Page 1

- 1 -

Eggtimer Proton

User’s Guide

Board RevA9

Software Rev. 1.01A

© 2018 Eggtimer Rocketry

All Rights Reserved

Page 2

- 2 -

Eggtimer Proton Features

WiFi-Enabled, SIX-Output logging flight computer with 120G Accelerometer

Flexible deployment and arming modes, to handle virtually any flight scenario

Any channel can perform any function… no dedicated "Drogue" or "Main" channels

First three channels can be set for standard servos during deployments, variable servo travel

Programming, arming, and downloading can all be done with any WiFi/browser-enabled device

No apps required on your device, just a browser

Size: 3.25” x 1.3”, fits easily in a 38mm coupler tube, weighs about 20 grams

Altimeter records data up to 60,000’

Detailed flight data for 14 flights is saved, and can be downloaded using your browser

Summary data can be downloaded or viewed on your browser, immediately after the flight

Fully “mach immune”, deployments are inhibited until the rocket is moving slowly near apogee

Battery input is fully polarity protected

Works with a 2S/7.4V LiPo battery, 300 mAH or more recommended

Optional separate battery input for deployment channels protects against “brownouts”

Works with almost all common deployment devices, will even light an Estes® igniter with a 2S LiPo

Each output channel can handle up to 10A/40V, system capacity 30A

Test mode so you can do an actual pyro test remotely up to 200’ away from your rocket

Dual-ended deployment outputs, igniters are essentially “dead” until well into the flight

No switch needed, since it’s disarmed and the igniters are dead until YOU arm it

“Fail-Safe” mode can fire main chute (in deployment mode) if a drogue failure is detected, preventing a

potential high-speed chute deployment or crash

Page 3

- 3 -

Disclaimers, Legal Stuff, Etc.

The Eggtimer Proton is meant to be used for hobby and experimental rocketry purposes.

Although hobby rocketry has an admirable safety record, largely due to the efforts of the good

people at the National Association of Rocketry (NAR) and the Tripoli Rocketry Association

(TRA), rocketry can be dangerous if proper safety precautions are not observed. This is

particularly true with some of the advanced techniques like pyrotechnic parachute deployment

and airstarting motors. People can and have been seriously injured by not following recognized

and accepted safety practices. We cannot be responsible for your actions.

We strongly recommend that if you are not a member of either the NAR or the TRA, you join

one of them, join a local rocketry club, and pick the brains of experienced members before you

try any kind of electronic deployment or airstart flight. The safety information included in these

instructions is by no means comprehensive or complete, and is no substitute for the supervision

and advice of experienced rocketeers.

Limited Warranty

Eggtimer Rocketry warrants that all of the parts on the packing list of this Eggtimer Rocketry kit

have been included, and that they are all in working condition. If you are missing something,

contact us immediately at support@EggtimerRocketry.com and we will send you whatever it is

that you are missing. If you are missing something really egregious (like the PC board or the

processor, for example), we may ask you to return the entire kit unbuilt, we will send you a

prepaid shipping label for this purpose. We’d especially like to see the packing list so we can

figure out what went wrong so it doesn’t happen again…

If your Eggtimer Proton does not work properly after assembly, take a deep breath, get out the

magnifying glass and a good light, and see if you have inadvertently created a solder bridge

somewhere. Chances are pretty good that you have, or that you have installed a part incorrectly.

We are a very small company and we just don’t have the resources to repair your board, but we

will be more than happy to give you advice and we might be able to help you find your error if

you send us some high resolution pictures, to support@EggtimerRocketry.com . We cannot take

responsibility for your assembly techniques; if you do not have experience building kits of this

nature, we recommend that you enlist some help. (Another reason for joining a rocketry club,

there is usually at least one electronically-inclined member who can be bribed with a beverage or

two to give you a hand. Engineering types love a challenge, especially it it’s easy for them but

hard for you.)

Eggtimer Rocketry warrants that when properly assembled this Eggtimer Rocketry product will

perform substantially according to the published documentation. This means that we spent a lot

of time trying to ensure that it’s going to work the way that we say it does, and we try to fix

things that don’t quite work right in a reasonable time. Nevertheless, we can not and do not

warrant that this product is perfect and will meet every rocketry purpose, for the simple reason

that we can’t test every possible rocket/motor/environmental combination. It is the buyer’s

responsibility to determine the suitability of the Eggtimer Proton for their particular purpose. If

you have a problem with this, please contact us and we will be happy to send you a prepaid

return label for your unbuilt kit and we will refund the purchase price on receipt of your kit.

Page 4

- 4 -

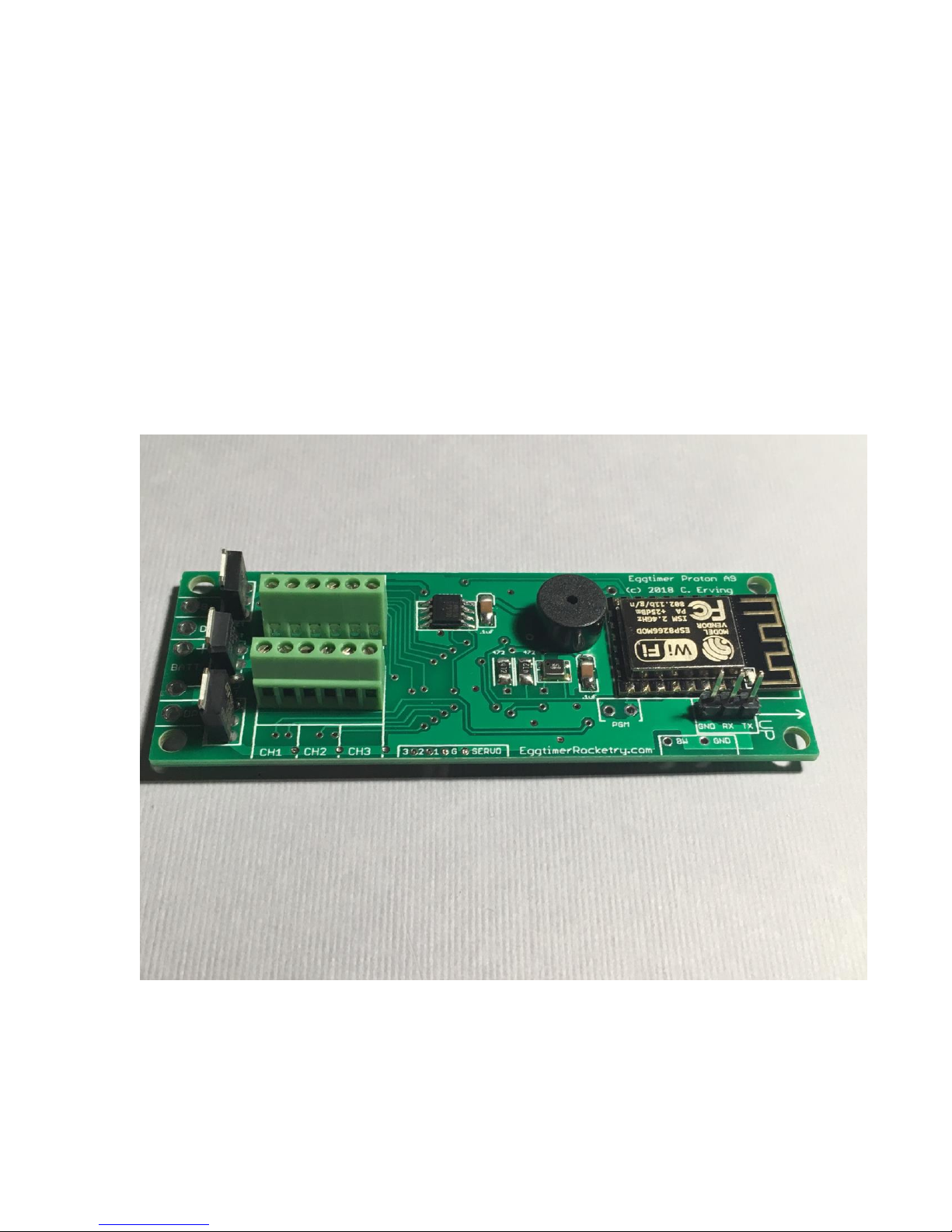

Meet the Eggtimer Proton

The Eggtimer Proton is an advanced hobby rocketry flight computer with a barometric pressure

sensor, 120G accelerometer, and six high-current output channels. Its job is to properly deploy

your parachutes and bring your high-powered rocket safely to the ground, and to record flight

information for later analysis. In addition, it can handle other events such as airstarting motors

or just about any other event that you can come up with. Each channel can be programmed

independently for whatever function you need. In addition, channels can be "clustered" so that a

single event triggers multiple channels, perfect for cluster airstarts. Channels can be triggered by

a number of different events for an almost unlimited combination of scenarios.

It’s nice to get your rocket down in one piece, but it’s also nice to know how the flight went.

The Proton can record your last 14 flights, and you can easily view and/or download both

summary statistical information and detailed time vs. event information. The detail output

format is a standard .csv file, which can be imported into virtually any data analysis program.

What makes the Proton different from most other flight computers is that it has a WiFi interface.

Instead of using switches, jumpers, or a data cable to your laptop to program it, you simply

connect to it with your phone, tablet, or computer using WiFi and a browser like Safari, Firefox,

Internet Explorer, or Chrome. You remotely arm it at the pad using your handheld device too, so

for many applications you do not need a mechanical switch… it won’t turn on until you tell it to.

Flight data is downloaded to your handheld device using WiFi, and with the installation of an

appropriate spreadsheet or other data analysis program you can actually get a flight graph within

seconds of recovering your rocket.

