GAS FIRED WALL MOUNTED CONDENSING

COMBINATION BOILER

FOR SEALED CENTRAL HEATING SYSTEMS AND MAINS FED DOMESTIC HOTWATER

THE APPLIANCE IS FOR USE

WITH NATURAL GAS OR L.P.G

EHC ECOSAVE 21K

EHC ECOSAVE 25K

EHC ECOSAVE 32K

EHC ECOSAVE 37K

INSTRUCTION MANUAL

INSTALLATION, COMMISSIONING

& SERVICING

Preface

About the instructions

The instructions contain important information for the safe,

professional installation and start-up of the EHC Ecosave gas-

Readers of the instructions need to be professional installers,

who have been trained and have experience for working on

heating and gas systems.

Subject to technical changes

The contents of the instructions are subject to changes due to

our policy of continuous improvement.

Regulations

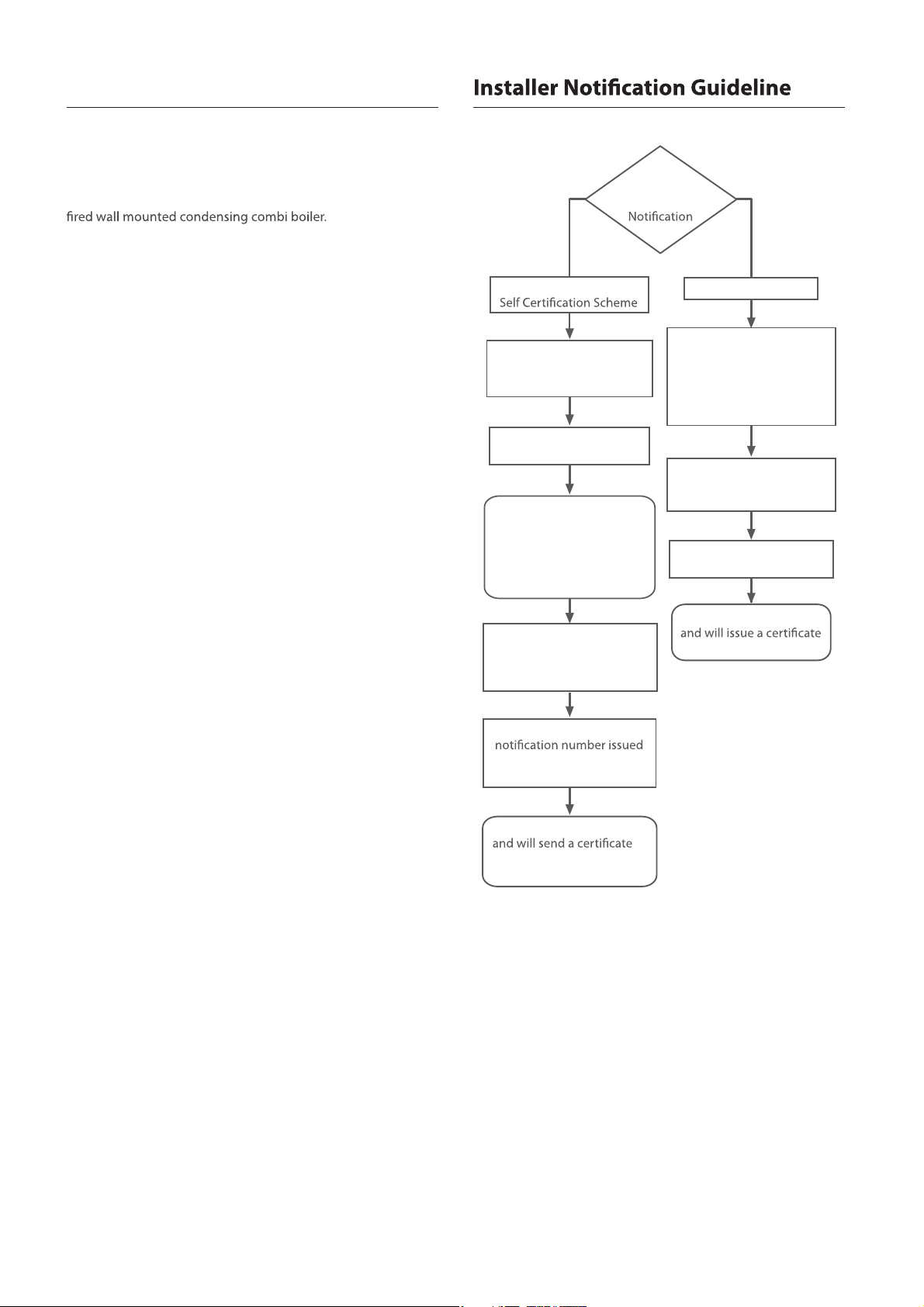

Competent Person's

Install and Commission

this appliance to

manufacturer's instructions

Complete the Benchmark

Checklist

If you notify via Gas

Scheme, Gas Safe will then

notify the relevant Local

Authority Building Control

Scheme on member's

behalf

Choose

Building

Route

Building Control

Contact your relevant Local

Authority Building Control

(LABC) who will arrange

an inspection or contact

a government approved

inspector

Install and Commission this

appliance to manufacturer's

instructions

Complete the Benchmark

Checklist

Scheme Members only

Contact Gas Safe or visit

www.gassaferegister.co.uk

You must ensure that the

by Gas Safe is written onto

the Benchmark Checklist

Gas Safe will record the data

of compliance to the

property

LABC will record the data

of compliance

2

Preface

EHC

Contents

1. Safety Considerations 4

1.1 Saf et y Denition s

1.2 Symbols Used in the Instructions

1.3 Important Safety Precautions

1.4 Legislation

1.5 CE Marking Information

2. Product Description 6

2.1 Description

2.2 Layout and Key Components

2.3 Control Panel

3. Technical Data 8

3.1 General Specications

3.2 Hydraulic Data

4. Dimensions 10

5. System Details 11

5.1 Operation Modes

5.2 Safety Functions

6. Installation Requirements 13

6.1 Location

6.2 Required Minimum Clearances

6.3 Ventilation

6.4 Gas Supply

6.5 Electrical Supply

6.6 Water Supply

6.7 Condensate Drain

6.8 Flue

7. Flue Options 18

7.1 Calculating the Overall Length of the Flue System

7.2 Fitting the Concentric Flue System

7.3 Fitting the Separate Flue System

8. Installation Procedure 21

9. Transporting and Unpacking 22

9.1 Transporting the Appliance

9.2 Unpacking and Checking the Accessories

13. Connecting the Flue 28

13.1 For a concentric ue system

13.2 For a separate ue system

14. Electrical Connections and Settings 29

14.1 Accessing the Controller Assembly

14.2 Accessing All the Electrical Connections

14.3 Connecting to Mains Power 230V

14.4 Connecting the Controller, Accessories and External Controls

14.5 Ensuring the DIP Switch Settings

15. Final Check and Commissioning 33

15.1 Connecting the Power Cable and Turning the Power ON/OFF

15.2 Checking the Gas Settings

15.3 Checking the Gas Equipment for Soundness

15.4 Checking and Adjusting the CO

15.5 Installing the Front Cover

15.6 System Filling and Pressurising

15.7 Operational Checks

15.8 Final Commissioning Check

16. Instructing the End User 41

16.1 Handing over the Instructions

16.2 Showing How to Operate

17. Error Code List 41

18. Electrical 42

18.1 Wiring diagram

19. Parts List 43

19.1 Base Parts

19.2 Burner Parts

19.3 Water Way Parts

20. Appendix 47

Appendix 'A' Gas Conversion

Appendix 'B' Warranty Conditions

Appendix 'C' Commissioning Check List

Value

2

10. Mounting the Appliance on the Wall 23

11. Making the Gas Connection 24

11.1 Gas Piping Materials

11.2 When using LPG

11.3 Gas Supply Pipe Installation Procedures

12. Fitting the Water Pipes and Condensate Pipe 26

12.1 Water Pipes and Condensate Pipe Connection Procedures

12.2 General Pipework Connections

12.3 Water Pipe Size and Water Pressure

12.4 Pressure R elief Valve

12.5 Frost Protection

EHC

3Contents

Safety Considerations1.

Safety Definitions1.1

All safety messages will refer to potential hazards. Precisely

follow the instructions to avoid the risk of injury.

This is the safety alert symbol. It is used to alert

you of potential personal injury hazards.

Adhere to all safety messages that follow this

Symbol to avoid possible injury or death.

List of safety symbols in the instructions

DANGER

Indicates an imminently hazardous situation which, if not

avoided, could result in severe injury or death.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in severe injury or death.

Important Safety Precautions1.3

DANGER

If you smell gas

Gas Leaks can cause explosions, which may

lead to serious injury..

Do not smoke. Prevent open ames and sparks.

Do not operate light switches or electrical equipment

switches.

Open the windows and doors.

Close the gas shuto valve.

Shut down the heating system.

Keep people away from the danger zone.

Observe the safety regulations of your local gas supplier,

found on the gas meter.

Notify your heating contractor from the outside of the

building.

Flue gas may lead to life-threatening poisoning.

Shut down the heating system.

Ventilate the location.

Close all doors leading to living spaces.

Do not operate electrical switches.

CAUTION

Indicates an imminently hazardous situation which, if not

avoided, could result in minor or moderate injury.

CAUTION

Used without the safety alert symbol indicates a potential

hazardous situation which, if not avoided, could result in

property damage.

Symbols Used in the Instructions1.2

The following symbols are used throughout the instructions to

bring attention to the important information concerning the

appliance.

Important

Note

Warns of a risk of material loss and

environmental pollution.

Indicates additional information that is

important but not related to personal injury

or property damage.

CAUTION

Working on the heating system

Isolate the system from the main electrical power supply, e.g.

by removing a separate fuse or by means of a main electrical

isolator, and check that it is no longer “live”.

Isolate the gas supply and safeguard it from unauthorized

reopening.

For propane appliances

Purging the liquid gas tank when installing the system:

Before installing the appliance make sure that the gas tank

has been purged. The liquid gas supplier is responsible for

properly purging the tank. Ignition ploblems may occur

if the tank is not bled properly. In such cases, frst contact the

person responsible for filling the tank.

Safety Considerations

4

EHC

Legislation1.4

EHC Declares that this appliance is free of any harmful

substances, and no harmful substances are used during

appliance manufacturing.

The appliance is suitable only for installation in GB and should

be installed in accordance with the rules in force, and only used

in a suitably ventilated location.

In GB, the appliance must be installed and commisioned by a

GAS SAFE Registered Installer.

The appliance must be installed also in accordance with the

relevant requirements of the:

Gas Safety (Installation & Use) Regulations.

The appropriate Building Regulations : either one of The

Building Regulations, The Building Regulations (Scotland) , or

The Building Regulations (Northern Ireland).

The Water Fittings Regulations or Water Byelaws in Scotland.

The Current I.E.E. Wiring Regulations.

For detailed information on the installation of condensing

boilers, reference should be made to the ODPM Guide to the

Condensing Boiler Assessment Procedure for Dwellings.

Standard Scope

BS 7074 Expansion vessels and ancillary

equipment for sealed water systems

BS 7593 Treatment of water in domestic hot

water central heating systems

BS 7671:2008 Requirements for electrical installations

BS EN 303-7:2006 Heating boilers

BS EN 483 Type C Boiler of nominal heat input not

exceeding 70 kW

CE Marking Information1.5

0051

The appliance complies with the basic requirements of the

relevant European directives.

Gas appliances directive (90/396/EEC)

Electromagnetic compatibility directive with threshold class B

(89/336/EEC)

Low voltage directive (73/23/EEC)

C.O.S.H.H.

Materials used in the manufacture of this appliance are

Non hazardous and no special precautions are required when

servicing.

Codes of Practice - refer to the most

recent version

Installation should also comply with the following British

Standards Codes of Practice:

Standard Scope

BS 1212-1:1990 Float operated valves

BS 4814:1990 Specication for expansion vessels using

an internal diaphragm

BS 5440 Part 1 Flues

BS 5440 Part 2 Ventilation

BS 5546 Installation of hot water supplies for

domestic purposes

BS 5449 Forced circulation hot water systems

BS 5482-2:1977 Domestic butane- and propane-gas-

burning installations

BS 6281-1:1992 Devices without moving parts for the

prevention of contamination of water

BS 6282-2:1992 Devices with moving parts for the

prevention of contamination of water

BS 6283-4:1991 Safety and control devices for use in hot

water systems

BS 6798 Installation of gas red hot water boilers

BS 6880-1:1988 Title code of practice for low

temperature hot water heating systems

BS 6891:2005 Gas Installation

directive (92/42/EEC) as condensing boilers.

The Gas Appliance (Safety) Regulations 1992

As a result of our policy of constant development, there may

be small diferences between illustrations, functional steps and

technical data.

EHC

5Safety Considerations

Product Description2.

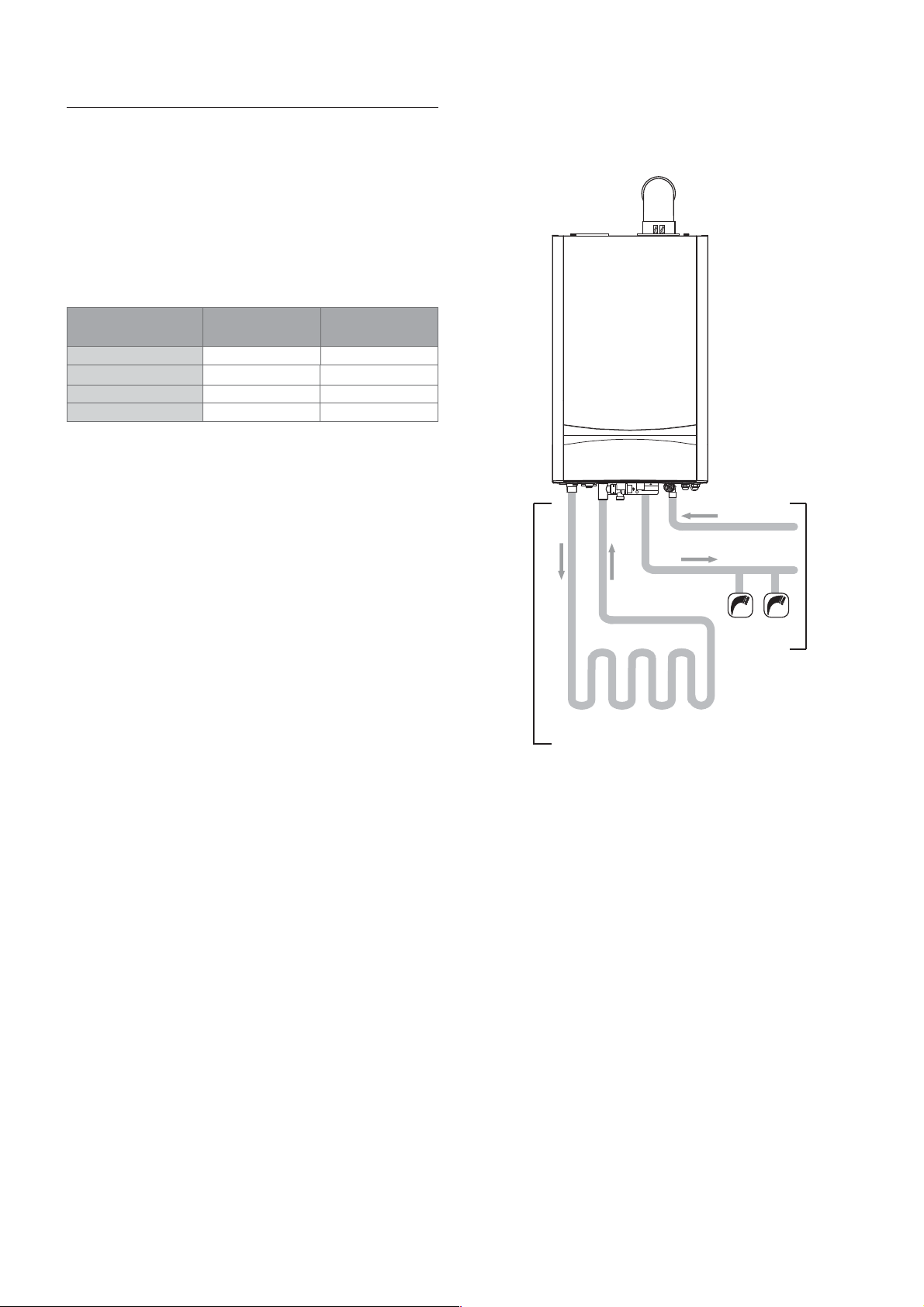

Description2.1

EHC Ecosave condensing gas boiler is a fully automatic, wall

hung, fan assisted balanced ue condensing boiler for use with

Natural Gas and Propane Gas. For gas type conversions see the

Appendix on Page 39.

