Effitherm AWT9-V5+, AWT13-V5+, AW11-V5+, AWT11-V5+, AW13-V5+ User Manual

...

Air/water/tank 9/11/13kw Split Heat Pump

Catalogue

1.Before use

1.

2. Safety precautions

3.

4.

5.

6. Specifications

7.

List of accessories

Main components

Outlines and dimensions

Working principles

Exploded view

4

5

8

10

14

14

17

2.Installation

1.

2. Installation of the indoor unit

3. Installation of the outdoor unit

4. Refrigerant pipe connection

Quick connector

Flare nut

5. Water pipe connection

.

7. Air purging of water system

8. Pre-Start up

Installation methods

6 Installation of the accessories

FOUR-way safety valve kit

L type decorative panel in back side

Pipings for mixture valve

9. Power supply and electric connections

22

31

32

34

36

37

39

40

40

41

41

42

44

45

4

22

3.Use

1. Introduction of wired controller

3. Basic operation

4. Advanced setting

5. Failure code

6.

2. Parameter setting overview

Error code

7. Electric heating

46

46

48

53

65

75

76

81

1

02

4.Service and maintenance

1. Attention

.

3. Maintenance

2 Service

Indoor unit

Outdoor unit

Cleaning of water filter

Cleaning of heat exchanger

Gas charging

Cleaning of plate exchanger

Antifreeze in winter

4. Troubleshooting

83

5.Wiring diagram

89

83

84

84

84

86

86

86

86

87

87

87

Catalogue

1

03

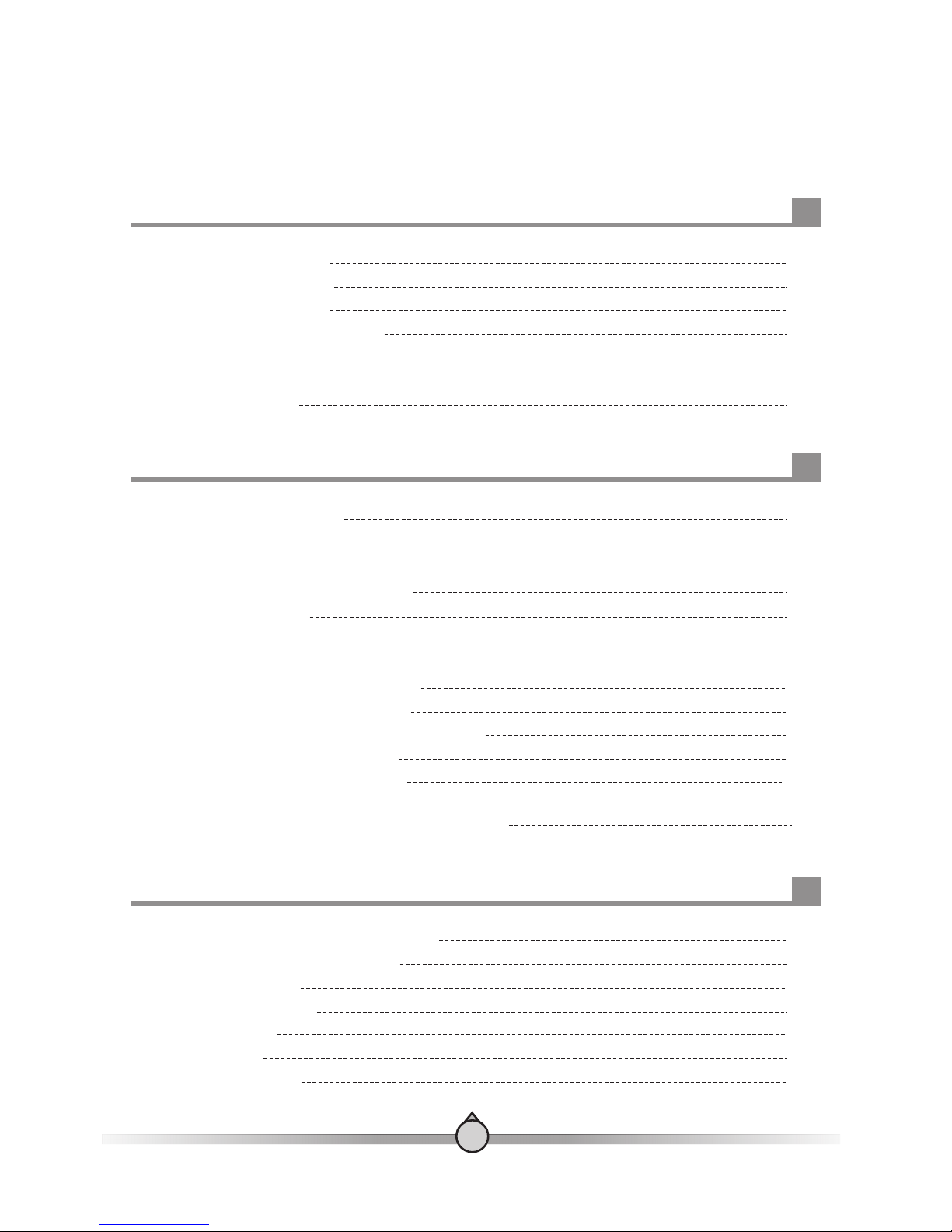

The accessories below are delivered together with the product .

Please check in time. If there is any shortage or damage, please contact local distributor.

【Indoor unit】

【 】List of accessories

1

1. List of accessories

Before use

1

04

User manual

Four-way Safety valve kit

Pressure release valve

Piping for mixture valve

Quantity

1pcs

1set

1pcs

1set

1pcs

2pcs

1pcs

L type decorative panel in

back side 2

Thermostat mixing valve

L type decorative panel in

back side 1

Attention

Dear Customer

Congratulation with your choice of heat pump. You have chosen a high quality product with

some of the latest technology within the heat pump market. This unit, will correctly installed

and set, provide you with cost efficient high level of comfort in your house regarding cooling,

heating and hot shower water.

Install and service the product with authorized and trained personnel only. Do not attend to do

the installation yourself, since the warranty of the product will not be valid. Please read this

manual carefully and make sure you follow the service and maintenance program to ensure

best lifetime and economy of the product. The longer the lifetime, the better investment.

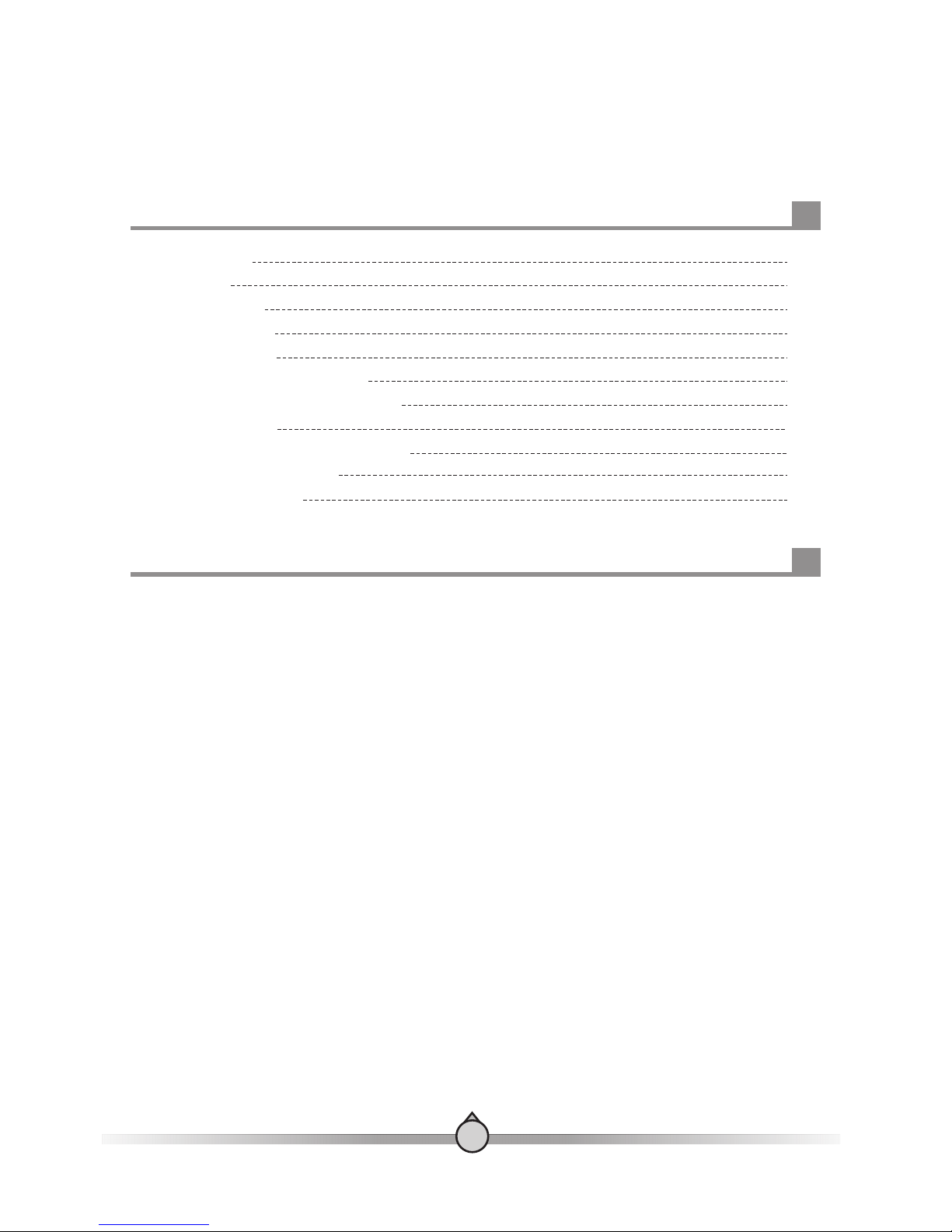

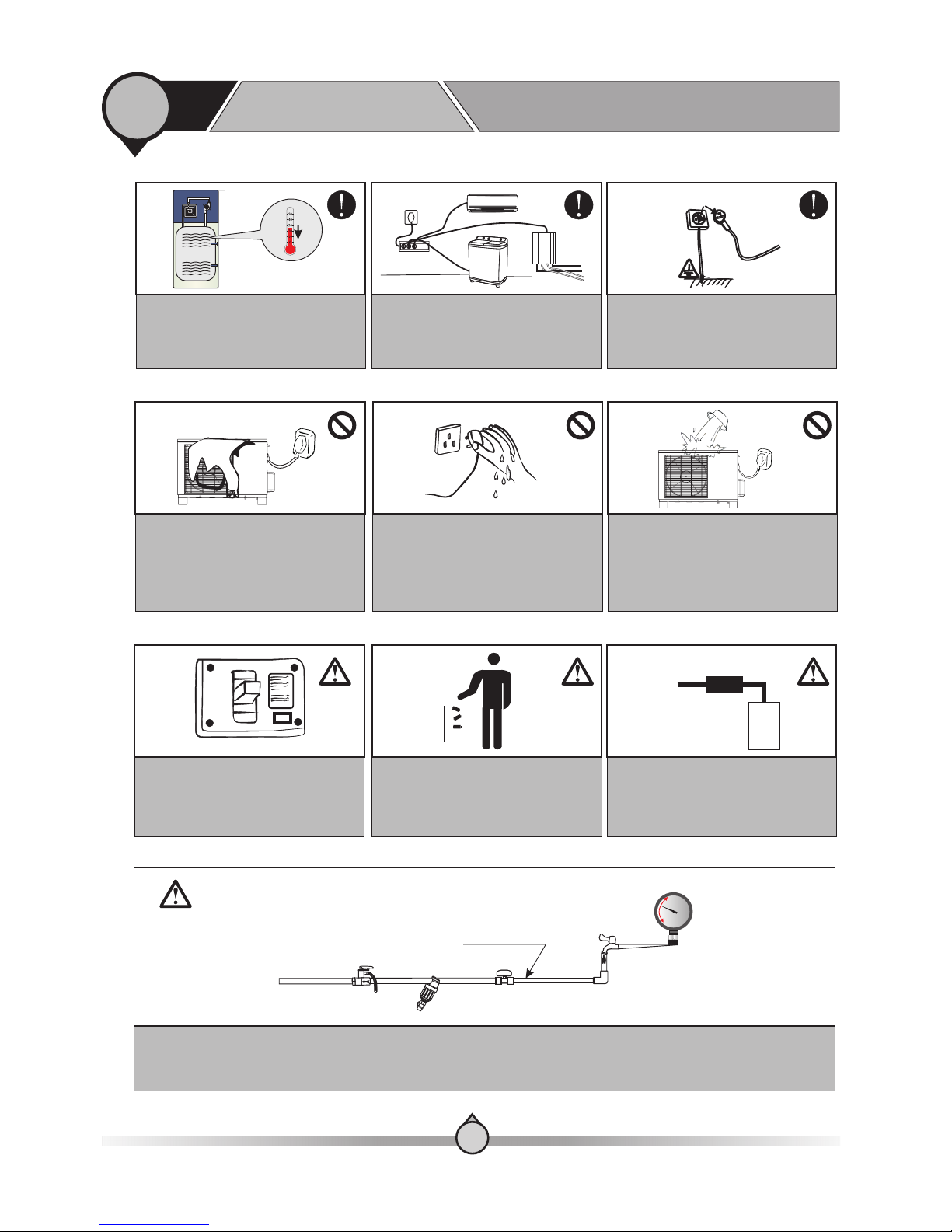

CautionWarning

Prohibition

which concerns the product and your personal safety.

