Efka DC 1550, AB320A5200 User Manual

CONTROL AB320A5200

0

I

P

E

+

-

>>

KL2334a

LIST OF PARAMETERS

CONNECTION DIAGRAM

TIMING DIAGRAMS

No. 402286 English

FRANKL & KIRCHNER EFKA OF AMERICA INC. EFKA ELECTRONIC MOTORS

GMBH & CO KG SINGAPORE PTE. LTD.

3

EFKA AB320A5200

CONTENTS Page

1 Table of Adapter Cords 5

2 Putting into Service 6

3 Setting and Putting into Service with the Aid of the Fast Installation Routine (SIR) 7

4 Operating Elements and Socket Connectors 8

4.1 Position of Operating Elements and Displays 8

4.2 Position of the Socket Connectors 9

4.3 Connection Diagram 10

4.4 Connection of a Sewing Light with Transformer 13

4.5 Adapter Cords 14

5 Timing Diagrams 29

6 List of Parameters 56

6.1 Preset Values Depending on Mode 56

6.2 Operator Level 58

6.3 Technician Level 60

6.4 Supplier Level 65

7 Error Displays 78

8 Slide-in Strips for the V810/V820 Control Panels 79

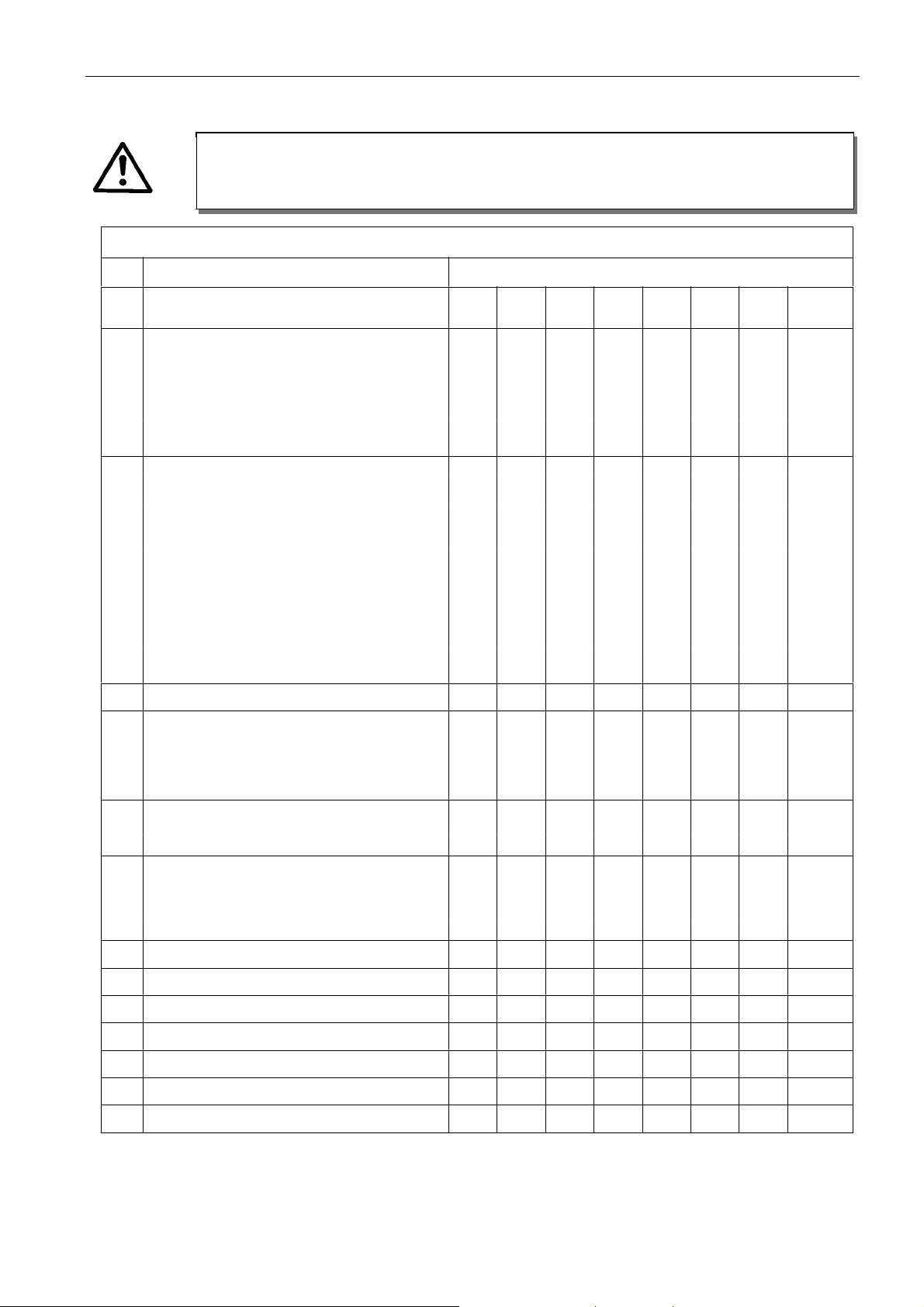

1 Table of Adapter Cords

Before switching functional sequences, detach cables from the inputs and outputs! Please ensure that the

machine installed provides the functional sequence to be set! Then proceed with the setting using parameter

Setting the functional sequence using parameter 29 0

Mode Designation Adapter Outputs

5

ATTENTION!

290!

EFKA AB320A5200

Power transistors !!!! FL VR M1 M2 M3 M4 M5 M6

0 Lockstitch; e. g. Functions FL VR FA1 FA2 FW FA1+2 ML MST

Brother (737-113, 737 -913) 1112814 FL VR FA1 + FA2 FW

Aisin (AD3XX, AD158, 3310; EK1) 1112815 FL VR FA1 + FA2 FW

Pfaff (563, 953, 1050, 1180) 1112841 FL VR FA1 FA2 FW ML

Dürkopp Adler (210, 270) 1112845 FL VR FA1 + FA2 FW

2 Lockstitch; e. g. Functions FL VR FA FSPL FL1 ML MST

Singer (212 UTT) 1112824 FL VR FA FSPL FL1

3Lockstitch; e. g. Dürkopp Adler (467) FL VR FA FSPL FW ML MST

4 Chainstitch; e. g. Union Special Functions FL FA-R M1 FA-V FW STV ML

(34000 and 36200 replacement for US80A) 1112865 FL FA-R FA-V FW ML

(CS100 and FS100) 1112905 FL FA-R M1 FA-V FW ML

5 Chainstitch; parallel sequence Functions FL STV M1 M2 M3 M4 ML MST

Bag sewing machine Union Special Functions FL IMP BR ML MST

Yamato (VC series) 1112818 FL STV FA FW

Yamato (VG series) 1113178 FL STV FA FW ML

Kansai (RX 9803) 1113130 FL FA FW ML

Pegasus (W500/UT, W600/UT/MS 1112821 FL STV FA FA FW

with or without st itch condensing)

Brother (FD3-B257) 1112822 FL STV FA FA FW

Union Special (34700) 1112844 FL STV FA FA FW NK

Global (CB2803-56) 1112866 FL FA

Rimoldi (F27) 1113096 FL FW FAO FAU ML

6 Chainstitch; tape cutter/fast scissors FL STV M1 M2 AH1 AH2 ML MST

7 Overlock FL KS M1 M2 AH FSPL ML MST

8 Backlatch Functions FL PD≤≤≤≤-1 PD≥≥≥≥1PD≥≥≥≥1* ML MST

Pegasus 1113234 PD≤-1 PD≥1

9 Backlatch Functions FL PD≤≤≤≤-1 PD≥≥≥≥1PD≥≥≥≥1* ML MST

Yamato (ABT3) 1112826 PD≤-1 PD≥1

Yamato (ABT13, ABT17) 1113205 PD≤-1 PD≥1

ST2/35 ST2/34 ST2/37 ST2/28 ST2/27 ST2/36 ST2/32 ST2/30

10 Lockstitch; e. g. Functions FL FA-R FSPL FA-V FW VR ML MST

Union Special (63900AMZ replacement 1112823 FL FA-R FA-V FW ML

for US80A) and on Refrey lockstitch machines

14 Lockstitch; e. g. Functions FL VR FA1+2 FA2 FW FA1 ML MST

Juki (5550-6) 1112816 FL VR FA1+2 FW

Juki (5550-7) 1113132 + FL VR FA1+2 FZ FW

(position sens or incorporated in the 1113157

handwheel)

15 Backlatch Pegasus (SSC100) FL KS/KB KB KS FSPL AH ML HP

16 Overlock; feed-off-the-arm machine e.g.Yamato (FD62) FL KS RB M2 AH FSPL ML MST

17 Chainstitch; Pegasus FL LFA FA STS ML

20 Lockstitch; Juki (LU1510-7) 1113200 FL VR FA FSPL ML MST

21 Chainstitch; Yamato (stitch lock) 1113178 FL STS FA STV FW ML

23 Lockstitch; Dürkopp Adler (271...275) FL VR FA ML FW FSPL HP MST

24 Chainstitch; Pegasus (MHG-100) 1113267 FL FA FA FW

*) The signal issued at this output is inverted!

EFKA AB320A5200

Explanation of letter symbols of the previous page and chapter ”Timing Diagrams“

Outputs:

FL = Sewing foot lifting FL1 = Sewing foot lifting without pulsing

VR = Backtacking STV = Stitch condensing

FA = Thread trimmer FA1 = Thread trimmer pos. 1...1A

FA2 = Thread trimmer pos. 1A...2 FA1+2 = Thread trimmer pos. 1...2

FA-V = Thread trimmer forward FA-R = Thread trimmer backward

FAU = Bobbin thread trimmer FAO = Needle thread trimmer

FSPL = Thread tension release AH = Tape cutter

FW = Thread wiper AH1/AH2 = Fast scisso rs

ML/NK = Machine running / Needle cooling KS = Chain suction

RB = Chain blowing in opposite direction STB = Blow fabric onto stack

KB = Chain blowing KS+KB = Chain suction + bl owing

MST = Machine at standstill HP/FF1 = High lift for walking foot /

PD≥1 = Pedal steps 1...12 flip-flop 1

PD=0 = Pedal step 0 PD≤-1 = Pedal steps –1 / -2

L-STL = Indicator lamp for stitch length PD-2 = Pedal step -2

FZ = Thread puller DR-UK = Reversal of motor direction

IMP = Impulse STS = Stitch lock

LFA = Top cover thread cutter BR = Hot thread chain cutting

6

2 Putting into Service

Before putting the control into service, the following must be ensured, checked and/or adjusted:

" The correct installation of the drive, position transmitter and accompanying devices, if necessary

"

The correct selection of the trimming operation by means of parameter 290

" If necessary, the correct adjustment of the direction of motor rotation by means of parameter 161

" The correct selection of the functions of keys (inputs) by means of parameters 240...249

" The setting of the transmission ratio between motor shaft and machine shaft by means of parameter 272

" The setting of the type of position sensor by means of parameter 270

"

If necessary, the setting of the number of angular degrees after the sensor position by means of parameter 271

" If necessary, the setting of the positions by means of parameter 171

(possible with all settings of parameter 270)

" The correct positioning speed by means of parameter 110

"

The correct maximum speed compatible with the sewing machine by means of parameter 111

" The setting of the remaining relevant parameters

"

Start sewing in order to save the set values

See instruction manual for details!

