Page 1

Power Supply/Chargers

Installation Guide

Models Include:

eFlow3NV/eFlow3NXV

- 2A @ 12VDC or 24VDC

eFlow3N4V/eFlow3NX4V eFlow3N4DV/eFlow3NX4DV

- 2A @ 12VDC or 24VDC - 2A @ 12VDC or 24VDC

- Four (4) Fused Outputs - Four (4) PTC Outputs

Rev. 3NVRP122713 More than just power.™

Installing Company: _____________________ Service Rep. Name: __________________________________________

Address: ________________________________________________________ Phone #: _________________________

Page 2

Overview:

The eFlow3NV power supply/chargers convert a 220VAC (working range 198VAC - 256VAC), 50/60Hz input to a

12VDC or 24VDC nominal output (see Power Supply Configuration Reference Chart and Specifications).

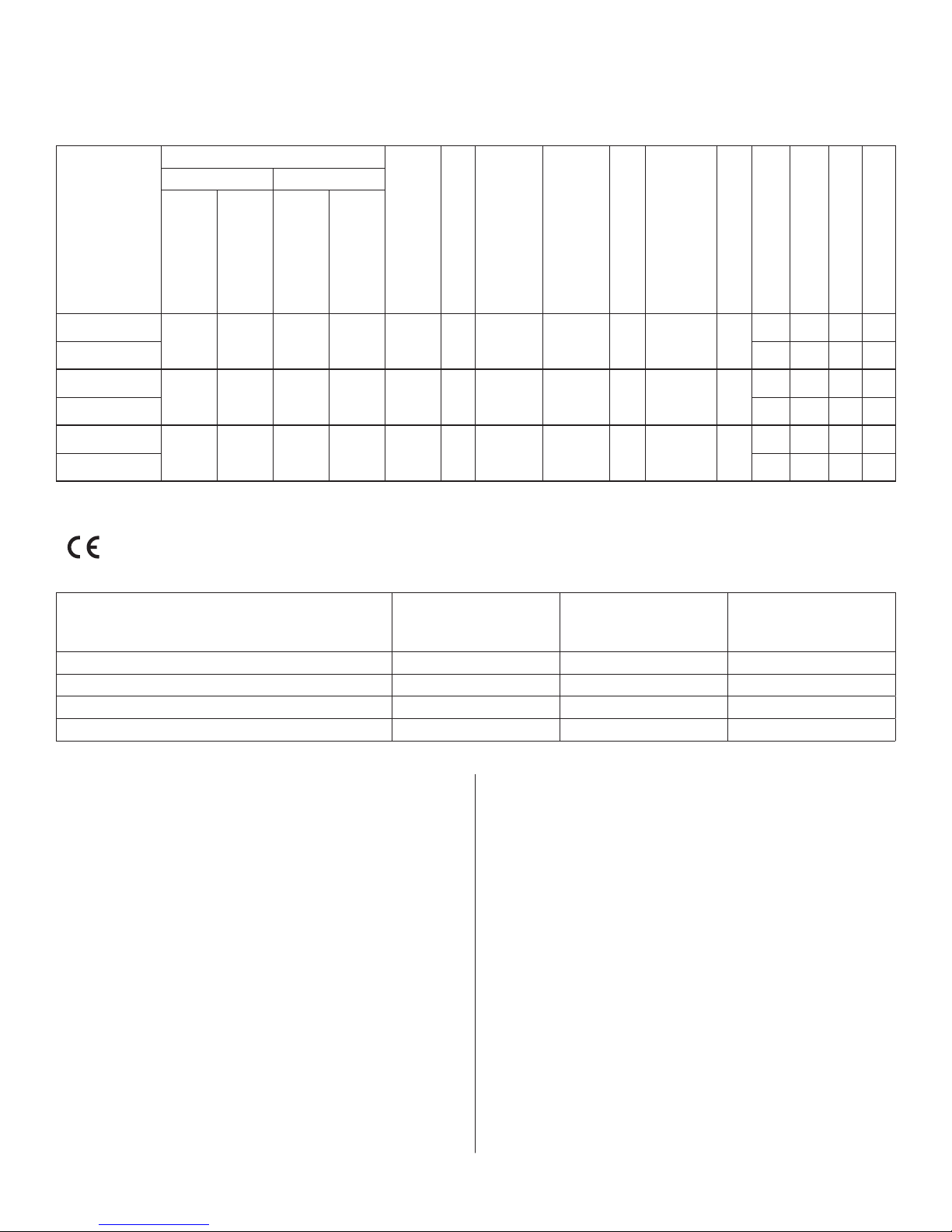

eFlow3NV Series Power Supply Configuration Reference Chart:

Nominal DC Outputs

[DC] [AUX]

Altronix

Model Number

eFlow3NV

eFlow3NXV – – –

12VDC Output

Range (V)

10.13-

13.2

20.28-

26.39

24VDC Output

Range (V)