This appliance is fully modulating and provides central heating

and domestic hot water. The following four models are available

according to their maximum outputs.

Model

EHC Ecosave-21K(A)

EHC Ecosave-25K(A) 23.1 kW 23.1 kW

EHC Ecosave-32K(A) 29.5 kW 34.2 kW

EHC Ecosave-37K(A) 34.2 kW 34.2 kW

The appliance always gives priority to DHW supply.

The appliance is designed to be used with a circulation pump,

a divert valve assembly, a ow sensor, a DHW plate heat

exchanger, a safety valve, and a CH expansion vessel. A separate

DHW expansion vessel is not required.

Internal frost protection and an electronic control unit are

incorporated within the boiler. Any volt free room thermostat

can be used with the boiler.

Maximum

Heating Output

19.3 kW 23.1 kW

Maximum

DHW Output

Central

Heating

(CH)

CH

ow

CH

return

Cold water

Domestic

hot water

Hot water tap

Domestic

Hot Water

(DHW)

Floor Heating Circuit or

Heating Circuit (Radiator)

Product Description

6

EHC

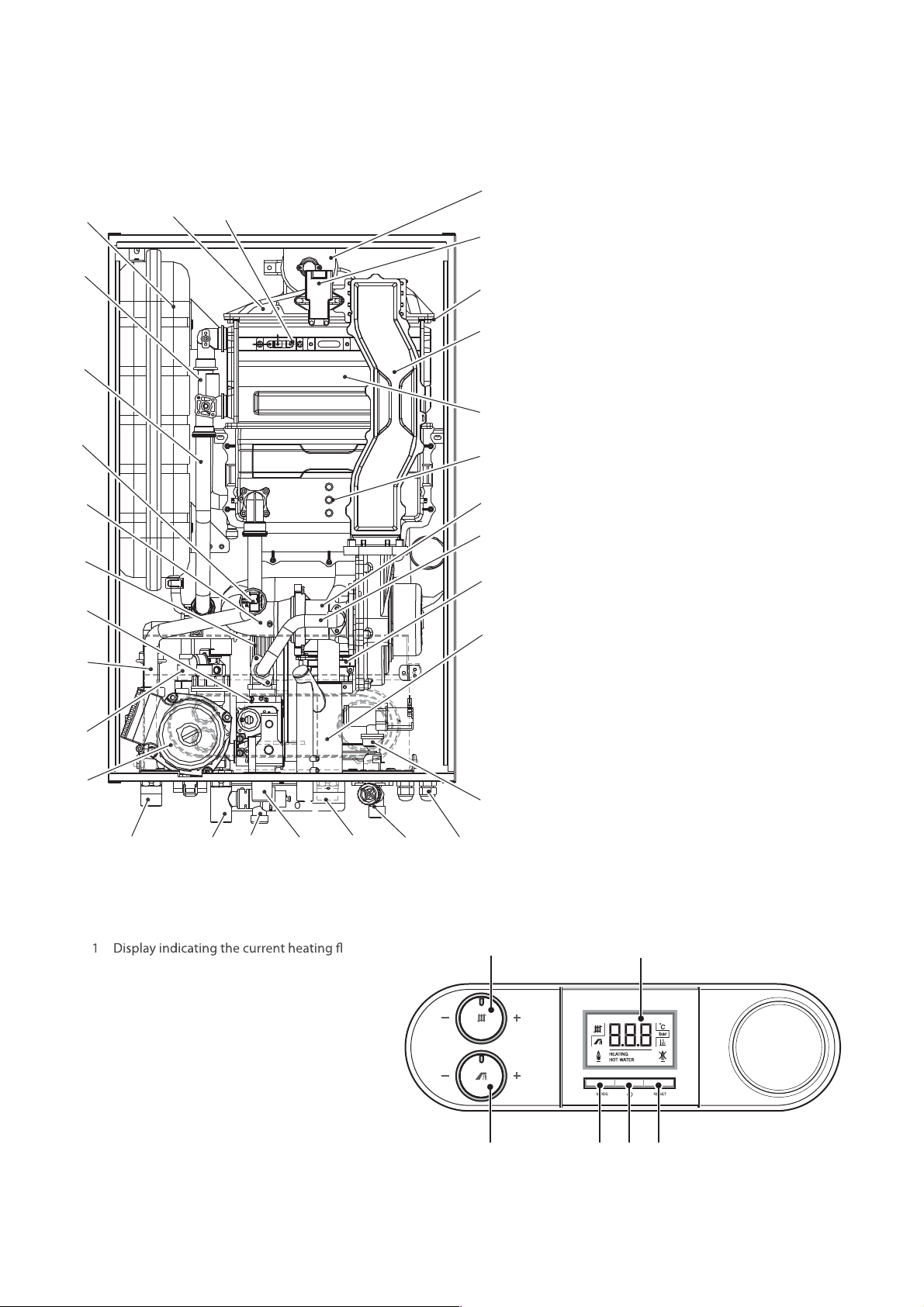

Layout and Key Components2.2

27

1

2

3

4

5

6

7

8

9

29

30

28

12

26

25

24

23

22

21

20

1 Expansion vessel

2 Heat exchanger & latent heat exchanger pipe

3 Heat exchanger outlet

4 Water pressure sensor

5 Air inlet

6 DHW

7 Gas control valve

8 Heat exchanger inlet

9 Magnetic Filter

10 Circulation pump

11 Flow

12 burner

13 Return

14 Pressure Relief

15 Gas Inlet

16 DHW outlet

17 Mains Water In

18 Cable Entry

19 DHW Flow

20 Condensate Syphon

21 Air Pressure Sensor

22 Gas

23 Gas/Air Mix

24 Latent Heat

25 Primary Heat

26 Mixing Flow

27 Exhaust

28 Electronic Ignition

29 Burner Mixing

30 Ignition

10

11

13

14

Control Panel2.3

temperature, the pressure in the heating

system, the operating mode and additional

functions.

2 CH temperature control knob

3 DHW temperature control knob

4 [MODE] button

5 [main ON/OFF] button

6 [RESET ] button

15

ow

16

17

19

18

12

3 654

EHC

7Product Description

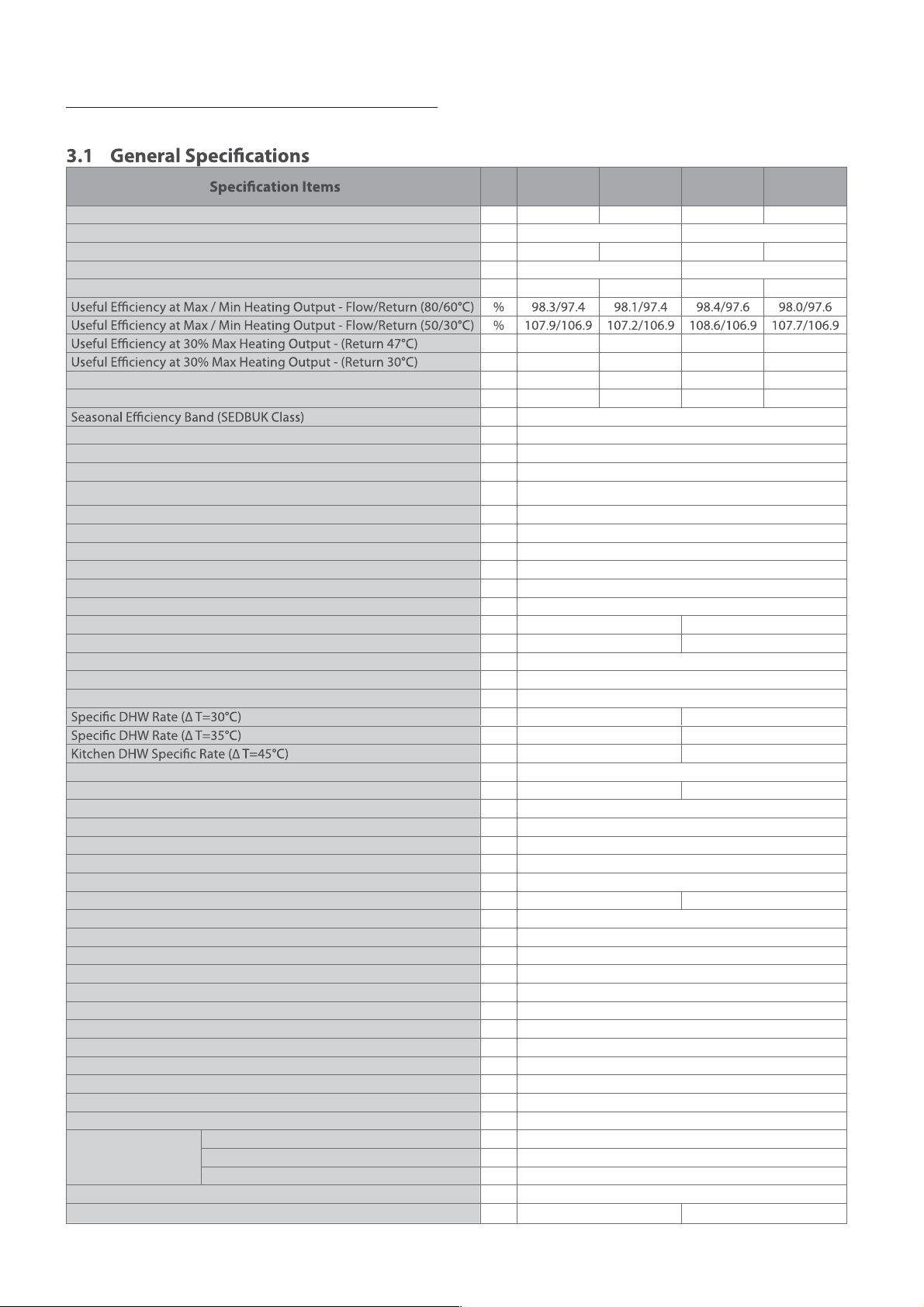

Technical Data3.

Unit

Heat Input (Max/Min) kW 19.6/4.9 23.5/4.9 30.0/7.0 34.9/7.0

Domestic Hot Water Input (Max/Min) kW 23.5/4.9 34.9/7.0

Heating Output (Max/Min) - Flow/Return (50/30°C) kW 19.3/4.8 23.1/4.8 29.5/6.8 34.2/6.8

Domestic Hot Water Output (Max/Min) kW 23.1/4.8 34.2/6.8

Condensing Heating Output (Max/Min) - Flow/Return (50/30°C) kW 21.1/5.2 25.2/5.2 32.6/7.5 37.6/7.5

Heat Loss through the Case with Burner On % 0.1 0.1 0.1 0.1

Heat Loss through the Chimney with Burner On % 1.6 1.8 1.5 1.9

NOx Class 5

Category II2H3P

Purpose Heating and Domestic Hot Water Production

Heating Adjustability Range Rated

Heating Water Circulation Method Air Close Type

Max Heating Water Pressure bar 3

Max Heating Temperature °C 85

Adjustable Temperature Heating Setting °C 30 - 85

Total Volume Expansion Vessel L 6.5

Expansion Vessel Pre-charge bar 1

DHW Output kW 23.1 - 4.8 34.2 - 6.8

Min. Dynamic DHW Pressure bar 0.3

Min. DHW Flow Rate l/min 2.5

Max. DHW Pressure bar 10

Adjustable DHW Temperature °C 30 - 65

l/min 11.7 17.6

l/min 10.0 15.1

l/min 7.8 11.7

Electrical Supply V/Hz 230 / 50

Nominal Absorption A 0.6 0.62

Power Consumption W 130

Electrical Protection IPX5D

Installation Type Wall Mounting Type

Intake/Exhaust Flue System Type B23-B33-B53-C13-C33-C43-C53-C63-C83

Intake/Exhaust Flue Diameter mm Concentric 60/100 – Separate 80/80

Max. Flue System Resistance Pa 167 294

Max. Horizontal Coaxial Ø60/100 Flue length (EHC System) m 20

Max. Vertical Coaxial Ø60/100 Flue length (EHC System) m 21

Equivalent Length of Ø60/100 Bend 90° m 1.3

Equivalent Length of Ø60/100 Bend 45° m 1

Max. Horizontal Coaxial Ø80/125 Flue length (EHC System) m 68

Max. Vertical Coaxial Ø80/125 Flue length (EHC System) m 70

Equivalent Length of Ø80/125 Bend 90° m 2.2

Equivalent Length of Ø80/125 Bend 45° m 1

Equivalent Length of Ø60/100 => Ø80/125 Adapter m 0.5

Max. Horizontal Separate Ø80-Ø80 Flue length (EHC System) m 110

Equivalent Length of Ø80 Bend 90° m 2.2

Equivalent Length of Ø80 Bend 45° m 1.4

Heating Water Connection mm 22

Connecting Diameter Domestic Hot and cold Water Connection mm 15

Gas Inlet Connection mm 22

Physical dimensions (Width × Depth × Height) mm 440 × 370 × 695

Technical Data

8

Ecosave

21K(A)

% 100.7 101.6 101.8 101.9

% 109.6 108.4 108.4 108.3

gkWeight 35 38

Ecosave

25K(A)

A

Ecosave

32K(A)

Ecosave

37K(A)

