdrawn for servicing

if required. The discharge pipework from the safety valves

should fall continuously and terminate safely.

IMMERSION

HEATER

COLD

MAIN

ISOLATING

VALV E

PRESSURE

REDUCING

VALV E

NON

RETURN

VALV E

EXPANSION

RELIEF

VALV E

TUNDISH

TEMPERATURE

& PRESSURE

RELIEF VALVE

BALANCED

COLD

CONNECTION

COLD

INLET VIA

DRAIN

NON

RETURN

VALV E

BRONZE

PUMP

SECONDARY RETURN CIRCUIT

( 210, 250 & 300 L SIZES )

DUAL

STAT

2 PORT

VALV E

BOILER

FLOW

BOILER

RETURN

HOT OUTLET

EXPANSION

VESSEL

WITH WALL

BRACKET

04

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

GENERAL INSTALLATION

COLD MAINS PIPEWORK

Run the cold main through the building to the place where

the EHC Neptune is to be installed. Take care not to run the

cold pipe near hot water or heating pipework so that the

heat pick-up is minimized. Identify the cold water supply pipe

and fit an isolating valve (not supplied).

A 22mm BS1010 stopcock can typically be used but a 22mm

quarter turn full bore valve would be better as it does not

restrict the flow as much. Do not use “screwdriver slot” or

similar valves. Make the connection to the cold feed of the

cylinder and incorporate a drain valve. Position the drain

valve no higher than the cold inlet to ensure sufficient

draining of cylinder when required. Position the inlet control

just ABOVE the Temperature & Pressure Relief Valve (TPRV)

mounted on the side of the cylinder. This ensures that

the cylinder does not have to be drained down in order to

service the inlet control set. Ensure that the arrow points

in the direction of the water flow. Select a suitable position

for the expansion vessel. Mount it to the wall using the

bracket attached to the vessel. Use suitable fittings capable

of supporting full vessel weight (and with appropriate

consideration to wall material). Connect the expansion

vessel to the cold feed pipework between the inlet control

set and the cold inlet on the cylinder. Ensure that the top of

the vessel is accessible for servicing.

CONNECTING TO THE CYLINDER

All of the pipework connections on the cylinder are 22mm

compression and supplied complete with gland nuts and

olives, in the Accessory Kit box. Only connect 22mm Table X

copper tube to these connections.

Cut the tube with a pipe cutter and ensure no sharp edges or

burrs protrude. Slide both gland nut and olive onto the tube

and push tube fully home into the connection, ensuring the

tube end fully bottoms on the connection recess. Smear the

outer wall of the olive with plumbing paste and tighten gland

nut in the prescribed manner. Upon filling/commissioning,

ensure all connections are completely watertight. Note:

No control or isolation valve should be fitted between the

expansion relief valve and the storage cylinder. The relief

valve connections should not be used for any other purpose.

