Page 1

Rev. JG.013-02-04

EFFECTA PELLETS 222

INSTALLATION

MAINTENANCE

SERVICE

ASSEMBLY

Page 2

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

2

We at Effecta would like to thank you for putting your trust in us when choosing your new boiler.

The ”Effecta 222” has been developed to give you maximum performance, comfort and quality.

In order to get the best results from your boiler, we suggest that you follow the recommendations

in this installation guide.

Checking your delivery

Check that the boiler has not been damaged during transportation. If the boiler has been

damaged, you must report this to the transportation company immediately.

Your safety

If you discover any faults or defects in our products, it is important that you report them as

quickly as possible to your installation engineer, so that the fault can be rectified. Make sure

that there are no flammable materials close to the boiler, to help prevent risk of fire. You must

use your own judgement when operating the pellet boiler. Remember that the hatches and some

surfaces can get hot. You must take caution to avoid being burnt.

The user

It is the user´s responsibility to operate the boiler according to our instructions. If you do not

operate and maintain your boiler correctly, the environmental impact of the boiler will be greater,

it´s efficiency will be reduced and the service life of some components will be shorter. If there

is anything that you are not sure about, please contact your installation engineer or Effecta for

advice.

Warranty

The warranty takes effect from the date on which the boiler is installed. The supplied installation

form must be completed and returned to Effecta. You can find the other guarantee terms on

(page 3).

▀

Scope of delivery

Please check all components delivered.

The standard delivery as follows:

- Effecta 222 boiler

- Cleaning handle with brush

- Rake with scraper

- Flue tube with draft stabiliser

- Turbulators, 6pcs.(mounted)

- Drain cock

- Shunt valve with return pex pipe

- Electrical heater 3+3+3 kW (mounted)

- Valve combination

▀

Introduction

Page 3

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

3

▀

System data:

▀

Warranty

Installer:

Date:

Electrical installer:

Effecta products are guaranteed to be free of defects in materials and workmanship for two years

from the installation date. This applies to wear parts, such as seals, the main body of the boiler and

electrical components. This guarantee also covers original spare parts. Any faulty products will be

replaced or repaired at the discrimination of the retailer or Effecta. If a faulty product is detected,

Effecta is entitled to replace it with a new or reconditioned product of the same or a similar type.

Effecta is liable for the costs of any servicing or repairs. Effecta gives a 5 year guarantee on the

remaining components. See the attached guarantee document.

If you have a complaint, you must contact Effecta before starting any servicing work. You must

submit your complaint without delay. You must always state the type of product, the date of

purchase and the serial number.

Otherwise the heating and plumbing industry's current regulations apply in case of complaints.

Guarantee terms:

The guarantee is valid on condition that:

- The boiler and the heating system have been installed in accordance with the installation instructions

and in a professional manner.

- The location where the product is installed is suitable for the purpose.

The guarantee does not cover:

- The overall functioning of the heating system, costs incurred as a result of the heating system

being out of operation, or the cost of the temporary replacement of products.

- Damage or injury caused by negligence during the installation or by operating the boiler in a

way which conflicts with the installation and user instructions.

- Damage caused by abnormal wear, incorrect operation and maintenance.

- Damage caused by the boiler being positioned in an unsuitable location.

- Damage caused by vermin.