0.5

EHC

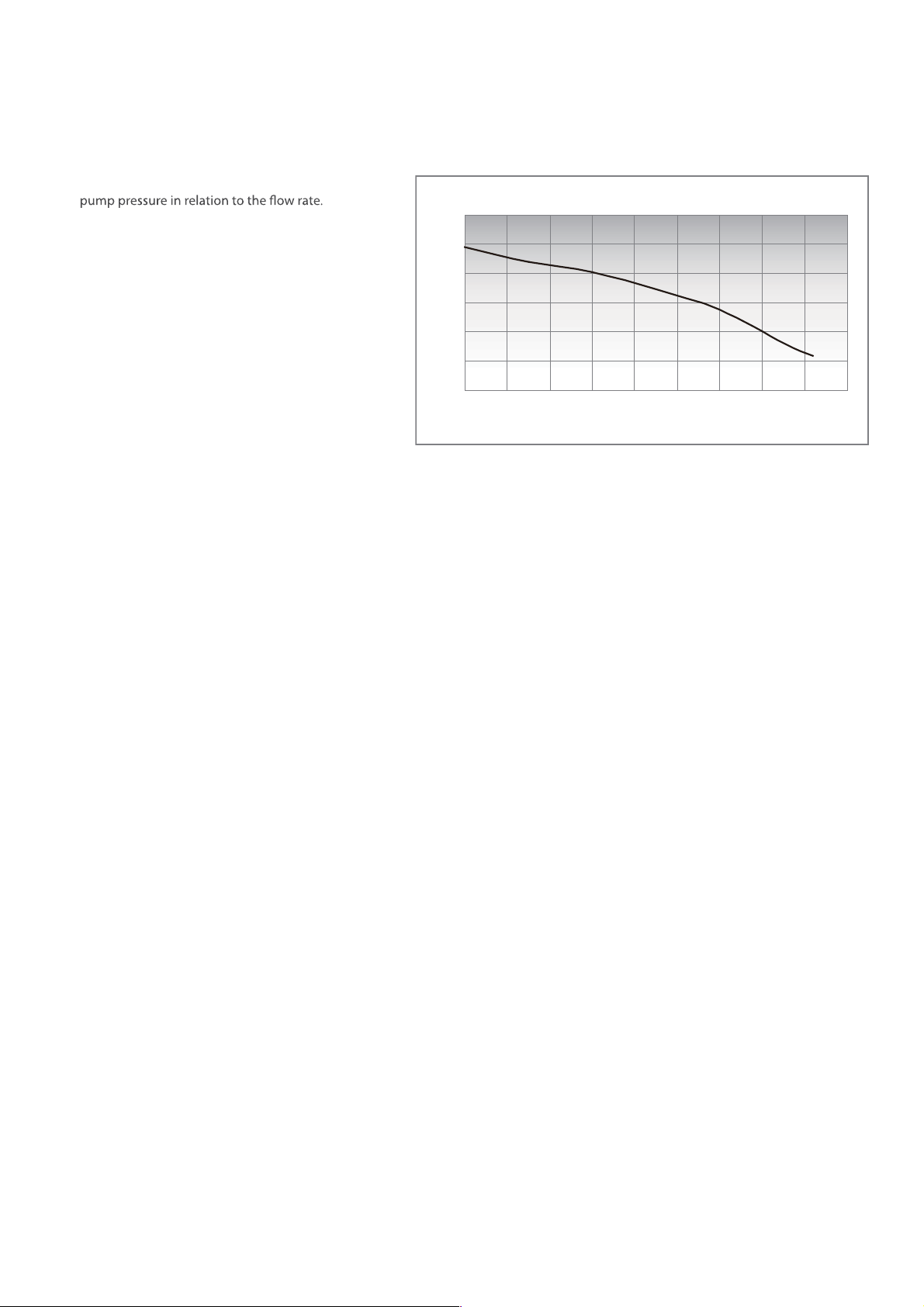

Hydraulic Data3.2

The following graph shows the development of the

Available Head Pump to the System

600

500

400

300

Head (mbar)

200

100

0

0 200 400 600 800 1000 1200 1400 1600 1800

Heating Flow Rate(l/h)

EHC

9Technical Data

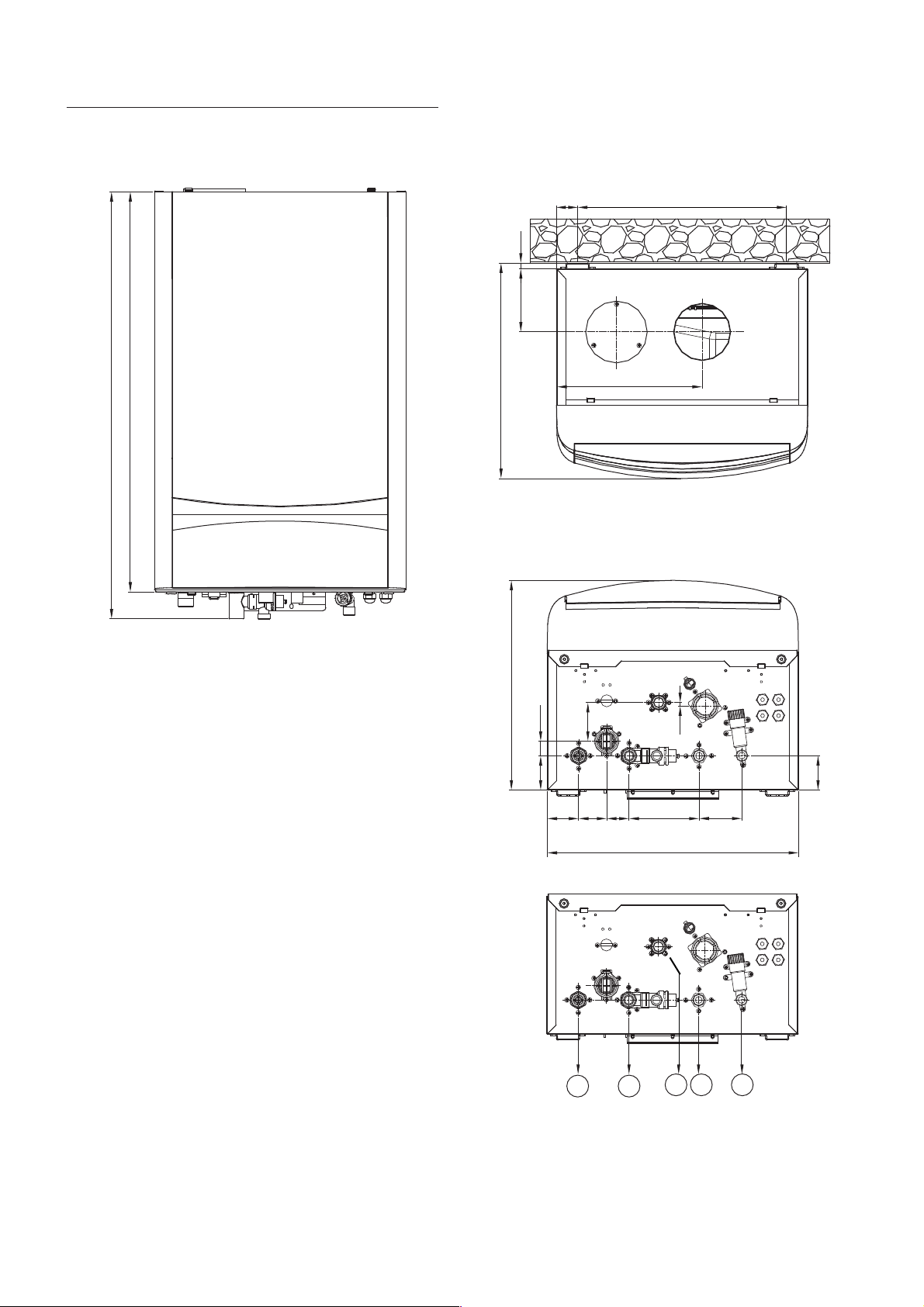

Dimensions4.

698.8

745.7

Front view

110.4

376.3

10

Overhead view

37

255

Bottom view

366

All dimensions in mm

366.3

67.5

25.5

60

49.2

55

39.1

ABC E

6.1

122.5

440

D

60.4

75

10

Dimensions

A: Heating outlet 22mm

B: Heating inlet 22mm

C: Gas inlet 22mm

D: DHW outlet 15mm

E: Main water inlet 15mm

EHC

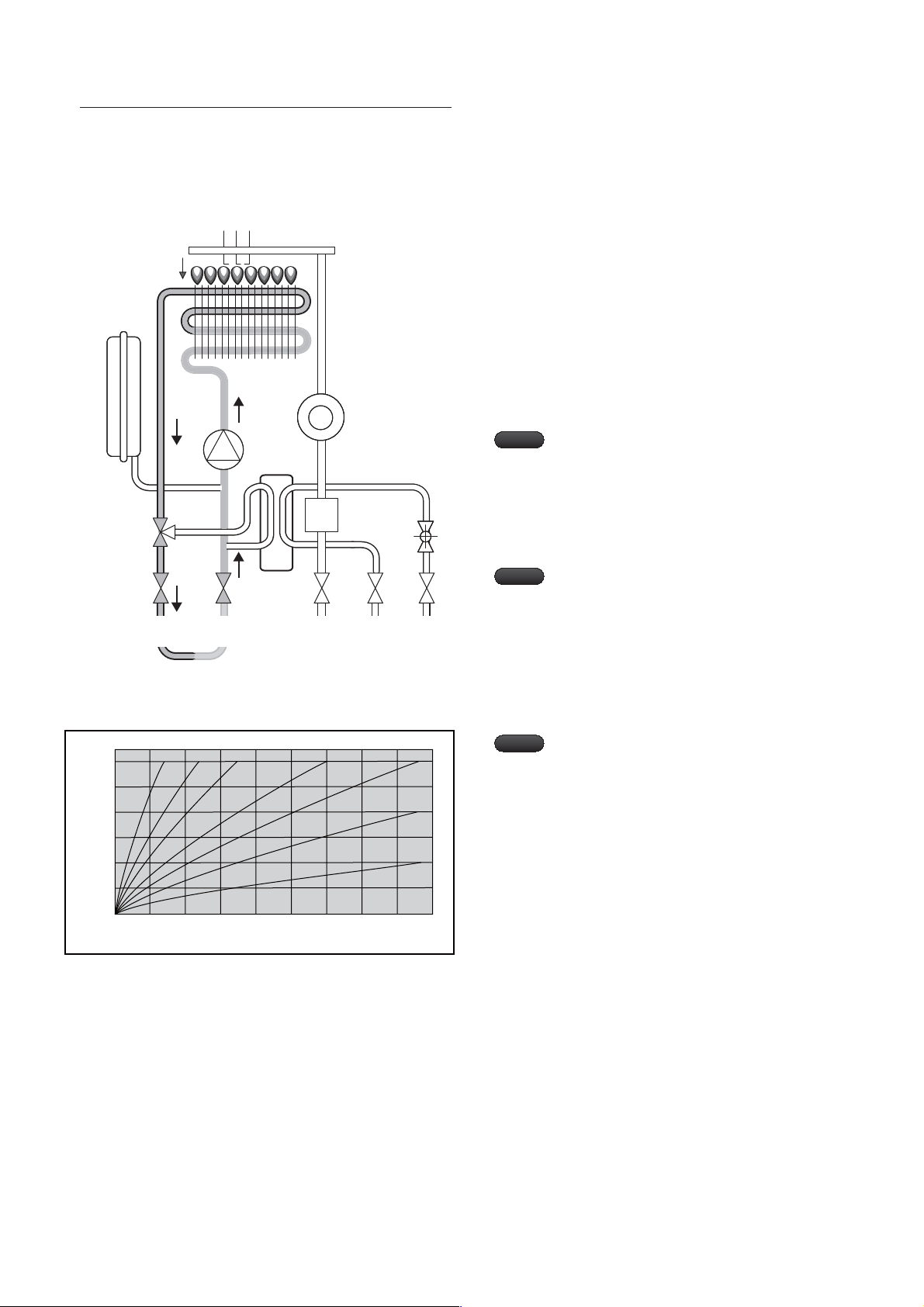

System Details5.

Operation Modes5.1

Circuit for CH (central heating) mode

Expansion

Vessel

Three-way

Valve

Ignition

Electrode

CH

Flow

CH

Return

Flame Sensing

Electrode

Heat

Exchanger

Circulation

Pump

Metal Fibre

Burner

Mixing Flow

Guide

Gas

Inlet

Blow Fan

Gas Valve

When central heating is in demand, the three-way valve1.

is set to CH mode position.

When the burner has ignited and the flame is detected,2.

the control starts heating up the CH water to the set

temperature. This control regulates the gas input rate by

changing the fan speed.

The pump runs from 0 to 600 seconds depending on the

3.

set temperature.

Note

Low water pressure error

cancelling function

If the water pressure falls below 0.4 bar, the low

water pressure error occurs on the control panel.

In this event re-pressurise the boiler to 1.5 bar

Note

The minimum operating

pressure can be adjusted in the

service menu.

80.0

70.0

60.0

50.0

40.0

30.0

Target primary temperature

20.0

20

15 10 5 0 -5 -10 -15 -20 -25

Outdoor Temperature (°C)

Relationship between primary and outdoor

K=1.5K=6 K=4 K=3 K=2

K=1

K=0.5

temperature: K-factor

Note

Weather Compensation

If an outdoor temperature probe is connected,

the weather compensation function can be used.

With this function, the target primary temperature

is automatically set according to the outdoor

temperature (K-factor).

Note - The control panel enables you to adjust

the parameters by resetting the K-factor.

EHC

11System Details

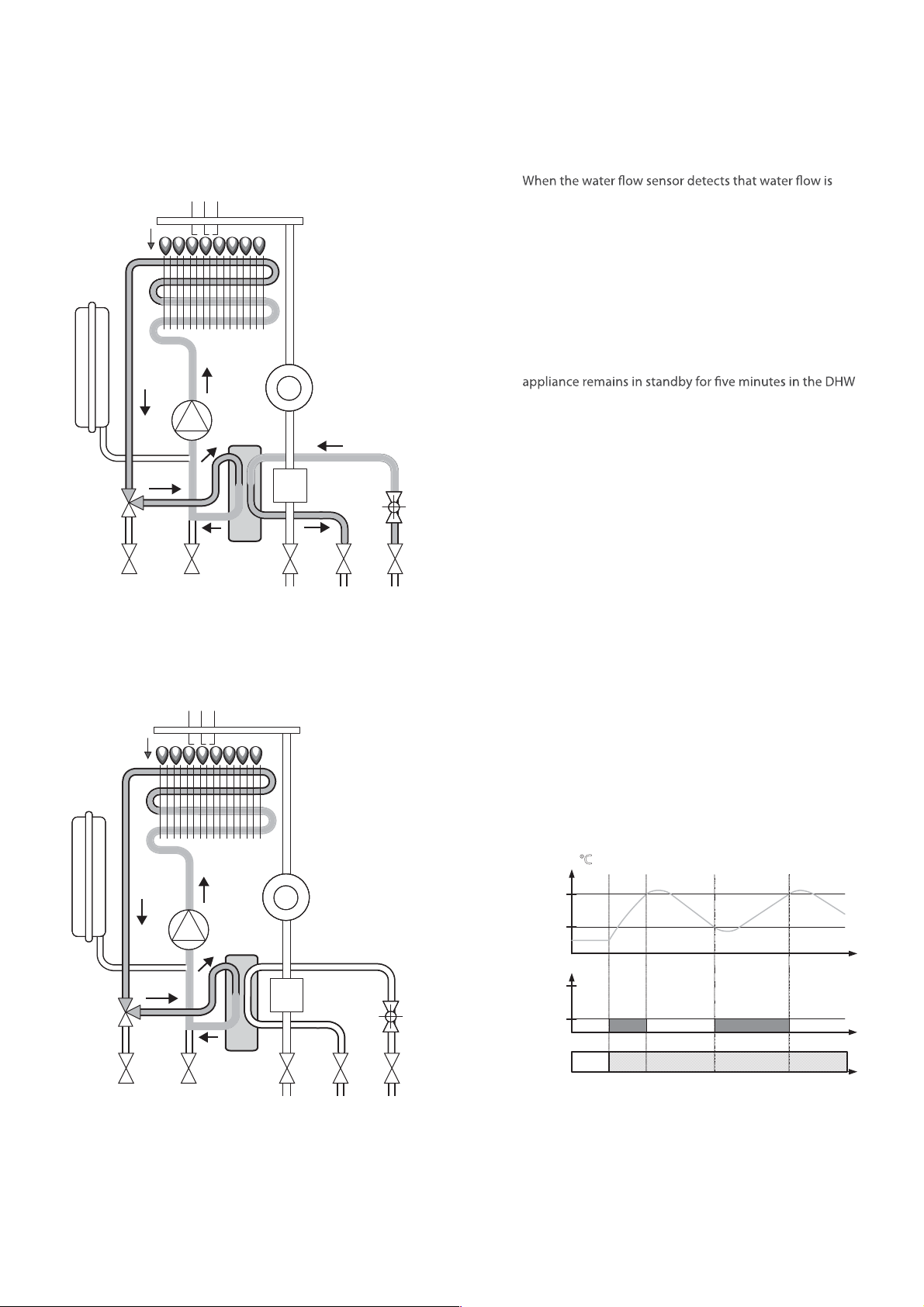

Circuit for DHW (Domestic Hot Water) mode

Expansion

Vessel

Ignition

Electrode

Flame Sensing

Electrode

Heat

Exchanger

Circulation

Pump

Metal Fibre

Burner

Mixing Flow

Guide

Blow Fan

1.

in demand by a tap or shower, the three-way valve

is set to DHW mode position as priority is given to the

DHW mode.

