Page 1

October 2003

Supersedes: Part No. 001-3139-003/004; 5/99

MULTI-NET®II

3000 S

ERIES

SWITCH

SET-UP AND

ALIGNMENT

SET-UP AND

ALIGNMENT

MULTI-NET®II SWITCH

Page 2

Page 3

MULTI-NET® II

3000 SERIES SWITCH

SETUP AND ALIGNMENT MANUAL

Copyright© 2003 by the EFJohnson Company

The EFJohnson Company, which was founded in 1923, provides wireless communication systems solutions for

public safety, government, and commercial customers. The company designs, manufactures, and markets conventional and trunked radio systems, mobile and portable subscriber radios, repeaters, and Project 25 digital radio

products. EFJohnson is a wholly owned subsidiary of EFJ, Inc.

Viking Head/EFJohnson logo, Multi-Net

other company and/or product names used in this manual are trademarks and/or registered trademarks of their

respective manufacturer.

Information in this manual is subject to change without notice. The EFJohnson Company will not be liable for any

misunderstanding due to misinformation or errors found in this document.

®

, and LTR®are registered trademarks of the EFJohnson Company. All

Page 4

SAFETY INFORMATION

The FCC has adopted a safety standard for human exposure to RF energy. Proper operation of this radio under

normal conditions results in user exposure to RF energy below the Occupational Safety and Health Act and Federal

Communication Commission limits.

WARNING

DO NOT allow the antenna to touch or come in very close proximity with the eyes, face, or any exposed body

parts while the radio is transmitting.

DO NOT allow the antenna to come close to or touch, the eyes, face, or any exposed body parts while the radio is

transmitting.

DO NOT operate the radio in explosive or flammable atmospheres. The transmitted radio energy could trigger

blasting caps or cause an explosion.

DO NOT operate the radio without the proper antenna installed.

DO NOT operate the radio unless all radio frequency connectors are secure and any open connectors are properly

terminated.

DO NOT allow children to operate or play with this equipment.

NOTE: The above warning list is not intended to include all hazards that may be encountered when using this

radio.

This device complies with Part 15 of the FCC rules. Operation is subject to the condition that this device does not

cause harmful interference. In addition, changes or modifications to this equipment not expressly approved by

EFJohnson could void the user’s authority to operate this equipment (FCC rules, 47CFR Part 15.19).

LAND MOBILE PRODUCT WARRANTY

The manufacturer’s warranty statement for this product is available from your product supplier or from EFJohnson

Company, 299 Johnson Avenue, Box 1249, Waseca, MN 56093-0514. Phone (507) 835-6222.

Page 5

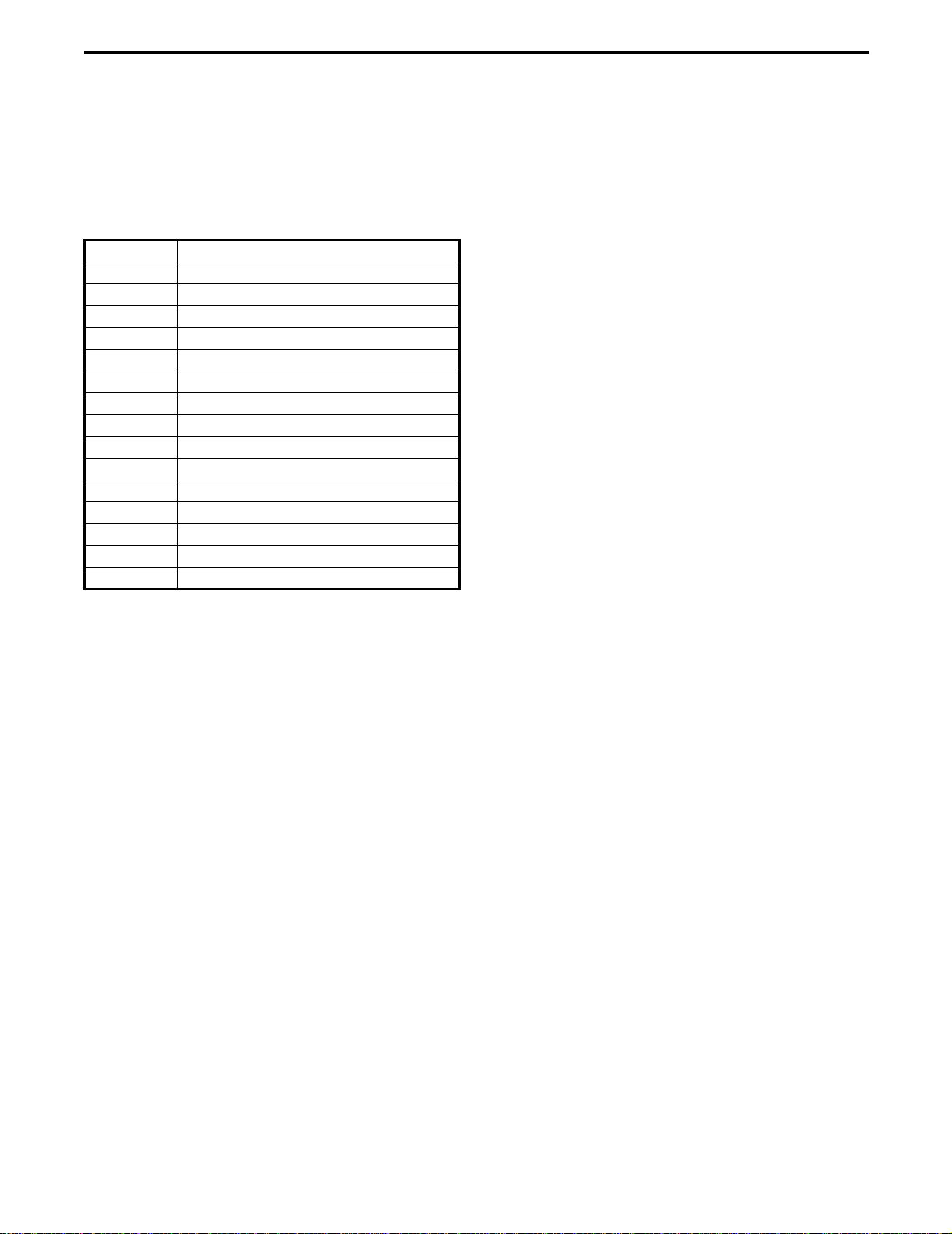

TABLE OF CONTENTS

TABLE OF CONTENTS

1 INTRODUCTION

1.1 SCOPE OF MANUAL . . . . . . . . . . . . . . . . . . . 1-1

1.2 DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Trunked System. . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

LTR Trunked System . . . . . . . . . . . . . . . . . . . . . 1-1

Multi-Net Trunked System . . . . . . . . . . . . . . . . . 1-1

Conventional System. . . . . . . . . . . . . . . . . . . . . . 1-1

3000 Series Switch . . . . . . . . . . . . . . . . . . . . . . . 1-1

Call Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System and Subscriber Manager . . . . . . . . . . . . . 1-1

Repeater Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Home Repeater Channel . . . . . . . . . . . . . . . . . . . 1-1

Status Repeater Channel . . . . . . . . . . . . . . . . . . . 1-2

Monitor Repeater Channel. . . . . . . . . . . . . . . . . . 1-2

Telephone Interconnect and Data Transmission . 1-2

Public Switched Telephone Network (PSTN). . . 1-2

Private Automatic Branch Exchange (PABX) . . 1-2

2 3000 SERIES SWITCH

2.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 ELEMENTS OF THE SWITCH. . . . . . . . . . . . 2-2

2.3 SWITCH MODULES (ELEMENTS). . . . . . . . 2-2

Voltage Adjustments . . . . . . . . . . . . . . . . . . . . . 4-8

Redundant Supply Adjustments. . . . . . . . . . . . . 4-8

Verify Fan Air Flow Direction. . . . . . . . . . . . . . 4-8

Verify Voltages On Power Distribution Cable . 4-8

System Test Procedure. . . . . . . . . . . . . . . . . . . . 4-9

Final Configuration Verification . . . . . . . . . . . 4-11

4.3 SIX SHELF 3000 SERIES SWITCH . . . . . . 4-13

Power Consumption. . . . . . . . . . . . . . . . . . . . . 4-13

Equipment Required . . . . . . . . . . . . . . . . . . . . 4-13

Verify Resistance of Bus Bar and Power Supply

Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Verify Cooling Fan Air Flow Direction. . . . . . 4-14

Verify Voltages On Power Distribution Cable 4-14

System Test Procedure. . . . . . . . . . . . . . . . . . . 4-14

Final Configuration Verification . . . . . . . . . . . 4-17

4.4 EIGHT SHELF 3000 SERIES SWITCH. . . . 4-20

Power Consumption. . . . . . . . . . . . . . . . . . . . . 4-20

Equipment Required . . . . . . . . . . . . . . . . . . . . 4-20

Verify Resistance of Bus Bar and Power

Supply Lines . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Verify Cooling Fan Air Flow Direction. . . . . . 4-21

Verify Voltages On Power Distribution Cable 4-21

System Test Procedure. . . . . . . . . . . . . . . . . . . 4-21

Final Configuration Verification . . . . . . . . . . . 4-23

3 ARCHITECTURE

3.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 SWITCH INTERFACES. . . . . . . . . . . . . . . . . . 3-1

3.3 BUS STRUCTURE. . . . . . . . . . . . . . . . . . . . . . 3-2

Data Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Control Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Voice Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4 SYSTEM RACK

4.1 TWO SHELF 3000 SERIES SWITCH. . . . . . 4-1

Power Consumption. . . . . . . . . . . . . . . . . . . . . . . 4-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . 4-1

Two Shelf Power Supply. . . . . . . . . . . . . . . . . . . 4-2

Power Supply Redundant Plate . . . . . . . . . . . . . . 4-2

Voltage Adjustments . . . . . . . . . . . . . . . . . . . . . . 4-2

Redundant Supply Adjustments . . . . . . . . . . . . . 4-2

Verify Fan Air Flow Direction . . . . . . . . . . . . . . 4-2

Verify Voltages on Power Distribution Cable. . . 4-3

System Test Procedure . . . . . . . . . . . . . . . . . . . . 4-3

Final Configuration Verification . . . . . . . . . . . . . 4-5

4.2 FOUR SHELF 3000 SERIES SWITCH. . . . . 4-7

Power Consumption. . . . . . . . . . . . . . . . . . . . . . . 4-7

Equipment Required . . . . . . . . . . . . . . . . . . . . . . 4-7

4-Shelf Power Supply . . . . . . . . . . . . . . . . . . . . . 4-7

Power Supply Redundant Plate . . . . . . . . . . . . . . 4-7

5 CALL PROCESSOR

5.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 DATA BUSES . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 CALL PROCESSOR CONTROL . . . . . . . . . . 5-2

System Configuration . . . . . . . . . . . . . . . . . . . . 5-2

Manual Device Control . . . . . . . . . . . . . . . . . . . 5-2

Subscriber Management. . . . . . . . . . . . . . . . . . . 5-2

Activity Log Utilities. . . . . . . . . . . . . . . . . . . . . 5-2

Call Completion. . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Keyboard Lock. . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Log Out/Log In . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.4 ALARM CONTROL . . . . . . . . . . . . . . . . . . . . . 5-3

5.5 SYSTEM ANALYZER . . . . . . . . . . . . . . . . . . .5-3

5.6 CALL PROCESSING . . . . . . . . . . . . . . . . . . . . 5-3

6 NETWORK INTERFACE MODULE

(NetNIM)

6.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.3 SETUP PROCEDURE . . . . . . . . . . . . . . . . . . . 6-2

Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 ALIGNMENT SPECIFICATIONS. . . . . . . . . .6-2

Detector Setting . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

i

Page 6

TABLE OF CONTENTS (CONT’D)

TABLE OF CONTENTS

7 BASIC BOARD MODULE (BBM)

7.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Main Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Secondary Communication . . . . . . . . . . . . . . . . . 7-1

Internal Communication . . . . . . . . . . . . . . . . . . . 7-1

7.2 BBM SETUP PROCEDURE. . . . . . . . . . . . . . 7-3

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Jumper Placement . . . . . . . . . . . . . . . . . . . . . . . . 7-3

BBM Backplane External Connections. . . . . . . . 7-3

7.3 BBM ALIGNMENT PROCEDURES . . . . . . . 7-4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4 TEST TASKS . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

System Switch Equals “1”. . . . . . . . . . . . . . . . . . 7-5

System Switch Equals “2”. . . . . . . . . . . . . . . . . . 7-5

System Switch Equals “3”. . . . . . . . . . . . . . . . . . 7-5

System Switch Equals “4”. . . . . . . . . . . . . . . . . . 7-5

System Switch Equals “5”. . . . . . . . . . . . . . . . . . 7-5

System Switch Equals “6”. . . . . . . . . . . . . . . . . . 7-5

System Switch Equals “7”. . . . . . . . . . . . . . . . . . 7-6

System Switch Equals “8”. . . . . . . . . . . . . . . . . . 7-6

System Switch Equals “9”. . . . . . . . . . . . . . . . . . 7-6

7.5 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . 7-6

Test “1” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Test “2” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Test “3” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Test “4” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Test “5” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Test “6” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Test “7” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Test “8” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Test “9” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.6 DS1 DISPLAY DEFINITIONS. . . . . . . . . . . . . 7-9

8 CHANNEL INTERFACE MODULE

(CIM)

External Connections . . . . . . . . . . . . . . . . . . . . . 8-6

Alignment Procedure . . . . . . . . . . . . . . . . . . . . . 8-6

9 CONVENTIONAL CHANNEL MODULE

(CCM)

9.1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . .9-9

Repeater Signaling . . . . . . . . . . . . . . . . . . . . . . . 9-9

Repeater Control. . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Voice Connection. . . . . . . . . . . . . . . . . . . . . . . . 9-9

Internal Communication. . . . . . . . . . . . . . . . . . . 9-9

9.2 CCM SETUP PROCEDURE . . . . . . . . . . . . . .9-9

CCM Switch Settings . . . . . . . . . . . . . . . . . . . . . 9-9

AFSK Communication on the Main Lines. . . . . 9-9

CCM Jumper Placement. . . . . . . . . . . . . . . . . . . 9-9

CCM Backplane External Contacts . . . . . . . . . 9-10

9.3 CCM ALIGNMENT SPECIFICATIONS . . . .9-10

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

CCM Alignment Procedure . . . . . . . . . . . . . . . 9-10

10 DISPATCH CHANNEL MODULE

(DCM)