Since one of the tenants of successful electronic deployment is ground testing, the Proton

incorporates a ground-test feature so that you can check YOUR battery with YOUR igniters to

make sure that they are compatible and will work in flight. This is done remotely over WiFi, so

you can even test with “live” pyro charges, standing up to 100’ away from your rocket.

The output channels are capable of triggering just about any load that you’re likely to encounter,

we’ve even fired a medium-current Estes igniter with it using a 2S/7.4V LiPo. You can set the

output on-time from 1-9 seconds, so it’s ideal for use with a hot-wire non-pyro deployment.

There’s a separate battery input for the deployment circuitry, so you can optionally use a second

battery on the deployment outputs that 100% guarantees that a deployment glitch will not cause

your Proton to “brownout” due to low voltage. Each channel is overload protected so they can't

be blown out with an accidental short.

You can also use standard PWM hobby servos with the Proton, for non-pyro deployments. This

makes it ideal for use by TARC teams that want to experiment with electronic deployment but

can’t use pyrotechnics, or for flights over 30,000’ in which pyro charges may not be effective.

In addition to deployment functions, the Proton can also be used to “airstart” additional motors in

flight, either for “strap on” boosters or for starting a second stage motor. It works as a timer that

starts at launch, and is qualified by breakwire support, velocity-at-time, and/or altitude at time.

There is also a Barometric-Altitude-Deviation calculation that won't fire your airstart motor if

the rocket is moving off-axis. This helps ensure that your second stage won’t light unless your

rocket is going “up”.

Page 5

- 5 -

Getting to know your Proton

Although the Proton seems relatively simple, you will want to familiarize yourself with it

BEFORE you install it in a rocket, and certainly before you try flying it.

Battery (BATT) – Two solder pads for connecting the Proton’s battery. It's polarity protected,

so if you hook up the battery backwards it won't damage anything. We recommend a 2S/7.4V

LiPo battery, 300 mAH or higher… more on that later.

Buzzer - “Beeps” out status, warnings, apogee at landing, and other important notifications.

Output Channels (CH1-CH6) - Six sets of deployment output terminals, each with a 10A/40V

capacity.

Battery Output (B+) – Used for the single-battery option when jumpered to the DP+ pad.

Deployment Power (DP+/DP-) – Two solder pads for connecting a separate deployment

battery. If you choose to use the Proton with a single battery for both the computer and the

deployment side, you simply jumper the DP+ pad to the B+ pad, which provides the power for

the deployment channels.

Servo Outputs - Three pads marked "1" through "3", and one labeled "G", for connecting logiclevel servos. These are mirrored to the CH1-CH3 output channels.

Programming Cable Header – 3-pin header that’s used with an Eggtimer USB-Serial cable for

updating the software or for viewing the WiFi passkey (in case you lose it).

Programming Jumper Pads (PGM) – Two pads used to put the Proton into programming

mode at boot-up, for uploading software updates. Normally you won’t do anything with these

pads.

Page 6

- 6 -

Mounting Your Eggtimer Proton

IMPORTANT: Your Proton must be mounted so that the "UP" labels on the board are

pointed towards the nose cone of your rocket!

The Proton is relatively small and light, and can be mounted several ways. The most common

way of mounting it is using four #4 screws, either self-tapping screws for wood sleds (put a drop

of CA glue in the hole first to prevent the screws from loosening in flight) or machine screws

(we recommend using Nylon-insert nuts so they don’t come loose). We recommend that you use

Nylon washers between the board and the screw heads to prevent any possibility of shorts.

You’ll also need to put some kind of spacer between the bottom of the board and the sled, about

3/16” high. There’s a mounting template on the Eggtimer Rocketry web site to help you plan

your installation.

We do NOT recommend using double-sided foam “servo” tape to mount the Proton to your AV

sled. There are parts on both sides of the board, so the bottom isn’t flat. You won’t get 100%

coverage with the servo tape, so there’s a potential for it coming loose in flight, which is bad.

Also, when you pull it off, you might lift a part off the PC board… that would be bad too.

However you mount it, be careful not to overtighten the screws and possibly bend the circuit

board. The parts on the bottom of the board can break if you force them against the bottom of

your sled… don’t ask us how we know. We recommend that you leave a little space between the

board and the sled… about the thickness of a credit card.

The Proton should be mounted so that the "UP" markings near the WiFi module face the nose of

your rocket. You also want to make sure that the holes are drilled properly so that it faces as

vertically as possible. If you get it a tiny bit crooked it's not going to matter much, but the more

care that you put into the mounting the better your results will be.

Since the Proton primarily uses a barometric pressure sensor to determine altitude, you’ll need to

drill a few holes in your AV bay to vent it to the outside air. There’s a lot of debate about what

the right size for the holes is, how many, etc., but the most accepted rule of thumb is: One ¼”

diameter hole for every 100 square inches of AV bay volume. For most average AV bays that's

going to be three 3/32" to 3/16" holes.

Now the tricky part is that you don’t want ONE vent hole… the optimum number is THREE,

equally spaced along the AV bay perimeter. This works out to about three 5/32” holes for every

100 square inches of volume. That’s just about the size of a 4” diameter AV bay that’s 8” long,

so you can work up or down based on that. We also recommend that you don’t mount it so that

the pressure sensor is directly across from the vent holes in your AV bay. You can get funny

currents during flight, which may compromise the accuracy of the altitude readings.

Wiring Your Eggtimer Proton

The Proton is designed to have the power connector wires directly soldered to the board, and

outputs connected using the screw terminal blocks. You can also omit the terminal blocks for

the outputs and solder pigtails to the output pads on the board, so you can use whatever method

Page 7

- 7 -

of terminating the connections you want: barrier strips, solder directly to pigtails, throughbulkhead terminals, etc. Soldering connections to the board prevents the connections from

coming loose in flight due to vibrations and G-forces.

We’ve found that simply wire-wrapping the igniters to a “pigtail” wire soldered to the board

works very well for smaller rockets. By soldering the pigtails to the board rather than having

screw terminal blocks, you eliminate the possibility that the wire may work loose from the

terminal in flight. It saves space too, which is usually at a premium with 38mm and skinnier

rockets. We also like the wiring kits sold by Binder Design Rocketry, the wire they supply is

Teflon-jacketed and lends itself well to solder-type wiring. Their charge wells with integral

through-bulkhead terminals als work great for 39mm-54mm rockets.

We recommend using #22-#26 gauge wire for wiring to the Proton board, we like to use the #24

gauge stranded wire that’s found in Cat-5 network cables. It’s cheap, easy to find, and just the

right size. It’s also twisted together in nice solid-striped pairs, so it’s easy to tell the “+” from

the “-“ wire. If you can, get the “plenum” cable, since it has a Teflon jacket and doesn’t melt as

easily when you solder to it as the standard “riser” cable. You can also use solid wire, but solid

wire is harder to work with and has a tendency to break after being bent a few times. These

breaks can be a pain to find, because they are typically inside the insulator jacket where you

can’t see them.

If you use stranded wire, you MUST TIN THE WIRES BEFORE SOLDERING TO THE

BOARD. This is to prevent stray “whiskers” of wire strands from coming loose and bridging

pads, or breaking off and landing on the board in some random place. We’ve seen the results of

this happening, it’s not pretty, and they can be very hard to find if the lodge underneath the

processor chip or in some other hidden spot on the board.

If you build the board with the terminal block option, be sure to tin whatever wires you are using

for your igniters before you insert them into the terminal block. Loose strands here can prevent

deployments, if a strand comes loose and lodges in the wrong place it could cause an immediate

deployment when you connect the battery. That would be bad…

Last, but not least, we strongly recommend that all wiring on your sled be zip-tied to the sled so

that there’s no chance of any wires coming loose in flight. We’ve seen it happen, and the results

are not pretty.

The Single-Battery Option

For a single battery, you only need to solder a jumper (or switch, see below) between the B+ and

DP+ pads that are located next to the two BATT pads. This will provide power to the

deployment circuitry directly from the battery. Nothing else is necessary... see the picture below.

Page 8

- 8 -

The Dual-Battery Option

Using separate batteries for the Proton’s computer and deployment side has some advantages,

and one disadvantage. The disadvantage is that it’s going to take more stuff… one more battery,

one more connector, and possibly, one more switch. The advantages that: 1) You can use a

different voltage battery than the computer side, which you may want to do for servos; and (the

big one) 2) No matter what happens on the deployment side, including a complete loss of battery

power, it’s not going to affect the computer side. This is the same philosophy behind the dualbattery architecture on other Eggtimer Rocketry flight computers such as the Eggtimer Classic

and the Eggtimer TRS.

Some other flight computers use a big capacitor on the power output, with a single battery to

prevent brownouts. This protects against momentary disconnects such as a glitch due to Gforces when your drogue deploys, but it won’t protect against a longer-term brownout such as a

shorted ematch after firing. Once that capacitor drains, your altimeter is done. With the dual-

battery setup, if you have a short on the drogue it’s going to cause a high current drain for a few

seconds until either the processor shuts the output transistor off, or until the transistor blows (not

likely, by the way). Either way, that high current draw is going to stop. Unless your battery gets

totally fried during these few seconds (also not very likely…), when the command is sent to the

main to fire it’s going to work.

To wire up your Proton for dual-batteries, wire the +/positive side of the battery connector to the

DP+ pad (next to the BATT pads), and the -/negative side of the battery to the DP- pad (located

between the deployment output pads). Leave the B+ pad unconnected. If you are going to be

using a separate disconnect switch for the deployment battery you will generally wire it in series

with the +/positive side, so that it goes between the DP+ pad and the +/positive lead of your

battery connector.

Page 9

- 9 -

If you use a separate deployment battery, remember that you will not see continuity on either

channel until you power on the deployment battery. If you use a switch, we recommend that

you turn it on to test igniter continuity at your work table BEFORE you add the pyro powder to

your charge wells, then shut it off until you’re safely on the pad. Turning on the deployment

power does NOT power on the deployment FET; it only allows the trickle current to go through

the circuitry to test continuity.

