EFO MFT4 User Manual

MFT4 Multifunction Installation

Tester

- 1 -

User manual

Index

Safety information and explanation of symbols used .............................. 3

Features of the MFT4 ................................................................................... 5

Special Polarity Test Function. .................................................................. 6

Audible tones ............................................................................................... 7

Overview of the switches and LCD ......................................................... 8

Test lead inputs ............................................................................................ 9

Continuity Test Function ........................................................................... 10

Continuity Test Procedure ....................................................................... 10

Lead Nulling ............................................................................................ 10

Hands Free Continuity Testing ................................................................ 11

Insulation Test Function............................................................................ 12

Insulation Test Procedure ........................................................................ 12

Hands Free Insulation Testing ................................................................. 13

Loop Test functions ................................................................................... 14

High Current mode .................................................................................. 14

No Trip Mode ........................................................................................... 14

PFC/PSC................................................................................................. 15

Test lead configuration ............................................................................ 15

Lead configuration for No-Trip testing ..................................................... 16

Lead configuration for High current 2-wire testing ................................... 16

Loop Test Procedures ............................................................................. 17

No Trip Loop test (Zs) ............................................................................. 17

High current test (Ze) .............................................................................. 18

Hands Free Loop testing ......................................................................... 18

RCD Test Function ................................................................ ..................... 19

Ramp test ................................................................................................ 20

Sinusoidal polarity (the 0° or 180° test) ................................................... 20

RCD test procedure ................................................................................ 21

User selected test ................................................................................... 21

30mA Automatic test ............................................................................... 22

Ramp test ................................................................................................ 22

Specifications and tolerances .................................................................. 23

Continuity Test Range Accuracy .............................................................. 23

Insulation Test Range Accuracy .............................................................. 23

Insulation Output Voltage ........................................................................ 23

Loop Test Range Accuracy ...................................................................... 23

RCD Test Range Accuracy ...................................................................... 24

- 2 -

Safety information and explanation of symbols used

Because the MFT4 is a multi function tester used for testing both live and dead

circuits there are different safety issues that apply to the individual functions.

Before using your MFT4 please read these instructions paying particular

attention to the general safety warnings below and those at the start of each

section.

Before using the tester check the case and the test leads for damage.

If any damage is noticed the unit should be withdrawn from service and

returned to place of purchase for repair.

It is important for safety that only one set of leads can be fitted at a time. In the

unlikely event that the interlock cover is damaged the tester should be

withdrawn from service and returned to place of purchase for repair.

Caution read this manual for safety information

The Continuity and Insulation functions are rated at 500V Category III

The Loop and RCD functions are rated at 300V Category IV

When installing batteries observe correct polarity do not mix old and new

batteries - Dispose of used batteries in accordance with local regulations.

Never incinerate batteries.

Do not use this tester in a manner other than that described in this booklet.

To clean the tester wipe with a damp cloth with a mild soap solution taking care

not to allow water ingress into the input terminals. Do not use solvents and do

not immerse. Allow the tester to fully dry before use.

The MFT4 is fuse protected against damage by accidental connection to an

over-voltage supply. The fuse is located inside the battery compartment and

can be accessed by removing the two small battery cover retaining screws on

the back of the case. Always ensure that test leads are disconnected before

removing the battery cover.

