Page 1

MOBILE

SERVICE

MANUAL

984X SERIES

(UHF)

988

X SERIES (800 MHZ)

989X S

ERIES (900 MH

Z)

25 or 40 Watts (UHF); 15 or 30 Watts (800/900 MHz)

13.6 VDC

Part No. 242-98xx-xxx

First Printing

January 2001

Supersedes: Part No. 001-9800-200, 9/99

Remote-Mount

Page 2

98xx-SERIES

FM TWO-WAY RADIO

SERVICE MANUAL

13.6 VDC

25 or 40 Watts, UHF

15 or 30 Watts, 800/900 MHz

Part No. 242-984x-2xx (UHF)

Part No. 242-988x-2xx (800 MHz)

Part No. 242-989x-2xx (900 MHz)

Copyright © 2001 by the E.F. Johnson Company

The E.F. Johnson Company, which was founded in 1923, provides wireless communication

systems solutions for public safety, government, and commercial customers. The company

designs, manufactures, and markets conventional and trunked radio systems, mobile and

portable subscriber radios, repeaters, and Project 25 digital radio products.

®

Viking Head/EFJohnson logo, LTR

of the E.F. Johnson Company. SMARTNET™ and SmartZone

Inc. All other company and/or product names used in this manual are trademarks and/or registered trademarks of their respective manufacturer.

Information in this manual is subject to change without notice.

, LTR-Net™, Multi-Net®, and Call Guard® are trademarks

®

are trademarks of Motorola,

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

1 GENERAL INFORMATION

1.1 SCOPE OF MANUAL. . . . . . . . . . . . . . . . . . . .1-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

®

LTR

, Low Tier, and Data Models . . . . . . . . . . 1-1

1.2 TRANSCEIVER DESCRIPTION. . . . . . . . . . . 1-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Available Frequency Bands . . . . . . . . . . . . . . . . 1-1

Front and Remote Mounting . . . . . . . . . . . . . . . 1-2

NPSPAC Models (800 MHz Only) . . . . . . . . . . 1-2

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Transceiver Alignment. . . . . . . . . . . . . . . . . . . . 1-2

1.3 PART NUMBER BREAKDOWN. . . . . . . . . . .1-2

1.4 TRANSCEIVER IDENTIFICATION . . . . . . . .1-3

1.5 ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.6 PRODUCT WARRANTY . . . . . . . . . . . . . . . . .1-4

1.7 FACTORY CUSTOMER SERVICE . . . . . . . .1-4

1.8 FACTORY RETURNS . . . . . . . . . . . . . . . . . . .1-5

1.9 REPLACEMENT PARTS. . . . . . . . . . . . . . . . .1-5

1.10 INTERNET HOME PAGE. . . . . . . . . . . . . . . . .1-5

2 INSTALLATION

2.1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Scope of Instructions . . . . . . . . . . . . . . . . . . . . . 2-1

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . 2-1

Transceiver Programming . . . . . . . . . . . . . . . . . 2-2

Required Power Source . . . . . . . . . . . . . . . . . . . 2-2

2.2 MOUNTING THE TRANSCEIVER . . . . . . . . .2-2

Selecting A Mounting Location . . . . . . . . . . . . . 2-2

Installation Components. . . . . . . . . . . . . . . . . . . 2-2

Attaching Mounting Bracket . . . . . . . . . . . . . . . 2-2

2.3 POWER CABLE INSTALLATION . . . . . . . . .2-3

2.4 ACCESSORY CABLE INSTALLATION . . . .2-4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Accessory Pigtail Installation. . . . . . . . . . . . . . . 2-5

Connecting Ignition Sense Wire. . . . . . . . . . . . . 2-5

Connecting Horn Alert Wire . . . . . . . . . . . . . . . 2-6

Other Accessory Cable Outputs . . . . . . . . . . . . . 2-6

2.5 REMOTE CONTROL UNIT INSTALLATION2-6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Mounting Remote Control Unit . . . . . . . . . . . . . 2-6

2.6 USING AN EXTERNAL SPEAKER . . . . . . . .2-7

2.7 DATA CABLE INSTALLATION . . . . . . . . . . .2-7

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Data Cable Installation . . . . . . . . . . . . . . . . . . . . 2-8

2.8 KEY CAP KITS . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Multi-Net and LTR-Net Models. . . . . . . . . . . . . 2-8

SMARTNET/SmartZone Models. . . . . . . . . . . . 2-9

3 CIRCUIT DESCRIPTION

3.1 GENERAL TRANSCEIVER DESCRIPTION 3-1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Circuit Protection (Fuses) . . . . . . . . . . . . . . . . . . 3-1

Synthesizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Audio/Logic Board . . . . . . . . . . . . . . . . . . . . . . . 3-1

Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 POWER DISTRIBUTION AND SWITCHING 3-2

Power Switching Control . . . . . . . . . . . . . . . . . . 3-2

Supply Switching . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 AUDIO/LOGIC BOARD DIGITAL CIRCUIT 3-4

Microcontroller (U101). . . . . . . . . . . . . . . . . . . . 3-4

Memory and Latch Programming. . . . . . . . . . . . 3-6

3.4 RECEIVE AUDIO/DATA PROCESSING . . . 3-7

Amplifier (U301B) . . . . . . . . . . . . . . . . . . . . . . . 3-7

Receive Audio Processing. . . . . . . . . . . . . . . . . . 3-7

Receive Data Processing. . . . . . . . . . . . . . . . . . . 3-8

Squelch Circuit (U304A, U304B). . . . . . . . . . . . 3-9

3.5 TRANSMIT AUDIO/DATA PROCESSING . 3-9

Microphone Amplifier (U303B),

High-Pass Filter (U303C) . . . . . . . . . . . . . . . . 3-9

Summing Amplifier (U303D), Pre-Emphasis/

Limiter (U303A). . . . . . . . . . . . . . . . . . . . . . 3-10

Splatter Filter (U302B, U302C) . . . . . . . . . . . . 3-10

Transmit Data Circuit (U302D, U302A). . . . . . 3-10

3.6 DISPLAY BOARD . . . . . . . . . . . . . . . . . . . . . 3-10

3.7 SYNTHESIZER CIRCUIT DESCRIPTION

(UHF MODELS)

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Voltage-Controlled Oscillator. . . . . . . . . . . . . . 3-11

Active Filter (Q800), Buffer Amplifier (Q801) 3-12

VCO and TCXO Modulation . . . . . . . . . . . . . . 3-14

Synthesizer Integrated Circuit (U804) . . . . . . . 3-14

Lock Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Charge Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Shift Register (U800, U801) and Digital

Potentiometer (U802) Programming. . . . . . . 3-15

3.8 RECEIVER CIRCUIT DESCRIPTION

(UHF MODELS)

Front End Filter. . . . . . . . . . . . . . . . . . . . . . . . . 3-16

RF Amplifier (Q201). . . . . . . . . . . . . . . . . . . . . 3-17

First Mixer (Q202), Injection Amplifier (Q204) 3-17

Second Mixer/Detector (U201). . . . . . . . . . . . . 3-17

3.9 TRANSMITTER CIRCUIT DESCRIPTION

(UHF MODELS)

First and Second Amplifiers . . . . . . . . . . . . . . . 3-19

Third Amp and Predriver . . . . . . . . . . . . . . . . . 3-19

Driver (Q600), Final (Q601). . . . . . . . . . . . . . . 3-20

Antenna Switch . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Directional Coupler, Low-Pass Filter . . . . . . . . 3-21

Power Control (U500A/B, Q500-Q503). . . . . . 3-21

. . . . . . . . . . . . . . . . . . . . . . 3-11

. . . . . . . . . . . . . . . . . . . . . . 3-16

. . . . . . . . . . . . . . . . . . . . . . 3-19

February 2001

ii

Part No. 001-9800-001

Page 4

TABLE OF CONTENTS (CONT’D)

TABLE OF CONTENTS

3.10 SYNTHESIZER CIRCUIT DESCRIPTION

(800/900 MHz MODELS)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Voltage-Controlled Oscillator . . . . . . . . . . . . . 3-22

VCO and TCXO Modulation . . . . . . . . . . . . . . 3-24

Active Filter (Q800) . . . . . . . . . . . . . . . . . . . . . 3-25

Buffer Amplifier (Q801), Tx/Tx Switch

(CR801/CR802) . . . . . . . . . . . . . . . . . . . . . . 3-25

Synthesizer Integrated Circuit (U804) . . . . . . . 3-26

Lock Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Charge Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Shift Register (U800, U801) and Digital

Potentiometer (U802) Programming . . . . . . 3-27

3.11 RECEIVER CIRCUIT DESCRIPTION

(800/900 MHz MODELS)

Front End Filter . . . . . . . . . . . . . . . . . . . . . . . . 3-27

RF Amplifier (Q201) . . . . . . . . . . . . . . . . . . . . 3-27

First Mixer (Q202), Crystal Filter (Z204) . . . . 3-28

Second Mixer/Detector (U201) . . . . . . . . . . . . 3-28

3.12 TRANSMITTER CIRCUIT DESCRIPTION

(800/900 MHz MODELS)

Predriver (Q506), Driver (Q507) . . . . . . . . . . . 3-29

Power Amplifier Module (U600), Final (Q651) 3-30

Antenna Switch . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Directional Coupler, Low-Pass Filter. . . . . . . . 3-30

Power Control (U500A/B, Q500-Q503) . . . . . 3-31

. . . . . . . . . . . . . . .3-22

. . . . . . . . . . . . . . .3-27

. . . . . . . . . . . . . . .3-29

4 SERVICING

4.1 GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Periodic Checks . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Schematic Diagrams and Component Layouts. . 4-1

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configuring Transceiver for Testing . . . . . . . . . 4-1

4.2 SURFACE MOUNTED DEVICES (SMDs) . .4-1

Servicing Techniques . . . . . . . . . . . . . . . . . . . . . 4-1

Identifying SMD Resistors. . . . . . . . . . . . . . . . . 4-1

SMD Capacitor Identification . . . . . . . . . . . . . . 4-2

SMD Inductor Identification . . . . . . . . . . . . . . . 4-3

Transistor/Diode Identification . . . . . . . . . . . . . 4-3

4.3 SYNTHESIZER TROUBLESHOOTING . . . .4-3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Reference Oscillator (U806). . . . . . . . . . . . . . . . 4-4

VCO Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Synthesizer IC (U804) . . . . . . . . . . . . . . . . . . . . 4-4

Determining Synthesizer Counter Divide

Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4 RECEIVER SERVICING. . . . . . . . . . . . . . . . . .4-5

4.5 TRANSMITTER SERVICING . . . . . . . . . . . . .4-5

4.6 AUDIO/LOGIC BOARD SERVICING. . . . . . .4-5

Digital Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Analog Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5 PARTS LIST

Front Panel Assembly and Mechanical Parts . . . 5-1

UHF RF and PA Boards . . . . . . . . . . . . . . . . . . . 5-3

800/900 MHz RF and PA Boards . . . . . . . . . . . 5-18

Audio/Logic Board . . . . . . . . . . . . . . . . . . . . . . 5-25

9800-Series Radio Mounting Kit . . . . . . . . . . . 5-30

9800-Series Remote Mounting Kit . . . . . . . . . . 5-30

DC Power Cable and Hardware Kit . . . . . . . . . 5-30

Accessory Wire Kit. . . . . . . . . . . . . . . . . . . . . . 5-30

Amplified Dynamic Microphone . . . . . . . . . . . 5-30

15 Watt, 4.7-Ohm Speaker (Black). . . . . . . . . . 5-30

Exploded Views

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Front and Top . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Bottom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-32

