Efka SM210A5710 Instruction Manual

Attention!

Parameter numbers

have been changed!

STEPPING MOTOR CONTROL SM210A5710

SM210A5710

KL2359

INSTRUCTION MANUAL

No. 402277 English

FRANKL & KIRCHNER EFKA OF AMERICA INC. EFKA ELECTRONIC MOTORS

GMBH & CO KG SINGAPORE PTE. LTD.

EFKA SM210A57103

CONTENTS Page

1 IMPORTANT SAFETY INSTRUCTIONS 7

2 RANGE OF APPLICATIONS 8

2.1 USE IN ACCORDANCE WITH REGULATIONS 8

3 SCOPE OF SUPPLY 8

3.1 SPECIAL ACCESSORIES 8

4 TECHNICAL DATA OF THE STEPPING MOTOR CONTROL 8

5 CONNECTION SCHEME FOR SM210A 9

5.1 OPERATING THE STEPPING MOTOR CONTROL WITH A SEWING CONTROL (E. G. AB62CV....) 9

6 SOCKET CONNECTORS 10

6.1 POSITION OF THE SOCKET CONNECTORS 10

6.2 CONNECTION DIAGRAM 10

7 STEPPING MOTOR CONTROL FUNCTIONS 13

7.1 STEPPING MOTOR FUNCTION “SYNCHRONOUS OPERATION“ (PA. 290=0) 13

7.1.1 TIMING DIAGRAM “SYNCHRONOUS STEPPING MOTOR OPERATION“ (PA. 290=0) 15

7.2 STEPPING MOTOR FUNCTION “AUTOMATIC METERING D EVICE“ (PA. 290=1 / 2) 16

7.2.1 TIMING DIAGRAM 1 “A UTOMATIC METERING DEVICE“ (PA. 290=1) 18

7.2.2 TIMING DIAGRAM 2 “A UTOMATIC METERING DEVICE AT THE START OF THE SEAM“ (PA. 290=1) 19

7.2.3 TIMING DIAGRAM1 “A UTOMATIC METERING DEVICE AT THE SEAM END“ (PA. 290=2) 20

7.2.4 TIMING DIAGRAM 2 “A UTOMATIC METERING DEVICE AT THE SEAM END“ (PA. 290=2) 21

7.3 STEPPING MOTOR FUNCTION “EXPANDER FEEDING“ (PA. 290=3) 22

7.3.1 TIMING DIAGRAM “EXPANDER FEEDING“ (PA. 290=3) 24

7.3.2 TIMING DIAGRAM “EXPANDER FEEDING/SYNCHRONOUS STEPPING MOTOR OPERATION“ (PA.290=3) 25

7.4 STEPPING MOTOR FUNCTION “FULLNESS SETTING“ (PA. 290=5) 26

7.4.1 TIMING DIAGRAM “FULLNESS SETTING“ (PA. 290=5) 27

7.5 TIMING D IAGRAM “MACHINE FOR ATTACHING CUFF AND HEEL TAPE WITH METERING DEVICE AT

THE SEAM END“ (PA. 290=7) 29

7.5.1 TIMING DIAGRAM “MACHINE FOR ATTACHING CUFF AND HEEL TAPE WITH METERING DEVICE AT THE

SEAM END“ (PA. 290=7) 31

7.6 STEPPING MOTOR FUNCTION “PULLER“ (PA. 290=8 / 9) 32

7.6.1 TIMING DIAGRAM “PULLER“ (P A. 290=8) 34

7.6.2 CONNECTION SCHEME FOR PULLER OPERATION (PA . 290=9) WITH OTHER CONTROLS 35

7.6.3 TIMING DIAGRAM “PULLER“ (P A. 290=9) 37

EFKA SM210A57105

CONTENTS Page

8 PARAMETER LIST 38

8.1 OPERATOR LEVEL 38

8.2 TECHNICIAN LEVEL 39

8.3 SUPPLIER LEVEL 44

8.4 INSERTABLE STRIPS FOR V810/V820 CONTROL PANELS 47

1 Important Safety Instructions

EFKA SM210A57107

When using an EFKA drive and accompanying devices (e g

for sewing machines), basic safety precautions should always

be followed, including the following:

§ Read all instructions thoroughly before using this drive.

§ Drive, its accessories and accompanying devices should be

mounted and put into operation by qualified personnel in

accordance with the guidelines provided in the instruction

manual.

To reduce the risk of burns, fire, electric shock, or

personal injury:

§ Use this drive only for its intended use as described in the

instruction manual.

§ Use only attachments recommended by the manufacturer or

as contained in the instruction manual.

§ Do not operate without corresponding protective devices.

§ Never operate this drive if one or more parts (e. g. cables,

plugs) are damaged, if it is not working properly, if any

damages can be identified or are to be suspected (e. g. after

it has been dropped). Only qualified personnel are

authorized to make adjustments, eliminate faults and

complete repair work.

§ Never operate the drive with the air openings blocked. Keep

ventilation openings of the drive free from the accumulation

of lint, dust and loose cloth.

§ Never drop or insert any object into any opening.

§ Do not use drive outdoors.