7

EFKA AB320A5200

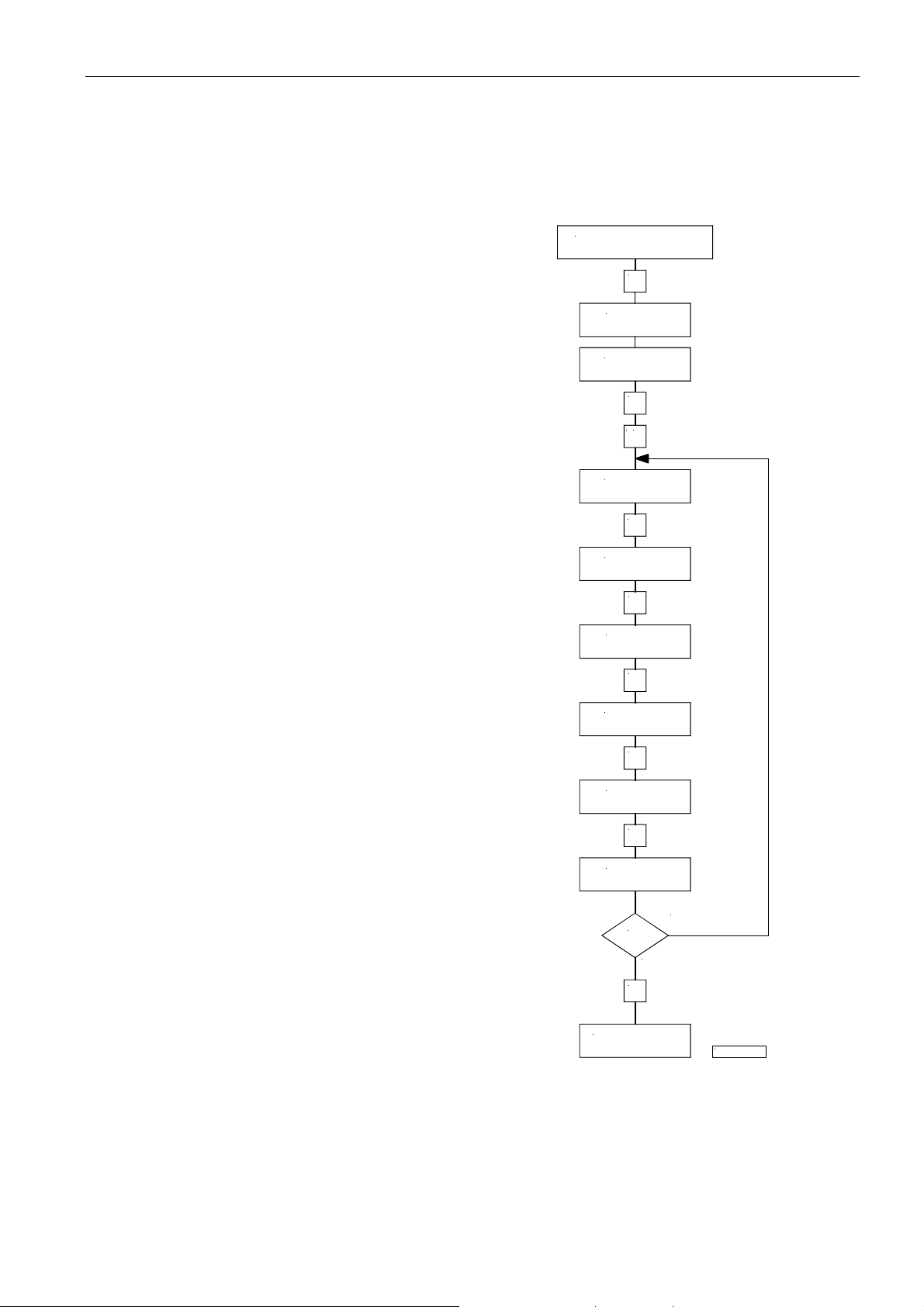

3 Setting and Putting into Service with the Aid of the Fast Installation

Routine (SIR)

The Fast Installation Routine (SIR) passes through all parameters necessary for programming the functional sequence and

the positions.

Code 3112

E

F-200

Input parameter 500

Parameter for functional sequence “thread trimming operations”

Parameter for direction of motor rotation

Parameter for transmission ratio

Important! The transmission ratio should be

determined and indicated as prec is ely as possible.

Parameter for type of position sensor

Parameter for position 1

F-500

E

>>

F-290

E

F-161

E

F-272

E

F-270

E

F-451

E

Parameter for position 2

F-453

Yes

E

No

P

End SIR

The values can be varied by pressing the +/- keys. When the parameter is displayed on the V810 control panel, press

the E key once more for the value to be displayed.

Exit the routine any time by pressing the P key once, and select a new parameter. Exit programming by pressing the P key

twice, and the drive is ready for a new sewing operation.

See instruction manual for details!

KL2438a

EFKA AB320A5200

8

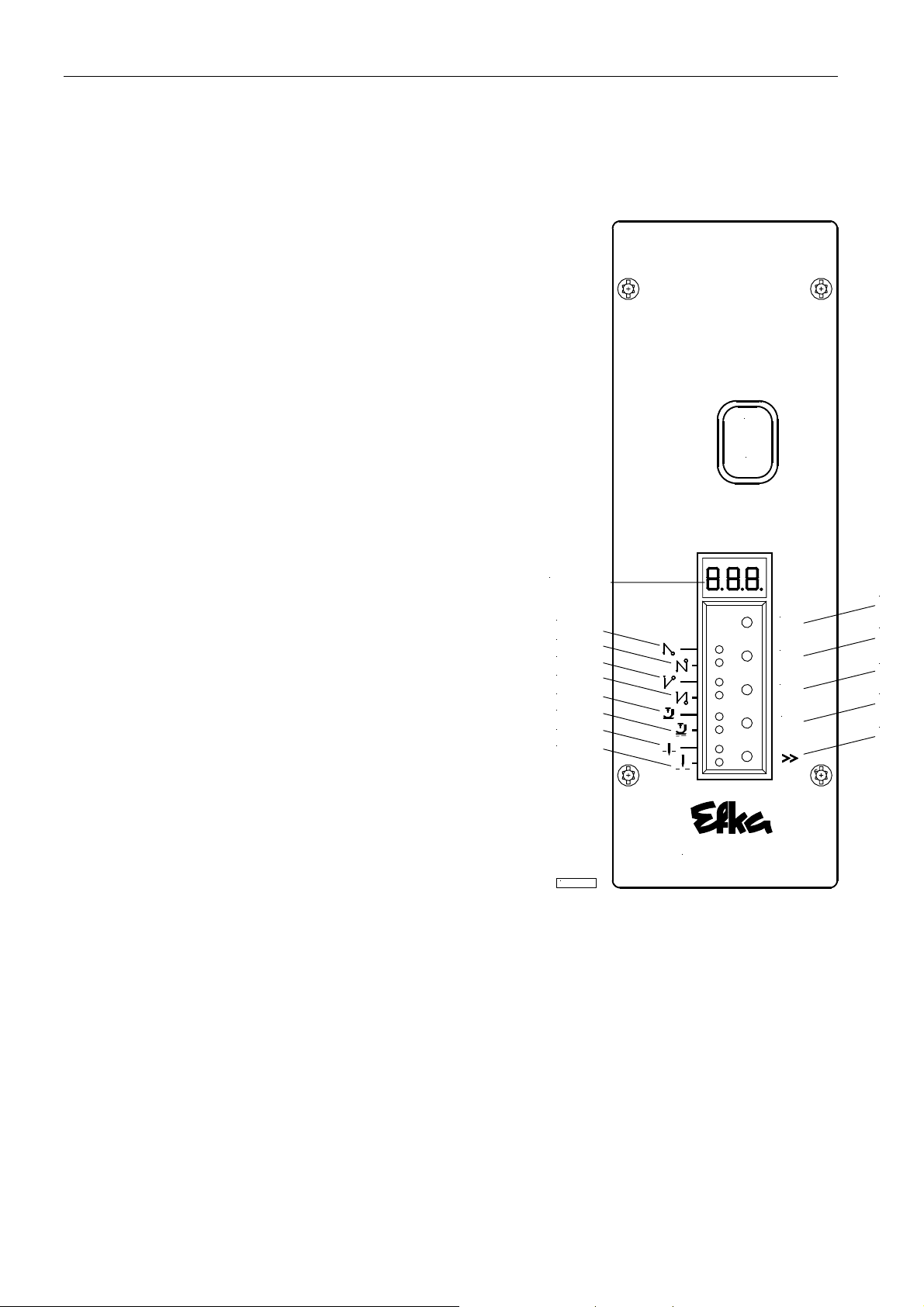

4 Operating Elements and Socket Connectors

4.1 Position of Operating Elements and Displays

S1 P key

" Call or exit programming mode

S2 E key

"

Start backtack single / double / off

" Enter key for modifications in the programming mode

S3 + key

" End backtack single / double / off

" Increase of the value indicated in the programming mode

S4 – key

"

Automatic sewing foot lifting at stop in the seam On/Off

" Automatic sewing foot lifting after thread trimming

On/Off

" Decrease of the value indicated in the programming mode

S5 >> key

" Basic position 1 or 2

"

Shift key in the programming mode

0

I

LED1 Indicator for single start backtack

LED2 Indicator for double start backtack

LED3 Indicator for single end backtack

LED4 Indicator for double end backtack

LED5 Indicator for automatic sewing foot lift at stop

in the seam

LED6 Indicator for automatic sewing foot lift after

the thread trimming operation

LED7 Indicator for basic position “needle position 1“

LED8 Indicator for basic position “needle position 2“

Display 3 digits

Display

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

KL2472

AB320A5200

S1

P

E

+

-

S2

S3

S4

S5

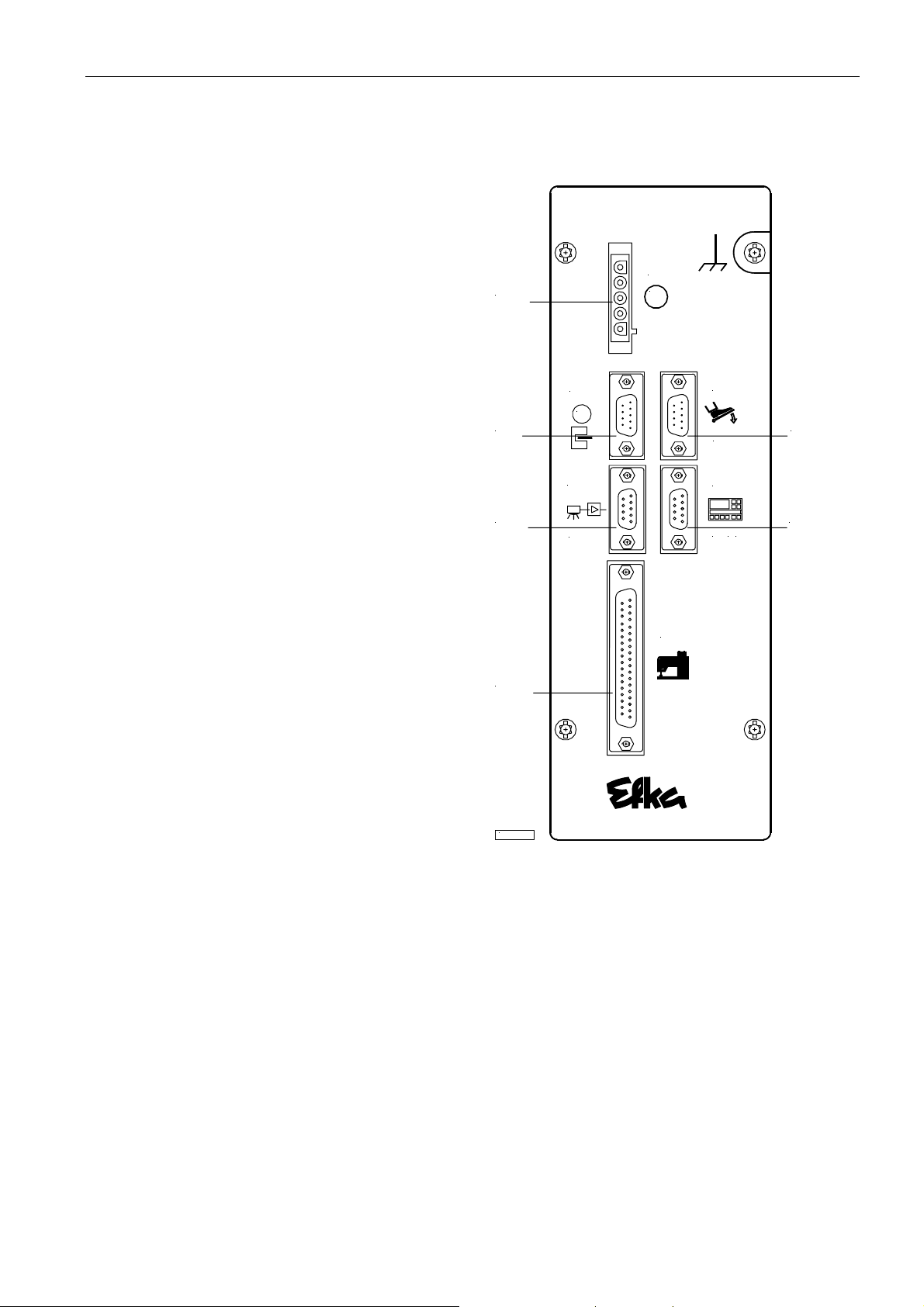

4.2 Position of the Socket Connectors

B2 Socket for sensors

9

EFKA AB320A5200

B18 Socket for light barrier module

B41 Socket for motor power supply

B80 Socket for actuator

B776 Socket for V810/V820 control panel

ST2 Socket for solenoid inputs and outputs /

solenoid valves / displays / keys and switches

B41

B2

B18

ST2

B2

M

B18

L S M ...

B41

M

ST2

B80

EB ...

B 776

V8 . .

