Installation & Start-up Guide

EGUANA Commercial AC BATTERY™

Model/Series

ACB15-480/208

For use only with battery model

LG Chem EM048126P3S7

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions for the Eguana Commercial AC Battery™ Energy

Storage System. The Eguana Commercial AC Battery™ components described by this manual

are intended to be used as part of an Energy Storage system and installed per all local building

codes and regulations in addition to the National Electrical Code, ANSI/NFPA 70 (for US) and

Canadian Electrical Code (for Canada).

CAUTION! Hazardous Voltages! This inverter contains hazardous voltage and energy that

may be lethal. It may only be installed by qualified personnel who have read this manual and

are familiar with its operation and hazards. The following safety procedures should be followed:

CAUTION! Equipment powered by two sources of power. Disconnect all power sources and

wait 5 minutes before servicing.

1 Only connect the PCS cabinet to a compatible electrical service as defined in the model

specifications. The PCS must be connected to a dedicated branch circuit in the main

electrical panel.

2 An external disconnect switch shall be provided in the end installation by others for the AC

Grid output circuit.

CAUTION! This equipment contains high energy lithium batteries. Qualified and trained

personnel should wear protective clothing and equipment when working inside the battery cabinet

and/or with battery modules.

3 The PCS is compatible with the LG Chem battery model EM048126P3S7 only.

CAUTION! The batteries provided with this system must be charged only by the PCS

included as part of the energy storage system. Do not attempt to charge batteries with any

other charger device or connect any devices directly to the DC battery bus.

4 Ensure proper electrical grounding in accordance with code requirements.

5 Ensure proper airflow path for active cooling.

6 Never operate system in a manner not described by this manual.

7 Only qualified personnel should service this product.

8 Ensure all covers are securely fastened after installation is complete.

9 This product must be stored indoors in an environmentally conditioned location prior to

installation, protected from rain and exposure to any hazardous chemicals.

10 Do not attempt to operate this product if there is any physical evidence of damage to any of

the cabinets or internal components.

CAUTION! This equipment is heavy. Mechanical lifts are recommended for safe installation.

Table of Contents

1 SAFETY ..................................................................................................................................................................................... 1

1.1 IN CASE OF EMERGENCY ............................................................................................................................................... 1

1.2 BATTERY MODULE SAFETY PRECAUTIONS ........................................................................................................................... 1

1.3 GENERAL SAFETY PRECAUTIONS .................................................................................................................................... 2

1.4 ENVIRONMENTAL PROTECTION ....................................................................................................................................... 2

2 INTRODUCTION ............................................................................................................................................................................... 3

2.1 ABOUT THIS MANUAL – TARGET AUDIENCE ............................................................................................................ 3

2.2 GLOSSARY ........................................................................................................................................................... 3

2.3 INITIAL INSPECTION OF MATERIAL LIST .................................................................................................................. 3

2.4 INSTALLATION MATERIALS NOT INCLUDED .............................................................................................................. 3

2.5 SPECIAL TOOLS ................................................................................................................................................... 3

3 INSTALLATION SITE PREPARATION .......................................................................................................................................... 4

3.1 INSTALLATION PLANNING ..................................................................................................................................... 4

3.2 CABINET PLINTH PAD-MOUNT DIMENSIONS ........................................................................................................... 4

3.3 CABINET LIFT METHOD ......................................................................................................................................... 5

3.4 SLD - AC COUPLED PV SYSTEM WITH BACK-UP POWER OPERATION .................................................................... 6

4 CABINET INSTALLATION INSTRUCTIONS ................................................................................................................................. 7

5 INTERNAL PRODUCT LAYOUT .................................................................................................................................................... 8

6 SYSTEM ELECTRICAL WIRING ................................................................................................................................................... 9

6.1 AC GRID AND AC LOAD WIRING .......................................................................................................................... 9

6.2 CHASSIS GROUNDING ....................................................................................................................................... 10

6.3 EMS TO PCS COMMUNICATION WIRING & RJ45 PIN-OUT .................................................................................. 10

6.4 AUXILIARY ACTUATOR RELAYS .......................................................................................................................... 10

7 START-UP SEQUENCE ................................................................................................................................................................ 11

8 OPERATION .................................................................................................................................................................................. 12

9 PCS DISPLAY PANEL .................................................................................................................................................................. 13

9.1 LED DISPLAY INDICATORS .................................................................................................................................. 13

9.2 PCS DISPLAY PANEL INDICATOR SUMMARY. ......................................................................................................... 13

9.3 SERVICE BUTTON ............................................................................................................................................... 14

10 MAINTENANCE ............................................................................................................................................................................ 14

11 TROUBLESHOOTING .................................................................................................................................................................. 14

12 SPECIFICATIONS ........................................................................................................................................................................ 15

Table 1: PCS Electrical / Mechanical Ratings.......................................................................................................................... 15

Table 2: PCS Field Wiring Ratings – AWG / Torque ............................................................................................................... 16

12.1 UL 1741 SA GRID SUPPORT UTILITY INTERACTIVE INVERTER SPECIFICATIONS.................................................. 17

Table 3: UL1741 SA grid support functions. ............................................................................................................................ 17

Table 4: Low and high voltage ride through settings. .............................................................................................................. 17

Table 5: Low and high frequency ride through settings. .......................................................................................................... 18

12.2 Thermal Performance of PCS and Battery Modules ................................................................................................... 22

APPENDIX A: ACB-15 SERIES ELECTRICAL BLOCK DIAGRAMS .............................................................................................. 24

A.1: THREE PHASE 480 V WYE ................................................................................................................................ 24

A.2: THREE PHASE 208 V DELTA ............................................................................................................................. 25

A.3 COMMUNICATION ................................................................................................................................................ 26

1 Safety

Symbol

Definition

Symbol

Definition

WARNING! A dangerous voltage or other

condition exists. Use extreme caution when

performing these tasks.

Meter measurement required.

CAUTION! This information is critical to the

safe installation and or operation of the inverter.

Follow these instructions closely.

Torque rating critical to operation.

NOTE: This statement is important. Follow

instructions closely.

Login to the remote monitoring system

for operating status

EMS

This manual contains important instructions for the Eguana Commercial AC Battery™ Energy Storage System. The

Eguana Commercial AC Battery™ components described by this manual are intended to be used as part of an Energy

Storage system and installed per all local building codes and regulations in addition to the National Electrical Code,

ANSI/NFPA 70 (for US) and Canadian Electrical Code (for Canada).

Throughout this manual, the following symbols will be used to highlight important information and procedures:

1.1 In case of emergency

In all cases:

If safe to do so, switch off the AC breakers (external to the system) .

Contact the fire department or other required emergency response team.

Evacuate the area, and if applicable, follow your emergency evacuation plan if others are in proximity to the

installed location.

In case of fire:

When safe, use a fire extinguisher suitable for use; including A, B, and C dry chemical fire extinguishers or

carbon dioxide extinguishers.

In case of flooding:

Stay out of water if any part of the system or wiring is submerged.

Do not attempt to operate batteries that have been submerged in water even after they have been dried.

In case of unusual noise, smell or smoke:

If safe to do so, ventilate the area.

1.2 Battery module safety precautions

This product is integrated with LG Chem EM048126P3S7 series battery modules. Refer to the LG Chem product

manual LG Chem P3S series 48V Standalone Battery Module Installation Manual, for complete safety instructions

regarding handling of battery modules.

1

1.3 General safety precautions

Risks of Fire

Do not expose the system to temperatures exceeding 60 degrees Celsius.

Avoid installation in direct sunlight.

Do not store objects on top of the cabinet.

Do not obstruct the airflow paths of the HVAC cooling system.

Do not obstruct the intake or exhaust of the forced airflow system.

Do not store combustible objects and corrosive chemicals directly adjacent to the system.

Risks of Shock

WARNING! Hazardous Voltages. The Inverter contains hazardous voltage and energy that may be lethal.