Remote Control Unit . . . . . . . . . . . . . . . . . . . 5-33

Remote Transceiver . . . . . . . . . . . . . . . . . . . 5-33

6 SCHEMATIC DIAGRAMS AND

COMPONENT LAYOUTS

Amplified Dynamic Microphone . . . . . . . . . . . . 6-2

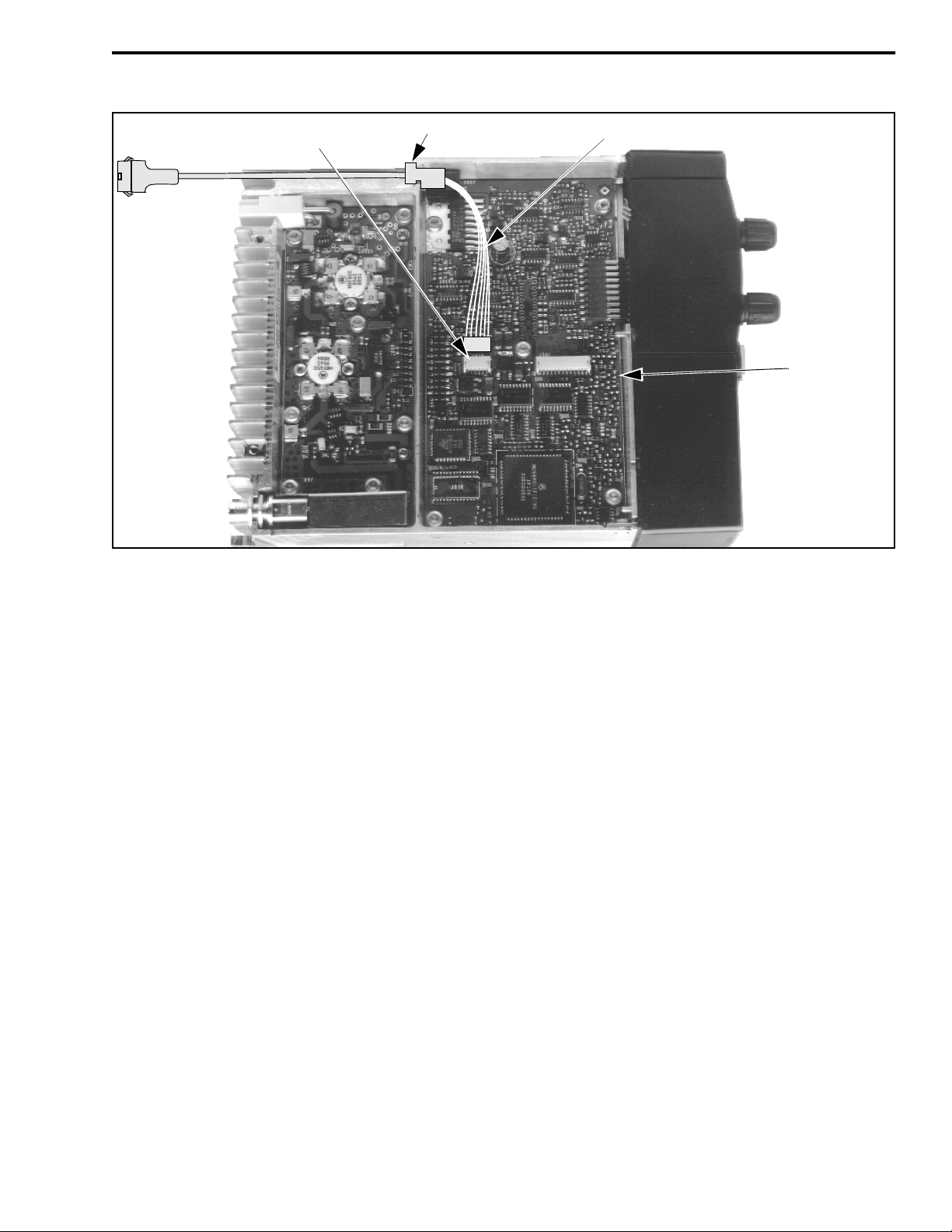

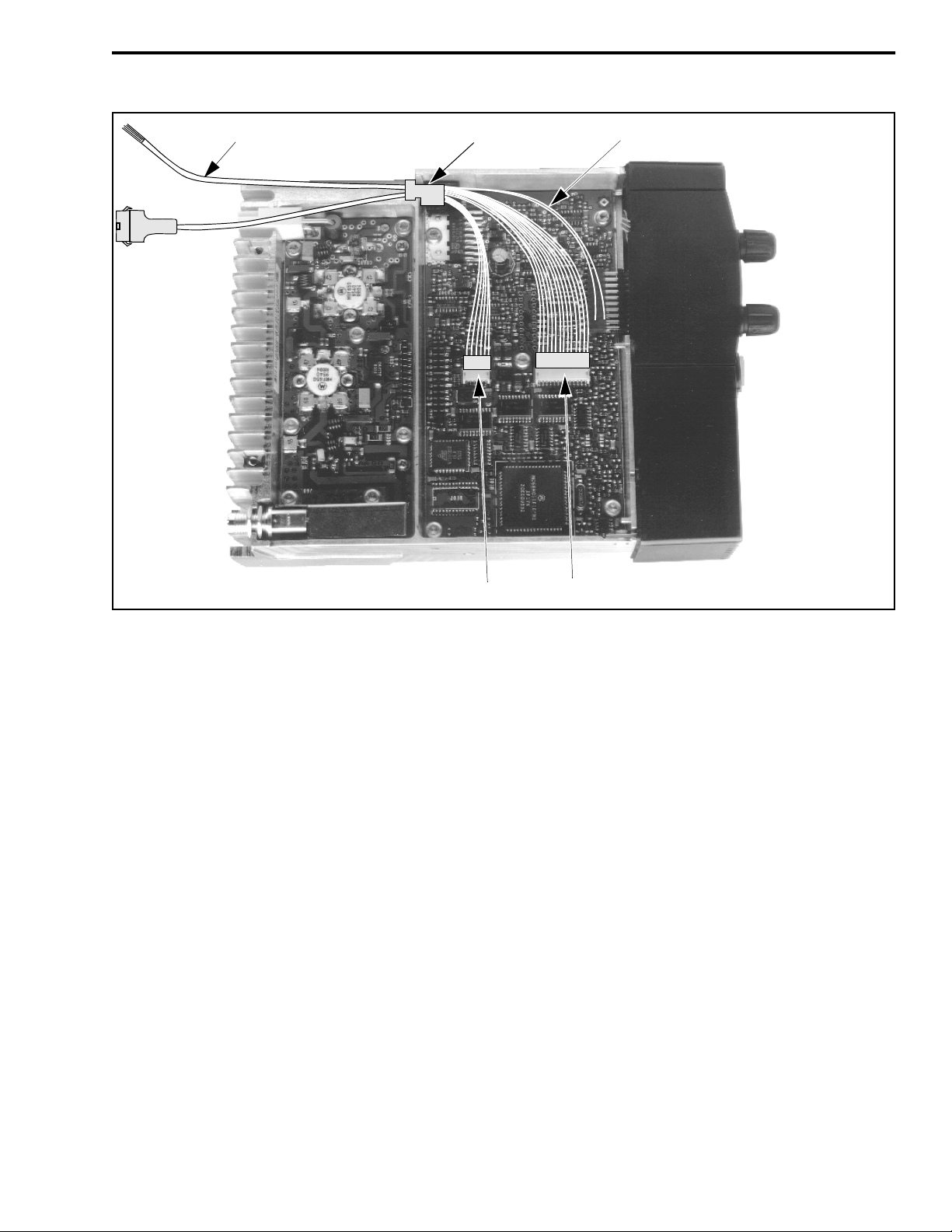

Transceiver Top Photo . . . . . . . . . . . . . . . . . . . . 6-3

Transceiver Bottom Photo. . . . . . . . . . . . . . . . . . 6-3

Interconnect Schematic. . . . . . . . . . . . . . . . . . . 6-4

Interface Board Layout. . . . . . . . . . . . . . . . . . . 6-4

Display Board

Top View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

RPI (P.N. 023-9800-000)

Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Programming Cable (P.N. 597-2002-200) . . . 6-6

Component Locator Guides

UHF RF Board . . . . . . . . . . . . . . . . . . . . . . . . 6-7

800/900 MHz RF Board . . . . . . . . . . . . . . . . 6-10

Audio/Logic Board . . . . . . . . . . . . . . . . . . . . 6-12

430-470 MHz RF

RF Board Schematic (Revised Board. . . . . . 6-15

PA Board Schematic (25W) . . . . . . . . . . . . . 6-15

RF Board Layout (Revised Board). . . . . . . . 6-16

VCO Board Layout. . . . . . . . . . . . . . . . . . . . 6-17

PA Board Layout (25W). . . . . . . . . . . . . . . . 6-17

PA Board Schematic (40W) . . . . . . . . . . . . . 6-18

PA Board Layout (40W). . . . . . . . . . . . . . . . 6-19

RF Board Schematic (Unrevised Board) . . . 6-20

RF Board Layout (Unrevised Board) . . . . . . 6-21

February 2001

iii

Part No. 001-9800-001

Page 5

TABLE OF CONTENTS (CONT’D)

TABLE OF CONTENTS

470-512 MHz RF

RF Board Schematic. . . . . . . . . . . . . . . . . . . 6-22

PA Board Schematic (25W). . . . . . . . . . . . . 6-23

VCO Board Layout . . . . . . . . . . . . . . . . . . . 6-24

PA Board Layout (25W) . . . . . . . . . . . . . . . 6-24

PA Board Schematic (40W). . . . . . . . . . . . . 6-25

PA Board Layout (40W) . . . . . . . . . . . . . . . 6-26

800/900 MHz RF

RF Board Schematic (800/900 MHz). . . . . . 6-27

PA Board Schematic (15W). . . . . . . . . . . . . 6-27

RF Board Layout (800 MHz). . . . . . . . . . . . 6-28

RF Board Layout (900 MHz). . . . . . . . . . . . 6-29

VCO Board Layout . . . . . . . . . . . . . . . . . . . 6-30

PA Board Layout (15W) . . . . . . . . . . . . . . . 6-30

PA Board Schematic (30W). . . . . . . . . . . . . 6-31

PA Board Layout (30W) . . . . . . . . . . . . . . . 6-32

800/900 MHz Audio/Logic Board

Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . .6 -33

Board Layout . . . . . . . . . . . . . . . . . . . . . . . . 6-34

LIST OF TABLES

1-1 Part Number Breakdown . . . . . . . . . . . . . . . . . . 1-2

1-2 Identification Number Breakdown . . . . . . . . . . . 1-3

1-3 98xx Accessories . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2-1 Data Cable Wire Chart . . . . . . . . . . . . . . . . . . . . 2-8