- 3 -

The broken fuse indicator on the LCD will flag if the fuse has blown. It must be

MEASUREMENT

RANGE

OPERATING

RANGE

PER EN61557

OTHER

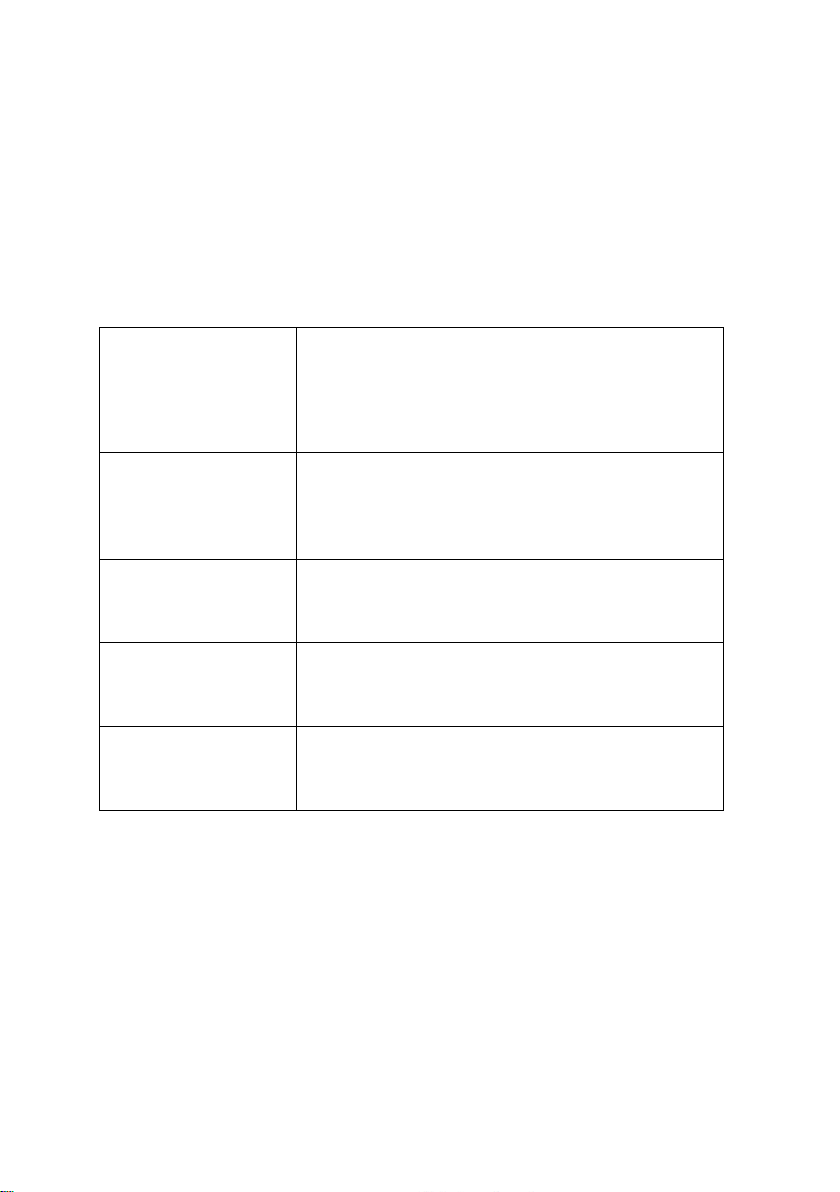

CONTINUITY

0.00 Ω - 19.99 kΩ.

0.1 Ω - 9.99kΩ.

IN>200mA

Uq < 7V

INSULATION

0.00 MΩ - 1999 MΩ

.

0.1 MΩ - 1990 MΩ.

IN = 1mA

LOOP HI-I

0.01 Ω - 500 Ω

1.04 Ω - 500Ω.

230V

50Hz

LOOP NO-TRIP

0.01 Ω - 500 Ω.

1.04 Ω - 500Ω.

230V

50Hz

RCD TRIP TIME

5 ms – 1999 ms

38 ms – 1999ms.

replaced with the correct type:

Fuse type: F 500mA fast blow ceramic 600V.

The enclosure is double insulated

Protected against over voltage to 550V

For safety reasons the tester is shipped without batteries fitted. To install

batteries remove the two small crosshead screws on the back of the

instrument that retain the battery cover and fit four Alkaline batteries type

AA / LR6 in accordance with the polarity shown.

The MFT4 complies fully with the requirements of EN61010.

The following table details the operating ranges for the individual functions

compliant with the performance requirements of EN61557.

- 4 -

Features of the MFT4

The MFT4 is packed with design features that maximise both convenience and

safety. These include:

Large display

To give the clearest results the MFT4 uses a large auto-backlit LCD which

makes reading the test results easy even when used in poorly lit areas.

Auto shut down

To preserve battery life when not in use the MFT4 incorporates an Auto-Off

function that powers the unit down after three minutes of inactivity. To resume

use after an Auto shut down a single press of any of the function buttons will

power up the unit.

Battery check

The first position either side of the off position of the rotary selector switch is a

battery check function.

Extended battery life

For simplicity the tester is powered by just four conventional AA (LR6) alkaline

batteries. The MFT4 has much lower power consumption than most testers

and therefore gives excellent battery life.

In addition to the battery status indicator that shows on the LCD, when the

battery power is becoming very low the Red warning LED will light to show that

imminent replacement is necessary. Always use Alkaline rather than zinc

carbon batteries.

Easy to locate

The test lead inputs are located on the top of the case allowing the tester to

stand vertically or be laid flat. Alternatively the unit can be carried by the

supplied neck strap.

Hands Free

Most of the test functions can utilise the Hands-Free mode in which the tester

is primed to automatically start the test as soon as the probes are connected to

a circuit, thereby leaving your hands free to hold the test probes.