§ Do not operate where aerosol (spray) products are being

used or where oxygen is being administered.

§ To disconnect, turn off main switch, then remove plug from

outlet.

§ Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

§ Keep fingers away from all moving machine parts. Special

care is required e. g. around the sewing machine needle and

the V-belt.

§ Before mounting and adjusting accompanying devices, i.e.

position transmitter, reversing device, light barrier, etc.,

disconnect drive from mains (turn off main switch, remove

mains plug from outlet [DIN VDE 0113 part 301; EN

60204-3-1; IEC 204-3-1]).

§ Always switch off (0) machine and remove plug from outlet,

when removing covers, mounting accompanying devices,

position transmitter especially, light barrier, etc., or any

other devices mentioned in the instruction manual.

§ Only qualified personnel are authorized to work on the

electrical components.

§ Work on high voltage circuit areas is forbidden, except as

stated in the respective regulations, e.g. DIN VDE 0105 part

1.

§ Only specially trained personnel are authorized to complete

repair work.

§ Cables to be wired must be protected against expectable

strain and fastened adequately.

§ Cables near moving machine parts (e. g. V-belts) must be

wired ata aminimum distance of 25 mm (see DIN VDE

0113 part 301; EN 60204-3-1; IEC 204-3-1).

§ For safety it is preferred to wire the cables separately from

each other.

§ Before connecting the mains line make sure that the mains

voltage corresponds to the specifications on the motor rating

plate and on the nameplate of the power pack.

§ Connect this drive to a properly grounded outlet only. See

Grounding Instructions.

§ Electric accompanying devices and accessories must only be

connected to safety low voltage.

§ EFKA DC drives are protected according to overvoltage

class 2 (DIN VDE 0160 § 5.3.1).

§ Observe all safety guidelines before undertaking

conversions or modifications.

§ For repair and maintenance use only original replacement

parts.

Warnings in the instruction manual which

point out particular risks of personal

injury or risk to the machine are marked

with this symbol wherever applicable.

This symbol is a warning on the control

and in the instruction manual. It indicates

hazardous voltage.

CAUTION – In the case of failure this

area can be current-carrying even after

having turned the power off (non

discharged capacitors).

§ The drive is not an independently operating unit, but is

designed to be incorporated into the machinery. It must not

be put into service until the machinery into which it is to be

incorporated has been declared in conformity with the

provisions of the EC Directive.

Save these instructions for future reference.

EFKA SM210A5710

8

2 Range of Applications

The stepping motor control can be used separately or as expansion unit for EFKA drives (AB60D, AB62CV, AB220A) and for

other controls in puller mode 9. See chapter „Stepping Motor Function ‘Puller’”.

2.1 Use in Accordance with Regulations

The drive is not an independently operating machine, but is designed to be incorporated into other machinery. It must not be

put into service until the machinery into which it is to be incorporated has been declared in conformity with the provisions of

the EC Directive (Appendix II, paragraph B of the Directive 89/392/EEC and supplement 91/368/EEC).

The drive has been developed and manufactured in accordance with the relevant EC standards:

EN 60204-3-1:1990 Electrical equipment of industrial machines:

Particular requirements for industrial sewing machines, sewing units and sewing systems.

The drive is to be operated only in dry areas:

CAUTION

When selecting the installation site and the layout of the connecting cable, the Safety

Instructions in Section 1 must be followed with no exceptions.

Particular attention should be paid to maintaining the proper distance from moving parts!

3 Scope of Supply

1 Stepping motor control SM210A5710

1 Set of standard accessories B157

consisting of: Documentation

1 Set of accessories Z55

consisting of 37-pin SubminD plug

Potential equalization cord

3.1 Special Accessories

Stepping motor SM200 part no. 7900069

Stepping motor SM250 part no. 7900070

Connecting cable from the stepping motor control to the AB62CV d.c. drive part no. 1113113

Connecting cable from the stepping motor control to the AB220A d.c. drive part no. 1113172