12VDC Output

Range (V)

10.15-

13.2

20.2-

26.39

Maximum Supply

Current for Main and

24VDC Output

Range (V)

Aux. Outputs (A)

2A 2.1A 5A/250V 3A/32V 960 N/A 1

Input Rating:

220VAC 50/60Hz

Input Fuse Rating

Battery Fuse Rating

Ripple Voltage (mV)

Under low battery condition

Power Distribution

Modiule

Number of Outputs

Fused Output Ratings

Auto-Resettable

PTC Output Ratings

– –

P

Accommodates up to

7AH Batteries

Accommodates up to

12AH Batteries

–

P

eFlow3N4V

eFlow3NX4V 2A – –

eFlow3N4DV

eFlow3NX4DV – 2A –

10.13-

13.2

9.78-

13.2

20.28-

26.39

20.0-

26.39

10.15-

13.2

10.15-

13.2

20.2-

26.39

20.2-

26.39

2A 2.1A 5A/250V 3A/32V 960 PD4 4

2A 2.1A 5A/250V 3A/32V 960 PD4CB 4

2A –

– 2A

P

–

P

P

–

P

These units are suitable to power sensors, electro-mechanical devices (e.g. electric door strikes) defined in the National Electrical Code/

NFPA70/NFPA72 and the Canadian Electrical Code, Part 1.

European Conformity

Stand-by Specifications:

Fire Applications

24 hr. Stand-by/

5 min. Alarm

Battery

Burg. Applications

4 hr. Stand-by/

15 min. Alarm

7AH 0.4A/2A N/A 1.5 Hours/2A

12AH 1A/2A 0.3A/2A 3.5 Hours/2A

40AH (for eFlow3NXV refer to Fig. 7, pg. 10) 2A/2A 1.2A/2A Over 4 Hours/2A

65AH (for eFlow3NXV refer to Fig. 7, pg. 10) 2A/2A 1.5A/2A Over 4 Hours/2A

Access Control

Applications

Stand-by

Specifications:

Input:

• 220VAC (working range 198VAC - 256VAC), 50/60Hz.

Output:

• For output voltage and supply current,

refer to eFlow3NV series Power Supply Configuration

Reference Chart, pg. 2.

• Auxiliary output rated @ 1A (unswitched).

• Overvoltage protection.

Battery Backup:

• Built-in charger for sealed lead acid or gel type batteries.

• Maximum charge current 1.54A.

• Automatic switch over to stand-by battery when AC fails.

Transfer to stand-by battery power is instantaneous with

no interruption.

Fire Alarm Disconnect:

• Supervised Fire Alarm disconnect (latching or non latching) 10K EOL resistor. Operates on a normally

open (NO) or normally closed (NC) trigger.

Supervision:

• AC fail supervision (form “C” contacts).

• Battery fail & presence supervision (form “C” contacts).

- 2 - eFlow3NV Series

Supervision (cont’d):

• Low power shutdown. Shuts down DC output terminals

if battery voltage drops below 71-73% for 12V units

and 70-75% for 24V units (depending on the power

supply). Prevents deep battery discharge.

Fuse Ratings:

• Refer to eFlow3NV Series Power Supply Configuration

Reference Chart, pg. 2.

Visual Indicators:

• Green AC Power LED indicates 220VAC present.

• AC input and DC output LED indicators.

Additional Features:

• Short circuit and overload protection.

• Unit is complete with power supply, enclosure,

battery leads and cam lock.

Enclosure Dimensions (approximate H x W x D):

eFlow3NV, eFlow3N4V, eFlow3N4DV:

13.5” x 13” x 3.25” (342.9mm x 330.2mm x 82.55mm)

eFlow3NXV, eFlow3NX4V, eFlow3NX4DV:

15.5” x 12” x 4.5” (393.7mm x 304.8mm x 114.3mm)

Page 3

Installation Instructions:

Wiring methods should be in accordance with the National Electrical Code/NFPA 70/NFPA 72/ANSI, The Canadian

Electrical Code, Part 1 and with all local codes and authorities having jurisdiction. The product must be located indoors

within the protected premises.

1. Mount unit in the desired location. Mark and predrill holes in the wall to line up with the top two keyholes in the

enclosure. Install two upper fasteners and screws in the wall with the screw heads protruding. Place the enclosure’s

upper keyholes over the two upper screws, level and secure. Mark the position of the lower two holes. Remove the

enclosure. Drill the lower holes and install the two fasteners. Place the enclosure’s upper keyholes over the two

upper screws. Install the two lower screws and make sure to tighten all screws (Enclosure Dimensions, pgs. 11-12).

Secure enclosure to earth ground.