It may only be installed by qualified personnel who have read this manual and are familiar with its operation and

hazards.

Only connect the PCS cabinet to a compatible electrical service as defined in the model specifications. The PCS

must be connected to a dedicated branch circuit in the main electrical panel.

Ensure proper electrical grounding in accordance with code requirements.

CAUTION! Both AC and DC voltage sources are terminated inside this equipment. Each circuit must be

individually disconnected before servicing

Risks of Damage

The PCS is compatible with the LG Chem battery model EM048126P3S7 only. Do not attempt to connect any

other battery to the system.

Do not connect any other loads directly to the battery power bus.

Do not drop, tip, or puncture the cabinet during transport and installation. Visible damage to the cabinet

and/or internal components should be reported to the manufacturer immediately.

Do not store this system for periods longer than six months without a battery maintenance charge. This may

result in permanent damage to the batteries.

Important! Installation, service, and operating personnel must read this document in its entirety, and observe all

safety and installation procedures as described in this manual. Never operate system in a manner not described by

this manual.

Only qualified personnel should service this product.

Ensure all covers are securely fastened after installation is complete.

Personal Protective Equipment (PPE) in compliance with local work place safety standards must be worn when

working inside the cabinet.

1.4 Environmental Protection

Do not dispose of the system or any of the components within the cabinet. Batteries, electronics, cables, and metal

parts are recyclable. Consult your municipal waste management authority to determine required methods of

component recycling.

2

2 Introduction

Term

Definition

Term

Definition

AC

Alternating Current

NC

Normally Closed

ARC

Auto Recovery Circuit

NEC

National Electrical Code

CPU

Central Processing Unit

NO

Normally Open

DC

Direct Current

PCS

Power Control System (Inverter)

EMS

Energy Management System

PE

Protective Earth

ESD

Electrostatic Discharge

PV

Photo-Voltaic

ESS

Energy Storage System

RF

Radio Frequency

GND

Ground

SOC

State Of Charge (Battery)

LED

Light Emitting Diode

SOH

State of Health (Battery)

2.1 About this Manual – Target Audience

This manual is intended to be used by qualified service and installation personnel for the purposes of product

installation. This manual contains instructions for the installation and start up sequence of the Eguana Commercial AC

Battery energy storage system. This product is permanently wired to the electrical service, and must be installed by a

licensed electrician only.

This system requires an externally supplied energy management system to operate and manage the battery system.

The energy management system must be qualified and approved for use by Eguana Technologies to be compliant with

the manufacturer warranty. Consult the manufacturer for a list of approved energy management systems prior to

installation of this product.

2.2 Glossary

2.3 Initial Inspection of Material List

In addition to the battery system, the following additional components are supplied with your Eguana Commercial AC

Battery™ Energy Storage system. Each component should be inspected visually for any damage that may have been

caused by shipment. If damage is present, please contact your local distributor.

Cabinet canopy

Hardware kit

Installation and Startup Guide

Antenna (optional)

2.4 Installation materials not included

The following materials should be readily available to install the system:

CAT 5e communication cable of appropriate length and gauge (non-integrated EMS)

RJ-45 connectors (EMS communication)

Mounting hardware for pad mounting of cabinet – up to ½” hardware supported.

2.5 Special Tools

In addition to standard tools required for cabinet mounting, the following tools should be readily available to

interconnect the battery and PCS cabinets.

RJ-45 crimp tool (EMS to PCS communication cable).

3

3 Installation Site Preparation

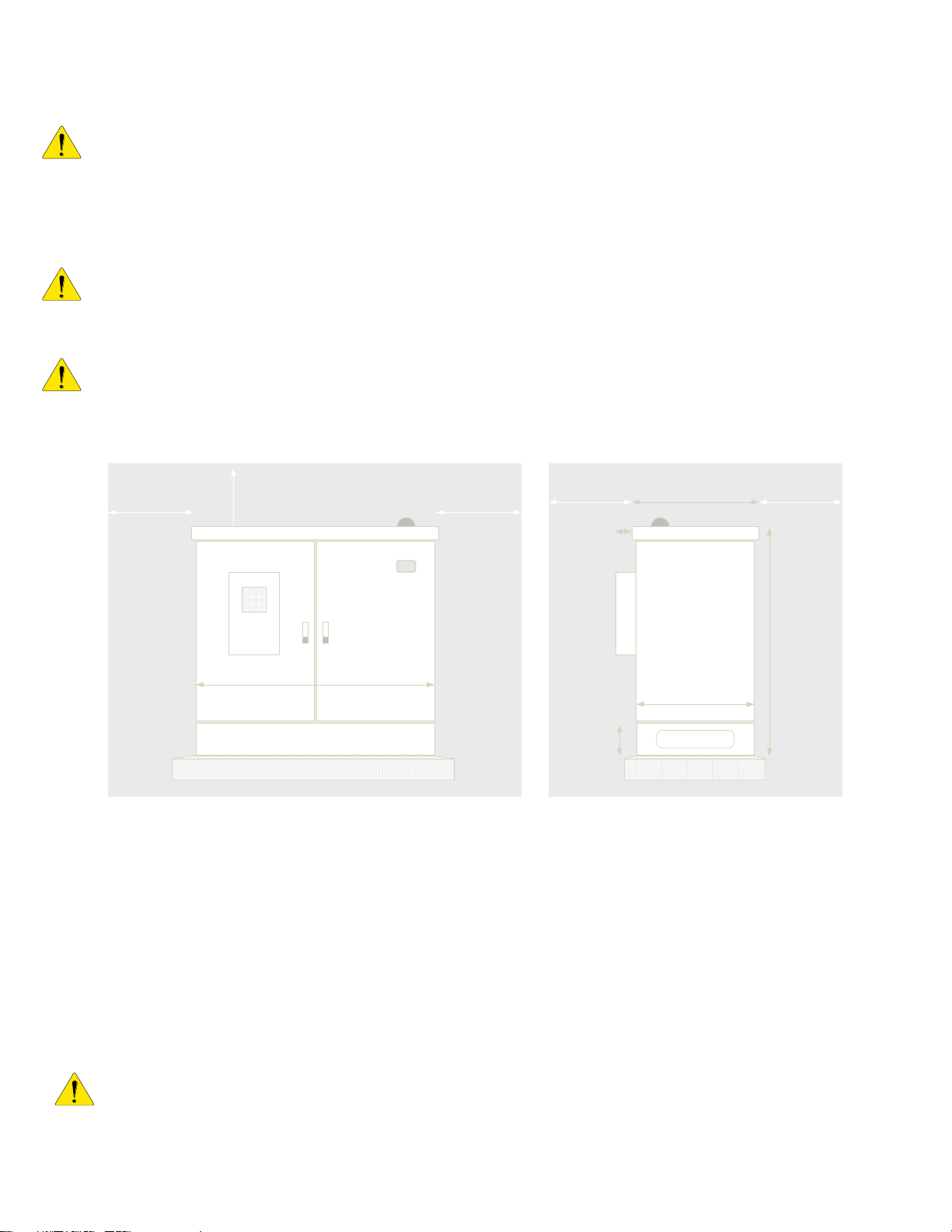

Figure 1: Mounting installation plan – minimum clearances required for installation and service access to the battery system.

1500 lbs

Clearance determined by boom lift

24"

6"

Front View

Canopy

Concrete pad

24"

PCS

Cabinet

Battery

Cabinet

Plinth

36"

Concrete pad

36"

Wiring port

Side (Right) View

31.9"

8"

53.75"

4"

47.6"

33.75"

Before installing the system, read all instructions and warnings in this manual.

CAUTION! All electrical and civil installation work should be performed in accordance with local building and

electrical codes.

3.1 Installation Planning

CAUTION! The cabinet weighs approximately 1500 lbs. Handle with care. All six lift points must be used to lift

the cabinet into its fixed position, and equal tension at all six lift points is required to prevent damage to the

interconnected cabinets. Ensure equipment and lift straps used are rated to safely install the system.