10.1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . .10-1

Repeater Signaling . . . . . . . . . . . . . . . . . . . . . . 10-1

Repeater Control. . . . . . . . . . . . . . . . . . . . . . . . 10-1

Voice Connection. . . . . . . . . . . . . . . . . . . . . . . 10-1

Internal Communication. . . . . . . . . . . . . . . . . . 10-1

10.2 DCM SETUP PROCEDURE . . . . . . . . . . . . .10-1

DCM Switch Settings. . . . . . . . . . . . . . . . . . . . 10-1

AFSK Communication on the Main Lines. . . . 10-1

DCM Jumper Placement. . . . . . . . . . . . . . . . . . 10-1

DCM Backplane External Contacts . . . . . . . . . 10-2

10.3 DCM ALIGNMENT SPECIFICATIONS . . . .10-2

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

DCM Alignment Procedure . . . . . . . . . . . . . . . 10-2

8.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Repeater Signaling. . . . . . . . . . . . . . . . . . . . . . . . 8-1

Repeater Control . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Voice Connection . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Internal Communication . . . . . . . . . . . . . . . . . . . 8-1

8.2 CIM SETUP PROCEDURE. . . . . . . . . . . . . . . 8-1

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Jumper Placement . . . . . . . . . . . . . . . . . . . . . . . . 8-2

CIM Backplane External Contacts . . . . . . . . . . . 8-2

External Connections. . . . . . . . . . . . . . . . . . . . . . 8-4

8.3 CIM ALIGNMENT SPECIFICATIONS . . . . . 8-4

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

CIM Alignment Procedure . . . . . . . . . . . . . . . . . 8-4

8.4 CIM AUDIO SUMMATION PERSONALITY

CARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Internal Connections . . . . . . . . . . . . . . . . . . . . . . 8-6

11 DISPATCH INTERFACE MODULE

(DIM)

11.1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . .11-1

11.2 DIM SETUP PROCEDUR E . . . . . . . . . . . . . .11-1

Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . 11-1

DIM Jumper Placement . . . . . . . . . . . . . . . . . . 11-1

E-Lead Selection. . . . . . . . . . . . . . . . . . . . . . . . 11-2

DIM Backplane External Contacts. . . . . . . . . . 11-2

11.3 DIM ALIGNMENT SPECIFICATION . . . . . .11-2

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Pre-Alignment With Tone Remote Personality

Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

11.4 ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

11.5 TONE REMOTE DTMF OPERATION . . . . .11-4

ii

Page 7

TABLE OF CONTENTS (CONT’D)

TABLE OF CONTENTS

12 INTELLIGENT DISPATCH MODULE

(IDM)

12.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12.2 IDM SETUP PROCEDURE. . . . . . . . . . . . . . 12-2

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

IDM Jumper Placement. . . . . . . . . . . . . . . . . . . 12-2

IDM Backplane External Contacts . . . . . . . . . . 12-2

12.3 IDM ALIGNMENT SPECIFICATION. . . . . . 12-4

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

12.4 ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

12.5 PCM SUMMATION PERSONALITY CARD12-5

Internal Connections . . . . . . . . . . . . . . . . . . . . . 12-5

External Connections. . . . . . . . . . . . . . . . . . . . . 12-5

Alignment Procedure. . . . . . . . . . . . . . . . . . . . . 12-5

13 SYSTEM NETWORK MODULE (SNM)

13.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 13-1

13.2 SNM SETUP PROCEDURE. . . . . . . . . . . . . 13-2

SNM Switch Settings. . . . . . . . . . . . . . . . . . . . . 13-2

AFSK Communication on the Main Lines . . . . 13-2

SNM Jumper Placement . . . . . . . . . . . . . . . . . . 13-2

SNM Backplane External Contacts . . . . . . . . . . 13-2

13.3 SNM ALIGNMENT SPECIFICATIONS. . . . 13-2

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

SNM Alignment Procedure . . . . . . . . . . . . . . . . 13-2

14 TELEPHONE INTERFACE MODULE

(TIM)

14.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Supervision . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

Signaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

Call Supervision. . . . . . . . . . . . . . . . . . . . . . . . . 14-2

Intra-terminal Communication . . . . . . . . . . . . . 14-2

Telephone Line Styles . . . . . . . . . . . . . . . . . . . . 14-3

Audio Processing. . . . . . . . . . . . . . . . . . . . . . . . 14-3

Receive Audio . . . . . . . . . . . . . . . . . . . . . . . . . . 14-3

Transmit Audio . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

14.2 4-WIRE E&M INTERFACE DESCRIPTION14-4

Audio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

E&M Leads . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-4

8-position Dip Switch S201. . . . . . . . . . . . . . . . 14-5

Type I and V . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

Type II and III . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

Type IV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

Type II Trunk-To-Trunk . . . . . . . . . . . . . . . . . . 14-6

Type V Trunk-to-Trunk. . . . . . . . . . . . . . . . . . . 14-7

14.3 LED STATUS FOR E&M LEADS. . . . . . . . .14-7

TELCO Side Status . . . . . . . . . . . . . . . . . . . . . 14-7

E&M Logic Status . . . . . . . . . . . . . . . . . . . . . . 14-7

14.4 E&M LEAD CIRCUIT THEORY OF

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . .14-8

E&M Interface . . . . . . . . . . . . . . . . . . . . . . . . . 14-8

Signal Conditioning . . . . . . . . . . . . . . . . . . . . . 14-8

14.5 TIM SETUP PROCEDURE . . . . . . . . . . . . .14-11

TIM Jumper Placement . . . . . . . . . . . . . . . . . 14-11

Main Board Switch Settings. . . . . . . . . . . . . . 14-11

14.6 2WY SETUP AND ALIGNMENT

PROCEDURES (-670). . . . . . . . . . . . . . . .14-11

2WY Jumper Setup. . . . . . . . . . . . . . . . . . . . . 14-11

2WY Pre-Alignment Procedures . . . . . . . . . . 14-11

14.7 2-WAY TIM ALIGNMENT

PROCEDURES (-670). . . . . . . . . . . . . . . .14-13

Main Receive . . . . . . . . . . . . . . . . . . . . . . . . . 14-13

Dial Tone Detector . . . . . . . . . . . . . . . . . . . . . 14-13

Output Hybrid Adjust. . . . . . . . . . . . . . . . . . . 14-14

14.8 DID SETUP AND ALIGNMENT (-660) . . .14-15

DID Personality Card Jumper Settings. . . . . . 14-15

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . 14-15

14.9 DID OPERATIONAL ALIGNMENT

PROCEDURES (-660). . . . . . . . . . . . . . . .14-16

14.10 E&M SETUP AND ALIGNMENT (-680) . .14-17

Equipment Required. . . . . . . . . . . . . . . . . . . . 14-17

Transmit Alignment . . . . . . . . . . . . . . . . . . . . 14-17

Receiver Alignment . . . . . . . . . . . . . . . . . . . . 14-18

4-Wire E&M Dial Tone Detector Receive

Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . 14-18

14.11 TERMSET MODULES . . . . . . . . . . . . . . . . .14-23

Equipment Setup. . . . . . . . . . . . . . . . . . . . . . . 14-23

Initializing the Tellabs Cards . . . . . . . . . . . . . 14-23

Switch Settings On 6132A (DID

Applications) . . . . . . . . . . . . . . . . . . . . . . . 14-24

XEL Termset Rack. . . . . . . . . . . . . . . . . . . . . 14-25

Connection To the Phone Lines . . . . . . . . . . . 14-26

Final Path Inspection . . . . . . . . . . . . . . . . . . . 14-27

14.12 BACKGROUND INFORMATION . . . . . . . .14-27

Standard Signal. . . . . . . . . . . . . . . . . . . . . . . . 14-27

Outlined Objective . . . . . . . . . . . . . . . . . . . . . 14-27

The Order of Things. . . . . . . . . . . . . . . . . . . . 14-27

14.13 TUNING A DOD OR DID 2-WIRE INTERFACE

TO THE 4-WIRE E&M BOARD.. . . . . . . .14-28

14.14 BALANCING TO THE CENTRAL

OFFICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-30

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 14-30

Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-30

Adding Capacitance to the Termset . . . . . . . . 14-30

Rural Areas. . . . . . . . . . . . . . . . . . . . . . . . . . . 14-30

Urban Areas . . . . . . . . . . . . . . . . . . . . . . . . . . 14-30

14.15 FCC USER INSTRUCTIONS AND

CUSTOMER INFORMATION. . . . . . . . . .14-31

iii

Page 8

TABLE OF CONTENTS (CONT’D)

TABLE OF CONTENTS

15 VOTER DIAGNOSTICS MODULE

(VDM)

15.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 15-1

15.2 VDM SETUP PROCEDURE . . . . . . . . . . . . . 15-1

Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Jumper Placement . . . . . . . . . . . . . . . . . . . . . . . 15-2

VDM Backplane External Contacts. . . . . . . . . . 15-2

15.3 VDM ALIGNMENT SPECIFICATIONS. . . . 15-2

16 POWER TERMINATION MODULE

(PTM)

16.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 16-1

16.2 SETUP PROCEDURE . . . . . . . . . . . . . . . . . . 16-1

17 LOGGING ENCODER MODULE (LEM)

17.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 17-1

17.2 LEM SETUP PROCEDURE . . . . . . . . . . . . . 17-2

LEM Switch Settings. . . . . . . . . . . . . . . . . . . . . 17-2

LEM Jumper Placement . . . . . . . . . . . . . . . . . . 17-2

LEM Backplane External Contacts . . . . . . . . . . 17-2

17.3 LEM ALIGNMENT SPECIFICATIONS . . . . 17-2

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . 17-2

LEM Alignment Procedure . . . . . . . . . . . . . . . . 17-2

18 VOICE TONE MODULE (VTM)

18.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 18-1

18.2 SETUP PROCEDURE . . . . . . . . . . . . . . . . . . 18-1

VTM Jumper Placement . . . . . . . . . . . . . . . . . . 18-1

VTM Switch Settings . . . . . . . . . . . . . . . . . . . . 18-1

18.3 ALIGNMENT SPECIFICATIONS. . . . . . . . . 18-1

20 MULTI-NET CONSOLE MODULE

(MCM)

20.1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . .20-1

20.2 MCM SETUP PROCEDURE . . . . . . . . . . . . . 20-2

Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . 20-2

MCM Jumper Placement . . . . . . . . . . . . . . . . . 20-2

MCM Backplane External Contacts. . . . . . . . . 20-2

20.3 MCM ALIGNMENT SPECIFICATION . . . . .20-2

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . 20-2

20.4 ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . .20-3

20.5 PCM SUMMATION PERSONALITY CARD20-4

Internal Connections. . . . . . . . . . . . . . . . . . . . . 20-4

External Connections . . . . . . . . . . . . . . . . . . . . 20-4

Alignment Procedure . . . . . . . . . . . . . . . . . . . . 20-4

21 CONVENTIONAL PATCH MODULE

(CPM)

21.1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . .21-1

21.2 PCM SETUP PROCEDURE . . . . . . . . . . . . .21-1

Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . 21-1

CPM Jumper Placement . . . . . . . . . . . . . . . . . . 21-1

E-Lead Selection. . . . . . . . . . . . . . . . . . . . . . . . 21-2

CPM Backplane External Contacts . . . . . . . . . 21-2

21.3 CPM ALIGNMENT SPECIFICATION . . . . .21-2

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . 21-2

Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-2

22 POWER SUPPLY

19 WIDE AREA MODULE (WAM)

19.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 19-1

19.2 WAM SETUP PROCEDURE . . . . . . . . . . . . 19-2

WAM Switch Settings. . . . . . . . . . . . . . . . . . . . 19-2

WAM Jumper Placement. . . . . . . . . . . . . . . . . . 19-2

WAM Backplane External Contacts . . . . . . . . . 19-2

19.3 WAM ALIGNMENT SPECIFICATIONS . . . 19-2

Pre-Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . 19-2

WAM Alignment Procedure . . . . . . . . . . . . . . . 19-2

19.4 WAM E&M-LEAD CONNECTIONS . . . . . . 19-4

One Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-5

Two Locations . . . . . . . . . . . . . . . . . . . . . . . . . . 19-5

Three Locations . . . . . . . . . . . . . . . . . . . . . . . . . 19-5

19.5 M-LEAD SPLITTER BOX . . . . . . . . . . . . . . . 19-5

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-5

19.6 WAM AUDIO CONNECTIONS. . . . . . . . . . . 19-6

22.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . 22-1

22.2 POWER CONSUMPTION . . . . . . . . . . . . . . .22-1

23 BACKPLANE

23.1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . .23-1

23.2 BACKPLANE SETUP PROCEDURE . . . . .23-1

Shelf Address Settings . . . . . . . . . . . . . . . . . . . 23-1

Termination Settings. . . . . . . . . . . . . . . . . . . . . 23-1

Jumper Definitions and Settings. . . . . . . . . . . . 23-1

23.3 STANDARD SHELF I/O CONNECTIONS .23-2

23.4 CIM SHELF I/O CONNECTIONS . . . . . . . . .23-3

Primary PCM . . . . . . . . . . . . . . . . . . . . . . . . . . 23-3

Secondary PCM . . . . . . . . . . . . . . . . . . . . . . . . 23-3

23.5 NetNIM SHELF WITH CIM/CCMs . . . . . . . .23-4

23.6 NetNIM SHELF WITHOUT CIM/CCMs . . . .23-5

iv

Page 9

TABLE OF CONTENTS (CONT’D)

TABLE OF CONTENTS

24 INTERCOM

24.1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 24-1

24.2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 24-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . 24-1

Installation Procedure . . . . . . . . . . . . . . . . . . . . 24-1

APPENDIX A ERROR MESSAGES

A.1 IDB Error Messages To Message

Accounting Bus From Modules. . . . . . . .A-1

A.2 MAB Error Messages From System

Management Module. . . . . . . . . . . . . . . . . .A-2

APPENDIX B CALL SEQUENCES

B.1 GROUP CALL. . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Mobile To Mobile On Same Site. . . . . . . . . . . . B-1

Mobile To Mobile With DIM Monitoring. . . . . B-1

B.2 Dispatch Console (DC) To Mobile Group

Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.3 Mobile Group Call To Dispatch Console. B-1

B.4 Mobile To Unique ID . . . . . . . . . . . . . . . . . . . B-2

B.5 Mobile To Unique ID For a Mobile Outside

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.6 Mobile To Directed Group Call (DTMF