2. Set desired DC output voltage by setting SW1 to the appropriate position on the power supply board (Fig. 1i, pg. 5).

3. Connect unswitched AC power (220VAC 50/60Hz) to the terminals marked [L, N] (Fig. 1a, pg. 5). Use 14 AWG or

larger for all power connections. Secure green wire lead to the ground lug. Keep power-limited wiring separate from

non power-limited wiring (220VAC 50/60Hz Input, Battery Wires). Minimum 0.25” spacing must be provided.

For Fire Alarm applications the outputs are “Special Applications” only, see list (refer to Appendix A, pg. 12).

Keep power-limited wiring separate from non power-limited wiring (220VAC 50/60Hz Input, Battery Wires).

Minimum 0.25” spacing must be provided.

CAUTION: Do not touch exposed metal parts. Shut branch circuit power before installing or servicing equipment.

There are no user serviceable parts inside. Refer installation and servicing to qualified service personnel.

4. Measure output voltage before connecting devices. This helps avoiding potential damage.

5. Connect devices to be powered:

a. For eFlow3NV/eFlow3NXV: connect devices to the terminals marked [- DC +] (Fig. 1h, pg. 3).

b. For other Power Distribution Models: connect devices to be powered to the terminal pairs 1 to 4 marked

[1P & 1N] through [4P & 4N] (Fig. 3a & 3b, pg. 6) carefully observing correct polarity.

For auxiliary device connection: this output will not be affected by Low Power Disconnect or Fire Alarm Interface.

Connect device to the terminals marked [+ AUX -- ] (Fig. 1f, pg. 5).

6. For Access Control applications batteries are optional. When batteries are not used, a loss of AC will result in the loss

of the output voltage. When the use of stand-by batteries is desired, they must be lead acid or gel type.

Connect battery to terminals marked [-- BAT + ] (Fig. 1g, pg. 5). Use two (2) 12VDC batteries connected in series for

24VDC operation (battery leads included). Use batteries - Casil CL1270 (12V/7AH), CL12120 (12V/12AH),

CL12400 (12V/40AH), CL12650 (12V/65AH) batteries BAZR2 batteries of an appropriate rating.

7. Connect appropriate signaling notification devices to AC FAIL & BAT FAIL (Fig. 1b, pg. 5) supervisory

relay outputs.

8. To delay AC reporting for 2 hrs. set dip switch [AC Delay] to the OFF position (Fig. 1c, pg. 5).

To delay AC reporting for 1 min. set dip switch [AC Delay] to the ON position (Fig. 1c, pg. 5).

Note: Must be set to the ON position for Burglar Alarm Applications.

9. To enable Fire Alarm Disconnect set dip switch [Shutdown] to ON position (Fig. 1c, pg. 5).

To disable Fire Alarm Disconnect set dip switch [Shutdown] to OFF position (Fig. 1c, pg. 5).

10. Trigger terminals are end of a line resistor supervised (10k ohms). Opening or shorting trigger terminals will cause

[DC] output to shutdown (Fig. 1d, pg. 5).

11. Place a jumper for non-latching FACP. A momentary short on these terminals resets FACP latching

[Trigger EOL Shutdown] (Fig. 1e, pg. 5).

12. For Access Control Applications: mount tamper switch (Sentrol model 3012 or equivalent) at the top of the enclosure.

Slide tamper switch bracket onto the edge or the enclosure approx. 2” from the right side (Fig. 4, pg. 7 or Fig. 6, pg. 9).

Connect tamper switch wiring to the Access Control Panel input or the appropriate reporting device.

Use 18 AWG or larger for all low voltage power connections.

Note: Take care to keep power-limited circuits separate from non power-limited wiring (220VAC, Battery).

Unit should be tested at least once a year for the proper operation as follows:

Output Voltage Test: Under normal load conditions, the DC output voltage should be checked for proper voltage level

eFlow3NV: 12VDC or 24VDC nominal rated @ 2A max.

Battery Test: Under normal load conditions check that the battery is fully charged, check specified voltage

(12VDC @ 13.2 or 24VDC @ 26.4) both at the battery terminal and at the board terminals marked [-- BAT + ] to ensure

that there is no break in the battery connection wires.

Note: Maximum charging current under discharges is 1.54A.

Note: Expected battery life is 5 years, however it is recommended changing batteries in 4 years or less if needed.

eFlow3NV Series - 3 -

Wiring:

Maintenance:

Page 4

LED Diagnostics:

Power Supply/Charger

Red (DC) Green (AC/AC1) Power Supply Status

ON ON Normal operating condition.

ON OFF Loss of AC. Stand-by battery supplying power.

OFF ON No DC output.

OFF OFF Loss of AC. Discharged or no stand-by battery. No DC output.

Power Distribution Module

Green (AC) Power Distribution Module Status

ON Normal operating condition.

OFF No Power Output.

Terminal Identification:

Power Supply/Charger

Terminal

Legend

L, N Connect 220VAC 50/60Hz to these terminals: L to hot, N to neutral (non power-limited) (Fig. 1a, pg.5).