About Switches…

The Proton is designed so that it will not self-arm itself. If you power it up, it will sit there on

the Status page forever, changing the validation code every 60 seconds… you have to actually

arm it using the validation code in order to start a flight. In addition, the unique dual-ended

deployment output prevents any significant current from getting to the igniter until it’s armed

and actually in-flight.

Because of this, for most flights using electronic deployments up through NAR/TRA Level 2

you do not necessarily need a separate power switch if you’re using the single-battery option.

You can simply connect the battery to a locking connector such as a JST connector and you’re

ready to go until you arm it on the pad. This makes your AV bay build easier and smaller, and of

course it makes your pre-flight procedure a lot simpler.

The Proton is different than most other altimeters because it has dual-ended switching on the

deployment outputs: BOTH the “+” and the “-“ side are switched off, leaving the igniter

essentially dead until it's actually in flight (except for a tiny trickle current that’s used to test

continuity). For the igniter to fire, both sides have to be activated independently, and this can’t

happen until you’re in the air and the deployment enabling logic has been triggered.

This meets the NFPA and Tripoli/NAR requirement that pyrotechnics be de-energized until

ready for flight. However, FOR LEVEL 3 CERTIFICATION FLIGHTS ONLY you may need

to add a switch to the pyro outputs. As of the date of publication (Sept. 2018) Tripoli allows

electronic switches for L3 certification projects, subject to the approval of the TAP's. NAR

requires a mechanical disconnect for L3 certification flights.

In the event that you do decide to add a switch, you have a few options, since the Proton can use

a separate power supply for the deployment devices.

If you are using a single battery for both the computer and the deployment side and you need to

use a deployment disconnect switch, you can simply put a switch between the B+ and DP+ pads

instead of a jumper. Turn on the switch when you’re on the pad to power up the igniters,

confirm that everything is OK, then arm your Proton and go.

If you are using a separate battery for the deployment side, you can put the switch in series with

the deployment power that goes on the DP+ pad. This is our recommended configuration for

Level 3 rockets because having the separate deployment battery 100% prevents any kind of

deployment glitch from affecting the flight computer side. Doing it this way allows you to

make whatever changes you may need to make (for example, lowering the Main deployment

altitude if the wind picks up a bit) while leaving the deployment side powered off.

Whatever switch you use, make sure that it can handle the expected G forces that you expect the

rocket to experience during flight. In general, we recommend that if you use a slide switch that it

Page 10

- 10 -

is mounted so that it slides sideways, not up and down. This will prevent G forces from possibly

causing the switch to “bounce”, interrupting the power to the Proton, which is not a good thing.

Any slide switch that you use must be rated to at least twice the G forces that you are likely to

see… a $1 Radio Shack special isn’t going to cut it, spend a few bucks and get a high-quality

switch.

You can also use a “push-on, push-off” type switch. Many users have had good success with

them, also mounted laterally. You can put the switch just behind one of the air ports, and actuate

it by pushing a small pin/wire through the hole. Just like with slide switches, spend the money to

get a good quality switch.

A better option would be a more positive switch, such as a rotary switch or a screw-type switch

that locks down positively. Since the major forces on rockets are almost entirely along the

longitudinal axis of the rocket, the contacts on a rotary switch are unlikely to be interrupted by G

forces. A popular choice is the Schurter 033.4501 rotary switch, they cost about $5. This is a

special-purpose rotary switch originally designed to be a 120v/220v power supply selector

switch, but it works very well for our purposes. You can get them from a number of online

rocketry suppliers, or you can order one directly from Allied Electronics, a direct distributor for

Schurter products. They’re actually about a buck cheaper from Allied, but you’ll have to pay

shipping, so chances are pretty good that you’re gonna come out ahead if you buy it from one of

the rocketry suppliers because you’re probably buying a bunch of stuff from them anyway.

Featherweight Rocketry and Missile Works also make good small screw-type switches, they use

a screw to positively lock down the contacts and completely eliminate any possibility of the

switch being jarred open. You can also make your own screw switch, Google around and you

can probably find some good examples.

Finally, if you want to avoid moving contacts altogether, check out our Eggtimer WiFi Switch

(www.EggtimerRocketry.com). You can turn it on or off using your mobile device too,

independently of your Proton. It may be a bit larger than other switch options but the

convenience of not having to fumble around looking for the switch inside the AV bay more than

makes up for the minor weight and size penalty, and you can safely arm your deployment

electronics from up to 200’ away from your rocket. And yes, the WiFi Switch will not interfere

with the WiFi signal from your Proton.

Proton Battery Options

For most installations, we recommend using a 2S 7.4V LiPo battery. You’ll need one that’s at

least 300 mAH, since the Proton draws 85 mA (it’s WiFi… that’s the nature of the beast). You

CAN get away with smaller batteries, IF (and ONLY IF) you connect the fully-charged battery

up right before flying. We’ve used batteries as small as 180 mAH in testing, but we have several

fully-charged batteries on-hand and we change them with a fresh one after each flight. With a

larger battery, you can take your time… a 500 mAH 2S LiPo is about the same size and weight

as a 9V alkaline battery, and will last all day. That’s what we use for all but the skinniest of

rockets. For 3" or larger diameter rockets, we like the skinny packs used for Airsoft guns…

Page 11

- 11 -

they’re about 100mm x 18mm x 12mm, so it’s easy to fit them on the back of the sled, and they

have a lot of capacity… about 1200 mAH. You can run all weekend on one charge.

While we’re on the subject of 9V alkaline batteries, DO NOT, repeat, DO NOT use a 9V battery

to power the Proton. At all. They don’t source much current, especially compared to a 2S LiPo.

While it will appear to work fine once it’s new, it will quickly drain, and you will find that the

range starts to rapidly decrease, and the Proton will appear to become unresponsive. If you’re

using the single-battery option, the chance of a low-voltage “brownout” is much higher than it

would be with a 2S LiPo. WiFi takes a lot of power, so make sure you feed it well.

In addition, if you are using a single battery we recommend that the current-sourcing capacity of

the battery should be at least 5x the all-fire current of the igniter (or the sum of the igniters, if

you're firing a cluster), to prevent any chance of the voltage dipping. To get that number,

multiply the capacity in mAH by the “C” number of the battery. For example, a 300 mAH

battery rated at 20C will easily put out 6,000 mA, or 6A. If you igniter is rated for 750 mA allfire, 5 x 750 = 3750 mA, so that 300 mAH/20C battery would be just fine.

If you’re using a separate battery for the deployment side, whatever battery will fire your igniter

or operate your other deployment device (hot wire, servo, etc.) is fine. Little 1S 3.7V 150 mAH

LiPo batteries work great with most ematches, and are so small that you can easily mount them

with a little servo tape just about anywhere you want in your AV bay. The output drivers will

each handle up to 10A and 40V, so if you have something really power-hungry (like a solenoid,

for example), you can simply use a bigger battery. You don't have to worry about "burning out"

the drivers, because they're internally current-limited and thermally-protected; if you try to push

too much current through them, they'll simply shut off until they cool off (kind of like a thermal

circtuit breaker).

You can use a 9V alkaline battery too for the deployment side only with a dual-battery setup

if that’s what you like, just be aware that they’re pretty big and heavy by contemporary

standards. If you do use a 9V battery, one more thing you need to be careful about is that some

brands of 9V batteries simply have cells pressed together in a metal case, so high G forces can

cause the battery to fail. If you absolutely HAVE to use a 9V battery, we recommend Duracell

9V batteries, because they use welded cells internally and are less likely to come apart than some

other brands. If you do decide to use an alkaline 9V battery, we recommend that you replace it

after EVERY flight. Yes, that can get expensive. And yes, you don’t have to worry about your

battery having been drained too much by a previous flight… enough said.

Regardless of what kind of batteries you choose, charge or swap out your batteries before

every session, and check the voltage with a digital voltmeter before every flight. The

voltage check on the Proton is only on the processor battery, it does not test the deployment

battery (assuming it’s separate). You don’t want to spend all the time to find the “perfect”

battery combination for your 54mm minimum-diameter mach-buster only to realize after you dig

it out of the ground after lawn-staking it that you forgot to charge the deployment battery.

Although you probably won't hurt the Proton itself by dead-shorting the outputs, the voltage drop

due to the short may cause the battery voltage to drop low enough to cause the processor to reset,

although the drivers have a low-voltage cutoff at about 4V that's designed to prevent this from

happening. This is why we recommend having a battery current capacity of at least 5x the allfire current of your igniter; if you get a short, chances are that the battery is going to simply

generate a little heat in the drivers and wires for the few seconds that it’s on, then it will be

Page 12

- 12 -

turned off and everything will be OK. If you battery only has a marginal current capability, the

same short may cause the Proton to reset if the voltage drops below the processor threshold

(about 2.8V). The deployment drivers are designed to shut down if the source voltage drops

below 4V, so that theoretically shouldn't happen, but it's better not to chance it. Depending on

when this happens, the effect could range from not getting your peak altitude reading (annoying),

to deploying only the drogue chute (if this happens when you fire the drogue), to a lawn stake if

you’re only using the drogue function and it fails to fire. Ouch. So, choose your battery wisely

if you're using a single battery.

If you’re using an ematch, you only need to set the deployment on-time to one second… if they

don’t fire in a few dozen milliseconds they probably won’t fire at all. If you’re using a hot-wire

(for example, to cut a cable tie or nylon fishing line) you’ll need to experiment with the on-time.

You’re going to want to do this on the ground, of course… flight-time is NOT for experimenting

with your deployment parameters!