The following symbols are very important. Please be sure to understand their meaning,

【 】Symbol description

The installation, dismantlement and maintenance of the unit must be performed

by qualified personnel. It is forbidden to do any changes to the structure of the

unit. Otherwise injury of person or unit damage might happen.

【 】Safety precautions

Make sure the power supply to the heat pump unit is off before any operations are

done on the unit. When the power cord gets loose or is damaged, always get a

qualified person to fix it.

1

2. Safety precautions

Before use

1

05

User Man ual

Be sure to read this manual before

use.

Keep the unit away from the

combustible or corrosive environment.

Before taking shower, please always

add a mixture valve before water tap

and set it to proper temperature.

This appliance can be used by children aged from 8 yearsand above and persons

with reduced physical, sensory or mental capabilities or lack of experienceand

knowledge if they have been given supervisionor instruction concerninguse of the

appliance in asafeway and understand the hazards involved. Childrenshall not play

with the appliance. Cleaning and user maintenance shall not be made by children

without supervision.

1.The heat pump is for “Closed pressurized water borne systems only, with

running pressure from 1-2,5 bars”.

2. Heat pump indoor unit should only be placed in a room with drainage in the floor.

(If any catastrophic leak from the water tank, no costly damage to the house can be

put on ES).

Water tank

1

2. Safety precautions

Before use

1

06

Ground wire

Use a dedicated socket for this

unit,otherwise malfunction may

occur.

The power supply to the unit must

be grounded.

Don't ru n th e heat pump unit

with water t emperature lowe r

than 25℃.

Do not tou ch t he power plug with

wet hand s. Never pull out the pu lg

by pulling t he power cable.

Water or any kind of liquid is strictly

forbidden to be poured into the

product, or may cause creepage or

breakdown of the product.

When running the unit, never cover

the product with clothes, plastic

cloth or any other material that

block ventilation on the product,

which will lead to low efficiency or

even non-operation of this unit.

Main

Power Cable

RCD

Indoor

unit

It is mandatory to use a suitable circuit

breaker for the heat pump and make

sure the power supply to the heater

corresponds to the specifications.

Otherwise the unit might be damaged.

Disposal of Scrap Batteries --Please discard the batteries as sorted

municipal waste at the accessible

collection point.

Installation of a residual current device

(RCD) having a rated residual

operating current not exceeding

30 mA is advisable.

ON

OFF

City water inlet

Connect to water tank

Min. 0.1 Mpa

Max. 0.7 Mpa

The maximum inlet water pressure, in pascals: 0.7Mpa.

The minimum inlet water pressure, in pascals, if this is necessary for the correct operation of the appliance: 0.1Mpa.

Sanitary hot

water

1

2. Safety precautions

Before use

1

07

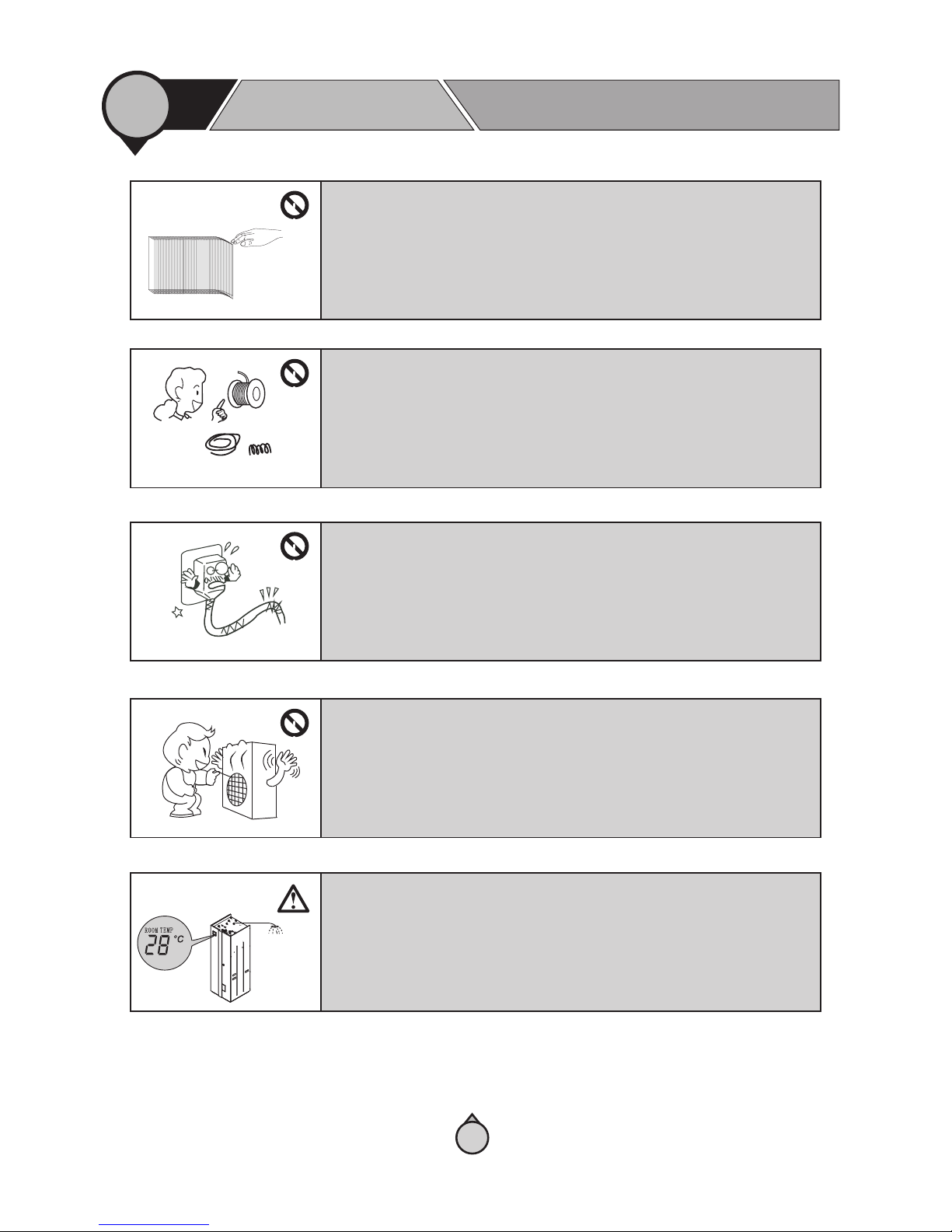

Be aware fin ger might be hurt by th e fin of the coil.

Coppe r

Steel

Fuse

Please s el ect the correct fus e or breaker as per rec ommended. Steel w ire or

copper w ir e cannot be taken as su bstitute for fuse o r breaker. Otherwise ,

damaged ma ybe caused.

When the power cord gets loose or is damaged, always get a qualified person to

fix it.

Do not touch the air outlet grill when fan motor is running.

Please mind that when the unit works under room temperature control mode, it

may not supply sanitary hot water with enough high temperature.

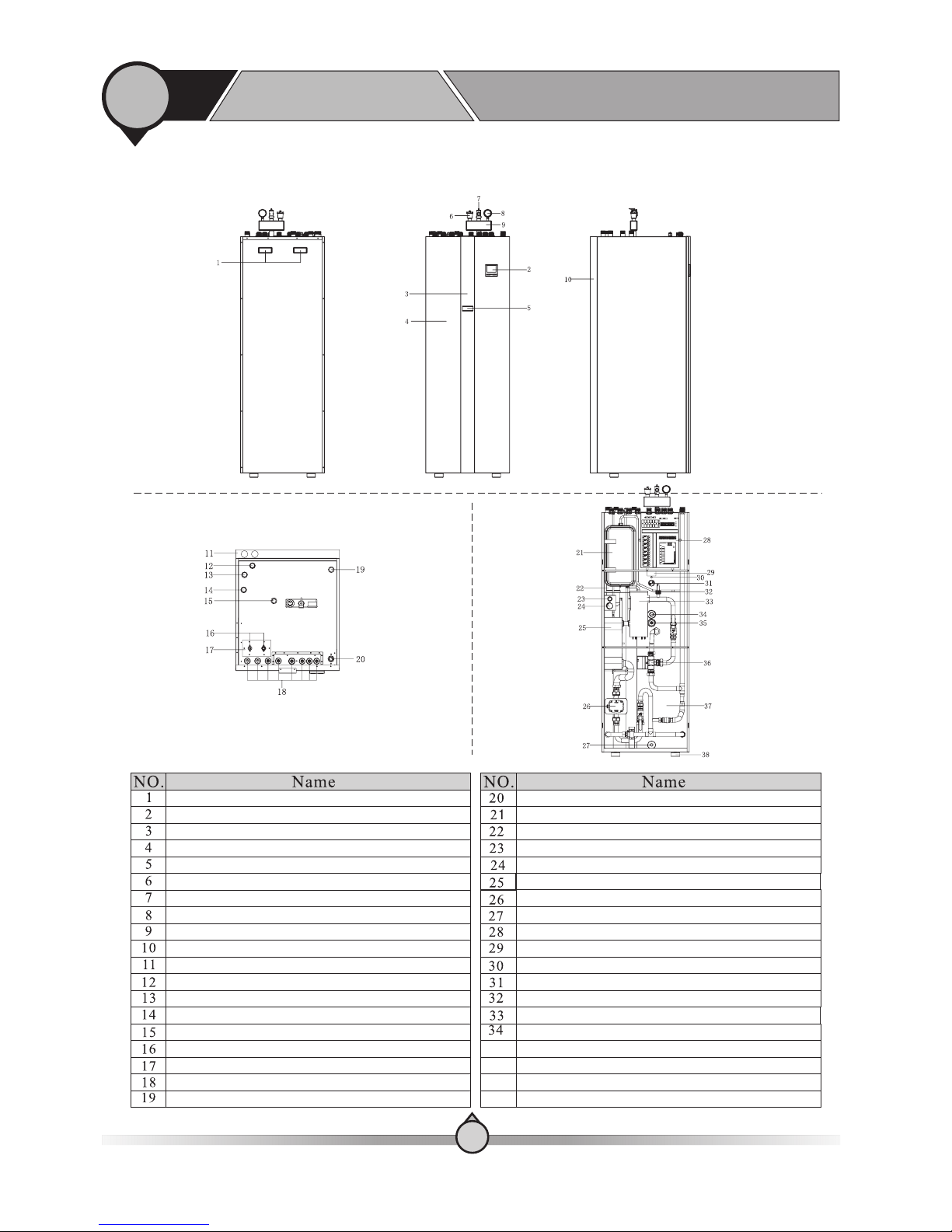

【 】 Indoor unit

Inside

Top

Outside

1

3. Main components

Before use

1

08

35

36

37

38

AWT9/11-V 5+

Handle

Wired controller

Decorative panel

Front panel

Digital thermostat

Automatic air purging valve

T/P valve

Water pressure gauge

Four-way safety valve kit

L type decorative panel in back side 1

L type decorative panel in back side 2

Middle temperature hot water outlet

Filling water to coil

Filling water to water tank

High temperature hot water outlet

Refrigerant connector(3/8’’~½’’)

Fixing plate for refrigerant connector

Cable gland

Water from heating/cooling system(G1’’male)

(G1’’male)

(G1’’male)

(G3/4’’male)

(G1’’male)

Water to heating/cooling system

Water expansion tank

Refrigerant expansion tank

Emergency Switch for 6KW electric heater

Thermostat knob

Plate heat exchanger

Water pump

Drainage

Electric box

Overheating protector for 1.5KW electric heater

Temperature sensor for 1.5KW electric heater

1.5KW electric heater 230V/50Hz/1Ph

Water flow switch

6KW electric heater 400V/50Hz/1Ph

Anode Rod

Temperature sensor for hot water mode

Motorized three-way valve

Water tank

Rubber absorber feet

(G1’’male)