CAUTION! Avoid installation in direct sunlight. Battery performance is dependent upon operating ambient

temperature. Radiant heat absorbed in direct sunlight will greatly reduce the performance of the batteries and will

prematurely cause degradation of the display indicator panel on the front of the cabinet. The HVAC option will be

required where direct sunlight installation is the only option. Refer to Section 12 for more details.

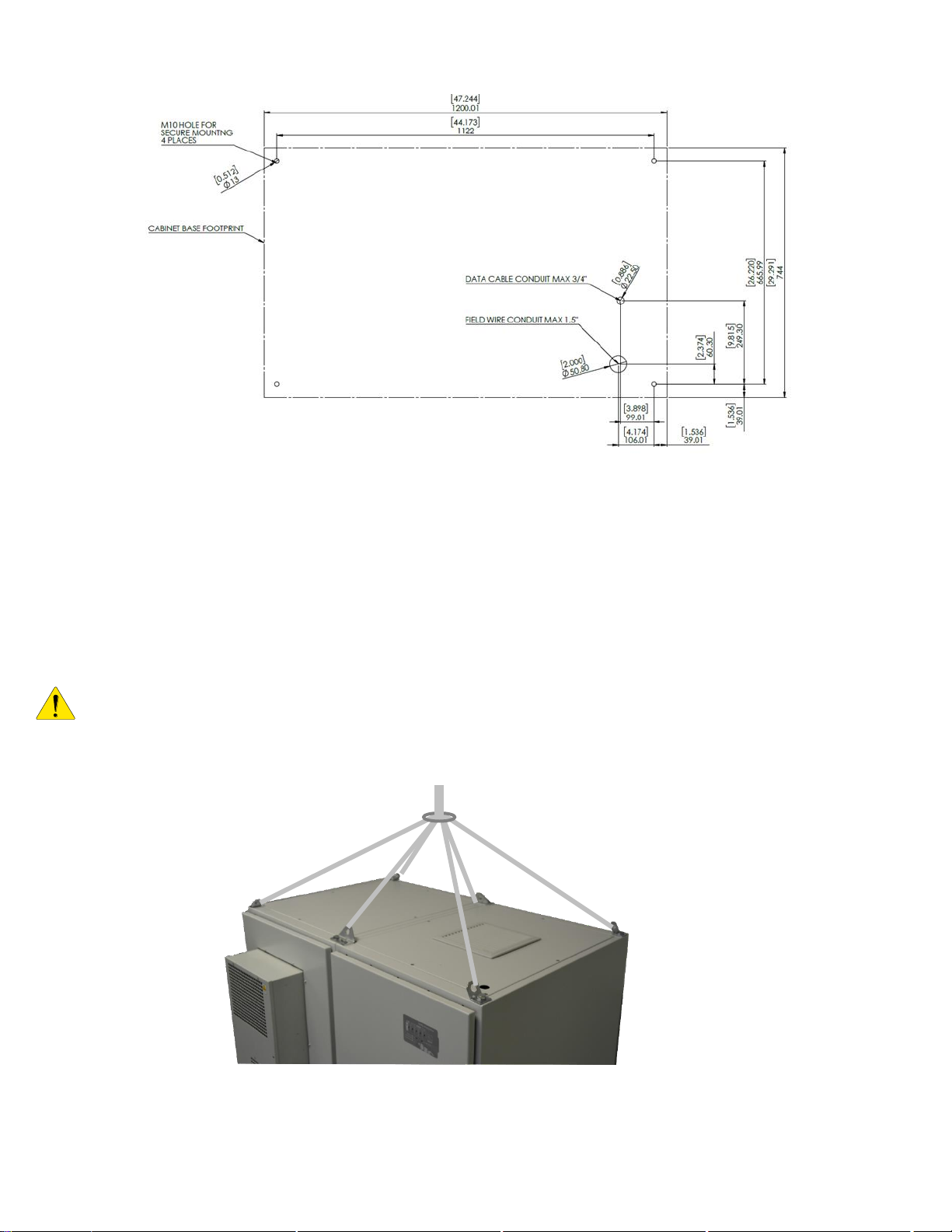

3.2 Cabinet Plinth Pad-mount Dimensions

The following diagram illustrates the pad-mount footprint dimensions for the cabinet plinth, with relative position of the

field wiring ports near the front-right corner of the cabinet plinth. Anchoring of the cabinet is supported by four

mounting holes rated up to ½” (13 mm) anchor bolts.

CAUTION! Concrete pad or floor must be level to ensure proper weight distribution of rack-mount components

within the cabinet. All civil work should be performed in accordance with local building codes.

4

Figure 2: Cabinet Plinth Pad-mount dimensions.

front

3.3 Cabinet lift method

The following diagram illustrates the lift points. The two cabinets are interconnected at the base plinth and the top

center lift hardware. Note that the product is shipped without the canopy installed, such that it is ready for direct lift off

of the shipping pallet.

CAUTION! The cabinet weighs approximately 1500 lbs. Handle with care. All six lift points must be used to lift

the cabinet into its fixed position, and equal tension at all six lift points is required to prevent damage to the

interconnected cabinets. Ensure equipment and lift straps used are rated to safely install the system.

Figure 3: Lift points on the battery system.

