Page 1

Engine controller

MCflex

Translation of the original operating instructions

Most recent revision: 08/05/2018

Version: 3.0

Page 2

2

Device Engine controller MCflex

Serial number Enter the serial number of your device here:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

ehb product

number

Publisher ehb electronics gmbh

ehb5200x

Hans-Böckler-Straße 20

30851 Langenhagen

GERMANY

Tel: +49( 0)511 12 32 07 - 0

Fax: +49( 0)511 12 32 07 - 77

E-mail: info@ehb-electronics.de

www: www.ehb-electronics.de

www.ehbservice.de

www.ehbshop.de

The document is protected by copyright. All rights reserved. Copying, reproduction, translation or conversion into an electronic medium or into a machine-readable form, as a whole document or in partial sections, is not permitted without the

approval of ehb electronics gmbh.

Subject to change without notice.

Suggestions and

tips

... about this document or the device can be sent to the above address.

Last modification 08/05/2018

Version 3.0

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 3

Table of Contents

1 DEVICE INFORMATION _________________________________________________________ 6

1.1 S

1.2 T

1.3 S

1.4 I

1.5 I

1.6 F

1.7 T

1.8 S

1.9 EU D

2 INFORMATION FOR THE READER _______________________________________________ 12

2.1 V

2.2 T

2.3 I

2.4 A

2.5 H

PECIFICATIONS ................................................................................................................... 6

YPE PLATE ......................................................................................................................... 6

COPE OF DELIVERY ............................................................................................................ 6

NTENDED USE...................................................................................................................... 7

MPROPER USE ..................................................................................................................... 7

UNCTIONAL DESCRIPTION.................................................................................................... 7

ECHNICAL DATA ................................................................................................................. 8

PARE PARTS ...................................................................................................................... 9

ECLARATION OF CONFORMITY .................................................................................... 10

ALIDITY ............................................................................................................................ 12

ARGET GROUP.................................................................................................................. 12

LLUSTRATIONS .................................................................................................................. 12

BBREVIATIONS USED ........................................................................................................ 13

IGHLIGHTING IN THE TEXT ................................................................................................. 14

2.5.1 P

2.5.2 N

2.5.3 S

2.5.4 W

2.5.5 H

ICTOGRAMS AND SYMBOLS ............................................................................. 14

AVIGATION PATH ............................................................................................ 15

AFETY INFORMATION ...................................................................................... 15

ARNINGS....................................................................................................... 15

ANDLING INSTRUCTION ................................................................................... 15

3

3 SAFETY _____________________________________________________________________ 16

3.1 S

3.2 D

3.3 L

3.4 Q

3.5 P

3.6 R

AFETY INFORMATION ........................................................................................................ 16

3.1.1 I

3.1.2 I

3.1.3 I

3.1.4 I

3.1.5 I

3.1.6 I

3.1.7 I

UTIES OF THE OPERATOR ................................................................................................. 18

OCAL REGULATIONS ......................................................................................................... 18

UALIFICATION OF PERSONNEL .......................................................................................... 19

ICTOGRAMS AND SYMBOLS ON THE DEVICE ....................................................................... 19

ESIDUAL RISK .................................................................................................................. 20

NFORMATION ABOUT OPERATIONAL SAFETY ...................................................... 16

NFORMATION ABOUT INITIAL COMMISSIONING .................................................... 16

NFORMATION ABOUT OPERATION...................................................................... 16

NFORMATION ABOUT DECOMMISSIONING AND STORAGE..................................... 16

NFORMATION ABOUT MAINTENANCE AND REPAIRS ............................................. 17

NFORMATION ABOUT ENVIRONMENTAL PROTECTION .......................................... 17

MPERMISSIBLE OPERATING CONDITIONS ........................................................... 17

4 PARTS OF THE DEVICE________________________________________________________ 22

4.1 F

4.2 D

4.3 R

4.4 B

RONT OF DEVICE .............................................................................................................. 22

ISPLAY VIEWS .................................................................................................................. 23

4.2.1 O

4.2.2 D

4.2.3 T

EAR OF DEVICE ................................................................................................................ 24

OTTOM OF DEVICE............................................................................................................ 25

PERATING PARAMETERS................................................................................. 23

AILY OPERATING DURATION ............................................................................ 24

OTAL OPERATING DURATION ........................................................................... 24

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 4

4

5 UNPACKING, CONNECTING AND INSTALLING_____________________________________ 26

5.1 U

5.2 C

5.3 M

6 PARAMETRIZATION ___________________________________________________________34

6.1 D

6.2 N

6.3 P

7 MENUS IN PARAMETRIZATION MODE____________________________________________35

7.1 O

7.2 M

7.3 S

7.4 S

7.5 S

7.6 S

7.7 S

NPACKING........................................................................................................................ 26

ONNECTING ...................................................................................................................... 27

5.2.1 C

5.2.2 C

5.2.3 C

OUNTING ......................................................................................................................... 30

5.3.1 T

5.3.2 M

ESIGN OF THE DISPLAY IN PARAMETRIZATION MODE........................................................... 34

AVIGATING IN PARAMETRIZATION MODE ............................................................................. 34

ARAMETRIZING THE DEVICE ............................................................................................... 34

VERVIEW.......................................................................................................................... 35

AIN MENU ........................................................................................................................ 36

UBMENU – SETTINGS........................................................................................................ 36

7.3.1 [1] S

7.3.2 S

7.3.3 S

7.3.4 H

7.3.5 G

7.3.6 G

7.3.7 A

7.3.8 F

7.3.9 F

7.3.10 L

7.3.11 I

UBMENU – SERVICE.......................................................................................................... 61

7.4.1 [2] S

7.4.2 [1] S

7.4.3 [2] F

7.4.4 [3] F.L.

UBMENU – SAFETY........................................................................................................... 63

7.5.1 [3] S

7.5.2 S

7.5.3 S

UBMENU – DAILY OPERATING HOURS COUNTER ................................................................ 65

7.6.1 [4] D

7.6.2 S

UBMENU – OPERATING HOURS COUNTER .......................................................................... 65

7.7.1 [5] OHC

7.7.2 S

ONNECTION DIAGRAM AND PIN ASSIGNMENT .................................................... 27

IRCUIT DIAGRAM............................................................................................. 28

ONNECTING THE DEVICE ................................................................................. 29

ECHNICAL DRAWING........................................................................................ 30

OUNTING THE DEVICE..................................................................................... 30

ETTINGS.................................................................................................... 36

UBMENU LANGUAGE........................................................................................ 37

ENSOR SUBMENU ........................................................................................... 38

IGH-POWER OUTPUT SUBMENU ....................................................................... 40

LOW TIMES SUBMENU..................................................................................... 46

ENERATOR.ER SUBMENU................................................................................ 49

UTOSTART SUBMENU ...................................................................................... 49

AULT EVENT SUBMENU .................................................................................... 51

AULT TIMES MENU........................................................................................... 54

IMIT VALUES SUBMENU .................................................................................... 57

NPUTS/OUTPUTS SUBMENU .............................................................................. 59

ERVICE ..................................................................................................... 61

ERVICE SETTINGS ...................................................................................... 62

AULT LIST.................................................................................................. 62

DELETE ................................................................................................ 63

AFETY....................................................................................................... 63

UBMENU – PIN NUMBERS ............................................................................... 63

UBMENU – SELF-TEST .................................................................................... 64

AY COUNTER............................................................................................. 65

UBMENU – DAY COUNTER ............................................................................... 65

COUNTER ........................................................................................... 65

UBMENU – OHC – MENU ............................................................................... 66

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 5

8 CANBUS FUNCTIONS _________________________________________________________ 67

8.1 F

8.2 M

8.3 M

UNCTIONS AND DISPLAY DEVICES ...................................................................................... 67

ESSAGE ON DEN CANBUS ............................................................................................... 67

8.2.1 PGN 61444 E

8.2.2 PGN 65253 E

8.2.3 PGN 65262 E

8.2.4 PGN 65263 E

8.2.5 PGN 65271 (R) V

8.2.6 PGN 65269 A

8.2.7 PGN 65276 D

8.2.8 PGN 65278 A

8.2.9 A

CTIVE DIAGNOSTIC TROUBLE CODES (DM1) ................................................... 69

8.2.10 PGN 42496 (R) A

ESSAGE FROM CANBUS .................................................................................................. 71

8.3.1 PGN 57344 C

LECTRONIC ENGINE CONTROLLER 1 - EEC1 ............................... 67

NGINE HOURS, REVOLUTIONS - HOURS..................................... 67

NGINE TEMPERATURE 1 - ET1.................................................... 68

NGINE FLUID LEVEL/PRESSURE 1 - EFL/P1 ................................ 68

EHICLE ELECTRICAL POWER 1 - VEP1.................................. 68

MBIENT CONDITIONS – AMB....................................................... 68

ASH DISPLAY - DD..................................................................... 68

UX WATER PUMP PRESSURE- AWP ........................................... 69

UXILIARY INPUT/OUTPUT STATUS 3 - AUXIO3 ...................... 69

AB MESSAGE 1 - CM1 ............................................................... 71

9 OPERATION _________________________________________________________________ 72

9.1 S

9.2 I

9.3 O

9.4 S

9.5 C

9.6 S

9.7 O

ETTING PULSES PER ROTATION ......................................................................................... 72

9.1.1 S

9.1.2 S

NITIAL COMMISSIONING ...................................................................................................... 73

9.2.1 I

9.2.2 C

PERATING THE DEVICE ..................................................................................................... 74

ETTING THE DEVICE MODE ................................................................................................ 74

OMMISSIONING ................................................................................................................. 75

9.5.1 R

9.5.2 S

WITCHING OFF THE DEVICE ............................................................................................... 75

PERATIONAL FAULTS........................................................................................................ 76

PEED MEASUREMENT USING AN INITIATOR (PICK UP) ........................................ 72

PEED MEASUREMENT BASED ON THE PULSES OF THE "W” TERMINAL AT PIN 13. 73

NFORMATION ABOUT INITIAL COMMISSIONING .................................................... 73

ARRYING OUT INITIAL COMMISSIONING............................................................. 74

EQUIREMENTS FOR COMMISSIONING ............................................................... 75

WITCHING ON THE DEVICE .............................................................................. 75

5

10 MAINTENANCE, REPAIR AND DISPOSAL _________________________________________ 77

10.1 I

NFORMATION ABOUT MAINTENANCE AND REPAIRS .............................................................. 77

10.2 FAQ.................................................................................................................................. 77

10.3 R

10.4 C

10.5 C

10.6 D

EPAIR .............................................................................................................................. 77

LEANING .......................................................................................................................... 78

OMMUNICATION WITH PC (OPTIONAL) ............................................................................... 78

ISPOSAL .......................................................................................................................... 78

10.6.1 D

10.6.2 D

ISPOSAL OF DEVICES...................................................................................... 78

ISPOSAL OF BATTERIES AND RECHARGEABLE BATTERIES ................................. 79

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 6

Specifications

6

Device information

1 Device information

1.1 Specifications

Enter the serial number of your device in the field with the dashed line.

Specifications of the device

Device name Engine controller

Device type MCflex

Serial number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

ehb product number ehb5200x

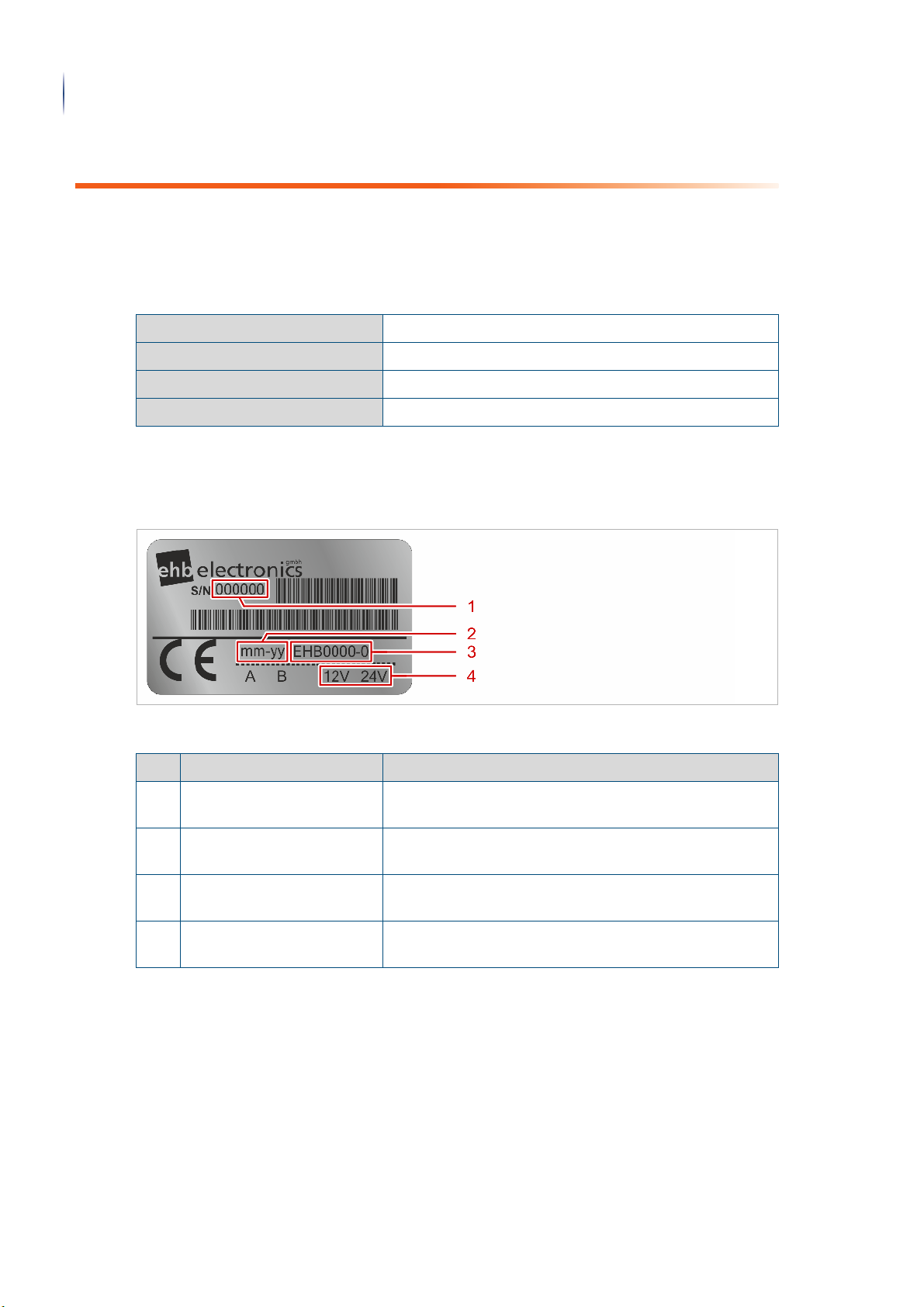

1.2 Type plate

The type plate is located on top of the housing of the device.