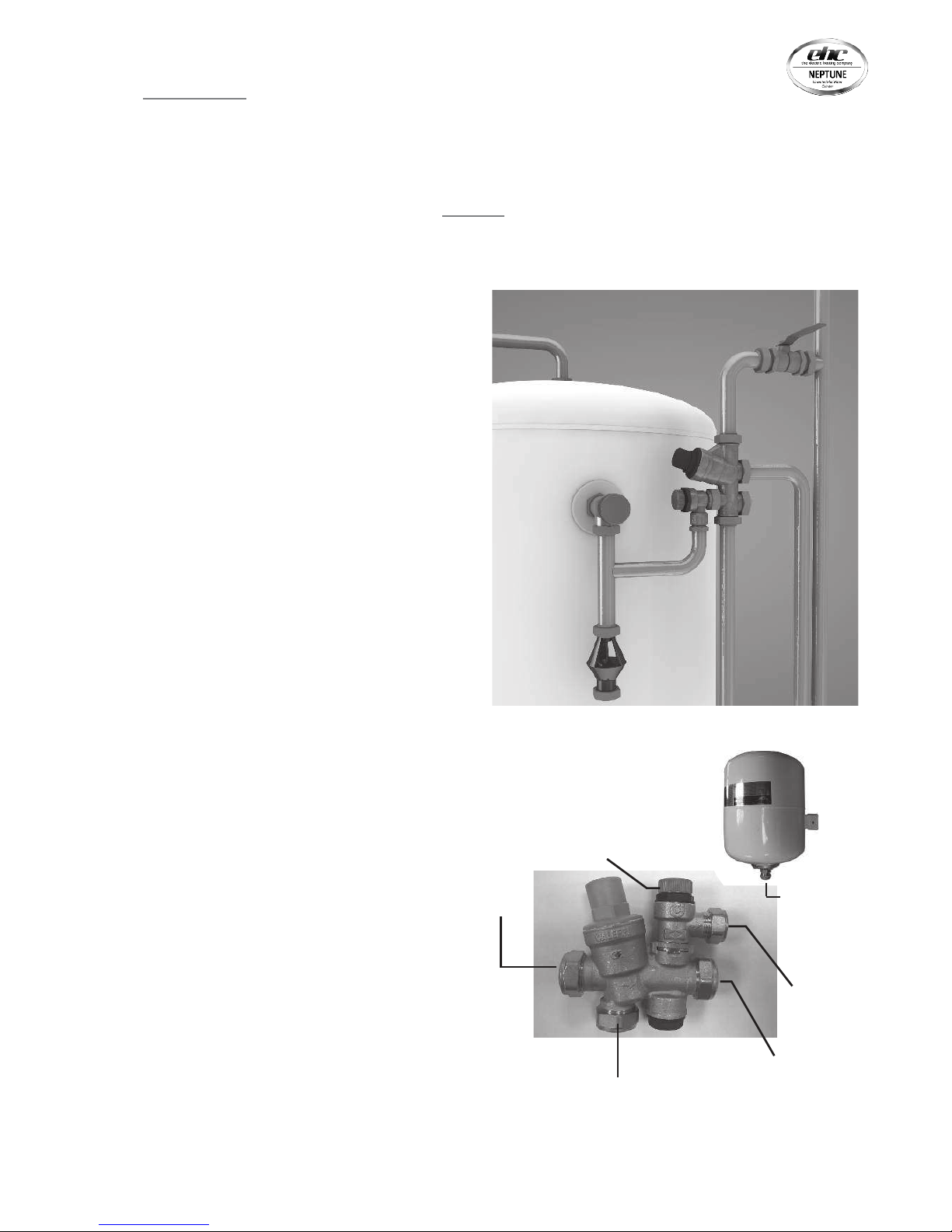

(expansion vessel not to scale)

Turn to

test

Cold

Mains In

Balanced Cold

Connection

Outlet to Cylinder

Expansion

Relief to

Tundish

Expansion

Relief

Connection

05

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

BALANCED COLD CONNECTION

If there are to be showers, bidets or monobloc taps in the

installation then a balanced cold supply is necessary. There

is a 22mm balanced connection on the inlet set.

HOT WATER PIPEWORK

Run the first part of the hot water distribution pipework

in 22mm. This can be reduced to 15mm and 10mm as

appropriate for the type of tap etc. Your aim should be

to reduce the volume of the hot draw-off pipework to a

practical minimum so that the time taken for the hot water

is as quick as possible. Where monobloc mixing taps and

showers are used, these should be installed to comply with

the Water Supply (Water Fittings) Regulations 1999. If these

devices are supplied with un-balanced supplies there should

be single check valves installed at both inlets, to stop over

pressurising of either supply.

PRIMARY COIL CONNECTIONS FOR INDIRECT UNITS

For Solar input models refer to pages 11-12 before making

any connections.

Connect the primary connections (Indirect only) using the

compression connections provided. The primary circuit must

be positively pumped. Gravity circulation is not suitable.

Either primary connection may be used as the primary flow,

reheat times are not effected. The primary circuit can be

open vented or sealed, with up to a maximum pressure of 3.5

bar. If you seal the primary circuit an additional expansion

vessel and safety valve is required. The boiler may be Gas,

Electric or Oil but must be under effective thermostatic

control. Uncontrolled heat sources such as some AGA’s, back

boilers, solid fuel stoves, etc. are NOT SUITABLE. Please

contact our Technical department for guidance. Connect the

two port zone valve ( indirect only ) into the primary flow

pipework. The direction of flow arrow should be towards the

primary flow connection.

SECONDARY CIRCULATION

The EHC Neptune can be used with secondary circulation.

An appropriate WRAS approved bronze circulator should

be used in conjunction with a non-return valve to prevent

backflow. On large secondary circulation systems it may

be necessary to incorporate an extra expansion vessel into

the circuit to accommodate the increased system water

volume. Secondary circulation should be avoided on Direct

electrically heated units being used on off-peak electricity

tariffs.

A secondary return boss is fitted as standard on 210, 250

& 300 ltr units. On smaller sizes, tee into the cold feed pipe

above the drain.

IMMERSION HEATERS

Only immersion heaters with a thermal cut-out may be used.

To help ensure this, the immersion heaters have a special

1 3/4” thread. They are rated at 3kW at 240V and are of a low

noise Incoloy construction.

