Page 1

Rua Central da Vergada, 1280

4535 - 166 Mozelos VFR

PORTUGAL

Tel (+351) 227 471 120 ● Fax. (+351) 227 471 129

E-mail: info@egitron.pt ● URL: www.egitron.pt

ExtraLab Plus

Extraction Force and Torque

Measuring System

Operation Manual

Version 2.0.0

Valid for PC interface software version 1.4.0

Valid for firmware version 3.0.0

Page 2

Page 3

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

RESPONSIBILITY EXEMPTION

This manual was written and revised to explain the ExtraLab Plus characteristics and functioning in

the most correct way possible, particularly regarding PC interface software. However, this user

manual and/or the equipment may be changed without previous notice. EGITRON is not

responsible for any damage caused by any direct or indirect error, omission or discrepancies

between the ExtraLab Plus operation and the instructions presented in this Manual.

This document, or any part of this document, cannot be reproduced or transmitted under any format

and for any purpose, without EGITRON written permission.

TRADE MARKS

Excel, Windows and Microsoft are Microsoft Corporation registered trademarks. Other trademarks

or registered trademarks not listed above can be used in this manual.

CONFORMITY DECLARATION

This product exhibits CE marking, according to European Union applicable directives.

GENERAL PRECAUTIONS

EGITRON equipment is produced to optimize security and minimize effort. Nevertheless, certain

precautions should be taken to reduce the risk of human physical damage or equipment damage.

Please read carefully the general precautions presented below and take attention to the warning

signs in this manual.

• Keep away from children;

• The machine should be operated only by persons with the appropriate training;

• Do not remove any cover or mechanical protection;

• All maintenance should be executed by specialized technicians;

III / 59

Page 4

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

• The machine should not operate on facilities with severe environment conditions,

like dust or humidity;

• The equipment should be connected to the ground by the power supply plug;

• In case of successive power supply breakdowns, the equipment should be

disconnected from the power supply;

• The equipment transport and handling should be done with extreme precautions, as

it has fragile parts. For transportation use an adequate packaging so that the

machine remains well accommodated and protected.

WARRANTY AND TECHNICAL SUPPORT

EGITRON guarantees the correct functioning of its products, in general for 1 year, or for a different

period whenever specifically written. The warranty covers workmanship and materials but not the

equipment transportation or onsite displacements, which will be charged according to the standard

prices in practice at the time.

This is valid with the exception of the first onsite displacement or equipment transport, if required

within the first month of the warranty period, which will be free. In this last case, EGITRON will

decide the most appropriate option between the technician onsite displacement or the equipment

transportation to EGITRON facilities and back to the client.

If the equipment presents any malfunctioning during the warranty period, EGITRON, according to

its own criteria, will repair or replace it without any charge, except in the situations described below.

Any product and/or part that have been replaced will become EGITRON property.

The warranty will have no effect in malfunctioning resulting from causes non imputable to the

equipment, such as:

• Anomalies caused by maltreatment, recklessness or handling contrary to the manual

instructions;

• Modifications or incorporations of non-authorized parts, and/or done by non-authorized

personnel;

• Defects caused by short circuit or mechanical injury;

• Indemnities for personal or material damages directly or indirectly caused by the equipment;

IV / 59

Page 5

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

• Defects caused by any installation service or user training at client facilities, when not

directly imputable to EGITRON technicians;

• Equipment replacement.

To request warranty services contact the EGITRON technical support. EGITRON can ask for the

purchase proof / equipment invoice. This equipment is suitable only for its design purposes and

EGITRON is not responsible for its improper use.

In case of malfunctioning or request for technical support

Before asking for EGITRON support read the Problems Resolution chapter, call your company

technical support (if available) and/or use all existing auto-help tools.

If the problem remains unsolved contact EGITRON, having with you the following information:

• Equipment name

• Serial number

• Purchase date

• Problem description

• Error message that may appear.

You can contact EGITRON by:

• Phone: (+351) 227 471 120

• Fax: (+351) 227 471 129

• E-mail: info@egitron.pt

• Post: Rua Central da Vergada, 1280

4535-166 Mozelos VFR - PORTUGAL

V / 59

Page 6

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

INDEX

WELCOME NOTES ................................................................................................................................................. 8

MANUAL CONTENTS ............................................................................................................................................. 8

1. CONVENTIONS ............................................................................................................................................... 9

2. EXTRALAB PLUS AND PC INTERFACE SOFTWARE SETUP ................................................................ 9

2.1.

ACCESSORIES SUPPLIED ................................................................................................................ 9

2.2.

PC INTERFACE SOFTWARE SETUP AND CONFIGURATION ..................................................... 9

2.3.

MACHINE SETUP .............................................................................................................................. 11

2.3.1. Back acrylic cover .................................................................................................................................................................... 11

2.3.2. Connecting ................................................................................................................................................................................ 11

3. OPERATION AND EQUIPMENT FEATURES ............................................................................................ 12

3.1.

GENERAL ASPECTS ........................................................................................................................ 13

3.1.1. Equipment description ............................................................................................................................................................ 13

3.2.

CONTROL THROUGH THE COMMAND BOX ................................................................................ 15

3.2.1. Operation Basic Concepts ...................................................................................................................................................... 15

3.2.1.1. Template for values introduction ...................................................................................................................................... 16

3.2.2. Welcome Window ..................................................................................................................................................................... 17

3.2.3. Main screen ............................................................................................................................................................................... 17

3.2.4. Configuration Menu ................................................................................................................................................................. 18

3.2.4.1. Test Type .............................................................................................................................................................................. 18

3.2.4.2. Test Mode Configuration .................................................................................................................................................... 19

3.2.4.3. Clousure Configuration ...................................................................................................................................................... 19

3.2.4.4. Set clock ............................................................................................................................................................................... 20

3.2.4.5. Set date ................................................................................................................................................................................. 20

3.2.4.6. Language .............................................................................................................................................................................. 20

3.2.4.7. About… ................................................................................................................................................................................. 20

3.2.5. Calibration screen .................................................................................................................................................................... 20

3.2.6. Initialization ............................................................................................................................................................................... 22

3.2.7. Stopping movements ............................................................................................................................................................... 23

3.3.

PC P

ROGRAM

3.3.1. Data Tables ................................................................................................................................................................................ 24

3.3.2. Report Configuration ............................................................................................................................................................... 25

3.3.3. Acquire Values .......................................................................................................................................................................... 26

3.3.4. Saving Reports ......................................................................................................................................................................... 28

3.3.5. Open Reports ............................................................................................................................................................................ 29

3.3.6. Printing Reports ....................................................................................................................................................................... 29

3.3.7. Export to Excel.......................................................................................................................................................................... 30

3.3.8. Calibration ................................................................................................................................................................................. 31

3.4.

COMMON EQUIPMENT AND SOFTWARE OPERATIONS .......................................................... 33

3.4.1. States ......................................................................................................................................................................................... 33

3.4.2. Test Configuration .................................................................................................................................................................... 33

3.4.3. Values Acquisition ................................................................................................................................................................... 35

3.4.4. Deleting Test ............................................................................................................................................................................. 35

3.4.5. Safety and Protection .............................................................................................................................................................. 36

3.5.

START A TEST ................................................................................................................................... 36

3.5.1. Connect the equipment ........................................................................................................................................................... 36

3.5.2. Place the bottle ......................................................................................................................................................................... 37

3.5.3. Configure the test ..................................................................................................................................................................... 37

3.5.4. Starting the Test ....................................................................................................................................................................... 37

3.5.5. Check information on the Display .......................................................................................................................................... 38

....................................................................................................................................... 23

4. EQUIPMENT MAINTENANCE ..................................................................................................................... 39

5. TROUBLESHOOT ......................................................................................................................................... 40

5.1.

CALIBRATION CURVE LOAD FAILURE AT STARTUP ............................................................... 40

5.2.

COMMUNICATION ERROR .............................................................................................................. 40

5.3.

SYSTEM BLOCKED .......................................................................................................................... 40

6 / 59

Page 7

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

ANNEX A – OPERATOR INTERFACE MENU TREE ......................................................................................... 41

ANNEX B – ACCESSORIES ................................................................................................................................. 43

1.

2.

A

NTI-SPLASH PROTECTION APPLICATION

C

LAMPS

.............................................................................................. E

............................................................................................... 43

RROR! BOOKMARK NOT DEFINED

ANNEX C – CALIBRATION ................................................................................................................................... 45

1.

2.

3.

C

ALIBRATION SETUP

C

ALIBRATE EXTRACTION

T

ORQUE CALIBRATION

............................................................................................................................. 45

....................................................................................................................... 46

.......................................................................................................................... 49

ANNEX D – FIRMWARE ACTUALIZATION ........................................................................................................ 54

ANNEX E – COMMUNICATION CABLE .............................................................................................................. 56

ANNEX F – TECHNICAL SPECIFICATIONS ...................................................................................................... 57

NOTES .................................................................................................................................................................... 58

.

7 / 59

Page 8

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

WELCOME NOTES

Congratulations for purchase ExtraLab Plus – Extraction Force and Torque Measuring System.

With this excellent equipment it is possible to assess the closure quality thru the analysis of different

physical tests, namely extraction force, opening torque, closing torque or breakage resistance,

following the standards in practice, allowing the user measuring a simple and reliable way to

perform these tests.

The users have at their disposal an equipment of control, with small dimensions, developed with

metrological precise techniques, assuring, a high standard and innovative quality control.

ExtraLab Plus is supplied with software for Windows compatible with all Microsoft Windows

9x/Me/NT/2000/XP/Vista/7 operating systems. This software was specifically developed for the

ExtraLab Plus and it allows the user to:

• Monitor the equipment;

• Collect the tests data from the ExtraLab Plus and present them graphically;

• Save the tests into a database for later use;

• Print reports in several languages;

• Setup the quality control tests configuration;

• Perform equipment calibration;

• Export data to Microsoft Excel.

This operation manual contains instructions to setup the ExtraLab Plus, providing detailed

information regarding its operation.

MANUAL CONTENTS

This operation manual describes the ExtraLab Plus and also the PC interface software. It starts with

ExtraLab Plus characteristics, the setup procedure, the connection to a PC and the interface control

software setup. After the setup, are described the ExtraLab Plus functionalities; the test process

and the data acquisition thru the interface software. In the following chapters, you can find

information about saving the tests, opening saved tests and printing reports. Next, the operation

manual explains how to export data to Microsoft Excel. At the end, the equipment calibration,

maintenance and troubleshooting are described.

8 / 59

Page 9

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

1. CONVENTIONS

Abbreviations:

In this operation manual you can find the following abbreviations:

• ExtraLab Plus – Extraction Force and Torque Measuring System

• Report – Group of tests on one or more corks

• Test – Extraction/Detaching/Rupture test for a single cork

• PC – personal computer

Messages

Some messages are used in this manual to call your attention for important information. Each

message type is identified as follows:

Pay attention! A warning signal informs that an improper equipment use or not following

the instructions, can cause personal and/or equipment damages.