Socket wiring check

To protect both the user and the instrument against harm caused by accidental

connection to an incorrectly wired supply the tester will automatically check the

polarity upon connection to a live supply. If the wiring has been incorrectly

connected testing will be inhibited an alarm will sound with flashing LED.

- 5 -

Special polarity test function.

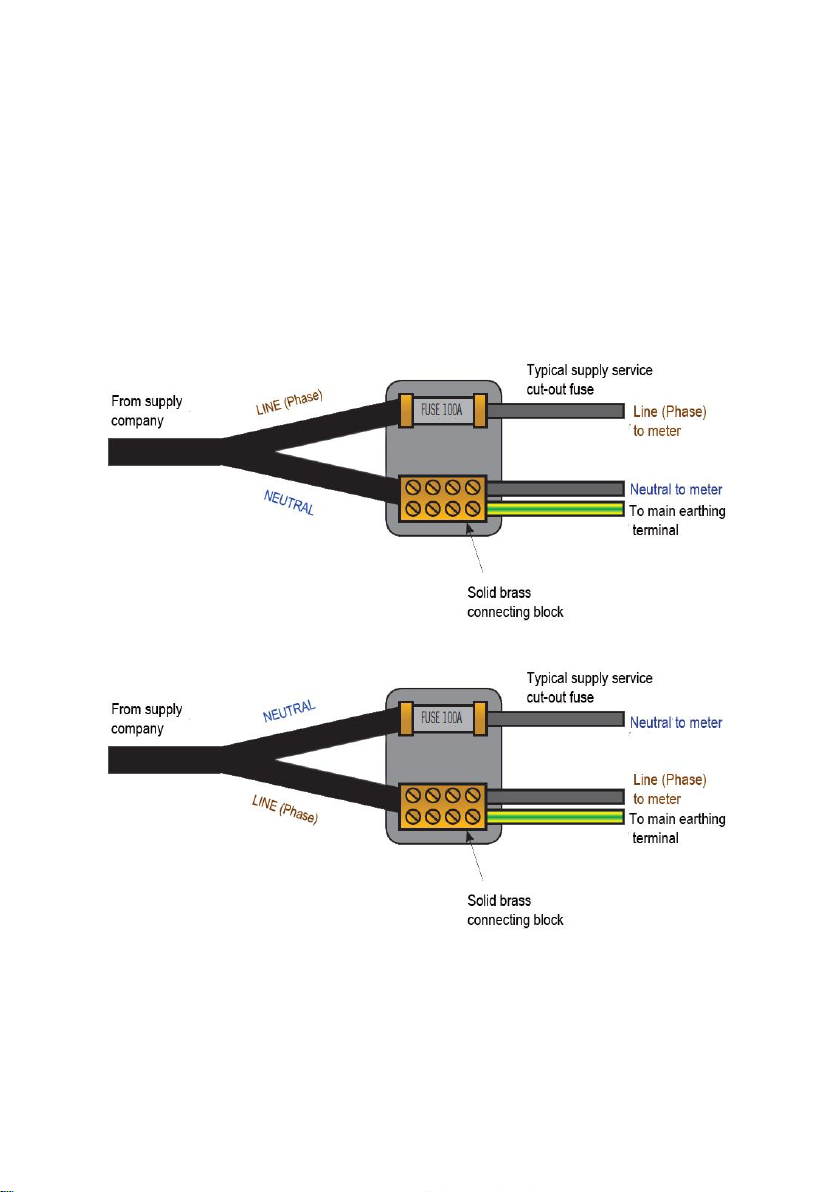

It is a little known fact that a system can be reverse wired with Line (Phase) to

earth/neutral and earth/neutral to Line (Phase). The sockets will all work and

conventional loop testers will show and test that everything is correct despite

this very dangerous wiring condition.

Although extremely rare, this miss wire condition can exist so if your test

shows this fault do not proceed – if in any doubt advise your customer to

contact their supply company immediately.

Correct Polarity

Reversed Polarity

- 6 -

Audible tones

Danger

A rising siren type

alarm

In the event of a potentially dangerous situation

such as connecting to a live supply when

configured for insulation testing. Will be

accompanied by the Red Voltage/Polarity warning

LED flashing.

Warning

A continuous 2 tone

alarm

An unsuitable supply configuration such as a

mains supply with incorrect polarity or having the

leads connected wrongly will be accompanied by

the Red Voltage/Polarity warning LED flashing.