They have both a thermostat and a high limit cutout. Please

order the correct replacement via ourselves; fitting nonapproved immersions may affect your guarantee. When

fitting, ensure the ‘O’ ring is positioned correctly on the head

of the immersion heater and lubricate before fitting. Fit it

by hand until almost home then tighten gently as the ‘O’

rings will seal easily. The electrical supply to each immersion

heater must be fused at 13A via a double pole isolating

switch to BS 3456. The cable must be 2.5mm2 heat resistant

(85°C HOFR) sheathed flex complying to BS 6141:1981 Table

8. Do not operate the immersion heater/s until the unit

is full of water. Do not operate the immersion heater/s if

any sterilisation liquid is in the cylinder as this will cause

premature failure.

ELECTRICAL CONNECTIONS

Complete the wiring – use the appropriate wiring diagrams

on page 12- 13.

06

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

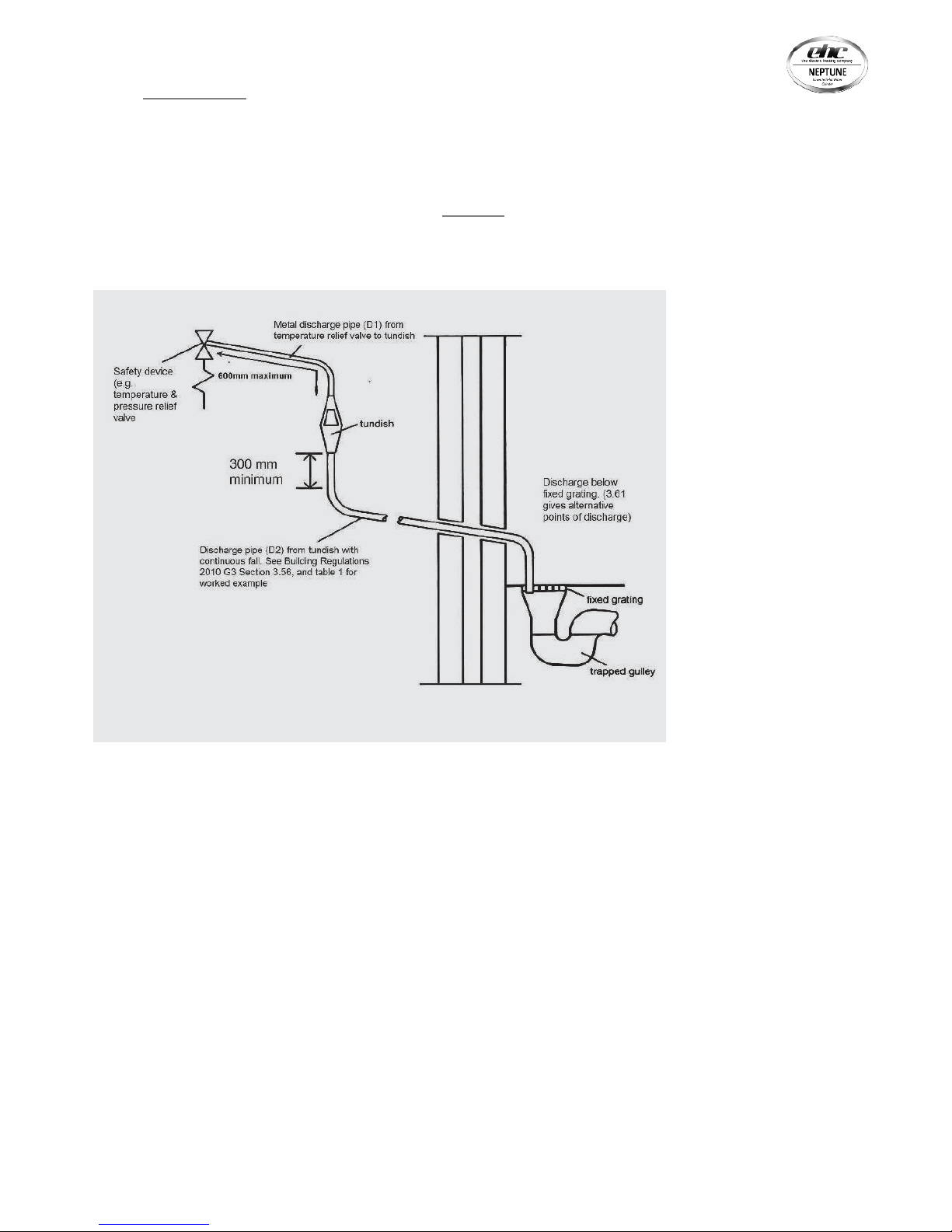

DISCHARGE ARRANGEMENT

Position the inlet control group so that the discharge from

both safety valves can be joined together via a 15mm end

feed Tee (see diagram above). Connect the Tundish and

route the discharge pipe. The discharge pipework must

be routed in accordance with Part G3 of schedule 1 of the

Building Regulations. The information that follows is not

exhaustive and if you are in doubt you should seek advice.

