Page 1

VR-CM50 CONSOLE SYSTEM

INSTALLATION GUIDE

Second Printing

February 1996

Supersedes 004-3039-274 May 1995

Page 2

Page 3

VR-CM50 CONSOLE SYSTEM

INSTALLATION GUIDE

Copyright 1995 by the E.F. Johnson Company

The E.F. Johnson Company designs and manufactures two-way radio equipment to serve a wide variety of communications

needs. Johnson produces equipment for the mobile telephone and land mobile radio services which include business, industrial, government, public safety, and personal users. In addition, Johnson designs and manufactures electronic components used

in communications equipment and other elect r oni c devi ces .

LAND MOBILE PRODUCT WARRANTY

The manufacturer’s warranty statement for this product is available from your product supplier or from the E.F. Johnson

Company, 299 Johnson Avenue, Box 1249, Waseca, MN 56093-0514. Phone (507) 835-6222.

WARNING

This device complies with Part 15 of the FCC rules. Operation is s ubject to the condition that this device does not cause

harmful interference. In addition, changes or modification to this equipment not expressly approved by E. F. Johnson could

void the user’s authority to operate this equipment (FCC rules, 47CFR Part 15.19 ).

DO NOT allow the antenna to come close to or touch, the eyes, face, or any exposed body parts while the radio is transmitting.

DO NOT operate the radio near electrical blasting caps or in an explosive atmosphere.

DO NOT operate the radio unless all the radio frequency connectors are secure and any open connectors are properly terminated.

DO NOT allow children to operate transmitter equipped radio equipment.

SAFETY INFORMATION

Proper operation of this radio will result in user exposure below the Occup ational Safety and Health Act and Federal Communication Commissi on limi t s .

The information in this document is subject to change without notice.

Page 4

Page 5

TABLE OF CONTENTS

1 PRE-INSTALLATION INFORMATION

1.1 RECEIVING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

VISIBLE LOSS OR DAMAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CONCEALED LOSS OR DAMAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

PACKING LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

UNPACKING THE SHIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

TOOLS REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 CENTRAL PROCESSOR PACKAGE INSTALLATION

2.1 LOCATION OF THE CENTRAL PROCESSOR PACKAGE (CPP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 ASSEMBLY OF THE CENTRAL PROCESSOR PACKAGE (CPP) CABINETRY. . . . . . . . . . . . . . . . . . . . 2-1

2.3 CONNECTION OF THE CENTRAL PROCESSOR PACKAGE CABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

CABLE ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 MOUNTING OF SURGE ARRESTOR BOXES AND GROUND BRACKET. . . . . . . . . . . . . . . . . . . . . . . . . 2-4

PLACEMENT OF SURGE ARRESTOR BOXES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

WALL OR PANEL BOARD INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.5 GROUNDING THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.6 GROUNDING INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.7 CPP I/O PANELS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.8 SAMPLE CUSTOMER DATA SHEETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.9 WIRING OF SURGE ARRESTOR BOXES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.10 DISPATCH POSITION CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.11 VOTER SYSTEM CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.12 LOGGING RECORDER CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.13 PRINTER INSTA LL ATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.14 MODEM INSTALLA TI ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.15 CONNECTION TO AUXILIARY CONTROL FUNCTIONS (Standard Cabinet) . . . . . . . . . . . . . . . . . . . . 2-13

2.16 CONNECTION TO AUXILIARY CONTROL FUNCTIONS (14 Card Central Cabinet) . . . . . . . . . . . . . . 2-15

2.17 PA SYSTEM FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.18 CONNECTIONS TO AC POWER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

3 CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

3.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 TOOLS REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 CONSOLE ARRANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.4 MAIN CONSOLE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.5 CONSOLE LEVELI NG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.6 FORMICA WRITING SURFACE ARRANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.7 WRITING SUPPORT RAIL MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.8 ATTACHING THE FORMICA WRITING SURFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.9 FORMICA WRITING SURFACE AND TRIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.10 CABINETRY OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

STABILIZER KIT (Option 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

ADJUSTABLE KEYBOARD SEAT (Option 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

UNIVERSAL KEYBOARD DRAWER MOUNTING (Option 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

UNIVERSAL PENCIL DRAWER MOUNTING (Option 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

TYPEWRITER EXTENSION ASSEMBLY (Option 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

PIE SUPPORT RAIL MOUNTING (Option 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

CRT MONITOR SHELF - FXM-192 (Option 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

1

Page 6

TABLE OF CONTENTS (CONT.)

4 CRT-BASED ELECTRONICS ASSEMBLY PART I

4.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 INSTALL THE PC/UPS SLIDE TRAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 CRT INTERFACE PROCESSOR (CIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

INSTALL THE CIP POWER SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

INSTALL THE CRT INTERFACE PROCESOR (CIP) TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

5 CRT-BASED ELECTRONICS ASSEMBLY PART II

5.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 INSTALL THE PC AND UPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 CONNECT THE PC CPU AND PC UPS POWER CORDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.4 CONNECT THE CRT INTERFACE PROCESSOR (CIP) TRAY CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.5 INSTALL THE CRT MONITOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -3

CRT MONITOR CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

ADDITIONAL CONNECTION FOR A 17 " OR 21 " IDEK MONITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.6 INSTALL CRT TOUCHSCREEN (Option TDV-OP492) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

MOUNT TABS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

INSTALL THE TOUCHSCREEN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

CONNECT THE TOUCHSCREEN CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.7 INSTALL CRT TRACKBALL OPTION/MOUSE OP TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.8 INSTALL HEADSET JACK (Options TDV-OP406, 407, 409). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.9 INSTALL SECOND VOLUME CONTROL KNOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.10 SET UP AND OPERATION OF THE HEADSET JACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.11 CONNECTING A TELEPHONE INSTRUMENT TO THE TELCO INTERFACE. . . . . . . . . . . . . . . . . . . . 5-5

6 EQUIPMENT CHECK-OUT AND ADJUSTMENTS

6.1 INITIAL POWER-UP AND CHECK-OUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 CPP ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 CONSOLE ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 ALIGN THE CRT TOUCHSCREEN WITH THE PC COMPUTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -3

6.5 AFTER SYSTEM CHECK-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

LIST OF FIGURES

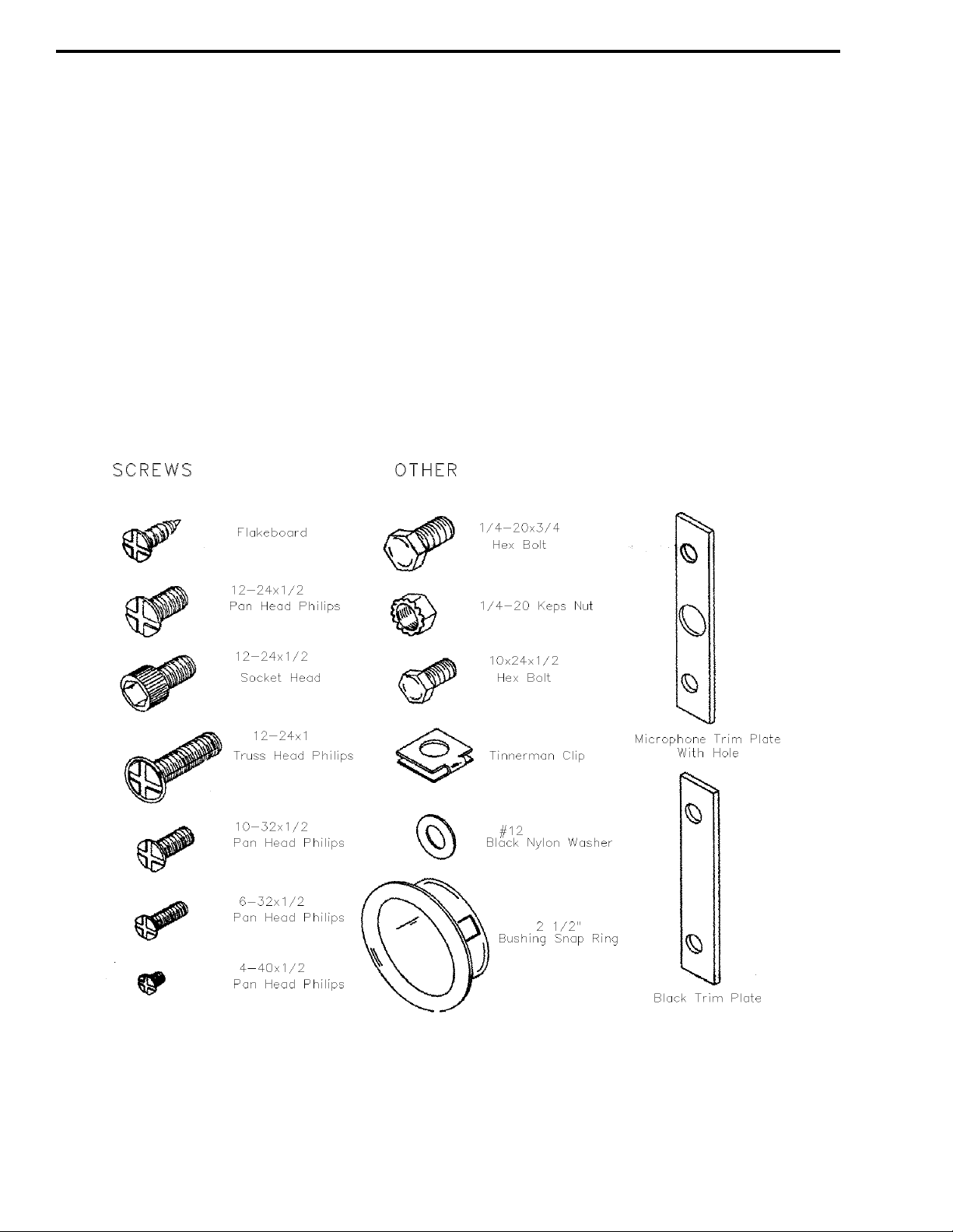

1-1 HARDWARE INCLUDED FOR INSTALLATION AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2-1 REAR VIEW - JOINING TWO CPU CABINETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 CPU CABINET CABLE CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 MOUNTING SURGE ARRESTOR BOXES AND GROUND BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-4 STAR GROUNDING CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-5 COMMON GROUND BRACKET ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2-6 CPP I/O PANELS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2-7 I/O CONNECTOR PANEL ASSIGNMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2-8 RTL I/O PANEL ASSIGNMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-9 VOTING COMPARATOR DISPLAY/CONTROL MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-10 LOGGING RECORDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-11 AUXILIARY CONTROL RELAY ASSIGNMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2-12 SURGE ARRESTOR BOX WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2-13 CPU RELAY PANEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2

Page 7

TABLE OF CONTENTS (CONT.)