Page 13

- 13 -

Using your Proton

What sets the Proton apart from other hobby rocketry flight computers is that it doesn’t use any

switches, jumpers, or cables to configure or download flight data. It’s all done over a WiFi

connection to your handheld device, using a common Internet browser. The pages have been

written very simply so that they do not require Java, Javascript, .NET, or any other scripting

language to operate… they’re all just simple HTML 1.1. The pages are simple text with minimal

formatting, and while they may not be particularly pretty they are very easy to read, and they

render virtually the same on every browser and platform we’ve tested.

About Browsers and OS’s…

All of the Proton’s functions will work almost identically with just about any browser that you

use. Because of the differences in the way that browsers display things and handle downloaded

files, however, you may find that one browser works better than another with your particular

platform. Interestingly enough, some browsers are much faster than others… generally the ones

that are provided by the vendor. Go figure…

In general, our recommendations are as follows, in order of preference:

Apple iOS: Safari, Firefox

Android: Firefox, Safari (yes, it’s an old version…), Chrome

Windows: Internet Explorer, Edge, Firefox, Safari, Chrome

Note that Chrome comes out last on all of these lists. The reason is that Chrome does not handle

the flight detail download function very well. In particular on an Android it can’t tell what to do

with the .CSV file that’s generated from the flight detail download, so it either hangs for awhile

or comes right back and does nothing. It’s a shame, because we really like Chrome, but for this

application it doesn’t work very well. If you have an Android, use Firefox instead, it will display

the .CSV file and launch your viewer if you have one installed.

Individual notes regarding browser compatibility and issues are in Appendix D.

Connecting to Your Proton

Each Proton has its own WiFi SSID network name, which is going to looks something like

Proton_2abcd

The last 5 or 6 characters are derived from the unique MAC address of the Proton’s WiFi

module, so they’re pretty much unique. The Proton uses the WPA2-PSK WiFi connection

protocol, so you need to enter an 8-digit passkey to connect. The passkey for your Proton is on a

label on the WiFi module that you got when you built it. It’s also on a label on the package. If

you accidentally lose it, you can also get it by connecting an Eggtimer USB-TTL data cable to

the programming header. See the Appendix for instructions on how to do this. We recommend

that you put a label on top of the WiFi module with the passkey… you’ll be glad you did at some

point.

Page 14

- 14 -

To connect to your Proton, hook up the battery and wait about 10 seconds for it to initialize.

You’ll hear some beeping as it goes through its self-test, and at the end of the long 3-second beep

it should be discoverable over WiFi. Go to the WiFi Settings on your handheld device, and

browse the wireless networks. You should see your Proton listed as something like

“Proton_1a2b3c”. Choose that network, and enter the passkey when prompted. Hint: When

asked, be sure to check “save the password” and/or “connect automatically when in range”. This

will keep you from having to do this every time. Note that if you have multiple Proton’s you

might NOT want to save the passkey… keep it handy by using a memo pad app on your device.

Open up your browser. If your home page is something on the Internet, you’re gonna get a

“Page can not be displayed” message because you’re connected to your Proton, not the Internet.

That’s OK and normal. Set your browser to the Proton’s home page:

192.168.4.1

and you should see the Status Page. At this point, you should Bookmark this page so you don’t

have to re-enter the address every time… you’re going to be going here a lot.

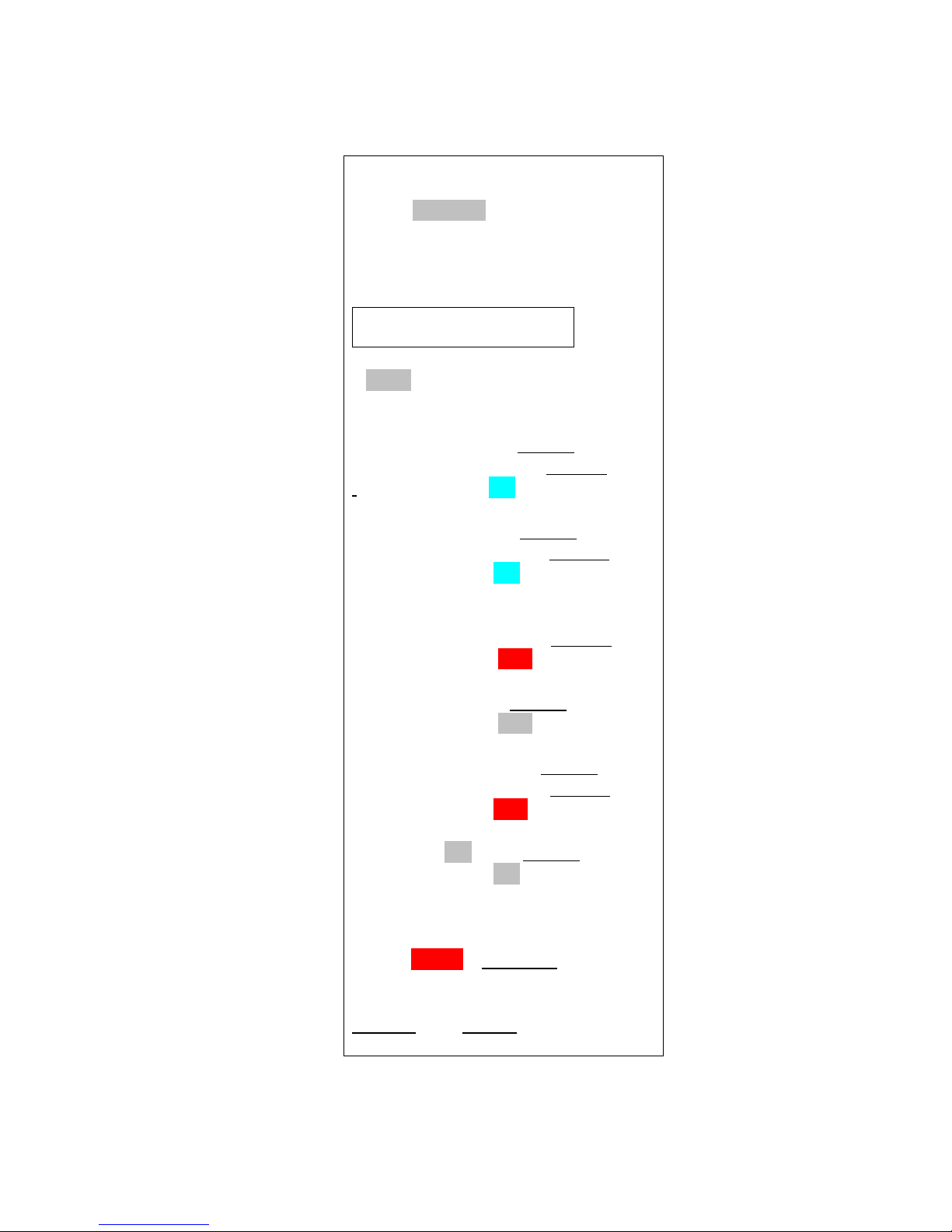

The Status Page

The first thing you will see is the Status Page. It tells you what your Proton is doing, and gives

you some other important information:

◦ Device Name (important if you have more than one of them in your rocket!)

◦ Flight Status: Armed or Disarmed

◦ Deployment channel status, settings, and link to change the settings (see below)

◦ Computer-side battery voltage

◦ Above-Sea-Level (ASL) altitude

◦ G's from the accelerometer (should be about 1.0 for vertical and 0.0 for horizontal)

◦ Temperature (it may read low for awhile… it takes 10-15 minutes to stabilize)

For arming:

◦ The current validation code (it changes every 60 seconds that you’re idle)

◦ A text box to enter the validation code into for arming

◦ An “ARM” button for arming (once you type in the validation code)

Links:

◦ Deployment channel “Change” links – for changing deployment channel in-flight settings

◦ Settings – takes you to the Global Settings page

◦ Flights – takes you to the Flight Select page, for displaying saved flight info

Page 15

- 15 -

Proton_2abcd 1.01a

Status: Disarmed

Validation Code:

4567

…………………………

ARM

Channel 1: Drogue Change

Delay: 0.0 Settings

Channel Status: ON

Channel 2: Main Change

Altitude: 500 Settings

Channel Status: ON

Channel 3: Airstart

Delay: 2.2 Settings

Channel Status: OFF

Channel 4: OFF Change

Channel Status: OFF

Channel 5: Clustered Change

Channel: 3 Settings

Channel Status: OFF

Channel 6: Off Change

Channel Status: ON

Battery: 8.0v

ASL Alt: 1050 ft

Accel: 0.03 G Calibrate

Temp: 74.2

Settings Flights

Page 16

- 16 -

Depending on what you have hooked up to the deployment channels and how it’s powered, you

may see the deployment channel status displayed in different colors. The colors are:

◦ Silver – Status does not affect arming (channel turned off, for example)

◦ Aqua - Good deployment status, i.e. channel is enabled and you have continuity

◦ Red – No continuity on enabled channel, arming not possible

The Proton updates the deployment status every time that the page refreshes. If you leave the

page alone, it will refresh every 60 seconds. When it refreshes, you’ll hear a little beep from the

speaker... this also lets you know that you’ve got power and are connected to your Proton. In

addition, every time the page refreshes a new validation code is created. You can force a page

refresh by hitting the refresh icon on your browser, or by clicking on the ARM button without

entering a validation code or entering an invalid validation code.