5

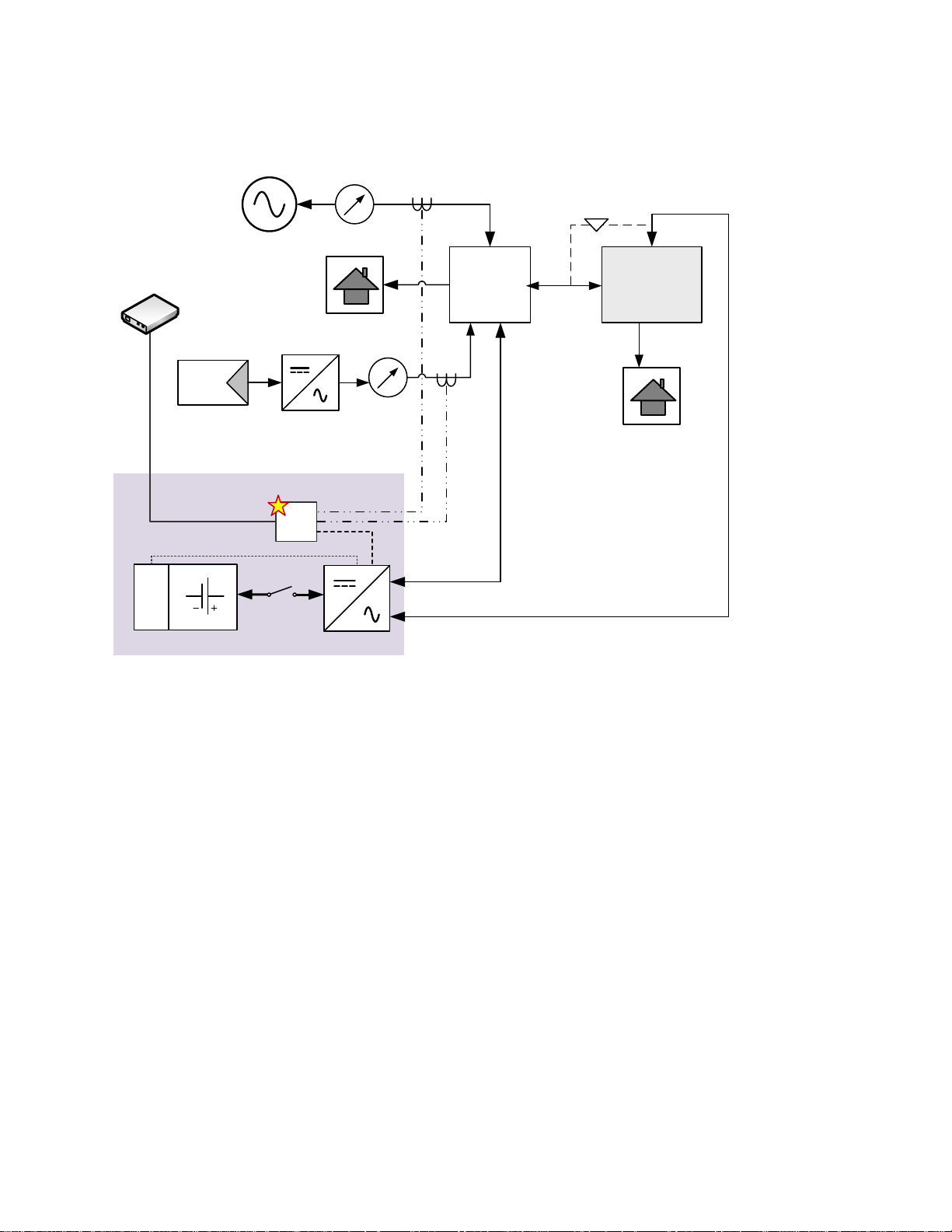

3.4 SLD - AC Coupled PV System with Back-up Power Operation

Eguana ACB15 ESS

Grid

BMS

PV Inverter

1

Main

Electrical

Panel

Sub-Panel

2

Critical loads

Loads

EMS

Loads

CAT-5

3

Grid

Load

ATS or Mechanical

Interlock

4

Home

network

The following block diagram is representative of an AC coupled solar plus storage system with backup power operation

(480V model only).

Important: The above diagram is a single line representation of a utility interactive battery system with AC coupled

PV to a critical load panel, based on the electrical ratings of the Eguana AC battery. Please consult your National and

local electrical codes for full compliance in an actual installation.

1 – PV Inverter should not exceed rating of base load plus battery inverter rating for optimal self-consumption and/or

where PV export to grid is not permitted.

2 – Sub-panel is grounded directly from the main panel.

3 – Refer to EMS/gateway specs for communication cabling requirements.

4 – An Automatic Transfer Relay (ATS) or Mechanical interlock is recommended in case of system service. This will

power critical loads directly from the grid.

Figure 4: Single Line Diagram: Typical AC coupled PV system.

6

4 Cabinet Installation Instructions

Figure 5: Wiring Port and Plinth mounting access.

Figure 6: Lowering canopy onto cabinet - antenna kit option

shown.

Figure 7: Fastening the canopy to the cabinet.

1. Lower the cabinet onto the concrete pad/floor, positioning

the cabinet over the mounting points. Remove the lift straps.

2. Secure the cabinet to the floor at the four corner mounting

points on the base of the plinth.

3. Lower the canopy cover onto the cabinets.

Note: Wi-Fi / Cellular antenna option; if your system was

delivered with an optional antenna kit, mount the antenna to

the canopy by adhering the gasket against the top of the

canopy and tightening the nut against the bottom side of the

canopy. Then lower the canopy onto the cabinets and route

the antenna cables through the cabinet port immediately

below the antenna. Propping the front of the canopy upward

towards the front will make cable routing easier.

4. Terminate the antenna cables at the EMS antenna inputs on

the inside of the PCS cabinet door. See the EMS installation

documentation for installation details.

5. Fasten the canopy to the cabinets using the 20 Phillips

screws and washers in the supplied hardware kit; 10 at the

front, and 10 at the rear of the cabinet.

7

5 Internal Product Layout

Ref

Definition

Ref

Definition

1

Air conditioner

9

Cabinet Plinth

2

Master Battery Module

10

Antenna

3

Battery Disconnect

11

AC Field Wiring Terminals

4

Canopy

12

EMS Control Panel (not included)

5

PCS Cabinet Exhaust Fan + Filter

13

Air Inlet + Filter

6

PCS Master – Phase A

14

(side) AC Wiring Port Access Panel

7

PCS Slave – Phase B

8

PCS Slave – Phase C

1

2

3 4 5 6 7 8 9

11

12

13

10

14

Figure 8: System Internal Layout.

8

6 System Electrical Wiring

Figure 10: PCS AC Grid and Load Wiring Terminals – 480 V

Wye model shown.

Figure 9: PCS AC Grid Wiring Terminals – 208 V Delta

model shown.

G

N

DL1 L2 L3

Grid

Note: This product is capable of providing utility interactive and islanded back up power and can be AC coupled to a

utility interactive photovoltaic inverter through the grid-coupled circuit. Wiring methods must be in accordance with

local electrical codes. The installer is responsible for ensuring that over-current protection is installed and sized

appropriately for the AC grid and off-grid output circuits, in accordance with the National Electrical Code, ANSI/NFPA

70, Canadian Electrical Code and local codes.

6.1 AC Grid and AC Load Wiring

CAUTION! To reduce the risk of fire, connect only to a dedicated circuit provided with appropriate branch circuit overcurrent protection in accordance with local electrical codes.

Refer to Figures 9 and 10 below for connection of AC Grid and AC load circuits. The AC wiring size for the AC grid

and AC Load is to be determined based on the AC over-current protection installed, and not to exceed ratings as

provided in table 2.

1. Route the AC Grid wiring (3 wire) from the main electrical panel to the [AC Grid] terminal block of the AC

Battery.

2. 480V model only: If applicable, route the AC Load wiring (3 wire) from the critical load panel to the [AC Load]

terminal block of the AC Battery.

WARNING! Improper connection of the wiring panel may result in equipment damage and cause personal

injury. Disconnect all AC and DC Sources prior to installation.

9

6.2 Chassis Grounding

EMS

PCS

PCS: RJ-45 Pin

G+shield G 3

A

A 4 B

B

5

EMS

Figure 11: EMS to PCS wiring.

1

In this section, “Chassis Ground” is referred to as “ground” or “grounding” unless otherwise mentioned.

The AC and DC grounding are intended to provide a low impedance signal path at all frequencies.

DC Ground Wiring Installation: The default setting for DC grounding is set for DC negative to ground. This is to indicate

that the DC negative terminal of the inverter is grounded within the PCS system.

AC Ground Wiring Installation: The AC power grounding is achieved through the ground terminal blocks which are

connected to the PE ground terminals on the AC Filter Boards If a neutral connection is present (ACB15-480), it is not

bonded to the AC power grounding within the unit. Refer to table 2 for wire ratings.

Note: The field ground wire rating applies to the AC circuit only. The DC source loop is internal to the battery

cabinet, and is rated accordingly.

Lightning Grounding: The inverter has built-in lightning protection. In order for the lightning protection to be effective,

the grounding for lightning currents must be provided via low impedance path from AC Filter Board to System Ground

and further to the building Ground/Earthing point.

6.3 EMS to PCS Communication Wiring & RJ45 Pin-out

The PCS provides the user with a communications link to an EMS controller via RS-485.

1. Connect the communication cable to the [EMS In] port (RJ-45) of the master PCS module (ref: fig 8, item 6).

Refer to the PCS pinout table below for terminating the PCS end. Refer to the EMS instruction manual for

communication wiring to the EMS. .

6.4 Auxiliary Actuator Relays

The AC Battery contains two actuators which can be used by the EMS to provide external alarm/control based on

different operating states or modes of service, referenced as shown (P10, P11 reference).

Refer to the EMS operator’s manual for implementation details.

10

7 Start-up Sequence

Battery Power Button Operation

Turn Batteries ON: Press and Release the

power button on the module designated as the

Master module (this is the top module within the

battery cabinet)

(PCS connected com cable).

Turn Batteries OFF: Press and hold 5

seconds the power button of any module

designated as a Slave Module. If all modules do

not shut off, repeat individually for each module.

Figure 12: Battery BMS interface.

CAUTION! Powering the energy storage system requires a specific start-up procedure. Please follow the

steps below.