Please read. This is a suggestion or advice which can help you to get more benefits from

the equipment.

2. EXTRALAB PLUS AND PC INTERFACE SOFTWARE SETUP

2.1.

ACCESSORIES SUPPLIED

Along with this user manual you can find the following items:

1. Installation Guide;

2. Software interface for PC ;

3. Set of accessories, according to the order made and as the package contents sheet.

2.2. PC INTERFACE SOFTWARE SETUP AND CONFIGURATION

To install the PC interface software, please follow the next steps:

1. Place the setup CD or PENDISK at the computer CD/DVD drive or USB port;

9 / 59

Page 10

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

2. Using the Start button, select the Run command and write “D:\Setup\setup.exe”, where D is

the CD/DVD or PENDISK drive letter. If the CD-ROM or PENDISK is accessed by another

letter, the user must type the corresponding drive letter. Afterwards press Enter. The

installation program must be executed following the indications until the installation is

successfully completed. The user can also run “Setup”, accessing installation folder thru

“My Computer” or using Windows Explorer.

After software installation, the user can start the Interface software from the shortcut “ExtraLab

Plus” on the programs menu (or a desktop shortcut may be created).

At startup, the software makes a communication test with the equipment. If there is no

communication, the user receives a warning with the possible causes. In this case, some software

options are inactive, including the option of performing tests. However, the user can still see the

existing tests on the Database and print some reports.

The most common causes for communication failure are:

1. Equipment not connected: connect the ExtraLab Plus (see next chapter).

2. The connection with the communication cable is not correct (see next chapter).

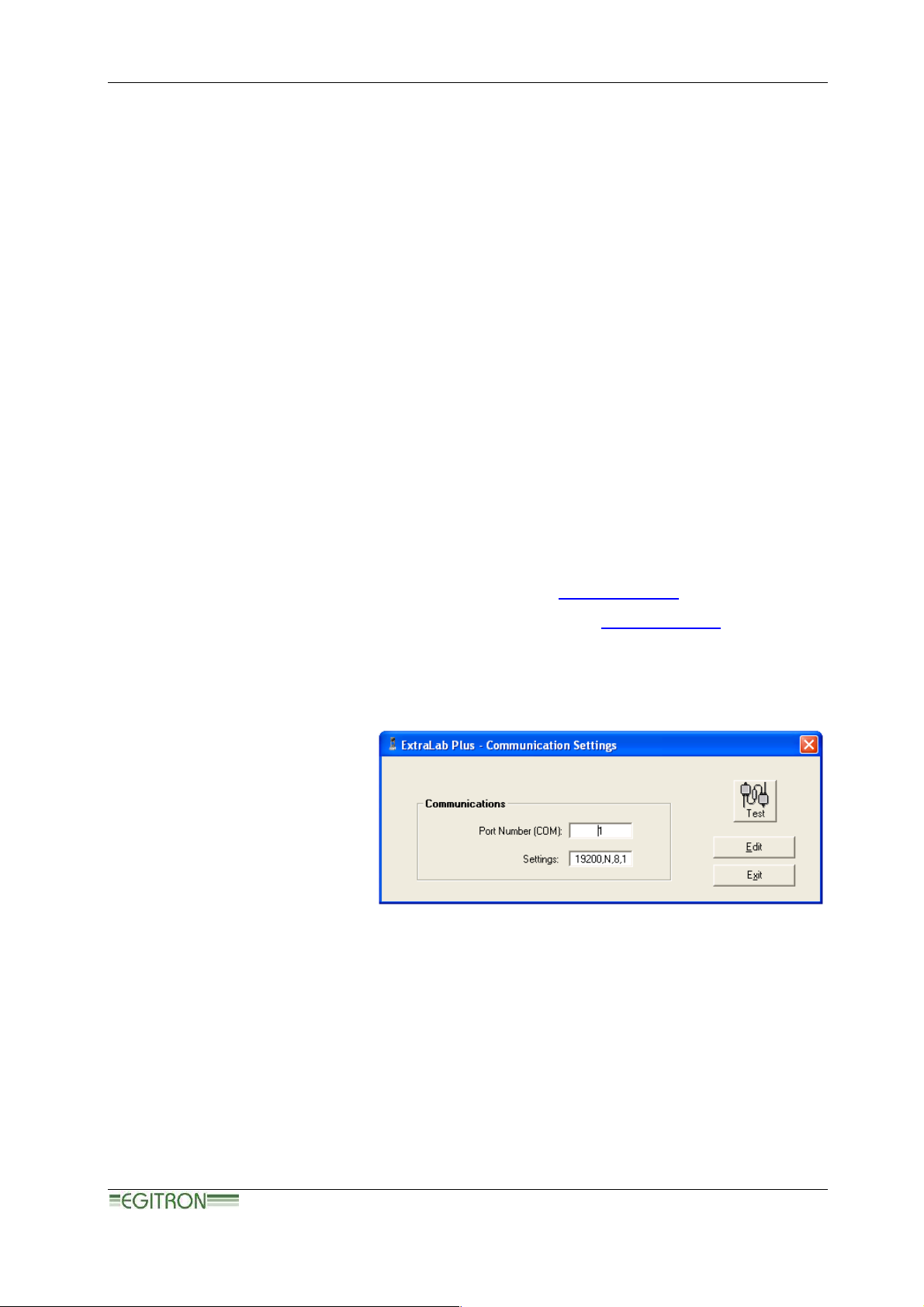

3. Communication parameters are not correct: For changing the communication settings the

user should select “Communications” on the “Configuration” menu at the main toolbar. After

this, a new window like

Figure 1

shows up. On the interface software it is possible to

configure the PC serial

port number (COM) where

the communication cable

is connected, and the

communication settings,

including Baud-Rate,

parity, bits number and

Figure 1 – Communication settings

Stop bits number. The communication settings for ExtraLab Plus are: “19200, N, 8, 1”.

After checking the causes for the communication fail, it will be necessary to press Test on the

communications settings window (

Figure 1

) or press the identical button on the main window to test

the communication with the equipment. If successful all software options will be activated.

10 / 59

Page 11

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

Screw with the existing

screws (4)

2.3. MACHINE SETUP

Before making any connection it is very important that the user understands the technical

specifications of the machine (see Annex F). The technical specifications and the

information next to the connectors must be followed, otherwise damages in the equipment may

occur which will not be covered by the warranty (see warranty conditions above). In case of doubt,

please contact EGITRON for technical support.

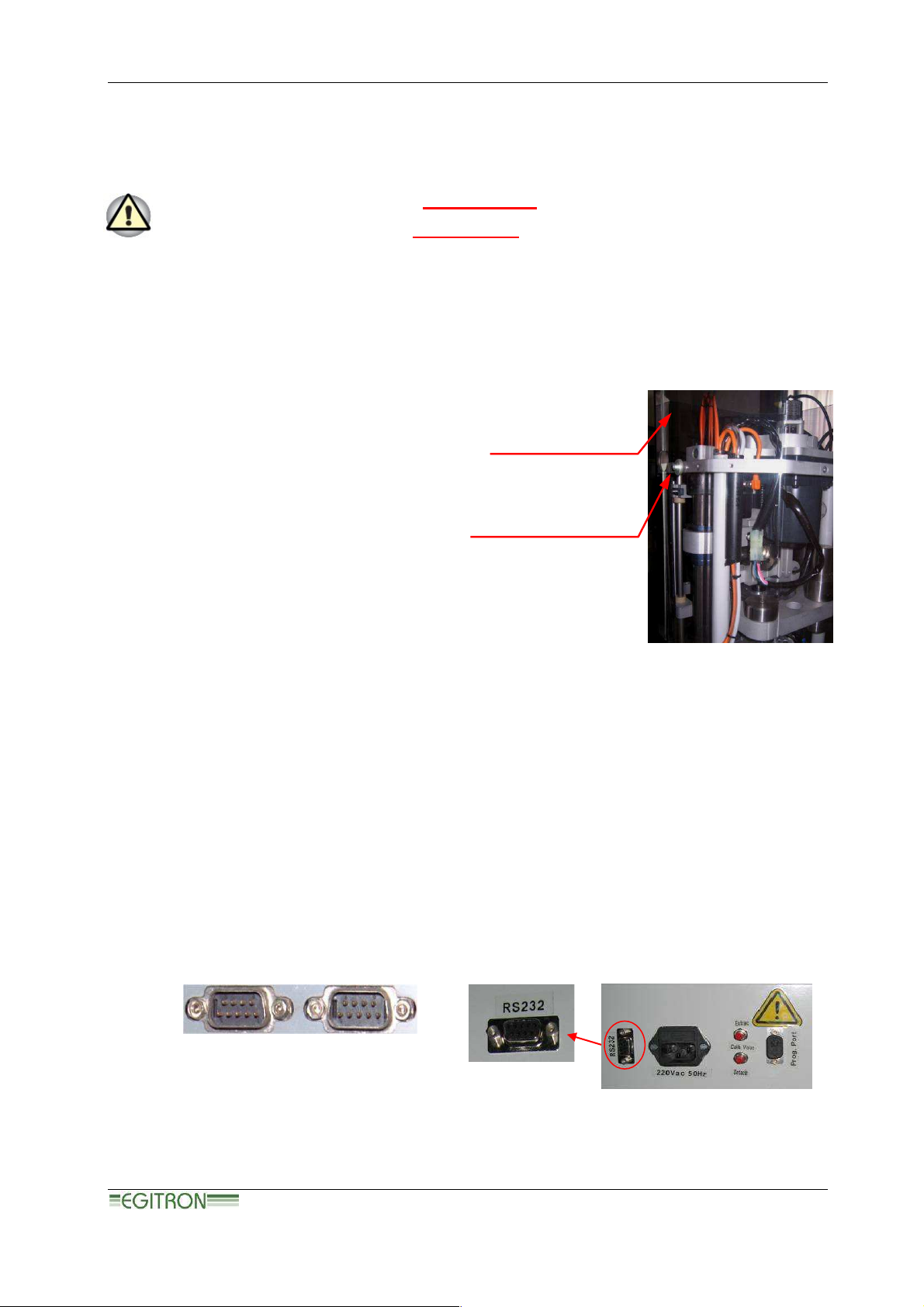

2.3.1. Back acrylic cover

a) After placing the equipment at its

workplace.

b) Apply the back cover (when supplied

separately) on the back of the

equipment and tight it with the existing

Apply the cover

screws.

Figure 2 - Back cover application

2.3.2. Connecting

a) Connect the ExtraLab Plus equipment to the pneumatic feeding thru the pneumatic

connection on the back panel. The feeding tube should have 6 mm of diameter (type

FESTO PUN-H-6x1-nt) and the pressure must be between 6 and 8 bar.

b) Connect the power cable according the indication on the label next to the power connector

(Figure 7 - Command Box).

c) Connect the communication cable on the PC communication port. If the PC only has USB

ports available, use a RS232/USB converter (If required contact EGITRON to order a

RS232/USB converter).