Entry Within Switch) . . . . . . . . . . . . . . . . . B-3

B.7 Mobile To Directed Group Call (DTMF

Entry Outside the Switch)B-4

B.8 Mobile Originated Telephone Call. . . . . . . B-5

B.9 Landside (TIM) Originate To Mobile

Within Switch Using a DID Line . . . . . . . B-6

B.10 Landside (TIM) Originate To Mobile

Within Switch Using a 2WY Line . . . . . . B-6

B.11 TIM Originate To Mobile Outside Switch

Using a DID Line . . . . . . . . . . . . . . . . . . . . . B-7

B.12 Landside Originate To Mobile Outside

Switch Using a 2WY Line . . . . . . . . . . . . . B-7

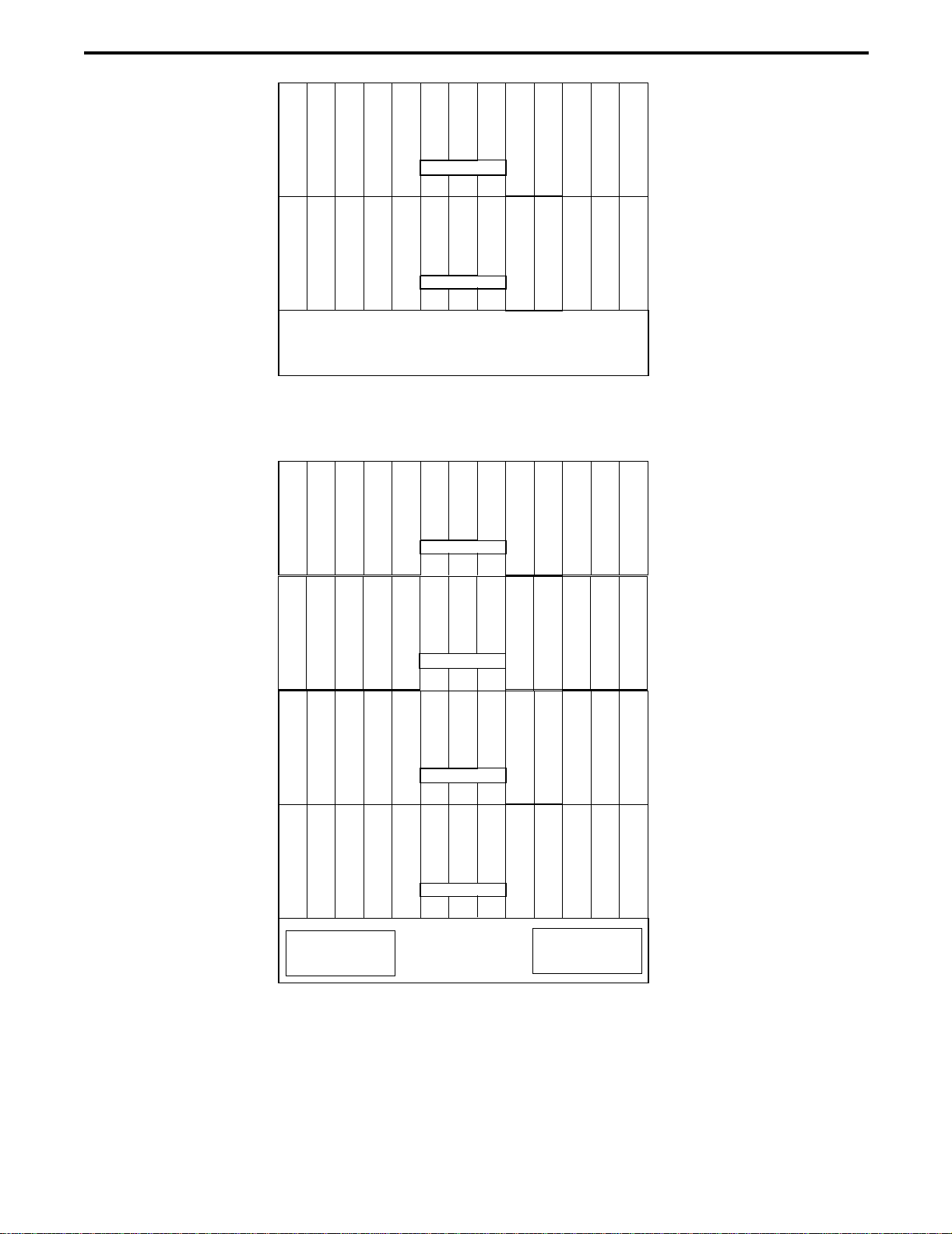

LIST OF FIGURES

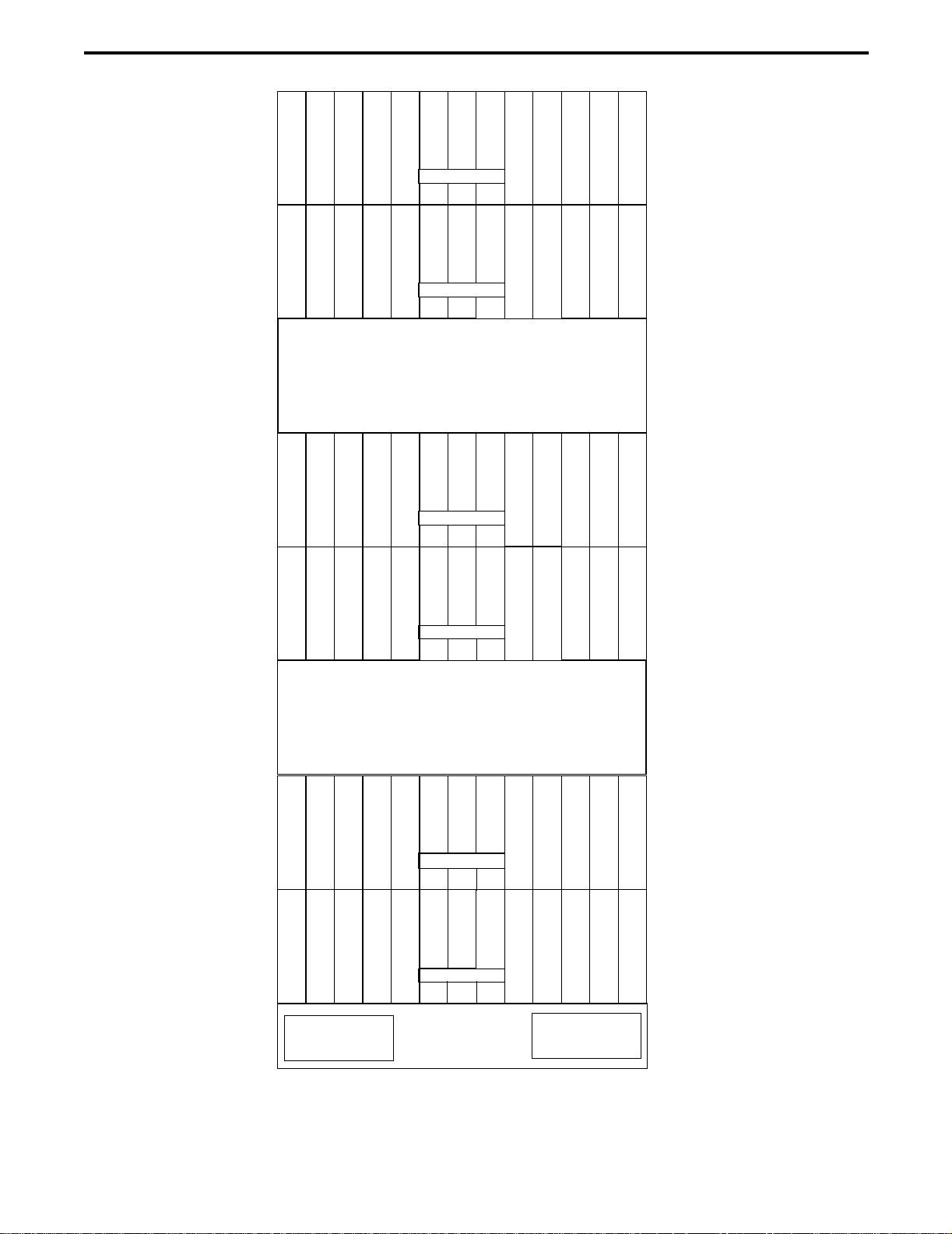

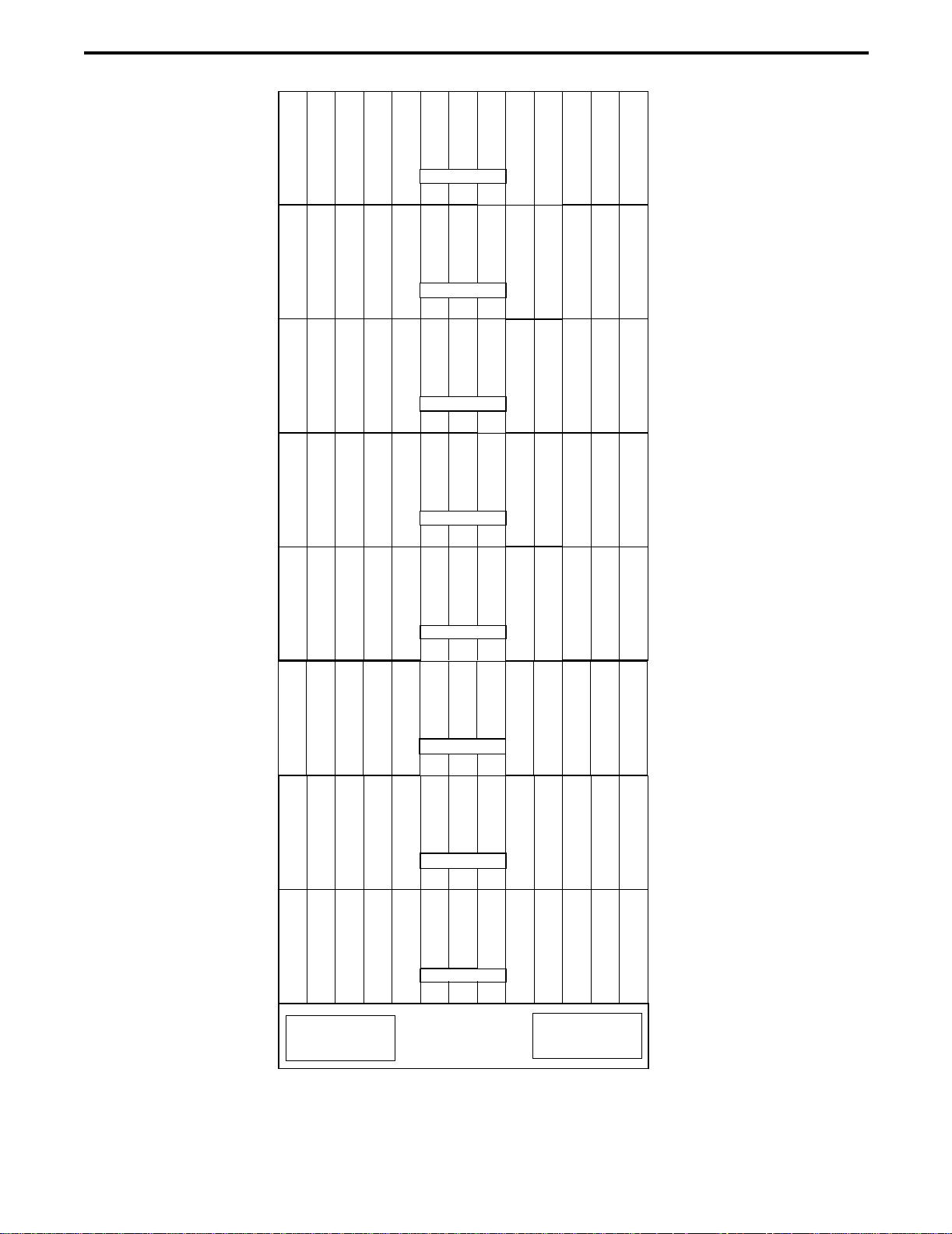

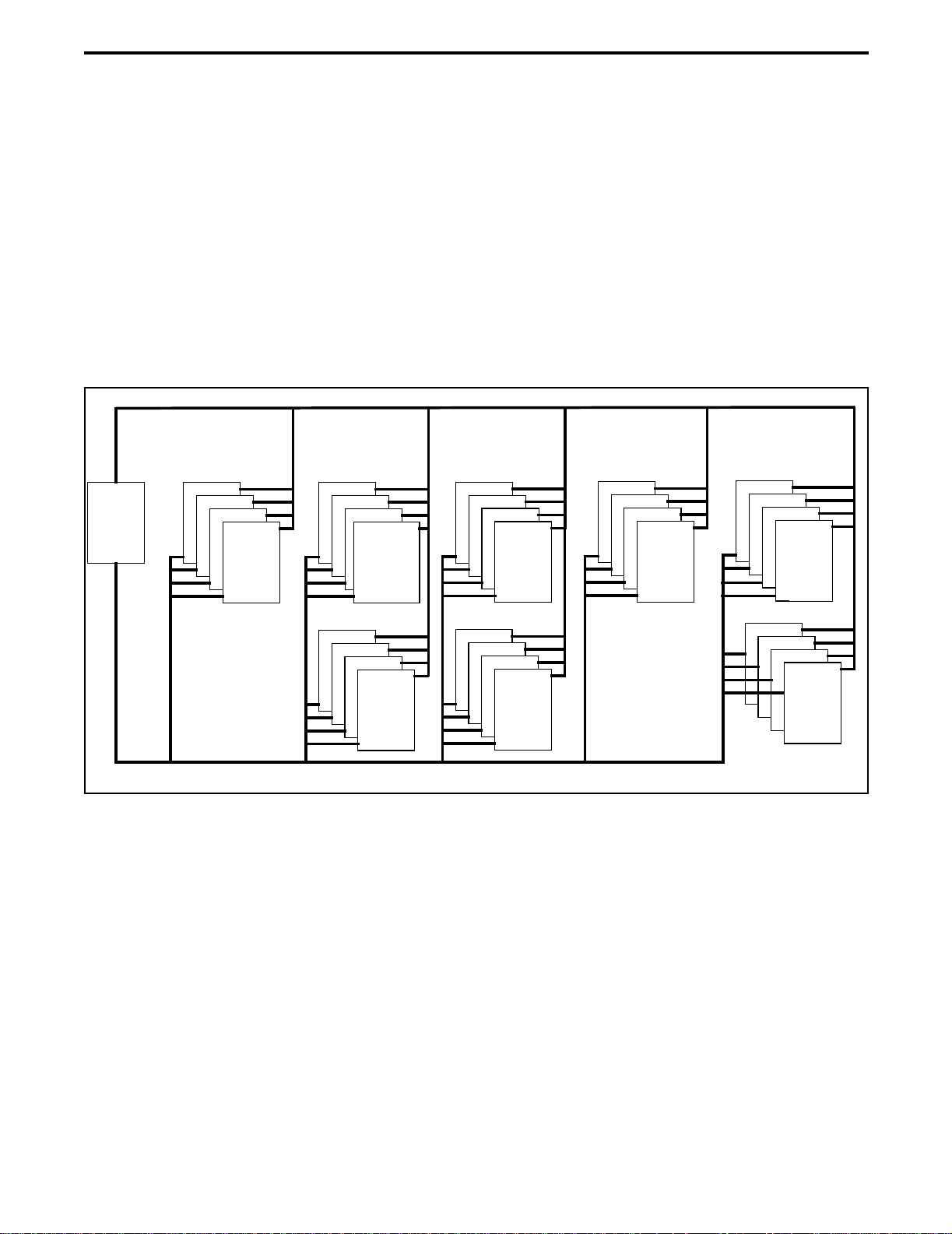

2-1 2-Shelf 3000 Series Switch . . . . . . . . . . . . . . . . 2-3

2-2 4-Shelf 3000 Series Switch . . . . . . . . . . . . . . . . 2-3

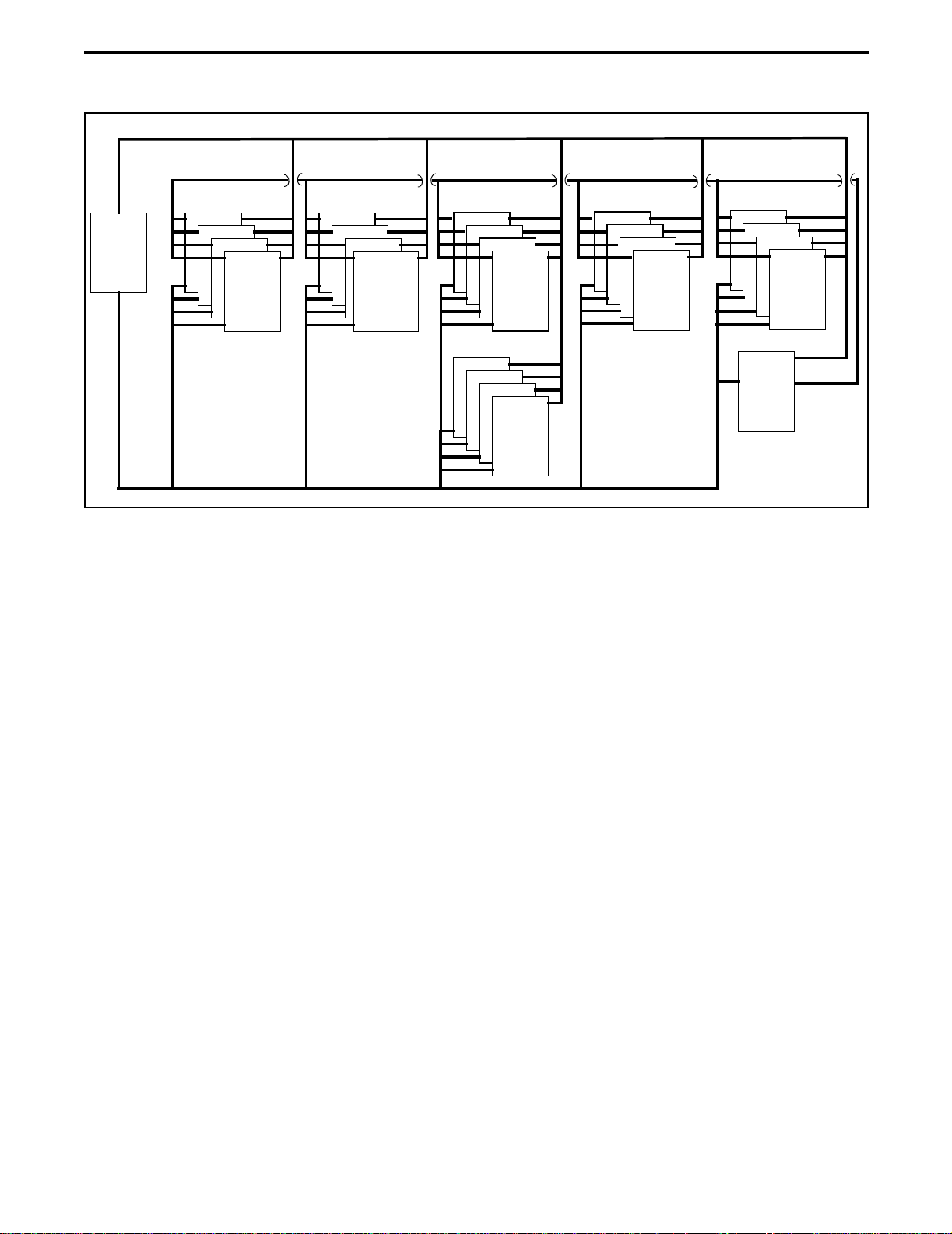

2-3 6-Shelf Switch Rack Layout . . . . . . . . . . . . . . . 2-4

2-4 8-Shelf Switch Rack Setup . . . . . . . . . . . . . . . . 2-5

3-1 Multi-Net System Switch . . . . . . . . . . . . . . . . . 3-1

3-2 Data Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3 Control Buses. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-4 Voice Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

4-1 2-shelf 30 00 Series Switch Backplane Cables. . 4-6

4-2 2-shelf 3000 Series Switch Setup . . . . . . . . . . . 4-6

4-3 4-shelf 30 00 Series Switch Backplane Cables. 4-12

4-4 4-shelf 3000 Series Switch Setup . . . . . . . . . . 4-12

4-5 Six Shelf 3000 Series Switch Backplane Cables 4-18

4-6 Six Shelf 3000 Series Switch Setup. . . . . . . . . 4-19

4-7 Eight Shelf 300 0 Series Sw Backplane Cables 4-25

4-8 8-Shelf 3000 Series Switch Rack Setup . . . . . 4-26

