EG corvus 540 60CC User Manual

EG AIRCRAFT

CORVUS 540 60CC

Giant Scale Aerobatic Aircraft

Specifications:

Scale: 30 %

Wing Span: 91”

Length: Including spinner 88 inches

Wing Area:1500 sq. in.

Flying Weight:16.5 to 18 lbs

Spinner:3.5”

Engine:50cc – 70cc Gas

Radio:4+ Channels

Servos :6 to 9 servos required 180 oz to 240 oz

All contents copyright 2013, EG Products

Version 2.0, Mar 2013

Dear EG Customer,

Thank you for purchasing the new EG 60CC Corvus 540. EG is known worldwide for the best aerobatic

aircraft designs available and include many innovative construction techniques. We’ve taken this

expertise and teamed up with EG Aircra ft to bring this new model to the radio control enth usiasts. The

Corvus is designed for the popular 50-70 cc engines and weighs about 16.5 lbs to 18 lbs. Perfect for

IMAC or Freestyle, this new EG giant offers everything you want in a giant scale aerobat i nc l u din g great

looks! Covered in genuine Ultracote, this ARF comes with premium hardware, carbon fiber landing gear,

carbon fiber wing and stab tubes, carbon fiber reinforced wing and fuselage spars, carbon fiber horns

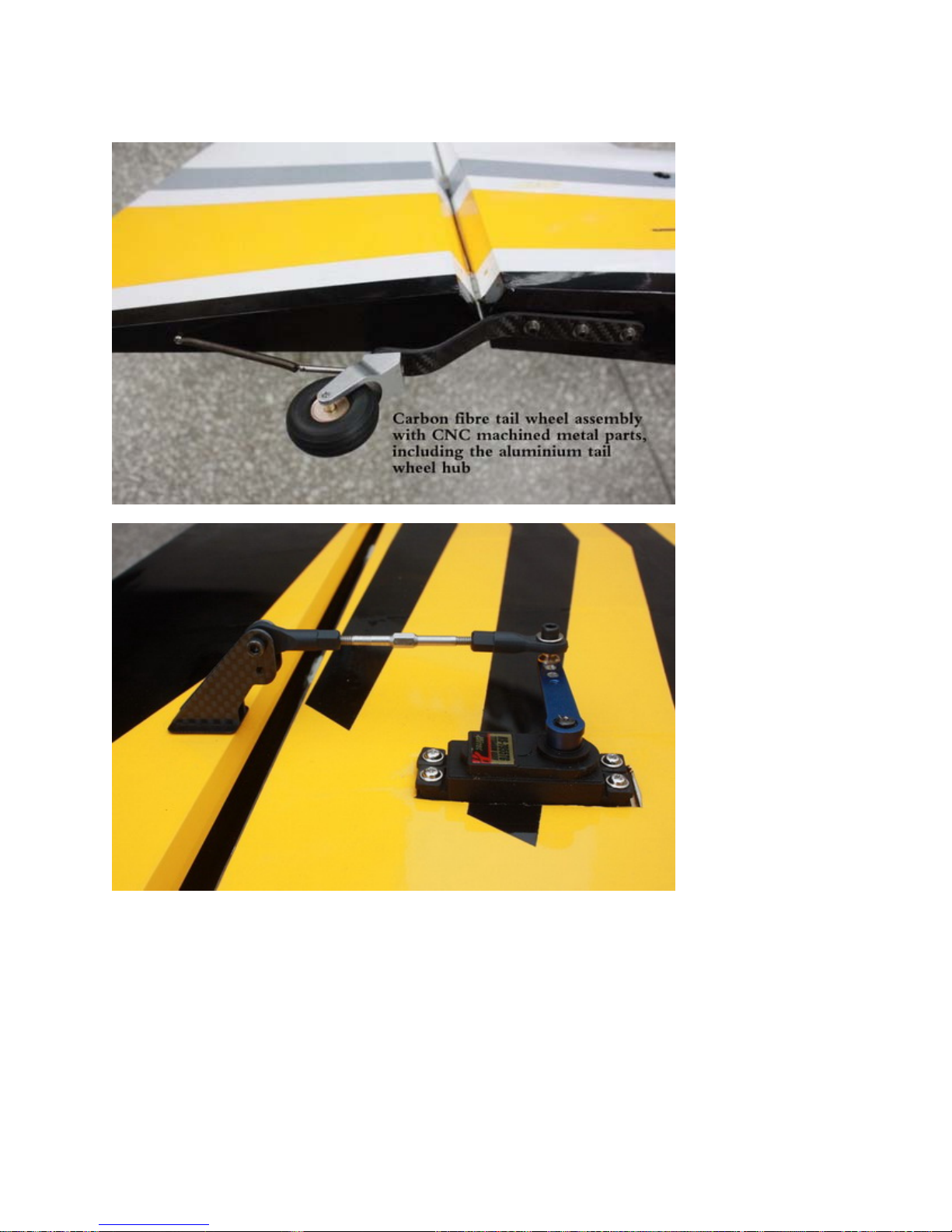

and pre-hinged elevators and ailerons. And also new Carbon fibre tail wheel assembly with CNC

machined metal parts, including the aluminium tail wheel hub.

We hope you will enjoy your new EG gia nt sca le aircraft as much as we have.

AN IMPORTANT MESSAGE ABOUT SAFETY AND RADIO CONTROL FLYING

MODELS

Flying radio control aircraft, like any hobby or sport, contains certain risks. The operator of these

models is responsible for these risks. If the airplane is misused or abused, you may cause serious bodily

injury and/or damage to property. With this in mind, you will want to be certain that you build your

model carefully and correctly. If you are not an experienced flier, have your work checked and ask for

help in learning to fly safely . This model aircraft is not a toy and must be operated and flown in a safe

manner at all times. Always perform a pre-flight check of the model including all control surfaces, proper

function of the radio gear, structure, radio range, and any other area relating to the safe operation of this

aircraft.

Models are not insurable but operators are. You can obtain coverage through membership in the