Figure 3 - PC Serial

Communication Ports RS232

Figure 4 - ExtraLab Plus Serial Communication Port

(Rear Command Box)

11 / 59

Page 12

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

Box

the equipment

area

Adjustment

ENCY

button

Console

Gripper

door

Measurement unit

(Extraction +Detaching)

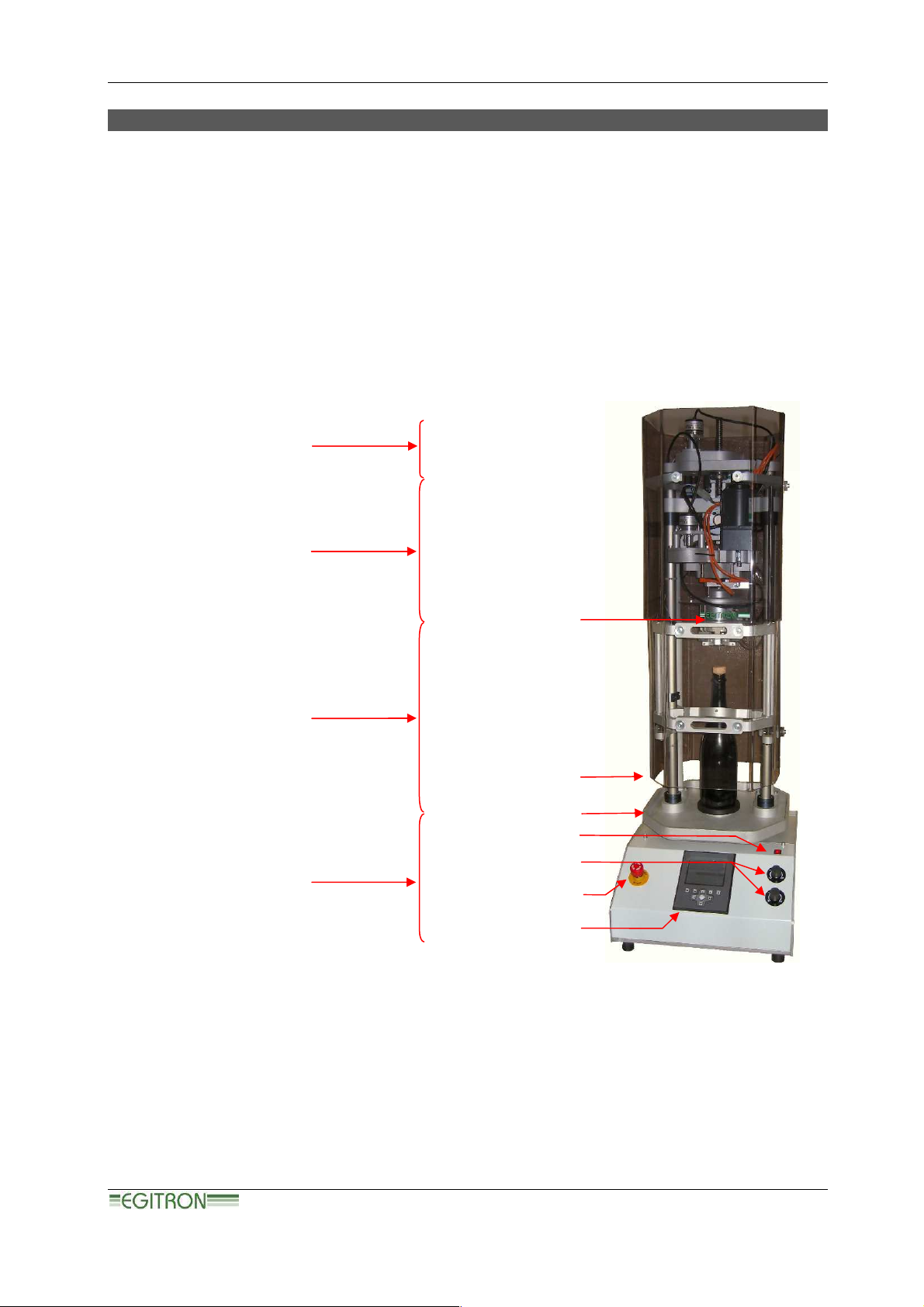

3. OPERATION AND EQUIPMENT FEATURES

On this chapter we will explain the functionalities of ExtraLab Plus, including the control by the

command box and the control by the interface software, in order to enable the user to correctly

operate the equipment and perform tests. On the next subchapters, the most important aspects to

consider when operating ExtraLab Plus will be analyzed, so that, after a careful reading the user will

be able to fully operate the equipment and understand some less intuitive operations .

Upper group of

(encoder + extraction motor)

Working

Security

Elevation Base

Power Switch ON/OFF

Command

Figure 5 - ExtraLab Plus (front panel)

EMERG

Command

(Keys and display)

12 / 59

Page 13

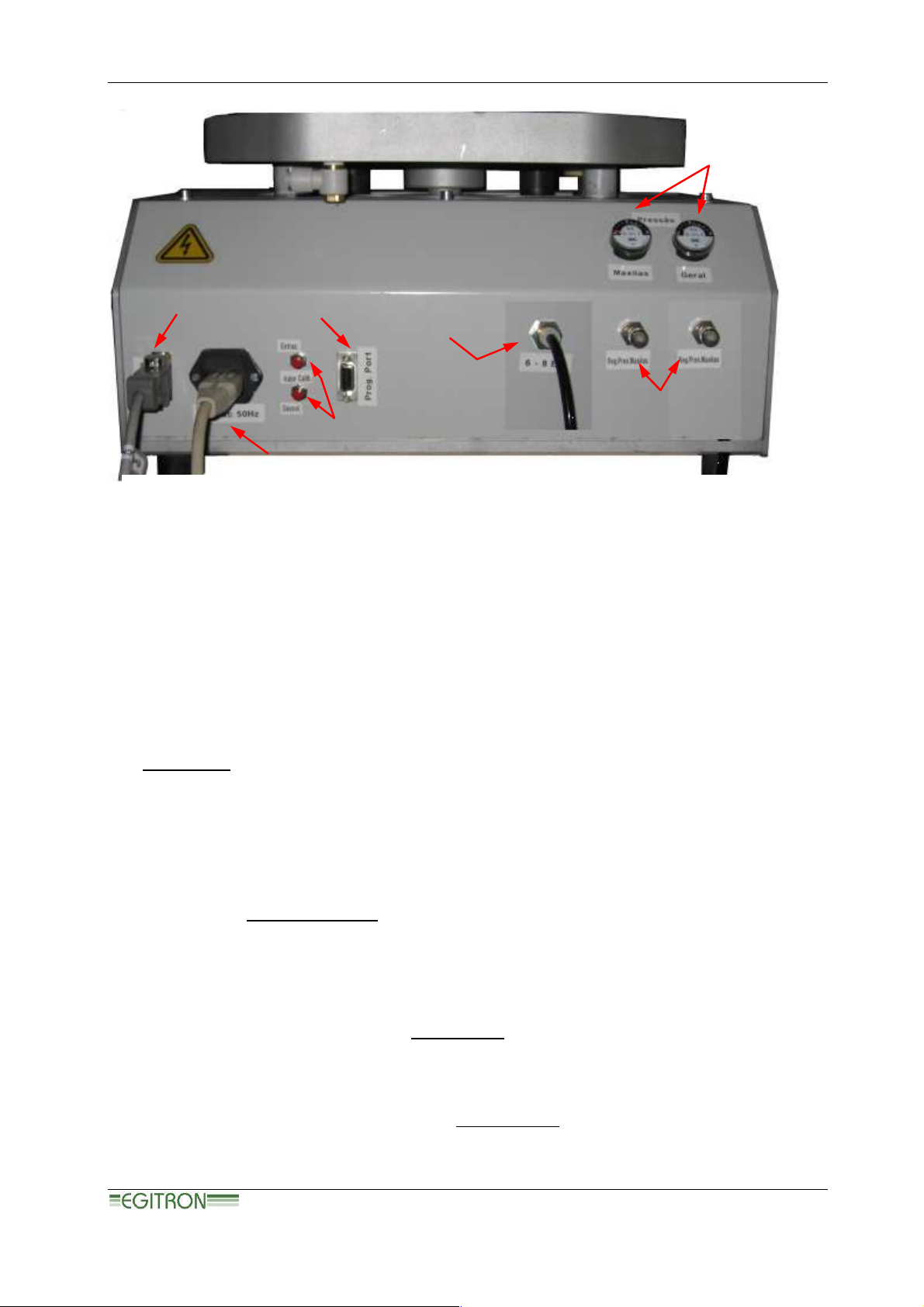

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

Programming port

Pressure gauges

Communication port

Power connector

Compressed air

feeding (6mm)

Pressure regulators

Calibration buttons

Figure 6 - ExtraLab Plus (back panel)

(ELEVATION) (GRIPPER)

3.1. GENERAL ASPECTS

3.1.1. Equipment description

The ExtraLab Plus has a tower format, supported by two cylindrical guides and an aluminum

enclosure which contains the electronic control (commands and processing unit). On the next

paragraphs, we will describe the main parts.

The upper group of this equipment is composed by:

• a motor which is responsible by the extraction movement,

• a vertical position sensor (encoder) and the initial position sensor;

• a lever to hold / release the security door

Below there is the measurement unit, composed by two load cells, used to measure the extraction

force and torque. In this unit, there is also a motor and a sensor for the torque movement. Finally

there is a gripper and a set of optical fibers to detect the approach to the closure.

Below the measurement unit, there is the working area, used for positioning the bottle, adjusting the

measurement unit to the test type and performing tests.

On the lower part of the equipment, there is the command box which contains the electronic control

system. On the frontal panel of the command box, there are the following items:

13 / 59

Page 14

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

• Operator interface where it is possible to easily operate the equipment.

• Regulators to set the speed of the extraction test and the torque test

• Emergency button to stop the equipment in case of emergency.

• Power Switch ON/OFF that allows the user to turn-on and off the equipment.

On the command box back panel, illustrated in

Figure 6

, the user will find the power supply

connector, the communication and programming ports. The first used to communicate with the PC

and the second used port is used for programming the machine and it should not be used

except when performing a firmware update. For more details, please see ANNEX D –

Firmware Actualization that contains information related to firmware update.

On the right of the power plug, there are two red buttons (one for the Extraction load cell and

another for the Torque load cell), used for checking if there are discrepancies between the factory

calibration values and the current values.

Over the right side, there is the plug for compressed air where the pneumatic connection is done.