4-9 2- 4 Shelf Power Supply Interconnect . . . . . . . 4-27

4-10 6-8 Shelf Power Supp ly Interconnect Diagram 4-28

5-1 Data Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6-1 Data Bus Block Diagram . . . . . . . . . . . . . . . . . . 6-1

6-2 NetNIM Card Edge Layout . . . . . . . . . . . . . . . . 6-3

6-3 NetNIM Alignment Points Diagram . . . . . . . . . 6-4

7-1 Basic Board Module Block Di agram . . . . . . . . . 7-2

7-2 Basic Board Module Alig n Poi nts Diagram. . . 7-12

7-3 Basic Board Module Card Edge Layou t. . . . . . 7-13

8-1 Alignment Points Diagram . . . . . . . . . . . . . . . . . 8-3

8-2 CIM Input and Output Levels. . . . . . . . . . . . . . . 8-5

8-3 Summati on Board Alignment Points Diagram. . 8-7

9-1 Alignment Points Diagram . . . . . . . . . . . . . . . . 9-11

10-1 Alignment Points Diagram . . . . . . . . . . . . . . . . 10-3

11-1 Alignment Points Diagram . . . . . . . . . . . . . . . . 11-5

11-2 PTT Tone Remote Card Block Diag ram . . . . . 11-6

11-3 PTT Tone Remote Card Align ment Points Diag 11-7

12-1 IDM Data Bus. . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

12-2 Alignment Points Diagram . . . . . . . . . . . . . . . . 12-3

12-3 Summation Board Alignment Points Diagram. 12-6

13-1 Data Bus Block Diagram . . . . . . . . . . . . . . . . . 13-1

13-2 Alignment Points Diagram . . . . . . . . . . . . . . . . 13-3

13-3 SNM Cable Layout. . . . . . . . . . . . . . . . . . . . . . 13-4

14-1 Data Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

14-2 E&M Interface Connections. . . . . . . . . . . . . . . 14-5

14-3 S201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-5

14-4 TYPE I and V . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

14-5 TYPE II and III. . . . . . . . . . . . . . . . . . . . . . . . . 14-6

v

Page 10

LIST OF FIGURES (CONT’D)