– DC + 12VDC or 24VDC nominal @ 2A continuous output (power-limited output) (Fig. 1h, pg. 5).

Trigger EOL

Supervised

NO, GND

RESET

+ AUX – Auxiliary Power-Limited output rated @ 1A (unswitched) (power-limited output) (Fig. 1f, pg. 5).

AC Fail

NC, C, NO

Bat Fail

NC, C, NO

– BAT + Stand-by battery connections. Maximum charge current 1.54A (non power-limited) (Fig. 1g, pg. 5).

Function/Description

Fire Alarm Interface trigger input from a short or FACP. Trigger inputs can be normally open,

normally closed from an FACP output circuit (power-limited input) (Fig. 1d, pg. 5).

FACP interface latching or non-latching (power-limited) (Fig. 1e, pg. 5).

Indicates loss of AC power, e.g. connect to audible device or alarm panel. Relay normally energized

when AC power is present. Contact rating 1A @ 30VDC (power-limited) (Fig. 1b, pg. 5).

Indicates low battery condition, e.g. connect to alarm panel. Relay normally energized when DC power

is present. Contact rating 1A @ 30VDC. A removed battery is reported within 5 minutes.

Battery reconnection is reported within 1 minute (power-limited) (Fig. 1b, pg. 5).

Power Distribution Module

Terminal Legend

PD4/PD4CB

1P to 4P Positive DC power outputs.

1N to 4N Negative DC power outputs.

Function/Description

- 4 - eFlow3NV Series

Page 5

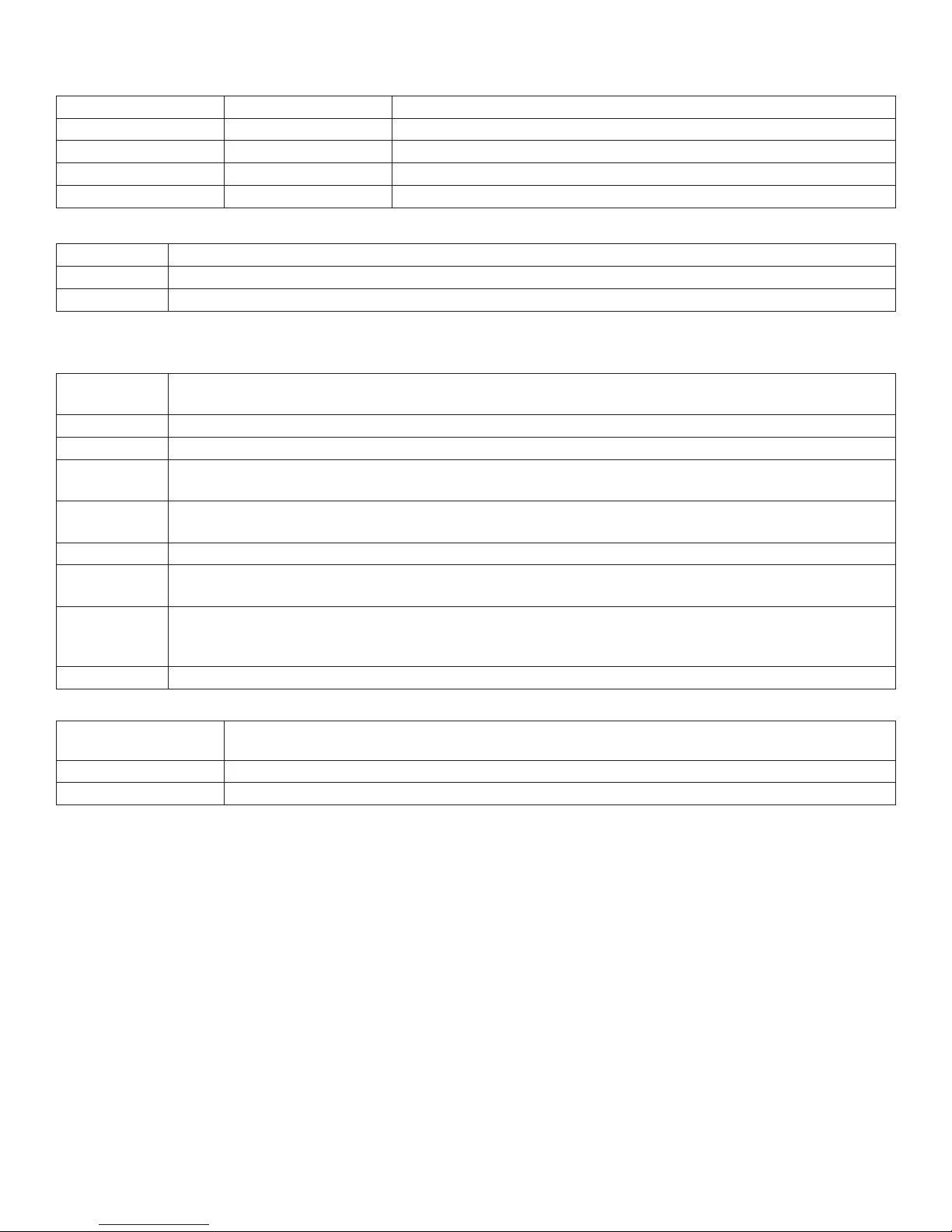

Fig. 1 - eFlow3NV Board configuration

OFF --- 24V

ON

1i

ON --- 12V

1h

--- DC +

3A

1g

--- BAT +

5A 250V

5A 250V

AC1

LG N

NC C NO NC C NO

1a 1b

AC FAIL

BAT FAIL

AC

AC DELAY SHUTDOWN

O

N

DC

1 min.