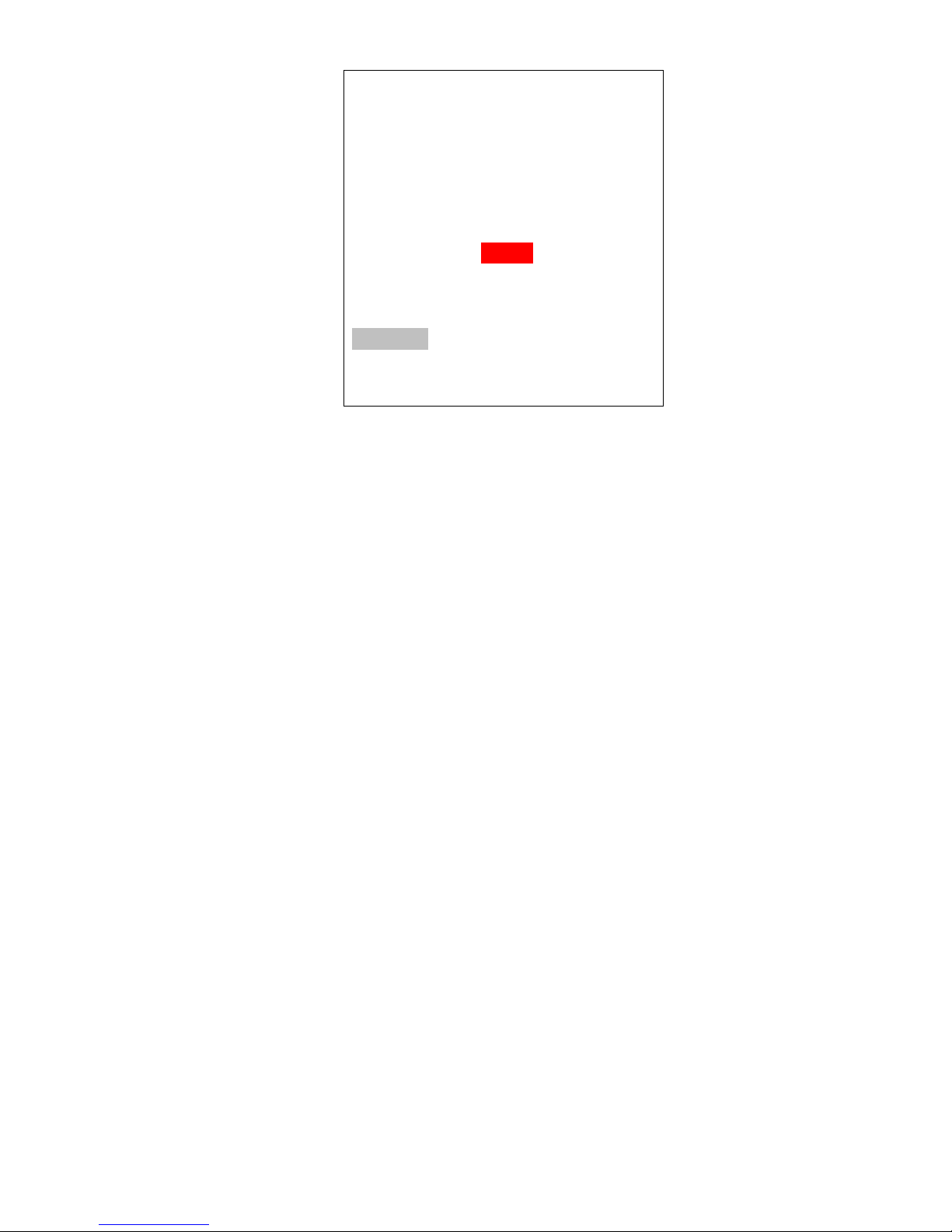

Calibrating the Accelerometer

You will notice that no matter which position you hold the Proton at after power-on, the Accel

number will be in RED. This is because the accelerometer has to "warm up" after power is

applied before the readings become stable; up until that point, the readings may drift from the

"actual" value. Once the accelerometer stabilizes, it can be used for flight, but first it needs to

be calibrated to compensate for whatever drift may have accumulated during the five minute

warm-up period. You CAN NOT arm the Proton for flight until the accelerometer has been

calibrated...

YOU NEED TO CALIBRATE THE ACCELEROMETER BEFORE EVERY FLIGHT

To calibrate the accelerometer, set the Proton horizontally; assuming that it's mounted in your

AV bay, just lay your AV bay on the table. Click on the "Calibrate" link next to the Accel

reading on the Status Page. If you do not see a "Calibrate" link, that means that the warm-up

period hasn't been reached yet... just be a little more patient. The warm-up period is five

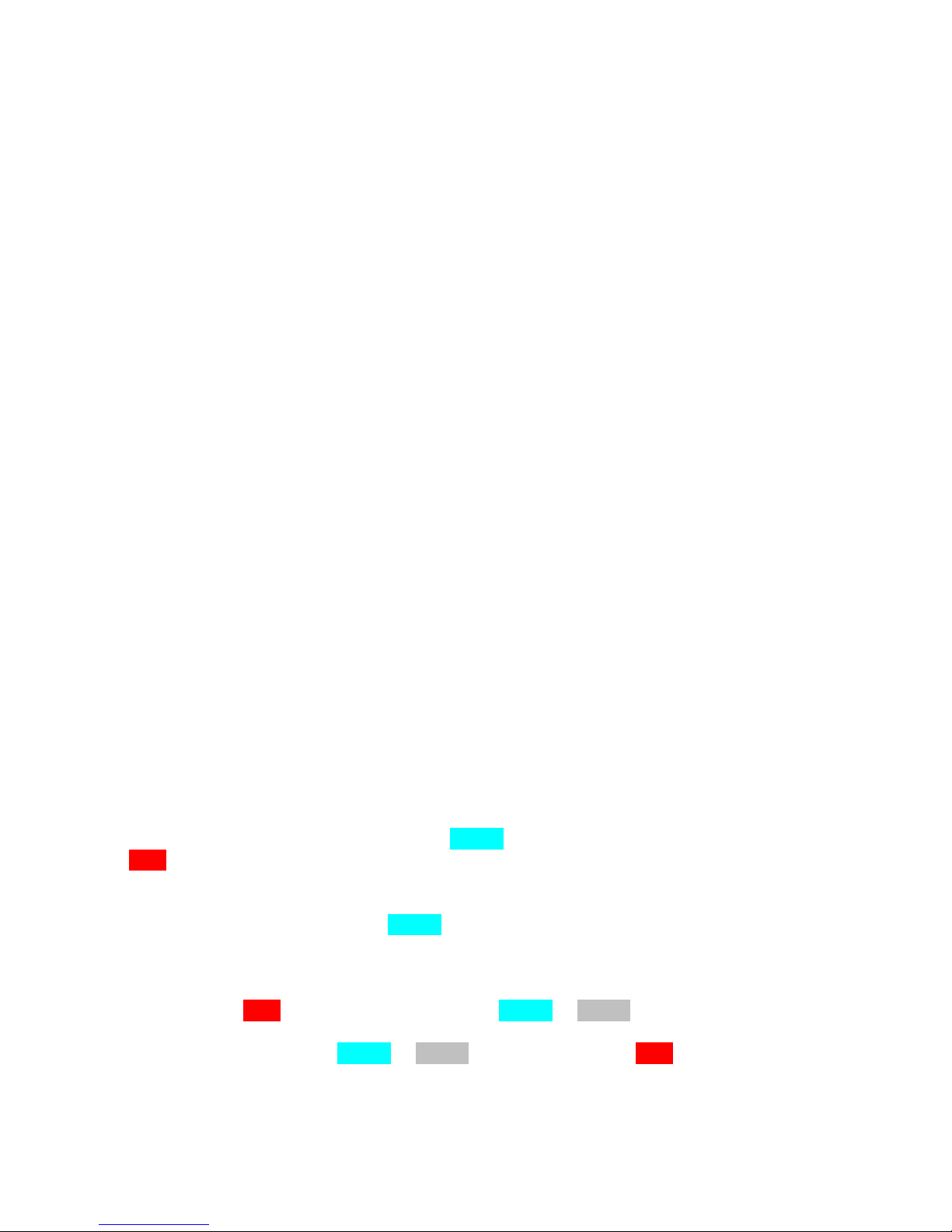

minutes, so it shouldn't be long. Once you click on the Calibrate link, you'll see this screen:

Page 17

- 17 -

Proton_2abcd 1.01a

Accel Calibration

Lay your Proton

HORIZONTALLY

then click on the button below

Current Accel: 0.03 G

Auto-Adjust v

Calibrate

The default Option is to auto-adjust the calibration, which will take a reading and subtract it from

zero (since you're horizontal...). This is what you should choose if you are going to fly. When

you click on "Calibrate", the accelerometer offset will be calculated and it will be used from that

point on until you reset the power; you will be then be returned to the Status Page.

You can also click the down tick next to Option and select "Zero Offset"; that will zero the

offset, allowing you to see what the uncorrected Accel value will be on the Status Page. If you

do that, you will need to go back to the Calibrate link and select Auto-Adjust; the Proton WILL

NOT ALLOW YOU TO ARM if you select Zero Offset. It's strictly for your edification...

sometimes it's interesting to see how far the accelerometer has drifted.

Arming Your Proton

In order to start a flight, you need to arm the Proton. For safety reasons, the Proton will not selfarm; that is, you must go to the Status page and arm it by entering the current Validation Code in

the text box and clicking on the Arm button for the flight sequence to begin. This is different

than most other flight computers, which will automatically go into an arming sequence a short

time after powering up, assuming that the continuity is OK. The Proton is a little bit different

because it’s assumed that you’re not using a power switch so you are basically using the arming

sequence as a remote switch. This is the reason why we have the dual-ended switching

architecture; it ensures that your ematch/igniter is essentially “dead” until the Proton has been

armed AND you have a flight in progress. This virtually guarantees that you cannot fire a

deployment charge (or an airstarted motor...) on the ground.

Before you can arm the Proton, any enabled deployment channels must be in a flyable status.