Representation of the type plate

Legend

No. Designation Function

1 Serial number Represents a unique and unambiguous number for

identification of the device.

2 Date of manufacturer Represents the date of manufacturer in the "month -

year” format.

3 ehb product number Represents the ehb product number of the device

series.

4 Operating voltage Represents the operating voltage with which the device

may be operated.

1.3 Scope of delivery

The following parts are included in the scope of delivery of the device:

• one device "MCflex”

• two ignition keys

• one label "Do not clean with high-pressure cleaner”

• two mounting brackets

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 7

Intended use

Device information

1.4 Intended use

This device is exclusively used to start and monitor mechanically controlled combustion

engines in machines.

The device is for the following use only:

• starting and monitoring the mechanically controlled combustion engines of mobile and

stationary construction machines

• starting and monitoring the mechanically controlled combustion engines of inland ships

Intended use also includes compliance with all specifications in these Translation of the original operating instructions.

1.5 Improper use

Any use not mentioned in section "Intended use" (Page 7) is considered improper and may

result in personal injury and property damage.

The device is expressly not intended for the following:

• starting and monitoring the mechanically controlled combustion engines of road vehicles

• starting and monitoring the mechanically controlled combustion engines of aircraft

• starting and monitoring the mechanically controlled combustion engines of helicopters

• starting and monitoring the mechanically controlled combustion engines of deep-sea

vessels

• Unauthorised structural changes

• Unauthorised repairs

7

Info

The manufacturer is not liable for damage caused by improper use of the device. The risk for

this is borne solely by the user or operator.

The guarantee expires in the event of improper use.

1.6 Functional description

The device offers a multitude of functions for the control and monitoring of conventionally

controlled combustion engines. You can individually configure the settings for very diverse

applications and different engine variants. The device is capable of pre-glowing, by-glowing

and after-glowing the engine to up to 70 A, using time or temperature variables. Oil pressure

and engine temperature can be monitored with switches or sensors. One additional input is

provided for monitoring the generator. The operating magnet is actuated by the outputs for

excitation and pick-up winding. There is also an alarm output available. The engine can be

switched off via an "external stop” input (hood switch , cover switch / housing switch, for

example).

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 8

Technical data

8

Device information

In the event of a fault, the display returns a corresponding message after an adjustable delay

time and an LED illuminates. If a corresponding function is programmed, the engine is

switched off. The input lock allows the clear identification of the cause of error and requires an

active acknowledgement of the fault message.

By pressing the arrow keys of the device, the operating hours, oil pressure, temperature and

number of revolutions of the engine are displayed in sequence on the two-line display. Other

parameters can be displayed using customised software.

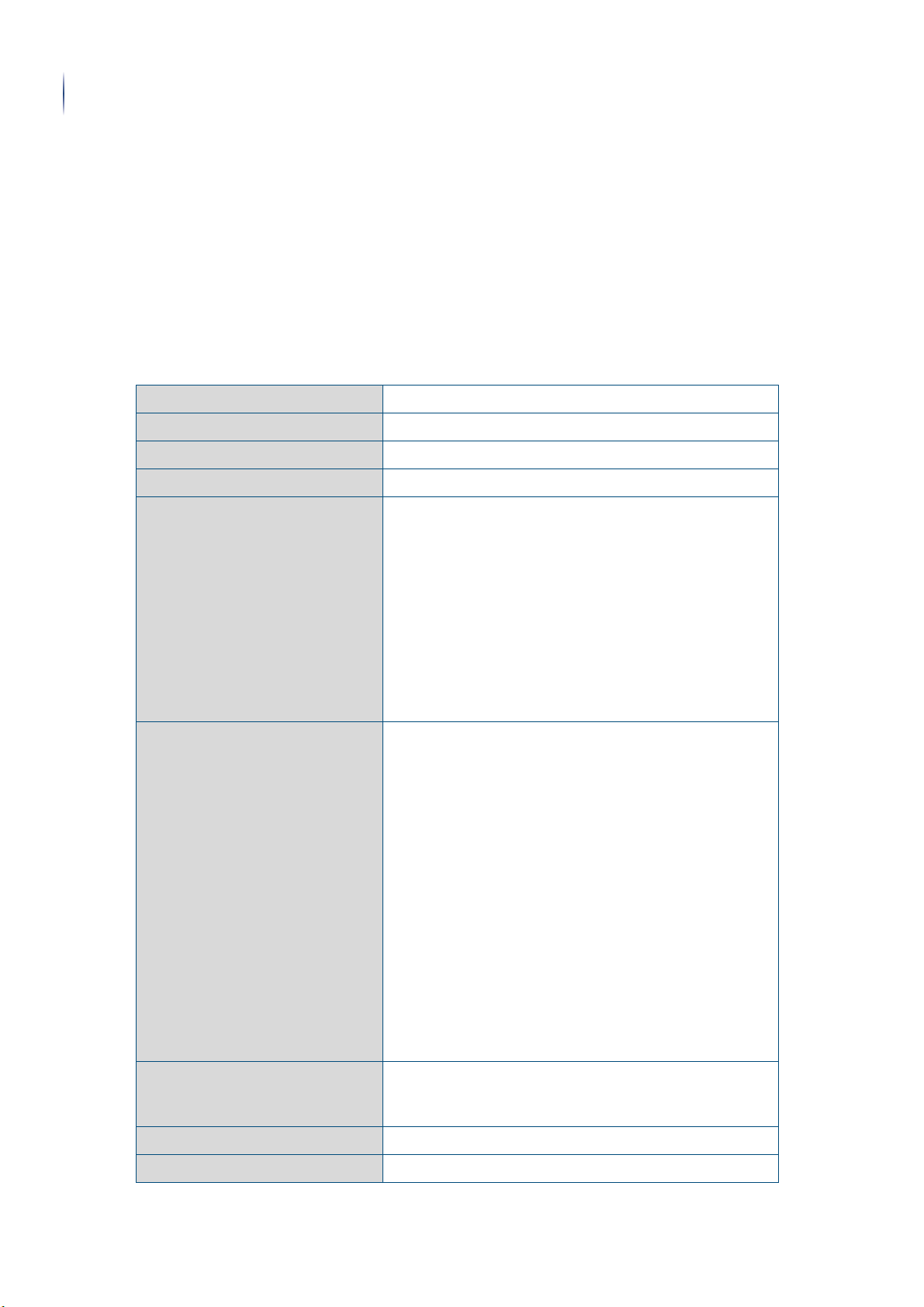

1.7 Technical data

Electrical data

Voltage range 6 V to 32 V (typically 12 V to 24 V)

Current consumption typically 50 mA (for UB 8 V to 24 V)

Operating temperature -20°C to+70°C

Storage temperature -30°C to+80°C

Inputs Inputs:

• PIN 01 | Oil pressure as NO/NC, programmable,

switching or analogue sensor

• PIN 02 | Generator monitoring, terminal D+

• PIN 03 | Temperature as NO/NC, programmable,

switching or analogue sensor

• PIN 04 | Diverse, NO/NC

• PIN 07 | Autostart, NO/NC

• PIN 09External stop, NO/NC

• PIN 13 | Speed monitoring, terminal W, sensor or

magnetic pick-up

Outputs Outputs:

• all outputs are short circuit-proof

• PIN 02 | Generator excitation, terminal D+, 0.5 A

• PIN 06 | Freely parametrisable, 7.5 A (maximum 1s)

/ 6.0 A

• PIN 08 | Freely parametrisable, 40 A (maximum 1s)

/ 20 A

• PIN 10 | Freely parametrisable, 70 A (maximum 1s)

/ 35 A

• PIN 11 | Freely parametrisable, 40 A (maximum 1s)

/ 20 A

• PIN 12 | Freely parametrisable, 70 A (maximum 1s)

/ 35 A

• PIN 15 | Freely parametrisable, 3.5 A (maximum 1s)

/ 3.0 A

• PIN 18 | Freely parametrisable, 40 A (maximum 1s)

/ 20 A

CAN bus interface PIN 17 / 19, CAN2.0B, 250kBit, SAE J1939, EEC1, ET1,

EFL/P1, VEP1, AMB, DM1 fault alarms/auto start, speed

adjustment, optionally adaptable

Operating hours counter Integrated

Daily operating hours counter Integrated

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 9

Spare parts

Device information

Visualisation

Display type Dot matrix LCD, transflective, dark-blue representation,

grey background

Resolution 16 x 2 characters, 5 x 8 dots per character

Brightness >1,000 cd/m²

Contrast ratio (CR) 8.24

Background lighting LED, white

Mechanical data

Housing dimensions (L x W) 72 mm x 72 mm

Installation dimensions (W x H x D)66 mm x 66 mm x 130 mm

Installation cut-out (W x H) 66 mm x 66 mm

Housing material PA 6 30 GB, black, UV-stabilised

Weight 340 g

9

Installation Mounting bracket or screw-fastening, 3 x M6

Protection class IP67

Connection Deutsch connector type HDP24-24-19PE

Test standards

Humidity DIN EN 60068-2-3

Vibration DIN EN 60068-2-6

Shock DIN EN 60068-2-27

CE marking According to Directive 2014/30/EU

Accessories

Connection cable, 19-pole, 3 m ehb2268

Deutsch plug set ehb1469

CANdongle with PC software

ehbTools

MCflex starter kit

CAN dongle, ehbTools,

connecting cable, power supply

unit

ehb5365

ehb5378

1.8 Spare parts

No spare parts are available for this device. If the device is faulty, contact the manufacturer.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 10

EU Declaration of Conformity

(8'HFODUDWLRQRI&RQIRUPLW\

DFFRUGLQJWR'LUHFWLYH(8$QQH[,9

'HYLFHW\SH (QJLQHFRQWUROOHU0&IOH[

HKESURGXFWQXPEHU HKE[

0DQXIDFWXUHU HKEHOHFWURQLFVJPEK

+DQV%|FNOHU6WUDH

/DQJHQKDJHQ

7KHPDQXIDFWXUHULVVROHO\UHVSRQVLEOHIRULVVXLQJWKLVGHFODUDWLRQRIFRQIRUPLW\

7KHVXEMHFWPDWWHURIWKHGHFODUDWLRQGHVFULEHGDERYHFRPSOLHVZLWKWKHUHOHYDQW

KDUPRQLVDWLRQOHJLVODWLRQRIWKH8QLRQ

(8 (OHFWURPDJQHWLFFRPSDWLELOLW\

(8 /RZYROWDJH'LUHFWLYH

(8 5R+6'LUHFWLYH

(8 :DVWH(OHFWULFDODQG(OHFWURQLF(TXLSPHQW'LUHFWLYH

(& 3URGXFW6DIHW\'LUHFWLYH

7KHGHYLFHFRPSOLHVZLWKWKHVWDQGDUGVOLVWHGEHORZ

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW*HQHULF

VWDQGDUGV(PLVVLRQVWDQGDUGIRULQGXVWULDOHQYLURQPHQWV

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV(PLVVLRQDQGLPPXQLW\WHVWLQJLQ

WUDQVYHUVHHOHFWURPDJQHWLF7(0ZDYHJXLGHV

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV(OHFWURVWDWLFGLVFKDUJHLPPXQLW\

WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV5DGLDWHGUDGLRIUHTXHQF\

HOHFWURPDJQHWLFILHOGLPPXQLW\WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV(OHFWULFDOIDVWWUDQVLHQWEXUVW

LPPXQLW\WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV6XUJHLPPXQLW\WHVW

',1(1 (OHFWURPDJQHWLFFRPSDWLELOLW\(0&3DUW7HVWLQJDQG

PHDVXUHPHQWWHFKQLTXHV,PPXQLW\WRFRQGXFWHG

GLVWXUEDQFHVLQGXFHGE\UDGLRIUHTXHQF\ILHOGV

',1(1 (QYLURQPHQWDOWHVWLQJ3DUW7HVWV7HVW)F9LEUDWLRQ

VLQXVRLGDO

,62 5RDGYHKLFOHV9HKLFOHWHVWPHWKRGVIRUHOHFWULFDOGLVWXUEDQFHV

IURPQDUURZEDQGUDGLDWHGHOHFWULFHQHUJ\3DUW*HQHUDO

SULQFLSOHVDQGWHUPLQRORJ\

10

Device information

1.9 EU Declaration of Conformity

EU Declaration of Conformity according to EMC Directive (1/2)

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 11

7KHQRWLILHGERG\0DUWLQ3IHLO75$:,'*PE+5HIKDVSHUIRUPHGDQ

HOHFWURPDJQHWLFFRPSDWLELOLW\WHVWDQGLVVXHGWKHIROORZLQJ(8W\SHH[DPLQDWLRQ

FHUWLILFDWH

'HYLFH 0&IOH[

$FFHVVRULHV

6LJQDWRULHVIRUDQG

RQEHKDOIRI

HKEHOHFWURQLFVJPEK

+DQV%|FNOHU6WUDH

/DQJHQKDJHQ

/DQJHQKDJHQGDWH

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

3ODFHGDWH %HUQG5HLQPROG0DQDJHU

EU Declaration of Conformity

Device information

11

EU Declaration of Conformity according to EMC Directive (2/2)

As soon as the device is improperly used, this declaration and the guarantee claim will expire.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 12

Validity

12

Information for the reader

2 Information for the reader

2.1 Validity

Safety information: Carefully read the Translation of the original operating instructions

Carefully read through these Translation of the original operating instructions before use.