B80

B776

KL2333

EFKA AB320A5200

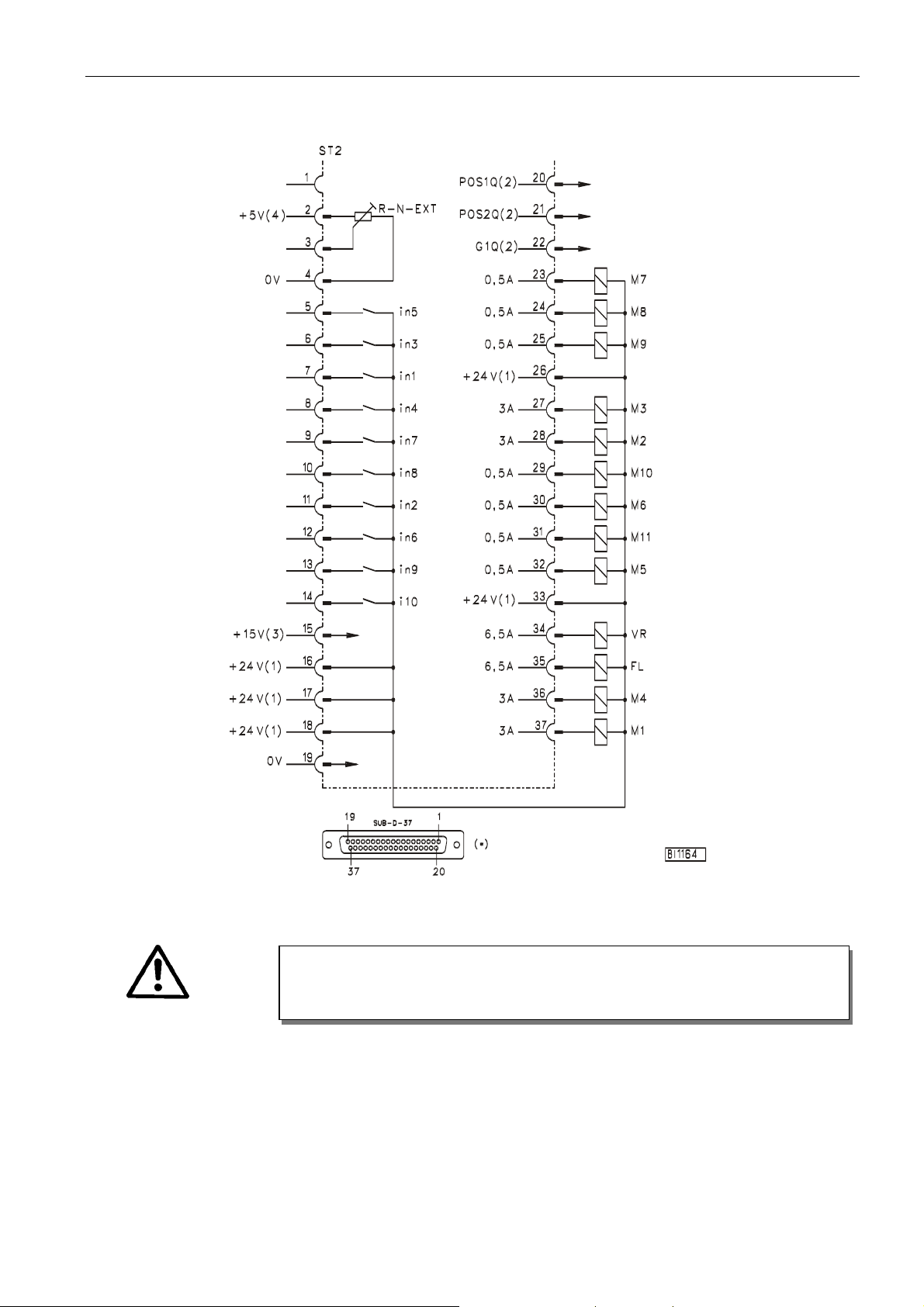

4.3 Connection Diagram

Inputs switched to 0V

10

ATTENTION!

When connecting the outputs, ensure that a total power of 96VA constant load will not

be exceeded!

in1 - Input 1 i10 - Input 10 M9 - Output 9

in2 - Input 2 M1 - Output 1 M10 - Output 10

in3 - Input 3 M2 - Output 2 M11 - Output 11

in4 - Input 4 M3 - Output 3 FL - Sewing foot lifting

in5 - Input 5 M4 - Output 4 VR - Backtacking

in6 - Input 6 M5 - Output 5 POS1 - Position 1

in7 - Input 7 M6 - Output 6 POS2 - Position 2

in8 - Input 8 M7 - Output 7 GEN - 512 generator impulses

in9 - Input 9 M8 - Output 8 R-N-EXT - External potentiometer for

speed limitation (50kΩ)

Inputs switched to +24V

11

EFKA AB320A5200

ATTENTION!

When connecting the outputs, ensure that a total power of 96VA constant load will not

be exceeded!

1)

Nominal vol t age 24V, no-load voltage max. 30V momentarily after power on

2)

Transistor output with open collector max. 40V, 10mA

3) Nominal voltage 15V, I

4)

Nominal voltage 5V, I

= 30mA

max

= 20mA

max

*) Front view of the socket (component side) and/or rear view of the plug (soldering side)

EFKA AB320A5200

POS2 OUT - Output for position 2

POS IN - Input for positions

G1/G2 OUT - Output of generator impulses

TXD/RXD - Serial transmission lines

LSM IN - Possibility of connecting a light barrier module to socket B18/8

LSM002 - Reflection light barrier module

12

(If parameter 239 = 0, the light barrier function is selected.

Identification of the signal when switched to 0V.)

If parameter 239 is set to 1...43, a key can be operated on the input of socket B18/8.

+5V = Connect lefthand pins 1 and 2 with jumper (factory setting)

+15V = Connect righthand pins 3 and 4 with jumper

B80

B2

B18

J4

ATTENTION!

efore opening the cover, turn power off!

B

J4

1 3

2 4

+5V

J4

31

42

+15V

KL2351

1) Nominal voltage +15V, 100mA (repluggable to +5V, 100mA)

2) Transistor output with open collector max. 40V, 10mA

*) Front view of the socket (component side) and/or rear view of the plug (soldering side)

13

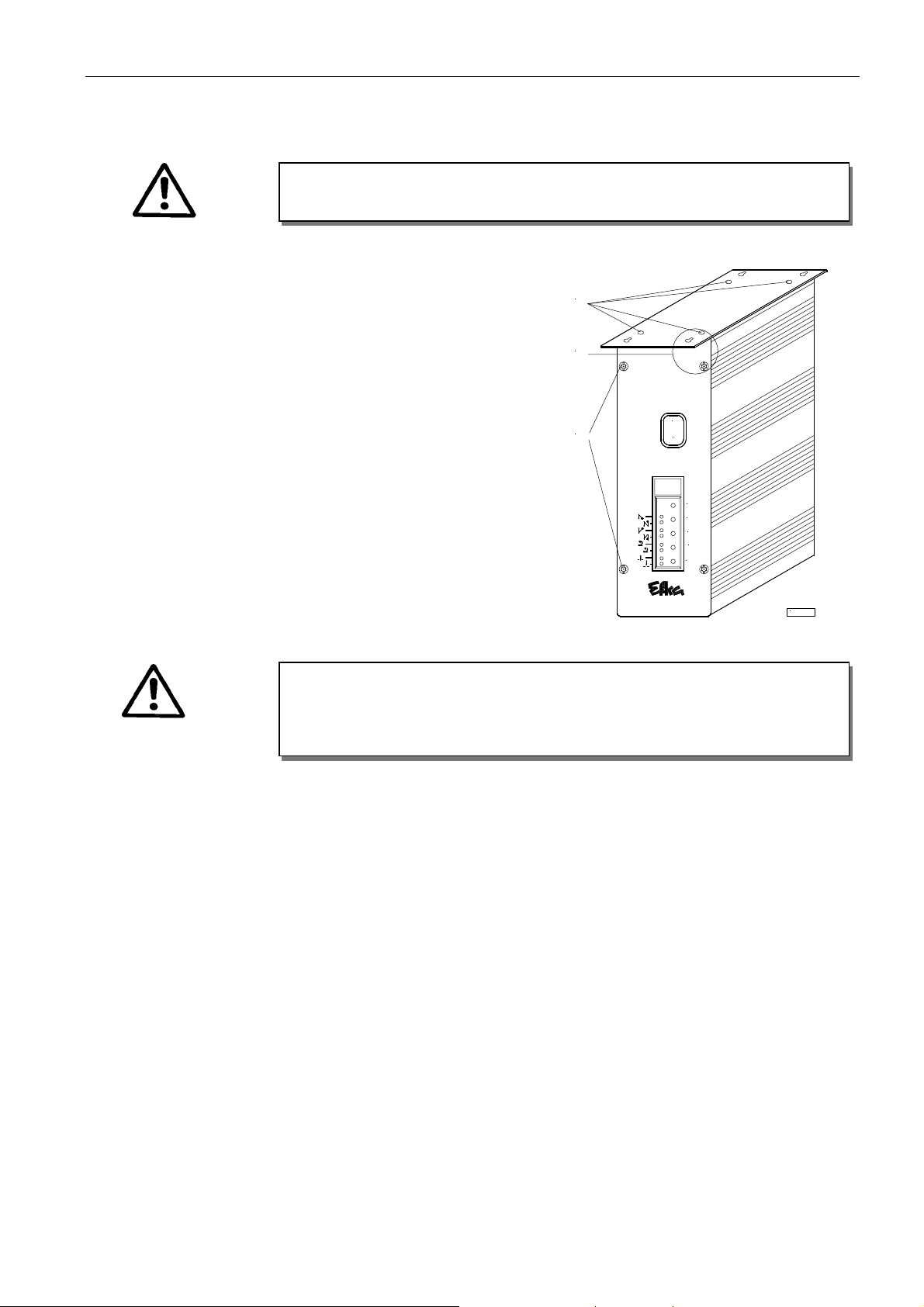

4.4 Connection of a Sewing Light with Transformer

ATTENTION!

efore opening the cover, turn power off!

B

EFKA AB320A5200

" Switch off the control and remove mains plug from outlet

"

Unscrew the control unit from the machine table

" Loosen 4 screws (A)

"

Remove the mounting plate

" Loosen 2 screws (B) each at the front and at the rear

" Open the left part of the housing

" Pull the sewing light cable through the cable bushing

"

Area (C): Connect strands with clamp on the printed circuit board

" Insert earth lead into plug-in device on the housin g part

"

Close and screw-connect the housing

" Mount the control unit on the machine table

When the sewing light is connected, it is always current-carrying (230V), even if

the control unit is switched off! Only one sewing light with transformer can be

connected to the control unit!

A

C

B

CAUTION!