Control panel Variocontrol V810 part no. 5970153

Control panel Variocontrol V820 part no. 5970154

4 Technical Data of the Stepping Motor Control

Motor driver voltage 35-45VDC

8 inputs 24VDC, active high/low

2 analog inputs 5VDC, Ri max. 1kΩ

5 outputs open collector, max. 60VDC, 0.5A, sum <2A

Mains voltage 230VAC, 50/60Hz

Stepping motors 2 phase s, with 4, 6, 8 connections, max. 3A/phase

Stepping motor control bipolar chopper, CW/CCW, half step

Weight 4.0 kg

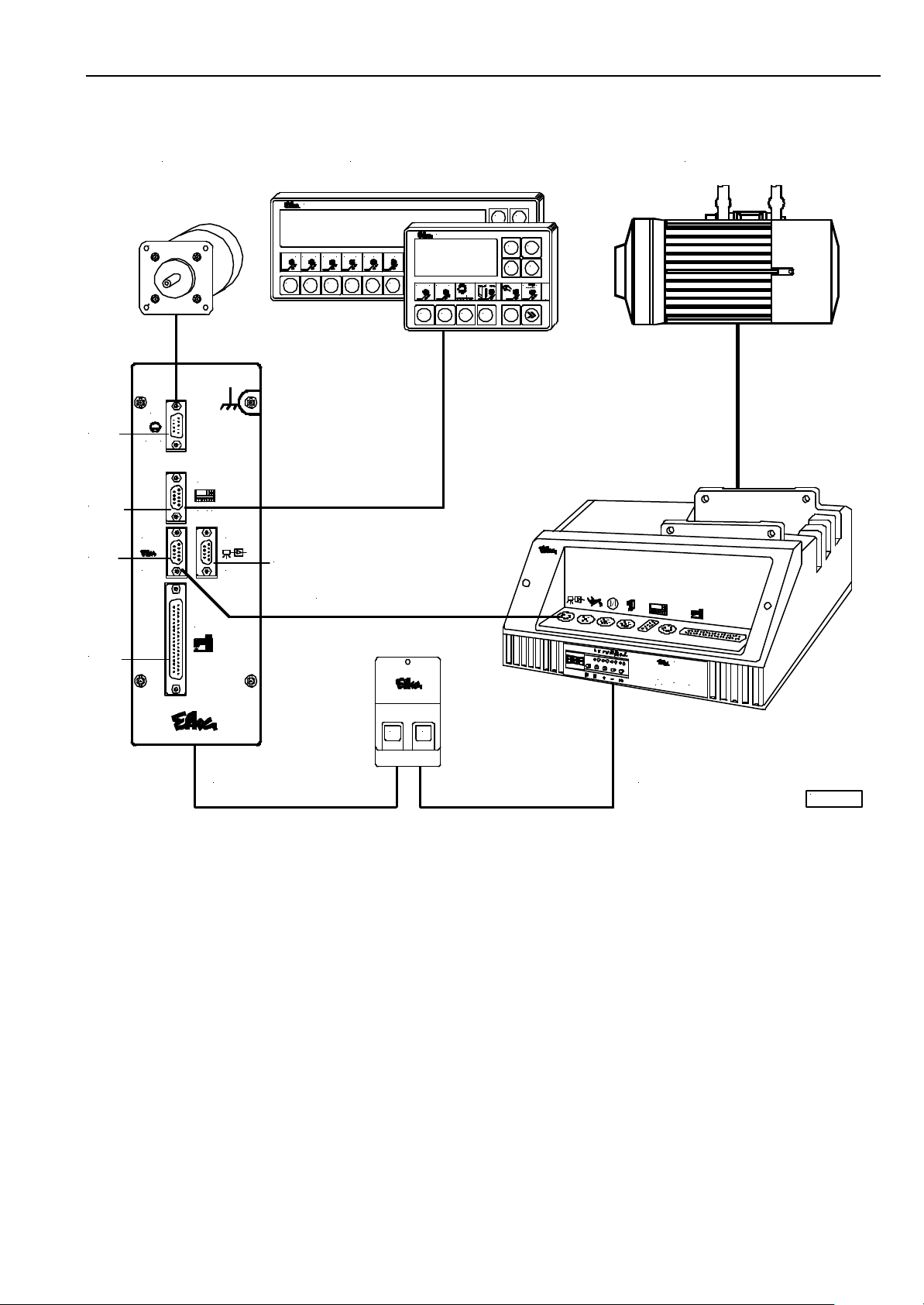

5 Connection Scheme for SM210A

mot

V810/V820

DC1600

EFKA SM210A57109

B5

B776

B18

M

motB51

B776

V8

. .

B18

control LSM...

B19

ST1

variocontrol 820

21 3

1 2 3 4 5 6

87654 11

B19

Nr. 1113113

9 10 12

1 2 3

1

variocontrol 810

4

2

P E

P

E

E

-

+

1

M

1

4

SM 01

43

M

ST1

0 I

SM210A.... AB62CV....

euramot

Steuerung Control Contrôle

Typ

AB62CV1466

KL2358

AB62CV.... control (B18) and SM210A....control (B18) are connected by adapter cord no. 1113113.

If a light barrier is required for the sewing process it must be connected to socket B9 on the stepping motor control. The light

barrier signal is transmitted via the connecting cable from the SM210A to the sewing drive.

5.1 Operating the Stepping Motor Control with a Sewing Control (e. g. AB62CV....)

Set parameter 162 of the sewing control with which communication is to be established, to “1”.