And there are also two pressure gauges that indicate the pressure for the elevation cylinder

(Elevation) and the pressure applied on the pneumatic Gripper (Gripper). To adjust the pressure

there is a regulator for which actuator (gripper and elevation cylinder). Both adjustments are

important:

• Gripper pressure: should be adjusted to prevent the sliding of the cork when testing

champagne or bar top cork, without damaging the cork. Generally, the pressure should be

between 2 and 2.5 bar, however the operator should adjust the equipment pressure having

in mind the following scenarios

- Insufficient pressure: Cork stopper “slides” during the test.

- Excessive pressure: After the test, the cork stopper shows damage, for example

disruptions in the clamps tightening area. This will change the test values.

• Elevation cylinder pressure: adjust so the bottle is not too much compressed against

bottle positioner (it may burst) and so the bottle does not rotate during torque tests.

Generally the pressure should be between 4 and 4.5 bar.

Please find information about the accessories usage at ANNEX B – Accessories.

14 / 59

Page 15

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.2. CONTROL THROUGH THE COMMAND BOX

Figure 7 - Command Box

3.2.1. Operation Basic Concepts

In this chapter we will be explain the basic concepts of navigation between the different windows

available in the operator interface (display) that is in the command box, as illustrated on

On de operator interface there is a graphic display and a keypad.

There are three operating modes:

• Test Mode: the default mode, in which it is possible to perform tests.

• Calibration Mode: accessible through the option “CALIB” in the main menu (

this mode are provided some features for calibration and for performing “manual”

movements.

• Configuration Mode: accessible through the option “CONFIG” in the main menu (

Figure 7

Figure 8

Figure 8

). In

),

.

where it is possible to configure the equipment and configure also the test to be done.

On the display it will be available, at every time, the information related with the active mode, i.e.,

the display will show information related with the tests when in test mode, will show information

about calibration in calibration mode and will show the configuration menus when in configuration

mode.

15 / 59

Page 16

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

The keys are the control means available for

navigating between the different modes. These also

allow to command individual movements

(Calibration Mode) and to configure the equipment

(Configuration Mode). The keys have the following

functionalities:

• Function Keys (

Figure 8/A

): These keys

command the equipment according to the function that appears on the lower edge of the

display.

• Navigation Keys (

Figure 8/B

– lighter background): these keys assume distinct functions

depending on the mode. Further the keys and will be designated as “up” and

“down”. And the keys and will be designated as “right” and “left”.

• Central Key (

Figure 8/C

): The role of this key will also depend on the active mode. On Test

Mode the function is for “OK” and the equipment will perform a test, or start the equipment

depending on the equipment status. On Calibration mode, it will be for raising the base for

A

B

Figure 8 - Keys of the console

C

bottle elevation and on configuration mode it will be used to confirm the selected option.

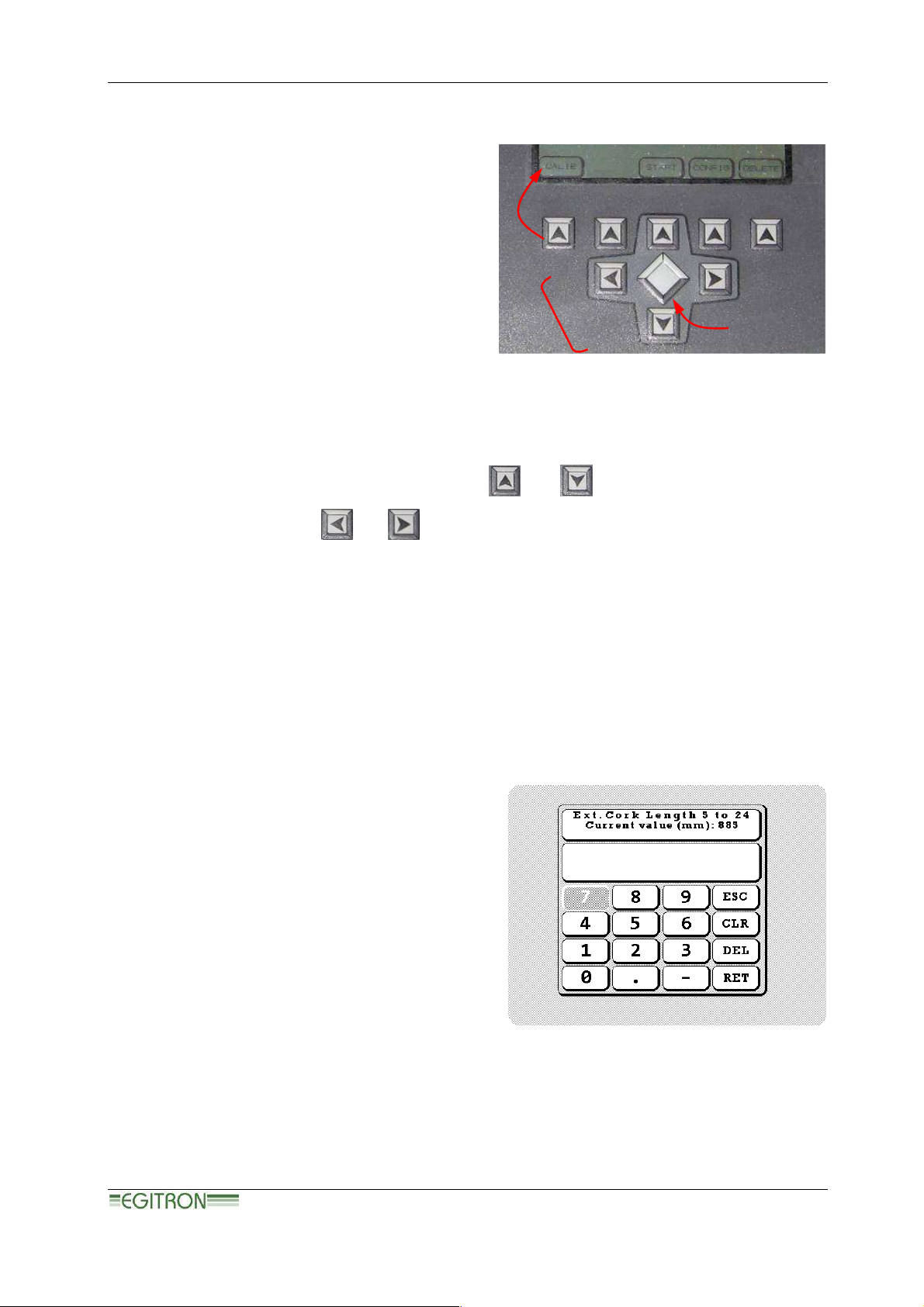

3.2.1.1. Template for values introduction

On the configuration menu there are some templates

for introducing values (

validated by the range of values indicated on the

upper side of the screen. To select a value, browse

through the characters available and press the

central key to confirm the value. Repeat this

operation until the end of the introduction. To confirm

the value, press “RET” and to cancel the introduction,

press “ESC”. If the value that is being introduced is

out of the validation range, this introduction will not be

allowed.

Figure 9

) which will be

Figure 9 – Values introduction

16 / 59

Page 17

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

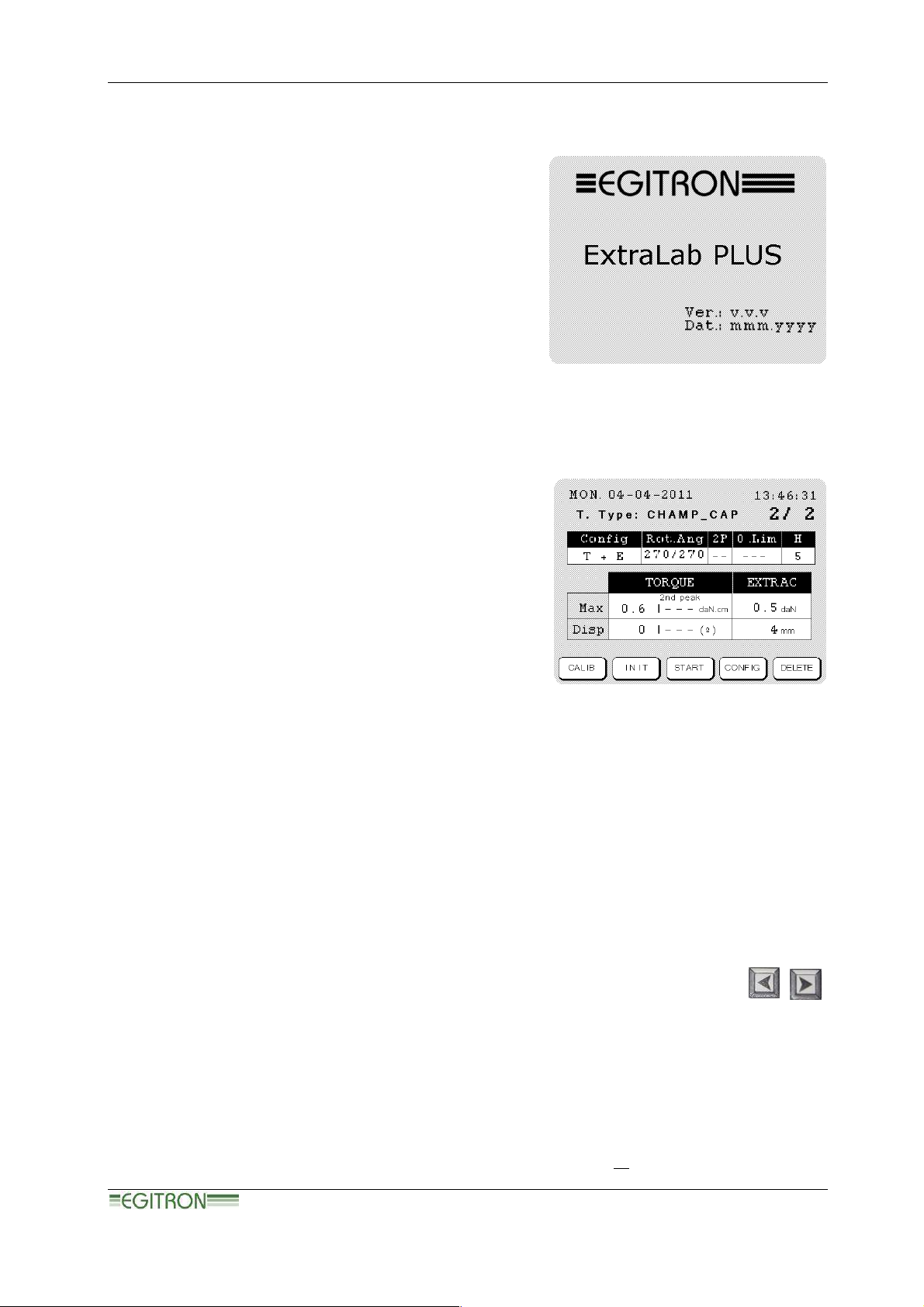

3.2.2. Welcome Window

Press the “Power” bottom on the front panel of the

command box to start the equipment. At starting, a

welcome screen will appear with an indication of the

installed Firmware version (

main screen will show (

Figure 10

Figure 11

). After 2 seconds the

).