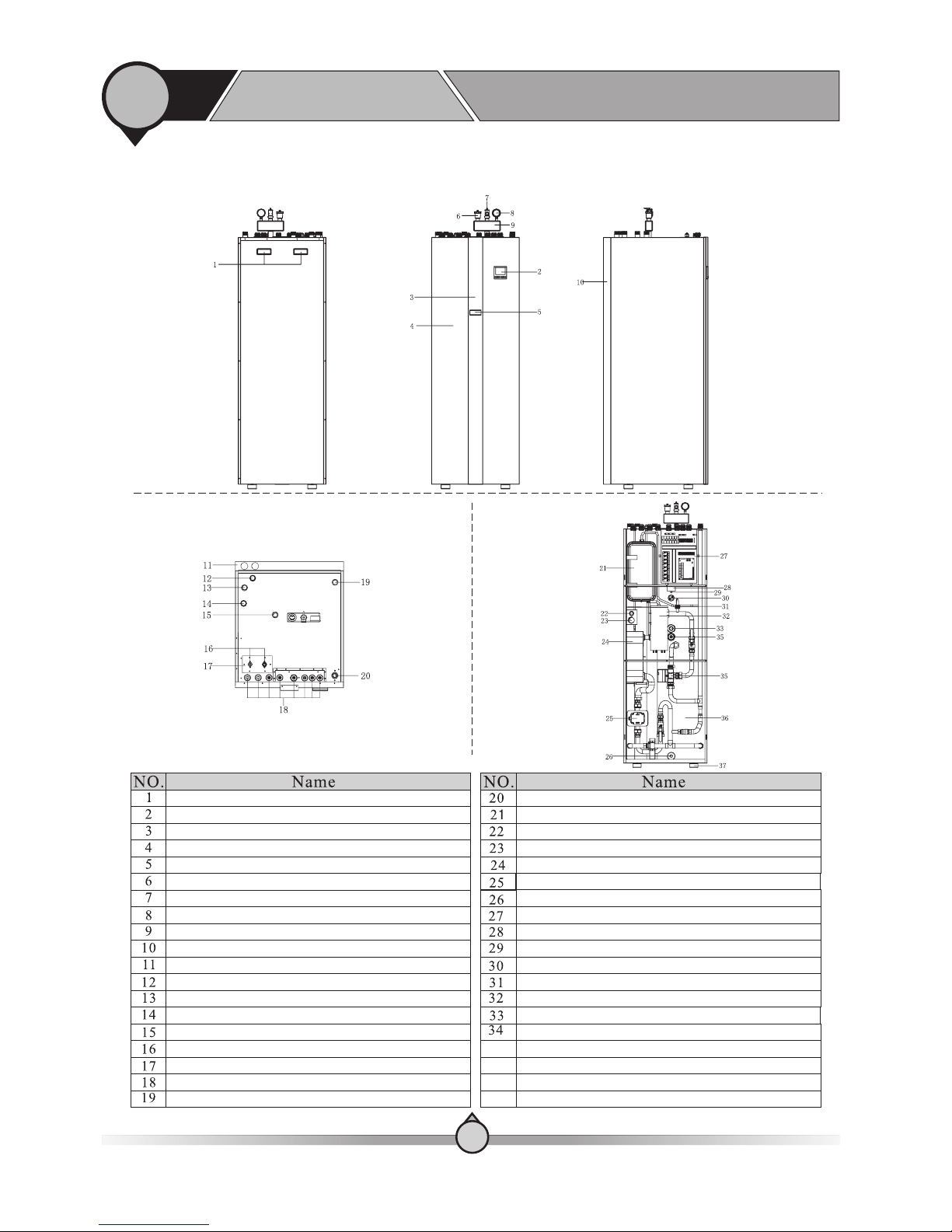

【 】 Indoor unit

Inside

Top

Outside

1

3. Main components

Before use

1

09

35

36

37

AWT13-V5+

Handle

Wired controller

Decorative panel

Front panel

Digital thermostat

Automatic air purging valve

T/P valve

Water pressure gauge

Four-way safety valve kit

L type decorative panel in back side 1

L type decorative panel in back side 2

Middle temperature hot water outlet

Filling water to coil

Filling water to water tank

High temperature hot water outlet

Refrigerant connector

Fixing plate for refrigerant connector

Cable gland

Water from heating/cooling system

(G1’’male)

(G1’’male)

(G3/4’’male)

(G1’’male)

(3/8’’~5/8’’)

(G1’’male)

Water to heating/cooling system

Water expansion tank

Emergency Switch for 6KW electric heater

Thermostat knob

Plate heat exchanger

Water pump

Drainage

Electric box

Overheating protector for 1.5KW electric heater

Temperature sensor for 1.5KW electric heater

1.5KW electric heater 230V/50Hz/1Ph

Water flow switch

6KW electric heater 400V/50Hz/1Ph

Anode Rod

Temperature sensor for hot water mode

Motorized three-way valve

Water tank

Rubber absorber feet

(G1’’male)

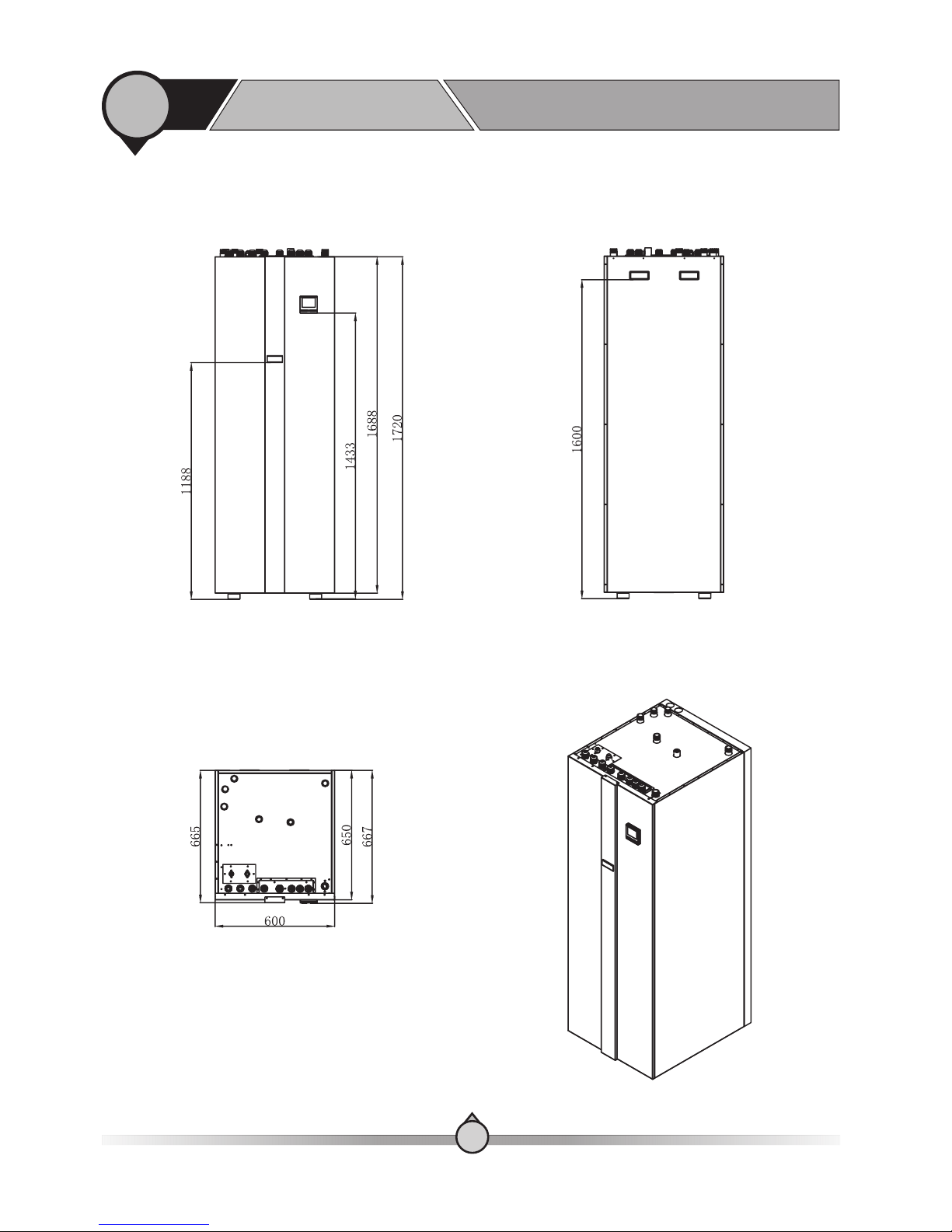

【 】 Indoor unit

1

4. Outlines and dimensions

Before use

Unit:mm

1

10

AWT9/11/1 3-V5+

1

4. Outlines and dimensions

Before use

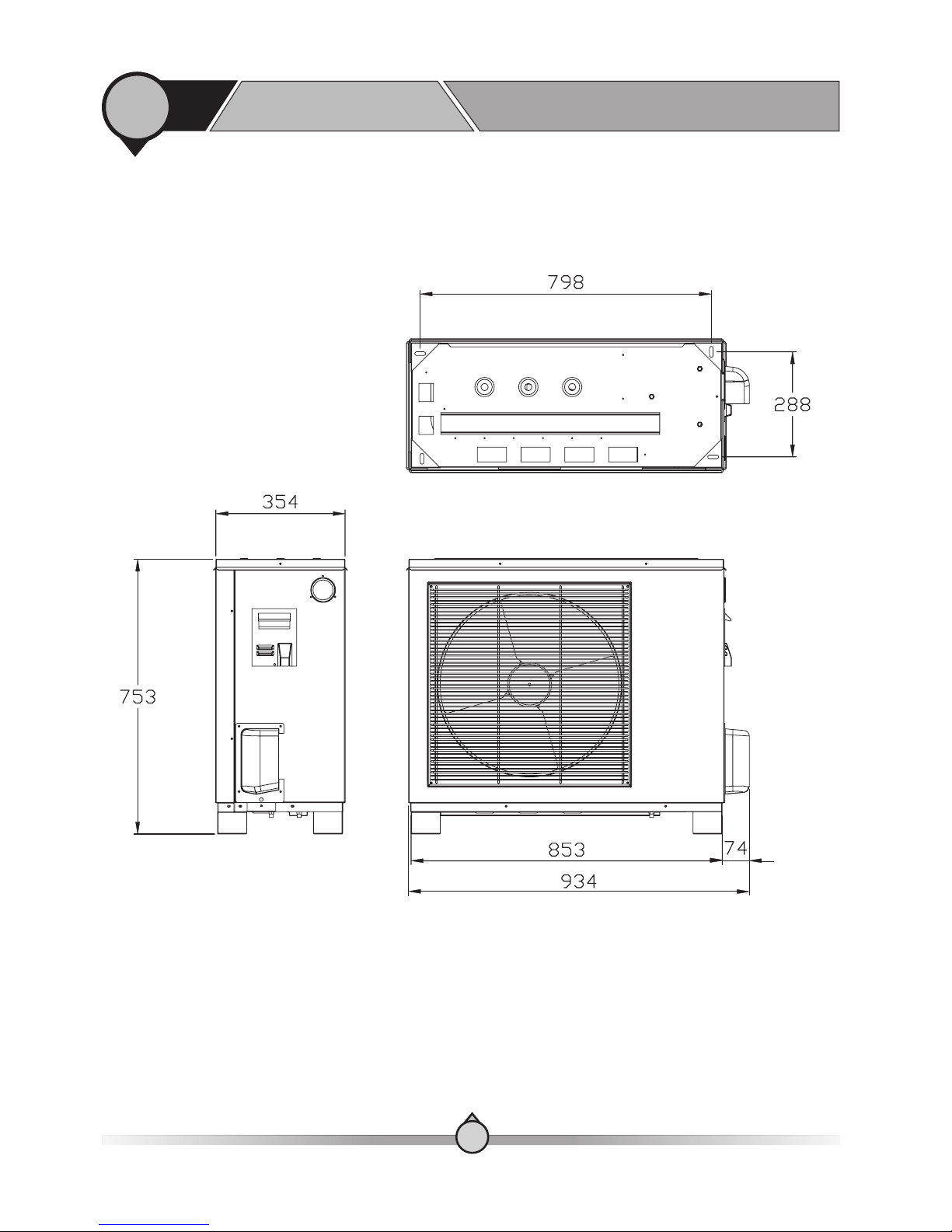

【 】 Outdoor unit

Unit:mm

1

11

AW9-V5+

Refrigerant connector

dimension:φ9.52&φ12.7

1

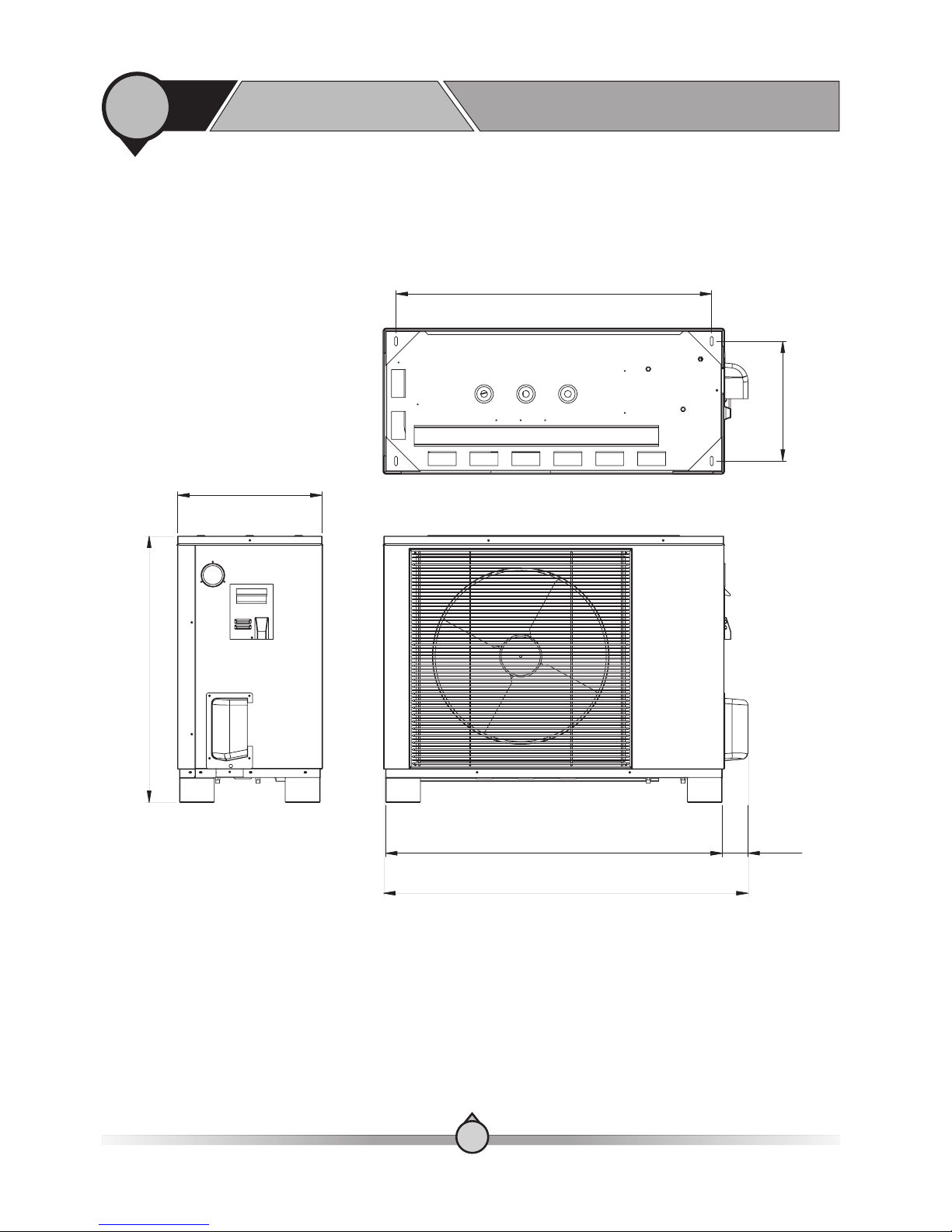

4. Outlines and dimensions

Before use

【 】 Outdoor unit

Unit:mm

1

12

Liquid pipe O.D. 9.52

Gas pipe O.D. 12.7

φ ( )