Keep these Translation of the original operating instructions for future consultation.

These Translation of the original operating instructions contain information and rules of

conduct for the safe use of the device.

Please hand over the Translation of the original operating instructions when passing on the

device.

To operate the device effectively, the Translation of the original operating instructions provide

you with information on the following topics, among others:

• Connecting and mounting the device

• Putting the device into operation

• Making settings on the device

• Maintaining the device

• Disposing of the device

2.2 Target group

These Translation of the original operating instructions are intended for the operator, user and

service personnel of the machine with integrated device "MCflex”.

Info

The service personnel must have certain qualifications in order to work on or with the device.

You can find the qualification of personnel in chapter "Safety" > "Qualification of personnel"

(Page 19).

2.3 Illustrations

The illustrations in these operating instructions show the device in simplified form in some

cases.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 13

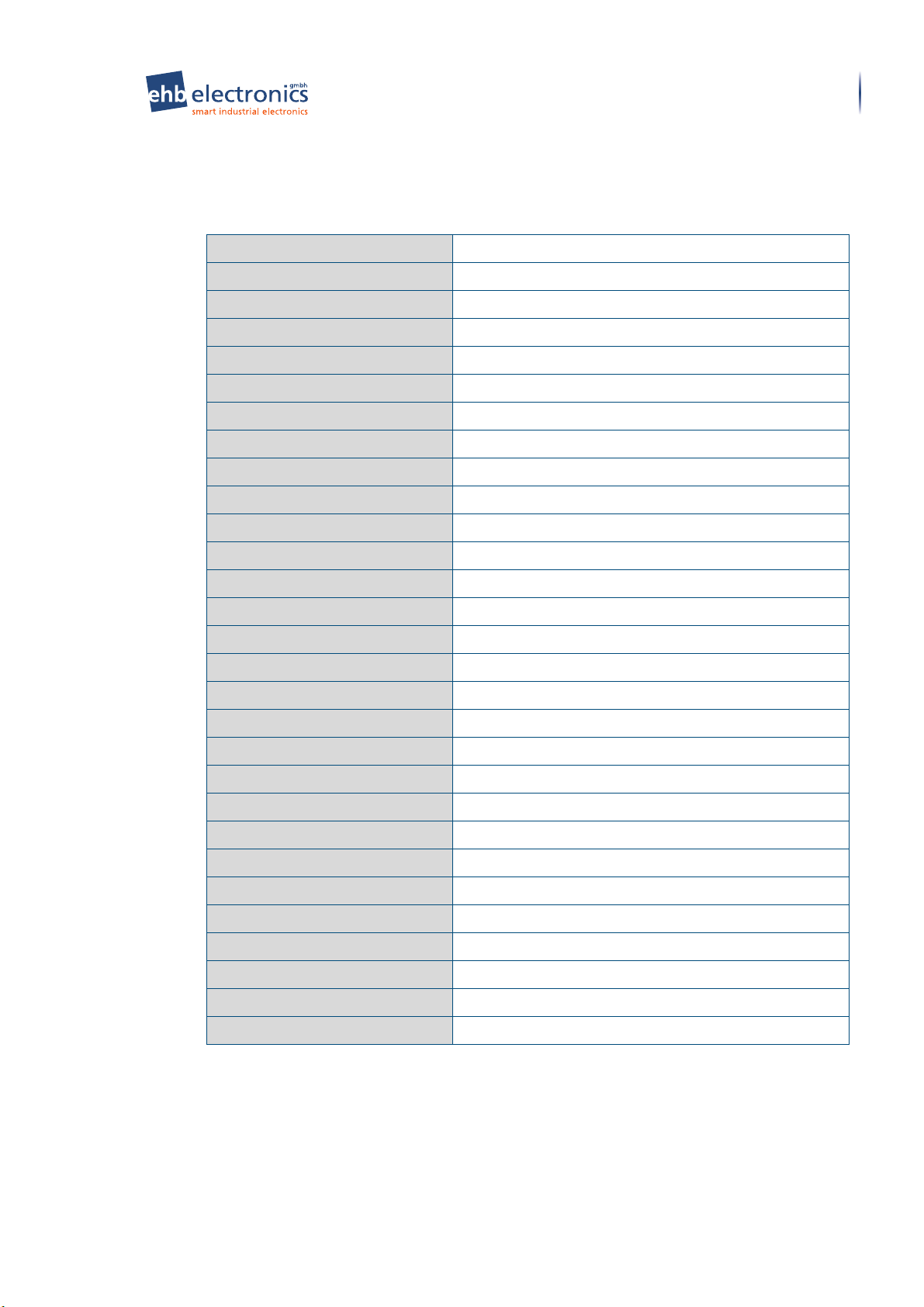

2.4 Abbreviations used

The following abbreviations are used in these operating instructions:

Abbreviations used

°C Degrees Celsius

A Ampere

AW Pick-up winding

bar Unit of pressure [force/area]

OHC Operating hours counter

Cd Cadmium

ECU Electronic Control Unit

FMI Failure Mode Identifier

GND Ground

h hours

Hg Mercury

Abbreviations used

Information for the reader

13

HW Excitation winding

ID Identification

PPR Pulses per rotation

kg kilogram

LCD Liquid Crystal Display

LED Light Emitting Diode

mA Milliampere

NC Normally Closed

NO Normally Opened

NTC Negative Temperature Coefficient

Pb Lead

PC Personal Computer

PTC Positive Temperature Coefficient

s second

SPN Suspect Parameter Number

rpm revolutions per minute

V Volt

ZSS Ignition starter switch

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 14

Highlighting in the text

14

Information for the reader

2.5 Highlighting in the text

In these Translation of the original operating instructions, important information is highlighted

with pictograms, symbols or special notations. The following examples show the most important highlights.

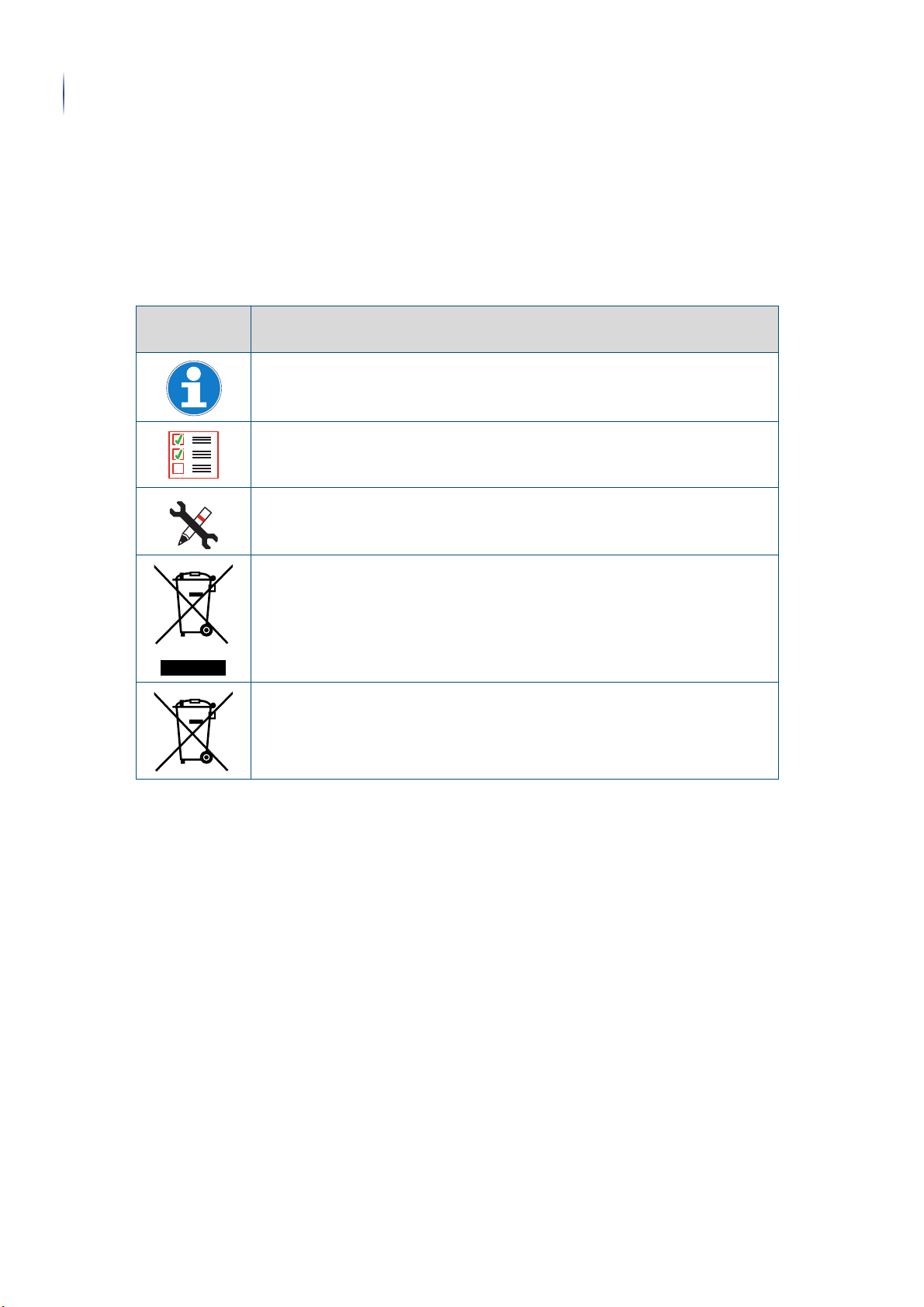

2.5.1 Pictograms and symbols

Pictograms and symbols

Pictogram /

symbol

Meaning

Further useful information.

Conditions that must be met to perform an action.

Tool or material required to perform an action.

The disposal of electrical and electronic equipment with household waste is

not permitted.

The disposal of rechargeable batteries and other batteries with household

waste is not

permitted.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 15

Highlighting in the text

WARNING

NOTICE

Information for the reader

2.5.2 Navigation path

The following representation helps you to navigate through the menus. Here you can see the

path of the menus that must be selected one after the other in order to reach the desired

submenu. In the digital version of the operating instructions, you can jump to the menu item

by clicking on the relevant path.

15

Main menu (page 0)

> Submenu (page 0) > Current submenu (page 0)

2.5.3 Safety information

Safety information: Special note for an informative section.

Explanation of the note.

• This item indicates measures to take the note into account.

2.5.4 Warnings

Warning of serious injuries.

Failure to follow the warning may result in serious damage to health or even death.

► The arrow indicates a precautionary measure that you must take to avert the hazard.

Warning of material damage.

Failure to observe the warning notice can result in considerable damage to the device or its

surroundings.

► The arrow indicates a precautionary measure that you must take to avert the hazard.

2.5.5 Handling instruction

Complete the following work steps: = Start of a handling instruction.

1. First step in a sequence of actions.

Required settings . . . . . . . . . . . . . .

Setting values

2. Second step in a sequence of actions.

▼ Result of this step.

» Done Handling is completed, the goal is achieved.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 16

Safety information

16

Safety

3 Safety

3.1 Safety information

This safety information is addressed to the operator, user and service personnel of the

device.

3.1.1 Information about operational safety

The device is safe to operate. It was built according to the current state of science and technology.

However, the device may constitute a hazard:

• if the device is used not as intended.

• if the device is improperly used.

• If the device is operated under impermissible conditions.

Safety information: Protect against unauthorised opening!

The device has a protective seal to prevent it being opened without authorisation. Note that

any unauthorised opening of the device will lead to it being irreparably damaged.

The following information applies to everyone who works on or with the device:

• Never insert any objects into the device openings not intended for this purpose. There is

a risk of interfering with the electronics.