3.2.3. Main screen

The main screen is illustrated on

represented, in a condensed way, the memory state, the

tests results, the current test configuration and time and

date information. For better understanding the different

information areas, these were identified in

letters, whose meanings we will describe below.

A. Information about time and date (chapters 3.2.4.4 and 3.2.4.5).

Figure 11

. Here it is

Figure 11

by

A

B

C

D

E

Figure 11 – Main screen

B. Information about memory state: on the example we have Test 1 that has been visualized

in a TOTAL of 1 test in memory.

C. Current test configuration, in this example we have the Test Type T + E (chapter 3.2.4.2),

Cork Type Plus (chapter Error! Reference source not found.) and Torque Angle 75

degrees (chapter Error! Reference source not found.).

D. Information about test results: On the example above, the Torque test had the maximum

value of 12.8 daN.cm at 28º and the Extraction Test had the maximum value of 12.3 daN at

a displacement of 2 mm. If one of the tests was not done, asterisks (****) will appear on the

corresponding column. Use the horizontal arrow keys to navigate between the

tests in memory.

E. Functions: show the modes / functions available since the main window:

o CALIB: Enter in the calibration screen (see chapter3.2.5).

o START: Start a test (it may also be done by the central key).

o CONFIG: Enter in the configuration menu (see chapter3.2.4).

o DELETE: Open the confirmation screen in order to delete all tests in memory.

17 / 59

Page 18

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

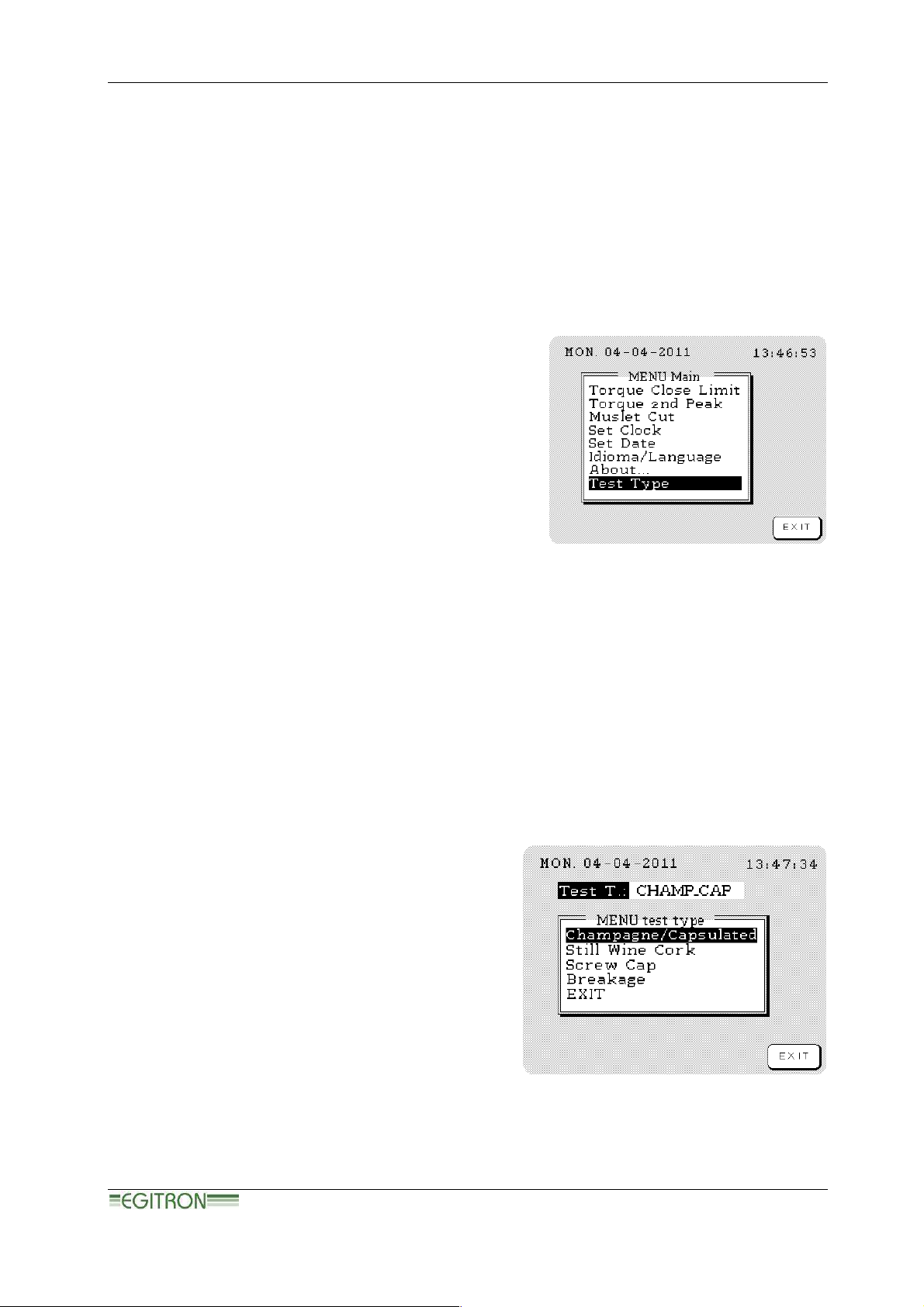

3.2.4. Configuration Menu

The configuration menu gives access to a set of settings that allow the user to choose some

generic parameters, such as language, date, time, and other parameters related with tests

preparation. These last parameters should be adjusted every time the user starts a new report (set

of tests) according with the test type to perform.

To access the configuration menu, press “CONFIG” and

the display should show the configuration menu (

12

).

Figure

Before we present each menu, it is important to have in

mind the following concepts, concerning the navigability

within the menus.

• As seen in 3.2.1 the keys “up” and “down” allows

the navigation between the available options

Figure 12 – Configuration Menu

• The central key selects the highlighted option being a submenu selection or a value

selection.

• Every time the user wants to leave a menu, select the key “EXIT” on the right. Next press

the central key to confirm. After this, the program returns the previous menu or exits the

configuration menu and returning to the main screen (for an overview of the screens tree

see

ANNEX A – Operator interface menu tree

).

3.2.4.1. Test Type

T

he ExtraLab Plus allows the execution of 4 test

types:

• Champagne/Capsulated;

• Still Wine Cork;

• Screw Cap;

• Breakage.

Figure 13 – Test type configuration

18 / 59

Page 19

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.2.4.2. Test Mode Configuration

T

he ExtraLab Plus allows the execution of 6 test modes. To

ease the identification of each test mode on the main

screen, these were coded through related letters. Next we

will describe the different tests types and the associated

letters:

Figure 14 – Test mode configuration

• Extraction (E): Only extraction test, without any rotation movement.

• Torque (T): only detaching test. The measurement unit moves towards the closure (cork

stopper or bar top), detaches it and at the end releases it without removing it from the bottle.

• Torque + Extraction (T + E): Torque (detaching) test followed by Extraction test.

• Torque and Extraction (T & E): Torque (detaching) test performed simultaneously with the

Extraction test.

• Overtorque (O): Overtorque test.

• Torque + Overtorque (T+O): Torque (detaching) test followed by Overtorque test.

• Insertion (INSER): Only insertion test (applies only to flat top capsulated corks).

3.2.4.3. Closure Configuration

Based on this parameter, the measurement unit

will define the position of the clamps on the

pneumatic gripper. The user can select one of the

five options available. The closure configuration is

also coded to ease the visualization on the main

screen. The closure options are:

• Champagne (Plus): 19 mm;

• Long Cap (Cap A): 15 mm;

• Short Cap (Cap B): 5 mm;

Figure 15 – Closure configuration

• Poly: 24 mm;

• Other (D(xx)): The distance may be set by the user, being xx a value between 5 and 30

(24mm for models before serial number 005). Selecting this option, the user will have to

19 / 59

Page 20

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

manually introduce the exterior cork length value (part of the cork that that remains out of

the bottle), according to the range validation and as referred on the chapter 3.2.1.1.

The appropriate configuration for the clousure type is very important. An incorrect

configuration can damage both the equipment and the bottle to be tested.

3.2.4.4. Set clock

After selecting this option, the user will have to use a value introduction template to enter the current

time. Which must be done according with the indications in chapter 3.2.1.1 and following the time

representation on the top of the template (HH-MM-SS) in an 24 hours format (example: 13-10-00 to

13 hours, 10 minutes and 0 seconds).

3.2.4.5. Set date

In this menu the user can set the date thought a value introduction template. This must be

completed according with the indications in chapter 3.2.1.1 and according to the date representation

on the top of the template (DD-MM-YYYY ex: 24-10-2009).

3.2.4.6. Language

In this menu it is possible to choose the language that the

user wants for the equipment operation. The options are

Portuguese and English (

Figure 16

).

3.2.4.7. About…

Screen with information about the embedded software

(Firmware) and EGITRON contacts.

Figure 16 – Language

3.2.5. Calibration screen

Pressing the “CALIB” key on the main window (

it is possible to access the calibration screen (

Figure 11

Figure 17

),

). In

this screen are displayed ‘live’ readings of the load cells

used in each test type and is also available a set of

commands which allow to command manually the

equipment.

Figure 17 – Calibration screen

20 / 59

Page 21

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

The calibration operation must be performed by an operator with high level of responsibility

and technically able to perform this operation. In this mode, some of the security functions

of the equipment will be inactive. Therefore it is recommended to keep, as far as possible, the

protection door closed and to have a very careful attitude whenever performing any command. In

case of doubt, please contact EGITRON.

Next we will describe the information fields and after the available commands.

Information fields:

• Vel: this field indicates the velocity on Extraction test and on Torque test. The reading of the

velocity is made only on the relevant movement of the test, for example during the

ascendant movement in Extraction test or during the counterclockwise rotation movement

on Torque test.

• ADC: represents the digital result of the analogical signal conversion from each load cell.

This value is important for the calibration procedure and to verify calibration value (see

procedure for calibration on

ANNEX C – Calibration

).

• For / Mom: This is the result of the digital value (ADC) conversion into a Force value or

Torque value. Below force or torque value there is a graphic bar associated the respective

value.

Available controls:

• MAXIL: Allows opening and closing the pneumatic gripper.

• ZERO: Allows sending a Zero (Tare) command to each of the load cells (Extraction and

Torque).

• Central Key: Allows the command of the cylinder responsible for moving the elevation base

(up and down). This action can be useful to verify the use of a certain type of bottle

concerning the position of the bottle in respect the centering bar when the elevation base is

at top (e.g. short bottles have to be tested using the supplied short bottles support – see

installation guide).

• Navigation Keys and : allow starting the pneumatic gripper rotation movement,

on each direction, simulating the Torque test.