4-1 Ceramic SMD Capacitor Identification . . . . . . . 4-2

4-2 SMD Inductor Identification . . . . . . . . . . . . . . . 4-3

LIST OF FIGURES

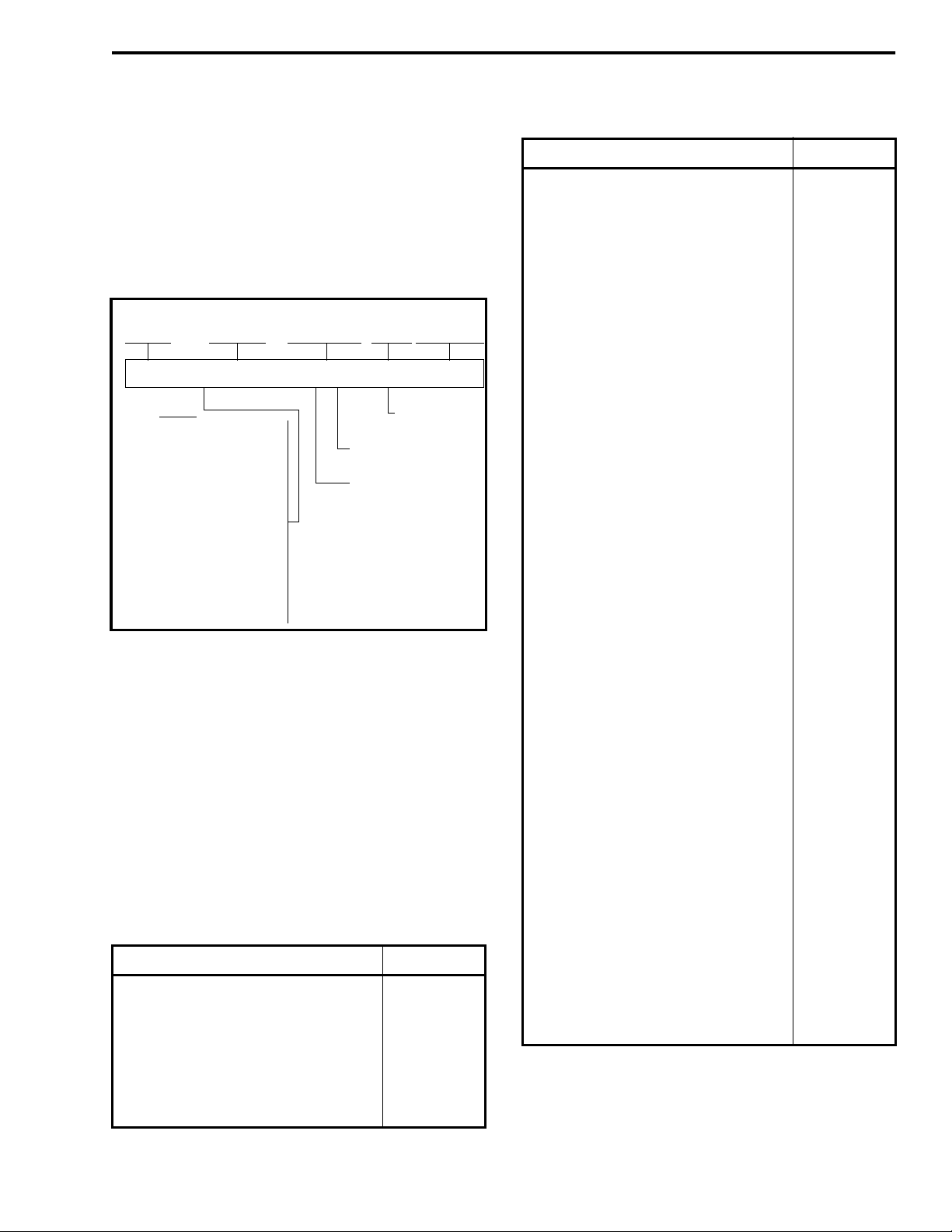

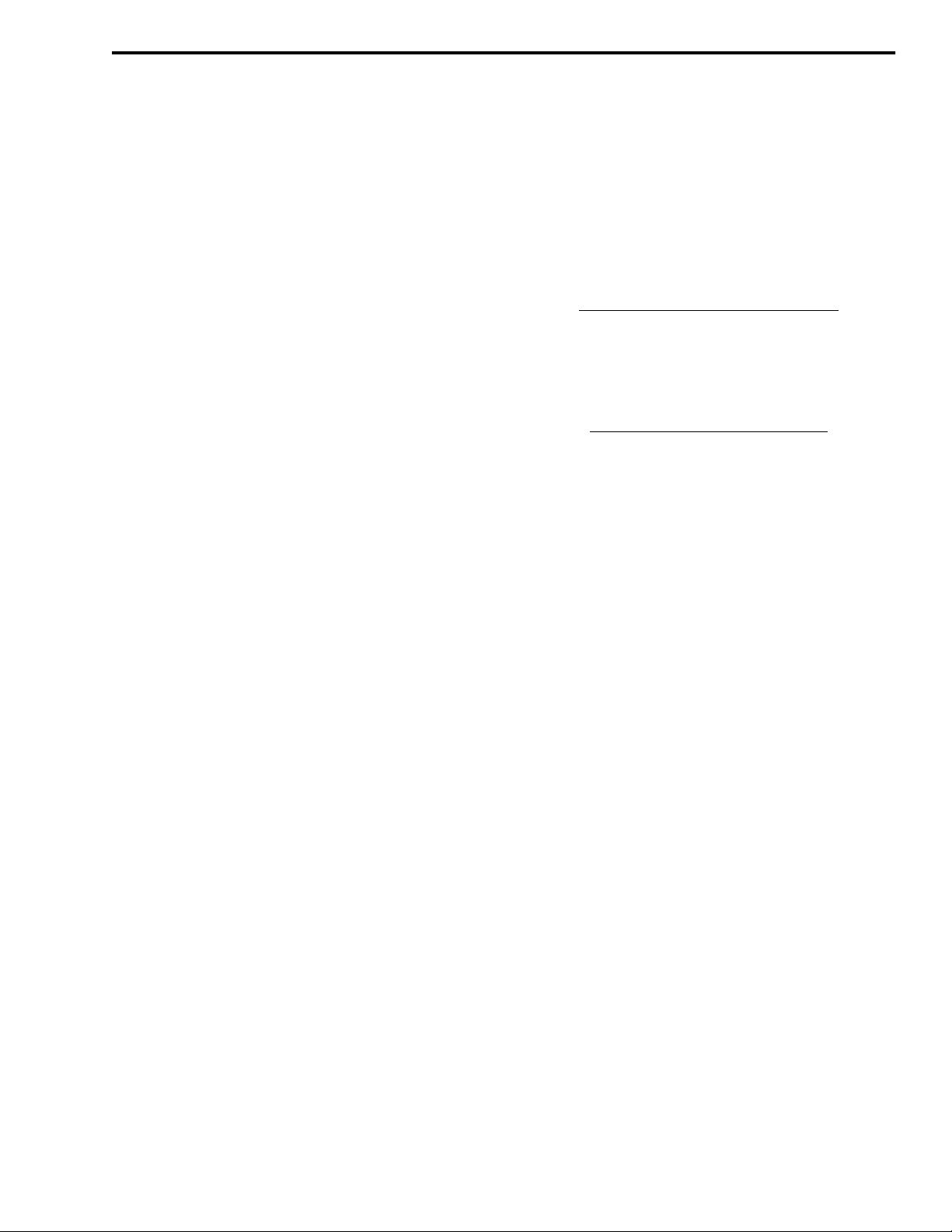

2-1 Front Mount Installation Components . . . . . . . 2-1

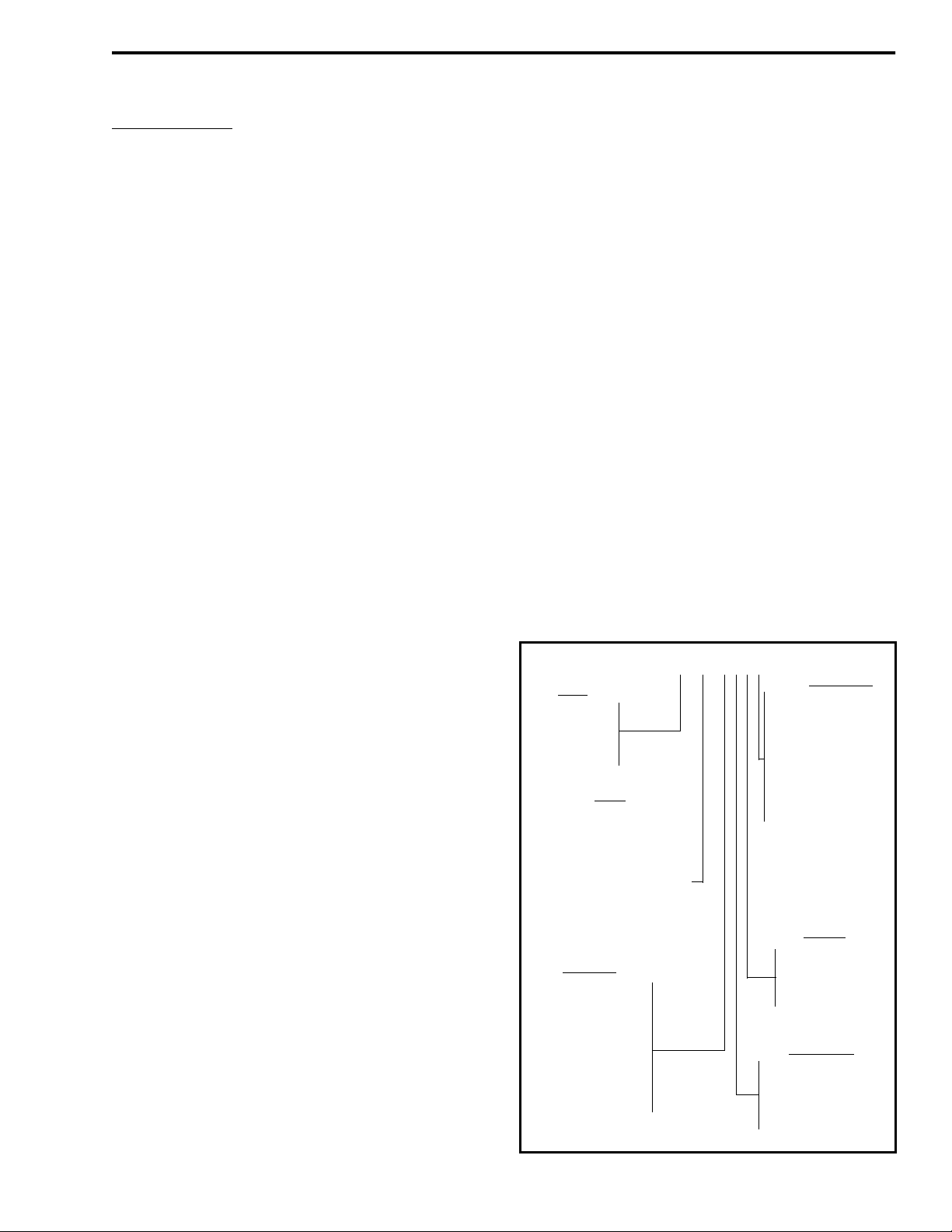

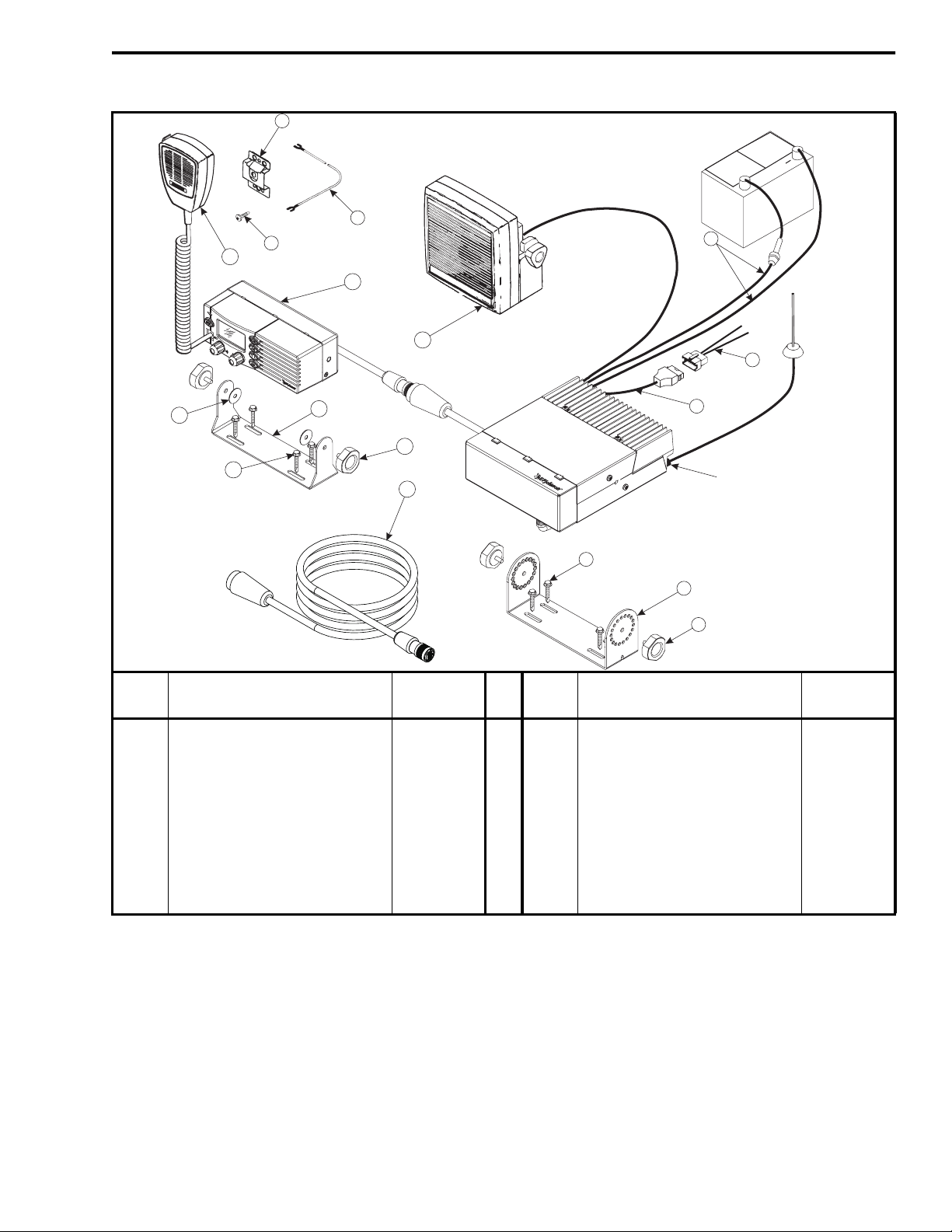

2-2 Remote Mount Installation Components. . . . . . 2-3

2-3 Accessory Cable Installation. . . . . . . . . . . . . . . 2-4

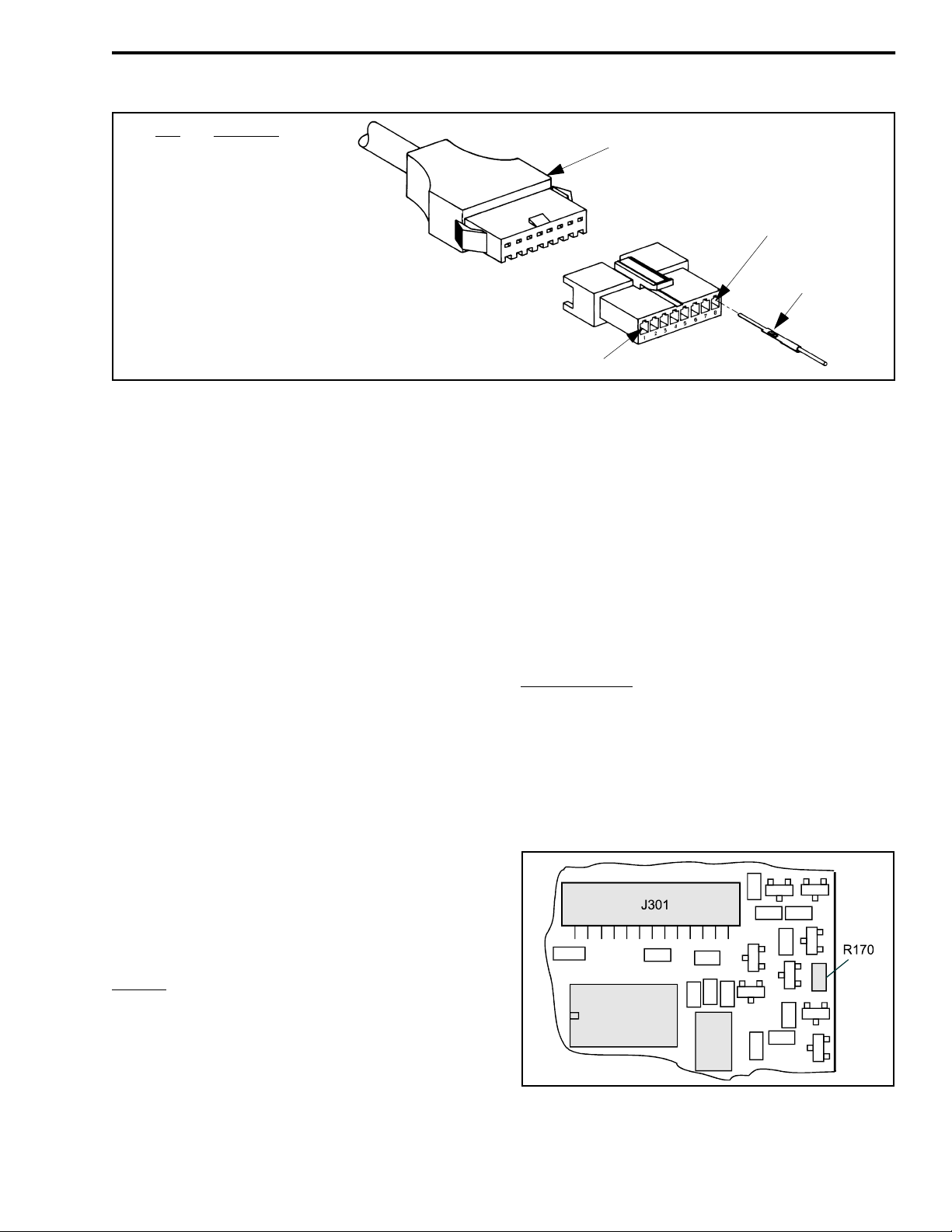

2-4 Accessory Cable Connector . . . . . . . . . . . . . . . 2-5

2-5 R170 Location Diagram . . . . . . . . . . . . . . . . . . 2-5

2-6 Data Cable Installation (-001 Cable Shown). . . 2-7

3-1 Power Distribution and Switching . . . . . . . . . . 3-3

3-2 Power On-Off Control Circuit. . . . . . . . . . . . . . 3-3

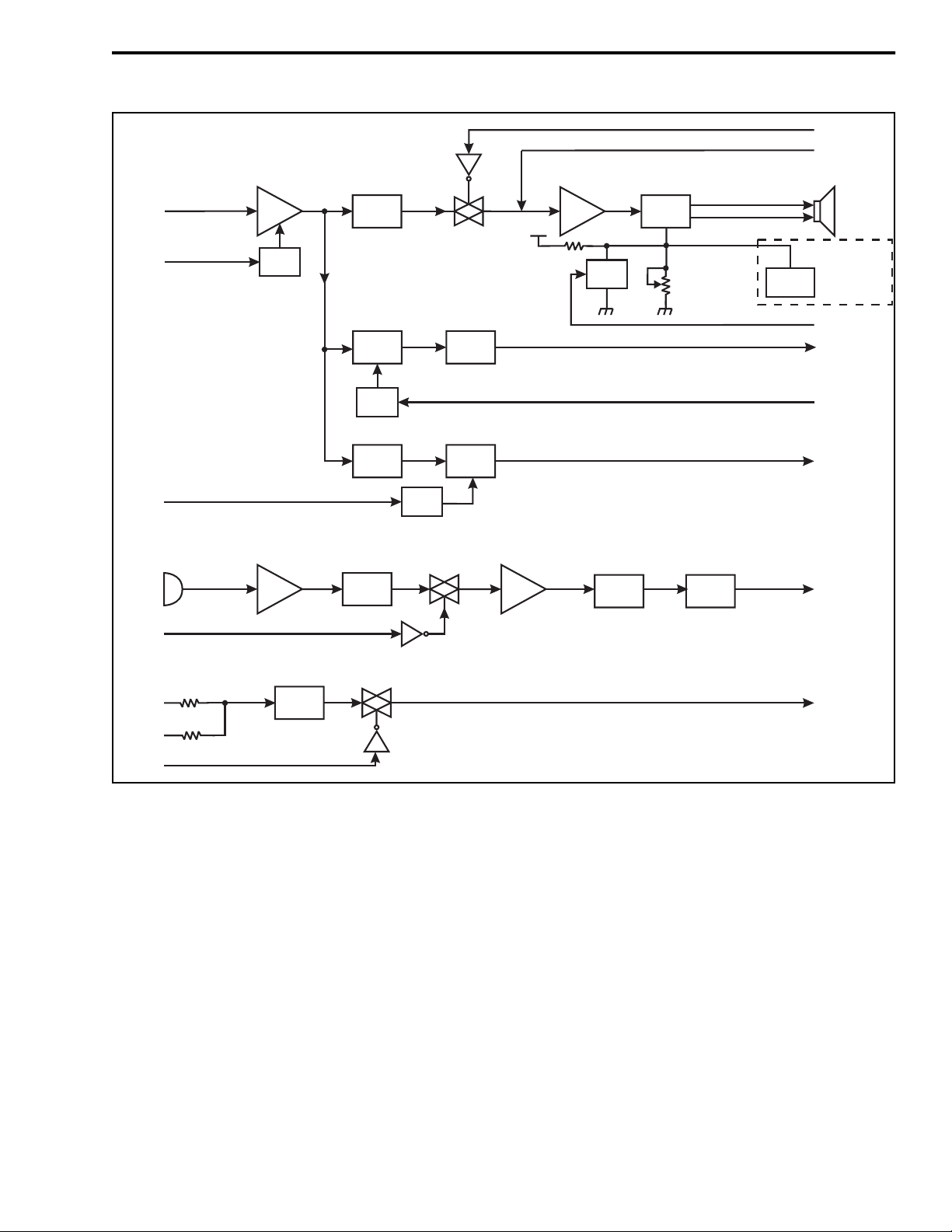

3-3 Audio/Data Processing Circuitry Block Diagram 3-8

3-4 RF Block Diagram (UHF Models) . . . . . . . . . 3-13

3-5 Synthesizer Chip U804 Block Diagram . . . . . 3-16

3-6 Limiter/Detector U201 Block Diagram. . . . . . 3-18

3-7 RF Block Diagram (800/900 MHz Models) . . 3-23

4-1 Simplified Synthesizer Block Diagram. . . . . . . 4-3

February 2001

iv

Part No. 001-9800-001

Page 6

SECTION 1 GENERAL INFORMATION

GENERAL INFORMATION

1.1 SCOPE OF MANUAL

1.1.1 GENERAL

This service manual contains installation and

service information for all current 9800 series mobile

transceivers. These include the UHF 984x, 800 MHz

988x, and 900 MHz 989x models.

This manual does not include operation, programming, or alignment information. This information is

covered by a separate operation/programming manual

(addendum) for each operating protocol as follows:

Protocol Operation and Programming

Manual

98xx Multi-Net

98xx LTR-Net

98xx SMARTNET

SmartZone

Therefore, use this manu al to install and service

98xx transceivers, and use the above manual for operation, programming, and tuning information.

®

001-9880-400

™

001-9800-600/-601

™

®

/ 001-9800-501

The data version of the 98xx transceiver has a

front panel that is blank except for the programming

jack. For servicing information on data models, refer

to the LTR manual just described.

The Multi-Net versio n of the 98xx tran sceiver has

a data interface that supports external data equipment.

For information on this interface and the serial control

protocol it uses, refer to th e Multi-Net manual

described in the preceding section.

NOTE: External data equipment is currently not

supported by the LT R-Net and SMARTNET/SmartZo ne

versions of this transceiver.

1.2 TRANSCEIVER DESCRIPTION

1.2.1 GENERAL

The 98xx-series transceivers combine the latest

two-way radio features and technology into a rugged

and dependable package for the business, industrial,

and public safety markets. These transceivers are digitally synthesized, microcomputer-controlled, and field

programmable.

NOTE: The above Multi-Net manual also includes

98xx servicing information but has not been updated

with the latest changes that are in this manual.

1.1.2 LTR®, LOW TIER, AND DATA MODELS

NOTE: LTR, low tier, and data versions of the 98xx

transceiver are no longer available.

The LTR versions of the 98xx are covered by

LTR 98xx Service Manual, Part No. 001-9800-200.

This is a complete LTR manual that includes LTR

operation and programming information and 98xx

hardware servicing information. There are also -201

and -202 revisions tha t sh oul d acc ompany thi s manual.

The LTR models of the 98xx mobile were available in both high and low tier versions, and the MultiNet, LTR-Net, and SMARTNET/SmartZone models

are available in only the high tier version. Therefore,

only high tier models are covered by this manual. For

servicing information on low tier models, refer to the

LTR manual described in the preceding paragraph.

1.2.2 AVAILABLE FREQUENCY BANDS

UHF Models

• 430-470 MHz or 470-512 MHz models available.

• All currently available models are dual bandwidth

(12.5/25 kHz). Theref ore , they can be programmed

to operate on both types of channels.

• High power (40W) or medi um power (25W) models

available.

800 MHz Models

• Full band (806-824 MHz) operation.

• All currently available models are dual bandwidth

(12.5/25 kHz).

• High power (30W) and medium power (15W)

models available.

1-1

February 2001

Part No. 001-9800-001

Page 7

GENERAL INFORMATION

900 MHz Models

• Full band (896-902 MHz) operation.

• Only narrow band (12.5 kHz) models are available

because the 900 MHz band has always had a 12.5

kHz channel spacing.

• High power (30W) and medium power (15W)

models available.

1.2.3 FRONT AND REMOTE MOUNTING

High tier models are available in both front- and