The primary water circulates through the DHW Heat 2.

Exchanger, and the water coming from the inlet is

heated.

The heating control function controls the burner until the 3.

DHW reaches the set temperature.

After DHW is used, the burner is extinguished and the 4.

three-way valve remains in the DHW mode position. The

mode.

When CH is demanded, the position of the three-way 5.

valve is changed to the CH mode position, and the system

returns to the CH mode.

Three-way

Valve

DHW Pre-heating mode

Ignition

Electrode

Expansion

Vessel

Heat

Exchanger

Three-way

Valve

DHW Heat

Exchanger

Flame Sensing

Electrode

Circulation

Pump

DHW Heat

Exchanger

Gas Valve

Gas

Inlet

Metal Fibre

Burner

Mixing Flow

Guide

Blow Fan

Gas Valve

DHW Water

outlet Inlet

Water

Flow

Sensor

If the CH mode is not used and the service setting for the DHW

pre-heating mode is set to ON, the DHW pre-heating mode

can be used.

The primary water circulates through the DHW Heat 1.

Exchanger. This pre-heats the unit in preparation for

DHW demand.

The burner is ON or OFF depending on the return 2.

temperature so that the set temperature is maintained.

Return Temp (°C)

Toff

Ton

Burner operation

MAX

MIN

DHW

pre-heating

mode

ONOFF

Time

System Details

12

Gas

Inlet

EHC

Installation Requirements6.

Safety Functions5.2

Frost Protection

In CH, DHW, and Weather Compensation modes, frost protection

is an integral function for protecting the appliance. This function

is the highest priority among the operation modes and this

There are two kinds of processes depending on the primary

water temperature.

6 -10°C

If the primary water temperature falls below 10°C, the control

system runs the pump for 10 minutes and stops the pump for

1 minute. This process is continued while the primary water

temperature is in the above mentioned range.

Below 6°C

The appliance ignites the burner in the CH mode until the

primary water temperature reaches 21°C.

High Temperature Protection (HTP)

In stand-by and while the burner is operating, if the High

pump and the fan start in order to reduce the temperature of

the appliance. The pump and the fan continue to run in the CH

mode until the primary water temperature falls below 80°C.

While the burner is operating, the safety shut-down process

takes place. At this point the pump and the fan re-start.

Actuator Protection

If the appliance is not operated for 24 hours, the fan and pump

automatically operate for 30 seconds to prevent seizing.

Location6.1

DANGER

The appliance must be tted to a suitable wall to prevent re

and explosion. At the installation site, the ue that passes

through the outside wall or roof must be routed properly

in order to satisfactorily remove flue products. Also, an

adequate air supply must be provided, and combustible

products need to be removed.

Do not t the appliance near paper, newspapers, magazines,

or any other combustible objects.

Do not t the appliance where rubbish is located.

WARNING

If the appliance is tted in a room with high humidity (e.g.

a room containing a bath or a shower), the appliance and

any electrical switch or appliance controller, etc. should

be situated specically in accordance with the current IEE

Wiring Regulations and Building Regulations.

If the appliance is tted into a building made of timber

frames, refer to the latest edition of the Institute of Gas

Engineers Publication IGE/UP/7 (Gas Installations in Timber

Framed Housing) or British Gas Document DM2 and DM3.

The appliance should not be ftted in the building unless it is

protected by an appropriate enclosure, such as a garage or

outbuilding. (The appliance may be tted inside a cupboard).

For other unusual locations, refer to BS 6798:2000 for

detailed guidance.

Note

Fit the appliance at an appropriate height.

Air Flow Checking

During the start-up sequence, the “no air check” function

supply.

EHC

13Installation Requirements

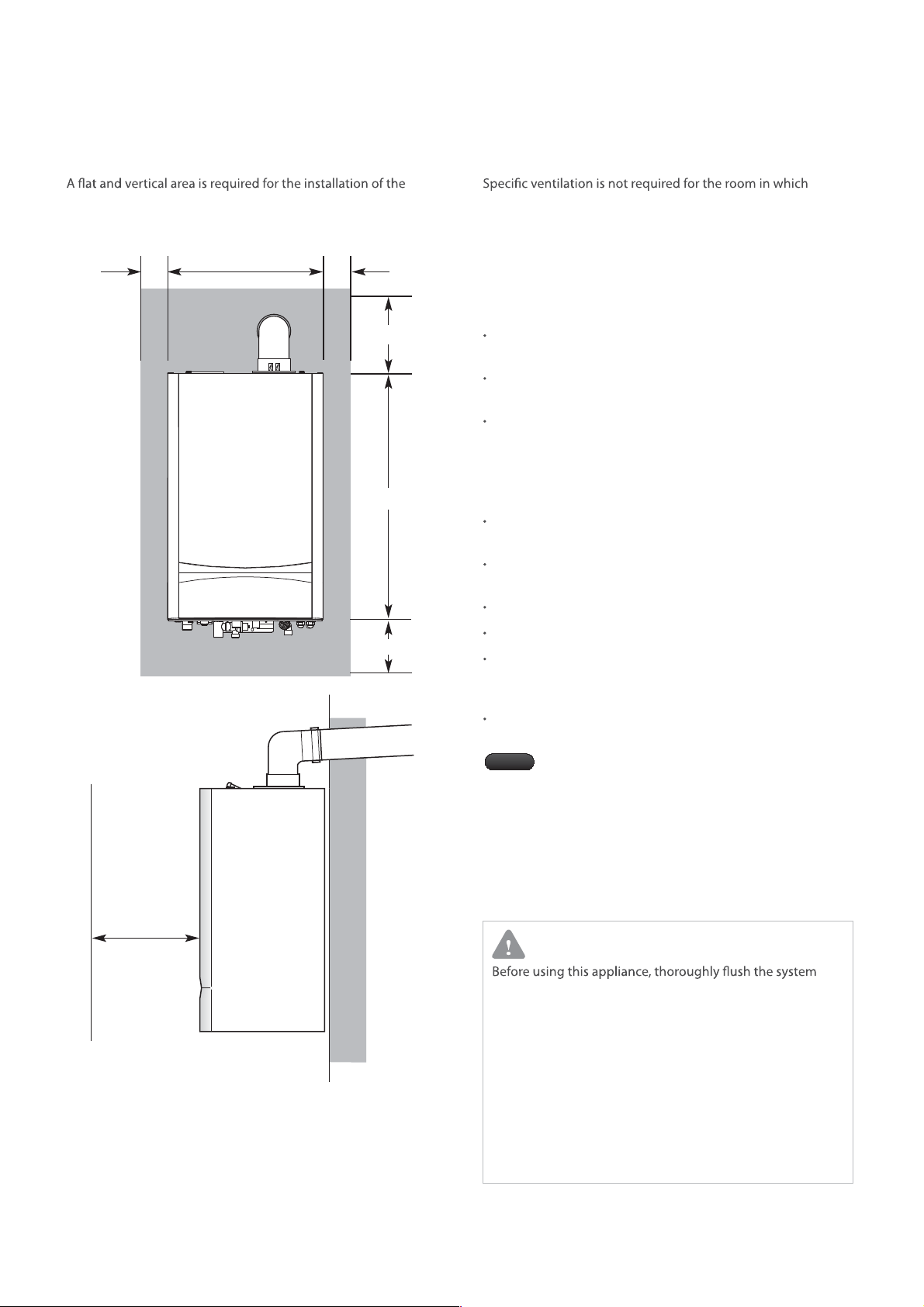

Required Minimum Clearances6.2

Ventilation6.3

appliance. The following minimum clearances (mm) must be

maintained for installing and servicing.

5 mm

440 mm

5 mm

250 mm

698.8 mm

200 mm

the appliance is installed. If it is installed in a cupboard or

compartment, permanent ventilation for cooling purposes is

not required. Detailed recommendations are given in BS 5440

Part 2.

Gas Supply6.4

Gas installation must comply with the requirements in BS

6891.

Check for leaks at every joint as described in BS 6891 to

check the soundness.

Ensure that the pipe sizes, including the ones for other gas

appliances on the same supply, are adequate for demand.

Electrical Supply6.5

Main supply : 230 V~/50 Hz with 3 Amp fuse certied BSI or

VDE.

Cable : PVC insulated 0.75 mm

rated to 90°C.

The appliance must be earthed.

All pipes to the appliance must be cross-bonded.

Wiring must comply with IEE Wiring Regulations and any

local regulations which may apply to a xed wired

stationary appliance.

External wiring must be correctly earthed, polarized and

must comply with related regulations/rules.

Note

The way the electricity supply is connected must

facilitate the complete electrical isolation of the

appliance. It may be connected via a fused doublepole isolator with a contact separation of at least

3 mm for all the poles for servicing the appliance

and system controls only.

2

(24 × 0.2 mm) temperature

600 mm min

Case

Removal

Purposes

These dimensions include the necessary clearances around the

appliance for case removal, spanner access and air movement.

Additional clearances may be required for the passage of pipes

around local obstructions.

Installation Requirements

14

Water Supply6.6

CAUTION

(ensure the appliance is not connected) to remove any sediment

and prevent the heat exchanger from being damaged by

build-up or corrosion due to any sediment.

Do not use petroleum-based cleaning and seals because

the system may be damaged and may result in substantial

property loss.

Immediately repair leaks in the appliance or piping in order

to prevent the build-up of mineral and corrosion in system

components due to the continuous water make up.

The build-up of minerals and corrosion will reduce the life

of the appliance.

EHC

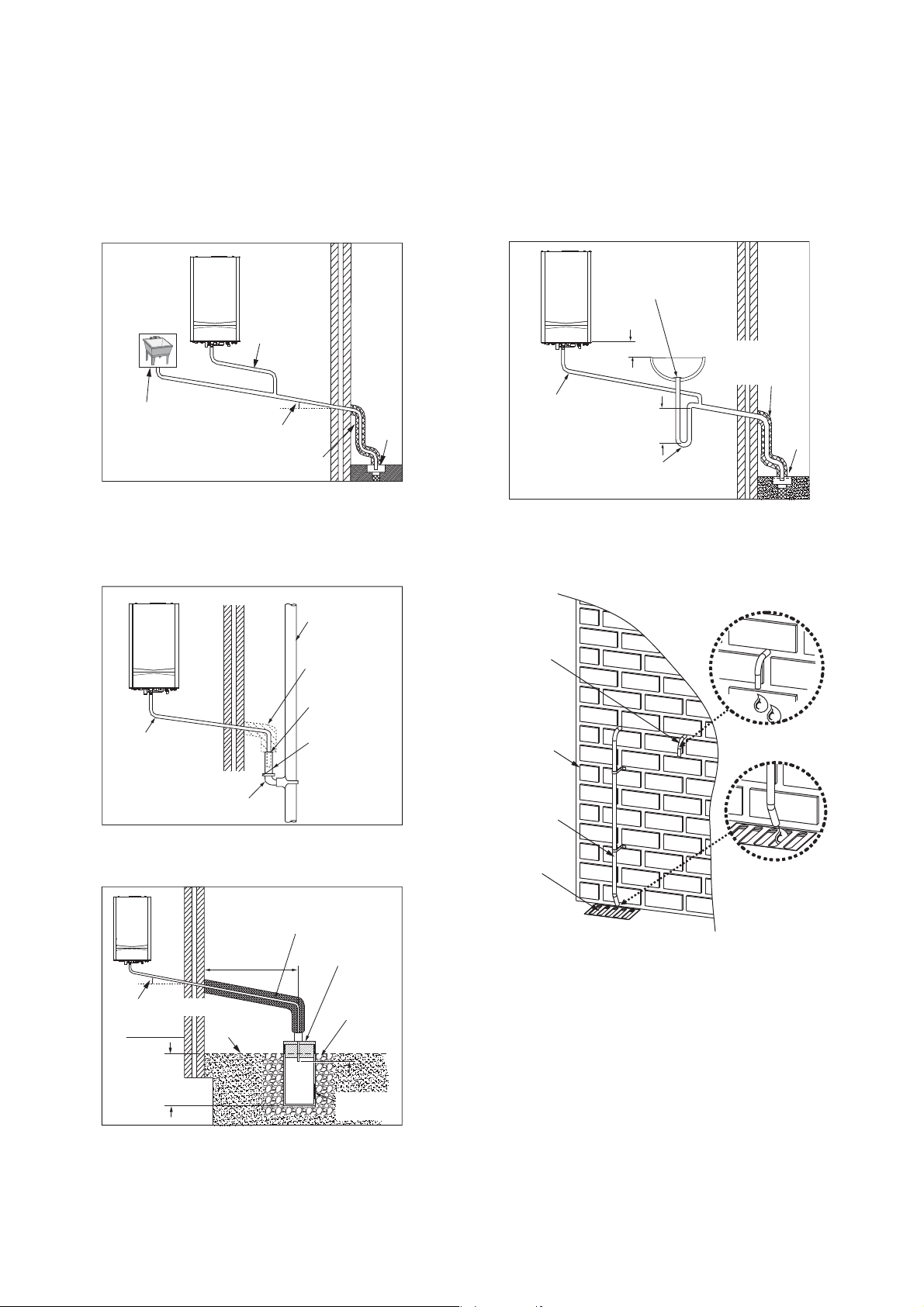

Condensate Drain6.7

General instructions

Important

Note

This appliance is a high eciency gas appliance that

creates condensate when operating. The condensate must

be discharged in accordance with any national or local

regulations in force since the condensate has an acidity (pH)

of approximately 3 - 4 (BS 6798:2000 & Part H1 of the Building

Regulations give further guidance).

A condensate trap is built into the appliance as standard.

Options for the condensate drain (see the gures on the

next page).

From the appliance to the drain/gully via a sink waste1.

(the bottom of the appliance must be above the top of the

sink and must be downward-sloping to properly discharge

condensate)

From the appliance to the internal soil and vent stack2.

From the appliance to a soakaway hole surrounded by 3.

limestone chipping

From the a4.

Of the above options, EHC recommends option 1 as the soap

from the sink neutralizes the acidic condensate.

If a sink waste is not abilable, EHC recommends options 2, 3, or

4. If permitted by local regulations, the condensate may

be drained directly into the drain/gully.

Note

If a soakaway hole is installed, periodical

replacement of the limestone chipping (or

neutralizing agent) is required. The rate of depletion

of the limestone varies depending on the usage

of the appliance. Occasionally check the depletion

of the neutralizer, and replace the limestone if any

depletion is observed.

The condensate must be drained from the

appliance in accordance with applicable

rules and regulations.

Reliable operation of the appliance will

be afected by an improperly connected

condensate piping.

The condensate pipe must retain a

downward slope of at least 2.5 degrees

throughout.

ppliance to the drain/gully

CAUTION

Requirements for the condensate piping are as follows.