This means that if a channel is enabled there must be continuity; if a channel fails the continuity

test then you will not be able to arm your Proton. You can tell very easily from the Status page if

it’s ready to fly, because any failed channels with have the continuity status highlighted in RED.

Note that if you've selected a servo deployment option the status will always be in GREY; there's

really no way to tell if a servo is connected or not, because they're an output-only connection.

It's assumed that they are always in a flyable state.

Page 18

- 18 -

In addition, your rocket must be in a vertical state, i.e. it must be pointing "UP" to arm it. If the

Proton_2abcd 1.01a

Status: ARMED

Please CLOSE

this Page!

Battery: 8.0v

Proton_2abcd 1.01a

Status: ARMED

Validation Code: 8509

…………………………

DISARM

Battery: 8.0v

Proton sees that the G's are under 0.80G or over 1.20G it will not arm. Note that the

accelerometer will drift over time, so you need to perform a calibration before you fly it in order

to compensate for this. See the previous section regarding accelerometer calibration.

To arm the Proton, enter the 4-digit validation code into the text box then click on the ARM

button. After about 5-10 seconds you should see an arming confirmation page:

This page looks a lot like the status page, but the status is changed to “ARMED”, it doesn’t

initially have the validation code/box, and only the battery voltage is displayed. A few seconds

later you should start hearing the buzzer beep about once per second. This is an audible

confirmation that the Proton is now in flight sequence mode, and you’re ready for launch. At

this point you should CLOSE the browser window on your handheld.

Until the flight actually starts, the Proton will be listening for activity from your handheld. If

you refresh this page or re-connect you will see the same page, but with a validation code, text

box, and “DISARM” button, as shown below:

Page 19

- 19 -

This allows you to end the flight sequence in case you have an issue, i.e. you burn an igniter and

the rocket doesn’t launch. In that case, you’d perform a disarm prior to approaching the rocket

to insert a new igniter, then re-arm it afterwards. Note that refreshing this page will halt the

flight sequence for about 5 seconds while it performs processing and updates the statuses, which

is why you should close the browser on your handheld after arming. Closing the browser

window after arming helps to prevent potential interruptions to the flight sequence. Note that if

you refresh the Disarm page without entering a validation code it will force a deployment status

and battery check; this is OK if you intentionally want to do this, but remember that it also halts

the flight sequence for about 5 seconds, so don’t do it right before launching, and remember to

close the browser when you’re done.

See the section titled “Flying With Your Proton” for a further discussion of flight events.

Page 20

- 20 -

The Deployment Flight Settings Pages

Each of the six channels can be programmed to perform in any of several different modes. Some

of them are "traditional" in the sense that if you've flown with other flight computers

(particularly an Eggtimer Quantum) you'll be familiar with their function. The modes are:

OFF - Just what it says… turns the channel off because you're not using it.

Drogue - Emulates a traditional drogue chute, firing the channel at some time past apogee. Also

supports servo deployments on CH1-CH3.

Main - Emulates a traditional main chute, firing the channel at some pre-programmed altitude

during descent. Also supports servo deployments on CH1-CH3.

Airstart - Fires the channel at some pre-programmed time after launch detect has been reached

on the way up. Designed for airstarting motors, you can qualify the channel with altitude,

velocity, and Barometic-Accelerometer-Deviation, as well as breakwire support.

Clustered - The channel is "clustered" with another channel, so when the other channel fires this

channel fires too. Designed for airstarting multiple motors, it adds some additional safety

options that you would not get by simply hooking up the igniters together. It also allows you to

devote a full 10A of current to each igniter, instead of divying it up among them. (Obviously,

your deployment battery has to be able to support the extra current!)

When you change a channel from one mode to another, it automatically clears the settings for

that channel and sets up some commonly-used defaults. For example, if you change a channel

from OFF to MAIN, it will set the channel to fire at 500' AGL, using igniter mode with a 1

second pulse width.

Changing a Channel's Mode

To change the mode, you click the Mode description link for that channel from the Status page.

You'll get a Mode Change screen for that channel:

Page 21

- 21 -

Proton_2abcd 1.01a

Mode Setting

Channel 1:

Mode: Main v

Off

Drogue

Main

Airstart

Clustered

Submit

Proton_2abcd 1.01a

Drogue Settings

Channel 1:

Delay: 0 secs v

Deploy Mode: Igniter v

Pulse Width: 2 secs v

Submit

Select the mode that you want to assign to that channel (you may have to click on "Done" or

"OK" depending on your browser), and click the Submit button. After you do that, you will get

the setting screen appropriate for the mode that you selected. Also, when you change modes

that channel's settings will reset to the default values for that mode.

Drogue Settings

The Drogue Settings page is accessed by clicking on the “Change” link next to the Drogue status

on the Status page. When you click on the link, you’ll see this page:

The purpose of this page is to set the delay from nose-over for firing the drogue, and other

related settings. For most dual-deployment flights, you’ll probably want the drogue to fire as

close to apogee as possible, in the Proton this would be approximately one second after apogee.

Page 22

- 22 -

That’s what we call “nose-over”, since it’s pretty much guaranteed that your rocket is pointing

downward. There’s also a low-velocity check, your rocket has to be going relatively slowly

before the deployment channels are enabled. For most flights that will be a second or two

before apogee.

In general, if you’re using dual-deployment then you should set this to ZERO. The other settings

are designed for delaying the drogue using the Proton as a backup deployment controller in a

dual-controller redundant setup, or for special-purpose uses (i.e. the 5-second setting is designed

for ejecting ARLISS CanSats... if you're not familiar with them, check out www.arliss.org, it's

very cool). Typically, the backup controller will have the drogue setting delayed slightly from

the primary controller, so that if the primary controller fails the backup will fire and deploy the

drogue. You should model your flight with a program such as OpenRocket or Rocsim in order to

determine the best delay setting, you want to make sure that the rocket won’t be going too fast

before the backup controller deploys the drogue. Typically, 1.0 to 3.0 seconds is adequate.

The fields are:

Delay (0-9 secs, default is 0):

Set the time delay from nose-over to deployment.

Deploy Mode (Igniter/Servo, default is Igniter):

Selects Igniter mode (on-off) or servo mode (CH1-3 only).

Pulse Width (Igniter mode only): (1-9 secs, default is 1):

Controls how long the output will fire in Igniter mode.

Servo Skew (Servo mode only): (CCW 100%-CW100%, CH1-3 only, def. is 100% CCW):

Controls how far the servo will move when triggered. When the servo is Reset, it will go in the

opposite direction the same amount, i.e. if you have it set to CCW 75% it will go to CW 75%

when reset.

About Servo Mode…

Servo mode assumes that the servo is going rotate to the selected position relative to the zero-

degree center position when actuated, and it’s going to rotate in the opposite position by the

same amount when reset. Typically, you’re going to use some kind of trap-door or pull-pin

mechanism, and there needs to be some way to close the door or reset the pin before you fly.

That’s done with the Test Menu… more on that in the Appendixes.

The servo pulses are sent for 2 seconds, which is plenty long enough for any servo. Once the

two seconds are up, no more servo pulses are sent, so the servo basically stays where it is, at the

end of its selected travel.

Direction/Skews are in relation to the center point of the servo’s travel. Ideally, a servo would

have 180 degrees of travel, so full counter-clockwise (CCW) would go 90 degrees to the left of

center, and full clockwise (CW) would go 90 degrees to the right of center. The reality is that

many servos do not have 180 degrees of travel, so we label them by percent of travel which is

ALWAYS related directly to the standard pulse-width of the servos (1.0 to 2.0 ms in a 20 ms

window).

Page 23

- 23 -

This label is the “Set” direction of the servo, i.e. the direction/skew that it will rotate when

triggered during deployment. The opposite direction/skew is the “Reset” direction, that’s what

you will normally use in the Test Menu.

Values are:

100% counter clockwise (CCW)

75% CCW

50% CCW

25% CCW

0% - Center (you can't select this, we just show it for reference here)

25% clockwise (CW)

50% CW

75% CW

100% CW

Important Note: If you change a channel from Igniter to Servo deploy mode (or back), the

servo direction/skew or igniter on-time settings will NOT be changed. These settings are

dependent on the mode that you choose. You MUST click on the Submit button to change the

mode, THEN you need to go back into the channel's settings menu and select the proper on-time

or direction/skew. This is because web pages are written when the page is first loaded, so any

change you make to that page that’s dependent on another setting requires the page to be

reloaded.

Main Settings

This page allows you to set the descent altitude at which the Main chute deploys, or to turn it off

if you’re not going to be using it. You can set it from 100’ to 500’ in 50’ increments, and 600’ to

2,000’ in 100’ increments.

The Main altitude that you use depends on a lot of things: the size and layout of your flying

field, how much wind is present, how many trees there are around you, the size of your rocket,

and not the least, how far you’re willing to walk to retrieve your rocket. 500’ is the default

setting when you first power up your Proton, it’s adequate for probably 80% of all flights. If you

field is smaller or if there's a fair amount of wind, you’re going to want to take that down a bit,

so your rocket doesn’t drift as far when the Main is deployed. If you have a big project, you may

want to turn that up a bit, since you may not want a larger rocket deploying that close to the

ground and the larger chute may take more time to open. If you’re not sure what setting to use,

ask your buddies at the field… it’s guaranteed that they will have an opinion on the subject!

To change this setting, click on the drop-down list and scroll to the setting that you wish to set.

Depending on your browser/OS, you will either click on it or click a “Done” button to select it.

Click on the Submit button to save it, and you will be returned to the Status page. An example of

the page is shown below.

Page 24

- 24 -

Proton_2abcd 1.01a

Main Settings

Channel 2:

Altitude: 500 v

Deploy Mode: Igniter v

Pulse Width: 2 secs v

Failsafe: Time 1.0 v

Vel. 100 v

Submit

Altitude (100'-2000', default is 500') :

Deployment altitude for the event. When your rocket descends from nose-over to this altitude or

below, the channel will fire.