0

I

P

E

+

-

>>

KL2399

EFKA AB320A5200

14

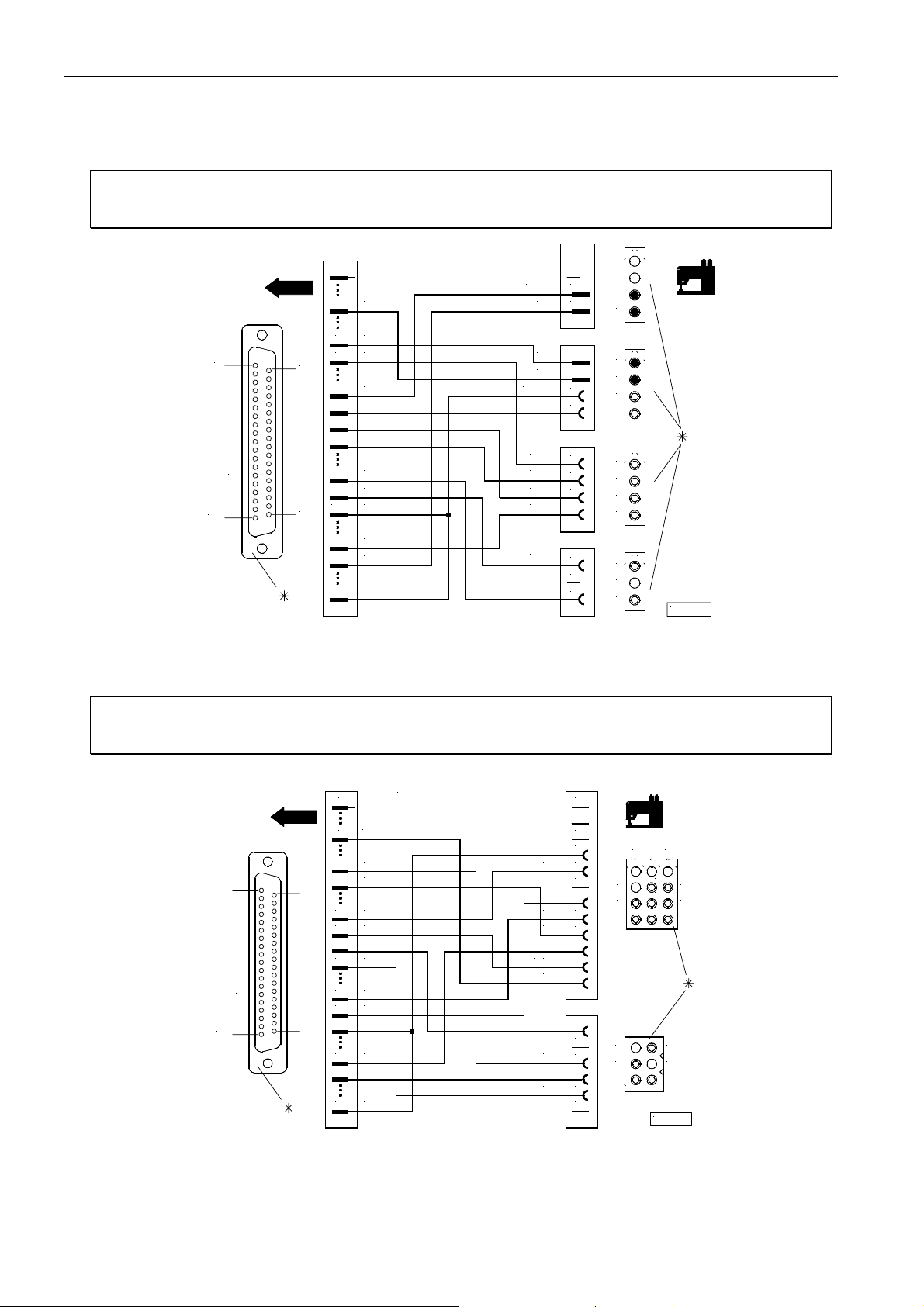

4.5 Adapter Cords

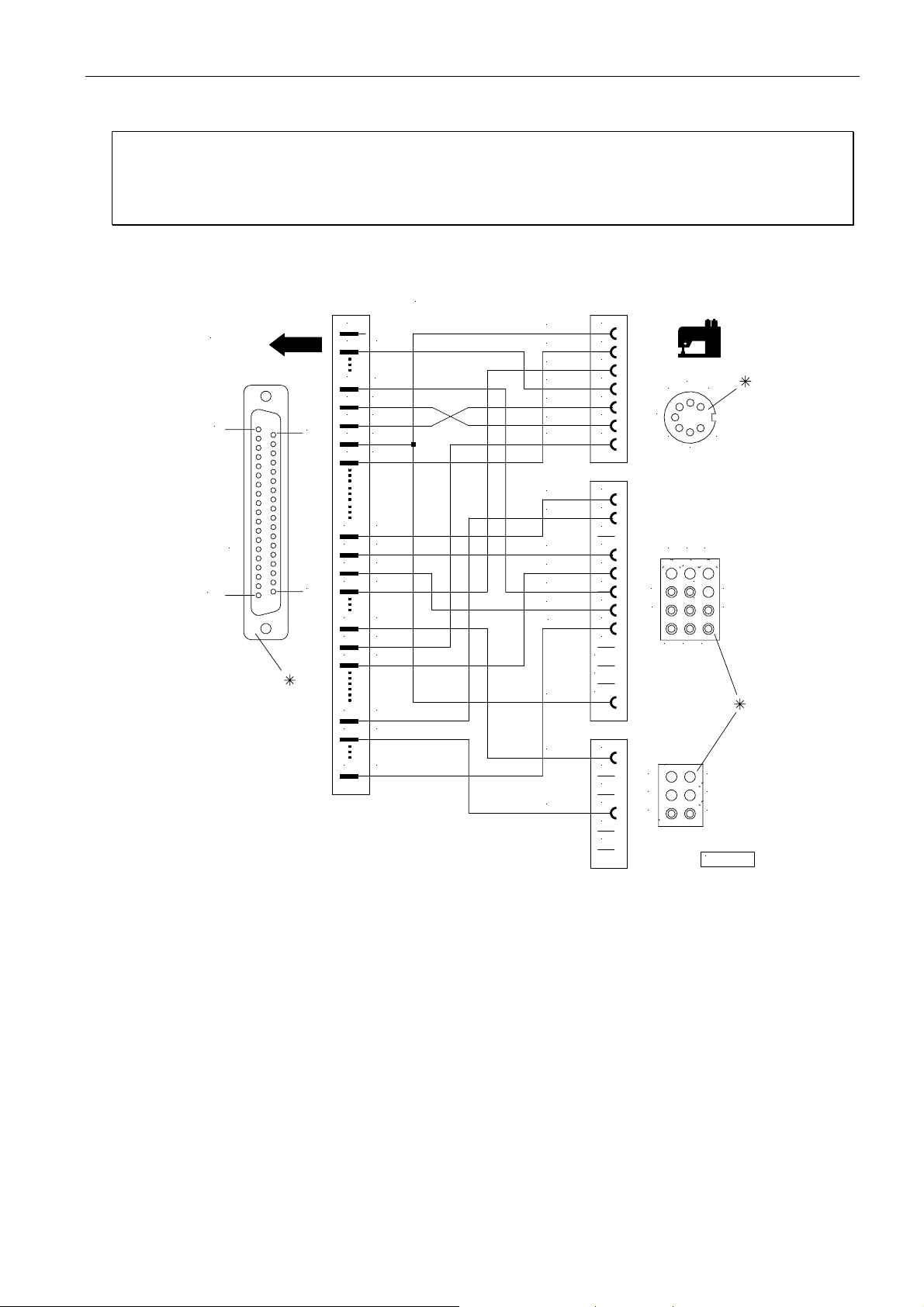

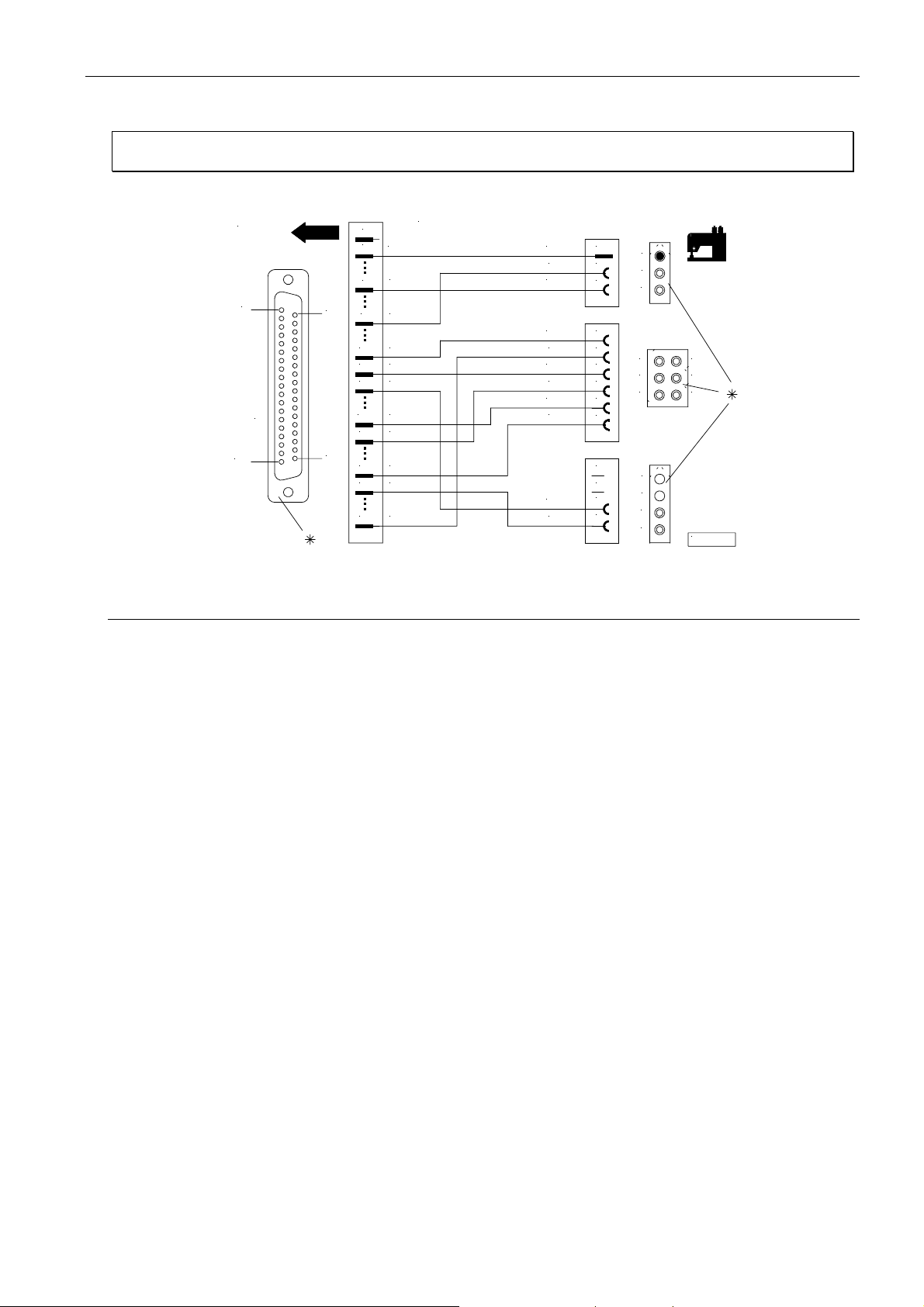

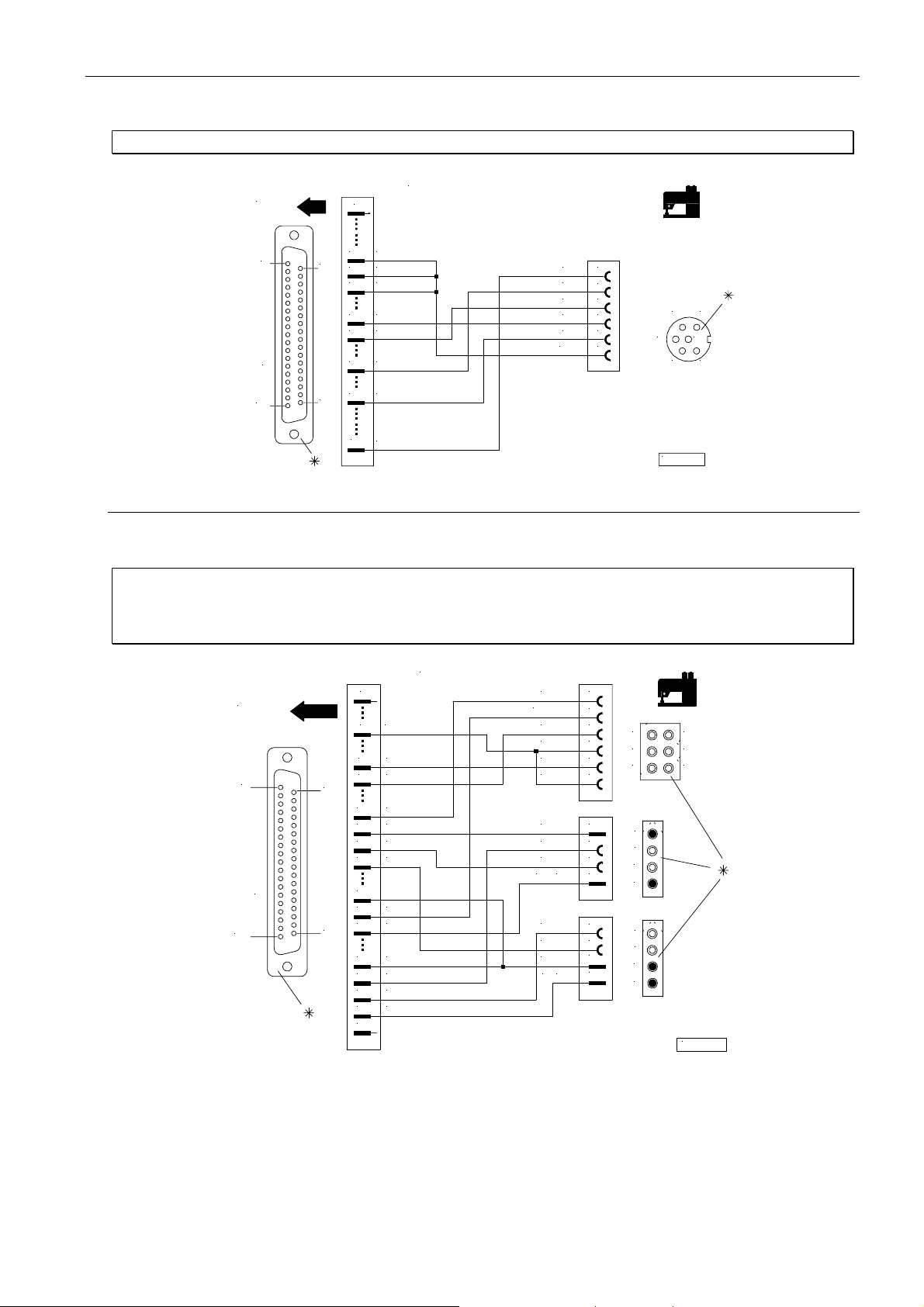

Adapter cord for AISIN models AD3XX, AD158, 3310 and EK1

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 0

Setting the functions of the keys Input in1 ! Set parameter 240 = 16

Input in3 ! Set parameter 242 = 1

1

ST2

Nr. 1112815

0V

4

6 in3

1

SUB - D- 37

19

20

37

7 in1

+24V

16

+24V

17

+24V

18

19 0V

+24V26

27 M3

28 M2

VR

3534FL

37

M1

Adapter cord for BROTHER models 737-113 and 737-913

+24V

FL

NHT

0V

FA1+ 2

+24V

ZVR

0V

+24V

VR

FW

+24V

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

1

1

2

2

3

3

KL2234

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 0

Setting the functions of the keys Input in1 ! Set parameter 240 = 16

Input in3 ! Set parameter 242 = 1

Nr . 11 12 8 14

0V

+24V

+24V

+24V

+24V26

FA1+ 2

24V

+

FW

24V

ZVR

VR

24V++

0V 12

24V

+

NHT

FL

0V

10

11

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

3

2 1

5

6

9

12

6

5

4

8

11 10

KL2233

4

7

3

2

1

ST2

1

19

SUB - D - 37

20

37

1

4

6 in3

7 in1

16

17

18

19 0V

27 M3

28 M2

34

35VRFL

37 M1

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