EFKA SM210A5710

10

M1L

M1L

M1L

M1L

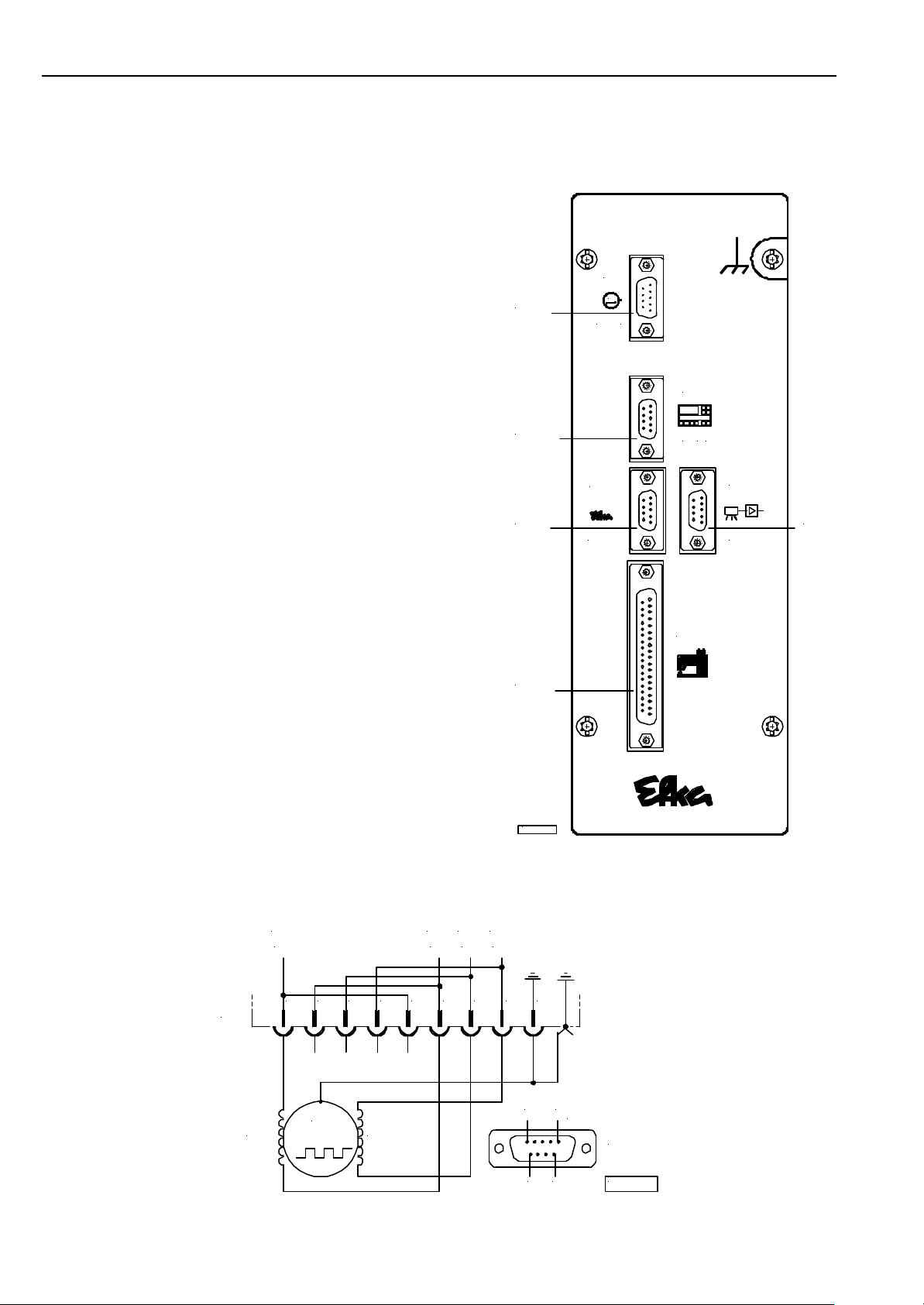

6 Socket Connectors

6.1 Position of the Socket Connectors

B5 Socket for stepping motor 1

B18 Socket for light barrier module or

transmission line

B19 Socket for light barrier module

B776 Socket for V810/V820 control panel

ST1 Socket for inputs and outputs of the solenoid

valves / displays / pushbuttons and switches

B5

B776

B18

ST1

mot1

B18

control

B5

M

B776

V8 . .

B19

B19

LSM...