Page 4

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

4

▀

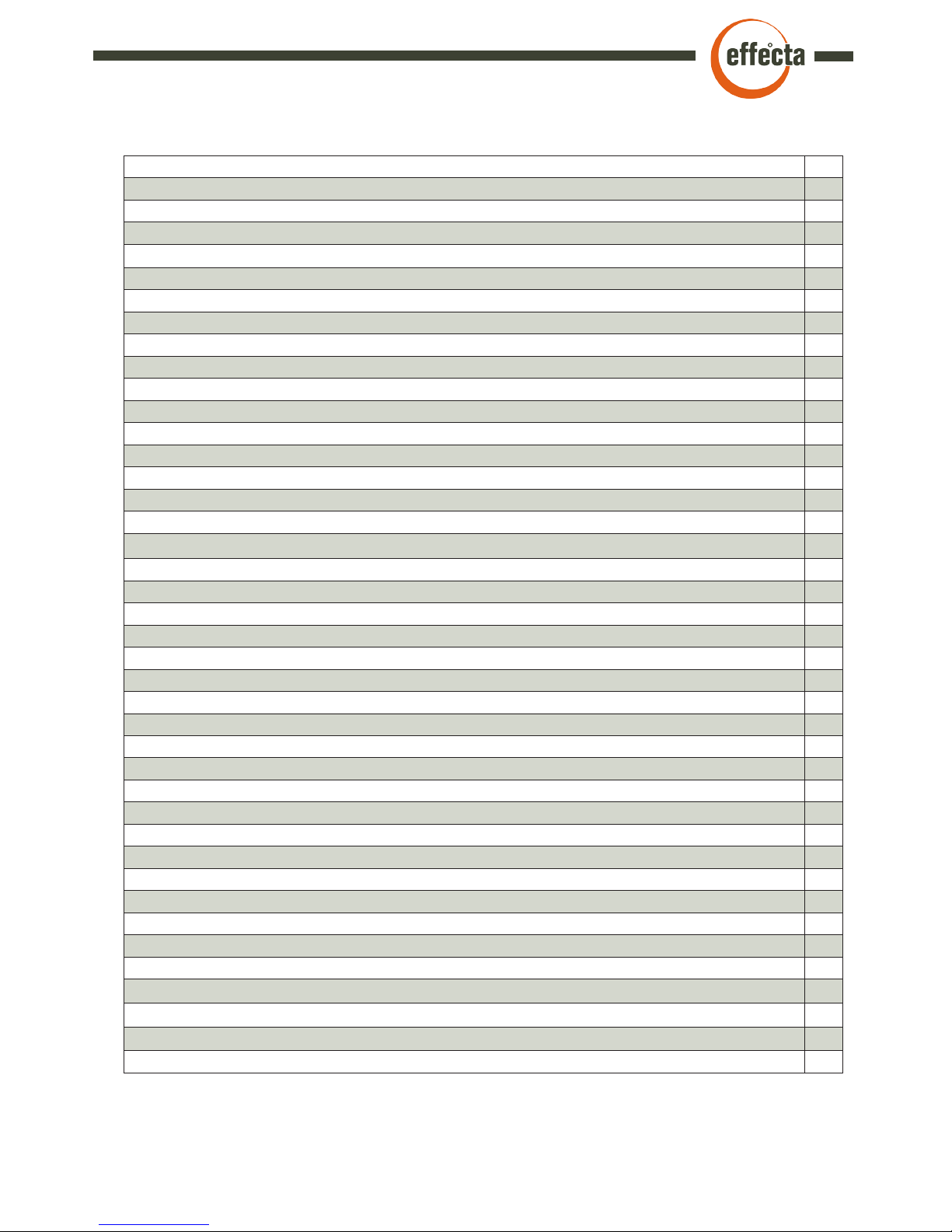

Contents

Introduction 2

Check of the delivery 2

Your safety 2

The user 2

Warranty 2

Scope of delivery 2

Warranty 3

System data 3

Contents 4

In general 5

Dismantling and disposal 5

Pellets 5

Symbols 5

To the installer 6

Boiler room 6

Chimney 6

Set up 6

System components 7

Shunt valve 7

Valve combination 7

Overheating protection 7

Micro switch 7

Seal 7

Cleaning 7

Flue gas temperature 7

Control panel 8

Placement of the components 9

Service and cleaning 10

Automatic cleaning 11

Hot water 12

Valve combination 12

Shunt valve 12

Cleaning 13

Electrical connection 14

Electrical connection 15

Electrical connection 16

Technical data 17

Hydraulic scheme 18

Draft stabiliser 19

Trouble shooting 20

CE-Mark 21

Page 5

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

5

▀

In general

The Boiler

Effecta 222 is a boiler which is to be fueled with wood pellets. No other kind of fuel is allowed to

be used. Not logs or oil.

Disassembly and disposal

It will be many years before your Effecta boiler is worn out, but it is important that you follow the

regulations in force at the time concerning disassembly and disposal of your boiler.

The fuel

The boiler should normally burn 6/8 mm pellets which come either in 16 kg sacks or are supplied

by bulk truck. If you have built a bulk storage, you should follow the current recommendations to

ensure that the quality of the pellets does not deteriorate. Never use pellets which do not meet

European pellet standards, as this may result in problems in operating the burner.

▀

Symbols in the manual

Information

This symbol is shown with info to the installer which can be important to know and understand.