The two safety valves will only discharge water under fault

conditions. When operating normally water will not be

discharged. The tundish should be vertical, located in the

same space as the unvented hot water storage system and

be fitted as close as possible to, and lower than, the safety

device, with no more than 600mm of pipe between the valve

outlet and the tundish. The tundish should be positioned

away from electrical devices.

Any Discharge should be visible at the tundish. The tundish

should be located such that any discharge is visible. In

addition, where discharges from safety devices may not

be apparent, e.g. people with impaired vision or mobility,

consideration should be given to the installation of a suitable

safety device to warn when discharge takes place, e.g.

electronically operated.

Diagram of a typical discharge pipe arrangement (extract from

Building Regulation G3)

Note: The discharge will

consist of scalding water and

steam. Asphalt, roofing felt

and non-metallic rainwater

goods may be damaged by

such discharges.

Note: D2 pipe from tundish

is now allowed to be

installed in soil stacks within

premises. This activity is not

recommended as discharge

from T&P may continue for

long periods of time. It is

the installer’s responsibility

to ensure the discharge

pipework can support the

discharge for prolonged

periods.

If used follow guidance on

mechanical seal without

water trap given in G3

Building Regulations.

As discharge can be in

excess of 90oC discharge

into plastic pipework is also

not recommended.

07

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

The discharge pipe (D2) from the tundish should:

A) Have a vertical section of pipe at least 300mm long,

below the tundish before any elbows or bends in the

pipework.

B) Be installed with a continuous fall of at least 1 in 200

thereafter.

The discharge pipe (D2) from the tundish should be of metal

or other material that have been demonstrated to be capable

of withstanding temperatures of the water discharged.

The discharge pipe (D2) should be at least one pipe size

larger than the nominal outlet size of the safety device

unless its total equivalent hydraulic resistance exceeds that

of a straight pipe 9m long i.e. discharge pipes between 9m

and 18m equivalent resistance length should be at least two

sizes larger than the nominal outlet size of the safety device,

between 18 and 27m at least 3 sizes larger, and so on. Bends

must be taken into account in calculating the flow resistance.

Refer to diagram 1, Table 1 and the worked example. An

alternative approach for sizing discharge pipes would be to

follow BS670 ce of services supplying water for domestic

use within buildings and their curtilages.

The discharge pipe (D2) should terminate in a safe place

where there is no risk to persons in the vicinity of the

discharge. Examples of acceptable discharge arrangements

are:

a. To a trapped gully with the end of the pipe below

the fixed grating and above the water

seal.

b. Downward discharges at a low level; i.e. up to 100mm

above external surfaces such as car parks, hard standings,

grassed areas etc. are acceptable providing that where

children play or otherwise come into contact with

discharges, a wire cage or similar guard is positioned to

prevent contact whilst maintaining visibility.

c. Discharges at a high level; e.g. in to metal hopper

and metal down pipe with the end of the discharge pipe

clearly visible or onto a roof capable of withstanding high

temperature discharges of water and 3m from any plastic

guttering systems that would collect such discharges.

d. Device to warn when discharge takes place.

WORKED EXAMPLE

The example below is for G1/2 temperature relief valve with

a discharge pipe (D2) having 4 No. elbows and length of 7m

from the tundish to the point of discharge.

From Table 1:

Maximum resistance allowed for a straight length of 22mm

copper discharge pipe (D2) from a G1/2 temperature relief

valve is: 9.0m. Subtract the resistance for 4 No. 22mm

elbows at 0.8m each = 3.2m. Therefore the maximum

permitted length equates to: 5.8m. 5.8m is less than the

actual length of 7m therefore calculate the next largest size.

Maximum resistance allowed for a straight length of 28mm

pipe (D2) from a G1/2 temperature relief valve equates to:

14m. As the actual length is 7m, a 28mm (D2) copper pipe

will be satisfactory.

TAB L E 1

Sizing of copper discharge pipe ‘D2’ for a temperature

relief valve with a G1/2 outlet size (as supplied).

Size of

discharge

pipework

Maximum length of

straight pipe

(no bends or

elbows)

Deduct the figure below

from the maximum length

for each bend or elbow in the

discharge pipe

22mm Up to 9m 0.8m

28mm Up to 18m 1m

35mm Up to 27m 1.4m

08

EHC NEPTUNE

UNVENTED HOT WATER CYLINDERS

Loading...

Loading...