ST1

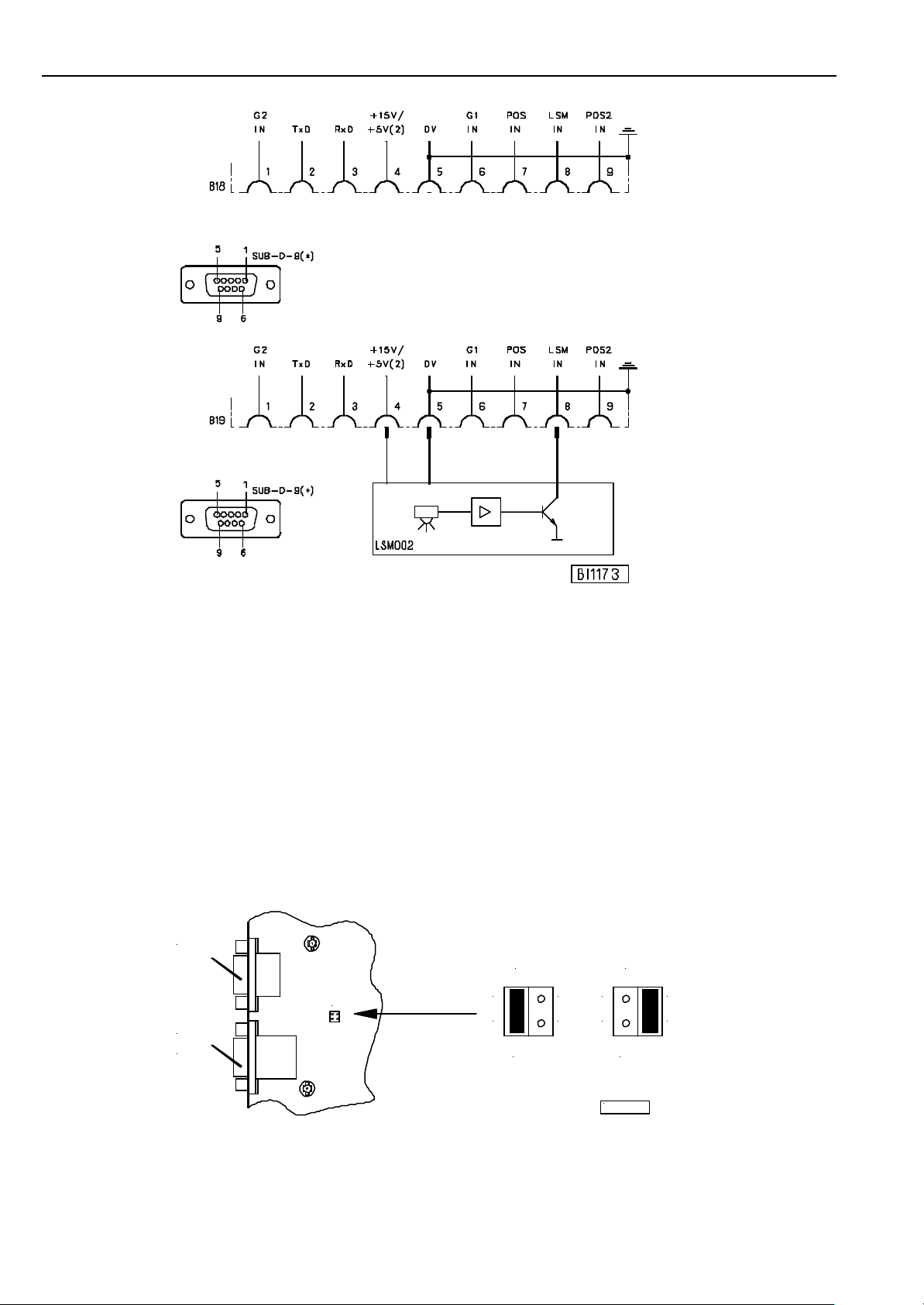

6.2 Connection Diagram

B5

PH2

KL2355

2R

M

PH1

2L

54 6321

1L1R

987

51

SUB-D-9

(*)