φ ( )

3/8”

1/2"

904

343

414

763

964

1044

74

AW11-V5+

1

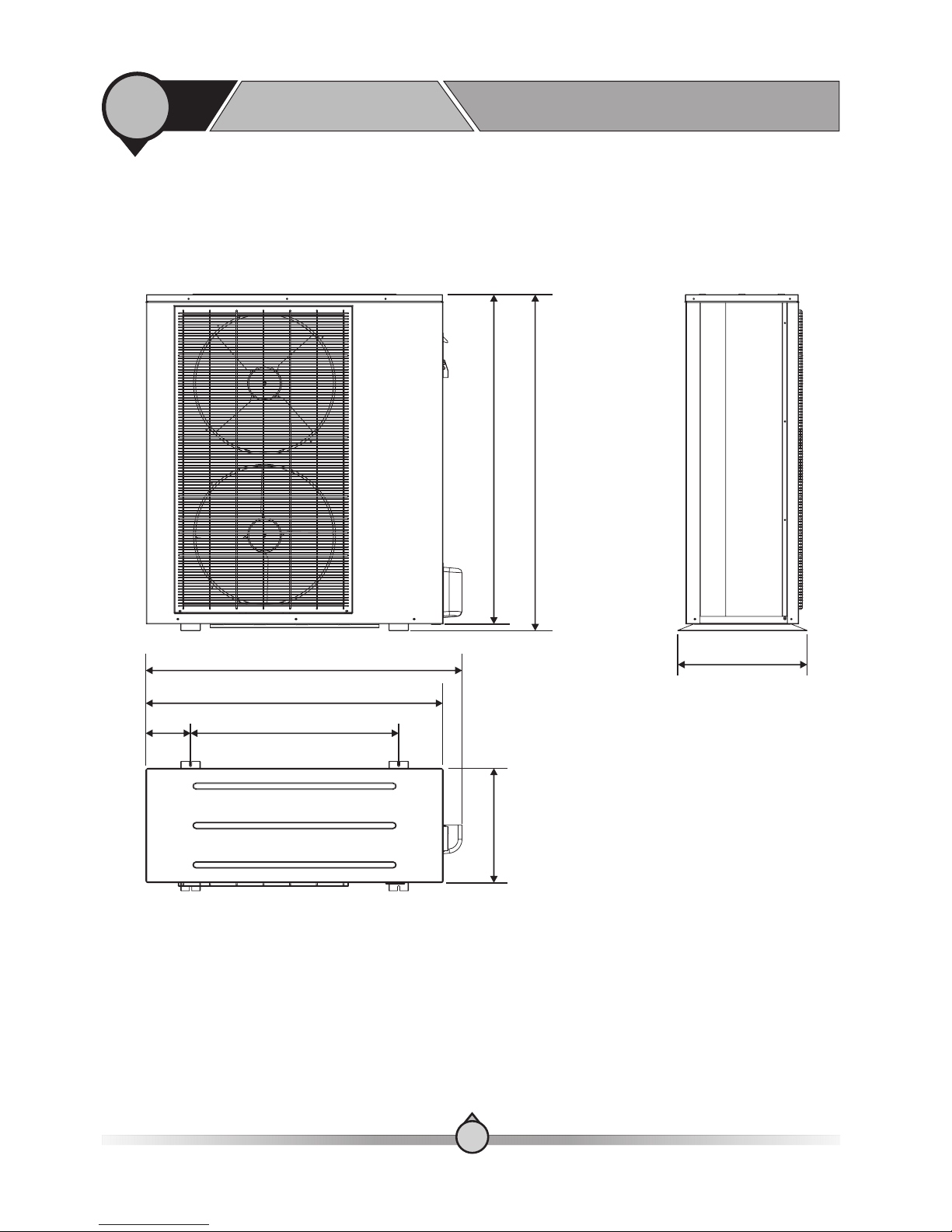

4. Outlines and dimensions

Before use

【 】 Outdoor unit

Unit:mm

1

13

AW13-V5+

Refrigerant connector

dimension:φ9.52&φ16

1195

1171407

740159

1058

1124

460

Outdoor Unit

Type

Water Pressure Drop

Rated Water Fl ow

Net Dimension

Packing Dimension

Net Weight

Gross Weight

Kpa

Inch

Piping Conn ec tion

3

m / h

Water ide Heat S

Exchanger

mm

mm

Kg

Kg

Model Number

Max. Water Temp.

℃

Tank Volume

L

Power supp ly a nd e lectric connections

Refrigeran t

Indoor Unit

Piping Kits

1

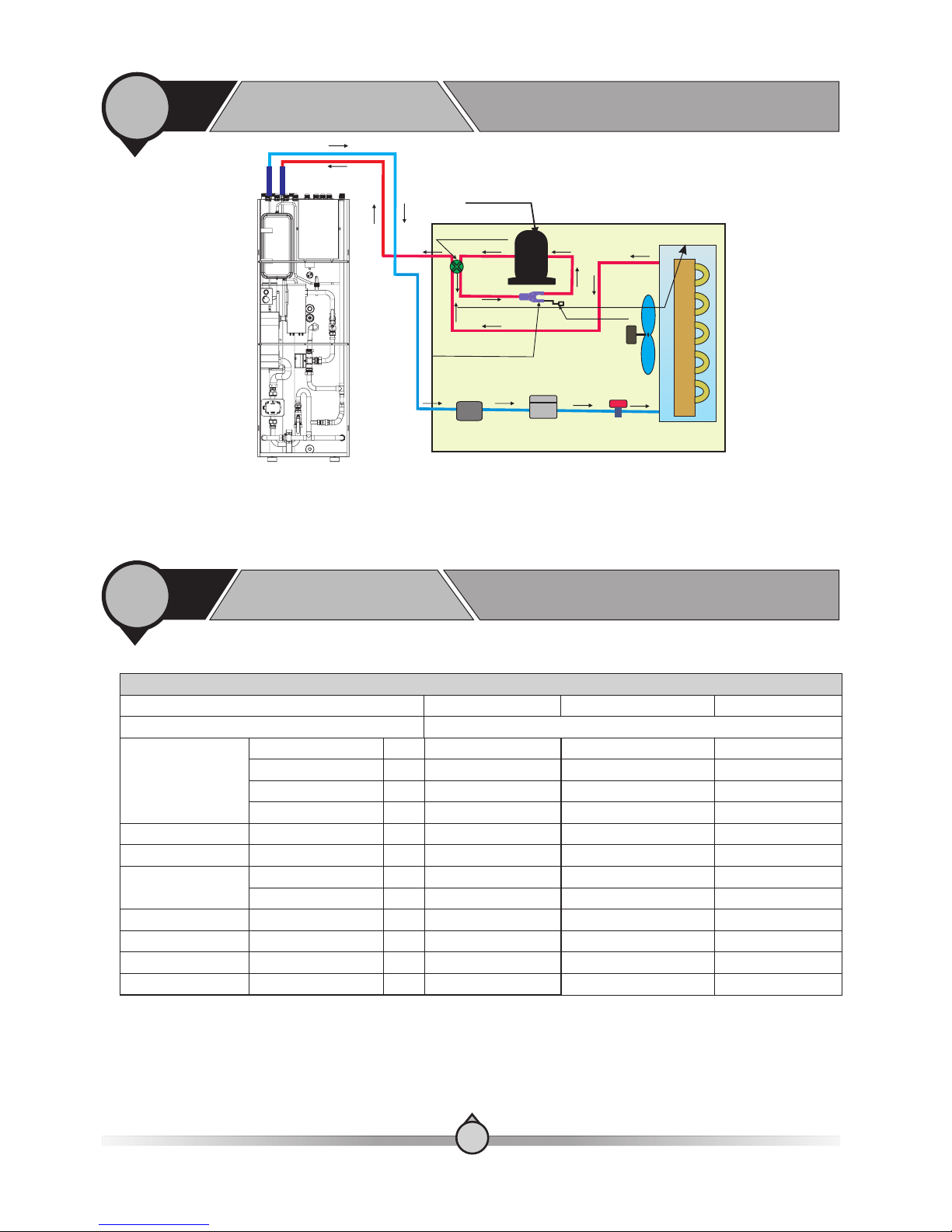

5. Working principles

Before use

Plate Heat Exchanger

Plate Heat Exchanger

Plate Heat Exchanger

30 3030

G1” G1”G1”

1.5 1.51 .5

600 650 1720× × 600 650 1720× ×600 650 1720× ×

638 708 1917× × 638 708 1917× ×638 708 1917× ×

AWT9 -V5+ AWT11-V5+ AWT1 3-V5+

75 7575

250L 250L250L

130 130 130

140 140 140

R410A R410AR410A

R410A R410AR410A

1

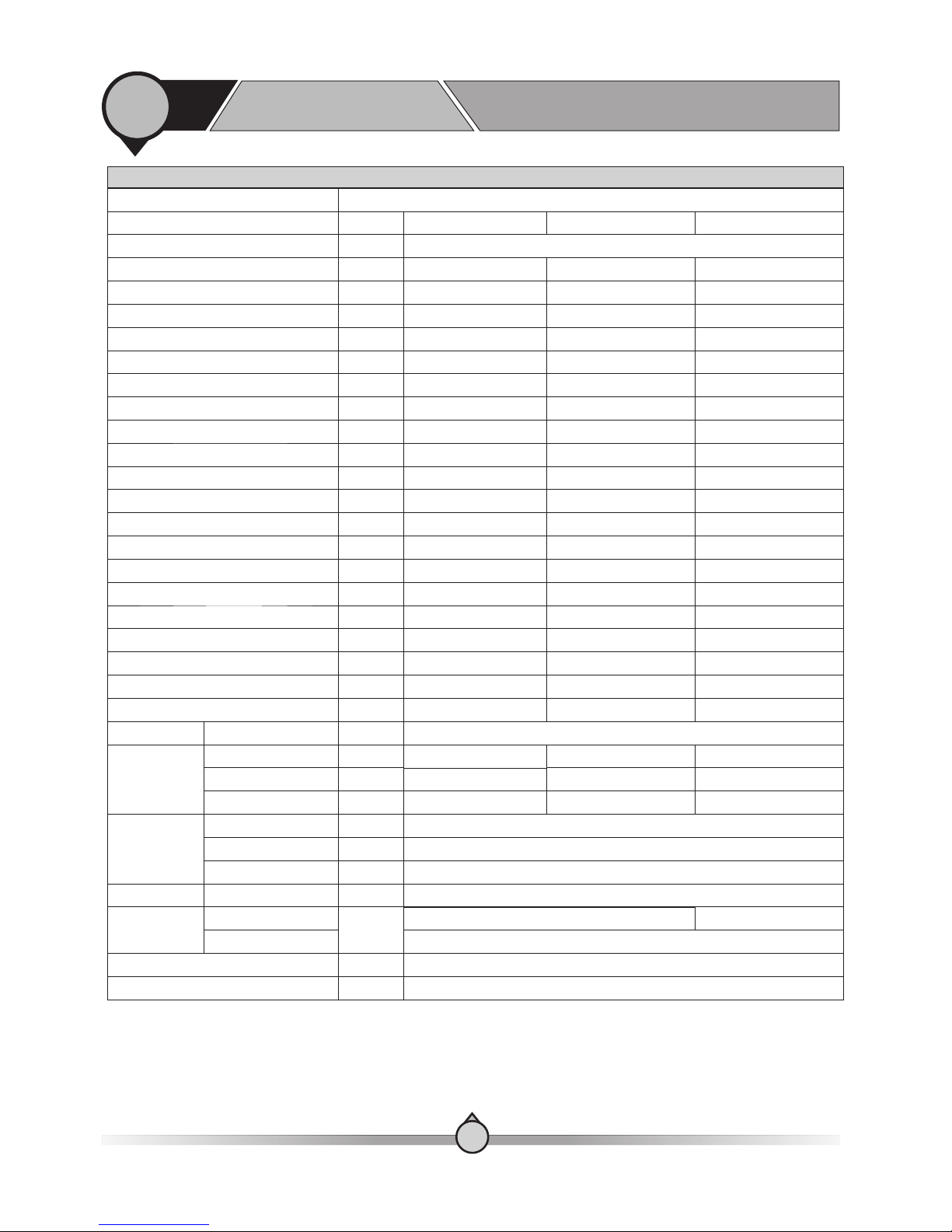

6. Specifications

Before use

1

14

Please check the chapter 2-9

Indoor unit

Expansion

Valve

Filter

Refrigerant

Three-Way Valve

Pressure Check

Valve

Power Supply

Compressor

Four-Way Vale

Fan Motor

Evaporator

1

6. Specifications

Before use

1

15

Outdoor Unit

Power Supply-Refrigerant

V/Hz/Ph

220-240/50/1- R410A

Max. Heating Capacity (1)