TABLE OF CONTENTS

14-6 TYPE IV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-6

14-7 TYPE II Trunk-Trunk . . . . . . . . . . . . . . . . . . . 14-7

14-8 TYPE IV Trunk-Trunk . . . . . . . . . . . . . . . . . . 14-7

14-9 E&M Personality Board . . . . . . . . . . . . . . . . . 14-7

14-10 Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-7

14-11 Type III Interface. . . . . . . . . . . . . . . . . . . . . . . 14-8

14-12 Charging Characteristic of C227. . . . . . . . . . . 14-8

14-13 4-Wire E&M Block Diagram (-680) . . . . . . . . 14-9

14-14 DT & MBS Personality Card Blk Diag (-670) 14-10

14-15 DID Personality Card Block Diagram (-660) 14-10

14-16 Transmit Diagram . . . . . . . . . . . . . . . . . . . . . 14-18

14-17 Receive Diagram . . . . . . . . . . . . . . . . . . . . . . 14-18

14-18 Alignment Points Diagram . . . . . . . . . . . . . . 14-19

14-19 DT & MBS Alignment Points Diagram (-670) 14-20

14-20 DID Alignment Points Diagram (-660) . . . . . 14-21

14-21 4-Wire E&M Alignment Points Diag (-680) . 14-22

14-22 TELLABS 6132B - POTS. . . . . . . . . . . . . . . 14-23

14-23 TELLABS 6132A - DID . . . . . . . . . . . . . . . . 14-24

14-24 XEL Termset Rack (Rear Close-up) . . . . . . . 14-25

14-25 Termset Rack (Front View). . . . . . . . . . . . . . 14-26

14-26 Network Link (Switch Rack Back View) . . . 14-26

14-27 E&M Interface. . . . . . . . . . . . . . . . . . . . . . . . 14-28

14-28 Tellabs 6132A/B Termset . . . . . . . . . . . . . . . 14-29

14-29 6132 Tellabs Card . . . . . . . . . . . . . . . . . . . . . 14-31

15-1 Data Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

15-2 VDM Connections . . . . . . . . . . . . . . . . . . . . . . 15-2

15-3 Alignment Points Diagram . . . . . . . . . . . . . . . 15-3

16-1 Power Terminat ion Mod Align Points Diag . . 16-2

17-1 Data Bus Block Diagram. . . . . . . . . . . . . . . . . 17-1

17-2 Alignment Points Diagram . . . . . . . . . . . . . . . 17-4

18-1 Voice Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2

18-2 VTM Card Edge Layout . . . . . . . . . . . . . . . . . 18-3

19-1 Data Bus Block Diagram. . . . . . . . . . . . . . . . . 19-1

19-2 Alignment Points Diagram . . . . . . . . . . . . . . . 19-3

19-3 WAM E&M Lead Cable Layout 1 Location. . 19-4

19-4 WAM E&M Lead Cable Layout 2 Locations . 19-5

19-5 M-Lead Splitter Box I/Os . . . . . . . . . . . . . . . . 19-5

19-6 WAM E&M Lead Cable Layout 3 Locations . 19-6

19-7 WAM Audio Cable Layout One Location. . . . 19-6

19-8 WAM Audio Cable Layout Two Locations . . 19-6

19-9 Audio Cabl e Lay. Tw o Loc. w/Ext Audio Dev 19-7

19-10 Audio Cable Lay. Host Loc. 3 Location Config 19-7

20-1 Data Bus Block Diagram . . . . . . . . . . . . . . . . . 20-1

20-2 Alignment Points Diagram . . . . . . . . . . . . . . . . 20-5

20-3 Summati on Board (-760 ) Align Points Diagram 20-6

21-1 CPM Alignm ent Points Diagram . . . . . . . . . . . 21-3

22-1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 22-1

22-2 6-8 Shelf Power Supply In terconnect Diagram 22-2

22-3 A3-A4 Connector . . . . . . . . . . . . . . . . . . . . . . . 22-3

22-4 A5-A6 Connector . . . . . . . . . . . . . . . . . . . . . . . 22-3

22-5 Power Supply Terminal Blocks . . . . . . . . . . . . 22-3

22-6 Power Supply Drawer. . . . . . . . . . . . . . . . . . . . 22-4

22-7 2-4 Shelf Power Supply In terconnect. . . . . . . . 22-5

22-8 2-4 Shelf Power Supply (Front View) . . . . . . . 22-6

22-9 2-4 Shelf Power Supply (R ear View) . . . . . . . . 22-6

23-1 Std Shelf Backplane Sw and Jumper Set tings . 23-2

23-2 S2 - S8 Switch Settings . . . . . . . . . . . . . . . . . . 23-3

23-3 CIM/CCM Shelf Backplane Sw & Jmpr Set.. . 23-3

23-4 NetNIM Shelf w/CIM/CCMs Sw & Jmpr Set.. 23-4

23-5 NetNIM Shelf w/o CIM/CCMs Sw & Jmpr Set. 23-5

23-6 2-Shelf 3000 Series Switch. . . . . . . . . . . . . . . . 23-6

23-7 4-Shelf 3000 Series Switch. . . . . . . . . . . . . . . . 23-6

23-8 6-Shelf Switch Rack Layout. . . . . . . . . . . . . . . 23-7

23-9 8-Shelf Switch Rack Setup. . . . . . . . . . . . . . . . 23-8

23-10 2-Shelf Switch Backplane Cables. . . . . . . . . . . 23-9

23-11 4-Shelf Switch Backplane Cables. . . . . . . . . . . 23-9

23-12 6-Shelf Switch Backplane Cables. . . . . . . . . . 23-10

23-13 8-Shelf Switch Backplane Cables. . . . . . . . . . 23-11

23-14 Basic Board Backplane Wiring Layout . . . . . 23-12

23-15 NetNIM Shelf Backplane Wiring Layout. . . . 23-12

23-16 Telephone Terminal Block Layout. . . . . . . . . 23-13

23-17 Backplane I/O Jacks . . . . . . . . . . . . . . . . . . . . 23-14

B-1 SNM Unique ID Request Flowchart . . . . . . . . B-8

B-2 DIM Unique ID Request Flowchart . . . . . . . . . B-9

B-3 CIM DTMF Auxiliary Call Flowchart . . . . . . . B-9

B-4 Dialed Digits and Number of Digits Flowch art B-10

B-5 Telephone TIM Incoming Flowchart . . . . . . . B-11

B-6 Telephone Calling CIM Call Req Flowchart . B-12

B-7 Dynamic Reass User Interface Req Flowchart B-13

B-8 Selective Unit Dis User Interface Req Flow . B-13

vi

Page 11

LIST OF TABLES

TABLE OF CONTENTS

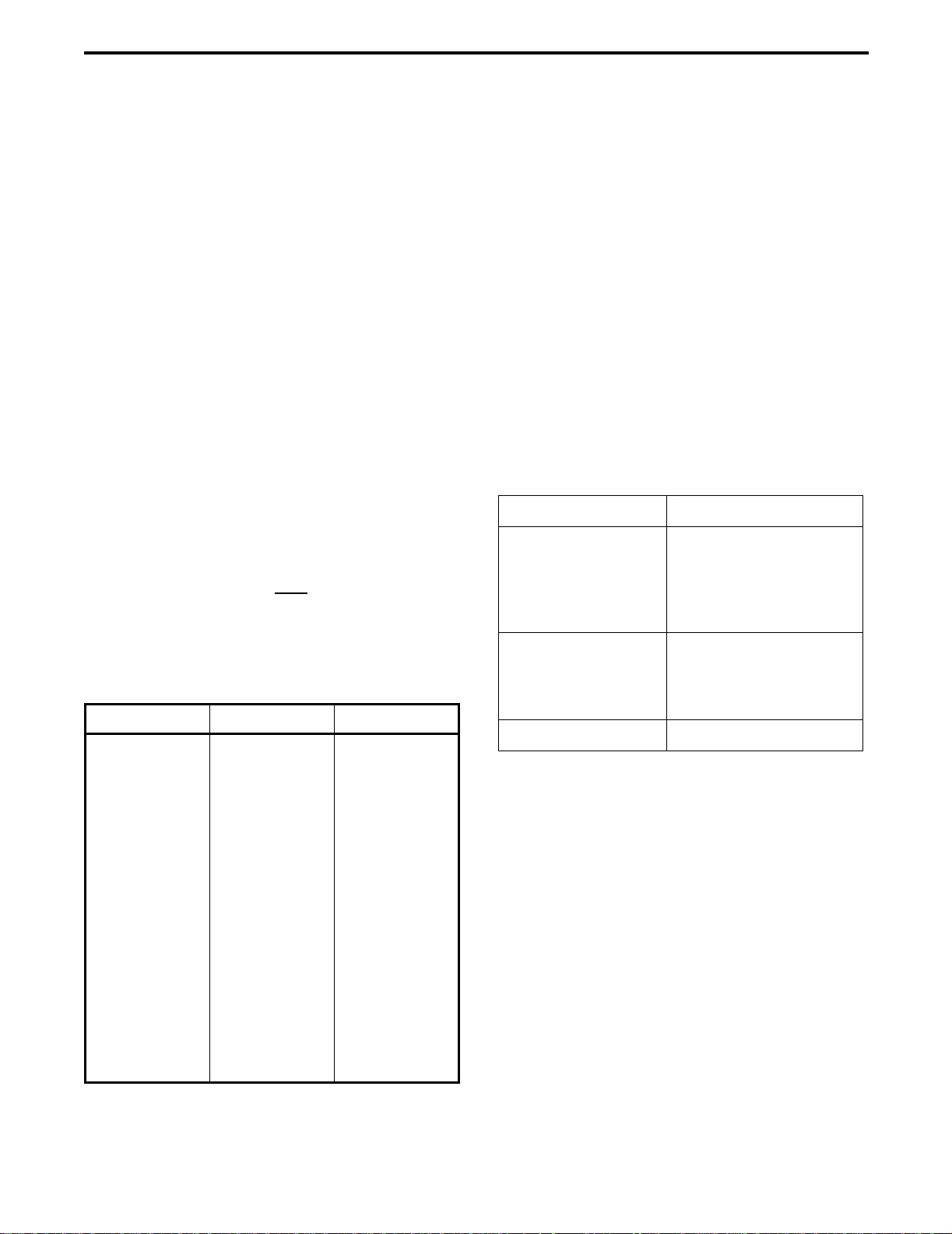

2-1 Switch Modules . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

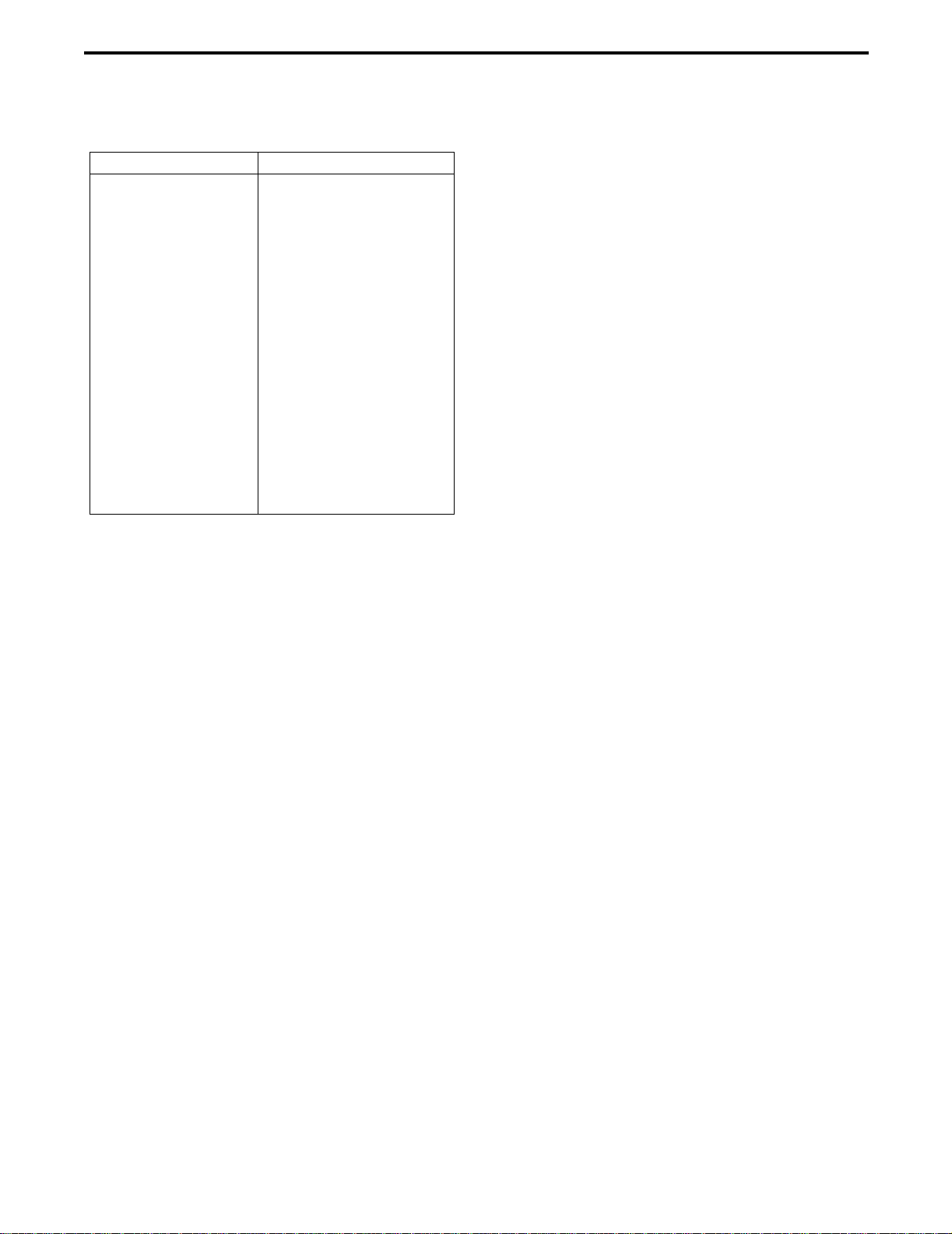

4-1 Average Voltage/Current/Power . . . . . . . . . . . . 4-1

4-2 Power Supply Connections . . . . . . . . . . . . . . . . . 4-2

4-3 Power Distribution Cable Voltages . . . . . . . . . . 4-3

4-4 PCM Cable Location . . . . . . . . . . . . . . . . . . . . . 4-3

4-5 S1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-6 Average Voltage/current/power . . . . . . . . . . . . . 4-7

4-7 Power Supply Connections . . . . . . . . . . . . . . . . . 4-8

4-9 PCM Cable Location . . . . . . . . . . . . . . . . . . . . . 4-9

4-8 Power Distribution Cable Voltages . . . . . . . . . . 4-9

4-10 S1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . 4-9

4-11 Average Voltage/Current/Power . . . . . . . . . . . 4-13

4-12 Bus Bar Resistance . . . . . . . . . . . . . . . . . . . . . . 4-13

4-13 Power Distribution Cable Voltages . . . . . . . . . 4-14

4-15 S1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . 4-15

4-14 PCM Cable Location . . . . . . . . . . . . . . . . . . . . 4-15

4-16 Average Voltage/Current/Power . . . . . . . . . . . 4-20

4-17 Bus Bar Resistance . . . . . . . . . . . . . . . . . . . . . . 4-20

4-18 Power Distribution Cable Voltages . . . . . . . . . 4-21

4-19 PCM Cable Location . . . . . . . . . . . . . . . . . . . . 4-21

4-20 S1 Switch Settings . . . . . . . . . . . . . . . . . . . . . . 4-22

6-1 NIM Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

7-1 Basic Board Switch Settings . . . . . . . . . . . . . . . . 7-3

7-2 Basic Board Jumper Placement . . . . . . . . . . . . . 7-3

7-3 Backplane Pin-outs . . . . . . . . . . . . . . . . . . . . . . . 7-3

7-4 DIM Card Display/tasks . . . . . . . . . . . . . . . . . . . 7-9

7-5 CCM Card Display Tasks . . . . . . . . . . . . . . . . . . 7-9

7-6 CIM Card Display/tasks . . . . . . . . . . . . . . . . . . 7-10

7-7 TIM Card Display/tasks . . . . . . . . . . . . . . . . . . 7-10

7-9 DCM Card Display/tasks . . . . . . . . . . . . . . . . . 7-10

7-8 SNM Card Display/tasks . . . . . . . . . . . . . . . . . 7-10

7-11 LEM Card Display/tasks . . . . . . . . . . . . . . . . . . 7-11

7-12 GPM Card Display/tasks . . . . . . . . . . . . . . . . . 7-11

7-13 VDM Card Display/tasks . . . . . . . . . . . . . . . . . 7-11

7-10 IDM Card Display/tasks . . . . . . . . . . . . . . . . . . 7-11

7-14 WAM Card Display/tasks . . . . . . . . . . . . . . . . . 7-11

8-1 CIM Switch Settings . . . . . . . . . . . . . . . . . . . . . . 8-2

8-2 CIM Board Jumper Placement . . . . . . . . . . . . . . 8-2

8-3 Backplane Pi nout s . . . . . . . . . . . . . . . . . . . . . . . 8-2

8-4 CIM External Connections . . . . . . . . . . . . . . . . . 8-4

9-1 CCM Switch Settings . . . . . . . . . . . . . . . . . . . . . 9-9

9-2 CCM Jumper Placement . . . . . . . . . . . . . . . . . . . 9-9

9-3 CCM External Connections . . . . . . . . . . . . . . . 9-10

10-1 DCM Switch Settings . . . . . . . . . . . . . . . . . . . . 10-1

10-2 DCM Jumper Placement . . . . . . . . . . . . . . . . . . 10-1

10-3 DCM External Connections . . . . . . . . . . . . . . . 10-2

11-1 DIM Switch Settings . . . . . . . . . . . . . . . . . . . . .11-1

11-2 DIM Board Jumper Placement . . . . . . . . . . . . .11-1

11-3 Backplane Placement . . . . . . . . . . . . . . . . . . . . .11-2

11-4 Tone Remote Formats . . . . . . . . . . . . . . . . . . . .11-4

12-1 IDM Switch Settings . . . . . . . . . . . . . . . . . . . . .12-2

12-2 IDM Board Jumper Placement . . . . . . . . . . . . .12-2

12-3 Backplane Pinouts . . . . . . . . . . . . . . . . . . . . . . .12-2

13-1 SNM Switch Settings . . . . . . . . . . . . . . . . . . . . .13-2

13-2 SNM Jumper Placement . . . . . . . . . . . . . . . . . .13-2

13-3 SNM External Connections . . . . . . . . . . . . . . . .13-2

14-1 E&M Card S201 DIP Sw itch Settings . . . . . . . .14-5

14-2 E&M Lead States . . . . . . . . . . . . . . . . . . . . . . . .14-6

14-3 TIM Jumper Placement . . . . . . . . . . . . . . . . . .14-11

14-4 TIM Switch Settings . . . . . . . . . . . . . . . . . . . .14-11

14-5 2WY Jumper Placement . . . . . . . . . . . . . . . . .14-11

14-6 DID Jumper Placement . . . . . . . . . . . . . . . . . .14-15

14-7 E&M Main Board Jumpers . . . . . . . . . . . . . . .14-17

14-8 E&M Jumper Placement . . . . . . . . . . . . . . . . .14-17

14-9 Tellabs 6132B - POTS . . . . . . . . . . . . . . . . . . .14-23

14-10 Tellabs 6132A - DID . . . . . . . . . . . . . . . . . . . .14-24

14-11 E&M To Termset Connections . . . . . . . . . . . .14-27

14-12 System Information . . . . . . . . . . . . . . . . . . . . .14-31

15-2 VDM Board Jumper Placement . . . . . . . . . . . . .15-2

15-3 Backplane Pinouts . . . . . . . . . . . . . . . . . . . . . . .15-2

15-1 VDM Switch Settings . . . . . . . . . . . . . . . . . . . .15-2

16-1 S5/S7 Switch Termination Settings . . . . . . . . . .16-1

16-2 S6/S8 Switch Termination Settings . . . . . . . . . .16-1

17-1 LEM Switch Settings . . . . . . . . . . . . . . . . . . . . .17-2

17-2 LEM Jumper Placement . . . . . . . . . . . . . . . . . .17-2

17-3 LEM External Connections . . . . . . . . . . . . . . . .17-2

18-1 VTM Board Jumper Placement . . . . . . . . . . . . .18-1

18-2 VTM Board Switch Settings . . . . . . . . . . . . . . .18-1

18-3 VTM PCM Bus Messages . . . . . . . . . . . . . . . . .18-2

19-1 WAM Switch Settings . . . . . . . . . . . . . . . . . . . .19-2

19-2 WAM Jumper Placement . . . . . . . . . . . . . . . . . .19-2

19-3 WAM External Connections . . . . . . . . . . . . . . .19-2

20-1 MCM Switch Settings . . . . . . . . . . . . . . . . . . . .20-2

20-2 MCM Jumper Placement . . . . . . . . . . . . . . . . . .20-2

20-3 Backplane Pinouts . . . . . . . . . . . . . . . . . . . . . . .20-2

21-1 CPM Switch Settings . . . . . . . . . . . . . . . . . . . . .21-1

21-2 CPM Board Jumper Placement . . . . . . . . . . . . .21-1

21-3 Backplane Placement . . . . . . . . . . . . . . . . . . . . .21-2

22-1 Average Voltage/Current/Power . . . . . . . . . . . .22-1

23-1 Shelf Address Settings . . . . . . . . . . . . . . . . . . . .23-1

23-2 Termination Settings . . . . . . . . . . . . . . . . . . . . . 23-1

vii

Page 12

TABLE OF CONTENTS (CONT’D)

TABLE OF CONTENTS

This page intentionally left blank.

viii

Page 13

SECTION 1 INTRODUCTION

INTRODUCTION

1.1 SCOPE OF MANUAL

This manual describes the 3000 Series Switch

modules and the alignment instructions for these

modules. This manual is not intended to explain the

®

entire Multi-Net

system, just the 3000-Series Switch

segment. For parts list, schematic diagrams, and

circuit board component layout information, refer to

the 3000 Series Switch Service Manual, Part No. 0013139-102. For more detailed information on the operation of the entire system, refer to Multi-Net Application Note, Part No. 009-3039-004CD.

1.2 DEFINITIONS

The following are brief definitions of terms and

their usage as they are applied to the Switch.

1.2.1 TRUNKED SYSTEM

Refers to systems which pool multiple channels

and use automatic switching so that all system users

can access any repeater channel that is not in use. This

results in minimum waiting to make a call.