Deploy Mode (Igniter/Servo, default is Igniter):

Selects Igniter mode (on-off) or servo mode (CH1-3 only).

Pulse Width (Igniter only, 1-9 secs, default is 1 sec):

Controls how long the output will fire in Igniter mode.

Servo Skew: (Servo Only, CCW 100%-CW100%, CH1-3 only, default is 100% CCW)

Controls how far the servo will move when triggered. When the servo is Reset, it will go in the

opposite direction the same amount, i.e. if you have it set to CCW 75% it will go to CW 75%

when reset.

Failsafe Time (OFF, 0.3-3.0 sec, default is OFF):

Controls the time for the failsafe check (see below).

Failsafe Vel. (50-300 fps, default is 100 fps):

Controls the velocity for the failsafe check (see below).

The Failsafe mechanism is designed to help prevent your rocket from coming in ballistic due to

drogue parachute failure. Your descent velocity is monitored from the time that nose-over

occurs. If the descent velocity exceeds the Failsafe Velocity parameter for the Failsafe Time

period, the channel will fire as programmed. The idea is that if your drogue chute doesn't

deploy, your main will be deployed at a relatively low velocity somewhat near apogee,

preventing your rocket from coming in at very high speed. Yes, it's going to cause your rocket

Page 25

- 25 -

to drift a lot more than a normal drogue-main deployment would, but that's better than having

your rocket impact the ground at high speed, and/or having the main chute shred because the

deployment velocity is several hundred feet per second, and still having a high speed ground hit.

The proper values of the Failsafe parameters will depend on the size of your drogue chute (or

lack thereof if you're going drogueless), the size of your Main chute (if it's large you may want to

deploy it a little slower to avoid damaging it), the size/weight of your rocket (smaller lighter

paper rockets will fall slower), and how your other channels are set. If you are going to use it,

100 fps for 1.0 sec is a good starting point assuming a standard dual-deploy rocket with a drogue

chute with a 50-70 fps descent rate. Note that if you have multiple channels set to Main Mode,

you can enable Failsafe for more than one of them, we recommend that they're separated by at

least 0.5 secs to prevent overpressurizing your main chute payload pay (assuming you're using

multiple charge wells).

Airstart and Clustered Settings

Airstart and Clustered modes are typically used for firing motors or separation charges while the

rocket is moving "up". There's a lot of complexity that goes along with this, so see Appendix B

for a thorough discussion of Airstarts and the Clustered mode.

Page 26

- 26 -

The Global Settings Page

The Global Settings page is used to change settings that are either hardware-specific or are not

generally changed from flight to flight. You get into this page by clicking on the “Settings”

link on the Status Page:

Launch Detect Altitude (LDA) (100’-500’ by 50’, default 200’)

This setting allows you to select at what altitude the Proton decides that a valid flight has started.

The 200’ default is good for most flights. However, there may be some cases in which you may

want to turn it up, and some very special cases in which you may want to turn it down.

If your flying site is subject to wind gusts, you may want to turn it up a bit so that when the wind

gust subsides the decrease in pressure isn’t viewed as the rocket ascending. That’s not likely to

happen, however, because we filter the readings to prevent this (and other similar occurrances).

You may also want to turn it up if you increase the Launch Samples per Second.

If you have a very low flight you may want to turn it down, although generally we don’t

recommend it.

Ascent Samples per Second (10,15, 20, 25, 30, 33 samples/sec. , default 20 samples/sec.)

This setting allows you to select the number of samples per second that are taken from the time

that you arm the Proton until it detects nose-over. The default setting (20 samples per second) is

adequate for most flights. However, there may be reasons why you want to turn it up or down.

For example, if you have a very short-burn motor (like a CTI V-Max) you may want to turn it up

to 33 samples per second to make the velocity and acceleration figures more accurate. If you

have a very long-burn motor you may want to turn it down to 15 samples per second, although

20 should be fine. Note that increasing the sample rate decreases the amount of memory at the

expense of flight data accuracy... more on that later.

Descent Samples per Second (1, 2, 4, 5, 8, 10 samples/sec, default 2 samples/sec.)

The setting allows you to select the number of samples per second that are taken after nose-over

is detected. When you’re coming down, you’re generally not going to be going very fast relative

to your velocity going up, even if you freefall for a few seconds and the FailSafe kicks in.

Consequently, there’s really no reason to have the same high rate of sampling that you use for

the ascent part of the flight. Reducing the sampling rate after nose-over saves a lot of memory,

and allows you to record longer flights. For most flights, the default 2 samples/sec. rate is fine.

If you are going over 20,000' you may want to take this down to 1 sample/sec... the reduction in

data accuracy by reducing the sampling rate is minimal.

Page 27

- 27 -

Accelerometer Launch Detect (ALD)

Accel G's: (OFF, 3-20, default 3G)

Accel Time: (0.2 - 2.0 sec, default 0.5 sec)

These settings control the accelerometer launch detect. When the G threshold has been

reached/exceeded for at least the programmed time, a launch detect is triggered and the launch

mechanisms begin. Note that launch detect occurs when EITHER the barometric LDA altitude

OR the ALD is triggered; the first one to trigger a launch detect starts the flight process. If

you're at 50' AGL and you hit the 3G/0.5s threshold, your launch detect altitude will be 50'.

For most flights, the default of 3G for 0.5 sec will be fine. This is high enough that it's unlikely

to be accidentally triggered, and low enough that almost any motor is going to trigger it. There

are a few exceptions of note, however. First are motors like the CTI VMax motors, which

produce a very high amount of thrust for a very short period of time. For those motors, we

recommend setting the time to the minimum (0.2 sec) and setting the G's to a higher than normal

value… 10 G's should work in most cases. For relatively low thrust motors, we recommend that

you turn it OFF, and let the barometric launch detect trigger the launch. We've seen some very

underpowered rockets that never made it to the 3G threshold.

Note that events triggered from the Start of Flight are NOT triggered directly from these points.

Rather, they're back-dated to either the last sample under 10' AGL, or the last sample under 1G

acceleration. It is assumed that whichever one of these came later is an accurate start of flight.

About Sampling Rates and Memory Usage

At this point you may be wondering about how long a flight the Proton can record before

running out of memory, and what happens if that occurs. The Proton saves about 2,000 samples

for each flight. When you’re sitting on the pad or launched and have not yet reached LDA, the

sampling rotates through those memory locations, saving the last altitude reading < 10’ AGL as

the barometric “start of flight”, and the last accelerometer reading under 1G as the accelerometer

start of flight. Once you get a launch detect, the recording continues until either 1) the End of

Flight benchmark (< 30’ AGL for at least 5 seconds) is reached, or 2) the memory wraps around

to the start of flight location. In either case, recording stops there (it won’t overwrite valid ascent

data), but this does NOT affect any pending deployment events… if you run out of memory

before the main chute is deployed, it will still be deployed, but you won’t see it in the data

downloads because it can’t be recorded.

Now, you may be wondering how long a flight you can have with “only” 2,000 memory

locations. Quite a long one, actually. Let’s say that you want to fly to 30,000’ and your motor

will get you there in 30 seconds. At 20 samples per second, that’s 600 samples. That leaves

about 1,400 samples left for the “down” part of the flight. At 2 samples per second, that’s 700

seconds, or over 11 minutes. You’d have to be coming down at a rate of about 40 ft/sec under

drogue to exhaust the memory, there’s no way you’re gonna be coming down that slow from

30,000’ (unless you really like walking a lot). More likely, it’s going to be 50-70 feet/sec. Let’s

say that we come down at 60 ft/sec from 30,000’, that’s about 500 seconds, or 1,000 memory

locations at 2 samples/sec. You’d still have over 400 samples left when you land, nearly 20% of

your memory.

Page 28

- 28 -

If you have an extreme flight, say 50,000’, it may take a bit longer to get up there, let’s say 45

seconds. That’s 900 samples, leaving 1100. If you take the rate down to 1 sample per second

(reasonable since the events are happening relatively slowly and the air is pretty thin at 50K),

you still have 1100 seconds, or over 18 minutes. No way it’s gonna take that long to come

down, unless for some reason the main comes out near apogee. At a conservative 50 ft/sec

average speed under drogue, it’s going to take 1,000 seconds, leaving you with at least 100

samples. Remember that at that altitude the air is very thin, so you’re going to be coming down

faster near apogee than you will be when the air thickens as you descend. It’s very likely that

you’re going to be using a lot less memory than that.

So, as you see, there’s plenty of memory for just about any flight scenario if you manage it

wisely. For just about any flight under 30,000’, just leave it at 20 samples per second for the

Launch rate and 2 samples per second for the Descent rate, and you’ll be fine.

The Flights Page

Clicking on the Flights link takes you to a page that allows you to select a flight for flight

milestone display, and download a detailed .csv file that you can use with Excel or other data

analysis programs to extract graphs and do other fun things. We’ll go into that a bit later…

Page 29

- 29 -

Flying with Your Proton

The Proton is very simple to operate. In general, a dual-deployment flight with the Proton will look

something like this:

At your Work Table

• Charge or swap out your battery/batteries and check it with a DVM to check the voltage

DON’T SKIP THIS STEP!

• Install your igniters with the deployment power switch off (if used), with NO powder.

• Connect your battery to the Proton.

• Turn on your deployment power switch (if used).

• Connect to the Proton and confirm that you have continuity on all selected outputs (unless they're

set for servos). If you don’t, disconnect the batteries and figure out why.

• With your AV bay horizontally on the work table, give it about five minutes to warm up. Check

the Accel reading on the Status Page; if it's near 1.0 then power cycle it (it should be near zero) and

start again. Adjust the Accel Offset from the Settings menu (we recommend using Auto Adjust).