• Navigation Keys and : allow to setup descent and ascent movements of the

measuring unit. In order to guarantee some security, some of the implemented rules should

be held in mind:

21 / 59

Page 22

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

o On calibration mode, if the measurement unit is not in the initial position (top), the

system does not allows the descent movement. First, the user must place the

measurement unit to its initial position (all the way to the top).

o There is an imposed limit for the descend movement. This limit prevents the

measurement unit to hit the bottle support, but does not protect the equipment if any

obstacle is placed on the path of the measurement unit.

o The readings of the load cells are activated during the up and down movements in

order to prevent the system from overloading the load cell.

3.2.6. Initialization

In order to start a test, the system needs to verify all

the startup conditions. Case these are not verified,

the user should initialize the system. During

initialization the following operations are executed:

• Reposition the movable parts in their original

positions;

• Check the system sensors (position

sensors, gripper obstruction, load cells

values, security door position, etc.).

Figure 18 – Inicialize

It is necessary to carry out the Initialization every time the equipment is at a non-Initialized status.

This happens when:

• the equipment is turned-on and before performing the first test;

• whenever a test is aborted;

• when a free movement is done during the Calibration mode,

• after the occurrence of an important error on the equipment.

It is also necessary to initialize the system whenever the bottle type is changed. The reason

for this is that in order to minimize the test time, the measurement unit stops at an

intermediate position according with the bottle being tested. Therefore when changing the bottle

type, the system should be initialized, once the intermediate position may not adjust to the new

bottle type.

22 / 59

Page 23

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

Info Toolbar

General Menu

3.2.7. Stopping movements

The operator can stop at any moment, any equipment action by performing the following step:

• At the Command Box: Pressing “ABORT” bottom.

After executing the stop command, it will not be possible to continue the testing, without initializing

the system.

3.3. PC Program

The software was developed having in mind that it could be used by any person, not requiring much

computer knowledge. Hard work was evolved to make it a very user-friendly interface. All input data

is properly validated, and the user is notified if any data is not valid or if any operation is not

possible, cutting to minimum the chance of introducing errors. By this way, we assure that the

equipment will not carry out any operation that can put in risk the operator or even the equipment.

The user can try by himself if it is or not possible to enter a specific value or to carry a specific

operation.

Results

Status

Toolbar

Visualization

and

configuration

of the test

type and

parameters

Command

Toolbar

Figure 19– Main window of the control program

23 / 59

Page 24

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

Whenever it is necessary to explain a particular value or button in the software windows, there are

yellow sticks with a brief description which can be opened by moving the mouse over that value box

or button.

After starting the program, the main window is presented (

Figure 19

). On this window there are

available several functionalities and from it the user can access to all the available menus and

windows.

On the top side there is the main menu where it is possible to access to other program windows, as

configuration, calibration, reports, tables, saving and consulting saved tests etc.

On the right side of the window, one will find a Status toolbar that contains some information about

the equipment status. This information appears in a form of a picture (fixed or intermittent) and

additionally there is an info toolbar at the bottom of the main window with short messages which

shows information on the equipment status.

Still on the right side, there is also a section where some test configuration parameters are

visualized. The user can choose a Test Type configuration, and all of the configuration parameters

will be sent to the machine.

Bellow, on the right low corner of the window, there is a Command toolbar that contains buttons

associated to procedures like reading values from the equipment.

The main part of this window is filled by the Results area that contain the values and graphics of the

tests performed or of a report previously saved in the program database.

On the following chapters we will explain with more detail, all the potentialities of this equipment and

its interface software, like changing tests configurations, consulting recorded tests and performing

the equipment calibration.

3.3.1. Data Tables

There are several data tables,

which help identifying the report

and its execution conditions.

When saving a report, it is

possible to complement the

report with the following

Figure 20

– Bottle Types Table

24 / 59

Page 25

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

information:

• Client/Supplier • Closure Types

• Size

• Treatment

• Washing

• Bottle type

• Cork Class

• Responsible

The different tables can be opened by selection the “Tables” option on the “Configuration” menu. All

tables have a similar construction and work the same way. For example,

Figure 20

shows the

Bottles Types table, where it is possible to add, delete, and change the Bottles Types.

In the tables, cork class, type of bottle, washing, closure type and treatment, there are fields where

the corresponding translations for each language should be introduced. For more information

please see the chapter Printing Reports.

3.3.2. Report Configuration

Select “Reports” on the menu “Configuration”,

to open the “Reports Configuration” window

(

Figure 21

). This window allows the

configuration of the company name and

address, the document code and the company

logo. The logo file should be in “BMP” format,

and to insert a new logo, press the “Edit”

button and select the folder containing the

logo on the “Folder” field, the “File” field will

show the names of all bmp files found in the

selected folder. By clicking on a file name, the

image will be displayed in the “Image” field. To

insert the selected image, double click it, the

image will then be displayed in the “Logo”

Figure 21 – Reports configuration window

field.

On the option “Default report language”, configure the default language to be used when printing

reports.

25 / 59

Page 26

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.3.3. Acquire Values

After performing one or more tests, it is possible to import the values into the interface software.

To collect the values the operator has to press “Acquire Tests” button. Doing so, all tests

results in machine memory, both maximum values and individual values, will be imported

and visualized with the help of tables and graphics.

The results area is formed by three tabs:

• Maximum Values (

Figure 22

): tab where it is possible to see the maximum force and torque

values of all tests

(accordingly to the test

configuration). Here it is

possible to see a table

which contains for each

test, the maximum value

of the force and the

value of the

displacement where the

maximum force was

achieved, and as well

the maximum torque

Figure 22– Window with maximum values

value and the angle where the maximum torque was achieved. There are also two graphics,

one for Extraction and another for Torque with the comparison between the maximum

values of each test.

Finally, there is a statistical summary where it is possible to see the maximum, minimum,

average and standard deviation for both force and torque readings.

26 / 59

Page 27

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

• Individual Values (

Figure 23

): this tab displays the individual values of a particular test.

There is a table with the

force and displacement

values and another with

the torque values and

angle (accordingly to the

test configuration). Below

these tables, it is possible

to find summary

information related with

the test, like number of

collected values and test

velocity.

Figure 23– Individual values

There are two graphics showing the moment and force evolution during the detaching and

extraction tests (accordingly to the test configuration). At the inferior left corner, there is a list

where the user can select the test to visualize. It is also possible to see a particular test, by

double-clicking the desired test, on the maximum values table.

At this tab it is also possible to delete the current test. For that, press the “Delete Test”

button. This will delete the test being visualized, only from the PC and not from the internal

memory of the machine.

27 / 59

Page 28

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.3.4. Saving Reports

After acquiring data or consulting a report, it is possible to save data into the database

(BDExtraLabPlus.mdb), for later consultation, visualization and printing reports. Instead of saving a

new report, it is also possible to add data to an existing report. To save or add data, follow the next

steps starting from the main window:

1. Select “Save Report”,

on the menu “Report”,

to open the “Save

Report” window

(Figure 24);

2. Type the code (report

identification name) if

saving a new report, or

select an existing

report. If the report

already exists: press

“Add” and in this case

all tests will be added

to the selected report.

Figure 24 – Save Report

Instead of adding, press “Save” to replace the report data with the new data. If the report

does not exist, pressing “Save” the new report code is added to the list of saved reports.

3. Afterwards, it is possible to select other report characteristics: Closure Type, Size, etc. It is

also possible to add some complementary information to the report on the “Comments”

field. In order to print reports in other languages, the “Comments” field translations must be

done in the “Comments” tab.

Please take note that when adding data to an existing report, all the report characteristics of the

existing report will remain the same.

28 / 59

Page 29

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.3.5. Open Reports

After saving a report into the

database

(“BD

ExtraLabPlus

possible to open the saved

report. For this, select the option

“Open” from the menu “Report”

and the “Open Report” window

(

Figure 25

list of the saved reports.

By selecting a particular report, all

the fields on this window are

updated with the corresponding

report information. By pressing

.mdb”), it is

) will open showing a

“Open” or double-clicking on any

report, the “Open Report” window

will close and the main window

Figure 25 – Open Report

will show the data of the selected report.

Still on the “Open Report” window there is a box named “Report Filters”, which allows the

introduction of filtering parameters such as Year, Code and Client / Supplier. This eases the

process of report finding. To filter the reports to visualize, use the characters “*” or "%" for any

character, or “?” or "_" for a single character. Please check the following examples:

1 - "A*": shows all reports started by “A”.

2 - "*AC*": shows the reports whose name contains the characters “AC”.

3 - "?A*": shows all reports which name has the character “A” as the second character.

To delete reports, select the desired report and press the “Delete” button. And finally, the “Exit”

button will close this window.

3.3.6. Printing Reports

Select the option “Print Report” at the menu “Report”, to open the print preview window. The report

(

Figure 26

according to the option “Individual Values”, a page for each test with the individual values.

) is formed by an initial page with the identification and the maximum values, and then,

29 / 59

Page 30

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

The reports can only be printed if previously saved into the database. The user can choose the

report language, on the language list available. By default the report is on the language selected on

the report configuration window (3.3.2) but it can be printed on the following languages:

Portuguese, English, Spanish (Castilian), French and German.

Figure 26

– Printing a report

The appropriate translations should be written in the Grade, Closing, Type of Bottle,

Washing and Treatment tables. The translation of the field “Comments” must be inserted in

the “Save Report” window.

3.3.7. Export to Excel

Selecting the option “Export Excel”

from the menu “Report”, the “Export

values to Excel…” window will open

(

Figure 27

opening an Excel file, save the file

and keep it opened. In the window,

on the field “File” introduce the Excel

file name and in the “Sheet” field the

sheet name where to export. It is

also possible to configure the 1st row

and the 1st column as starting point to export the information. Other option is to select if is necessary

). The next step must be

Figure 27 – Export to Excel configuration

to export the maximum values or individual values and the file extension (xls or xlsx). The Excel

Language list allows configuring the language of the Microsoft Excel installed on the PC.

30 / 59

Page 31

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.3.8. Calibration

Like any laboratory equipment, the ExtraLab Plus is subject to calibrations in order to prove and

check the values acquired. If required, EGITRON can supply a Calibration Kit for ExtraLab Plus, as

referred in Annex C.

.

It is not possible to simultaneously perform calibration and tests.

Calibration is an operation with a high level of responsibility and only technical staff with

metrology knowledge should perform this operation. For this reason, the calibration

window is protected with a password that is by default “egitron”. To increase security this

password should be changed – for this select the option “Password” on the menu “Configuration”.

To open “Calibration” window,

select “calibration” on the

main menu. Afterwards, it is

necessary to type the

password in order to validate

the user (see note above).

After that, the “Calibration”

window will open (

Figure 28

).

On the upper side of the

window, there is a list for

choosing the load cell, which

will be calibrated. (Extraction

or Torque)

Figure 28

– Calibration Window

Below this, there is the load cell value, where is indicated the value obtained thru the Analogue-toDigital Converter (ADC value) and the corresponding value in daN.cm and in Kgf.cm (depending on

the load cell). The reading can be set to “zero”, pressing on the button “Zero Adjust”.