• Protect the locking cylinder of the ignition starter switch from penetrating dirt and water.

• Only open a battery master switch in an emergency or when the engine is at standstill

and the device is switched off.

• When operating the device, comply with the general accident prevention regulations.

• Operate the device under the conditions specified by the manufacturer (see page 8:

Device information > Technical data).

• Never open the housing of the device. The device does not contain components that can

be serviced, replaced or repaired by the customer or third-party service personnel.

3.1.2 Information about initial commissioning

The following principles apply for initial commissioning:

• Make sure that the device is only connected and installed by personnel qualified for this.

• Make sure that no one can be injured when switching on the device.

3.1.3 Information about operation

Safety-conscious and precautionary behaviour of personnel avoids dangerous situations

during operation.

Observe the following points when handling the device:

• The device may only be connected and installed by personnel qualified for this. Observe

the information from the manufacturer of the plugs and cable harnesses.

• The environment must be free of interfering electrical installations (high frequency) and

electromagnetic compatibility (EMC Directive) must be observed.

• Never make any structural changes to the device.

• Only operate the device with accessories approved by the manufacturer.

3.1.4 Information about decommissioning and storage

The following principles apply for decommissioning and storage:

• Clean all dirt from the device.

• Store the device according to the specifications of the manufacturer (see page 8: Device

information > Technical data).

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 17

Safety information

Safety

3.1.5 Information about maintenance and repairs

The following principles apply for maintenance and repairs:

• The device requires no maintenance and no special actions.

• Only clean the device with a mild cleaning agent.

• Never clean the device with a high-pressure cleaner.

• The device is to be shipped either in its original packaging or in suitable sturdy alternative

packaging. Improper packaging is regarded as negligence and results in any claims for

repair under guarantee being forfeited.

3.1.6 Information about environmental protection

Safety-conscious and precautionary behaviour of personnel avoids adverse effects on the

environment.

All packaging materials and devices are equipped with markings and test seals for proper and

professional disposal.

The following principles apply for environmentally-friendly actions:

• Always comply with the regulations for the prevention, disposal and recycling of waste.

• Always dispose of packaging materials and electrical devices and their components

through collection points or disposal companies authorised for this.

• Used electrical devices and electronic devices must not be disposed of with household

waste.

17

The devices comply with legal requirements, in particular the Electrical and Electronic Equipment Act and the REACH Regulation.

3.1.7 Impermissible operating conditions

Operational safety cannot be guaranteed under impermissible operating conditions. Always

avoid impermissible operating conditions.

Do not operate the device under the following conditions:

• Operation could injure persons.

• Objects could be damaged or destroyed unintentionally during operation.

• Malfunctions have been detected.

• Damage has been detected.

• Impermissible changes to operating parameters have been made.

• For example, the device has been modified.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 18

Duties of the operator

18

Safety

3.2 Duties of the operator

This chapter contains information on the duties of the operator of the machine in which the

device is installed.

It is the operator’s duty of care to plan safety measures and to check their implementation.

The following principles apply to minimise the risk of injury:

• Make sure that damaged devices are no longer used.

• Make sure that the device is installed and connected by authorised specialist personnel.

The following principles apply for faultless operation:

• Only use the device for its intended purpose.

• Only operate the device when it is in a perfect and functional condition.

• Make sure that the device is never opened by personnel. Damage caused by opening the

• Make sure that the device is properly transported and stored by personnel.

• Make sure that the device is never cleaned with a high-pressure cleaner. Give the service

Info

device will void the warranty.

personnel comprehensive instructions that cleaning with a high-pressure cleaner will

cause damage and that the warranty will be excluded.

Carry out regular checks. This allows you to ensure that these measures are actually

followed.

3.3 Local regulations

In addition to these instructions, correct operation of the device is regulated by laws and regulations.

The following regulations also apply for the operation of the device:

• Regulations for operating machines in which the device is installed (laws and regulations

not expressly mentioned here as well).

• Accident prevention regulations.

• Internal company regulations.

• Information on the device.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 19

Qualification of personnel

Safety

3.4 Qualification of personnel

All work on the device requires special training of the personnel.

Everyone working on the device must meet the following requirements:

• Persons between the ages of 14 and 18 may only work on and with the device under the

supervision of a person trained to use the device.

• Personally suitable for the respective activity.

• Sufficiently qualified for the respective activity.

• Trained to handle the device.

• Familiar with these operating instructions, especially with safety information and with the

sections that are relevant for the activity.

• Familiar with basic occupational safety and accident prevention regulations.

These operating instructions distinguish between the following user groups:

User groups

Personnel Qualification

19

Operating

personnel

Service

personnel

Training by the operator of the machine in which the device is installed.

The following topics must be covered in this training:

• Intended operation of the device

• Correct behaviour in the event of malfunctions, errors, damage

• Cleaning the device

• Competences and responsibilities for the activity

The required knowledge for the operating personnel is given in these

operating instructions. The operator must train the user to use the

machine in which the device is installed. Operating personnel must have

read and understood the operating instructions.

Training as a mechatronics engineer or at least equivalent training.

The tasks of the service personnel include the following activities:

• Connecting the device

• Mounting the device

• Parametrizing the device

Service personnel must have sound knowledge of the design and function of the device and must have read and understood the operating

instructions.

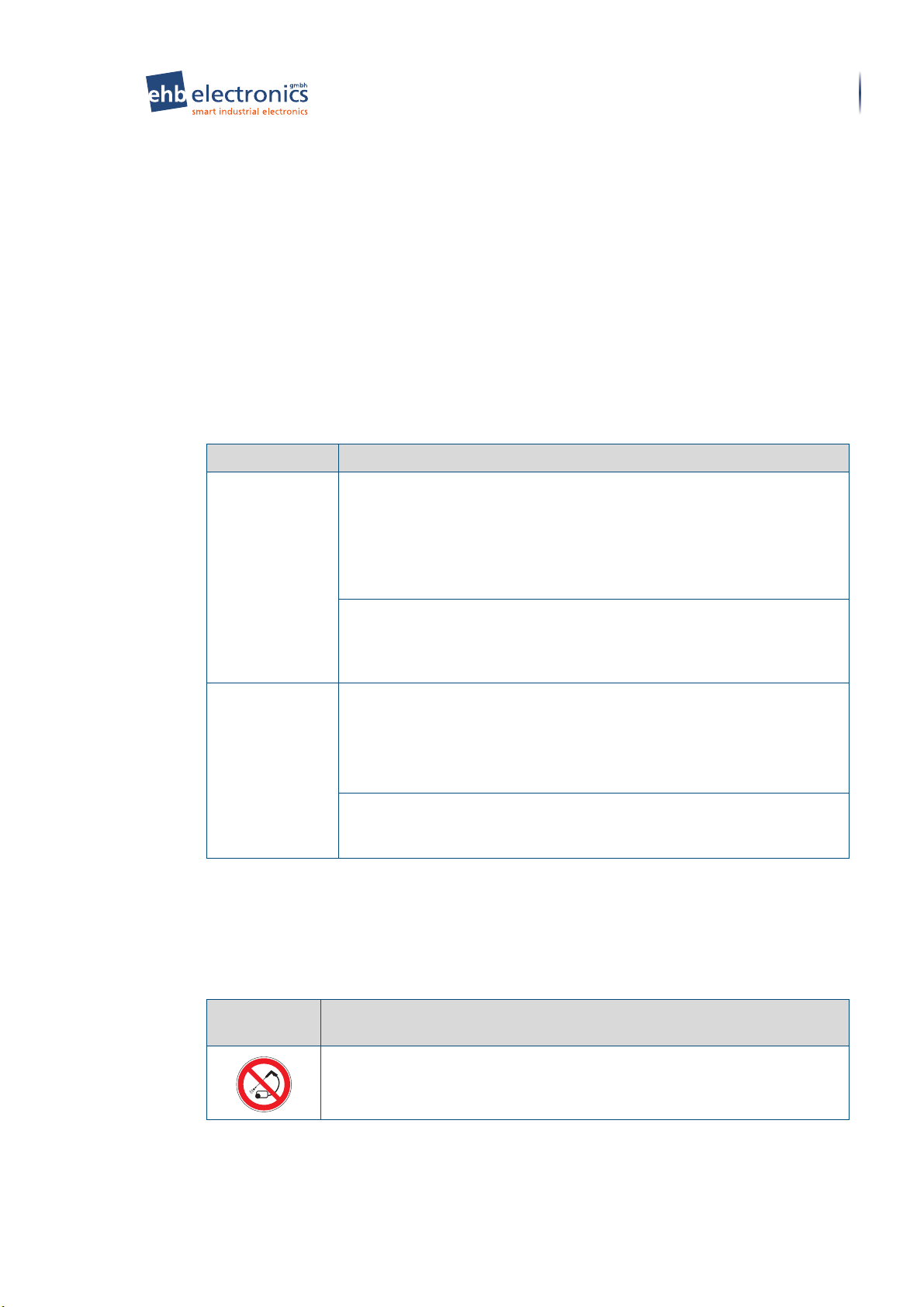

3.5 Pictograms and symbols on the device

Pictograms and symbols are attached to the device. The following table explains the meanings of the pictograms and symbols.

Pictograms and symbols on the device

Pictogram /

symbol

Meaning

Prohibited: Cleaning with a high-pressure cleaner is prohibited.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 20

Residual risk

20

Safety

3.6 Residual risk

The device is built according to the currently valid rules of technology and is safe to operate.

The device has been tested and has left the factory in a perfectly safe condition.

Residual hazards cannot be completely ruled out. Safety-conscious and precautionary behaviour of personnel avoids dangerous situations. Read and observe the safety information and

warnings to prevent risks.

Residual risks at the device and measures

Danger Cause Measure

Material damage due to

missing protective function of the starter!

Material damage due to

incorrect wiring of the

outputs!

Risk of injury due to

misuse of pin 9

(external stop) for the

emergency stop function of the engine!

Material damage due to

incorrect type of installation!

The starter of the

engine can be damaged

due to the missing

signal. The signal is

required for the integrated protective function of the starter.

If the outputs are

connected in parallel,

there is a risk that transistors may blow.

Misuse of pin 9

(external stop) for the

engine emergency stop

function may cause

serious injury at parts of

the engine. The input is

not designed for this

purpose. This can result

in delays of up to one

second.

Installation with

mounting brackets is

intended exclusively for

locations without the

influence of vibrations. If

the device with

mounting brackets is

mounted at locations

subject to vibration,

there is a risk of serious

damage to the device!

Make sure that a speed signal is

connected to pin 13 (terminal "W”).

Make sure that the transmission ratio

(PPR) and the maximum start speed are

set correctly.

Never connect the outputs in parallel.

Never use pin 9 (external stop) for the

emergency stop function of the engine!

Mount the device at locations subject to

vibration with rubber-bonded metals

(accessories).

Only carry out installation with mounting

brackets if you can ensure that no vibrations can have an effect! (For example,

in a switch cabinet)

Material damage due to

load on ignition starting

switch!

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

If weight is attached to

the ignition key (e.g.

heavy keychain,...),

there is a risk of

damaging the ignition

lock.

Do not hang any other weight or other

objects on the ignition key.

Page 21

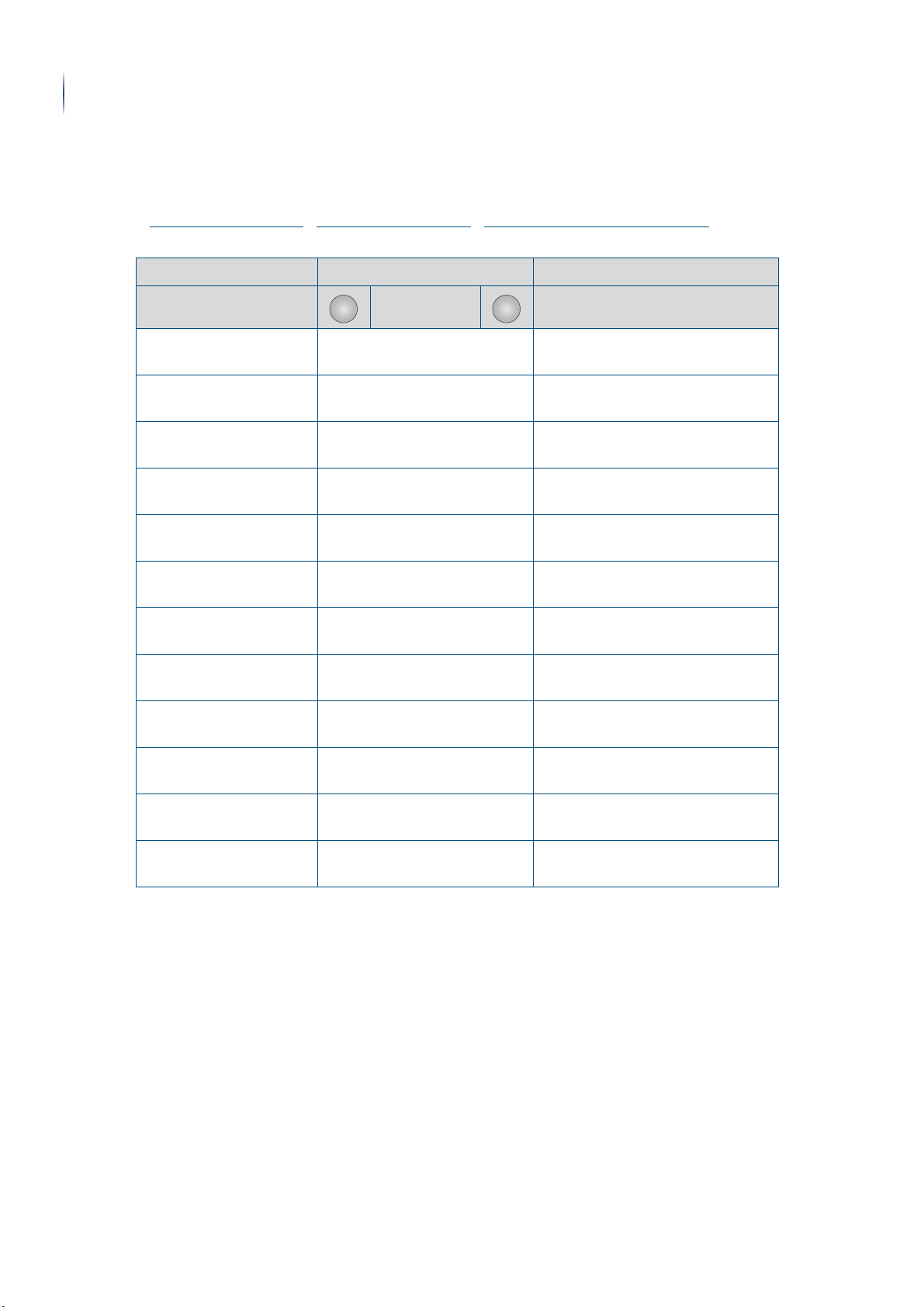

Residual risks at the device and measures (cont.)