2-14 14 CARD RELAY PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2-15 CPP POWER SUPPLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

3-1 SAMPLE CONSOLE LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 WRITING SUPPORT MOUNTING HOLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3 ASSEMBLY OF CONSOLE SECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-4 FORMICA SURFACE ARRANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-5 LEVELING THE CONSOLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-6 WRITING SUPPORT RAIL MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-7 CTP TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-8 JOINING FORMICA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-9 SECURING THE FORMICA WRITING SURFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-10 FORMICA WRITING SURFACE AND TRIM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-11 STABILIZER KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-12 ADJUSTABLE KEYBOARD SEAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-13 KEYBOARD DRAWER MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-14 UNIVERSAL PENCIL DRAWER MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-15 TYPEWRITER EXTENSION ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3-16 PIE SUPPORT RAIL MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-17 INSTALLING TINNERMAN CLIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-18 CRT MONITOR SHELF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

4-1 PC AND UPS SLIDE TRAY ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2 CIP POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-3 CIP TRAY WITH MICROPHONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

5-1 CPU AND UPS POWER CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2 CIP POWER SUPPLY LINE TERM BOARD - A1709230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-3 TOUCHSCREEN INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-4 CABLE CONNECTION TO CIP PS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5-5 HEADSET JACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-6 CIP BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-7 CONNECTOR HEADSET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-8 TELCO CONNECTION TO CIP PS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

LIST OF TABLES

1-1 SAMPLE PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

2-1 CPU CABINET HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-2 I/O PANEL REPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-3 STANDARD COLOR CODE ASSIGNMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

3-1 MONITOR SHELF HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

4-1 PC UPS OPTION NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-2 SLIDE TRAY HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-3 POWER SUPPLY HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-4 CIP TRAY HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4-5 CIP TRAY CABLE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

5-1 PC UPS OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5-2 CRT CABLE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5-3 VOLUME CONTROL HARDWARE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

3

Page 8

Page 9

PRE-INSTALLATION INFORMATION

SECTION 1 PRE-INSTALLATION INFORMATION

1.1 RECEIVING INFORMATION

I M P O R T A N T

This merchandise was carefully packed and thoroughly inspected before leaving our factory. Responsibility for its saf e delive ry was assumed by the carr ier

upon acceptance of the shipment. Claims for loss or

damage sustained in transit must therefore be made

upon the carrier as follows:

1.1.1 VISIBLE LOSS OR DAMAGE

Any external evidence of l o ss or d amage mu st b e

noted on the freight bill or express receipt and signed

by the carrier’s agent. Failure to adequately describe

such external evid ence of loss o r damage may result in

the carrier refusing to honor a damage claim. The

form required to file such a claim is supplied by the

carrier.

1.1.2 CONCEALED LOSS OR DAMAGE

tor, PC and UPS units for CRT-based consoles. You

are strongly advised to save at least one shipping carton for each of these devices in the event a return for

repair is needed.

You as the consignee, are responsible for filing

any claims for loss or damage. E.F. Johnson will

assist you in establishing the value of the claim after

you have filed the claim with the carrier. Call the

Customer Service Department at 1-800-328-3911 for

further assistance.

1.1.3 PACKING LIST

Since this product is cus tom designed to meet our

customer’s needs, it is not practical to pack our products in any specific pattern.

As each loose item (see Note below) is packed it

is noted on the Packing List (see Table 1-1).

1.1.4 UNPACKING THE SHIPMENT

Concealed loss or damage means ; loss or damag e

that is not apparent until the merchandise has been

unpacked. The contents may be damaged in transit

due to rough handling even though the carton or cabinet may not show external damage. When the damage is discovered upon unpacking, you must make a

As each item is removed from the container,

please check it against the Packing List. If there are

any discrepancies, please contact Customer Service,

1-800-328-3911, within 7 days of receipt. E.F.

Johnson cannot be held responsible for discrepancies beyond this 7 day period.

written request for inspection by the carrier’s agent

within 15 days of the delive ry date . Then file a claim

with the carrier since such damage is the carrier’s

responsibility .

Note: Commercial items packaged in the original

manufacturer’s container(s) are considered loose

items. Items packaged within their containers, by the

manufacturer (power cords, etc.), are not considered

It is a requirement of certain OEM vendors that

equipment returned for repair must be shipped in its

loose items and are not listed on the E.F. Johnson

Packing List.

original carton. This specificallyapplies to the Moni-

Table 1-1 SAMPLE PACKING LIST

Container Number Part Number Description Quantity

1 A100960 Headset Jack Assy 2

... ... ... ...

1-1

February 1996

Part No. 004-3039-274

Page 10

PRE-INSTALLATION INFORMATION

1.1.5 TOOLS REQUIRED

The following tools are needed for the mechanical assembly and installation of the VR-CM50 Console System:

1/4" Flat Blade Screwdriver

#1 Phillips Screwdriver

#2 Phillips Screwdriver

7/16" Open End Wrench

3/8" Nut Driver

3/16" Ball Point Driver

3/8" Square Drive 3/16" Hex Bit

If you are in stalling cabinetry, the tools required

for those as semblies are listed in Section 3.

3/16" Hex Key

3/8" Square Drive 7/16" Socket

3/8" Drive Ratchet Wrench

Wire Strippers

Carpenter’s Level

Hand Terminal Crimp Tool - "Champ" Tool

Figure 1-1 HARDWARE INCLUDED FOR INSTALLATION AND ASSEMBLY

February 1996

Part No. 004-3039-274

1-2

Page 11

CENTRAL PROCESSOR PACKAGE INSTALLATION

SECTION 2 CENTRAL PROCESSOR PACKAGE INSTALLATION

2.1 LOCATION OF THE CENTRAL PROCESSOR PACKAGE (CPP)

In selecting a location for the Central Processor

Package (CPP) equipment cabinet, the following criteria should be considered :

1. Avoid locations which are subject to high ambient

temperatures, excessive moistu re, fl oodi ng, excessive dust or infestation by insects or small animals.

2. The cabinet must be placed in an indoor location

having a floor area l arge enough to allow access to

both the front and rear of the cabinet. The minimum

cabinet size is 21" wide by 26" deep. In addition,

wall space will be re qui red for the common ground

bracket, surge arrestor box(es) and any additional

RTL punch block(s).

3. A single, 120 VAC, 15/20 amp dedicated branch cir-

cuit is require d for CPPs of 60 c ard capacity or l ess.

Two such branch circuits are required for packages

equipped with 60 to 120 cards. Systems ordered

with options TDM-OP200/E, /GB, /I and /NZ

require 230 VAC circuits. If the building is

equipped with an emergency generator, the CPP

branch circuits should be part of the emergency

power system.

4. An earth ground bond must be provided. A contin-

uous copper cold water pipe or driven copper

ground rod are suitable grounds. Electrical con duit,

steam lines, sprinkler system l ines, util ity ma ins or

building steel may not be used as ground bonds.

Note: Verify the ground integrity yourself. It is

risky to blindly trust grounds used by others.

5. The cable run to any console location may not

exceed 4000 feet, using E.F. Johnson-provided

cable. If the console is located in a different building or if the cabl e route place s its proximity t o other

electrical lines that can induce interference, the use

of a Remote Interface Adapter (RIA) is required.

6. In placement of the cabinet, the front door of the

enclosure must be readily accessible for service.

7. A connection to an ou tside telephone lin e is required

for diagnostic modem access. If a dedicated

modem line cannot be provided, an administrative

line or a phone pa tch line can be used by r outing the

line through the modem. Progr amming the modem

to auto-answer after several rings, will allow the

line to be used for normal voic e operation as well as

CPP diagnostics.

8. Mounting space will be required for the system

diagnostic printer (TDM-OP205). If the CPP is

housed in a 60" c abinet, the printer can be p laced on

top of the CPP. If the CPP is housed in a 88" cabinet, a shelf must be provided for the printer. The

printer is supplied with a tab le-top stand which provides paper supply storage and an output tray. Do

not attempt to mount the printer inside the CPP cabinet.