1.2.2 LTR TRUNKED SYSTEM

The LTR

®

(Logic Trunked Radio) systems utilize

a concept called trunking. Trunking makes all repeater

channels on a system automatically available to the

users. This is done by logic control system that continually monitors the system and updates the mobiles and

repeaters using data messages. These data messages

tell the mobiles which repeater channels are free and

can be accessed if a call is to be made.

1.2.4 CONVENTIONAL SYSTEM

Refers to systems which are licensed on a single

repeater channel. Operation is similar to that of a

community repeater because there is no automatic

access to several repeater channels.

1.2.5 3000 SERIES SWITCH

The Switch connects several forms of communication together in a “Network” that allows communication between users in the system.

1.2.6 CALL PROCESSOR

The Call Processor controls the databases for the

Switch and provides processing for certain types of

calls within the system.

1.2.7 SYSTEM AND SUBSCRIBER MANAGER

The Switch along with the System and Subscriber

Manager control the Multi-Net System. The System

and Subscriber Manager is an IBM

®

PC or compatible

computer that is running the Johnson management

program. The System and Subscriber Manager is used

by the System Manager to program, control and

continuously monitor Switch operation. Refer to

System and Subscriber Manager Operating Manual,

Part No. 002-3139-078CD for more information.

1.2.8 REPEATER SITE

A location where one or more repeaters are

housed. Trunked system repeaters are connected to the

same high-speed data bus and are required to be

located close together.

1.2.3 MULTI-NET TRUNKED SYSTEM

A trunking system similar to the LTR Trunked

System, but which offers a number of additional and

enhanced features.

1.2.9 HOME REPEATER CHANNEL

All mobiles have one site repeater channel

assigned as their “Home” repeater. The Home

repeater and Group ID information identifies mobiles

for standard dispatch calls.

1-1

Page 14

INTRODUCTION

1.2.10 STATUS REPEATER CHANNEL

The Status Repeater Channel is one repeater in a

site that is designated to transmit update messages

occurring on all other repeaters at the site. This

repeater is available for voice traffic, but is not

normally assigned as the Home repeater for any

mobiles.

1.2.11 MONITOR REPEATER CHANNEL

This is the repeater channel that a mobile is

currently monitoring for update messages. This

repeater may be either the mobile's Home repeater or

the site Status repeater. A special algorithm is used by

the mobile to determine which is to be monitored.

Generally, it is the last repeater that a valid data

message was detected on.

1.2.12 TELEPHONE INTERCONNECT AND

DATA TRANSMISSION

Mobile transceivers can be used to access the

Public Switched Telephone Network (PSTN) on the

800 and 900 MHz bands. However, this interconnect

operation must be on a secondary basis to dispatch

operation. An exception is when the trunked system or

channel is assigned exclusively to one user. In addition, interconnect calls in a private radio service must

be related to the business activities of the particular

user.

The actual connection to the public telephone

system may take place at any location such as the

repeater or a control station. The interconnect device

can be separate or shared. Timers which limit the

maximum length of transmissions are not required.

However, the equipment must automatically turn off

the transmitter within 3 minutes of the last transmission (except if another dispatch or interconnect call is

initiated within this interval).

Data transmission and paging are also allowed on

these frequencies. It also must be secondary to voice

communication. Refer to applicable FCC rules and

regulations for more information.

1.2.13 PUBLIC SWITCHED TELEPHONE

NETWORK (PSTN)

If interconnect calls are to be placed by mobiles

or landside users to mobiles, the Switch is connected

to the Public Switched Telephone Network. The

specific mobiles which can place calls and other interconnect parameters are determined by how the system

manager programs the Call Processor and by the

programming of each mobile transceiver.

1.2.14 PRIVATE AUTOMATIC BRANCH

EXCHANGE (PABX)

The system has the ability to connect to a PABX

or PBX. This allows mobile originated calls to use the

dial access codes and the least cost routing facility of

the PABX/PBX.

1-2

Page 15

SECTION 2 3000 SERIES SWITCH

3000 SERIES SWITCH

2.1 INTRODUCTION

A Multi-Net radio system is a combination of

several key elements that together make up a communication system. By using the basic elements of a

Multi-Net system as building blocks, a Multi-Net

system can be designed to meet the communication

needs of almost any type of user. Elements of a MultiNet system are:

• Backbone

This consists of repeater site equipment including

the links to the Switch.

• Control Consoles

Used for dispatch operators.

• Switch

Provides the interface between the Backbone and

Control Consoles.

• RF Equipment

Consists of mobiles, control stations, and handheld

portables.

A Switch contains a Channel Interface Module

(CIM) for each repeater it controls, a Telephone Interconnect Module (TIM) for each telephone line used

for interconnect calls, an Intelligent Dispatch Module

(IDM) or Multi-Net Console Module (MCM) for each

dispatch console and others described in this section.

A single Switch can control up to 30 re peater channels

all at one site or divided among a combination of sites

(e.g. 3-10 channel Localities on one Switch). Each

repeater has an identical Switch interface/logic panel

that performs the call processing for the channel. The

Switch provides interface between the Locality equipment and the control consoles and directs all activity

in Multi-Net site applications.

RF units in the coverage area of one repeater site

can communicate with RF units in the coverage area

of other repeater sites through the Switch. Where more

than 30 channels are required, multiple Switches can

be used with communication between them to direct

calls. Wide area radio coverage is provided to allow a

mobile to talk to another mobile using a repeater

hundreds of miles away. That repeater may be part of

the same Multi-Net system or another Multi-Net

system with phone lines or some other type of link that

provides the communication path.

Each Multi-Net site is an independent trunking

system that processes calls between RF units, maintains fleet partitioning, and provides priority access

control. The backbone elements are interconnected by

either microwave, fiber optics, RF links or private telephone lines equivalent to a 4-Wire voice grade phone

circuit.

One or more dispatch consoles can be connected

to the Switch using; direct connection, phone lines, or

some other type of link. Depending on the capabilities

of the particular console, the dispatcher can perform

such functions as; place calls to specific mobiles, place

calls to other dispatchers, and make a patch between

two mobiles.

2-1

Page 16

3000 SERIES SWITCH

2.2 ELEMENTS OF THE SWITCH

The Switch is a rack of modules. The rack may

contain the following modules: (Table 2-1).

Table 2-1 SWITCH MODULES

NetNIM Network Interface Module

CIM Channel Interface Module

CCM Conventional Channel Module

DCM Dispatch Channel Module

DIM Dispatch Interface Module

IDM Intelligent Dispatch Module

SNM System Network Module

TIM Telephone Interface Module

VDM Voter Diagnostics Module

PTM Power Termination Module

VTM Voice Tone Module

LEM Logging Encoder Module

MAM Multi-Net Acquisition Module

MCM Multi-Net Console Module

CPM Conventional Patch Module

WAM Wide Area Module

• Telephone Interface Module (TIM), to the PSTN or

a PABX.

• System Network Module (SNM), to other SNM,

Switches.

• Network Interface Module (NetNIM), to the Call

Processor.

• Dispatch Channel Module (DCM), to the Conven-

tional Channel, network side.

• Voter Diagnostics Module (VDM), to the Voter

system.

• Power Termination Module (PTM), provides fusing

of power and termination for a shelf.

• Intelligent Dispatch Module (IDM), to the Tracer

Series Dispatch Consoles.

• Logging Encoder Module (LEM), interface to a

logging recorder.

2.3 SWITCH MODULES (ELEMENTS)

The Switch is constructed of different modules

that interface from the Switch to external devices. The

modules are:

• Channel Interface Module (CIM), to the Multi-Net

or LTR System.

• Conventional Channel Module (CCM), to a

Conventional Channel, channel side.

• Dispatch Interface Module (DIM), to the Dispatch

Consoles.

• Multi-Net Acquisition Module (MAM), interface

from the Switch to the VR-CM50 CR T Consoles for

Tone Paging.

• Multi-Net Console Module (MCM), to VRCM-50

CRT Consoles.

• Conventional Patch Module (CPM), to dynamically

patch a single conventional channel to a single

trunked group.

• Wide Area Module (WAM), to other WAMs,

Switches.

2-2

Page 17

P

C

T

M

C

I

M

M

16 17 18 19

3000 SERIES SWITCH

W

C

C

C

C

D

D

L

I

I

I

C

C

C

M

M

M

M

SHELF 2

20 21 22 23

M

C

M

L

E

E

M

M

24 25 26 27

A

M

W

A

M

P

e

T

t

M

N

I

M

01234567891011

e

t

N

I

M

V

V

T

T

M

M

12

S

N

NMI

M

M

SHELF 1

S

T

T

I

M

N

N

M

T

T

I

M

D

I

I

M

POWER SUPPLY

Figure 2-1 2-SHELF 3000 SERIES SWITCH

W

W

P

T

M

P

T

M

W

A

A

M

M

48 49 50 51

D

D

C

C

M

M

32 33 34 35

W

E

M

A

M

L

W

A

M

L

E

M

W

A

A

M

M

SHELF 4

52 53 54 55 56 57

SHELF 3

36 37 38 39

40 41 42 43

58

D

I

M

59

P

C

C

C

C

C

C

C

C

T

I

I

I

I

I

I

M

M

M

M

M

M

SHELF 2

16 17 18 19

N

N

P

e

T

t

M

N

I

M

01234567891011

e

t

N

I

M

V

T

M

12

“A”

Figure 2-2 4-SHELF 3000 SERIES SWITCH

20 21 22 23

V

S

T

N

M

M

SHELF 1

POWER SUPPLY

M

S

NMI

M

I

M

T

C

I

I

M

M

24 25 26 27

T

T

I

I

M

M

C

M

T

M

I

I

“B”

C

C

M

D

I

M

C

C

M

D

I

M

2-3

Page 18

P

T

M

SHELF 6

80 81 82 83 84 85 86 87 88 89 90 91

P

T

M

SHELF 5

64 65 66 67 68 69 70 71

72 73 74 75

3000 SERIES SWITCH

P

W

T

A

M

M

48 49 50 51 52 53 54 55 56 57 58 59

P

D

T

C

M

M

32 33 34 35

P

C

T

I

M

M

16 17 18 19

W

A

M

D

C

M

C

M

W

A

M

L

E

M

C

I

I

M

W

A

M

SHELF 4

W

A

M

W

A

M

L

E

M

SHELF 3

36 37 38 39 40 41

C

C

C

I

I

M

M

SHELF 2

20 21 22 23

M

C

I

I

M

C

C

I

I

M

M

M

24 25 26 27

42

43

C

C

M

C

C

M

C

I

P

e

T

t

M

N

I

M

01234567891011

Figure 2-3 6-SHELF SWITCH RACK LAYOUT

e

N

M

“A”

t

I

V

V

S

T

M

T

M

N

M

S

NMI

M

12

SHELF 1

POWER SUPPLY

2-4

T

T

I

M

N

N

T

M

T

D

M

D

I

M

I

I

M

“B”

I

Page 19

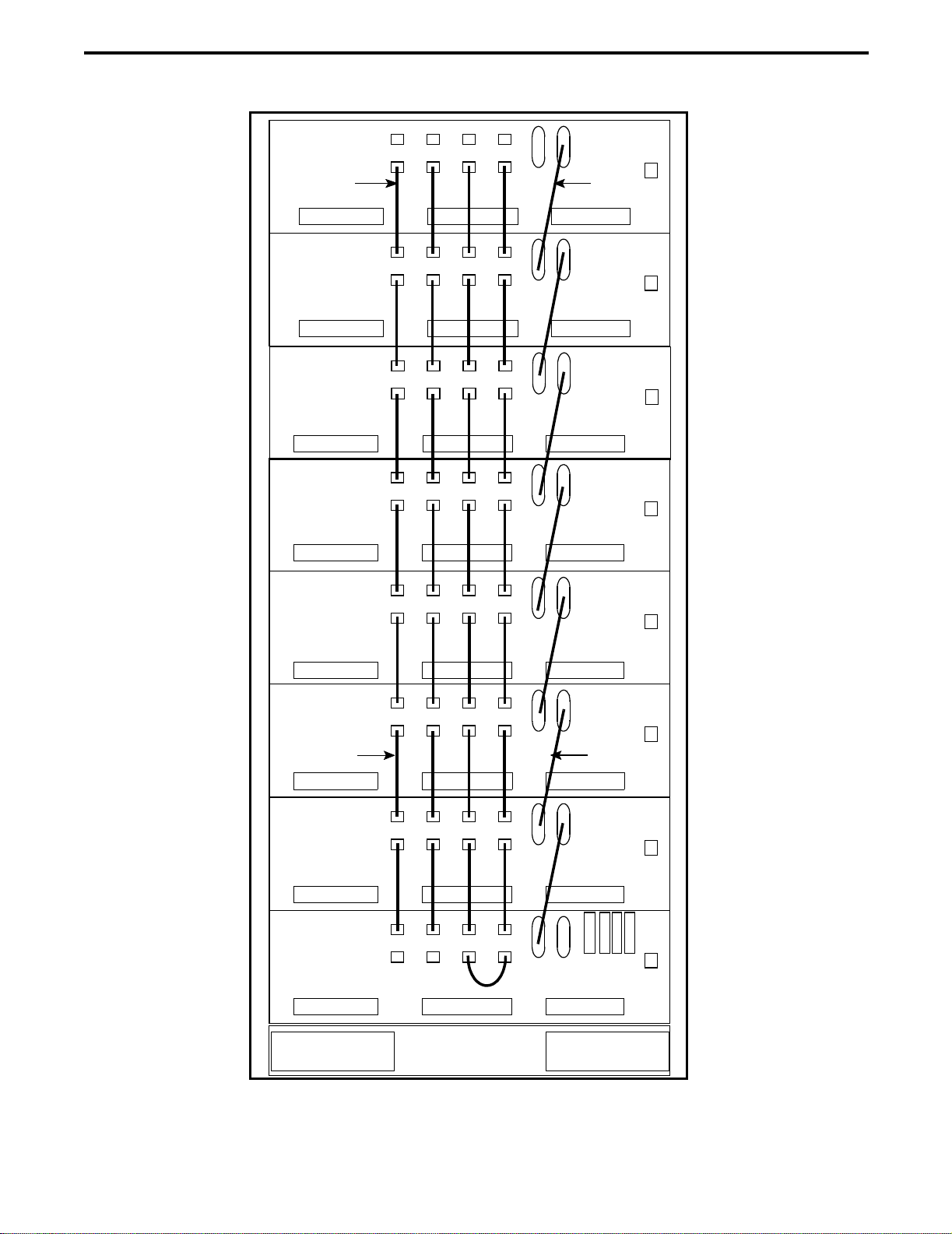

P

T

M

SHELF 8

112 113 114 115 116 117 118 119 120 121 122 123

P

T

M

SHELF 7

96 97 98 99 100 101 102 103 104 105 106 107

P

T

M

SHELF 6

80 81 82 83 84 85 86 87 88 89 90 91

P

T

M

3000 SERIES SWITCH

SHELF 5

64 65 66 67 68 69 70 71 72 73 74 75

W

W

P

T

M

P

T

M

P

T

M

P

T

M

W

A

M

M

48 49 50 51

D

D

C

M

M

32 33 34 35

C

I

M

16 17 18 19

N

e

t

N

I

M

0

W

W

A

A

C

C

I

M

N

e

t

N

I

M

1234567891011

A

M

M

L

L

E

E

M

M

C

C

I

I

M

M

V

V

T

T

M

M

12

W

A

A

M

M

SHELF 4

52 53 54 55 56 57

M

C

M

SHELF 3

36 37 38 39

C

C

I

M

S

NMI

M

SHELF 1

C

I

M

T

I

M

SHELF 2

20 21 22 23

S

N

M

40 41 42 43

C

C

I

I

M

M

24 25 26 27

T

T

I

I

M

M

C

P

M

C

M

T

M

58

59

C

P

M

1

2

C

C

C

M

D

M

C

M

D

I

I

M

I

I

“A”

Figure 2-4 8-SHELF SWITCH RACK SETUP

POWER SUPPLY

2-5

“B”

Page 20

3000 SERIES SWITCH

This page intentionally left blank.