Danger Cause Measure

Residual risk

Safety

21

Material damage due to

the ingress of water!

If the device is cleaned

with a high-pressure

cleaner, there is a risk

that water ingresses in

the housing and

damages the device.

Never clean the device with a high-pressure cleaner.

Information for the operator: Instruct your

service personnel about the consequences of using high-pressure

cleaners.

Apply the supplied label "Do not clean

with high-pressure cleaner” visibly in the

immediate vicinity of the device at the

installation site.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 22

Front of device

22

Parts of the device

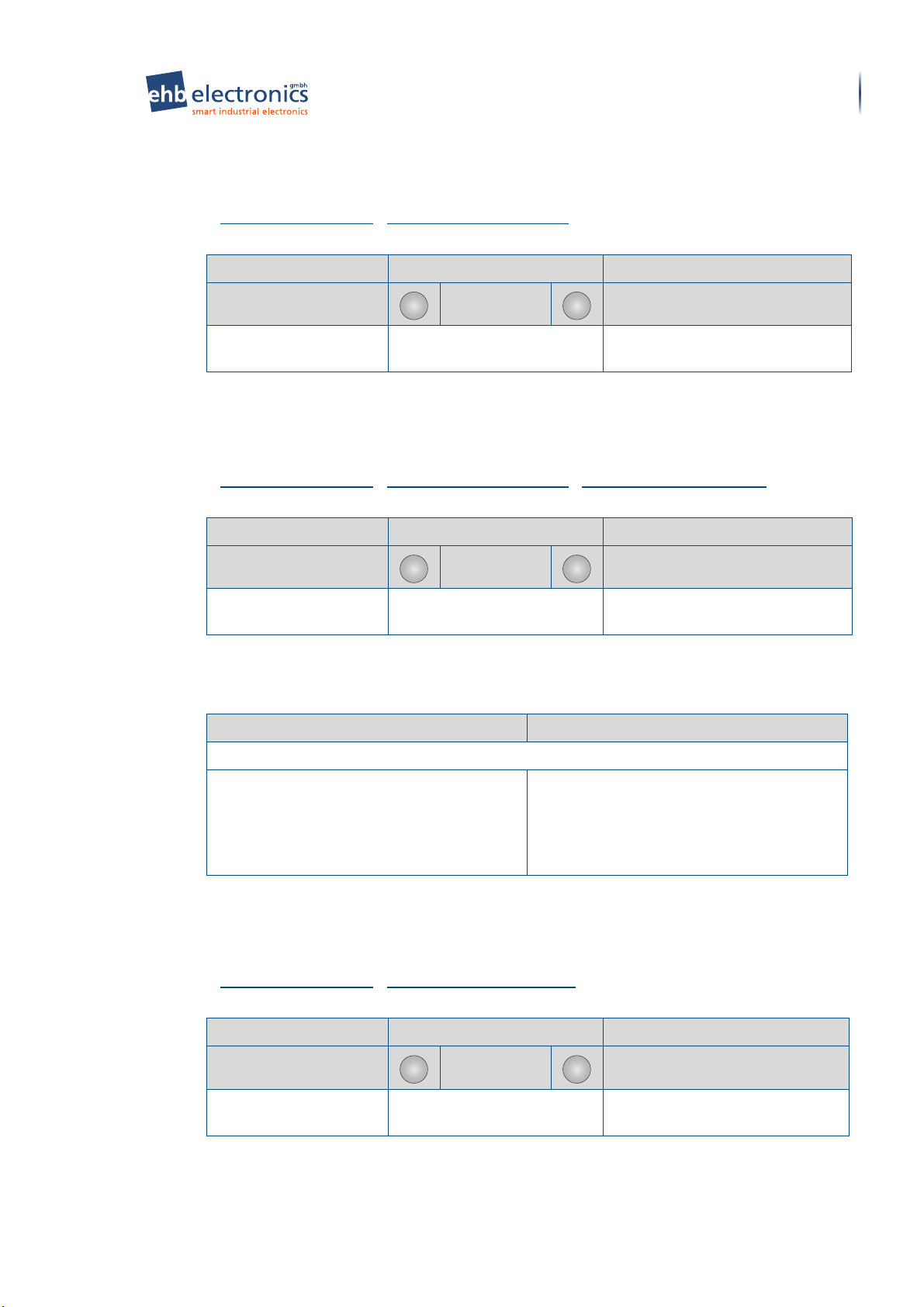

4 Parts of the device

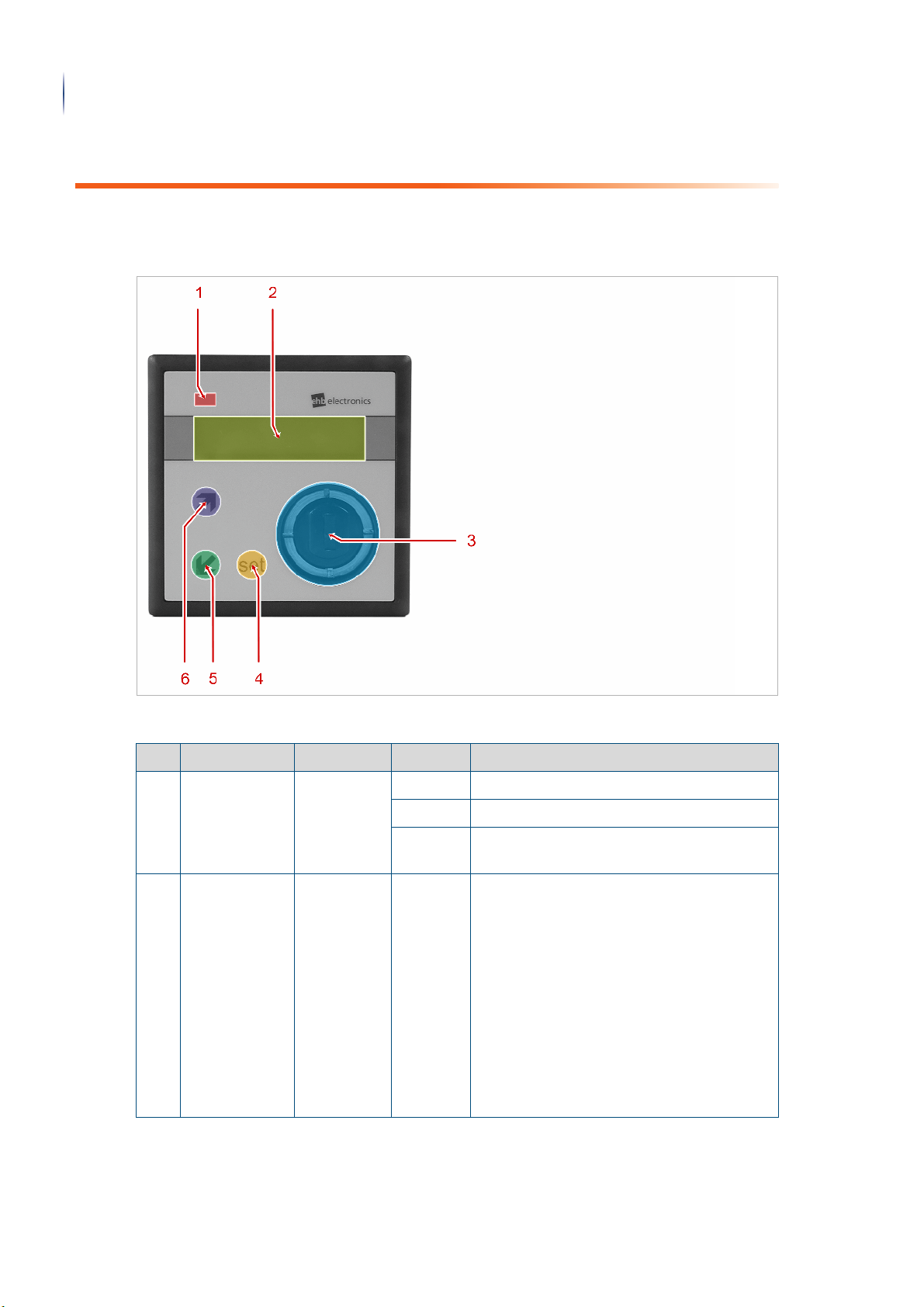

4.1 Front of device

Front of device

Legend

No. Designation Type Setting Function

1 Operation LED LED off shows that the device is switched off.

Green shows that the device is switched on.

Red shows that an error message is present on

the device.

2 Display LCD - The two-line display shows messages and

parameters during operation. Each line has

16 characters.

The following display views can be viewed

during operation:

• Operating parameters

• Daily operating hours counter

• Total operating hours counter

You can find the functions in the parametrizing mode in chapter "Parametrization" > "Design of the display in

parametrization mode" (Page 34).

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 23

Legend (cont.)

set

ì

ì

No. Designation Type Setting Function

Display views

Parts of the device

23

3 Ignition lock Ignition

starter

switch

4 Pushbutton press Used to confirm messages.

5 Pushbutton press Used to navigate through the

6 Pushbutton press Used to navigate through the

0 The device is switched off.

1 The device is supplied with power.

The "ignition” is switched on.

A connected diesel engine pre-glows.

2 The connected engine starts.

You can find the functions in the parametrizing mode in chapter "Parametrization" > "Navigating in parametrization

mode" (Page 34).

menus/display views.

The next menu item is displayed.

You can find the functions in the para-

metrizing mode in chapter "Parametrization" > "Navigating in parametrization

mode" (Page 34).

menus/display views.

The previous menu item is displayed.

You can find the functions in the para-

metrizing mode in chapter "Parametrization" > "Navigating in parametrization

mode" (Page 34).