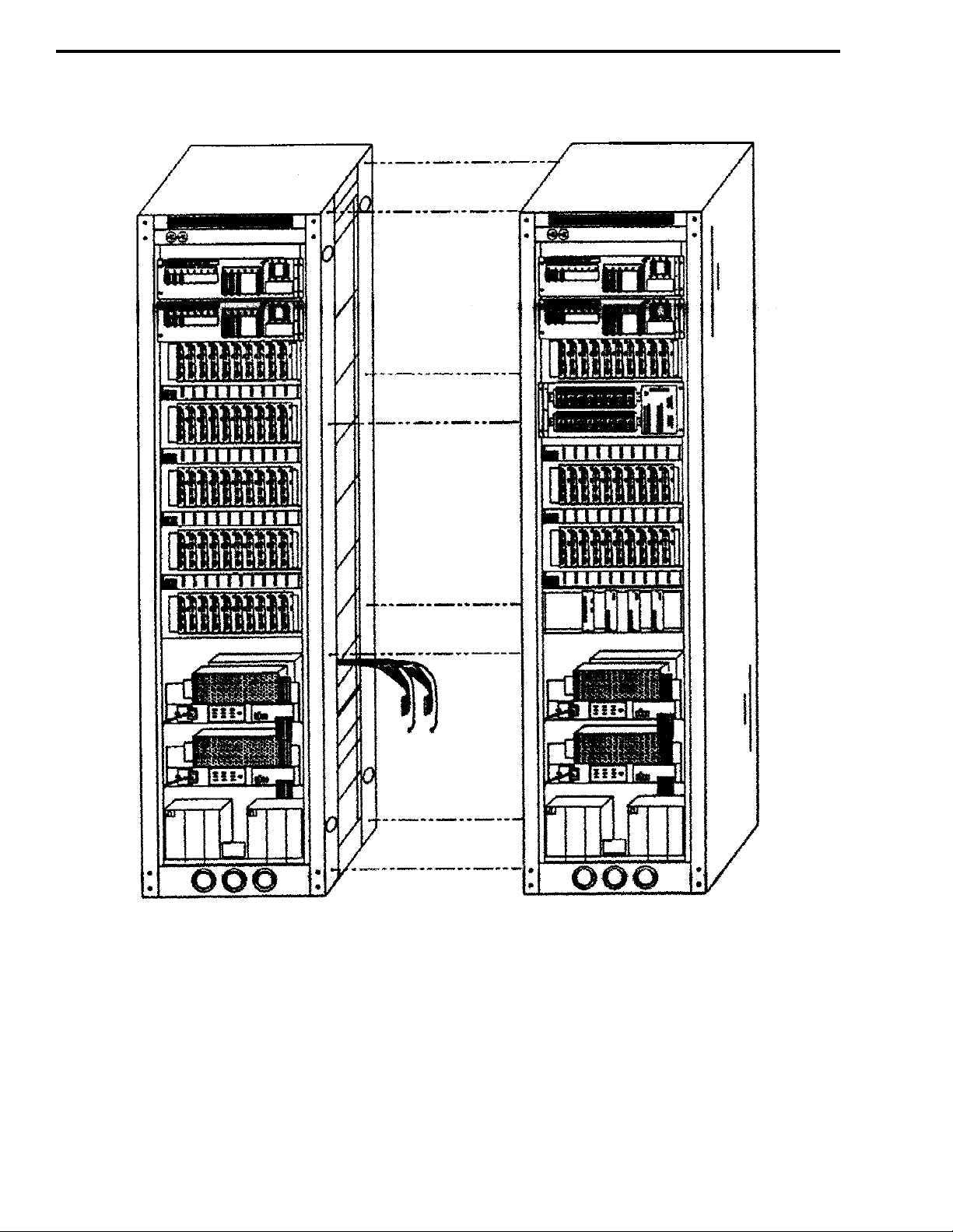

2.2 ASSEMBLY OF THE CENTRAL PROCES-

SOR PACKAGE (CPP) CABINETRY

If the CPP is housed in a single cabinet (30 cards

or less in a 60" cabinet, 60 cards or less in a 88" cabinet), no field assembly is required. If the CPP

requires two or more cabinets, each cabinet section

will be shipped separately to facilitate handling.

Assembly of the cabinets is illustrated bel ow in Figure 2-1. Be sure to install all of the required hardware; do not omit any bolts or lockwashers.

The hardware in Table 2-1 is included in Assembly A2809201 for joining 2 - 60" CPU Cabinets and

Assembly A2809301 for joining 2 - 88" CPU Cabinets:

Table 2-1 CPU CABINET HARDWARE

Qty. Part No. Description

Joining 2 - 60" CPU Cabinets

6

28011H0B2012

6

280211082041

2

240B25312420

Joining 2 - 88" CPU Cabinets

8

28011H0B2012

8

280211082041

2

240B25312420

1/4"-20 Hex Bolt

1/4"-20 Keps Nut

2.5" Bushing Snap Ring

1/4"-20 Hex Bolt

1/4"-20 Keps Nut

2.5" Bushing Snap Ring

2-1

February 1996

Part No. 004-3039-274

Page 12

CENTRAL PROCESSOR PACKAGE INSTALLATION

February 1996

Part No. 004-3039-274

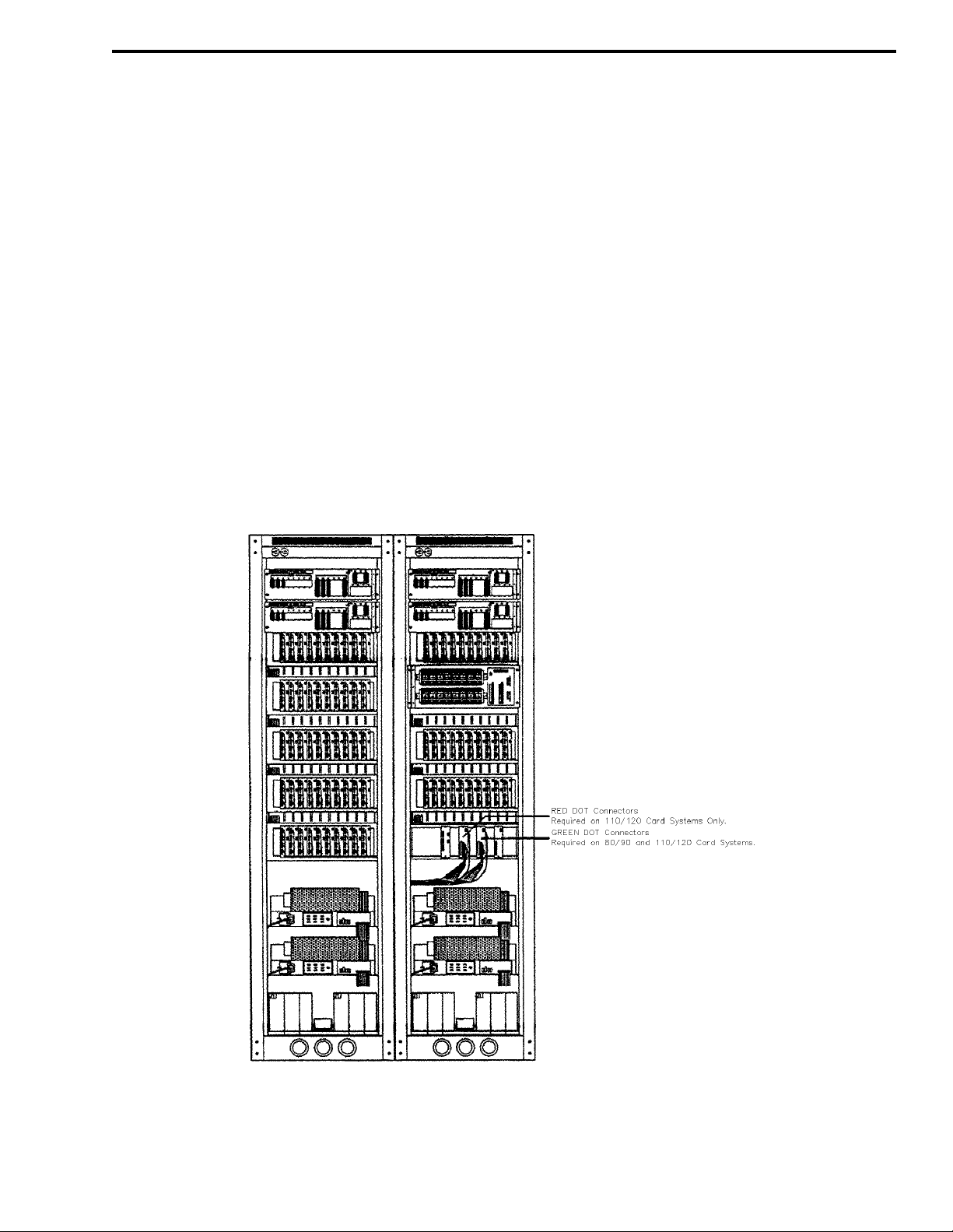

Figure 2-1 REAR VIEW - JOINING TWO CPU CABINETS

2-2

Page 13

CENTRAL PROCESSOR PACKAGE INSTALLATION

2.3 CONNECTION OF THE CENTRAL PROCESSOR PACKAGE CABLES

When multiple CPP cabinets are reuired, the system layout will have been designed to minimize the

cabling needed between cabinets. At minimum, it will

be necessary to connect the ribon cables from the

Inter-Cabinet Repeater (ICR) cards in the first cabinet,

to the backplanes and power supplies in the expansion cabinets. Depending on the size of the CPP, the

cables are marked with either RED DOTS or GREEN

DOTS.

Connect the cables ma rked wit h a RED do t to the

Line Terminator Board, which is also marked with a

RED dot. Perform the same procedure if the cables

are marked with GREEN dots (see Figure 2-2.

In some cases, it may be neces sary to co nnect I/O

ribbon cables or intercabinet mute wiring. Instructions for these details are unique to each system and

will be found in a doc ument titled "Installat ion Notes"

at the front of the "Customer Data" Section in in Volume 1 of the VR-CM50 Console Service Manual.

2.3.1 CABLE ROUTING

60" CPP cabinets are designed for cable feed

from the bottom of the cabinet.

80" CPP cabinets are designed to accept cable

feeds from either the top or the bottom of the cabinet.

88" CPP cabinets are shipped with the assumpt ion that

the cables will feed from the top or from beneath the

floor. If cable access through the bottom rear cowl is

desired, remove the black hole plugs from the cowl

and exchange them with the cable bushings in the top

vent panel.

Figure 2-2 CPU CABINET CABLE CONNECTIONS

2-3

February 1996

Part No. 004-3039-274

Page 14

CENTRAL PROCESSOR PACKAGE INSTALLATION

2.4 MOUNTING OF SURGE ARRESTOR BOXES AND GROUND BRACKET

2.4.1 PLACEMENT OF SURGE ARRESTOR

BOXES

The surge arrestor box(es) may be mounted

directly on a wall or on a plywood board at a location

near the central equipment cabinet. (Be sure the

ground lug is on top).