Neglecting these informations can affect the performance of the product.

Dangerous electricity

This symbol means that extra caution should be taken. Otherwise serious personal injury

might occur. When maintaining the product where this symbol is present the power must be

disonnected. All electrical wiring must be done by a proffesional.

This product manual is a living document. You will always find the latest verion on our

webpage, www.effecta.se

▀

Type plate

2012 2012 2013 2014 2015

Tillverknings år. / Manufacturing year

Tillverkare / Manufactory

Hersteller / Fabricants

Modell / Model

Typ / Modéle

Max drifttemp. / Max temp. (C)

Max. Betriebstemp. / Temp d’opération max

Effekt / Heat output

Heizleistung /Puissance nominale (kW)

Elinstallation / Electrical supply

Strom / Branchement électrique (VAC)

El-patron / Electrical heater (kW)

El-Patrone / El-cartouche

Vattenvolym / Water volume

Wasserinhalt / Contenance d`eau (litre)

Tillverknings nr / Manufacturing number

Herstell Nr / Numéro de fabrication

Effecta Energy Solutions AB

Effecta 222

100

20

230/380~50Hz

2 /6 / 9

205

Effecta AB - Sweden - Kungsbacka - www.effecta.se

Max drifttryck / Max pressure

Max Betriebsdruck / Pression maximum (bar)

1,5

Tillverknings månad / Manufacturing month

1 2 3 4 5 6 7 8 9 10 11 12

Godkänd enl. / Approved by

Zugelassen nach / Approuvé á

EN-303-5

The type is placed on the top of the boiler. Here you can see

production number, month and year.

Page 6

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

6

▀

To the installer

It is time to install the Effecta 222 pellet boiler. Please follow the examples we provide for a safe

installation. After installation, be sure to instruct the customer on how the heating system and the

boiler work, in order to avoid unnecessary complications in the future.