C.O.P (1)

Heating Capacity Min./Max.(1)

Heating Power Input Min./Max.(1)

C.O.P Min./Max.(1)

Max. Heating Capacity(2)

C.O.P (2)

Heating Capacity Min./Max.(2)

Heating power input Min./Max.(2)

C.O.P Min./Max.(2)

Max. Cooling Capacity(3)

E.E.R (3)

Cooling Capacity Min./Max.(3)

Cooling Power Input Min./Max.(3)

E.E.R Min./Max.(3)

Max. Cooling Capacity(4)

E.E.R(4)

Cooling Capacity Min./Max.(4)

Cooling Power Input Min./Max.(4)

E.E.R Min./Max.(4)

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

KW

W/W

KW

W

W/W

11.510.1

3.824.03

4.67/11.54.33/10.1

915/3029

975/2153

3.82/5.054.02/4.65

10.79.53

2.953.17

4.14/10.74.19/9.53

1218/3624

1230/2990

2.95/3.563.12/3.55

9.26.84

2.682.09

4.33/9.24.1/6.84

993/34651230/3280

2.68/4.112.09/3.32

6.745.05

2.151.58

2.17/6.742.34/5.05

924/31321080/3200

2.15/3.01.58/2.4

Compressor

Twin Rotary-1

Fan

Quantity

Airflow

Rated Power

m³/h

W

31003000

7676

11

Noise Level

Outdoor

Intdoor

DC Inverter Air to Water Heat Pump Unit

Water Pump

L

℃

Max Water Head

250

30-52 52 75℃- -

7.5

dB(A)

m

12.6

3.89

4.2/12.6

926/3072

3.89/4.77

11.5

3.08

3.76/11.5

1267/3723

2.97/3.28

10.3

3.29

4.29/10.37

957/3156

3.29/4.63

7.9

2.63

2.34/7.91

1000/3012

2.33/3.12

4200

150

59

2

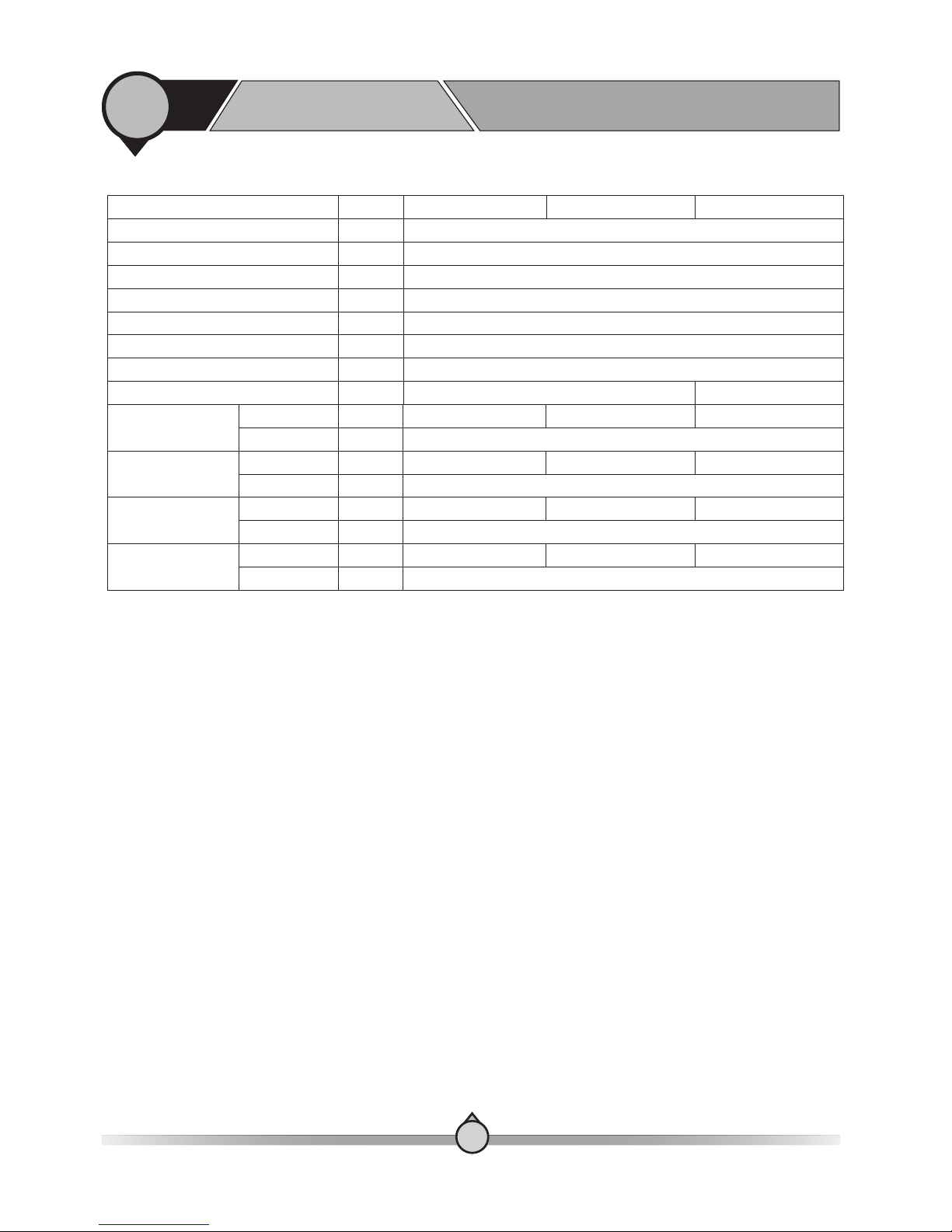

Model no.

Type of Product

Type - Quantity/System

lnch

Water Side

Heat

Exchanger

Type

Water Pressure Drop

Piping Connection

Kpa

Plate Heat Exchanger

30

G1"

56

35

Water Volume

Range of setting temperature℃

AW9- V5+ AW11-V5+ AW13-V5+

1

6. Specifications

Before use

1

09

1

6. Specifications

Before use

1

16

NOTE:

(1) Heating condition: water in/out temperature:30℃/35℃, ambient temperature:DB/WB 7/6℃;

(2) Heating condition: water in/out temperature:40℃/45℃, ambient temperature:DB/WB 7/6℃;

(3) Cooling condition: water in/out temperature:23℃/18℃, ambient temperature:35℃;

(4) Cooling condition: water in/out temperature:12℃/7℃, ambient temperature:35℃.

(5) The specifications are subject to change without prior notice.

For actual specifications of the unit, please refer to the specification stickers on the unit.

Kg/h

inch

240 300 360

Hot water capacity*

Refrigerant pipe connection

inch

KW

KW

℃

Mpa

G1"

Water pipe connection

Inbuilt Electric Heater

Inbuilt Electric Heater

Range of working temperature

Max. Pressure of Water

Control of 2KW electric heater

Control of 6KW electric heater

- ~25 45

0.7

Manual

Auto/Manual

2(220-240V/50Hz/1PH)

6(400V/50Hz/3PH)

3/8 、″ 1/2″ 3/8 、″ 5/8″

Net Dimension

(L×D×H)

Packing Dimension

(L×D×H)

Net Weight

Shipping Weight

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

Outdoor Unit

Indoor Unit

mm

mm

mm

mm

Kg

Kg

Kg

Kg

934×354×753

900×440×810

1044×414×763

1123×400×1195

600×650×1720

1130×500×815 1330×490×1330

638×708×1917

62.5

130

72.5

140

113

123

65

75

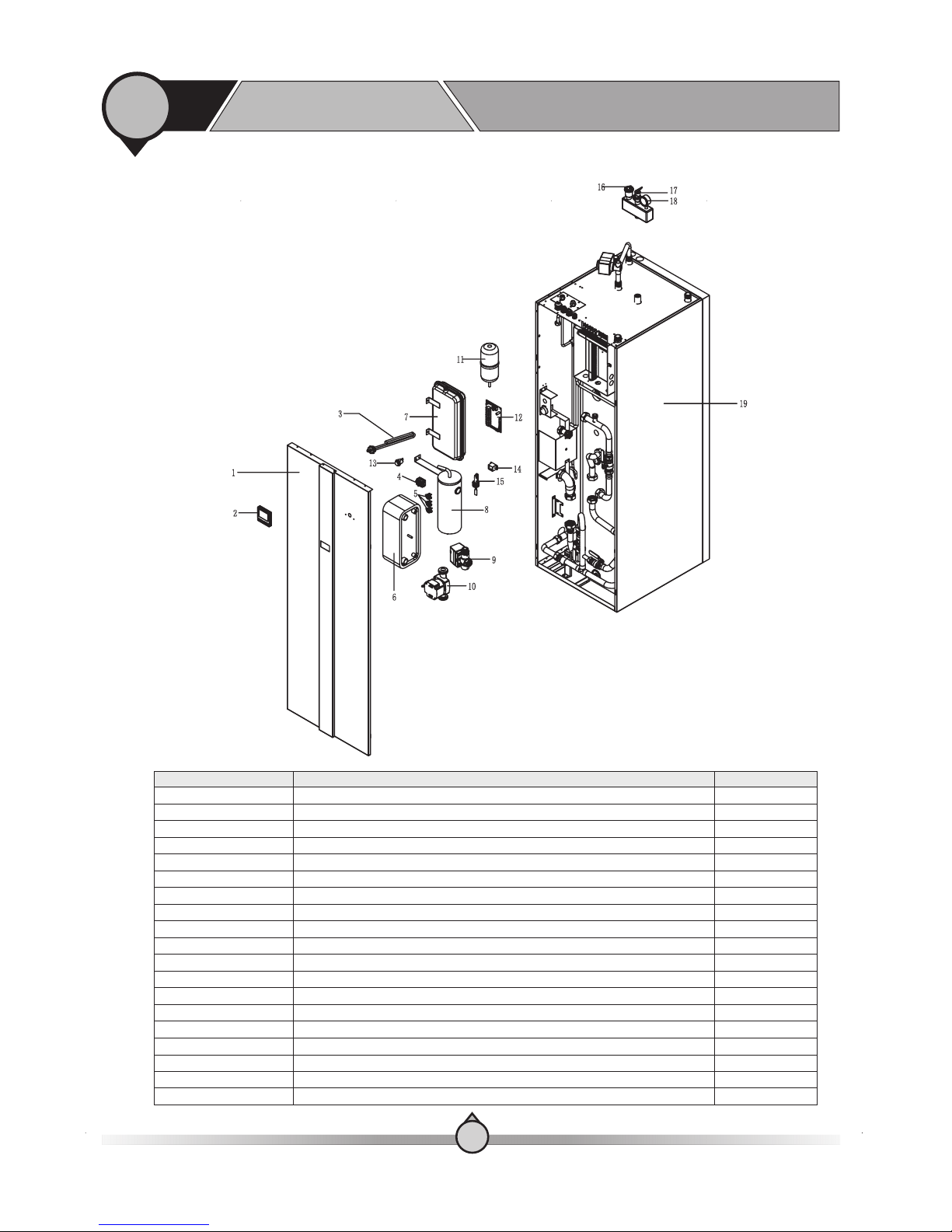

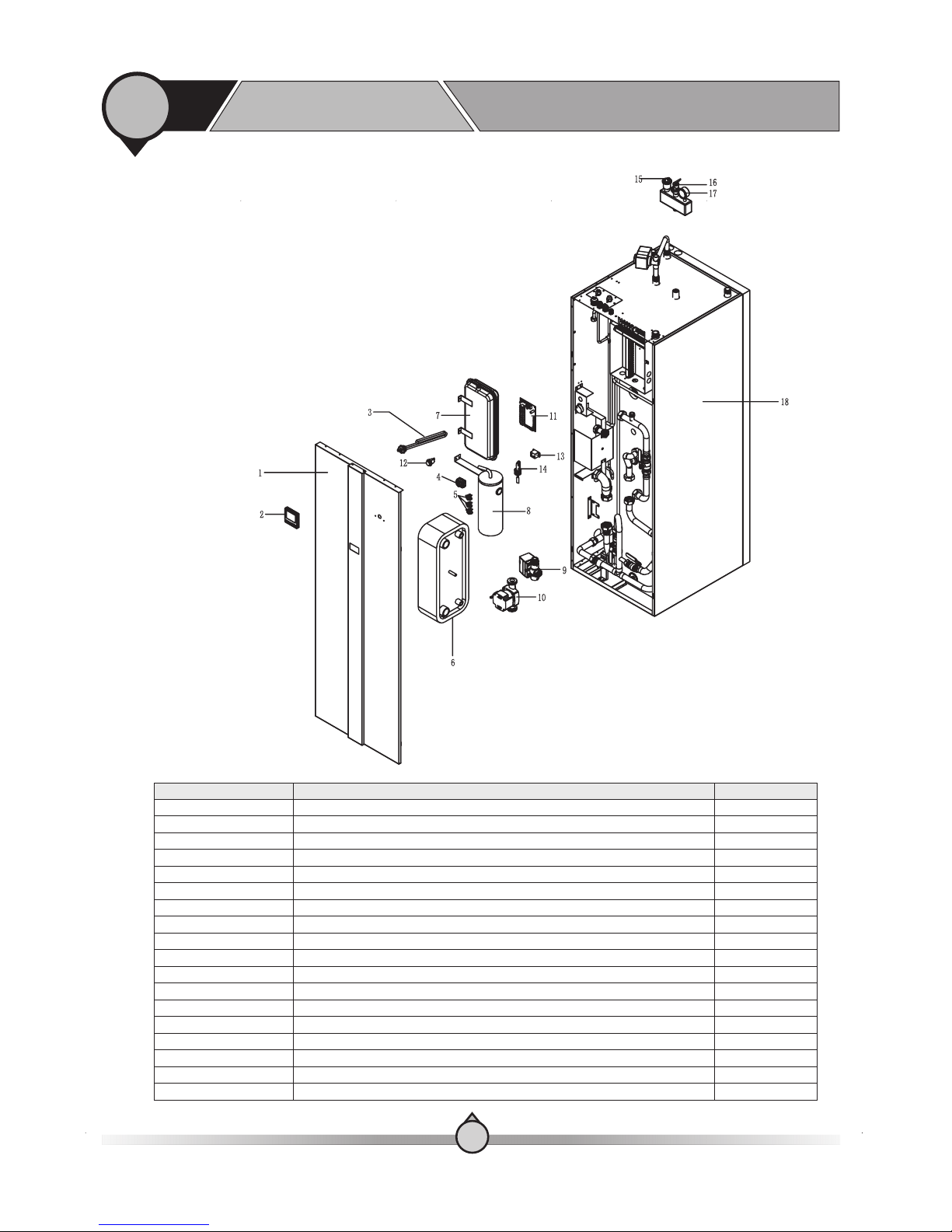

【 】 Indoor unit

1

7. Exploded view

Before use

1

17

AWT9/11-V 5+

Quantity

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Emergency switch for 6KW electric heater