2-6

Page 21

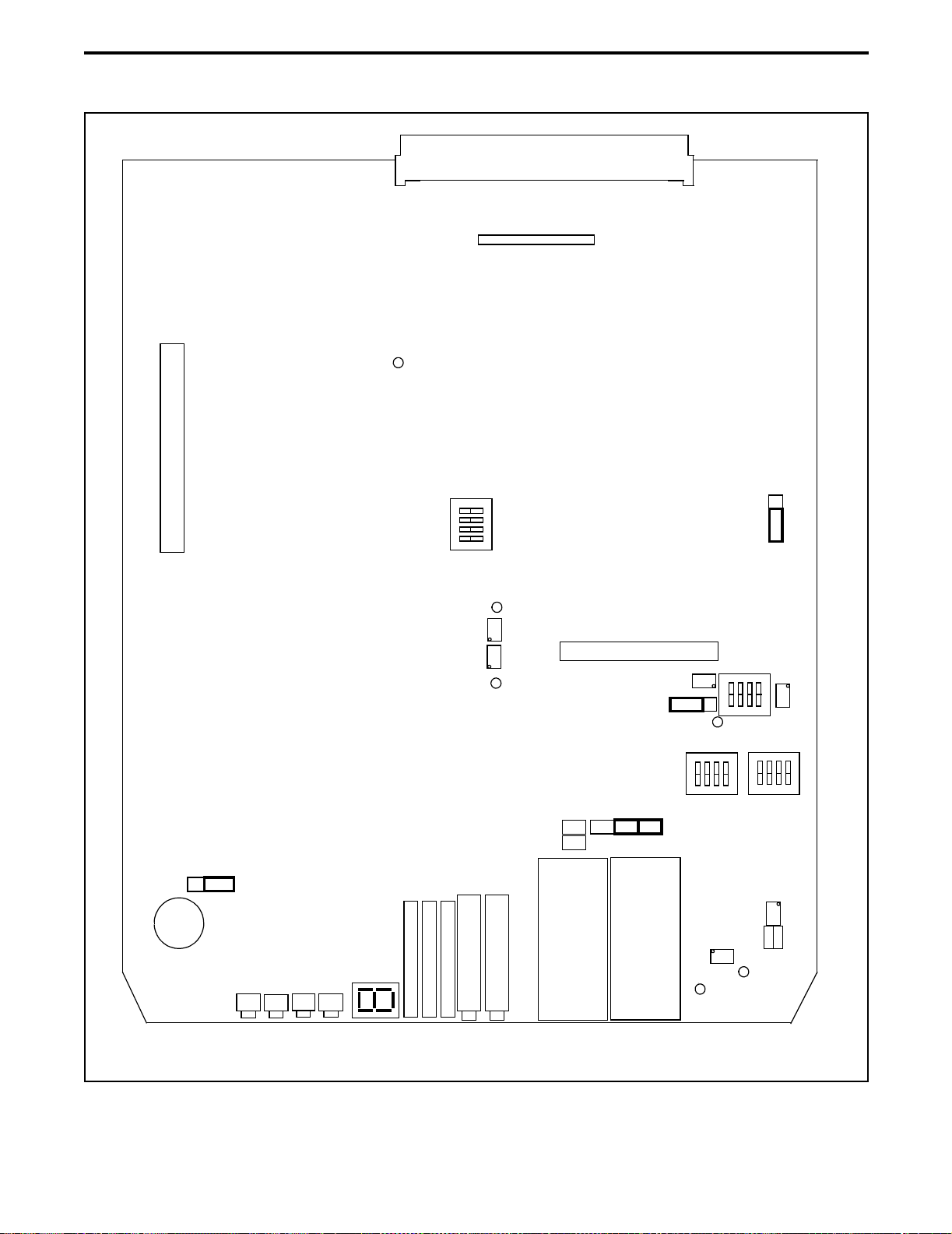

SECTION 3 ARCHITECTURE

ARCHITECTURE

3.1 INTRODUCTION

The architecture of the Switch includes the

modules or elements that make up the physical

portions of the switch and the busses that carry data,

control and voice information.

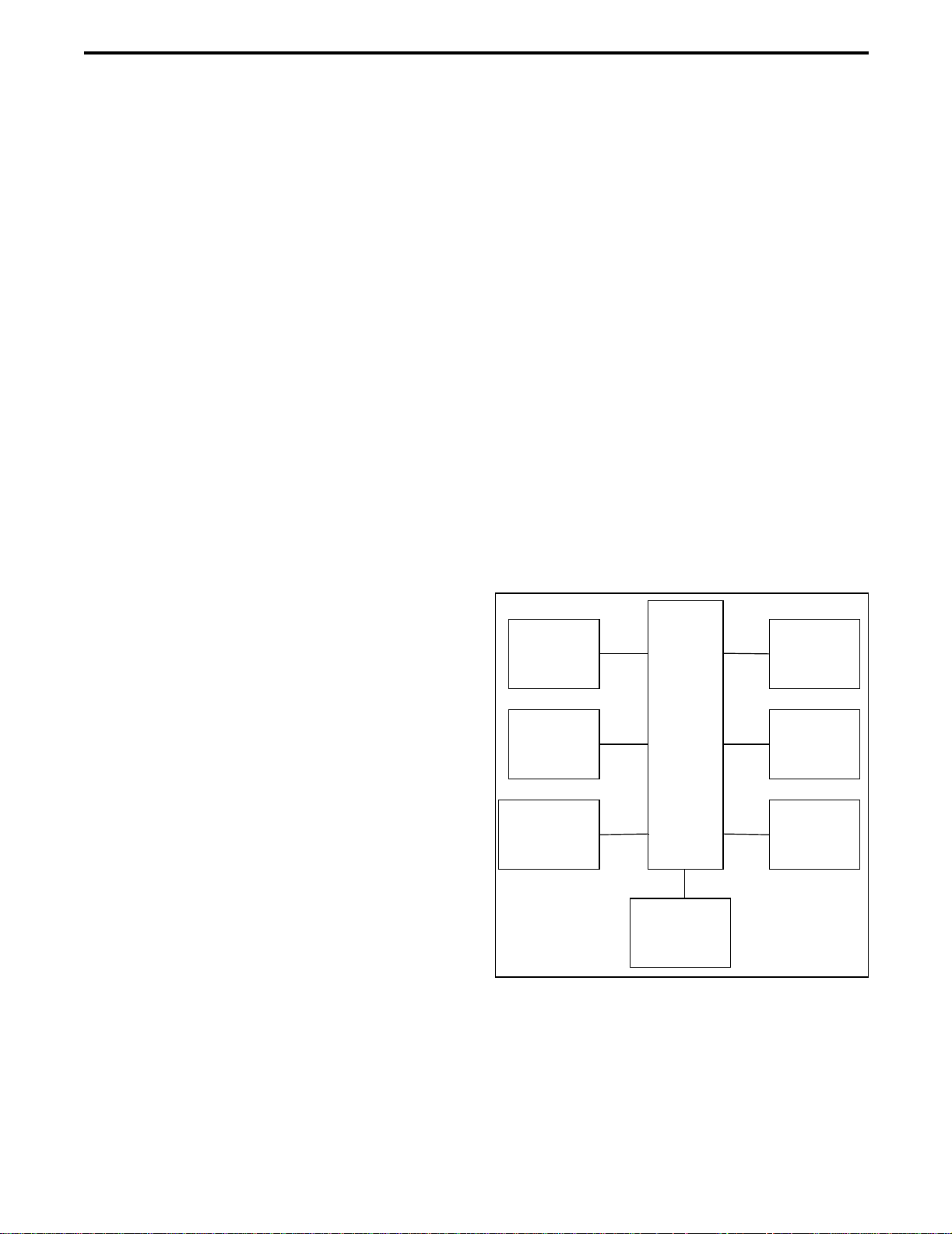

3.2 SWITCH INTERFACES

The main interfaces to the switch are as follows

(see Figure 3-1):

a. Channel Interface to Multi-Net RF

b. Channel Interface to LTR Systems

c. Channel Interface to Conventional Channels

d. Interface with Dispatch Consoles

e. Interface with the Public Switched Telephone

Network

a

MULTI-NET DISPA TC H

CIM

DCM

d

S

W

LTR

b

CIM

I

TIM

e

PSTN

T

C

H

CONVENTIONAL

CHANNEL

c

CCM

NetNIM

WAM

SNM

g

CALL

PROCESSOR

Figure 3-1 MULTI-NET SYSTEM SWITCH

f

OTHER

SWITCHES

f. Interface to other Switches

g. Interface to the Call Processor

3-1

Page 22

INTRA-TERMINAL DATA BUS (IDB)

ARCHITECTURE

CALL

PROCESSOR

ETHERNET

BUS

NETWORK

INTRA-TERMINAL

DATA BUS

(NetIDB)

NETWORK

CHANNEL

STATUS BUS

(NetCSB)

SYSTEM

AND

SUBSCRIBER

MANAGER

NetNIM

NETWORK

INTERFACE

MODULE

CHANNEL INTERFACE BUS

(CIB)

CHANNEL

INTERFACE

MODULE

CIMs CCMs

CHANNEL INTERFACE BUS

CHANNEL STATUS BUS (CSB)

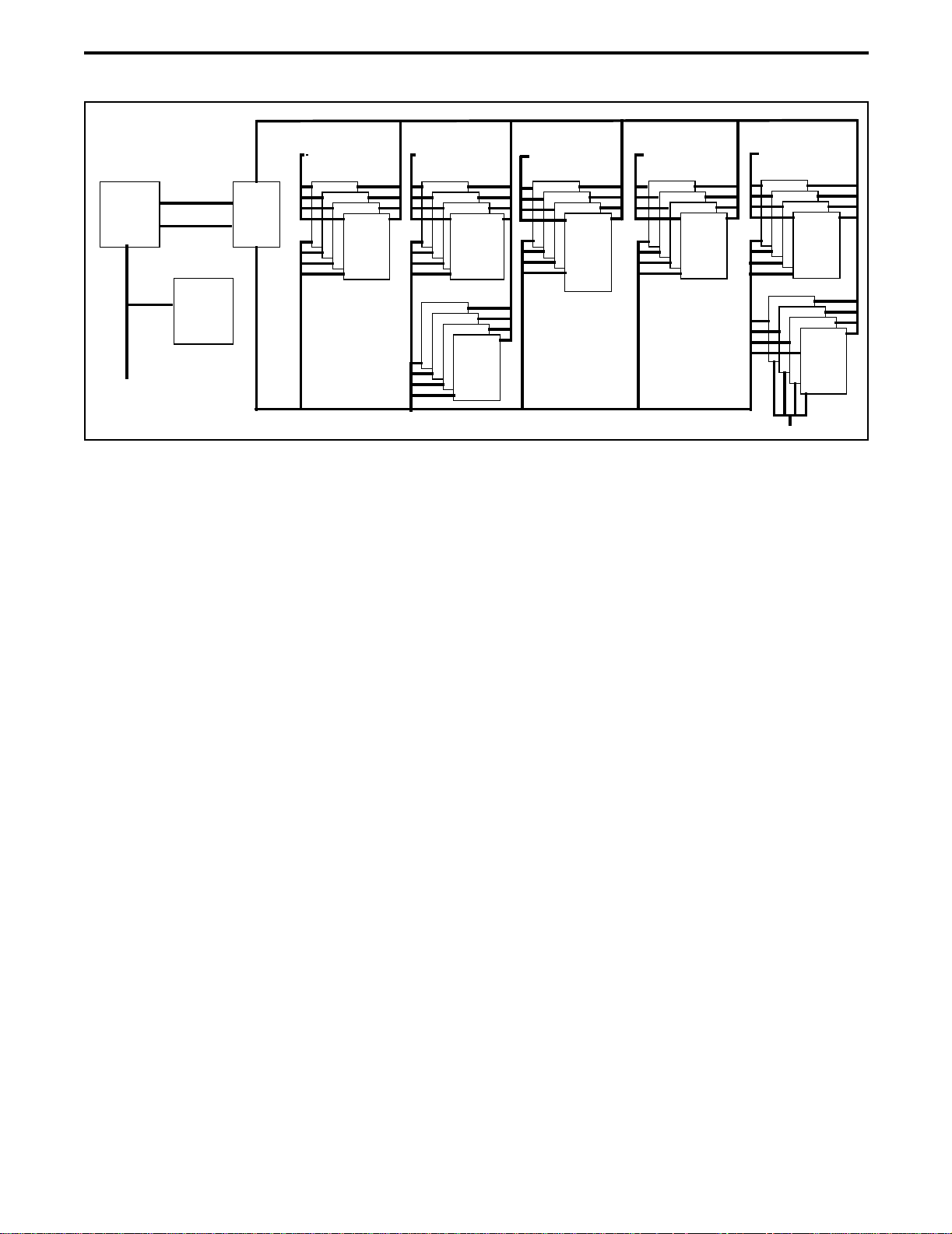

Figure 3-2 DATA BUSES

3.3 BUS STRUCTURE

The modules in the system are connected by

various busses as described in the following sections.

3.3.1 DATA BUS

• Ethernet Bus

The Ethernet Bus is a broadcast networking technology that can use several different physical media,

including twisted-pair cable and coaxial cable. The

Ethernet bus connects multiple Call Processors and

the System and Subscriber Manager together using

TCP/IP for communication. This allows the Call

Processors and the System and Subscriber Manager to

pass information to keep each other up to date. The

bus passes data for Subscriber Management,

Subscriber Registration, and Switch Configuration

Management.