96 KL2443

EFKA SM210A571011

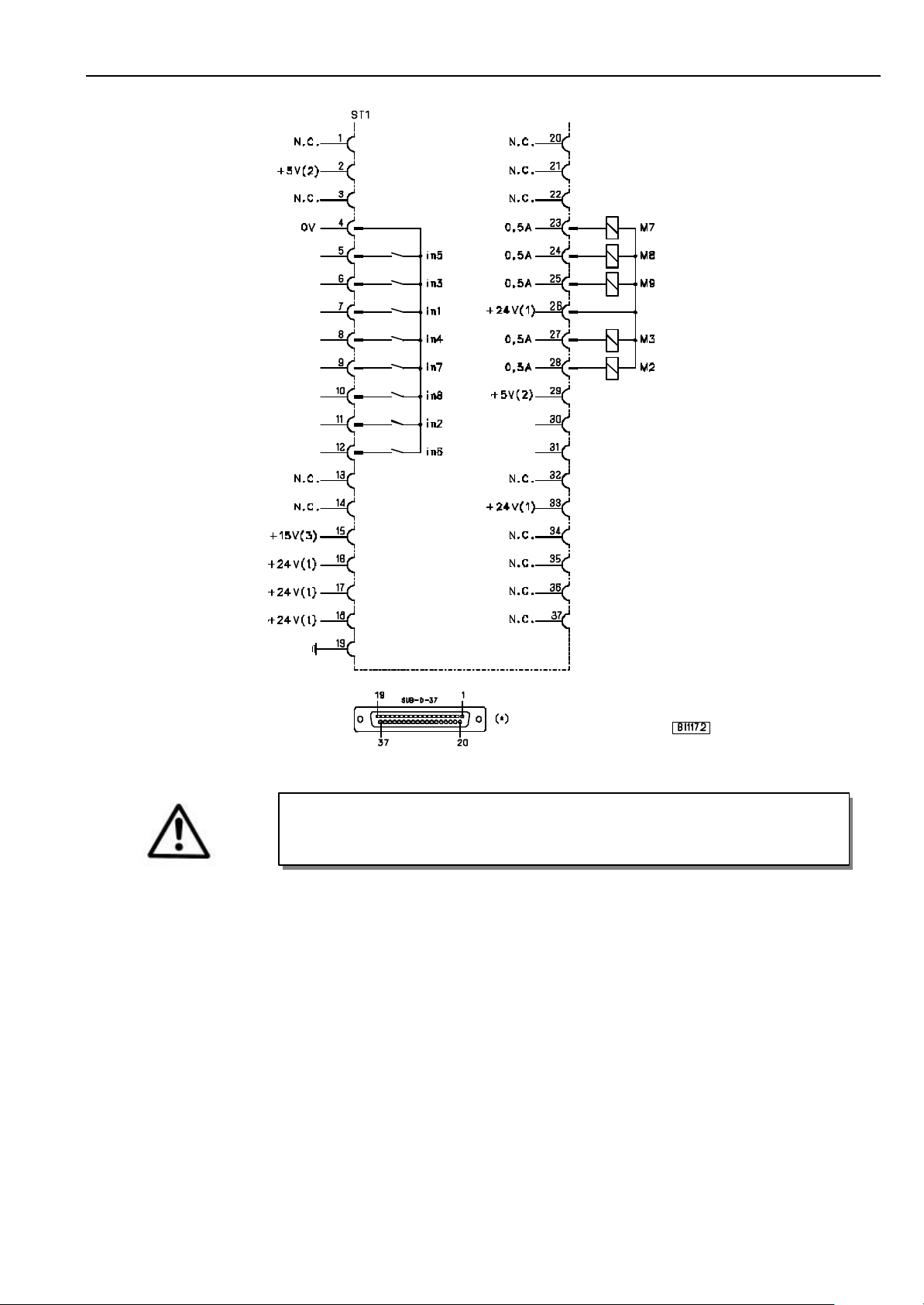

ATTENTION

When connecting the outputs, ensure that a total power of 48VA constant load will not

be exceeded !

in1 - Input 1 M2 - Output 2

in2 - Input 2 M3 - Output 3

in3 - Input 3 M7 - Output 7

in4 - Input 4 M8 - Output 8

in5 - Input 5 M9 - Output 9

in6 - Input 6

in7 - Input 7

in8 - Input 8

The input and output functions depend on the mode set with parameter 290.

1) Nominal voltage 24V, no-load voltage max. 30V momentarily after power On

2) Nominal voltage 5V, I

3) Nominal voltage 15V, I

*) Front view (component side) of the socket and/or rear view (soldering side) of the plug

= 20mA

max

= 30mA

max

EFKA SM210A5710

12

POS IN - Input for position

POS2 IN - Input for position 2

G1/G2 IN - Input for generator impulses

TXD/RXD - Serial transmission lines

LSM IN - Possibility of connecting a light barrier module to socket B18/8

(sensing of the signal upon switching to 0V)

LSM002 - Reflection light barrier module

For external devices there is a supply voltage of +5Von socket B19/4. After opening the cover, this voltage can be changed to

+15V by moving a multipole connector J3 to a different position on the printed circuit board.

+5V = Connect lefthand pins 1 and 2 with jumper (factory setting)

+15V = Connect righthand pins 3 and 4 with jumper

B776

B18

B19

J3

J3

1 3

2 4

J3

1

2

+15V+5V

3

4

KL2444

2) Nominal voltage 5V, I

= 20mA

max

*) Front view (component side) of the socket and/or rear view (soldering side) of the plug