remote-mount versions, and low tier models were

available in a fr ont mou nt version onl y. Remote mount

versions are intended to be mounted in a remote location up to appr oximat ely 17 feet away from t he co ntr ol

unit such as the vehicle’s trunk. Front mount versions

are intended to be mounted within reach of the

operator.

The control unit connects to the remote pigtail

cable coming from the back panel of the transceiver.

This cable is standard with remote mount models and

optional with front mount models. The remote control

unit uses the high tier front panel assembly. A Remote

Conversion Kit is available for converting a front

mount high tier model to remote mounting (see Table

1-3). The transceiver does not have dual-control capability. Therefore, either the front pa nel or a remote

control unit can be used for control, but not both.

1.2.4 NPSPAC MODELS (800 MHZ ONLY)

All 800 MHz 988x transceivers capable of operating on 25 kHz channels meet the stricter specifications established by NPSPAC (National Public Safety

Panel Advisory Committee) for public safety frequencies from 821-824 and 866-869 MHz. Since deviation

is less on NPSPAC channels, an additional screen is

may be displayed by the tuning software with 800

MHz models for setting NPSPAC deviation. Then

when a public safety channel is selected, the deviation

automatically changes to the level set in this scree n.

1.2.5 PROGRAMMING

Transceiver programming is performed using a

PC-compatible computer, the E.F. Johnson Remote

Programming Interface (RPI), and E.F. Johnson

programming software. Programming is described in

separate manuals as described in Section 1.1.1.

1.2.6 TRANSCEIVER ALIGNMENT

Alignment is performed using the standard

Personality programming setup and special Radio

Tune software. There are only two or three adjustments that are made by physically adjusting a component on the PC board. All other adjustments are set

digitally. The desired setting is selected using the

computer, and it is then automatically stored in the

transceiver memory. If the manual adjustments do not

need to be readjusted, transceiver alignment can

usually be performed without removing the covers.

Alignment is described in separate manuals as

described in Section 1.1.1.

1.3 PART NUMBER BREAKDOWN

The breakdown of the part number used to

identify th is transceiver is shown in Table 1-1. With

LTR-Net and Multi-Net models, digits 4-7 of this

number are displayed briefly at power up.

Table 1-1 Part Number Breakdown

242 - 9 8 x x -x x x x

Band

1 = VHF*

4 = UHF

8 = 800 MHz

9 = 900 MHz

Type

1 = Low tier, dual BW

2 = Mid tier, dual BW*

3 = High tier, dual BW

4 = Low tier, 12.5 kHz

5 = Mid tier, 12.5 kHz*

6 = High tier, 12.5 kHz

8 = High tier rem, dual BW

0 = High tier rem, 12.5 kHz

Signaling

2 = LTR

3 = SMARTNET

4 = Multi-Net

5 = Smartzone

6 = LTR-Net

8 = Data LTR

9 = Data M-Net

0 = Conv only*

* These configurations are currently not available

B/N = Comp/Data

C/O = Compander

D/P = Data Cable

E/Q = Enc/Comp

F/T = Enc/C o mp/Dat

G/U = Comp/Acsry

H/V = Horn/Acsry

I/W = Enc/Comp/

Acsry Cable

[1] N-W models are

LTR-Net upgradeable

Config.

2 =Mid Pwr std

3 = High Pwr std

7 = M.P. no acc

8 = H.P. no acc

Freq Range

0 = Full band (800/

900 MHz)

3 = 430-470 MHz

5 = 470-512 MHz

Options [1]

1-2

February 2001

Part No. 001-9800-001

Page 8

GENERAL INFORMATION

1.4 TRANSCEIVER IDENTIFICATION

The transceiver identification number is printed

on a label that is attached to the chassis. The information is contained in this number is shown i n Table 1-2.

This number is stored electronically and can be read

using the programming software.

Table 1-2 Identification Number Breakdown

Model Revision

Letter

98xx x A 10 0 A 12345

Type

1 = Low pwr LTR

2 = High pwr LTR

3 = High pwr Data MN

4 = Low pwr LTR-Net

5 = High pwr LTR-Net

6 = Low pwr Multi-Net

7 = High pwr Multi-Net

8 = Low pwr Da ta LTR

9 = High pwr Data LTR

0 = Low pwr Da ta MNet

A =

SMARTNET/ Sm ar tZon e

Manufacture

Date

NOTE: Low power = 25W

UHF, 15W 800/900 MHz;

High power = 40W UHF,

30W 800/900 MHz)

PlantFrom P.N.

Last Digit of Year

Week No. of Year

Warranty

Number

A = Waseca

1.5 ACCESSORIES

The accessories available for this transceiver are

listed in Table 1-3. The following is a brief description

of most of these accessories.

Mounting Accessories - The -030 mounting kit

contains mounting knobs an d four s elf-dri lling screws.

The -610 kit contains mounting knobs, a remote

mounting bracket, and four self drilling screws. The

10- and 22-ft. cable kits include a fused power cable

and microphone hanger with a ground wire

Table 1-3 98xx Accessories

Accessory Part No.