Refrigerant expansion tank

Part name

Mechanical thermostat

Overheating protector

1.5kw electric heater

Plate heat exchanger

6kW electric heater

6L expansion tank

Water flow switch

Three-way valve

Air purging valve

Wired controller

Front panel

Water pump

Indoor PCB

T/P valve

Manometer

Water tank

Relay

Item no.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

【 】 Indoor unit

1

7. Exploded view

Before use

1

AWT13-V5+

18

Item no. Part name

Quantity

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

Front panel

Wired controller

1.5kw electric heater

Mechanical thermostat

Overheating protector

Plate heat exchanger

6L expansion tank

6kW electric heater

Three-way valve

Water pump

Indoor PCB

Relay

Water flow switch

Emergency switch for 6KW electric heater

Air purging valve

T/P valve

Manometer

Water tank

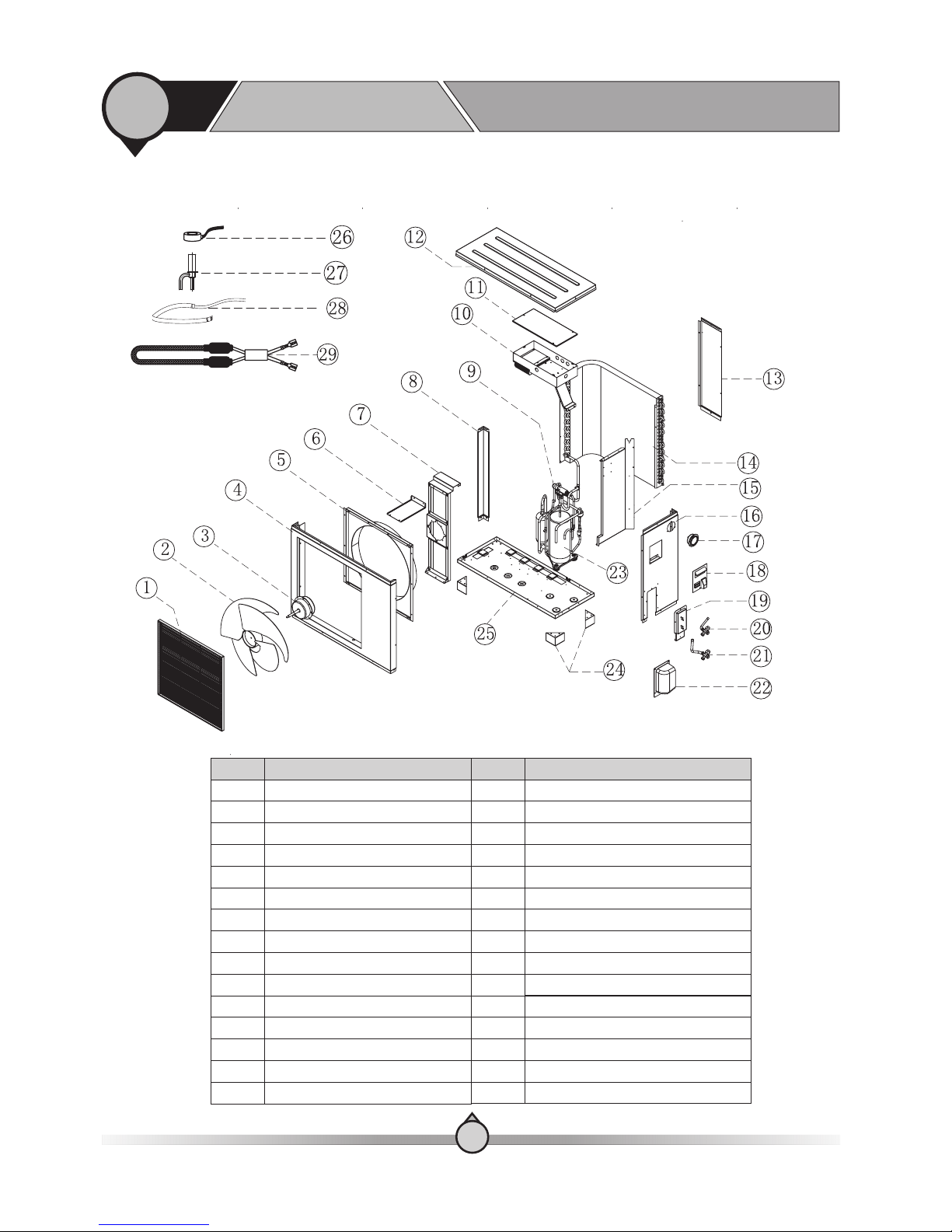

【 】 Outdoor unit

1

7. Exploded view

Before use

Compressor

Feet

EEV Coil

NO

Name

NO

Name

Outdoor Fan

Outdoor Motor

Front Panel

Air Guide

Fixture

Motor Bracket

Column Support

Four-Way Valve

Electrical Box

Decorative Panel

Top Panel

Electric Box Cover

Back Panel

Right Plate

Pressure

Big Handle

3/8 Valve

1/2 Valve

Valve Cover

Electrical Expansion Valve

Bulkhead

Bottom Plate

Condenser

Compressor Heater

Bulkhead

Condebser Heater

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

AW9-V5+

19

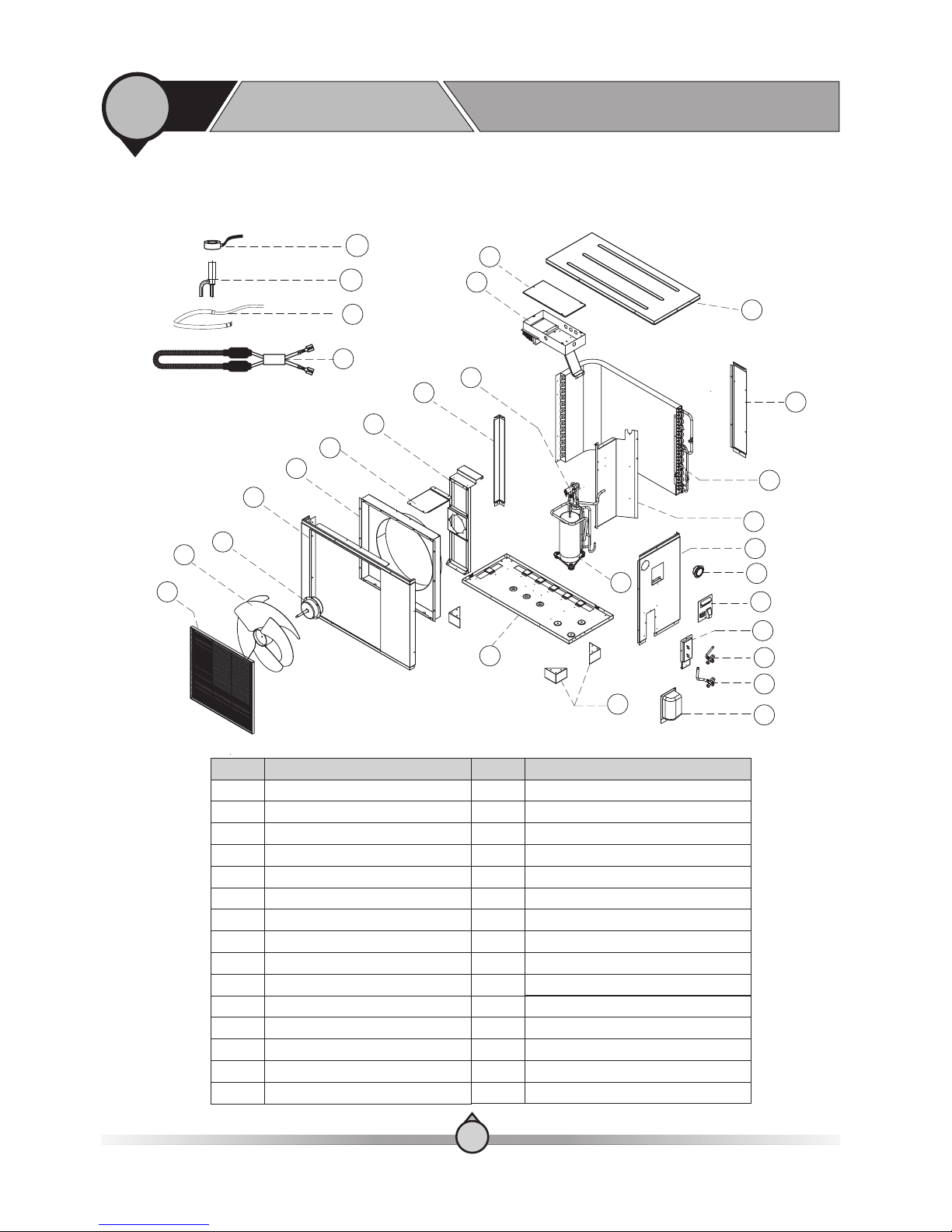

【 】 Outdoor unit

1

7. Exploded view

Before use

Compressor

Feet

EEV Coil

NO

Name

NO

Name

Outdoor Fan

Outdoor Motor

Front Panel

Air Guide

Fixture

Motor Bracket

Column Support

Four-Way Valve

Electrical Box

Decorative Panel

Top Panel

Electric Box Cover

Back Panel

Right Plate

Pressure

Big Handle

3/8 Valve

1/2 Valve

Valve Cover

Electrical Expansion Valve

Bulkhead

Bottom Plate

Condenser

Compressor Heater

Bulkhead

26

27

28

29

8

9

5

6

7

1

2

3

4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Condebser Heater

1

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

AW11-V5+

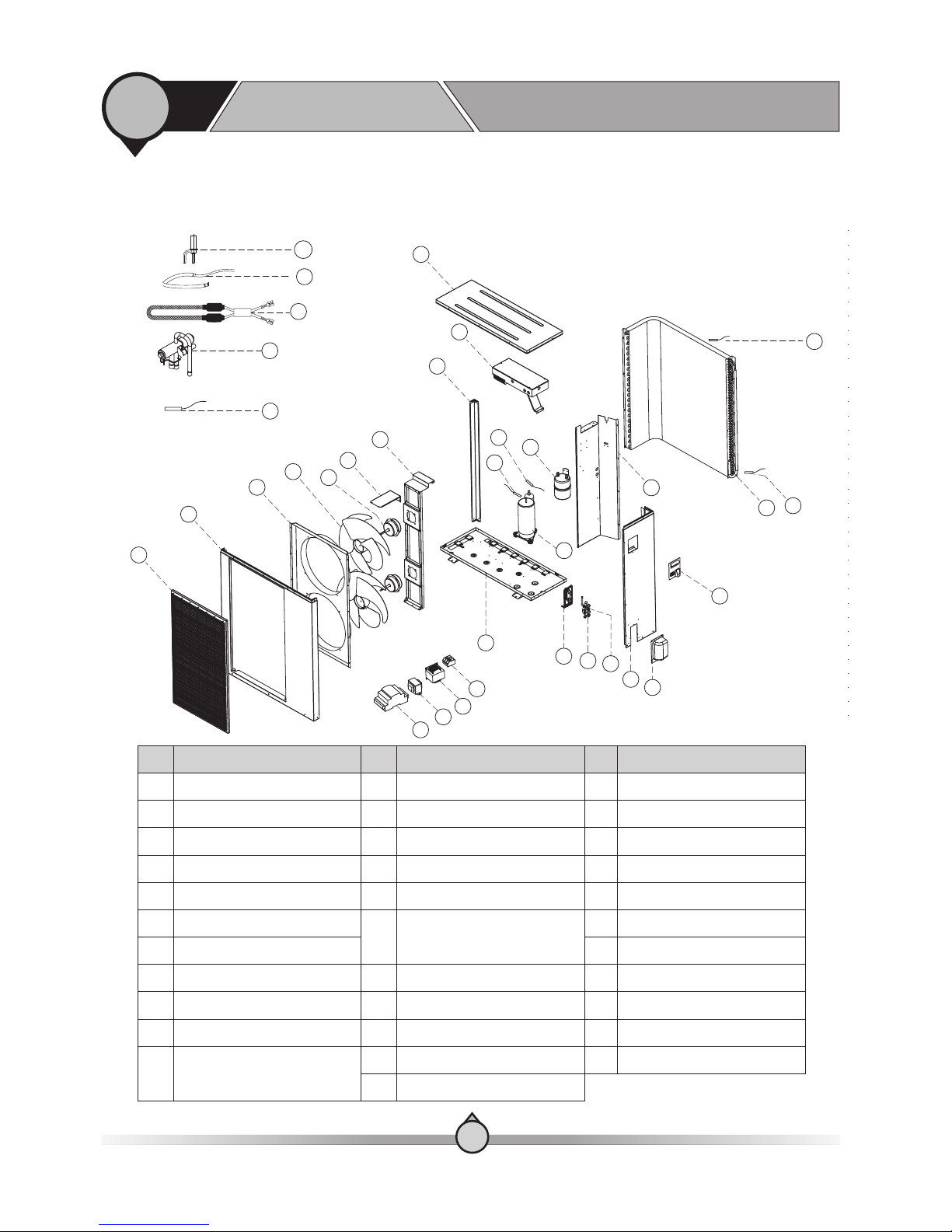

【 】 Outdoor unit

1

7. Exploded view

Before use

1

AW13-V5+

1

2

3

4

6

7

8

9

10

5

12

13

14

15

18

11

16

17

19

20

21

22

23

24

11

29

30

32

31

33

25

26

27

28

13

NO

Name

NO

Name

Decorative panel

Name

NO

14

15

16

17

18

19

20

21

25

26

27

28

29

30

NO NO

Fixture

Front panel

Outdoor fan

Motor bracket

Column support

Controller

Outdoor motor

Air guide

31

32

1

2

3

4

5

6

7

8

9

Top panel

Coil and ambient

temperature sensor

Condenser

10

11

12

22

33

Bulkhead

Compressor

Handle

Suction temperature sensor

Bottom plate

Valve plate

5/8” Valve

Compressor discharge

temperature sensor

Sperator

3/8” Valve

Terminal block

Crankcase heater

PFC transducer

EEV controller

Condenser heater

4-Way valve

Electronic expansion valve

Transformer

EEV temperature sensor

23

24

Side panel

Valve cover

21

【Installation methods】

Sanitary hot water, floor heating hot water and radiator heating hot water can all be get from the

indoor unit. With its inbuilt 1.5kW and 6kW electric heater, it ensures its heating capacity in cold

days and guarantees enough high temperature sanitary hot water.

By using a mixture water to mix high temperature sanitary hot water and medium temperature

sanitary hot water together, it ensures the ideal temperature of sanitary hot water, as well as

increases the amount of sanitary hot water.

2

1. Installation methods

Installation

1

22

Ambient temperature: ℃ to

Media temperature: + ℃ to ℃

0 40

0 95

℃

【 】In the storage environment temperature range

2

1. Installation methods

Installation

1

23

【Installation

methods】

In the following pages you will find how to connect different system applications to this heat