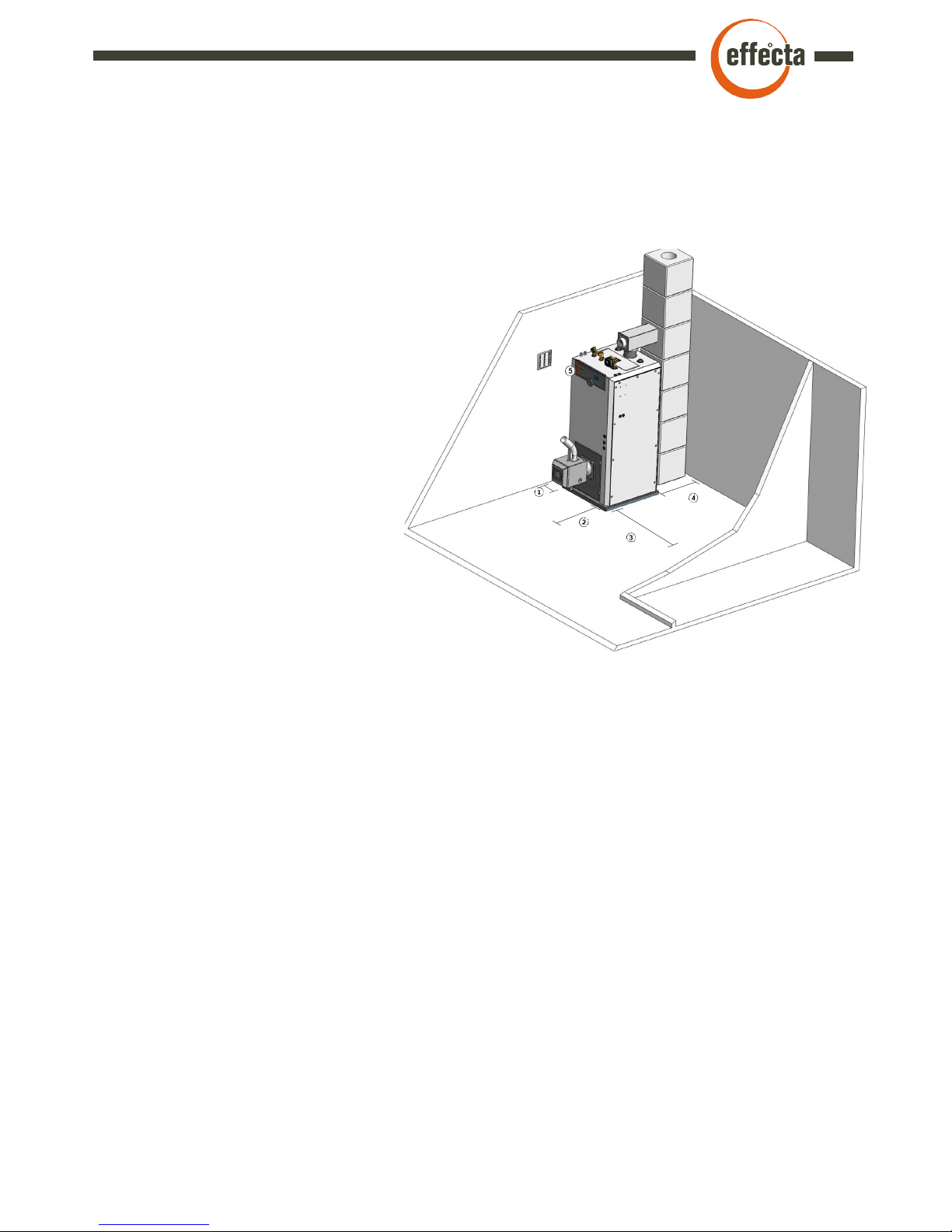

Set up

The boiler is positioned so that the surface

temperature of flammable building material does

not exceed 80°C. The boiler should be positioned

at least 15 cm (1) from the wall. The distance

from the flue tube on the boiler to a flammable

wall with ignition protective covering must

be at least 30 cm (4). In order to clean the

boiler, a minimum clear space of 1 metre

(2) is required in front of the boiler and

on the side at the convection section

and at any inspection panel in the

chimney. A passage with a minimum

width of 0.5 (3) m is required along

one of the long sides of the boiler.

The pellet hopper isn`t allowed to

stand closer than 120 cm from

the boiler.

The boiler room

The boiler must be installed in a boiler room or

boiler house. The ceilings and walls must be fitted with

ignition protective covering and the floor must be made of noncombustible material. Minimum ceiling height at the boiler is 2 metres. The boiler room or boiler

house must be equipped with a fresh air intake with the minimum dimensions 150 x 150 (5.) mm

or with a sufficiently large free sectional area to avoid low pressure in the boiler room. It must be

impossible to close the air intake.

Chimney

The chimney should have a diameter of at least 120 mm. If your chimney is smaller, Effecta should be

consulted before installation. The draught in the chimney should be about 15 pa at low temperatures.

It is important that the chimney is tested and approved by a certified chimney sweep before a new

boiler is installed. If the chimney has a strong draught, a draught controller may need to be installed

for good boiler operation. If you have a tall chimney and an outgoing flue gas temperature below

170°C, there is a risk of condensation in the chimney, which can damage the chimney in the long

term. A suitable temperature is 70-80°C one metre down into the chimney. Ask your local chimney

sweep for help to measure the temperature. If the chimney is tall and has a large area, a draught that

is too strong may mean high levels of flue gas and over ignition in the ash compartment. If this is the

case, a draft stabiliser must be installed.

Page 7

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

7

▀

System components

The shunt valve

The shunt valve controls the heat supply from the boiler to the radiator circuit.

The room temperature can be adjusted on a scale on the thermostat. An automatic system

will significantly reduce fuel usage and provide a more comfortable environment.

The valve combination

The mixing valve is used to ensure that the temperature of the hot water in your shower

and elsewhere in the house is comfortable. Set the system to the temperature you want by

turning the thermostat between +/-.

Overheating protection

The overheating protection is a safety device if the burners thermostat should malfunction.

If the boiler has been overheated you must reset the overheating protection manually, by

pressing the red button (press hard) on the control panel.

Micro switch

The micro switch stops the auger alt. the whole burner, (depending on installed burner) if the

ash door is open. It´s important that this functions works and is checked regurlarly.

The sealings

The seals on the hatches must be checked every year. If the hatches do not seal properly,

the efficiency and the combustion process of the boiler will deteriorate.

Control panel

The functions of the control panel should be checked every year to avoid downtime of the

boiler or burner.