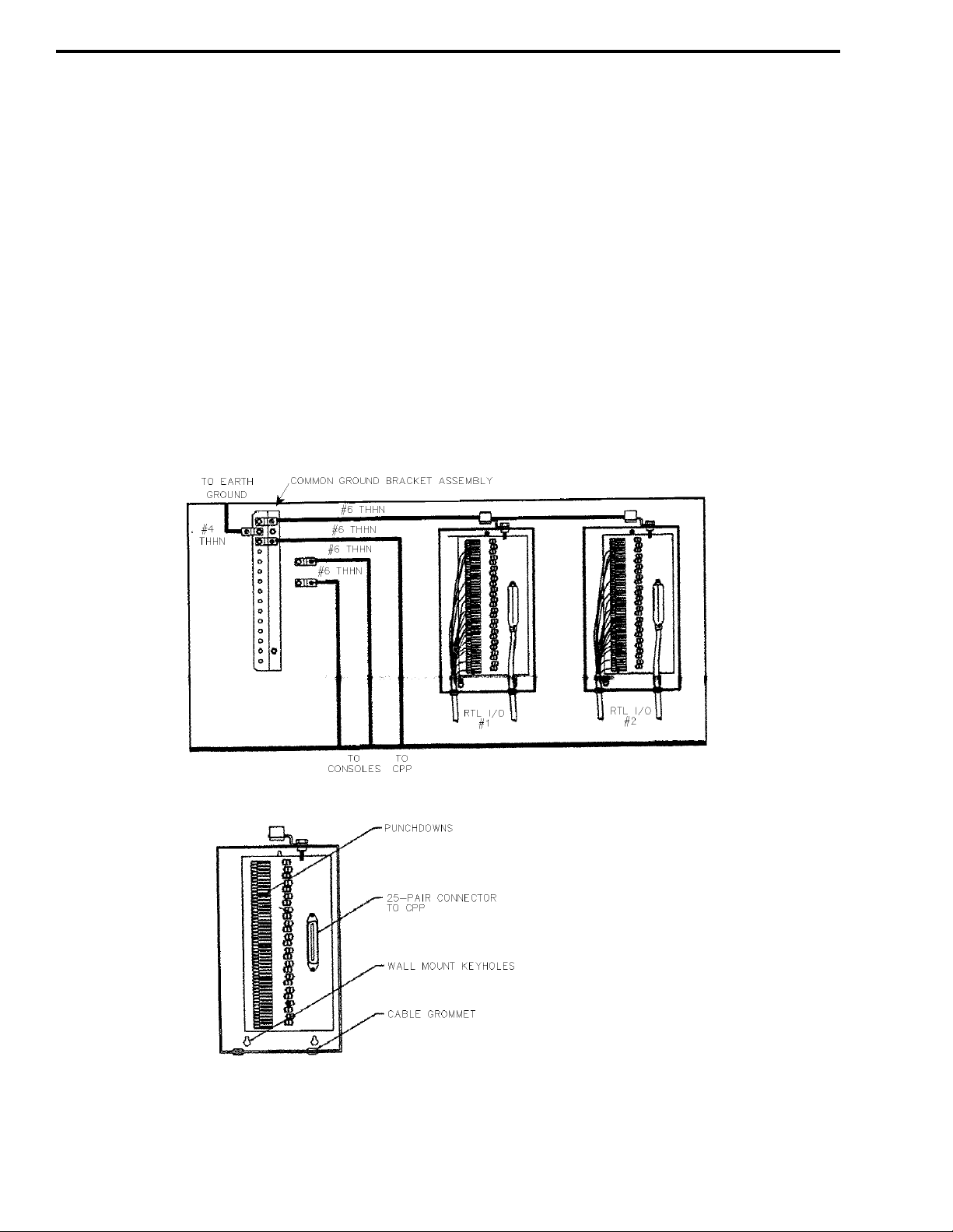

Figure 2-3 gives a general idea of how the Surge

Arrestor Boxes would appear o n a t ypical pane l boar d

complete with the common copper ground bracket

assembly.

2.4.2 WALL OR PANEL BOARD INSTALLATION

Use 1/4" diameter screws (not furnished) to

attach the surge arrestor boxes and the common

ground bracket assemb ly t o the wall . Wall mount keyholes (see Figure 2-3) are provided on the surge arrestor boxes. If the wall is of masonry construction,

again, the use of a plywood sub-panel is recommended.

C A U T I O N

DO NOT mount with the ground lug on the bottom.

Figure 2-3 MOUNTING SURGE ARRESTOR BOXES AND GROUND BRACKET

February 1996

Part No. 004-3039-274

2-4

Page 15

CENTRAL PROCESSOR PACKAGE INSTALLATION

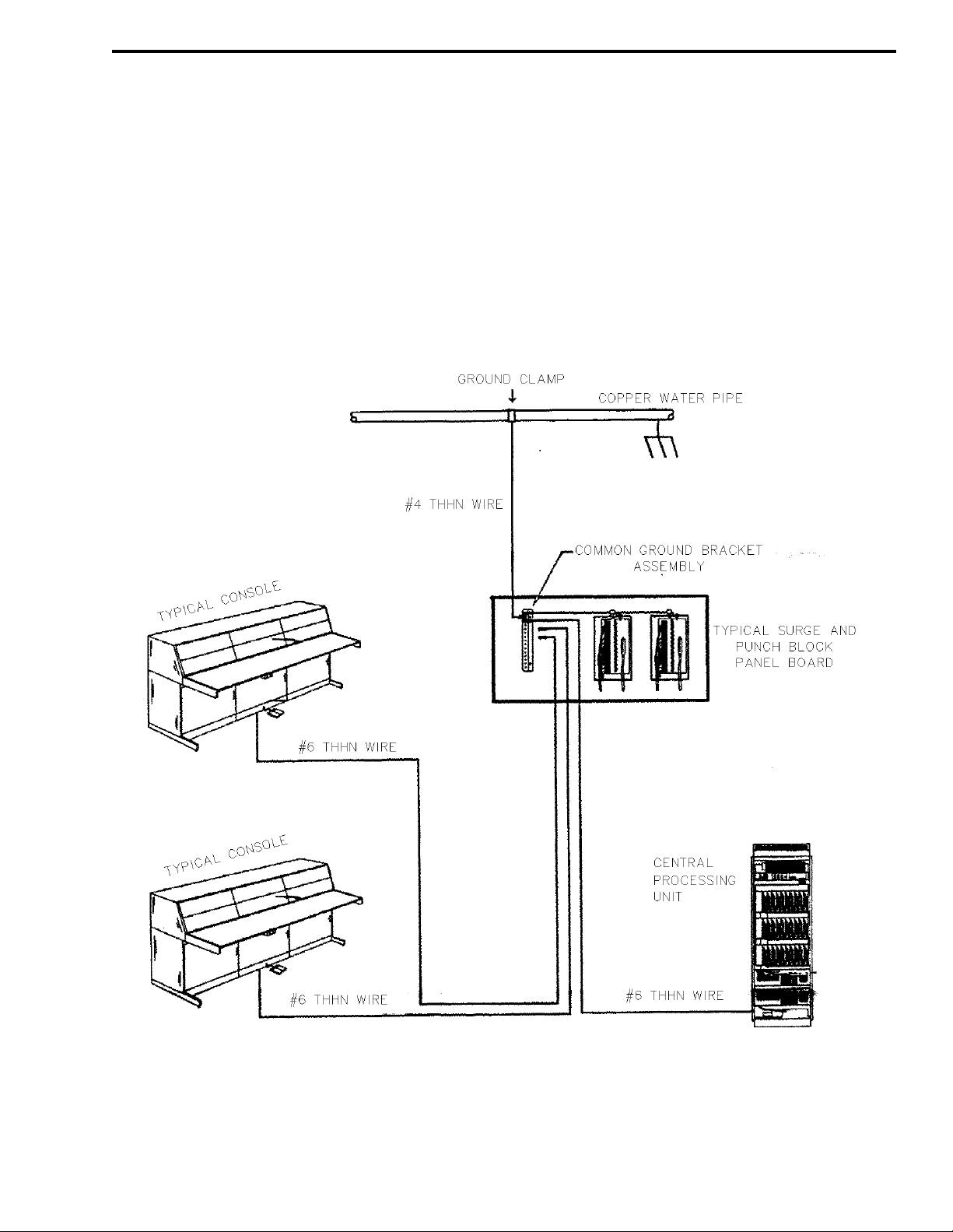

2.5 GROUNDING THE SYSTEM

Proper grounding is the single most important

consideration in installing the system. Poor or incorrect grounding can lead to unpredictable and erratic

performance problems, damage to system components in the event of lightning or power surges and

injury to personnel in extreme cases.

The VR-CM50 uses a STAR GROUNDING SYSTEM (below) in which each console is individually

bonded to a common point at the CPP using a #6

insulated wire. Connectivity instructions with

exploded views are continued on the following pages.

I M P O R T A N T

Ground the system before connecting any radio tie

lines or AC power to the system.

Figure 2-4 STAR GROUNDING CONFIGURATION

2-5

February 1996

Part No. 004-3039-274

Page 16

CENTRAL PROCESSOR PACKAGE INSTALLATION

Figure 2-5 COMMON GROUND BRACKET ASSEMBLY

2.6 GROUNDING INSTALLATION

#1 Lug

Connect a #6 THHN bare ground wire to the T OP

RIGHT (first) copper lug on the common ground

bracket asse mbly to all RTL kits (make this by taking

a length of the #6 THHN wire and stripping it). If

multiple surge arrestor boxes are used, run the #6

THHN wire through the lugs of all boxes in a straight

line. Tight en all clamps securely using the proper size

screwdriver ( 1/4" flatblade).

#2 Lug

It is very important to connect the earth ground

wire to lug #2, the lug opposite the CPP Cabinet lug

and RTL kits lugs. Refer to Figure 2-5 for acorrect

placement of the connections on the common ground

bracket assembly. Use #4 THHN wire to connect to

the ground clamp.

#3 Lug

Connect a #6 THHN wire to lug #3 (third from

top) on the common ground bracket assembly to the

ground lug in the CPP cabinet. Refer to Figure 2-5

for the location of the ground lug in the CPP cabinet.