So that condensate can be properly drained the t

diameter of the plastic piping should be a minimum of

22 mm.

The condensate pipe should be made of a non-corrosive t

material, such as PVC, PVC-U, ABS, PVC-C or PP. Metal

materials are NOT suitable.

For safety reasons the ends of the pipes should extend t

as close as possible to the ground or drain/gully.

To reduced the risk of the condensate becoming trapped

as few elbows and fttings as possible should be used.

When draining the condensate into an internal soil and t

vent stack, the plumbing eect must be considered.

If the pipes are easily aected by internal pressure

uctuations, when WC's are ushed or sinks are emptied,

back-pressure may force water out of the appliance trap

and a lockout may occur.

The length of the external pipework should be kept to t

a minimum and routed as vertically as possible. Where

the pipework is subjected to extreme cold or windchill,

weatherproof insulation should be used. If insulation is

not used then the condensate pipework should have a

minimum diameter of 32 mm.

For 22 mm diameter condensate drainage pipe, the t

maximum length is 3 metres.

If the appliance is tted in an unheated location, the t

entire pipe system should be treated as an external run.

In order to prevent sagging, any external runs need to t

be propped up with supporting clips.

EHC

15Installation Requirements

Examples of available options for

condensate drain

1. From the appliance to the drain/gully via a sink

22 mm plastic

condensate

pipe

sink

2.5º minimum drop

Frost proof insulation

(if necessary)

The end of the pipe must be above water level

*

but below the surrounding surface.

2. From the appliance to the external rain water pipe into

foul water

External rain water

pipe into foul water

Internal soil

and vent stack

Drain/Gully

4. From the appliance to the gully

Visible air break

at pulg hole

Sink with

integral

100mm

overow

22 mm plastic

condensate pipe

75 mm

min.

75 mm sink

waste trap

The end of the pipe must be above water level

*

but below the surrounding surface.

Condensate drain termination

PRV

Frost proof

insulation

(if necessary)

Drain/Gully

Extarnal air break

22 mm plastic

condensate pipe

running through

the external wall

43 mm 90°

M &F bend

3. From the appliance to a soakaway hole surrounded by

limestone chipping

22 mm plastic condensate

drainage pipe, max extarnal

length 3 metres

500 mm min.

2.5º minimum drop

Hole depth

400 mm min.

(by 300 mmΦ)

Holes in the soakaway must face away from the

*

building.

Ground

level

Air gap

68 mmΦ PVC-u

strap on fitting

100 mm Φmin.

sealed plastic tube

Limestone

chippings

25 mm

Drainage

holes

Outside wall

Condensate

pipe

External

drain

Installation Requirements

16

EHC

8.6eulF

The minimum distances between the terminals and elements of

the building are as per the following.

A

G

BCD

F

J

H, I

A

A

A

E

G

L

K

N

L

K

Use of terminal guards needs to be considered.

Description

A

From openings (e.g. doors, windows, ventilation tiles)

B

Below gullies, down-pipes, or drain pipes

C

Below gutters

D

Below balconies

E

From down pipes

F

From external and internal corners

G

Above the ground, a roof or balconies

From the opposite wall of a carport (when another

H

ue is not installed)

From a terminal, that is facing the terminal, on the

I

opposite wall of a carport

Next to openings (e.g. doors, windows) within a

J

carport

K

Vertically away from a terminal on the same wall

L

Horizontally away from a terminal on the same wall

M

From an adjacent vertical ue pipe

N

From openings in a directly opposing building

*1 The terminal should not be located within 15 cm from openings

in the building material made for a built-in object (e.g. window

frame)

*2 This length is according to BS 5440-1.

CAUTION

Terminal guards must be provided for any terminals which are

located less than 2 metres above a balcony, above a at roof, or

above ground which people can access.

B

F

M

G

F

F

Minimum

Distance

(cm)

30(*1)

7.5

20

20

2.5

30

30

60

120

120

150

30

50

200(*2)

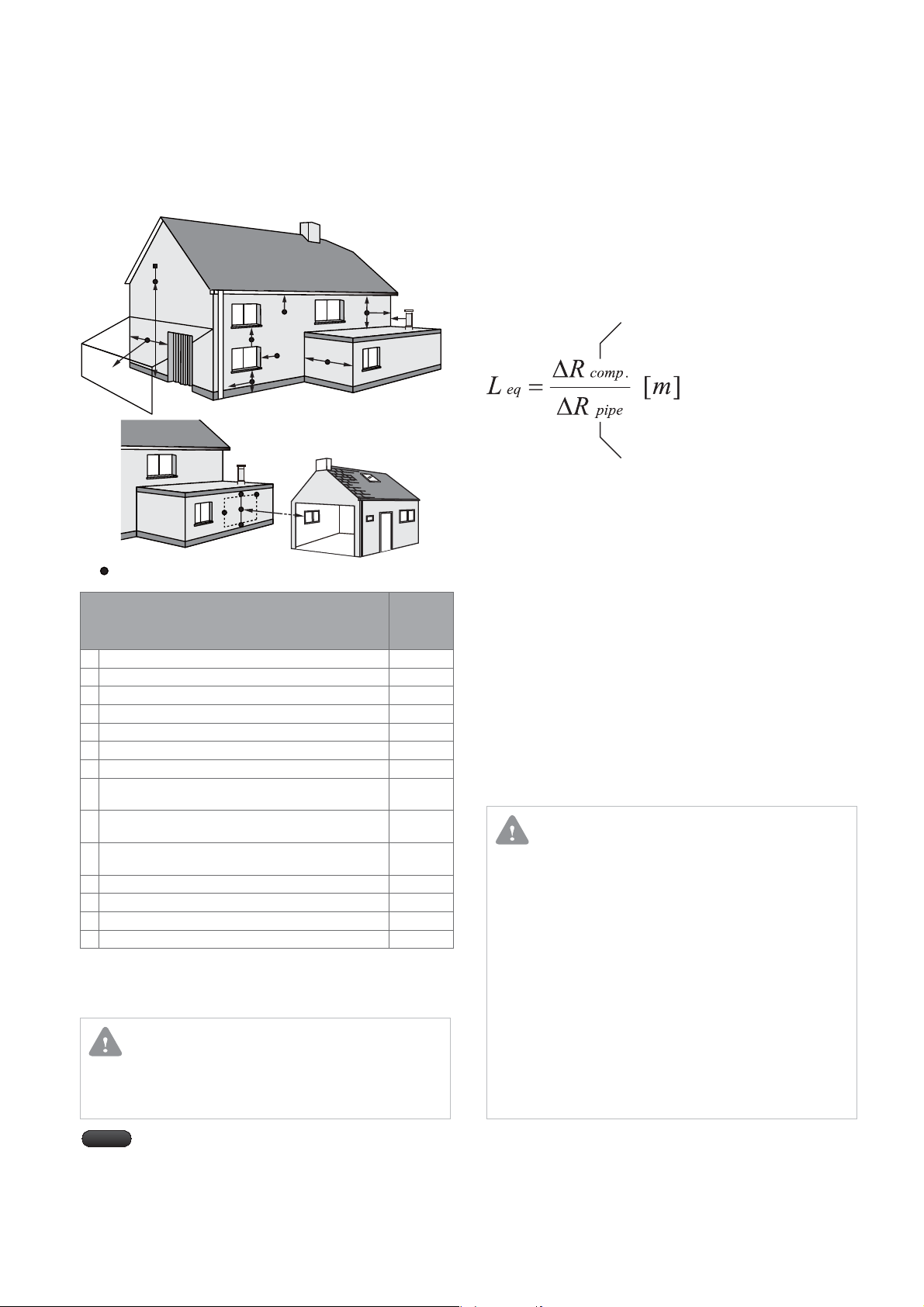

Formula of Length Equivalency

This is the formula for sizing the pipes for the intake of the

combustible air and the discharge of the combustion products.

The Length equivalency (L eq) in these instructions are for the

lengths of the pipes which share the same cross-sectional

dimensions.

Resistance of the component

under standard condition

Resistance of a 1-metre-long pipe

(with pre-established diameter)

under standard condition

Standard conditions are experimental values for the

capacities, fume temperature and air temperature for various

thermal power values. They represent dierent operating

conditions.

Example of coaxial system calculations

Planning the system run.1.

Measuring the length of the system run.2.

Determining the values of the length equivalency for all 3.

components.

Calculating the value of the total length.4.

Comparing the values with the maximum permissible 5.

length.

CAUTION

The wall on which the intake/exhaust ue is set must be

made of incombustible interior materials and must connect

to the outside. Dangerous materials or obstructions must

not be near the intake/exhaust ue.

The exhaust ue should be covered with over 20 mm of

incombustible material when it passes through a wall made

of combustible material and must be kept at least 50 mm

away from any combustible materials.

Connection parts of the exhaust ue must be properly

connected by proper sealing gasket. Check for any exhaust

gas leaks.

Before cleaning the intake/exhaust ue, turn o the

appliance and wait until the pipes have cooled down.

Safeguard the ue terminals from snow buildup.

Note

EHC

For vertical ue pipes, the terminal must not be t

within 60 cm of any openings

17Installation Requirements

Flue Options7.

Calculating the Overall Length of the 7.1

Flue System

These ue systems may be oriented in all the various directions

of the compass, north, south, west and east. Some special

components such as concentric bends are used so that

certain positions can be reached. Each concentric ue system

kit includes an adapter, which allows the appliance to be

connected to the ue system.

However, the total ue length cannot exceed the prescribed

maximum ue length. If concentric bends are required, please

bear in mind that each of them has resistance that corresponds

to its specic linear length.

There are 2 separate connections (horizontal and vertical) for

the concentric ue system and separate ue system.

Study the following connection depictions to determine which

ue system is the most suitable.

Maximum Flue Length

Concentric

Flue

System

Separate

Flue

System

Diameter of

Pipe [mm]

Φ 60/100

Φ 80/125

Φ 80/80

Orientation

Horizontal 20

Vertical 21

Horizontal 68

Vertical 70

Horizontal

Vertical

Maximum Flue

Length [m]

110

Fitting the Concentric Flue System7.2

Concentric Horizontal Flue

a) Standard ue system (Φ 60/100 mm)

”A” is the combined length of the ue outlet/

ventilation pipe maximum 20 m.

A

B 500 or 1,000

851

“B” is the ue outlet/ventilation pipe

(can be shortened as necessary).

Standard ue system: A = 20 m

b) Extended ue system (Φ 60/100 mm)

140 min

Wall

Reduced Flue Length

Diameter of

Pipe [mm]

Φ 60/100 - >

Φ 80/125

Concentric

Flue

System

Separate

Flue

System

Note

Φ 60/100

Φ 80/125

Φ 80/80

The adapter for Φ 60/100 mm ues or Φ 80/125 mm

ues is 0.5 m.

Angle

- 0.5

45° 1.0

90° 1.3

45° 1.0

90° 2.2

45° 1.4

90° 2.2

Reduced Flue

Length [m]

B

A

Total ue length: A + B – (1 x 90° elbow)

= 20 – 1.3 =18.7 m

18

Flue Options

EHC

Concentric Vertical Flue

A

B

Standard ue system : A = 21 m

Φ 60/100 mm)

b) Extended vertical ue system (Φ 60/100 mm)

A

Minimum 350 mm

B

Total ue length :

A + B – (2 x 45° elbow) = 21 – 2 x 1 = 19.0 m

Diameter of

Pipe [mm]

Φ 60/100

Φ 80/125 70

Grey coloured numbers are used in the calculation of

this sample.

Max Flue

Length [m]

21

(a/b)

Reduced Flue

Length [m]

45°

90° 1.3

45° 1.0

90° 2.2

1.0

(b)

EHC

19Flue Options

Fitting the Separate Flue System7.3

4

Separate Horizontal Flue

Extended separate horizontal fue system

(Φ 80/80 mm)

D

E

A

Total ue length:

A + B + C + D + E + F – (4 x 90° elbow)

= 110 – 4 x 2.2 = 101.2 m

Diameter of

Pipe [mm]

Φ 80/80

Grey coloured numbers are used in the calculation of this

sample.

B

Max Flue

Length [m]

110

(a/b)

F

C

Reduced Flue Length [m]

45° 1.4(a)

90° 2.2

Separate Vertical Flue

A

Total ue length:

A + B + C + D – (2 x 45° elbow) = 110 – 2 x 1.4 = 107.2 m

Diameter of

Pipe [mm]

Φ 80/80

Grey coloured numbers are used in the calculation of this

sample.

D

C

B

Max Flue

Length [m]

110

(a)

Minimum 350 mm

Reduced Flue Length [m]

2.2

(a)

.

45° 1.4

90°

Flue Options

20

EHC

Installation Procedure8.

*GUIFøVFTBSFOPUöUUFECFGPSFUIFJOTUBMMBUJPOPGUIFBQQMJBODF

Transporting and

Unpacking

section 9.

Mounting the Appliance

on the Wall

section 10.

(BTDPOWFSTJPO

*GOFDFTTBSZ

"QQFOEJY

Making the Gas Connection

section 11.

Fitting the Water Pipes and

Condensate Pipe

section 12.

Fitting the ues

t'JUUJOHUIFDPODFOUSJDøVFTFDUJPO

t'JUUJOHUIFTFQBSBUFøVFTFDUJPO

Connecting the Flue

TFDUJPO

Electrical connections

and Settings

section 14.

Final Check and

Commissioning

section 15.

Instructing the End User

section 16.

EHC

21Installation Procedure

Transporting and Unpacking9.

Transporting the Appliance9.1

CAUTION

The appliance may be damaged if it is not properly transported.

Transport the appliance using the right transportation t

equipment, such as a hand truck with a fastening belt or

special equipment for maneuvering steps.

Protect all parts against impact when they are t

transported.

Observe the transportation markings on the packaging.t

Packaged appliances must always be lifted and carried to

their destination by two people, or you must use a hand

truck or special equipment to transport them to their

destination.

Unpacking and Checking the 9.2

Accessories

Before actually installing, be sure to verify the gas supply, type,

pressure, and the electrical power supply.

Remove the boiler and accessories form the box.1.

Check the accessories inside the box.2.

The appliance is delivered fully assembled. After receiving

the delivery, check if the packaging is intact and all the items

listed below are included.

EHC Gas-Fired Wall Mounted Condensing Combination

Boiler

Wall Mounting Bracket

(including washers and

nuts)

User instructionst

Installation Instructionst

Tapping Screws & Anchors

(4 sets)

Flue Adapter

Condensate Drain Hose

Gas Conversion Kit

Transporting and Unpacking

22

EHC

Mounting the Appliance on the Wall10.

Mount the appliance on the wall using the following procedures.

Mark the installation points for the ues and screws on 1.

130

167

165

Boiler

mounting

plate.

Boiler

NOTE: Boiler will be 20cm higher

than mounting plate

the wall. Ensure that the points are both horizontally and

vertically level.

Make a hole for the ues (minimum diameter 116 mm).2.

Drive the supplied anchor bolts for the bracket into the 3.

marked points (minimum diameter 13 mm).

Fit the wall mounting bracket with the tapping screws and 4.

anchors.

Take great care when applying the boiler to the wall 5.

mounting bracket.

CAUTION

This appliance must always be lifted and carried by two

people.

Hook

EHC

23Mounting the Appliance on the Wall

Making the Gas Connection11.

WARNING

Before completing the gas pipe connection, ensure that

the type of gas is suitable for the appliance. If you use a type

of gas other than the one specied on the data plate on the

lower right corner of the appliance, it may cause incomplete

combustion and result in re or explosive ignition. Ensure

that the gas supplier supplies an adequate supply of gas. The

installation and connection of the gas supply to the boiler

must be in accordance with BS 6891.