Cleaning

Cleaning is done from the top of the boiler. Take away the top cover and unscrew the nuts

on the lid over the tubes. Remove the turbulators and clean the tubes with the cleaning

handle with brush. Then open the ash compartment door and clean the burner and the ash

compartment. If your boiler is equipped with automatic cleaning of tubes, read the

instructions on pg. 11.

Flue gas temperature

The temperature that leaves the boiler should be in the range of 160-230°C if there is

condensation in the chimney the temperature must be higher.

To achieve a higher flue gas temperature you can cut the turbulators 5cm.

Page 8

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

8

1 Overheating protection Cuts power when the temperature exceeds 95ºC

2 Display Status of the heating system

2 Keypad Maneuvering in the menus

▀

Control panel

Page 9

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

9

Front Top Back

1 Adjustable feet 1 Smoke connection 1 Drain

2 Soot door 2 Cable gland 2 Return hotwater

3 Microswitch (inside the door) 3 Valve combination 3 Cable gland

4 Handle 4 Shuntvalve

5 Hole for burner 5 Lid

6 Control panel 6 Expansion / hotwater

7 Power for burner* 7 Hole for measuring instrument

8 Flame sensor*

9 Power for auger*

▀

Placement of the components

*Only with Effecta Supra/Aero.

Page 10

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

10

▀

Service and cleaning

Cut the power to the boiler before starting the service. We recommend a good service/

cleaning of the burner and boiler 2-3 times a year. Do as follows for best result and

minimizing the chances for downtime.

Cleaning the ash compartment

Cleaning the ash compartment is done through the ash door on the front. The easiest way is to

use some type of ash cleaner. If you do not have access to a an ash cleaner, remove the ash

with a scrape and keep it in a fireproof bin. Remember that ashes can contain hot particles for

a long time and may not be stored near flammable materials.

Cleaning the burner

Clean the burner according to the manufacturer´s instructions. If you have an Effecta Supra

read more about service and cleaning in the burner manual.

Cleaning of the convection part

Clean the tubes with the supplied brush, follow instructions how to remove the turbulators on

pg 13. It´s important for the boilers efficiency that these are cleaned thoroughly at the service.

Cleaning of sootbox and fluetube

Soot box, which is placed above the tubes must be emptied of ash, if the soot box is full, the

flue gas has no place to escape out through the chimney and you will receive a disruption. Also

clean the flue tube that goes to the chimney, when it is not certain that the chimney sweep do it.

Sweeping range

1. Ash compartment, after about 3 tons of pellet consumption

2. Burner, according to the manufacturer´s instructions

3. Convection part, after about 3 tons of pellet consumption

3. Without automatic cleaning every other week in winter

4. Ashbox when necessary

5. Sootbox after about 3 tons of pellet consumption

6. Flue tube after about 3 tons of pellet consumption

Page 11

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

11

Magnet motor

The magnet motor is mounted on the right side of

the soot hatch on the top of the boiler. The magnet

motor flips the turbulators up and down to keep the

tubes clean.

1 Magnet motor

2 Lyfting shaft

3 Flipper

4 Suspension

5 Turbulator

Turbulators

The turbulators in the tube helps reducing the flue

gas temperature and also cleaning the tubes when

pulled up and down.

▀

Automatic cleaning system (optional)

Function and service

Cut the power to the boiler before servicing. The magnet motor is mounted on the boiler to keep

the convective part clean. It is controlled from the menu ”Cleaning” on the control panel. It can

be set to work/not work in different times during the day.

Suspensions

On every suspension there are three turbulators

that is removed when you clean the tubes with a

brush.

Lyfting shaft

The shaft is pulled up by the magnet making the

turbulators also being pulled up.

Flipper

Flips when the magnet motor activates.

There must be no embers/glow in the burner when you start the cleaning

Page 12

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

12

1 Temperature control 6 Flow control valve

2 Hot water out 7 Mixing valve

3 Cold water 8 Vent pipe

4 Hot water 9 Safety valve

5 Cold water in 10 Overflow pipe

▀

Hot water

Hot water is produced in a copper coil. There are flanges on the

outside on the coil for best heat absorption. The cold incoming

water is mixed with the heated water from the coil in the mixing

valve (1). The mixing valve includes a thermostat where you set

the temperature on the outgoing water. If you don’t run the boiler

with pellets there also is a possibility to heat the hot water with the

electrical heater which should be set to 70°C for good hot water

comfort. If the operating temperature of the burner or electrical

heater is too low, the coil will not deliver the quantity of hot water

as desired for larger amounts.