2 hr.

enable

disable

3A 32V

TRIGGER EOL

SUPERVISED

NO GND

RESET

1e 1f1d1c

+ AUX –

Trouble/Time Limited Warning of Stand-by Batteries:

The Time Limited Warning circuit must be connected for local or remote annunciation with an Amber or Red LED to indicate DC Trouble (low battery, loss of battery or when 95% of the stand-by battery has been depleted). Connect the circuit

to the Batt Fail relay contacts to an appropriate input of a Burglar Alarm or Access Control Panel. The following figure

shows the circuitry needed for local annunciation.

Fig. 2 - Battery trouble indication -

Wire one leg of a power source to the indicating lamp. Wire the second leg of the power source to the indicating lamp in

series with the battery fail relay contact terminals marked [BAT FAIL - C, NO] (Fig. 2, pg. 5).

BAT FAILAC FAIL

eFlow3NV Series - 5 -

POWER

SOURCE

NC C NO NC C NO

RED INDICATING

LAMP

Page 6

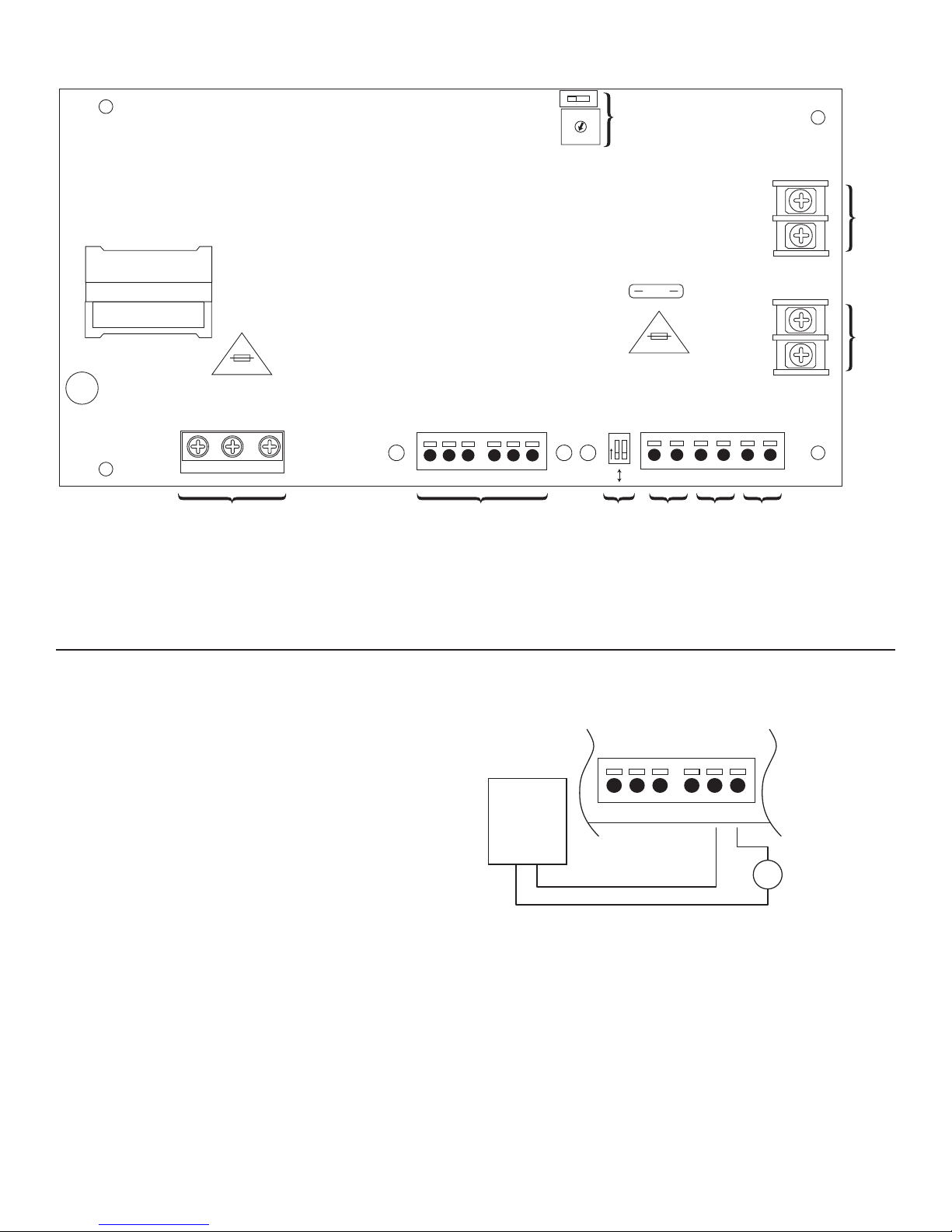

Power Distribution Module(s):

Replace fuses with the same type and rating 3.5A, 250V.