pump, based on your system design. It is of course many ways to do this and it is impossible

tocover every possible system design in the market. We therefore use the following as our

standard applications that is safe, workable and that we recommend. Other applications and

settings for this is possible, but we leave this design to the installer, according to his knowledgeand

understanding of this specific unit menu and possible settings. It is some basic specifications

that applies for all system drawings which is highlighted, and that we ask you read carefully when

considering which system application to use.

-Sensor locations

-System with or without buffer tank

-Internal and external water pump

Sensor locations applies differently for different applications. As a general standard, please refer

to the following.

Sensor locations applies differently for different applications. As a general standard,

please refer to the following.

Without buffer tank: For more stable running of the heat pump, we suggest to place the

sensors on the return line and adjust the heating curve or cooling

temperature accordingly, to fit the normal Delta T for your heating/

cooling system.

With buffer tank(s): For more stable running of the heat pump, we suggest to place the

sensors in the buffer tank(s). As general standard, you should place the

heating sensor in the upper part and cooling sensor in the lower part.

Circulation pump: This unit has a built in circulation pump that makes it possible to

connect the unit directly to a heating system using the internal

circulation pump to circulate the water in the heating system. For bigger

system or in systems with too big pressure drop, the capacity of the

internal water pump is not enough, and a secondary water pump for the

system is required. An external water pump can be controlled by the

heat pump. Please refer to the following pages for different system

applications.

Observe! It is always the installer's responsibility to control that the pressure drop in the

heating system is not higher than the internal circulation pump can handle.

2

1. Installation methods

Installation

1

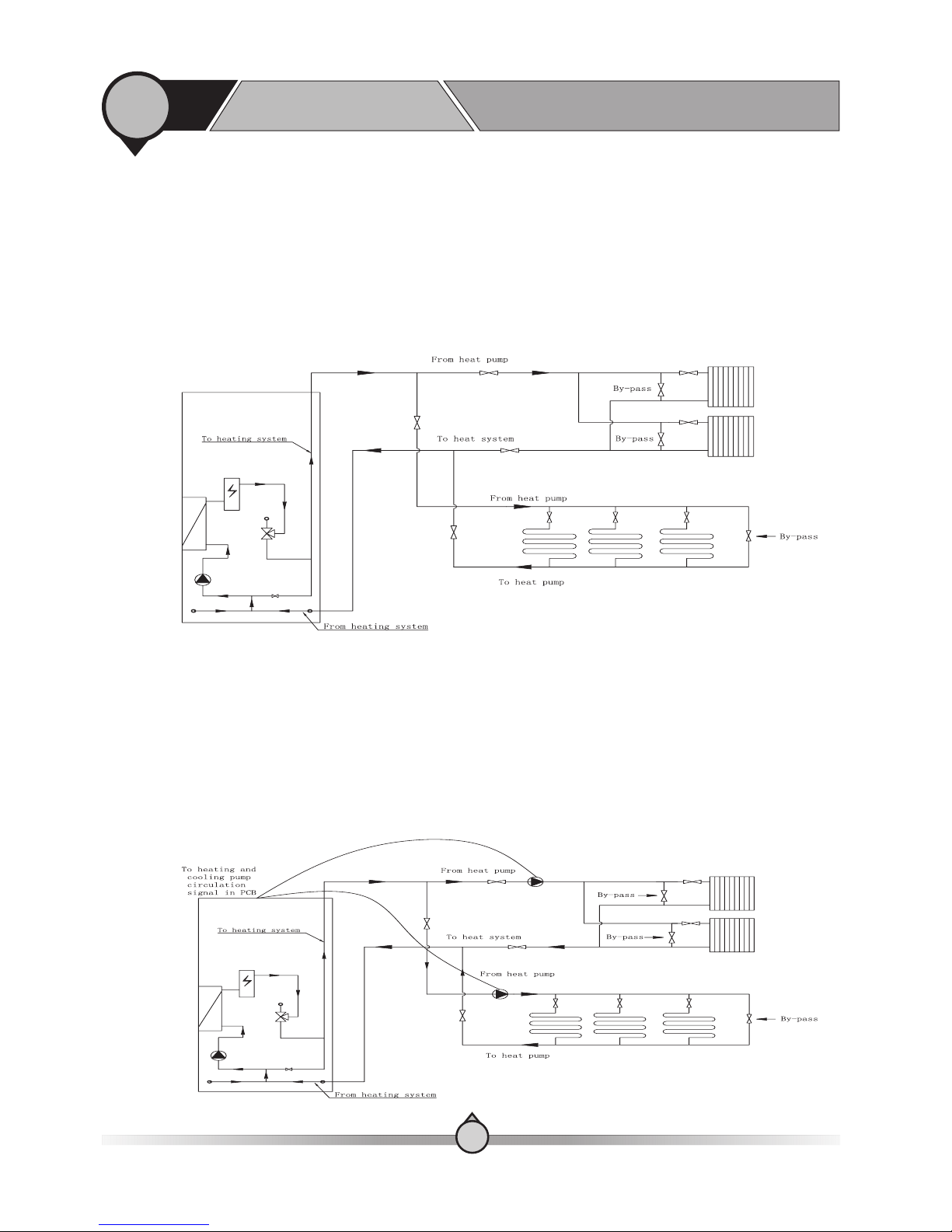

【1.Directly to heating system

】

【2.Directly to heating system

】

Observe! thermostatic controlled heating systems like floor heating,For radiators or fan

coils, an external bypass between turn and return manifold or thermostat valve, is

required.Minimum 28 mm copper piping or similar is required for heating system.

Observe! When external circulation pump is installed it must be connected to and powered

by the unit internal PCB

-No shunt valve

-No external circulation pump

-Internal bypass should be closed

-No shunt valve

-No external circulation pump for heating system installed

-Internal bypass should be closed -, and be partly in open position to balance the pressure

drop in the heating system.

. Thermostat controlled systems needs bypass in application 1.

24

Minimum 28 mm copper piping or similar is required for heating system.

2

1. Installation methods

Installation

1

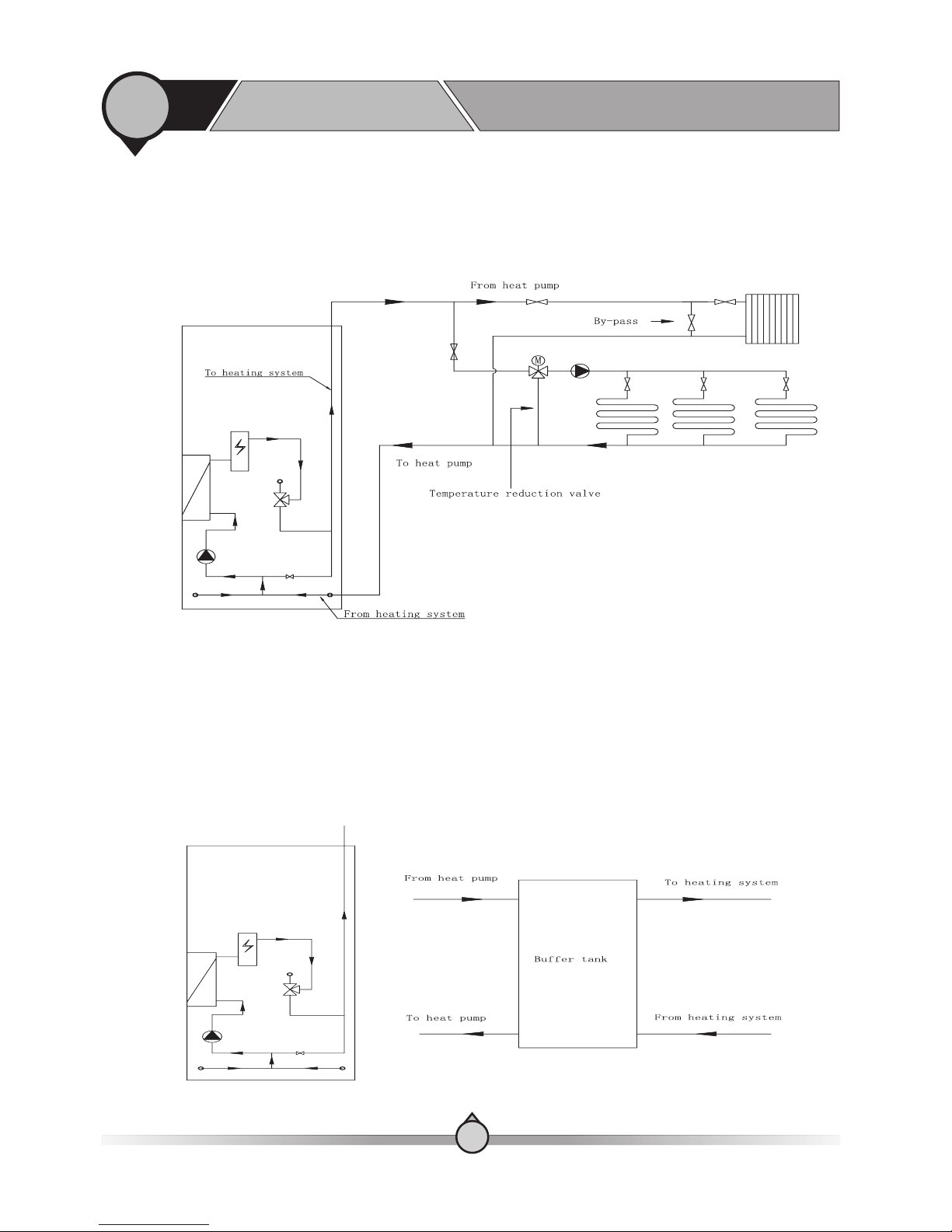

【3.Connected directly to combined high and low temperature heating system.

】

【4.Connected to a buffer tank

】

Observe! Temperature reduction valve and separate circulation pump for low temperature

heating system is required.Minimum 28 mm copper piping or similar is required for heating

system.

-Close the internal bypass

-External circulation pump is required

-Internal bypass closed.

-Optional power to external circulation pump

-Parameter in the menu “Heating buffer tank” and/or “cooling buffer tank” in “Group 0” of

advanced setting should be set to “1” = “with buffer tank”.

Minimum 28 mm copper piping or similar is required for heating system.