At the center there is the Conversion Function stored on the machine memory. This function is a 3rd

degree equation, used to convert the digital value (ADC) acquired from the load cell (converted by

the analogue-to-digital converter) into N (Newton). The coefficients of this function are read from

31 / 59

Page 32

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

ExtraLab Plus every time the calibration window is opened, or after selecting a different load cell, or

after pressing the “Cancel” button when editing the function.

The last sub-group shows the conversion function stored in the database. The process of saving

the conversion function into the Database is quite transparent for the operator: at the

first time that Pc software is used, it will automatically read the function on the

machine‘s memory and store this into the database. Then, every time the software is

initialized, it will compare the previously stored values, with the conversion function on

the machine memory. If there are discrepancies, the user is warned and is given the

possibility to correct this, entering on the calibration window. After opening the calibration window,

the user can: (1) send stored values at the database to the machine memory, choosing the “Send”

button on “Conversion Function Stored in the Database” box; or (2) update the database with the

values on the equipment memory, choosing the “Import” button.

This functionality is quite useful, mainly in the case of the machine losing its conversion function.

One of the most important ExtraLab Plus characteristics is the possibility to calibrate the

conversion function. After reading the calibration values it is possible to determine a new

conversion function using Microsoft Excel or a similar software. After, the new equation

coefficients can be sent to ExtraLab Plus, with the purpose of adjusting the reading to the

calibration values. These coefficients will be saved into the non volatile memory of ExtraLab Plus,

and kept until these are changed again by the user. This functionality allows at any moment to

correct any deviation detected on the ExtraLab Plus readings.

To send a new conversion function to ExtraLab Plus, press the “Edit” button, at the conversion

function stored on the machine memory group, introduce the new coefficients of the 3rd degree

equation and after confirm this new parameters, then press “Send” button. Beware that before

saving, it is possible to cancel the changes by pressing the “Cancel” button, and like this continue

using the existing conversion function.

To perform the calibration of the ExtraLab Plus readings, please see the

ANNEX C – Calibration

32 / 59

Page 33

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.4. COMMON EQUIPMENT AND SOFTWARE OPERATIONS

3.4.1. States

The equipment can assume five different states:

• Stopped: The machine is ready to perform the tests;

• Not initialized: Whenever the system requires a reposition;

• Machine in movement: The equipment is in movement;

• Calibration: When the equipment is performing calibration operations;

• Emergency: Whenever the stop emergency is activated.

These states can never occur simultaneously.

Following we will describe the functionalities that are available, either through the interface

program or through the operator interface at the command box. For more information about

the functionalities of the operator interface, refer to chapter 3.2.1.

3.4.2. Test Configuration

The Test Configuration Window

allows the user to create tests

configurations by default, with all

the parameters related to the

tests to perform by ExtraLab

Plus.

There are four types of tests:

• Champagne/Cap. Cork;

• Still Wine Cork;

• Screw Cap;

• Breakage.

The application will allow

Figure 29

configuring certain fields, according to the selected Test Type.

– Test Configuration

33 / 59

Page 34

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

For each Test Type, it is possible to perform different test modes:

• Torque followed by extraction;

• Torque and extraction, simultaneously;

• Extraction;

• Torque;

• Overtorque;

• Torque followed by Overtorque;

• Insertion.

After configuring the test type, the user must configure also the Closure Height. According to the

Closure Height, the distance between the top of the Closure and the pneumatic gripper tightening

point must be configured. Some Closure Height examples are:

• Champagne – 19 mm;

• Long Cap – 15 mm;

• Short Cap – 5 mm;

• Poly – 24 mm;

• Other – Distance configurable by user, between 5 and 30mm (24 mm for machines with

serial number before 005).

If the test have Torque, it is possible to configure the equipment to acquire the Torque 2nd Peak, the

percentage for the calculation of the Torque 2nd Peak as well as the Torque Angle.

If the test have Overtorque, it is possible to configure the Overtorque Angle and the Overtorque

Limit.

If the test type is “Champagne/Capsulated Cork”, it is possible to configure the ‘Muslet’ Cut Stop.

This option allows to enable/disable the stop after the closure (champagne cork stopper) is grabbed

by the gripper. This allows to cut the ‘Muslet’ while the closure is being held, avoiding the stopper

from popping out before the test is performed.

Fields Limits:

• Torque Angle: 10-270º

• Torque 2nd Peak Percentage: 5-90%

• Overtorque Angle: 10-270º

• Overtorque Limit: 1-50 daN.cm

34 / 59

Page 35

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

To configure these parameters:

• At the Command Box: see chapter 3.2.4.

• At the PC Software: Create a new test configuration, and through the application main

window, send the configuration to the machine.

Tests of different types cannot be stored in ExtraLab Plus memory. So, if the user wishes

to change the test type, firstly the values on the machine should be transferred into the

interface application and afterwards the memory of the machine can be cleaned.

3.4.3. Values Acquisition

After performing a test, it is possible to collect the values using the Acquire Tests button

on the main toolbar. After this, all tests values will be copied into the PC. Afterward, the

user has the possibility to see the statistical calculations, graphics, export to Excel, save

into a database and print reports on different languages.

3.4.4. Deleting Test

The equipment can save 99 tests in its memory. The equipment memory is battery backed up;

hence the tests remain in memory, even if the equipment is powered off, until being erased by the

operator.

Deleting all tests in memory, can be done by two different ways:

b. At the Command Box: Pressing the “delete” button and then the central

key.

c. At the PC Software: Pressing “Delete” button at the maximum values tab.

To delete one test, the user must use the delete button at the individual values tab on the PC

program (see 3.3.3). This functionality is only available at the PC Software.

To delete all tests in memory, the equipment cannot be in calibration mode.

35 / 59

Page 36

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.4.5. Safety and Protection

The ExtraLab Plus has built-in protections, to assure the user and the equipment security. The

software is permanently checking the equipment status monitoring if any anomaly is detected.

Every time an anomaly occurs, the operator is immediately noticed, by command box display and

by the PC software.

The most important safety/errors warnings that may happen are:

• Emergency Pressed: Front panel emergency button activated (to deactivate turn

clockwise the mushroom and release it);

• Security door open: The security door was open, during machine movement;

• Extraction Test Null: The extraction test value was null;

• Torque Test Null: The torque test value was null;

• Memory Full: The maximum number of test has been reached (99 tests). In this

situation, the user should acquire the values from the equipment, save them and

afterwards delete the existing tests on the equipment, like described in previous

chapters;

• Extraction - Maximum Force Exceeded: The load cell responsible for the Extraction

Force exceeded it maximum capacity;

• Torque - Maximum Force Exceeded: The load cell responsible for the Torque test

exceeded its maximum capacity;

• Communication Fail: A communication fault with the equipment has occurred (see

chapter 2.2.

3.5. START A TEST

3.5.1. Connect the equipment

After performing the setup of the machine like described on chapter 2.3 and 2.2, connect the

equipment, pressing the “power” button or “0/1” at command box the frontal panel (Figure 7)

36 / 59

Page 37

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

3.5.2. Place the bottle

Choose the bottle to test. At this time, it is important to check, according to the bottle to test, if the

small bottles support will be necessary (~250mm) and if the clamps installed are the more

appropriated (for example: for the test with a champagne bottle with 75 cl of capacity the support for

small bottles is not necessary and the clamps recommended are the A type) – for changing the

clamps see

ANNEX B – Accessories

.

After choosing the bottle, follow the next points:

• Open the protection door.

• Place the bottle on the black base, making it pass thought the bottle centering bar.

• Close the protection door.

It is important to assure that the bottle has a closure (champagne cork stopper or bar top)

and it is proper for the test type to perform. Please note that this equipment does not have

any sensor to detect the closure nonexistence. So if the user initializes the test in this condition, the

bottle can be broken by the pneumatic gripper.

3.5.3. Configure the test

Before initializing the test, the system must be configured according to the test type and for the

closing type present in the bottle. Another aspect to consider is the speed to perform the test

(extraction and torque). To change this, refer to the calibration screen description (chapter 3.2.5).

3.5.4. Starting the Test

At this time, in the display will appear a screen like (

showing, press “Abort” or leave the menus until returning to the main screen.

a. Press “START” or the central key to start the Test.

b. Depending if the system recognizes or not the ExtraLab Plus actual position, the display

should show one of the following messages:

b1. “Positioning System?” (

Figure 18

) In this case the user must confirm so that the system

returns to is initial position (continue from point a.).

Figure 11

). If this screen, for some reason is not

37 / 59

Page 38

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

b2. “Execute test xx”, where xx is the new test number. Press “CONT” or central key to

confirm the test starting (to cancel press “ABORT”).

c. At this time, the bottle is elevated and the measurement unit will seek the Closing Type

position. After this, the gripper will be positioned according to the selected Closing Type and

the test will be performed according to the previous test type selection.

d. In order to minimize the test duration time, the measurement unit will be positioned in an

intermediate position a few millimeters above the test ending. The test results will be then

available at the display (like show in

Figure 11

).

Due to the fact that the measurement unit, after the test, is stopped in an intermediate

position (related to the bottle type used), it is necessary to initialize the system whenever

the bottle type is changed.

3.5.5. Check information on the Display

After each test the number of tests in memory is increased. Using the navigation keys and

it is possible to navigate between the tests in memory and check the maximum values and the

corresponding angle from every test visualized.

38 / 59

Page 39

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

4. EQUIPMENT MAINTENANCE

This equipment doesn’t require significant maintenance cares. However for prevention it is

recommended to have in mind the following points:

1. Take in consideration that the machine will handle products that are under pressure, and

consequently splash of liquids may occur with some frequency. And also there will be

accumulation of cork dusts. Therefore, it’s recommended to clean daily the equipment in

order to avoid the accumulation of these products.

During cleaning operations, use only a cloth moistened with water or alcohol. The

utilization of inappropriate products may damage the equipment and this is not warranty

covered.

2. Check if there are darker areas on the compressed air tubes. This could indicate presence

of oil on the pneumatic circuit which can cause the pneumatic components failure.

3. Check the values of the load cells: Enter on Calibration Menu (Press “CALIB”). Ensure that

the measurement unit is unobstructed. Press button “Extract. Val.” and “Torque Val”, on the

back panel of the command box and check for both loads cell (Extraction and Torque) if the

ADC value that appears on the display is equal to the value written next to “Calibration

Values” on the serial number label, located at the command box back panel. If there are

differences larger than 3 or 4 ADC units, follow the calibration procedure (

Calibration

) or in case of doubt contact EGITRON.

ANNEX C –

39 / 59

Page 40

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

5. TROUBLESHOOT

5.1. CALIBRATION CURVE LOAD FAILURE AT STARTUP

Description: During start-up, the equipment could not load the conversion function. This error

occurs when the conversion function has been lost or is corrupted. This is signalized with the

message “Invalid function”.