EFKA SM210A571013

7 Stepping Motor Control Functions

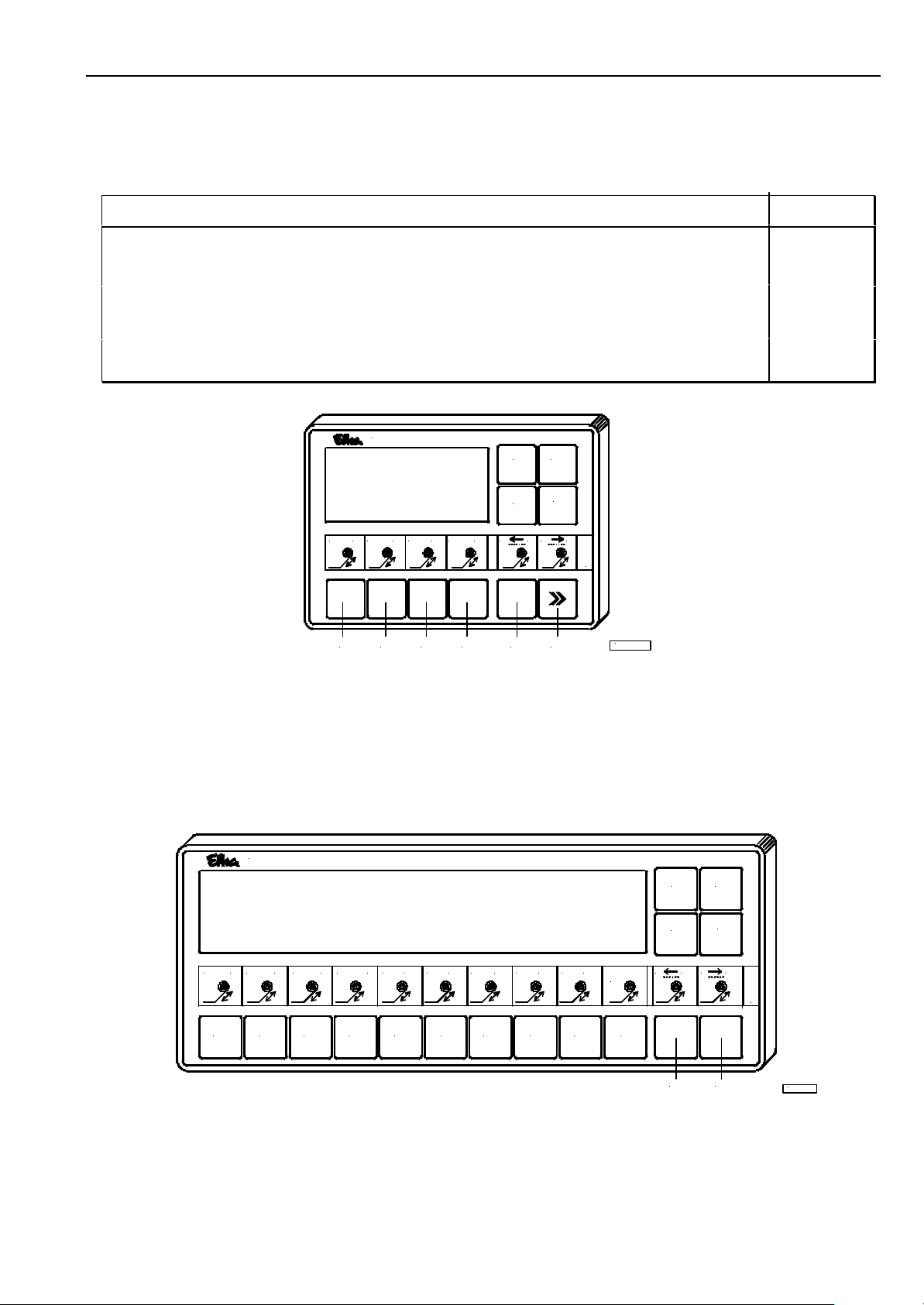

7.1 Stepping Motor Function “Synchronous Operation“ (Pa. 290=0)

Functions Parameter

Metering device 290 = 0

Insertable strip SM 05 for V810 control panel 291 = 5

Insertable strip SM 05 for V820 control panel 292 = 5

Connection of a pushbutton for tape cutter to socket ST1/7 (in1)

Connection of a pushbutton for selection of tape tension 8...1 and/or 18...1 to socket ST1/6 (in3)

Connection of a pushbutton for selection of tape tension 1...8 and/or 1...18 to socket ST1/8 (in4)

Connection of a pushbutton for metering device by means of a sensor on socket ST1/5 (in5)

Connection of a pushbutton for metering device on socket ST1/12 (in6)

variocontrol 810

P

E

-

+

1 2 3 4 5 6

1 32

4 A B

17 8 1 8

8

SM 05

KL2445

Pushbutton 1 = - Setting tape tension 1 or 2 (ratio stepping motor/d.c. drive)

Pushbutton 2 = - Setting tape tension 3 or 4 (ratio stepping motor/d.c. drive)

Pushbutton 3 = - Setting tape tension 5 or 6 (ratio stepping motor/d.c. drive)

Pushbutton 4 = - Setting tape tension 7 or 8 (ratio stepping motor/d.c. drive)

Pushbutton A = - Selection of tape tension 8...1 (parallel with input in3)

Pushbutton B = - Selection of tape tension 1...8 (parallel with input in4)

variocontrol 820

1 2 3

4 5 6 7 8 9 10 11 12 13

14

15 1716 18 1181

C

E

P

-

+

18

SM 05

1 2

3 4 5 6

7

98

0

B

A

Pushbutton 1...9 = - Setting tape tension 1...18 (ratio stepping motor/d.c. drive)

Pushbutton 0 = - Correction factor for switching between 2 tape tension values

Pushbutton A = - Selection of tape tension 18...1 (parallel with input in3)

Pushbutton B = - Selection of tape tension 1...18 (parallel with input in4)

KL2446

EFKA SM210A5710

14

Valid parameters if parameter 290 = 0 (synchronous stepping motor operation)