When connecting a gas meter to the pipe,t

the gas meter must be connected to the pipe by a gas supplier or contractor only.

an existing meter should be checked to ensure that it is capable of measuring the required gas supply rate.

When tting the gas pipe, t

do not use pipes that are smaller than the boiler gas connection (22 mm).

pipes must be directly connected to the main pipe, they must not be connected to other gas appliances.

Gas Piping Materials11.1

WARNING

Installation pipes should be fitted in accordance with BS6891.

All pipework must be adequately supported.

An isolating gas valve is provided and should be fitted on the

boiler gas inlet. Please wait 10 minutes when lighting from

cold before checking the gas rate at the gas meter.

Gas pressure should be checked after the boiler has operated

for 10 minutes to reach thermal equilibrium.

When using LPG11.2

WARNING

If the boiler is used with LPG it must be connected to a

regulator. Connection and installation must conform to

BS 5482: Pt1 Domestic butane and propane gas burnig

installations.

DANGER

The complete installation must be tested for gas soundness

and purged as described in BS6891 as a gas leak may cause

serious injury or death.

If an appliance using LPG is installed in a room or internal

space below ground one side of the building must be open

to the ground.

Note

The outlet pressure regulated by the governor t

should be in accordance with BSEN-13785.

The diameter of the gas pipes for this unit is 22mm.t

See the specifications in these instructions.

DANGER

When using a gas container, place the container in a cool

shady place away from direct sunlight outdoors and fix the

container properly to prevent it from tipping over.

Othewise an explosion may occur.

Making the Gas Connection

24

EHC

Gas Supply Pipe Installation 11.3

Procedures

Connect the gas supply pipe to the gas inlet adapter 1.

located at the bottom of the appliance.

Check for gas leaks.2.

Valve kit for external connections.3.

Each boiler is supplied with an EHC Valve Kit for each external

connection. Please refer to the installation instructions within

the valve kit packaging.

DANGER

After completing installation, the gas pipes must be checked

for leaks and purged as described in the standards. Gas

leaks may cause an explosion that induces serious harm

or property damage. When purging, open all doors and

windows, and extinguish cigarettes, pipes or any other

naked lights.

EHC

Bottom view

Gas inlet adapter

25Making the Gas Connection

Union

Fitting the Water Pipes and Condensate Pipe12.

WARNING

Do not add anti-freez to the system as this may shortent

the life of the appliance and cause malfunctions.

Tighten the boiler connection valves with care to avoid t

Condensate Drain

Hose

damage.

Before using this appliance, thoroughly flush the system t

(ensure the appliace is not connected) to remove any

sediment and prevent the heat exchanger from being

damaged by build-up or corrosion due to any sediment.

Any contaminants inside the pipes may reduce heating

and hot water efficiency as well as causes malfunctions.

Any exposed pipes must be insulated with insulation t

material because they may freeze during winter. If hot

water cannot be used because the supply water in the

pipes freezes or because the water inside the heating

pipes is insucient, the water cannot be replenished. As a

result, the appliance may not function.

Do not use excessive force to connect the pipes. This t

might damage external parts and cause leaks.

CH ow

CH

return

Under Floor Heating Circuit or

Heating Circuit (Radiator)

Condensate Pipe

Bottom view

Cold Water

Supply

Hot Water Supply

Water Pipes and Condensate Pipe 12.1

Connection Procedures

Connect the water pipe to the water inlet adapter and 1.

DHW outlet adapter located at the bottom of the appliance

which is clearly indicated on the boiler.

Connect the water pipe to the heating supply adapter and 2.

to the heating return adapter that is located at the bottom

of the appliance which is clearly indicated on the boiler.

Connect the condensate drain hose which is clearly indicated3.

on the boiler. See Claus 6.7 Condensate Drain (How to drain

the condensate).

Condensate

Drain cock

Heating supply adapter

26

Heating return adapter

Fitting the Water Pipes and Condensate Pipe

outlet

Water Inlet

adapter

DHW outlet

adapter

EHC

General Pipework Connections12.2

Frost Protection 12.5

Refer to Code of Practice

BS7074:1 Domestic and hot water supply

BS6891 Installation of low pressure gas pipework up to

28mm(R1).

Copper pipework is the prefered material type.

If plastic pipework(barrier pipe) is used a minimum of 600mm

of copper pipe must be used from the boiler connection.

The discharge must not be above a window, entrance or

other pubic access. Consideration must be given to the

possibility that boiling water/steam could discharge from

the pipe.

The end of the pipe should terminate facing down and

towards the wall.

Water Pipe Size and Water Pressure12.3

The connection diameter of the cold water supply pipes for this

appliance is 15mm

To use the unit, the inlet pressure must be more than 0.5 bar

A water pressure of more than 1.0 bar is needed to supply

hot water to the second foor.

If the appliance is connected to a system that is potentially

frozen isolate the boiler's water and power supply.

The frost protection is an integral function to protect the appliance

in CH, DHW and OTC mode. This function has the highest priority

among the operation modes and this function works even if the

The Energy Saving 2 staged Frost Protection system protects both

inside the unit automatically operates to circulate water when the

water temperature for the heating falls below 10 *C. In the second

stage the boiler operates the burner when the temperature falls

below 6 *C.

All exposed pipework should be insulated to meet current standards.

When the boiler will not be used for long periods please observe

the following.

completely drain the water from the appliance to prevent

freezing.

isolate gas supply valve,

-

isolate the electrical supply.

-

If the appliance is installed in an extremely cold location, take

necessary measures, such as covering the exposed pipes and

electrics with insulation material.

Pressure Relief Valve12.4

The pressure relief valve is set at 3 bar, therefore all pipe

work, fttings, etc. should be suitable for pressures over 3 bar

and temperature in excess of 100°C.

The pressure relife valve should be connected to 15 mm copper

pipe. It should run continuously downward, and discharge

outside the building preferably over drains.

in such a manner that no hazard occurs to occupants or causes

damage to wiring or electrical components. The end of the pipe

should terminate facing down and towards the wall.

The discharge must not be above a window, entrance or other

pubic access. Consideration must be given to the possibility

that boiling water/steam could discharge from the pipe.

It should be routed

EHC

27Fitting the Water Pipes and Condensate Pipe

Connecting the Flue13.

WARNING

Adapter

The exhaust gas ducts must not come in to contact with t

or be located close to combustible materials and must not

pass through building structures or walls made of

combustible materials.

When replacing an old appliance, the ue system must be t

changed.

Adapter or connection methods vary depending on the type

of ue system (concentric type or separate type). Follow the

following instructions carefully.

For a concentric flue system13.1

Flue

Blanking plate

Air intake

Flue outlet

Each concentric ue system kit includes an adapter, as shown

in the gure, which helps connect the appliance to the ue

system.

Assemble the components and seals as shown in the gure.

Connect the ue adapter to the appliance.1.

connect the flue bend to the adapter and seal.2.

For a separate flue system13.2

Each separate ue system kit includes an adapter, as shown in

the gure, which helps connect the appliance to the ue system.

Assemble the components and seals as shown in the gure.

Flue Outlett

Install the ue adapter to the appliance.1.

Connect the flue bend to the adapter and seal.2.

Adapter

Connecting the Flue

28

Adapter

Flue

Air Intaket

Remove the blanking plate.1.

Connect the ue adapter to the appliance. (The adapter 2.

comes with this appliance.)

Connect the flue bend to the adapter and seal.3.

EHC

Electrical Connections and Settings14.

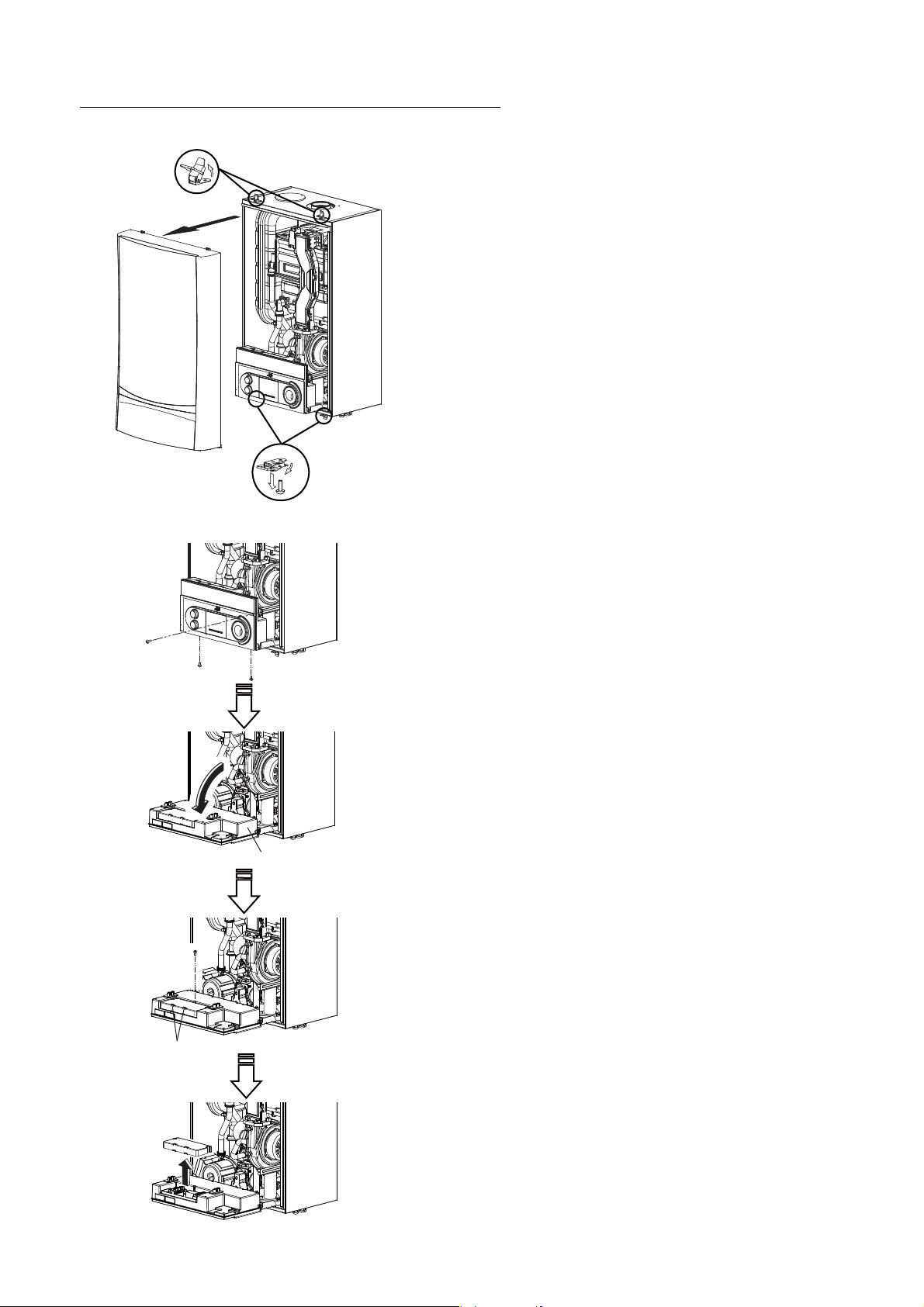

Accessing the Controller Assembly14.1

Remove the 2 screws from the underside of the appliance.1.

Unlatch all the clips, and pull up the hooks (2 on the top2.

and 2 on the bottom of the appliance).

Lift o the front panel from the wall mounted unit.3.

Remove the 3 screws on the underside of the controller assembly,4.

and 1 screw to the right of the controller assembly. Then pull

the controller assembly downward.

5. Remove the screw on the front of the controller cover, and then

the controller cover remove

EHC

Controller assembly

Clamp

29Electrical Connections and Settings

Accessing All the Electrical 14.2

Connections

DANGER

Isolate the main electrical supply before starting any work

and check all relevant safety precautions

Note

Important

1

A

2

B

C

Note

Short circuiting risk: When connecting the cables,

ensure that no pieces of cable fall into the electrical and

and electronic connections.

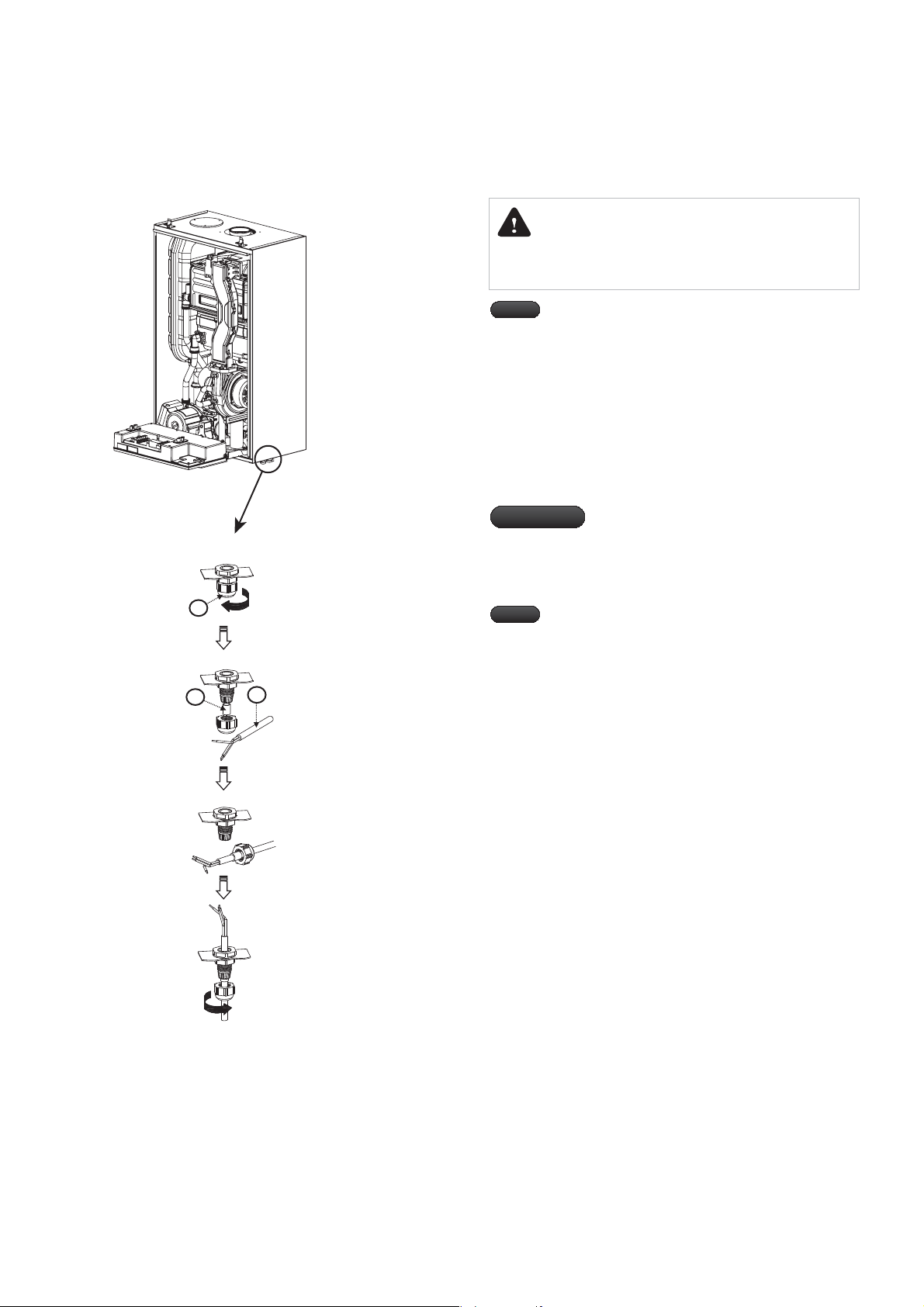

Release cap "A" on the cable gland which is located at the 1.

bottom of the appliance.