Wait-Test in progress

A steady beeping

sound

Emitted whilst a measurement is in progress. The

same tone is sounded when used in Hands free

mode to indicate that continual measurement is

being made

Test completed

A single beep

Sounded upon completion of a measurement to

indicate that the result is being displayed

Alert

A short 2 tone alarm

Sounded when a test returns a result that is likely

to be regarded as a failure e.g. An insulation test

that gives a result of less than 2 MΩ

A simple selection of audible tones is used to supplement the visual display.

These help the user by providing intuitive feedback during testing. In addition

to warning about dangerous or unstable supply conditions they provide a very

quick confirmation that the measurement process is taking place and, upon

completion of the test, a warning if the results are likely to be regarded as a

failure.

The meaning of the tone for each individual function is covered in detail in the

relevant section. Generally however there are five types of tone emitted.

- 7 -

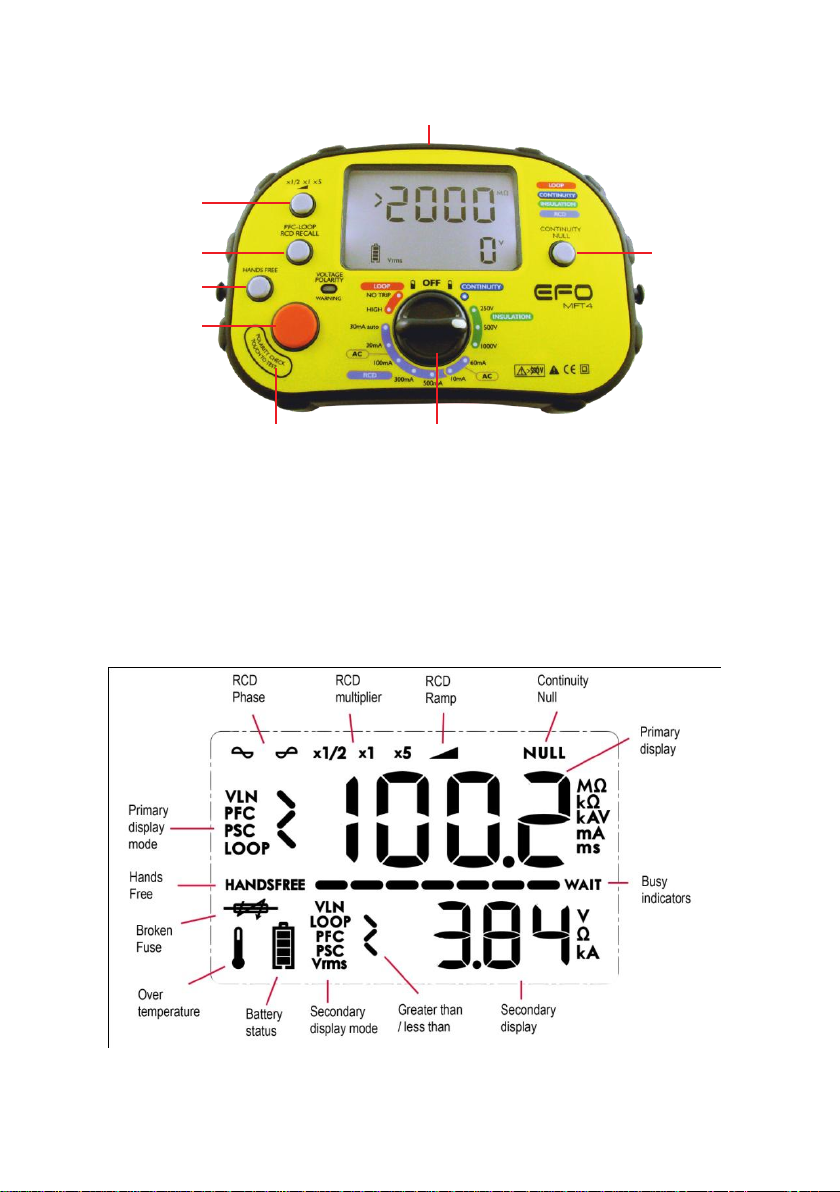

Test lead inputs

RCD

Muliplier

PFC-PSC /

RCD Recall

Polarity test

touch pad area

Hands free

Button

Test

Button

Function Selector

Continuity

Null Button

Overview of the switches and LCD

The Primary display of the large LCD shows the result of the test being

conducted. At the same time a secondary display area shows supporting

information e.g. for an insulation test the main display shows the resistance of

the insulation whilst the secondary display confirms the test voltage applied.

- 8 -

Loading...

Loading...