CAUTION! If the battery disconnect has been placed in the OFF position at any time during operation, wait

one minute before returning to the ON position. Rapid cycling (less than one minute) of the battery

disconnect can cause damage to the pre-charge circuits of the PCS modules.

CAUTION! During the first start-up sequence after installation, the battery modules may require a battery

maintenance cycle to balance the SOC. This maintenance cycle requires a grid connection so that the PCS can be

commanded to charge the batteries. The PCS battery SOC alarm light will flash yellow if maintenance and/or other

battery faults are present. This procedure may take from a few minutes to a few hours, depending on the difference in

battery module SOC. Please refer to the PCS Service Manual for more information.

1. Remove the front cover from the battery cabinet adjacent to the

PCS cabinet.

2. Press the [Power] button (see above, label #8) on the master

battery module. The master battery module has communication

wired from the battery BMS port (label #3) to the PCS [BMS in]

port.

WARNING! When the batteries are turned ON, the battery voltage

will be present at the power panel assembly busbar where the

battery modules are terminated.

3. This step may take up to one minute.

Verify that the indicators are as shown in “Normal Operation” as shown below.

11

Figure 13: Battery breaker disconnect

turned ON.

EMS

Green indicator: The left indicator indicates normal operation.

Blue indicators (SOC): In normal operation, the four indicators on the right show the module’s state of charge (SOC).

Each indicator represents 25% of a full charge. If the SOC value is 50%, the three rightmost indicators are on solid

BLUE. The blue indicators of the slave modules look as below.

Whereas, the leftmost blue indicator on the master module flashes.

4. Also, verify that the module with the left-most flashing blue SOC indicator corresponds to the module which

has communication wired from the BMS to the PCS [BMS in] port.

Caution! If the battery module other than the module designated as a master has a flashing SOC light at startup, shut

down all battery modules by holding the [Power] button for 5 seconds. In this state, it may be necessary to shut down

battery modules individually. After all modules are OFF. Repeat steps 2 and 3.

5. Turn ON the Battery disconnect switch inside the battery cabinet (see Figure 13).

6. The PCS module will initialize, indicated by a brief flash of all

LEDs on the display panel, followed by a status of the battery

and PCS. Refer to table 5 for indicator status of the PCS.

7. Turn ON the AC breaker at the main electrical panel to the

PCS.

8 Operation

This product does not operate without a 3rd party supplied energy management system. Please consult the EMS

manual for operation of this system.

12

9 PCS Display Panel

Indicator

Status

Display mode

Display Color

Battery

Status

State of charge

(L-R): 5 LEDs, 20% SOC per LED

Green >20%, Yellow <20%

Initialized

One time blink

Multi

Charging

Flashing pattern - right

Green

Discharging

Flashing pattern - left

Green (Yellow <20%)

PCS

Status

Sleep/Standby

Blinking pattern

Green

Pre grid-connect notification

Flashing pattern

Blue

Grid connected

ON

Blue

Off-grid mode

ON or Blinking pattern

Green/Yellow

Service Status

Service

ON

Orange

Programming mode

ON

Green

Active sleep

Blinking pattern

Green

Pre-charge

Blinking pattern

Green

DC Ground Fault

Blinking pattern

Yellow

Auto-Recovery

All lights rapid blinking – See section 11 for more details.

Figure 14: PCS display panel.

Blink

Flash

Solid

ON

OFF

ON

OFF

ON

9.1 LED Display Indicators

The PCS cabinet is equipped with a display panel that provides

indication of the following:

Battery Operating State

PCS Operating State

(out of) Service Indicator

Refer to section 9.2 for a complete definition of indicator states.

To conserve energy, the LEDs will turn off after 5 minutes from

being activated. They can be re-activated by pressing the

service button.

9.2 PCS display panel indicator summary.

The LEDs on the PCS identify operating states by both display

mode and color.

The display mode patterns (shown right) are defined as:

Blink: short ON, long OFF

Flash: equal ON/OFF

Solid: steady ON

13

9.3 Service Button

PCS indicator status

Definition/Action

Service light ON

System is prevented from normal operation due to an internal fault. Upon first power up of the

system, the PCS can also go into service mode if the PCS is powered by the battery but there is no

valid AC source. Check the AC breaker for the ESS at the main panel. Log into the EMS via web

browser to retrieve the service code before attempting to clear the service code.

All panel lights flashing

The PCS has a valid AC power input, but does not detect a battery voltage, and the system is

attempting battery recovery. Check the battery disconnect. Check the communication cable from the

master battery module to the PCS’s BMS port (Appendix A – ref: A1). Notify service personnel if

this condition persists more than 30 minutes.

All panel lights OFF after service button

wake command

This indicates loss of both AC And DC sources to the PCS. Check AC and DC circuit breakers and

disconnects.

Sleep/standby mode engaged

This is a normal operating mode initiated by the EMS when the battery SOC reaches the maximum

or minimum SOC. Loss of EMS communication will also engage the PCS into sleep/standby mode.

If on initial power up of the system, the PCS does not exit sleep/ standby mode, and one to four

battery SOC lights are ON, inspect the EMS to PCS communication cable , and verify that the EMS

is powered.

Observed state

Action

Service button command

All panel lights off

Wake panel display

Press and release

Service light on

Exit service mode

Press and hold 5 seconds

The service button can be used to wake the LED display, and either place the system into or out of service mode, as

well as cycle through various operating modes. If the system has gone into service mode, the user can attempt to

bring the system back into normal operation using the service button. Note that on the Commercial AC Battery the

service button is only accessible from the inside of the PCS cabinet (on the LED circuit board, mounted on the door).

Refer to section 11 – Troubleshooting if the service button does not perform the action requested.

10 Maintenance

The energy storage system requires very little maintenance; annual inspections of the airflow path, and replacement of

the air intake and exhaust filters are all that is required. For models including the air conditioner, annual maintenance

is also required. Consult the Envicool manual included with the system for more details. There are two filters to

inspect and replace, if necessary (see- section 5, figure 8 for location of filters):

1. Exhaust fan filter – Inside the PCS cabinet, top-center.

2. Air inlet filter – Inside the front door of the PCS cabinet.

11 Troubleshooting

System faults are reported and logged in the monitoring system. All fault logs are also accessible remotely by your

installer.

IMPORTANT! Contact your system installer as recommended below if any of the following conditions are present on

the front display of the inverter panel.

14

12 Specifications

Model

ACB15

AC Grid Specifications

-208

-480

Nominal AC Voltage

208 V (L-L), 3 Phase Delta

480 V (L-L), 3 Phase Wye

AC Voltage Range (default)

-12% to +10% of nominal AC voltage

Nominal AC Frequency

60 Hz

Frequency Range (default)

59.3 to 60.5 Hz

Rated AC Current

41.6 A (Line)

18.1 A (Line)

Continuous AC Power

15000 VA

Power Factor

> 0.99 (fixed) / 0.8 leading to 0.8 lagging (adjustable)

Harmonic Distortion

< 5%

Efficiency (PCS only)

96% Peak

Maximum Output Overcurrent Protection

60 A

Maximum AC Short-circuit Current

99 A

pk-pk

, 2.1 A

rms

(50 ms)

Maximum Synchronization In-rush Current

32 A

pk-pk

, 2.0 A

rms

(50 ms)

Galvanic Isolation

Integrated transformer

Protective Class (I, II, or III)

Class I

Over-Voltage Category (OVC I, II, III, or IV)

OVC III

Pollution Degree

3

Lightning Protection

IEEE 62.41.2, location category C, low exposure

Active Anti-islanding Method

Sandia frequency shift

Grid Monitoring

Active in all states

Configurable Grid Management Functions

Watt Reduction, VAR Control, VRT/FRT Control

Power Ramp Rate

0.1% to 100% / sec, programmable

Energy Storage Specifications

-39

Rated AC Energy

39.1 kWh

Rated Charge / Discharge Current

300 Adc / 375 Adc

Nominal DC Voltage

48 Vdc

Operating DC Range

40 to 65 Vdc

DC Overcurrent Protection

525 Adc

Mechanical

Base Model

-H (HVAC option)