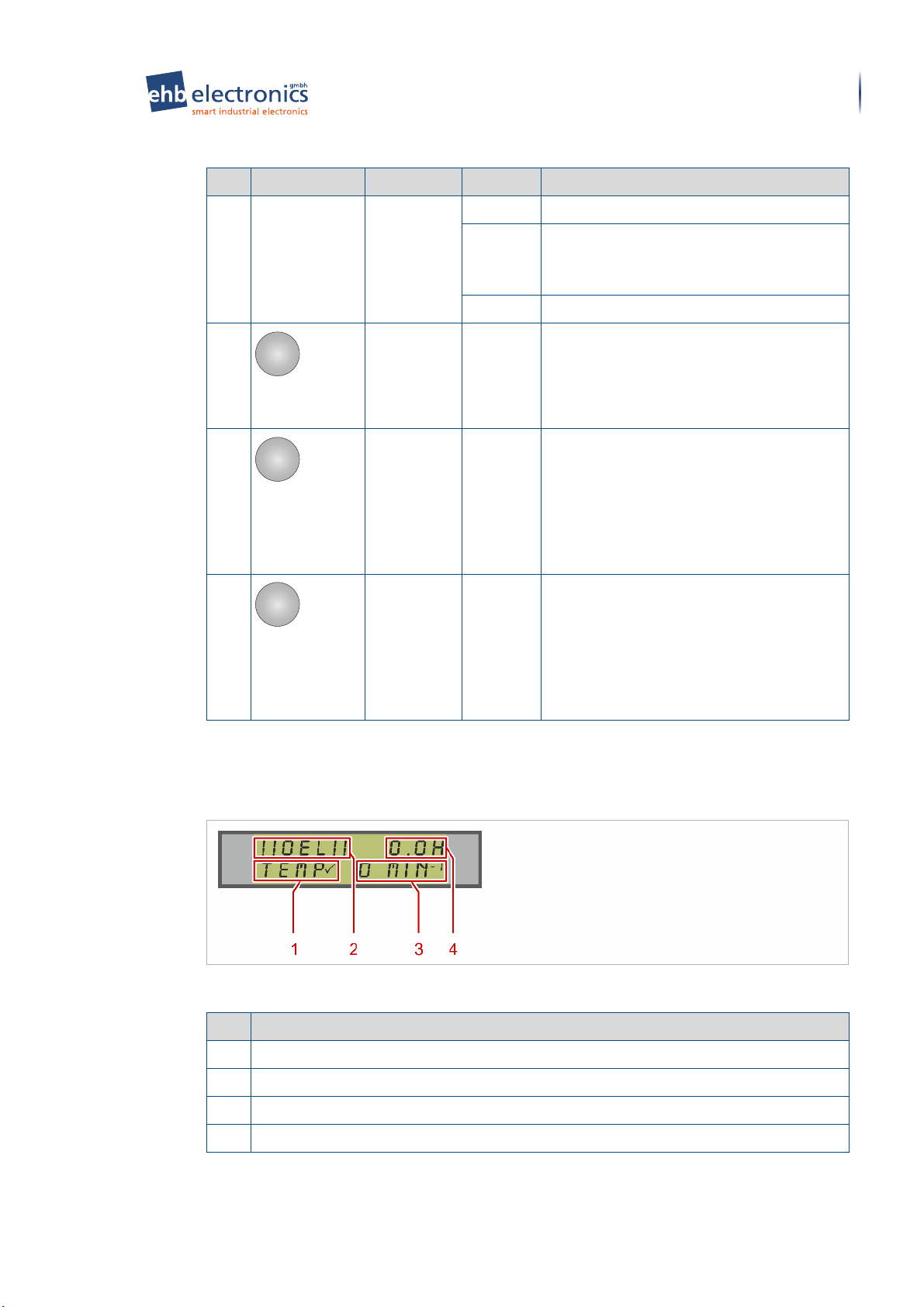

4.2 Display views

4.2.1 Operating parameters

Operating parameters

Legend

No. Function

1 Displays the current state of the engine temperature.

2 Displays the current state of the oil pressure.

3 Displays the current engine speed. (only when engine is running)

4 Displays the current daily operating duration.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 24

Rear of device

24

Parts of the device

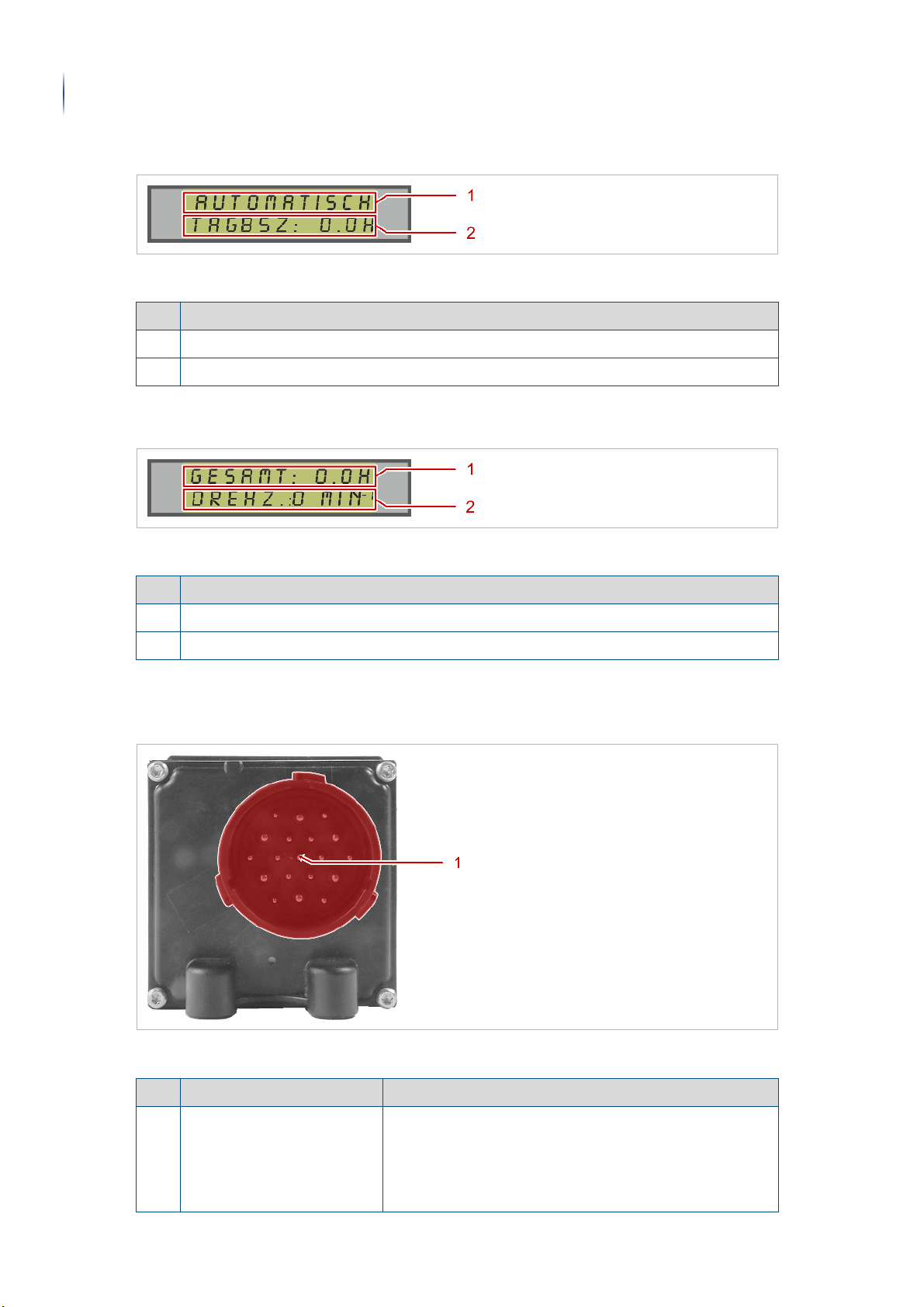

4.2.2 Daily operating duration

Daily operating duration

Legend

No. Function

1 Displays the current set operating mode of the device.

2 Displays the current daily operating duration.

4.2.3 Total operating duration

Total operating duration

Legend

No. Function

1 Displays the total operating duration.

2 Displays the current engine speed. (only when engine is running)

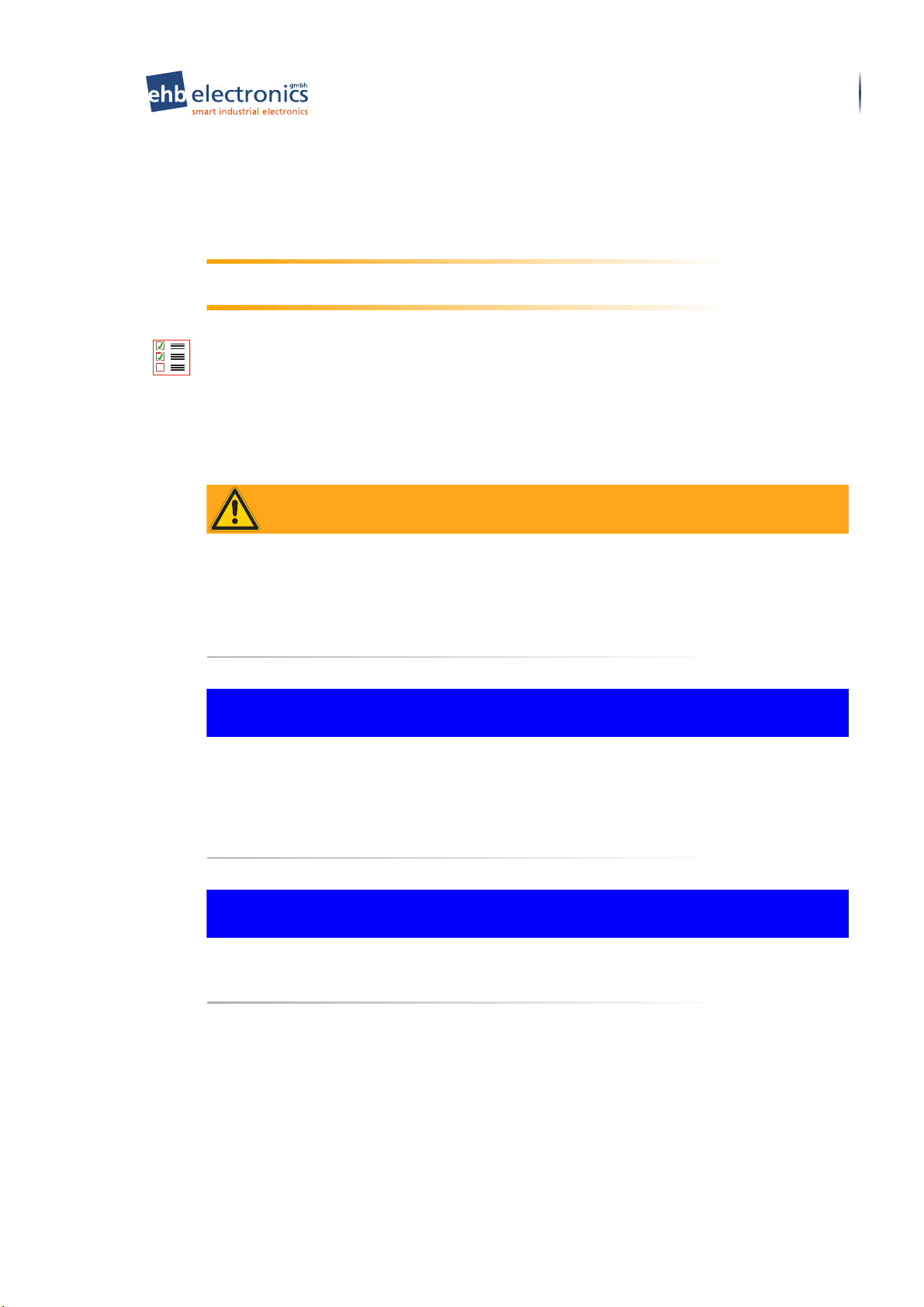

4.3 Rear of device

Rear of device

Legend

No. Designation Function

1 Device connection –

Deutsch connector

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Used as a connection point for a Deutsch connector

socket housing.

You can find an example or the pin assignment in

chapter "Unpacking, connecting and installing" >

"Connection diagram and pin assignment" (Page 27).

Page 25

4.4 Bottom of device

Bottom of device

Bottom of device

Parts of the device

25

No. Designation Function

1 Threaded bushings The three threaded bushings are used to attach the

device with the aid of M6 threaded screws.

Information about installation with fastening screws can

be found in chapter ""Unpacking, connecting and

installing" > "Installation with fastening screws"

(Page 30)".

2 Mounting bracket sockets A total of four mounting bracket sockets (two additional

mounting bracket sockets are on the top of the device)

are used to attach the mounting bracket. For example,

the device can be mounted in a switch cabinet door with

the aid of the mounting brackets.

Information about installation with mounting brackets

can be found in chapter ""Unpacking, connecting and

installing" > "Installation with mounting brackets"

(Page 31)".

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 26

Unpacking

26

Unpacking, connecting and installing

5 Unpacking, connecting and installing

5.1 Unpacking

Check the device for the following points after unpacking:

• Has any damage been found?

• Is the delivery complete? Compare the delivered parts with the information on the delivery

note.

If the device is damaged or the delivery is incomplete, inform the supplier immediately.

Carefully store any documents supplied. Enter the serial number of your device at the places

provided in these operating instructions.

Dispose of the packaging material in accordance with local regulations.

Info

Keep the original packaging in case the device needs to be shipped to the manufacturer for

maintenance at a later date.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 27

Connecting

Unpacking, connecting and installing

5.2 Connecting

5.2.1 Connection diagram and pin assignment

The following connection diagram and the associated table show as an example the pin

assignment for the ehb standard connection with a Deutsch connector, type HDP 26-24-19

SE.