Resolution: Through the “Calibration” window at the PC software, introduce the conversion

function or use the database saved function, and send it to ExtraLab Plus.

5.2. COMMUNICATION ERROR

Description: The PC control software could not communicate with the equipment.

Resolution: Check if the communication settings on the software are according to the equipment

communication settings (shown at start-up). Verify if the communication cable is properly

connected.

5.3. SYSTEM BLOCKED

Description: The equipment does not answer to orders from the command box.

Resolution: Turn the machine off and after a few seconds turn it on again. If the problem persists,

check the error messages that appear on the screen of the equipment or on the interface

application. For further assistance contact EGITRON.

40 / 59

Page 41

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

ANNEX A – Operator interface menu tree

Level 1 Level 2 Level 3

Calibration Calibration screen - -

Initialize

Initialize Confirmation screen Movement information

Start

Start test Confirmation screen Movement information

Abort

(return to level 1)

Test Type

Main

Test mode

screen

Configuration

Cork Type

Torque angle Data entering

Overtorque angle Data entering

2nd Peek

Set Clock Data entering

Set Date Data entering

About Information screen

EXIT -

Delete Confirmation screen - -

Level 4 Level 5

- CHAMP_CAP

SCREW CAP

BREAKAGE

STILLWINE

Extraction

Torque

Torque + Extraction

Torque and Extraction

Overtorque

Torque + Overtorque

Insertion

EXIT

(return to level 3)

Champagne

Short Cap

Other Data entering

EXIT

(return to level 3)

-

10% -

Other Data entering

Recalculate -

-

-

- Long Cap

-

-

41 / 59

Page 42

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

42 / 59

Page 43

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

ANNEX B – Accessories

1. Anti-splash protection application

This application protects the mechanisms

and components that are on the upper part

of the ExtraLab Plus, if the liquid splashes

when testing bottles with sparkling wines.

1.1.

Application

Annex B . Figure 1-1

a) Open the door and fix it at the opened

position.

b) Apply the anti-splash protection very

carefully avoiding damaging any

component, especially the optical

fibers.

1.2. Removing:

a) To remove the anti-splash protection, execute step

a) from the previous point (1.1).

b) Remove the anti-splash protection by twisting a

little the protection, to release from one side first

and the push to release it completely.

Lever for blocking

the security door

Annex B . Figure 1-2

Annex B . Figure 1-3

2. Grippers

There are different types of clamps for ExtraLab Plus, which allow extending the measurement

range for others cork types or other types of closures.

The standard supply includes:

43 / 59

Page 44

ExtraLab Plus – Cork Extraction Force and Torque Measuring System

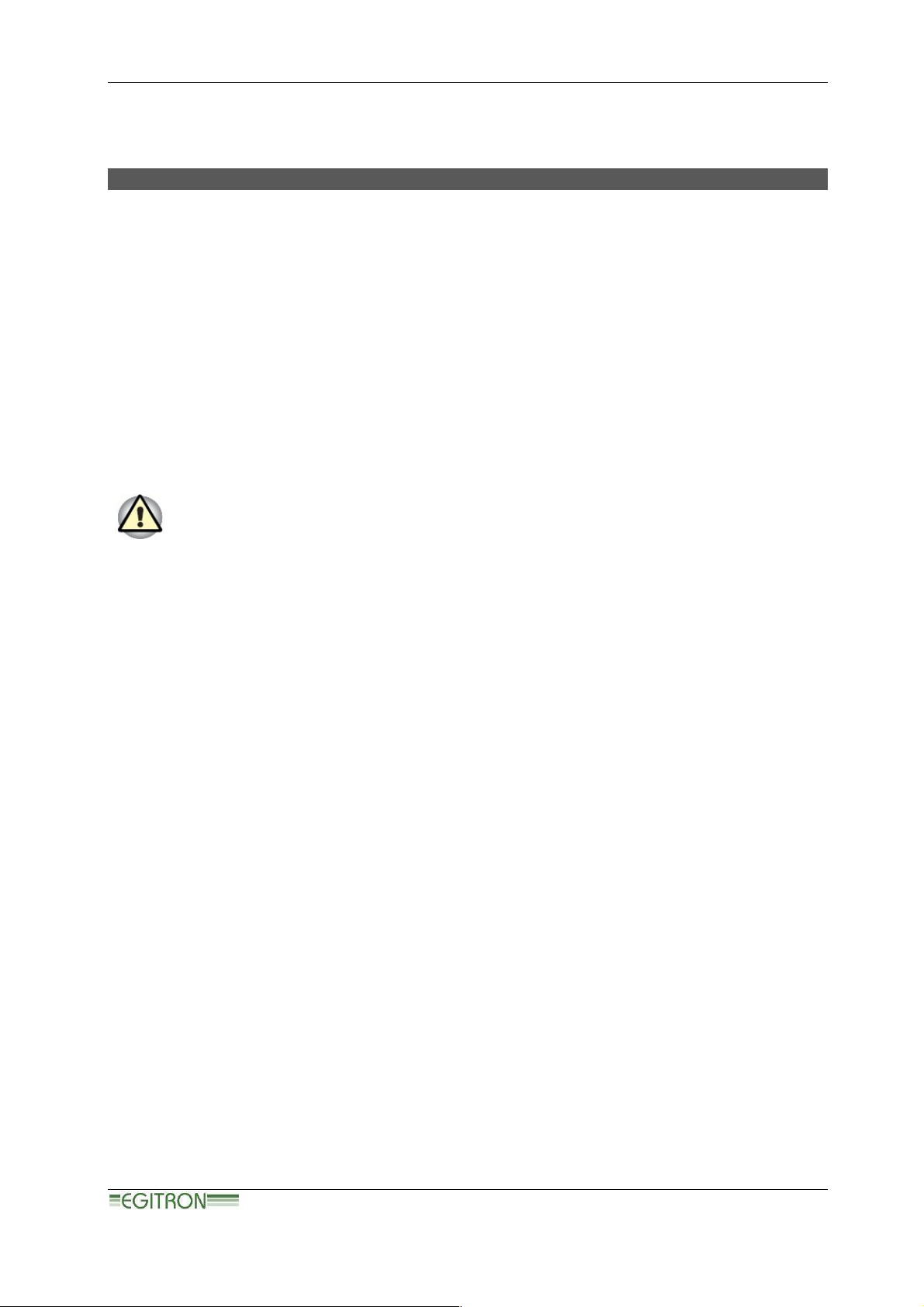

- 3 Pins for Grippers attachment

Supplied with the equipment

- 3 grippers (type 13) (

stoppers – opening diameter 35 mm and closing

diameter 19 mm)

. S

upplied with the equipment

for champagne cork

Table 2-1

Please contact EGITRON for other possibilities.

2.1.

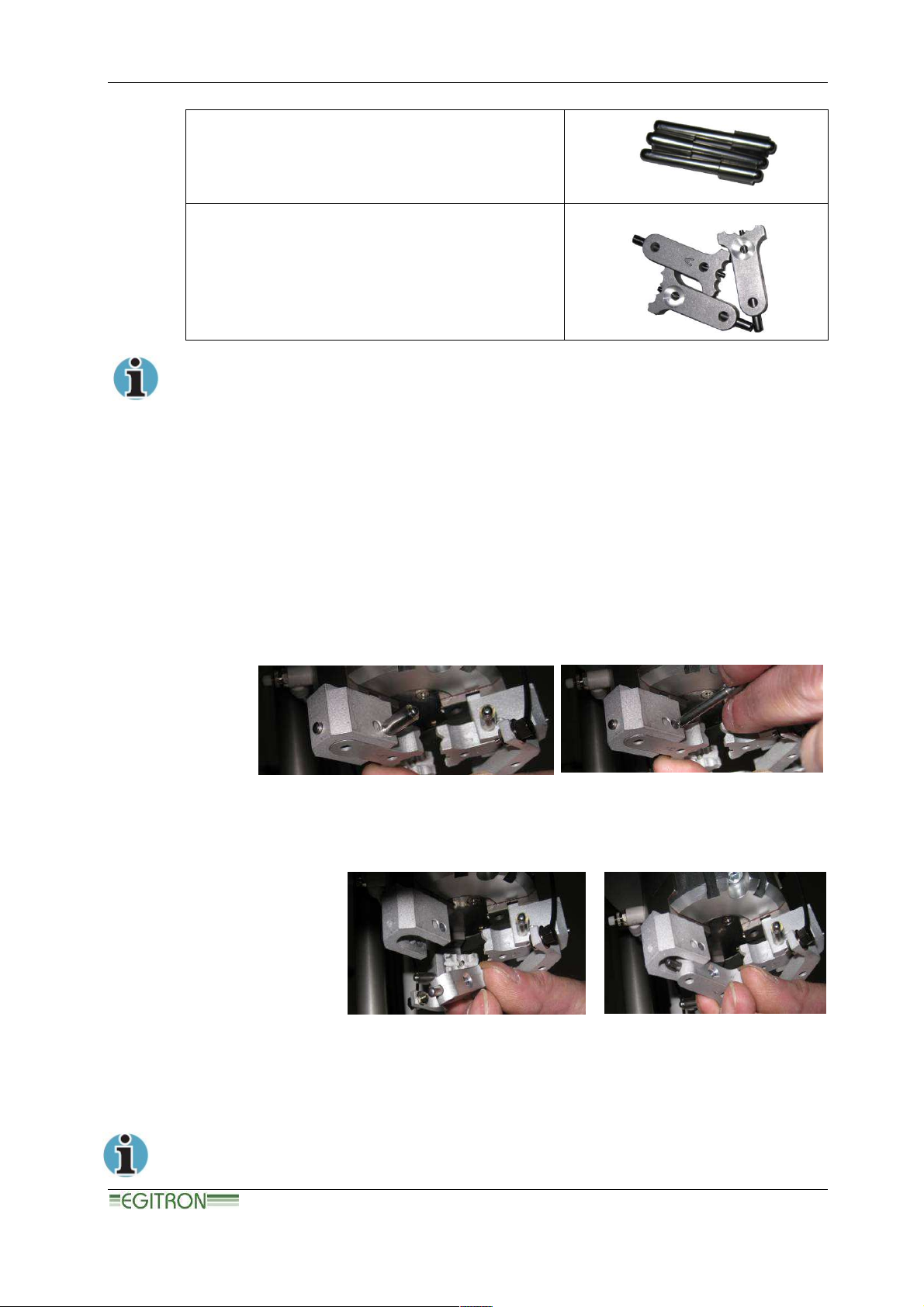

Grippers replacing

Procedure for clamps substitution:

a) If the anti-splashes protection is installed, remove it as previously explained (Annex B chapter

1.2).

b) Remove the three position pins from the clamps and after take out the three installed clamps.

Annex B . Figure 2-1

c) Choose the appropriate clamps according to the test to perform.

Annex B . Figure 2-2

d) Install the ‘new’ clamps and insert the fixing pins for the clamps fixation.

e) If required re-install the anti-splash protection.