25

2

1. Installation methods

Installation

1

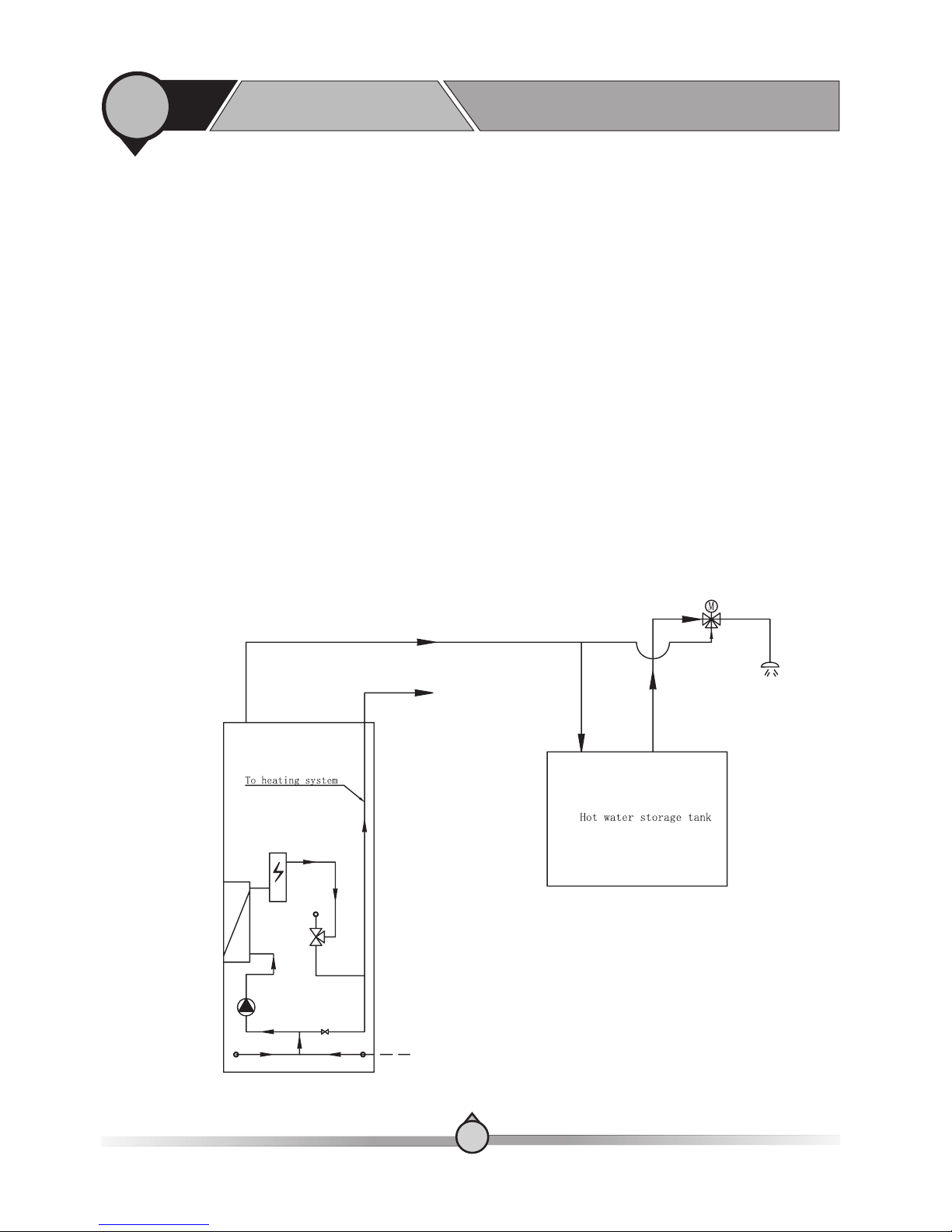

【5.Connecting external hot water heater.

】

Observe! This set up requires that the external water heater have its own heater with

thermostat control and a mixing valve on the outlet to your hot water supply lines. The

units mixing valve is not required, but will increase the efficiency.Minimum 28 mm copper

piping or similar is required for heating system.

-Reconnect the thermostatic valve on top of the unit so “hot water” from the unit is put to the

“cold” side of the mixing valve.

-“Plug” the medium hot water outlet

-Connect a bypass from units “hot water” outlet to the “coldwater” inlet on the external water

heater. Set the internal electronic hot water heater thermostat to 0

This unit have internal 250-liter water tank preserved for hot water for a normal family usage.

Some households use more hot water than normal, due to for example big bathtubs or the

number of family members. If so, we recommend connecting an extra water heater tank in series

with the heat pump hot water tank.

Heat pump will now either mix between heat pump and electric water heater or preheat the hot

water to the external water heater.

26

2

1. Installation methods

Installation

1

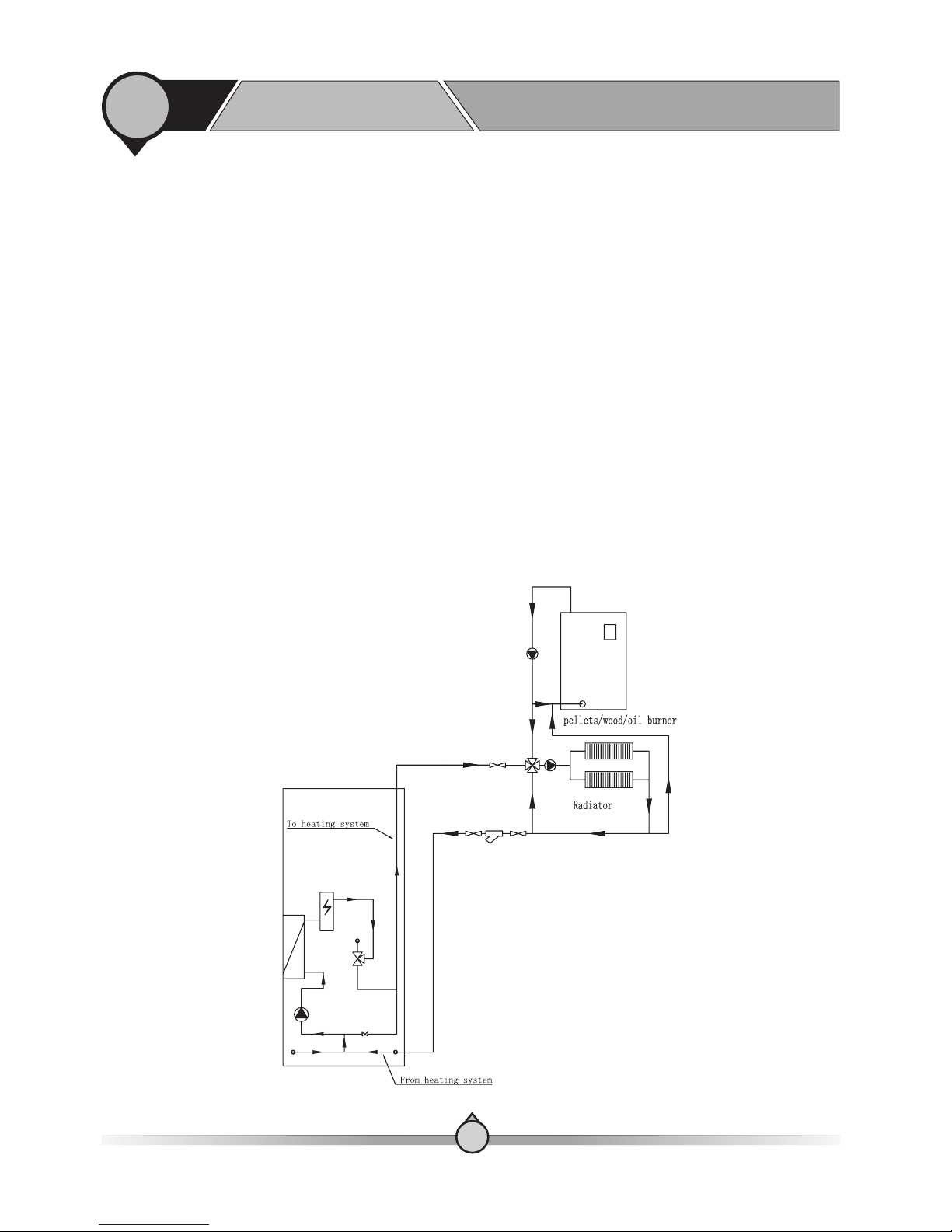

【6.Connecting an existing external boiler or other heating device as back up.

】

Observe! The installer must fulfill the installation and system design in accordance to both

functionality of heat pump and heating system, and in accordance to, local laws and

installation standards and regulations. A separate shunt valve with external controller is

required to mix in the heat from the boiler.Minimum 28 mm copper piping or similar is

required for heating system.

This unit is designed to be a total heating source for a normal house within a normal outdoor

temperature range. The heat pump has its own output and an additional built in 2 step 6 kW

(3+3 kW) electric heater for taking care of the peak load of your heating system the coldest days,

or if heat pump have functional failure. In some cases, the local lowest ambient temperatures or

the maximum heat load in the building is higher than the available output from the unit. For

some houses, the available electric power may not be enough to cover the input to the built in

electric heater. In these cases, you can connect an existing gas, oil or pellets burner to the system.

It is several ways to do this, so please use the below drawings as a template for how to design the

system. The heat pump can also control the start and stop of two external boiler or heating device

based on heat demand and prioritize between them, but external boiler or heating device always

needs to have its own internal temperature control and safety device.

27

2

1. Installation methods

Installation

1

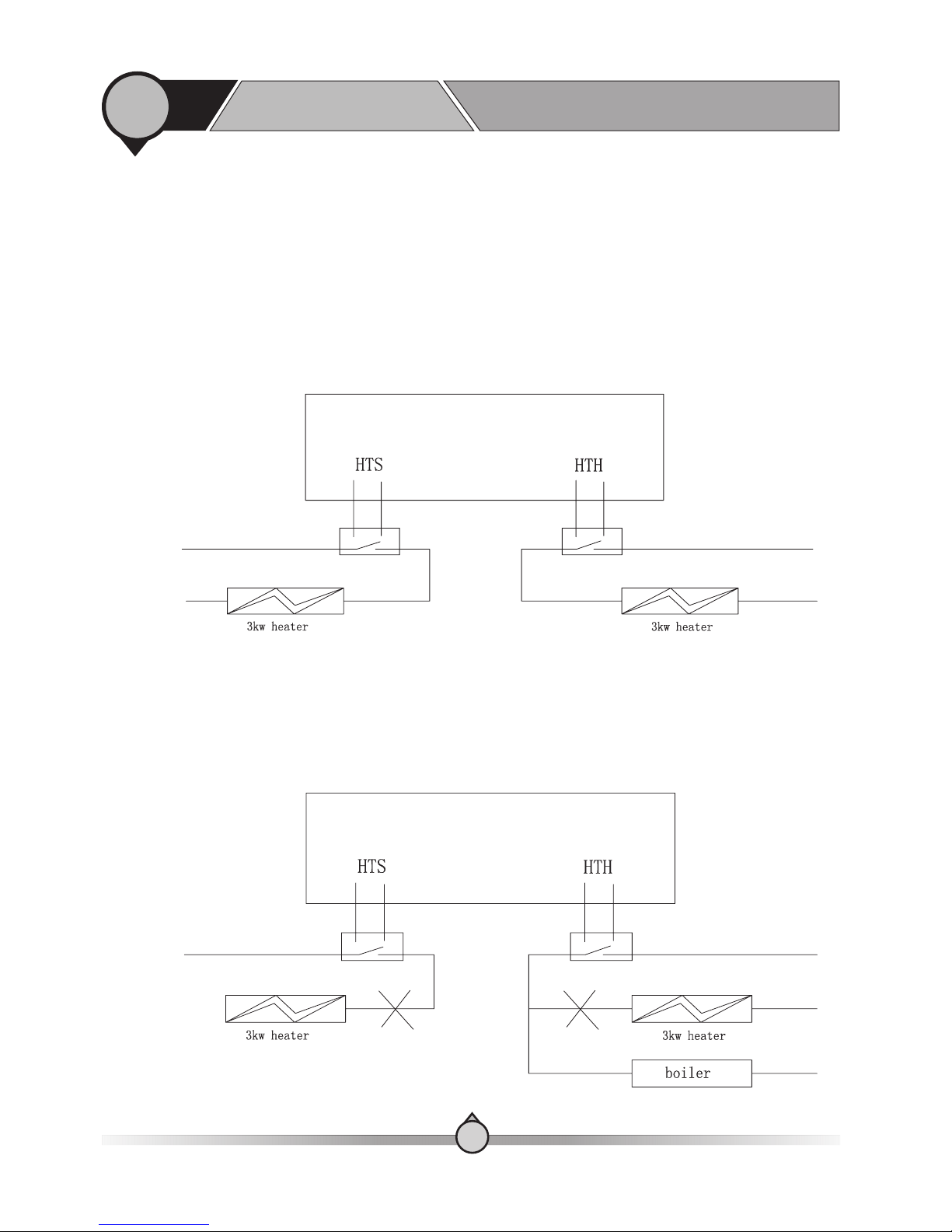

【6.1Control start of external boiler

】

6.1.1: If the available electricity is enough to over the power consumption of heat pump

only only:

Observe! HTH only valid when parameter setting C7 in Advanced Setting Group C to 1

(default factory setting).Minimum 28 mm copper piping or similar is required for heating

system.

HTS: 3kW auxiliary heater valid for both heating and domestic hot water operation

HTH: 3kW back-up heater for heating operation only

Default setting: HTH has higher priority than HTS, which means, HTS will be activated only

after HTH is activated, if heating capacity is not enough. Installer can choose from following

ways to add a boiler to the system:

-Leave the 3kW heater connected to HTS and HTH not connected with power supply.

-have boiler parallel connected to HTH port, so boiler will be activated if unit capacity is not

enough to cover the house heating demand.

28

Loading...

Loading...