When hot water is prepared in a coil, legionella bacteria cannot

occur.

▀

Valve combination

The valve combination is there so the hot water temperature doesn’t get to scalding temperature. In order to increase the temperature

turn (1) against +. You may also need to tune

the flow valve (6) to reduce the flow through

the coil. There is a safety valve (9) that releases the water out of overflow tube (10) if the

pressure in the hot water circuit is too high.

Note that overflow pipe should always have

drainage to a floor drain.

The shunt valve is not mounted from factory. This because you

should be able to choose side to be the flow and return to the

boiler. The supplied plastic pipe (1) is placed on the side for

the return of the radiator circuit. Then screw the pipe in the

shunt valve, do not forget the gasket. Note that you may need

to pull the two m8 bolts tightly against gasket for it to be tight.

Also note that the electrical connection (open / close) will be

different depending on which side the return pipe is placed.

▀

Shunt valve

Page 13

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

13

After about 3 tons the tubes should be cleaned manually with the brush, for the boiler to maintain a high

efficiency. Follow the instructions below.

Start by removing the lid on the top of the boiler

(1). Then loosen the two nuts(2) and remove the

hatch(3). Lift up the two suspensions with turbulators(4).

Clean the tubes with the brush

The ash compartment(5) is normally cleaned after

about 1,5 tons consumption of pellets.

Note that there can be glow a long time after

burning

1 Lid

2 Nuts

3 Soot hatch

4 Suspension turbulators

5 Ashbox (inside of the door)

6 Turbulators

▀

Cleaning

Page 14

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

14

▀

The motherboard

G1 Temp sensor boiler NTC 22 kΩ

G2 Sensor flue gas PT1000

G3 Extern control

G4

G5 Sensor accumulator tank low NTC 22 kΩ

G6 Sensor accumulator tank high NTC 22 kΩ

G7 Sensor, radiator flow NTC 22 kΩ

G8 Flame sensor

1U. Connection to display board

2U. Connection electricity board

1. Outdoor sensor

2. Outdoor sensor

3. Room sensor (6)

4. Room sensor (1)

5. Room sensor (4)

PE Incoming Earth

N Incoming zero

L1 Incoming phase 6,3 A/230 VAC

PE Earth

N Zero

11 Radiator pump 2A/230 VAC

12 Shunt motor

N Zero

13 Shunt motor 2A/230 VAC

PE Earth

N Zero

14 Solenoid valve AERO 2A/230 VAC

PE Earth

N Zero

15 Compressor 2A/ 230 VAC

PE Earth

N Zero

16 Magnet motor tube cleaning 2A/230 VAC

N Zero

17 Loading pump 2A/230 VAC

Remember to always cut the power to the boiler before starting any work

on it. All electrical work should be done by a certified electrician, for everyones safety.

▀

Change of e-prom

Cut the power to the boiler. Remove the front panel on the boiler so you can reach the backside

of the display. Gently remove the e-prom. Fit the new e-prom and gently push it into place.

Reassembly the front panel.

Check so that the marking of the

prom is set at the correct side.

Before shifting a e-prom make sure to write down all the settings that has been done

to the boiler. This since all the changes that has been done will be lost.

While mounting the e-prom make

sure that the ”legs” isn´t damaged

Page 15

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

15

▀

Electrical scheme

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

012-11-28

51-12-21

E.A

G8

G7

G6

G5

G4

G3

G2

G1

EL

17

N

16

N

PE

15

N

PE

14

N

PE

13

N

12

11

N

PE

L1

N

PE

M

NEUTRAL

OPEN

CLOSE

LOW VOLTAGE

HIGH VOLTAGE 230 VAC

L1

N

EARTH

6 1 4

DISPLAY CARD

CHARGE PUMP

COMPRESSOR

SHUNTMOTOR

RADIATOR PUMP

OVER HEAT PROTECTION 95 ˚C

POWER SUPPLY 230 V

BLUE

BROWN

YELLOW GREEN

BLUE

BROWN

YELLOW GREEN

YELLOW GREEN

BROWN

BLUE

EXPANSIONS CARD EL. HEATER

ROOM SENSOR

N

L1

EL 2a EL 2b

EL 1b

EL 1a

L2

L2

E-PROM

M

TUBE CLEANING

M

BLUE

BROWN

YELLOW GREEN

L3

EL 3a EL 3b

L3

51

52

53

54

55

56

57

58

AMPERE METERS

JOINT

12345

OUT DOOR SENSOR

RC 482

Display

YELLOW GREEN

BROWN

BLUE

SOLENOID VALVE

24

23

22

21

N

YELLOW/GREEN

M

FAN MOTOR

IGNITOR

O.H

PROTECTION

FALL SHAFT

EARTH CENTER SOCKET

EARTH CENTER PIN

FEEDER MOTOR

PALE BLUE

6.