Max Humidity

< 95% (non-condensing)

Enclosure Type

Type 3R outdoor

Cooling - PCS Cabinet

Fans

Fans

Cooling - Battery Cabinet

Natural convection

Air conditioned

Enclosure Dimensions (WxHxD)

1245 x 1365 x 857 mm

1245 x 1365 x 959 mm

(excluding antenna)

49" x 53.75" x 33.75"

49" x 53.75" x 37.75"

Antenna Height

82 mm

3.2”

Enclosure Weight

653 kg

1437 lbs

674 kg

1483 lbs

Operating Temperature

-10 to +45 C

-15 to +50 C

Full Load Operating Temperature

0 to +40 C

-5 to +45 C

Air Conditioner, Base Load Power

-

300 Watt

General Specifications

External Communication

Modbus RTU (RS-485)

Display

LED indication

Self-consumption Power (without HVAC)

< 300 W (operating), 15 W (sleep)

Ground Fault Monitoring

DC grounded system configuration

Auxiliary Dry Contacts (programmable, x2)

240V, 10A rated

Table 1: PCS Electrical / Mechanical Ratings

15

Standards & Certifications

EMC

FCC, part 15-B

Utility Interface and Safety

UL1741 SA, IEEE 1547, CSA C22.2 No. 107.1

Battery System Safety

UL 9540, UL1973

AC Voltage / Frequency Trip Limits: UL1741 (IEEE 1547.1)

Model

-208

-480

Low Volt Trip (adj), AC voltage

Default

183.0 V (L-L)

243.8 V (L-N)

Min/Max

104.0 - 183.0 V (L-L)

138.5 - 243.8 V (L-N)

Low Volt Trip Time (adj.)

Default

117 cycles (1.95 sec)

Min/Max

0 - 3600 cycles (60.0 sec)

High Volt Trip (adj.), AC voltage

Default

228.8 V (L-L)

304.7 V (L-N)

Min/Max

228.8 - 249.6 V (L-L)

304.7 - 332.4 V (L-N)

High Volt Trip Time (adj.),

Default

57 cycles (0.95 sec)

Min/Max

0 - 3600 cycles (60.0 sec)

Undervoltage: (Very Low) Trip Limit, AC voltage

< 104.0 V (L-L)

< 138.5 V (L-N)

Undervoltage: (Very Low) Trip Time

< 10 cycles (0.16 sec)

Overvoltage: (Very High) Trip Limit, AC voltage

> 249.6 V (L-L)

332.4 V (L-N)

Overvoltage: (Very High) Trip Time

< 10 cycles (0.16 sec)

Underfrequency Trip (adj), frequency

Default

59.3 Hz

Min/Max

55.0 - 59.3 Hz

Underfrequency Trip Time (adj)

Default

< 10 cycles (0.16 sec)

Min/Max

0 - 3600 cycles (60.0 sec)

Overfrequency Trip (adj), frequency

Default

60.5 Hz

Min/Max

60.5 - 65.0 Hz

Overfrequency Trip Time (adj)

Default

< 10 cycles (0.16 sec)

Min/Max

0 - 3600 cycles (60.0 sec)

Frequency Trip Limit Accuracy

0.01 Hz

Frequency Trip Time Accuracy

0.05 sec

AC Voltage Trip Limit Accuracy

1% of nominal

AC Voltage Trip Time Accuracy

0.05 sec

Field Wiring

Use Copper Wire Only, 90°C or higher rated

Terminal

Minimum Wire Size mm2

(AWG)

Maximum Wire Size mm2

(AWG)

Tightening Torque, Nm (in.

lbs)

Ground Lug

16 mm2 (6 AWG)

16 mm2 (6 AWG)

1.7 (15.0)

AC Grid Terminals*

6 mm2 (10 AWG)

16 mm2 (6 AWG)

1.7 (15.0)

AC Load Terminals*

6 mm2 (10 AWG)

16 mm2 (6 AWG)

1.7 (15.0)

Table 2: PCS Field Wiring Ratings – AWG / Torque

*Note: See rated AC current in table 1 for nominal phase currents. Wire ratings are based on product terminal ratings.

16

12.1 UL 1741 SA Grid Support Utility Interactive Inverter Specifications

Grid Support Function Tested

Test Standard

Anti-Islanding protection – unintentional islanding with grid support functions enabled

UL 1741 SA 8

Low/high voltage ride through

UL 1741 SA 9

Low/high frequency ride through

UL 1741 SA 10

Ramp rates

UL 1741 SA 11

Reconnect by “Soft Start”

UL 1741 SA 11

Specified power factor

UL 1741 SA 12

Dynamic Volt/VAR operations

UL 1741 SA 13

Frequency-Watt

UL 1741 SA 14

Volt-Watt

UL 1741 SA 15

SA9 Low and High Voltage Ride Through - Rule 21

Region

Voltage Range

[%Vnom]

Ride

Through

Duration [s]

Maximum

Trip Time [s]

Operating Mode During Ride

Through

High Voltage 2 (HV2)

V > 120%

N/A

0.16

N/A

High Voltage 1 (HV1)

110% < V ≤ 120%

12

13

Momentary Cessation (zero power)

Near Nominal (NN)

88% ≤ V ≤ 110%

Indefinite

N/A

Continuous Operation

Low Voltage 1 (LV1)

70% ≤ V < 88%

20

21

Mandatory Operation

Low Voltage 2 (LV2)

50% ≤ V < 70%

10

11

Mandatory Operation

Low Voltage 3 (LV3)

V < 50%

1

1.5

Momentary Cessation (zero power)

SA9 Low and High Voltage Ride Through - Rule 14H

Region

Voltage Range

[%Vnom]

Ride

Through

Duration [s]

Maximum

Trip Time [s]

Operating Mode During Ride

Through

Over Voltage 2 (OV2)

V > 120%

N/A

0.16

Cease to Energize

Over Voltage 1 (OV1)

110% < V ≤ 120%

0.92 1 Mandatory Operation (VW)

Continuous Operation

(CO)

88% ≤ V ≤ 110%

N/A

N/A

Continuous Operation (VW)

Under Voltage 1 (UV1)

70% ≤ V < 88%

20

21

Mandatory Operation

Under Voltage 2 (UV2)

50% ≤ V < 70%

10

11

Mandatory Operation

Under Voltage 3 (UV3)

V < 50%

1

1.5

Momentary Cessation (zero power)

Parameter

Abbreviation

Value for Rule 21

Value for Rule 14H

Nominal AC voltage [V]

Vnom

208 or 277

AC voltage accuracy [%Vnom or V]

MSA-vac

1%

Voltage trip time accuracy [s]

MSA-ttv

0.05

Voltage range of adjustability [%Vnom]

Vvrtmin-Vvrtmax

0.0% - 120.0%

Trip time range of adjustability [s]

Tvrtmin-Tvrtmax

0.0 - 50.0

Default function status

Enabled

Enabled

The PCS within the Commercial AC Battery complies with the UL 1741SA standard for grid support utility interactive

inverters. These functions are intended to be either enabled or disabled in accordance with local utility interconnection

requirements. The UL 1741 SA testing was conducted in accordance with both Rule 21 and Rule 14H (V1.1) as

source requirements documents (SRD), which are applicable in jurisdictions within California and Hawaii, respectively.

The corresponding default settings and specifications are listed below.

Table 3: UL1741 SA grid support functions.

Table 4: Low and high voltage ride through settings.

17

Table 5: Low and high frequency ride through settings.