Mounting Accessories

Front mounting kit

Remote mounting kit

10 ft. DC power cable and hardware kit

22-ft. DC power cable and hardware 023-9800-422

Standard mounting bracket 017-2229-005

Low-profile mounting bracket 017-2229-010

023-9800-030

023-9800-040

023-9800-410

Table 1-3 98xx Accessories (Continued)

Accessory Part No.

Standard Key Cap Kits (5 key caps)

Multi-Net 587-9840-001

LTR-Net 587-9840-002

SMARTNET/SmartZone 587-9840-003

Optional Key Cap Kits (20+ key caps)

Multi-Net/LTR-Net 587-9840-004

SMARTNET/SmartZone 587-9840-105

Microphones

Standard amplified dynamic 250-0740-300

Standard DTMF w/lighted keypad 250-0751-021

WR 805 DTMF (weather resistant) 589-0016-029

Desk-type 250-0742-010

Remote Speaker, 5”, 15W, 4.7 ohm 250-0151-010

Remote conversion kit

Remote control extension cable, 11 ft. 597-9800-009

Remote control pigtail cable (for xcvr) 597-9800-011

Accessory cable components

Accessory pigtail cable 597-9800-003

Accessory wire kit 023-9750-011

Data/accessory cable kit (both cables

included, w/o data connector)

Data pigtail cable (data cable only w/o data

connector)

Compander kit 250-9800-310

Encryption kit, Transcrypt

Desktop Power Supply

15 A, 117 VAC 239-0226-113

15 A, 230 VAC 239-0226-213

Wedge mounting pedestal ki t (includes

10 ft. power cable)

Programming Accessories

Remote Programming Interface (RPI) 023-9800-000

Cable, RPI to transceiver 597-2002-200

Cable, RPI to computer, 6 ft.

(DB9F to DB9M)

Programming software (see manual

listed in Section 1.1.1)

®

SC20-4xx SC20-4xx

250-9800-001

597-9800-001

597-9800-005

023-8610-914

597-5900-002

Key Cap Kit - A key cap kit which in cludes five caps

labeled for common functions is standard with each

transceiver. Optional kits are also available. Refer to

Section 2.8 for more key cap information.

1-3

February 2001

Part No. 001-9800-001

Page 9

GENERAL INFORMATION

Microphones and Speaker - The microphones have

an impedance of 620 ohms, and all DTMF models

have backlighted keypad but no memory for storing

numbers. The WR805 microphone is environmentally

sealed against such things as rain, sand, and dust. The

desk microphone has a monitor button that can be

locked down if desired.

The remote 15-watt speaker can be used instead

of the internal sp eak er. It is non-amplified and weather

resistant, and has a 6-ft. cable. It plugs into the

external speaker jack in the back panel (with both

front and remote mount applications), and the internal

speaker is a utomaticall y disabled w hen it is used.

Remote Mounting Components - The remote

conversion kit converts the front panel of a front

mount high tier transceiver to a remote control unit. It

includes a blank front cover for the transceiver, a

housing and 5-ft. control cable for the front panel, and

a 1-ft. pigtail cable for connecting the control unit to

the transceiver. If the control unit is to be mounted

more than approximately 6 feet from the transceiver,

the 11-ft. extension cable is required (see Figure 2-2).

Accessory Cable - The -003 pigtail cable installs in

the transceiver, and the wire kit is used to connect

accessories to this cable. Included in the wire kit are

two 22-ft. and three 2-ft. wire assemblies that can be

used as desired. The accessory cable is required if such

things as ignition switch control of power or the horn

alert are use d. Refer to Section 2.4 for installation

information.

Data/Accessory Cable - The -001 cable assembly

includes a data pigt ail c able t hat pl ugs int o J301 o n th e

audio/logic board and also the accessory pigtail

described above. The -005 cable assembly is a data

cable only without the accessory cable. Neither cable

includes the connector that interfaces with the data

equipment, so it must be user supplied and installed.

Installation of this cable is described in Section 2.7.

Compandor and Encryption Kits - The compandor

kit includes a board assembl y that insta lls in the opt ion

wire-outs on the audio/logic board to provide

companding. Likewise, the encryption kit includes a

board assembly that connects to the other option wireouts on the audio/logic board. Contact your sales

representative for more information on available

encryption options.

Desktop Accessories - The -113 and -213 power

supplies include a pedestal for mounting the transceiver and also inclu de an inte rnal sp eaker. The wedge

mounting pedestal includes a 10-ft power cable. Also

required when this pedesta l is used is one of the power

supplies and the -010 low profile mounting bracket.

Programming Accessories - This RPI has design

enhancements required for Flash programming the

9800-series transc eiver s. It also h as jacks for i nject ing

a microphone audio signal and monitoring receive

audio when aligning the transceiver. Earlier RPIs

(such as 023-9750-000 an d 023-5810-000) ca n be used

to program personality information if desired.

1.6 PRODUCT WARRANTY

The warranty statement for this transceiver is

available from your product supplier or from the

Warranty Department, E.F. Johnson Company, 299

Johnson Avenue, P.O. Box 1249, Waseca, MN 56093-

0514. This information may also be re quested from the

Warranty Department by phone as described in

Section 1.7. The Warranty Department may also be

contacted for Warranty Service Reports, claim forms,

or any other questions concerning warranties or

warranty service.

1.7 FACTORY CUSTOMER SERVI CE

The Customer Service Department of the E.F.

Johnson Company provides customer assistance on

technical problems and the availability of local and

factory repair facilities. Regular Customer Service

hours are 7:30 a.m. - 5:30 p.m. Central Time,

Monday - Friday. The Customer Service Department

can be reached at the following telephone numbers:

Toll-Free: 1-800-328-3911

(From within continental United States only)

International: (507) 835-6911

FAX: (507) 835-6969

E-Mail: First Initial/Last Name@efjohnson.com

(You need to know the name of the person you

want to reach. Example: jsmith@efjohnson.com)

NOTE: Emergency 24-hour technical support is also

available at the 800 and preceding numbers during off

hours, holidays, and weekends.

1-4

February 2001

Part No. 001-9800-001

Page 10

GENERAL INFORMATION

When your call is answered, you will hear a brief

message informing you of number s that can be ente red

to reach various departments. This number may be

entered during or after the message using a tone-type

telephone. When you enter some numbers, another

number is requested to further categorize the type of

information you need.

You may also contact the Customer Service

Department by mail. Please include all information

that may be helpful in solving your problem. The

mailing address is as follows:

E.F. Johnson Company

Customer Service Dep artment

299 Johnson Avenue

P.O. Box 1249

Waseca, MN 56093-0514

1.8 FACTORY RETURNS

Repair service is normal ly availa ble through local

authorized EFJohnson Land Mobile Radio Service

Centers. If local service is not ava ilable, the equipmen t

can be returned to the fac tory for repair. However, it is

recommended that you contact the Customer Service

Department before returning equi pment. A service

representative may be able to suggest a solution to the

problem making return of the equipment unnecessary.

Be sure to fill out a Factor y Re pai r Req ues t For m

#271 for each unit to be repaired, whether it is in or

out of warranty. These forms are available free of

charge by calling Customer Service (see Section 1.7)

or by requesting them when you send a unit in for

repair. Clearly describe the difficulty experienced in

the space provided and also note any prior physical

damage to the equipment. Include this form in the

shipping container with each unit. Your telephone

number and contact name are important as there are

times when the technicians may have specific questions that need to be answered in order to completely

identify and repair a problem.

When returning equipment for repair, it is also a

good idea to use a PO number or some other reference

number on your paperwork in case you need to call the

repair lab about your unit. These numbers are referenced on the repai r or de r maki ng it easier and fas te r t o

locate your unit in the lab.

Return Authorization (RA) numbers are not

necessary unless you have been gi ven one by the Fie ld

Service Department. RA numbers are required for

exchange units or if the Field Service Department

wants to be aware of a specific problem. If you have

been given an RA number, reference this number on

the Factory Repair Request Form sent with the unit.

The repair lab will then contact the Field Service

Department when the unit arrives.

1.9 REPLACEMENT PARTS

EFJohnson replacement parts can be ordered

directly from the Service Parts Department. To order

parts by phone, dial the toll-free number as described

in Section 1.7. When ordering, please supply the part

number and quantity of each part ordered. EFJohnson

dealers also nee d to g ive th eir a cco unt numbe r. If there

is uncertainty about the part number, include the designator (C512, for example) and the model number of

the equipment the part is from.

You may also send your order by mail or FAX.

The mailing address i s as follows and the FAX number

is shown in Section 1.7.

E.F. Johnson Company

Service Parts Department

299 Johnson Avenue

P.O. Box 1249

Waseca, MN 56093-0514

1.10 INTERNET HOME PAGE

The E.F. Johnson Company has a site on the

World Wide Web that can be accessed for inform ation

on the company about such things as products,

systems, and regulations. The address is

http://www.efjohnson.com.

1-5

February 2001

Part No. 001-9800-001

Page 11

GENERAL INFORMATION

UHF 984x SPECIFICATIONS

The following are general specifications intended for use in testing and servicing this transceiver. For current

advertised specifications, refer to the specification sheet available from your sales representative. Specifications

are subject to change without notice.

GENERAL

Frequency Range 430-470 MHz and 470-512 MHz

Operating Modes LTR (trunked) and Conventional (non-trunked)

Systems and Groups Selectable Low Tier: Up to 16 system/group combinations

High Tier: Variable from 100 1-group systems up to 40 16-group systems

Mounting Location Dash (low tier), Dash or Remote (high tier)

Transmit/Receive Separation Any frequency within the range

Channel Spacing 12.5 kHz (2.5 kHz maximum deviation)

25 kHz (5 kHz maximum deviation)

(12.5 kHz or dual bandwidth models available)

Frequency Stability 2.0 PPM from –22° to +140° F (–30° to +60° C)

Dimensions 2.1” x 6.0” x 7.5” (HxWxD)

Weight 3.5 lbs (1.59 kg)

Power Requirement 13.6 volts DC nominal, negative ground

Current Drain 300 mA maximum (receive standby)

1.5 A maximum (receive, rated audio output)

10.0 A maximum (transmit, 25 W output)

15.0 A maximum (transmit, 40 W output)

FCC Compliance Parts 15 and 90

RECEIVER

Sensitivity (12 dB SINAD) 0.35 µV

Selectivity –70 dB at 25 kHz, –60 dB at 12.5 kHz

Spurious and Image Rejection –70 dB

Intermodulation –70 dB

Hum and Noise –45 dB at 25 kHz, –40 dB at 12.5 kHz

Maximum Frequency Spread Any spread within the range

Audio Power Output 5 watts (external 4.7-ohm speaker), 3 watts (internal 8-ohm speaker)

Audio Distortion Less than 5% at 1 kHz with 60% deviation

Audio Response +1, –3 dB per octave de-emphasis per standard TIA

RF Input Impedance 50 ohms

TRANSMITTER

RF Power Output 25W Version - 25 watts (adjustable to 2-25 watts)

40W Version - 40 watts (adjustable to 10-40 watts)

Spurious and Harmonic Emissions –70 dB

FM Hum and Noise –40 dB (25 kHz), –35 dB (12.5 kHz)

Audio Modulation 25 kHz - 16K0F3E (voice) 16K0F1D (data)

Audio Distortion Less than 3% at 1 kHz with 40% modulation

Audio Frequency Response 6 dB per octave pre-emphasis per standard TIA

Maximum Frequency Spread Any spread within the band

RF Output Impedance 50 ohms

Duty Cycle 20% standard TIA

1-6

February 2001

Part No. 001-9800-001

Page 12

GENERAL INFORMATION

800 MHz 988x SPECIFICATIONS

The following are general specifications intended for use in testing and servicing this transceiver. For current

advertised specifications, refer to the specification sheet available from your sales representative. Specifications

are subject to change without notice.

GENERAL

Frequency Range Transmit - 806-824 MHz Std., 851-869 MHz conv. talk-around

Receive - 851-869 MHz

Operating Modes LTR (trunked) and Conventional (non-trunked)

Systems and Groups Selectable Low Tier: Up to 16 system/group combinations

High Tier: Variable from 100 1-group to approx. 40 16-group systems

Mounting Location Dash (low tier), Dash or Remote (high tier)

Transmit/Receive Separation 45 MHz standard, 0 MHz conventional talk-around

Channel Spacing 12.5 kHz (2.5 kHz maximum deviation)

25 kHz (5 kHz max deviation std, 4 kHz max NPSPAC)

Frequency Stability 1.5 PPM from –22° to +140° F (–30° to +60° C)

Dimensions 2.1” x 6.0” x 7.5” (HxWxD)

Weight 3.5 lbs (1.59 kg)

Power Requirement 13.6 volts DC nominal, negative ground

Current Drain 300 mA maximum (receive standby)

1.5 A maximum (receive, rated audio output)

7.0 A maximum (transmit, 15 W output)

11.0 A maximum (transmit, 30W output)

FCC Compliance Parts 15 and 90

RECEIVER

Sensitivity (12 dB SINAD) 0.35 µV

Selectivity –70 dB at 25 kHz, –60 dB at 12.5 kHz

Spurious and Image Rejection –70 dB

Intermodulation –70 dB

Hum and Noise –40 dB at 25 kHz, –35 dB at 12.5 kHz

Maximum Frequency Spread Any spread within the range

Audio Power Output 5 watts (external 4.7-ohm speaker), 3 watts (internal 8-ohm speaker)

Audio Distortion Less than 5% at 1 kHz with 60% deviation

Audio Response +1, –3 dB per octave de-emphasis per standard TIA

RF Input Impedance 50 ohms

TRANSMITTER

RF Power Output Medium power version - 15 watts (adjustable to 2-15 watts)

High power version - 30 watts (adjustable to 10-30 watts)

Spurious and Harmonic Emissions –70 dB

FM Hum and Noise –45 dB (25 kHz), –38 dB (12.5 kHz)

Audio Modulation 25 kHz - 16K0F3E (voice) 19K6F1D (data)

NPSPAC - 14K0F3E (voice) 17K6F1D (data)

Audio Distortion Less than 5% at 1 kHz with 40% modulation

Audio Frequency Response 6 dB per octave pre-emphasis per standard TIA

RF Output Impedance 50 ohms

Duty Cycle 20% standard TIA

1-7

February 2001

Part No. 001-9800-001

Page 13

GENERAL INFORMATION

900 MHz 989x SPECIFICATIONS

The following are general specifications intended for use in testing and servicing this transceiver. For current

advertised specifications, refer to the specification sheet available from your sales representative. Specifications

are subject to change without notice.