27

Connection diagram and pin assignment

Example of the pin assignment

Pin Designation ehb wire code

Low-power contacts

1 Oil pressure green | 1 mm

2 Terminal "D+” (excitation) white | 1 mm

3 Temperature brown | 1 mm

4 Diverse grey | 1 mm

5 Terminal "31”, GND, earth blue | 1 mm

6 Operating magnet, excitation winding black | 1 mm

7 Autostart "(positive-switching)” orange | 1 mm

9 External stop grey/red | 1 mm

11 Speed adjustment pick-up winding green/white | 1 mm

13 Terminal "W” green/grey | 1 mm

15 Speed adjustment excitation winding green/black | 1 mm

2

2

2

2

2

2

2

2

2

2

2

17 CAN Low brown | twisted pair or shielded

19 CAN High white | twisted pair or shielded

High-power contacts

8 50f to starter purple | 2.5 mm

10 19/17 pre-glowing yellow | 2.5 mm

2

2

12 19/17 pre-glowing (or terminal 15 programmable) yellow | 2.5 mm2 or red 2.5 mm

14 Terminal "30”, battery + brown | 2.5 mm

16 Terminal "30”, battery + brown | 2.5 mm

18 Operating magnet, pull-in winding black | 2.5 mm

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

2

2

2

2

Page 28

Connecting

28

Unpacking, connecting and installing

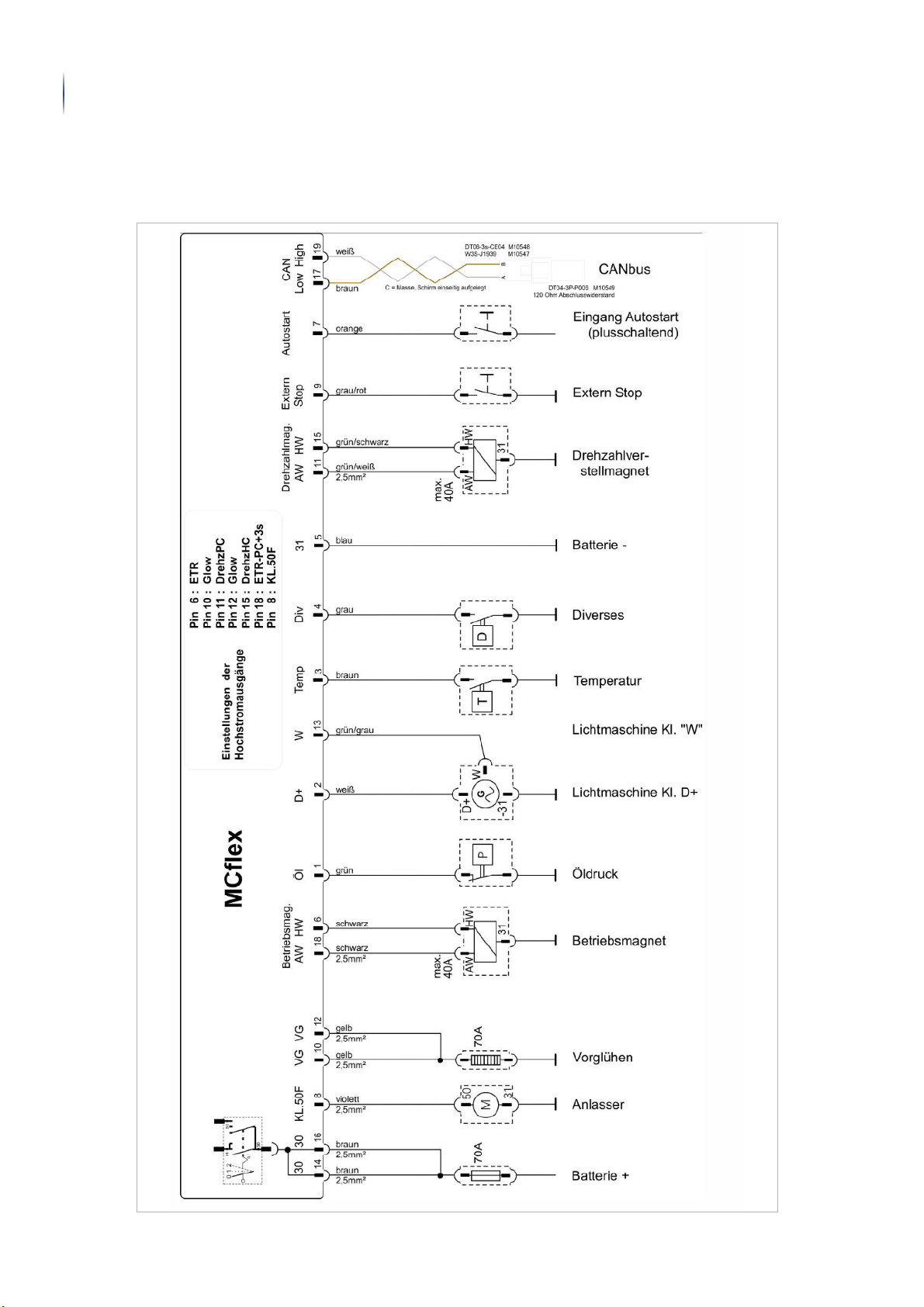

5.2.2 Circuit diagram

The following circuit diagram shows the wiring for the ehb standard connection as an

example.

Circuit diagram

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 29

Connecting

WARNING

NOTICE

NOTICE

Unpacking, connecting and installing

5.2.3 Connecting the device

The device can be used for engine monitoring in conventional engines. For this purpose, the

engine parameters to be monitored must be appropriately connected.

Safety information: Observe the information from other manufacturers!

When connecting the device, observe the information from the manufacturer of the plugs and

cable harnesses!

Requirements:

• All switching inductors have been equipped with a free-wheeling diode.

• The connection of the main power supply to the battery terminals must be direct with a suf-

ficient cross-section.

• The connection of the main power supply is fused in accordance with regulations. You can

find additional information in chapter "Device information" > "Technical data" (Page 8).

29

Risk of injury due to misuse of pin 9 (external stop) for the emergency

stop function of the engine!

Misuse of pin 9 (external stop) for the engine emergency stop function may cause serious

injury at parts of the engine. The input is not designed for this purpose. This can result in

delays of up to one second.

► Never use pin 9 (external stop) for the emergency stop function of the engine!

Material damage due to missing protective function of the starter!

The starter of the engine can be damaged due to the missing signal. The signal is required

for the integrated protective function of the starter.

► Make sure that a speed signal is connected to pin 13 (terminal "W”).

► Make sure that the transmission ratio (PPR) and the maximum start speed are set

correctly.

Material damage due to incorrect wiring of the outputs!

If the outputs are connected in parallel, there is a risk that transistors may blow.

► Never connect the outputs in parallel.

Complete the following work steps:

1. Wire the Deutsch connector socket housing for the device according to the connection di-

agram (see page 27: Connection diagram and pin assignment).

! Note that the device must be permanently connected to terminal "30” for subsequent

operation.

2. Connect the Deutsch connector socket housing with the ‹device connection - Deutsch

connector› on the device.

» Done

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 30

Mounting

30

Unpacking, connecting and installing

5.3 Mounting

5.3.1 Technical drawing

Technical drawing

5.3.2 Mounting the device

5.3.2.1 Installation with fastening screws

Requirements:

• The installation opening and holes for the fastening screws have been prepared and drilled

at the installation site according to the technical drawing (see page 30: Technical drawing).

• The device is connected (see page 29: Connecting the device).

Complete the following work steps:

1. Remove the Deutsch connector socket housing from the ‹device connection - Deutsch

connector› on the device.

2. Guide the cable harness with the Deutsch connector socket housing through the installation

opening.

3. Connect the Deutsch connector socket housing with the ‹device connection - Deutsch

connector› on the device.

4. Install the device at the desired location.

! For better vibration damping, you should provide a rubber buffer for each of the three

fastening points.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 31

Mounting

NOTICE

Unpacking, connecting and installing

5. Fasten the device from below using three M6 x 10 threaded screws

(maximum 10 mm!).

! Tighten the three M6 threaded screws by hand.

6. Apply the supplied label ‹"Do not clean with high-pressure cleaner”› visibly in the imme-

diate vicinity of the device at the installation site.

! Apply the label so that it is visible to cleaning personnel.

31

» Done

5.3.2.2 Installation with mounting brackets

Requirements:

• The installation opening has been prepared and drilled at the installation site according to

the technical drawing (see page 30: Technical drawing).

• The device is connected (see page 29: Connecting the device).

Material damage due to incorrect type of installation!

Installation with mounting brackets is intended exclusively for locations without the influence

of vibrations. If the device with mounting brackets is mounted at locations subject to vibration,

there is a risk of serious damage to the device!

► Mount the device at locations subject to vibration with rubber-bonded metals (see

page 30: Installation with fastening screws).

► Only carry out installation with mounting brackets if you can ensure that no vibrations can

have an effect! (For example, in a switch cabinet)

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 32

Mounting

32

Unpacking, connecting and installing

Complete the following work steps:

1. Remove the Deutsch connector socket housing from the ‹device connection - Deutsch

connector› on the device.

2. Guide the cable harness with the Deutsch connector socket housing through the installation

opening.

3. Connect the Deutsch connector socket housing with the ‹device connection - Deutsch

connector› on the device.

4. Install the device at the desired location.

5. Insert the two ‹mounting brackets› in the four ‹mounting bracket sockets› on the device.

! There are two mounting bracket sockets on the top and bottom of the device.

6. Swivel the two mounting brackets against the inside of the installation opening at the instal-

lation site.

! Make sure that the mounting brackets securely clamp the device at the installation site.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 33

Mounting

Unpacking, connecting and installing

7. Apply the supplied label ‹"Do not clean with high-pressure cleaner”› visibly in the imme-

diate vicinity of the device at the installation site.

! Apply the label so that it is visible to cleaning personnel.

» Done

33

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 34

Design of the display in parametrization mode

ì

ì

set

34

Parametrization

6 Parametrization

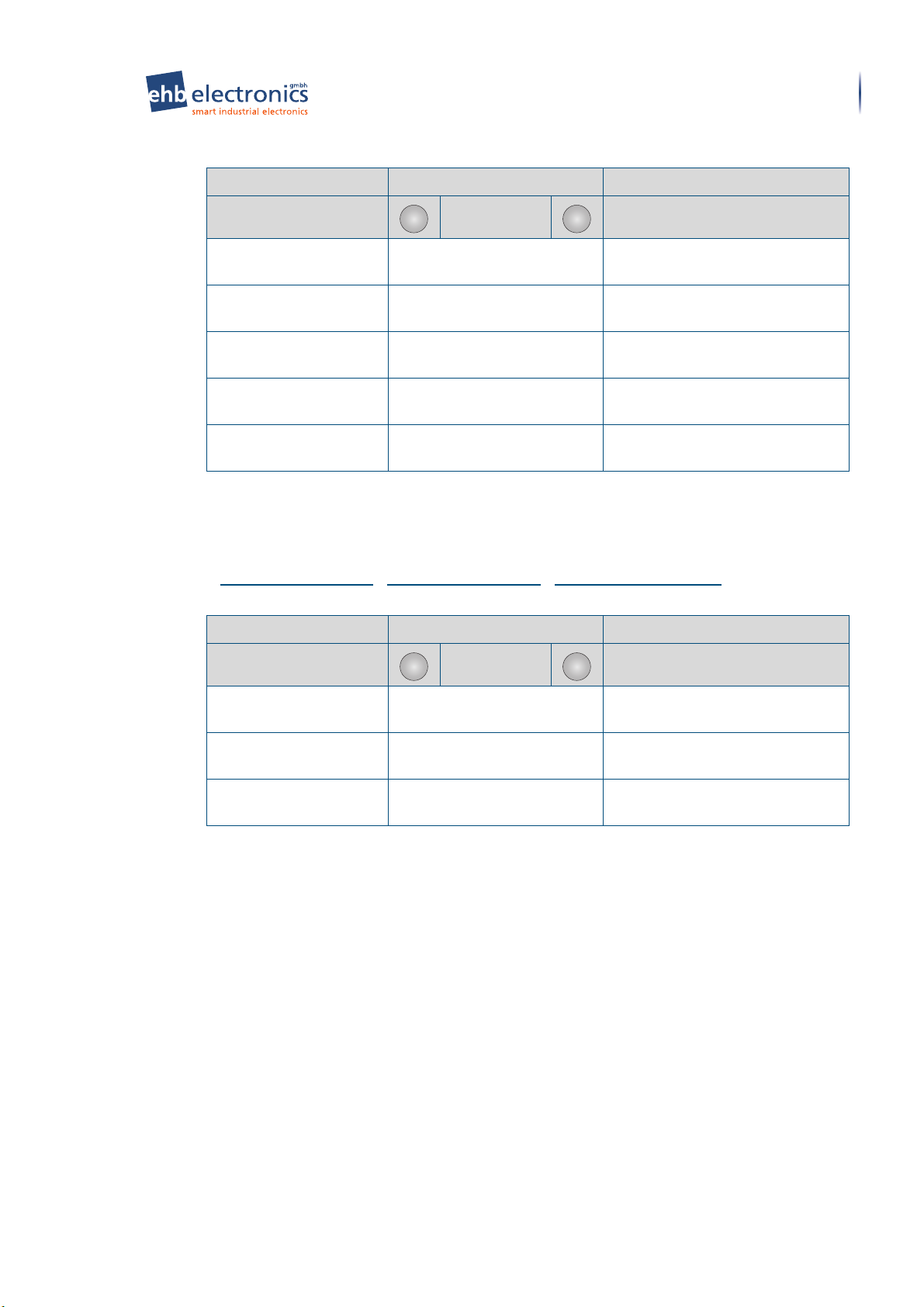

6.1 Design of the display in parametrization mode

Design of the display in parametrization mode

Legend

No. Designation Function

1 Menu line Generally the name of the relevant menu is shown in the

2 Entry line The parameters of the relevant menu are displayed and

menu line.

entered in the entry line.

6.2 Navigating in parametrization mode

Navigating in parametrization mode

Designation Function

Used to navigate through the menu.

Used to navigate through the available parameters.

Increase or decrease parameter values.

Used to select a menu to open a submenu.

Used to select an available parameter.

Used to confirm a parameter value entered.

6.3 Parametrizing the device

Requirements:

• The device is correctly mounted (see page 30: Unpacking, connecting and installing >

Mounting).

• The engine is switched off.

Complete the following work steps:

1. Press and hold the ‹set› pushbutton.

2. Turn the ‹ignition key› in the ‹ignition lock› to

▼ The device is switched on.

▼ Parametrizing mode is started.

▼ The "MENU SELECTION”* message is shown in the display.

3. Make the required settings.

! You can find a description of the menus in chapter "Menus in parametrization mode"

(Page 35).

» Done

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

position 1

.