2.

5.

4.3.1.

M

ELSCHEMA

EFFECTA 222 MED SUPRA

ELKOPPLING 3+3+3 KW

N

BOILER SENSOR

FLUE GAS SENSOR

EXTERNAL CONTROL

ACC. HIGH

ACC. LOW

FLOW SENSOR

FLAME SENSOR

M

EXTERNAL FAN

MICRO SWITCH

Depending on how the boiler is equipped, the wiring digram

differs:

- Tube cleaning

- Compressor

- Solenoid valve

- Shunt control

Other deviations may occur due to the customer request.

Alarm

Alarm

Lambda

Rev:Natek

HIGH VOLTAGE

CIRCUIT DIAGRAM

EFFECTA 222 WITH SUPRA

ELECTRICAL HEATER 3+3+3KW

Page 16

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

16

▀

Electrical connection

When power should be connected to the boiler you need to

loosen the front panel which covers the motherboard(2). There

are two glands (1) located on the backside of the boiler, these

leads to front. Use them to connect main power and sensors.

Do not place high voltage and low voltage in the same gland, as

there may be interference, causing incorrect temperature display.

Connect the power according to the electrical scheme on page

14-15.

The boiler must be filled with water before you start any electrical

installation

Load limiter

If the electrical use in the facility is high at the

same time as the eletrical heater in the boiler is

running, there is a chance that the main fuses

trips. Effecta Pellets 222 is equipped with a load

limiter which distributes the power between the

phases, or disconnects if there is a overload on

any of the phases.

Current sensor*

To measure the current, a current sensor

installed on each incoming phase conductor to

the distribution box. This is best done directly

in the distribution box. Connect the power

sensors to a multi leader in an enclosure next to

the distribution box. Use a multi-core cable 0,5

mm ² from the enclosure to the mother board

on Effecta Pellets 222. In the menu ”Electrical

heater”, set the maximum load you can have on

the main fuses.

*Current sensor is optional

Page 17

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

17

▀

Technical data

EFFECTA PELLETS 222 / 20 KW

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

012-02-01

V50-04-48

E.A

TECHNICAL DATA

1. SHUNT

2. HOT WATER COIL

3. FLOW HOT WATER 1”

4. RETURN HOT WATER 1”

5. DRAIN COCK 1/2”

EXPLANATION

Width

Depth incl. hatch

Height

Weight

Max pressure

Smoke angle

Flue tube diameter

Floor to cc flue tube

Water volume

Recommended draft

Minimum chimney area

Electrical connection

Sheet tickness mantle

Shhet tickness combustion

Ash compartment volume

Ash compartment depth

Max effect

Max operating temperature

690 mm

740 mm

1560 mm

240 kg

1,5 bar

150X150 mm

126 mm

1630 mm

192 liter

15 pa.

120 mm

230 / 380 VAC

4 mm

4 mm

106 liter

510 mm

20 kW

99 gr

4

5

535

690

158

223

740

415

500

1456

164

350

630

150

1545

1702

690

2

1

3

3

NYA EFFECTA LAMBDA 35

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

010-08-15

V50-05-23

E.A

630

153

535 95

Skorstensdrag rek.

Min skorstensarea

Elanslutning

Plåttjocklek mantel

Plåttjocklek eldstad

Eldstadsvolym

Eldstadsdjup

Effekt fläktmotor

Effekt

Max driftstemperatur

Påfyllningslucka

Rek. tankvolym

15 pa.

130 mm

230 VAC

4 mm

5 mm

145 liter

540 mm

100 w

35 kW

99 gr

400x260 mm

1500-3000 liter

Page 18

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

18

▀

Hydraulic scheme

PRINCIPSCHEMA

EFFECTA PELLETS 222 MED VARMVATTENKRETS

OCH RADIATORER.