GENERAL

Frequency Range Transmit - 896-902 MHz Std., 935-941 MHz conv. talk-around

Receive - 935-941 MHz

Operating Modes LTR (trunked) and Conventional (non-trunked)

Systems and Groups Selectable Low Tier: Up to 16 system/group combinations

Mid Tier: Up to 16 systems with up to 16 groups each

High Tier: Variable from 100 1-group to approx. 40 16-group systems

Mounting Location Dash (low tier), Dash or Remote (high tier)

Transmit/Receive Separation 39 MHz standard, 0 MHz talk-around

Channel Spacing 12.5 kHz

Frequency Stability 1.5 PPM from –22° to +140° F (–30° to +60° C)

Dimensions 2.1” x 6.0” x 7.5” (HxWxD)

Weight 3.5 lbs (1.59 kg)

Power Requirement 13.6 volts DC nominal, negative ground

Current Drain 300 mA maximum (receive standby)

1.5 A maximum (receive, rated audio output)

7.0 A maximum (transmit, 15 W output)

11.0 A maximum (transmit, 30W output)

FCC Compliance Parts 15 and 90

RECEIVER

Sensitivity (12 dB SINAD) 0.35 µV

Selectivit y –65 dB

Spurious and Image Rejection –70 dB

Intermodulation –70 dB

Hum and Noise –38 dB

Maximum Frequency Spread Any spread within the range

Audio Power Output 5 watts (external 4.7-ohm speaker), 3 watts (internal 8-ohm speaker)

Audio Distortion Less than 5% at 1 kHz with 60% deviation

Audio Response +1, –3 dB per octave de-emphasis per standard TIA

RF Input Impedance 50 ohms

TRANSMITTER

RF Power Output Medium power version - 15 watts (adjustable to 2-15 watts)

High power version - 30 watts (adjustable to 10-30 watts)

Spurious and Harmonic Emissions –70 dB

FM Hum and Noise –40 dB

Audio Modulation 12.5 kHz - 11K0F3E (voice) 11K6F1D (data)

Audio Distortion Less than 5% at 1 kHz with 40% modulation

Audio Frequency Response 6 dB per octave pre-emphasis per standard TIA

Maximum Frequency Spread Any spread within the band

RF Output Impedance 50 ohms

Duty Cycle 20% standard TIA

1-8

February 2001

Part No. 001-9800-001

Page 14

SECTION 2 INSTALLATION

INSTALLATION

2

1

4

5

3

10 ft

8

7

6

10

2

9

Install

15A Fuse

Optional

11

Antenna

6 ft

Optional

Speaker

Miniature UHF

Jack

Item

No.

1 Amplified dynamic microphone 250-0740-300 7 Screw, No. 10 self-drilling (4) 575-9077-545

2 Tri-knob (2) 547-0016-008 8 10-ft. DC power cable & hardware 023-9800-410

3 Standard mounting bracket 017-2229-005 9 Accessory pigtail cable (optional) 597-9800-003

4 Microphone hanger 023-3514-001 10 Accessory wire kit (optional) 023-9750-011

5 Screw, 4-24 x 5/16” sheet metal (3) 575-3604-010 11 5”, 4.7 ohm external spkr (optional) 250-0151-010

6 Hanger grounding wire assembly 023-7171-911

Description Part No.

Item

No.

Description Part No.

Figure 2-1 Front Mount Installation Components

2.1 GENERAL

2.1.2 PERFORMANCE TESTS

2.1.1 SCOPE OF INSTRUCTIONS

Although each transceiver is carefully tested and

Since each installation is somewhat unique, the

installation instructions which follow are intended

only as a general guide to installing this transceiver.

aligned at the factory, it is good practice to verify

transceiver performance before it is placed in service.

Performance tests are located in Sections 7.5 and 7.6.

2-1

February 2001

Part No. 001-9800-001

Page 15

INSTALLATION

2.1.3 TRANSCEIVER PROGRAMMING

The transceiver needs to be pro grammed before it

is placed in service unless it was ordered as factory

programmed. Programming i nst ructions are locate d i n

the manuals listed in Section 1.1.1. Transceivers are

normally shipped with preprogrammed factory test

channels and test parameters.

2.1.4 REQUIRED POWER SOURCE

This transceiver is designed for installation in

vehicles which have a nominal 12-volt, negative

ground electrical system (negative battery terminal

connected directly to the chassis). If the vehicle has

some other type of electrical system, a voltage

converter is required.

2.2 MOUNTING THE TRANSCEIVER

2.2.1 SELECTING A MOUNTING LOCATION

addition, do not place any other objects in the

deployment area.

2.2.2 INSTALLATION COMPONENTS

The following mounting kits are used to install

the transceiver. These components and other components are shown in Figure 2-1.

Mounting Kit, Part No. 023-9800-030

• Two tri-knobs for attaching the transceiver to the

mounting bracket

• Four No. 10 self-drilling screws

Universal Cable and Hardware Kit

Part No. 023-9800-410 (10 ft)

Part No. 023-9800-422 (22 ft)

• 10 ft or 22 ft fused power cable

• Microphone clip and grou nd wire

• One 7A and one 15A fuse (7A not used)

Front mount transceivers are designed for

mounting in a location within convenient reach of the

operator such as the dash, console, or floor. Remote

mount models are designed for mounting in a remote

location such as under a seat or in the trunk that is up

to 6 feet (or up to 17 feet with optional extension

cable) from the control unit.

WARNING

The mounting location of the transceiver or control

unit can affect safe operation of the vehicle. Follow

these precautions when mounting this transceiver:

• Mount it where it does not interfere with operation

of the vehicle controls.

• Mount it where the operator can easily see the

display and reach the controls.

• Mount it wher e it will be leas t likely to cau se injury

in case of an accident.

• Airbags deploy with great force. Therefore, do not

mount it anywhere near the deployment area. In

2.2.3 ATTACHING MOUNTING BRACKET

Either Standard Mounting Bracket, Part No. 0172229-005, or Low Profile Mounting Bracket, Part No.

017-2229-010, can be used to mount the transceiver.

Proceed as follows:

1. Check the area underneath the selected mounting

surface for such things as wires, electrical components, and brake and gas lines that could be

damaged when the mounting bracket screws are

installed. Then install the mounting bracket using

the included self-tapping screws or other screws if

desired.

2. Install the transceiver in the bracket using the

included knobs.

3. With front mount transceivers, install the included

microphone hanger in a convenient location using

the included sheet metal screws or others. For

proper operation of functions such as the monitor

mode and scan, the hanger must be connected to

chassis ground. If req uired, ground the hanger using

the included ground wire.

2-2

February 2001

Part No. 001-9800-001

Page 16

10

INSTALLATION

7

NEG

+

6 ft.

9

8

11

POS

6

10 or 22 ft.

5

4

Miniature

UHF Jack

1

3

Antenna

Description Part No.

Item

No.

15

5 ft.

13

14

11 ft.

17

12

16

Description Part No.

1 ft.

2

Item

No.

1 Low profile mounting bracket 017-2229-010 9 Hanger ground wire assembly 023-7171-911

2 Screw, No. 10 self-drilling (4) 575-9077-545 10 Amplified dynamic microphone 250-0740-300

3 Tri-knob (2) 547-0016-008 11 Remote control unit --4 Accessory pigtail cable (optional) 597-9800-003 12 Tri-knob (2) 547-0016-008

5 Accessory wire kit (optional) 023-9750-011 13 Mounting bracket, control unit 017-2227-057

6 10-ft. DC power cable & hardware 023-9800-410 14 Screw, No. 10 self-drilling (4) 575-9077-545

22-ft DC power cable & hardware 023-9800-422 15 Flat washer, vulcanized (2) 596-6400-030

7 Microphone hanger 023-3514-001 16 Extension control cable, 11 ft (opt.) 597-9800-009

8 Screw, 4-24 x 5/16” sheet metal (3) 575-3604-010 17 5”, 4.7 ohm external spkr (optional)250-0151-010

Figure 2-2 Remote Mount Installation Components

2.3 POWER CABLE INSTALLATION

It is recommended that both wires of the power

cable be connected directly to the vehicle battery.

Connection of either wire to ot her point s may resul t in

increased interference from the vehicle’s electrical

system. If noise is still a problem with both wires

connected to the battery, a noise filter should be used.

NOTE: With LTR-Net models, do not connect the

power cable to a switched power source such as the

ignition switch or a relay. Always use the front panel

power switch or the ignition sense input described in

Section 2.4.3 to switch power. When power is switch ed

externally with LTR-Net models, the de-registration

message cannot be sent and the current user settings

are not saved.

February 2001

2-3

Part No. 001-9800-001

Page 17

INSTALLATION

J101

Strain Relief Grommet

Accessory Pigtail Cable

Figure 2-3 Accessory Cable Installation

R170

Proceed as follows to install the power cable:

1. Before beginning power cable installation, remove

the negative cable from the battery to prevent

damage from accidental short circuits.

2. Route the red and blue wires of the power cable to

the vehicle battery. Y ou may need t o cut the cabl e if

it must be routed through an opening that is not

large enough to clear the fuseholder. The -422 kit

includes butt splice connectors that can be used to

splice the cable back together.

3. Connect the red power cable to the positive (+)

battery terminal. To minimize the chance of a short

circuit occurring in an unfused part of the power

cable, the fusehol der should be as clos e as possible

to the battery terminal.

4. Connect the blue power cable wire to the negative

(–) battery terminal.

5. Both 7- and 15-ampere fuses are included with the

power cable. Install the 15-ampere fuse in this

application.

6. Plug the power ca ble int o the tr ansceive r and re connect the negative battery cable.

7. Install the antenna according to the manufacturer’s

instructions. This transceiver has a miniature UHF

connector. If the antenna has some other type, an

adapter is required. Che ck VSWR. Reflected power

should be less than 4% of forward power (VSWR

less than 1.5 to 1).

2.4 ACCESSORY CABLE INSTALLATION

2.4.1 GENERAL

If transceiver power is to be controlled by the

vehicle’s ignition switch, a horn alert installed,

or other accessory connector outputs utilized, the

optional accessory pigtail cable is i nstalled in the

transceiver (see Figure 2-1). Also required is the

accessory wire kit which includes two 8-pin connectors which plug into the pigtail cable, two 22-ft and

three 2-ft wire assemblies, and a fuseholder assembly.

These components are installed as required for each

applicatio n. Proceed as follows to install this cable.

2-4

February 2001

Part No. 001-9800-001

Page 18

INSTALLATION

Pin Function

1 Speaker Out*

2 Sw Bat Out

3NC

4 Horn Alert

5 Ground

6Ign Sense

7Output D

8NC

* This is a low level output (see

Section 2.4.5)

Figure 2-4 Accessory Cable Connector

2.4.2 ACCESSORY PIGTAIL INSTALLATION

1. Remove the bottom cover of the transceiver to

access the audio/logic board.

2. Plug the pigtail cable from the kit into J101 as

shown in Figure 2-3. The plug can be inser te d only

one way.

3. Position the strain relief in the external speaker jack

slot of the chassis (see Figure 2-3).

4. If installing the ignition sense function, proceed to

the next section to remove R170. Otherwis e,

reinstall the bottom cover.

2.4.3 CONNECTING IGNITION SENSE WIRE

NOTE: If the ignition sense function is not used, no

transceiver modifications are required and this

section can be skipped. However, then be sure that the

Ignition Sense Delay T ime is se t t o “Forever/Infinite”.

If it is not, improper transceiver operation may result

when starting the vehicle.

Accessory Cable

From Transceiver

Pin 8

Insert Pin With

Tang Up

Pin 1

• The horn alert (LTR-Net/Multi-Net) may be auto-

matically disabled when the ignition switch is on.

• A transceiver power turn-off delay can be

programmed. Standby curr ent (receive mode, audio

squelched) is about 1 ampere.

• With LTR-Net models, the de-registration message

is sent and settings saved (see NOTE on page 2-3).

Removing R170

When the ignition sense function is used, resistor

R170 on the audio/logic board must be removed. The

general location of th is resi stor is shown in Figure 2- 3,

and the exact location is shown in Figure 2-5. Carefully remove R170, taking care not to damage board

traces or adjacent components.

General

When the ignition sense line is connected, the

following additional functions are provided:

• The transceiver turns on and off with the vehicle

ignition switch (if the front panel power switch is

on).

