EFM Heating VT 700 E, VT 1000 E Installation Instructions Manual

Installation Instructions

Boiler Burner Unit

Model VT 700 E

Model VT 1000 E

(For Hot Water Heating Systems)

e•f•m

•

Sa l e s Compa n y

Em ma us , P enn s yl v ani a

Specifications

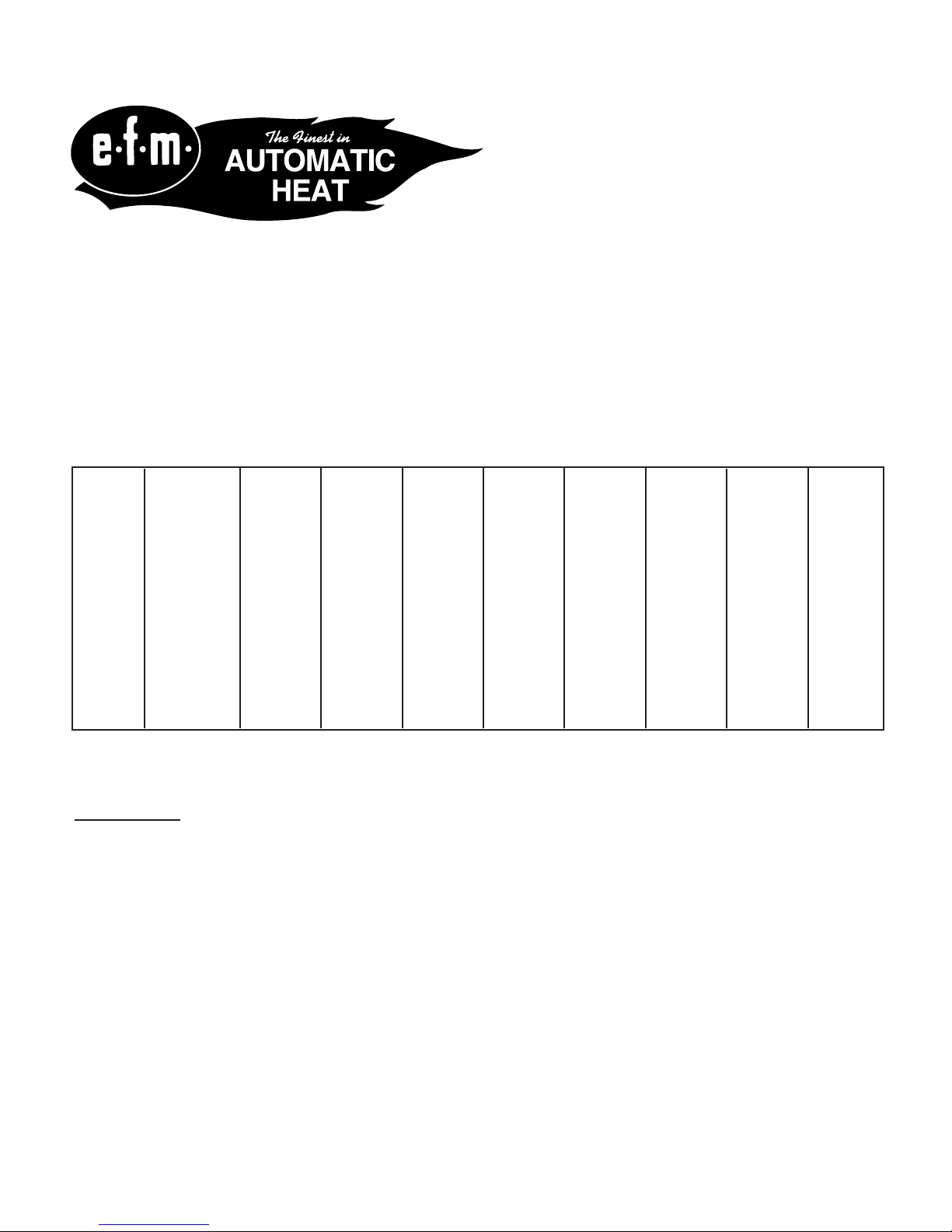

MODEL CAPACITY OUTPUT OUTPUT CAPACITY OUTLET WEIGHT

______________________________________________________________________________________

VT 700 E AFG76XN 968X8X15 315

______________________________________________________________________________________

VT 1000 E AFG76YB 19 7 8X8X15 435

Installation Instructions

NOZZLE SIZE BECKETT CHIMNEY

GPH + TYPE BURNER SIZE

1.00 - 80 H 116,000 100,000 664

_____________________________________

0.85 - 80 H 100,000 86,000 570

_____________________________________

0.75 - 80 H 88,000 77,000 510

_____________________________________

0.65 - 80 H 77,000 67,000 444

1.65 - 80 H 193,000 166,000 1,107

_____________________________________

1.50 - 80 H 174,000 151,000 1,006

_____________________________________

1.35 - 80 H 159,500 137,000 915

_____________________________________

1.10 - 80 H 131,500 113,000 754

HEATING NET NET WATER SMOKE SHIPPING

BTUH BTUH SQ. FT. GAL. SIZE POUNDS

CAUTION:

1. Installer must be a trained, experienced serviceman.

2. Inspect the boiler, jacket and all components to be sure damage has not occurred in shipment. If

damage is evident you must file a claim with the freight carrier immediately.

3. Disconnect power supply before connecting wiring.

4. Refer to local installation codes for oil burning equipment, for recommended installation practice.

5. A complete heat loss calculation is necessary to choose the proper size unit to install. The boiler

should be sized to within 25% of the actual heat loss of the structure.

6. Conduct thorough checkout when installation is complete.

1) Place the boiler on a level non-combustible

floor, preferably raised and as close to the

chimney as possible. The following minimum

clearances must be adhered to during installation and maintained thereafter to properly

clean, inspect and service your boiler: sides

and back - 6"; front - 24" and vent connector

18". Reduced clearance installations must

follow NFPA-31 guidelines.