Page 35

7 Menus in parametrization mode

7.1 Overview

Overview

Level 1 Level 2 Level 3

Main menu

Submenu – Settings

Overview

Menus in parametrization mode

Submenu language

Sensor submenu

High-power output

submenu

Glow times submenu

35

Submenu – Service

Submenu – Safety

Submenu – Daily operating hours counter

Generator.Er submenu

Autostart submenu

Fault event submenu

Fault times menu

Limit values submenu

Inputs/outputs submenu

[1] Service settings

[2] Fault list

[3] F.L. delete

Submenu – PIN numbers

Submenu – Self-test

Submenu – Day counter

Submenu – Operating

hours counter

Submenu – OHC – Menu

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 36

Main menu

set

set

set

set

36

Menus in parametrization mode

7.2 Main menu

Main menu

Selection and entry options

Menu name Action Result

[1] Settings Pin No.:

Pin No.:

reset to the factory setting! All

preset values are deleted and

must be parametrized again.)

[2] Service Pin No.:

[3] Safety Pin No.:

[4] Day counter Pin No.:

[5] TOH counter Pin No.:

End! Select Programming mode is terminated.

Info

You have three attempts to enter the correct PIN no. in the prompts of the submenu. The

main menu opens automatically after three incorrect entries. If the PIN number is not known,

you have the option to terminate the query with the ignition starter switch.

1000

(factory-set)

1272

(the device is

2000

(factory-set) "Submenu – Service" (Page 61) is

3000

(factory-set) "Submenu – Safety" (Page 63) is

4000

(factory-set) "Submenu – Daily operating hours

5000

(factory-set) "Submenu – Operating hours

"Submenu – Settings" (Page 36)

is opened.

opened.

opened.

counter" (Page 65) is opened.

counter" (Page 65) is opened.

7.3 Submenu – Settings

7.3.1 [1] Settings

> Main menu (Page 36) > [1] Settings (Page 36)

[1] Settings

Selection and entry options

Menu name Action Result

[1] Language Select "Submenu language" (Page 37) is

opened.

[2] Sensors Select "Sensor submenu" (Page 38) is

opened.

[3] High-power output Select "High-power output submenu"

(Page 40) is opened.

[4] Glow times Select "Glow times submenu" (Page 46)

is opened.

[5] Generator.Er Select "Generator.Er submenu"

(Page 49) is opened.

[6] Autostart Select "Autostart submenu" (Page 49) is

opened.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 37

Submenu – Settings

set

set

set

set

Menus in parametrization mode

[1] Settings (cont.)

Selection and entry options

Menu name Action Result

[7] Fault event Select "Fault event submenu" (Page 51)

is opened.

[8] Fault times Select "Fault times menu" (Page 54) is

opened.

[9] Limit values Select "Limit values submenu" (Page 57)

is opened.

[10] Inputs/Outputs Select "Inputs/outputs submenu"

(Page 59) is opened.

Finish set-up Select The previous upper menu is

opened.

7.3.2 Submenu language

37

7.3.2.1 [1] Language

> Main menu (Page 36) > [1] Settings (Page 36) > [1] Language (Page 37)

[1] Language

Selection and entry options

Menu name Action Result

Language German, English, French,

Russian (optional)

Units C/bar, F/bar, C/psi, F/psi The parameter is selected and

Back Select The previous upper menu is

The parameter is selected and

saved.

saved.

opened.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 38

Submenu – Settings

set

set

38

Menus in parametrization mode

7.3.2.2 Descriptions of the menu entries

Descriptions of the menu entries

Description Parameter information

LANGUAGE

In this menu, the language shown can be

selected in the display.

UNITS

In this menu, the unit for temperature and

the unit for pressure can be selected.

Available languages:

• German

• English

• French

• Russian

Available units for temperature:

• C/bar

• F/bar

Available units for pressure:

• C/psi

• F/psi

7.3.3 Sensor submenu

7.3.3.1 [2] Sensors

> Main menu (Page 36) > [1] Settings (Page 36) > [2] Sensors (Page 38)

[2] Sensors

Selection and entry options

Menu name Action Result

Oil (oil pressure pin1) 0-2bar, 0-3bar, 0-5bar,

0-10bar, 0-16bar, 0-25bar

Temp. (temperature

pin 3)

Imp/rot. 0.1 - 999.9 The parameter value entered is

Terminal W: PNP / (NPN) The parameter is selected and

Back Select The previous upper menu is

KTY, PT100, PT1000,

92-027-004, 92-027-006,

92-027-016, 92-027-022,

92-027-064, 92-027-081,

LDW1603

The parameter is selected and

saved.

The parameter is selected and

saved.

saved.

saved.

opened.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 39

Menus in parametrization mode

7.3.3.2 Descriptions of the menu entries

Descriptions of the menu entries

Description Parameter information

OIL PRESSURE (PIN 1)

Submenu – Settings

39

In this menu, the type of oil pressure

sensor can be selected.

This requires pin 1 being set to sensor

when parametrizing the inputs and

outputs (see page 59: Inputs/outputs

submenu). This menu item is not

displayed when selecting N.C., N.O. or

Without.

TEMPERATURE (PIN 3)

In this menu, the type of temperature

sensor can be selected.

This requires pin 3 being set to sensor

when parametrizing the inputs and

outputs (see page 59: Inputs/outputs

submenu). This menu item is not

displayed when selecting N.C., N.O. or

Without.

IMP/ROT.

In this menu, the number of pulses per

rotation from the pulse generator or the

number of pole pairs of the generator

including the transmission ratio can be

set. You can find information about the

calculation of the correct parameter value

in section "Operation" > "Setting pulses

per rotation" (Page 72).

Available oil pressure ranges:

• 0-2 bar

• 0-3 bar

• 0-5 bar

• 0-10 bar

• 0-16 bar

• 0-25 bar

Available sensor types:

• KTY

• PT100, PT1000,

• 92-027-004, 92-027-006, 92-027-016, 92-

027-022, 92-027-064, 92-027-081

• LDW1603

Available input range of 0.1 to 999.9.

TERMINAL W (PIN 13)

In this menu, the input wiring of terminal

W can be set to pin 13. This value can

only be set for hardware version 8.0 or

higher.

PNP:

• 10 kΩ pull-down resistor

• Operates with a terminal W connection of a

generator, a PNP inductor or other pulse

generators.

NPN:

• connected 2.5 kΩ pull-up resistor

• Operates with a NPN inductor connected to

ground.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 40

Submenu – Settings

set

set

40

Menus in parametrization mode

7.3.4 High-power output submenu

7.3.4.1 [3] High-power output

> Main menu (Page 36) > [1] Settings (Page 36) > [3] High-power output (Page 40)

[3] High-power output

Selection and entry options

Menu name Action Result

Pin 6 Diverse, see section "Selec-

tion options" (Page 42).

Pin 10 Diverse, see section "Selec-

tion options" (Page 42).

Pin 11 Diverse, see section "Selec-

tion options" (Page 42).

Pin 12 Diverse, see section "Selec-

tion options" (Page 42).

Pin 15 Diverse, see section "Selec-

tion options" (Page 42).

Pin 18 Diverse, see section "Selec-

tion options" (Page 42).

Pin 8 Diverse, see section "Selec-

tion options" (Page 42).

DrzMagTime 1-99 seconds The parameter value entered is

CDownTime 0-15 minutes The parameter value entered is

ChokeTime 0-255 seconds The parameter value entered is

The parameter is selected and

saved.

The parameter is selected and

saved.

The parameter is selected and

saved.

The parameter is selected and

saved.

The parameter is selected and

saved.

The parameter is selected and

saved.

The parameter is selected and

saved.

saved.

saved.

saved.

Automatic idle 0-99 seconds The parameter value entered is

Back Select The previous upper menu is

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

saved.

opened.

Page 41

Menus in parametrization mode

7.3.4.2 Descriptions of the menu entries

Descriptions of the menu entries

Description Parameter information

PIN 6, PIN 10, PIN 11, PIN 12, PIN 15, PIN 18, PIN 8

Submenu – Settings

41

In this menu, the relevant function of the

selected pin of the high-power output is

adjusted.

DRZMAGTIME

In this menu, the speed magnet time can

be set. After the set time has elapsed, the

high-power outputs ‹DrehzHC› and

‹DrehzPC› are activated (see page 42:

Selection options).

CDOWNTIME

In this menu, the follow-up time and

cooling time of the engine can be set.

CHOKETIME

In this menu, the choke time when starting

the engine can be set in seconds.

All SpeedHC and speedPC functions

support this function.

This means that these functions are activated during the starting process and

remain active for the programmed time in

seconds after the engine has been

successfully started. This means more

fuel is injected when starting and for a

short time afterwards.

Detailed information about the parameters that

can be selected can be found in chapter "Selection options" (Page 42).

Available input range of 1 to 99 seconds.

Available input range of 0 to 15 minutes.

Available input range of 0 to 255 seconds.

If the value 255 is entered, the function is

switched off.

AUTOMATIC IDLE

In this menu, the delay time for deactivating the output when the signal at pin 9

drops can be set. Note that the time is

restarted at pin 9 each time the signal

drops.

Available input range of 0 to 99 seconds.

If the value 0 is entered, the speed parameter

functions. HC pin 9 as described in section

"Selection options" (Page 42).

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 42

Submenu – Settings

42

Menus in parametrization mode

7.3.4.3 Selection options

Selection options

OFF The selected output pin of the Deutsch connector is deacti-

ETR-HC The selected output pin of the Deutsch connector has the func-

ETR-PC The selected output pin of the Deutsch connector has the func-

ETR-PC+3s The selected output pin of the Deutsch connector has the func-

vated.

tion of an operating magnet ETR excitation winding.

The operating magnet – Energise To Run (ETR) is a lifting

magnet that enables the fuel feed when live. This must be

switched on during engine operation.

This function is not activated until the start procedure.

tion of an operating magnet ETR pick-up winding.

The operating magnet ETR pick-up winding allows a short-term

activation of approximately 0.5 seconds to engage the operating magnets.

tion of an operating magnet ETR pick-up winding.

The output is activated with the starter and remains active for

another 3 seconds after the starter is switched off. This function is especially for HATZ engines.

ETS-HC The selected output pin of the Deutsch connector has the func-

tion of a stopping solenoid ETS excitation winding.

The stopping solenoid – Energised To Stop (ETS) – is a lifting

magnet requiring voltage to stop the engine.

ETS-PC The selected output pin of the Deutsch connector has the func-

tion of a stopping solenoid ETS pick-up winding.

The stopping solenoid ETS pick-up winding allows a short-term

activation of approximately 0.5 seconds to engage the stopping

solenoids.

KL.15 The selected output pin of the Deutsch connector has the func-

tion of a switched output terminal 15 of the ignition starter

switch.

After an external stop signal at pin 9, it is deactivated.

This is regardless of whether the ignition starter switch is still in

position 1.

Glow The selected output pin of the Deutsch connector has the func-

tion of a pre-glow output.

This output is then active for pre-glowing, by-glowing and after-

glowing.

Alarm The selected output pin of the Deutsch connector has the func-

tion of an alarm output. The output is then active for warnings

or fault events.

SpeedHC The selected output pin of the Deutsch connector has the func-

tion of a speed-adjusting solenoid excitation winding. The

output is automatically activated after the ‹SpeedMagTime›

has elapsed when the engine is running.

SpeedPC The selected output pin of the Deutsch connector has the func-

tion of a speed-adjusting solenoid pick-up winding. The output

is automatically activated for approx. 0.5 seconds after the

‹SpeedMagTime› has elapsed when the engine is running.

Translation of the original operating instructions • Engine controller MCflex • 08/05/2018 • 3.0 • GB

Page 43

Submenu – Settings

Menus in parametrization mode

Selection options (cont.)

Mot.Running The selected output pin of the Deutsch connector has the func-

tion of a signal output. The output is active when the engine is

switched on.

Mot.Stopped The selected output pin of the Deutsch connector has the func-

tion of a signal output. The output is active when the engine is

switched off.

SpeedHC CAN The selected output pin of the Deutsch connector has the func-

tion of a speed-adjusting solenoid excitation winding. The

output is activated and deactivated via a CANbus message

when the engine is switched on.

The CANbus message can be transmitted with the aid of an

ehb CANmodule ehb5002-14.

SpeedPC CAN The selected output pin of the Deutsch connector has the func-

tion of a speed-adjusting solenoid pick-up winding. The output

is active via a CANbus message for approximately 0.5 seconds

when the engine is switched on.

The CANbus message can be transmitted with the aid of an

ehb CANmodule ehb5002-14.

43

KL.50F The selected output pin of the Deutsch connector has the func-

tion of a starter output. The output has a direct connection to

the starter. In addition, the output has built-in starter protection.

The starter protection prevents start-up if the engine is

switched on or still stopping. This prevents damage to the

starter, pinion and engine sprocket.

ALARM_DIV The selected output pin of the Deutsch connector has the func-

tion of a signal output. The output sends the status of pin 4

(diverse).

For example, a low tank level (tank level switch) can be acoustically signalled by a horn.

KL.75 The selected output pin of the Deutsch connector has the func-

tion of a switched output terminal 75 of the MCflex ignition

starter switch.

SpeedHC Key The selected output pin of the Deutsch connector has the func-

tion of a speed-adjusting solenoid excitation winding. The

output is activated when the engine is switched on using the