15

EFKA AB320A5200

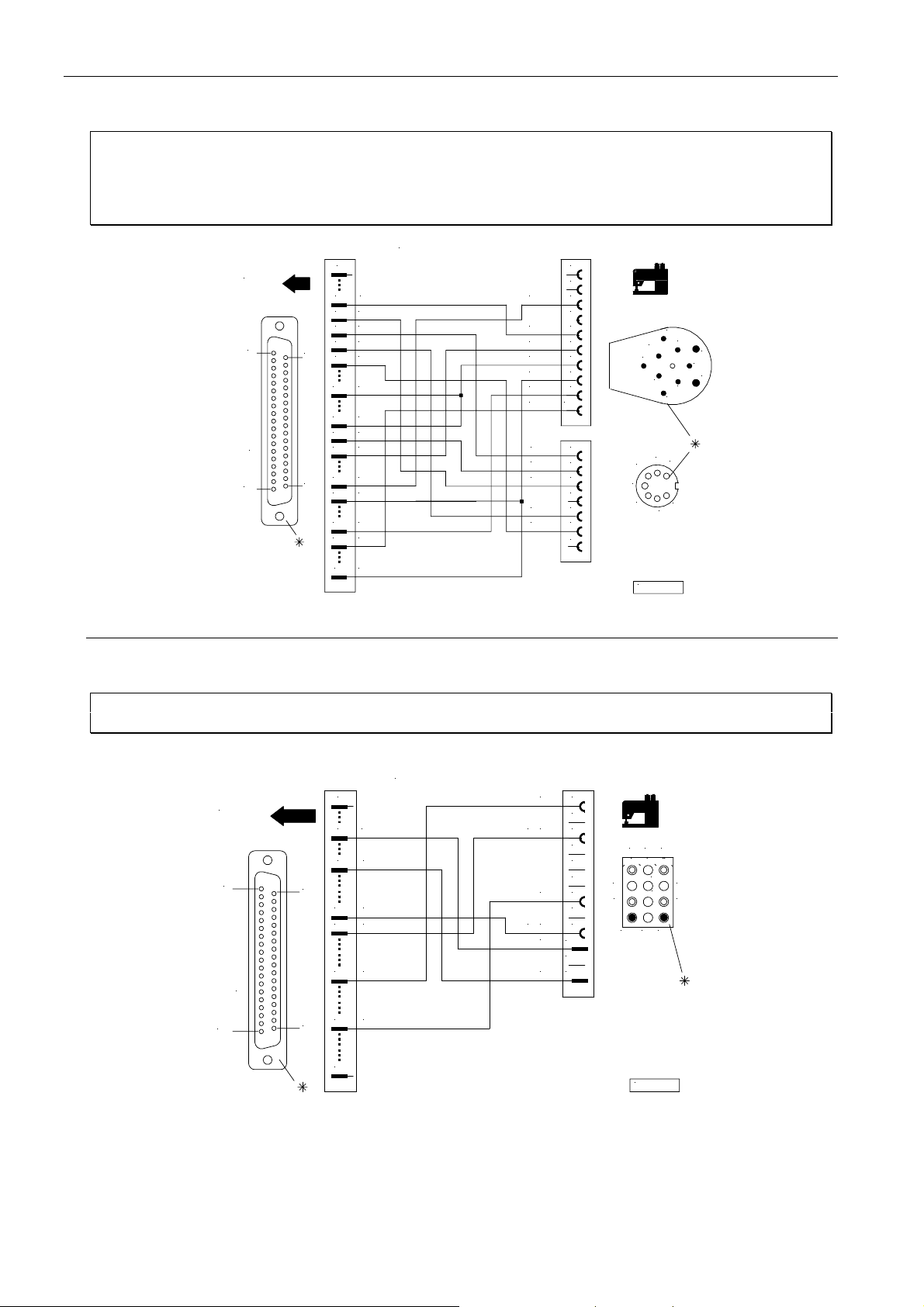

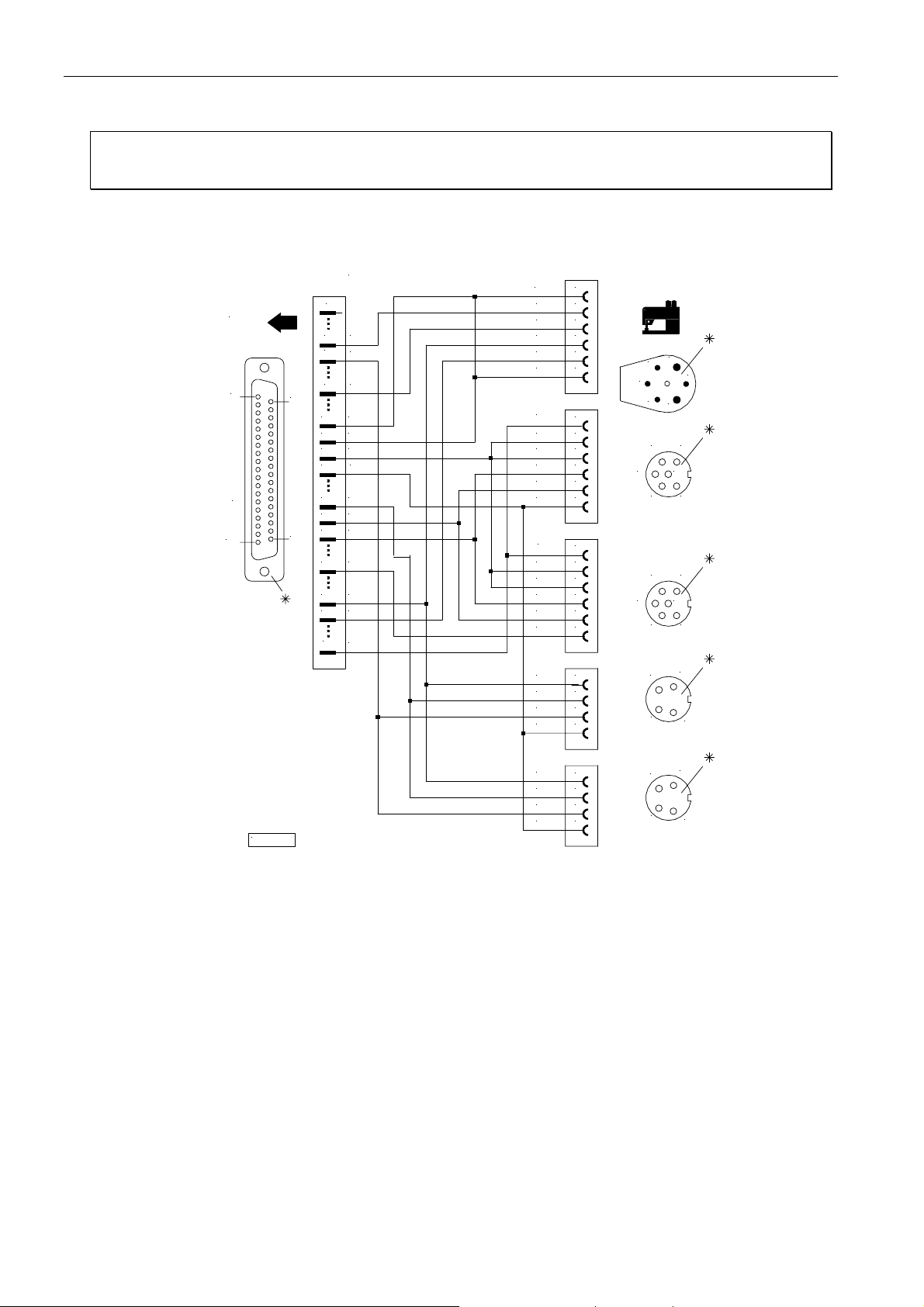

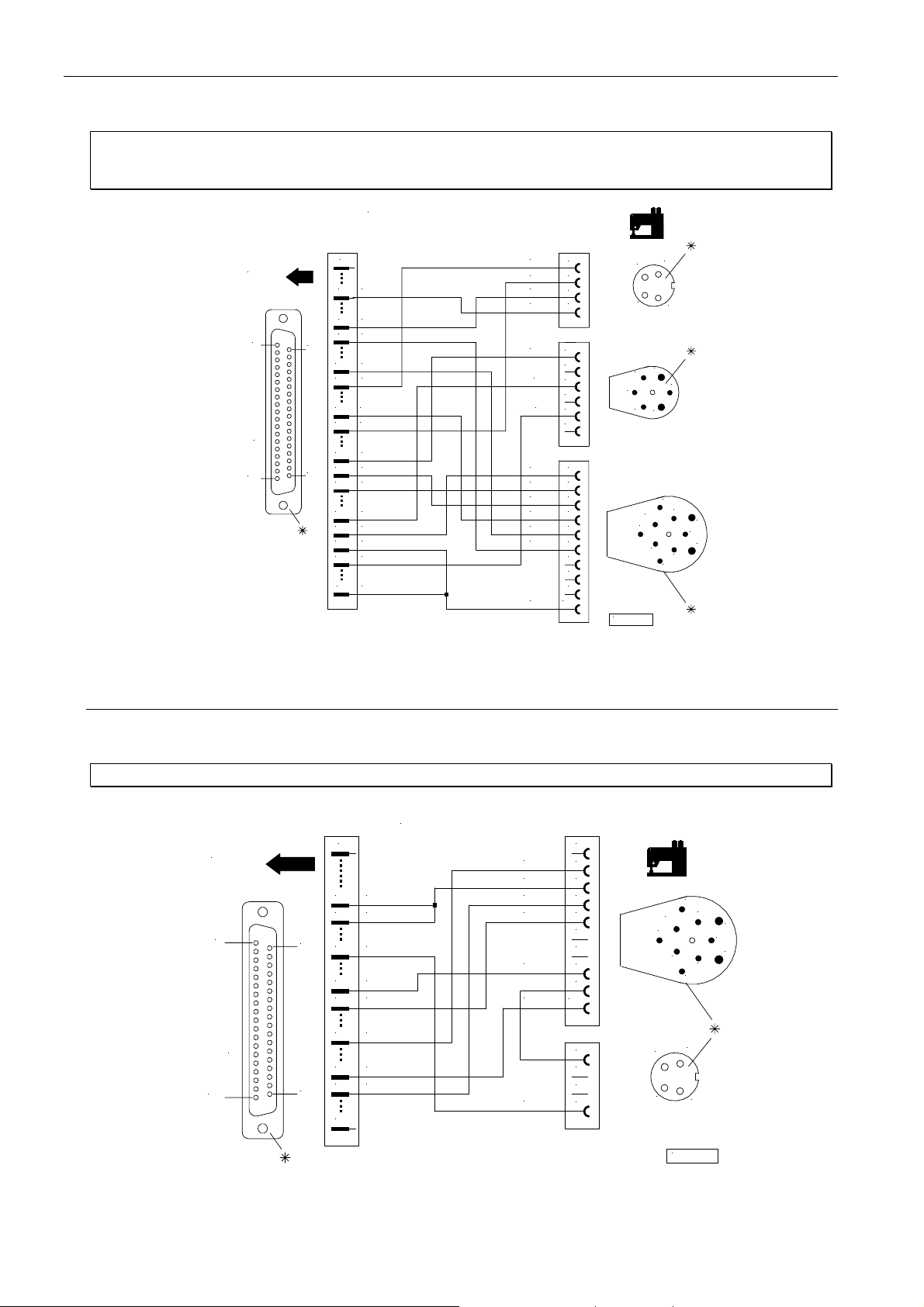

Adapter cord for BROTHER model FD3 B257

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 5

Setting the functions of the keys Input in1 ! Set parameter 240 = 7

Input in3 ! Set parameter 242 = 18

Input in4 ! Set parameter 243 = 16

Input in5 ! Set parameter 244 = 17

ST2

1

19

SUB - D - 37

20

37

1

+5V

2

4

0V

in55

in36

in17

in4

8

+ 24V

16

+ 24V

17

+ 24V

18

19 0V

+ 24V

26

27

M3

28 M2

34

VR

35 FL

37

M1

Nr. 1112822

LSP

ZSTV

0V

+5V

EN TK

STVU

FW

+ 24V

STV

+ 24V

FA

0V

+ 24V

FA

LSP

+ 24V

FL

10

11

12

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

1

3

12

3

2 1

6

7

5

8

1011

3

2

1

KL2241

4

7

4

2

5

6

9

6

5

4

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

EFKA AB320A5200

16

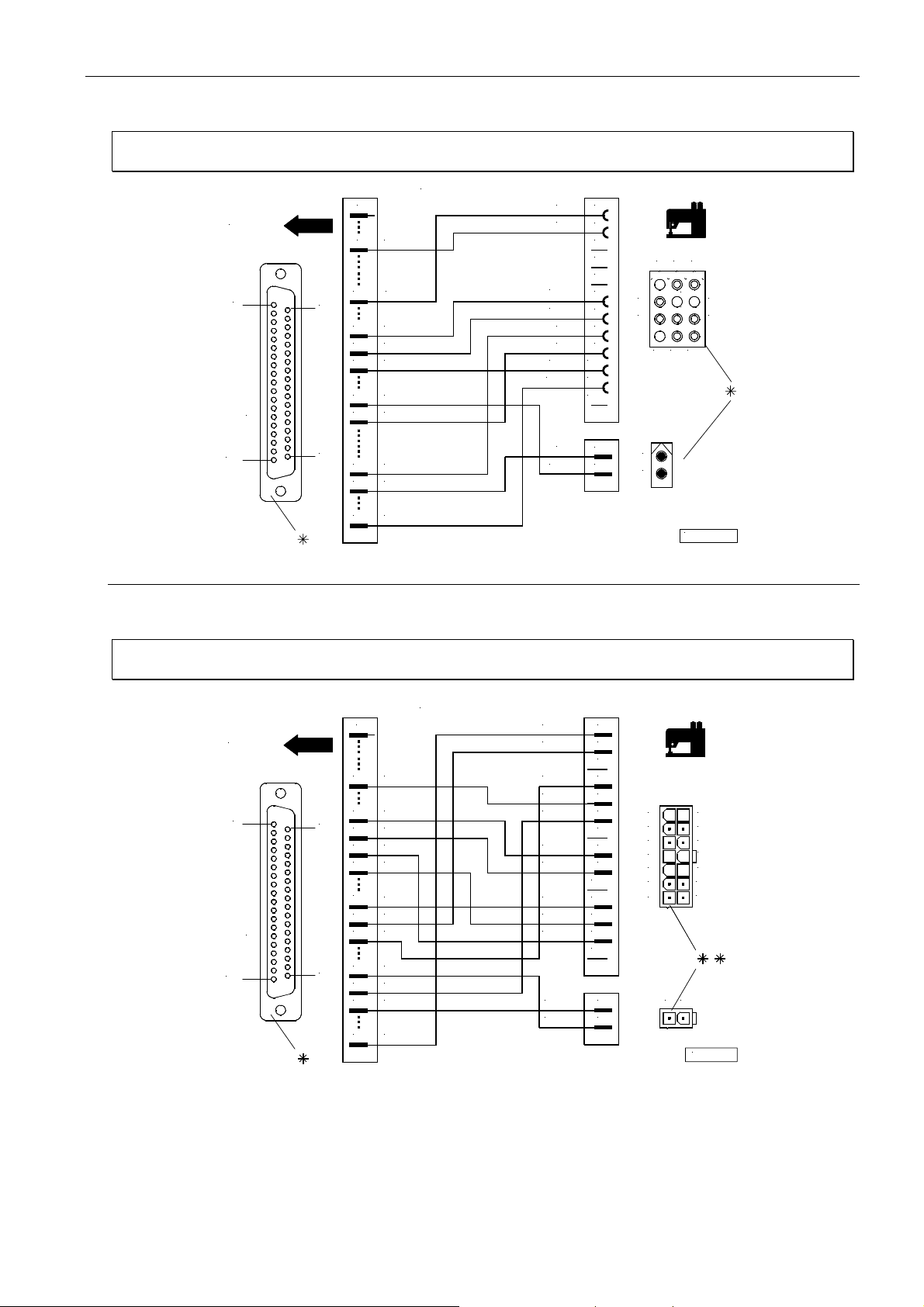

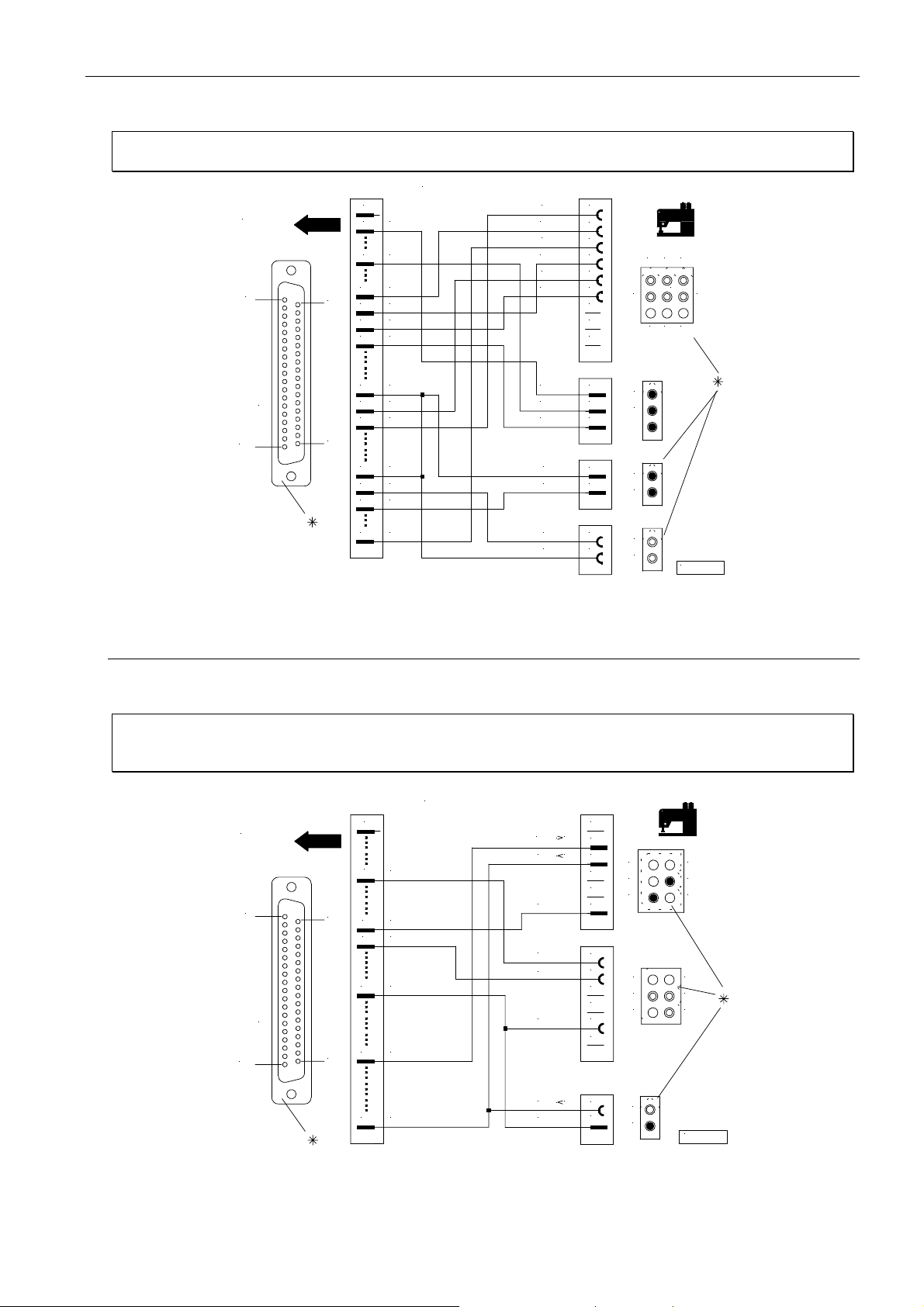

Adapter cord for DÜRKOPP ADLER models 210, 270

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 0

Setting the functions of the keys Input in1 ! Set parameter 240 = 16

Input in3 ! Set parameter 242 = 1

Input in4 ! Set parameter 243 = 3

Input in5 ! Set parameter 244 = 17

Nr. 1112845

0V

in5

in3

in4

+ 24V

+ 24V

M2

FW