Fig. 3a - PD4 Power Distribution Board Fig. 3b - PD4CB - Power Distribution Board

F1 F2 F3 F4

2N

2P

1N

1P

DC Output to devices

1P-4P Power Outputs,

)

1N-4N Common Outputs

3N

3P

4N

4P

From Power Supply

)

(Factory Installed)

LED

Board

F1 F2 F3 F4

2N

2P

1N

1P

POWER OUTPUTS

DC Output to devices

1P-4P Power Outputs,

( )

1N-4N Common Outputs

3P

3N

4N

4P

From Power Supply

(Factory Installed)

LED

INPUT

Board

- 6 - eFlow3NV Series

Page 7

Edge of

Enclosure

to Access Control

Panel or

Reporting

Device

Enclosure

Sentrol

model # 3012

Tamper Switch

or equivalent

(Not Included)

Fig. 4 - eFlow3NV configuration

Door

Wire

Strap

(from

Enclosure

to Door)

Ground

Lug

L

G

N

5A 250V

220VAC

power mains

PD4/PD4CB

AC1

NC

C

Battery & AC

AC FAIL

NO

NC

C

NO

2 hr.

disable

TRIGGER EOL

RESET

– AUX +

1 min.

enable

SUPERVISED

GND NO

AC

DC

AC DELAY

O

SHUTDOWN

N

Supervision

BAT FAIL

Battery

Connections

Circuit

--- BAT +

Optional Rechargeable

Stand-by Battery

Switch Detail

Switch On - 12V

ON

Switch Off - 24V

ON

--- DC +

1

1

DC Output to devices

ON

OFF --- 24V

ON --- 12V

(refer to Fig. 3a or 3b

for board configuration pg. 6)

Optional Rechargeable

Stand-by Battery

CAUTION: When power supply board is set for 12VDC use only one (1) 12VDC stand-by battery.

Keep power-limited wiring separate from non power-limited. Use minimum 0.25" spacing.

7AH Rechargeable batteries are the largest batteries that can fit in this enclosure.

eFlow3NV Series - 7 -

An external battery enclosure must be used if using 12AH, 40AH or 65AH batteries.

Page 8

NEC Power-Limited Wiring Requirements for eFlow3NV Models:

Incorrect Wire

Correct Wire

Power-limited and non power-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25” away from any non power-limited circuit wiring. Furthermore, all power-limited circuit wiring

and non power-limited circuit wiring must enter and exit the cabinet through different conduits. One such example of this

is shown below. Your specific application may require different conduit knockouts to be used. Any conduit knockouts may

be used. For power- limited applications, use of conduit is optional. All field wiring connections must be made employing

suitable gauge CM or FPL jacketed wire (or equivalent substitute).

Optional battery enclosure must be mounted adjacent to the power supply.

Note: Refer to wire handling drawing below for the proper way to install the CM or FPL jacketed wire (Fig. 5a).

Fig. 5

220VAC Input

50/60Hz

(non power-limited)

Optional Battery

Enclosure

(non power-limited)

Supervisory,

Fire Alarm

Interface and

Aux. output

Connections

(power-limited)

Fig. 5a

Handling

Wire

Insulation

External

Jacketed

Shield

Handling

Power

Distribution

(powerlimited)

DC Outputs

(power-limited)

Battery

Connections

(non power-limited)

Solid Copper

Conductors

- 8 - eFlow3NV Series

Pull back

external jacketed

shield approx. 1/2”.

Page 9

Edge of

Enclosure

to Access Control

Panel or

Reporting

Device

Enclosure

Sentrol

model # 3012

Tamper Switch

or equivalent

(Not Included)

Fig. 6 - eFlow3NXV configuration

Door

Wire Strap

(from

Enclosure

to Door)

– AUX +

GND NO

--- BAT +

Battery connections

--- DC +

RESET

Battery & AC Supervision

TRIGGER EOL

disable

SUPERVISED

enable

SHUTDOWN

OFF --- 24V

ON --- 12V

PD4/PD4CB

NO

2 hr.

1 min.