SA10 Low and High Frequency Ride Through - Rule 21

Region

Frequency

Range [Hz]

Ride

Through

Duration [s]

Maximum

Trip Time [s]

Operating Mode During Ride

Through

High Frequency 2 (HF2)

f > 62.0

N/A

0.16

N/A

High Frequency 1 (HF1)

60.5 < f ≤ 62.0

299

300

Mandatory Operation (FW)

Near Nominal (NN)

58.5 ≤ f ≤ 60.5

Indefinite

Indefinite

Continuous Operation

Low Frequency 1 (LF1)

57.0 ≤ f < 58.5

299

300

Mandatory Operation

Low Frequency 2 (LF2)

f < 57.0

N/A

0.16

N/A

SA10 Low and High Frequency Ride Through - Rule 14H: Oaho, Maui, Hawaii

Region

Frequency

Range [Hz]

Ride

Through

Duration [s]

Maximum

Trip Time [s]

Operating Mode During Ride

Through

Over Frequency 2 (OF2)

f > 64.0

N/A

0.16

N/A

Over Frequency 1 (OF1)

63.0 < f ≤ 64.0

20

21

Mandatory Operation (FW)

Continuous Operation

(CO)

57.0 ≤ f ≤ 63.0

Indefinite

Indefinite

Continuous Operation (FW)

Under Frequency 1 (UF1)

56.0 ≤ f < 57.0

20

21

Mandatory Operation

Under Frequency 2 (UF2)

f < 56.0

N/A

0.16

N/A

SA10 Low and High Frequency Ride Through - Rule 14H: Lanai, Molokai

Region

Frequency

Range [Hz]

Ride

Through

Duration [s]

Maximum

Trip Time [s]

Operating Mode During Ride

Through

Over Frequency 2 (OF2)

f > 65.0

N/A

0.16

N/A

Over Frequency 1 (OF1)

63.0 < f ≤ 65.0

20

21

Mandatory Operation (FW)

Continuous Operation

(CO)

57.0 ≤ f ≤ 63.0

Indefinite

Indefinite

Continuous Operation (FW)

Under Frequency 1 (UF1)

50.0 ≤ f < 57.0

20

21

Mandatory Operation

Under Frequency 2 (UF2)

f < 50.0

N/A

0.16

N/A

Parameter

Abbreviation

Value for Rule 21

Value for Rule 14H

Nominal frequency [V]

fnom

60

AC frequency measurement accuracy [Hz]

MSA-f

0.02

Frequency trip time accuracy [s]

MSA-ttf

0.05

Frequency range of adjustability [Hz]

ffrtmin-ffrtmax

50.0 - 66.0

Trip time range of adjustability [s]

Tfrtmin-Tfrtmax

0.0 - 1000.0

Default function status

Enabled

Enabled

18

Table 6: Ramp rate settings.

SA11 Ramp Rates

Parameter

Abbreviation

Value for Rule 21

Value for Rule 14H

Output current rating [A]

Irated

41.6 A (208 V Delta), 18.1 A (480 V Wye)

Minimum normal ramp up rate [%Irated/sec]

RRnorm_min

1.0%

Maximum normal ramp up rate

[%Irated/sec]

RRnorm_max

100.0%

Minimum output current [A]

Ilow

0

Ramp Rate Accuracy [%Irated/sec]

MSA-rr

N/A

Minimum soft start ramp up rate

[%Irated/sec]

RRss_min

0.1%

Maximum soft start ramp up rate

[%Irated/sec]

RRss_max

100.0%

Default normal ramp up rate [%Irated/sec]

RRnorm

100.0%

100.0%

Default soft start ramp function status

Enabled

Enabled

Default soft start ramp up rate [%Irated/sec]

RRss

2.0%

0.33%

SA12 Specified Power Factor

Parameter

Abbreviation

Value for Rule 21

Value for Rule 14H

Apparent power rating [VA]

Srated

15000

Output power rating [W]

Prated

15000

DC input voltage range with function

enabled [V]

Vdcmin-Vdcmax

40.0 - 80.0

Nominal AC voltage [V]

Vnom

208 (L-L, Delta) or 277 (L-N, Wye)

AC voltage range with function enabled

[%Vnom]

Vmin-Vmax

88.0% - 110.0%

AC voltage accuracy [%Vnom or V]

MSA-vac

1%

DC voltage measurement accuracy [V]

MSA-vdc

0.05

Active power range of function [W]

Plow, Prated

3000 - 15000

750 - 15000

Power Factor Accuracy

MSA-pf

0.01

Power Factor settling time [sec]

Ts-pf

5

Minimum inductive power factor

PF min,ind

-0.8

Minimum capacitive power factor

PF min,cap

0.8

Mid inductive power factor

PF mid,ind

-0.9

Mid capacitive power factor

PF mid,cap

0.9

Default function status

Disabled

Disabled

Power factor default

PF

-0.95

-0.95

SA13 Volt-VAr Mode

Parameter

Abbreviation

Value for Rule 21

Value for Rule 14H

Apparent power rating [VA]

Srated

15000

Output power rating [W]

Prated

15000

EUT input voltage range with function

enabled [V]

Vdcmin-Vdcmax

40.0 - 80.0

Nominal AC EPS voltage [V]

Vnom

208 (L-L, Delta) or 277 (L-N, Wye)

Table 7: Specified power factor settings.

Table 8: Volt- VAr settings.

19

AC EPS voltage range with function

enabled [V]

Vmin-Vmax

96.0 - 144.0

Reactive power accuracy [%Srated, VAr]

MSA-q

5%, 250VAr

Maximum ramp rate [VAr/s]

RRvar

500

Maximum rated reactive power production

(capacitive, overexcited) [VAr]

Qmax,cap

6600

Maximum rated reactive power production

(inducitive. underexcited) [VAr]

Qmax,ind

-6600

Minimum rated reactive power production

(capacitive, overexcited) [VAr]

Qmin,cap

750

Minimum rated reactive power production

(inducitive. underexcited) [VAr]

Qmin,ind

-750

Maximum slope [VAr/V]

KVARmax

1587

Deadband range [%Vnom]

Deadmand_min

0.0 - 20.0

Deadband_max

Time accuracy [s], related Tr-vv

MSA-t

2

Settling time [s]

Ts-vv

3

Default function status

Enabled

Enabled

Default response time, ramp to Qmax,ind

[s]

Tr-vv

10

10

Default power prioritization

P/Q Priority Q Q

Default Voltage at Q1 [%Vnom]

V1

94.3%

94.0%

Default max reactive power production

setting [VAr]

Q1

4500

6600

Default voltage at Q2 [%Vnom]

V2

98.0%

97.0%

Default reactive power setting at lower

voltage deadband limit [VAr]

Q2

0

0

Default voltage at Q3 [%Vnom]

V3

102.0%

103.0%

Default reactive power setting at upper

voltage deadband limit [VAr]

Q3

0

0

Default voltage at Q4 [%Vnom]

V4

105.7%

106.0%

Default max reactive power absorption

setting [VAr]

Q4

-4500

-6600

SA14 Frequency Watt

Parameter

Abbreviation

Value for Rule 21

Value for Rule 14H

Output Power Rating [W]

Prated

15000

AC frequency range with function enabled

[Hz]

fmin, fmax

60.0 - 65.0

AC frequency measurement accuracy [Hz]

MSA-f

0.02

P(f) accuracy [%Prated or W]

MSA-p(f)

2%, 300W

Settling time [sec]

Ts-fw

3

Adjustment range of response time [s]

Tr-fw

0.5 - 3.0

* Volt-VAr mode can function with active or reactive power priority. When an inverter is set in Volt-VAr mode with

reactive power priority and the inverter's apparent power kVA limit is reached, active power is reduced to maintain

reactive power production. When an inverter is set in Volt-VAr mode with active power priority and the inverter's

apparent power kVA limit is reached, the reactive power is reduced to maximize active power production.