• Check your settings, especially the deployment channel settings

• Close up the AV bay

• Turn OFF the deployment power switch (if used)

• Add powder to the charge wells, and finish prepping your rocket

• CALIBRATE THE ACCELEROMETER

At the RSO Table

• Get your rocket safety-checked, get your pad assignment, and swagger out to the pad. Note that

your Proton will beep shortly once every 60 seconds that it’s powered on, as the web page refreshes.

You may need to show your RSO the Status Page on your phone to show him that it’s disarmed if

he’s not familiar with the Proton, since most Altimeters only beep when they’re armed.

At the Pad

Put the rocket up on the rail/rod, raise it, then go to the Proton’s status page. You should see that the

Accel value is close to 1.00, and it should be AQUA, indicating that it thinks it's pointed "up". If it

is RED, lower the rocket to a horizontal position, go into the Settings menu, select the Calibrate link,

and select Auto Adjust. The Accel value on the Status Page should be near zero, at this point you

can raise the rocket to vertical, if you refresh the Status Page your Accel value should be near 1.00

and the value should be displayed in AQUA.

If you’re using a deployment power switch, turn it on. Make sure that you have continuity on

whatever channels you’re using… if you do not, it’s going to be easy to tell because the status will

be highlighted in RED. If it’s OK, it will be either AQUA or GRAY.

Assuming that all settings are AQUA or GRAY and none of them are RED, enter the validation code

into the box and click on the SUBMIT box, after a second or two you should see the armed page.

Once that happens, CLOSE THE WEB PAGE. Closing the page prevents any data from interfering

with the flight sequence.

Page 30

- 30 -

After a few seconds, you’ll hear a few beeps, then after about 10 seconds of silence (as it takes

baseline measurements) you’ll hear the “I’m ready” beeping, approximately once per second.

Connect your igniter, test the continuity, then go back to the safety zone to await your flight.

If you’re new to dual-deployments, you can see that it’s a lot more involved than just stuffing some

wadding and the parachute into the tube, popping in the motor, and hooking up the igniter. Multiple

deployments require discipline in order to make them work reliably; we’ve seen way more than our

share of failed deployments, on everything from a small mid-power E-size rocket all the way up to

an M-sized 200 pound beast. We’ve seen deployments fail with the top-end flight computers and

with the low-cost units, even with redundancy. The reality is that most deployment failures are not

the fault of the electronics; it’s usually something mechanical like a bad connection, a nose cone

that’s too tight, a chute that gets stuck in the tube, etc. Having your blood, sweat, and tears free-fall

from 10,000’ bury itself in six feet of dirt is going to ruin your whole day.

We STRONGLY recommend that you use a checklist every flight so that you don’t forget anything.

We also recommend that you get a copy of the book Modern High Power Rocketry , it’s full of good

information too, and subscribing to a forum like The Rocket Forum (www.rocketryforum.com) is a

really good idea, too.

In the Air…

Once your rocket is launched, barometric altitude and accelerometer samples are taken at whatever

ascent rate you’ve selected, typically 20 samples per second. These samples are run through a filter

to eliminate “noise” that may be caused by a number of different factors, primarily aerodynamic but

also some external factors such as wind and temperature.

Velocity readings are computed based on the difference between successive accelerometer samples

over time, as well as the difference between successive barometer altitude readings over time. In a

perfect world, this would give you a precise and 100% accurate velocity reading. The reality is

somewhat different, however. There are several things that can introduce errors into the velocity

reading: angle of attack, wind, errors in the pressure readings due to aerodynamic influences, and

time differences. If the pressure ports in your payload bay aren’t sized properly, this can introduce

an error, particularly if they’re too big and you have two of them opposite each other (you’ll get a

crossflow through the payload bay which makes the pressure readings very noisy). Finally,

differences in the processor’s timing may introduce errors, although the readings are taking at

relatively precise intervals so it’s going to be very small.

The good news is that the magnitude of these errors tend to be proportionate to velocity as the rocket

ascends, so they respond well to being filtered with mathematical noise filters. Velocity-related

events are run through a digital filter to smooth out any sharp peaks or valleys that may develop due

to pressure-induced noise.

Mach Transition…

As your motor continues to burn and the velocity increases, if the velocity exceeds 800 ft/sec

aerodynamic shock wave buildup can fool the pressure sensor into thinking that the rocket is

descending when in fact it is actually ascending at a rather rapid speed. If this were not taken into

account, the flight computer might deploy the main parachute at near-mach speed, which would

Page 31

- 31 -

undoubtedly break something and ruin your day, not to mention what an object falling from the sky

at these speeds could do.

To prevent this from happening, the Proton uses a predictive mechanism to hold off deployments

until it’s safely out of the mach “danger zone”. Deployments are initially disabled when the Proton

is armed. When the noise-filtered barometric velocity drops below 100 ft/sec for at least 1 second

after the Launch Detect Altitude has been reached, deployments are enabled. Typically, this will be

a second or two before apogee, although it may be a little later in some cases (i.e. a very draggy

rocket). In any case, it guarantees that your rocket isn’t going very fast when the drogue deployment

occurs, which is the ultimate goal. This is the same logic that we’ve used for several years with all

Eggtimer Rocketry altimeters, and in several thousand flights we’ve never heard of a zipper due to

an early/late deployment that wasn’t due to the rocket going horizontal (or a motor-eject backup

charge firing early).

Apogee and Nose-Over

Assuming that your rocket is moving more or less straight up, it will continue to slow down during

the coast phase until it gets as high as it’s going to go. If the rocket was going absolutely straight up,

the velocity at this point would be zero; it would simply start falling to the ground. In reality, this

almost never happens, because for safety you usually angle the rod/rail at a slight angle so that the

rocket takes off away from the flight line. This results in the velocity disparity that we’ve previously

mentioned. The rocket usually has some forward velocity at apogee; hopefully it’s relatively small

so your parachute deployment happens at a low velocity and won’t cause any mechanical problems

like a broken shock cord or a zippered tube. It also means that you really don’t know that you’ve

reached apogee until after you’ve been there.

Accordingly, the Proton fires the drogue parachute at Nose-Over, which we define as one second

past apogee (highest recorded altitude). If the rocket is still going up, chances are that its altitude is

going to keep increasing before a one second interval elapses, so you’re unlikely to get a false

apogee detection. If the rocket hasn’t gained any more altitude after one second then you must be

starting on your way down, so the Proton fires the drogue at that point, for one second.

When Nose-Over is detected, the Proton begins using the Descent Samples value for altitude

sampling. This setting is very low, typically 2 samples/sec. As the rocket descends, when the

altitude drops below the Main deployment altitude the Main channel is triggered, for one second.

At this point your Main chute should pop out, to thundering applause and a hearty round of highfives all around.

On the Ground

The Proton detects that your rocket is on the ground when the barometrically-detected AGL altitude

varies by less than 30 feet for over 5 seconds. Once on the ground, the Proton will start beeping out

the maximum altitude continuously for anyone within earshot to hear. The beeps work like this:

Page 32

- 32 -

1 Beep = 1

2 Beeps = 2

…..

9 Beeps = 9

10 Beeps = 0

So, if you fly to 12, 360’ you will hear:

Long Pause…

Long Beep… (“I’m going to give you’re the apogee reading…”)

Short Pause…

1 Beep (10,000’)

Short Pause

2 Beeps (2 x 1000’)

Short Pause

3 Beeps (3 x 100’)

Short Pause

6 Beeps (6 x 10’)

Short Pause

10 Beeps (zero 1’ reading)

<sequence repeats>

The beeps continue until you turn off the power, and also act as a verification that you had a

successful flight, but getting your rocket back in one piece pretty much told you that, didn’t it?

In addition, the WiFi interface will start back up again, and will take you directly to the Flight

Summary page for the flight that you just completed. Note that it may take 10-15 seconds to bring

up the Flight Summary page after you connect to the Proton, because it sends out the page after it’s

done beeping out the altitude, so you have to wait until it goes quiet for a few seconds. Once you the

connection, you'll get the Flight Summary page that you see below. Note that this is a "dead end"

page… you cannot go back to the normal Status Page or any other Proton page. This is because

once your flight has ended, it's assumed that you're going to take it back to your work table to open

up the AV bay and recharge the batteries, replace the deployment charges, etc.

Page 33

- 33 -

Proton_2abcd 1.01a

Flight Select

Idx: 01 Flt: 1 No LDA More

Idx: 02 Flt: 2 Apogee: 1827 More

Iex: 03 Flt: 3 Apogee: 3875 More

Idx: 04 Flt: 4 Apogee: 5202 More

Idx: 05 Flt: 5

Idx: 06 Flt: 6

Idx: 07 Flt: 7

Idx: 08 Flt: 8

Idx: 09 Flt: 9

Idx: 10 Flt: 10

Idx: 11 Flt: 11

Idx: 12 Flt: 12

Idx: 13 Flt: 13

Idx: 14 Flt: 14

Exit

Post-Flight Analysis

The Proton saves your last 14 flights: settings, summary data, and detail data. Clicking on the

‘Flights’ link in the Proton’s Status page takes you to an index page that allows you to select the

flight that you want to review. Note that each flight has an index number from 1-14, this is the

memory location that it’s in, and each flight has a Flight number that is sequential from 1 to however

many flights you’ve had with your Proton. If you fly it enough, you’ll probably get to the point at

which flights drop off, and the flight numbers won’t start with 1 anymore, but the indexes will

always be from 1 to 14. Your Proton will roll the flights over to the oldest memory location as

necessary.

Each entry in the Flight Select page shows the Flight Index, the Flight Number, the Apogee, and a

‘More’ link that takes you to the Flight Summary page. Note that after you land and while it’s