Remove the black silicone tube "B" from the cable gland.2.

Insert wire "C" into cap "A" and the silicone tube "B".3.

Insert the prepared cable into the cable gland, put the cap4.

back on, and secure.

Please ensure tha all electrical connectionst

are tight and secure.

This unit must be earthed.t

The appliance is designed with an IPX5D

t

protection rating.

The main supply to the boiler must be t

connected through a double pole isolator

situated local to the appliance. The isolator

must have a minimum contact separation

of 3mm acros all poles.

3

4

Electrical Connections and Settings

30

EHC

Connecting to Main Power 230 V14.3

Detail view

1

2

3

4

5

6

1,2 : Room Thermostat / Room Controller

3,4 : Tank Storage Thermostat

5,6 : Outdoor Temperature Sensor

9 : P.E 10 : Neutral 11 : Live

12 : EXT. 3-WAY [ CH ]

13 : EXT. 3-WAY [ DHW ]

14 : EXT. 3-WAY [ COM ]

9

10

11

12

13

14

Note

The appliance must be connected to the mains

terminals which are clearly marked on the rear of

the control panel with a suitable 3 core flex (supplied).

Contact a qualied electrician

if the power cable needs replacing.

The boiler must be wired to current IEE Regulations.

Fuse replacement (if necessary)

When replacing the main fuse on the PCB, use a 3A quick blow

E

N

L

fuse.

Isolate the boiler at the mains.1.

Remove the plastic access cover at the rear of the control 2.

panel to gain access.

Locate and replace the fuse in the upper portion of the PCB.3.

EHC

31Electrical Connections and Settings

1

2

3

4

5

6

1,2 : Room Thermostat / Room Controller

3,4 : Tank Storage Thermostat

5,6 : Outdoor Temperature Sensor

9 : P.E 10 : Neutral 11 : Live

12 : EXT. 3-WAY [ CH ]

13 : EXT. 3-WAY [ DHW ]

14 : EXT. 3-WAY [ COM ]

9

10

11

12

13

14

Connecting the Controller, 14.4

Accessories and External

Controls

Connecting the Room Thermostat /

Programmable Room Stat

The appliance is designed to be connected to a volt free room

thermostat. Connect the cable to terminal blocks No. 1 and 2.

Connecting the Weather Compensation

Sensor

The appliance is designed to be connected to an outdoor

weather compensating temperature sensor. Connect the cable

to terminal blocks No. 5 and 6.

OFF

12345678910

ON

DIP Switch Settings14.5

The dip switches are on the top of the control panel as shown on

the diagram.

Refer to the following table to ensure that the dip switches are

properly set to the correct position depending on boiler type

i,e LPG or Natural Gas. Note: All boilers are pre-set to Natural Gas

Switch No.

1- 2 Maximum operation Normal operation

3 Minimum operation Normal operation

4 LPG(G30) 5- 6- 7 Natural Gas -

8-10 Heat Capacity

ON OFF

Switch No.

21K(A) 25K(A) 32K(A) 37K(A)

8 OFF OFF OFF ON

9 ON ON OFF OFF

10 ON OFF ON OFF

Function

Heat Capacity

Electrical Connections and Settings

32

EHC

Final Check and Commissioning15.

Connecting the Power Cable and 15.1

Turning the Power ON/OFF

DANGER

Before turning on the power, replace the controller cover t

to the original position.

Replace the controller cover, insert and tighten the screw. 1.

Connect the power cable which is connected to the 2.

appliance to the 3 Amp fused spur.

DANGER

Controller cover

Before turning on the power, ensure that the appliance is t

earthed. Electrocution may occur if the appliance is not

properly earthed.

EHC

To 3 Amp power supply

Turning the Power ON/OFF

Press the [main ON/OFF] button on the control panel to turn on

the power.

Hold the button for more than one second to turn the power off.

[main ON/OFF] button

33Final Check and Commissioning

Checking the Gas Settings15.2

1.

Loosen the test point "A" that is clearly marked on the2.

diagram.

Connect a digital manometer or U gauge to the test point.3.

4.

pressure, the boiler is set for natural gas G20 the supply

pressure should be 20mb.

If the supply pressure is not within the permissible range 5.

contact the gas supply company to rectify the problem.

If the connection pressure is within the

permissible range

Gas

test point "A"

Digital

pressure

manometer

After the gas service pipe- work has been purged and tested 1.

for soundness, turn the power onto the boiler. (The heating

system will be full of water at this stage and set to a pressure

of 1.5bar and free of air as per the filling and pressurising

instructions)

Now check the Inlet working pressure with all other gas 2.

appliances turned “ON”, and the boiler set to maximum,

you can set the boiler to maximum output by selecting dip

switch No 2 to “ON” we recommend the minimum working

pressure with the boiler running at maximum should read

17mb at test point “A” on the gas valve.

Gas Rate: As you cannot test the boiler burner pressure 3.

you will have to gas rate the appliance from the supply

meter. The boiler will have to be set to maximum (select dip

switch No2 to ON) calculate the gas rate after the boiler has

been running for at least 10 minutes, Gas flow rates can be

found in the table on page (remember to select dip

switch 2 to off after this test, the boiler will stabilize after

about 15 min to normal operation)

You can set the boilers output by percentage, 4.

CH output: CH

by pressing the mode and reset button on the boilers front

control panel for 5 seconds, this will enter you into the

service parameter menu, the service table can be found on

page 38.

percentage range from 20% to 100%(FH- Full heat) you can

also change some other parameter functions that are shown

on this table if required.

You can change the boilers output by a

48

CH

Final Check and Commissioning

34

Checking the Gas Equipment for 15.3

Soundness

DANGER

Gas leak could result in explosion. Check all fittings for

soundness.

EHC

Checking and Adjusting the CO15.4

Value

2

As described on the data plate, this appliance is set for natural

gas by default. Furthermore, this appliance can be used without

adjusting the CO

Subject to the WEBBER INDEX, the CO

8.9% and 9.3%. The CO

2

.

2

2

adapter test point.

If the actual CO

2

value deviates from the stated ranges by more

than 1.0%, check the ue system for leaks.

Note

Gas-air Ratio

adjustment

screw “C”

For more information about the CO2 values for each

model, refer to "CO

2

Level" table on appendix.

Check the discharge amount, and adjust the CO

the following procedures.

1.

2.

Set the 3rd dip switch to the "ON" position. 3.

The burner is now set to the minimum rated input.

For details about setting dip switches, see "14.5 the

DIP Switch Settings".

Check the CO4.

2

value.

If the actual value deviates more than 1.0% from the -

2

If the measured CO-

value is not correct, adjust the gasair ratio adjustment screw “C” on the gas control valve

after removing the cap on the gas-air ratio adjustment

screw “C”. Turn it to the right to increase the CO

turn it to the left to decrease it.

Enter actual values in the service report.5.

The following mentioned items are done in conjunction 6.

with the checking and adjusting of the CO

6-1. Prepare the water column meter or manometer

6-2. Wait for around 30 seconds.

6-3. Read the gas-air ratio.

If the gas/air ratio is not between in 0 and -0.1 mbar,

you should adjust the adjustment screw “C” on

the gas valve.

2

value using

2

level and

2

level.

EHC

Gas

test point “B”

Digital

pressure

manometer

Maintain the appliance at the minimum

rated output while checking the gas-air ratio

with a water column meter or manometer.

Set the 3rd dip switch to “OFF” and set the 2nd dip switch to 7.

“ON”.

The burner is now set to the maximum rated input.

Check the CO8.

Note

2

value.

If the actual value deviates more than 1.0%

from the above range, check the seals in the

Enter the actual values in the service report.9.

Note

Note that the process will automatically end

after 15 minutes.

Set the 2nd dip switch to “OFF”.10.

35Final Check and Commissioning

Controller assembly

Installing the Front Cover15.5

Replace the controller assembly. 1.

Install the front cover and secure.2.

Final Check and Commissioning

36

EHC

System Filling and Pressurising 15.6

The appliance is supplied with a lling loop by-law kit which

must be used to ll the system. It should be connected between

the main water inlet pipe and central heating return pipe and

removed after completion.

This can be supplied as a stand alone filling loop or it will be

incorporated within the valve kit supplied with the boiler

depending on boiler type.

Fill the system to 1.5/2.0 bar and bleed the complete system of

air, this process may have to be repeated more than once, open

the automatic air vent within the boiler, this is located just above

the pump housing, bleed the pump by turning the screw on the

front face of the pump anti clockwise.

You will be able to view the system pressure by pressing the

mode key on the boilers front control panel, if the pressure is

below 0.4 bar the boiler will show an error code E02 This can be

reset by simply pressing the reset key on the control panel.

Ball valve

Appliance

Ball valve

Flushing

New systems:

Method statement for cleaning and treating new domestic systems

Procedure

1. Fill the system with cold mains water to the recommended

pressure and check for leaks, then drain the system thoroughly

making sure all drain cocks are fully open and that the system is

completely drained.

2. Add Fernox Cleaner F3 through via a radiator using either a

Fernox Injector, Express or Superconcentrate at the recommended

dose. One pack must be used as a minimum per dwelling. If you are

not sure of the dose rate, then contact Fernox Technical Services on

+44 0870 870 0362.

3. Fill the system back up and circulate the Fernox Cleaner F3

before the boiler is fired up. Then commission the system in the

normal way. Cleaner F3 must be in the system for a minimum of

1 hour with the system at normal operating temperature. A longer

period of time would be more beneficial to the cleaning process

especially if excess flux was used.

4. Drain and flush the system thoroughly to remove the cleaning

chemical and debris present. This is a crucial part of the cleansing

process and must be done correctly. Use a rinse test meter such as the

Fernox TDS meter to ensure that the Total Dissolved Solids have

been satisfactorily removed. The system can be regarded as being

thoroughly flushed when the system water value is within 10% of

the mains water value. Differences over 10% mean that significant

cleaner residues have been left in the system and further flushing is

required. If not removed cleaner residues will promote corrosion and

negate the cleaning process.

Central heating

return

Temporary

loop

Double

check

valve

Water inlet

5. Once the system has been cleaned thoroughly, then add a Fernox

Protector F1, to the system. The product must be added as per the

manufacturer's instructions. This will protect against the formation of

scale, corrosion and microbiological growths. It is crucial, however,

that for a Protector F1 to work correctly, the system must be properly

cleaned and flushed.

6. The sticker on the base of the Fernox Protector F1 back label

should be correctly filled in and attached adjacent to the boiler.

7. Please note: we recommend Protector levels are checked on an

annual basis (usually during the service) or sooner if the system

content is lost. This should be carried out using a Fernox Protector

test kit or 60 second Protector Check strip.

8. Fernox Technical Services can be contacted on +44 (0) 870 870

0362 for further assistance.

EHC

37Final Check and Commissioning

Flushing existing systems

Where an old boiler is being replaced we recommend that the

boiler as dirt and debris from the old system may cause damage

to the boilers internal components, or the method below is

followed.

content is lost. This should be carried out using a Fernox Protector

test kit.

11. Fernox Technical Services can be contacted on +44 (0) 870 870

0362 for further assistance.

Method statement for cleaning and treating existing domestic

systems

Cleaning and inhibiting an existing central heating installation

using Fernox Cleaner F3 and a Fernox Protector F1.

Procedure

water.

2. Add Fernox Cleaner F3 through a radiator using either a Fernox

Injector, Express or Superconcentrate at the recommended dose.

3. Turn on the appliance and circulate product for a minimum of

one hour hot or for a longer period of time if preferred.

4. Isolate all radiators except that furthest away from the appliance,

Repeat step 5 throughout the system including appliance and

circulator pipes.

5. Isolate all radiators except that furthest away from the appliance.

Open the full bore drain point; at the same time introduce fresh

water via the temporary mains connection.

Flush through thoroughly until the water runs clear.

Use a rinse test meter such as the Fernox TDS meter to ensure that

the Total Dissolved Solids have been satisfactorily removed. The

Note

Failing to follow theses instructions will invalidate

the boilers warranty.

system water value is within 10% of the mains water value.

removed cleanser residues will promote corrosion and negate the

cleaning process.

6. Repeat step 6 on all radiators, appliance and circulator pipework.

7. Re-open all radiators, and circulate for a further 15 minutes and

take a further TDS reading.

8. Once the system has been cleansed thoroughly, then add a

Fernox Protector F1, to the system. The product must be added as

per the manufacturer's instructions. This will protect against the

formation of scale, corrosion and microbiological growths. It is

crucial, however, that for a Protector to work correctly, the system

9. The retreatment sticker provided with all Fernox Protectors

should be correctly completed and applied to the boiler casing.

10. Please note: we recommend Protector levels are checked on an

annual basis (usually during the service) or sooner if the system

Final Check and Commissioning

38

EHC

Operational Checks15.7

Check the following items with the control panel. For detailed operational procedures, refer to "Instructions for Use" for further

information.

Check Items Conrmation Methods Display

Check whether the

appliance works normally

when the power is ON.

Check whether the water

pressure for the heating

system is normal.

Check whether the

temperature setting for

the CH mode is normal.

Check whether the

temperature setting for

the DHW mode is normal.

Check whether the reset

operation is normal.

Press the [main ON/OFF] button.1.

Check whether the display is the same as shown on the right2.

Display the water pressure by pressing the [MODE] button.1.

Check whether the water pressure is in the normal range.2.

Set the central heating temperature by turning the CH temperature 1.

control knob.

Display the supply water temperature by pressing the [MODE] button.2.

Check whether the set temperature and the supply water temperature 3.

are the same.

Set the hot water temperature with the DHW temperature control knob.1.

Display the domestic hot water temperature by pressing the [MODE] 2.

button.

Check whether the set temperature and the domestic hot water 3.

temperature are the same.

Press the [RESET] button.1.

Check whether the display is the same as shown on the right2.

Display the service menu by holding the [MODE] and the [RESET] 1.

button simultaneously for 5 seconds.

Press the [MODE] button until the desired parameter number is 2.

Check whether the

operation set in the

service menu is correct.

Parameters for service menu

displayed.

Refer to the following table for parameter numbers.

Change the setting with the CH temperature control knob.3.

Wait for 10 seconds until the display goes back to the main display.4.

Ensure that the parameter set is in eect.5.