2-5

Figure 2-5 R170 Location Diagram

February 2001

Part No. 001-9800-001

Page 19

INSTALLATION

Installing Ignition Sense Wire Assembly

The ignition sense input is connected using the

connector with the 22- foot red wi re pre-i nstalled i n pin

6. The white jumper between pins 1 and 3 is not used

with this transceiver, so it can be clipped off or left as

is. It is used only Summit

®

or Vik ing® HT/GT transceivers to route a udio to t he inter nal spea ker. The other

connector and wire assemblies in the kit can also be

used if desired.

The red wire from pin 6 (see Figure 2-4) is

connected to a 13.6-volt source that is switched by the

vehicle ignition switch. Connect this wire using the

included fuseholder and 1-amp fuse. Be sure to install

the fuse as close as possi ble to the connection point so

that it provides optimum short circuit protection.

2.4.4 CONNECTING HORN ALERT WIRE

NOTE: The horn alert feature is not available with

SMARTNET/SmartZone models.

To utilize the horn alert, the horn alert output of

the accessory connector is connected and special

programming is required. When the horn alert sounds,

pin 4 of the accessory connector goes low. The

disabled condition is a high impedance state.

Maximum sink current of the horn alert output is

500 mA. Therefore, some type of horn alert driver

circuit is usually required. If connecting to a relay, a

diode should be connected across the relay coil with

the cathode toward the battery side. This protects

Q100 on the audio/logic board when the relay deenergizes.

The horn alert output is connected by using one

of the 22- or 2-foot wire assemblies included in the

Accessory Wire Kit. Insert the pin of the wire

assembly into the pin 4 slot of the connector as shown

in Figure 2-4. Then connect the other end to the horn

alert driver.

For this output to operate properly, the audio

amplifier requires an 8-ohm load. Therefore, if not

using the internal speaker and no speaker is connected

to the external speaker jack, connect an 8-ohm, 5-watt

resistor to the external speaker jack.

Sw Bat Out (pin 2) - This output can provide a

switched battery output current of up to 1.5 A

(including the current supplied to the microphone

connector). This cur ren t i s limited by fuse F100 on the

audio/logic board. CAUTION: Do not chan ge this fuse

to one with a higher current rating because PC board

damage may result.

Horn Alert (pin 4) - See Section 2.4.4.

Ignition Sense (pin 6) - See Section 2.4.3.

Output D (pin 7) - This output is available with LTR-

Net/Multi-Net models only. It is controlled by the

menu OPTION parameter or by an option switch

programmed for that functi on. It can al so be contro lled

by several I/O functions (see Appendix B).

2.5 REMOTE CONTROL UNIT INSTALLATION

2.5.1 GENERAL

NOTE: Install the remote mount transceiver, power

cable, and accessory cable as described in Sections

2.2, 2.3, and 2.4, respectively.

No special control uni t pro gra mming o r PC boar d

modifications are required prior to installing the

remote control unit. An d iagram showing a remote

installation is located in Figure 2-2. As indicated in

this diagram, the control unit has a 5-ft pigtail cable

and the transceiver has a 1-ft pigtail cable. These

cables can be directly connected if the control unit is

mounted within approximately 6-ft of the transceiver.

Otherwise, the optional 11-ft extension cable can be

used to allow a mounting distance of up to approximately 17 feet.

2.4.5 OTHER ACCESSORY CABLE OUTPUTS

Speaker Output (pin 1) - This is a low-level, volume

controlled, speaker output. It provides drive to an

external device such as an audio power amplifier. The

input impedance of the external device should be

greater than 20k ohms.

2.5.2 MOUNTING REMOTE CONTROL UNIT

1. Check the area underneath the selecte d mounti ng

surface for such things as wires, electrical components, and brake and gas lines that could be

damaged when the mounting bracket screws are

February 2001

2-6

Part No. 001-9800-001

Page 20

INSTALLATION

Data Pigtail Cable

Accessory

Pigtail Cable

Strain Relief

Two User-Definable Wires

J701

Figure 2-6 Data Cable Installation (-001 Cable Show n)

installed. Then install the mounting bracket using

the included self-tapping screws or other screws if

desired.

2. Install the control unit in the bracket using the

included knobs and vulcanized washers (the

washers are installed between the bracket and

control unit).

3. Install the included microphone hanger in a convenient location usi ng the included shee t metal screws

or other screws. For proper operation of functions

such as the monitor mode and scan , the hanger must

be connected to c hass is ground. If requir ed, gr ound

the hanger using the included ground wire.

2.6 USING AN EXTERNAL SPEAKER

Power output with the internal 8-ohm speaker in

the front panel or remote control unit is approxi mately

3 watts. For up to 5 watts of p ower, a 4.7-ohm exter nal

speaker can be used. This speaker is plugged into the

external speaker jack on the back of the transceiver.

This is a standar d 1/8”, two- conductor p hone jack. Th e

J301

internal speaker is automatically disabled when an

external speaker is used.

The impedance of the external speaker must not

be less than 4.0 ohms. Using a speaker with an impedance less than 4.0 ohms could result in audio amplifier U306 overheating and does not provide 5 watts of

power. Therefore, to allow for tolerances, a speaker

with a nominal impedance of 4.7 ohms is recommended. The E.F. Johnson remote speaker listed in

Figure 2-1 or Table 1-3 meets this requirement. This

speaker has a 6-ft cable, and in some applications

(such as remote mounting) an extension cable may be

required to connect it to the transceiver.

2.7 DATA CABLE INSTALLATION

CAUTION

DO NOT apply power a transceiver that has one of the

data cables ins talled wi thout fir st pr op erly te rminating

the wires of that cable. These wires carry differing

potentials and transceiver damage may result if they

inadvertently contact each other.

2-7

February 2001

Part No. 001-9800-001

Page 21

INSTALLATION

2.7.1 GENERAL

The optional data pigtail cable is supported by

Multi-Net versions only. It is installed when a modem

or some other type of data de vi ce i s to b e con nec ted to

the transceiver. This cable connects the data equipment to data connector J301 on the audio/logic board.

Two data cables are available (see Table 1-3), and

descriptions of each follow.

Data/Accessory Pigtail Cable, Part No. 597-9800-001

This cable is a combination data and accessory

pigtail cable. It does not include a connector for interfacing with

the data equipmen t. The wires are untermi-

nated and connected to a user-supplied connector as

desired. The cable has 15 conductors. All 13 pins of

J301 are brought out, and there are two additional

wires that can be connected inside the transceiver as

desired.

Data Pigtail Cable, Part No. 597-9800-005

This is a data cable only (it does not include the

accessory cable). The data cable is similar to the one

included with the -001 cable. It has 15 unterminated

wires, and a user supplied connector is installed as

desired.

2.7.2 DATA CABLE INSTALLATION

1. Remove the bottom cover of the transceiver to

access the audio/logic board.

Table 2-1 Data Cable Wire Chart

J301 Pin No. Functi on Wire Color

1 Sw Bat Out White

2 Rx Filt Out Green

3 Tx Filt In Yellow

4 TxD Blue

5 RxD Orange

6TransmitGray

7IN2 Brown

8 Ext Serv Req White/Red

9 Option 1 White/Green

10 Output C White/Black

11 Ext Pwr Sw White/Blue

12 8V Out Red

13 Ground Black

NC User Defined Purple

NC User Defined Pink

2.8 KEY CAP KITS

NOTE: To remove a key cap, in ser t a t ool wi th a sharp

tip in the slot on the bottom of the cap and carefully

pry against the front panel to release the cap.

2.8.1 MULTI-NET AND LTR-NET MODELS

Key Cap Kit, Part No. 587-9840-001, is standard

with each Multi-Net transceiver and includes the five

caps indicated below.

2. Refer to Figure 2-6 an d plug the 13-pin connector of

the data cable into J301. If also installing the accessory cable, plug the 7-pi n connector into J701. Refer

to Section 2.4 for more accessory cable installat ion

information.

3. Refer to the wiring chart in Table 2-1 and connect

the data cable wires to the user supplied connector

as required for the data equipment being used.

4. If required, install the purple and pink wires to the

desired points in the transceiver.

5. Position the strain relief grommet of the accessory/

data cable in the external speaker jack slot of the

chassis as shown in Figure 2-6 and reinstall the

bottom cover. bottom cover.

FCN SCAN A/D TA AUX

Key Cap Kit, Part No. 587-9840-002, is standard

with each LTR-Net transceiver and includes the five

caps indicated by an asterisk (*) in the list which

follows.

An optional key cap kit, Part No. 587-9840-004,

is also available which includes all of the caps in the

following list:

FCN* SCAN* A/D* ROAM* TEL*

TA AUX HOME PAGE HORN

C/G PRI USR1 USR2 MON

CPND MHNG STLH MICPA BANK

EMER ENCPT Rx PA CALL

(Blank) (Blank)

February 2001

2-8

Part No. 001-9800-001

Page 22

2.8.2 SMARTNET/SMARTZONE MODELS

Key Cap Kit, Part No. 587-9840-003, is included

with each SMARTNET/SmartZone transceiver. This

kit includes the five key caps listed below.

EMER F1 F2 F3 SCAN

Key Cap Kit, Part No. 587-9840-105, is also

included with each transceiver. This kit includes the

key caps shown below.

F1 F2 F3 F4 SCAN

BKLHT MSG HORN C/S DISP

PRIED SELSQ MON TGSEL PHONE

RESP NUIS STATUS TXPWR (Blank)

ALERT EMER RWS TONES (Blank)

INSTALLATION

2-9

February 2001

Part No. 001-9800-001

Page 23

SECTION 3 CIRCUIT DESCRIPTION

CIRCUIT DESCRIPTION

3.1 GENERAL TRANSCEIVER DESCRIPTION

3.1.1 INTRODUCTION

NOTE: A block diagram of the audio and data

processing circuitry on the audio/logic board is

located in Figure 3-3, and block diagrams of the RF

boards are located in Figures 3-4 and 3-7.

The 9800-series transceivers contain the PC

board assemblies listed below. Components are

mounted on only the top side of all boards. Therefore,

most components can be changed without removing

the board from the chassis.

Audio/Logic - Control logic and audio processing.

Display - This board contains the LCD display and

controller and interface microcontroller.

Interface - This small board provides the electrical

connections between the display and audio/logic

boards, and contains the front panel rotary controls

and microphone jack.

(F300, 0.6A) limits the c urrent of the 8-vol t supply fe d

to modem jack J301. For information on power distribution and switching, refer to Section 3.2.

3.1.3 SYNTHESIZER

The synthesizer output signal is the transmit

frequency in the transmit mode and the receive first

injection frequency in the receive mode. The synthesizer also pr ovides the r ecei ver s econ d inj ectio n sign al

by tripling the TCXO frequency.

Channels are selected by programming the main

divider in synthesize r integra ted circuit U804 to divide

by a certain number. This programming is provided by

microcontroller U101 on the audio/logic board. The

minimum frequency resolution is 6.25 or 10 kHz. The

frequency stabili ty of the synthesizer i s de termined by

the stability of TCXO U806 (Temperature Compensated Crystal Oscillator). The TCXO has a frequency

stability of ± 2.0 PPM (UHF) or ± 1.5 PPM (800/900

MHz) from –22° to +140° F (–30 to +60° C).

3.1.4 AUDIO/LOGIC BOARD

RF Board - Receiver, synthesizer, and exciter.

PA Board - Transmitter power amplifier.

General descriptions of the main sections such as

the receiver, synthesizer, and exciter follow, and

detailed descriptions are located in later sections.

3.1.2 CIRCUIT PROTECTION (FUSES)

Circuit protection is provided by a 15-ampere inline power cable fuse, 4-ampere fuse F500 on the RF

board (in the unswitched battery supply line from the

PA board), and by voltage regulators which automatically limit current. The 15-ampere power cabl e fuse

protects the power amplifier module and final stages

on the power amplifier board, and the 4-ampere fuse

protects the remainder of the circuitry. In addition,

there are two fuses on the audio/logic board. One fuse

(F100, 2A) limits the current of the switched battery

supply fed to accessory connector J101, the microphone jack, and also the display board. The other fuse

Microcontroller U101 on the audio/logic board

provides transceiver control functions including

synthesizer programming, system and group scan,

data encoding and decoding, squelch, and gating of

audio and data signals. The audio /l ogi c boar d als o has

analog circuitry which provides filtering, amplification, and other processing of the audio, data, and Call

Guard signals.

The U101 operating program is stored in Flash

EPROM U108. This type of memory can be reprogrammed in the field using the standard programming

setup and special programming software. This allows

the operating software to be easily update d without the

need to change a microprocessor or EPROM. Flash

EPROM memory devices retain data indefinitely

without the need for battery backup, and can be reprogrammed many times.

Parameters which change from transceiver to

transceiver such as programmed system and groups

and option key programming are also stored in the

3-1

February 2001

Part No. 001-9800-001

Page 24

POWER DISTRIBUTION (ALL MODELS)

CIRCUIT DESCRIPTION

Flash EPROM and also EEPROM U102. This information is programmed when data is downlo aded to the

transceiver by the programming software described in

Section 4.

A second microcontroller (U2) on the display

board controls the front panel display and tri-color

indicator and also detects the option switch, Select

switch, and microphone on/off hook state. Control

information is exchanged between U101 and this

microcontroller via a serial bus. The use of a second

microcontroller minimizes the number of interconnections that are required between the audio/logic and

display boards. The operating program for this microcontroller is permanently stored on the chip and cannot

be changed.