#4, #5 Lug

Connect a #6 THHN ground wire from lugs 4, 5,

etc. of the ground bracket assembly to the ground lug

on each console position. A ground lug and hardware

has been furnished with the cable kit for each console.

February 1996

Part No. 004-3039-274

2-6

Page 17

CENTRAL PROCESSOR PACKAGE INSTALLATION

2.7 CPP I/O PANELS

CPPs with a capacity of twenty or more cards

will have one or more CPP I/O panels as shown in

Figure 2-6. If there is more than one I/O panel, each

panel is numbered. The I/O pane ls are h inged to a llow

easy access to the rear of the card cages. In routing

the I/O cables, all wiring should be dressed from the

hinge side of the panel.

Fourteen card CPPs have a single I/O panel as

shown in Fig. 2-9. This panel is at the lower left side

of the cabinet as viewed from the rear. This panel is

fixed in position - no rear access is required.

Figure 2-6 CPP I/O PANELS

2-7

February 1996

Part No. 004-3039-274

Page 18

CENTRAL PROCESSOR PACKAGE INSTALLATION

2.8 SAMPLE CUSTOMER DATA SHEETS

The Customer Data Sheets which are included in

the VR-CM50 Console Service Manual, Volume 1,

will detail t he connector and pair assignments for all

I/O functions. Connect or as signment s are defi ned in a

report titled I/O CONNECTOR PANEL ASSIGNMENTS located behind the T/R CHANNEL CONTROL PROGRAMMING sheets. If there is more

than one connector I/O panel, a report will be provided for each panel.

An illustration of the I/O Connector Panel

Assignments report is shown in SAMPLE 1 below.

Separate reports for RTL I/O Lines are shown as

SAMPLES 2, 3 and 4. A sample Auxiliary Con-

trol Relay Assignments report is shown as SAMPLE

5. These can be found on the following pages.

A separate report is provided for each I/O Con-

nector Panel.

Table 2-2 I/O PANEL REPORT

I/O Conn. Panel Report 14 Card

Dispatch position I/O Lines

RTL I/O Lines

Data I/O Lines

P1-P3

P4-P7

P8-P11

CPP

20+ Card

CPP

P1-P8

P9-P14

P15-P21

February 1996

Part No. 004-3039-274

Figure 2-7 I/O CONNECTOR PANEL ASSIGNMENTS

2-8

Page 19

CENTRAL PROCESSOR PACKAGE INSTALLATION

Figure 2-8 RTL I/O PANEL ASSIGNMENTS

Figure 2-9 VOTING COMP ARATOR DISPLAY/CONTROL MODULE

2-9

Part No. 004-3039-274

February 1996

Page 20

CENTRAL PROCESSOR PACKAGE INSTALLATION

Figure 2-10 LOGGING RECORDER

February 1996

Part No. 004-3039-274

Figure 2-11 AUXILIARY CONTROL RELAY ASSIGNMENTS

2-10

Page 21

CENTRAL PROCESSOR PACKAGE INSTALLATION

2.9 WIRING OF SURGE ARRESTOR BOXES

Typically, connectors P9 through P13 on the standard I/O panel (connectors P4 through P6 on 14 card

cabinets) will be assigned for RTL I/O connectors.

1. Connect the female end of an A600950A, 25 pair

cable to the connector in the surge box. Dress the

cable as shown in Fig. 2- 10. above . Use a s plit rub ber grommet (furnished) to pr otect the cable where

it passes through the surge box bottom flange.

Connect the male end of this cable to the appropriate mating connector in the CPP cabinet. Use a

CHAMP LOC spring (furnished) to secure each end

of the connector. Coil and t ie any excess cable - do

not shorten the cable length.

2. Use 25 pair inside telephone cable to connect the

surge arrestor block to an RTL demarcation point

punch block following the standard color code

assignment shown in Table 2-3. Since not all

installations us e all pairs presen t o n the surge arr estor block, some insta llers prefer to use indi vidual 24

gauge solid twisted pair cross-connect wires rather

than a 25 pair cable. Dress the cable or wire pairs

using standard te lephone wire management de vices

and techniques to ef fect a neat installa tion. The use

of bridging clips on each demarcation block is

strongly recommended to allow the console sys tem

to be isolated for tro ubleshooting. The connections

are defined in reports titled RTL I/O PAIR

ASSIGNMENTS. A separate report is provided for

each I/O connector.

3. Be sure to replace the lids on all surge arrestor

boxes. It is suggested that you place a copy of the

pair assignments for each box inside the box for

future reference.

Figure 2-12 SURGE ARRESTOR BOX WIRING

2-11

February 1996

Part No. 004-3039-274

Page 22

CENTRAL PROCESSOR PACKAGE INSTALLATION

Table 2-3 STANDARD COLOR CODE

ASSIGNMENTS

CABLE LINE COLOR

Pair

1

Pair

2

Pair

3

Pair

4

Pair

5

Pair

6

Pair

7

Pair

8

Pair

9

Pair

10

Pair

11

Pair

12

Pair

13

Pair

14

Pair

15

Pair

16

Pair

17

Pair

18

Pair

19

Pair

20

Pair

21

Pair

22

Pair

23

Pair

24

Pair

25

February 1996

Part No. 004-3039-274

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

1

2

3

4

5

6

7

8

9

White/Blue

Blue/White

White/Orange

Orange/White

Green/White

White/Green

White/Brown

Brown/White

White/Slate

Slate/White

Red/Blue

Blue/Red

Red/Orange

Orange/Red

Red/Green

Green/Red

Red/Brown

Brown/Red

Red/Slate

Slate/Red

Black/Blue

Blue/Black

Black/Orange

Orange/Black

Black/Green

Green/Black

Black/Brown

Brown/Black

Black/Slate

Slate/Black

Yellow/Blue

Blue/Yellow

Yellow/Orange

Orange/Yellow

Yellow/Green

Green/Yellow

Yellow/Brown

Brown/Yellow

Yellow/Slate

Slate/Yellow

Violet/Blue

Blue/Violet

Violet/Orange

Orange/Violet

Violet/Green

Green/Violet

Violet/Brown

Brown/Violet

Violet/Slate

Slate/Violet

2.10 DISPATCH POSITION CONNECTIONS

Each dispatch position will plug directly into the

J1 connector on the PIC line terminator board as

shown in Figure 2-15. Console posit ions hav ing more

than four speakers will have two or more PICs and

line terminator bo ar ds assigned. A label on the top of

the line terminator board, as shown in Figure 2-15,

will identify the position with the Console ID. The

jumpers on the line terminator board determine

whether the selected audio is sent to the le ft or right

speaker on the console. Refer to the VR-CM50 Console Service Manual to adjust them. Refer to Section

2.6 for grounding information.

2.11 VOTER SYSTEM CONNECTIONS

If this system is specified for use with a voter

system, the CPP is equipped with a TDM-AUX/V

card for each voter shelf to be connected. The connection to each voter is through a 25 pair, male ribbon

connector and a l ocal inter face board to be inst alle d at

the voter shelf. The I/O CONNECTOR PANEL

ASSIGNMENTS report will define the connector

position for each voter. The VOTING COMPARATOR DISPLAY/CONTROL MODU LE report, as

shown in Figure 2-9, defines the site and control connections. This report is formatted for either General

Electric or Motorola voters in accordance with the

data furnished to E.F. Johnson at the time of order.

These reports are interleaved with the RTL I/O PAIR

ASSIGNMENTS sheets at the designated connector

locations . Refer to the VR-CM50 Voter Modification

Kit Installation Guide - P/N 700901 ECL A, for specific voter shelf connection details.

2.12 LOGGING RECORDER CONNECTIONS

Mixed Tx/Rx audio for each individual channel

is provided for connection to a logging recorder. The

logging recorder output is a 600W balanced line at a

level of -10 dBm. On tone controlled channels, the

transmit audio will be stripped of guard tone (2175

hz) and function tones. On DC controlled channels,

the transmit audio is DC blocked.

In the case of multi-receiver base stations, the

audio from all receivers is summed with the transmit

audio by bridging the logging recorder outputs of the

LIC and the QRC cards. Jumpers on the QRC card,

associated with the base station, can be set to isolate

individual receiver audio, if required.

2-12

Page 23

CENTRAL PROCESSOR PACKAGE INSTALLATION

Typically, logging recorder audio appears on connector P14 on the standard I/O panel (connector P7 on

14 card CPP cabinets). If the CPP is housed in more

than one cabinet, a separate logging recorder output

will be provided from each cabinet to minimize the

need for intercabinet wiring. Logging recorder connections are defined in reports titled RTL I/O PAIR

ASSIGNMENTS , as shown in Figure 2-10. A separate report i s provided for each conne ctor.

2.13 PRINTER INSTALLATION

The Logging Diagnostic Printer option, TDMOP205 is strongly recommended. In the event of a

system reset, either manually or automatically initiated, the printed record is the only way to determine

what actually happened.

Assemble the printer stand in accordance with the

instructions supplied. If your CPP is housed in a 60"

cabinet, the printer may be placed on top of the CPP.

If your CPP is housed in an 88" cabinet, a separate

printer shelf will be required. Do not attempt to mount

the printer in the CPP cabinet. Unpack the printer and

remove all shipping mat erial . Inse rt th e paper, making

sure the tractor feed in engaged and the friction feed is

disengaged.

Two 120 VAC convenience outlets for the printer

and modem transformer are located in the upper left

side of the CPP vent housing. If your CPP is housed

in a 26" cabinet, the print er can be plac ed on top of the

CPP, but no outlet is provided.

Special note for 230 volt system users: The printer

supplied with your system is configured for 120 VAC

operation. The convenience outlets on the CPP are

powered via an approved 230V/120V step-down

transformer. The printer must be connected to this

outlet.