0V

POS1

+24V 7

FA1+ 2

VR

FL

NHT

0V

VRU

ZVR

EST

10

1

2

3

4

5

6

8

9

1

2

3

4

5

6

7

1

4

2

5

KL2259a

10

9

8

7

6

2

1

3

5

4

3

6

7

ST2

1

SUB - D- 37

19

20

37

1

4

5

6

78in1

16

18

19 0V

20 POS1

27 M3

28

34 VR

35 FL

37 M1

Adapter cord for GLOBAL model CB2803-56

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 5

Setting the functions of the keys Input in1 ! Set parameter 240 = 6

1

ST2

0V

4

7 in1

1

SUB - D- 37

19

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

20

37

+ 24V

17

+ 24V

18

27 M3

35 FL

37

FA

24V

+

FL

24V

0V

LSP+12

10

11

1

2

3

4

5

6

7

8

9

6

9

3

12

2 1

5

8

11

10

KL2301

4

7

Nr. 1112866

17

1112816

1113132

EFKA AB320A5200

Adapter cord for JUKI model 5550-6

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 14

Setting the functions of the keys Input in1 ! Set parameter 240 = 16

ST2

1

SUB - D - 37

19

20

37

Adapter cord for JUKI model 5550-7

1

0V

4

11 in2

+ 24V

16

+ 24V

17

+ 24V

18

+ 24V

26

27 M3

3435VR

FL

37 M1

Nr.

ZVR0V1

+24V

+24V

VR

FW

+24V

10

11FA1+ 2

12

+24VFL2

2

3

4

5

6

7

8

9

1

2

3

1

5

6

9

12

1

2

8

11

10

KL2235b

4

7

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 14

Setting the functions of the keys Input in1 ! Set parameter 240 = 16

Nr.