(CIB)

CONVENTIONAL

CHANNEL

MODULE

WIDE

AREA

MODULE

DISPATCH INTERFACE BUS

(DIB)

DISPATCH

INTERFACE

MODULE

DIMs

DISPATCH

CHANNEL

MODULE

DCMs

LOGGING RECORDER

LOGGING

ENCODER

MODULE

LEMs

PSTN OR PABX

WAMs

SYSTEM NETWORK BUS (SNB)

• Intra-Terminal Data Bus (IDB)

A 19200 baud sync-escape protocol bus that

modules communicate on to pass control information

to each other using high speed CSMA.

• Channel Status Bus (CSB)

A 19200 baud sync-escape protocol bus that

passes channel status from channel modules to other

system modules using high speed Carrier Sense

Multiple Access (CSMA).

• Channel Interface Bus (CIB)

A 1200 baud sync-escape protocol bus that

passes system channel control and status to and from

the CIM.

TELEPHONE

INTERFACE

MODULE

TIMs

SYSTEM

NETWORK

MODULE

SNMs

• Network Intra-Terminal Data Bus (NetIDB)

A 19200 baud sync-escape protocol bus that

passed information from the Call Processor to and

from other modules via the NetNIM.

• Network Channel Status Bus (NetCSB)

A 19200 baud Sync-escape protocol bus that

passes the CSB data to the Call Processor or external

peripheral equipment via the NetNIM.

• System Network Bus (SNB)

A 1200 baud sync-escape protocol bus that

passes control and status between SNMs.

• PSTN or PABX

Connects to a PSTN (Public Switch Telephone

Network) or a PABX (Private Automatic Branch

Exchange) for outgoing and incoming telephone calls.

3-2

Page 23

ARCHITECTURE

3.3.2 CONTROL BUS

The following are descriptions of control buses.

Refer to Figure 3-3.

1. The IDB Idle/Collision line is a three level line that

indicates if the line is idle, busy or collision

occurred for the IDB communication process. This

provides for high speed CSMA of the IDB.

INTRA-TERMINAL DATA BUS (IDB) IDLE / COLLISION

NetNIM

NETWORK

INTERFACE

MODULE

CHANNEL

INTERFACE

MODULE

CIMs CCMs

CONVENTIONAL

CHANNEL

MODULE

2. The CSB Idle/Collision line is a three level line that

indicates if the line is idle, busy or collision

occurred for the CSB communication process. This

provides high speed CSMA of the CSB.

WIDE

AREA

MODULE

WAMs

LOGGING

ENCODER

MODULE

LEMs

TELEPHONE

INTERFACE

MODULE

TIMs

DISPA TCH

INTERFACE

MODULE

DIMs

CHANNEL STATUS BUS (CSB) IDLE / COLLISION

Figure 3-3 CONTROL BUSES

DISPATCH

CHANNEL

MODULE

DCMs

SYSTEM

NETWORK

MODULE

SNMs

3-3

Page 24

VTM

VOICE

TONE

MODULE

CHANNEL

INTERFACE

MODULE

CIMs CCMs

CONVENTIONAL

CHANNEL

MODULE

VOICE TONE MODULE BUS

TX/RX PCM

WIDE

AREA

MODULE

WAMs

DISPATCH

CHANNEL

MODULE

DCMs

LOGGING

ENCODER

MODULE

LEMs

ARCHITECTURE

TELEPHONE

INTERFACE

MODULE

TIMs

SYSTEM

NETWORK

MODULE

SNMs

MASTER SYNC / MASTER CLOCK

Figure 3-4 VOICE BUSES

3.3.3 VOICE BUS

The following are descriptions of voice buses.

Refer to Figure 3-4.

1. VTM Bus

A 2.048 MHz Pulse Code Modulated (PCM) bus

containing 32 slots of tones or voice the modules use

to indicate call progress to an end user by means of

audio information.

2. Tx PCM BUS

A 2.048 MHz Pulse Code Modulated (PCM) bus

containing 32 slots. Audio received from the RF

channel is transmitted on these slots by the channel

modules and received by the other system modules.

3. Rx PCM Bus

A 2.048 MHz Pulse Code Modulated (PCM) bus

contains 32 slots. Audio is transmitted from the other

system modules to these slots and received by the

channel modules to be transmitted on the RF channel.

4. Master Sync

Provides the synchronization signal for the PCM

bus communication to begin the frame of 32 PCM

slots.

5. Master Clock

Provides the 2.048 MHz clocking signal for the

PCM buses.

3-4

Page 25

ARCHITECTURE

SPECIFICATIONS

SYSTEM RACK

Dimensions 19" W x 31" D x 83.5" H

Environment 0°C to 50°C (32°F to 122°F) at 20% to 80% humidity (noncondensing)

Average Power 72 Modules x 5.1W ÷ 0.7 (efficiency) = 525W

Average Heat 525W x 3.6 = 1890 Btu/Hr

Weight

MODULES

Dimensions 11.5" W x 8" H (8.6" including extractors)

Weight 0.95 lbs. (module only)

1.47 lbs. (module with Personality Card)

Environment 0°C to 50°C (32°F to 122°F) at 20% to 80% humidity (noncondensing)

Maximum Power and Current +5V DC at 0.65A = 3.25W

+12V DC at 0.1A = 1.2W

-12V DC at 0.05A = 0.6W

-48V DC at 0.03A = 1.44W (TIM-DID only)

Total Power (less TIM-DID) = 5.05W

Total Power (with TIM-DID) = 6.49W

Maximum Power (with TIM-DID) = 8.0W

SYSTEM and SUBSCRIBER MANAGER

Computer

Dimensions 21.3" W x 18.7" D x 6.4" H

Weight 45 pounds

Power and Current 115V AC at 8A or 230V AC at 5A

CRT

Dimensions 14.1" W x 15.3" D x 14.7" H

Weight 35 pounds

Power and Current 120V AC at 2A or 240V AC at 1.5A

Environment 10°C to 40°C (50°F to 104°F) at 20% to 80% humidity (noncondensing)

3-5

Page 26

ARCHITECTURE

This page intentionally left blank.

3-6

Page 27

SECTION 4 SYSTEM RACK

SYSTEM RACK

4.1 TWO SHELF 3000 SERIES SWITCH

The system rack is a framework for modules that

consists of up to two shelves with thirteen slots per

shelf. In each shelf, twelve slots are for function

modules and one slot is reserved for the power

module. The power supplies for the shelves are

located in the lower portion of the rack framework.

The framework also provides support for interconnection wiring, routed between shelves, and external

devices.

4.1.1 POWER CONSUMPTION

The following tables shows the average voltage,

current and power for each supply voltage per card

(based on loading of 24 cards).

Table 4-1 AVERAGE VOLTAGE/CURRENT/

POWER

Voltage

Current Power

normal modules. The total wattage of the terminal is

found by multiplying the wattage of a module by the

number of modules.

Total Watts x No. of Modules = Terminal Power

The wattage required by the power supply is

found by dividing the total wattage of the terminal by

the efficiency of the power supply (0.7).

Terminal Power ÷ 0.7 = Wattage of Power Supply

The BTUs per hour are found by multiplying a known

value (3.6) by the wattage required by the power

supply.

3.6 x Wattage of Power Supply = Btu/Hr.

EXAMPLE:

4.3W x 12 = 51.6W

51.6W ÷ 0.7 = 73.7W

+5V DC 0.50A 2.50W

+12V DC 0.10A 1.20W

-12V DC 0.05A 0.60W

-48V DC 0.03A* 1.44W

Total 5.74W

* DIDs only.

Total watts including TIM-DID is 5.74W.

Excluding the TIM-DID provides a total of 4.3W for

3.6 x 73.7W = 265 Btu/Hr

4.1.2 EQUIPMENT REQUIRED

1. Digi tal Multimet er, voltmeter resolution to 0.001V.

2. Transmission test set, HP 3551A.

3. IBM NT compatible computer , with Call Processor

Software.

4. Two CIMs (023-3039-035)

4-1

Page 28

SYSTEM RACK

4.1.3 TWO SHELF POWER SUPPLY

The Power Supply has a 115/230V AC 50/60 Hz

input and 4 continuous duty outputs as follows:

+5V DC 24A.

-5V DC 6A.

+12V DC 3A.

-12V DC 5A.

The power supply can handle 2-shelves and has

the following connections:

4 separate +5V 2A connections.

2 separate -5V connections.

2 separate +12V connections.

2 separate -12V connections.

6 separate ground connections.

4.1.4 POWER SUPPLY REDUNDANT PLATE

The power supply drawer can be made redundant by the use of the redundant diode plate (PN 0233039-553). The redundant plate allows two power

supply drawers to share the load via diodes. One of the

power supply drawers may be removed and the

remaining drawer will supply the full load. (See

Figure 4-10.)

4.1.5 VOLTAGE ADJUSTMENTS

See Figure 4-10 for location of components and

Table 4-2 for wire connections.

1. Connect a voltmeter to U1, pin 76 on an R VM (DO

NOT use an extender card).

2. Adjust the +5V pot on the power supply for a

reading of 5.1V.

3. If +5.1V cannot be obtained, change R84 to a 5.6k

ohm 1/4W resistor.

4.1.6 REDUNDANT SUPPLY ADJUSTMENTS

See Figure 4-10 for location of components and

Table 4-2 for wire connections.

1. Remove the AC voltage to one of the supplies.

2. Connect a voltmeter to U1, pin 76 on an R VM (DO

NOT use an extender card).

3. Adjust the +5V pot for a reading of 5.1V. (If +5.1V

cannot be obtained, change R84 to a 5.1k ohm 1/4W

resistor.)

4. Connect a voltmeter to output of CR3 and verify

that the -5V line is -4.8V to -5.2V. (If not, make

R68 lower to raise voltage.)

Table 4-2 POWER SUPPLY CONNECTIONS

TB1 Wire

Term 1

Term 2

Term 3

TB2

Term 1

Term 2

Term 3

Term 4

Term 5

Term 6

Term 7

Term 8

Term 9

W1

W1

W1

W1

W2

W6

NC

W7

W4

W5

W3

W8

No.

Color From

Blk

Wht

Grn

Red

Red

Blu

Blu

Blu

Wht

Grn

Blu

AC (Hot)

AC (Ntrl)

AC (Gnd)

+5V

+5V

Gnd

Gnd

+12V

-12V

-5V

Gnd

Line

Line

Line

F1

F1

Gnd

Gnd

F3

F4

F2

Gnd

5. Remove the AC voltage to the adjusted supply and

connect AC voltage to the other power supply.

6. Connect a voltmeter to U1, pin 76 on an R VM (DO

NOT use an extender card).

7. Adjust the +5V pot for a reading of 5.1V. (If +5.1V

cannot be obtained, change R84 to a 5.1k ohm 1/4W

resistor.)

8. Connect a voltmeter to output of CR3 and verify

that the -5V line is -4.8V to -5.2V. (If not, make

R68 lower to raise voltage.)

4.1.7 VERIFY FAN AIR FLOW DIRECTION

1. Connect the power cables to a 1 10V AC source.

4-2

Page 29

SYSTEM RACK

2. Connect the Plus lead of the Fan Cable to Bus Bar

D1-16.

3. Verify both power supplies are turned OFF.

(Power Supply "A", is located on the left side at the

bottom of the rack. Power Supply "B" is located on

the right side at the bottom of the rack.)

4. Install both power supplies.

5. Turn Power Supply "A" on.

6. Verify that the Power On indicator is "ON" for

Power Supply "A".

7. Verify that the air flow from the fan is to the outside.

4.1.8 VERIFY VOLTAGES ON POWER DISTRI-

BUTION CABLE

1. Verify voltages in Table 4-13 for the Power

Termination Cables for Shelves 1-6.

2. Turn Power Supply "A" OFF

.

4.1.9 SYSTEM TEST PROCEDURE

The following test procedure is for the Switch

with six Power Termination Modules (PTMs), one

Network Interface Module (NetNIM) and one Voice

Termination Module (VTM).

1. Install all Power Termination Cables onto the back-

plane at mating connector P33.

2. Unplug all modules from the backplane card slots

(leave unplugged modules in the card guides).

3. Verify the installation of the PCM W1 and W3

cables as shown in Table 4-14 (see Figure 4-5).

Table 4-4 PCM CABLE LOCATION

From To

Shelf 1 - J25

Shelf 1 - J5

Shelf 1 - J6

Shelf 1 - J23

Shelf 1 - J24

Shelf 1 - J26

Shelf 2 - J3

Shelf 2 - J4

Shelf 2 - J25

Shelf 2 - J26

Table 4-3 POWER DISTRIBUTION CABLE

VOLTAGES

Pin Color

1 Green -48V ±2V

2 Not Used None

3 Black Common

4 White -12V ±1V

5 Not Used None

6 Black Common

7 Red +5V +0.5/-0.1V

8 Not Used +12V ±1V

9 Black Common

10 Red +5V +0.5/-0.1V

11 Blue +12V ±1V

12 Black Common

13 Red +5V +0.5/-0.1V

14 Blue +12V ±1V

15 Black Common

Shelf 2 - J5

Shelf 2 - J6

Shelf 2 - J23

Shelf 2 - J24

Shelf 3 - J3

Shelf 3 - J4

Shelf 3 - J25

Shelf 3 - J26

4-3

Page 30

SYSTEM RACK

Table 4-5 S1 SWITCH SETTINGS

Shelf Number Switch 1, Open Sections

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

ALL Closed

1

2

1,2

3

1,3

2,3

1,2,3

4

1,4

2,4

1,2,4

3,4

1,3,4

2,3,4

1,2,3,4

5

1,5

Shelf S1 Switch Settings

Verify switch settings of S1 in Table 4-15 for

each shelf address (see Figure 4-5).

Backplane Switch Settings

Verify the backplane switch settings for S2 - S8

on each shelf are set with all sections closed.

PTM Switch Settings

2. NetCSB Connection: Use the 20’ RS-232 cable to

connect Shelf 1-J101 to Port 2 of the Call Processor

computer.

3. Install a Power Termination Module in the first slot

on the left side of each shelf.

4. Install the NetNIM in Shelf 1, Slot 0.

5. Turn "On" both Power Supplies, turn "On" the Call

Processor and note that the four LEDs on each PTM

card are "On".

a. Verify that the Call Processor comes up in the

Switch mode.

b. V erify that the Call Processor displays the Net-

NIM’s clock status, "A Pass B Pass" in the Call

Processor’s Device Activity window. If necessary, press the reset button S1on the NetNim to

activate the clock status.)

PCM Bank Verification

PCM Bank Verification requires two Channel

Interface Modules (CIMs).

1. On both CIMs place a patch cord from the top jack

of J1 to the top jack of J2 (see Figure 10-1).

2. Close S1, sections 3-4; open sections 1-2 on each

module.

Verify the switch settings of the Power Termina-

tion Module (PTM) are as follows:

S5, S7 all sections closed;

S6, S8 section 8 closed;

sections 1, 2, 3, 4, 5, 6, 7 open

Call Processor Connection To Switch

Verify the Call Processor connection to the

System rack as follows:

1. NetIDB Connection: Use the 20’ RS-232 cable to

connect Shelf 1-J100 to Port 1 of the Call Processor

computer.