Parameter Functions max min Preset

002 c3 Number of stepping motor steps for metering device 9999 0 600

051 01- Value 1 of ratio on pushbutton 1 (V810/V820) 999 10 180

052 02- Value 2 of ratio on pushbutton 1 (V810/V820) 999 10 200

053 03- Value 3 of ratio on pushbutton 2 (V810/V820) 999 10 230

054 04- Value 4 of ratio on pushbutton 2 (V810/V820) 999 10 270

055 05- Value 5 of ratio on pushbutton 3 (V810/V820) 999 10 320

056 06- Value 6 of ratio on pushbutton 3 (V810/V820) 999 10 380

057 07- Value 7 of ratio on pushbutton 4 (V810/V820) 999 10 450

058 08- Value 8 of ratio on pushbutton 4 (V810/V820) 999 10 500

059 09- Value 9 of ratio on pushbutton 5 (V820) 999 10 550

060 10- Value 10 of ratio on pushbutton 5 (V820) 999 10 600

061 11- Value 11 of ratio on pushbutton 6 (V820) 999 10 650

062 12- Value 12 of ratio on pushbutton 6 (V820) 999 10 700

063 13- Value 13 of ratio on pushbutton 7 (V820) 999 10 750

064 14- Value 14 of ratio on pushbutton 7 (V820) 999 10 800

065 15- Value 15 of ratio on pushbutton 8 (V820) 999 10 850

066 16- Value 16 of ratio on pushbutton 8 (V820) 999 10 880

067 17- Value 17 of ratio on pushbutton 9 (V820) 999 10 900

068 18- Value 18 of ratio on pushbutton 9 (V820) 999 10 940

069 19- Value 19 of ratio on pushbutton 0 (V820) 999 10 960

070 --- Value 20 of ratio on pushbutton 0 (V820) 999 10 230

071 21- Value 21 of ratio on pushbutton 0 (V820) 999 0 208

112 n1 Fixed stepping motor speed with asynchronous operation [RPM] 600 0 100

113 n2 Fixed stepping motor speed with manual operation by means of pushb. A / B [RPM] 600 0 10

120 SnS From this sewing drive speed onwards signal M9 is emitted at the SM control 9990 0 0

130 rPd Select how to start metering device 7 1 1

131 bEE End of metering device at the start of the seam / seam end 2 0 0

132 Flo Lift sewing foot when feeding the tape On/Off 1 0 1

134 t7 Prolongation of blowing signal during metering device 9990 0 0

135 t5 Delay time until start of stepping motor for metering device [ms] 990 0 300

136 nFd Initiate end of stepping motor operation by thread trimming (see Parameter List) 1 0 1

137 nEd Initiate end of stepping motor operation by seam end (see Parameter List) 1 0 1

140 mbS Activate tape cutting by means of external pushbutton on input in1 / pedal –1 / 2 0 0

141 rbS Stepping motor runs parallel during tape cutting On/Off 1 0 0

142 t6 Activation time when operating the tape cutter manually at machine standstill [ms] 990 0 300

143 Ft2 Tape cutter until seam end or over time 1 0 0

152 SbS Function start tape tension. Last tape tension value or value selected by means 1 0 0

190 mbS Ratios are selected via inputs in3 and in4 1 0 0

220 d01 Percental adaptation of the stepping motor speed up to 500 RPM 200 0 100

221 d02 Percental adaptation of the stepping motor speed up to 1000 RPM 200 0 100

222 d03 Percental adaptation of the stepping motor speed up to 1500 RPM 200 0 100

223 d04 Percental adaptation of the stepping motor speed up to 2000 RPM 200 0 100

224 d05 Percental adaptation of the stepping motor speed up to 2500 RPM 200 0 100

225 d06 Percental adaptation of the stepping motor speed up to 3000 RPM 200 0 100

226 d07 Percental adaptation of the stepping motor speed up to 3500 RPM 200 0 100

227 d08 Percental adaptation of the stepping motor speed up to 4000 RPM 200 0 100

228 d09 Percental adaptation of the stepping motor speed up to 4500 RPM 200 0 100

229 d10 Percental adaptation of the stepping motor speed up to 5000 RPM 200 0 100

230 c7 Correction factor when switching to fast tape feeding 9999 0 25

231 c8 Correction factor when switching to slow tape feeding 9999 0 90

291 810 Selection of insertable strip for V810 5 1 5

292 820 Selection of insertable strip for V820 5 1 5

293 tF1 Function of pushbutton A on the V810/V820 control panels 10 0 0

294 tF2 Function of pushbutton B on the V810/V820 control panels 10 0 0

pedal -2

of pushbutton 1

See chapter “Parameter List” for values of the general parameters as well as for more detailed explanations of the above

parameters.

DC drive parameters:

Sign Function Parameter

n1 Positioning speed 110

n2 Maximum speed 111

n7 Trimming speed 116

t3 Start delay from lifted foot 202

7.1.1 Timing Diagram “Synchronous Stepping Motor Operation“ (Pa. 290=0)

1

-

1/2

0

+

-1

-2

EFKA SM210A571015

MODE-0a

POS.1

ST2/20

DC

POS.2

ST2/21

FL

ST2/35

SM

SM

in1

ST1/7

in2

ST1/11

SM

in6

ST1/12

M2

ST1/28

M3

ST1/27

M7

ST1/23

M8 (BM)

ST1/24

M9

ST1/25

n

t3 tx

n2 n1 n2 n7

9

(FF)

(BL)

(SML)

(DR)

SM SM

10

MODE-0b

Abbreviations for d.c. drive:

POS1 = Position 1 on the sewing machine

POS2 = Position 2 on the sewing machine

FL = Sewing foot lift

Abbreviations for stepping motor:

SM>> = Direction of rotation of stepping motor: cw (speed synchronous with d.c. drive)

SM<< = Direction of rotation of stepping motor: ccw (speed synchronous with d.c. drive)

in1 = Pushbutton for tape cutter

in2 = Pushbutton for metering device

M3 (BL) = Signal “blowing”

M7 (SML) = Signal “stepping motor running”

M8 (BM) = Tape cutter

M9 (DR) = Signal “direction of rotation”

*9 Synchronous operation according to d.c. drive speed. The transmission ratios are selected by means of pushbuttons 1...4

on V810 and pushbuttons 1...9 on V820.

*10 Signal “direction of rotation remains On until the direction of rotation is reversed.

Loading...

Loading...