ST2

1

19

1

in2

11

17

18

19

26

27

33

34

35

37

+ 24V16

+ 24V

+ 24V

0V

+ 24V

M3

M228

+ 24V

VR

FL

M1

20

SUB - D - 37

37

FA1+ 2

FW

FZ

ZVR 5

VR 6

+ 24V

+ 24V

+ 24V

0V

+ 24V

FL

+ 24V

10

11

12

13

14

1

2

3

4

7

7

8

9

1

2

6

5

4

3

2

1

1 2

14

13

12

11

10

9

8

KL2363

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

**) Front view (component side) of the Molex Minifit plugs.

EFKA AB320A5200

18

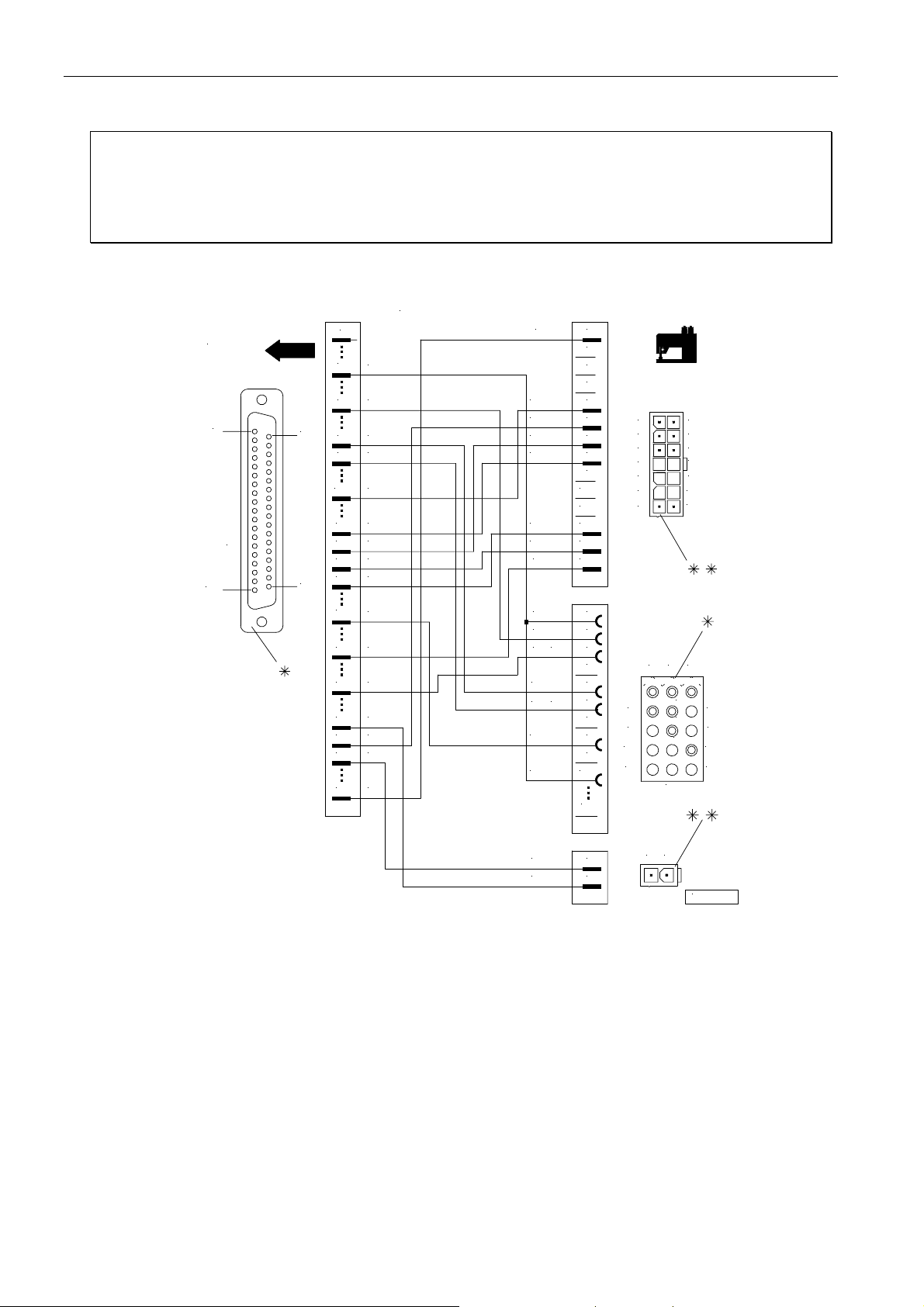

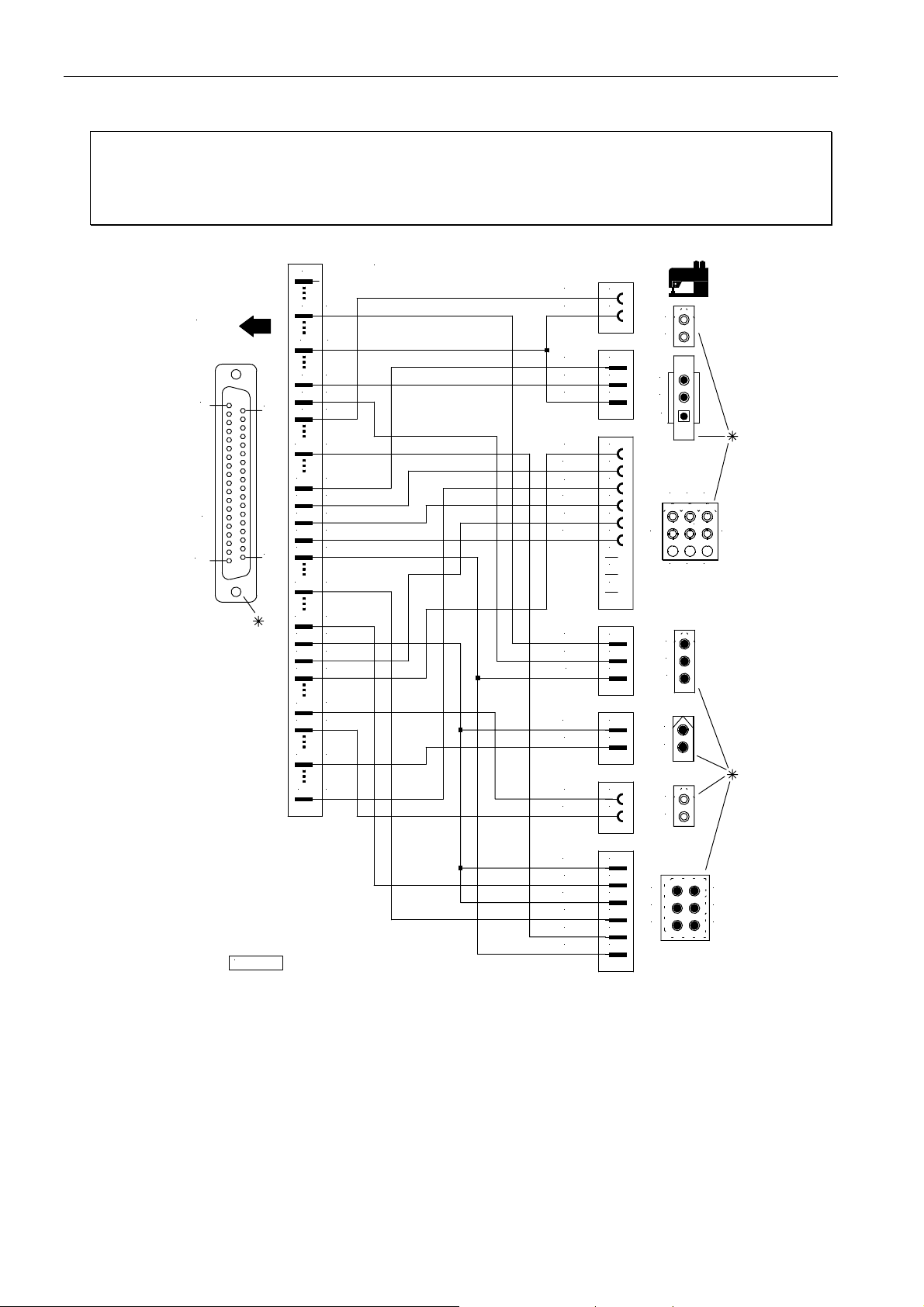

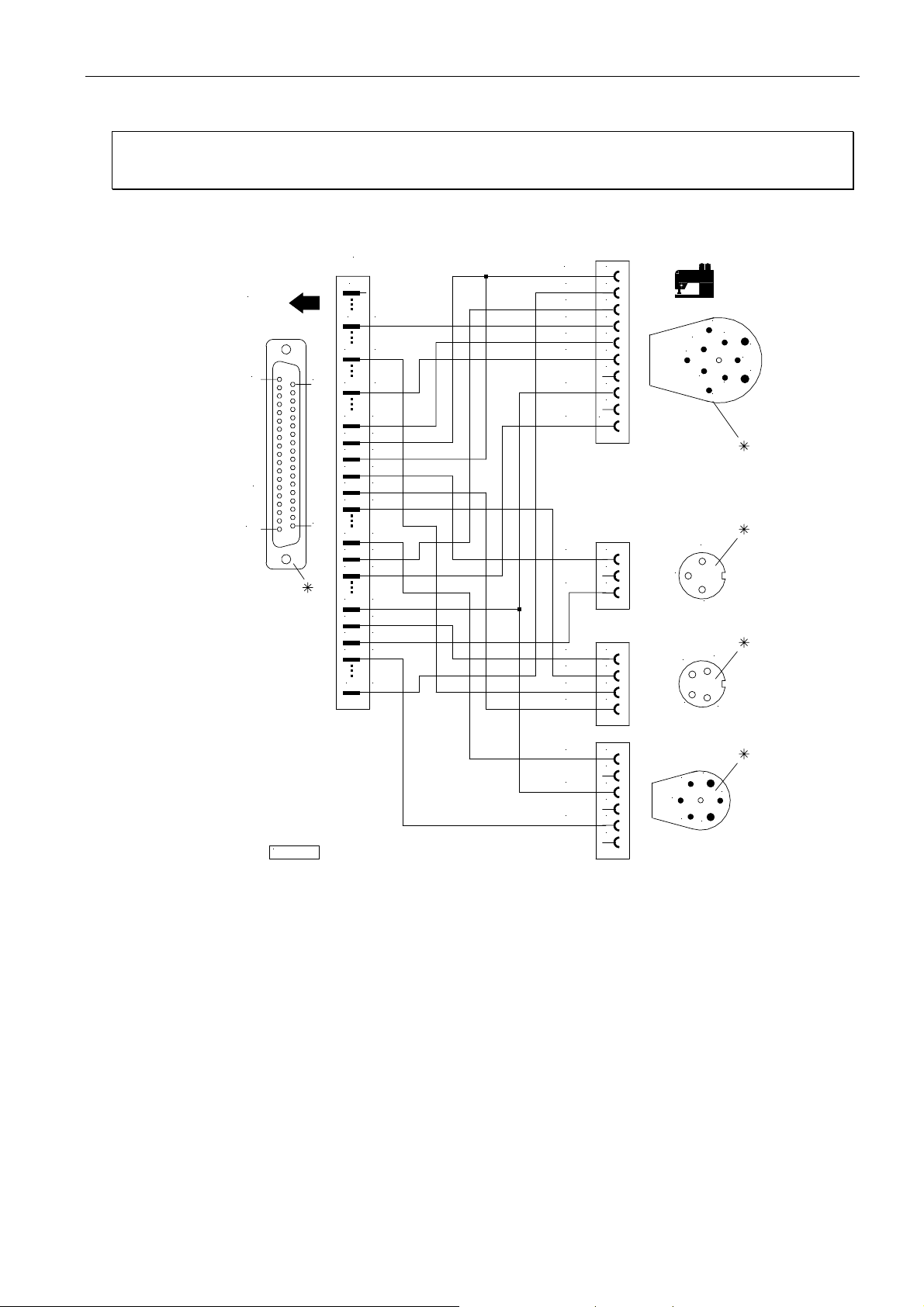

Adapter cord for JUKI model LU1510-7

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 20

Setting the functions of the keys Input in1 ! Set parameter 240 = 13

(Automatic setting) I nput in3 ! Set parameter 242 = 31

Input in4 ! Set parameter 243 = 32

Input in6 ! Set parameter 245 = 16

Input in7 ! Set parameter 246 = 13

ST2

1

19

SUB - D - 37

20

37

12

16

17

18

19

26

28

30

33

34

35

37

1

4

6

8

9

Nr. 1113200

0V

in3

in4

in7

in6

+ 24V

+ 24V

+ 24V

0V

+ 24V

M2

M6

+ 24V

VR

FL

M1

FA

ZVR

VR

+ 24V

+ 24V

0V

+ 24V

FSP L

0V

S1

HPout

S2

HP in

+ 24V

0V

10

11

12

13

14

10

15

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

7

6

5 12

4

3

2

1

14

13

11

10

9

8

3 2 1

6 4

9

12

15

5

8

11

14

7

10

13

FL

+ 24V

1

2

1 2

KL2437

in1 = Input high lift for walking foot with speed limitation n10 (operational mode not stored) for knee switch

in3 = Input speed limitation bit 0 (S1)

in4 = Input speed limitation bit 1 (S2)

in6 = Input intermediate backtack

in7 = Input high lift for walking foot with speed limitation n10 (operational mode not stored) for additional

pushbutton at the machine head

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

**) Front view (component side) of the Molex Minifit plugs.

19

EFKA AB320A5200

Adapter cord for KANSAI model RX9803

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 5

Setting the functions of the keys Input in1 ! Set parameter 240 = 7

ST2

1

19

1

2

4

20

7

16

17

18

SUB - D- 37

37

26

32

35

37

Nr. 1113130

+5V

0V

in1

+24V

+24V

+24V

+24V

M327

M5

FL

M1

+5V

LSP

0V

+24V

FA

+24V

FW

+24V

ML

+24V

FL

1

1

2

2

3

3

1

2

6

3

5

4

4

5

6

1

1

2

2

3

3

4

4

3

2

1

KL2362

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

EFKA AB320A5200

20

Adapter cord for PFAFF models 563, 953, 1050, 1180 without thread monitor

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 0

Setting the functions of the keys Input in4 ! Set parameter 243 = 12

Input in5 ! Set parameter 244 = 16

ST2

1

SUB - D- 37

19

20

37

Nr. 1112841

1

4

0V

5

in5

8

in4

16

+ 24V

17

+ 24V

18

+ 24V

19

0V

26 + 24V

27

28

M2

32M3M5

34 VR

35 FL

37

M1

+ 24V

0V

FLEX

VR

FL

+ 24V

FA1

+ 24V

+ 24V

FA2

FW

0V

FA1

+ 24V

+ 24V

FA2

FW

ML

VR

+ 24V

ZVR

0V

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

3

3

4

2

3

2

1

6

4

5

2

1

6

4

5

1

2

3

4

VR

1

+ 24V

2

ZVR

3

0V

4

KL2261

*) Rear view (soldering side) of 37-pin plug (ST2) and of the remaining sockets.