2.14 MODEM INST ALLATION

This system is equipped with a modem to allow

remote diagnostics and programming via a dial-up

phone line. The modem has been p roperl y conf igure d

for 2400 baud operation and tested at the factory prior

to shipment. Do not c hange t he modem pr ogrammin g

without specific authorization from E.F. JOHNSON

Technical Support. If you wish to access the system

via modem, your PC must be equipped with TDMOP208/PC Maintenance Software. Contact E.F.

Johnson Technical Support for details.

Connect the RS232 jack on the modem to the

modem port on the I/O panel designated in the I/O

CONNECTOR PANEL ASSIGNMENTS report.

Usually, this is P17 on 60" and 88" cabinets, P10 on

26" cabinets.

T wo 1 20 VAC convenience outle ts for the mode m

transformer and printer are located in the upper left

side of the CPP vent housing o n 60" and 88" ca binets.

If your CPP is housed in a 26" cabinet, no outlet is

provided.

Special note for 230 volt system users: The modem

transformer supplied wi th your system is designed for

120 VAC operation. The convenience outlets on the

CPP are powered via an approved 230V/120V stepdown transformer. The modem must be connected to

one of these outlets.

Connect the RJ-11 modular LINE jack on the

modem to the telephone line designated for modem

communications. If additional instruments are to be

routed through the modem for voice use, these should

be connected to the RJ-11 PHONE jack on the

modem.

2.15 CONNECTION TO AUXILIARY CONTROL

FUNCTIONS (Standard Cabinet)

Connect the printer to th e port on the I /O panel

designated in the I/O CONNECTOR PANEL

ASSIGNMENTS report. Usually, this is P15 on 60"

and 88" cabinets, P8 on 26" cabinets. The printer has

been programmed and tested prior to shipment. Refer

to the printer instruction manual should problems be

encountered.

If the console was ordered with auxiliary switch

functions specified, the CPP cabinet will have one or

more auxiliary relay panels installed. A typical relay

panel is shown in Figure 2-13. The standard relay

panel, furnished with a TDM-AUX includes eight

relays. An additional eight relays can be added by

specifying option T DM-AUX/E8. Rela ys 1 t hrough 8

are located at the bottom of the panel. Expansion

February 1996

2-13

Part No. 004-3039-274

Page 24

CENTRAL PROCESSOR PACKAGE INSTALLATION

relays 9 through 16 mount at the top of the panel.

The Customer Data Sheets which are included in the

VR-CM50 Console Service Manual, Volume 1, will

define the relay panel assignments for all Auxiliary I/

O functions. Individual relay and input assignments

are defined in a report titled AUXILIARY CONTROL RELAY ASSIGNMENTS located behind the

RTL I/O PAIR ASSIGNMENTS sheets.

Each auxiliary function key has two logic inputs

and one output relay assigned to it. Input functions

vary widely from system to system but typically, the

inputs control key indications. In most cases, A

inputs control the lef t or of f indic ation and B inputs

control the right or "on" indication. Inputs must be a

logic ground which can sink approximately 20 ma.

Use extreme caution in wiring the auxiliary func-

tions. The application of AC line voltage to an A or

B input terminal will cause serious damage to the processor circuitry.

Each auxiliary output is a 4PDT relay having a

contact rating of 5 amperes at 120 VAC. If higher

voltages or currents must be controlled, use the relay

in the CPP as a pilot relay to operate an external contactor. Each relay is mounted in a DIN socket with

screw terminals that can accept up to #12 wire. Refer

to Figure 2-13, for a detail of the relay connections.

I M P O R T A N T

The relay panel in the CPP is hinged to allow access

to the backplane circuitry behind it. In wiring to the

auxiliary inputs and relays, dress all wiring from the

hinge side of the panel.

February 1996

Part No. 004-3039-274

Figure 2-13 CPU RELAY PANEL

2-14

Page 25

CENTRAL PROCESSOR PACKAGE INSTALLATION

2.16 CONNECTION TO AUXILIARY CONTROL

FUNCTIONS (14 Card Central Cabinet)

The 14 card Central Processor can accommodate

only one Auxiliary Control Relay card with a maximum of 16 relays. A somewhat different relay

mounting arrangement is used due to space limitations. Relays 1 through 8 are mounted ve rtica lly wit h

RY1 at the bottom of the mounting strip. Note carefully the loca tion of the COIL terminals; the relay

sockets are rotated 900 clockwise from the

CPU main Relay Panel as shown in Figure 2-14.

The TDM-AUX/E8 accessory provides relays 9

through 16, just as in the larger cabinets. In this package however, the accessory relay strip is stacked

above the primary relay strip as shown in Figure 2-14

with addition of AUX/E8.

The A and B control inputs are contained on a

circuit board which mounts on the sidewall of the

relay housing to the left of the primary relay strip.

All control functions are identical to those shown for

larger CPP cabinets.

Figure 2-14 14 CARD RELAY PANEL

2-15

February 1996

Part No. 004-3039-274

Page 26

CENTRAL PROCESSOR PACKAGE INSTALLATION

2.17 PA SYSTEM FEED

The CPP can be connected to a building public

address to permit paging via the dispatch console(s).

The console(s) must be equipped with programming

option TDM-OP431 or TDV-OP431 to use this feature.

1. Connection to the PA system is made from TB4 on

the CSC line terminator I/ O board, located on the

rear of the CPP power supply as shown in (see Figure 2-15 for terminal locations on the Line Terminator Board).

2. PA feed audio is obtained from terminals A1 and

A2. The audio output is a 600W balanced line at 10 dBm.

3. PA PTT is obtained fr om termi nals K1 an K2. PTT

is an isolated, normally open dry contact closure,

which may be wired into the audio path or used to

control an amplifier gate (preferable).

2.18 CONNECTIONS TO AC POWER

The CPP is connected to its AC power feed via a

surge protect ed power dist ribution strip in the CPP

cabinet. One strip will be provide d for every two , 60"

cabinets or each individual 88" cabinet. An IEC-320

input connector and l ine cor d is l ocate d on the b ottom

of the AC strip. The line cor d co nnector has been supplied in accordance with the power supply option

specified at the time of order.

February 1996

Part No. 004-3039-274

Figure 2-15 CPP POWER SUPPL Y

2-16

Page 27

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

SECTION 3 CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

3.1 INTRODUCTION

This section contains the instructions to assemble VR-CM50 CABINETRY. If you purchased a

complete VR-CM50 system, most electronic components will be pre-installed in your VR-CM50 cabinetry.

3.2 TOOLS REQUIRED

The following tools are needed for mechanical

assembly of the TDM-150 Console cabinetry.

#2 Phillips Screwdriver

Power Screwdriver with #2 Phillips Bit

3/8" Open End Wrench

7/16" Open End Wrench

1/2" Open End Wrench

3/8" Square Drive 7/16" Socket

Carpenter’s Level

White Carpenter s Glue (Required only if multiple

writing surfaces must be joined)

3.3 CONSOLE ARRANGEMENT

Consoles are shipped in 2, 3 or 4 bay sections

depending on the final cabinet configuration. Before

assembly begins, arrange the console sections (bays)

in their proper room layout positions. Individual sections will be identified with letters A , B , and C ,

beginning with left-most section. The letter designations will appear on the inside ends of the console

frame. Refer to your proposal diagram for the correct

layout positions. A sa mple propos al diagr am is shown

in Figure 3-1.

It is important to note that the console sections

should not be forced to conform to surrounding walls

or structures. This will ultimately bend the console

frames so that the Formica will not fit properly as

designed.

Once the Formica writing surface is permanently

mounted, DO NOT ATTEMPT TO MOVE THE

CONSOLES!

Figure 3-1 SAMPLE CONSOLE LA YOUT

3-1

February 1996

Part No. 004-3039-274

Page 28

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

3.4 MAIN CONSOLE ASSEMBLY

4. Remove the front a nd rear keylocke d enclosure panels from each bay and set them aside.

C A U T I O N

Keylocks will scratch keylock enclosure panels if they

are stacked or leaned against each other.

5. Accurately place the console s ection at it s final lo cation before continuing with STEP 3.

6. Using #1/4-20 x 3/4 hex bolts and #1/4-20 x 3/4

Keps nuts, attach the consol e sections together using

pass-through holes in the sides.

Note: Be consistent when orienting the bolts in the

pass-through holes. Refer to Figure 3-3.

Figure 3-3 ASSEMBLY OF CONSOLE SEC-

TIONS

Do not attach the consol es at the centermost hole s.

These holes will be used to fasten the writing support rails. Refer to Section 3.7.

7. Be sure the sections are in p erfect alignment before

securing the fasteners.

HINT: When aligning console sections, a #2 Phillips screwdriver may be placed through one of the

centermost holes and used as an alignment tool.

3.5 CONSOLE LEVELING

1. Consider carefully where the consoles are located.

Any gross unevenness in the flooring should be

eliminated. Small deviations can be compensated

using the individual levelers at each console.

Note: Levelers are screwed in all the w ay in shipment. Refer to Figure 3-5.

2. Level the console assembly both side-to-side and

front-to-back using the threaded levele rs in each

cabinet section. Levelers can be adjusted by using

an 1/2" open end wrench o r by ha nd tu rning. Hin t:

a piece of scrap wood may be used to prop up the

console to aid in leveling. Be sure each leveler is

snug against the floor and supports its proper share

of the overall weight.

Figure 3-2 WRITING SUPPORT MOUNTING

HOLES

February 1996

Part No. 004-3039-274

NOTE: Once the levelers have been extended, do

not shift the console position. Lateral movement

can bend the leveler stems making proper adjustment extremely difficult.

3-2

Page 29

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

Figure 3-4 FORMICA SURFACE ARRANGEMENT

Figure 3-5 LEVELING THE CONSOLE

3.6 FORMICA WRITING SURFACE ARRANGEMENT

1. Locate all writing surface Formica and arrange on

the floor in front of console. A typical layout is

shown in Figure 3-4. Permanent mounting can be

accomplished more easily if the Formica is arranged

on the floor directly in line to its mo unting positio n

on the console.

2. Mark the console face where the breaks occu r in the

Formica writing surface. The marks should be

made below the writing surface plane so that they

will be hidden when the Formica is installed.