Table 9: Frequency-watt Settings

20

Adjustment range of the start of frequency

droop [Hz]

fstart_min,

fstart_max

60.017 - 63.0

Maximum slope of frequency droop

[%Prated/Hz]

Kpower-freq_max

100.0%

Minimum slope of frequency droop

[%Prated/Hz]

Kpower-freq_min

23.8%

Default function status

Enabled

Enabled

Default response time, ramp to 10% Prated

[s]

Tr-fw

0.5

0.5

Default start frequency [Hz]

fstart

60.1

60.036

Default slope of frequency droop

[%Prated/Hz]

Kpower-freq

50.0%

41.7%

Default use of hysteresis (symmetric

recovery)

Enabled

Enabled

SA15 Voltage Watt

Parameter

Abbreviation

Value for Rule 21

Value for Rule 14H

Output power rating [W]

Prated

15000

AC voltage range with function enabled

[%Vnom]

Vmin-Vmax

1.00 - 1.12

Nominal AC voltage [V]

Vnom

208 (L-L, Delta) or 277 (L-N, Wye)

AC voltage accuracy [%Vnom or V]

MSA-vac

1%

Output power accuracy [%Prated or W]

MSA-watts

2%, 300W

Time accuracy [s], related to treturn_min,

treturn_max, Tr-vw

MSA-t

2

Setting time [sec]

Ts-vw

3

Adjustment range of the start of active

power reduction [%Vnom]

Vstart_min,

Vstart_max

102.0% - 106.0%

Adjustment range of the stop of the

curtailment function [V]

Vstop_min.,Vstop_

max

101.0% - 105.0%

Maximum Slope of active power reduction

[%Prated/V]

Kpower-volt_max

36.1%

Minimum slope of active power reduction

[%Prated/V]

Kpower-volt_min

4.5%

Range of adjustment of a delay before

return to normal operation [sec]

treturn_min,

treturn_max

1.0 - 60.0

Adjustment range of the rate of return to

normal operation [%Prated/sec]

Kpower_rate_min.

Kpower_rate_max

10.0 - 100.0%

Default function status

Disabled

Disabled

Power duration reference

Pre-disturbance

Rated

Default response time, ramp to 10% Prated

[s]

Tr-vw 1 10

Default start voltage [%Vnom]

Vstart

106.0%

106.0%

Default stop voltage [%Vnom]

Vstop

105.0%

106.0%

Default active power slope [%Prated/V]

Kpower_volt

20.8%

20.8%

Default use of hysteresis (symmetric

recovery)

Disabled

Enabled

Default delay before return to normal

operation [s]

treturn 1 N/A

Default active power rate of return to normal

operation [%Prated/s]

Kpower_rate

100

N/A

Table 10: Voltage-watt Settings

21

12.2 Thermal Performance of PCS and Battery Modules

0

2000

4000

6000

8000

10000

12000

14000

16000

0 10 20 30 40 50 60 70 80 90 100

AC POWER (VA)

SOC (%)

Commercial AC Battery

AC Power Charge Derating

Charge (VA)

50

15 to 45°C

10°C

-10°C

50°C

The following charts indicate the power performance of the PCS and batteries based on the outside ambient operating

temperature. Note that direct sunlight can significantly raise the internal temperature of the batteries. Avoiding

installation in direct sunlight is critical to the long term performance and operation of the battery.

22

0

2000

4000

6000

8000

10000

12000

14000

16000

0 10 20 30 40 50 60 70 80 90 100

AC POWER (VA)

SOC (%)

Commercial AC Battery

AC Discharge Power Derating

Discharge (VA)

50

5°C

0°C

-5°C

-10°C

15°-45C

50°C

Figure 15: Thermal operating range of PCS and Battery.

23

Appendix A: ACB-15 Series Electrical Block Diagrams

Battery Cabinet

PCS Cabinet

Battery 1

DC+ Busbar

Circuit Breaker

DIN mount

ABB S201-C3

Bidirex, L3

Bidirex, L2

L1

Bidirex, L1 master

G

3-pole breaker

175A / pole

80V

ABB ATA175TW

Cellular

Antenna

N

Battery 2

Battery 3

Battery 4

Battery 5

Battery 6

DC+, DC- Cables

6 AWG

DC Feeder Cables

THHW, 2/0

300V

90C min

1323 x 30

DC+/DC-: Red/Black

L

AC Line/Load Cables

6 AWG

L1/L2/L3/N/G:

Heat shrink color labels

Feed-through

Terminal Blocks

DIN mount

ABB ZS16 (-PE)

Feed-through

Terminal Blocks

DIN mount

ABB ZS4 (-PE)

AC Aux Cables

14 AWG

Red/White/Green

DC- Busbar

N

G

AC

Grid

AC

Load

L

N

G

L

N

L

N

G

L

N

L

N

G

L

N

AC

Grid

AC

Load

AC

Grid

AC

Load

DC+

DC-

DC+

DC-

DC+

DC-

Grid Main

Panel

L2

L3

L

N

N

AK1

N/O

AK2

N/O

AK1 AK2

AK1 AK2

G

G

G

PE

PE

PE

PE

PE

Cabinet/cabinet

ground continuity

DC- PE cable

THHW, 2/0

300V

90C min

1323 x 30

Terminated to chassis

L1

N

L2

L3

N

Aux Load Circuit

230Vac

Max 3A

Int

Load

L

N

N

Energy Management System

Max 30W

L3

AC Backup (optional)

AC Grid

Exhaust Fan

Max 80W

L

L

Backup

Load Panel

Heating/Air Conditioning Unit

Max 500W

A.1: Three Phase 480 V Wye

24

A.2: Three Phase 208 V Delta

Battery Cabinet

PCS Cabinet

Battery 1

DC+ Busbar

Circuit Breaker

DIN mount

ABB S201-C3

Bidirex, L3

Bidirex, L2

L1

Bidirex, L1 master

G

3-pole breaker

175A / pole

80V

ABB ATA175TW

Cellular

Antenna

L1

Battery 2

Battery 3

Battery 4

Battery 5

Battery 6

DC+, DC- Cables

6 AWG

DC Feeder Cables

THHW, 2/0

300V

90C min

1323 x 30

DC+/DC-: Red/Black

AC Line/Load Cables

6 AWG

L1/L2/L3/N/G:

Heat shrink color labels

Feed-through

Terminal Blocks

DIN mount

ABB ZS16 (-PE)

Feed-through

Terminal Blocks

DIN mount

ABB ZS4 (-PE)

AC Aux Cables

14 AWG

Red/White/Green

DC- Busbar

L2

L3

G

AC

Grid

AC

Load

L

N

G

L

N

L

N

G

L

N

L

N

G

L

N

AC

Grid

AC

Load

AC

Grid

AC

Load

DC+

DC-

DC+

DC-

DC+

DC-

Grid Main

Panel

L2

L3

N

N

AK1

N/O

AK2

N/O

AK1 AK2

AK1 AK2

G

G

G

PE

PE

PE

PE

PE

Cabinet/cabinet

ground continuity

DC- PE cable

THHW, 2/0

300V

90C min

1323 x 30

Terminated to chassis

Aux Load Circuit

230Vac

Max 3A

L

Int

Load

L

N

AC Grid

Energy Management System

Max 30W

Exhaust Fan

Max 80W

L

Heating/Air Conditioning Unit

Max 500W

L

L

25

A.3 Communication

Battery 5

Battery 1

Bidirex, L3

Bidirex, L2

PCS Cabinet

Cellular

Antenna

Battery 2

Battery 3

Battery 4

Battery 6

Ext

Int

Int

Ext

Int

Int

Ext

Int

Int

Ext

Int

Int

Ext

Int

Int

Bidirex, L1 master

Comm 1

Comm 1

Comm 1

Comm 2

sync

Comm 2

sync

Comm 2

sync

Energy Management System

Heating/Air Conditioning Unit

Ext

Int

Int

Battery Cabinet

BMS

Exhaust Fan

AUX1

AUX2

BMS

BMS

CAN bus

Modbus

Proprietary

Protocol

Relay

control

Relay

control

Modbus

26

THIS PAGE INTENTIONALLY LEFT BLANK

27

Loading...

Loading...