Academy of Model Aeronautics (AMA). For an AMA information package call 1-800-435-9262, ext.

292 or visit the AMA website at "www.modelaircraft.org

".

By the act of using the final assembled model, the purchaser/operator accepts

all resulting liability.

EG WARRANTY AND RETURN POLICY

EG guarantees this product to be free from defects in both material and workmansh i p at the date of

purchase. This does not cover any parts dam a ge d b y use, misuse or modification. In no case shall EG's

liability exceed the original cost of this kit. Because EG has no control over the final ass embly or

equipment/components used in the final assembly, no liability shall be assumed for any damage resulting

from the use of this model by the user. By the act of using the final asse mbled model, the user accepts

all resulting liability. If you should find any missing or damaged parts, or have any questions about this

product, please contact Red Aero RC within 30 days of the purchase in order to be covered by o ur

warranty. You may contact

Red Aero RC at sales@redaerorc.com or call Red Aero RC at

239-560-8175. If you wish to return this product you must first contact Red Aero RC and a 15%

restocking fee will be assessed. O nl y unused products may be returned. The cus tomer is responsible for

all return shipping charges both wa ys an d any damage as a result of misuse or shippi ng.

Included Features:

• Carbon fiber tail wheel assembly with

CNC machined metal parts, including

the aluminum tail wheel hub

• Carbon reinforced fuselage and

wings.

• Air foiled Carbon Fiber Landing Gear

• Carbon Fiber Wing and Stab Tubes

• Extra strength Carbon Fiber control

Horns

• 3.5"(89mm) Carbon Fiber Spinner

• Servo Lead Safety Clips

• High Density Rubber Wheels

• Adjustable pushrods for easy fine

tuning

• Pre-hinged Control Surfaces

• Pre-assembled and mounted Fuel

Tank

• Extra covering provided for small

repairs

• Installed Servo Wire Guide Tube

• Covered in Genuine Ultracote /

Oracover

• Complete and Detailed Instructions

on CD

• Fits new DA60 and 3W55 Engines

• Stronger design for fuselage and

wings

• Flat nylon hinges

• Honeycomb board carton packing

for safer transportation

• Larger C.F wing tube Diameter. Two

piece C.F tube for stab

• Larger aileron and rudder design. Up

to 60 degrees of throw on all control

surfaces for excellent 3D aerobatic

flying.