3.7 WRITING SUPPORT RAIL MOUNTING

The writing support rails are necessary for

mounting and providing support to the Formica writing surfaces of consoles. One support rail is provided

for each side-by-side cabinet bay consisting of two or

more consoles including pie-shaped pieces. For twobay cabinetry, one support rail is provided at each end

and in the middle. For conveni ence, t he rai ls an d their

mounting locations are numbered.

1. Install the writing support rail number at the corre-

sponding location number found on the side of the

console frame.

3-3

February 1996

Part No. 004-3039-274

Page 30

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

Figure 3-6 WRITING SUPPORT RAIL MOUNTING

2. Fasten the writing support ra il with thr ee #1/4-20x3 /

4 Keps nuts as shown in Figure 3-6. One support

rail must be used on either side of writing surface

break as previously marked.

3. All other bays use only one support rail per bay as

shown in Figure 3-6.

4. It may become necessary to partially remove the

equipment in the sloped turret to access holes for

mounting the support rails. Removal of four panel

mounting screws allows the t ray t o sl ide out and r et

on hinges as shown in Figure 3-7.

February 1996

Part No. 004-3039-274

NOTE: If the console has a keyboard recess, a

shorter keyboard support rail is used in place of a

writing support rail. Refer to Figure 3-11.

If the system configuration includes 45° sections:

1. Remove the front #1/4-20x3/4 hex bolt.

2. Slide the support rail through the slot and replace

the bolt.

3-4

Page 31

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

3. Pass the driver through the access in the bottom of

the support rail and drive #10x3/4" flakeboard

screws* up into the Form ica wr iting surfa ce. Refe r

to Figure 3-9.

4. Align as necessary using an electric screwdriver

with a #2 Phillips driver.

NOTE: Hex extensions or long hex driver s will no t

pass through the holes.

C A U T I O N

Use only VR-CM50-provided flakeboard screws to fasten the writing surface. Longer screws will protrude

through the Formica surface.

Figure 3-7 CTP TRAY

3.8 ATTACHING THE FORMICA WRITING SURFACE

1. Position all writing s urfac es on the wri ting support

rails.

2. Where a split occurs i n the Formica writi ng surface,

insert wood biscuit s into the slots on the sides of the

surfaces. Refer to Figure 3-8.

HINT: To help align the Formica writing surfaces

flush, it is advisable to glue the biscuits into place

using white carpenter’s glue.

Figure 3-8 JOINING FORMICA

Figure 3-9 SECURING THE FORMICA WRIT-

ING SURFACE

3-5

February 1996

Part No. 004-3039-274

Page 32

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

Figure 3-10 FORMICA WRITING SURFACE AND TRIM

3.9 FORMICA WRITING SURFACE AND TRIM

1. Align the Formica writing surface end trim with the

double holes in the las t writing support ra il. Use the

bottom-most hole, on the rail, to mo unt the Formica

writing surface end trim.

2. Fasten the Formica writing surface end trim using

the two (2) fender 1/4x1" washers and two (2) 832x1/2 screws as shown in Figure 3-10.

3. A correctly mounted Formica writing surface end

trim is show n in Fig. 3-15. Notice that the bottom

of the end trim aligns perfectly with the co nsole end

kit metal.

February 1996

Part No. 004-3039-274

Replace all keylocked enclosure panels. The

standard mechanical assembly is now complete. If

your console configuration has optional equipment,

PLEASE CONTINUE.

3.10 CABINETRY OPTIONS

VR-CM50 offers the following cabinetry options

for your system. Installation instructions begin in the

follow sections:

3.10.1 STABILIZER KIT (OPTION 1)

Refer to Figure 3-11. For cabinetry consisting o f

two or more in-line cabinet bays, two (2) stabilizer

kits are required - one at each end of the console. For

3-6

Page 33

cabinetry consisti ng of a pi e-shap e secti ons al ong with

2 or more cabinet bays in-line before the turn, one (1)

stabilizer kit only is required at the end opposite the

pie-shaped section. For assembly purposes, each console that is required to have a stabilizer installed, is

identified with a label: Mount Stabilizer Leg Here

1. Align the stabili zer l eg wit h the bottom holes of the

console bay as indicated.

2. Fasten with two (2) # -20x hex bolts.

3. Conceal the bolts b y placing hole plu gs as shown in

Figure 3-11.

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

Figure 3-12 ADJUSTABLE KEYBOARD SEAT

3.10.3 UNIVERSAL KEYBOARD DRAWER

MOUNTING (OPTION 3)

Figure 3-11 STABILIZER KIT

3.10.2 ADJUSTABLE KEYBOARD SEAT (OPTION 2)

Refer to Figure 3-12.

1. Mount the keyboard sup port rail (#2 short rail) in the

rear of the keyboard opening.

2. Align the adjustable keyboard seat with the wri ti ng

surface cutout.

Refer to Figure 3-13.

1. Mount the #2 short keyboard support rails as in

Option 2, behind the keyboard drawer.

2. Position the keyboard drawer 1" back from the

front of the Formica writing surface.

3. Drive six (6) #10 x 3/4 flakeboard screws up into

the wood.

3. Drive seven (7) #10 x 3/4 flakeboard screws up into

the wood using the pre-drilled holes.

Figure 3-13 KEYBOARD DRAWER MOUNT-

ING

February 1996

3-7

Part No. 004-3039-274

Page 34

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

3.10.4 UNIVERSAL PENCIL DRAWER MOUNTING (OPTION 4)

1. Remove the pencil drawer from the mounting frame

by depressing th e black slide retainers. Refer to Fig ure 3-14.

2. Position the mounting frame in the desi red loc ation

between the writing support rails - 1 " back from the

front of the Formica writing surface.

3. Drive six (6) #10 x 3/4 flakeboard screws up into

wood. Refer to Figure 3-14

4. Re-insert the pencil drawer.

3. Attach the typewriter extension support to the typewriter extension using four (4) 10x3/4 flakeboard

screws. (On 21" typewriter extensions, five (5)

10x3/4 flakeboard screws are used) .

4. Attach the entire assembly to the position desired on

the Formica writing surface. Use four (4) 10x3/4

flakeboard screws to secure t he assembly to the For mica writing surface. (On 21" typewriter extensions, five (5) 10x3/4 flakeboard screws are used).

5. Hand turn the leveling fe et at the bottom of t he modesty panel to ensure a level typewriter extension

surface.

Figure 3-14 UNIVERSAL PENCIL DRAWER

MOUNTING

3.10.5 TYPEWRITER EXTENSION ASSEMBLY

(OPTION 5)

Refer to Figure 3-15. The Typewriter Extension

Assembly consists of a typewriter extension, a typewriter extension support, two (2) triangle braces and

hardware. It is packed flat for shipping and must be

assembled in the field.

NOTE: The following asse mbly instr uctions pertain t o

both 18" and 21" typewriter extension lengths.

1. Attach the triangle brace to the modesty pan el using

three (3) 10-32x1/2 p an head screws for each tr ian gle brace.

2. Flip the typewriter extension over on its top side to

attach the other side of the triangle brace. Use three

(3) 10x3/4 flakeboard screws for each triangl e brace

and attach to the typewr iter extensio n.

Figure 3-15 TYPEWRITER EXTENSION AS-

SEMBLY

3.10.6 PIE SUPPORT RAIL MOUNTING (OPTION 6)

Refer to Figure 3-16. The Pie Support Rail is

attached using the same hole pattern as the writing

support rail.

1. Mount the rail with the angle of the rail following

the angle of the break in the writing surface.

2. When the Formica writing surface is attached, use

two (2) flakeboard scre ws on each si de of t he writ ing surface break. Refer to the Section 3.5.

February 1996

Part No. 004-3039-274

3-8

Page 35

Figure 3-16 PIE SUPPORT RAIL MOUNTING

3.10.7 CRT MONITOR SHELF - FXM-192 (OPTION 7)

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

2. Mount the CRT Monitor Shelf

The monitor shelf is mounted in the base section

of the FC192 cabinet. Refer to Figure 3-18.

a. Snap Tinnerman clips to the 6th hole countin g

down from the top of the lower frame side on both

the front left and right sides of the cabinet.

b. Snap Tinnerman clips to the 8th hole counting

down from the top of the lower frame side on both

the rear left and right sides of the cabinet.

c. Install the monitor shelf with the four (4) 12-24x

pan head Phillips screws provided. The monitor

shelf mounts with the 2.5" hole to the rear.

d. Remount the distribution rail to holes 31 and 33

(counting up from the console bottom) using the

(4) -20x3/4 hex bolts previously removed.

The hardware in Table 3-1 is included with the

Monitor Shelf assembly (FXM-192):

1. Mount the Tinnerman Clips

a. Snap the Tinnerman clips onto the left and right

sides of the console frame at the second, third and

seventh hole, counting up from the bottom cowl.

Repeat the same, counting down from the top

cowl.

b. Attach the EIA Shims - Attach the EIA shims using

two (2) 12-24x pan head Phillips screws per shim

to the Tinnerman clips at holes 3 and 7, 12 and 16,

counting down from the top cowl.

c. Remove the Distribution Rail - Remove the

distribution rail at the rear of the cabinet by

removing the four (4) 1/4-20x3/4 hex bolts. Put

them aside to use for reassembly.

d. Install the Right and Left Inner Closures - Install

the right-side inner closure by sliding it in from the

front of the console and placing its shim between

the already installed "EIA" shims" and "inner

closure" itself. (All holes line up when seated

properly). Screw in the right-side closure with the

four (4) 12-24x1" black truss head Phillips screws

and #12 black nylon washers. Repeat this

procedure for the left side.