1

2

3

4

21

EFKA AB320A5200

Adapter cord for PEGASUS models W500/UT, W600/UT/MS with or without stitch condensing

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 5

Setting the functions of the keys Input in1 ! Set parameter 240 = 7

Attention!

Nr. 11128 21

1

20

37

2 +5V

7 in1

+24V

16

+24V

17

+24V

18

19 0V

+24V

26

27 M3

28 M2

+24V

33

34 VR

35 FL

37 M1

ST2

1

SUB - D- 37

19

When using this adapter cord on a Pegasus machine, the 9-core cable no. 742373-91 must be

removed from the machine!

FA

+24V

FA

+24V

FW

+24V

+5V

LSP

0V

+24V

FL

STV

+24V

1

2

3

4

5

6

7

8

9

1

2

3

1

2

1

2

2

3

1

5

6

1

2

1

2

1

2

4

8

9

7

KL2240

Adapter cord for PEGASUS backlatch machines

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 8

Setting the functions of the keys Input in1 ! Set parameter 240 = 6

(Automatic setting) I nput in3 ! Set parameter 242 = 10

Nr . 1113234

ST2

1

19

1

4

0V

20

67in3

in1

19 0V

SUB - D- 37

28 M2

37

37 M1

Ped

Ped -1

N- AUTO

0V

LSP

0V

Ped -1

0V

1

1

=

2

3

=

=

4

5

6

1

2

3

4

5

6

1

2

4

5

6

6

5

4 1

1

2

1

2

3

3

2

KL2458

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

EFKA AB320A5200

22

Adapter cord for PEGASUS model MHG

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 24

Setting the functions of the keys Input in1 ! Set parameter 240 = 6

Input in2 ! Set parameter 241 = 13

Input in3 ! Set parameter 242 = 28

Input in4 ! Set parameter 243 = 22

ST2

1

SUB - D- 37

19

20

37

1

+5V

2

0V4

6 in3

7

in1

8

in4

11

in2

+15V

15

16

+24V

17

+24V

18

+24V

19

0V

23

M7

25

M9

26

+24V

27

M3

28

M2

M5

32

33 +24V

3537FL

Nr.1113267

in4

0V

0V

SEN

+15V

FA

FA

+24V

FW

+24V

+5V

LSP

0V

+24V

FL

1

2

1

2

3

1

2+24V

3

4

5

6

7

8

9

1

2

3

1

2

1

2

1

2

3

23 1

5

6

1

2

3

1

2

4

79 8

M1

KL2482

M5

+24V

+24V

M7

+24V

M9

in2

0V

1

2

1

2

3

4

5

6

1

2

4

5

6

1

2

3

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

23

EFKA AB320A5200

Adapter cord for RIMOLDI model F27

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 5

Nr. 1113096

20

37

1

16 + 24V

1718+ 24V

+ 24V

M3

27

M2

28

M532

35 FL

37

M1

FW

1

ML

2

FAO

FAU

FL

+ 24V

3

4

5

6

2

356

4

KL2346

1

Input in3 ! Set parameter 242 = 16

ST2

1

SUB - D- 37

19

Adapter cord for SINGER models 211, 212 and 591

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 2

(Singer model 212UTT)

Setting the functions of the keys Input in1 ! Set parameter 240 = 1

ST2

1

19

SUB - D- 37

20

37

1

0V

4

6 in3

7 in1

+ 24V

16

+ 24V

17

+ 24V

18

19 0V

26

27 M3

28 M2

+ 24V

33

3435VR

FL

M436

37

Nr. 11128 24

+ 24V

FW /FSPL

NHT

0V

ZVR

0V

+ 24V

VR

+ 24V

FA2/FA

FL

0V

+ 24V

FL 1

1

2

3

6

4

5

5

4

6

1

1

2

2

3

3

4

4

1

1

2

2

3

3

4

4

3

2

1

KL2243

*) Rear view (soldering side) of 37-pin plug (ST2). Front view (component side) of the remaining plugs/sockets.

EFKA AB320A5200

24

Adapter cord for UNION SPECIAL models CS100 and FS100

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 4

Setting the functions of the keys Input in1 ! Set parameter 240 = 6

Input in3 ! Set parameter 242 = 6

Nr. 1112905

+ 24V

POS1

LSP

0V

+ 24V

ML

FL

+ 24V

FA- V

FW

0V

+ 15V

LSP

FA- R

1

2

3

4

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

ST2

1

SUB - D- 37

19

20

37

1

4

0V

6

in3

7

in1

15

+ 15V

16

+ 24V

19

0V

20

POS1

26

+ 24V

27

M3

28

M2

32

M5

33

+ 24V

34

VR

35 FL

37 M1

in1 = Input machine run blockage for thread trimming control proximity switch

in3 = Input machine run blockage for thread monitor

2

3

6

1

2

KL2306

1

4

5

4

3

9

8

10

1

7

6

5

2

4

3

Adapter cord for UNION SPECIAL model 63900AMZ

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 10

Nr. 1112823

ST2

1

19

SUB - D - 37

20

37

1

+ 24V

16

+ 24V

17

19 0V

27 M3

28 M2

32 M5

34 VR

35 FL

37

ML

+ 24V

FL

FA- V

FW

FA- R

0V

10

1

2

3

4

5

6

7

8

9

1

9

8

10

1

2

2

7

6

5

4

3

1

2

3

4

3

4

KL2242

*) Rear view (soldering side) of 37-pin plug (ST2) and of the remaining sockets.

25

EFKA AB320A5200

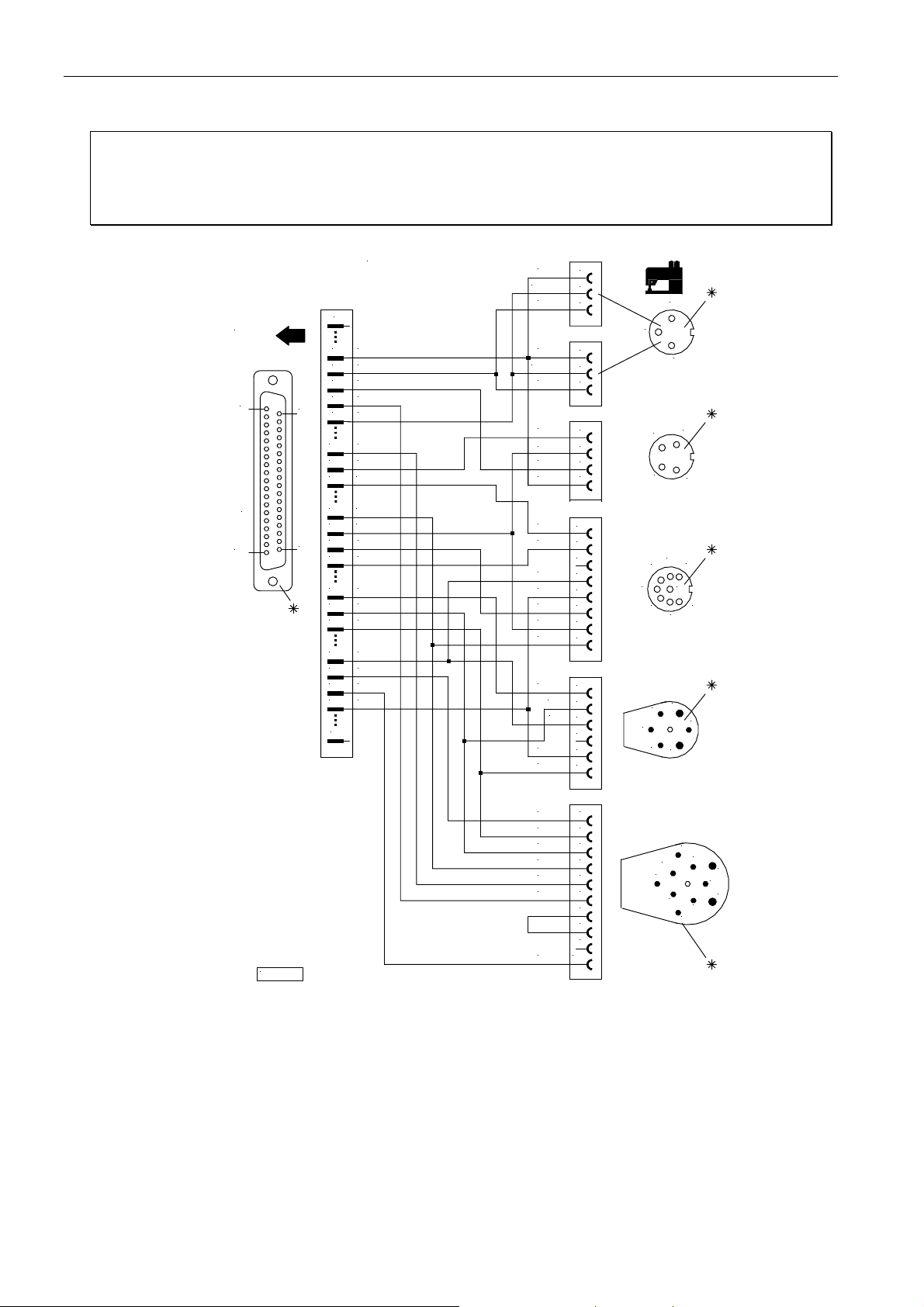

Adapter cord for UNION SPECIAL model 34700 with stitch lock

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 5

Setting the functions of the keys Input in8 ! Set parameter 247 = 7

Input in9 ! Set parameter 248 = 6

ST2

1

SUB - D- 37

19

Nr. 11128 44

1

4

10

20

13

15

16

17

18

19

20

37

26

27

28

32

33

34

0V

in8

in9

+ 15V

+ 24V

+ 24V

+ 24V

0V

POS1

+ 24V

M3

M2

M5

+ 24V

VR

FL35

M137

+ 24V

FA

FW

0V

+ 15V

LSP

NKFA8

+ 24V

STV

+ 24V

POS1

STOP

0V

10

1

2

3

4

5

6

7

9

1

2

3

1

2

3

4

9

8

10

1

2

1

2

3

2

3

7

6

5

4

3

1

4

+ 24V

ML

FL

KL2260

*) Rear view (soldering side) of 37-pin plug (ST2) and of the remaining sockets.

1

2

3

4

5

6

5

6

1

4

2

3

EFKA AB320A5200

26

Adapter cord for UNION SPECIAL models 34000 and 36200

Setting the functional sequence Thread trimming mode ! Set parameter 290 = 4

Setting the functions of the keys Input in1 ! Set parameter 240 = 6

Input in3 ! Set parameter 242 = 6

Input in4 ! Set parameter 243 = 18

Input in5 ! Set parameter 244 = 12

ST2

1

SUB - D - 37

19

20

37

Nr. 1112865

1

4

0V

5

in5

6

in3

7

in1

8

in4

15

+15V

16

+24V

17

+24V

19

0V

20

POS1

21

POS2

22

GEN

26

+24V

27 M3

28

M2

32

M5

33

+24V

34

VR

35

FL

37

0V

FLAT- S

FLEX

0V

FLAT- S

FLEX

+24V

POS1

LSP

0V

+24V

GEN

ML

FL

POS2

POS1

0V

+24V

FW

ML

FL

FA- V

1

2

2

2

3

1

4

2

5 7

6

1

2

1

3

1

4

6

8

3

5

4

3

3

1

2

3

1

2

3

4

1

2

3

4

5

6

7

8

1

2

3

4

5

6

+24V

1

FA- V

2

FW

3

0V

4

+15V

5

LSP

6

7

8

9

10

FA- R

KL2289

in1 = Input machine run blockage for thread trimming control proximity switch

in3 = Input machine run blockage for thread monitor

in4 = Input unlocking the chain corresponds to function flatseamer (FLAT-S)

*) Rear view (soldering side) of 37-pin plug (ST2) and of the remaining sockets.

9

8

10

1

2

7

6

5

4

3

Loading...

Loading...