2) For location of piping refer to the installation

drawing in Figure 5 and 6. The circulator is

shipped loose. Wire the circulator as shown

on the wiring diagrams in this manual. The

circulator may be located on the return line

as shown in the diagram or in the supply

iping if desired. The aquastat is wired at the

p

factory. For power and thermostat wiring see

Figures 2, 3 and 4 in this manual and the

wiring diagrams in the thermostat manufacturer’s manual. For piping and wiring of other

system components, see the manufacturer’s

installation manuals. An Expansion Tank (not

provided) must be matched to the system

and installed in accordance with the manufacturer’s recommendations. See the manufacturer’s instructions for sizing the expansion tank. Do not under-size the expansion

tank. A bypass loop may be installed to

improve tankless coil performance. See

Figure. 7.

3) The tankless water heater may be piped as

shown in Figure 6. A mixing valve, not supplied, must be used to reduce the water

temperature at kitchen or bathroom taps.

High temperature water for a dishwasher

may be obtained by piping as shown in

Figure 6. The nuts that secure the tankless

coil flange should be tightened before the

boiler is filled with water, after initial firing and

once a year during the annual maintenance.

DETERIORATION DUE TO COIL GASKET

LEAKS WILL VOID THE WARRANTY.

4) The VT series boilers are equipped with an

air eliminator feature that uses a dip tube

construction on the boiler supply fitting. This

feature allows quiet air free operation of your

hot water system by assuring the removal of

air pockets without the installation of Air

Scoops to trap noisy air.

The 1-1/4" supply line or Riser tapping in the

top of the boiler extends approximately 1"

below the top or waterline of the boiler, thus

allowing only air free water to enter the supply

to the heating system. The air trapped in the

top of the boiler is then purged through a 3/4"

vent tapping to be released with an (1) automatic float vent (2) a manual vent or (3) piped

into a conventional type expansion tank.

Relief valve discharges and drain valve piping should be piped to a safe place of discharge. All plugs and water connections

should be checked for leaks upon installation and annually.