• Full length Tuned pipe design in

fuselage

• All high performance cap head

screws

Items Required to Complete This Model:

• 50-70 cc gas engine with stock or

aftermarket exhaust systems

• Appropriate propeller for your en gine

• All required engine and exhaust mounting

hardware

• Ignition battery and switch

• One quality throttle servo and appropriate

servo arm

• Four high quality metal gear servos of 180

in-oz or better for the ailerons and elevators

• One high quality rudder servo of least 240

in-oz or better

• Appropriate servo arms for the above

• Heavy duty servo wire extensions.

Recommended installation includes two 36”,

two 18”,, two 6” extensions. Your

installation though may vary.

• Two heavy duty switches with charging

jacks for the Rx

• Two high quality Rx batteries of high

capacity to power your choice of servos.

• Receiver of your choice

Shop Supplies/Tools

• Covering Iron and heat gun

• Assortment normal hobby tools such as

screwdrivers, hobby knife, drill and drill

bits, pliers, etc.

• Thick and Thin CA adhesives

• 30 minute Epoxy

• Isopropyl alcohol

• Ruler or tape measure

• Blue thread-lock or equivalent

Note: As with all kits, to correctly understand the construction of your airplane it is

important that you read all the instructions and study the parts before you begin

construction. Handle the parts of this kit with care so you do not damage any of the

structure or covering. Inspect all the parts for any shipping damage and report any

issues to EG as soon as you can. Make sure you have a flat and sturdy workbench

and follow all safety rules for the tools and adhesives you plan to use.