AC DELAY

DC

AC

O

N

BAT FAIL

ON

Circuit

NC

NC

NO

C

C

AC FAIL

Switch Detail

Switch On - 12V

ON

Switch Off - 24V

ON

Ground

Lug

AC1

220VAC power mains

G

L

N

1

1

5A 250V

DC Output to devices

(refer to Fig. 3a or 3b

for board configuration pg. 6)

Optional Rechargeable

Stand-by Battery

Optional Rechargeable

Stand-by Battery

CAUTION: When power supply board is set for 12VDC use only one (1) 12VDC

stand-by battery.

Keep power-limited wiring separate from non power-limited. Use minimum 0.25" spacing.

12AH Rechargeable batteries are the largest batteries that can fit in this enclosure.

An external battery enclosure must be used if using the 40AH or 65AH batteries.

eFlow3NV Series - 9 -

Page 10

NEC Power-Limited Wiring Requirements for eFlow3NXV Models:

Incorrect Wire

Correct Wire

Power-limited and non power-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring

must remain at least 0.25” away from any non power-limited circuit wiring. Furthermore, all power-limited circuit wiring

and non power-limited circuit wiring must enter and exit the cabinet through different conduits. One such example of this

is shown below. Your specific application may require different conduit knockouts to be used. Any conduit knockouts may

be used. For power- limited applications, use of conduit is optional. All field wiring connections must be made employing

suitable gauge CM or FPL jacketed wire (or equivalent substitute).

Optional battery enclosure must be mounted adjacent to the power supply.

Note: Refer to wire handling drawing below for the proper way to install the CM or FPL jacketed wire (Fig. 7a).

Fig. 7

Supervisory, Fire Alarm Interface

and Aux. output Connections

(power-limited)

Optional Battery

Enclosure

(non power-limited)

DC Output

(power-limited)

220VAC Input

50/60Hz

(non power-

limited)

Power

Distribution

(power-limited)

Battery

Connections

(non power-

limited)

Fig. 7a

- 10 - eFlow3NV Series

Handling

Insulation

Solid Copper

Conductors

External

Jacketed

Shield

Wire

Handling

Pull back

external jacketed

shield approx. 1/2”.

Page 11

Enclosure Dimensions (BC300):

(

)

(

)

(

)

eFlow3NV, eFlow3N4V, eFlow3N4DV

13.5” x 13” x 3.25” (342.9mm x 330.2mm x 82.55mm)

1.40”

(36mm)

5.10”

(130mm)

1.20”

(31mm)

13.0”

(330mm)

1.40”

(36mm)

0.75”

(19mm)

4.85”

(123mm)

12.5”

(318mm)

11.0”

(279mm)

4.85”

(123mm)

1.40”

(36mm)

0.75”

(19mm)

1.20”

(31mm)

0.9375”

(24mm)

3.25”

(83mm)

1.20”

(31mm)

1.40”

(36mm)

5.10”

(130mm)

5.10”

(130mm)

3.25”

(83mm)

1.0”

(25mm)

1.0”

25mm

10.5”

267mm

1.0”

25mm

0.9375”

(24mm)

1.0”

(25mm)

3.25”

(83mm)

3.25”

(83mm)

6.5625”

(167mm)

eFlow3NV Series - 11 -

Page 12

Enclosure Dimensions (BC400):

eFlow3NXV, eFlow3NX4V, eFlow3NX4DV

15.5” x 12” x 4.5” (393.7mm x 304.8mm x 114.3mm)

1.5”

(38.1mm)

1.25”

(31.75mm)

4.5”

(114.3mm)

0.91”

(23.114mm)

1.5”

(38.1mm)

1.1”

(27.94mm)

4.615”

(117.22mm)

12.23”

(310.64mm)

4.615”

(117.22mm)

1.5”

(38.1mm)

1.1”

(27.94mm)

1.75”

(44.45mm)

0.91”

(23.114mm)

1.375”

(34.925mm)

1.125”

(28.575mm)

4.5”

(114.3mm)

1.25”

(31.75mm)

1.5”

(38.1mm)

2.0”

(50.8mm)

2.0”

(50.8mm)

5.0”

(127.0mm)

1.25”

(31.75mm)

1.5”

(38.1mm)

4.615”

(117.22mm)

4.615”

(117.22mm)

1.1”

(27.94mm)

1.5”

(38.1mm)

(393.7mm)

0.79”

(20.06mm)

1.75”

(44.45mm)

15.5”

1.25”

(31.75mm)

5.0”

(127.0mm)

- 12 - eFlow3NV Series

Page 13

Appendix A - Compatible Devices

A.1 Four (4) Wire Smoke Detectors

Table A-1 below lists four (4) wire smoke detectors compatible with eFlow3NV output.