5) Be certain the chimney is clean and free of

obstructions. Connect boiler flue outlet to

himney using galvanized smoke pipe. The

c

flue pipe should be pitched upward at least

1/4" per foot of run. Refer to Page 1 in this

manual for proper size flue pipe for your

model boiler. Use only elbows and straight

sections. Tees may be used in a straight section in conjunction with a barometric draft

regulator; however, they must not be used

for a 90° turn. Each joint should be securely

fastened with sheet metal screws. The flue

pipe must not be inserted beyond the inside

wall of the chimney. Install barometric draft

regulator in the horizontal or vertical section

of the flue pipe. The chimney should provide

a minimum of .04 draft at the boiler flue outlet. A draft of .04 is ideal. The draft losses for

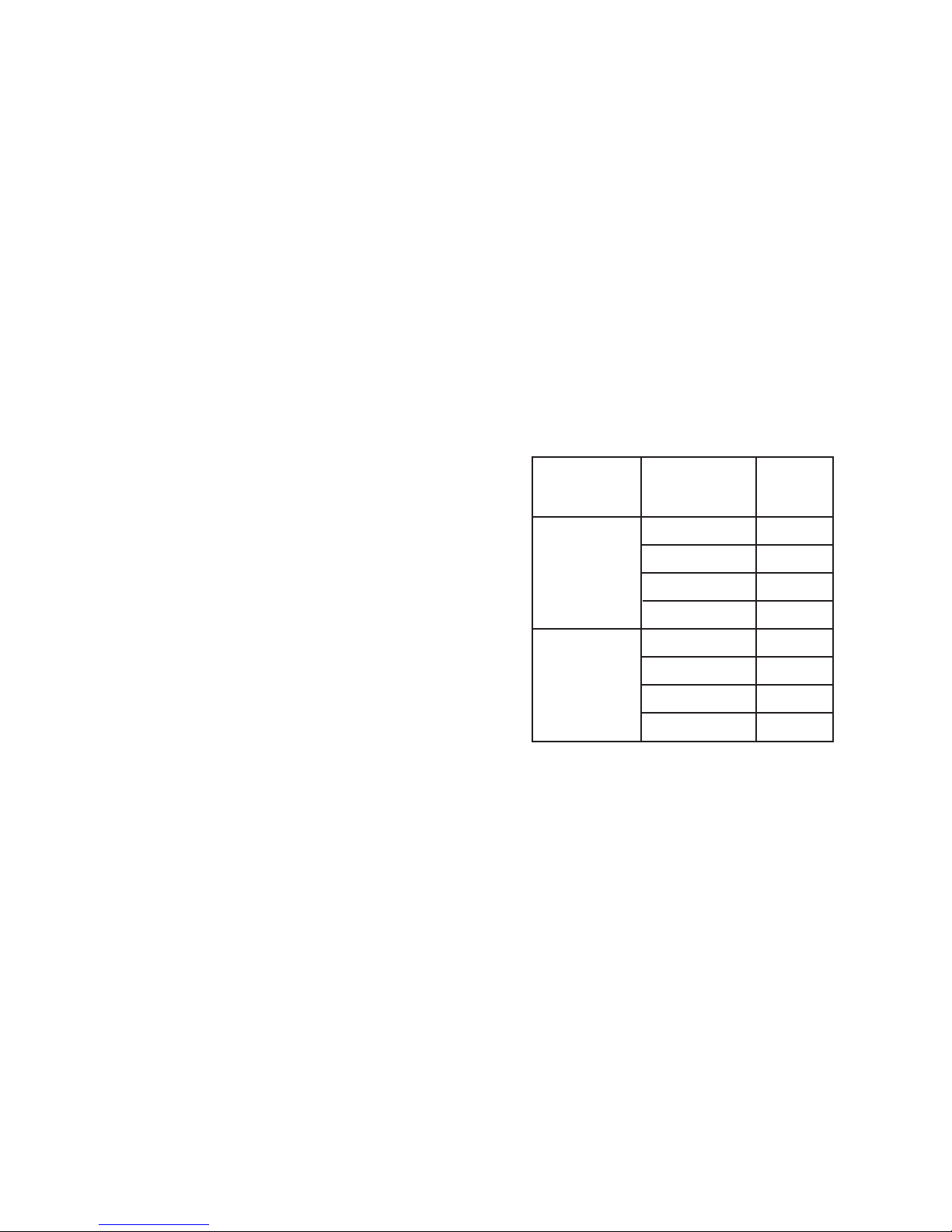

VT Series Boilers are listed below.