EFFECTA AB

Västra Rågdalsvägen 21 - 43496 kungsbacka

Tel: 0300-22320 - Fax: 0300-22395

E-post:info@effecta.se - www.effecta.se

012-06-20

V50-05-93

E.A

EXPLANATIONS

8.

1. ROOM THERMOSTAT/OUTDOOR THERMOSTAT/BOTH

2. RADIATOR VALVE

3. RADIATOR PUMP

4. REFILL

5. SHUNTVALVE WITH MOTOR

6. MIXING VALVE

7. EXPANSION VESSEL WITH SAFETY VALVE1,5BAR

8. DRAIN (PLUGS)

9. DIRT FILTER

RADIATORS

3.

7.

4.

5.

2.

1.

2.

WATER MEASUREMENT

DOMESTIC WATER

9.

6.

PRINCIPAL SCHEME

EFFECTA 222 WITH HOT WATER CIRCUIT

AND RADIATORS

HOT

COLD

Page 19

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

19

▀

Mounting and adjusting of the draft stabiliser.

A draft stabiliser makes sure that a constant and stable draft is achieved. Also condensation

in the chimney is avoided.

Adjusting the balancing shaft

To adjust this shaft, loosen the two screws a bit and turn the shaft so that it is horizontally when

the hatch is closed. Then fasten the screws.

Adjusting the draft

By moving the counterweight along the balance shaft, the draft needed to open the hatch is

adjusted. About 1Pa per 2mm.(fig.2) The hatch is preset at about 1Pa. A professional should

measure the draft and make the adjustments.

Functions

Tigex draft stabiliser opens the hatch just as much as needed depending on the current draft.

The draft varies a lot depending on the chimney, weather and also if the burner is running or

not. This means that the hatch can be open a lot, a little or closed, depending the situation.

Page 20

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

20

▀

Trouble shooting

Low room temperature - Incorrect set on shunt valve

- Radiator pump not activated

- Air in radiators

- Low boiler temp.

- Adjust

- Activate

- Vent the system

- Check burner/electrical heater

Burner ”puffs” at start - Incorrect start dose - Adjust start dose

The panel is ”black” - Overheating protection has tripped - Reset (pg 7)

Overheating protection on the

burner activated

- Low draft

- Burner filled with ash

- Check draft

- Clean burner

Ash is black, not grey/white - Poor combustion - Contact installer

Poor hot water capacity - Low boiler temp

- Ti high flow in the pipes/system

- Set the burners stop-temp higher

- Adjust the flow on the mixing valve

Soot in the boiler room - Leaking seals - Check seals, contact installer

High flue gas temperature - Sooty boiler

- Poor combustion

- Broken sensor

- Clean boiler

- Contact installer

- Contact installer

White smoke from the chimney - Low flue gas temperature

- To big chimney

- Rainwater in the chimney

- Cut turbulators/increase power

- Contact installer

- Mount a rain hood

The burner doesn´t start - Micro switch broken

- Overheating protection activated

- No fuel

- Check switch

- Reset protection

- Fill up with fuel

Fault Cause Action

There are actions that the end user can take to fix a disruption. However, a professional should

always be contacted before any adjustment is done.

Page 21

Effecta AB - Västra Rågdalsvägen 21 - 434 99 Kungsbacka - +46(0)300 - 22320 - info@effecta.se

21

Försäkran om överensstämmelse:

Effecta Pannan AB

Västrarågdalsvägen 21

43496 Kungsbacka

Försäkran avser under eget ansvar produkten:

Effecta Pellets 200,220: Värmepanna för pellets

Nummer: 01-756697-01

Direktiv:

89/336/EEG med tilläggen 92/31/EEG, 93/68/EEG (EMC)

73/23/EEG med tillägget 93/68/EEG (LVD)

97/23/EC (PED)

Harmoniserande standarder:

SS-EN 60204-1 Elektrisk utrustning för industrimaskiner -

Del 1: Allmänna fordringar Kopplat till maskin och LVD.

SS-EN 50081-2 För emission-industri ( EMC –standard)

SS-EN 50082-2 För immunitet-industri (EMC- standard)

Kungsbacka 2004-12-12

Erik Andersson

Effecta Pannan AB

Page 22

Loading...

Loading...