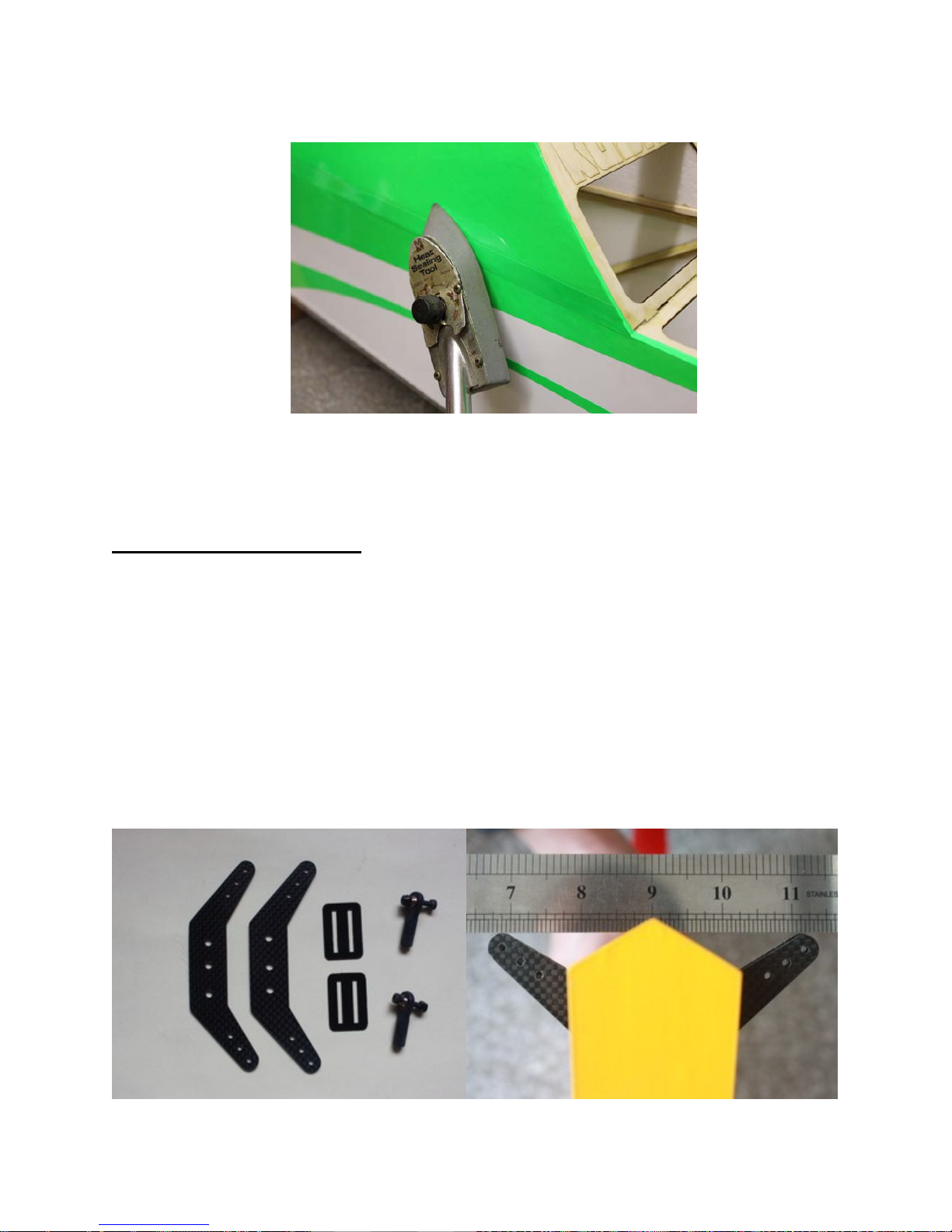

AIRCRAFT COVERING:

1. With all ARFs, varying temperatures and storage delays can cause covering material to loosen over

time and transportation. EG recommends lightly going over all the covering with a covering iron set

at medium temperatures. Be sure to use a soft cover over your iron so you d o not sc ratch the covering

surface. Be sure you go over all seams and edges of the covering to assure it is secure to the airframe

and other covering. Be careful not to apply too much heat or you may cause bubbles or damage to the

covering. A heat gun may also be used alon g with a soft cotton cloth to shrink and adhere the

covering. Again, be extremely careful when using a heat gun.

2. Be sure to seal any exposed wood with a thin coating of epoxy to prevent engine oil from soaking

in. This is especially important around the engine compartment and servo openings with exposed

areas.

3. Some modelers prefer to seal the hinge gaps using strips of appropriate covering or clear trim tape.

We have found this to be helpful with models intended for higher speed flight or models with

unusually large hinge gaps. EG aircraft utilize a very tight double beveled hinge line and do not

normally require this step. Sealing the hinge gaps is therefore left as an option for the modeler.