Figure 3-17 INSTALLING TINNERMAN CLIPS

3-9

February 1996

Part No. 004-3039-274

Page 36

CABINETRY ASSEMBLY FOR CRT CONSOLE SYSTEMS

Figure 3-18 CRT MONITOR SHELF

Table 3-1 MONITOR SHELF HARDWARE

Qty. Part No. Description

280621122400

16

280114122408

12

280129122416

4

280359120010

4

141140093B

4

144153069

2

144153161I

1

144153161R

1

144153162

1

Tinnerman Cli ps

12-24x1/2 Pan Head Philips Screw

12-24x1 Truss Head Philips Screw

#12 Black Nylon Washer

"EIA" Shim

10.5 inch Long Shim

Left Inner Closure

Right Inner Closure

Monitor shelf

February 1996

Part No. 004-3039-274

3-10

Page 37

CRT-BASED ELECTRONICS ASSEMBLY PART I

SECTION 4 CRT -BASED ELECTRONICS ASSEMBLY PART I

4.1 INTRODUCTION

Since you have purchased the E.F. JOHNSON

console system as electronics only and intend to use

another manufacturer s cabinetry, these install instructions will have to be interpreted broadly.

4.2 INSTALL THE PC/UPS SLIDE TRAY

Table 4-1 PC UPS OPTION NUMBERS

PC CPU Part No. 200TC4862501

Possible option numbers for the PC UPS

Part Number Country

TDV-OP400/A

TDV-OP400/GB

TDV-OP400/E

TDV-OP400/I

TDV-OP400/NZ

North America

Great Britain, S. Africa

Europe

India

New Zealand/Australia

Table 4-2 SLIDE TRAY HARDWARE

4. Slide the Slide Tray Assembly onto the slide

mounts. Refer to Figure 4-1.

Qty Part No. Description

88280621122400

280124102412

2 Slide Assembly (see Figure 4-1)

Qty.

2

2

1 Slide Assembly (see Figure 4-1)

1

1

1

Part No.

144233259

146563216

144233258

124163270

144233386

Tinnerman Clips

12-24x1/2 PH Phil Screw

Description

Mounting Bracket

16" Slide Assembly

Tray

Swivel Mount

PC Tray Bracket

3. Attach the slide mount assembl ies to the bottom of

the console using eight (8) Tinnerman clips

(280621122400) and eight (8) 12-24x pan head

Phillips screws (280124102412) to the left and

right sides. If you have E.F. JOHNSON cabinetry,

use the second hole and eighth hole from the bottom.

Figure 4-1 PC AND UPS SLIDE TRAY AS-

SEMBLY

4.3 CRT INTERFACE PROCESSOR (CIP)

Table 4-3 POWER SUPPLY HARDWARE

Qty Part No. Description

44280621122400

280124102412

Tinnerman Cli ps

12-24x1/2 PH Phil Screw

4.3.1 INSTALL THE CIP POWER SUPPLY

1. Install the CIP Power Supply is installed in the

upper turret of the console directly behind the CIP

tray. Use the four (4) Tinnerman cli p s a nd four (4)

12-24x1/2 pan head Phillips screws to secure the

power supply to the console frame.

4-1

February 1996

Part No. 004-3039-274

Page 38

CRT-BASED ELECTRONICS ASSEMBLY PART I

Figure 4-2 CIP POWER SUPPLY

NOTE: If the CIP power-supply and the CIP tray are

being mounted over the monitor in a 5 or 10 turret,

a shield plate has to be installed between the monitor

and turret. Use a 16 ga cold rolled steel magnetic

shield plate. The part number used in cabinetry is

144113434.

A UPS Power Fail

B CPP Data

C PC COM3

D Circu it Breaker

E Power Connector

F 13.7V DC Accessory Outlets

G Touchscreen (DIN) Connector

4.3.2 INSTALL THE CRT INTERF ACE PROCESOR (CIP) TRAY

Table 4-4 CIP TRAY HARDW ARE

Qty Part No. Description

280621122400

8

280114122408

4

280129122416

4

280359120010

4

141230970A

1

Tinnerman Clips

12-24x1/2 PH Phil Screw

12-24x1 Truss Head Phil

#12 black nylon washer

Black trim strip

Mount The CIP Tray

Install the CIP tray at the location indicated in the

Customer Specification s Do cumen tat i on or as per the

customer s preference.

1. If the cabinetry you are using does not have a panel

reveal depth of 5/8", you may have to perform one

of the following two procedures to ensure flush

mounting :

a. remove the "mounting slides" if the cabinetry is too

shallow or,

b. use a shim if it is too deep.

2. Slide the CIP tray into the cabinet and attach the

slide shims of the tray using the (4) 12-24x pan

head Phillips screws on the two innermost Tinnerman clip positions (see Figure 4-3).

NOTE: These instructions will have to be interpreted

broadly when using another manufacturer’s cabinetry.

February 1996

Part No. 004-3039-274

4-2

Page 39

Figure 4-3 CIP TRAY WITH MICROPHONE

Table 4-5 CIP TRAY CABLE CONNECTIONS

CRT-BASED ELECTRONICS ASSEMBLY PART I

3. After the CIP tray is mounted, connect the following cables using Table 4-5.

4. Mount the panel microphone (TDV-OP402/HR) to

the CIP:

All other microphone options, i.e., Dual Arm

Boom Microphone (TDV-OP403), Desk-Top Microphone (TDV- OP404), and Auxiliary Microphone

Location (TDV-OP405), have customer specific

installation requirements and will not be included in

this Installation Guide.

CIP Tray Board Connections (A1709228) CIP PS Line Term Boar d Connections (A1709230)

1st Line Term Cable - P9 (I/O 1) Connect to P1 (I/O 1)

2nd Line Term Cable - P6 (I/O 2) Connect to P1 (I/O 2)

Red/Black CIP Power Cable Connect to P2 (13.7V DC) on CIP Tray

Ground Cable (A600966.18) Connect to CIP Power Supply

The ground cable is attached to the center

Pem nut on the rear of the CIP tray.

Remove the 5-32x1/2 Philips head screw at location marked

with a ground symbol on the rear of the power supply and

attach the ground cable.

4-3

February 1996

Part No. 004-3039-274

Page 40

CRT-BASED ELECTRONICS ASSEMBLY PART I

This page intentionally left blank.

February 1996

Part No. 004-3039-274

4-4

Page 41

SECTION 5 CRT-BASED ELECTRONICS ASSEMBLY P ART II

5.1 INTRODUCTION

CRT-BASED ELECTRONICS ASSEMBLY PART II

7. Place the PC UPS (TDV-OP400/XX) onto the

swivel mount so that the feet engage the holes.

Refer to Figure 4-1.

If you have ordered a CRT-Based console system

installed in E.F. JOHNSON cabinetry, most of the

assembly will already have been done at the factory.

This section, CRT-Based Electronics Assembly - Part

II , details the additional assembly required for e ither

a complete E.F. Johnson CRT-Based system or an

Electronics Only CRT- Based system.

5.2 INSTALL THE PC AND UPS

Table 5-1 PC UPS OPTIONS

PC CPU Part No. 200TC4862501

Possible option numbers for the PC UPS

Part Number Country

TDV-OP400/A

TDV-OP400/GB

TDV-OP400/E

TDV-OP400/I

TDV-OP400/NZ

North America

Great Britain, S. Africa

Europe

India

New Zealand/Australia

5.3 CONNECT THE PC CPU AND PC UPS POWER CORDS

Part Numbers:

PC UPS - TDV-OP400/xx

PC CPU - 200TC4862501

Refer to Figure 5-1.

1. Connect one end of the supplied power cord to the

PC CPU. Plug the other end into the top left receptacle at the rear of the PC UPS. (Coil up th e excess

cable and secure).

2. Connect one end of the other supplied power cord to

the PC UPS. Plug the other end into the customerfurnished receptacle box feeding the console.

(Leave enough slack on the power cord so that it

will not unplug when the tray is fully extended).

5. Remove the two bottom screws of the PC CPU

(holding the PC cover together) and completely

slide the PC CPU into the PC tray bracket.

6. Replace the two sc rews that were removed wit h two

(2) 6-32x1/2 pan head Phillips screws (furnished).

Figure 5-1 CPU AND UPS POWER CONNEC-

TIONS

February 1996

5-1

Part No. 004-3039-274

Page 42

CRT-BASED ELECTRONICS ASSEMBLY PART II

5.4 CONNECT THE CRT INTERFACE PROCESSOR (CIP) TRAY CABLES

Refer to Figure 5-2 and Table 5-2.

Figure 5-2 CIP POWER SUPPLY LINE TERM BOARD - A1709230

Table 5-2 CRT CABLE CONNECTIONS

CIP Power Supply Line Term Board

(A1709230) Cable Conn

Footswitch Cable (A210906) Connect to Footswitch Jack

Red to AUX-FSPTT (TB11)

Green to AUX-FSMON (TB11)

Black to AUX-GND (TB11)

Power Fail Cable (A2109116) Connect to PC UPS (see Figure 5-1)

Green to AUX-AUX1 (TB11)

Red to AUX-AUX2 (TB11)

Black to AUX-GND (TB11)

Console Serial Cable (A600991.6) Connect to PC CPU (see Figure 5-1)

P8 (CONSOLE) COM 3 (CIP Control Tray) connector

ections

Mounts in the 5/8" hole at the base of the bay where the CIP

is installed. If there is no hole, provide one.

POWER FAIL connector

February 1996

Part No. 004-3039-274

5-2

Page 43

CRT-BASED ELECTRONICS ASSEMBLY PART II

5.5 INSTALL THE CRT MONITOR

5.5.1 CRT MONITOR CONNECTIONS

Refer to Figure 5-1.

1. Plug the female end of the IEC cord into the CRT

monitor.

2. Plug the other end of the IEC cord into the 2nd top

outlet on the PC UPS.

NOTE: Leave enough slack on the power cable so

that it will not unplug when the tray is fully extended.

3. Connect the VGA connect or from the monitor to the

"Monitor" port on the PC CPU.

5.5.2 ADDITIONAL CONNECTION FOR A 17 "

OR 21 " IDEK MONITOR

1. Connect the RGB cable to the 15 pin connector on

the rear of the CRT monitor.

5.6.2 INSTALL THE TOUCHSCREEN

Install the Touchscreen: Place the Touchscreen

onto the monitor, slipping the sides of the touchscreen