System Sensor

Smoke Detector/Base

Detector Type

Max Stand-by

Current (mA)

Alarm

Current (mA)

B112LP Base 0.12 36

B114LP Base * *

B404B Base * *

DH100ACDC Photoelectric 0.15 0.70

DH100ACDCLP Photoelectric 0.15 0.70

DH100ACDCLPW Photoelectric 0.15 0.70

DH400ACDCI Ionization Duct 25 95

DH400ACDCP Photoelectric Duct 25 95

1112/24/D Ionization 0.05 50

1424 Ionization 0.10 41

1451 (w/B402B Base) Ionization 0.10 39

2112/24ATR Photoelectric 0.50 60/70

2112/24AITR Photoelectric 0.50 60/70

2112/24/D Photoelectric 0.05 50

o

2112/24T/D Photoelectric w/135

o

2112/24TSRB Photoelectric w/135

Thermal Supervisory Relay 15 45

Thermal 0.05 50

2312/24TB Photoelectric 0.12 50

2412 (12 volt) Photoelectric 0.12 77

2424 Photoelectric 0.10 41

2451 Photoelectric 0.10 39

2451TH (with/B402B Base) Photoelectric 0.10 39

2W-MOD Loop Test/Maintenance Mod. 30 50

4W-B (12/24 volt) Photoelectric I

3

4WT-B (12/24 volt) Photoelectric I

3

4WTA-B (12/24 volt) I

4WTR-B (12/24 volt) I

3

4WITAR-B (12/24 volt) I

Photo w/Isolated Therm/Sounder/Relay 0.05 50

2W-MOD2 I

RRS-MOD I

Photo w/Therm/Sounder 0.05 35

3

Photo w/Therm/Relay 0.05 35

3

Loop Test/Maintenance Mod. 0.05 *

3

Reversing Relay/Sync Module 0.05 *

w/Therm 0.05 23

3

0.05 23

6424 Projected Beam 10 28.4

Beam 1224(S) Projected Beam 17 38.5

* Contact manufacturer for current draws.

A.2 Relays

Table A-2 below lists relays compatible with eFlow3NV output.

Manufacturer Model Current (mA) Manufacturer Model Current (mA)

PR-1**

PR-2*

System Sensor

* Compatible only with eFlow3NV, eFlow3NXV, eFlow3N4V, eFlow3NX4V.

** Compatible only when unit is set for 24VDC.

eFlow3NV Series - 13 -

PR-3*

EOLR-1

R-10T**

R-14T**

15

30

30

30

23

23

System Sensor

R-20T**

R-24T**

R-10E**

R-14E**

R-20E**

R-24E**

40

40

23

23

40

40

Page 14

Notes:

- 14 - eFlow3NV Series

Page 15

Notes:

Altronix is not responsible for any typographical errors. Product specifications are subject to change without notice.

140 58th Street, Brooklyn, New York 11220 USA | phone: 718-567-8181 | fax: 718-567-9056

website: www.altronix.com | e-mail: info@altronix.com | Lifetime Warranty | Made in U.S.A.

IIeFlow3NV Series F02P

eFlow3NV Series - 15 -

MEMBER

Page 16

Power Supply/Chargers Operating Guide

Models Include:

Model

Input

220VAC, 50/60Hz

eFlow3NV,

eFlow3N4V,

eFlow3N4DV

2.1A 2A 2A

eFlow3NXV,

eFlow3NX4V,

eFlow3NX4DV

The eFlow3NV series power supply/chargers convert a 220VAC 50/60Hz input to a 12VDC or 24VDC output.

Stand-by Specifications:

Output

12VDC 24VDC

Overview:

Power-

Limited

3

Auxiliary Power-Limited

Output (unswitched)

1A 960mV

Ripple

Voltage

Battery

7AH 0.4A/2A N/A 1.5 Hours/2A

12AH 1A/2A 0.3A/2A 3.5 Hours/2A

40AH 2A/2A 1.2A/2A Over 4 Hours/2A

65AH 2A/2A 1.5A/2A Over 4 Hours/2A

Burg. Applications

4 hr. Stand-by/15 min. Alarm

Fire Applications

24 hr. Stand-by/5 min. Alarm

Access Control

Applications Stand-by

Battery Backup:

• Built-in charger for sealed lead acid or gel type batteries.

• Maximum charge current 1.54A.

• Automatic switch over to stand-by battery when AC fails. Transfer to stand-by battery power is instantaneous

with no interruption.

LED Diagnostics:

Red (DC) Green (AC/AC1) Power Supply Status

ON ON Normal operating condition.

ON OFF Loss of AC. Stand-by battery supplying power.

OFF ON No DC output.

OFF OFF Loss of AC. Discharged or no stand-by battery. No DC output.

CUT ALONG DOTTED LINE

Installing Company: _________________________________ Service Rep. Name: ___________________________________________________

Address: _______________________________________________________________________ Phone #: _______________________________

Refer to the eFlow Power Supply/Chargers Installation Guide: IIeFlow3NV Series, Rev. 3NVRP122713 for complete

instructions. This sheet is to be removed, framed and posted next to the unit.

Rev. 3NVRP122713

Loading...

Loading...