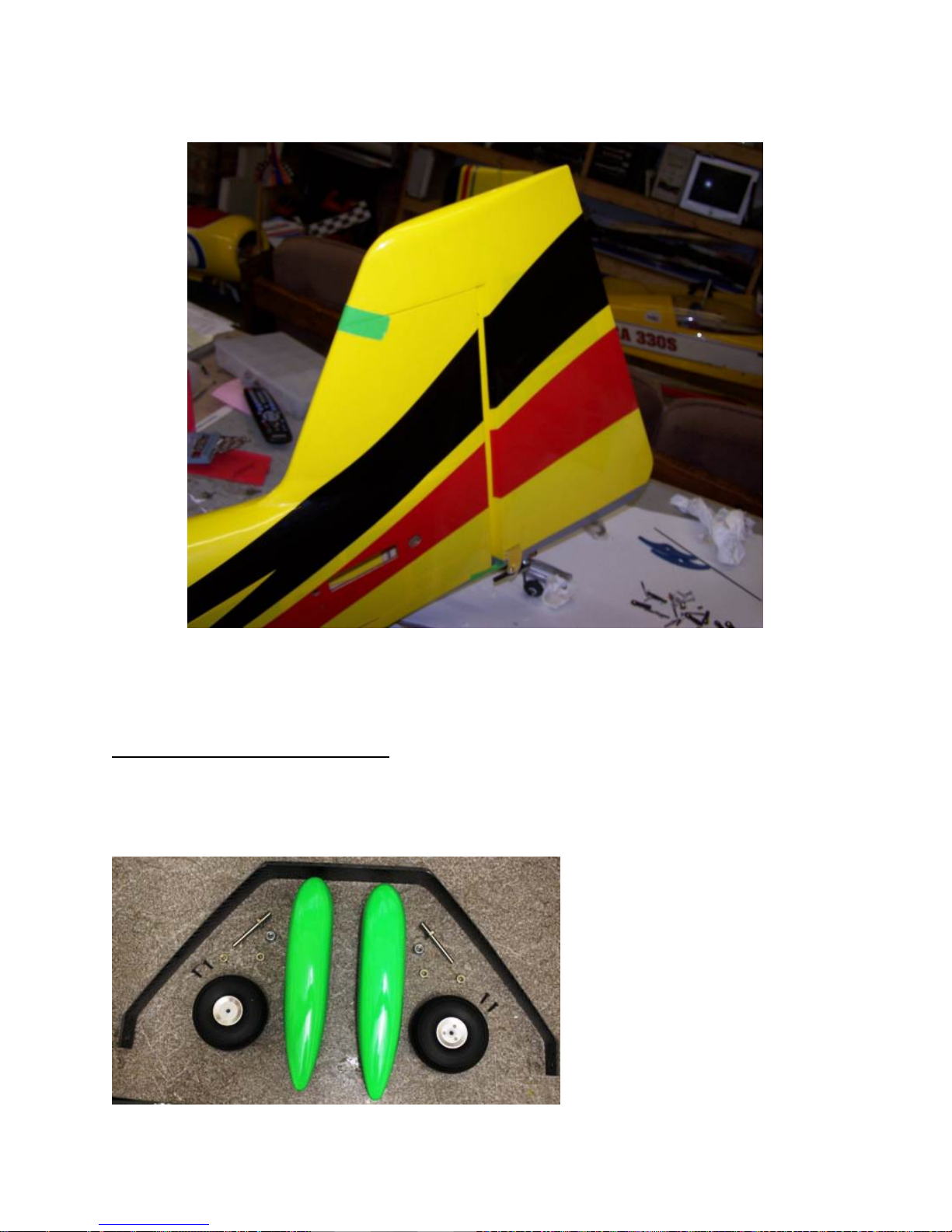

RUDDER INSTALLATION:

1. It is much easier to install the twin control horns before installing the rudde r. Loca te the Ca rbon Fiber

rudder control horns, ball links, and associated bolts and nylon-insert lock nuts. Use some fine

sandpaper to roughen up the center areas of the two control horns so that the glue adheres better.

Using a sharp hobby knife cut the covering away from the slots in the rudder and trial fit the two

control horns.

2. Mix up some 30 minute epoxy and coat the inside of the slots and the center of the control horns. Hint:

a scrap piece of 1/16” ply, tooth pick, or old hobby blade can be used to coat the inside of the rudder

slots. Slide the control horns in place and make sure they are centered perfectly by using a ruler to

measure between the pivot holes and the hinge line. Wipe any excess glue off with isopropyl alcohol

and paper towels. Install the ball links, bolts and nuts into the holes to help assure alignment of both

control horns while the glue cures. Set aside until cured. NOTE: There are pictures of different planes

in this manual, however, this plane’s rudder is assembled the same way.

3. The slots for the supplied flat hinges are pre cut. Locate the flat hinges and dry fit the hinges and

rudder into place and test the o peration. The hinges should seat fully into the slots so that the hinge

line gap is minimal while still allowing full rudder deflection.

4. Before gluing the hinges in you must first c lean the hinges of any mold release agent usin g isopropyl

alcohol, and scuff up the plastic with light sandpaper for maximum glue adhesion.

5. Mix up some 30 minute epoxy and using a toothpick or small wooden dowel coat the inside of each

hinge slot with epoxy. Also put a thin layer of epoxy on one end of the flat hinges. Install this end

into the slots of the rudder and make sure each hinge is properly aligned at exactly 90 degrees to the

hinge line.

6. Now coat the other end of the flat hinges with epoxy and install the rudder into the trailing edge of the

vertical stabilizer. Again, make sure the hinges remain in proper alignment. Using paper towels and

some isopropyl alcohol clean off any excess ep oxy from the hinges and surrounding areas.

7. Make sure the rudder is fully seated so that the hinge gap is minimal while still allowing full deflection

of the rudder. When satisfied, use some masking tape to hold the rudder in pl ace along the bottom and

counterbalance. After the epoxy has cured, remove the masking tape and check for proper operation.

If the hinges are dry some light oil carefully placed on each hinge will help greatly.

LANDING GEAR ASSEMBLY:

1. Locate the supplied main and tail wheel la nding gear parts and sort them out on your workbench.

NOTE: There are pictures of other planes in this manual, however, the Corvus is assembled the same

way.

Loading...

Loading...