3.1.5 RECEIVER

The receiver is a double conversion type with the

following intermediate frequencies:

UHF Models - 45 MHz and 450 kHz

800 MHz Models - 52.950 MHz and 450 kHz

900 MHz Models - 45 MHz and 450 kHz

T w o bandp ass f ilt ers i n the f ront end a ttenu ate t he

image, half IF, injection, and other f requencies outsid e

the selected receive band. Receiver selectivity is

enhanced by a four -pol e cryst al fi lter a nd two 450 kHz

ceramic filters.

3.1.6 TRANSMITTER

The transmitter amplifies the synthesizer signal to

produce a power output of up to either 25 or 40 watts

(UHF) or 15 or 30 watts ( 800/90 0 MHz) a t the an tenna

jack. Frequency modulation of the transmit signal is

performed by modulating the synthesizer TCXO and

VCO frequencies. A control circuit senses forward

power to maintain constant power output. It also

senses final amplifier cur r ent and cuts back power if it

becomes excessive.

The use of a digital potentiometer allows the

power output to be set from the front panel when the

test mode is selected and also allows two different

power levels to be programmed for each system. The

microcontroller also monitors power amplifier

ambient temperature and voltage and cuts back power

or disables the transmitter if either are excessive.

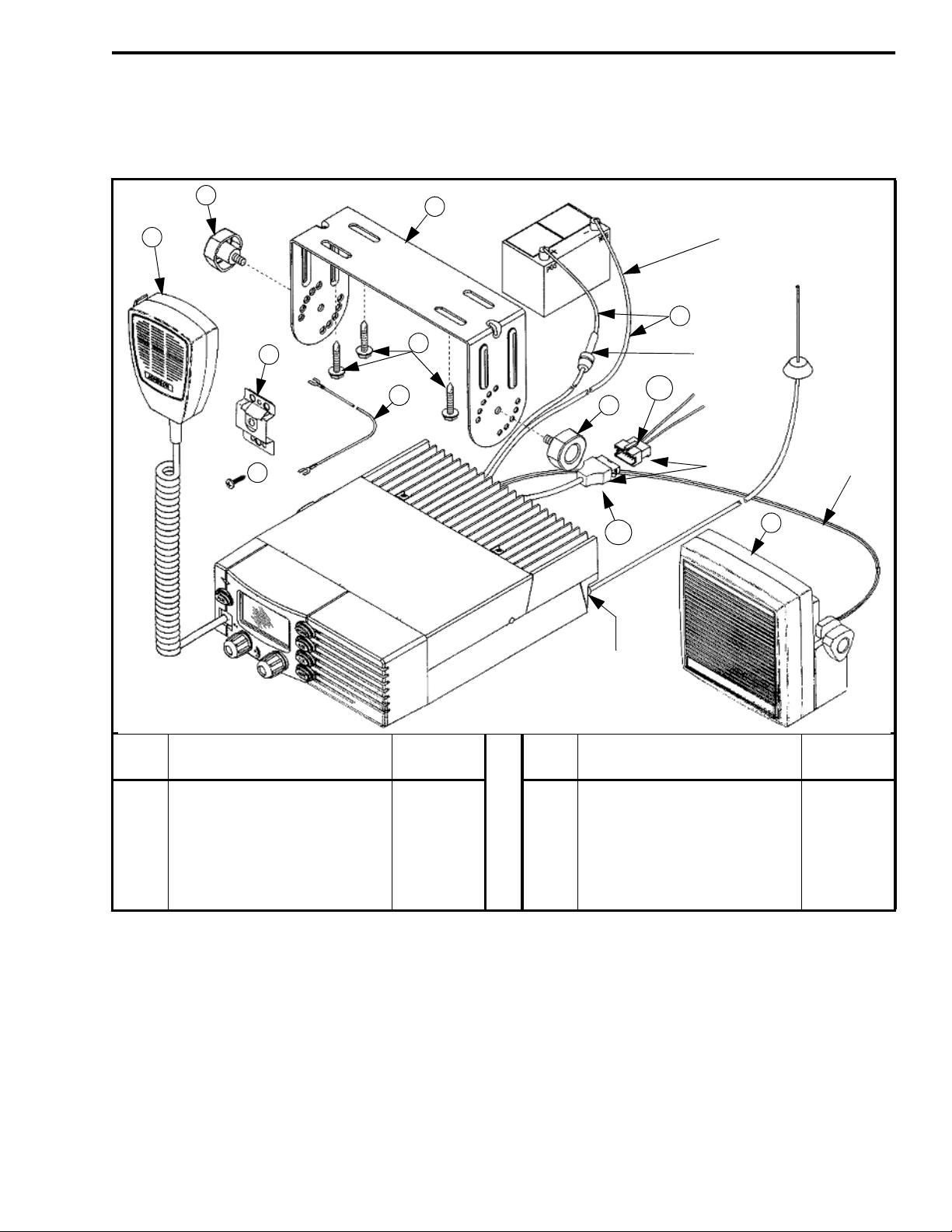

3.2 POWER DISTRIBUTION AND SWITCHING

3.2.1 POWER SWITCHING CONTROL

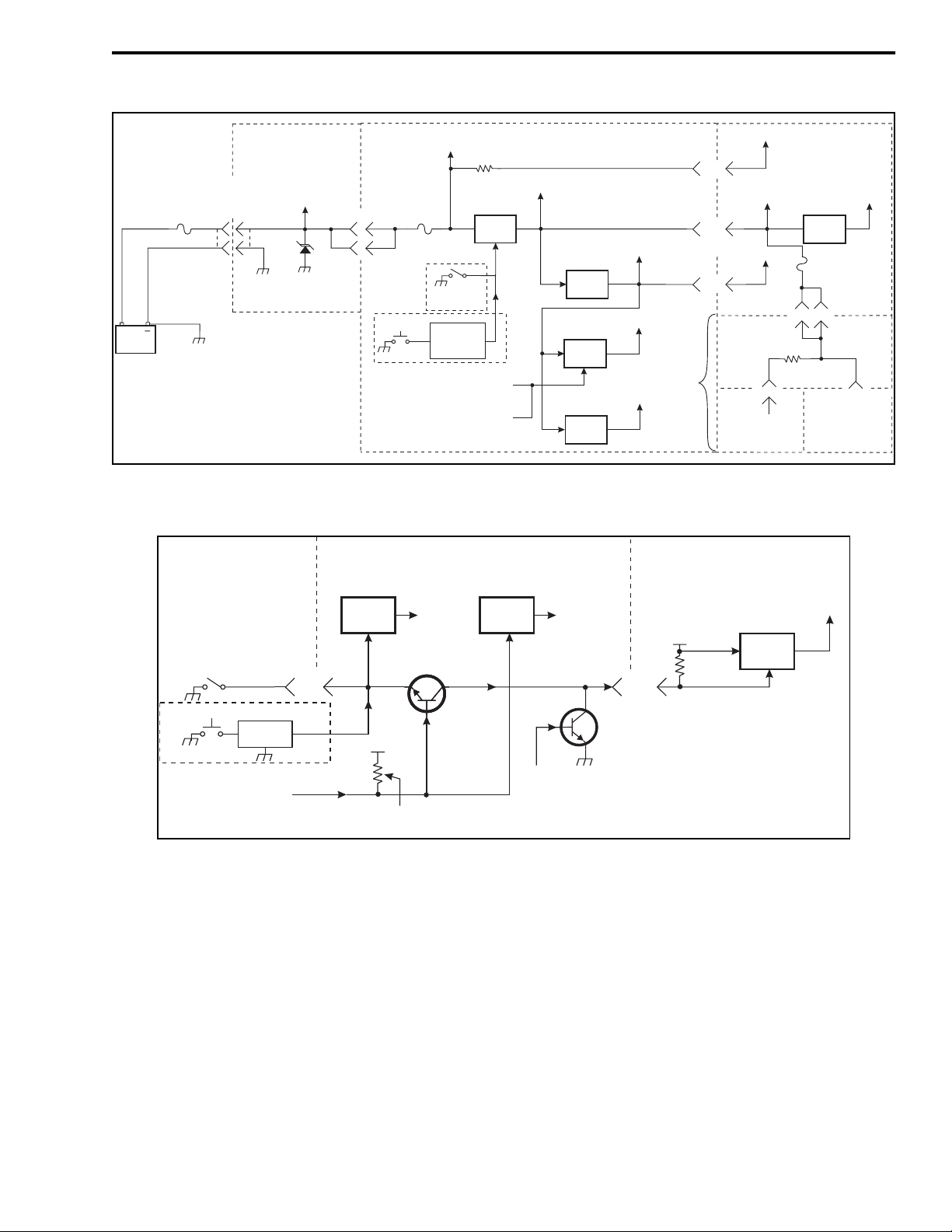

A diagram of the power distribution and

switching circuits is shown in Figure 3-1. The main

power switching is performed on the RF board by

Q510 and other transistors. This switch is controlled

by the front panel power switch, the ignition sense

input, and the microcontroller as shown in Figure 3-2.

For the front panel on-off switch to be detected, Q109

must be turned on by a high signal applied through

R170 or from the ignition switch. R170 is installed if

the ignition switch is not used to control power. Q107

and Q108 provide power switch on and ignition on

signals to the mi crocontroller so t hat it can sense those

conditions.

Q110 allows the microcontroller to hold power

on for a time after it has been turned off by the power

or ignition switch. For example, when the microcontroller senses that power was switched off by the front

panel switch, it holds power on for a short time so that

switch settings can be saved to memory. It also holds

power on when a power-off de la y i s use d. Once power

turns off, power is also removed from the microcontroller. Therefore, power can be turned on only by the

power and ignition switches.

NOTE: The front panel power switch is a push on,

push off type (pressing it toggles between open and

closed). It is not a momentary switch.

3.2.2 SUPPLY SWITCHING

When power is turned on by the front panel

power switch, the base of Q514 on the RF board is

grounded through the power switch. Q514 then turns

on which also turns on the Darlington amplifier

formed by Q511 and Q512. These transist ors are

turned on by a 13.6-volt signal applied through R535.

Series-pass transistor Q510 is then turned on and 13

volts appears on its collector. The diodes in CR505

and CR506 become forward biased only if the 8-volt

supply applied to the collector of Q514 becomes

shorted. This provides current limiting which prevent s

damage to the transistors.

Q513 controls the Q511 base current in order to

maintain approximately a 0.8-volt drop across the

emitter and collector of Q510. This provides noise

3-2

February 2001

Part No. 001-9800-001

Page 25

POWER DISTRIBUTION (ALL MODELS)

CIRCUIT DESCRIPTION

Power

Cable

+

Vehicle

Battery

Transceiver

Chassis

Ground

Power

Connector

15A

Fuse

Interface Board

(High Tier Only)

Front Panel

On-Off Sw

Power On-Off Latch

Low Tier Only

From Ignition

Power Amplifier

Board

CR600

J3 J302

U113A-D

Switch

R533

Switch

Q510

RF Board

Sw Bat

8V

Regulator

U501

8V Tx

Switch

Q504

5.5V

Regulator

U502

Unsw Bat

Transient

Suppressor

J600

1

2

J501

On-Off Sw

Low Tier

F500

4A

Unsw Bat

High Tier

Front Panel

On-Off Sw

On-Off

Latch

(A/L Bd)

From Latch

U112 A/L Bd

From Shift

Reg U801

Figure 3-1 Power Distribution and Switching

Audio/Logic Board RF Board

Power Switch

Sense

Q107 Q108

J100

To uC,

Pin 60

Q109

20 18

Unsw Bat

R170

This Resistor Installed If

Ignition Sense Not Connected

Ignition On

Sense

To uC,

Pin 62

Power Hold

From Shift Reg

U111, Q7

Unsw Bat

J201

J302

4

2

Sw Bat

Sw Bat

8V

8V Tx

5.5V

High

Tier Only

10

5

11

15

Display Board

Interface

Board

J2 J1

J1

Sw Bat

Supply

Switching

Circuit

Unsw Bat

Q510

J201

51

Q110

Note: Arrows Indicate Signal Flow.

Audio/Logic

Board

5V

2A

J100

12

J3

Sw Bat

5

Microphone

Jack

Vcc

Regulator

U105

8V

F100

Sw Bat

11

R2

2

Sw Bat

Figure 3-2 Power On-Off Co ntrol Circuit

filtering of the 13.6-volt supply. The emitter of Q513

is biased at about 4.5 volts by R538 and R542 (with a

battery voltage of 13.6 volts). CR504 mirrors the baseemitter voltage of Q513, and the voltage across R541

is the same as the voltage across R542 when the

voltage applied to R536 is approximately 12.8 volts.

Noise pulses less than 1.6 volt P-P then do not

appear on the output of Q510 because of the emitter

voltage filtering provided by C565. This reduces the

amount of noise applied to circuits powered by the

switched 13.6-volt supply such as audio power amplifier U306. Additional filtering of the switched and

unswitched battery supplies is provided by C548C553. Resistor R534 turns Q514 off when power is

turned off.

February 2001

3-3

Part No. 001-9800-001

Page 26

AUDIO/LOGIC DESCRIPTION (ALL MODELS)

CIRCUIT DESCRIPTION

3.3 AUDIO/LOGIC BOARD DIGITAL CIRCUIT

3.3.1 MICROCONTROLLER (U101)

General

The control logic is based on an MC68HC11F1

eight-bit microcontroller (U101). This device has an

internal 1K-byte static RAM and 512-byte EEPROM