MODEL Firing Draft

Rate Loss

0.65GPH .002

0.75GPH .005

VT700E

0.85GPH .015

1.00GPH .020

1.10GPH .005

1.35GPH .010

VT1000E

1.50GPH .020

1.65GPH .025

6) The boiler room must be well ventilated to

allow sufficient make-up air to support combustion. Lack of adequate combustion air

may result in erratic operation of the burner,

noisy combustion or fuel odors. Remember

your need for outside air will be greatly

increased if you have a vented dryer in the

basement or other venting fans in the home.

Boilers located in confined spaces shall be

provided with two permanent openings, one

near the top and one near the bottom of the

enclosure. Each opening shall have a free

area of not less than one square inch per

1000 BTU per hour input rating of the boiler,

freely communicating with interior areas having adequate infiltration from the outside.

7) Fill boiler and system with water. Be sure

entire system has been purged of air and the

desired pressure is obtained.

2

8) The boiler is shipped with a nozzle installed.

Check the nozzle and change it if a different

firing rate is desired. Connect burner to oil

upply. Refer to fuel unit manufacturer litera-

s

ture for piping, connections, lift and tank

installation.

9) Connect the electric supply to the boiler as

indicated on the wiring diagrams. The wiring

must be installed in accordance with the

National Electrical Code and any other state

and local codes.

10) One pipe oil supply line installations must be

absolutely air tight or loss of prime may

result. Maximum lift on one pipe installations

is about 8 feet. See burner literature for two

pipe installations. Install a shutoff valve and

oil filter in the oil supply line. Locate shutoff

valve close to tank with oil filter between

valve and burner.

Operational Sequence

1) Boilers with Tankless Coil - This boiler is

equipped with a combination aquastat control which has high and low limits to be set

at 180° and 160° respectively by the installer.

When room temperature falls below thermostat setting, thermostat calls for heat starting

the burner and circulating pump. The burner

and pump continue to operate until room

heating requirements are satisfied (thermostat setting is reached), or until boiler water

temperature reaches the high limit control

temperature setting. If the high limit control

temperature setting is reached, the burner

shuts off and the circulating pump continues

to operate until the room heating requirements are satisfied. If the thermostat continues to call for heat after the boiler water

temperature has dropped below the temperature setting of the high limit control, the oil

burner will start again, while the circulating

pump will continue to run. The boiler water

temperature is normally maintained at 160°F

around the tankless coil by the operating

control so that an abundance of hot water is

available. If the boiler water temperature

should fall below the operating control setting (160°F) the oil burner will be started

again by that control (and the circulating

pump will be prevented from operating) until

the operating control setting is satisfied. See

control manufacturers literature included in

the data package for detailed wiring, operating and safety instructions.

2) Boilers Less Tankless Coil. This boiler is

equipped with a combination aquastat con-

rol which has high and low limits to be set

t

at 180° and 120° respectively by the installer.

The control acts exactly as described for a

boiler with a tankless coil except that the low

limit is set lower since the boiler does not

need to be kept hot to provide heat to the

domestic hot water coil. By maintaining the

boiler at or above 120° the system will

remain warm enough to avoid cycles of hot

and cold that can produce condensation

which can cause deterioration of the boiler

heat exchanger.

3) A cadmium sulfide flame scanner (cad cell)

and relay are provided with the oil burner.

The cad cell will stop the oil burner within a

predetermined number of seconds if the fuel

fails to ignite or if the flame goes out during

operation. The oil burner will remain off until

the red reset button on the relay has been

pushed. RESET MUST NEVER BE

PRESSED MORE THAN ONCE DURING A

SINGLE FLAME FAILURE.

Start-Up and Check-Out Procedure

CAUTION

Only a trained, experienced serviceman should

attempt the checkout procedure outlined below.

Read the burner manufacturers instructions for

start-up for special instructions and special features of the burner and control.

1) Combustion test equipment required for

proper burner adjustment:

a) CO

b) Draft Gauge

c) Oil Pressure Gauge 0-200 PSI

d) Stack Thermometer

e) Smoke Test Gun

f) Vacuum Gauge 0-30 in. of Hg

2) In order to take flue gas samples for combustion testing a 1/4" hole must be drilled in

the flue pipe between the boiler and the

barometric draft regulator.

3) Open all shut-off valves in the oil supply line

to the burner.

4) Set thermostats substantially above room

temperature.

5) Check electrode settings and readjust air

setting if required. Electrode settings are

2

Analyzer

3

Loading...

Loading...