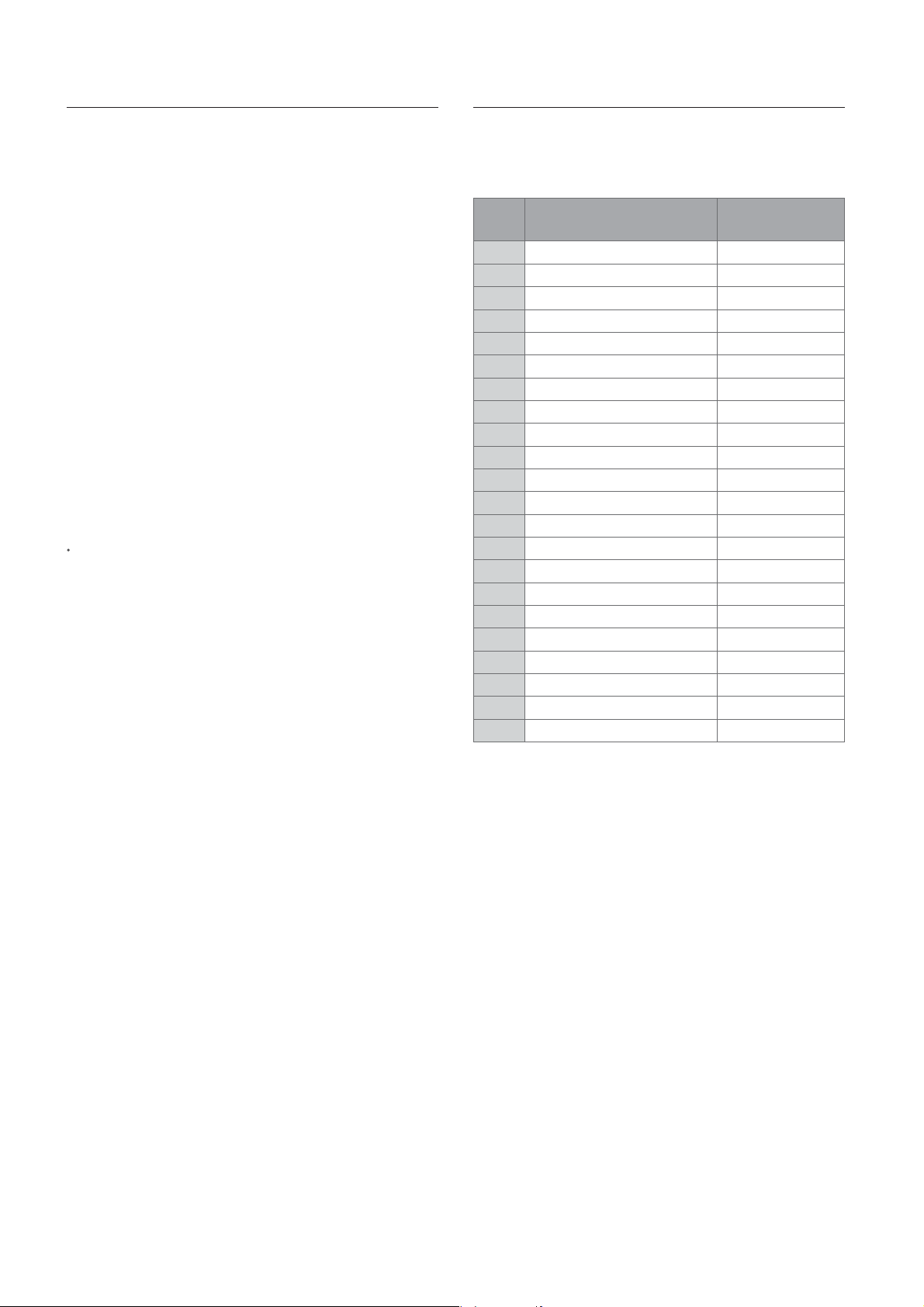

No. Parameter Range Default

0 Rated range heat capacity 20 - 99, FH* (%) FH*

1 Pump over run time 3 - 40 minute 3 minute

2 DHW post delay time 0 - 20 minute 5 minute

3 Anti-cycling timer 0 - 10 minute 0 minute

4 DHW Pre-heating ON/OFF OFF

5 Rated range water pressure 0.5 - 2.0 bar 1.0 bar

6 Minimum/Maximum operation setting OFF/MIN/MAX OFF

FH* = Full (Maximum) Heat Capacity = 100 %

EHC

39Final Check and Commissioning

Final Commissioning Check15.8

The trial run should be performed in accordance with the following check items.

If errors occur during commissioning, error codes will be displayed on the control panel.

Please refer to section 17 "Error Code List" and take the appropriate action.

Activities Measured Value Remarks

Check water ling and leaks in the heating system

Check the gas settings

Gas type

If the data plate is changed when doing a gas conversion.

Check the gas pressure, CO settings

Check the gas equipment for soundness

Check the operation of the control panel

If it works normally when the switch is ON.

If the water pressure for the heating system is normal.

If the temperature setting for the heating system is normal.

If the temperature setting for the domestic hot water is normal.

If the reset operation is normal.

If the operation set in the service menu is correct.

Check the CO

2

settings

Check if the weather compensation function works normally

Check if the condensate drain pipe discharges normally

2

Final Check and Commissioning

40

EHC

Instructing the End User16. Error Code List17.

Handing over the Instructions16.1

Hand over the instructions and the checklist, and explain the

following points to the end user.

Explanation of the data platet

Countermeasures for gas leakst

Risks of fire due to combustibles, dust, and explosivest

Risks of placing flammable liquids near the appliancet

Risks of placing oxides such as chlorine near the appliancet

Risks of placing rubbish near the appliancet

Frost proof insulationt

Precautions about the intake and exhaust uet

Precautions about the condensate drain pipet

Necessity of annual periodical checks by service engineerst

Cleaning methodst

Precautions about not using the appliance for long periods of t

time

Ensure client is made aware of Warranty Conditions.

Showing How to Operate16.2

Use the “Instructions for Use”, to explain the following points

concerning how to operate the appliance. Also, congure the

settings for the user.

Appliance functionst

Operating the control panelt

Power ON/OFF

-

Display details

-

Temperature settings for central heating

-

Temperature settings for domestic hot water

-

Explain and operate the service menu

-

Operations when error codes are displayed

-

Precautions against using the appliance incorrectly.t

Countermeasures for appliance malfunctionst

Location and operation of the gas shuto valvet

Explain the following error codes if the appliance malfunctions.

The error codes will blink and be displayed on the digital control

Panel.

Error

Code

E02 Low water-level Contact Engineer.

E03 Ignition failure Reset the appliance.

E04 Flame simulation

E05 Supply water thermistor: Open

E06 Supply water thermistor: Short

E07 Hot water thermistor: Open

E08 Hot water thermistor: Short

E09 Abnormal fan Reset the appliance.

E10 Abnormal air pressure Reset the appliance.

E11 Water pressure sensor fault

E12 Flame failure Reset the appliance.

E15 Abnormal BMC Reset the appliance.

E16 Over heat: Heat exchanger Reset the appliance.

E17 DIP Switch Setting fault Reset the appliance.

E18 Return water thermistor: Open

E19 Return water thermistor: Short

E21 Inlet water thermistor: Open

E22 Inlet water thermistor: Short

E27 Abnormal air pressure sensor Reset the appliance.

E30 Over heat: Exhaust Reset the appliance.

E40 Outdoor thermistor: Short

E93 Key button failure

Reason Action required

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

Contact Engineer.

EHC

Instructing the End User

41Error Code List

18.

lacirtcelE

Wiring Diagram18.1

42

Electrical

EHC

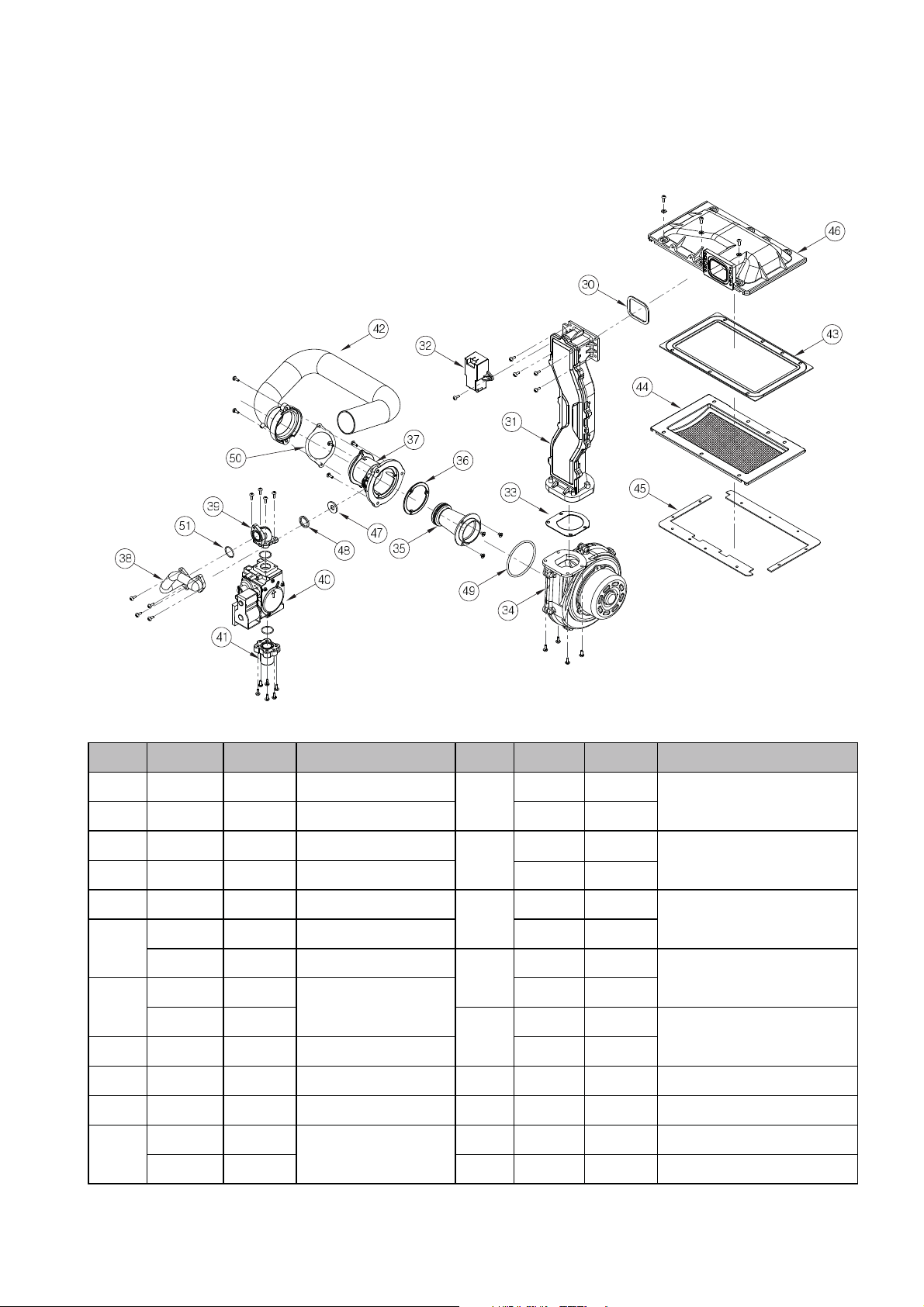

Parts List19.

Case Parts19.1

Item No Part No. Boiler Size Description Item No Part No. Boiler Size Description

1 ECP20001 ALL Case 10 ECP20010 ALL APS (Air Pressure Sensor)

2 ECP20002 ALL Top bracket 11 ECP20011 ALL APS bracket

3 ECP20003 ALL Bottom bracket 12 ECP20012 ALL Tube

4 ECP20004 ALL Lock out 13 ECP20013 ALL Cover

5 ECP20005 ALL Insulation top 14 ECP20014 ALL Controller Ass’y

6 ECP20006 ALL Insulation side 15 ECP20015 ALL Air Intake Packing

7 ECP20007 ALL Controller bracket (L) 16 ECP20016 ALL Air Intake Plate

8 ECP20008 ALL Controller bottom bracket 17 ECP20017 ALL Case Clip

9 ECP20009 ALL Controller Bracket (R)

EHC

43Parts List

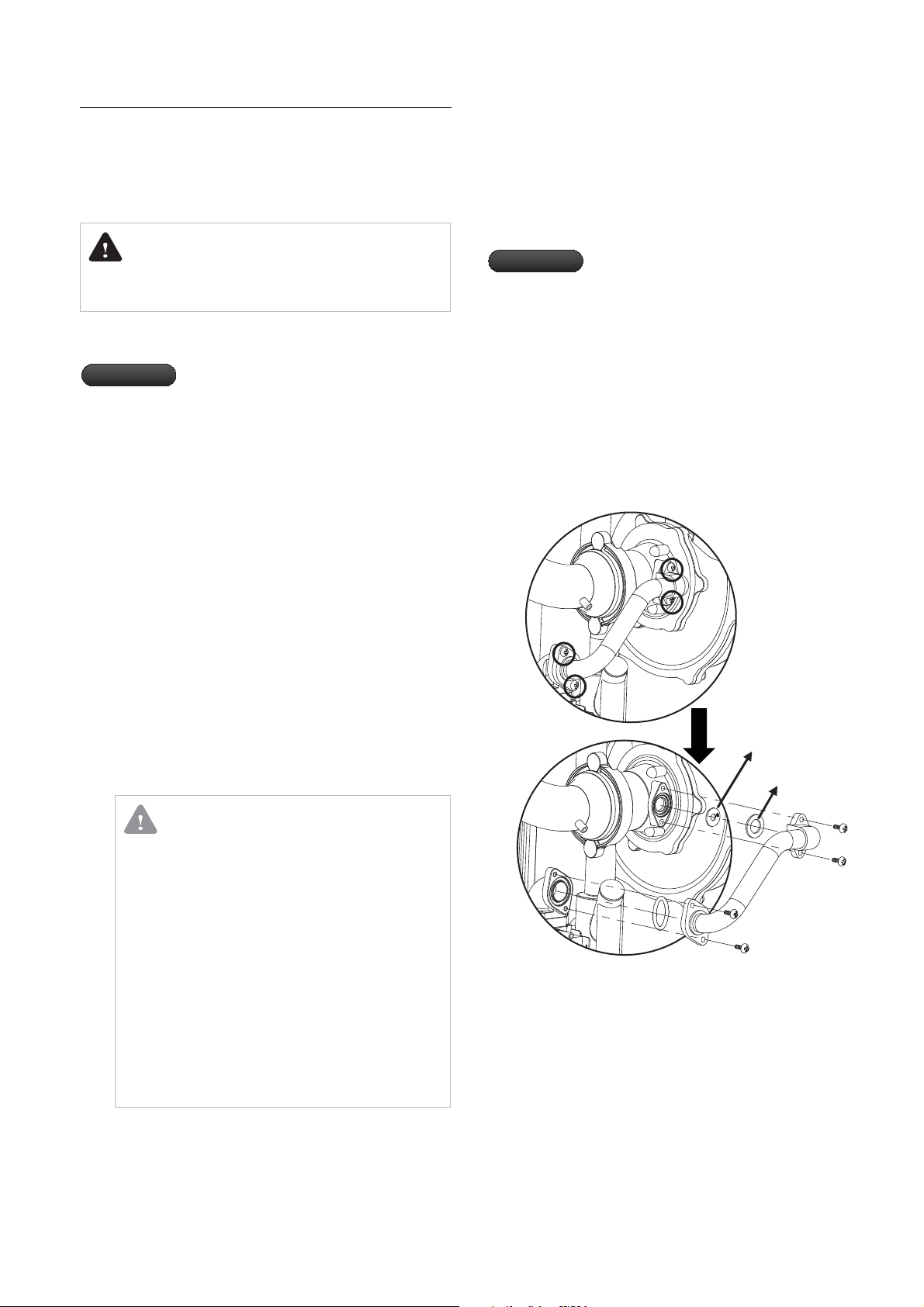

Burner Parts19.2

Item No Part No. Boiler Size Description Item No Part No. Boiler Size Description

30 ECP20030 ALL Mix chamber packing ECP30043 21/25kW

31 ECP20031 ALL Mixing flow guide ECP40043 32/37kW

32 ECP20032 ALL Ignition trans ECP30044 21/25kW

33 ECP20033 ALL Fan packing ECP40044 32/37kW

34 ECP20034 ALL Fan assay ECP30045 21/25kW

ECP50035* 21/25kW Mixer Chamber Assembly ECP40045 32/37kW

35

36

37